Page 1

Alaris

®

Gateway Workstation

Technical Service Manual

Page 2

This manual has been prepared for use by qualified service personnel only.

Cardinal Health cannot accept any liability for any breakdown or deterioration in performance of parts or equipment

resulting from unauthorised repair or modification.

t Cardinal Health, 1180 Rolle, Switzerland

Alaris® and Asena® are registered trademarks of Cardinal Health, Inc. or one of its subsidiaries.

All other trademarks are the property of their respective owners.

© 2005-2008 Cardinal Health, Inc. or one of its subsidiaries. All rights reserved.

Alaris® Gateway Workstation 2/67 1000SM00015 Issue 4

Page 3

Contents

Chapter

General Information1. 4

Routine Maintenance2. 8

Troubleshooting3. 17

Circuit Descriptions4. 19

Spare Parts Replacement Procedures5. 22

Appendix

Electromagnetic Compatibility 5A. 1

Spare Parts Listing 5B. 6

Disposal 6C. 2

Service Contacts 6D. 4

Document History 6E. 6

Alaris® Gateway Workstation 3/67 1000SM00015 Issue 4

Page 4

General Information

In this chapter

Introduction 5

General Precautions 6

Chapter 1

Features of the Workstation 7

Page 5

General Information

Introduction

The Alaris® Gateway Workstation (herein after referred to as "Workstation") has been designed as a modular system providing a

communications gateway between the Alaris® Infusion Pump and any Patient Data Management System (PDMS), Patient Monitoring

(PM) System or Clinical Information System (CIS) that requires access to the infusion data retained within the pump.

• Central management system for multiple Alaris® Infusion Pumps

• Medical Device Interface (MDI) – a unique mounting mechanism providing data communications and mains power to the Alaris®

Infusion Pump

• Reduced cable clutter with the use of a single AC power inlet

• Simple to set up with adaptable modular design

• E cient organisation of multiple infusion lines and con gurations

• Battery back-up in the event of power supply interruption

• Optional high visibility beacon assists with the location of pumps in an alarm state

• Nurse call interface for all Alaris® Infusion Pumps attached to the Workstation

• Software running on the Workstation allows remote access to the device

The device supports optional upgrades to enhance the data communication interfaces and to support software for connections to

such client / server systems.

Data can be accessed and the software installed on the Workstation can be configured from a client PC using a standard Web browser;

this may be performed over an Ethernet network or by directly linking to the Workstation.

The software is provided under and is subject to a license from Cardinal Health, Inc.

The Asena® brand name has been recently changed to the Alaris® brand name. This change in brand name has no effect on the

intended use or functionality of the product.

Product Familiarity

The Workstation provides power and communications for the complete range of Alaris® Infusion Pumps (excluding the Alaris® System).

Prior to operation of the Workstation and prior to attempting any repairs or servicing, carefully read the Directions for Use (DFU)

As part of continuous improvement, product enhancements and changes are introduced from time to time.

Purpose of this Manual

This Technical Service Manual describes how to set up, test and maintain the Workstation. This manual is intended for use by personnel

experienced in medical equipment testing and maintenance procedures .

Conventions Used in this Manual

BOLD Used for Workstation controls and indicators and Web Service software buttons referenced in this

manual, for example, ON/OFF button, press OK to continue.

'Single quotes' Used to indicate cross-references made to another section of this manual. For example, see Chapter 2,

'Configuration & Calibration'

underline Used to indicate links to another section of this manual.

Italics Used to refer to other documents or manuals. For example, refer to the relevant Directions for Use (DFU)

for further information. Also used for emphasis, for example, ...position the narrow end of the tool...

Wherever this symbol is shown a Hints & Tips note is found. These notes provide useful advice or

information that may help to perform the task more effectively.

Wherever this symbol is shown a Toolbox note is found. These notes highlight an aspect of test or

maintenance that is important to know about. A typical example is drawing attention to a software

upgrade that should be checked that it has been installed.

Alaris® Gateway Workstation 5/67 1000SM00015 Issue 4

Page 6

General Information

General Precautions

Prior to using the Workstation, carefully read the Operating Precautions in the Directions for Use (DFU).

w

This Workstation contains static sensitive components. Observe strict precautions for the protection of static

V

B

A

Refer all servicing to qualified service personnel only. Circuit board repairs are not recommended - replacements are available.

sensitive components when attempting to repair and service the Workstation.

An explosion hazard exists if the equipment is used in the presence of flammable anaesthetics. Exercise care to

locate the equipment away from any such hazardous sources.

Dangerous Voltage. An electrical shock hazard exists if the Workstation casing is opened or removed. Refer all

servicing to qualified service personnel.

If the equipment is dropped, subjected to excessive moisture or spillage, humidity or high temperature,

or otherwise suspected to have been damaged, remove it from service for inspection by qualified service

personnel.

Alaris® Gateway Workstation 6/67 1000SM00015 Issue 4

Page 7

Features of the Workstation

General Information

Horizontal 4 tile assembly

Vertical 2 tile assembly

Base Module

Tile Warning

Indicator

Battery

Indicator

AC Power

Indicator

ON/OFF

Barcode Reader

RS232 Serial Interface

(optional)

3 MDI Tile Base Unit

Front View

A/B Status

Indicators

ON Status

Indicator

System Fault

Indicator

Rear View

RS232 Serial Interface

(optional)

RS232 Serial Interface

(optional)

a

j

k

Nurse Call

Interface

Standard RS232

Serial Interface

AC Power

Input

115-230V

~50-60Hz

350VA

AU Patent No. 144,124;

CA Patented/Breveté 90,905;

GB Patent No. 2,083,562;

IE Patent No. D13002;

JP Patent No.⊓㍳╙1,117,998ภ;

U.S. Patent No. 6,593,528; 6,407,335.

115-230V

AUX

~50-60Hz

Auxiliary

Interface

Ethernet

Interface

Potential

Equalisation (PE)

Connector

AC Power

Output

ON/OFF Button Press once to switch the Workstation on. Press and hold for 1 second to switch

the Workstation off. In the event that the system needs to be reset, depress and

hold for at least 4 seconds, then press again to switch the Workstation on.

Battery Indicator When illuminated the Workstation is operating from the internal battery; when

flashing the battery power is depleted.

AC Power Indicator When illuminated the Workstation is connected to the AC power supply and

the battery is being charged.

‘A’ Status Indicator Provides a visual indication that the software is operational.

‘B’ Status Indicator Provides a visual indication that the network is operational.

‘ON’ Status Indicator When illuminated the Workstation is operational.

System Fault Indicator The Workstation will illuminate this indicator when an internal fault is present

and detected.

w

Alaris® Gateway Workstation 7/67 1000SM00015 Issue 4

(Consult accompanying documents for further information).

Page 8

Routine Maintenance

In this chapter

Required Test Equipment 9

Required Tests 9

Chapter 2

Electrical Safety Test 10

Power-up Check 12

Beacon (where fitted) 12

Pump Loading/Removal Checks 12

Battery Test 13

Setting the Time and Date 14

Recommended Cleaning and Inspection 15

Performance Verification Procedure 16

Page 9

Routine Maintenance

Required Test Equipment

The following test equipment is required to perform the tests in this chapter.

Metron QA-90 Medical grade electrical safety tester1.

PC with Ethernet LAN connection, COM port and Internet Explorer 6.0 installed2.

Cat5e Ethernet cable (2m)3.

Cat5e Ethernet Crossover cable (2m)4.

Alaris® Infusion Pump with IrDA enabled which has been serviced within the past 12 months.5.

IEC AC Mains Lead, straight, 134748 (5A)6.

Required Tests

The following tests are required to test the different Workstation configurations.

Functional test

Electrical Safety Test

Power-up check

Beacon (when fitted)

Pump Loading/Removal Test

Battery Test

Setting the Time and Date

Auxiliary

Workstation

(Option 1)

Workstation Configuration

Workstation

(Option 2)

Workstation with

Wireless LAN

(Option 3)

Alaris® Gateway Workstation 9/16 1000SM00015 Issue 4

Page 10

Routine Maintenance

Electrical Safety Test

The Electrical Safety Test MUST be performed twice.

The first test will ensure the PE and Insulation Resistance are acceptable for safe AC

power application.

The second test, with the Workstation on AC power, is to ensure the Leakage Current

values are correctly measured.

Electrical Safety Test Calibration

Ensure that no physical contact is made with the unit under test during the electrical safety test cycle.

Connect a Medical grade electrical safety tester, (e.g. Safety Tester) to a main's outlet, ensuring that the connections for Live and Neutral

are correct.

Connect the enclosure lead to the PE point of the Workstation. Plug the mains test lead from the safety tester into the Workstation 1.

mains inlet.

Switch on the Workstation.2.

Set up and perform a standard electrical safety test to IEC/EN60601-1 Class I, using an Earth Continuity test current of 25A. If the 3.

safety tester requires an applied 'Type' to be entered, select 'Type B' but no applied parts should be specified.

The required test result limits are as follows:

Protective Earth Resistance (all test points) <100m

Earth Leakage Current:

Open Supply Reverse Mains (OSRM) <1000µA

Normal Condition Reverse Mains (NCRM) <500µA

Enclosure Leakage Current:

Open Supply Reverse Mains (OSRM) <500µA

Normal Condition Reverse Mains (NCRM) <100µA

Open Earth Reverse Mains (OERM) <500µA

First Electrical Safety Test

PE Connector - Earth Continuity Test

Connect the AC lead from the Safety Tester to the Workstation Mains Inlet.1.

Connect the enclosure lead from the Safety Tester to the PE stud on the rear cover of the Workstation with a crocodile clip.2.

Perform the Earth Continuity Test.3.

Disconnect the enclosure lead from the PE stud.4.

Current Consumption <300mA

Insulation Resistance >200M

Open Supply (OS) <1000µA

Normal Condition (NC) <500µA

Open Supply (OS) <500µA

Normal Condition (NC) <100µA

Open Earth (OE) <500µA

IEC Mains Outlet Screw/Tile - Earth Continuity Test

Apply the free end of the enclosure lead firmly to one of the IEC Mains Outlet screws on the bottom tile.1.

Perform the Earth Continuity Test.2.

Repeat the test for one screw on 3. every IEC Mains Outlet in turn.

Repeat the test for one screw on the tile plate.4.

Alaris® Gateway Workstation 10/16 1000SM00015 Issue 4

Page 11

Routine Maintenance

Electrical Safety Test continued

Tile Module/Mounting Bar - Earth Continuity Test

Fit a high current probe to the enclosure lead.1.

Firmly apply the probe point to one of the module tile plate mounting screws.2.

Perform the Earth Continuity Test. 3.

Repeat the test for each tile plate mounting screws in turn.4.

Carefully apply the probe point to one end of the tile mounting bar.5.

Perform the Earth Continuity Test. 6.

Repeat the test for each tile mounting bar in turn.7.

Note: Ensure that, in all cases, the resistance to earth of any continuity test DOES NOT

exceed 100mΩ.

IEC Outlet Earth Pin - Earth Continuity Test

Connect the enclosure lead to the Tile IEC Earth Point1. .

Fit the test equipment to the rear IEC Mains Outlet.2.

Perform the Earth Continuity Test.3.

Repeat the test for 4. each IEC Mains Outlet in turn.

Note: Ensure that, in all cases, the resistance DOES NOT exceed 100mΩ.

Insulation Resistance Test

Disconnect the Earth Lead from the Tile IEC and reconnect the enclosure lead to the crocodile clip.1.

Attach the crocodile clip to the PE stud on the rear cover of the Workstation.2.

Perform the Insulation Resistance Test.3.

Second Electrical Safety Test

Earth and Enclosure Leakage Current Test

Ensure all Earth Continuity Tests and the Insulation Resistance Test results pass

before proceeding with the Earth and Enclosure Leakage Current Test.

Connect the Safety Tester AC lead to the Workstation Mains Inlet.1.

Ensure that the enclosure lead is connected to the PE stud. Ensure that the Battery Indicator on the front panel keypad is 2.

illuminated. If the Battery Indicator is flashing or is not illuminated, the Workstation will require charging for at least 30 minutes

before proceeding.

On the Safety Tester, conduct a single Earth Continuity Test.3.

Disconnect the Safety Tester from the Workstation.4.

Alaris® Gateway Workstation 11/16 1000SM00015 Issue 4

Page 12

Routine Maintenance

Power-up Check

This test checks that the speaker and the keypad LEDs are operating correctly after power-up.

Observing the front panel keypad, 1. connect the Workstation to the AC Mains supply using an IEC Mains Lead and ensure that the

AC Power Indicator is illuminated.

Switch the Workstation on using the 2. ON/OFF button.

Check that the3. 'ON' Status indicator is illuminated, the System Fault indicator flashes rapidly and the secondary speaker

produces a beep. After a few seconds, the primary speaker, situated at the rear of the Workstation, will produce a tone.

The secondary speaker will then buzz for 1 second followed by a 1 second tone from the primary speaker.4.

The5. 'A' Status indicator will start flashing once per second.

After 30 seconds, the 6. 'B' Status indicator will flash approximately once every 30 seconds.

Beacon (where fitted)

This test checks that the Beacon is working correctly.

C1. onnect the Workstation to the AC Mains supply using an IEC Mains Lead and ensure that the AC Power Indicator is illuminated.

Observing the end Beacon, switch the Workstation on using the 2. ON/OFF button.

Check the red LED on the Beacon glows dimly.3.

Check that the red LED on the beacon flashes brightly and then dims.4.

Check that the amber LED on the beacon flashes brightly and then dims.5.

No more beacon activity should occur unless a pump is alarming.6.

Pump Loading/Removal Checks

Connect the Workstation to the AC Mains supply using an IEC Mains Lead and ensure that the AC Power Indicator is illuminated.

Load pump to each tile in turn and check:

Pump is properly located on its electrical connectors•

Pump is mechanically locked into position•

Pump mains indicator turns on when fully fitted•

When removing the pump from the tile check:

Pump mains indicator turns off•

Check that the red LED on the tile turns OFF when the pump is removed. If the LED stays ON, the Workstation should be serviced •

by a qualified service engineer.

Alaris® Gateway Workstation 12/16 1000SM00015 Issue 4

Page 13

Routine Maintenance

Battery Test

This test verifies that the battery is functioning correctly, with and without AC mains attached to the Workstation:

Barcode Reader

Connector

Nurse Call

Connector

Rear View of

Workstation

Cat5e Ethernet

Crossover Cable

Test PC

with Wireless LAN card

Connect the Workstation to the test equipment as shown. Connect Workstation to AC mains using IEC Mains Lead.1.

Connect the Cat5e crossover cable between the Auxiliary Connector port on the rear of the Workstation and the test PC ethernet 2.

port.

Switch on the Workstation. Wait for the Workstation to initialise (approx. 45 seconds).3.

Manually set the test PC's IP address to 192.168.0.130, Subnet mask 255.255.255.0. 4.

On the Test PC, launch Internet Explorer. In the address bar at the top of the screen enter the following address:5.

http://192.168.0.128

Confirm that the Workstation web service startup page is displayed. Click the 6. Refresh icon and confirm that the startup page

continues to be displayed when the refresh is complete.

Click 7. OK on the startup screen.

Check that, at the bottom right hand corner of the monitoring page on the test PC, the battery symbol shows a capacity 8.

percentage of between 5% and 100%. If the capacity is less than 5% then the Workstation must remain connected to AC mains

until the capacity reaches 50%.

Remove the AC mains lead and ensure that the Workstation continues to operate and shows a capacity percentage of between 9.

5% and 100%. If the unit does not operate or shows a percentage less than 5% then it is likely that a battery sub-system fault has

Alaris® Gateway Workstation 13/16 1000SM00015 Issue 4

Page 14

Routine Maintenance

Setting the Time and Date

Ensure that the Cat5e crossover cable between the Auxiliary Connector port on the rear of the Workstation and the test PC 1.

ethernet port.

Connect the Workstation to AC mains using an IEC Mains Lead. Switch on the Workstation.2.

Manually set the test PC's IP address to 192.168.0.130, Subnet mask 255.255.255.0.3.

On the Test PC, launch Internet Explorer. In the address bar at the top of the screen enter the following address:4.

http://192.168.0.128

Click 5. OK on the startup screen. Confirm that the tile monitoring page is displayed.

Click on 6. Date & Time in the navigation panel on the left of the screen. The following screen is displayed:

Enter the correct date and correct time .7.

Click 8. Update to confirm.

Click on9. Event Logs in the navigation panel on the left of the screen. An entry for Time Changed and Date Changed at the

bottom of the list indicates that the time and date have been updated successfully.

Alaris® Gateway Workstation 14/16 1000SM00015 Issue 4

Page 15

Routine Maintenance

Recommended Cleaning and Inspection

Cleaning the Workstation: -

Before the transfer of the Workstation to a new patient and periodically during the use, clean the Workstation by wiping over with a

lint-free cloth lightly dampened with warm water and a standard disinfectant / detergent solution.

Recommended cleaners are:

Brand Concentration

Hibiscrub 20% (v/v)

Virkon 1% (w/v)

Do not use the following disinfectant types:

- NaDcc (such as PRESEPT)

- Hypochlorites (such as CHLORASOL)

- Aldehydes (such as CIDEX)

- Cationic Surfactants (such as Benzalkonium Chloride)

- Iodine (such as Betadine)

- Concentrated Isopropyl alcohol based cleaners will degrade plastic parts.

Before cleaning always switch OFF and disconnect from the AC power supply.

Never allow fluid to enter the casing and avoid excess fluid build up on the pump.

Do not use aggressive cleaning agents as these may damage the exterior surface

of the Workstation.

Do not steam autoclave, ethylene oxide sterilise or immerse this Workstation in

any fluid.

To ensure that this Workstation remains in good operating condition, it is important to keep it clean and carry out the routine

maintenance procedures described below.

Interval Routine Maintenance Procedure

When loading pumps Check that each pump is properly located on its electrical connectors and is mechanically locked into position.

When removing pumps Check that the red LED turns OFF on the Tile Plate when the pump is removed. If the LED stays ON, the

Workstation should be serviced by a qualified service engineer.

As required Thoroughly clean external surfaces of the equipment before and after prolonged periods of storage.

12 Monthly Inspect AC outlets, communication connectors and the AC inlet for damage.

Perform electrical safety checks. The complete unit leakage current must be measured. If more than 500µA the

equipment should not be used, but should be serviced by a qualified service engineer.

Alaris® Gateway Workstation 15/16 1000SM00015 Issue 4

Page 16

Routine Maintenance

Performance Verification Procedure

Model / Serial Number: Service Order / Inventory Number:

Hospital Name / Reference: Software Version:

INSPECTION Physical inspection and clean

OPERATION

CH2

Power-up Check

Ensure that the speaker and Keypad LEDs are functioning correctly.

Check Beacon operation (if fitted).

Pump Removal/Loading Checks

Battery Test

SETUP

CH2

Set the correct Date and Time.

Class I (no applied parts)

Perform tests with no pumps attached

Earth Resistance Test <= 200mΩ

ELECTRICAL

CH2

SAFETY TESTS

Earth Leakage Current <= 500 µA

Enclosure Leakage Current <= 100 µA

attach printed test results

Verification

Performed

By

CHX

indicates the chapter number in the Technical Service Manual (TSM) - 1000SM00015.

CH2

E.G.

= Refer to TSM Chapter 3.

_______________________________

Sign

_____________________________

Print

__________________________

Date

Alaris® Gateway Workstation 16/16 1000SM00015 Issue 4

Page 17

Troubleshooting

In this chapter

Troubleshooting Guide 18

Chapter 3

Page 18

Troubleshooting

Troubleshooting Guide

Warnings

Use extreme caution when servicing equipment whilst it is connected to the AC mains.

This equipment contains static-sensitive components. Wherever the ESD symbol

precautions for the protection of static-sensitive components when attempting to service and repair the

equipment.

Always visually inspect the tiles, communications cables and connectors, power cord and plug for damage. If the

power cord or plug are damaged they should be replaced.

Should further technical assistance be required call your local Cardinal Health Service Centre.

Workstation has been Dropped or Damaged

If the equipment is damaged, the damaged parts should be identified and replaced before any further troubleshooting is carried

out.

During inspection, careful attention should be paid to the power tile and each docking tile, which may be damaged if the docking

station is dropped.

Workstation has been Exposed to Fluids

Excessive fluid spills can lead to fluid ingress into the docking station. Even if the fluid dries out, deposits can be left which cause

the equipment to fail.

If fluid ingress is suspected the docking station should be inspected internally.

Clean and dry out the equipment.

Take care to ensure dried out deposits do not remain on the PCBs or other electrical components. Replace permanently damaged

tiles.

V appears observe strict

Workstation Will Not Power from AC Supply

First check the function of the AC power cable with another piece of working equipment.

Check that the AC power is switched on at the outlet, if applicable.

Check that the power cord is seated properly in the AC power inlet. Also check the fuse in the AC power plug.

If the AC Power switch does not illuminate when the pump is connected to a live AC cable, check the fuses at the AC power inlet.

Power Not Present at Pump

Check that the docking station is switched on and has power.

Check that the pump is correctly seated on the tile.

Hold a magnet next to the Infra-Red communications port on the tile. If the Warning LED does not light up the tile must be

replaced. If the LED does light up, suspect a problem with the pump and remove from service to be examined by qualified service

personnel.

Warning LED Remains Lit when Pump is Removed from Tile

Replace the complete tile, following the instructions in chapter 5 'Spare Parts Replacement Procedures'.

Alaris® Gateway Workstation 18/67 1000SM00015 Issue 4

Page 19

Circuit Descriptions

In this chapter

Functional Module Block Diagram 20

Module Overview Functional Description 21

Chapter 4

Page 20

Circuit Descriptions

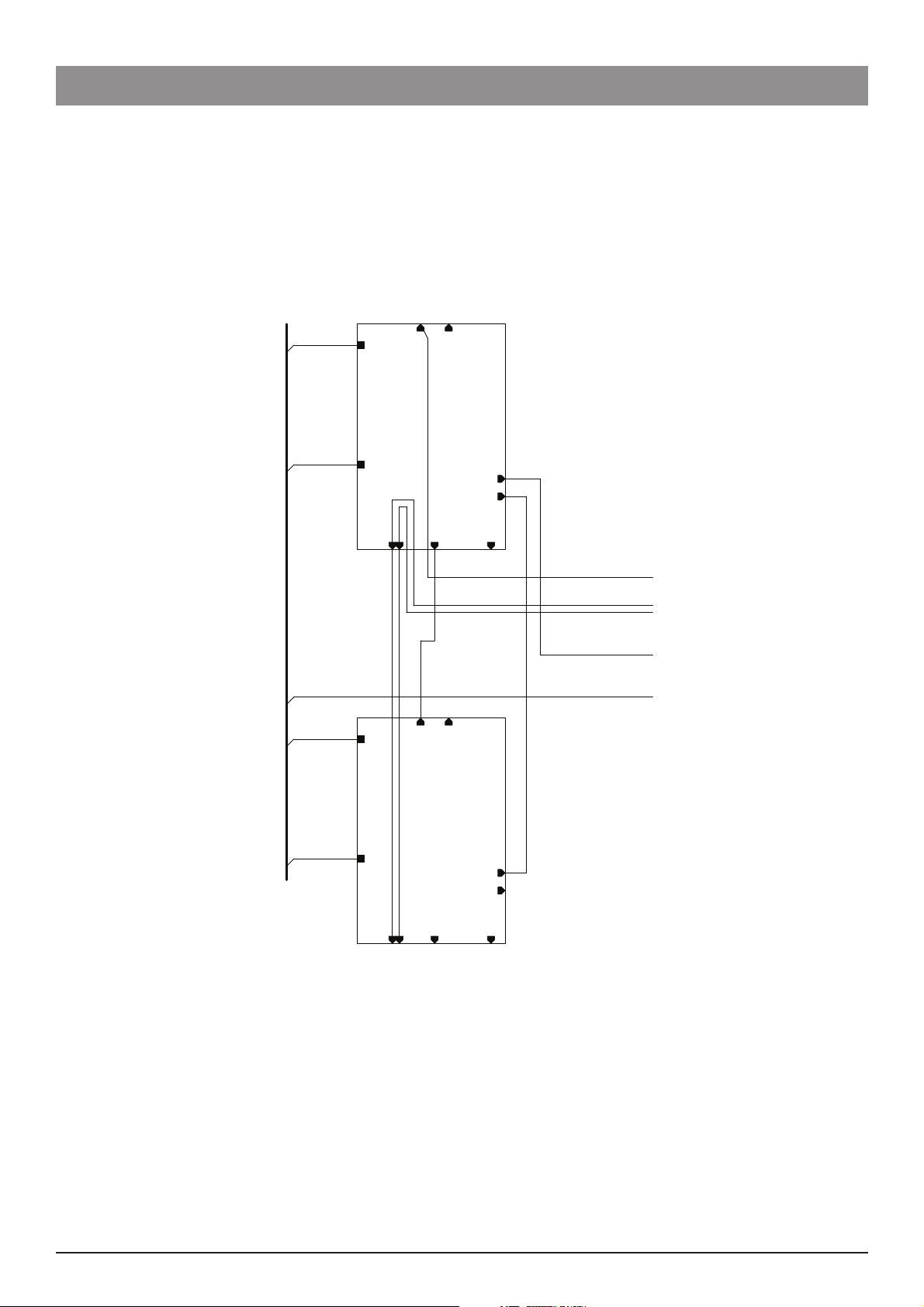

AA1100

Single Board Comput er*

Services Board PCB*

J5

J6

J14

J1

J5

J4

J3

J2

4 Port RS232

Serial Isolat ion

PCB**

J5

J6

J3

J11 Audio (Mono)

J13

LVDS

Display

J12 UART 1

J15

Barcode

Reader

J14

Isolated

RS232

J3

Isolated

Ethernet

Speaker

Colour LCD Display with

Resis tiv e Touc hsc reen**

Barcode Reader*

RS232 Serial Port - C om1

External N etw ork R J45

J2

Tile PCB

J1

J13

Visual Stat us I ndicat or

J10

Internal

USB 2

J8 PCMC IA

J9

Internal

Network

Power Supply U nit

J1

J1

Battery Pack

J3

Nurse C all Int erfac e

J5

Mains

Inlet

Mains

Outlet

Expansion

Expansion

LVDS

Display

J1

Compac t

Flash

128MByt e CF Card*

J1

J2

Power

J7

Internal

USB 1

Cisc o AIR -LMC 352* Cisco AIR-ANT4941*

J4 Quad UART

RS232 Serial Port - C om2* *

RS232 Serial Port - C om3* *

RS232 Serial Port - C om4* *

RS232 Serial Port - C om5* *

J1

J3

J6

J5

J2

Ethernet

Isolat ion PCB*

Auxiliary Gateway RJ45

Internal

Netw ork

Nurse C all

J4

AC Power t o Pumps

IrDA Interface to Pumps

J4,

J5

J6

J5

J4

J3 LVPS Control

J6

J2

Low Voltage Pow er

Syst em PC B

Mains

Dist ribution

J6

Tile Power

Dist ribution

Power

Keypad / St atus LEDs

Power and

Control

+15v Power

J1 Mains Pow er

Key

Data Lines

Power Lines

Combinat ion

* Available as a Us er Option

** N ot av ailable at t ime of initial releas e

Functional Module Block Diagram

The Alaris® Gateway Workstation

The Workstation has been designed as a modular system providing a communications gateway between the Alaris® Infusion Pump and

any Patient Data Management System (PDMS), Patient Monitoring (PM) System or Clinical Information System (CIS) that requires access

to the infusion data retained within the pump.

The device supports optional upgrades to enhance the data communication interfaces and to support software for connections to such

client / server systems.

The user can access data and configure software installed on the Workstation from a client PC using a standard Web browser; this may

be performed over an Ethernet network or by directly linking to the Workstation.

The software is provided under license from Cardinal Health, Inc.

Feature Summary

• Central management system for multiple Alaris® Infusion Pumps

• Medical Device Interface – a unique mounting mechanism proving data communications and mains power to the Alaris® Infusion

Pump

• Reduced cable clutter with the use of a single AC power inlet

• Simple to set up with adaptable modular design

• E cient organisation of multiple infusion lines and con gurations

• Battery back-up in the event of power supply interruption

• High visibility beacon assists with the location of pumps in an alarm state (where tted)

• Nurse call interface for all Alaris® Infusion Pumps attached to the Workstation

• Software running on the Workstation allows remote access to the device

Electronics Architecture

The Alaris® Gateway Workstation

Alaris® Gateway Workstation 20/67 1000SM00015 Issue 4

Page 21

Circuit Descriptions

Module Overview Functional Description

Services Board and Single Board Computer

The Single Board Computer (SBC) is an off the shelf processor board supplied to Cardinal Health, Inc. by DSP Designs. The SBC connects

both mechanically and electrically to the Services Board PCB which provides the processor with the peripheral external interfaces. The

SBC also contains the 128 MByte Compact Flash card. Also available on the Services Board is a PCMCIA connector into which attaches

the Cisco wireless card and antenna.

Low Voltage Power System Board

The Low Voltage Power System Board (LVPS) provides the Workstation with low voltage DC power. The LVPS Board gets power from the

PSU module connected to the AC mains supply. A smart rechargeable battery pack is connected to the LVPS Board as a second power

source used when the AC mains is unavailable; this makes the LVPS Board act as a UPS.

The LVPS Board has an on-board charger that is responsible for keeping the smart battery pack charged. The LVPS Board provides

regulated 3.3V and 5V to the Services Board and also provides either +15V from the power supply or battery terminal voltage to the

Tile Boards. The circuitry for switching on and off the Docking Station is on the LVPS Board, which the User activates with an externally

mounted keypad.

Tile Board

In the Workstation the Tile Board provides the interface to the pumps providing power (directly from the AC mains) and an IrDA port for

communication with the pumps. The Tile board itself communicates via the Internal Switched Ethernet to the SBC. The Tile board also

controls the Visual Status Indicator and Nurse Call interface directly without the need for the SBC to be fitted.

The Tile Board is designed in four different configurations:

• Vertical mount, two tiles high

• Vertical mount, three tiles high

• Horizontal mount, two tiles wide

• Horizontal mount, three tiles wide

To enable the modular construction, Tile Boards connect in series to extend the number of tiles within the Workstation as the

configuration shape grows.

Ethernet Isolation Board

The function of the Ethernet Isolation Board is to provide electrical separation between the internal electronics of the Workstation

and the external Ethernet connections. This board isolates both the primary 10 Base T / 100 Base-Tx interface and also the Ethernet

connection with an Auxiliary Docking Station. The board also provides the relay for the nurse call function.

Power Supply Unit

The Power Supply Unit (PSU) converts AC mains voltage into +15VDC used to power all electronic sub-systems within the Workstation

when AC mains is connected. The AC mains input is implemented as a spur off the Live and Neutral wiring within the device that also

provides AC mains power to the pumps and to the AC mains outlet connector.

Battery Pack

A 9.6v, 2.7A internal battery provides a UPS function should a temporary disconnection from the AC mains power supply occur. The

NiMH battery pack includes a gas gauge and supports the SMB interface.

Alaris® Gateway Workstation 21/67 1000SM00015 Issue 4

Page 22

Chapter 5

Spare Parts Replacement

Procedures

In this chapter

Introduction 23

Torque Guide 23

3 Tile Assembly 24

Front Cover and LVPS PCB 25

Power Supply Unit 26

Battery Pack 27

Services Board 28

Upper Comms Pod 30

Lower Comms Pod 31

IEC Pod/Rear Cover 33

Saddle Kit 35

Cabling Diagrams 36

Labels 46

Trolley Mounting Kit 47

Bar Mounting Kit 49

Pole Mounting Kit 50

Page 23

Spare Parts Replacement Procedures

Introduction

Ensure the Workstation is disconnected from the AC power supply and switched off before

attempting to service

The Workstation contains static-sensitive components. Observe strict ESD precautions at all times

Only use Cardinal Health recommended spare parts

Following all spare part replacement and repair activities, testing must be performed in accordance

with the Performance Verification Procedure (PVP), see 'Chapter 2, 'Routine Maintenance'

Torque Guide

The torque levels established during the manufacturing process are outlined in the 'Refitting Notes' sections of this chapter. Torque

levels selected apply throughout product life for the Workstation.

Use the information as a guide to the 'do not exceed' torque levels when servicing the Workstation. When servicing, it is recommended

that torque is applied gradually until the component is secure. In any process do not exceed the stated levels.

If a torque driver is available for servicing this will help control the applied torque; otherwise, be aware that excess force may cause the

component to fail.

Where a torque level is not stated in the 'Refitting Notes' sections of this chapter then fixing should be

hand-tight.

The force required to create a thread for the first time is more than when reassembling a previously made joint.1.

Always use the correct torque level when first making an assembly stage.2.

Take care with the torque applied when re-assembling parts. Less torque is required, so a hand tool may be more appropriate.3.

In many situations a stripped thread will require replacement of the failed component.4.

The head patterns of the fasteners are of the following types:5.

Snake Eye Tool Workstation ( ts into a ¼" drive socket, used on tie rods when pulling modules together)•

Pozi Number 1 (smaller X head)•

Torx Number T10 (Medium star profile, used on the majority of Torx fasteners)•

Torx Number T20 (Larger star shape, typically for case securing screws)•

M3 nuts (Hex head with 5.5mm across flats (AF) drivers)•

M4 nuts (Hex head with 7mm across flats (AF) drivers)•

Always select the correct tool and bit pattern for the fastener.6.

Alaris® Gateway Workstation 23/67 1000SM00015 Issue 4

Page 24

Spare Parts Replacement Procedures

3 Tile Assembly

Replacement Procedure

Remove the eight Screws (A) on the tile assembly (B).1.

Disconnect the Ethernet Cable Out (red), Neutral Wire, Live Wire, DC Power Cable (J6), Ethernet Cable In (grey), Nurse Call Cable 2.

(J19) and the three Earth Cables.

Replace the Tile Assembly.3.

Refitting Note:

Ensure that all connectors are pushed fully home and that the cables are not trapped under relays. Torque screws to 170cNm

(A) Screw (x8)

Ethernet Cable In

Nurse Call Cable

(B) Tile Assembly

Earth Cable (x3)

Neutral Wire

Live Wire

DC Power Cable

Ethernet Cable Out

Spare Parts

Item Description Part Number

A M4x10 CSK TORX HD A2 BN13278 1000SP01217

B ASSY TILE PLATE 3 HIGH ASENA GATEWAY 1000SP00599

Alaris® Gateway Workstation 24/67 1000SM00015 Issue 4

Page 25

Spare Parts Replacement Procedures

Front Cover and LVPS PCB

Replacement Procedure

Remove the 3 Tile Assembly.1.

Remove the four Screws (A) securing the Front Cover Assembly.2.

Disconnect the Cable Assembly Services LVPS (J3), Cable Assembly Services Power (J4), Cable Assembly Battery LVPS (J6) and the 3.

Cable Assembly Tile LVPS (J5) from the LVPS PCB (B).

Remove the four screws (C), four washers (D) & (E) and Ground Wire securing the LVPS PCB to the Front Cover (F).4.

Release the locking tabs for Molex connector (J2) and remove the Keypad Panel (G) flexi tail.5.

Remove the Front Cover Seal (H).6.

Reassemble in reverse order.7.

Refitting Note:

When replacing the Front Cover Seal, fit the Seal to both edges of the Front Cover. The flat edge goes against the side of the Front

Cover and the edge with the tube goes into the Front Cover recess. Ensure that all connectors are pushed fully home. Torque screws to

45cNm. Fit the Front Cover to the extrusion and torque to 170cNm.

(B) LVPS PCB

Ground Wire

(C) Screws (x4)

(D) Washer

(E) Washers (x3)

J1

(F) Front Cover

(H) Seal (x2)

J5

J6

J4

J3

LVPS and Front Cover Assembly

(A) Screws (x4)

(G) Keypad

Spare Parts

Item Description Part Number

A M4x20 PAN HD TORX A2 BN5653 1000SP01217

B ASSEMBLY PCB LVPS 1000EL00628

C M3x8 PAN HD TORX A2 ISO14583 1000SP01217

D WASHER M3 PLAIN Z+C "

E FLAT WASHER NYLON M3 TO ISO 7089 "

F COVER FRONT AGW 1000SP01215

G LABEL AGW FRONT "

H SEAL FRONT COVER AGW "

Alaris® Gateway Workstation 25/67 1000SM00015 Issue 4

Page 26

Spare Parts Replacement Procedures

Power Supply Unit

Replacement Procedure

Remove the 3 Tile Assembly.1.

Remove the Front Cover and disconnect plug from LVPS PCB.2.

Remove the five Screws (A) & (C), the five Washers (B) & (D) and the Ground Wires securing the PSU to the Extrusion.3.

Remove the PSU (F). Ensure that the Thermal Pad (F) is fully removed from the Extrusion.4.

Reassemble in reverse order. 5.

Refitting Note:

Ensure that the Thermal Pad is fitted to the side of the PSU, the protective film has been removed and the PSU is replaced with the

Thermal Pad tight to the side of the extrusion. Torque screws to 170 cNm.

(E) PSU

(F) Thermal Pad

(B) Washers (x4)

Ground Wire

Ground Wire

(D) Washer

Spare Parts

Item Description Part Number

A M4x10 PAN HEAD BIN 5653 1000SP01217

B STAR WASHER M4 DIN6797 "

C M3x8 PAN HD TORX A2 ISO14583 "

D WASHER M3 SHAKEPROOF EXTERNAL "

E ASSEMBLY PSU SWITCH MODE 1000SP01216

F THERMAL PAD PSU "

(A) Screws (x4)

(C) Screw

Alaris® Gateway Workstation 26/67 1000SM00015 Issue 4

Page 27

Spare Parts Replacement Procedures

Battery Pack

Replacement Procedure

Remove the eight Screws (A) and Washers (B) securing the Rear Cover Assembly to the Power Base Module.1.

Open the Cover Assembly by hinging along one long face. Avoid stressing the connected cables and lay the Cover along side the 2.

assembly.

Disconnect the Battery (C) and remove from saddle slot.3.

Reassemble in reverse order. 4.

Refitting Note:

Ensure cable assemblies are not trapped and the Back Cover Seal is fitted to the Saddle Lug before fitting the Back Cover. Torque Screws

to 45 cNm.

Rear Cover Assembly

(B) Washer (x8)

(A) Screw (x8)

(C) Battery Pack

Spare Parts

Item Description Part Number

A M3x16 PAN HD TORX A2 ISO 14583 1000SP01217

B WASHER M2 WAVEY SST "

C GATEWAY ASSEMBLY BATTERY PACK 1000SP00605

Alaris® Gateway Workstation 27/67 1000SM00015 Issue 4

Page 28

Spare Parts Replacement Procedures

Services Board

Replacement Procedure

Remove the eight Screws (A) and Washers (B) securing the Rear Cover Assembly to the Power Base Module.1.

Open the Cover Assembly by hinging along one long face. Avoid stressing the connected cables and lay the Cover along side the 2.

assembly.

Disconnect the Speaker (J11), RS232 Cable Assembly (J14) and Barcode Reader Assembly (J15) (if fitted).3.

Disconnect Grey Ethernet Cable Assy (J9) and the Services Ethernet Cable Assy (J3).4.

Disconnect the Earth Services Cable Assy (J16), the Service Power Cable Assy (J2) and the Services LVPS Cable Assy (J1).5.

Disconnect the Wireless LAN Card (C) from the PCMCIA slot (option 3 only).6.

Remove the six Screws (D) and Washers (E).7.

Remove the Services Board (F).8.

Reassemble in reverse order.9.

Refitting Note:

Ensure the Wireless LAN card and all cable connections are pushed fully home.

Torque Screws to 45 cNm.

(B) Washer (x8)

(A) Screw (x8)

Rear Cover Assembly

(F) Services Board

(E) Washer (x6)

(D) Screw (x6)

Alaris® Gateway Workstation 28/67 1000SM00015 Issue 4

Page 29

Spare Parts Replacement Procedures

Services Board (continued)

J8

J3 J6 J9

J1

J2

J15

J14

J11

Spare Parts

Item Description Part Number

A M3x8 PAN HD TORX A2 ISO14583 1000SP01217

B FLAT WASHER NYLON M3 TO ISO 7089 "

C CISCO AIR-PCM352 PCMCIA WIRELESS CARD 1000EL00824

D M3x8 PAN HD TORX A2 ISO 14583 1000SP01217

E FLAT WASHER NYLON M3 TO ISO 7089 "

F SERVICES BOARD 1000EL00638

* ASSEMBLY CABLE EARTH SERVICES BOARD 1000EL00799

* GATEWAY CABLE ASSY ISOLATED RS232 1000EL00679

* GATEWAY CABLE ASSY SERVICES ETHERNET 1000EL00681

* GATEWAY CABLE ASSY SERVICES POWER 1000EL00683

* GATEWAY CABLE ASSY SERVICES LVPS 1000EL00682

* GATEWAY CABLE ASSY TILE ETHERNET IN 1000EL00675

(C) Wireless LAN

Card

* Item not shown

Alaris® Gateway Workstation 29/67 1000SM00015 Issue 4

Page 30

Spare Parts Replacement Procedures

Upper Comms Pod

Replacement Procedure

Remove the eight Screws (A) and Washers (B) securing the Rear Cover (C) to the Power Base Module.1.

Open the Cover Assembly by hinging along one long face. Avoid stressing the connected cables and lay the Cover along side the 2.

assembly.

Disconnect the Barcode Cable Assembly (D) from the Services Board (J15).3.

Remove the labels from the Comms Pod Cover (G). Remove the four Screws (E) and four Washers (F) securing the Comms Pod 4.

Cover. Remove the Pod Cover and Pod Seal (J).

Remove the Plate Connector (H), unclip the Ferrite (I) and remove.5.

Remove the Barcode Cable Assembly Nut using an 11mm spanner.6.

Remove the Barcode Cable Assembly.7.

Reassemble in reverse order. 8.

Refitting Note:

Ensure the Barcode Cable Assembly is in the correct orientation.

Ensure that the Ferrite is properly secured and does not move.

Torque screws to 45 cNm.

(B) Washer (x8)

(A) Screw (x8)

(J) Pod Seal

(G) Pod Cover

(F) Washer (x4)

(E) Screw (x4)

(I) Ferrite

(C) Rear Cover

(D) Barcode Cable

Assembly

(H) Plate Connector

Barcode Cable Assembly

correct orientation

Spare Parts

Item Description Part Number

A M3x16 PAN HD TORX A2 ISO 14583 1000SP01217

B WASHER M3 WAVEY SST "

C COVER REAR ASENA GATEWAY 1000ME00595

D BARCODE CABLE ASSEMBLY 1000EL00679

E M3x8 PAN HD TORX A2 ISO14586 1000SP01217

F WASHER M3 WAVY SST "

G POD COMMS ASENA GATEWAY 1000SP01214

H PLATE CONNECTOR BARCODE 1000ME01642

I FAIR-RITE 0431173951 0000EL00940

J SEAL COMMS POD ASENA GATEWAY 1000SP01214

Alaris® Gateway Workstation 30/67 1000SM00015 Issue 4

Page 31

Spare Parts Replacement Procedures

Lower Comms Pod

Replacement Procedure

Remove the labels from the Comms Pod Cover (C) Remove the four Screws (A) and four Washers (B) securing the Comms Pod 1.

Cover and Seal (D).

Slide the Speaker (E) (if fitted) from the retainer in the rear of the Comms Pod Cover and disconnect from the Services Board (J11). 2.

Remove the Pod Cover.

Disconnect the Nursecall Connector (J5), Nursecall Cable Assembly (J6), red Ethernet Cable (J3) and the Services Ethernet Cable 3.

Assembly (J1) from the Ethernet Isolation Board (F).

Remove the two Screws (G), Nylon Washer (H), Shakeproof Washer (I) and Ethernet Earth Cable crimp connector securing the 4.

Ethernet Isolation Board. Remove the Ethernet Isolation Board.

Disconnect the RS232 Cable Assembly (J) from the Services Board (J14).5.

Remove the RJ45 Plate Connector (K) and the Multi Plate Connector (L).6.

Remove the Nurse Call Connector Assembly (M) using an 11mm spanner.7.

Remove the two Washers, Nuts and Standoffs (N).8.

Remove the RS232 Cable Assembly.9.

Reassemble in reverse order. 10.

Refitting Note:

Ensure that the RJ45 connectors are pushed firmly into the connector plate.

Apply Loctite 243 to the threaded end of the Standoffs (N) and torque to 25cNm.

Ensure that the Nurse Call Connector is in the correct orientation.

Torque screws to 45cNm

J3

J6

J5

(C) Pod Cover

(B) Washer (x4)

(A) Screw (x4)

(D) Seal

(E) Speaker

(M) Nurse Call

Assembly

(L) Multi Plate

Connector

(J) RS232 Cable

Assembly

(F) Ethernet

Isolation Board

(I) Shakeproof

Washer

(G) Screws (x2)

(H) Nylon

Washer

(N) Nut (x2),

Washer (x2),

Standoff (x2)

(K) RJ45 Plate

Connector

Alaris® Gateway Workstation 31/67 1000SM00015 Issue 4

Page 32

Spare Parts Replacement Procedures

Lower Comms Pod (continued)

Spare Parts

Item Description Part Number

A M3x8 PAN HD TORX A2 ISO14583 1000SP01217

B WASHER M3 WAVEY SST "

C POD COMMS ASENA GATEWAY 1000SP01214

D SEAL COMMS POD ASENA GATEWAY "

E ASSEMBLY SPEAKER ALARM AGW 1000SP00652

F ASENA GATEWAY ETHERNET ISOLATION BOARD 1000EL00655

G M3x8 PAN HD TORX A2 ISO14583 1000SP01217

H FLAT WASHER NYLON M3 TO ISO 7089 "

I WASHER M3 SHAKEPROOF EXTERNAL "

J GATEWAY CABLE ASSY ISOLATED RS232 1000EL00679

K PLATE CONNECTOR RJ45 TYPE2 ASENA GATEWAY n/a

L PLATE CONNECTOR TYPE MULTI ASENA GATEWAY n/a

M GATEWAY CABLE ASSY ISOLATED NURSE CALL 1000EL00677

N SCREW LOCK KIT FEMALE RS232 1000SP01217

* LOCTITE 243 0000ME00672

* Item not shown

Alaris® Gateway Workstation 32/67 1000SM00015 Issue 4

Page 33

Spare Parts Replacement Procedures

IEC Pod/Rear Cover

Replacement Procedure

Ensure the Mains Inlet Cable Assembly (A) is disconnected from the Tile PCB (see '3 Tile Assembly') and the Power Supply Unit (see 1.

'Power Supply Unit')

Remove the eight screws (B) and washers (C) securing the Rear Cover (D) to the Power Base Module.2.

Remove the PE Connector Nut (E), Washer (F).3.

Remove the Ethernet Earth Cable, the Services Earth Cable and the Mains Inlet Cable crimp connectors.4.

Remove the Shakeproof Washer (G), Nut (H) and M6 Washer (I).5.

Remove the PE Stud (K) and Earth Symbol Washer (J).6.

Remove the three Screws (L) and Washers (M) securing the IEC Pod Cover (N) and Seal (O). Remove the IEC Pod Cover.7.

Remove the Mains Inlet Cable Assembly (A) from the slot in the Rear Cover Assembly.8.

Reassemble in reverse order.9.

Refitting Note:

Torque Nuts (H) and (E) to 150cNm. Torque Screw (B) and (L) to 45 cNm.

(D) Rear Cover

(C) Washer (x8)

(B) Screw (x8)

(N) IEC Pod

Cover

(M) Washer (x3)

(L) Screw (x3)

Alaris® Gateway Workstation 33/67 1000SM00015 Issue 4

(O) Seal

(A) Mains Inlet

Cable Assembly

(K) PE Stud

(J) Earth Symbol

Washer

(H) Nut

(G) Washer

(F) Washer

(E) Nut

(I) Washer

Page 34

Spare Parts Replacement Procedures

Rear Cover (continued)

Spare Parts

Item Description Part Number

A GATEWAY CABLE ASSY MAINS IN 1000EL00685

B M3x16 PAN HD TORX A2 ISO 14583 1000SP01217

C WASHER M2 WAVEY SST "

D COVER REAR ASENA GATEWAY 1000ME00595

E NUT M6 PLAIN DIN 934 A2 1000SP01217

F WASHER M6 BRASS ISO 7092 "

G WASHER M6 SHAKEPROOF DIN 67898, A2 "

H NUT M6 THIN 4035 A2 "

I WASHER M6 PLAIN "

J WASHER EARTH "

K PE STUD M6x20 0000ME00547

L M3x8 PAN HD TORX A2 ISO14583 1000SP01217

M WASHER M3 WAVEY SST "

N POD IEC ASENA GATEWAY 1000SP01214

O SEAL IEC POD ASENA GATEWAY "

* ASSEMBLY CABLE EARTH SERVICES BOARD 1000EL00799

* ASSEMBLY CABLE EARTH ETHERNET ISOLATION 1000EL00802

* Item not shown

Alaris® Gateway Workstation 34/67 1000SM00015 Issue 4

Page 35

Spare Parts Replacement Procedures

Saddle Kit

Replacement Procedure

Remove the Rear Cover Seal (A).1.

Remove the eight Screws (B) securing the Rear Cover (D) to the extrusion.2.

Remove the Saddle Gasket (D), PSU Chimney Seal (E) and the Comms Chimney Seal (F) from the Rear Cover.3.

Refitting Note:

Ensure that all seals and gaskets are pushed fully home and are fitted in the correct orientation.

Torque the eight Screws (B) to 200cNm.

(D) Saddle Gasket

(C) Rear Cover

(A) Rear Cover Seal

(B) Screw (x8)

(E) PSU Chimney Seal

(F) Comms Chimney Seal

Spare Parts

Item Description Part Number

A SEAL COVER REAR ASENA GATEWAY 1000SP01213

B SCREW SKT CAP M6x20 DIN 6912 1000SP01217

C SADDLE REAR COVER ASENA GATEWAY 1000SP01213

D SADDLE GASKET ASENA GATEWAY "

E SEAL PSU CHIMNEY AGW "

F SEAL COMMS CHIMNEY AGW "

Alaris® Gateway Workstation 35/67 1000SM00015 Issue 4

Page 36

Cabling Diagrams

2 Horizontal Module

Spare Parts Replacement Procedures

Beacon

BEACON LONG

1000EL 00 784

EARTH

1000SP 00452

100 0E L 00712

ETHERNET 2 ( J7)

ETHE RNET IN(J3)

2-H Tile board

EARTH

1000SP 00452

POWER IN (J6)

POWER OUT (J1)

J13- Beacon

1000EL 00675

1000EL 00690

1000EL 00689

1000SP 00452

EXTRUSION CENTRE RAIL

J4-NEUTRAL

J5 -LIVE

ETHERNETOUT (J2)

Alaris® Gateway Workstation 36/67 1000SM00015 Issue 4

Page 37

Spare Parts Replacement Procedures

Cabling Diagrams (continued)

2 Vertical Module

Beacon (J13)

1000EL 00689

POWER IN (J6)

POWER OUT (J1)

2-V Til eBoard

ETHERNET OUT(J2)

J4 - NEUTRAL

J5 - LIVE

EARTH

1000SP 004 52

EARTH

1000SP00452

EXTRUSION CENTRE RAIL

100 0EL 00 708

ETHERNET 2 (J7)

ETHERNET IN(J3)

1000EL 00675

1000SP 00452

1000EL 00690

SEENOTE

NOTES:

In systems larger than a 3XX, connect cable 1000EL00674 to J7ofthe2VModule

Alaris® Gateway Workstation 37/67 1000SM00015 Issue 4

Page 38

Spare Parts Replacement Procedures

Cabling Diagrams (continued)

3 Horizontal Module

Beacon

BEACON L ONG

1000E L0 0784

Nurse call (J18)

ETHERNET IN (J3)

EARTH

1000SP 00452

EARTH

1000SP 00452

1000EL00716

POWER IN (J1)

1000SP 00452

1000EL 00675

1000EL 00689

3-HTile board

EXTRUSION CENTRE RAIL

EARTH

1000SP 00452

1000EL 00691

POWER OUT (J6)

J5 -LIVE

ETHERNE T OUT(J 2)

J4 -NEUTRAL

Beacon (J13)

Alaris® Gateway Workstation 38/67 1000SM00015 Issue 4

Page 39

Spare Parts Replacement Procedures

Cabling Diagrams (continued)

4 Horizontal Module

1000SP 00452

EARTH

1000EL 00712

ETHERN ET 2 ( J7)

ETHERNET IN (J3)

EXTRUSIONCENTRE RAIL

EARTH

1000SP 00452

J5 - LIVE

J4 - NEUTRAL

1000EL 00691

EARTH

1000SP 00452

EARTH

1000SP 00452

1000EL 00675

ETHERNET IN (J3)

2-HTileboard

ETHER NET OUT (J2)

ETHERNE T 2 (J 7)

2-H Tileboard

POWER IN (J6)

POWER OUT (J1)

J13- Beacon

1000EL 00785

1000EL 00690

1000EL 00689

1000SP 00452

1000E L 00 712

1000EL 00 688

POWER IN (J6)

POWER OUT (J1)

J4 - NEUTRAL

ETHERNE T OUT(J 2)

J5 - LIVE

J13-Beac on

BEACON NOT FITTED TO 4H MODULE

Alaris® Gateway Workstation 39/67 1000SM00015 Issue 4

Page 40

Spare Parts Replacement Procedures

Cabling Diagrams (continued)

Base Unit (option 1)

KEYPAD

1000L B00617

1000EL 00688

J13-Beacon

J1-POWER OUT

J2-E THERNET OUT

J4-NEUTRAL

J5-LIVE

EARTH

1000S P 00 452

J6- POWER IN

3-V Tile board

EARTH

1000SP00452

1000EL006 74

J18-Nurse call

J2-Keypad[9..0]

J3-E THERNET IN

J5-TILE POWER

CHASS IS

J1-1 5V IN

LV P S BOARD

EARTH

1000EL 00636

1000S P 00 452

1000EL00675

1000E L0079 9

1000EL 006761000E L00677

J3-S ERVICES

J4-S E R VICES POW ER OUT

J6-B ATT E R Y

1000E L006 28

EXTRUSION CENTRE RAIL

1000EL 00682

1000E L 0068 3

CHASSIS 1000EL00687

100 0EL 0068 4

BATTERY

BATTERY PACK

100 0SP 00605

1000EL 00686

J3-15V OUT

PSU

MAINS E

CHASSIS

MAINS L

MAINSN

1000EL 00685

NEUTRAL

LIVE

IE C MAINSIE C MAINS

IEC MAINSIEC MAINS

MAINS OUT

MAINS IN

1000EL 00765

PE S TUDPE S TUD

EARTH

1000EL008 02

CHASSIS

J6-Nurse call

J3-Tile E thernet

J1-Servic es Ethernet

UPPER POD

J5-NURSECALL OUT

J2- EXT ETHER

J4- AUX ETH ER

ETHERNET ISOLAT ION BOARD

1000EL00 655

1000E L0 0679

LOWER POD

1000SP00636

BASE UNIT WITH OPTION 01

Alaris® Gateway Workstation 40/67 1000SM00015 Issue 4

Page 41

Spare Parts Replacement Procedures

Cabling Diagrams (continued)

Base Unit (option 2)

Beacon

BEACON

1000EL 0069 3

KEYPAD

1000L B00617

1000EL 00688

J13-Beacon

J1-POWER OUT

J2-E THERNET OUT

J4-NEUTRAL

J5-LIVE

EARTH

1000S P 00452

Connect 1000EL00674 to J7 on 2V moduleswhen fitted

J6-POWER IN

3-V Tile board

EARTH

1000SP 00452

100 0EL006 74

J18-Nurse call

J2-Keypa d[9..0]

J3-E THERNET IN

J5- TI LE POWER

CHASSIS

J1-15VIN

1000EL00687

LV P S BOARD

EARTH

1000E L 00636

1000SP 00 452

100 0E L 00675

1000EL 0079 9

J16- CHAS S IS

J9-ETHE R NET S

AA1100

1000E L 00 676

J4- QU AD R S 232

J13-L CD DISPLAY

GSBUNIT

3-ET HERNET

J

J3-S ERVICES

J4-S E R VICES POWER O UT

J6-BATTERY

1000EL00628

EXTRUSION CENTRE RAIL

1000EL 006 83

100 0EL 00682

VICES

J1- SER

J2-POWER IN

J11 -SP E AKER

J15-BARCODE

J14-ISO RS232

1000EL006 38

CHASSIS

1000EL00684

BATTERY

SMART BATTE R Y

1000S P 00605

1000EL006 86

J3-15V OUT

PSU

MAINS N

CHASSIS

MAINS L

MAINS E

1000EL 00685

NEUT R AL

LIV E

S

IE C MAINSIE C MAIN

IEC MAINSIEC M AINS

MAINS OUT

MAINSIN

1000E L0 07 65

PE STUDPE STUD

EARTH

1000EL 00680

BARCODE

1000E L0 0802

CHASSIS

J6-Nurse ca ll

J3-TileEthe rnet

J1-S ervices Ethernet

UPPER POD

J5- NUR S EC ALLOU T

J2- EXT ETHER

J4- AUXETHER

ETHERNET ISOLATIONBOARD

1000EL0067 7

1000EL00681

1000E L 00 679

SPEAKER ASSY 1000S P 006 52

100 0EL006 55

LOWER POD

CONFIGURATION SHOWN IS 3X0

BASE UNIT 02INCLUDING SERVICES BOARD

Alaris® Gateway Workstation 41/67 1000SM00015 Issue 4

Page 42

Spare Parts Replacement Procedures

Cabling Diagrams (continued)

Base Unit (option 3)

Beacon

BEACON

100 0EL006 93

KEYPAD

100 0L B00617

1000EL 00688

J13-Beacon

J1-POWER OUT

J2-E THERNET OUT

J4-NEUTRAL

J5-LIVE

EARTH

100 0SP00452

Connect 1000EL00674 to J7 on 2V modules when fitted

J6- POWER IN

3-V Tileboard

EARTH

100 0SP00452

1000EL006 74

J18-Nurse call

J2- Keypad[9..0]

J3-E THERNET IN

J5- TILE POWER

CHASS IS

J1-1 5VIN

LVPS BOARD

J3- SERVICES

J4- SERVICES POWER OUT

EARTH

100 0EL00636

100 0SP00452

100 0EL00675

1000E L00799

WiFiPCMCIA

1000EL 00676

100 0EL00824

AA1100

J4-Q U AD R S232

J13-L CD DISPLAY

GSBUNIT 2

J1-S ERVICES

J16- CH ASS IS

J9-E THERNET S

J3- ETHERNET

J11-S P E AK E R

J15-B AR C ODE

J6- BATTERY

1000EL 0 062 8

EXTRUSION CENTRE RAIL

1000EL 00682

1000EL 0068 3

J2-POWER IN

J14-ISO R S232

100 0EL 00638

CHASSIS 1000EL006 87

100 0EL 006 84

BATTERY

SMAR T BATT E R Y

1000SP00 60 5

100 0E L00686

J3- 15V OUT

PSU

MAINS E

MAINS L

CHASSIS

MAINSN

1000EL 00685

NEUT R AL

LIVE

IE C MAINSIE C MA IN S

IE C MAINSIEC MAINS

MAINS OUT

MAINS IN

100 0EL007 65

PE S TUDPE S TUD

EARTH

BARCODE READER

1000EL00769

1000EL00 802

CHAS SIS

J6-N urse call

J3-Tile E thernet

100 0E L 00680

UPPER POD

ETHERNET ISOLATIONBOARD

BARCODE

J1-Servic es Ethernet

J5-NUR S E CAL L OUT

J2- EXT ETHER

J4- AUX ETH ER

1000EL 0067 7

100 0EL00681

1000EL 00679

SPEAKER ASSY 1000SP0065 2

1000EL00 655

LOWER POD

AND OPTIONAL BARCODE READER

CONFIGURATION SHOWN IS 3X0 WITH BEACON

AND WIRELESS LAN.

BASE UNIT03INCLUDING SERVICES BOARD

Alaris® Gateway Workstation 42/67 1000SM00015 Issue 4

Page 43

Spare Parts Replacement Procedures

Cabling Diagrams (continued)

Configurations - 3X, 5X

J3

J7

SEE NOTE 2

J7

J3

4H MODULE

1000SP00635

J2

J13

BEACON LONG

1000EL00784

J3

3H MODULE

1000SP00634

J13

J2

1000EL 00690

1000EL 00674

1000EL 00785

1000SP 00452

1000EL 00689

BASE MODULE

J1 L/NEJ2

100 0EL007 85

1000EL 00690

1000EL 00674

1000EL 00675

1000SP 00452

1000EL 00689

BASE MODULE

J1 L/NEJ2

OR

1000SP00636+1000SP00649OR1000SP00650

1000SP00651

OR

1000SP00636+1000SP00649OR1000SP00650

1000SP00651

3X4

4H MODULE

J2

1000SP00635

BEACON LONG

1000EL00784

3H MODULE

1000SP00634

J2J2

J13

J3

J13

1000EL 00690

1000SP00632

2V MODULE

J7

2V MODULE

SEE NOTE2

J7

1000EL 00785

1000SP 00452

1000EL 00689

J1 L/NE J2

1000EL 00691

1000EL 00675

1000SP 00452

1000SP00632

1000EL 00689

J1 L/NEJ2

1000EL 00689

1000EL 00674

1000EL 00675

J2

1000SP 00452

1000EL 00690

J1 E L/N

1000EL 00689

1000EL 00674

1000EL 00675

J2

1000SP 00452

1000EL 00690

OR

BASE MODULE

1000SP00636+1000SP00649

BASE MODULE

1000SP00636OR1000SP00650OR1000SP00651

5X4

1000SP00650OR1000SP00651

1000E L 00675

BEACONLONG

3X2 3X3

3X0

1000EL00784

J7

2HMODULE

1000SP00633

J13 J3

BEACON

SEE NOTE 2

1000EL 00690

1000EL 00675

1000SP 00452

1000SP00632

1000EL 00689

1000EL00693

2V MODULE

J1L/NEJ2

J7 J7

1000SP00632

2V MODULE

J13

1000EL 00689

1000EL 00674

1000EL 00675

J2

1000SP 00452

1000EL 00690

BASE MODULE

1000SP00636OR1000SP00650OR1000SP00651

SEE NOTE 2

1000EL 00689

1000EL 00674

1000EL 00675

J2

1000SP 00452

1000EL 00690

BASE MODULE

1000SP00636OR1000SP00650OR1000SP00651

J1 EL/N J1EL/N J1 E L/N

5X0 5X2 5X3

BEACON LONG

1000EL00784

SEE NOTE 4 SEE NOTE 4 SEE NOTE 4

J7

J3

2HMODULE

1000SP00633

J2

J13

1000EL 00675

BEACON

1000EL 00675

1000SP 00452

1000EL 00689

SEENOTE1

1000EL00693

1000EL 00690

1000EL 00674

+

1000SP00636

1000SP00649OR1000SP00650

OR

OR

1000SP00650

1000SP00651

OR

1000SP00651

1000EL 00674

J2

J1 L/NE

J2

BASE MODULE

J13

BASE MODULE

1000SP00636

3) NO BEACON FITTED TO XX4HMODULES

4) USE ETHERNET COUPLER 0000EL00942

2) IN 5XX SYSTEMS, CABLE 1000EL00674CONNECTED TO J7 OF2V MODULE

NOTES:

1) IN 3X0 SYSTEMS, CABLE 1000EL00674 CONNECTED TO J2 OF BASE MODULE

Alaris® Gateway Workstation 43/67 1000SM00015 Issue 4

Page 44

Spare Parts Replacement Procedures

Cabling Diagrams (continued)

Configurations - 7X

J7

J3

EENOTE 1

S

4H MODULE

J2

1000SP00635

BEACON LONG

3H MODULE

J2

1000EL00784

1000SP00634

1000EL 00690

1000EL 00785

1000SP 00452

1000EL 00689

J1 L/NEJ2

J13

J7

1000EL 00691

J3

J13

1000EL 00675

1000SP 00452

1000SP00632

1000EL 00689

J1 L/NEJ2

J7

1000SP00632

2V MODULE

2V MODULE

1000EL 00689

1000EL 00675

1000SP 00452

1000EL 00690

J1L/NE J2

1000EL 00689

1000EL 00675

1000SP 00452

1000SP00632

1000EL 00690

J1 L/NEJ2

J7

1000SP00632

2V MODULE

SEE NOTE 1

J7

2V MODULE

1000EL 00689

1000EL 00674

1000EL 00675

J2

1000SP 00452

1000EL 00690

BASEMODULE

1000SP00636+1000SP00649OR1000SP00650OR1000SP00651

J1 E L/N

1000EL 00689

1000EL 00674

1000EL 00675

J2

1000SP 00452

1000EL 00690

BASEMODULE

1000SP00636OR1000SP00650OR1000SP00651

7X4

BEACON LONG

1000EL00784

J7

2H MODULE

1000SP00633

J13 J3

J2

1000EL 00690

1000EL 00675

1000SP 00452

1000EL 00689

BEACON

1000EL00693

2V MODULE

1000SP00632

J1 L/NEJ2

J7 J7 J7

1000SP00632

2V MODULE

J13

1000EL 00689

1000EL 00675

1000SP 00452

1000SP00632

1000EL 00690

J1 L/NE J2

1000EL 00689

1000EL 00675

1000SP 00452

1000SP00632

1000EL 00690

J1 L/NE J2

2V MODULE

2V MODULE

SEE NOTE 1

1000EL 00689

1000EL 00674

1000EL 00675

J2

1000SP 00452

1000EL 00690

BASE MODULE

1000SP00636OR1000SP00650OR1000SP00651

SEE NOTE 1

1000EL 00689

J7 J7

1000EL 00674

1000EL 00675

J2

1000SP 00452

1000EL 00690

J1 E L/N J1 E L/N J1 E L/N

BASE MODULE

1000SP00636OR1000SP00650

OR

7X0 7X2 7X3

1000SP00651

2) NO BEACONFITTEDTOXX4H MODULES

NOTES:

1) IN 7XX SYSTEMS, CABLE1000EL00674 CONNECTED TOJ7OF 2V MODULE

Alaris® Gateway Workstation 44/67 1000SM00015 Issue 4

Page 45

Spare Parts Replacement Procedures

Cabling Diagrams (continued)

Configuration - 9-2

2H MODULE

J2

1000SP00633

J13 J3

1000SP00452

1000EL00689

1000EL00675

L

J1

J1 L/NE J2

J1 L/NE J2

1000SP00632

2V MODULE

J7

1000SP00452

1000EL00690

1000EL00675

1000SP00632

2V MODULE

J7

1000SP00452

1000EL00690

1000EL00675

/NEJ2

J7

1000EL00690

1000EL00689

1000EL00689

BEACON LONG

1000EL00784

Configuration - 2-3-5

J1 L/NEJ2J13

1000SP00632

2V MODULE

1000EL00690

1000SP00452

BASE MODULE

1000SP01282

1000EL00962

BEACON

1000EL00693

J7

1000EL00675

1000EL00674

J2J1 E L/N

1000EL00961

0000EL00951

1000EL00959

1000EL00689

0000EL00953

This module may be upgraded with

OPTION 2 KIT - 1000SP00650

1000SP00632

2V MODULE

J7

1000SP00452

1000EL00690

1000EL00675

1000EL00674

J2

J1 E L/N

BASE MODULE

1000SP00636

OR

1000SP00650

OR

1000SP00651

1000EL00689

SEE NOTE 1

9x2

NOTES:

1) CABLE1000EL00674 CONNECTED TOJ7OF 2V MODULE

L/N

J2

J6

0000EL00952

E

3H MODULE

1000SP01281

E

J1

1000EL00689

1000SP00452

J1

J2

1000SP01290

2V MODULE

J7

J3

J3

1000EL00691

L/NE

Alaris® Gateway Workstation 45/67 1000SM00015 Issue 4

Page 46

Labels

Spare Parts Replacement Procedures

(A5)

(A3)

(A2)

(A5)

(A3)

(A4)

(A1)

(A3) (A3)

(A2)

(A4)

(A5)

(B)

(B)

(A5)

(A1)

Alaris®

Gateway Workstation

Spare Parts

Item Description Part Number

A LABEL SET ALARIS GATEWAY 1000LB01415

B LABEL AGW LOGO 1000LB01416

Alaris® Gateway Workstation 46/67 1000SM00015 Issue 4

Page 47

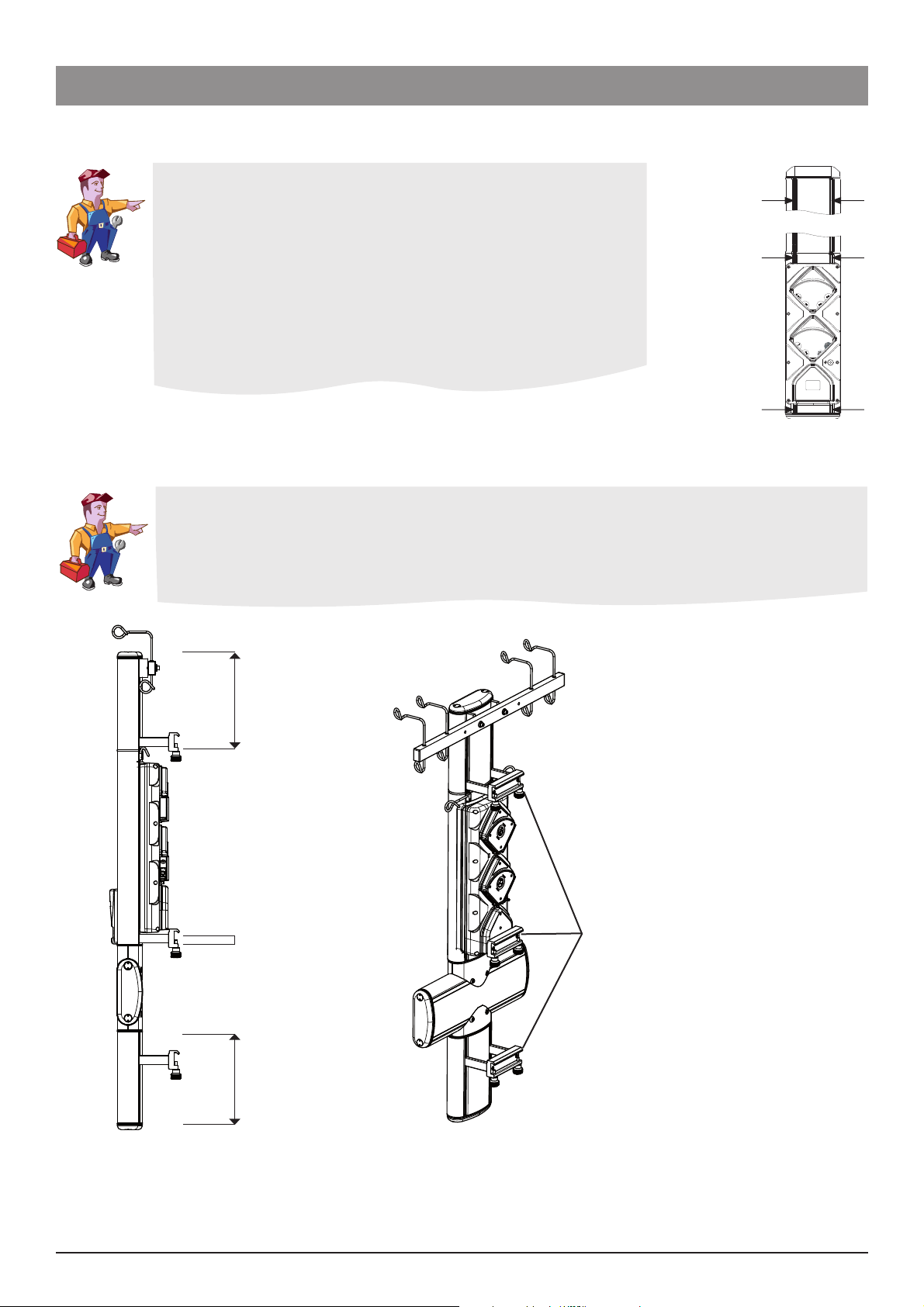

Trolley Mounting Kit

Fitting Procedure

Remove the plastic coating from the inner and outer surfaces of the Ring Clamp (A).1.

Slide one ring clamp over each trolley pole.2.

Align the Cross Bar (B) fixing holes with those in each of the Ring Clamps.3.

Insert the Fixing Screw (C) through the assembly positioning washers (D) and (E) as shown.4.

Position the support bar and tighten the Thin Nut (G), Dome Nut (F) and screw to 3Nm.5.

(C) Screw

Spare Parts Replacement Procedures

(E) Bellville

Spring (x4)

(A) Ring Clamp

(F) Dome Nut

(E) Washer (x4)

(B) Cross Bar

(G) Nut (x2)

Spare Parts

Item Description Part Number

A RING CLAMP 1000SP01187

B CROSS BAR "

C SCREW SKT TAP M6 X 25 DIN 912 "

D WASHER PLAIN M6 DIN 125 "

E BELLVILLE WASHER, LEE SPRINGS 250-025-500 "

F NUT DOME M6 DIN 1587 "

G THIN NUT "

Alaris® Gateway Workstation 47/67 1000SM00015 Issue 4

Page 48

Spare Parts Replacement Procedures

Trolley Mounting Kit (continued)

Fitting the Workstation to a trolley

When fixing the Workstation to the trolley, the mounting kits should be 1.

positioned and tightened so that the mount clamps align with the 10 x

25mm bars on the trolley.

The Workstation should then be mounted so both top and bottom mount 2.

clamps fit over the 10 x 25mm bars on the trolley.

The knobs should be tightened in order to fully restrain the Workstation 3.

into position.

Note: The mounting locations for the Workstation must be positioned as

shown dependant on the configuration.

5X, 7X and 9X

All Con gurations

All Con gurations

Mounting Locations

Fitting the Workstation configuration 2x3x5 to a trolley

Con gurations where volumetric pumps are not located at the top require three separate rail clamps

Points 1,2 and 3 must always be located within the area shown below.

1

2 (Fixed location)

3 Rail Clamps

3

Alaris® Gateway Workstation 48/67 1000SM00015 Issue 4

Page 49

Spare Parts Replacement Procedures

Bar Mounting Kit

Fitting Procedure

Remove Sealing Cord from the channel. Using an Allen key, remove the fasteners from the pre-fitted Square Nuts (A) in the 1.

extrusion channel. Using a screwdriver or similar pointed tool, slide the loosened Square Nuts along the channel to the required

position.

Insert the two Screws (C) through the Clamp (B) and Spacers (D).2.

Tighten the Screws ensuring that the mounting kit remains level.3.

Insert the Mounting Knobs (E) into the Clamp.4.

Repeat the process for the second kit.5.

Cut a length of Sealing Cord to fill the channel between the mounting kit and the end caps.6.

Carefully press the cord into place.7.

Repeat the operation for the remaining sections of the channel.8.

NOTE: C.H.A.P. only recommend mounting kits to be fitted to the vertical extrusion.

(C) Screw (x2)

(B) Clamp

(D) Spacer

(E) Mounting

Knob (x2)

(A) Square Nut (x2)

See Trolley Mounting Kit section for mounting location instructions.

Spare Parts

Item Description Part Number

A NUT SQUARE M6 DS 0000ME00432

B GATEWAY MOUNTING KIT EXTENDED TYPE 1 1000SP00655

C SCREW SKT HEAD CAP M6x100 A2 ISO4762 "

D SPACER, MOUNTING AGW "

E KNOB MOUNTING "

Alaris® Gateway Workstation 49/67 1000SM00015 Issue 4

Page 50

Spare Parts Replacement Procedures

Pole Mounting Kit

Fitting Procedure

Remove Sealing Cord from the channel. Using an Allen key, remove the fasteners from the pre-fitted Square Nuts (A) in the 1.

extrusion channel. Using a screwdriver or similar pointed tool, slide the loosened Square Nuts along the channel to the required

position.

Insert the two Screws (C) through the Clamp (B) and Spacers (D).2.

Tighten the Screws ensuring that the mounting kit remains level.3.

Insert the Mounting Knobs (E) into the Clamp.4.

Repeat the process for the second kit.5.

Cut a length of Sealing Cord to fill the channel between the mounting kit and the end caps.6.

Carefully press the cord into place.7.

Repeat the operation for the remaining sections of the channel.8.

(C) Screw (x2)

(B) Clamp

(D) Spacer

(A) Square Nut (x2)

See Trolley Mounting Kit section for mounting location instructions.

Spare Parts

Item Description Part Number

A NUT SQUARE M6 DS 0000ME00432

B POLE CLAMP MOUNTING ASSEMBLY NARROW 1000SP00169

C SCREW SKT HEAD CAP M6x100 A2 ISO4762 *

D SPACER, MOUNTING LONG *

* Not available separately only as part of the Gateway Mounting Kit Extended Type 1 (1000SP00655). When replacing the bar mounting

kit with the pole clamp mounting kit the spacers and screws already fitted should be used where possible.

Alaris® Gateway Workstation 50/67 1000SM00015 Issue 4

Page 51

Appendix A

Electromagnetic Compatibility

Page 52

Electromagnetic Compatibility

Electromagnetic Compatibility

Warning:

• The use of any accessory, transducer, or cable with the Workstation other than those specified may result in increased emissions or

decreased immunity of the Workstation.

• The Workstation should not be used adjacent to or stacked with other equipment, however if adjacent or stacked use is necessary,

the Workstation should be observed to verify normal operation in the configuration in which it will be used.

Caution:

• The Workstation is a CISPR 11 Group 1 Class A Medical Equipment System and intended for use by healthcare professionals only.

• Medical Electrical Equipment needs special precautions regarding EMC and needs to be installed, put into service and used

according to the EMC information provided in the accompanying documents.

• Portable and Mobile RF communications can affect Medical Electrical Equipment.

• Operating the Workstation near equipment which radiates high energy radio frequencies (electro surgical or cauterizing equipment,

portable radios, cellular telephones, etc.) may cause false alarm conditions. If this happens, reposition the Workstation away from

the source of interference or turn off the Workstation and manually regulate the flow.

Guidance and Manufacturer’s Declaration – Electromagnetic Emissions

The Workstation is intended for use in the electromagnetic environment specified below.

The customer or the user of the Workstation should assure that it is used in such an environment.

Emissions Test Compliance Electromagnetic Environment – Guidance

CISPR 11

RF Emissions

CISPR 11

RF Emissions

EN 61000-3-2

Harmonic Emissions

EN 61000-3-3

Voltage Fluctuations,

Flicker Emissions

Group 1

Class A system when

used in conjunction

with pumps

Class B in stand alone

operation

Class A

Complies

The Workstation uses RF energy only for its internal function in the normal

product offering. Therefore, its RF emissions are very low and are not likely to

cause any interface in nearby electronic equipment.

The Workstation is suitable for use in all establishments, other than domestic,

and those directly connected to the public low-voltage power supply network

that supplies buildings used for domestic purposes.

Alaris® Gateway Workstation 52/67 1000SM00015 Issue 4

Page 53

Electromagnetic Compatibility

Guidance and Manufacturer’s Declaration - Electromagnetic Immunity

The Workstation is intended for use in the electromagnetic environment specified below.

The customer or the user of Workstation should assure that it is used in such an environment.

Immunity Test

EN 61000-4-2 Electro-Static

Discharge (ESD)

EN 61000-4-4

Electrical Fast Transient, Burst

(EFT) (Note 3)

EN 61000-4-5

Power Line Surge

(Note 3)

EN 61000-4-8 Power

Frequency Magnetic Field

(50/60 Hz)

EN 61000-4-11

Voltage Dips, Short

Interruptions, and Voltage

Variations

(Note 3)

EN 60601-1-2

Test Level

±6 kV contact

±8 kV air

Compliance Level Electromagnetic Environment – Guidance

±8 kV contact (Note

2)

±15 kV air (Note 2)

±2 kV for power

supply lines

±1 kV for input/

±2 kV for power

supply lines

N/A (Note 4)

output lines

±1 kV Line(s) to

Line(s)

±2 kV Line(s) to

Earth

±1 kV Line(s) to

Line(s)

±2 kV Line(s) to Earth

3 A/m 400 A/m 50 Hz

(Note 2)

<5 % UT (Note 1)

(>95 % dip in UT)

for 0.5 cycle

40 % UT

(60 % dip in UT)

for 5 cycles

70 % UT

(30 % dip in UT)

for 25 cycles

<5 % UT

(>95 % dip in UT)

for 0.5 cycle

40 % UT

(60 % dip in UT)

for 5 cycles

70 % UT

(30 % dip in UT)

for 25 cycles

Floors should be wood, concrete, or ceramic tile.

If floors are covered with synthetic material, the

relative humidity should be at least 30 %.

Mains power quality should be that of a typical

commercial or hospital environment.

Mains power quality should be that of a typical

commercial or hospital environment.

Power frequency magnetic fields should be at

levels characteristic of a typical location in a typical

commercial or hospital environment.

Mains power quality should be that of a typical

commercial or hospital environment.

If the user of the Workstation requires continued

operation during power mains interruptions, it is

recommended that the Workstation be powered

from an uninterruptible power supply or a battery.

The Workstation does employ an internal short

duration battery.

<5 % UT

(>95 % dip in UT)

for 5 sec

Note 1—UT is the AC mains voltage prior to application of the test level.

Note 2—Compliance levels raised by EN 60601-2-24.

Note 3—Performed at the Minimum and Maximum Rated Input Voltage.

Note 4—Cardinal Health recommends using signal cables of less than 3 meters in length and this requirement is applicable only if signal cables are 3

meters or more in length. (EN 60601-1-2:2002, Clause 36.202.4)

Alaris® Gateway Workstation 53/67 1000SM00015 Issue 4

<5 % UT

(>95 % dip in UT)

for 5 sec

Page 54

Electromagnetic Compatibility

Guidance and Manufacturer’s Declaration—Electromagnetic Immunity

LIFE SUPPORT Equipment

The Workstation is intended for use in the electromagnetic environment specified below.

The customer or the user of the Workstation should ensure that it is used in such an environment.