Page 1

SERVICE MANUAL

Model:

PDP

Safety Precaution

Technical Specifications

Block Diagram

Circuit Diagram

Basic Operations & Circuit Description

Main IC Specifications

Product Specification of PDP Module

Trouble Shooting Manual of PDP Module

Spare Part List

Exploded View

If you forget your V-Chip Password

Software Upgrade

This manual is the latest at the time of printing, and does not

include the modification which may be made after the printing,

by the constant improvement of product.

Page 2

Safety Precaution

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated

“dangerous voltage” within the product’s enclo

sure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

CAUTION: TO REDUCE THE RISK OF

ELECTRIC SHOCK, DO NOT REMOVE COVER

(OR BACK). NO USER-SERVICEABLE PARTS

INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL ONLY.

PRECAUTIONS DURING

SERVICING

1. In addition to safety, other parts and

assemblies are specified for conformance with

such regulations as those applying to spurious

radiation. These must also be replaced only

with specified replacements.

Examples: RF converters, tuner units, antenna

selection switches, RF cables, noise-blocking

capacitors, noise-blocking filters, etc.

2. Use specified internal Wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

3. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulating Tape

2) PVC tubing

3) Spacers (insulating barriers)

4) Insulating sheets for transistors

5) Plastic screws for fixing micro switches

4. When replacing AC primary side components

(transformers, power cords, noise blocking

capacitors, etc.), wrap ends of wires securely

about the terminals before soldering.

5. Make sure that wires do not contact heat

generating parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.)

6. Check if replaced wires do not contact sharply

edged or pointed parts.

7. Make sure that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

MAKE YOUR CONTRIBUTION

TO PROTECT THE

ENVIRONMENT

Used batteries with the ISO symbol

for recycling as well as small accumulators

(rechargeable batteries), mini-batteries (cells) and

starter batteries should not be thrown into the

garbage can.

Please leave them at an appropriate depot.

W ARNING:

Before servicing this TV receiver, read the

SAFETY INSTRUCTION and PRODUCT

SAFETY NOTICE.

SAFETY INSTRUCTION

The service should not be attempted by anyone

unfamiliar with the necessary instructions on this

apparatus. The following are the necessary

instructions to be observed before servicing.

1. An isolation transformer should be connected in

the power line between the receiver and the

AC line when a service is performed on the

primary of the converter transformer of the set.

2. Comply with all caution and safety related

provided on the back of the cabinet, inside the

cabinet, on the chassis or picture tube.

3. To avoid a shock hazard, always discharge the

picture tube's anode to the chassis ground

before removing the anode cap.

4. Completely discharge the high potential voltage

of the picture tube before handling. The picture

tube is a vacuum and if broken, the glass will

explode.

Page 3

5. When replacing a MAIN PCB in the cabinet,

always be certain that all protective are

installed properly such as control knobs,

adjustment covers or shields, barriers, isolation

resistor networks etc.

6. When servicing is required, observe the original

lead dressing. Extra precaution should be given

to assure correct lead dressing in the high

voltage area.

7. Keep wires away from high voltage or high

tempera ture components.

8. Before returning the set to the customer,

always perform an AC leakage current check

on the exposed metallic parts of the cabinet,

such as antennas, terminals, screwheads,metal

overlay, control shafts, etc., to be sure the set

is safe to operate without danger of electrical

shock. Plug the AC line cord directly to the

AC outlet (do not use a line isolation

transformer during this check). Use an AC

voltmeter having 5K ohms volt sensitivity or

more in the following manner.

Connect a 1.5K ohm 10 watt resistor paralleled

by a 0.15µF AC type capacitor, between a

good earth ground (water pipe, conductor etc.,)

and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination

of the 1.5K ohm resistor and 0.15 uF

capacitor. Reverse the AC plug at the AC

outlet and repeat the AC voltage measurements

for each exposed metallic part.

The measured voltage must not exceed 0.3V

RMS.

This corresponds to 0.5mA AC. Any value

exceeding this limit constitutes a potential

shock hazard and must be corrected

immediately.

The resistance measurement should be done

between accessible exposed metal parts and

power cord plug prongs with the power switch

"ON". The resistance should be more than

6M ohms.

AC VOLTMETER

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this

apparatus have special safety-related

characteristics.

These characteristics are offer passed

unnoticed by visual spection and the protection

afforded by them cannot necessarily be obtained

by using replacement components rates for a

higher voltage, wattage, etc.

The replacement parts which have these

special safety characteristics are identified by

marks on the schematic diagram and on the parts

list.

Before replacing any of these components,

read the parts list in this manual carefully. The

use of substitute replacement parts which do not

have the same safety characteristics as specified

in the parts list may create shock, fire, or other

hazards.

9. Must be sure that the ground wire of the AC

inlet is connected with the ground of the

apparatus properly.

Good earth ground

such as the water

pipe, conductor,

etc.

AC Leakage Current Check

Place this probe

on each exposed

metallic part

Page 4

Technical Specifications

MODEL : PDP4206EM

42” Plasma Monitor

DATE FIRST ISSUED

REVISIONS

ISSUED DATE DESCRIPTION RAISED BY :

ISSUE

1

RAISED BY

CHECKED BY

NUMBER OF PAGES

9

SPECIFICATION AGREED : SIGNATURE DATE

R & D DEPARTMENT

COMMERCIAL DEPARTMENT

PRODUCTION DEPARTMENT

Q/A DEPARTMENT

CUSTOMER

SPECIFICATION APPROVED :

.

NOTE :

Only documents stamped “Controlled Document” to be used for manufacture of production parts.

......................................................................................

......

......................................................................................

......

......................................................................................

.......

......................................................................................

.......

......................................................................................

.......

SIGNATURE :

...........................

...

...........................

...

...........................

...

...........................

...

...........................

...

DATE :

Page 5

Technical Specifications

PDP420

CONTINUATION PAGE

NUMBER

2 OF 9 PAGES

1. Standard Test Conditions

All tests shall be performed under the following conditions, unless otherwise specified.

1.1 Ambient light : 150ux (When measuring IB, the ambient luminance

≦0.1Cd/m2)

1.2 Viewing distance : 50cm in front of PDP

1.3 Warm up time : 30 minutes

1.4 PDP Panel facing : no restricted

1.5 Measuring Equipment : PC, Chroma 2225 signal generator (with Chroma digital

additional card) or equivalent, Minolta CA100 photometer

1.6 Magnetic field

: no restricted

1.7 Control settings : Brightness, Contrast, Tint, Color set at Center(50)

1.8 Power input : 110~120Vac

1.9 Ambient temperature : 20°C ± 5°C (68°F ± 9°F)

1.10 Display mode : 31.5KHz/60Hz (Resolution 852 x 480)

1.11 Other conditions :

1.11.1 With image sticking protection of PDP module, the luminance will descend

by time on a same still screen and rapidly go down in 5 minutes. When

measuring the color tracking and luminance of a same still screen, be sure

to accomplish the measurement in one minute to ensure its accuracy.

1.11.2 Due to the structure of PDP, the extra-high-bright same screen should not

hold over 5 minutes for fear of branding on the panel.

Page 6

Technical Specifications

PDP4206EM

CONTINUATION PAGE

NUMBER

3 OF 9 PAGES

ELECTRICAL CHARACTERISTICS

2. Power Input

2.1 Voltage : 110 ~120VAC

2.2 Input Current : 3.5 / 1.5A

2.3 Maximum Inrush Current : <30 A (FOR AC110V ONLY)

Test condition : Measured when switched off for at least 20 mins

2.4 Frequency : 50Hz to 60Hz(±3Hz)

2.5 Power Consumption : ≤ 330W

Test condition : full white display with maximum brightness and

contrast

2.6 Power Factor : Meets IEC1000-3-2

2.7 Withstanding voltage : 1.5kVac or 2.2kVdc for 1 sec

3. Display

3.1 Screen Size : 42” Plasma monitor

3.2 Aspect Ratio : 16:9

3.3 Pixel Resolution : 852x480

3.4 Peak Brightness : 1000 cd/m² (Panel module without filter)

3.5 Contrast Ratio (Dark room) : 3000:1 (Panel module without filter)

3.6 Viewing Angle : Over 160°

3.7 OSD language : English

4. Signal

4.1 AV & Graphic input

4.1.1 Composite signal : CVBS

4.1.2 Y,C Signal : S-Video

4.1.3 Component signal : Y, Pb/Cb, Pr/Cr, HDTV compatible

4.1.4 Graphic I/P : Analog: D-sub 15pin detachable cable

Digital: DVI

4.1.5 PnP compatibility : DDC 1.0

4.1.6 I/P frequency : f

: 31.5kHz to 60kHz/fV: 56.25Hz to 75Hz (640x480

H

recommended)

Page 7

Technical Specifications

PDP4206EM

CONTINUATION PAGE

NUMBER

4 OF 9 PAGES

4.2 Audio input

Audio I/P(L/Rx5) : 1 for DVI / D-Sub

1 for Y/ Pb/Pr

1 for Y/ Cb/Cr

1 for Video

1 for S-Video

4.3 Audio output

Audio O/P(L/Rx1) : 1 for Line out

4.4 Other function : PIP, 16:9, 4:3, Zoom

5. Environment

5.1 Operating environment

5.1.1 Temperature : 5ºC ~ 33°C

5.1.2 Relative humidity: 20% ~ 85%(non-condensing)

5.2 Storage and Transport

5.2.1 Temperature : -20°C to 60°C(-4º to 140°F)

5.2.2 Relative humidity: 5% to 95%

6. Panel Characteristics

6.1 Type : LG V6

6.2 Size : 42”, 1005mm(width)x597mm(height)x61mm(depth)±1

mm)

6.3 Aspect ratio : 16:9

6.4 Viewing angle : Over 160°

6.5 Resolution : 852x480

6.6 Weight : 14.8kg ±0.5 kg (Net)

6.7 Color : 16.77 million colors by combination of 8 bits R,G,B digital

6.8 Contrast : Average 60:1 (In a bright room with 150Lux at center)

Typical 3000:1 (In a dark room 1/25 White Window

pattern at center).

6.9 Peak brightness : Typical 1000cd/㎡ (1/25 White Window)

6.10 Color Coordinate Uniformity : Contrast; Brightness and Color control at normal

setting

Test Pattern : Full white pattern

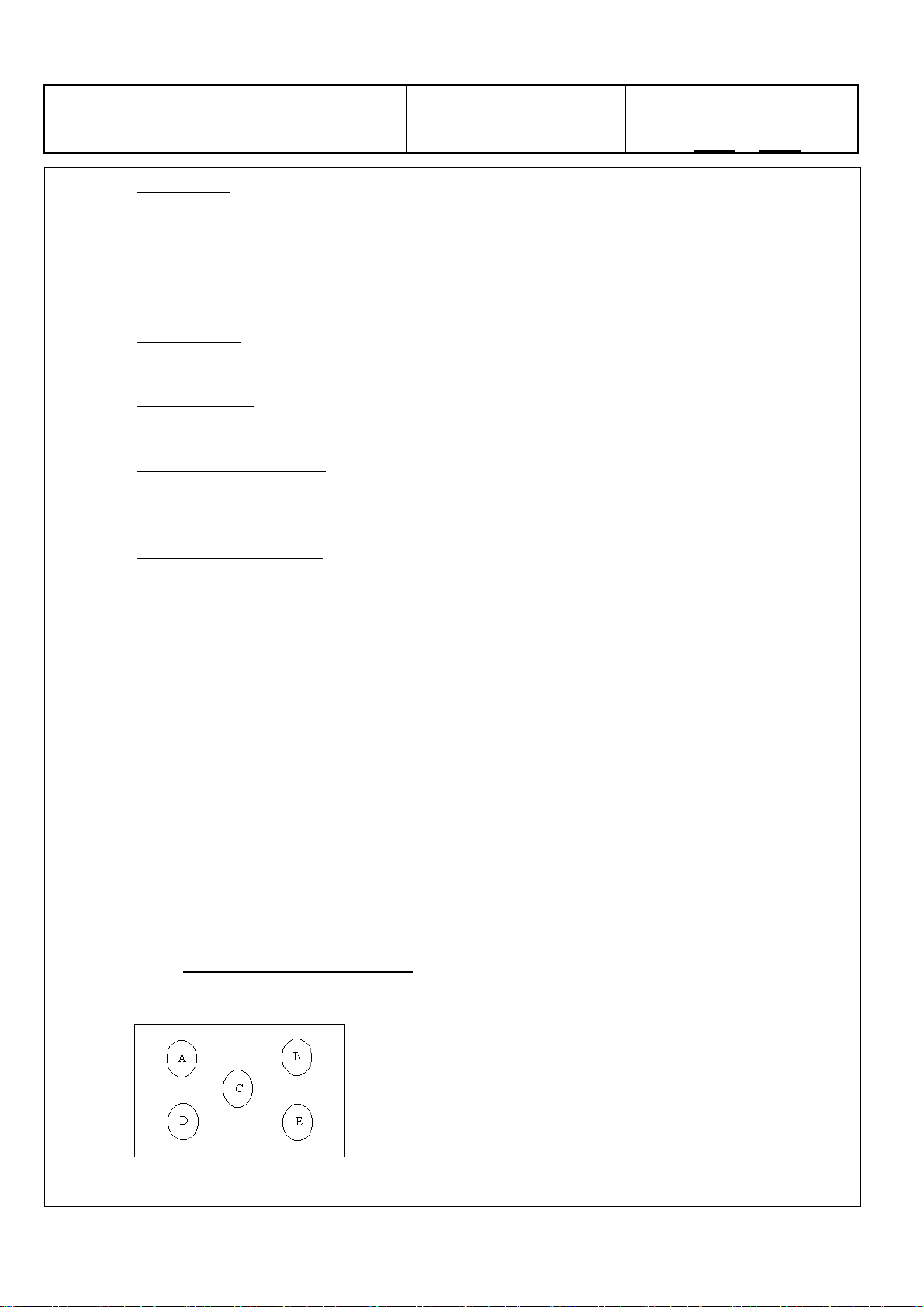

Average of point A,B,C,D and E +/- 0.01

Page 8

Technical Specifications

PDP4206EM

CONTINUATION PAGE

NUMBER

5 OF 9 PAGES

6.11 Color temperature : Contrast at center (50); Brightness center (50);

Color temperature set at Natural

x=0.285±0.02

y=0.293±0.02

6.12 Cell Defect Specifications

Subject to Panel supplier specification as appends.

7. Front Panel Control Button

7.1 SEL. UP/Down Button : Push the key to selecting the item on OSD menu

Volume Up/ Down Button : Push the key to increase the volume up or down.

When selecting the adjusting item on OSD menu

increase or decrease the data-bar.

Menu Button : Enter to the OSD menu.

Input Select Button : Push the key to select the input signals source.

7.2 Stand by Button : Switch on main power, or switch off to enter power

Saving modes.

7.3 Main Power Switch : Turn on or off the unit.

8. OSD Function

8.1 Audio : Adjust or Select Volume; Bass; Treble; Balance; SRS; BBE; AVC;

Int./Ext. Speaker.

8.2 Picture : Adjust or Select Brightness; Contrast; Sharpness; Scaling (Picture

changes According to Fill or One to One.; DNR; Video Format;

More options for Y/Pb/Pr and VGA ( H. Position, V. Position Phase,

Frequency)

8.3 OSD : Position; OSD H. Position; OSD V. Position; OSD Timeout;

OSD Backgroud; Language.

8.4 Tools : Factory Reset; Source Scan; Blank Color; Turn Off Timer; Screen

Saver; Saver Mode.

8.5 CC-V Chip : TV Channel Blocking; Movie Blocking; Change Blocking Password;

Clear Password; CC Mode; CC Background.

Page 9

Technical Specifications

PDP4294LV1

CONTINUATION PAGE

NUMBER

6 OF 9 PAGES

9. Agency Approvals

Safety UL60950

Emissions FCC class B

10. Reliability

11.1 MTBF : 20,000 hours(Use moving picture signal at 25°C ambient)

11. Accessories : User manual x1, Remote control x1, Stand x1, Power cord x1,

Battery x 2, Accessories box x 1.

Page 10

Technical Specifications

PDP4206EM

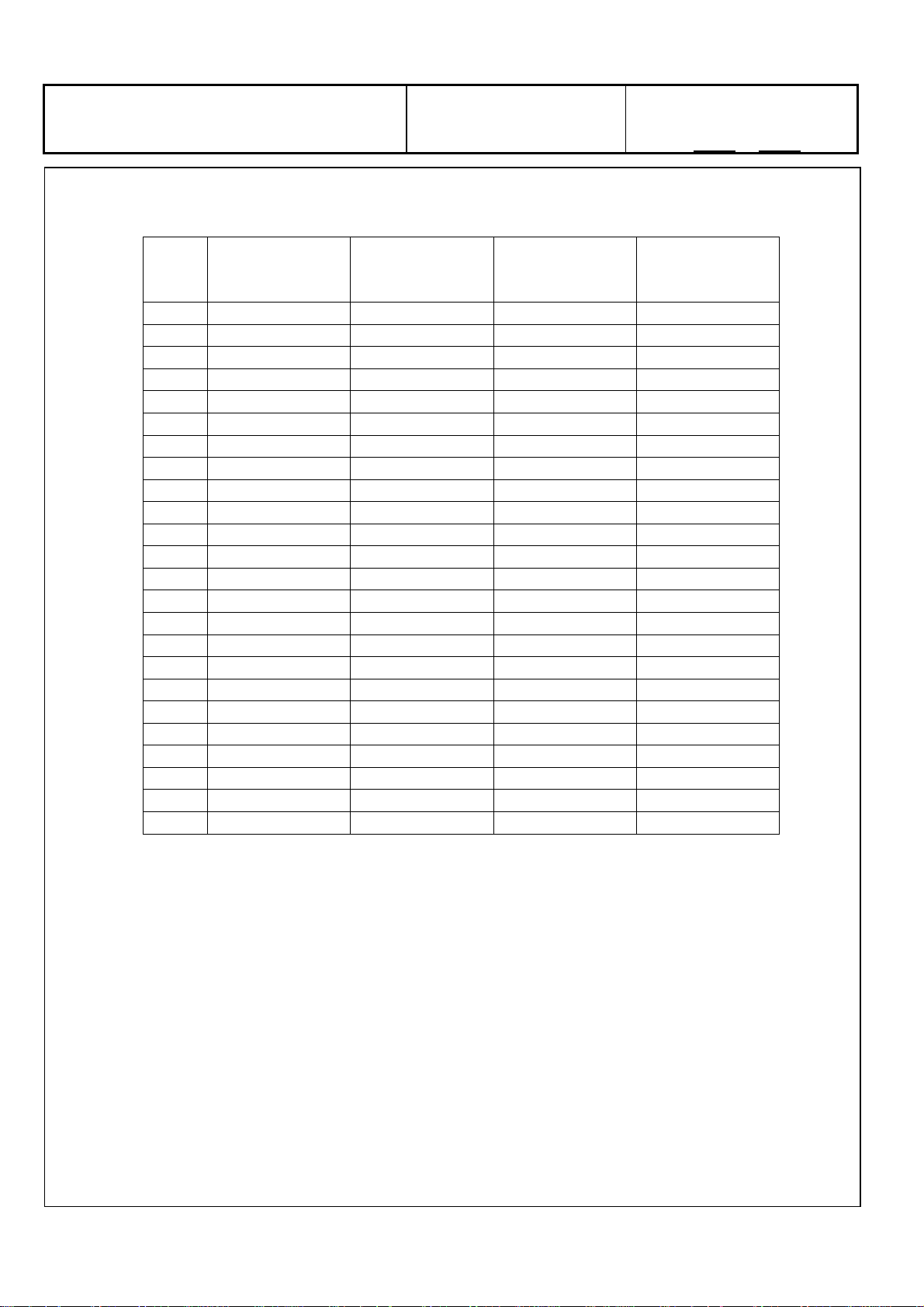

12. Supportthe Signal Mode

The PDP can support the different from DVI or VGA Signal Mode in 24 kinds

NO. Resolution Horizontal

Frequency

(KHz)

Vertical

Frequency

(Hz)

1# 640 x400 31.47 70.08 25.17

2# 640 x400 37.90 85.00 31.5

3 640 x480 31.50 60.00 25.18

4 640 x480 35.00 67.00 30.24

5 640 x480 37.50 75.00 31.50

6 640 x480 37.86 72.81 31.50

7# 640 x480 43.30 85.00 36.00

8 800 x600 35.16 56.25 36.00

9 800 x600 37.90 60.32 40.00

10 800 x600 46.90 75.00 49.50

11 800 x600 48.08 72.19 50.00

12 800 x600 53.70 85.00 56.25

13 832 x624 49.00 75.00 57.27

14 1024 x768 48.40 60.00 65.00

15 1024 x768 56.50 70.00 75.00

16 1024 x768 60.00 75.00 78.75

17 1024 x768 68.70 85.00 94.50

18* 1152x864 54.53 60.00 80.37

19 1152x864 67.52 75.02 108.03

20* 1152x864 63.86 70.02 94.51

21 1280x1024 63.37 60.01 111.51

22 1280 x960 75.02 75.02 126.00

23 1280 x960 60.02 60.02 108.04

24# 1280x720 44.96 59.95 74.19

Note: DVI could not support * of signal mode.

VGA could not support # of signal mode.

- Press “DISPLAY” button to confirm the input signal format.

Note: Some data will be updated in five seconds if you change them.

CONTINUATION PAGE

NUMBER

7 OF 9 PAGES

Dot Clock

Frequency

(MHz)

Page 11

V-CHIP

I. P. C

I. S. C

C/C

Technical Specifications

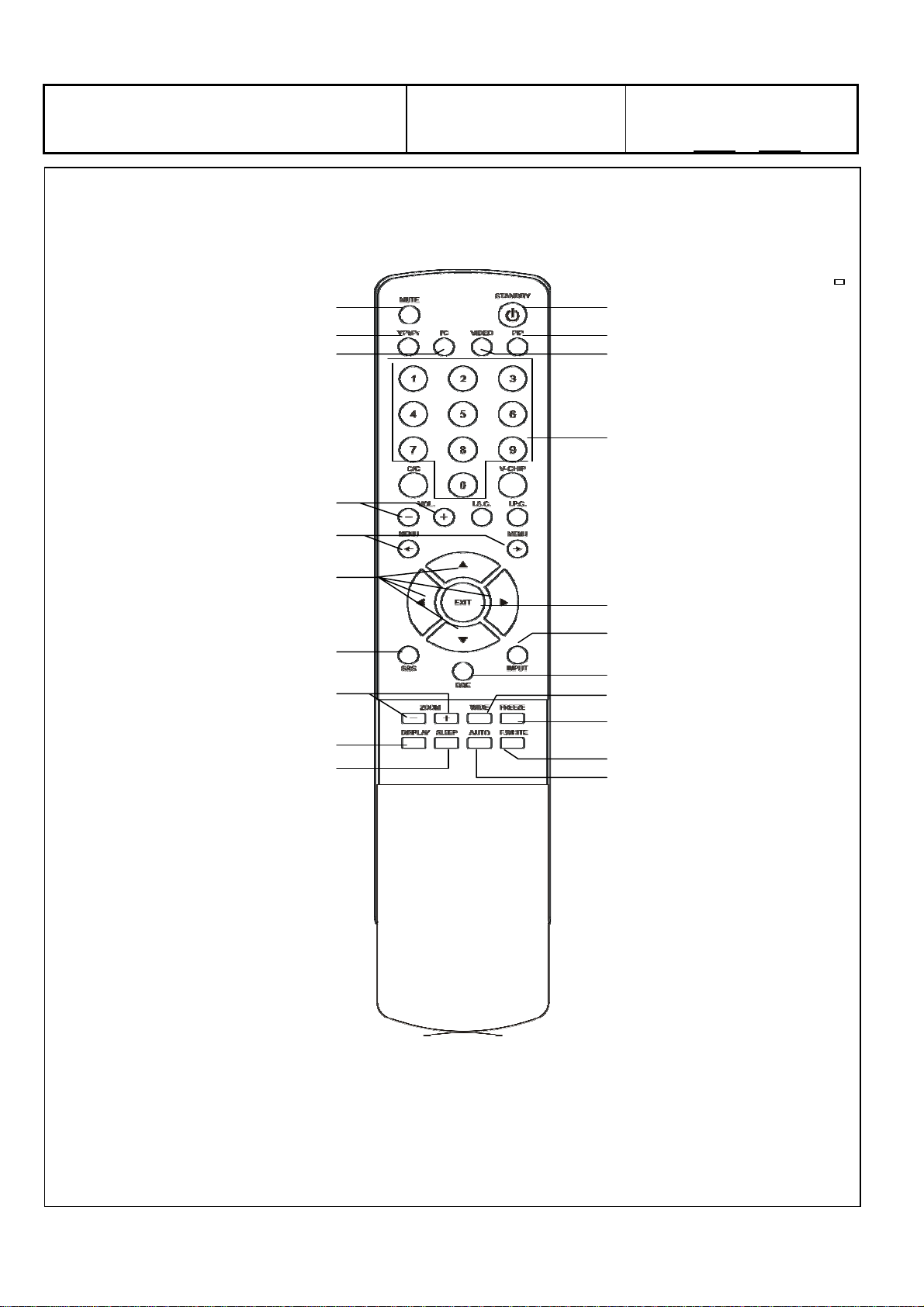

13. Remote Function+

YPbPr

Mute

PC

VOL +/-

PDP4206EM

Standby on/off

PIP

Video

Number Buttons/

Channel up/

Channel down/

Return

CONTINUATION PAGE

NUMBER

8 OF 9 PAGES

Menu Left/Right

Up/Down

Left/Right

Button

SRS

ZOOM plus/minus

Display

Sleep

EXIT Button

Input

BBE

Wide

Freeze

F.WHITE

AUTO

Page 12

(286mm)

Technical Specifications

PDP4206EM

CONTINUATION PAGE

NUMBER

9 OF 9 PAGES

PHYSICAL CHARACTERISTICS

14. Power Cord

Length : 1.8m nominal

Type : optional

15. Cabinet

15.1 Color : “Black” colour as defined by colour plaque reference number

15.2 Weight (with stand)

Net weight : 84.5lbs (38.3kg)

15.3 Dimensions(with stand)

Width : 40-7/8 inches (1040mm)

Height : 27-1/4 inches (692mm)

Depth : 11-1/4 inches

Page 13

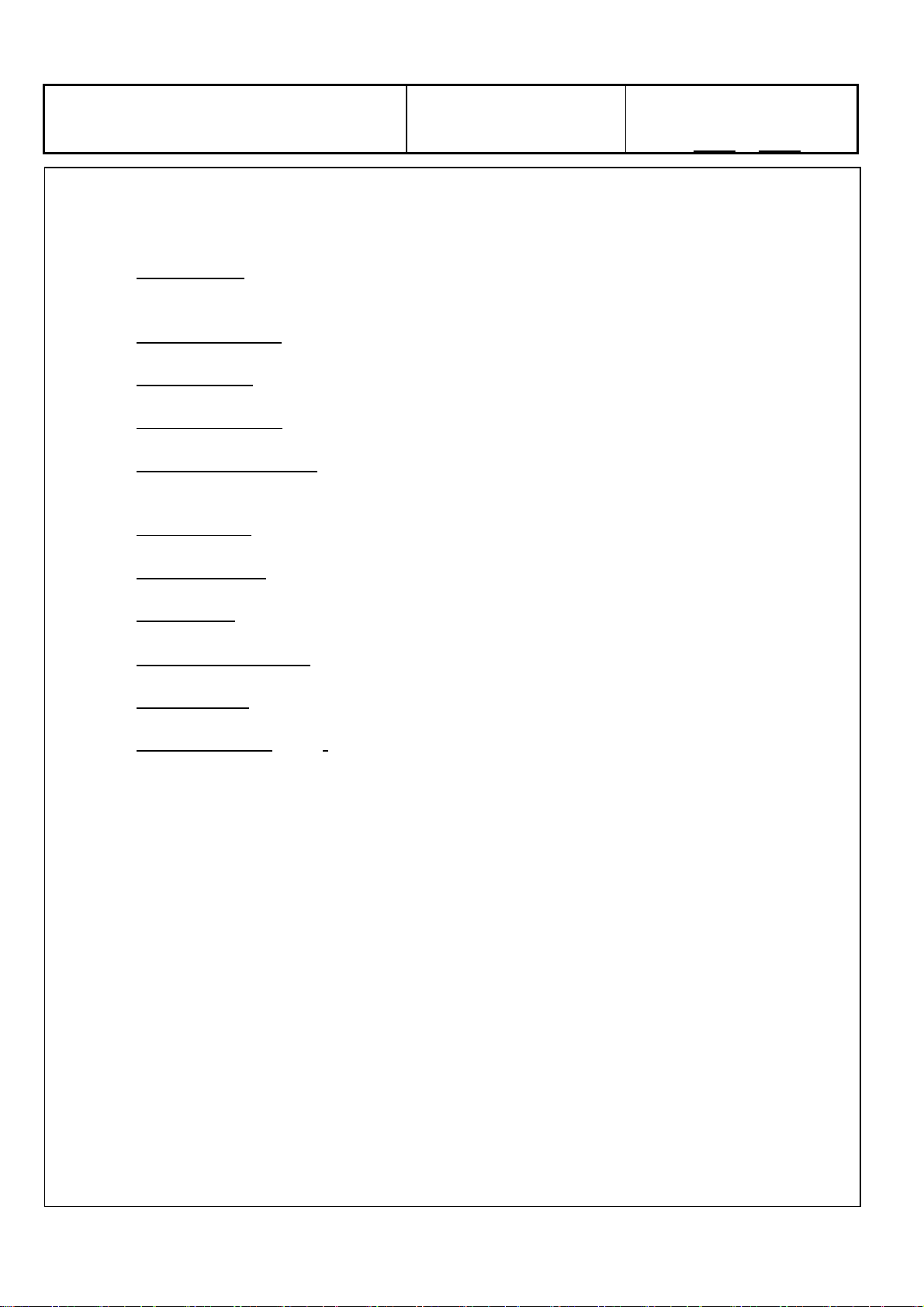

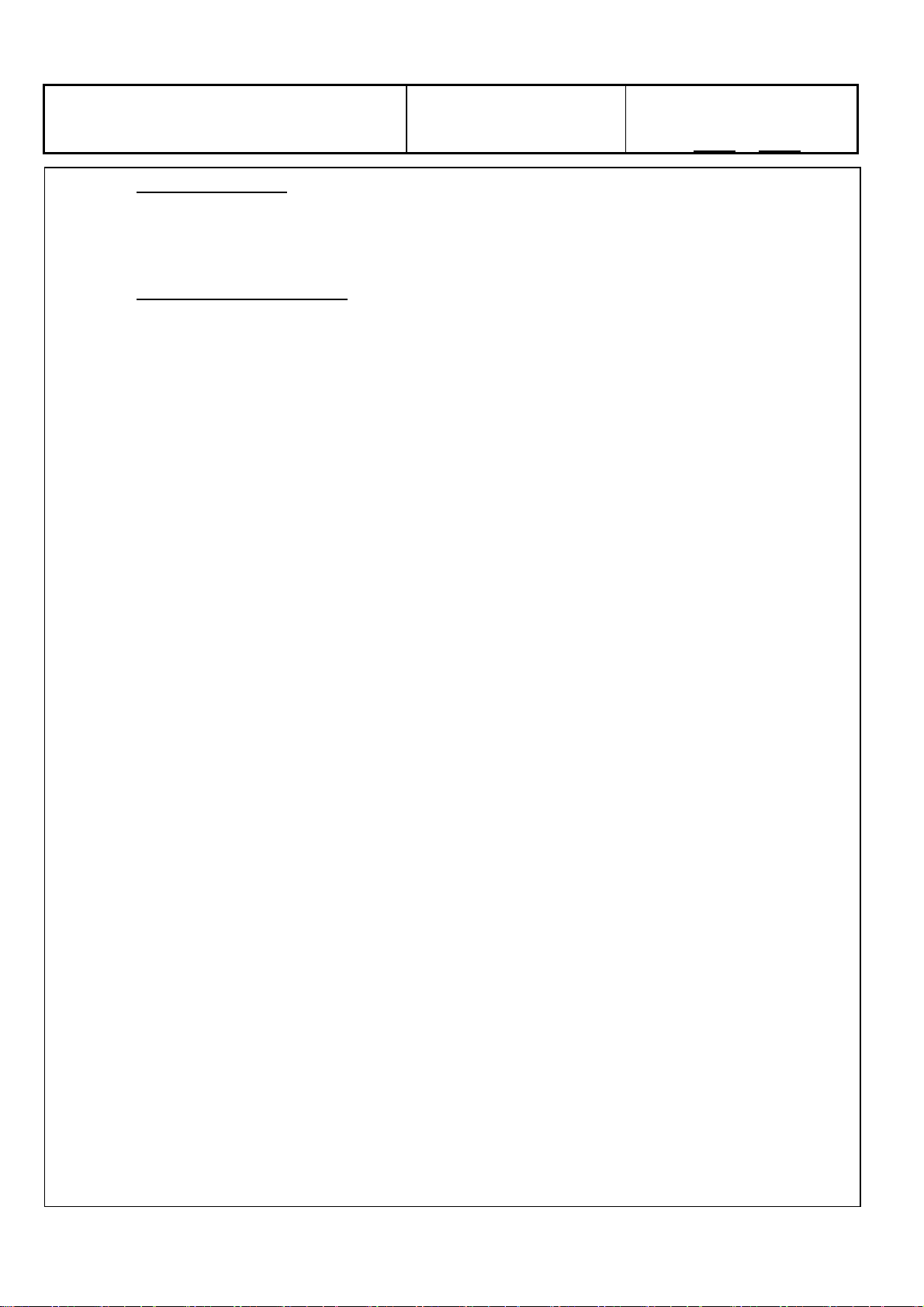

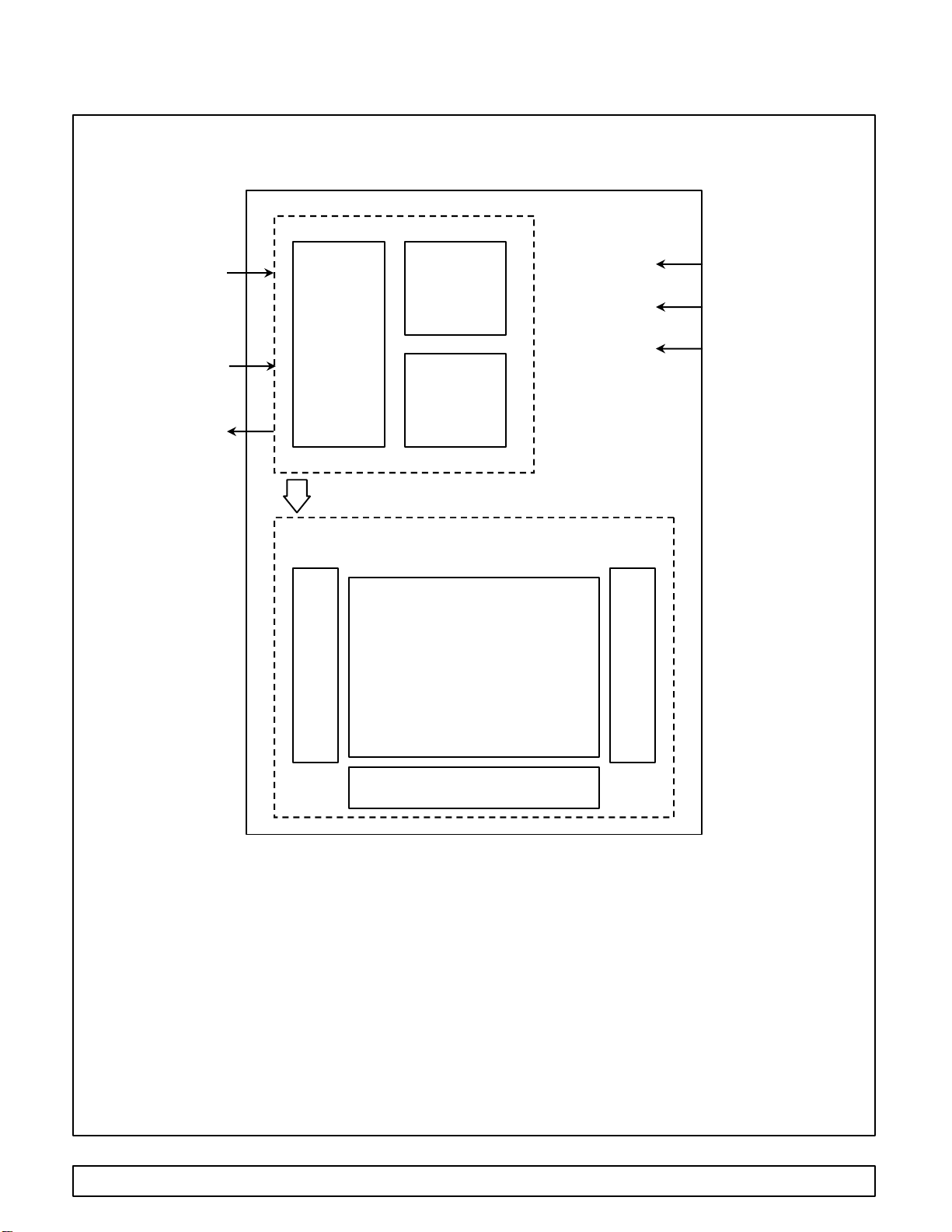

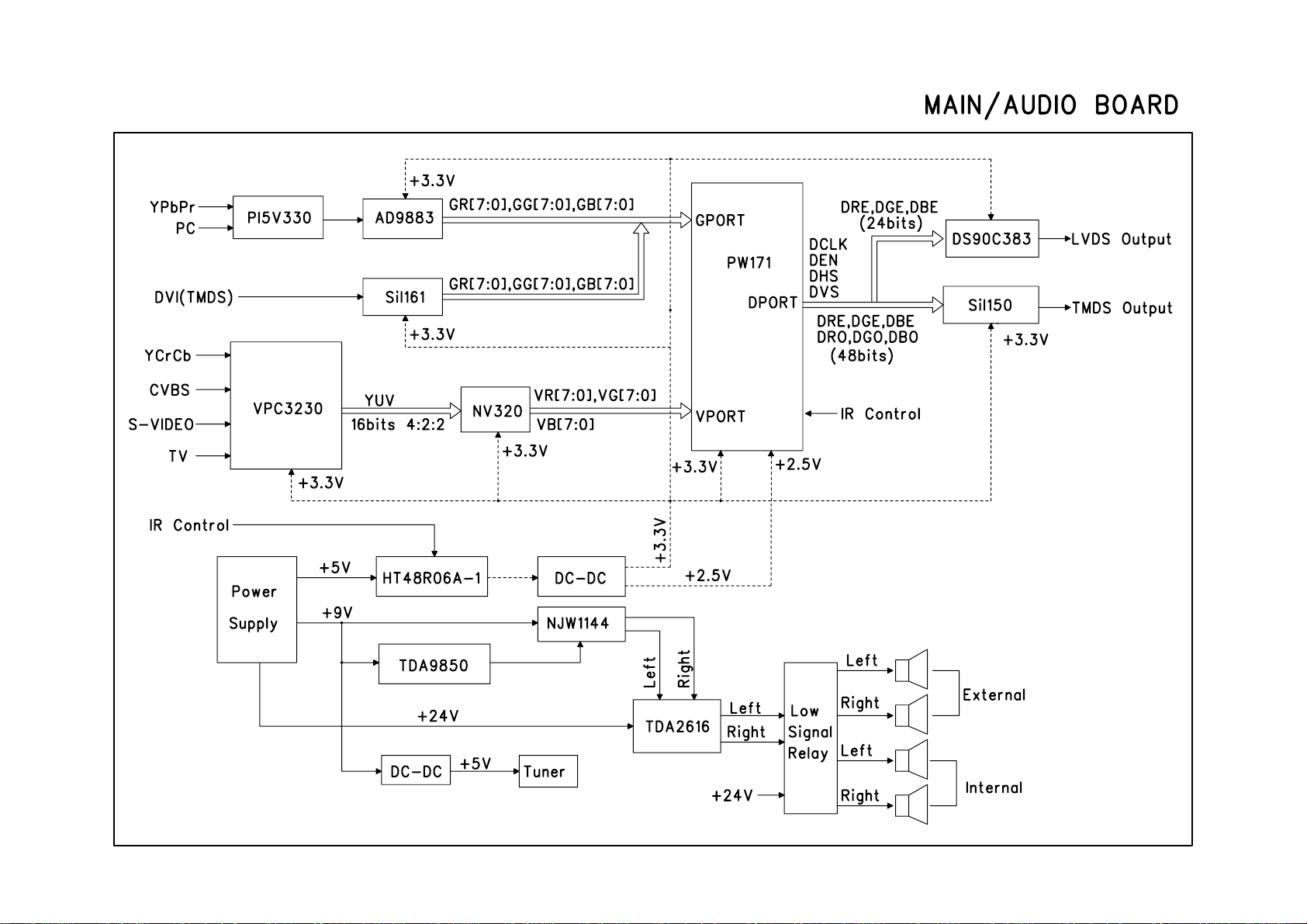

Block Diagram

Product Specification of PDP Module

LVDS Input

Control Signal

(Serial Interface)

APL Data

Memory

Input

Controller

Interface

Controller

Driver

Timing

Controller

Display data, Driver timing

Color Plasma Display Panel

852 X 480 pixels

Scan Driver

Vs(180V~190V)

Va(55V~65V)

Vcc(+5V)

Common sustain driver

Address Driver

☞ Applied Voltage level is specified at the time when Full-White pattern is displayed on the panel.

Page 14

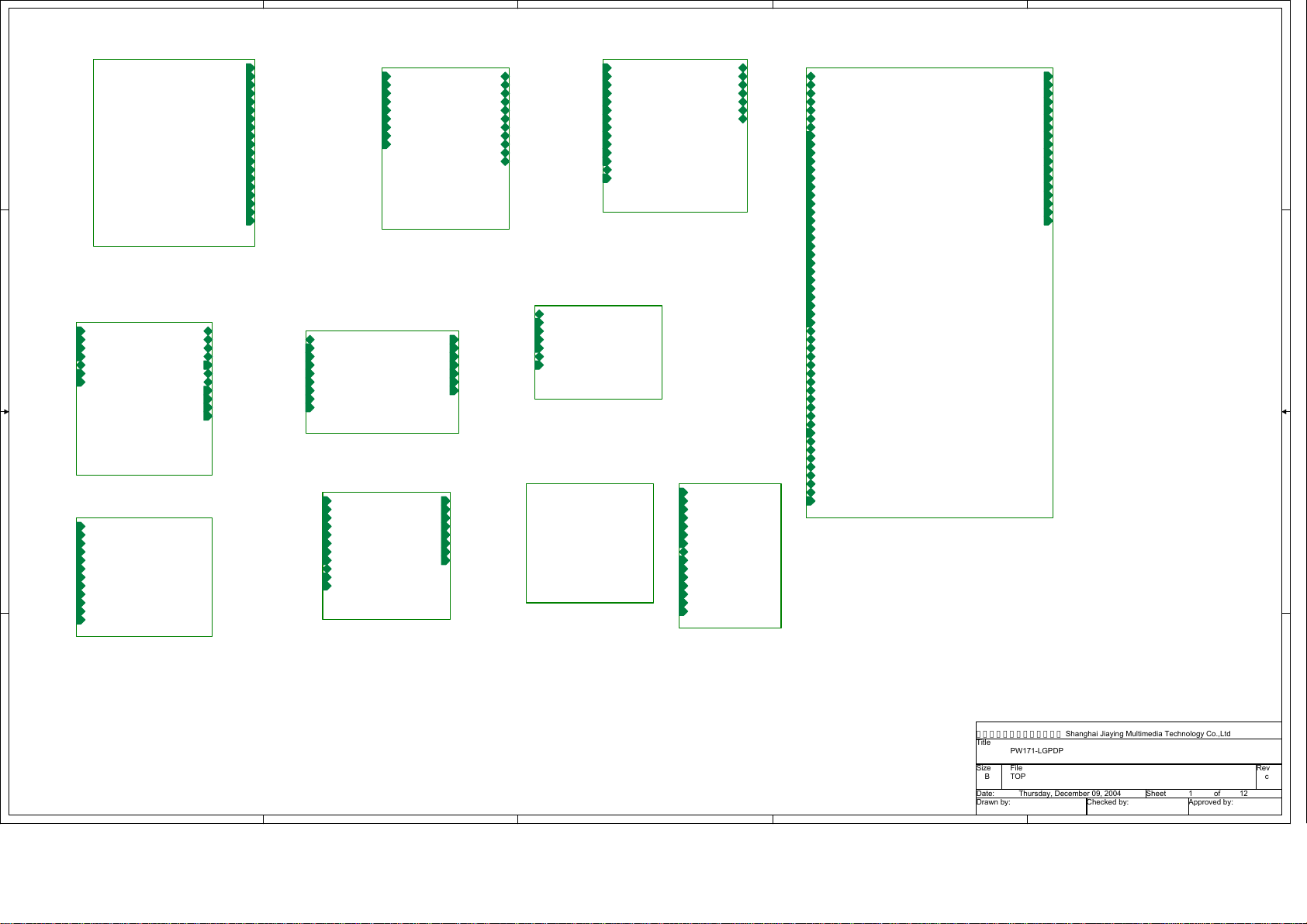

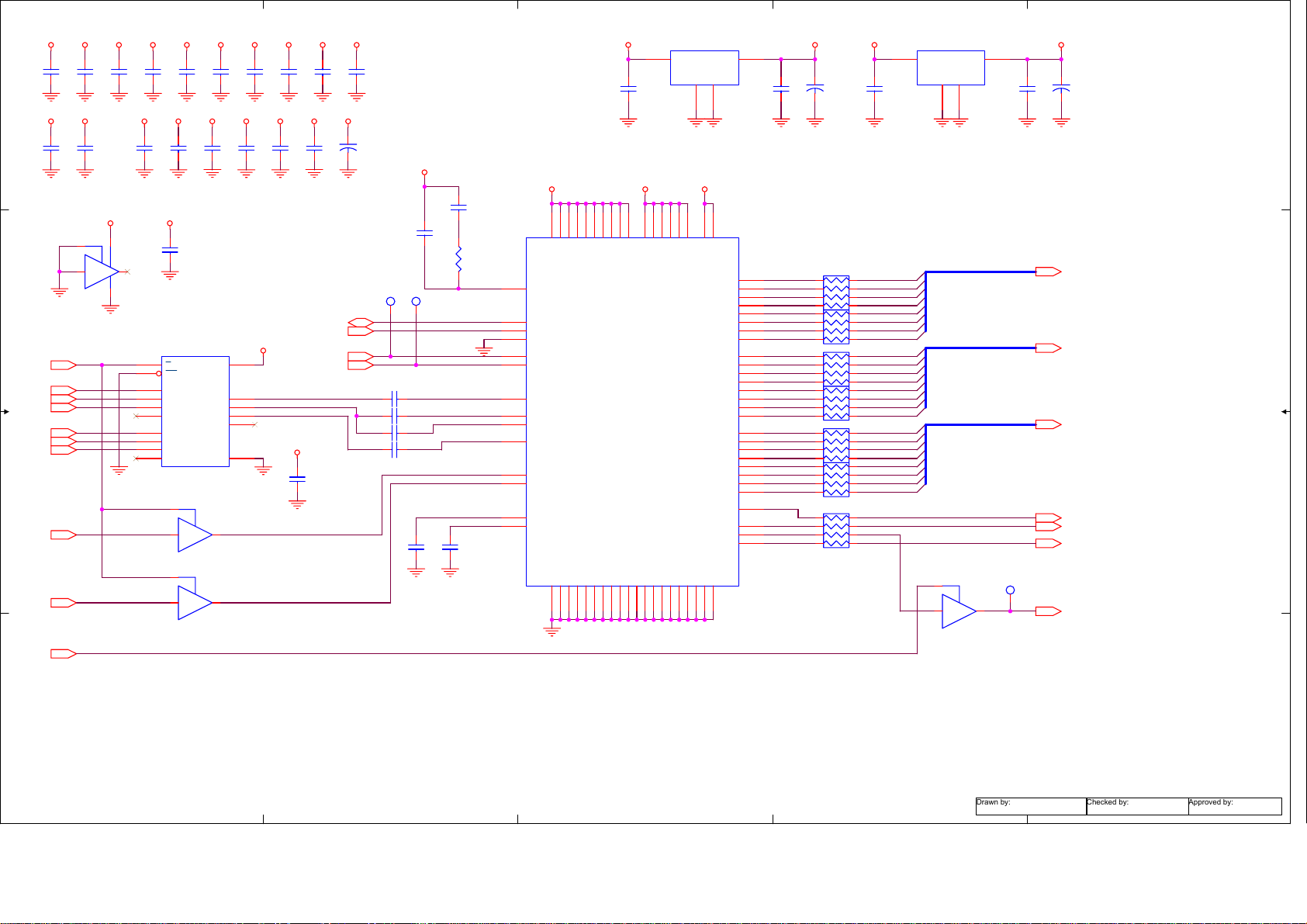

Block Diagram

Page 15

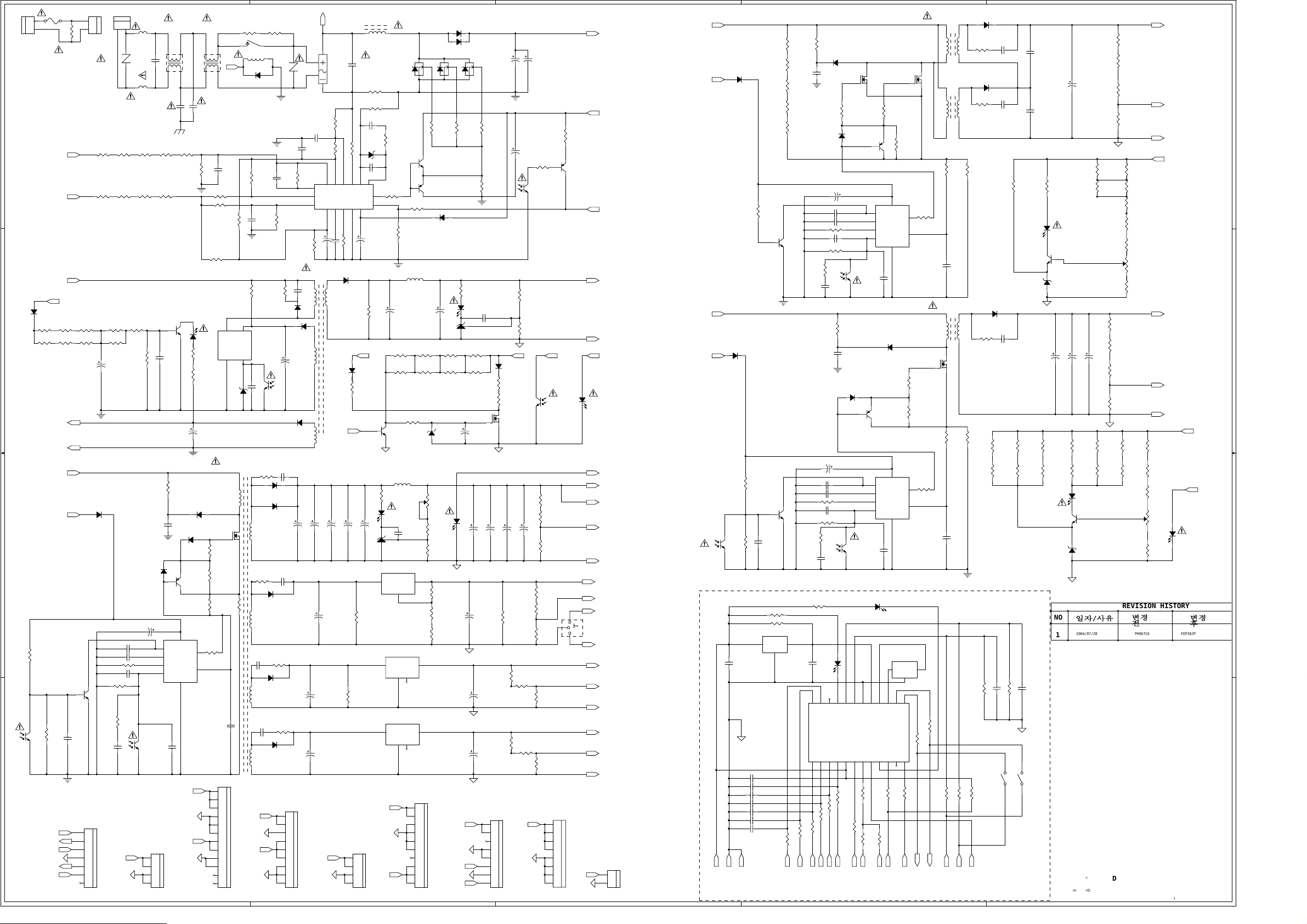

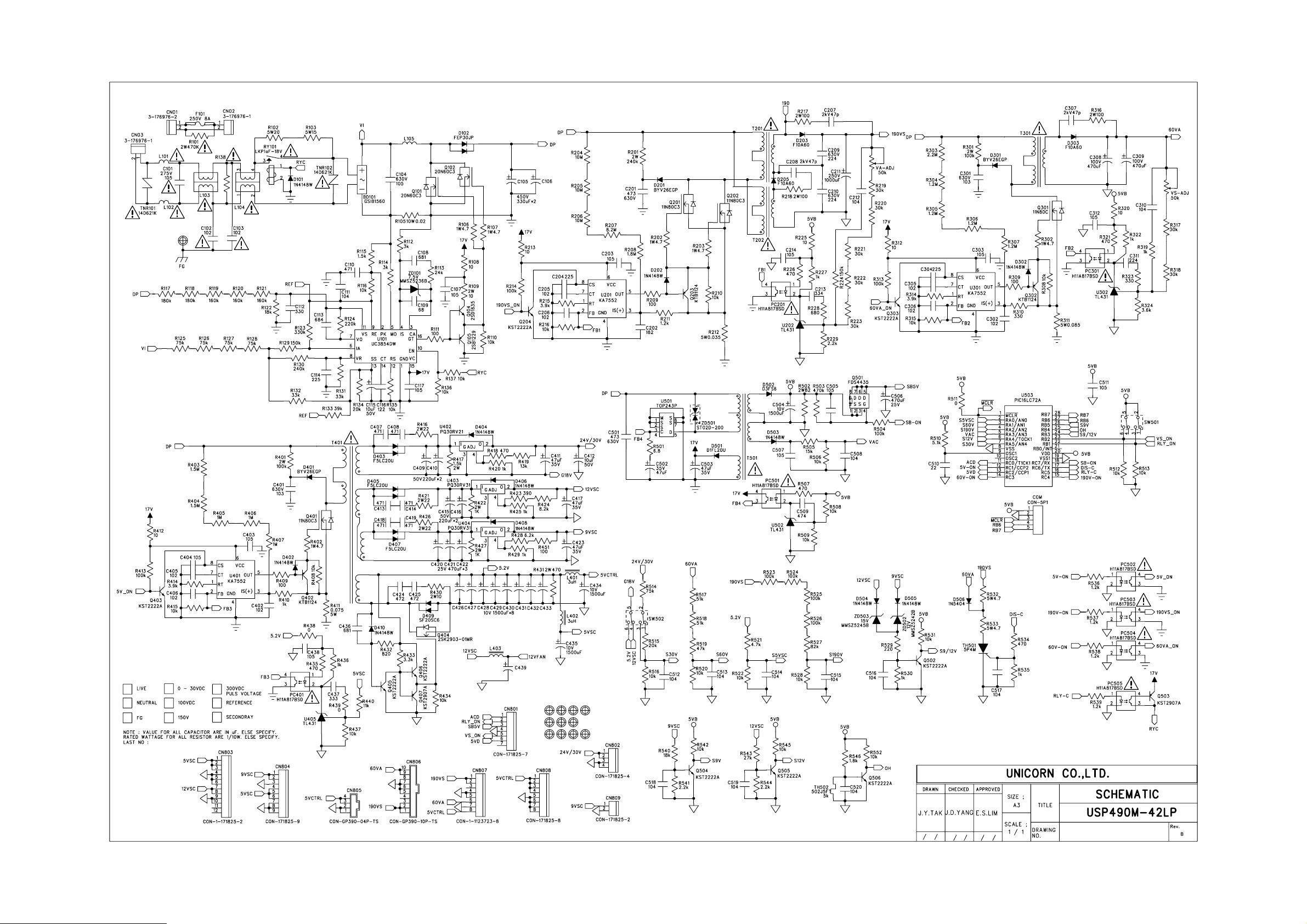

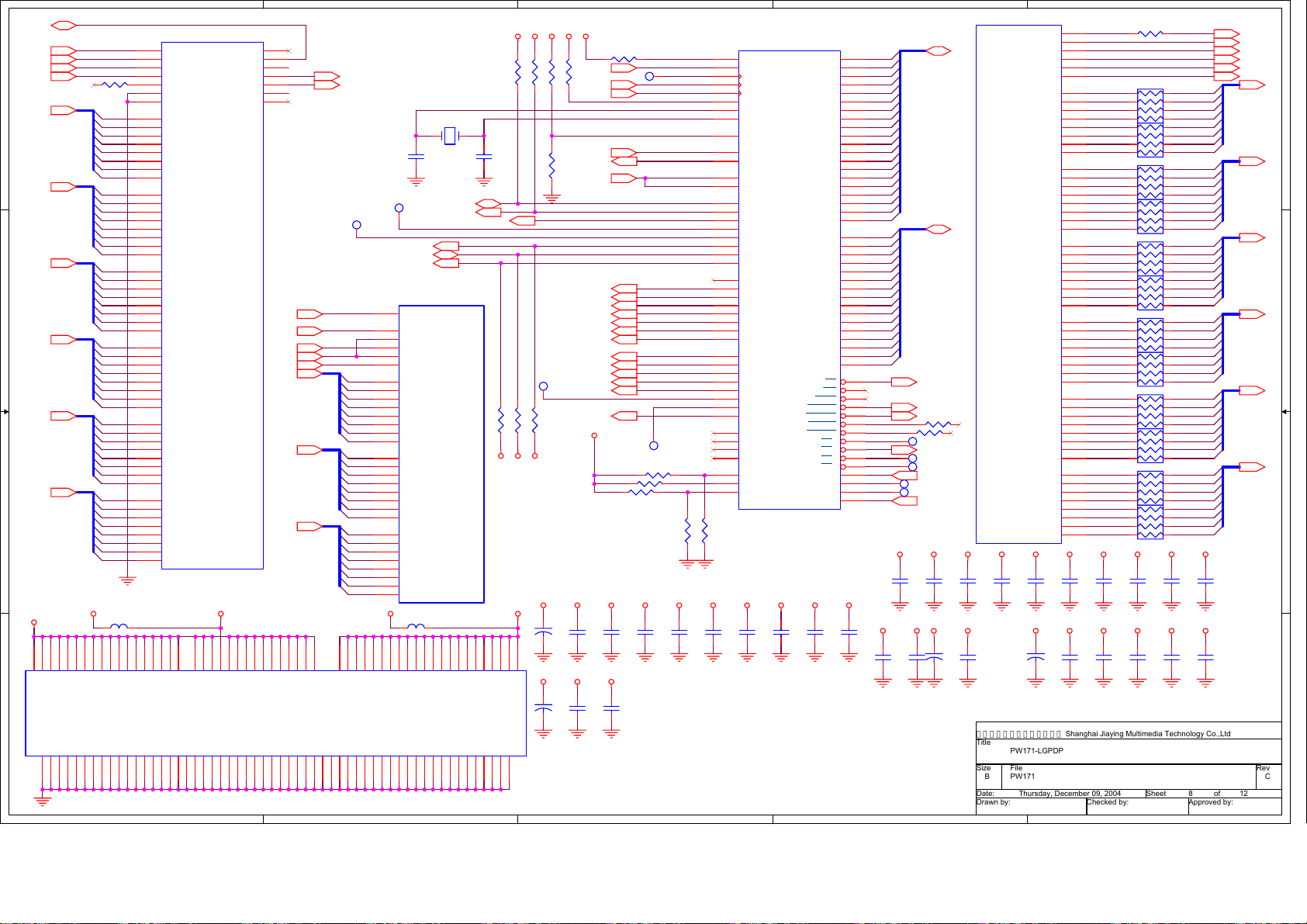

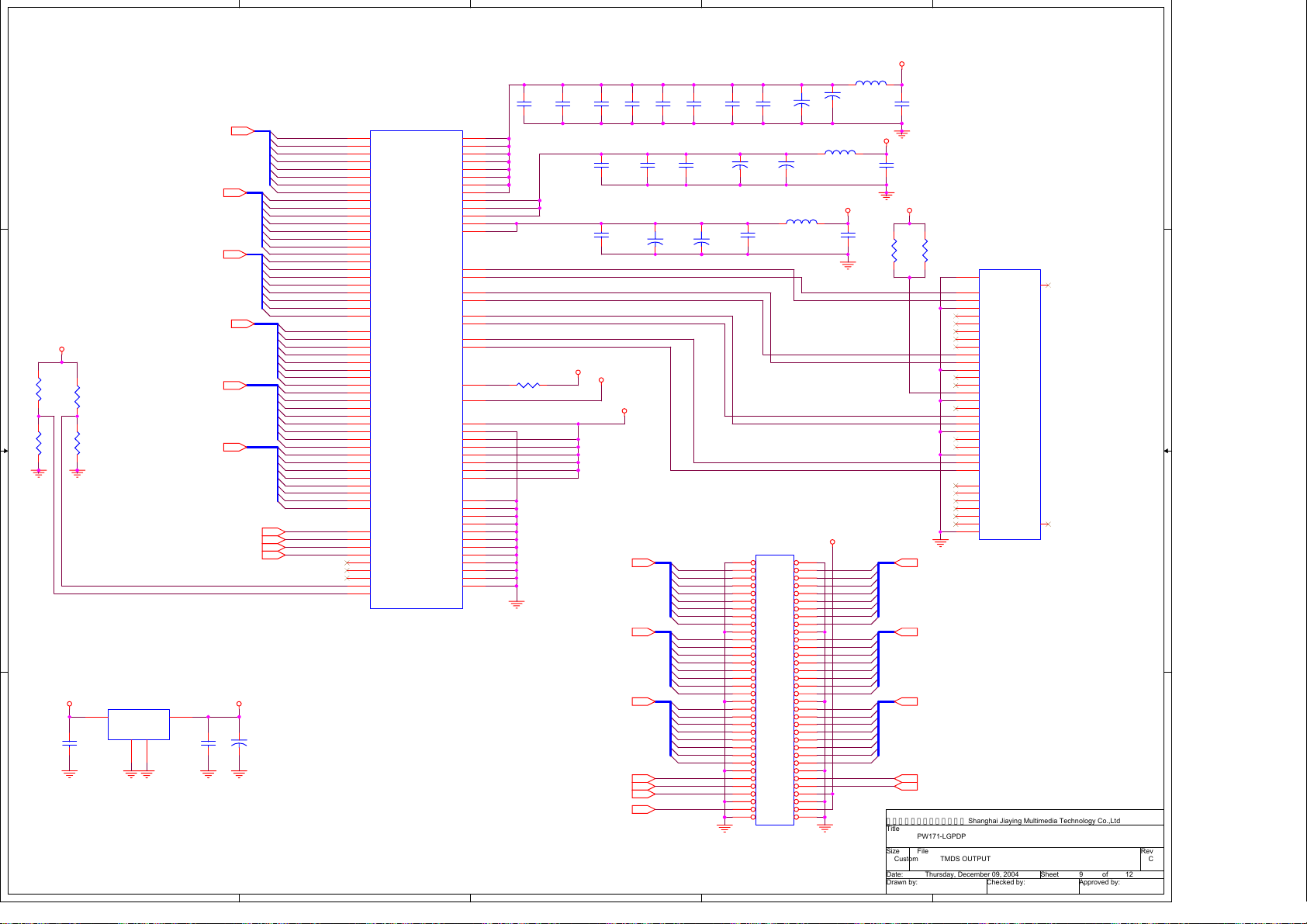

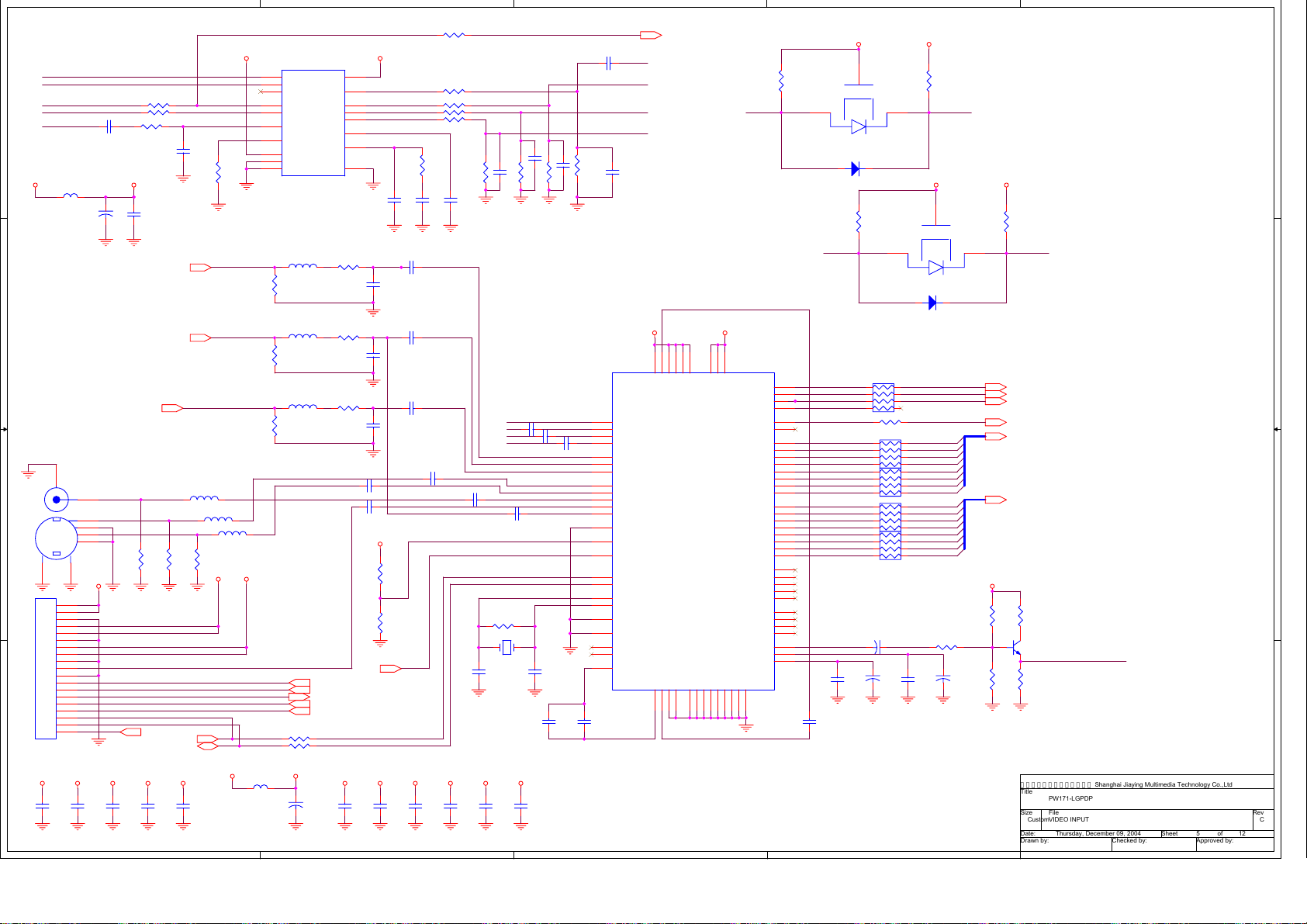

Circuit Diagram

- Power supply board of PDP Module, DGP-420WXGA

- Power supply board of PDP Module, USP490M-42LP

- Main (Video) board

- Audio/Tuner board

- Keypad board

- Remote control receiver board

- External L/R Speakers board

- Remote control board

Page 16

5

1

2

14D 621K

1

2

3

4

5

6

7

TNR101

R117

180KF

R125

75KF

D200

LL4148

CN01

3-176976-2

R189

200KF

R190

200KF

C126

250V 0.47uF

R219

10K

R262

1KF

C262

4.7uF

24V/30V

2

R118

180KF

R126

75KF

1

5

L103

L101

CH108200S

23mH

C101

275VAC 1uF

L102

23mH

R120

R119

160KF

180KF

R127

R128

75KF

75KF

Q107

R140

KTC3198Y

7.5KF

R141

C118

4.7KF

0.01uF

D203

LL4148

C202 35V 47uF

1uFC203

8

4.7KFR218

PC-17K1C

PC202

C227

0.001uF

CN802

1

2

3

4

171825-4

CS

7

CT

1

RT

2

FB

0.001uFC204

0.22uFC205 D502

R121

160KF

R122

18KF

R209

2W 240K

C200

630V 0.01uF

D206

LL4148

Q200

KTA1281

6

VCC

GND

4

IC200

KA7552A

5VSC

12VSC

D202

BYV26EGP

SPW11N80C3

R214

360RF

OUT

IS +

L104

CH108200S

C102,103

250V 0.001uF

PC100

R142

6.8KF

R175

0

C128

35V 470uF

MULTI EER4042

5

R220

1/4W 100R

3

470pF

C112

330pF

R129

150KF

R130

240KF

R133

33KF

R132

33KF

T207

Q201

R210

1W 10F

R212

10KF

R237

5W 0.1

C208

CN803

1

2

3

4

5

6

7

8

9

10

11

12

1-171825-2

RYC

3W 470K

GND DRAIN

1 2

R108

5W 15

RELAY1

SDT-SH-118DM

R143

34

VCCFB

D108 1N5236B

9VSC

5VSC

R103

5W 20

D103

LL4148

R123

330KF

C114

0.68uF

R145

2W 240K

U100

5M0280R-YDTU

0.1uF

C119

R500

1W 10

D500

SF30SC6

D5001

SF30SC6

R505

1W 4R7

D501

SUF30J

C519

31GF6

C520

D503

D10L20U

C113

2.2uF

R131

33KF

D104

US1M

PC-17K1C

PC101

C500

1KV0.001uF

C505

1KV 0.001uF

R531

35V 470uF

R526

171825-9

TNR102

14D 621K

C111

0.1uF

C120

35V 47uF

D106

US1M

C506

50V 220uF

C510

CN804

1

2

3

4

5

6

7

8

9

C110

470pF

R124

220KF

R134

24KF

STBY EE1927

C121

D105

US1M

5VCTRL

VI

BD101

D25XB60

R116

10KF

7

VO

6

IA

8

VR

T100

630V 0.01uF

C550~C554

10V 2200uF*5

C516

35V 1000uF

91011

VS

RE

U101 UC3854N

50V 10uFC115

C116 0.0022uF

D300

SB560

방전 CTL

R507

5W 2.7K

1-1123723-4

F101

250VAC 8A

1

2

CN02

3-176976-1

D D

PFC+

D107

US1M

R199

56KF

R198

C C

B B

A A

56KF

PFC GND

MULTI VCC

R216

100KF

PC201 PC-17K1C

RLY_ON

VS_ON

PFC VCC

ACD

SB5V

5VD

PFC +

R217

10KF

PFC+

VI

R102

1W 390KJ

AC-1

R196

56KF

R195

56KF

Q202

KRC103M

C201

0.01uF

CN03

3-176976-1

R193

56KF

R192

56KF

CN801

171825-7

R115

1.5KF

R114 3K

234

PK

RSSSCT

121314

10KF

R135

2W 100

5

MO

GND

1

R146

D301

US1M

R305

5W15

R532

1W 2.7K

CN805

4

3

2

1

C104

630V 1uF

IS

VC

15

4

R104

10W 0.02

R112 3KF

C108

680pF

R111

CA

100F

16

GT

EN

C117

35V 470uF

VA

Q108

KTC3198Y

R520

470F

PC202

IC500A

KA431AZ

1 2

Adj Output

1 2

Vin Vo

1 2

Vin Vo

60VA

190VS

4

T208

PFC COI L 200uH

R113

24KF

D109

1N5236B

C109

68PF

R137

R136

10KF

L301

27uH

C301,301A

10V 2200uF*2

R155

100KF

R151

100KF

R156

1KF

L500

6*20 2.5uH

C530

1uF

IC500

KA317

Input

3

IC501

KIA278R12PI

GND

ON/OFF

3

4

IC502

KIA378R09PI

GND

ON/OFF

3

4

1-1123723-0

Q102,Q103,Q109

SPW20N60C3*3

1W 4.7

Q104

KTC3209

Q105

KTA1281

10KF

R152

100KF

R150

100KF

VR500

2K

R501

3.3KF

R522

4.7KF

CN806

10

9

8

7

6

5

4

3

2

1

D102

FEP30JP

R109

R106

R107

1W 4.7

1W 4.7

R110

10KF

D111

1N4148

R301

220F

PC101

IC300

KA431AZ

R154

R153

100KF

100KF

R149

R148

100KF

100KF

D303

1N5245B

PC201

R525

56KF

R509

3.3KF

R508

0R

C304

50V 4.7uF

C504,C555~C557

10V 2200uF*4

C507

35V 47uF

C511

35V 47uF

C514

35V 47uF

190VS 5VCTRL

60VA

5VCTRL

1-1123723-8

C302

0.68uF

CN807

1

2

3

4

5

6

7

8

D302

US1M

R306

5W6.8

R307

5W6.8

Q300

FQP17N40

R510

5W 1K

R514

2KF

R515

1.8KF

R518

3.9KF

C123

35V 47uF

R302

1.02KF

R303

1KF

VS

R513

2.7KF

J2

0

C105,106

450V 330uF

R176

10KF

PC102

PC-17K1C

R511

15KF

R512

15KF

R516

1KF

R519

1.5KF

R502

0

R503

1KF

R504

1.8KF

AC DET

PC100

PC-17K1C

CN808

1

2

3

4

5

6

7

8

171825-8

R144

10F

Q106

KSP2907

9VSC

PFC+

PC102

SEL

CABLE

3

PFC VCC

RYC

+5VSTBY

GND

PFC ON/OFF

MULTI ON/OFF

+5VCTRL

5VSC

+5V DET

GND

+30V/1.0A (+24V/1.25A)

+30V DET

5VCTRL

GND

+12V /1.0A

+12V DET

GND

9VSC

+9V DET

GND

CN809

1

2

171825-2

3

PFC +

VA VCC

PFC +

VA VCC

D204

LL4148

R233

100KF

Q207

KRC103M

D226

LL4148

R248

100KF

Q210

KRC103M

R249

10KF

R401 1KF

R402 4.7KF

1

C400

50V 0.1uF

C403 50V 0.68uF

C404 50V 0.1uF

C405 50V 0.1uF

C406 50V 0.1uF

C407 50V 0.1uF

C408 50V 0.1uF

C409 50V 0.1uF

6

GND

GND

C214

0.01uF

KIA7045AP

VCC

PC205

PC-17K1C

11 1221 819

7

+5VSTBY

IC400

2

OUT

GND

R221

2.2M

R222

2.2M

R223

2.2M

R224

2.2M

R225

1M

3

C401

50V 0.1uF

R403 1KF

VS DET

2

R232

1K

R247

1.2K

C219

0.01uF

FSF10A60

R600

1W4R7

FSF10A60

R603

1W4R7

R231

5W 0.05

1W 10

R246

5W 0.2

D600

D601

FSF10A60

R700

D700

C600

1KV 220pF

C601

1KV 220pF

C700

1KV 100pF

R715

45.3KF

R718

45.3KF

R620

2W 100K

C701,702,704

100V 330uF

R716

45.3KF

R717

45.3KF

C222

630V 0.1uF

C221

630V 0.1uF

R720

45.3KF

R721

45.3KF

R602

2W 100K

PC204

Q702

KTC3207

D211

1N5234B

NO

일자

R253

2W 240K

R400

1KF

R226

2W 240K

D205

BYV26EGP

C206

630V 0.047uF

D213

LL4148

R260

2.4KF

C263

10uF

35V 47uFC215

1uFC216

0.001uFC217

4.7KFR250

0.047uFC218

10KFR251

R261

1KF

C261

4.7uF

R227

1W 4.7

35V 47uFC220

1uFC209

0.001uFC210

4.7KFR235

0.001uFC211

10KFR236

C213

630V 0.01uF

D209

LL4148

Q206

KTA1281

PC204

PC-17K1C

PC206

PC-17K1C

0.001uF

Q203,204

SPW11N80C3*2

8

CS

7

CT

1

RT

2

FB

C225

0.1uF

BYV26EGP

Q208

KTA1281

8

CS

7

CT

1

RT

2

FB

C226

LED401

RED

D208

R228

1W 4.7

6

VCC

GND

4

6

VCC

GND

4

OUT

IC201

KA7552A

OUT

IC202

KA7552A

R230

4.7KF

5

3

IS +

Q209

SPW11N80C3

R229

1W 4.7F

R245

10KF

5

3

IS +

R243

1W 47R

0.0047uF

R252

1W 100R

C212

T204,205

VS EER4042

T206

VA EER4042

1

Vss

RD1

2

VA,VS ON/OFF

1

Xin

Xout

|RESET

AN0/AVref/RB0

BUZ/RB1

INT0/RB2

R412 1KF

R423 1KF

AC DET

방전CTL

CRST400

4MHZ

Xin

1415161718192021222324

RD3

INT1/RB3

3

Xout

GND

2

R421 10KF

R416 1KF

R415 100F

PWM0/COMP0/RB4 RD2

12 13

R414 2KF

151323

MULTI ON/OFF

R417 1KF

R420 4.7KF

R418 1KF

9

4

VS ON

RLY ON

5VD OUT

ACD OUT

RY ON/OFF

C410 50V0.01uF

R422 10KF

HIC_MICOM

50V0.01uF

C411

SW400

JSS 2209

DGP-420WXGA

LED400

GREEN

RC0

RC1

RA0/EC0

RA1/AN1

RA2/AN2

RA3/AN3

AN4/RA4

1

1KF

1KF

R405

R404

20

VA DET

+5V DET

2

1KF

R406

18 1516

AN5/RA5

R407 1KF

17

+12V DET

AN6/RA6

R408 1KF

+9V DET

IC401

HMS87C1304A

VDD

AN6/RA6

6

534

R409 2KF

+30V DET

RD0

7891011

R411 330F

R410 330F

PFC ON/OFF

1

R609

300KF

R610

300KF

C602

250V 820uF

R710

18KF

R712

18KF

PC206

Q701

KTC3207

D212

1N5234B

R604

120KF

R606

270KF

R701

18KF

R714

18KF

R704

22KF

R705

20KF

R706

20KF

R707

2.7KF

R611

300KF

R612

12KF

R708

18KF

R719

18KF

R613

120KF

R627

120KF

R628

120KF

R607

130KF

R608

120KF

VR601

5K

R615

18KF

REVISION HISTORY

/

사유

2004/07/28 FEP30JPPH967C6

변경

전

D

<D<m

1

R702

33KF

R703

36KF

R709

36KF

VR700

5K

R711

11KF

190VS

VS DET

GND

190VS

60VA

VA DET

GND

1

PC205

변경

후

60VA

VA ON/OFF

Page 17

USP490M-42LP

Page 18

5

4

3

2

1

INPUT

GBAIN

GGAIN

RXCm

RX0m

GHSYNC

D D

RX1m

RXCp

HDCBIN

HDYIN

RX1p

RX2p

GRAIN

RX0p

RX2m

GVSYNC

HDCRIN

Y

CB

CR

DVI

RXCm

RX0m

RX1p GBE[7:0]

RX1m

RX0p

GDFEOE

RX2m

RX2p

RXCp

GRE[7:0]

GPEN

GVS

GBO[7:0]

GFBK

GHS

GGE[7:0]

GCLK

GRO[7:0]

GGO[7:0]

03_DVI

02_INPUT

MEMORY

C C

VCP3230

VVINT VUV[7:0]

CB

RESETn

Y

SDA

STBLED

POWER_ON

VVHS

VY[7:0]

VVCLK

SCL

VVVSCR

VFIELD

MUTE

MUTE1

NV320

SDA

SCL

VVHS

RESETn

VVCLK

NDSP_EN

VUV[7:0]

IR

VVVS

VG[7:0]

VB[7:0]

VR[7:0]

VCLK

VVS

VHS

VPENVY[7:0]

SDA

SCL

ROMWEn

ROMOEn

VPPEN

D[15:0]

A[19:1]

07_MEMORY

06_NV320

05_VCP3230

B B

TMDS

DBO[7:0]

DHS

DENG

DENR

DGE[7:0]

DRE[7:0]

DGO[7:0]

DRO[7:0]

DCLK

DVS

09_TMDS

DENB

DBE[7:0]

MISC

LED-G

ICSSTM

ICSCLK

ICSSTD

LED-R

ICSDAT

TXD

RDn

D[7:0]

CS1n

STBLED

10_MISC

DCKEXT

MCKEXT

RXD

RESET

RESETn

POWER_ON

IRRCVR1

NMI

POWER

11_POWER

AFE

HDCBIN GBE[7:0]

GAFEOE

VGASEL

GVSYNC

GCOAST

HDCRIN

GRAIN

SCL

GBAIN

GBLKSPL

GGAIN

SDA

GHSYNC

04_AFE

LVDS

DENG

DCLK

DVS

DHS

DTXON

RESET-2

SCL

SDA

CPUGO

PDPGO

PDWN

IRQ

DGE[7:0]

DRE[7:0]

DBE[7:0]

12_LVDS

GRE[7:0]HDYIN

GHS

GCLK

GFBK

GGE[7:0]

GVS

PW171

D[15:0]

SDA

A[19:0]

GFBK

CS1n

VPPEN

RDn

NMI

VR[7:0]

VCLK

VG[7:0]

VB[7:0]

GHS

GCLK

GRE[7:0]

GBO[7:0]

GBE[7:0]

GGO[7:0]

GRO[7:0]

GVS

GGE[7:0]

MCKEXT

RXD

08_PW171

IRRCVR1

RESET

DCKEXT

VPEN

VVS

VFIELD

GPEN

ICSCLK

ICSSTD

ICSSTM

ICSDAT

LED-R

LED-G

NDSP_EN

DTXON

VGASEL

GAFEOE

GDFEOE

VVINT

VHS

MUTE

SLEEP1

PIO3

CPUGO

PDPGO

RESET-2

PDWN

IRQ

DGE[7:0]

DBE[7:0]

DRO[7:0]

DGO[7:0]

DRE[7:0]

DBO[7:0]

DCLK

GBLKSPL

GCOAST

ROMWEn

ROMOEn

TXD

DVS

DENB

DENG

DENR

DHS

SCL

A A

上海家影多媒体技术有限公司

Title

PW171-LGPDP

Size File Rev

TOP c

B

Date: Sheet

Drawn by: Checked by: Approved by:

5

4

3

2

Shanghai Jiaying Multimedia Technology Co.,Ltd

of

112Thursday, December 09, 2004

1

Page 19

5

4

3

2

1

C46

47uF

VCCAVDD AVDD

C47

0.1uF

U6

LM2937_SOT223

1

VI

GNDVOTAB

234

C48

0.1uF

C49

47uF

PVDD

C35

0.1uF

C51

0.1uF

AVDD

AVDD

C36

0.1uF

V33 V33

C52

0.1uF

C37

0.1uF

C53

0.1uF

C38

0.1uF

V33

C54

0.1uF

C39

0.1uF

AVDD AVDD

V33

C55

0.1uF

C40

0.1uF

C56

0.1uF

C41

0.1uF

V33

AVDD

C57

0.1uF

C42

0.1uF

VCCAVDD

C43

0.1uF

C44

0.1uF

U5

LM2937_SOT223

1

VI

GNDVOTAB

234

V33V33

C58

47uF

PVDD

PVDD

C45

0.1uF

AVDD AVDDAVDD

C34

0.1uF

D D

PVDD

C50

0.1uF

AVDD V33 PVDD

C59

V33

1

U8A

2 3

74LVC126A

7 14

C C

VGASEL

HDCRIN

HDYIN

HDCBIN

GRAIN

GGAIN

GBAIN

B B

GHSYNC

GVSYNC

V33

C61

0.1uF

U9 PI5V330

1

A/B

15

2

5

11

14

3

6

10

13 8

VCC

OE

A1

A2

A3

A4

B1

B2

B3

B4 GND

Y1

Y2

Y3

Y4

10

U8C

9 8

74LVC126A

4

U8B

5 6

74LVC126A

39nF

C60

GFLT1

3.9nF

R16

3.3K

GFILT

SDA

SCL

TP7

TP8

VCC

GMRED

GMGRN

GMBLU

VCC

GBLKSPL

GCOAST

C6247nF

C6347nF

C641nF

C6547nF

GRIN

GGIN

GSOGIN

GBIN

16

4

7

9

12

C66

0.1uF

GVREF

GBHSY

GMIDV ADHS

C68

C67

0.1uF

0.1uF

GBVSY

2627394245465152596211222369787934

AVD1

AVD2

AVD3

AVD4

AVD5

AVD6

AVD7

AVD8

33

FILT

57

SDA

56

SCL

55

A0

38

CLAMP

29

COAST

54

RAIN

48

GAIN

49

SOGIN

43

BAIN

30

HSYNC

31

VSYNC

58

REFBYP

37

MIDSCV

GND1

GND2

GND3

GND4

GND5

AD9883A_140

GND6

GND7

GND8

11020212425283236

AVD9

GND9

35

PVD1

VDD4

VDD5

VDD6

GND16

GND17

GND15

6061636880

53

PVD2

RED0

RED1

RED2

RED3

RED4

RED5

RED6

RED7

GREEN0

GREEN1

GREEN2

GREEN3

GREEN4

GREEN5

GREEN6

GREEN7

BLUE0

BLUE1

BLUE2

BLUE3

BLUE4

BLUE5

BLUE6

BLUE7

DATACK

HSOUT

SOGOUT

VSOUT

GND18

GND19

GND20

ADR0

77

ADR1

76

ADR2

75

ADR3

74

ADR4

73

ADR5

72

ADR6

71

ADR7

70

ADG0

9

ADG1

8

ADG2

7

ADG3

6

ADG4

5

ADG5

4

ADG6

3

ADG7

2

ADB0

19

ADB1

18

ADB2

17

ADB3

16

ADB4

15

ADB5

14

ADB6

13

ADB7

12

ADCK

67

66

ADSOG

65

ADVS

64

RP1447R

RP1547R

RP1647R

RP1747R

RP1847R

RP1947R

RP2047R

ADSOGR

GRE0

GRE1

GRE2

GRE3

GRE4

GRE5

GRE6

GRE7

GGE0

GGE1

GGE2

GGE3

GGE4

GGE5

GGE6

GGE7

GBE0

GBE1

GBE2

GBE3

GBE4

GBE5

GBE6

GBE7

13

U8D

12 11

TP9

GRE[7:0]

GGE[7:0]

GBE[7:0]

GCLK

GFBK

GVS

GHS

VDD1

VDD2

VDD3

AVD10

U7

GND10

GND11

GND12

GND13

GND14

40

41

444750

74LVC126A

GAFEOE

A A

Main (Video)

Drawn by: Checked by: Approved by:

5

4

3

2

1

Page 20

5

PVCC VCC

OVCC

CVCC

AVCC

1829435778638679782848895

D D

AVCC

OVCC1

OVCC2

OVCC3

OVCC4

OVCC5

VCC1

VCC2

VCC3

PVCC

AVCC1

AVCC2

R15

510

SIRES

96

EXT_RES

RX0p

RX0m

RX1p

RX1m

RX2p

RX2m

C C

RXCp GBO[7:0]

RXCm

90

RX0p

91

RX0m

85

RX1p

86

RX1m

80

RX2p

81

RX2m

93

RXCp

94

RXCm

SII161

U4

OVCC

100

OCK_INV

4

PIXS

1

DFO

7

STAG_OUT

3

ST

GDFEOE

B B

9

PDO

2

PD

99

RSVD

OGND1

OGND2

OGND3

OGND4

OGND5

GND1

GND2

GND3

PGND

AGND1

AGND2

1928455876539689879838789

AVCC3

AGND3

AVCC4

AGND4

AGND5

4

SCDT

QE0

QE1

QE2

QE3

QE4

QE5

QE6

QE7

QE8

QE9

QE10

QE11

QE12

QE13

QE14

QE15

QE16

QE17

QE18

QE19

QE20

QE21

QE22

QE23

QO0

QO1

QO2

QO3

QO4

QO5

QO6

QO7

QO8

QO9

QO10

QO11

QO12

QO13

QO14

QO15

QO16

QO17

QO18

QO19

QO20

QO21

QO22

QO23

ODCK

VSYNC

HSYNC

CTL1

CTL2

CTL3

SISCDT

8

SIBE0

10

SIBE1

11

SIBE2

12

SIBE3

13

SIBE4

14

SIBE5

15

SIBE6

16

SIBE7

17

SIGE0

20

SIGE1

21

SIGE2

22

SIGE3

23

SIGE4

24

SIGE5

25

SIGE6

26

SIGE7

27

SIRE0

30

SIRE1

31

SIRE2

32

SIRE3

33

SIRE4

34

SIRE5

35

SIRE6

36

SIRE7

37

SIBO0

49

SIBO1

50

SIBO2

51

SIBO3

52

SIBO4

53

SIBO5

54

SIBO6

55

SIBO7

56

SIGO0

59

SIGO1

60

SIGO2

61

SIGO3

62

SIGO4

63

SIGO5

64

SIGO6

65

SIGO7

66

SIRO0

69

SIRO1

70

SIRO2

71

SIRO3

72

SIRO4

73

SIRO5

74

SIRO6

75

SIRO7

77

SICLK

44

SIDE

46

DE

SIVS

47

SIHS

48

40

41

42

TP1

RP1 47R

RP2 47R

RP3 47R

RP4 47R

RP5 47R

RP6 47R

RP7 47R

RP8 47R

RP9 47R

RP10 47R

RP11 47R

RP12 47R

RP13 47R

GBE0

GBE1

GBE2

GBE3

GBE4

GBE5

GBE6

GBE7

GGE0

GGE1

GGE2

GGE3

GGE4

GGE5

GGE6

GGE7

GRE0

GRE1

GRE2

GRE3

GRE4

GRE5

GRE6

GRE7

GBO0

GBO1

GBO2

GBO3

GBO4

GBO5

GBO6

GBO7

GGO0

GGO1

GGO2

GGO3

GGO4

GGO5

GGO6

GGO7

GRO0

GRO1

GRO2

GRO3

GRO4

GRO5

GRO6

GRO7

TP2

3

U3

LM2937_SOT223

1

VI

C14

0.1uF

GNDVOTAB

234

2

1

V33T

C15

C16

0.1uF

47uF

GBE[7:0]

V33T

L15

FB_420_OHM_200MA

OVCC

OVCC

OVCC

OVCC

OVCC

OVCC

GGE[7:0]

C21

0.1uF

C22

0.1uF

GRE[7:0]

V33T

V33T

L16

FB_420_OHM_200MA

L17

FB_420_OHM_200MA

CVCC

PVCC

C17

10uF

C23

10uF

C27

10uF

CVCC

PVCC

C18

0.1uF

C24

0.1uF

C28

0.1uF

CVCC

C19

0.1uF

C25

0.1uF

C20

0.1uF

CVCC

C26

0.1uF

GGO[7:0]

AVCC

C29

10uF

AVCC

AVCC AVCC

C30

C31

0.1uF

0.1uF

C32

0.1uF

AVCC

C33

0.1uF

TP3

GRO[7:0]

TP4

TP5

TP6

V33T

L18

FB_420_OHM_200MA

GCLK

GPEN

GVS

GHS

GFBK

92

A A

上海家影多媒体技术有限公司

Title

PW171-LGPDP

Size File Rev

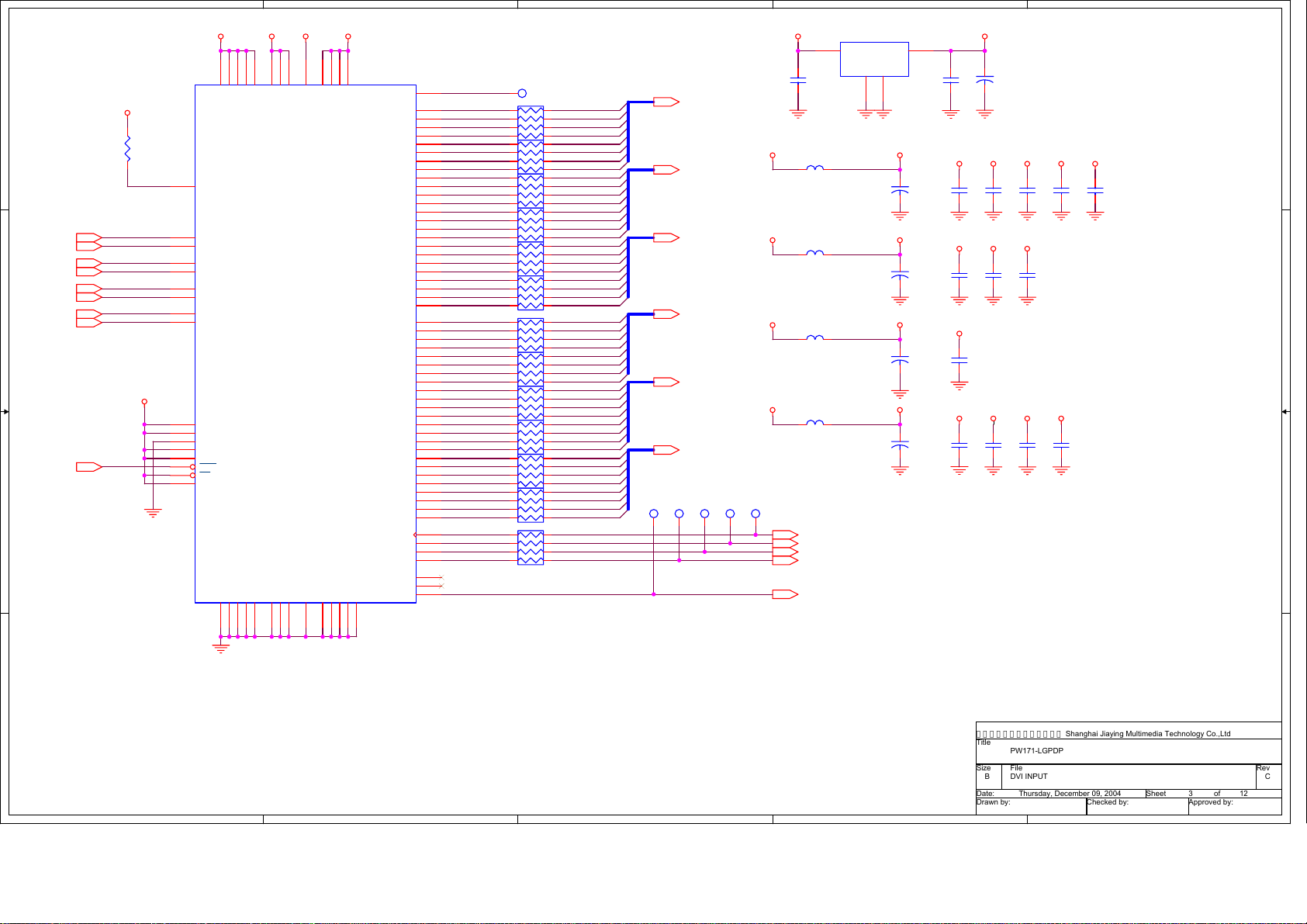

DVI INPUT C

Main (Video)

5

4

3

2

B

Date: Sheet

Drawn by: Checked by: Approved by:

Shanghai Jiaying Multimedia Technology Co.,Ltd

of

312Thursday, December 09, 2004

1

Page 21

5

4

3

2

1

D[15:0]

V33 V33

ROMOEn

D D

V33

VPPEN

C C

ROMWEn

JP1

12

34

HDR_2X2

R69

3.3K

FWPn

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10 VP1

A11

A12

A13

A14

A15

A16

A17

A18

A19

R70

3.3K

R71

3.3K

U16

26

CE

28

OE

11

WE

12

RP

14

WP

47

BYTE

25

A0

24

A1

23

A2

22

A3

21

A4

20

A5

19

A6

18

A7

8

A8

7

A9

6

A10

5

A11

4

A12

3

A13

2

A14

1

A15

48

A16

17

A17

16

A18

Flash_8M

V33

VPP

VCC

D10

D11

D12

D13

D14

D15

D16

GND1

GND2

13

37

D1

D2

D3

D4

D5

D6

D7

D8

D9

D1

31

D2

33

D3

35

D4

38

D5

40

D6

42

D7

44

D8

30

D9

32

D10

34

D11

36

D12

39

D13

41

D14

43

D15

45

46

27

VPPON

FCEn

ICEn

JP2

12

34

R68 10K

V33

D0

29

HDR_2X2

VPP

C167

22uF

C169

3 2

1

Q4

3906

1

VP3

VP2

2 3

R67

1K

Q5

3904

V33

SCL

SDA

U17

6 8

SCL VCC

5

SDA

1

NC0

NC1

NC2

WP

GND

2

3

24C16

V33

7

4

C168

0.1uF

0.1uF

R72 3.3K

R73 3.3K

R74 3.3K

R75 3.3K

V33

D7

D6

D13

D12

D11

D10

D1

D0

A1

A3

A5

A7

A8

A10

A13

A15

A16

A18

ROMWEn

上海家影多媒体技术有限公司

Title

Main (Video)

3

2

PW171-LGPDP

Size File Rev

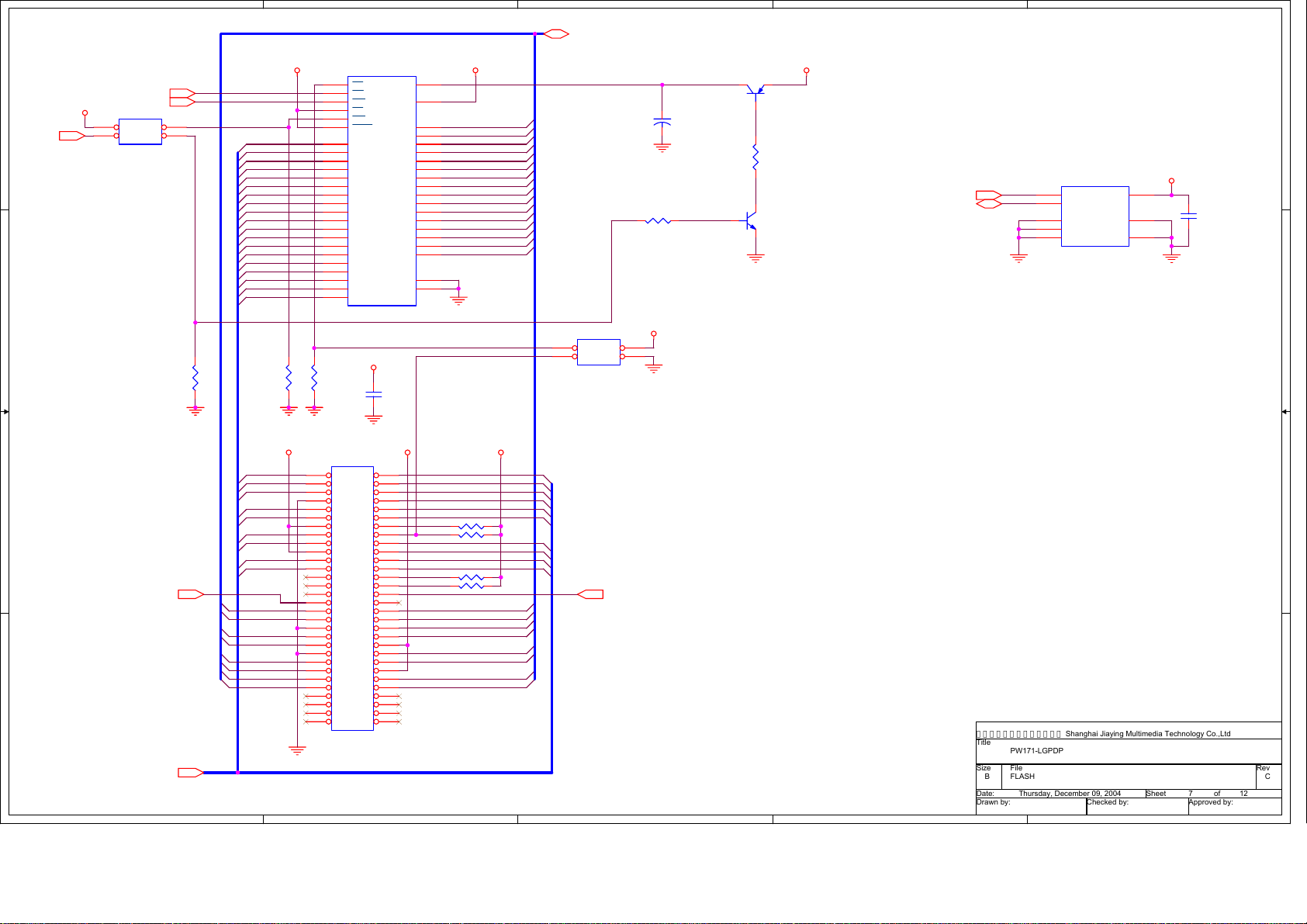

FLASH C

B

Date: Sheet

Drawn by: Checked by: Approved by:

Shanghai Jiaying Multimedia Technology Co.,Ltd

of

712Thursday, December 09, 2004

1

VCC

A2

A4

A6

A9

B B

A11

A12

A14

A17

A19

ROMOEn

D15

D14

D5

D4

D3

D2

D9

D8

A A

JP3

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

51 52

53 54

55 56

57 58

59 60

VCC

IRPn

IA20

IA21

HDR_30X2

A[19:1]

5

4

Page 22

5

4

3

2

1

L1 FB_40_OHM_500MA

HDCR

J1

1

Y

3

D D

6

9

GVCC

BAV99L

C C

J2

27

NC1

DATA2/4_SHLD

DDC_DATA

DATA1/3_SHLD

28

NC2

H_PLUG_DET

DATA0/5_SHLD

DVI_V

B B

SHELL1

DATA2-

DATA2+

DATA4-

DATA4+

DDC_CLK

A_VSYNC

DATA1-

DATA1+

DATA3-

DATA3+

+5V

GND

DATA0-

DATA0+

DATA5-

DATA5+

CLK_SHLD

CLK+

CLK-

A_RED

A_GREEN

A_BLUE

A_HSYNC

A_GND1

A_GND2

SHELL2

25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

C1

C2

C3

C4

C5

C6

26

2

4

CB

5

7

CR

8

YUV

GVCC

GVCC

GVCC

R4

3.3K

GDC5V

VCC

2

R5

3.3K

3

BAV99L

D7

1

D14

1

3

2

BAV70L

2

3

D6

1

GVCC

GVCC

Y

CB

CR

R9

3.3K

U2

GVCK

7

GSCL

GSDA

VCLK

6

SCL

5

SDA

RX2m

RX2p

RX1m

RX1p

RX0m

RX0p

RXCp

RXCm

VCC

L13

NS C13

L3 FB_40_OHM_500MA

HDY

L5 FB_40_OHM_500MA

HDCB

VCC

NC1

NC2

NC3

GND

24LC21A

C10

GVCC

8

1

C5

2

3

0.1uF

4

VCC

GVCC

NS

C11

0.1uF

HDCRF

HDYF

HDCBF

R1

75

J15

DB15HD_V

6

1

11

7

2

12

8

3

13

9

4

14

10

5

15

16 17

VCC

L14

C12

L2 FB_40_OHM_500MA

L4 FB_40_OHM_500MA

L6 FB_40_OHM_500MA

R2

R3

75

75

GRED

GGREEN

GBLUE

G5V

D13

1

2

BAV70L

GVCC1

0.1uF

GVCC1

2

BAV99L

D4

1

3

AVDD

BAV99L

3

GVCC1

AVDD

2

3

C1

D1

12pF

1

GVCC1

2

3

BAV99L

D5

1

L7 FB_40_OHM_500MA

L9 FB_40_OHM_500MA

L11 FB_40_OHM_500MA

GVCC1

GVCC1

2

3

BAV99L

D11

1

AVDD

2

BAV99L

D2

1

R13

2K

3

GVCC1

R6

3.3K

2

3

BAV99L

C2

12pF

GVCC1

R7

3.3K

GVCC1

GVCC1 AVDD

2

3

BAV99L

D12

1

D3

1

GVCC1

R14

2K

R8

3.3K

CVCK

CSCL

CSDA

C3

12pF

7

6

5

GREDF

GGREENF

GBLUEF

R10

75

VCLK

SCL

SDA

HDCRIN

HDYIN

HDCBIN

U1

VCC

NC1

NC2

NC3

GND

24LC21A

L8 FB_40_OHM_500MA

L10 FB_40_OHM_500MA

L12 FB_40_OHM_500MA

R12

R11

75

75

8

1

2

3

4

D8

2

BAV99L

1

GVCC1

3

C4

0.1uF

C7

12pF

AVDD

2

BAV99L

D9

1

GRAIN

GGAIN

GBAIN

GHSYNC

AVDD

2

C8

12pF

3

BAV99L

D10

1

3

GVSYNC

C9

12pF

A A

5

47uF_NS

4

47uF_NS

上海家影多媒体技术有限公司

Title

Main (Video)

3

2

PW171-LGPDP

Size File Rev

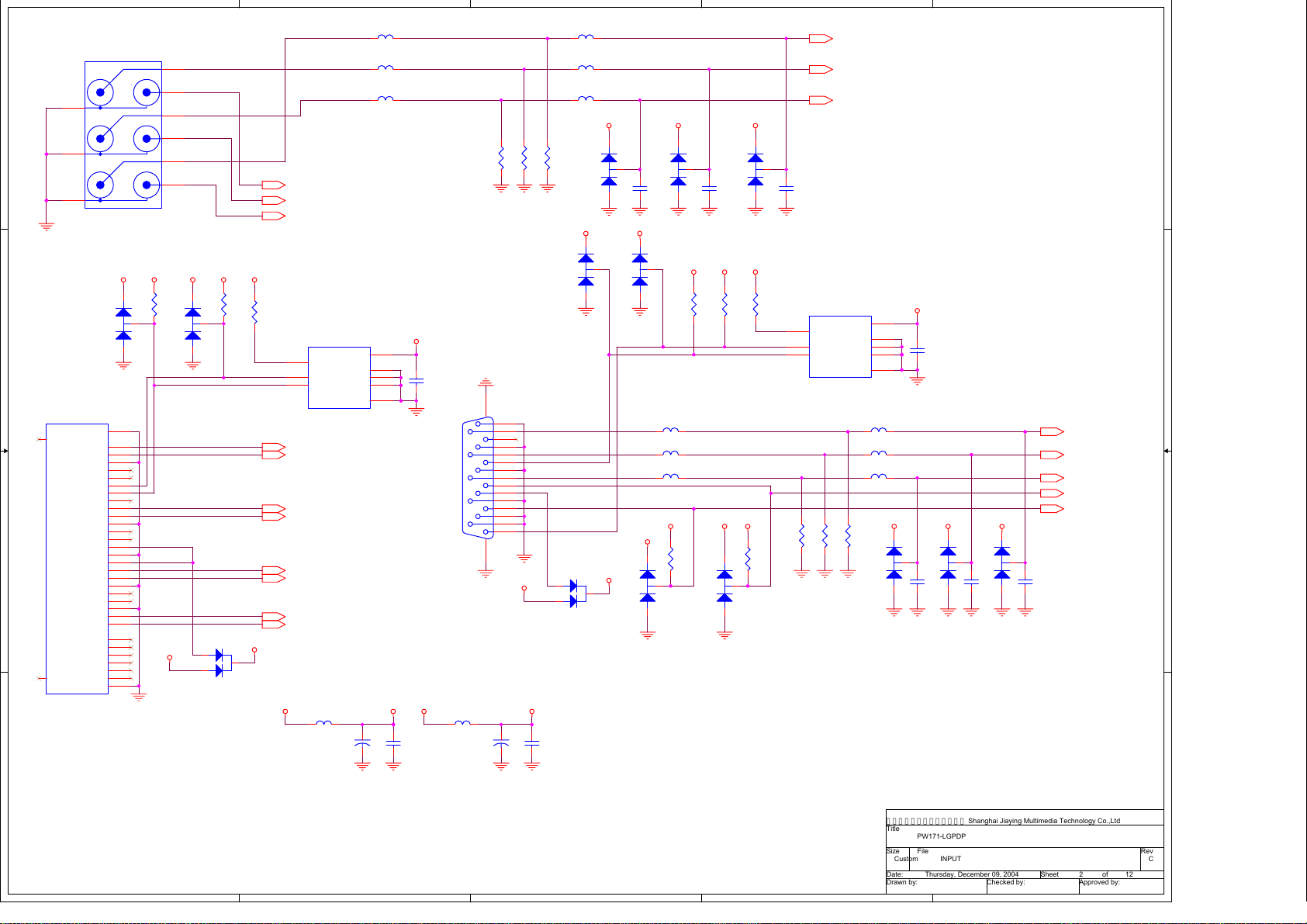

Custom

Date: Sheet

Drawn by: Checked by: Approved by:

Shanghai Jiaying Multimedia Technology Co.,Ltd

INPUT C

212Thursday, December 09, 2004

of

1

Page 23

5

DRE[7:0]

D D

DGE[7:0]

DBE[7:0]

C C

DRE[7:0]

DGE[7:0]

B B

DBE[7:0]

DRE0

DRE1

DRE2

DRE3

DRE4

DRE5

DRE6

DRE7

DGE0

DGE1

DGE2

DGE3

DGE4

DGE5

DGE6

DGE7

DBE0

DBE1

DBE2

DBE3

DBE4

DBE5

DBE6

DBE7

DRE0

DRE1

DRE2

DRE3

DRE4

DRE5

DRE6

DRE7

DGE0

DGE1

DGE2

DGE3

DGE4

DGE5

DGE6

DGE7

DBE0

DBE1

DBE2

DBE3

DBE4

DBE5

DBE6

DBE7

ARE0

RP6047R

ARE1

ARE2

ARE3

ARE4

RP6147R

ARE5

ARE6

ARE7

AGE0

RP6247R

AGE1

AGE2

AGE3

AGE4

RP6347R

AGE5

AGE6

AGE7

ABE0

RP6447R

ABE1

ABE2

ABE3

ABE4

RP6547R

ABE5

ABE6

ABE7

ARE6

RP5047R

ARE7

ARE0

ARE1

ARE2

RP5147R

ARE3

ARE4

ARE5

AGE6

RP5247R

AGE7

AGE0

AGE1

AGE2

RP5347R

AGE3

AGE4

AGE5

ABE6

RP5447R

ABE7

ABE0

ABE1

ABE2

RP5547R

ABE3

ABE4

ABE5

4

V33

V33V33V33V33

DCLK

DTXON

C273

0.1uF

DHS

DVS

DENG

C274

0.1uF

C275

0.1uF

ARE0

ARE1

ARE2

ARE3

ARE4

ARE5

ARE6

ARE7

AGE0

AGE1

AGE2

AGE3

AGE4

AGE5

AGE6

AGE7

ABE0

ABE1

ABE2

ABE3

ABE4

ABE5

ABE6

ABE7

C277

C276

0.1uF

0.1uF

31

51

52

54

55

56

3

50

2

4

6

7

11

12

14

8

10

15

19

20

22

23

24

16

18

27

28

30

25

17

R1440

32

CLKIN

TXIN0

TXIN1

TXIN2

TXIN3

TXIN4

TXIN6

TXIN27

TXIN5

TXIN7

TXIN8

TXIN9

TXIN12

TXIN13

TXIN14

TXIN10

TXIN11

TXIN15

TXIN18

TXIN19

TXIN20

TXIN21

TXIN22

TXIN16

TXIN17

TXIN24

TXIN25

TXIN26

TXIN23

R_F

PWRDN

3

V33

19263444

VCC1

DS90C383A

GND1

GND2

513212953

U31

VCC2

GND3

VCC3

GND4

GND5

OGND1

364349

OVCC

OGND2

PVCC

TXOUT0

TXOUT0

TXOUT1

TXOUT1

TXOUT2

TXOUT2

TXOUT3

TXOUT3

TXCOUT

TXCOUT

PGND1

OGND3

33

35

PGND2

2

SDA

SCL

1

J13

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

CON20A

TXE0m

47

48

45

46

41

42

37

38

39

40

3WSDA

3WSCL

3WSLE

PDWN

TXE0p

TXE1m

TXE1p

TXE2m

TXE2p

TXECKm

TXECKp

TXE3m

TXE3p

R1410

R1420

R1430

SCL

SDA

J14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

R1390

R1400

3WSDA

3WSCL

3WSLE

PDWN

JEA31

A A

上海家影多媒体技术有限公司

Title

PW171-LGPDP

Main (Video)

5

4

3

2

Size File Rev

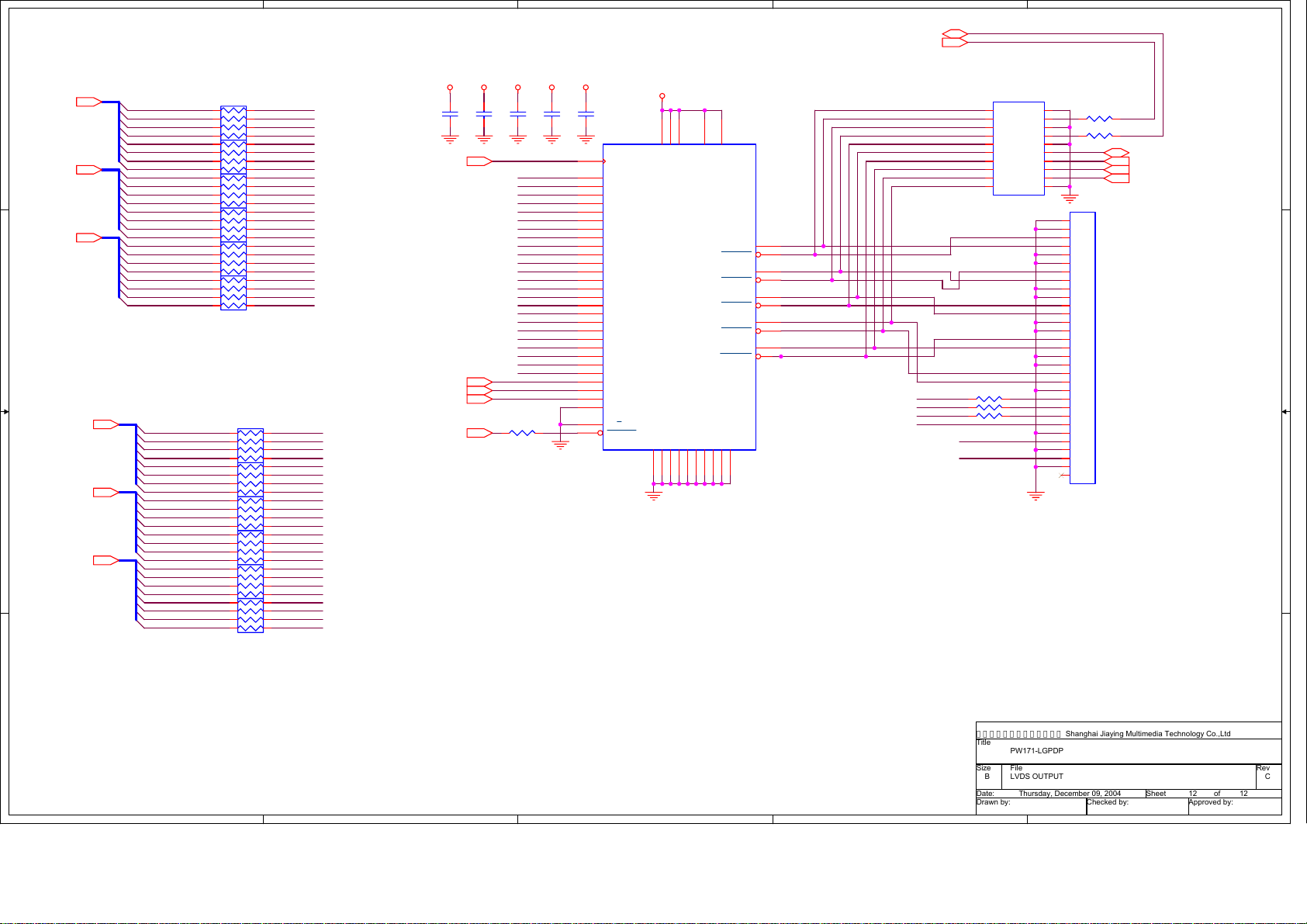

LVDS OUTPUT C

B

Date: Sheet

Drawn by: Checked by: Approved by:

Shanghai Jiaying Multimedia Technology Co.,Ltd

of

12 12Thursday, December 09, 2004

1

Page 24

5

CLOCK GENERATOR

ICSCLK

ICSDAT

ICSSTM

D D

ICSSTD

Y3

XTAL14.31818

C C

1 4

SW1

SW_MOM_4P

2 3

B B

U26 74LVC541AD

D[7:0]

A A

10

GND

D7

11

O7

D6

12

O6

D5

13

O5

D4

14

O4

D3

15

O3

D2

16

O2

D1

17

O1

D0

18

O0

20

VCC

V33

V33

V33

IX1

IX2

OE2

OE1

5

U21

13 3

OE VDD

12

DATA

9

STROBE

1

X1

16

X2

ICS307

ICSREF

U23

13 3

OE VDD

12

DATA

9

STROBE

1

X1

16

X2

ICS307

V33

V33

R103

10K

RSTINn

TLCCT

C234

0.1uF

R109

10K

V33

9

I7

8

I6

7

I5

6

I4

5

I3

4

I2

3

I1

2

I0

19

1

R110

10K

V33

C243

0.1uF

CLK1SCLK

CLK2

GND

CLK1SCLK

CLK2

GND

7

2

3

1

R111

10K

C244

0.1uF

118

6

5

118

6

5

U24

SENSE

RESIN

CT

CONTROL

TLC7733

R112

10K

V33

C245

0.1uF

V33

V33

V33

RESET

RESET

R113

10K

V33

C246

0.1uF

C233

0.1uF

VDD

GND

RMCK

RDCK

8

6

5

4

R114

10K

V33V33

C247

0.1uF

V33

R115

10K

V33

C248

0.1uF

V33

4

C230

0.1uF

R118 NS

CS1n

RDn

4

R9947

V33

R10247

RESET

RESETn

R116

10K

V33

C249

0.1uF

MCKEXT1

C231

0.1uF

DCKEXT1

+5V

MCKEXT

DCKEXT

+5VIN

VOL_UP

VOL_DOWN

MUNE

P_UP

P_DOWN

TV_AV

POWER_ON(MUNE)

IR

STBLED

RXD

TXD

LED

J10

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PH-14A

V33

POWER_ON

3

1 4

2 3

VCC

3

R106 1K

NMI1

R107

SW2

SW_MOM_4P

R1051K

1

JP5

2

HDR_4X1

3

4

R104200

4.7K

C240

0.1uF

C238

0.1uF

Remove for Production

Main (Video)

C239

0.1uF

NMI

MC1P

RRXD

MC2P

MC2M

STBLED

2

J8

1

2

3

4

5

6

STBLED

PH-6A

PH-3A

J9

U25

VCCC1P

12 13

ROUT1 RIN1

11

TIN1

10

TIN2

4

C2P

5

C2M

MAX232A

2

VPC1M

RIN2ROUT2

T1OUT

TOUT2

VM

GND

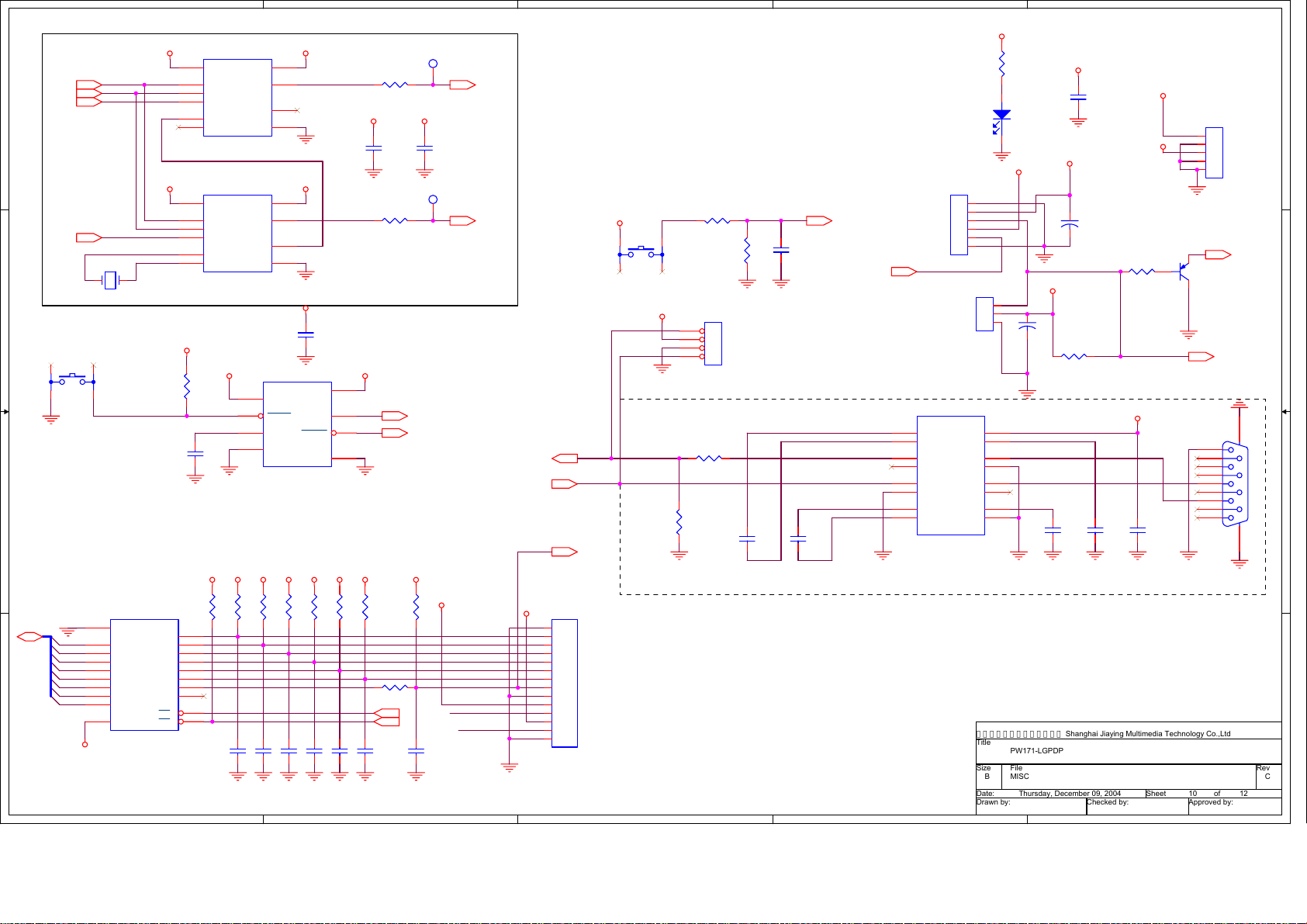

上海家影多媒体技术有限公司

Title

Size File Rev

Date: Sheet

Drawn by: Checked by: Approved by:

1

V33

R98

510

D19

LED RED

+5VIN

3

2

1

161

23

89

14

7

6

15

PW171-LGPDP

MISC C

B

VCC

C232

0.1uF

+5V

C241

4.7uF

C236

0.1uF

R389

1K

VCC

C237

0.1uF

IR

+5V

C242

4.7uF

R108

20K

MVPMC1M

MRXD

MTXD

MVM

C235

0.1uF

Shanghai Jiaying Multimedia Technology Co.,Ltd

+5VIN

+5V

1

1

FROM PDP

Q6

3906

3 2

10 12Thursday, December 09, 2004

J16

1

2

3

4

5

CON5

IR

5

9

4

8

3

7

2

6

1

of

IRRCVR1

1011

J7

DB9_V

Page 25

5

MA0

C129

0.1uF

C147

0.1uF

V33N

V33N

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

DQM0

CLK_M

MWECASRASMCS-

VCC

C112

C127

0.1uF

C144

0.1uF

0.1uF

C128

0.1uF

C145

0.1uF

C146

0.1uF

V33N

C124

D D

0.1uF

V33N

C140

0.1uF

C141

0.1uF

C123

0.1uF

C142

0.1uF

C125

0.1uF

C126

0.1uF

C143

0.1uF

4

U12

21

A0

DQ0

22

A1

DQ1

23

A2

DQ2

24

A3

DQ3

27

DQ4

A4

28

DQ5

A5

29

DQ6

A6

30

DQ7

A7

31

DQ8

A8

32

DQ9

A9

20

DQ10

A10

DQ11

19

DQ12

BA

DQ13

14

DQ14

LDQM

36

DQ15

UDQM

35

NC

CLK

34

NC

CKE

15

WE

16

CAS

17

RAS

18

CS

1

VDD

VSS

25

VDD

VSS

7

VDDQ

VSSQ

13

VDDQ

VSSQ

38

VDDQ

VSSQ

44 4

VDDQ VSSQ

HY57V161610D-7

MD0

2

MD1

3

MD2

5

MD3

6

MD4

8

MD5

9

MD6

11

MD7

12

MD8

39

MD9 MD25

40

MD10

42

MD11

43

MD12

45

MD13

46

MD14

48

MD15

49

33

37

26

50

47

41

10

V33N

V33N

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

DQM1

CLK_M

MWECAS-

RAS-

MCS-

MA10

U13

21

A0

22

A1

23

A2

24

A3

27

A4

28

A5

29

A6

30

A7

31

A8

32

A9

20

DQ10

A10

DQ11

19

DQ12

BA

DQ13

14

DQ14

LDQM

36

DQ15

UDQM

35

CLK

34

CKE

15

WE

16

CAS

17

RAS

18

CS

1

VDD

25

VDD

7

VDDQ

VSSQ

13

VDDQ

VSSQ

38

VDDQ

VSSQ

44 4

VDDQ VSSQ

HY57V161610D-7

3

MD16

2

DQ0

MD17

3

DQ1

MD18

5

DQ2

MD19

6

DQ3

MD20

8

DQ4

MD21

9

DQ5

MD22

11

DQ6

MD23

12

DQ7

MD24

39

DQ8

40

DQ9

MD26

42

MD27

43

MD28

45

MD29

46

MD30

48

MD31

49

33

NC

37

NC

26

VSS

50

VSS

47

41

10

V33N

V33N

C113

0.1uF

X7R

0603

C130

0.1uF

X7R

0603

C114

0.1uF

X7R

0603

C131

0.1uF

X7R

0603

C115

0.1uF

X7R

0603

C132

0.1uF

X7R

0603

C116

0.1uF

X7R

0603

C133

0.1uF

X7R

0603

2

C120

0.1uF

X7R

0603

C134

0.1uF

X7R

0603

C121

0.1uF

X7R

0603

C135

0.1uF

X7R

0603

C122

0.1uF

X7R

0603

C136

0.1uF

X7R

0603

C117

0.1uF

X7R

0603

C137

0.1uF

X7R

0603

C118

0.1uF

X7R

0603

C138

0.1uF

X7R

0603

C119

0.1uF

X7R

0603

C139

0.1uF

X7R

0603

1

MD7

MD6

MD3

MD5

MD8

MD1

MD4

MD2

MD0

U15

NV320XO

C166

22pF

171

172

173

174

175

176

178

179

180

181

183

184

185

186

187

188

189

190

191

192

193

194

195

196

159

163

164

165

197

198

199

200

201

202

203

24

27

167

168

169

204

118

119

116

115

34

35

107

114

113

111

110

132

133

NV320

V33N

9865421

Y0

DQ0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

U0

U1

U2

U3

U4

U5

U6

U7

V0

V1

V2

V3

V4

V5

V6

V7

DVDLLC

DVDB

DVDHS

DVDVS

ODD

VS

HS

HREF

CREF

LLC

HRC

LLAD2

HRA

CLV

HREFO

LLA

RESET

CSA0

CSA1

I2C3W

SCS

SDA

SCL

TEST

RFLOCK

APLLF

OEQ

P60

XI

XO

VCCIO_1

31119314048618393

VY[7:0]

C C

VUV[7:0]

VUV0

VUV1

VUV2

VUV3

VUV4

VUV5

VUV6

VUV7

VVVS

VVHS

VVCLK

B B

RESETn

SDA

SCL

NDSP_EN

V33N

R64

100

NO STUFF

R65

0

A A

RP28

6

7

6

7

RP29 47R

NV320XI

C165

22pF

47R

45

3

2

18

45

3

2

18

10.000MHZ

HC-49/SD

R66 2M

5

Y1

VY0

VY1

VY2

VY3

VY4

VY5

VY6

VY7

LLC320

DQ1

DQ2

VCCIO_2

VCCIO_3

DQ3

DQ4

DQ5

DQ6

VCCIO_4

VCCIO_5

VCCIO_6

VCCIO_7

V33N

MD9

2082018171614131210

DQ7

DQ8

VCCIO_8

VCCIO_9

MD17

MD15

MD14

MD12

MD11

MD18

MD13

MD16

MD10

147

146

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

DQ16

DQ17

VCCIO_10

VCCIO_11

VCCIO_12

VCCIO_13

VCCIO_14

VCCIO_15

VCCIO_16

VCCIO_17

104

112

121

130

144

153

162

1702885

L2710uH

MD26

MD24

MD21

MD22

MD20

MD19

145

DQ18

VCC_CORE_1

MD27

MD23

MD25

143

142

141

140

138

158

156

155

DQ19

DQ20

DQ21

DQ22

DQ23

DQ24

DQ25

DQ26

VCC_CORE_2

VCC_CORE_3

VCC_CORE_4

VCC_PLL1

VCC_PLL2

VCC_PLL3

131

182

102

206

160

VCC320P

C162

C161

0.1uF

+

X7R

10uF

0603

4

MD29

MD30

MD28

154

152

151

150

DQ27

DQ28

DQ29

GND_PLL1

GND_PLL2

GND_PLL3

101

205

161

C163

0.1uF

X7R

0603

MA2

MD31

MA1

MA0

149

124

123

A0A1A2A3A4A5A6A7A8

DQ30

DQ31

GND1

GND2

GND3

GND4

71523364453798998

C164

0.1uF

X7R

0603

MA3

MA4

122

12033323029

GND5

GND6

GND7

MA6

MA5

GND8

MA10

MA8

MA9

MA7

1252612721137

A9

GND9

GND10

GND11

GND12

108

117

126

139

MCS-

MWE-

CAS-

RAS-

CLK_M

DQM1

DQM0

136

135

129

128

22

72

YQ0

CS

WE

A10

CAS

DQM0

DQM1

GND13

GND14

GND15

GND16

GND17

GND_CORE1

GND_CORE2

148

157

166

2072578

V33N

134

RAS

GND_CORE3

GND_CORE4

177

CLK

PCLK

ADVDD

ADGND

COMP

DAC-VCC

DAC-GND

RSET

VREFOUT

VREFIN

RED-VDD

RED-GND

GRN-VDD

GRN-GND

BLU-VDD

BLU-GND

67

YQ1

66

YQ2

60

YQ3

59

YQ4

52

YQ5

49

YQ6

47

YQ7

46

YQ8

45

YQ9

91

UQ0

90

UQ1

88

UQ2

87

UQ3

86

UQ4

84

UQ5

82

UQ6

81

UQ7

80

UQ8

73

UQ9

106

VQ0

105

VQ1

103

VQ2

100

VQ3

99

VQ4

97

VQ5

96

VQ6

95

VQ7

94

VQ8

92

VQ9

37

41

VSQ

38

HSQ

39

HVQ

42

VBQ

109

DVQ

51

50

68

77

75

43

74

76

56

YA

57

58

63

BYA

64

65

69

RYA

70

71

L2810uH

C156

+

10uF

GRN_Y0

GRN_Y1

GRN_Y2

GRN_Y3

GRN_Y4

GRN_Y5

GRN_Y6

GRN_Y7

BLU_Cb0

BLU_Cb1

BLU_Cb2

BLU_Cb3

BLU_Cb4

BLU_Cb5

BLU_Cb6

BLU_Cb7

RED_Cr0

RED_Cr1

RED_Cr2

RED_Cr3

RED_Cr4

RED_Cr5

RED_Cr6

RED_Cr7

COMP320

RSET320

+

10uF

C157

0.1uF

X7R

0603

REF320

C154

VCC320A

RP26

6

7

7

6

RP27 47R

RP30 47R

6

7

6

7

RP31 47R

RP32 47R

1 8

2

3

4 5

1 8

2

3

4 5

RP33 47R

R62 0

V33N

R63 100

C155

0.1uF

X7R

0603

C158

0.1uF

X7R

0603

VG[7:0]

47R

VG0

45

VG1

3

VG2

2

VG3

18

VG4

18

VG5

2

VG6

3

VG7

45

VB[7:0]

VB0

45

VB1

3

VB2

2

VB3

18

VB4

45

VB5

3

VB6

2

VB7

18

VR[7:0]

VR0

VR1

7

VR2

6

VR3

VR4

TPVCK

VR5

7

6

C159

0.1uF

X7R

0603

TPVS

VR6

VR7

C152

C153

+

0.1uF

1uF

X7R

0603

C160

0.1uF

X7R

0603

TPHS

VG[7:0]

VB[7:0]

VR[7:0]

VCLK

VVS

VHS

VPEN

VCC

C149

+

22uF

C150

0.1uF

U14

LM2937_TO263

1

VI

VO

GND

2

Main (Video)

3

2

V33N

3

C148

+

C151

+

22uF

22uF

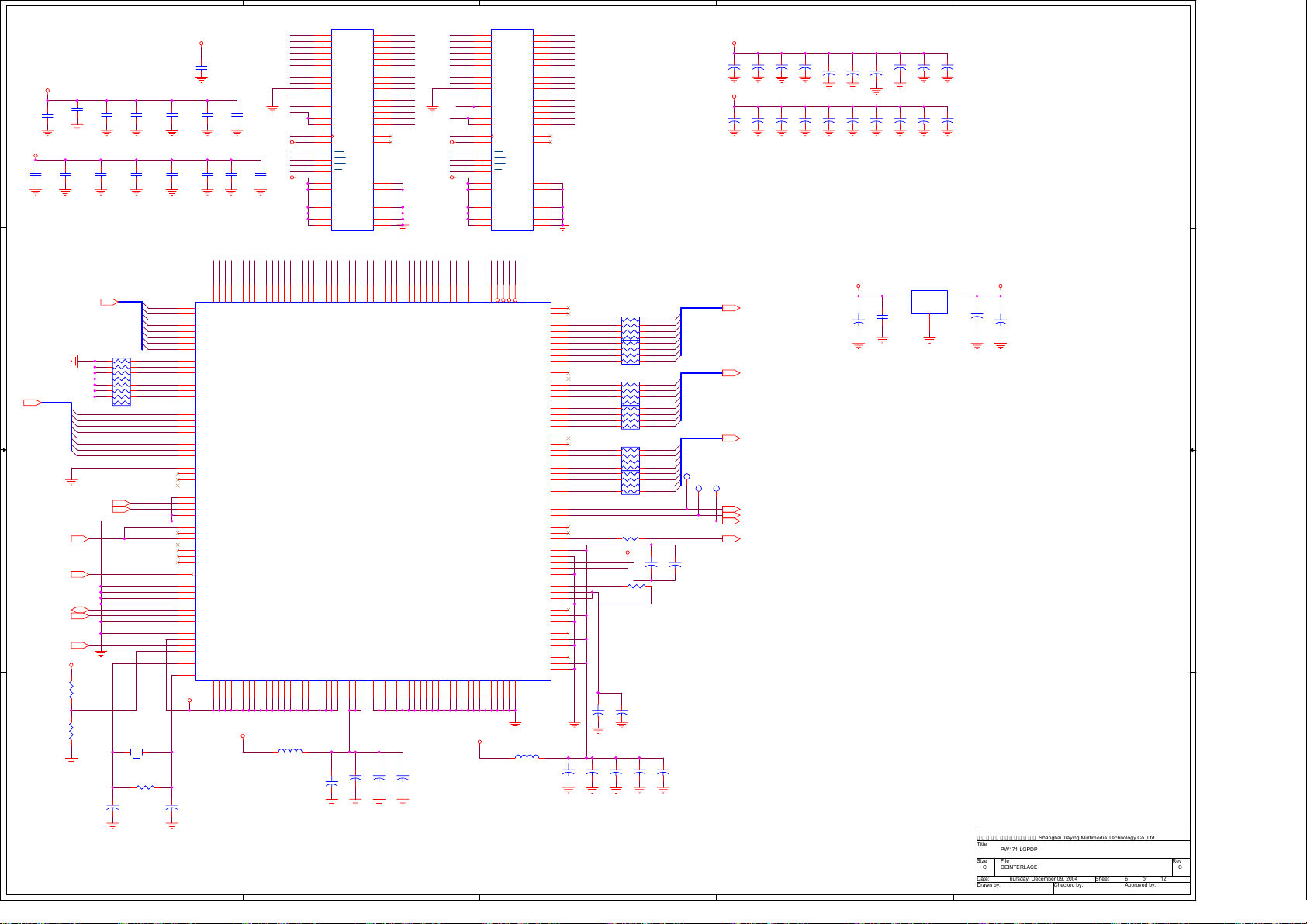

上海家影多媒体技术有限公司

Title

Size File Rev

C

Date: Sheet

Drawn by: Checked by: Approved by:

Shanghai Jiaying Multimedia Technology Co.,Ltd

PW171-LGPDP

DEINTERLACE C

1

612Thursday, December 09, 2004

of

Page 26

5

4

3

2

1

VCC

U27

V25

LM317S

VOVI

C253

0.1uF

12

12

C250

+

22uF

+

C251

0.1uF

ADJ

1234

TAB

D D

R126

510

C252

22uF

C254

1000uF-16V

V25ADJ

R129

510

C C

+5VIN

VCC

12

+

C259

C261

0.1uF

220uF-16V

C262

1000pF

VCC V33

U29 LM3940IS-3.3

23

VOVI

B B

C267

0.1uF

ADJ

1

12

C268

+

22uF

C269

0.1uF

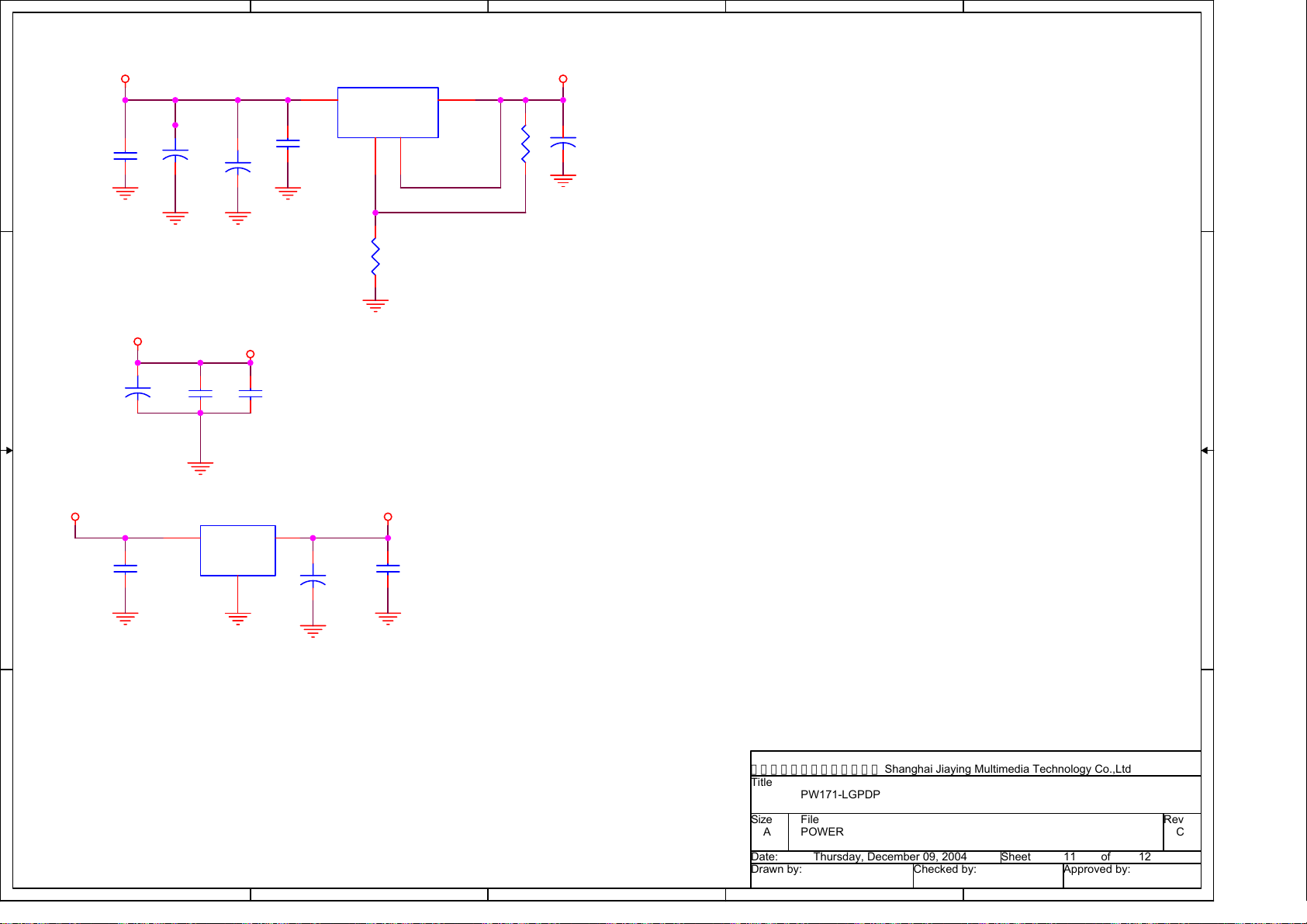

上海家影多媒体技术有限公司

A A

Title

PW171-LGPDP

Shanghai Jiaying Multimedia Technology Co.,Ltd

Size File Rev

POWER C

A

Main (Video)

Date: Sheet

11 12Thursday, December 09, 2004

of

Drawn by: Checked by: Approved by:

5

4

3

2

1

Page 27

5

GFBK

GCLK

GPEN

GVS

GHS

GRE[7:0]

D D

GGE[7:0]

GBE[7:0]

C C

GRO[7:0]

GGO[7:0]

GBO[7:0]

B B

A25C4C7

VDD2

VDD3

GND1

GND2

A1

A17

A18

VDD4

GND3

C10

A19

VDD5

GND4

C17

B19

VDD6

GND5

V25

C18

VDD7

GND6

B20

C19

B24D4D7

V25

A20

VDD1

A A

L24

GCLK

K26

GPEN

L25

GVS

J26

GHS

R82NS

K25

GSOG

L26

GFIELD

L23

GRE0

GRE1

GRE2

GRE3

GRE4

GRE5

GRE6

GRE7

GGE0

GGE1

GGE2

GGE3

GGE4

GGE5

GGE6

GGE7

GBE0

GBE1

GBE2

GBE3

GBE4

GBE5

GBE6

GBE7

GRO0

GRO1

GRO2

GRO3

GRO4

GRO5

GRO6

GRO7

GGO0

GGO1

GGO2

GGO3

GGO4

GGO5

GGO6

GGO7

GBO0

GBO1

GBO2

GBO3

GBO4

GBO5

GBO6

GBO7

L29 FB_11_OHM_500MA

C20

D18

D19G3G24H4K3

VDD8

VDD9

VDD10

GND7

GND8

GND9

D10

PLLCLK

U26

GRE0

V24

GRE1

V23

GRE2

V25

GRE3

V26

GRE4

W25

GRE5

W24

GRE6

W23

GRE7

H23

GGE0

G26

GGE1

H25

GGE2

P23

GGE3

P24

GGE4

P25

GGE5

P26

GGE6

R23

GGE7

B25

GBE0

A26

GBE1

D24

GBE2

E23

GBE3

C25

GBE4

B26

GBE5

C26

GBE6

E24

GBE7

R24

GRO0

R25

GRO1

R26

GRO2

T23

GRO3

T24

GRO4

T25

GRO5

T26

GRO6

U25

GRO7

F23

GGO0

D25

GGO1

D26

GGO2

F24

GGO3

E25

GGO4

E26

GGO5

F25

GGO6

F26

GGO7

D21

GBO0

B22

GBO1

C22

GBO2

A23

GBO3

B23

GBO4

D22

GBO5

C23

GBO6

A24

GBO7

K24

N26U3U24

VDD11

VDD12

VDD13

VDD14

VDD15

VDD16

VDD17

VDD18

GND10

GND11

GND12

GND13

GND14

GND15

GND16

GND17

D13

D17

D20

D23G4G23

H24J2K4

5

PW365

Graphics Port

V25P

Y24

AA2

AC19

VDD20

VDD21

VDD22

GND18

GND19

GND20

GND21

K23M2M23

GCLKOUT

GHSFOUT

GADCCLK

U18A

AD4

GFBK

GREF

GBLKSPL

GCOAST

AD7

AD10

VDD23

VDD24

VDD25

GND22

GND23

GND24

N23

N25P4U4

M25

H26

J25

J23

J24

M24

M26

VCLK

VPEN

VVS

VHS

VFIELD

VR[7:0]

VG[7:0]

VB[7:0]

AD17

AD19

AD20

AD25

AE21

AF14

VDD26

VDD27

VDD28

VDD29

VDD30

VDD31

U18EPW365

GND25

GND26

GND27

GND28

GND29

GND30

U23

W26Y1D3

AF18

VDD32

GND31

Y23

AF19

AF26C3C13

VDD33

VDD34

GND32

GND33

AA4

AB1

AB25

GND34

AC4

GBLKSPL

GCOAST

GND35

AC7

4

PA3

PA4

3WSCL

3WSDA

3WSLE

B16

VCLK

B18

VPEN

A21

VLAV

B21

VVS

A22

VHS

C21

VFIELD

A9

VR0

B10

VR1

A10

VR2

D11

VR3

C11

VR4

B11

VR5

A11

VR6

D12

VR7

C12

VG0

B12

VG1

A12

VG2

B13

VG3

A13

VG4

D14

VG5

C14

VG6

B14

VG7

A14

VB0

D15

VB1

C15

VB2

B15

VB3

A15

VB4

D16

VB5

C16

VB6

A16