Page 1

Alaris

®

GW Volumetric Pump

Technical Service Manual

Page 2

This manual has been prepared for use by qualified service personnel only.

Cardinal Health cannot accept any liability for any breakdown or deterioration in performance of parts or equipment

resulting from unauthorised repair or modification.

t Cardinal Health, 1180 Rolle, Switzerland

Alaris® and Asena® are registered trademarks of Cardinal Health, Inc. or one of its subsidiaries.

All other trademarks belong to their respective owners.

© 2003-2006 Cardinal Health, Inc. or one of its subsidiaries. All rights reserved.

Alaris® GW Volumetric Pump 2/77 1000SM00006 Issue 4

Page 3

Contents

Chapter

1.

2.

3.

4.

5.

6.

Appendix

Introduction & Start up 4

Configuration & Calibration 10

Routine Maintenance 15

Troubleshooting 24

Circuit Descriptions 28

Spare Parts Replacement Procedures 32

Specifications 5

A.

Disposal 6

B.

Spare Parts Listing 6

C.

Fitting and Replacement Guidelines 6

D.

Compatible IV Infusion Sets 6

E.

Configuration Records 7

F.

Service Contacts 7

G.

Document History 7

H.

2

0

2

6

9

2

4

6

Alaris® GW Volumetric Pump 3/77 1000SM00006 Issue 4

Page 4

Introduction & Start up

In this chapter

Introduction 5

General precautions 5

Chapter 1

Views of the Alaris® GW Volumetric Pump 6

Controls and indicators 7

Operating the Alaris® GW Volumetric Pump 8

Starting the Alaris® GW Volumetric Pump 9

Features of the Alaris® GW Volumetric Pump 9

Page 5

Introduction & Start up

Introduction

The Alaris® GW Volumetric Pump is designed to deliver a continuous and accurate infusion. High performance, comprehensive alarm

protection and sophisticated monitoring systems, combined with simple operation, make this pump ideal for general care and critical

care in a variety of areas within a hospital.

The Asena® brand name has been recently changed to the Alaris® brand name. This change in brand name has no effect on the

intended use or functionality of the product. Recommended disposable products for use with this product may refer to either the

Asena® brand name or Alaris® brand name and both types are suitable for use with this infusion pump.

Familiarity

Before operation, ensure that you are fully familiar with this pump by carefully studying the Directions for Use (DFU) prior to

attempting any repairs or servicing.

As part of a policy of continuous improvement, product enhancements and changes are introduced from time to time.

Purpose

This Technical Service Manual describes how to set up, test and maintain the Alaris® GW Volumetric Pump. It is intended for use by

personnel experienced in medical equipment testing and maintenance procedures.

Symbols

Wherever you see this symbol in the manual you will find a Hints & Tips note that we hope you will find useful.

These notes provide useful advice or information that may help you perform the task more effectively.

Wherever you see this symbol in the manual you will find a Toolbox note that highlights an aspect of test or

maintenance that is important for you to know about. A typical example is a software upgrade that you should

check has been installed.

General precautions

Please read the general Operating Precautions described in the Directions for Use carefully prior to using this pump.

w

This pump contains static-sensitive components. Observe strict precautions for the protection of static sensitive

components when attempting to repair and service the pump.

V

An explosion hazard exists if the pump is used in the presence of flammable anaesthetics. Exercise care to locate the

pump away from any such hazardous sources.

B

An electrical shock hazard exists if the casing of the pump is opened or removed. Refer all servicing to qualified

service personnel.

A

This pump is protected against the effects of high energy radio frequency emissions and is designed to fail safe if

extremely high levels of interference are encountered. Should false alarm conditions be encountered, either remove

M

the source of the interference or regulate the infusion by another appropriate means.

If the pump is dropped, subjected to excessive moisture, humidity or high temperature, or otherwise suspected to

have been damaged, remove it from service for inspection by a qualified service engineer.

*

When connected to an external power source, a three-wire (Live, Neutral, Earth) supply must be used. If the integrity

of the external protective conductor in the installation or its arrangement is in doubt, the pump should be operated

Alaris® GW Volumetric Pump 5/77 1000SM00006 Issue 4

from the battery.

Page 6

Introduction & Start up

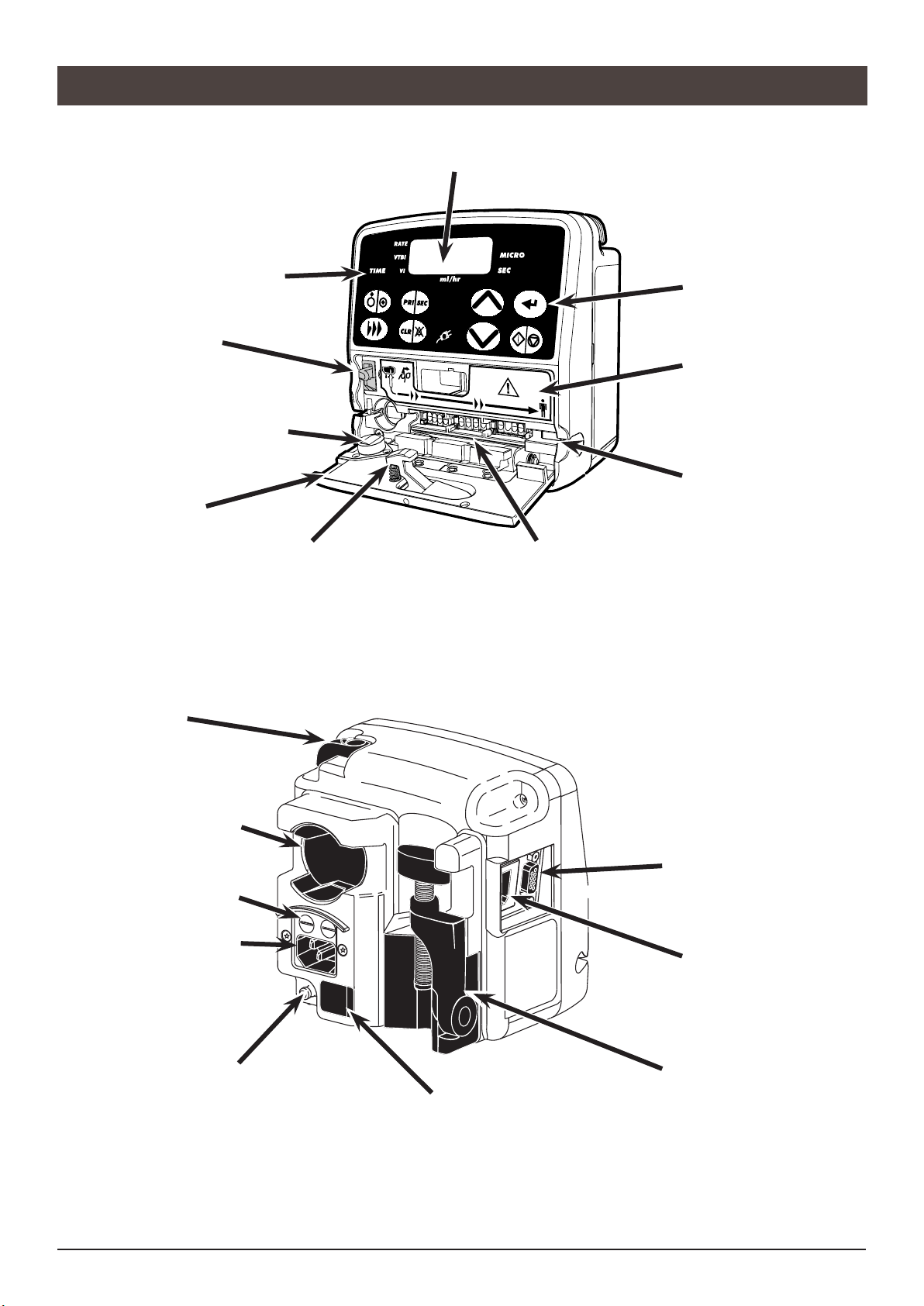

Views of the Alaris® GW Volumetric Pump

Front view

Display Indicators

Flow Stop Mechanism

When activated the

mechanism will stop fluid

flow.

Air Sensor

Bevel

Releases the flow stop

mechanism lever arm when

the door is closed.

Main Display - Displays the infusion rate, VTBI, VI and time

remaining for VTBI / Time infusions. Display will flash when

pump is operating on battery.

Door Latch

Press outer latch to open

the door.

Tubing Guide

Guide to assist in the loading of

the IV infusion set.

Keypad

Flow Direction Label

Pressure Sensor

Rear view

Release Lever

Rotates cam to release

the pump from horizontal

rectangular bars.

Rotating Cam

Attaches the pump to

rectangular bars or Alaris®

DS Docking Station.

AC Fuses

AC Power Connector

Potential Equalisation (PE)

Connector

RS232 Connector / Nursecall

Flow Sensor Interface

Folded Pole Clamp

Infrared Communications port (IrDA)

Alaris® GW Volumetric Pump 6/77 1000SM00006 Issue 4

Page 7

Controls and indicators

PRIMARY / SECONDARY

Switches the pump between Primary and Secondary infusion modes (if enabled).

ON / OFF

Switches the pump on and off.

PRIME / BOLUS

Primes the IV infusion set.

Administers bolus during the infusion.

CLEAR / SILENCE ALARM

Resets numeric values to zero.

Silences alarms and warnings for 1 minute.

ENTER

Scrolls between rate, time, VTBI and total volume infused (VI).

Enters values for selected infusion/configuration parameters.

Confirms the rate during an infusion titration.

RUN / HOLD

Starts and stops the infusion.

Cancels alarm.

CHEVRONS

Increases or decreases the infusion rate, TIME limit and VTBI.

Press and hold to increase the selection speed.

Used to adjust user selectable options.

Introduction & Start up

When any of the following are illuminated:

AC POWER INDICATOR - The pump is connected to an AC power supply.

RATE The pump is displaying the infusion rate in millilitres per hour (ml/h).

VTBI The pump is displaying the Volume To Be Infused (VTBI) in millilitres (ml).

VI The pump is displaying the Volume Infused (VI) in millilitres (ml).

TIME The pump is displaying the infusion time in hours : mins.

MICRO The pump is operating in the MICRO mode. When not illuminated, the pump is in the STANDARD

mode.

SEC The pump is operating in the SECONDARY mode. When not illuminated, the pump is in the PRIMARY

mode.

ml/hr (Millilitres / hour) When ml is illuminated the pump displays the VTBI or VI. When the hr is illuminated

the pump displays the rate or infusion time.

Infusion indicator - Infusing in STANDARD mode.

Infusion indicator - Infusing in MICRO mode.

Infusion indicator - Displays fluid drops detected by the flow sensor when infusing in STANDARD mode.

Infusion indicator - Displays fluid drops detected by the flow sensor when infusing in MICRO mode.

Alaris® GW Volumetric Pump 7/77 1000SM00006 Issue 4

Page 8

Introduction & Start up

Operating the Alaris® GW Volumetric Pump

Follow the instructions supplied with the individual IV infusion set.

Use of non-specified IV infusion sets may impair the operation of the pump and the

accuracy of the infusion.

Refer to the "Compatible IV Infusion Sets" section in Appendix D, for a list of

recommended IV infusion sets.

Ensure that the tubing is inserted completely into the pumping channel, avoiding any

slack.

Position the IV fluid container to avoid spillage onto the pump.

When using 273-003 IV infusion sets, ensure a separation of at least 30cm is

maintained between the pump and the upper Y-site.

1.

Close the in-line clamp on the IV infusion set. Press the door

latch to open the door.

Release the flow stop mechanism by pushing the lever arm up

2.

and to the right.

3.

Insert the IV infusion set from left to right into the slot provided,

following the flow direction label, avoiding any slack.

Re-engage the flow stop mechanism by pushing the lever left

4.

and down.

Close the door. Use the recesses in the door to press firmly to

5.

ensure the latch is correctly applied. Open in-line clamp on the

IV infusion set.

Observe fluid chamber and check for no fluid flow.

6.

Alaris® GW Volumetric Pump 8/77 1000SM00006 Issue 4

Page 9

Introduction & Start up

Starting the Alaris® GW Volumetric Pump

Close in-line clamp.

1.

Load IV infusion set.

2.

Half fill the drip chamber.

3.

Open in-line clamp.

4.

Press to switch pump on.

5.

Prime () set: Press once. Whilst is displayed press again and hold to clear all visible air from the line.

6.

Connect to test equipment as required.

7.

Set-up pump as described below:

8.

RATE / VOLUME

Enter rate using .

1.

Press once to scroll to VTBI.

2.

Enter VTBI using .

3.

Press to scroll to VI.

4.

If necessary, press to clear VI.

5.

Press to start infusion.

6.

On completion, infusion will continue at KVO rate until is

pressed.

If a flow sensor is used, VTBI is set to

OFF; by pressing the a VTBI may be

set.

Features of the Alaris® GW Volumetric Pump

VTBI / TIME

If necessary, press to put pump on hold.

1.

Press for 2 seconds, press twice and will

2.

display, use Keys to scroll to On.

Press twice to return to hold mode.

3.

Enter VTBI using .

4.

Press to scroll to TIME .

5.

Enter TIME using .

6.

Press to scroll to VI

7.

If necessary, press to clear VI.

8.

Press to start infusion.

9.

Panel Lock - prevents certain key operations

Press together to turn Loc On or to turn Loc Off.

1.

Rate Titration - while infusing

Press to adjust rate.

1.

Press to confirm change of rate.

2.

Bolus Infusions - while infusing

Press twice and hold, release after administering the desired bolus volume.

1.

Micro Mode* - pump must be on hold

Press and hold for 2 seconds.

1.

Press three times - will be displayed.

2.

Use to turn micro mode on or off.

3.

Press once to return to or set-up.

4.

* configurable options, refer to Directions For Use.

Alaris® GW Volumetric Pump 9/77 1000SM00006 Issue 4

Page 10

Chapter 2

Configuration & Calibration

In this chapter

Access codes 11

Configurable options 11

Calibration procedures 13

Page 11

Configuration & Calibration

Configuration & Calibration

Access codes

The pump software contains a number of configuration and test routines that can be accessed by the user. The majority of tests are

driven from a technical access code (see below).

Entering Access Codes

With the pump OFF.

1.

Press and hold and press and release .

2.

The pump will alarm and briefly show the software version

3.

installed in the pump. It will then display “CodE”.

Release the key and the pump will display "0".

4.

Use the keys to select the code required from the list.

5.

Press the key to confirm your choice.

6.

If an invalid code is entered, the pump will display “CodE”

7.

followed by “0”.

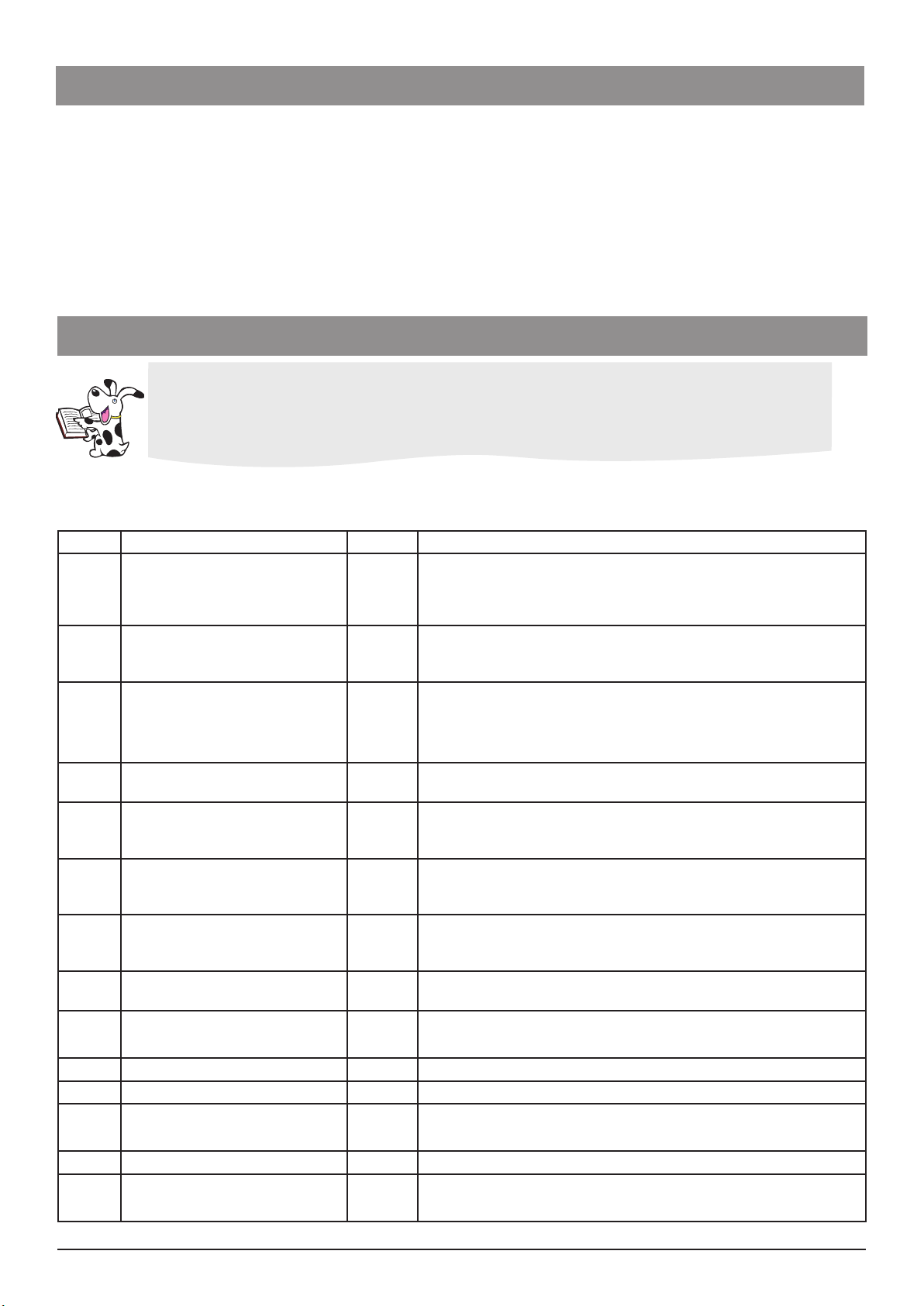

Configurable options

The default settings are configurable as displayed in the table below.

Each of the configurable options has a code which must only be altered by a qualified service

engineer with reference to the technical service manual.

Any changes made that are not confirmed by pressing will not be saved on power up.

Use the keys to adjust the selected option. Press the key to confirm your choice. The following access codes can be used to

configure the pump:

Code Description Default Summary

Select one of the two available infusion modes:

21 Enable Volume/Time Infusions OFF

22 Maximum Priming Volume 40ml

23

24 Maximum VTBI in MICRO Mode 999ml

25 Bolus Rate 400ml/h

26 Maximum Bolus Volume 5ml

27 Keep Vein Open (KVO) Rate 5ml/h

28 Single Bubble Alarm Volume* 100µL

30 Enable Secondary Infusions OFF

31 Default Occlusion Pressure Hi Set the default occlusion alarm value (Lo, Normal or Hi) at power-on.

32 Alarm Volume Level 4 Set alarm volume level between 1 (low) and 7 (high).

35 Enable MICRO Mode OFF

36 Maximum Infusion Rate 999ml/h Set the maximum infusion rate between 1 and 999ml/h.

38 ASCII Mode Comms OFF

Clear Infusion Parameters to Zero

on Power On

OFF

(CLoC) OFF: Input a Flow Rate and Volume to be Infused (VTBI)

(CLoC) ON: Input a Volume to be Infused (VTBI) and Time for infusion.

The Maximum volume (OFF, 1 - 40ml) to be infused during priming

sequence. Before starting an infusion, pressing the b key will initiate set

priming sequence.

OFF: Previous infusion parameters: last rate, VTBI (and time of

infusion if applicable) and volume infused are displayed on

power on.

ON: Previous infusion parameters are reset to zero on power on.

Set the maximum allowable VTBI between 0.1ml and 999ml, in micro

mode only.

Set the Bolus rate between 1 and 999ml/h (providing the default bolus

volume is greater than zero). Pump will infuse at this rate when b key is

pressed twice and held.

Set the maximum bolus volume between Off and 99ml. Maximum

volume that will be delivered whilst the b key is held down during an

infusion.

Set the Keep Vein Open (KVO) rate (OFF, 1.0 - 5.0ml/h). At the end of the

infusion, the pump can either stop pumping or continue infusing at a

Keep Vein Open (KVO) rate.

Set the maximum size of air bubble (50µL, 100µL, 250µL, 500µL) that

can be passed through the pump without causing an alarm.

OFF: Disable automatic secondary infusions.

ON: Enable automatic secondary infusions.

OFF: Standard infusion mode.

ON: Enable micro mode.

OFF: Disable ASCII communications mode.

ON: Enable ASCII communications mode.

Alaris® GW Volumetric Pump 11/77 1000SM00006 Issue 4

Page 12

Configuration & Calibration

Configuration & Calibration

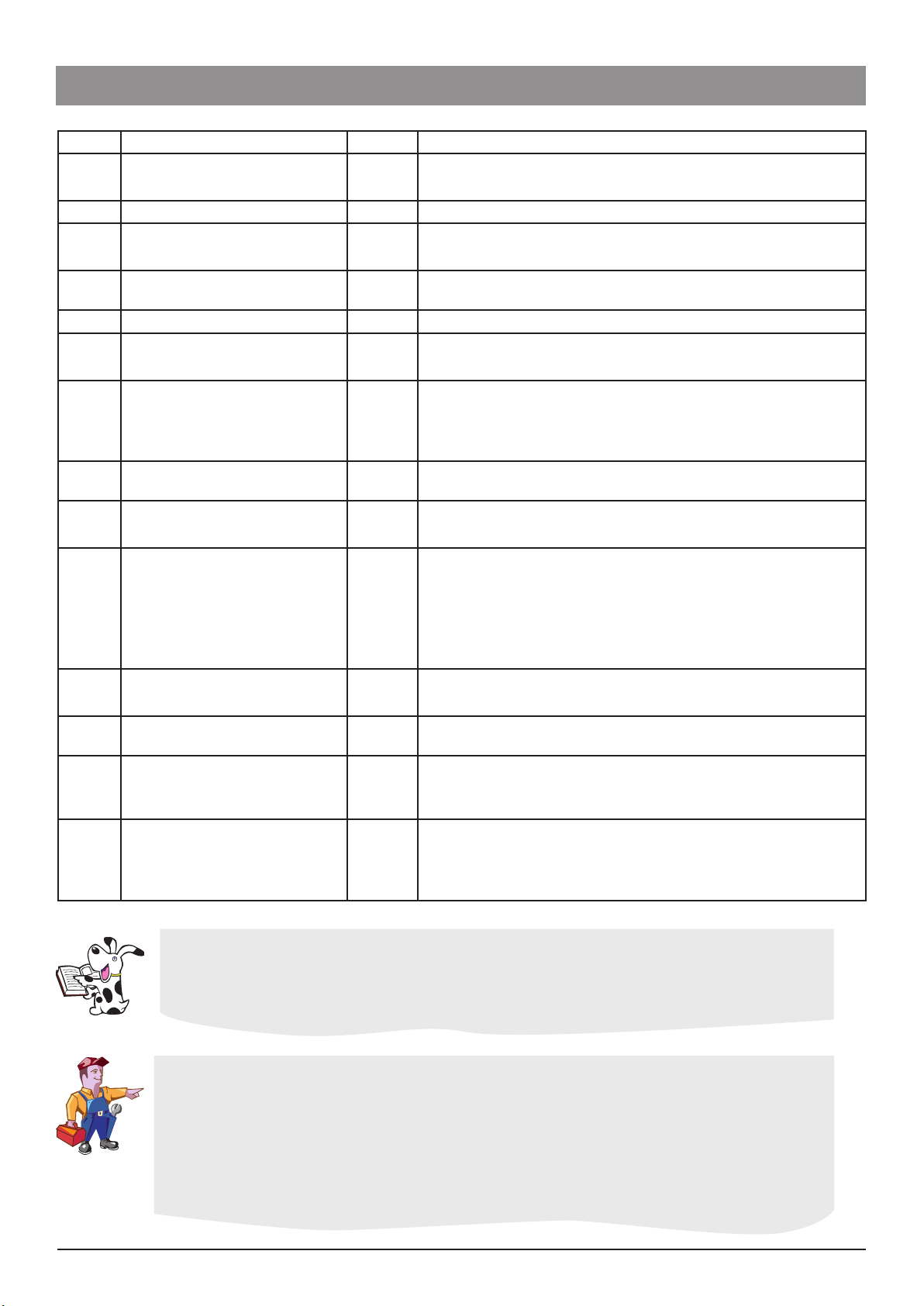

Configurable options (continued)

Code Description Default Summary

39 Odd Parity Comms OFF

40 Pump Address Comms 1 Set pump address used for communications (1 to 250).

41 Flow Sensor Connection Mode AUTO

42 Set-up of Current Time and Date

44 Language Selection EnGL Set language used (EnGL, dEut, FrAn, ItAL, ESPA, nEd, SE).

45 IrDA Communications Selection ON

46 Nurse Call Activation ON

47 Drops per ml of Fluid 20

48 Silent Mode OFF

User Select Mode Configuration:

• Pressure Limit Enabled

49

50 Flow Sensor Sensitivity Level nor

200

201 Reset EEPROM data -

202 Repair EEPROM data -

• Alarm Volume Enabled

• Timed Infusions Enabled

• Micro Infusions Enabled

Reset all configurable options to

default

OFF

- Resets all configurable options to factory default.

OFF: Disable odd communications parity bit generation.

ON: Enable odd communications parity bit generation.

AUTO: Pump automatically detects flow sensor if connected.

ON: Pump will only operate with a flow sensor connected.

Set current time (00:00 to 23:59), and date (01/01/00-31/12/99) for

event logging. Does not automatically adjust for Summer time.

OFF: RS232 comms enabled.

ON: IrDA comms enabled.

OFF: Disable activation state of the nurse call (active low output from

pump).

ON: Enable activation state of the nurse call (active high output

from pump).

Select number of drops per ml of fluid (1 to 200). Defined by the type of

set. Reference the packaging of IV infusion set.

OFF: Audible response to a key press is given.

ON: No audible response to a key press is given.

OFF: Disable mode.

ON: Enable mode.

nor: Normal sensitivity.

Hi: High sensitivity.

Reset EEPROM data code to a defined state if EEPROM checksum error.

NOTE: The pump will need to be returned to factory for reconfiguration

if this option is used.

Detects and repairs any corrupted memory segments, resetting any

repaired areas back to the factory defaults.

NOTE: The pump will need to be returned to factory for reconfiguration

if this option is used.

*Single Bubble Alarm Volume

Although an individual bubble may not exceed the pre-programmed threshold, the

accumulative volume of bubbles, in a 15 minute window, may be sufficient to initiate an air-inline alarm, indicated by an “Air OCCL” message.

Before making any amendments to configuration settings:

Care should be taken to document existing configuration settings to enable changes

to be reverted if required. Configuration requirements may vary from ward to ward

therefore care should be taken to ensure any configuration settings are appropriate

for the ward concerned and users are aware of any changes to configuration settings

prior to use.

Subsequently, sharing of Alaris® GW Volumetric Pumps between wards may be

inappropriate.

Alaris® GW Volumetric Pump 12/77 1000SM00006 Issue 4

Page 13

Configuration & Calibration

Configuration & Calibration

This section outlines the procedures for calibration of the Alaris® GW Volumetric Pump.

All of these calibrations should only be carried out by qualified biomedical engineers. If in any doubt about how to perform the tests,

in particular the pressure sensor calibration checks, contact your local Cardinal Health Service Centre who will be able to assist.

Calibration procedures

Recommended Calibration Equipment

Specialised test equipment is not required for the majority of the functional tests to be carried out on the pump. In order to calibrate

or verify the occlusion alarm point or volumetric accuracy, the following equipment will be necessary:

IV infusion set, suitable for the Alaris® GW Volumetric Pump with standard LUER lock taps for connecting to other test equipment.

If the standard sets are not available, it is possible to order a basic "test set" that is available from your local ALARIS® Service Centre

- part number 0000TG00074. Note that all sets should only be used for a single calibration operation.

Pressure gauge for measuring liquid pressure, with a full scale of 0-2 bar (0-1500mmHg) ±20mmHg.

either:

Class A 50ml glass burette with graduations down to 0.1ml and calibrated down to ± 0.05ml.

or:

Calibrated scales accurate to at least ± 0.01g.

Volumetric Accuracy Calibration (CODE 18)

Volumetric Accuracy Calibration (CODE 18)

The volumetric accuracy calibration routine is used for manufacture of the pump only.

The volumetric accuracy calibration routine is used for manufacture of the pump only.

Displaying the Volumetric and Pressure Calibration Values (CODE 2)

Use of this access code simply displays the calibration values stored in the software.

Enter the access code 2.

1.

Press to step through all Cal values.

2.

Switch the pump "OFF" if there are no further tests to be done at that time.

3.

Battery Calibration (CODE 4)

The pump must be connected to the AC power source throughout the duration of the test. The test can be aborted at any time by

switching the pump off using the key; no change is made to the battery low point calibration value stored previously in the

pump. This calibration should only be performed on a fully charged battery. Ensure the pump is plugged into the mains for at least

24 hours before starting this procedure.

Plug a mains lead into the pump.

1.

Prepare a fluid-filled looped tubing, load it into the pump and close the door.

2.

Enter the access code 4.

3.

The test will start automatically. The pump infuses at 999 ml/h internally switching to the battery power source to discharge the

4.

battery; the air-in-line alarm is disabled. Throughout this test the time indicator will increase in minute intervals.

As soon as the pump detects that the battery is discharged, the time shown on the main display will stop increasing and begin to

5.

flash.

If the time is greater than two hours and the low point voltage value is within the allowable range of 6.5 to 7.8 volts, then the

6.

display shows "PASS" / "xx:xx" / "bx.x", the pass indication, elapsed time and battery low point value in volts. Otherwise the

display shows "FAIL" / "xx:xx" / "bx.x".

Press the key. When the key is pressed, the low point calibration value will be stored.

7.

If the pump is switched off before the key is pressed, the calibration value will be lost and the

If the pump is switched off before the key is pressed, the calibration value will be lost and the

test will have to be repeated. When is pressed, the pump will revert to the technical service

test will have to be repeated. When is pressed, the pump will revert to the technical service

entry mode and flash CodE, followed by 0, this allows you to begin other tests. Switch the pump

entry mode and flash CodE, followed by 0, this allows you to begin other tests. Switch the pump

OFF if there are no further tests to be done at that time.

OFF if there are no further tests to be done at that time.

If the pump fails the calibration, try to charge the battery, and repeat the test. If this fails again then replace the battery and / or

8.

Power Supply Unit.

Alaris® GW Volumetric Pump 13/77 1000SM00006 Issue 4

Page 14

Configuration & Calibration

Configuration & Calibration

Calibration procedures (continued)

Pressure Sensor Calibration (CODE 17)

An internal pressure sensor is used to detect downstream occlusions. This sensor requires calibration whenever a new sensor, Main

PCB is fitted or if door is changed or removed. It is necessary when servicing a pump, to carry out an occlusion pressure test to verify

that the sensor is calibrated correctly (see self test routine in Chapter 3 Routine Maintenance). A calibrated pressure gauge will be

needed in order to perform this calibration.

PRI

SEC

Pressure gauge

± 20mmHg

When the pressure sensor is replaced the null pressure value must be checked and adjusted, if required, prior to

calibration. Check the null pressure value as follows:

1. Enter the access code 12. Go to test 8 and press e.

2. With no set loaded and door open check displayed value is 11 ±4.

3. If the reading is outside of tolerance then adjust R2 on the Pressure Sensor PCB until displayed value is within

tolerance.

Load a set into the pump to be calibrated and prime the set. Connect to pressure gauge as shown in diagram above.

Enter the access code 17.

Apply pressure required for each step and when pressure required is displayed on pressure gauge for 10 seconds (allows pressure to

settle) press e. Calibration values will be returned. Press e to go to next step.

PrES step - 150mmHg ± 40mmHg

HI step - 650mmHg ± 40mmHg.

CAP step - 1000mmHg ± 40mmHg.

Difference step

XX or XXX indicates calibration values, that have

no tolerance values applicable.

YYY indicates calibration values that should be

between 115 and 214.

ZZ indicates a calibration value that is the

difference between XXX and XX and should be

between 37 and 54.

Alaris® GW Volumetric Pump 14/77 1000SM00006 Issue 4

Page 15

Routine Maintenance

In this chapter

Routine maintenance 16

Test procedures 16

Chapter 3

General cleaning and inspection for damage 20

Storage 20

Data transfer 21

Performance verification procedure 23

Page 16

Routine Maintenance

Routine Maintenance

Routine maintenance

For routine maintenance, the following self-test and performance verification procedures should be performed in addition to the tasks

described in the section on General Cleaning and Inspection for Damage.

Refer to the relevant “Directions for Use” for the recommended routine maintenance period.

Test procedures

Important Service Information:

Important Service Information:

Testing and Calibration of Volumetric pumps is very dependent on the tubing set used.

Testing and Calibration of Volumetric pumps is very dependent on the tubing set used.

For this reason, a new set of tubing should be used for each pump tested, and the tubing

For this reason, a new set of tubing should be used for each pump tested, and the tubing

should be thrown away once all tests are completed. Recommended test set is part number

should be thrown away once all tests are completed. Recommended test set is part number

0000TG00074.

0000TG00074.

Entering Access Codes (Technician Mode)

Note: See Chapter 2 Configuration & Calibration for information on how to enter access codes

Code Test Description

1

2

3 Main Self Test See Self Test Routine Table.

4

5 Volumetric Accuracy Verification Test See Volumetric Accuracy Verification Test (code 5) detailed description in this document.

10 Alarm history log

11 Display current time and date -

12

17 Pressure Calibration Refer to Chapter 2 Configuration & Calibration.

18 Volumetric Calibration This is a manufacturing code, volumetric calibration should not be carried out.

19 Reduced Volumetric Calibration This is a manufacturing code, volumetric calibration should not be carried out.

67 Learn configuration settings See Teach Learn procedure.

Input a pump reference number, and

service date

Display volumetric, pressure

calibration and battery Cal values

Automatic Battery Maintenance/

Discharge Test

Access to individual tests within the

Main Self Test

This enables the user to put in their own 4 digit reference number or asset number, together with

the date the pump was last serviced in the format Wk:Yr (15:01) week 15 of 2001. Defaults to 0 &

0:00.

Reference only, 4 values shown:

CAL - 20.00 if pump has not been calibrated (range 16-24)

Pres - DXXX delta value, (range 36 to 55, default to 46)

CAP - CXXX Maximum value, (range 110 to 219, default 163)

bAt - bx.xx (range 6.44 to 7.86, default 7.15)

Takes approximately 2-5 hours, if it takes less than 2 hours it will display ‘fail’ The pump will then

switch to charging, it is recommended this be done for 24 hours.

This will show the last 10 error/alarm codes Use the key to step through.

Note: Not in Sequential Test (code 3), available only through code 12.

Test Nr. Description

9 EEPROM Checksum Test. Display two 16-bit EEPROM check sums. During power

up the processor calculates EPROM checksums values and checks them against

those stored, if a difference is detected a corruption in data has occurred.

11 Pumping Mechanism Test. This test disables the pressure, door and AIL sensors.

The pump will pump into a pressure gauge and display the pressure reached, this is

exited by pressing the enter key.

12 Bubble Measurement Test. This displays the size of the air bubble detected in

microlitres.

Alaris® GW Volumetric Pump 16/77 1000SM00006 Issue 4

Page 17

Routine Maintenance

Routine Maintenance

Test procedures (continued)

Self test routine

Enter access code 3. Press the key to advance to next test.

Level Test Description

Confirm display indicates correct button pressed.

When level is entered the display will show “b-1”, press buttons 1 to 8, after pressing button 8 the test

will automatically proceed to level 2.

1 Keypad Test

b-1 b-2 b-3 b-4 b-5 b-6 b-7 b-8

Check all LEDs.

The pump will run through a count-up series to illuminate each segment of the 7 segment LEDs, and

2 Display Test

3 Alarm Test

4 Door Test

5 Air Sensor Test

7 Motor Opto Test

8 Occlusion Pressure Test

cycle through all of the green LEDs.

Confirm all LEDs are working. At the end of this test all LEDs will illuminate.

Press the key to advance to level 3.

Confirm the alarm is working and a distinctive change is heard between volume levels. Pump displays

‘ALAR’ and alarms for 0.5 seconds at each volume (1 to 7).

Press the key to advance to level 4.

Confirm the change of state between door open (d-0) and door closed (d-1).

Press the key to advance to level 5.

Confirm the change of state between an air filled set (a-0) and a fluid filled set (a-1).

Press the key to advance to level 7.

Displays PASS or FAIL. Confirm displays PASS. The pump runs the motor forwards a turn, then backwards

a turn. The processor checks that it sees both motor optos come on at the correct time.

Press the key to advance to level 8.

Test requires a calibrated pressure gauge.

Connect the pump IV Infusion set to the pressure gauge via a 3 way tap.

Press the key for 10 seconds. Press the key, the pump will run at 125ml/h and the display will

show the current pressure sensor reading ‘xxx’.

After 10 seconds close off the 3 way tap so that the pump delivers into the pressure gauge.

Confirm that an alarm occurs and a ‘’ appears on the pump display. The pressure displayed on the

pressure gauge should be 500 mmHg +/- 150 mmHg.

Carry out the next test or press the key to advance to level 10.

10 Drop Sensor Test

Check for correct drop count.

This test counts the number of drops detected, if the sensor is not present then ‘Off’ will be displayed.

Alaris® GW Volumetric Pump 17/77 1000SM00006 Issue 4

Page 18

Routine Maintenance

30cm

30cm

30cm

30cm

Routine Maintenance

Test procedures (continued)

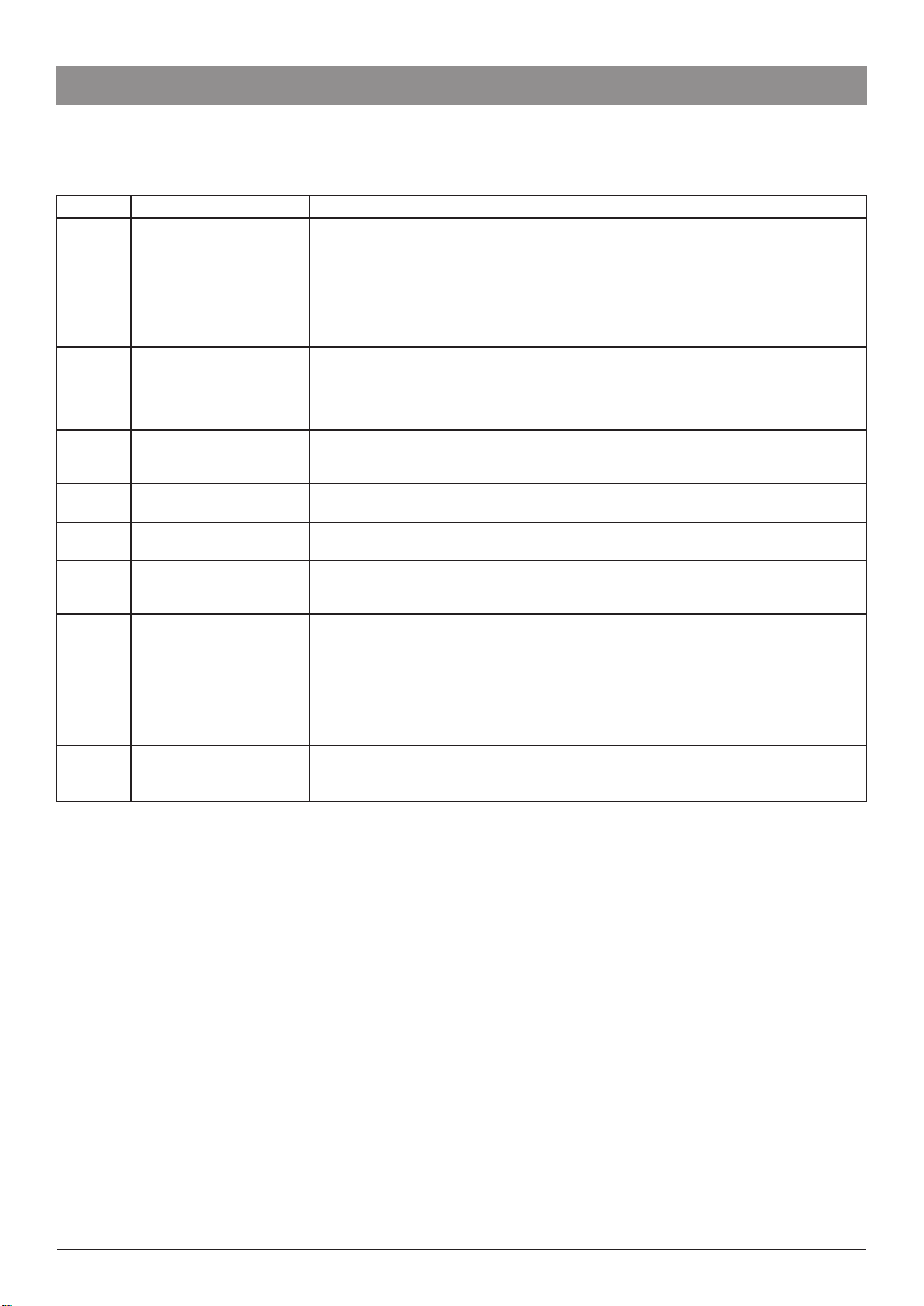

Volumetric Accuracy Verification Test (CODE 5)

Important Notes:

Important Notes:

The balances need to be switched on for 30 minutes prior to use to enable the electronics to

The balances need to be switched on for 30 minutes prior to use to enable the electronics to

warm up and settle.

warm up and settle.

Always use new test tubing for each test. If the test ever has to be repeated, a new set of tubing

Always use new test tubing for each test. If the test ever has to be repeated, a new set of tubing

must be used.

must be used.

Do not move the desk during testing, it will upset the balance readings.

Do not move the desk during testing, it will upset the balance readings.

This test is used to confirm that the pumping accuracy of the system as a whole, including the tubing, is within the specified limits.

In the most controlled conditions, a needle should be used to pump liquid into the weighing beaker to prevent liquid touching the

sides of the beaker and to provide some back-pressure so that leaks/overflows do not affect the readings. As a result of these and

other errors, if the system fails just marginally, it is worth performing the test a second time. If it still fails, return the pump to your local

ALARIS® Service Centre for further analysis. The head height on IV infusion set should be approximately 30cm.

Setup A Setup Bor...

Setup A Setup Bor...

Class A Burette (50ml)

Class A Burette (50ml)

0.1ml graduations

0.1ml graduations

Burette clamp

Burette clamp

Equipment stand

Equipment stand

Table or bench

Table or bench

Needle

Needle

Beaker

Beaker

Scales (±0.01g)

Scales (±0.01g)

Enter access code 5. The pump will initially display “”.

1.

If it is necessary to prime the set, press and hold the button. The pump will display "" and allow the set to be primed,

2.

ignoring any air-in-line alarms.

Release once the set is primed and the pump will again display “”.

3.

Alaris® GW Volumetric Pump 18/77 1000SM00006 Issue 4

Page 19

Routine Maintenance

Routine Maintenance

Test procedures (continued)

Zero scales or burette. Press to begin the verification check.

4.

The pump will automatically pump at 125ml/h for a total of 20ml, which will take approximately 9½ minutes. During the run, it

5.

will display the volume infused up to that point and intermittently flash "r" with the run indicator, to show that this is a

verification run. At the end of this run, the pump should display "20.00" and “wait”.

Allow the scales to settle and then note the reading on the scales. If using a burette, take the final reading of volume infused.

6.

The volume infused should be 20.00ml ± 5%.

Press the key and the pump will revert to the technical service entry mode and flash "CodE", followed by "0", enabling you to

7.

begin other tests if required. Switch the pump "OFF" if there are no further tests to be done at that time.

Flow Stop Mechanism Test

It is necessary to check that the flow stop device can hold sufficient pressure and thus prevent free flow.

Load set into the pump. Use same setup as for pressure calibration (see Chapter 2 Configuration & Calibration).

1.

Open the door and check that the arm stays in the UP position by lifting the arm onto the ledge.

2.

Close the door fully.

3.

Reopen the door and note that the flow stop arm has activated into the down position.

4.

Pull the test tubing out of the pump and place the tube in front of the flow stop mechanism arm in the down position.

5.

Close the door and reopen the door. Check the tubing locator has loaded the tube fully under the clamp and is flat. This checks

6.

whether the tubing locator is the correct way around and works.

Ensure the door is open and the flow stop is closed. Apply 650mmHg to the distal end of the IV infusion set for 10 seconds. Then

7.

reduce pressure to 500mmHg to the distal end and verify pressure gauge reading is 500mmHg. Ensure the pressure does not

drop by more than 15mmHg in 30 seconds.

Alaris® GW Volumetric Pump 19/77 1000SM00006 Issue 4

Page 20

Routine Maintenance

Routine Maintenance

General cleaning and inspection for damage

To ensure that this pump remains in good operating condition, it is important to keep it clean and carry out the routine procedures

described below. All servicing should only be performed by a qualified service engineer, with reference to this manual.

Thoroughly clean external surfaces of the pump by wiping over with a lint-free cloth, lightly dampened with warm water and a

standard disinfectant/detergent solution.

Do not use the following disinfectant types:

- NaDcc (such as PRESEPT)

- Hypochlorites (such as CHLORASOL)

- Aldehydes (such as CIDEX)

- Cationic Surfactants (such as Benzalkonium Chloride)

- Iodine (such as Betadine)

- Concentrated Isopropyl alcohol based cleaners will degrade plastic parts.

Recommended cleaners are:

Brand Concentration

Hibiscrub 20% (v/v)

Virkon 1% (w/v)

Before cleaning always switch OFF and disconnect from the AC power supply. Never allow liquid

Before cleaning always switch OFF and disconnect from the AC power supply. Never allow liquid

to enter the casing and avoid excess fluid build up on the pump. Do not use aggressive cleaning

to enter the casing and avoid excess fluid build up on the pump. Do not use aggressive cleaning

agents as these may damage the exterior surface of the pump. Do not steam autoclave, ethylene

agents as these may damage the exterior surface of the pump. Do not steam autoclave, ethylene

oxide sterilise or immerse this pump in any fluid.

oxide sterilise or immerse this pump in any fluid.

Labels should be flat and legible. Any label, if no longer fully adhered, must be replaced if it represents a path for fluid ingress.

Case components must be checked for damage that may affect function, fluid ingress route or present a user hazard and be re-

placed if necessary.

Check the pole clamp screws are not loose and that the threads are not damaged. Check that it folds away and ensure arm is not

bent.

Inspect the AC power supply plug and cable for damage.

Clean the flow sensor by wiping over with a cloth, lightly dampened with warm water and a

Clean the flow sensor by wiping over with a cloth, lightly dampened with warm water and a

standard disinfectant/detergent solution. Ensure the connector does not get wet. Dry flow sensor

standard disinfectant/detergent solution. Ensure the connector does not get wet. Dry flow sensor

before use.

before use.

To aid cleaning of flow sensors which have been heavily soiled, contaminated or if handles

To aid cleaning of flow sensors which have been heavily soiled, contaminated or if handles

operation is not free, the flow sensor may be immersed and soaked in clean soapy water.

operation is not free, the flow sensor may be immersed and soaked in clean soapy water.

Activating the spring mechanism of the sensor whilst immersed will assist in cleaning the inside

Activating the spring mechanism of the sensor whilst immersed will assist in cleaning the inside

of the mechanism. After cleaning the sensor should be allowed to dry fully prior to use.

of the mechanism. After cleaning the sensor should be allowed to dry fully prior to use.

Caution: the plug of the sensor should not be immersed as damage will occur.

Caution: the plug of the sensor should not be immersed as damage will occur.

Storage

If the pump is to be stored for an extended period it should be cleaned and the internal battery fully charged. Store in a clean, dry

atmosphere at room temperature and, if available, employ the original packaging for protection.

Once every 3 months during storage, carry out functional tests as described in this chapter and ensure that the internal battery is fully

charged.

Please note during long term storage of the pump the Real Time Clock circuitry is being

Please note during long term storage of the pump the Real Time Clock circuitry is being

maintained by BT1 on the control PCB. Under long term storage conditions it is recommended

maintained by BT1 on the control PCB. Under long term storage conditions it is recommended

that the pump is powered in Technician Mode for a period of 24 hours so as to keep the BT1

that the pump is powered in Technician Mode for a period of 24 hours so as to keep the BT1

charged, and eliminate the possibility of depleting BT1 and inducing Err9 faults at power up.

charged, and eliminate the possibility of depleting BT1 and inducing Err9 faults at power up.

Alaris® GW Volumetric Pump 20/77 1000SM00006 Issue 4

Page 21

Routine Maintenance

Routine Maintenance

Data transfer

Upgrading Software

The optional upgrade of the Alaris® GW Volumetric Pump software to V5R1F should be considered at the next product service for all

Alaris® GW Volumetric Pumps fitted with software version V4R2C. Perform upgrades by acquiring the software upgrade kits specified

in the spares parts listings. Note: when upgrading Alaris® GW Volumetric Pumps from software version V4R1B, first install the V4R2C

software upgrade kit to enable the flash upload capabilty.

The major features of the V5R1F software include:

Teach / Learn Capability;

Additional configuration options:

Silent Mode;

SELECT Mode Options;

Drop Sensor Connection Mode;

Drop Sensor Light Sensitivity Level;

Alarm volume level factory default now 4 (was 7);

Clear Infusion Parameters to Zero default now OFF (was ON).

Additional Technician Mode Configuration options:

New Volumetric Calibration Mode to reduce calibration time (Code 19);

New EEPROM Memory Management to improve work with Teach / Learn and to eliminate need to recalibrate pumps

following firmware upgrade (Codes 200, 201, 202).

Automatic setting of VTBI to OFF when used with drop sensor;

Elimination of '' error in Mode resulting in nuisance alarms;

VI now cleared in Mode and retained upon power down.

Recalibration is not required when upgrading from software version V4R2C, although all configuration parameters will be returned to

factory defaults.

PC Requirements

Microsoft Windows 95, 98, 2000 or NT operating system

9pin D-type PC serial port or IrDA port.

Tools required

CD-ROM 1000SP00493 - Alaris® GW Volumetric Pump Software Distribution Disk V5R1F

Programming Kit 1000SP00172 (Suitable for all ASENA® Infusion Pumps) or RS232 Cable 1000SP00336

Follow the programming instructions given in publication 1000PB01365 (supplied with 1000SP00493).

1.

Load the software program onto your PC from the Distribution Disk.

2.

Select the Alaris LVP SMU icon (WinSmug)

3.

Place the infrared programming device approximately 50mm directly behind the IrDA window on the rear case or connect

4.

the RS232 cable to the 9 pin D type serial port connector situated on the side of the pump.

Select the appropriate port (e.g. COM1) on the Alaris LVP SMU program and Press 'Upload'.

5.

Briefly depress the key on the pump to be upgraded; the pump will now display "PROG".

6.

Switch the pump on for normal operation when the upgrade is complete. If required, the pump will display whilst

7.

automatically completing a test sequence during which the EEPROM memory will be re-partitioned.

When the upgrade is complete, enter the Technician Mode and verify the correct software version has been installed;

8.

initiate a factory Reset (Code 200).

Perform the Self Test checks (Code 3).

9.

Power failure. Power failures may occur when using laptops when communicating with the Alaris®

Power failure. Power failures may occur when using laptops when communicating with the Alaris®

GW Volumetric Pump due to power requirements. External power may be used in conjunction

GW Volumetric Pump due to power requirements. External power may be used in conjunction

with IrDA or RS232 to compensate for lack of power from the laptop.

with IrDA or RS232 to compensate for lack of power from the laptop.

Bright sunlight and strong fluorescent lighting affect the Infrared programming system. If any

Bright sunlight and strong fluorescent lighting affect the Infrared programming system. If any

errors are reported then the RS232 method of upgrading the software should be used.

errors are reported then the RS232 method of upgrading the software should be used.

Alaris® GW Volumetric Pump 21/77 1000SM00006 Issue 4

Page 22

Routine Maintenance

Routine Maintenance

Data transfer (continued)

Teach Learn (Software Versions V5R1F and above)

For both the teach and learn pumps in Technician Mode enable IrDA communications (Code 45), and ensure that ASCII / Binary

1.

mode and parity bit options (Codes 38 and 39 respectively) are the same.

Turn the teaching pump on in normal operation. Note: For multiple teach-learn operations, to avoid call-back alarm every

2.

2 minutes, turn the teaching pump on in Technician Mode.

Enter Technician Code 67 on the learning pump.

3.

Align the two IrDA ports on the pumps (optimum distance 50 mm).

4.

Depress the key to initiate learning.

5.

A progress bar will travel across the learn pump.

6.

When successful, the learn pump will display 'PASS'.

7.

If the learning pump is unable to learn all configuration parameters then the display will show 'ConF' followed by a list of the

8.

configuration parameters that could not be learnt; these will instead contain the factory default settings. This could occur if, for

example, the software version of the learning pump is newer than that of the teaching pump.

Possible Reasons for failure

Possible Reasons for failure

IrDA not enabled on both pumps;

IrDA not enabled on both pumps;

ASCII / Binary and parity bit options are not the same;

ASCII / Binary and parity bit options are not the same;

If the software versions are not compatible;

If the software versions are not compatible;

If the pump models are different;

If the pump models are different;

The line of sight between the IrDA windows was obstructed during data

The line of sight between the IrDA windows was obstructed during data

transfer.

transfer.

Event Log Download

A PC application known as the Event Log Download Utility (ELDU) is available to download the event log from the Alaris® GW

Volumetric Pump.

ELDU Operation

Click on ELDU icon on PC.

1.

Click Accept to agree with Restrictions of Use and continue;

2.

Select Configure from drop-down menu;

3.

Select Setup Pump and choose Alaris® GW as pump type;

4.

Select Settings to select log to be downloaded;

5.

Check communications are set up as follows:

6.

Required PC Comm port selected

Character type and parity match pump configuration

Click OK to confirm

7.

Align the IrDA converter with the IrDA window (optimum distance 50 mm), or connect an RS 232 cable.

8.

Power up the pump by pressing the key.

9.

Click Download log from the main PC screen.

10.

Press Close when finished.

11.

Select File from drop-down menu and save file. Log may be printed here as required.

12.

Alaris® GW Volumetric Pump 22/77 1000SM00006 Issue 4

Page 23

Routine Maintenance

Routine Maintenance

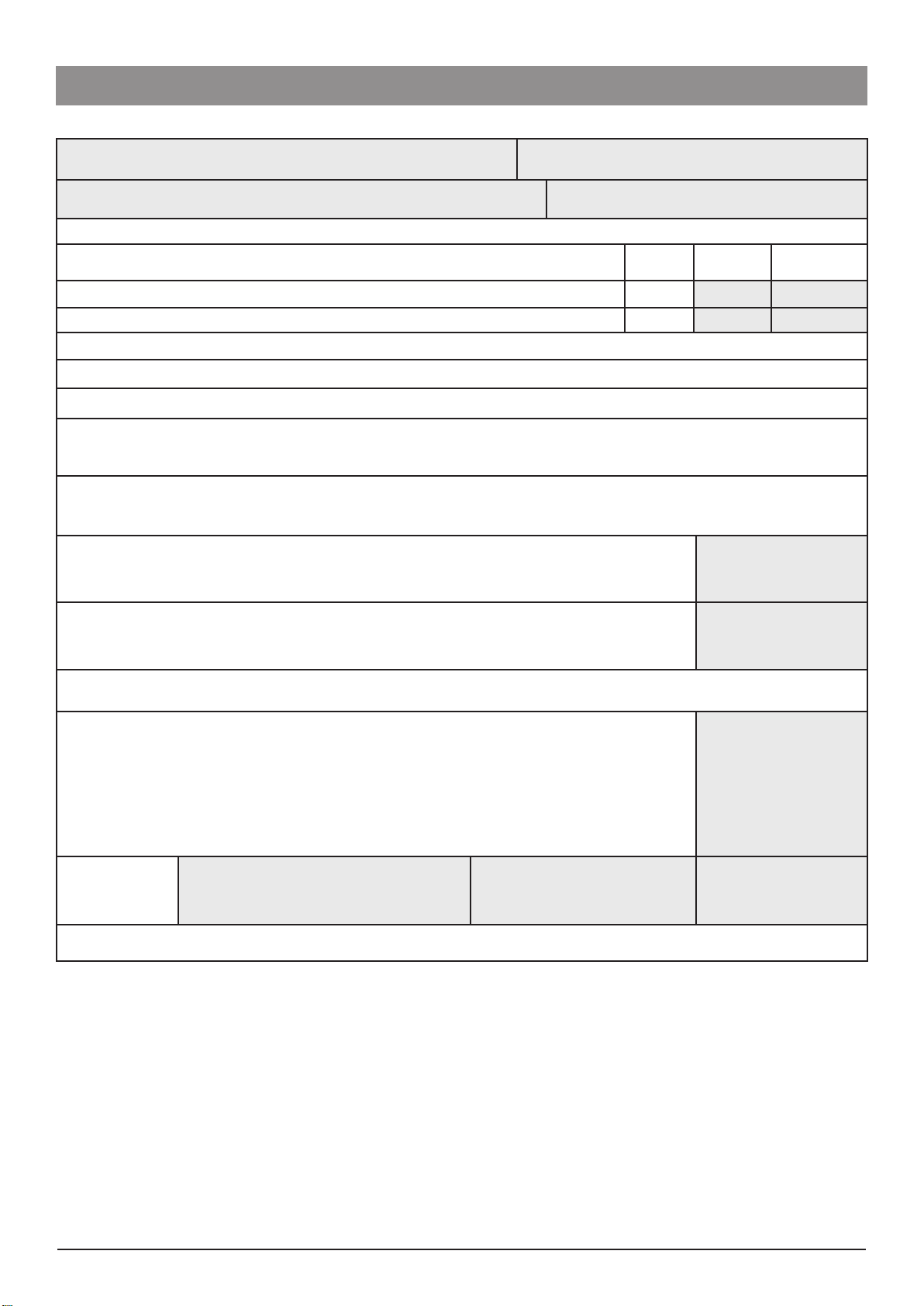

Performance verification procedure

Model / Serial Number: Service Order / Inventory Number:

Hospital Name / Reference: Software Version:

Physical Inspection and Clean

Recommended When Serviced Updates

Grease the pumping mechanism with Molykote PG54. TSM

Upgrade to software version V5R1F or above. TSM

Set/Confirm time and date - access code 42

Set service date - access code 1

Check all functions in Self Test - access code 3

During standard infusion check the following:

KVO Operation

Flow-stop mechanism test

Alarms Functionality Check

Door , AIL (OCC/AIR), Upstream Occlusion (OCC/AIR), Power fail, Time Out, Downstream Occlusion (HI PRESS).

Ensure pump works on battery and AC mains

UPDATE

REF.

Fitted

Not fitted / Not

Applicable

Rate Accuracy Verification Test

(Automatic test in Code 5)

Rate set to 125ml/h, VTBI set to 20ml. Volume infused = 19 to 21ml. _____________ml

Pressure Tests

(Automatic test in Code 12 test 8)

Pump set to alarm at 500mmHg. Pressure = 350 to 650mmHg. _____________mmHg

Set Rate to Zero (or lowest value possible), Clear Volume infused and VTBI

Clear Error/Alarm/Battery logs (As required)

Electrical Safety Test

Class I Type CF

Alternatively attach printed test results

Earth Resistance Test <=0.2 Ω _____________Ω

Earth Leakage Current <=500 µA _____________µA

Enclosure Leakage Current <=100 µA _____________µA

Verification

Performed

By ________________________

Sign

For additional information, refer to:

1000SM00006 - Alaris® GW Volumetric Pump Technical Service Manual (TSM)

_______________________

Print

_________________

Date

Alaris® GW Volumetric Pump 23/77 1000SM00006 Issue 4

Page 24

Troubleshooting

In this chapter

Software alarm codes & displayed messages 25

Alarm types 27

Chapter 4

General fault diagnosis 27

Page 25

Troubleshooting

Troubleshooting

Software alarm codes & displayed messages

Note: The alarm codes are intended only for fault finding and diagnostic purposes and are therefore not displayed directly to the

user. The alarm history log stores the last ten alarm codes in a “first in, first out” sequence once the maximum ten codes have been

exceeded.

Display

Attn

boL A bolus is being administered. boL display replaced with a volume counter during infusion.

ErrA - N

Errb - N Fatal micro-controller failure.

End Indicates end of infusion. Re-program the VTBI to resume infusion.

Err 1 N Motor controller is out of bounds.

bAt 2 N

Lo bAt

Air OCCL 3 R Upstream occlusion/air-in-line. Check AIL sensor function.

HI PrES 4 R

HoLd Indicates the pump is on hold. Audible alarm after 2 minutes.

door 5 R Door is open whilst pump is infusing. Check door magnet or sensor is flat against case.

bAd SEt 6 R

Err 7 N Pressure sensor failure.

Err 8 N Power failure on AC power.

Err 9 N Safety circuit supply failure.

Err 10 N

Err 11 N

Err 12 N

Err 13 N

Err 15 N Micro-controller stack overflow. Replace Control PCB.

Err 16 N

Err 19 N Hardware initiated motor brake.

Err 20 N No. of encoder revolutions too high.

Alarm

Code

Type Description Troubleshooting Guide

The pump has been left unattended

for 2 minutes and the infusion has not

started.

Communications failure with external

memory.

Internal battery depleted /

disconnected.

Battery voltage threshold of 7v

reached. approximately 30 minutes of

running time left.

Downstream occlusion IV line

pressure exceeds limit threshold.

IV set used fails automatic set test

(incorrectly loaded).

Motor is idle at very low infusion

rates.

Motor controller drive voltage limit

exceeded.

Incorrect number of encoder steps/

revolutions.

Encoder rotation time incorrect for

set rate.

Communication failure with external

real time clock (RTC).

Press to temporarily silence for 1 minute.

Replace the Control PCB.

Replace the Control PCB. If pump does not subsequently

power up, replace the pressure sensor / encoder assembly.

Check the mechanical parts around the gears / encoder for

obstructions.

Charge pump for 12 hours, check mains, battery fuses and

battery.

Charge pump for 12 hours, check mains, battery fuses and

battery.

Check pressure and recalibrate.

Check the function of the pressure sensor.

Replace pressure sensor/encoder assembly. If error recurs,

replace the Control PCB.

Check cables around the power connector to Control PCB.

Ensure battery is connected. Check PSU Comms PCB and

replace if necessary. If error recurs replace Control PCB.

Ensure JP12 is firmly connected. Check voltage on realtime clock battery. If low, power-up in technician mode to

recharge whilst connected to AC mains. If problem persists,

replace the Control PCB.

Check around the motor assembly, check for loose wires.

Check for mechanical obstruction around the gear area.

Check cabling to motor. Apply grease to pumping finger

cams as per Chapter 6. Replace the pressure sensor / encoder

assembly, if necessary. If error recurs, replace the Control PCB.

Check for damaged/distorted motor encoder wheel. Replace

the pressure sensor/encoder assembly, if necessary. If error

recurs, replace the Control PCB.

Withdraw the pump from service and ensure it is inspected

by a qualified service engineer.

Replace Control PCB.

Replace Control PCB. If error recurs, replace the pressure

sensor/encoder assembly.

Withdraw the pump from service and ensure it is inspected

by a qualified service engineer.

Alaris® GW Volumetric Pump 25/77 1000SM00006 Issue 4

Page 26

Troubleshooting

Troubleshooting

Software alarm codes & displayed messages (continued)

Display

Err 21 N No. of encoder revolutions too low.

Err 24 N Time base difference.

Err 28 N Watchdog timeout. Replace the Control PCB.

Err 29 N Keypad failure.

Err 30 N Calibration data out of bounds.

Err 31 N External memory checksum Replace the Control PCB.

Err 32 N Software execution error. Replace the Control PCB.

FLo SEnS 33 R Flow sensor error.

FLo Err 34 R

Err 35 N Pump not calibrated.

Err 36 N

Err 38 N 7-segment LED display failure. Replace the Control PCB.

Err 39 N Audible alarm failure. Check cable to speaker. Replace the Control PCB if necessary.

Err 40 N Critical variable corruption. Replace the Control PCB.

Err 41 N State invariant corruption. Replace the Control PCB.

Err 42 N ADC out of range. Replace the Control PCB.

Loc On/Loc

oFF

Sec

Fill Pump priming IV infusion set.

Alarm

Code

Type Description Troubleshooting Guide

Withdraw the pump from service and ensure it is inspected

by a qualified service engineer.

Ensure JP12 is firmly connected. Replace the Control PCB if

necessary.

One or more of the keypad switches on the Control PCB is

faulty. Replace the Control PCB. Note: may also be caused by

pressing an invalid key during power-up. If this case, there is

no fault.

Reset pump with code 200 and recalibrate. Replace the

Control PCB if necessary.

Occurs if flow sensor is connected or disconnected whilst

pump is infusing, or if the flow sensor is disconnected and

the VTBI is off.

Flow error. Gross over / under

infusions, bag empty, or flow

detected when not infusing.

Logic error (invalid RTC data update

during infusion).

Indicates keypad panel locked/

unlocked.

Pump is running in secondary

operation mode.

Check set, fluid and correct loading. Check flow sensor and

connection to pump.

If a new Control PCB is fitted, calibrate pressure and

battery and perform a volumetric verification accuracy test.

Otherwise, withdraw the pump from service and ensure it is

inspected by a qualified service engineer.

Replace the Control PCB.

Activate/deactivate by pressing o for two seconds.

Key:

N : Non Recoverable Alarm

R : Recoverable Alarm

Alaris® GW Volumetric Pump 26/77 1000SM00006 Issue 4

Page 27

Troubleshooting

Troubleshooting

Alarm types

Non Recoverable Alarms

In this state the pump will stop the infusion and give an audible and visible warning to alert the user that a non recoverable

alarm (registered on the pump as a Fatal alarm) has occurred. With the exception of a micro-controller (MCU) error or internal

communications fault with the external EEPROM, each alarm condition is identified by a unique code, which is stored in the alarm

history log each time an alarm occurs, to enable the qualified service engineer to trace the error condition. From a non recoverable

alarm the user is able only to enter the POWER DOWN mode. The non recoverable conditions are defined in the alarm code table.

Recoverable Alarms

In this state the pump stops the infusion and gives an audible and visible warning to alert the user to the alarm condition, and to

provide an indication of the nature of the alarm. Each alarm is identified by a unique code, which is stored in the alarm history log each

time an alarm occurs to enable the technician to trace the alarm condition.

The recoverable alarms are defined in the alarm code table. After a recoverable alarm has occurred, the pump responds only to the

following three actions: the user may temporarily silence the alarm for one minute by depressing the key; this action will suspend

only the audible indicator, with the visual message remaining. After one minute the audible indicator will return.

The pump may be switched off directly from the ALARM mode by depressing and holding the key, to initiate the power down

sequence. If the power down sequence is not completed, then the pump immediately returns to the ALARM mode and initiates the

audible alarm.

To return the pump to the “HoLd” mode, the user presses the key; this action clears the alarm message on the main display and

silences the audible indicator.

General fault diagnosis

Dropped or damaged

Exposed to fluids

No battery power

General Fault

No AC mains power

Parts to Check/Test

Front Case

Rear Case

Labels

Mechanism

Control PCB

Power PCB

Battery

Mains Lead

Fuses

Delivery rates out of

tolerance

Alaris® GW Volumetric Pump 27/77 1000SM00006 Issue 4

Page 28

Circuit Descriptions

In this chapter

Module overview functional description 29

Control Board 29

Chapter 5

Power Supply Unit and Communications Board 30

Pressure Sensor and Encoder Board 30

Functional module block diagram 31

Page 29

Circuit Descriptions

Circuit Descriptions

Module overview functional description

The pump is designed to be serviced generally to major assembly level. The PCBs are designed as non-serviceable items and as such,

can only be replaced as complete parts.

Cardinal Health will make available, on request, circuit diagrams, which will assist appropriately qualified technical personnel to repair

those parts of the pump which are designated by the manufacturer as repairable.

The main circuitry within the Alaris® GW Volumetric Pump is contained on three printed circuits boards - Control PCB, Power Supply

and Communications PCB, and a small Pressure Sensor and Encoder PCB and additional plug in sensors.

Control Board

Microcontroller Block

All control and display functions are controlled by this part. Safety functions are spread around the pump with various parts. The

controller is supported by a watchdog and power reset circuit. An EEPROM is used to store logged data for the pump. There is a

battery backed real-time clock.

Power Control Block

Raw DC power is connected from the Power Supply unit to JP1 connector. In the event of the raw DC exceeding 36 volts, components

form a crowbar. Components form a 12 volt Switch Mode Power Supply (SMPS). Components form a 12-volt monitor circuit for the

Microcontroller. The battery is connected to pin 3 of JP1 and is constantly charged when connected to the mains. Components form

a 5-volt reference voltage to the main processor. A switch mode regulator supplies 5-volts (VCC) to the pump. There are two 5-volt

crowbar protection circuits.

Motor Driver

A Microcontroller I/O is used to control the motor speed. The modulated signal is smoothed to a DC voltage appropriate to control

motor speed. Relay 1 is used to reverse the voltage applied to the motor. This reversal is used for some modes of operation. Safety

devices stop the motor if necessary.

User Interface

Microcontroller drives the seven segment displays and the LEDs. The keyboard is scanned for key depressions .The display currents are

monitored. Time division multiplexing enables complete control of a user interface display and input with the Microcontroller.

Air-in-line sensor

A phase shift oscillator drives the Air-in-Line sensor; the output of the phase shift oscillator signal is fed into a voltage controlled

oscillator. The signal is transmitted through the fluid filled tubing and received by the ultrasonic sensor. The received signal is then

passed through a window detector and then to a level detector and input into the Microcontroller.

Air-in-Line

Two ultrasonic transducers continuously check for the presence of air in the IV infusion set throughout the infusion. This air-in-line

feature operates in two modes:

Single Bubble Detection - The pump will alarm and display Air OCCL whenever a single air bubble greater than the air-in-line volume

alarm limit is detected. The alarm limit can be configured to 50, 100, 250 or 500µl. See also “Configurable Options” section of Chapter 2.

Air-in-Line Accumulation - This accumulation feature monitors the volume of air that passes through the IV infusion set by

accumulating the volume of individual bubbles over a 15 minute window. The accumulation will alarm if more than 500µL of air is

registered. This feature is particularly useful with infusions for patients that are highly sensitive to air (i.e., neonates, paediatrics) or

when infusing products that create significant volumes of small air bubbles.

Flow sensor

The flow sensor is input into the Main Processor.

Door sensor

A Hall effect sensor detects if the door is open or closed and a Microcontroller reads the state of the sensor.

Buzzer

The Microcontroller is used to switch on the alarm (buzzer).

Audio Alarm

The input to the Audio alarm section is driven by a signal from the Microcontroller, fed into a phase shift oscillator and through an RC

network to remove any DC present on the signal. The signal is amplified and drives the speaker.

Alaris® GW Volumetric Pump 29/77 1000SM00006 Issue 4

Page 30

Circuit Descriptions

Circuit Descriptions

Power Supply Unit and Communications Board

Power module

The selection of 115V or 230V is made via S1. The secondary is rectified to an unregulated DC Voltage. F2 is a Polyswitch resetable fuse.

The raw DC is output to the Control PCB. The battery is connected via JP3, the maximum current being limited by F1.

RS232 & Nursecall

The external RS232 connection is made via JP5 where power for the 4kV isolated interface is taken from pins 4 and 7. This voltage is

converted to a 5-volt supply and in turn converts the RS232 communications levels to TTL which are then sent to the Microcontroller.

The Nursecall interface is controlled from the Microcontroller to energise the relay which causes the contact to change over.

IrDA Module

IrDA or RS232 is selectable. The IrDA communication signal is output from IC7.

Pressure Sensor and Encoder Board

Motor encoder

Diodes D1 and D2 are the emitters in the motor encoder and OPT1 and OPT2 being the receivers. The signals are sent to the Control

PCB where they are used in conjunction with the Pressure Sensor and Encoder PCB to provide a quadrature detection scheme from the

rotary encoder on the drive motor. These signals are then processed via the Microcontroller.

Pressure sensor

The strain gauge is connected to the Pressure Sensor PCB, the sensor o/p signal is then amplified and then output to the Control PCB

and used to provide a second stage of amplification for the pressure sensor signal. This signal is processed via the Microcontroller.

Alaris® GW Volumetric Pump 30/77 1000SM00006 Issue 4

Page 31

Circuit Descriptions

Circuit Descriptions

Functional module block diagram

Control PCB

Key

Switches

(Includes motor encoders)

Pressure Sensor PCB

Pressure

Sensor

JP10

Air

Sensor

(Door)

Air Sensor

(Front panel)

Audible

Alarm

JP5

JP11JP8 JP9

Door

Sensor

Display

LEDs

Air

Sensors

Audible

Alarm

Motor

Encoders

Motor

Control

Safety

Backup

Main Processor

Backup

Speaker

JP3

Pumping

Block

Flow Sensor

Programming

Connection Box

RS232/

Nursecall

Connector

JP5

Flow

Sensor

Programming

Comms

IrDA

Backup

Battery

Comms

JP6

Power

Distribution

Power

Module

PSU & Comms PCB

JP1

JP2JP4

JP1

JP3

AC Mains

Inlet

Battery

Alaris® GW Volumetric Pump 31/77 1000SM00006 Issue 4

Page 32

Chapter 5

Spare Parts Replacement Procedures

In this chapter

Separation of front and rear cases 33

Front case assembly 34

Door assembly 35

Pumping block assembly 36

Air sensor assemblies 37

Pressure sensor assembly 38

Flow-stop assembly 39

Control PCB 40

Rear case assembly 41

Battery 42

PSU & Comms PCB 43

Speaker 44

Rear case connectors 45

Rear Case Rail Cam Mechanism 46

Mains inlet 47

PE Stud and Pole Clamp 48

Labels 49

Page 33

Spare Parts Replacement Procedures

Separation of front and rear cases

These instructions apply only to the Alaris® GW Volumetric Pumps. Ensure the pump is disconnected

from AC power supply and switched off before attempting to service the pump.

The pump contains static-sensitive components. Observe strict precautions for the protection of staticsensitive components when attempting to service and repair the pump. As a minimum, carry out all

servicing on a workbench with a static dissapative surface and wear a grounded wrist strap.

Ensure that all test and calibration procedures are carried out as recommended in the service manual

after any component fitting.

For fastener torque settings, refer to Appendix C Fitting & Replacement Guidelines.

For additional technical assistance, contact your local Cardinal Health Service Centre.

Remove the 4 corner screws, which secure the rear case to the front case.

1.

For many subsequent operations it is possible to make all repairs with the two halves still joined, however to disassemble the two

2.

halves completely:

(a) Disconnect the four-way cable assembly that links the PSU and Comms PCB with the Control PCB.

(b) Unplug the 8-way connector from the Control PCB.

(c) Unplug the flow sensor cable and the speaker cable.

(d) Remove screw, collect washer and remove the earth connection from the Pumping block.

Reassemble in reverse order.

3.

Flow sensor cable

Earth cable

Speaker cable

8-way cable

Corner screws (x4)

4-way cable

Description Part Number Description Part Number

ASENA GW, KIT, FRONT CASE 230V GERMAN 1000SP00343 ASENA GW, KIT, REAR CASE 230V SWEDISH 1000SP00325

ASENA GW, KIT, FRONT CASE 230V SPANISH 1000SP00333 ASENA GW, KIT, REAR CASE 230V NORWEGIAN 1000SP00368

ASENA GW, KIT, FRONT CASE 230V FRENCH 1000SP00331 ASENA GW, KIT, REAR CASE 230V DUTCH 1000SP00340

ASENA GW, KIT, FRONT CASE 230V ENGLISH 1000SP00252 ASENA GW, KIT, REAR CASE 230V ITALIAN 1000SP00323

ASENA GW, KIT, FRONT CASE 110V ENGLISH 1000SP00327 ASENA GW, KIT, REAR CASE 110V ENGLISH 1000SP00326

ASENA GW, KIT, FRONT CASE 230V ITALIAN 1000SP00332 ASENA GW, KIT, REAR CASE 230V ENGLISH 1000SP00261

ASENA GW, KIT, FRONT CASE 230V DUTCH 1000SP00344 ASENA GW, KIT, REAR CASE 230V GERMAN 1000SP00339

ASENA GW, KIT, FIXINGS (SCREWS,WASHERS,ETC) 1000SP00489 ASENA GW, KIT, REAR CASE 230V SPANISH 1000SP00324

ASENA GW, KIT, FRONT CASE 230V 1000SP00334 ASENA GW, KIT, REAR CASE 230V FRENCH 1000SP00322

SWEDISH/NORWEGIAN

Alaris® GW Volumetric Pump 33/77 1000SM00006 Issue 4

Page 34

Spare Parts Replacement Procedures

Front case assembly

In order to replace a front case, it will be necessary to fully strip down the old case and insert all of the components into the new

1.

front case. The task requires a good knowledge of the pump, so be certain that you are fully conversant with all of the procedures

in this section before undertaking this replacement. In order to simplify the task, new front cases are supplied with the flow stop

mechanism, air sensors, and the finger and pressure sensor covers already fitted, so it is not necessary to remove these from the

old case.

For each sub-assembly to be stripped down, follow the instructions in the relevant section of this manual. The recommended

2.

order for stripping down a front case is described below :

Separate the front and rear case halves;

Remove the Control PCB;

Remove the door assembly;

Remove the Pumping block assembly (keeping the motor on the chassis);

Remove the pressure sensor.

When re-assembling these sub-assemblies into the new case, it is advisable to simply reverse the order of dis-assembly.

3.

It will also be necessary to apply a new front panel label, door label and flow direction label at the

end of assembly. These labels are language specific. Refer to the “Spare Parts Listing” in this service

manual to ensure that you order the correct label set. The part number should also be shown on the

labels that were removed from the old case.

Write the serial number of the pump on the label provided and stick it onto the inside of the new

case.

Alaris® GW Volumetric Pump 34/77 1000SM00006 Issue 4

Page 35

Spare Parts Replacement Procedures

Door assembly

Remove the air sensor assembly from the back of the door and retain the small screws for re-assembly later.

1.

Remove circlips and push out the two shafts that form the hinge of the door so that they clear the first part of the hinge.

2.

Do not free the main pressure plate that is sprung on the door.

The old door assembly will now come free from the front of the pump.

3.

Reassemble in reverse order.

4.

When fitting the door, take care to keep the air sensor on the correct side of the door

and do not crush its wires.

(A) Door magnet

(C) Circlips (x2)

(B) Door assembly

(C) Screws (x2)

Air sensor

Item Description Part Number

A MAGNET DOOR 1000ME01151

B ASENA GW, KIT, DOOR 1000SP00253

C ASENA GW, KIT, FIXINGS(SCREWS,WASHERS,ETC) 1000SP00489

Alaris® GW Volumetric Pump 35/77 1000SM00006 Issue 4

Page 36

Pumping block assembly

Spare Parts Replacement Procedures

Unplug the motor wiring loom from the Control

1.

PCB in the front case.

Remove the flow direction indication label from

2.

the front of the pump.

(D) Strip finger

(E) Fixing screws (x4)

Washers (x2)

(C) Motor wiring loom

Pumping fingers

(A/B) Pumping block assembly

Unscrew the four screws, collect two washers that secure the pumping block to the front case, two of which are located behind

3.

the label and two that are near the door hinge.

It should now be possible to push out the pumping block and completely separate it from the front case. When doing this, take

4.

care not to lose any of the pumping fingers, or copper finger strip, which will be free to fall out when the main chassis is removed.

Retain all of them for re-assembly later.

Reassemble in reverse order. Tighten the countersunk screws first, then the pan head screws. Ensure the pumping fingers are

5.

the correct way around with the narrow curved end in contact with the tubing. Fit a new flow direction label to the front of the

pump.

IMPORTANT: Recommended when serviced, grease should be applied a minimum of once every 12

months.

The Alaris® GW Volumetric Pump uses Molykote grease (F) to lubricate the moving mechanical

parts of the pumping mechanism to reduce the current draw of the pump. Only Molykote PG54

grease has been approved as compatible with the pump components. Each of the cams should

have a thin layer applied to the circumference so that the fingers run smoothly over the cam face.

The grease can be applied by a lint-free cloth or finger for example, to achieve an even layer over

each cam.

Item Description Part Number

A ASENA GW, KIT, PUMP BLOCK 230V 1000SP00257

B ASENA GW, KIT, PUMP BLOCK 110V 1000SP00329

C ASENA GW, ASSY, MOTOR WIRING LOOM 1000SP01077

D ASENA GW, ASSY, STRIP FINGER (Be Cu) 0000EL00816

E ASENA GW, KIT, FIXINGS(SCREWS,WASHERS,ETC) 1000SP00489

F ASENA GW SPARES KIT MOLYKOTE GREASE 1000SP00469

Alaris® GW Volumetric Pump 36/77 1000SM00006 Issue 4

Page 37

Spare Parts Replacement Procedures

Air sensor assemblies

1. Unplug the four-way connector for the two air sensors.

2. Unscrew the door air sensor from the back of the door and pull out the two wires through the hole to free the sensor.

(A) Front panel air sensor

(A) Door air sensor

3. Carefully push out the front panel air sensor, while moving the three retaining lugs towards the centre of the sensor, by

pressing gently on the encapsulated area with a screwdriver. Again, pull the two wires free from the front case.

4. Reassemble in reverse order.

4-way connector

Rear of front panel air sensor mounting

(A) Front panel air sensor

(A) Door air sensor

The two air sensors are similar, but can easily be distinguished. The door sensor has a flange

with two countersunk holes in it. The front panel sensor has three sprung clips to hold it in

the case.

Insert the crimps into the four-way connector provided, as indicated by the following

diagram:

Pin 1 Door Sensor White

Pin 2 Door Sensor White

Pin 3 Front Panel Sensor Blue

Pin 4 Front Panel Sensor Blue

1 2 3 4

Item Description Part Number

A ASENA GW, KIT, AIR SENSORS 1000SP00265

Alaris® GW Volumetric Pump 37/77 1000SM00006 Issue 4

Page 38

Spare Parts Replacement Procedures

Pressure sensor assembly

Remove the three screws that hold the pressure sensor assembly in place. Unplug the assembly from the Control PCB. Carefully

1.

remove the pressure sensor from the case.

Reassemble in reverse order. Tighten the larger 2 screws first, then the smaller screw.

2.

(C) Backstop

(D) Screws (x3)

Side View

Underside View

(A or B) Pressure sensor and encoder assembly

Item Description Part Number

A ASENA GW, KIT, PRESSURE SENSOR 230V 1000SP00256

B ASENA GW, KIT, PRESSURE SENSOR 110V 1000SP00330

C ASENA GW, ASSY, BACKSTOP/MEMBRANE CLAMP 1000ME01592

D ASENA GW, KIT, FIXINGS(SCREWS,WASHERS,ETC) 1000SP00489

Alaris® GW Volumetric Pump 38/77 1000SM00006 Issue 4

Page 39

Spare Parts Replacement Procedures

Flow-stop assembly

Remove the flow direction label to reveal one of the screws holding the flow-stop assembly. Remove the two screws that hold

1.

the flow-stop housing mechanism onto the front case and remove the whole assembly as a single item. This includes the sprung

arm and the small cover that provides the locking position for the arm.

Assemble a new flow-stop mechanism (see instructions below), if required.

2.

Reassemble in reverse order.

3.

(A or B) Flow-stop

housing

Fitting a new flow-stop mechanism

New flow-stop mechanisms are provided as a kit of parts,

1.

so it will be necessary to assemble the mechanism prior

to fitting. Use the old mechanism that has been removed

as a guide to this process and if necessary refer to the

assembly drawings shown here.

Insert the flow-stop clamp into the flow stop housing

2.

and align the holes and secure them together with the

pinching arm shaft and star fastener.

Insert the spring through the hole in the flow-stop

3.

housing. Locate the opposite end of the spring on the tag