Page 1

imeci

5.1

INTRODUCTION

This

section

instructions,

procedures,

and

reassembly

operational

GEMINI

Potentially

within

performance

PC-2º

the

instrument

AC

power.

for

maintenance

recommended

operated

Printed

damaged

removed

applied

pads

can

metal

foil

that

type

therefore,

irons

and

should

replacing

on

integrated

be

cut

removal.

CMOS

electrical

damaged

activity

protected

ESD

protective

personnel

contains

maintenance

preventive

mode

troubleshooting

procedures

test

Volumetric

Pump/Controller.

WARNING

lethal

voltages

PC-2

case

is

operated

When

using

the

action,

the

instrument

the

internal

CAUTION

circuit

be

before

boards

when

and

replaced.

to

the

circuit

cause

and

base

is

essentially

only

vacuum

used

components

circuit

attempting

(PCBs)

integrated

board

de-lamination

material.

low-temperature

solder

when

removing

on

components

NOTE

devices

is

are

charges

during

not

environment

and

repair

performed

sensitive

procedures

grounding.

SECTION

maintenance

operating

routines,

and a comprehensive

for

when

using

case

it

Excessive

irreparable;

removal

PCBs.

unsoldering

may

if

using

disassembly

the

IMEDS

are

present

the

external

is

opened

is

be

battery.

are

circuits

traces

of

the

Damage

soldering

and

Leads

should

to

be

the

repair

in

an

approved

including

easily

are

heat

and

of

tools

and

static

ESD

5 - MAINTENANCE

5.2

PREVENTIVE

The

GEMINI

with

the

requirements.

incorporates a diagnostic

instrument's

parameters.

irregularities

functional

Alarms

notification.

in

use

troubleshooting

Maintenance-free

scheduled

can

on an

interval

once a year

Verification

responsibility

such

the

graphs

forming

5.2.1

Exterior

using

solutions.

permit

or

the

non-volatile

by

biotechnical

be

‘as

tests

factory

describe

Cleaning

Always

before

sterilize/

Do

solution.

any

cleanup

PC-2

goal

of

The

subsystems

Detection

or

operation

Malfunction

Problems

preventive

enhanced

required’

for

preventive

based

of

proper

of

and

at

nominal

general

unplug

cleaning.

autoclave

not

immerse

surfaces

of

the

This

MAINTENANCE

is

designed

minimizing

integral

routine

and

of

operating

failures

that

activates

alerts

of

RAM

error

this

personnel

and

repair

operation

maintenance

by

performing

basis.

The

maintenance

on

normal

operation

the

user,

verification

cost.

in

detail

the

maintenance

Instructions

CAUTION

the

AC

Do

the

the

of

the

PC-2

following

list

is

considered

of

all

expected

and

assembled

maintenance

microprocessor

that

monitors

operating

system

affect

the

instrument's

audio

and

for

operator

nature

log

actions.

between

At

the

may

The

procedures

on

power

not

instrument.

PC-2

are

for

subsequent

in

performing

regularly

inspections

routine

recommended

inspections

use

and

operation.

is

the

user’s

be

performed

following

the

PC-2.

cord

steam-

in

any

may

be

cleaned

recommended

adequate

contaminates.

the

visual

recorded

cleaning

option,

at

para-

for

per-

to

is

5-1

UPDG3

Page 2

тес]

Isopropyl

Warm

Household

household

These

free

swab.

moved, a cloth

be

and

Then

completely

moistened

water

dried

solutions

cloth; a soft

Once

used

diluting

the

rinses

with a soft,

Prior

the

of

the

electrolyte

female

contamination;

the

alcohol

soapy

water

Bleach

bleach

may

bristle

the

contamination

soaked

to

rinse

the

all

of

the

entire

instrument

rinsed

with

using

fresh

the

instrument

lint

to

reattaching

instrument,

power

and

contacts

power

cord.

(10%

to 9 parts

be

applied

brush

with

entire

residual

another

water.

free

cloth.

WARNING

the

ensure

input

module

dry

thoroughly.

on

the

if

contaminated,

solution,

and/or a cotton

has

fresh

instrument

cleaning

surface

Following

must

AC

that

power

i.e. 1 part

water)

using a soft,

been

water

should

cloth

thoroughly

the

be

thoroughly

power

the

is

clean

Check

cord

lint

re-

should

removing

solution.

be

fresh

cord

to

male base

of

any

the

for

replace

utilizing

(sys

(reading

the

in

the

read

instruments

should

operating

to

check.

should

replaced.

5.2.3.2

1.

2.

the

batt)

test

will

instrument

sestion

5.5

battery

6.5

volts

be

charged

condition,

stabilize

Batteries

be

subjected

Lithium

Turn

instrument

cord

from

Open

the

A/D

terminals.

primarily

for 4 hours

5.5.1).

3.

Connect a digital

(TP3)

and

Board.

Voltage

to

check

be 0.5 true

disassembly

and

display’s

the

battery

voltage),

procedures

connecting a voltmeter

Battery

+0.3

volts.

Batteries

operated

for

12

hours

then

unplugged

prior

to

testing

Battery

to

further

off

less

Check

and

unplug

outlet.

instrument

Vaay

case

voltmeter

(U8,

pin

system

voltage

or

by

voltage

installed

on

battery

in a non-

and

performing

than

62

testing

AC

(see

section

between

16)

on

the

battery

following

described

across

should

in

power

allowed

voltage

volts

or

be

power

ground

Analog

5.2.2

Perform

section

checks:

ㆍ

+

Mechanical

the

mechanical

2.2

of

this

Inspect

excessive

or

damaged

Perform a pumping

spring

roller

the

functioning

Replace

5.2.3

Perform

described

5.2.3.1

Perform a battery

entering

for

Maintenance

the

wear

1000

hours

or

integrity

clamp

Pump

mode.

the

damaged

Electrical

the

standard

in

section

Battery

the

maintenance

Inspection

manual

urethane

and/or

of

instrument

worn

replace

test

while

the

If

channel

or

Inspection

electrical

2.3.2

Voltage

voltage

Mode

inspection

plus

the

pumping

holes

the

mechanism

by

closing

pump

only

one

will

missing

inspections

of

this

Check

check

mode

operating

described

following

seal

for

every

90

operating

seal.

extension

the

IV

is

operating

spring

not

by

(see

procedures)

is

occlude.

spring.

manual.

either

section

in

days

time.

set

in

5.3

and

4.

Disconnect

Power

5.

After

display

the

meter

Volts.

If

6.

Reconnect

POWER

7.

If

the

lithium

should

5.3

MAINTENANCE/DIAGNOSTIC

The

PC-2

Diagnostic

access

the

the

Maintenance/Diagnostic

biotechnician

to

verify

operation

features,

independent

check

access

keypad,

system

the

and

communications

Supply

the

audio

to

stabilize

reading.

ON

voltage

battery

be

replaced.

is

configured

Mode

software

can use

to

operate

of

Analog

error

to

the

battery

Board.

initiates,

(~30

Reading

the

battery

control

reading

that

to

is

(B1)

on

with a Maintenance/

allows

diagnostic

the

diagnostic

of

the

operator

the

pumping

the

alarm/malfunction

to

Digital

log,

to

test

check

port.

the

input

harness

allow

at

the

seconds},

should

harness

silence

<2.25

the

and press

the

Volts,

Logic

Board

MODE

biotechnicians

subsystem.

Mode

is

enabled,

test

interface

mechanisms

interrupts,

voltages,

the

lamps

port

and

J6

on

the

voltmeter

then

note

be

>2.25

audio.

the

to

Once

the

routines

to

and

serial

the

to

UPDD3

5-2

Page 3

Integer

The

selection

parameters.

Keypad/Series

Maintenance

and

to

2.xx

Mode

is

set serial

Software

utilized

communications

for

language

1.

Unplug

recommended

be

possible).

the

performed

AC

power

that

maintenance

using

battery

imed

cord

(it

is

power

operations

whenever

Fractional

The

Setup

and

to

5.3.1

Keypad/Series

Mode

set

communications

Maintenance/Diagnostic

Sequence

Integer

The

the

initialization:

Keypad/Series

Maintenance

following

order

TIMEBASE

LAMP

TEST

KEYPAD

ERROR

MOTOR

PUMP

TEST

SERIAL

A/D

VOLTAGE

INPUT

COMMUNICATIONS

LANGUAGE

POWERDOWN

Fractional

The

following

Keypad/Series

Diagnostic

sequence

initialization:

ERROR

PUMP

MOTOR

A/D

VOLTAGE

INPUT

LAMP

TEST

KEYPAD

TIMEBASE

SERIAL

ROM

CRC DISPLAY

POWERDOWN

5.3.2

Maintenance/Diagnostic

is

Mode

TEST

LOG

HOMING

PORT

PORT

Mode

LOG

TEST

HOMING

PORT

TEST

PORT

3.xx

utilized

2.xx

test

after

Maintenance

CHECK

DISPLAY

TEST

TESTS

DISPLAY

DISPLAY

SELECTION

TEST

test

routines

after

diagnostic

DISPLAY

TEST

DISPLAY

DISPLAY

CHECK

TESTS

TEST

Software

for

language

parameters.

Mode

Software

sequence

SETUP

3.xx

Software

appear

mode

Mode

selection

Test

appears

Mode

in

Operation

in

the

2.

Software

Install

Call/Maintenance

Software

Press

MONITOR

3.

Press

ㆍ

Integer

+

Release

the

Maintenance

Release

and

hold

switch.

the

POWER

All

LEDs

and

seconds

then

Keypad/Series

"maintenance

on

the

Channel B Operator

display

(2.xx

version).

Fractional

+

"diagnostics

Keypad/Series

<stop>" - scrolls

channel B Operator

(v3.xx = installed

4.

The

PC-2

is

now

Maintenance/Diagnostic

Software

The

to

next

5.3.3

The

both

Where

Fractional

feature,

Maintenance

following

the

Release

maintenance

change

v2.xx

differences

both

and

during

procedural

and

keypad

procedures

from

V2.13

Plug

in

Plug

connector

V2.33

the

and

COMPUTER

ON

control

Subsequent

displays - illuminate

extinguish.

2.xx

Software

v2.xx" - scrolls

is

the

installed

3.xx

PC2

v3.xx

to

continuously

Information

software

initialized

version).

in

the

Mode.

NOTE

V2.13

plug

must

be

one

test

routine

the

Mode

steps

v3.xx

software

occur

between

controls

are

motor

used

homing

Test

Suite

are

versions.

the

to

described.

select a test

the

Nurse

(rear

panel).

CONTROL/

and check:

for

continuously

Information

software

Software

exit

press

on

the

display

installed

to

the

test.

applicable

Integer

and

3

to

Performing

will

diagnostic

Prior

to

operating

Maintenance

instrument

the

provide

access

mode

WARNING

the

Mode

is

not

connected

following

to

the

tests:

PC-2

in

ensure

that

procedures

PC-2's

maintenance/

the

the

to a patient.

as

described

Software

The

used

maintenance

Software

The

used

maintenance

5-3

Release

press

function

to

sequence

Release

COMPUTER

to

sequence

V2.13

of

the

through

mode

tests.

V2.33 and

CONTROUMONITOR

through

mode

tests.

Audio

the

individual

Subsequent

the

individual

Control

switch

switch

UPDO3

is

is

Page 4

im

Each

confirmation

pressed

scrolled

displayed

select

test

deselect

in

test

Integer

Actuation

identifier

sequence

Fractional

Diagnostic

Diagnostic

scrolling

routine.

TIMEBASE

1.

Press

and

»

2.

Integer

Fractional

test

routine

is

identified

message.

to

initiate a specific

test

identifier

test

phase

control

the

the

Maintenance

may

current

test

Keypad/Series

of

the

is

or

PAUSE/STOP

scrolling

and

Keypad/Series

mode

mode

via a powerdown

will

powerdown

can

or

powerdown

CHECK

the

appropriate

check:

"timebase

Information

Press

Keypad/Series

*

"running" - displays

«

Channel B VTBI

check" - scrolls

display.

START

and

between 0 and

"failed"

Information

clear

allow

*

"swing" - displays

+

numerical

channel B VTBI

windows.

-

-

-

will

display

display.

the

Operator

the

test

Keypad/Series

values

Press

PAUSE/STOP

display

+

*

If

expected

and

Rate

Pressing

for

data

"(halted)

channel A Operator

press

the

displays

PAUSE/STOP

‘swing’

deviation, a failure

"FAIL"

display.

CLEAR

resume.

by a scrolled

Once

the

START

test

routine,

is

replaced

identifier.

be

used

and

Mode

2.xx

interrupt

the

only

be

test

by a statically

The

appropriate

at

any

proceed

test

sequence.

Software

key

while a test

the

instrument.

3.xx

Software

exited

test

in

the

Pump

select

on

check:

2.xx

Software

statically

display - alternates

1.

If

displayed

on

the

Operator

Pressing

CLEAR

Information

to

resume.

3.xx

Software

statically

sequence

display's

recording.

tenths

once

rapidly

to

statically

Information

again

value

exceeds

appears

in

will

the

allow

channel

key

is

the

time

to

to

the

next

test

when

the

identifier

Test

control

the

value

once

Operator

is

will

display

and

in

and

the

units

freeze

in

the

display

to

unfreeze.

the

is

invoked

B

the

test

to

are

22,

the

Press

the

between

user

between

user

difference

readings

modes.

LAMP

1.

Press

and check:

«

"lamp

Information

Press

2.

+

Rate

sequentially

9 9

(The

display a decimal

position;

Indicator

+

Operator

alphabet

"ου,

*

Controller

Secondary

Traffic

illuminate

test

+

Audio

KEYPAD

1.

Press

and

*

Press

+

Press

provides

or

and

active

corresponding

displays

information

either

display

to

old

keypress),

old

keypress)

between

updated

TEST

(with

the

appropriate

test" - scrolls

START

and

VTBI

followed

channel B VTBI

instead

will

Information

in

"*,

"and

and

cycle

alert - sounds

TEST

the

appropriate

check:

“keypad

Information

"start”

Information

test" - scrolls

START

displays

each

no

COMPUTER

Subsequent)

test)

on

the © or © controls

the

"max"

(maximum

and

new

timer

reading

"min"

(minimum

and

new

timer

or

"dynamic"

old

every

AUDIO)

test

display.

and

check:

displays - Flash

numbers

by

1.1.1.1.

point

the

illuminate)

upper

case,

and

10

on

Operator

1 1

Display

Battery

displays - scroll

difference

reading

(current

new

msec)

seleot control

1 1

through

will

in

the

Operation

the

numbers

"?"

and

Pump

(Piggyback),

Battery

steadily

display

and

display

key

response,

indicator

during

check:

statically

(except

delivery

once

test

on

POWER

Audio

mode,

Communication

LEDs

one

half

per

select control

Operator

on

Operator

Control

CONTROUMONITOR

which

one

nomenclature

the

channel B Operator

display.

always

at a time

terminates

and

verify

for

to

taggle

difference

since

last

since

last

timer

data

once

through 9 9

9.9.9.9.

not

Units

the

"0"

of

the

second.

once

ON

which

(V2.13)

(V2.34

the

that the

the

key

-

UPDO3

5-4

Page 5

ERROR

1.

Press

and

*

2.

Press

+

«

3.

Press

log:

+

4.

Press

+

LOG

DISPLAY

the

appropriate

check:

“error

log

display" - scrolls

information

START

“empty”

(no

display

and

check:

errors

channel B Operator

this

case

proceed

mode

test.

"newest"

"nn:

the

(nn = number

=

error

[v2.xx]

Next

format

followed

ccc"

[v3.xx]

channel B Operator

identification

or

00

Units

(1)

oldest

or

"no

CLEAR

Error

log

clears - "wait"

on

the

Operator

a

one

second

either

“okay”

to

or

by

will

of

entry

to

129

digit

key

entry

will

older“

key

and

Information

verification

or

"fail".

test

select

on

logged)

appears

Information

the

next

"nn:

cc”

display

statically

Information

from

00

code - 00

[v3.xx]).

to

read

display

will

appear.

check:

displays

display

stage

control

Operator

on

once

the

display.

maintenance

[v2.xx]

the

in

to

to

"nn:

or

display

09,

99

error

cc"

on

οσ(ο)

statically

during

followed

In

by

5.

Press

«

Pumping

‘sync’

and

Operator

»

Pumping

“failed”

Information

Software

2.

Press

+

Channel A VTBI

the

"homestep"

channel A Operator

3.

Use

(between 0 and

>199

4.

Press

+

Pumping

selected

display

the

*

Pumping

channel A VTBI

numerical

step

START

“homing”

and

mechanism

position

displays

check:

(number 7 finger

Information

mechanism

displays

Release

START

statically

display.

V2.33

and

check:

and

displays

last

selected

home

displays

Information

the

Data

Entry

Controls

199)

for

will

revert

display

START

and

check:

mechanism

step,

"-

- -

-"

and

"homing"

channel A Operator

mechanism

display

value

of

the

imed

operates

statically

display.

stops and

step

statically

homing. A selection

to

operates

appears

displays

stops

selected

to

seek

extended)

in

the

"homed"

in

the

Operator

Subsequent

either a "0"

and

in

the

display.

to

select a step

"0".

to

seek

in

the

statically

Information

and

the

shaws

the

homing

display.

the

or

or

the

VTBI

in

MOTOR

Software

1.

2.

3.

4.

HOMING

Press

the

and

check:

«

“motor

Operator

Release

Press

START

+

“chan

A*

information

Press

START

+

Pumping

‘sync’

position

and

"homing"

Operator

+

Pumping

“failed”

Informatian

Press

START

*

"chan

B

Operator

TEST

appropriate

homing

test" - scrolls

Information

V2.13

and

displays

display.

and

mechanism

(number 7 finger

displays

Information

mechanism

displays

display.

and

B"

displays

Information

test

select

display.

check:

statically

check:

operates

statically

display.

stops

statically

in

check:

statically

display.

control

on

in

the

to

and

the

in

the

once

channel

Operator

seek

the

extended)

in

the

“homed”

Operator

Channel

B

or

+

"homed"

channel A Operator

«

Press

channel

#4.

PUMP

1.

TEST

Press

and

check:

*

"pump

the

information

Software

2.

Press

+

The

Release

START

upper

CONTROLLER

Rate

indicator

*

"PG-2

Operator

channels

or

"failed"

PAUSE/STOP

B,

then

repeat

appropriate

test"

scrolls

display.

V2.13

and

position

Delivery

illuminates

Vx.xx"

scrolls

Information

displays

Information

once

steps

test

select

on

the

check:

of

either

Mode/Retative

once

display

statically

display

to

select

#2

through

control

Operator

the

PUMP

for

each

across

of

both

in

once

channel

the

UPDO3

the

or

Page 6

imeci

*

"ACCESS

the

channels

+

“MAINTENANCE”

the

channels.

Use

the

section

abbreviated

Operators

operate

The

instrument

independent

Software

2.

Press

+

"normal"

A

Operator

Use

the

select

test

mode.

step

between

mode

channel B Operator

Press

operation.

+

"MAINTENANCE"

both

*

Channel A Rate and

"о"

*

Last

mode/Operating

Use

the

3.3.1

instrument.

When

ACCESS

operation.

When

pressing

following:

+

Calculated

threshold

is

displayed

CHANNEL"

Operator

Operator

detailed

3.3.1.1

Information

Information

procedures

of

procedures

Reference

the

instrument.

will

of

any

Release

START

V2.33

and

displays

Information

Units

(1)

either

the

‘normal’

Each

normal

selected

START

Operator

selected

procedures

to

set

channel A is

will

to

Information

Pump

up

channel A and

CHANNEL

in

the

Pressure

START

occlusion

for

selected

in

scrolls

scrolls

this

manual

described

Guide

NOTE

continue

alarm

and

Subsequent

check:

statically

display.

digit

Data

or

actuation

and

pressure.

display

Information

enable

the

scrolls

VTBI

or

Controller

indicator

described

operating,

B

then

mode

in

step

45

pressure

infusion

the

RATE

once

across

display

of

both

continuously

display

of

described

or

the

in

to

set

up

both

the

and

operating

conditions.

on

the

channel

Entry

Control

‘pressure’

will

alternately

pump

The

statically

on

display.

PC-1

for

continuously

displays

displays

show

delivery

will

illuminate.

in

Section

operate

press

setup

for

and

after

above,

check

voltage

parameters

display

on

in

the

on

the

to

the

»

Voltage

Strain

Any

time

while

in

and

VTBI

selected

VTBI

values.

Three

the

tarily

then

a

mode

the

To

press

switch

routine

motor

pumping

to

resumes

one

time

presentation

infusion

change

COMPUTER

once.

back

communication

the

communications

Fractional

2.

Press

-

3.

Use

the

4.

Press

Keypad/Series

START

"normal"

A

Operator

the

"normal"

START

operation.

+

"MAINTENANCE"

both

Operator

e

Channel A Rate and

+

Operating

selected

5.

Follow

3.3.1

operate

6.

When

pressing

following:

*

the

to

the

in

Calculated

threshold

is

displayed

*

Voltage

Strain

relative

Beam

displays

NOTES

the

pumping

the

pressure

display

infusion

revolutions

mechanism

check

occlusion

operation.

interruption

parameters.

pump

This

to

step

cable

and

displays

Information

or © control

and

"pressure"

to

enable

Information

indicator

delivery

procedures

set

up

channel(s) A and/or B and

instrument.

the

Pressure

START

relative

Beam

in

occlusion

for

selected

in

the

displays

to

pressure

mode,

revert

Rate

sensed

in

the

VTBI

mechanism

the

to

displaying

and

decremented

following

stops

pressure

This

of

the

with a flash

test

mode

selection,

CONTROL/MONITOR

will

loop

the

#3

providing

is

NOT

data

port

3.xx

Software

check:

staticaily

on

display.

to

toggle

options.

the

PC-2

scrolls

continuously

displays

VTBI

displays

illuminates

mode.

described

mode

and

step

#5

above,

pressure

infusion

RATE

to

pressure

in

the

display

sensed

VTBI

at

the

display.

stops

RATE

the

START,

momen-

and

will

result

pressure

display

test

a

connected

(RS-232C).

the

channel

between

for

on

show

for

last

in

Section

after

check

voltage

parameters

at

display.

in

of

to

the

the

UPDO3

5-6

Page 7

Any

time

while

and

VTBI

selected

VTBI

Three

the

pumping

tarily

then

a

one

mode

the

infusion

To

change

press

switch

routine

communication

the

communications

SERIAL

1.

PORT

Press

check:

+

“serial

Information

Install

RS-232-C

may

terminal

Press

«

"echo"

Information

Press

*

Each

communications

a ? (e.g. A

*

"okay"

display

3

seconds;

the

To

rerun

loop

Press

+

"send"

Information

NOTES

the

pumping

in

the

pressure

display

infusion

revert

Rate

values.

motor

revolutions

mechanism

to

check

resumes

time

presentation

occlusion

operation.

interruption

with a flash

parameters.

pump

COMPUTER

once.

back

test

CONTROL/MONITOR

This

will

to

step

cable

TESTS

the

appropriate

port

tests”

scrolls

display.

Communications

connector

also

be

performed

vice a communications

START

displays

on

and

check:

statically

display.

START

alpha,

appears

if

each

and

check:

numeric

character

?)

in

in

byte

sequence.

the

otherwise

channel B VTB!

the

test,

press

the

test

sequence

PAUSE/STOP

displays

display.

and

statically

mechanism

mode,

the

to

displaying

and

decremented

following

stops

momen-

pressure

This

will

of

the

pressure

display

mode

#3

is

data

test

Emulator

selection,

loop

the

providing

NOT

port

select

on

the

the

rear

test

connected

(RS-232-C).

control

plug

panel.

using a remote

plug.

on the

and

symbol

set

is

Operator

sent

is

echoed

“FAIL”

appears

display.

CLEAR.

back

to

step 3 above.

check:

on

the

stops

RATE

the

START,

and

result

in

of

a

to

and

Operator

in

the

Test

Operator

in

the

sent

with

Information

within

in

This

will

Operator

ni

Press

+

Byte

selected

“okay”

display

display.

8.

To

loop

9.

Press

+

"receive"

Information

+

Pressing

display.

10.

(To

be

C2

PC-2).

A/D

VOLTAGE

1.

Press

and

+

"A/D

Operator

2.

Press

+

"A

B

*

Channel À strain

the

Integer

3.

Press

«

"B

Channel B Operator

+

Channel B strain

the

R

Press

+

"sys

Channel B Operator

+

System

Channel B VTBI

m

Press

+

"Vímains)"

Channel B Operator

+ A numerical

Channel B VTBI

present;

display.

START

stream

rerun

the

and

is

baud

appears

or

"FAIL"

the

test,

test

sequence

PAUSE/STOP

displays

display.

START

conduct

connected

the

to a computer

Communication

DISPLAY

the

appropriate

check:

voltage

display”

Information

START

strain"

Operator

channel B VTBI

Keypad/Series

and

displays

Information

PAUSE/STOP

strain“

displays

Channel B VTBI

PAUSE/STOP

batt"

displays

battery

PAUSE/STOP

displays

value

otherwise

check:

sent

out

rate.

Upon

on the

Operator

appears

press

CLEAR.

back

and

check:

statically

causes

"receive"

protocol

test

scrolls

display.

check:

statically

beam

display.

2.xx

Software

and

statically

Information

beam

display.

and

statically

Information

voltage + 2

display.

and

statically

Information

(=2.50)

display

approximately

и

imecl

at

the

currently

completion

Information

in

the

VTBI

This

will

to

step 6 above.

on

the

Operator

"input

?" to

test

the

PC-2

must

terminal

or

another

select

on

on

display

voltage

check"

on

voltage

check:

on

displays

check:

appears

if

AC

control

the

the

displays

the

display

displays

the

display

on

the

display

power

00.01

using

once

channel

on

on

the

is

will

in

in

the

UPD03

Page 8

тес]

AC

a

quantitative

for

6.

Press

+

"V

B

+

A/D

(=2.50)

VTBI

voltage

presence

PAUSE/STOP

(ref)"

displays

Operator

converter

is

display.

МОТЕ

measurement

evaluation,

or

absence

and

statically

Information

reference

displayed

on

(V

mains)

but

rather a test

of

AC

voltage.

check:

on

the

display

voltage + 2

the

Channel

is

not

Channel

B

7.

Press

(O)

+

"V(audio)” displays

Operator

»

Normally

active.

occur,

8.

Press

+

"V(NiCad)"

Operator

+

NiCad

channel B VTBI

acceptable

and

check:

Information

00.00

(Random

if

keypad

and

check:

displays

Information

battery

voltage + 2

reading

statically

display

will

display

numerical

controls

statically

display

display

2.71).

on

as no

display

are

pressed).

of

displays

(minimum

the

audio

the

may

on

is

the

7.

Press

+

«

I

Fractional

3.

Press

»

+

4.

Press

«

*

5.

Press 回 and

»

> A numerical

AC

a

for

6.

Press

«

+

PAUSE/STOP

“V(audio)"

Operator

Normally

active.

occur,

"B

strain"

displays

Information

0000

will

(Random

if

keypad

Keypad/Series

the

[0 control

displays

numerical

controls

Channel B Operator

Channel B strain

the

Channel 8 VTBI

(O)

and

"sys

batt"

displays

B

Operator

System

channel B VTBI

battery

"V(mains)"

channel B Operator

channel B VTBI

present;

otherwise

beam

check:

Information

voltage

display.

check:

displays

value

display

display.

NOTE

voltage

quantitative

presence

"V

(ref)"

B

Operator

A/D

(=2.50)

VTBI

measurement

(0)

and

displays

converter

is

displayed

display

evaluation,

or

absence

check:

statically

Information

reference

and

check:

statically

on

display

display

3.xx

as no

display

are

pressed).

Software

and check:

statically

Information

display.

statically

statically

Information

(=2.50)

approximately

on

on

voltage

on

display

+ 2

displays

on

appears

if

AC

power

(V

mains)

but

rather a test

of

AC

on

the

display

voltage + 2

the

channel

the

audio

may

the

display

displays

the

channel

on

the

display

on

is

00.01

is

voltage.

channel

B

is

in

the

the

will

not

INPUT

1.

2.

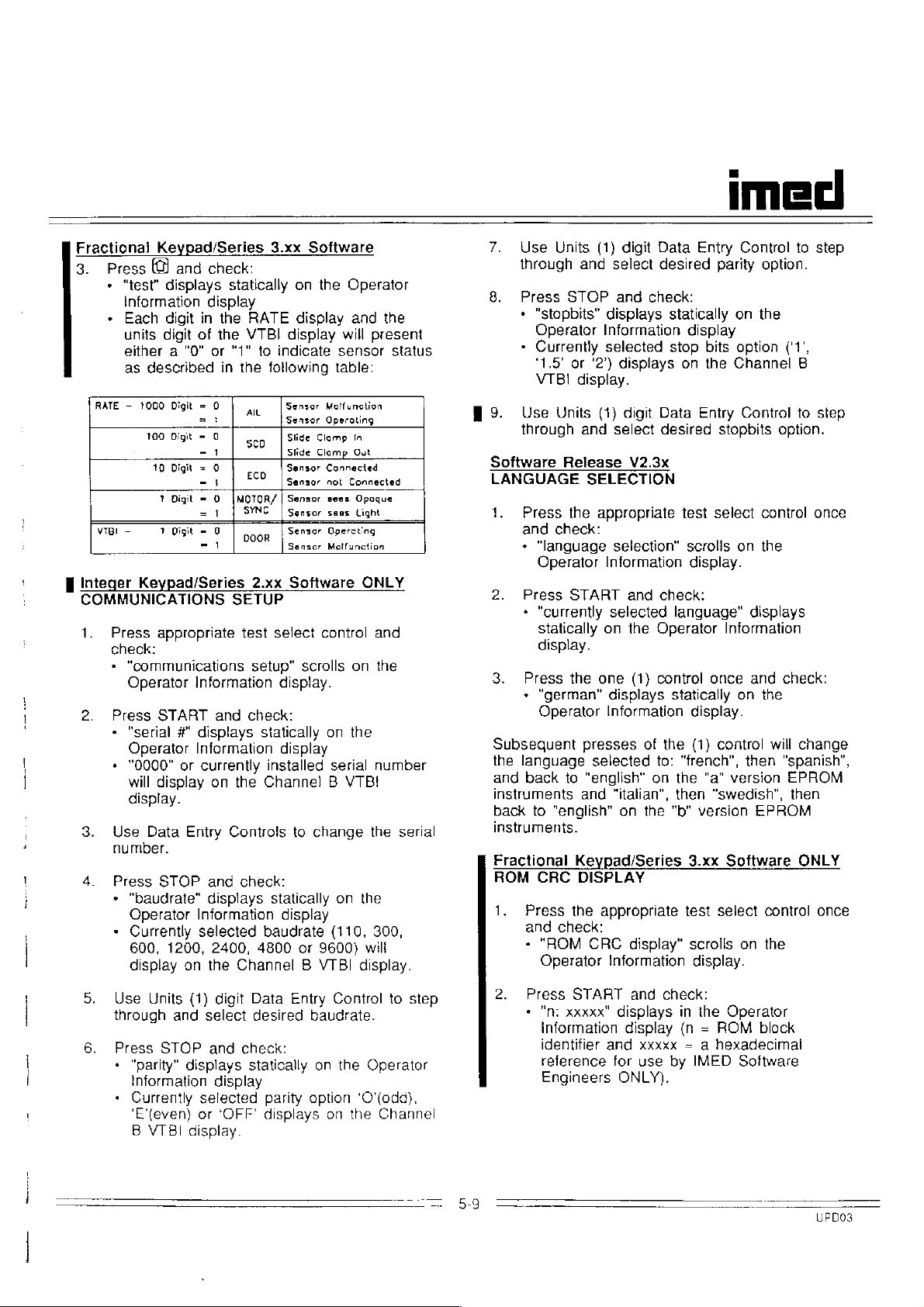

RATE — 1000

γι

B

integer

3.

PORT

Press

the

and

check:

»

“input

Information

The

RATE

during

for

Press

»

+

BI

this

both

START

"normal"

Information

Each

units

digit

either a "0"

as

described

100

10

1

- git

3

Keypad/Series

Press

+

+

PAUSE/STOP

"selftest"

Information

Each

units

either a "0"

as

described

DISPLAY

appropriate

port

display”

display.

test

scrolls

NOTE

and

VTBI

display

test

have

the

channels.

and

check:

displays

digit

in

of

Digit = 0 | 。

=}

Digit = G

=1

Digit = 0

-3

Ogit

= O

=1

=

Digit = 0 | ga | Door

=

displays

digit

in

digit

of

statically

display

the

RATE

the

VTBI

or

"1"

to

in

the

sco

Eo

|MOTOR/ | Sensor

SYNC | Sensor

2.xx

statically

display

the

RATE

the

VTBI

or

"1"

to

in

the

display

display

indicate

following

[Fluid

Air

Sensor

MALFUNCTION

Air

Fluid

Daor

Software

and

check:

display

indicate

following

select control

on the

Operator

presentations

same

on

meaning

the

Operator

and

will

present

sensor

the

table:

in

sensor

in

sensor

disobied

in

sensor

.

in

Open

Closed

on

display and

sensor

sees

Opoque

sces

tight

the

will

sensor

table:

for

Operator

the

present

once

output

lest

status

UPDO3

5-8

Page 9

Fractional

3.

Press © and

*

*

RATE - 1000

VTBI — Y

E

Integer

COMMUNICATIONS

1.

2.

3.

4.

Keypad/Series

"test"

displays

information

Each

digit

units

digit

either a "0"

as

described

Digit

100

Digit - 0

10

Digit

Y

Digit = O

digit - 0 | ooog | Sensor

Keypad/Series

Press

appropriate

check:

*

"communications

Operator

Press

START

-

“serial

Operator

+

"0000"

will

display.

Use

number.

Press

*

"baudrate"

Operator

+

Currently

600,

display

#"

or

display

Data

STOP

1200,

Entry

on

3.xx

Software

check:

statically

on

the

Operator

display

in

the

RATE

of

the

VTBI

or

"1"

in

the

= 0

=

Information

displays

Information

дк

seo. | Slide

-1

= 0

-4

=!

currently

eco | Sensor

|MOTOR/|

SYNC | Sensor

1

SETUP

test

and

check:

on

the

Controls

and

check:

displays

Information

selected

2400,

the

Channel B VTBI

display

display

to

indicate

following

[Sensor

Sensor

Slide

Sensor

Sensor

Sansor

2.xx

Software

select

setup"

display.

statically

display

installed

Channel B VTBI

to

statically

display

baudrate

4800

sensor

table:

МоНипейол

Operating

Clamp

Clamp

Connected

nol

sees

sees

Opercting

Malfunction

control

scrolls

on

serial

change

on

(110, 300,

or

9600)

will

and

present

In

Out

Connected

Opaque

Light

ONLY

and

on

the

the

number

the

the

will

display.

the

status

serial

7.

Use

Units

through

8.

Press

+

"stopbits”

Operator

»

Currently

‘1.5’

VTBI

9.

Use

Units

through

Software

Release

LANGUAGE

1.

Press

check:

and

*

"language

Operator

2.

Press

*

"currently

statically

display.

3.

Press

+

"german"

Operator

Subsequent

the

language

and

back

instruments

back

to

"english"

instruments.

Fractional

ROM

CRC

1.

Press

and

check:

+

"ROM

Operator

(1)

digit

and

select

STOP

and

check:

displays

Information

selected

ог

'2")

displays

display.

(1)

digit

and

select

V2.3x

SELECTION

the

appropriate

selection"

Information

START

the

and

selected

on

the

one

(1)

displays

Information

presses

of

selected

to

"english"

and

on

"italian",

on

the

Keypad/Series

DISPLAY

the

appropriate

CRC

display”

Information

Data

Entry

desired

statically

display

stop

bits

on

the

Data

Entry

desired

test

scrolis

display.

check:

language"

Operator

control

statically

display.

the

(1)

to:

"french",

the

"a"

then

"b"

version

3.xx

test

scrolls

display.

imed

Control

parity

on

option

Channel

Control

stopbits

select control

on

Information

once

on

control

then

version

"swedish",

Software

select

on the

to

option.

the

(‘1',

B

to

option.

the

displays

and

check:

the

will

change

"spanish",

EPROM

then

EPROM

ONLY

control

step

step

once

once

2.

Press

5.

Use

Units

(1)

digit

Data

Entry

Control

through

6.

Press

*

*

and

STOP

"parity"

information

Currently

'E'(even)

B

VTBI

displays

selected

or

display.

select

and

check:

display

‘OFF’

desired

statically

baudrate.

parity

option

displays

on

the

on

to

Operator

'O'(odd),

the

Channel

step

START

«

"m

xxxxx"

information

identifier

reference

Engineers

and

displays

display

and

xxxxx

for

use

ONLY).

check:

in

the

(n = ROM

= a

by

IMED

Operator

block

hexadecimal

Software

40003

Page 10

imeci

POWERDOWN

1.

Press

the

and

check:

*

"powerdown

Information

2.

Press

START

+

"POWER"

across

Information

seconds

[v3.xx])

+

One

shuts

The

maintenance

prior

to

service

TEST

appropriate

test”

test

select control

scrolls

display.

and

check:

"OFF

n"

displays

the

channel A and B Operator

displays

('n'

counts

from 5 to 1 [v2.xx]

second

down.

aíter

'n' = 1

WARNING

plug

must

returning

for

patient

the

instrument

care.

on

the

statically

or 3 to

the

instrument

be

once

Operator

down

in

1

removed

to

5.4

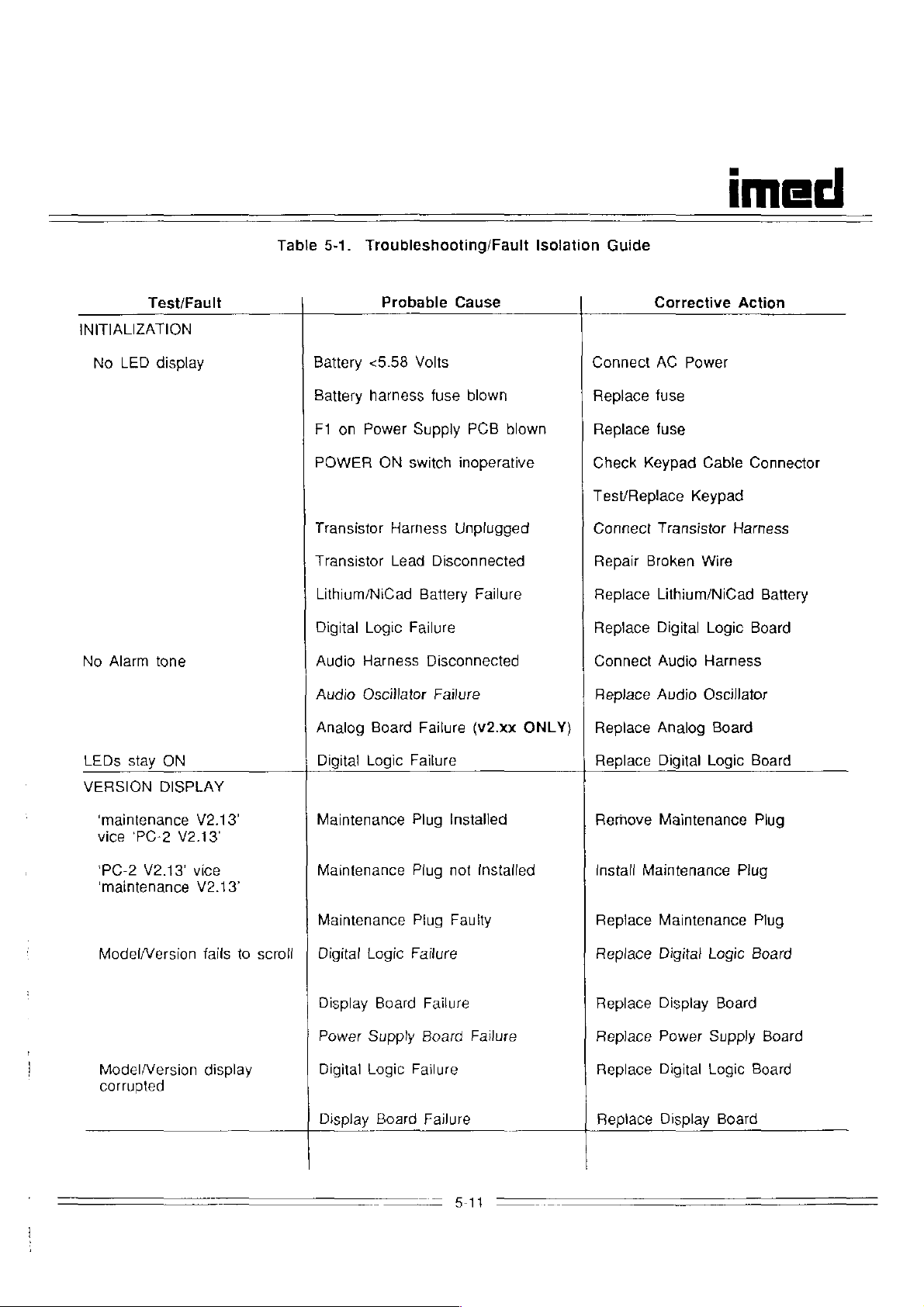

TROUBLESHOOTING

The

troubleshooting

Table

5-1

are

maintenance

section

procedure

test

that

if a control

Keypad

Lamp

test;

check

The

order

the

corrective

of

corrective

should

the

instrument

If

the

test

repair a microprocessor

your

facility,

returned

mode

5.3.

The

is

to

replicates

key

test;

if a LED

if

the

probable

failure

actions

reduce

equipment

it

to

the

routines

correlated

test

recommended

perform

the

is

not

instrument

causes

actions

probability.

in

repair

to

patient

is

recommended

factory

presented

directly

sequence

the

reported

functioning - run the

segment

are

the

sequence

time

care

required

system

for

to

described

troubleshooting

Maintenance

discrepancy;

is

out - run

fails

to

under

Initialization.

listed

in a descending

Performing

and

expedite

service.

to

troubleshoot

is

the

repair.

the

power-up

provided

not

instrument

in

the

in

Mode

e.g.

the

-

the

returning

and

available

at

be

UPDO3

5-10

Page 11

imed

Table

5-1.

Troubleshooting/Fault

Isolation

Guide

LED

Alarm

Test/Fault

display

tone

INITIALIZATION

No

No

Probable

Battery

Battery

F1

POWER

Transistor

Transistor

Lithium/NiCad

Digital

Audio

Audio

Analog

<5.58

harness

on

Power

ON

Logic

Harness

Oscillator

Board

Harness

Lead

Cause

Volts

fuse

blown

Supply

switch

Battery

Failure

Failure

PCB

inoperative

Unplugged

Disconnected

Failure

Disconnected

Failure

(v2.xx

blown

ONLY)

Corrective

Connect

Replace

Replace

Check

Test/Replace

Connect

Repair

Replace

Replace

Connect

Replace

Replace

AC

fuse

fuse

Keypad

Transistor

Broken

Lithium/NiCad

Digital

Audio

Audio

Analog

Action

Power

Cable

Keypad

Harness

Wire

Logic

Harness

Oscillator

Board

Connector

Battery

Board

LEDs

VERSION

‘maintenance

vice

'PC-2

‘maintenance

Model/Version

Model/Version

corrupted

stay

'PC-2

V2.13'

ON

DISPLAY

V2.13'

V2.13'

vice

V2.13°

fails

display

to

scroll

Digital

Maintenance

Maintenance

Maintenance

Digital

Display

Power

Digital

Display

Logic

Logic

Board

Supply

Logic

Board

Failure

Plug

Plug

Piug

Failure

Failure

Installed

not

Faulty

Failure

Board

Failure

—

5-11

Installed

Failure

Replace

Remove

install

Replace

Replace

Replace

Replace

Replace

Replace

Digital

Maintenance

Maintenance

Maintenance

Digital

Display

Power

Digital

Display

Logic

Logic

Supply

Logic

一

Board

Plug

Plug

Plug

Board

Board

Board

Board

Board

Page 12

imed

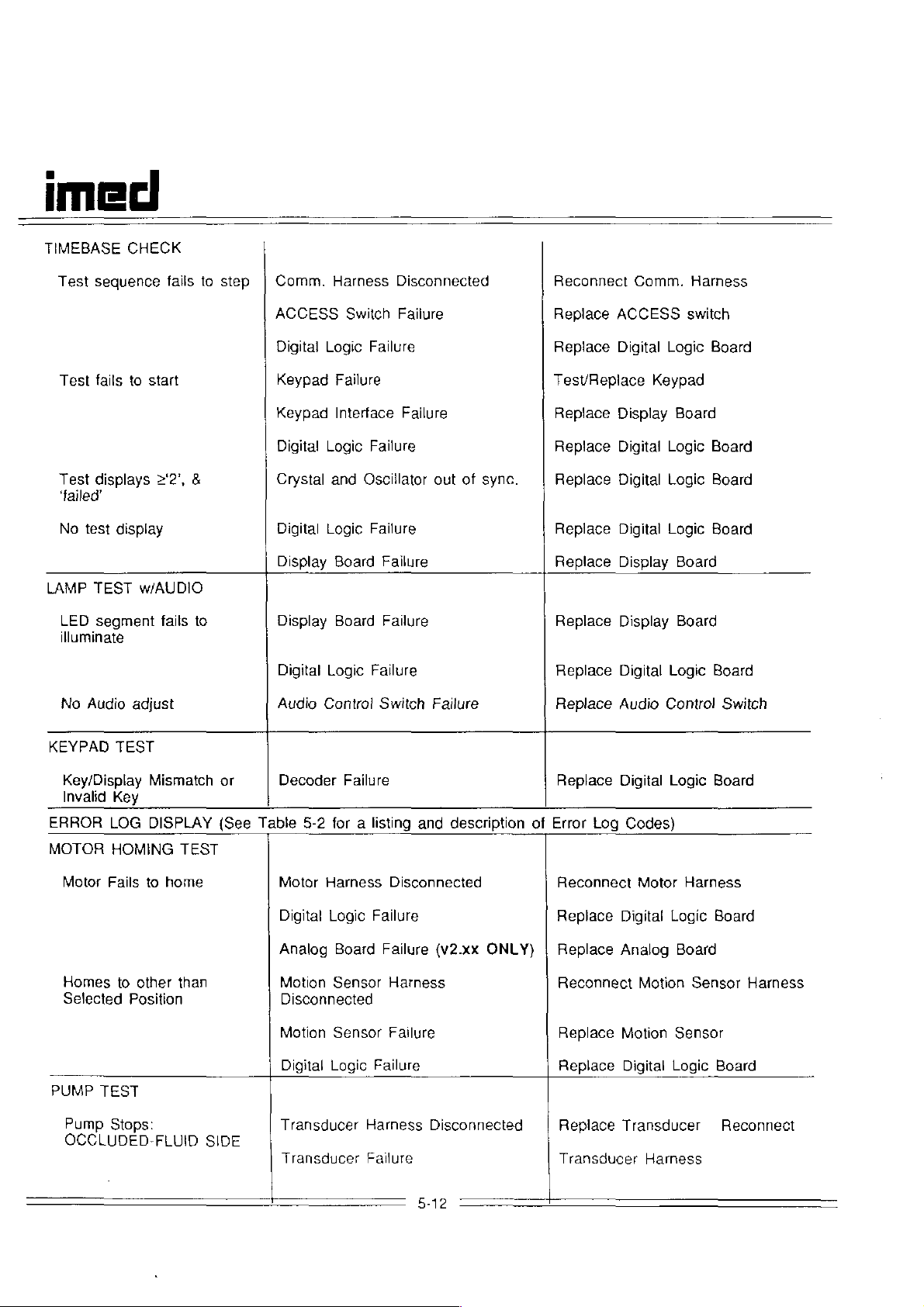

TIMEBASE

Test

sequence

CHECK

fails

to

step

Comm.

Harness

Disconnected

Reconnect

Comm.

Harness

Test

Test

displays

‘failed’

No

test

LAMP

TEST

LED

illuminate

No

Audio

KEYPAD

fails

to

display

segment

adjust

TEST

start

=2',

w/AUDIO

fails

&

to

ACCESS

Digital

Keypad

Keypad

Digital

Crystal

Digital

Display

Display

Digital

Audio

Switch

Logic

Failure

Failure

Interface

Logic

Failure

and

Oscillator

Logic

Failure

Board

Board

Logic

Failure

Control

Failure

Failure

Failure

Failure

Switch

out

of

Failure

sync.

Replace

Replace

Test/Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

ACCESS

Digital

Display

Digital

Digital

Digital

Display

Display

Digital

Audio

switch

Logic

Keypad

Board

Logic

Logic

Logic

Board

Board

Logic

Control

Board

Board

Board

Board

Board

Switch

Key/Display

Invalid

ERROR

MOTOR

Motor

Homes

Selected

PUMP

Pump

OCCLUDED-FLUID

Key

LOG

HOMING

Fails

to

TEST

Stops:

Mismatch

DISPLAY

TEST

to

home

other

than

Position

or

(See

SIDE

Decoder

Table

Motor

Digital

Analog

Motion

Disconnected

Motion

Digital

Transducer

Transducer

Failure

5-2

for a listing

Harness

Logic

Board

Sensor

Sensor

Logic

and

Disconnected

Failure

Failure

Harness

Failure

Failure

Harness

Failure

description

(v2.xx

Disconnected

ONLY)

Replace

of

Error

Reconnect

Replace

Replace

Reconnect

Replace

Replace

Replace

Transducer

Digital

Log

Codes)

Digital

Analog

Motion

Digital

Transducer

Logic

Motor

Logic

Motion

Logic

Harness

Board

Harness

Board

Board

Sensor

Sensor

Board

Harness

Reconnect

Page 13

u

imeci

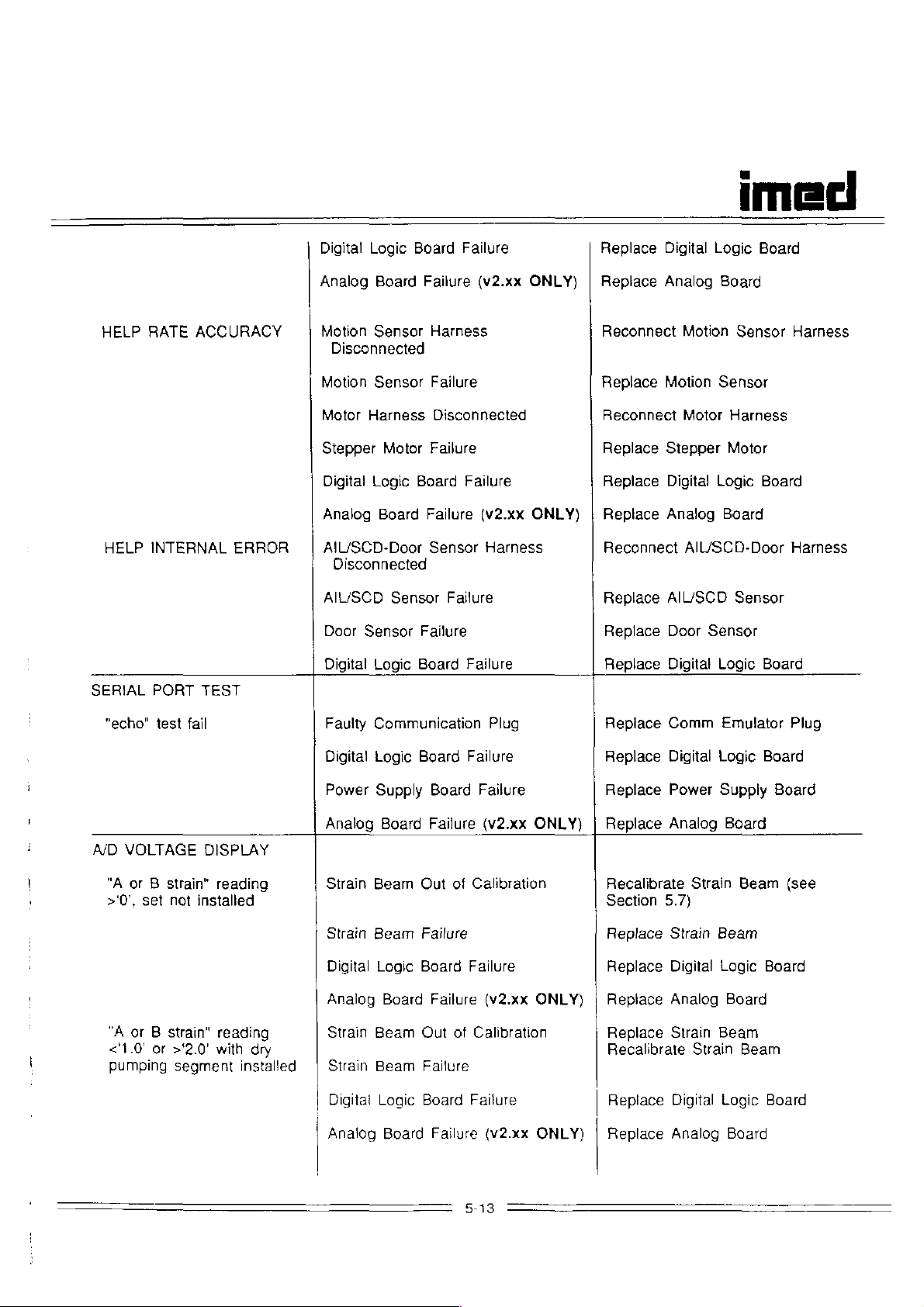

HELP

HELP

SERIAL

RATE

ACCURACY

INTERNAL

PORT

TEST

ERROR

Digital

Analog

Motion

Motion

Motor

Stepper

Analog

Logic

Board

Sensor

Disconnected

Sensor

Harness

Motor

Digital

AIL/SCD-Door

AIL/SCD

Door

Digital

Logic

Board

Disconnected

Sensor

Sensor

Logic

Board

Failure

Failure

Harness

Failure

Disconnected

Failure

Board

Board

Failure

Failure

Sensor

Failure

Failure

Failure

(v2.xx

(v2.xx

Harness

ONLY)

ONLY)

Replace

Replace

Reconnect

Replace

Reconnect

Replace

Replace

Replace

Reconnect

Replace

Replace

Replace

Digital

Analog

Logic

Motion

Motion

Stepper

Digital

Analog

AIL/SCD

Door

Digital

Sensor

Motor

Logic

AIVSCD-Door

Sensor

Logic

Board

Board

Sensor

Harness

Motor

Board

Sensor

Harness

Board

Harness

Board

"echo"

AID

|

i

"А

>'0’,

"A

<1.0

pumping

test

fail

VOLTAGE

or B strain"

set

or B strain"

or

DISPLAY

not

installed

>2.0

segment

reading

reading

with

dy

installed

Faulty

Digital

Power

Analog

Strain

Strain

Digital

Analog

Strain

Strain

Analog

Communication

Logic

Supply

Beam

Beam

Logic

Beam

Beam

Digital

Logic

Board

Board

Board

Board

Board

Failure

Out

of

Failure

Board

Failure

Out

of

Failure

Board

Failure

Plug

Failure

Failure

(v2.xx

Calibration

Failure

(v2.xx

Calibration

Failure

(v2.xx

ONLY)

ONLY)

ONLY)

Replace

Replace

Replace

Replace

Recalibrate

Section

Replace

Replace

Replace

Replace

Recalibrate

Replace

Replace

Comm

Digital

Power

Analog

Strain

5.7)

Strain

Digital

Analog

Strain

Strain

Digital

Analog

Emulator

Logic

Board

Supply

Board

Beam

Beam

Logic

Board

Board

Beam

Beam

Logic

Board

Board

Plug

Board

(see

Page 14

imeci

"sys

batt"

or

>'3.55*

reading

<'2.79'

Power

Supply

Board

Failure

Check

fuse

Battery

Voltage

at

in-line

"V(mains)

ог

>'2.55'

"V(ref)"

+.02

INPUT

PORT

Normal

AIL

Sensor - wrong

for

condition

reading

other

TEST

mode

than

<2.45'

‘2.49’

digit

Digital

Battery

Wrong

Power

Digital

Power

Digital

Ultrasonic

Analog

Digital

Logic

Board

Failure

Battery

Supply

Logic

Board

Supply

Logic

Board

Emitter/Receiver

Circuit

Logic

Board

Failure

Installed

Board

Board

Failure

Failure

Failure

Failure

Failure

Failure

NOTE

failure

Replace

Replace

Replace

Install

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Power

Digital

Battery

|.P.B.

Power

Digital

Power

Digital

AIL/SCD

AIL/SCD

Digital

Listed

Supply

Logic

Battery

Supply

Logic

Supply

Logic

Assembly

PC

Logic

Board

Board

Board

Board

Board

Board

Board

Board

The

logic

Normal

than

the

SCD

for

ECD

for

Motion

for

mode

sensor

Selftest

Sensor - wrong

condition

Sensor - wrong

condition

Sensor - wrong

condition

for

the

test

operation.

mode.

SCD

the

sensor

SCD

The

digit

digit

digit

is

reversed

sensor

following

Light

Analog

Digital

Light

Communication

Power

Digital

Sensor

Digital

is

being

SCD

Emitter/Receiver

Circuit

Logic

Emitter/Receiver

Supply

Logic

Failure

Logic

in

relation

tested

sensor

Failure

Failure

Cable

Board

Board

Board

to

for

operation

failure

Failure

Failure

Failure

Failure

Failure

the

other

response

test

sensors.

to

the

processor

is

the

response

Replace

Replace

Replace

Replace

Reconnect

Communication

Replace

Replace

Replace

Replace

AIL/SCD

AIL/SCD

Digital

ECD

Power

Digital

Sensor

Digital

Consequently,

strobe

expected

Assembly

PC

Board

Logic

Board

or

Replace

Cable

Supply

Logic

Logic

Board

Board

Board

in

the

rather

from

Page 15

Door

for

condition

In

the

protocol.

response

strabe

POWER

Sensor - wrong

Selftest

The

to

mode

digital

the

strobe.

circuitry.

DOWN

TEST

digit

the

Sensor

Digital

microprocessor

presentation

If

the

response

Failure

Logic

seen

Board

is

in

is

the

Failure

NOTE

strobing

RATE

not

the

the

sensors

and

VTBI

expected

Replace

Replace

in

displays

response a problem

Sensor

Digital

accordance

reflect the

imed

Logic

Board

with a software

sensors

exists

within

the

Displays

remain

On

Digital

Logic

Board

Failure

Replace

Digital

Logic

Board

=

5-15

Page 16

alemyos

XXA

ci

esne9

91420014

gın

pjeog

91607

Bujueew

이

бо!

607

ола

10413

luapls9JJo

841

dnpels

sso]

Buunp

ul

04110581

Åjuo

sJn99O

19584

Sgl9S/DedAayl

』9B9jUl

2-Od

SepoD

Bo7

10113

‘5-6

эает

uond¡19seq

ane

03SN

607

LON

10113

aunyey

:09A

ABYEG

Ave

ane]

QVOIN

le

95ellonA

nono

-

A027

40842

Auayeg

HI

“SaHlue

ane;

pagog

21607

luaumlsul

umop

*ULIETE

suamod

:dn-Jewmod

InOHLIAW

Pue

2945

Buunp

Alalelpsuuuul

Эно

pal5a130

$1

824

WOH

(1#

00003

10113

995)

unie

ange,

nono

pieog

ÁlSgeg

91507

|

uoisnui

gJnIIB

jo

uonod

paissales

‘SIIe}

ey

189]

AISNOIASIT

“dn-s2Mod

949

E

ol

Jo

Buunp

paloalqns

SSOJ

U!

pajosjea

S]INS84

NYH

BY

cA

эзвэюн

эле

элемцоб

ИУНАМ

9/n|1ey

pleog

아

007

οἱ

이

payejai

Sul

1581

*Aejdsip

SlEJjuouunjisul

WYH

jou

syajaweed

SANONUISEP

S1U8ul69S

ynejag

‘siajeweled

aasn

LON

'5JsleuueJgd

VH

E

dn-18mod

UO

DSuJOJ8d

uolsnuut

Buung

gJnlIBd

VH

인

미비

01608

91607

INOHLIM

이

10949

4406

94600

95Bue」

B

046

"dn-JeAod

12840

Аирнел

5uun

“uueje

ロ

で

LC

て

A

(L#

8PO9

10113

969)

аапие;

иполо

Алэдез

|

$591

UI

“siajauesed

D9O1S

зупвел

S』919UJBJBd

UOISTJUI

UO

9SB919H

9』BAJOS

'pakeıdsıp

хоецо

UOISTyUI

SIL

ae

payoajas

JO

9JnHEB

Apsnoiaeid

ゴ

D9uJJOJ9d

WVHAN

JO

"Ans

Y

EE

ZA

9S6SI9H

52949

ÂNUEŞ

элемцо$

idwayy

‘pebeyosip

94004

Ajanisseoxa

+

10)

95JBUO9』

Layeg

имор

asned

‘paysayo

1эмо4

JCA

Аэуерашиш!

0€'S>

s|

aBeyoa

40

suajawesed

ynejaq

jo

Ino

Siajawesed

[BONO

Q'8<

‘dn-samod

O1

Siueuu9JnSBaul

1U9UHTJISUI

Buying

SU]

인

미티

30461

시

9469

(14

ap00

1003

99$)

эллие}

ane)

иполо

preog

Álspeg

91607

UueIY

LNOHLIM

XINO

εἰ

ane;

6

элпие;

958Ε8ΙΘΗ

peog

рлеов

DIEMYOS

BoleuY

91607

10

49945

Аэцеа

Чп-лэмоЧ

биипр

$11590

пизи

jo

0

uohelduuoo

Ol

y

uy

“UoISISAUCO

q/y

antes

GAY

841

99062

яцрзоэуэр

uodn

[^

MOPUIM

pouuuueJ6oJjd

с}

ssnie4

luanbasqns

Aue

99STİ

‘sbuipeai

09

si

1dnJJ81Ul

E

UYUM

DAY

:0}

1U8UHTM1SUI

‘ON

9P09

00

LO

20

£0

#0

5-16

SO

90

£0

Page 17

品

21

59003

ame,

элпив;

pieog

реоа

Áeidsiq

91607

„HOHYJ

SI

ui

yey)

paniadas

si

epooksy

Ἴ81Λ

ΡΗΕ

2

UOYM

ojeH

$21990

Sul

uy

‘abuel

IVNEJLNÍ

apooday

JT3H.

|e6al

'PoBGoj

SU}

jo

apisino

Si

10183

pañeldsip

"dnG

цве

DUP

2p09

LNOHLIM

CE

ELZA

эзеэ1эн

dIEMHOS

10118

て

A

0Stojey

SU]

UAODP

UM

dIEMHOS

J9Aod

dn

490]

apookey

geodde

ulB

‘ON

peubisseun

内

SABIdSIP

8P09

1013

au}

DUB

pallo49S

의

‘pueog

1A

UE

SeA12981

PUB

ABIdSI

コ

1VH

10859901

SU)

9U]

LOL)

Ul

Kay

pre

aul

aasn

LON

80

11-60

ALON

10443

101

1994104

2p09

pjeog

10112

91607

ou}

Áejdsip

ATNO

IM

yuenbesans

DUB

OE'ZA

9589191

э4емцоз

SILUEIJ6oud

JO

YO9UO

suhnol

AEMEUN

140,

e

©

MOUS

6uunp

B

UBUM

[IM

paloalep

S1NDD0

Åejdsip

ojeH

SIBMYOS

041

'4810510

10113

WA

QIBM}OS

painSyuos

1817.

041

[PJ9UDD)

비

S1U83UJr1J1SUi

66

46004

el

peIIOJoS

SECA

YÖNOYI

SI

YOUNS

ÇE'ZA

TYØNHILNI!

asSeal3H

DIEMYOS

d

13H«

“oil6ol

eu)

ul

sieadde

'SABIdSID

‘on

apoo

IdB1A

103

PUE

94]

ヨ

1VH

pue

人

]NO

9Jnllej

EL

と

USIuBU99W

BuldUund

эапие;

A

956919Н

реоа

э4лемцо$

баечу

JO

„HOUHA

ajdwies

e

ui

%G'|<

1018

UB

USYM

Y

"YO

sieadde

gu1

Aq

“ON

TVNH

D9129j8D

9p09

ヨ

1NI

10113

SI

1

SUOIInIOASj

ヨ

9041

H。

0SUSS

2046

0

」O19UJ

히

el

OHOUU

09

10105

SI

$11550

HO

DUAS

J010N

“sAeldsip

IgLA

PUB

ALYH

041

녀

人

INO

9JnllE」

&SrzA

dusluguoeW

_6uldtund

ane)

3aSeelaH

Pieog

SJEMNOS

Bojeuy

Jo

„HOH4I

ajdujes

€

Ul

%G'1<

10149

UB

UDUM

&

‘U9

sapadde

341

0

‘ом

IVNHILNI

00129190

8p09

1013

SI

07311,

SUONN|OAA

'709499

JOJO

SINIIO

40404

OG

HO

AUAS

1010

Pi

3U

PUR

P3||OJ0S

SI

ainllej

usSIuedosm

인

미티

07609

6uldund

91607

841

0cL

JolOU

10

S19918D

9AlJBJ9dOU!

UUJUUGO

』OSUSS

“SAeldsip

O1

SI

UONOLW

』OSU9S

9JnIIB」

1381

J91JB

91}

Pu

ヨ

1VH

841

ul

UOI1OUJ

USUM

Sd81S

9U1

SINDIO

JO10UM

"9UAS

Y

“yo

pejoajap

6elj

9uAS

ON

gi

NINO

Е

[СЛ

ane

9569195

peog

э1емцо$

Воецу

ay)

pue

DUE

ЗЕУН

5110195

eu

,HOHH3

ul

siesdde

"Bulu」n1

1IVNUIINI

ON

'SABIdSIP

1OU

8DOO

SI

dIIH.

JOQ1OUU

JO』

[1」A

ヨ

5-17

Page 18

ci

80161

01608

91607

ATNO

인

ELFCA

미비

wsiueysay

9SBel9H

SIEMYOS

Buidund

ane)

plgod

Bolguy

paysıuluıg

AnoJlO

Ayoedeg

」95JeuO

4ΙΘΗΕΒ

Asayeg

pieog

AddnS

9A0d

ane]

Åjgquossy

элпие;

sseuseH

рвов

5607

1000

einlel

AIqulessY

gunpie;

SSAUIEH

piueog

21607

4000

SS9UIBH

gine)

pieog

J0O0Q/IV

IV

94/18]

espe)

pieog

91607

GINE)

pieog

IV