Page 1

DVD PLAYER

Model:

DVP3470S/SK

DVP3570S/SK/DS/DSK/DPSK

SERVICE MANUAL

www.akai.ru

Page 2

CONTENTS

1. PRECAUTIONS-------------------------------------------------------------------------------------------------------------------------1

1-1 SAFETY PRECAUTIONS-------------------------------------------------------------------------------------------------------------1

1-2 SERVICING PRECAUTIONS ---------------------------------------------------------------------------------------------------------2

1-2-1 General Serving Precautions------------------------------------------------------------------------------------------------2

1-2-2 Insulation Checking Procedure---------------------------------------------------------------------------------------------3

1-3 ESD PRECAUTIONS-----------------------------------------------------------------------------------------------------------------3

2. REFERENCE INFORMATION------------------------------------------------------------------------------------------------------4

2-1 COMPONENT DESCRIPTIONS ------------------------------------------------------------------------------------------------------4

2-1-1 DVD ATAPI Loader ---------------------------------------------------------------------------------------------------------4

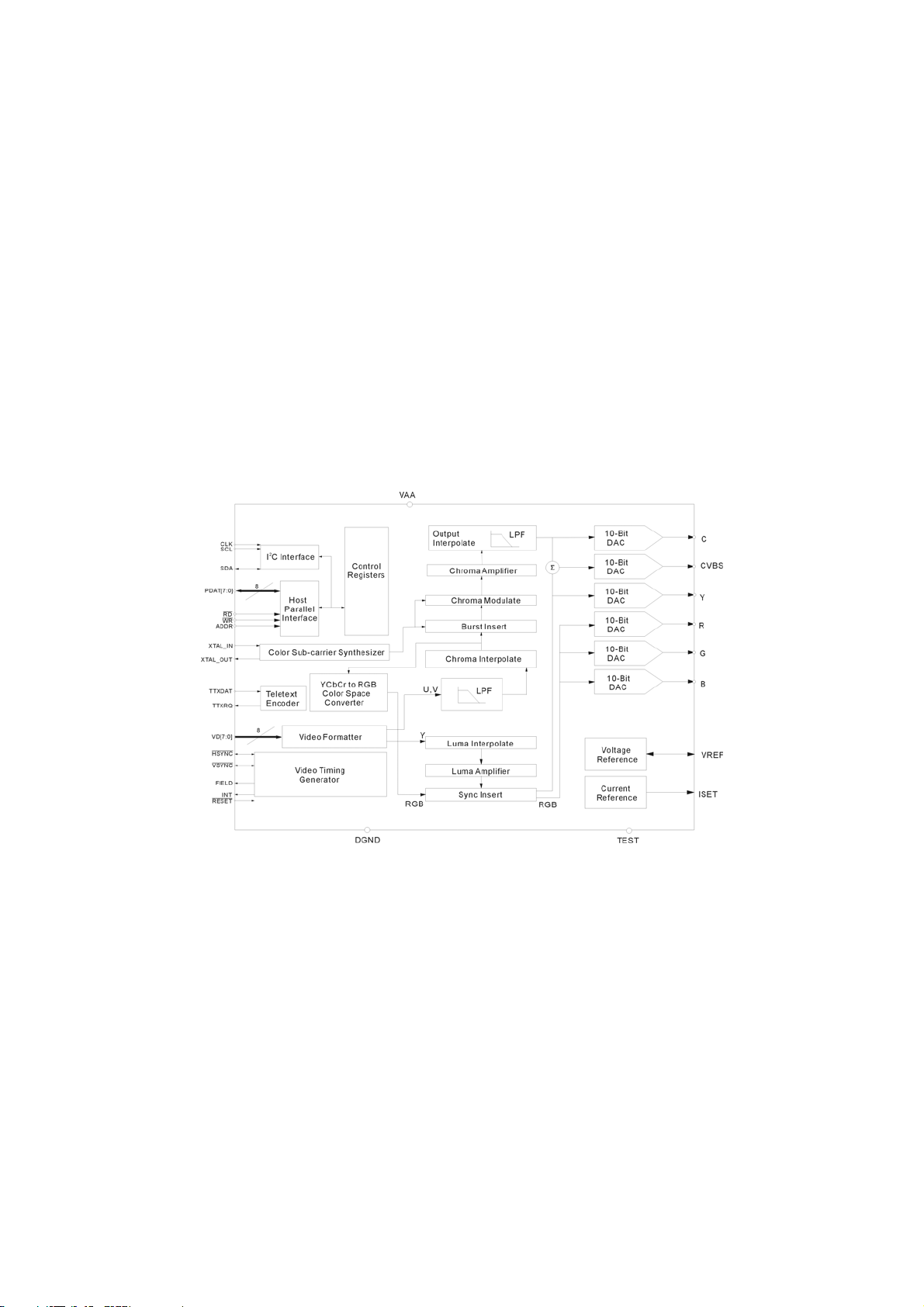

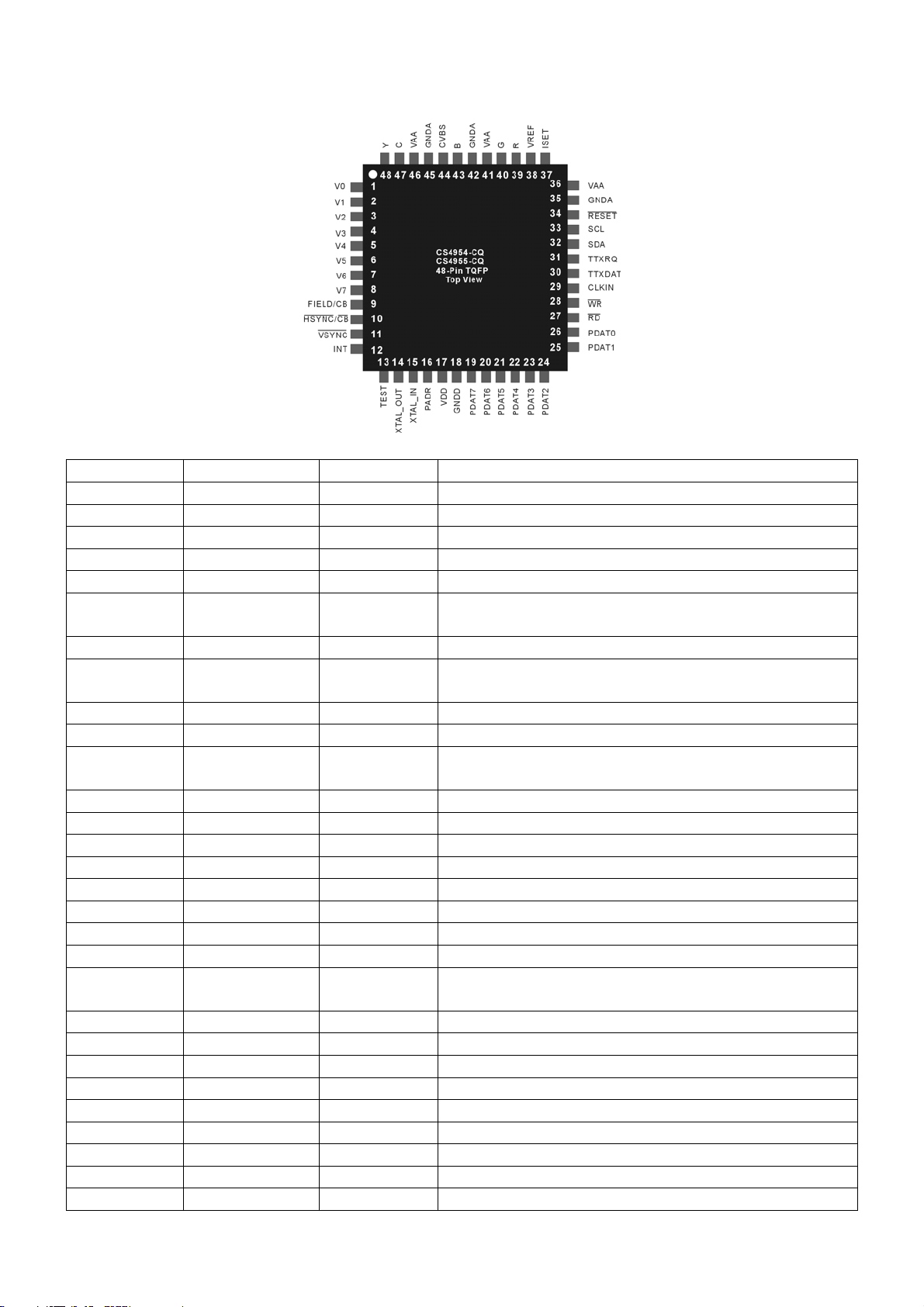

2-1-2 NTSC/PAL Digital Video Encoder (CS4955) ----------------------------------------------------------------------------6

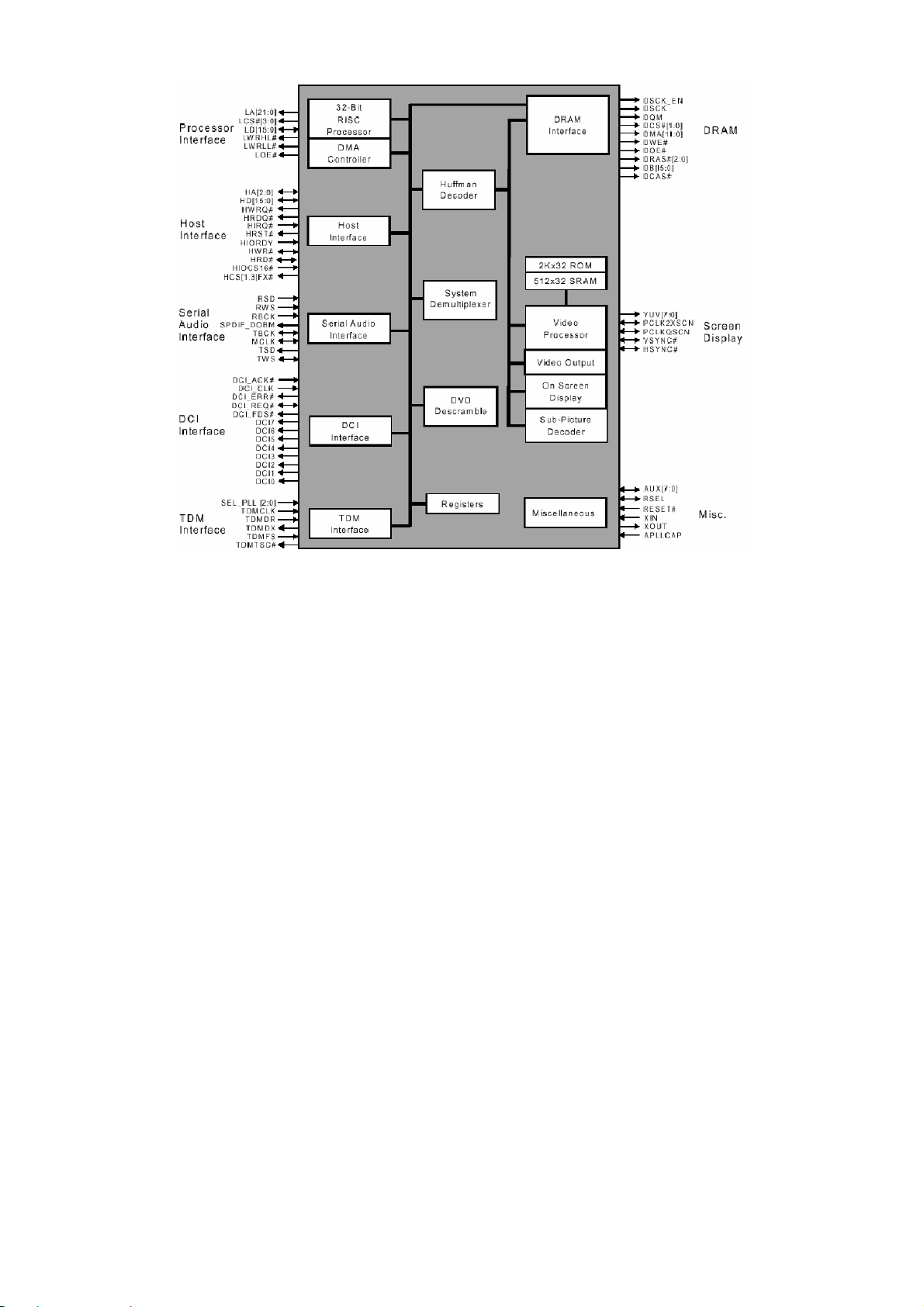

2-1-3 DVD Processor Chip (MT1369AE) ---------------------------------------------------------------------------------------8

2-1-4 8-Pin, 24-Bit, 96kHz Stereo D/A CONVERTER (WM8720)-------------------------------------------------------- 17

2-1-5 Serial EEPROM, 2K (256 x 8) (24C16,ST-S08)----------------------------------------------------------------------- 20

2-1-6 8-Megabit (512 x 8) FLASH RAM (29F800)-------------------------------------------------------------------------- 20

2-1-7 512K X 16 Bit X 2 Banks Synchronous DRAM (A43L0616) ------------------------------------------------------- 23

3. PRODUCT SPECIFICATIONS ---------------------------------------------------------------------------------------------------- 26

4. OPERATING INSTRUCTIONS ------------------------------------------ ОШИБКА! ЗАКЛАДКА НЕ ОПРЕДЕЛЕНА.

4-1 BASIC CONNECTIONS -------------------------------------------------------------- ОШИБКА! ЗАКЛАДКА НЕ ОПРЕДЕЛЕНА.

4-2 Selecting Video Mode------------------------------------------------------------------------------------------------------24

4-2 Selecting the desired DVD Menu item---------------------------------------------------------------------------------- 25

4-4 Selecting the desired MP3 folder----------------------------------------------------------------------------------------- 26

4-5 Selecting the desired MP3 title------------------------------------------------------------------------------------------- 27

4-6 Searching---------------------------------------------------------------------------------------------------------------------28

4-7 Resume Play-----------------------------------------------------------------------------------------------------------------29

4-10 Selecting Subtitle Language----------------------------------------------------------------------------------------------31

4-11 Selecting Angle----------------------------------------------------------------------------------------------------------- -32

5. DISASSEMBLY AND REASS EM B LY------------------------------------------------------------------------------------------- 27

6. TROUBLESHOOTING ------------------------------------------------------------------------------------------------------------- 28

7. ELECTRICAL PART LIST --------------------------------------------------------------------------------------------------------- 29

8. BLOCK DIAGRAM----------------------------------------------------------------------------------------------------------------- 35

9. CIRCUIT DIAGRAMS-------------------------------------------------------------------------------------------------------------- 36

10. WIRING DIAGRAM--------------------------------------------------------------------------------------------------------------- 44

Page 3

1-1 Safety Precautions

1) Before returning an instrument to the customer, always

make a safety check of the entire instrument, including, but

not limited to, the following items:

(1) Be sure that no built-in protective devices are defective

or have been defeated during servicing.

(1) Protective shields are provided to protect both the

technician and the customer. Correctly replace all

missing protective shields, including any remove for

servicing convenience.

(2) When reinstalling the chassis and/or other

assembly in the cabinet, be sure to put back in place

all protective devices, including, but not limited to,

nonmetallic control knobs, insulating fish papers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate

this instrument or permit it to be operated without all

protective devices correctly installed and functioning.

(2) Be sure that there are no cabinet opening through which

adults or children might be able to insert their fingers

and contact a hazardous voltage. Such openings

include, but are not limited to, excessively wide

cabinet ventilation slots, and an improperly fitted

and/or incorrectly secured cabinet back cover.

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an

isolation transformer during this test.) Use a leakage

current tester or a metering system that complies with

American National Standards institute (ANSI) C101.1

Leakage.

Current for Appliances and underwriters Laboratories

(UL) 1270 (40.7). With the instrument’s AC switch

first in the ON position and then in the OFF position,

measure from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal cabinets,

screwheads, metallic overlays, control shafts, etc.),

especially and exposed metal parts that offer an

electrical return path to the chassis.

Any current measured must not exceed 0.5mA.

Reverse the instrument power cord plug in the outlet

and repeat the test.

AC Leakage Test

Any measurements not within the limits specified

herein indicate a potential shock hazard that must be

eliminated before returning the instrument to the

customer.

(4) Insulation Resistance Test Cold Check-(1) Unplug the

power supply cord and connect a jumper wore

between the two prongs of the plug. (2) Turn on the

power switch of the instrument. (3) Measure the

resistance with an ohmmeter between the jumpered

AC plug and all exposed metallic cabinet parts on the

instrument, such as screwheads, antenna, control

shafts, handle brackets, etc. When an exposed

metallic part has a return path to the chassis, the

reading should be between 1 and 5.2 megohm. When

there is no return path to the chassis, the reading must

be infinite. If the reading is not within the limits

specified, there is the possibility of a shock hazard,

and the instrument must be re-pared and rechecked

before it is returned to the customer.

Insulation Resistance Test

2) Read and comply with all caution and safety related

1

Page 4

notes non or inside the cabinet, or on the chassis.

3) Design Alteration Warning-Do not alter of add to the

mechanical or electrical design of this instrument.

Design alterations and additions, including but not

limited to, circuit modifications and the addition of

items such as auxiliary audio output connections,

might alter the safety characteristics of this instrument

and create a hazard to the user. Any design alterations

or additions will make you, the service, responsible

for personal injury or property damage resulting there

from.

4) Observe original lead dress. Take extra care to assure

correct lead dress in the following areas:

(1) near sharp edges, (2) near thermally hot parts (be

sure that leads and components do not touch

thermally hot parts), (3) the AC supply, (4) high

voltage, and (5) antenna wiring. Always inspect in all

areas for pinched, out-of-place, or frayed wiring. Do

not change spacing between a component and the

printed-circuit board, Check the AC power cord for

damage.

5) Components, parts, and/or wiring that appear to have

overheated or that are otherwise damaged should be

replaced with components, parts and/or wiring that

meet original specifications. Additionally determine

the cause of overheating and/or damage and, if

necessary, take corrective action to remove and

potential safety hazard.

6) Product Safety Notice-Some electrical and mechanical

parts have special safety-related characteristics which

are often not evident from visual inspection, nor can

the protection they give necessarily be obtained by

replacing them with components rated for higher

voltage, wattage, etc. Parts that have special safety

characteristics are identified by shading, an (

(

) on schematics and parts lists. Use of a substitute

replacement that does not have the same safety

characteristics as the recommended replacement part

might created shock, fire and/or other hazards.

Product safety is under review continuously and new

instructions are issued whenever appropriate.

) or a

1-2 Servicing Precautions

CAUTION: Before servicing Instruments covered by this

service manual and its supplements, read and follow the

Safety Precautions section of this manual.

Note: If unforeseen circument create conflict between the

following servicing precautions and any of the safety

precautions, always follow the safety precautions.

Remember; Safety First

1-2-1 General Serving Precautions

(1) a. Always unplug the instrument’s AC power cord from

the AC power source before (1) removing or

reinstalling any component, circuit board, module or

any other instrument assembly. (2) disconnecting

any instrument electrical plug or other electrical

connection. (3) connecting a test substitute in

parallel with an electrolytic capacitor in the

instrument.

b. Do not defeat any plug/socket B+ voltage interlocks

with which instruments covered by this service

manual might be equipped.

c. Do not apply AC power to this instrument and/or any

of its electrical assemblies unless all solid-state

device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting th e

test instrument positive lead. Always remove the test

instrument ground lead last.

Note: Refer to the Safety Precautions section ground

lead last.

(2) The service precautions are indicated or printed on the

cabinet, chassis or components. When servicing,

follow the printed or indicated service precautions

and service materials.

(3) The components used in the unit have a specified flame

resistance and dielectric strength.

When replacing components, use components which

have the same ratings, by (

circuit diagram are important for safety or for the

characteristics of the unit. Always replace them with

the exact replacement components.

(4) An insulation tube or tape is sometimes used and some

components are raised above the printed wiring board

for safety. The internal wiring is sometimes clamped

to prevent contact with heating components. Install

such elements as they were.

(5) After servicing, always check that the removed screws,

components, and wiring have been installed correctly

) or by ( ) in the

2

Page 5

and that the portion around the serviced part has not

been damaged and so on. Further, check the insulation

between the blades of the attachment plus and

accessible conductive parts.

1-2-2 Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and

turn the power ON. Connect the insulation resistance meter

1-3 ESD Precautions

(500V) to the blades of the attachment plug. The insulation

resistance between each blade of the attachment plug and

accessible conductive parts (see note) should be more than

1 Megohm.

Note: Accessible conductive parts include metal panels,

input terminals, earphone jacks, etc.

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid static electricity) devices can

be damaged easily by static electricity.

Such compo9nents commonly are called Electrostatically

Sensitive Devices (ESD). Examples of typical ESD devices

are integrated circuits and some field-effect transistors and

semiconductor chip components. The following techniques

of component damage caused by static electricity.

(1) immediately before handling any semiconductor

components or semiconductor-equipped assembly,

drain off any electrostatic charge on your body by

touching a known earth ground. Alternatively, obtain

and wear a commercially available discharging wrist

strap device, which should be removed for potential

shock reasons prior to applying power to the unit

under test.

(2) after removing an electrical assembly equipped with

ESD devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD device.

(4) Use only an anti-static solder removal devices. Some

solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage

ESD devices.

(5) Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ESD

devices.

(6) Do not remove a replacement ESD device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable

conductive materials).

(7) Immediately before removing the protective materials

from the leads of a replacement ES device touch the

protective material to the chassis or circuit assembly

into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handling unpackaged

replacement ESD devices. (Otherwise harmless

motion such as the brushing together of your clothes

fabric or the lifting of your foot from a carpeted floor

can generate static electricity sufficient to damage an

ESD device).

3

Page 6

2. Reference Information

2-1 Component Descriptions

2-1-1 DVD SANYO HD60 PUH

Connector Pin Definition

I/F Signals I/O Pin #

F- 1

F+ 2

T+ 3

T- 4

C 5

D 6

CD/DVD 7

RF 8

A 9

B 10

F 11

GND-PD 12

VC 13

VCC 14

E 15

NC 16

VR-CD 17

VR-DVD 18

LD-CD 19

MD 20

HFM 21

NC 22

LD-DVD 23

GND-LD 24

4

Page 7

4. Block Diagram

Disc

Disc motor unit

Spindle

Motor

BA6208

Spindle Motor Drive

Focus

Coil

Laser

pickup

Track

Coil

BA5954FP

4ch motor Drive

MT1369

(RF AMP)

Laser Driver

Equalizer

Error Gen

Sied

Motor

Loading

Motor

MT1369

(Decode/Servo)

ATAPI

Buffer Manager

Demodulator

Error Correction

PLI

Focus & Tracking

Loading

AuDdio D/A

WM8720

SDRAM

1*16MHzX2

Video D/A

CS4955

1/F

Conn

(frant pannel)

80c52

System Controller

Spindle motor single for CLV

Fiash

Memory

8Mbit

5

Page 8

2-1-2 NTSC/PAL Digital Video Encoder (CS4955)

FEATURES

• Six DACs providing simultaneous composite, S-video,

and RGB or Component YUV outputs

• Programmable DAC output currents for low

imped-ance(37.5Ω) and high impedance(150

Ω)loads.

• Multi-standard support for NTSC-M, NTSC-JAPAN,

PAL (B, D, G, H, I, M, N, Combination N)

• ITU R.BT656 input mode supporting EAV/SAV codes

and CCIR601 Master/Slave input modes

• Porgrammable HSYNC and VSYNC timing

• Multistandard Teletext(Europe, NABTS, WST)

support

• VBI encoding support

• Wide-Screen Signaling (WSS) support,

EIA-JCPX1204)

• NTSC closed caption encoder with interrupt

• CS4955 supports Macrovision copy protection

Version 7

2

• Host interface configurable for parallel or I

C

compatible operation

• On-chip voltage reference generator

• +.3.3V or +5V operation, CMOS, low-power modes,

tri-state DACs

Ordering Information

CS4955-CQ 48-pin TQFP

DESCRIPTION

The CS4955 provides full conversion from digital video formats YcbCr or YUV into NTSC and PAL Composite,

Y/C (S-video) and RGB, or YUV analog video. Input formats can be 27MHz 8-bit YUV, 8-bit YcbCr, or

ITUR.BT656 with support for EAV/SAV codes. Video output can be formatted to be compatible with NTSC-M,

NTSC-J, PAL-B, D, G, H, I, M, N, and Combination N systems. Closed Caption is supported in NTSC. Teletext is

supported for NTSC and PAL.

Six 10-bit DACs provide two channels for an S-Video output port, one or two composite video outputs, and three

RGB or YUV outputs. Two-times oversampling reduces the output filter requirements and guarantees no DAC-ralated

modulation components within the specified bandwidth of any of the supported video standards.

Parallel or high-speed I

parallel interface doubles as a general purpose I/O port when the CS4954 is in I

board area.

6

2

C compatible conpatible control interfaces are provided for flexibility in system design. The

2

C mode to help conserve valuable

Page 9

PIN DESCRIPTIONS

Pin Name Pin Number Type Description

V[7:0] 8,7,6,5,4,3,2,1 IN Digital video data inputs

CLK 29 IN 27MHz input clock

PADDR 16 IN Address enable line

XTAL_IN 15 IN Subcarrier crystal input

XTAL_OUT 14 OUT Subcarrier crystal input

HSYNC/CB 10 I/O Active low horizontal sync, or composite blank

signal

VSYNC 11 I/O Active low vertical sync

FIELD/CB 9 OUT Video field ID. Selectable polarity or composite

blank

RD 27 IN Host parallel port read strobe, active low

WR 28 IN Host parallel port write strobe, active low

PDAT[7:0] 19,20,21,22,23,

I/O Host parallel port/general purpose I/O

24,25,26

SDA 32 I/O I2C data

SCL 33 IN I2C clock input

CVBS 44 CURRENT Composite video output

Y 48 CURRENT Luminance analog output

C 47 CURRENT Chrominance analog output

R 39 CURRENT Red analog output

G 40 CURRENT Green analog output

B 43 CURRENT Blue analog output

VREF 38 I/O Internal voltage reference output or external

reference input

ISET 37 CURRENT DAC current set

TTXDAT 30 IN Teletext data input

TTXRQ 31 OUT Teletext request output

INT 12 OUT Interrupt output, active high

RESET 34 IN Active low master RESET

TEST 13 IN TEST pin. Ground for normal operation

VAA 36,41,46 PS +5V or +3.3V supply(must be same as VDD)

GNDD 18 PS Ground

VDD 17 PS +5V or 3.3V supply (must be same as VAA)

7

Page 10

GNDA 35,42,45 PS Ground

2-1-3 DVD Processor Chip (MTK1369AE)

* Features

z Single-chip DVD video decoder in a 208-pin PQFP package

z Supports MPEG-1 system and MPEG-2 program streams

z Programmable multimedia processor architecture

z Compatible with Audio CD, Video CD, VCD 3.0, and Super Video CD (SVCD)

z DVD Navigation 1

z Built-in content Scrambling System (CSS)

- Audio

z Built-in Karaoke key-shift functio n

z DolbyTM Digital 2-channel down mix audio output for DolbyTM

z Dolby Pro Logic

z Linear PCM streams for24 bit / 96KHz

z Concurrent S/PDIF out and 2-channel audio output

z Sensaura Dolby Digital Virtual Surround

z DTS Digital Surround 2-channel down mix stereo output

z S/PDIF output for encoded AC-3, DTS Digital output or Linear PCM

- Peripheral

z Glueless interface to DVD loaders (ATAPI or A/V bus I/F)

z Bi-directional 12C audio interface

z 8 general-purpose auxiliary ports

z Single 27MHz clock input

- Smart Technology

z SmartZoomTM for motion zoom & pan

z SmartZoomTM for NTSC to PAL conversion and vice versa

SmartZoomTM for video error concealment

z

* Functional Description

8

Page 11

* Pinout Diagram

9

Page 12

10

Page 13

PIN DESCRIPTON

PIN Symbol Type Description

1 IREF Analog Input

2 PLLVSS Ground Ground for data PLL and related analog circuitry

3 LPIOP Analog output Positive output of the low pass filter

4 LPION Analog output Negative output of the low pass filter

5 LPFON Analog output Negative output of loop filter amplifiter

6 LPFIP Analog input Positive input of loop filter amplifier

7 LPFIN Analog input Negative input of loop filter amplifier

8 LPFOP Analog output Positive output of loop filter amplifier

9 JITFO Analog output RF jitter meter output

10 JITFN Analog input Negative input of the operation amplifier for RF jigger meter

11 PLLVDD3 Power Power for data PLL and related analog circuitry

12 FOO Analog output Focus servo output. PDM output of focus servo compensator

13 TRO Analog output Tracking servo output.PDM output of tracking servo compensator

14 TROPENPWM Analog outpu

15 PWMOUT2 Analog outpu The general PWM output

16 DVDD2 Power 2.5V power

17 DMO Analog outpu Disk motor control output.PWM output

18 FMO Analog outpu Feed motor control. PWM output

19 FG Inout, pull up Motor Hall sensor input

20 DVSS Ground Ground

21 HIGHA0 Inout, pull up Microcontroller address 8

22 HIGHA1 Inout, pull up Microcontroller address 9

23 HIGHA2 Inout, pull up Microcontroller address 10

24 HIGHA3 Inout, pull up Microcontroller address 11

25 HIGHA4 Inout, pull up Microcontroller address 12

26 HIGHA5 Inout, pull up Microcontroller address 13

27 DVSS Ground Ground

28 HIGHA6 Inout, pull up Microcontroller address 14

29 HIGHA7 Inout, pull up Microcontroller address 15

30 AD7 Inout Microcontroller address/data 7

31 AD6 Inout Microcontroller address/data 6

32 AD5 Inout Microcontroller address/data 5

33 AD4 Inout Microcontroller address/data 4

34 DVDD3 Power 3.3V power

35 AD3 Inout Microcontroller address/data 3

36 AD2 Inout Microcontroller address/data 2

37 AD1 Inout Microcontroller address/data 1

38 AD0 Inout Microcontroller address/data 0

39 IOA0 Inout, pull up Microcontroller address 0/GPIO0

40 IOA1 Inout, pull up Microcontroller address 0/GPIO1

41 DVDD2 Power 2.5V power

42 IOA2 Inout, pull up Microcontroller address 0/GPIO2

43 IOA3 Inout, pull up Microcontroller address 0/GPIO3

44 IOA4 Inout, pull up Microcontroller address 0/GPIO4

45 IOA5 Inout, pull up Microcontroller address 0/GPIO5

46 IOA6 Inout, pull up Microcontroller address 0/GPIO6

47 IOA7 Inout, pull up Microcontroller address 0/GPIO7

48 A16 Outpu Flash address 16

49 A17 Output Flash address 17

50 IOA18 Inout Flash address 18 / GPIO10

51 IOA19 Inout Flash address 19 / GPIO11

52 DMVSS Ground Ground for DRAM clock circuitry

53 DMVDD3 Power Power for DRAM clock circuitry

Current reference input.it generate reference current for data PLL

Connect an external 100K resistor to this pin and PLLVSS.

Tray open output,co nt r ol l ed b y m i croco ntroller.

This is PWM output for TRWMEN

TRWMEN

27Hrw2=0

27hRW2=1 or is digital output for

11

Page 14

PIN Symbol Type Description

54 ALE Inout,pull up Microcontroller address latch enable

55 IOOE# Inout Flash output enab le,active low /GPIO13

56 IOWR# Inout Flash write enable,active low /GPIO17

57 IOCS# Inout,pull up Flash chip select,active low /GPIO18

58 DVSS Ground Ground

59 UP1_2 Inout,pull up Microcontroller port 1-2

60 UP1_3 Inout,pull up Microcontroller port 1-3

61 UP1_4 Inout,pull up Microcontroller port 1-4

62 UP1_5 Inout,pull up Microcontroller port 1-5

63 UP1_6 Inout,pull up Microcontroller port 1-6

64 DVDD3 Power 3.3V power

65 UP1_7 Inout,pull up Microcontroller port 1-7

66 UP3_0 Inout,pull up Microcontroller port 3-0

67 UP3_1 Inout,pull up Microcontroller port 3-1

68 INT0# Inout,pull up Microcontroller in terrupt 0,active low

69 IR Input IR control signal input

70 DVDD2 Power 2.5V power

71 UP1_4 Inout Microcontroller port 3-4

72 UP1_5 Inout Microcontroller port 3-5

73 UWR# Inout,pull up Microcontroller write strobe,active low

74 URD# Inout,pull up Microcontroller read strobe,active low

75 XTALI Input Crystal input,27MHz

76 XTALO Output Crystal output

77 DVSS Ground Ground

78 RD7 Inout DRAM data 7

79 RD6 Inout DRAM data 6

80 RD5 Inout DRAM data 5

81 RD4 Inout DRAM data 4

82 DVDD2 Power 2.5V power

83 RD3 Inout DRAM data 3

84 RD2 Inout DRAM data 2

85 RD1 Inout DRAM data 1

86 RD0 Inout DRAM data 0

87 RWE# Output DRAM write enable,active low

88 CAS# Output DRAM column address strobe,active low

89 RAS# Output DRAM row address strobe,active low

90 RCS# Output DRAM chip select,active low

91 BA0 Output DRAM bank address 0

92 DVDD3 Power 3.3V power

93 RD15 Inout,pull up/down DRAM data 15

94 RD14 Inout,pull up/down DRAM data 14

95 RD13 Inout,pull up/down DRAM data 13

96 RD12 Inout,pull up/down DRAM data 12

97 DVSS Ground Ground

98 RD11 Inout,pull up/down DRAM data 1 1

99 RD10 Inout,pull up/down DRAM data 10

100 RD9 Inout,pull up/down DRAM data 9

101 RD8 Inout,pull up/down DRAM data 8

102 VPVDD3 Power Power for varipitch VCO circuitry

103 VCOCIN Analog input Connect capacitor for compensator loop filter

104 VPVSS Ground Ground for varipitch VCO circuitry

105 DVSS Ground Ground

106 CLK Output DRAM clock

107 CLE Output DRAM clock enable

108 RA11 Output DRAM address bit 11 or audio serial data 3 (channel 7/8)

109 RA9 Output DRAM address 9

110 RA8 Output DRAM address 8

111 DVDD2 Power 2.5V power

112 RA7 Output DRAM address 7

12

Page 15

PIN Symbol Type Description

113 RA6 Output DRAM address 6

114 RA5 Output DRAM address 5

115 RA4 Output DRAM address 4

116 DVSS Ground Ground

117 DQM1 Output Mask for DRAM input/output byte 1

118 DQM0 Output Mask for DRAM input/output byte 0

119 BA1 Output DRAM bank address 0

120 RA10 Output DRAM address 10

121 DVDD2 Power 2.5V power

122 RA0 Output DRAM address 0

123 RA1 Output DRAM address 1

124 RA2 Output DRAM address 2

125 RA3 Output DRAM address 3

126 DVSS Ground Ground

127 RD31 Inout,pull up/down DRAM data 31

128 RD30 Inout,pull up/down DRAM data 30

129 RD30 Inout,pull up/down DRAM data 29

130 RD29 Inout,pull up/down DRAM data 28

131 DVDD3 Power 3.3V power

132 RD27 Inout,pull up/down DRAM data 27

133 RD26 Inout,pull up/down DRAM data 26

134 RD25 Inout,pull up/down DRAM data 25

135 RD24 Inout,pull up/down DRAM data 24

136 DVSS Ground Ground

137 DQM3 Output Mask for DRAM input/output byte 3

138 DQM2 Output Mask for DRAM input/output byte 2

139 RD23 Inout,pull up/down DRAM data 23

140 RD22 Inout,pull up/down DRAM data 22

141 DVDD2 Power 2.5V power

142 RD21 Inout,pull up/down DRAM data 21

143 RD20 Inout,pull up/down DRAM data 20

144 RD19 Inout,pull up/down DRAM data 19

145 RD18 Inout,pull up/down DRAM data 18

146 DVSS Ground Ground

147 RD17 Inout,pull up/down DRAM data 17

148 RD16 Inout,pull up/down DRAM data 16

149 ABCK Output Audio bit clock

150 ALRCK Input,pull down

151 DVDD3 Power 3.3V power

152 ASDATA0 Input,pull down Audio serial data 0 (left/right channel)

153 ASDATA1 Input,pull down Audio serial data 1 (surround left/surround right channel)

154 ASDATA2 Input,pull down Audio serial data 2 (center/LFE channel)

155 ACLK Inout Audio DAC master clock (384/256 audio sample frequency)

156 APVDD3 Power Power for audio clock circuitry

157 APVSS Ground Ground for audio clock circuitry

158 SPDIF Output SPDIF output

159 MC_DAT Input Microphone serial input

160 BLANK# Inout Video blank area, active low / GPIO14

161 VSYN Inout Vertical sync / GPIO16

162 HSYN Inout Horizontal sync / GPIO15

163 DVSS Ground Ground

164 YUVO Output Video data output bit 0

165 YUV1 Output Video data output bit 1

166 YUV2 Output Video data output bit 2

167 YUV3 Output Video data output bit 3

168 YUV4 Output Video data output bit 4

169 DVDD2 Power 2.5V power

170 YUV5 Output Video data output bit 5

171 YUV6 Output Video data output bit 6

(1) Audio left/right channel clock (2)Trap value in power-on reset.

1:use external 373, 0:use internal 373

13

Page 16

PIN Symbol Type Description

172 YUV7 Output Video data output bit 7

173 ICE Input,pull down Microcontroller ICE mode enable

174 PRST Input,pull down Pow e r on reset input, active high

175 DVSS Ground Ground

176 VFO13 Output The 1st, 3rd VFO pulse output of DVD-R AM ID header

177 IDGATE Output DVD-RAM ID header detect signal output

178 DVDD3 Power 3.3V power

179 UDGATE Output DVD-RAM recording data gate signal o ut p ut

180 WOBSI Input Wobble signal input

181 SDATA Output RF serial data input

182 SDEN Output RF serial data latch enable

183 SLCK Output RF serial clock output

184 BDO Input,pull down Flag of defect data status input

185 DVDD3 Power 3.3V power

186 PDMVDD3 Power Power for PDM circuitry

187 PWMVREF Analog input A reference voltage input for PWM circuitry.A typical value of 2.8v

188 PWM2VREF Analog input A reference voltage input for PWM circuitry.A typical value of 1.4v

189 PDMVSS Ground Ground for PDM circuitry

190 ADCVSS Ground Ground for ADC circuitry

191 ADIN Analog input General A/D input

192 RFSUBI Analog input RF subtraction signal input terminal

193 TEZISLV Analog input Tracking error zero crossing low pass input

194 TEI Analog input Tracking error input

195 CSO Analog input Central servo input

196 FEI Analog input Focus error input

197 RFLEVEL Analog input Sub beam add input or RFRP low pass input

198 RFRP_DC Analog input RF ripple detect input

199 RFRP_AC Analog input RF ripple detect input (through AC coupling)

200 RFRPSLV Analog input RFRP slice level input

201 HRFZC Analog input High frequency RF ripple zero crossing

202 ADCVDDS Power Power for ADC circuitry

203 RFDTSLVP Analog output Positive RF data slicer level output

204 SCON Analog output Negative analog slicer current output

205 SCOP Analog output Positive analog slicer current output

206 RFDTSLVN Analog output Negative RF data slicer level output

207 RFIN Analog input Negative input of RF differential signal

208 RFIP Analog input Positive input of RF differential signal

MT1336

GENERAL DESCRIPTION

MT1336 is a high performance CMOS analog front-end IC for both CD_ROM driver up to 48xs and DVD-ROM driver up

to 16xs. It also supports DVD-RAM read up to 4xs Version 2. It contains servo amplifiers to generate focusing error,

3-beam tracking error, 1 beam radial push-pull signal, RF level and SBAD for servo functions. It also includes DPD

tracking error signal for DVD_ROM application. For DVD-RAM disks, there are also Differential Push-Pull (DPP) method

for generating tracking signal and Differential Astigmatic Detection (DAD) for processing focusing signal. Programmable

equalizer and AGC circuits are also incorporated in this chip to optimize read channel performance. In addition, this chip

has dual automatic laser power control circuits for DVD-ROM (DVD-RAM) and CD-ROM seperately and reference

voltage generators to reduce external components. Programmable functions are implemented by the access of internal

register through bi-directional serial port to configure modes selection.

FEATURES

. RF equalizer with programmable f

. MT1336 supports at least eight different kinds of pick-up heads with versatile input configuration for both RF input stages

and servo signal blocks.

from 3MHz to 70MHz and programmable boost from 3db to 13db.

c

14

Page 17

. Versatile on-line AGC.

. 3 beams tracking error signal generator for CD_ROM application.

. One beam differential phase tracking error (DPD) generator for DVD_ROM application.

. Differential push pull tracking error (DPP) generator for DVD_RAM application.

. Focusing error signal generator for CD-ROM, DVD-ROM and DVD-RAM (DAD method).

. RF level signal generator.

. Sub-beam added signal for 3 beams CD_ROM.

. One beam push-pull signal generator for central servo application.

. High speed RF envelop detection circuit with bandwidth up to 400KHz for CD-ROM.

. Defect and Blank detection circuits

. Dual automatic laser power control circuits with programmable level of LD monitor voltage.

. Vref-1.4V voltage and V2ref=2.8V voltage generators.

. V20=2.0V voltage for pick - up head refe rence.

. Bi-directional serial port to access internal registers.

. 128-pin LQFP

Block Diagram…………………………………..P.3

Pin Assignment and Description………………..P.4-9

Functions

1.) RF Path Description………………….P. 10-13

2.) Servo Signal…………………………..P. 14-17

. Focusing Error

. Central Servo

. Tracking Error

. RFLVL & SBAD (LVL)

3.) ALPC & RFRP ( RF Ripple)………….P. 18

4.) WOBBLE Detection…………………..P. 19

Command Access Timings………………………P. 20

Programmable I/O ………………………………P. 21

Register

1.) Register Map………………………….P. 22-24

2.) Register Description………………….P . 25-50

MT1336 PIN DESCRIPTIONS

Pin Numbers Symbol Type Description

LQFP128

RF Flag interface

23 DEFECT Digital input Flag of bad data output status

RF SIO interface

56 SCLK Digital input RF serial clock input

58 SDEN Digital inpu t RF serial data enable

59 SDATA Digital IO RF serial data IO

60 RST Digital input Reset (active high)

55 XCK16M Digital input 16.9MHz for verification

RF SERVO interface

40 UDGATE Digital input Control signal for DVD-RAM

41 IDGATE Digital input Control signal for DVD-RAM

38 VFO13 Digital input DVD-RAM Header signal

RF

15

Page 18

100 DVDA Analog input AC coupled DVD RF signal input A

99 DVDB Analog input AC coupled DVD RF signal input B

98 DVDC Analog input AC coupled DVD RF signal input C

97 DVDD Analog input AC coupled DVD RF signal input D

95 DVDRFIN Analog input AC coupled DVD RF signal input RFIN

96 DVDRFIP Analog input AC coupled DVD RF signal input RFIP

94 CDA Analog input AC coupled CD RF signal input A

93 CDB Analog input AC coupled CD RF signal input B

92 CDC Analog input AC coupled CD RF signal input C

91 CDD Analog input AC coupled CD RF signal input D

90 OSN Analog RF Offset cancellation capacitor connection

89 OSP Analog RF Offset cancellation capacitor connection

85 CEQP Analog RF Offset cancellation capacitor connection

84 CEQN Analog RF Offset cancellation capacitor connection

88 RFGC Analog RF AGC loop capacitor connecting for DVD-ROM

87 RFGCU Analog RF AGC loop capacitor connecting for DVD-ROM

86 RFGCI Analog RF AGC loop capacitor connecting for DVD-ROM

101 MA Analog input DC coupled DVD-RAM main-beam RF signal input A

102 MB Analog input DC coupled DVD-RAM main-beam RF signal input B

103 MC Analog input DC coupled DVD-RAM main-beam RF signal input C

104 MD Analog input DC coupled DVD-RAM main-beam RF signal input D

105 SA Analog input DC coupled DVD-RAM sub-beam RF signal input A

106 SB Analog input DC coupled DVD-RAM sub-beam RF signal input B

110 SC Analog input DC coupled DVD-RAM sub-beam RF signal input C

111 SD Analog input DC coupled DVD-RAM sub-beam RF signal input D

108 IR Analog External current bias resistor (R=20K)

119 AGC1 Analog Wobble AGC loop1 capacitor

121 AGC2 Analog Wobble AGC loop2 capacitor

122 AGC3 Analog Wobble AGC loop3 capacitor

127 RFSUBO Analog output Header push-pull RF output signal

1 WOBSO Analog output Wobble signal output

6 RFOP Analog output RF positive output

7 RFON Analog output RF negative output

TRACKING ERROR

32 DPFN Analog DPD amplifier negative input

33 DPFO Analog DPD amplifier output

61 DPDMUTE Digital input DPD mute control input

116 TNI Analog input 3 beam satellite PD signal negative input

115 TPI Analog input 3 beam satellite PD signal positive input

21 TEO Analog Output Tracking error output

FOCUSING ERROR & RF LEVEL & CENTRAL SERVO SIGNAL

112 CDFOP Analog input CD focusing error positive input

113 CDFON Analog input CD focusing error negative input

18 FEO Analog output Focusing error output

19 LVL Analog output RF level output

20 CSO Analog output Central servo signal output

ALPC

124 MDI1 Analog input Laser power monitor input

125 LDO1 Analog Output Laser driver output

123 MDI2 Analog input Laser power monitor input

126 LDO2 Analog Output Laser driver output

RF RIPPLE

26 CRTP Analog RF top envelop filter capacitor connecting

27 CRTPLP Analog Defect level filter capacitor connecting

25 HRFRP Analog output High frequency RF ripple output or Blank detector’s output

24 LRFRP Analog output Low frequency RF ripple output

POWER

67,69 AVDD Power Master PLL Filter power

65,73 AGND GND GND for Master PLL Filter

64 AVDD Power DPD Power

62 AGND GND DPD GND

16

Page 19

109 AVDD Power RF path Power

107 AGND GND RF path GND

114 SVDD Power Servo Power

117 SGND GND Servo GND

2,120 WAVDD Power Wobble Power

128,118 WAGND GND Wobble GND

5 AVDDO Power Power for RF output

8 AGNDO GND GND for RF output

14 AVDDT Power Power for trimming PAD

12 AGNDT GND GND for trimming PAD

22 VDDP Power Peak Detection Power

31 GNDP GND Peak Detection GND

37,54 VDD Power Serial I/O Power

39,57 GND GND Serial I/O GND

REFERENCE VOLTAGE

16 VREFO Analog output Reference voltage 1.4V

15 V2REFO Analog output Reference voltage 2.8V

17 V20 Analog output Reference voltage 2.0V

ALPC TRIMMING

9 TM1 Analog input Trimming pin for ALPC1

10 TM2 Analog input Trimming pin for ALPC1

11 TM3 Analog input Trimming pin for ALPC2

13 TM4 Analog input Trimming pin for ALPC2

HIGH SPEED TRACK COUNTING

29 TRLP Analog Low-pass filter capacitor connecting

28 TRLPA Analog Low-pass filter capacitor connecting

30 HTRC Digital output High speed track counting digital output

PCS

74 HALLSIN Analog input Negative input of amplifier for hall sensor signal

75 REFSIN Analog input Positive input of amplifier for hall sensor signal

76 SINPHI Analog output Amplifier output for hall sensor signal

71 HALLCOS Analog input Negative input of amplifier for hall sensor signal

72 REFCOS Analog input Positive input of amplifier for hall sensor signal

70 COSPHI Analog output Amplifier output for hall sensor signal

FOR MONITOR ONLY

81 MON Analog output

80 MOP Analog output

66 VCON Analog output

77 SWO Analog output Output from mux of SW1 & SW2

78 SW2 Analog input External input for servo input select

79 SW1 Analog input External input for servo input select

FOR SERIAL I/O

42 IO0

43 IO1

44 IO2

45 IO3

46 IO4

47 IO5

48 IO6

49 IO7

50 IO8

51 IO9

52 IOA

53 IOB

2-1-4 20-Pin, 24-Bit, 96kHz Stereo D/A with Volume Control (WM8720)

Features

♦ Performance:

-102dB SNR (‘A’ weighted @48kHz),

-THD: -95dB @ 0dB FS

♦ 5V or 3.3V supply operation

♦ Sampling frequency: 8kHz to 96kHz

17

Page 20

♦ Input data word: 16 to 24-bit

♦ Hardware or SPI compatible serial port control

modes:

-Hardware mode:system clock, reset, mute,

de-emphasis

-Serial control mode: mute, de-emphasis, digital

attenuation(256 steps), zero mute, phase

reversal, power down

♦ Compatible with PCM1720

Description

The WM820 is a high performance stereo DAC

designed for audio applications such as CD, DVD,

home theatre systems, set top boxes and digital TV.

The WM8720 supports data input word lengths from

16 to 24-bits and sampling rates up to 96kHz. The

WM8720 consists of a serial interface port, digital

interpolation filter, multi-bit sigma delta modulator and

stereo DAC in a small 20-pin SSOP package. The

WM8720 also includes a digitally controllable mute

and attenuator function on each channel.

The WM8720 supports a variety of connection

schemes for audio DAC control. The SPI-compatible

serial control port provides access to a wide range of

features including on-chip mute, attenuation and

phase reversal. A hardware controlllable interface is

also available.

The programmable data input port supports a variety

of glueless interfaces to popular DSPs, audio

decoders and S/PDIF and AES/EBU receivers.

APPLICATIONS

. CD, DVD audio

. Home theare systems

. Set top boxes

. Digital TV

18

Page 21

BLOCK DIAGRAM

PIN DESCRIPTIONS

PIN NAME TYPE DESCRIPTION

1 PWDN Digital input Powerdown control; low is ON, high is POWER OFF, Interal pull-down.

2 SCKI Digital input System clock input(256 or 384fs).

3 TEST Digital output Reserved.

4 ML/I2S Digital input Latch enable (software mode) or input format selection (hardware mode)

Internal pull-up.

5 MC/IWL Digital input Serial control data clock input (software mode) or input word length

selection (hardware mode). Internal pull-up.

6 MD/DM Digital input Serial control data input (software mode) or de-emphasis selection

(hareware mode). Internal pull-up.

7 RSTB Digital input Reset input-active low. Internal pull-up.

8 ZERO Digital output Infinite zero detect-active low. Open drain type output with active

pull-down.

9 VOUTR Analogue output Right channel DAC output.

10 AGND Supply Analogue ground supply.

11 AVDD Supply Analogue positive supply.

12 VOUTL Analogue output Left channel DAC output.

13 CAP Analogue output Analogue internal reference.

14 BCKIN Digital input Audio data bit

15 DIN Digital input Serial audio data input.

16 LRCIN Digital input Sample rate clock input.

17 MUTE Digital IO Mute control pin, input or automute output.

Low is not mute, high is mute, Z is automute.

18 MODE Digital input Mode select pin. Low is software mode, high is hardware control.

Internal pull-down.

19 DVDD Supply Digital positive supply.

20 DGND Supply Digital ground supply.

Note:

19

Page 22

Digital input pins have Schmitt trigger input buffers.

2-1-5 Serial EEPROM, 2K (256 x 8) (24C16)

* Features

z Low-Voltage and Standard-Voltage Operation

-5.0 (V CC = 4.5V to 5.5V)

-2.7 (V CC = 2.7V to 5.5V)

-2.5 (V CC = 2.5V to 5.5V)

-1.8 (V CC = 1.8V to 5.5V)

z Internally Organized 128 x 8 (1K), 256 x 8 (2K), 512 x 8 (4 K) , 10 2 4 x 8 (8 K) or 2048 x 8 (16K)

z 2-Wire Serial Interface

z Schmitt Trigger, Filtered Inputs for Noise Suppression

z Bi-directional Data Transfer Protocol

z 100 kHz (1.8v, 2.5V, 2.7V) and 400 kHz (5V) Compatibility

z Write Protect Pin for Hardware Data Protection

z 8-Byte Page (1K, 2K), 16-Byte Page (4K, 8K, 16K) Write Modes

z Partial Page Writes Are Allowed

z Self-Timed Write Cycle (10 ms max)

z High Reliability

- Endurance: 1 Million Write Cycles

- Data Retention: 100 Years

- ESD Protection: >3000V

z Automotive Grade and Extended Temperature Devices Available

z 8-Pin and 14-Pin JEDEC SOIC, 8-Pin PDIP, 8-Pin MSOP, and 8-Pin TSSOP Packages

* Pin Configurations

* Pin Description

Pin Name Function

A0-A2 Address Inputs

SDA Serial Data

SCL Serial Clock input

WP Write Protect

NC No Connect

2-1-6 8M-BIT [1Mx8/512Kx16] CMOS FLASH MEMORY

FEATURES

• 1,048,576 x 8/524,288 x 16 switchable

• Single power supply operation

- 5.0V only operation for read, erase and program

20

Page 23

operation

• Fast access time: 70/90/120ns

• Low power consumption

- 50mA maximum active current

- 0.2uA typical standby current

• Command register architecture

- Byte/word Programming (7us/12us typical)

- Sector Erase (Sector structure 16K-Bytex1,

8K-Bytex2, 32K-Bytex1, and 64K-Byte x15)

• Auto Erase (chip & sector) and Auto Program

- Automatically erase any combination of sectors with

Erase Suspend capability.

- Automatically program and verify data at specified

address

• Erase suspend/Erase Resume

- Suspends sector erase operation to read data from,

or program data to, another sector that is not being

erased, then resumes the erase.

• Status Reply

- Data polling & Toggle bit for detection of program and

erase operation completion.

• Ready/Busy pin (RY/BY)

- Provides a hardware method of detecting program

or erase operation completion.

• Sector protection

- Sector protect/chip unprotect for 5V/12V system.

- Hardware method to disable any combination of

sectors from program or erase operations

- Tempory sector unprotect allows code changes in

previously locked sectors.

• 100,000 minimum erase/program cycles

• Latch-up protected to 100mA from -1V to VCC+1V

• Boot Code Sector Architecture

- T = Top Boot Sector

- B = Bottom Boot Sector

• Low VCC write inhibit is equal to or less than 3.2V

• Package type:

- 44-pin SOP

- 48-pin TSOP

• Compatibility with JEDEC standard

- Pinout and software compatible with single-power

supply Flash

21

Page 24

22

Page 25

2-1-7 512K X 16 Bit X 2 Banks Synchronous DRAM (A43L0616)

Features

JEDEC standard 3.3V power supply

LVTTL compatible with multiplexed address

Dual banks / Pulse RAS

MRS cycle with address key programs

- CAS Latency (2,3)

- Burst Length (1,2,4 ,8 & full page)

- Burst Type (Sequential & interleave)

All inputs are sampled at the positive going edge of the system clock

Burst Read Single-bit Write operation

DQM for masking

Auto & self refresh

64ms refresh period (4K cycle)

50 Pin TSOP (II)

Pin Configuration

23

Page 26

24

Page 27

Block Diagram

Pin Descriptions

Symbol Name Description

CLk System Clock Active on the positive going edge to sample all inputs

CS Chip Select Disables or Enables device operation by masking or enabling

all inputs except CLK, CKE and L(U)DQM

Masks system clock to freeze operation from the next clock cycle.

CKE Clock Enable CKE should be enabled at least one clock + tss prior to new command.

Disable input buffers for power down in standby.

A0~A10/AP Address

Row/Column addresses are multiplexed on the same pins.

Row address: RA0 ~ RA10, Column address: CA0 ~ CA7

BA Bank Select Address

Selects bank to be activated during row address latch time.

Selects band for read/write during column address latch time.

RAS Row address Strobe

Latches row addresses on the positive going edge of the CLK with

RAS low.

Enables row access & precharge.

CAS

Column Address Strobe

Latches column addresses on the positive going edge of the CLK with CAS

low. Enables column access.

WE Write Enable Enables write operation and Row precharge.

25

Page 28

Symbol Name Description

L(U)DQM

DW0-15 Data Input/Output Data inputs/outputs are multiplexed on the same pins .

VDD/VSS Power Supply/Ground Power Supply: +3.3V±0.3V/Ground

VDDQ/VSSQ

NC/RFU No Connection

Data Input/Output Mask

Data Output

Power/Ground

Makes data output Hi-Z, t SHZ after the clock and masks the output.

Blocks data input when L(U)DQM active.

Provide isolated Power/Ground to DQs for improved noise immunity.

3. Product Specifications

Playback System

DVD Vi deo

Video CD (1.1, 2.0, 3.0)

SVCD and CVD

CDDA

CD-ROM with MP3 data

PICTURE CD

Television Signal System

NTSC/PAL

Video Performance

Video Out 1 Vpp into 75 ohm

S-Vi deo Out Y: 1Vpp into 75 ohm

C: 0.286 Vpp into 75 ohm

D/A Converter 27MHz/10bit

Audio Performance

Frequency Response DVD: fs 48/96KHz, 4Hz~22/44K Hz

Video CD: fs 44.1KHz, 4Hz~20KHz

Audio CD: fs 44.1KHz, 4Hz~20KHz

Output Level Analog: 2Vrms(1KHZ)

Digital: 1.15 Vpp

D/A Converter 96KHz/24bit

S/N Ratio 90dB

Connections

Coaxial digital out X1

Audio Analog out for 2-channel X1

S-Vi deo out X1

Power Supply

Power Source AC100~255V, 50/60Hz

Power Consumption <25 Watt

Set

Dimensions (W X H X D) 430 X 52 X 295 (mm)

Net W ei ght 2.6 Kg

Gross Weight 4.0 Kg

26

Page 29

5. Disassembly and Reassembly

27

Page 30

6. T roubleshooting

N

No power Insert the AC power plug securely into the power outlet.

Make sure that the equipment is connected properly.

No picture

No sound Make sure that the equipment is connected properly.

Distorted sound

No fast forward or fast reverse Some discs may have sections that prohibit fast forward or fast reverse.

No proper aspect ratio Select the correct setup for TV aspect ratio that matches your TV set.

o operations can be performed with

the remote controller

No button operation

Audio soundtrack and/or Subtitle

language is not the one you selected.

No Angle change

Make sure that the input setting for TV is Video (AV).

Make sure that the input settings for the TV and stereo system are correct.

Check the batteries are installed with the correct polarities.

Point the remote control unit at the remote control sensor and operate.

Remove the obstacles between the remote control unit and remote control

sensor.

Set the POWER button to OFF and then back to ON.

Alternatively, turn off the power, disconnect the power plug and then

reconnect it.

If the audio soundtrack and /or subtitle language does not exist on the

disc, the language selected at the initial settings will not be seen.

This function is dependent on software availability. Even if a disc has a

number of angles recorded, these angles may be recorded for specific

scenes only .

28

Page 31

p

7. Electrical Part List CO-01 PRODUCT DESIGN PACKAGE LIST

No. Name Counts Blueprint No. Material No. Notes

1 CO-01 surface subassembly 1

2 SANYO HD60 loader 1

Two-channel decoding sub-

4

assembly for CO-01 DVD

5 CO-DPA118 subassembly 1 CO-DPA118

6 Interface subassembly of SCART 1

7 CO-01 motherboard 1 CO-DZCO-01 silver-gray, use electrolyzed iron

8 CO-01 backboard 1 CO-01HB silk-screen file No.: CO9

ower supply switch 1 PS8-4 6A 250V AC 10A 125V AC

10 pyrocondensation conducting tube

11 outer cover 1 CO-01WZ with mark of DECCAVIDEO

1 CO-DJA1369XE+SANYO with microphone and s-video output

12 wire of power-supply 1 black,two round-heads, ,with VDE certification

13 PE bag for power-supply wire 1

14 nylon-ribbon fastening string 5

15 black fastening string 1 for power-supply wire

17 CO-01 CD gate-bar 1 CO-01CDM for SANYO HD60 loader

18 sticker for DVD trademark 1 with background black and characters silvery

19 strut for circuit board 8

21 plastic nut cap 8

unit80*160mm with mark of

environment-protecting

2 for decodeing board6 for power-supply

board

decodeing board 4power-supply board 6

29

Page 32

No. Name Counts Blueprint No. Material No. Notes

r

p

p

22

rubber mat

23 VCD rubber mat 3

2

thickness 2mm diameter 12mm

thickness 19.5mmdiameter 9.5mm

24 Remote controller-V1 1

25 battery 2

26 PE bag for remote controller 1

7# environment-protecting battery

ENGLISH

Unit: 05*80*260mm with

environment-protecting mark

27 manual 1

28 PE bag for manual 1

English

unit: 05*80*260mm with

environment-protecting mark

29 foam 1 CO-108PM 355*110*80

30 handle for colourbox 1

31 colourbox 1

32 pearl cotton 480*580 1

Unit: mm with environment-protecting mark

33 nail BTV3*10 colouful zinc 4 4 for loader

with-cap hardened nailBTPW3*8

34

colorful zinc

8

4 for outer cover4 for loader

round-headed self-fastened

35

hardened nailBTV3*6 colorful

zinc

14

3 for backboard, 4 for outer cover, 2 for side

cover, 3 for cover and motherboard, 2 fo

shielding

round-headed self-fastened

36

hardened nailBTV3*16

8

ower-supply board: 6decoding board: 2

colorful zinc

37

30

lain-headed triangular nail

colorful zinc

2

2 for component and audio output 2 for scart

board

Page 33

No. Name Counts Blueprint No. Material No. Notes

p

P

P

P

P

P

acute-headed nail BA3*8 colorful

38

zinc

39 1.5mm SCART wire 1 with two terminals 40-pins

video two-terminator yellow wire

40

1.5mm

audio four-terminator red-white

41

1.5mm

1 for coaxial output

1 linear figure,black

1 linear figure,black

42 bar code

43 assembly line number

44 safety sticker 1

2.0 connector/2.0connctor 6

45

red-white row-wire 160mm

2.0 connector/2.0connctor 5

46

red-white row-wire 280mm

2.54 connector/2.54connctor 6

47

red-white row-wire 220mm

2.54 connector/2.54connctor 4

46

red-white row-wire 280mm

2.54 connector/2.54connctor 8

47

red-white row-wire 360mm

1 from decoding board to loader

1 from decoding board to loader

1 from control board to decoding board

1 from control board board to power-supply

1 from power-supply board to decoding board

rovided by client

provided by client

31

Page 34

The list for cover subassembly design of CO-01

p

p

No. Name Counts Blueprint No. Material No. Notes

1 trademark 1

MODELL :DDV2140(DDV2141.

2

DVD6722M.DVD5000.DVD412

.fl d402)panel

3 CO-01 power-supply button 1 CO-01

4 CO-01 knob 2 CO-01

5 number button 1 CO-01

6 fast forward button 1 CO-01

7 pause button 2 CO-01

8 load/unload button 1 CO-01

9 light-transporting canister 1 CO-01

1 CO-01

silk-screen file No.:

silver

silver

silver

silver

silver

silver

10 CO-01 VFD screen lens 1 CO-01XSJ

subassembly of CO-DCBC0-01 control

12

annel

Subassembly of CO-DHACO-02

13

earphone board

lain-headed triangular nail BB3*8

14

colorful zinc

15 ordinary green round-headed LED 1 diameter: 3mm round-headed

1

1

16

silk-screen blueprint No.:

control panel:9, bracket for cover: 4,

microphone board:1, power-supply

switch: 2

The components design list for control panel(CO-DCBCO-01)

32

Page 35

No. Name/Specification Counts Position in the paper Material No. Notes

p

p

p

r

resistor

1 resistor 10E 1/4W 10% 2 R1,R9

2 resistor 220E 1/4W 10% 2 R11,R12

3 resistor 10K 1/4W 10% 7 R7,R6,R3,R2,R4,R8,R10

4 resistor 56K 1/4W 10% 1 R5

orcelain capacitor

5

orcelain capacitor 104 50V 1 C3 diameter: 5mm

electrolyzed capacitor

electrolyzed capacitor47 uF 16V 1 C1,C2 diameter:5mm

6

Diode

diode IN4148 4 D1~D4

7

IC

16312(AD16312) 1 U1

8

accessories

11

12

13

14

15

16

17

18

19

VFD screen 1 IC2 BJ732GNK

left bracket of screen 1

right bracket of screen 1

control panel 1 CO—DCBCO-01 2001-3-18

touching-softly switch 12 K1~K12 6*6*5

remote control receiver 1 TD138

ower switch 1

2.54connector 4P without-terminato

red-white row-wire 230mm

2.54 connector 6P red-white row-wire

220mm

3.96connector 2P no-terminator 150 red

20

both-insulated

1 CN2 from control board to power-supply board

1 CN1 from control board to decoding board

1 from switch board to power-supply board

TV-5KDC-A10-1D8A/128A AC250V

21 iron thread 8mm 3 J2,J3, JMP2 diameter: 0.6mm

33

Page 36

No. Name/Specification Counts Position in the paper Material No. Notes

22 iron thread 10mm 2 J1,J5 diameter: 0.6mm

23 iron thread 12mm 1 JMP1 diameter: 0.6mm

34

Page 37

8. Block Diagram

35

Page 38

9. Circuit Diagrams

1.Control Part

2. INDEX

3.SERVO&RF

4.MEMORY

5.Audio&Video D/A

6.AV PORT

7.Power Part

8. Wiring Diagram

36

Page 39

1.Control Part

F1

F2

GND

-27V

4

APPROVED BY

REM

3

VCC

2

SIG

1

GND

REM

6PINCZ1

1

2

3

4

5

6

+5V

IR

GND

CLK

CS

DATA

CZ2

1

2

3

4

4PIN

F1

F2

GND

-27V

A/O

2002-09-15

D

C

B

A

321

D

13

14

F1

F1

F2

F2

NP

NC

NC

NC

NC

NP

IC1

COSMIC P

1G42G53G64G75G86G

VFD

1

F1

2

31

F2

32

30

12

C

B

A

11

10

9

3

G7

15

P15

16

P14

17

P13

18

P12

19

P11

20

P10

21

P9

22

P8

23

P7

24

P6

25

P5

26

P4

27

P3

28

P2

29

P1

D5

4148

R7

10k

R8

10k

R9

10k

R10

10k

K5

K10

K15

K20

K4

K9

K14

K19

D4

4148

K3

K8

K13

K18

D3

4148

D2

4148

K2

K7

K12

K17

K1

K6

K11

K16

D1

4148

29

28

26

25

24

23

22

21

20

19

18

17

16

15

Sg14/Gr9

Sg13/Gr10

Sg12/Gr11

Sg11

Sg10

Sg9

Sg8

Sg7

Sg6/KS6

Sg5/KS5

Sg4/KS4

Sg3/KS3

Sg2/KS2

Sg1/KS1

30

6312

13

Gr137Gr236Gr335Gr434Gr533Gr632Gr731Gr8

VDD

VDD

GND

GND

DOUT

DIN

CLK

STB

OSC

VEE

LED4

LED3

LED2

LED1

S11S22S33S44K110K211K312K4

R1(OPEN)

220

LED(OPEN)

LED

IC2

DP6312

14

38

7

43

5

6

8

9

44

27

39

40

41

42

R2(OPEN)

220

LED(OPEN)

LED

COMPANY

FILE

SHEET

DESIGN

R3

56KR410KR510KR610K

COSMIC

CO-DCACO-01

SHEET 1 OF 1

1

DRAMWE BY

C3

47uF/50V

C1

100uF/16V

TITLE

REV

TATE

CHECKED BY1

1 2 3 4

BT

37

Page 40

2. INDEX

HD60_C001

1 INDEX & POWER, RESET

2 RF / SERVO & MPEG - MT1336E / MT1369E

3 MEMORY - SDRAM, FLASH/EEPROM

4 AUDIO - WM8720&WM8746, VIDEO - CS4954/55

5 AV FILTER.

38

J2

8

STBY

7

-12V

6

AVGND

5

+12V

4

AGND

3

+3.3V

2

GND

1

+5.0V

PWR, 8P,PITCH=2.54M/M

|

V

1

Pitch=2.54 m/m

NAME

VCC

RVCC

AVCC

V33

DV33

AV33

V25

+5VA

+3VV

+5VV

+12V

PGND

SGND

+P5V

TYPE

Digital 5V

Servo 5V

RF 5V

Digital 3.3V

Digital 3.3V

Servo 3.3V

Digital 2.5V

Audio 5V

Video 3.3V

Video 5V

Audio 12V

PWR_STBY

-P12V

+P12V

+P3V3

+P5V

L8

FB / 0805

L9

FB / 0805

DEVICE

SUPPLY

MT1336E

PICKUP HEADER

SDRAM, Flash, VideoDAC

MT1369E

MT1369E

MT1369E

Audio DAC

Video DAC

Video DAC

Audio filter

+P12V

+

CB59

0.1u

-P12V

CB60

0.1u

VCC

VCC

AVCC

RVCC

+

C65

CB62

220u

0.1u

AVCC

+

C67

220u

CB65

0.1u

RVCC

+

C69

CB66

220u

0.1u

C61

220u

C63

+

220u

+P5V

+

C68

100u

CB68

0.1u

NAME

GND

SGND

AGND

VGND

CB64

0.1u

+P3V3

U11

G960T63U

312

VI

SOT223

VO

GND

TYPE

Digital Ground

Servo Analog Ground

Audio Ground

Video Ground

L6

DV33

FB , 1210

U12

G950T63U

3

VI

VO

GND

SOT223

V33

+P5V

+

C62

10uF

URST

D1

1N4148

AV33

+

CB61

0.1u

L7

FB / 0805

CB63

0.1u

2

CB67

1

0.1u

C64

220u

V33

+

C66

220u

12

+

C70

220u

AV33

DV33

DV33

D2

1N4001,DIP,PITCH=10M/M

V25

V25

R59

10k

1 2

+P12V

-P12V

VCC

RVCC

AVCC

DV33

V33

AV33

V25

GND

SGND

URST

PWR_STBY

+P5V [ 2,3,4,5 ]

+P12V [ 5 ]

-P12V [ 4,5 ]

VCC [ 2,3,4,5 ]

RVCC [ 2 ]

AVCC [ 2 ]

DV33 [ 2,3,4 ]

V33 [ 2,3,4 ]

AV33 [ 2 ]

V25 [ 2 ]

GND [ 2,3,4,5 ]

SGND [ 2,3,4,5 ]

URST [ 2 ]

PWR_STBY [ 2 ]

Page 41

3.SERVO&RF

R? 100K

3

1

2

2

2SK3018

Q?

2SK3018

3 1

SF-HD60AV/0.5mm,24P

TOP SIDE CONTACTED

24

GND-LD

23

LD-DVD

Z17

22

NC

21

TP

HFM

MDI1

20

MD

19

LD-CD

18

VR-DVD

17

VR-CD

GND-PD

CD/DVD

CON1

R25 20k

C36

150p

VCC

C48

10u

NC

E

Vc

F

B

A

RF

D

C

TT+

F+

F-

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R17

1,0805

CB39

0.1u

VCC

+

CB?

0.1u

VCC

1

Pitch=2.54 m/m

VFD, 6P, 2.54 m/m

RS232/4P,2.0 m/m

E

V20

FB / 0805

F

B

A

RFO

IOA

D

C

R18

1,0805

SL+

SL-

CB43

0.1u

CB44

0.1u

|

V

J1

1

2

3

4

5

6

CON4

4

3

2

1

|

V

1

Pitch=2.0 m/m

Z24

TP

CB? 0.1u

FMSO

TRSO

V1P4

STBY

V33

RxD

TxD

R? 10K

Q?

3904

2

Q?

2SK3018

AVCC

3 1

L?

10uH,DIP

15

16

17

18

19

20

21

22

23

24

25

26

27

28

CB41

0.1u

U4

1

VCC

2

BOUT

3

GND

4 5

AOUT BIN

BA6208F

VSDA

VSTB

VSCK

CB?

0.1u

U2

VOTK+

VOTKVOLD+

VOLDPGND

VNFTK

PVCC2

PREGND

VINLD

CTK2

CTK1

VINTK

BIAS

STBY

AVCC

R? 10K

R? 100K

Very Important

to reduce

Noise

L?

10uH,DIP

Q?

2SB1132

R? 22

R? 22

Q?

2SB1132

GND

GND

29

30

8

AIN

7

GND

6

NC

R48

10

VOFC+

VOFCVOSL+

VOSLPGND

PVCC1

VNFFC

VINSL-

VINSL+

VINFC

VOSL

BA5954

+

B

2SB1132

VCC

CF2

CF1

GND

TRCLOSE

R1 10k

TROPEN

R2 10k

CB1

AGNDF

VCON

AVDDF

AGNDX

AVDDM

COSPHI

HALLCOS

REFCOS

AGNDM

HALLSIN

REFSIN

SINPHI

SW0

SW2

SW1

MOP

MON

AGNDX

AGNDX

CEON

CEOP

RFGCI

RFGCU

RFFGC

OSP

OSN

CDD

CDC

CDB

CDA

DVDRFIN

DVDRFIP

DVDD

DVDC

DVDB

DVDA

MA

MB

C25

CB2

0.1u

47u

URST

SDEN

PWMOUT2

SDATA

64

RST

SDEN

SDATA

AVDDP

AGNDP

AGNDX

DPDMUTE

MT1336E

AVDDIRAGNDSBSAMDMC

109

108

107

106

105

104

103

R21

33k

+

CB36

0.1u

OPO

R32

330k

J8

ZZ

1

2

3

4

5

6

SLED/6P,2.0mm

SCLK

GNDS

111

110

C32

200p

R27 0

0.1u

STBY

ENDM

IOA

TRCLOSE

IO8

IO9

IOA

IOB

SCLK

VDDS

XCK16M

SGND

TNI

TPI

SVDD

CDFON

CDFOPSDSC

117

116

115

114

113

112

F

E

CB38

0.1u

R30

750k

IOA

RVCC

+

RFO

D

A

B

C

R20

1,0805

R23

10K

R28 20K

5

C14 1u

V

C1

100u

CB11 0.1u

OPO

OPOP+

C15 1u

C16 1u

C17 1u

C

B

A

D

R24

20k

1

|

65

66

67

68

69

CB12 0.1u

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

C10 0.1u

85

86

87

88

CB22 0.1u

CB23 0.1u

89

90

91

92

93

94

95

96

C122 1u

DD

97

AA

98

BB

99

CC

100

101

102

RVCC

C33 C

DMSO

R26 750k

C37

150p

R31

R34

330k

1

SPSP+

LIMIT

SLSL+

C?

100u

MDI2

MDI1

C

E

C

LDO2

C?

+

47u

AVCC

+

C?

47u

LDO1

R19

1,0805

14

13

SP-

12

SP+

11

10

VCC

9

8

7

6

5

V1P4

4

3

2

FOSO

1

+

C38

10u

CON3

LOAD-

1

LOAD+

2

TROUT

3

4

TRIN

5

R44

TRAY IN / OUT,5P,2.0 m/m

10k

TRCLOSE

TROPEN

R45

10k

VCC

R46

4.7k

IR

C54

100p

ENDM

R3 10k

STBY

R4 10k

LIMIT

TRIN

TROUT

IO3

IO4

IO5

IO6

IO7

AGC3

AGC2

WAVDD

AGC1

WGAND

123

122

121

120

119

118

MDI2

C23

0.015u

CB35

0.1u

ADIN

OP-

OP+

V1P4

VCC

39404142434445464748495051525354555657585960616263

IO0

IO1

IO2

GND

UDGATE

HDGATE

VFO13

AGNDX

AGNDX

AGNDX

DPFO

DPFN

GNDP

HTRC

TRLP

TRLPA

CRTPLP

CRTP

HRFRP

LRFRP

DEFECT

VDDP

VREFO

V2REFO

AVDDT

AGNDT

AGNDO

RFON

RFOP

AVDDO

AGNDX

AGNDX

WVDD

WOBSO

WGND

RFSUBO

LDO2

LDO1

MDI1

MDI2

MT1336E

128

127

126

125

124

LDO1

LDO2

MDI1

Z22

DMSO

V25

CB82

0.1u

CB3

U1

0.1u

38

37

VDD

36

Z4 HRFRP

35

34

33

32

31

30

29

28

27

26

RFRP

25

24

23

BDO

22

CB20

21

0.1u

TEO

20

CSO

19

LVL

18

FEO

17

V20

16

15

14

13

TM4

12

11

TM3

10

TM2

9

TM1

8

RFON

7

6

RFOP

5

4

3

2

1

+

C21

47u

Z20

FOSO

Z21

TRSO

DMSO

FMSO

Z23

FMSO

DV33

CB83

0.1u

CB24 0.1u

CB28 0.1u

RVCC

C7 390p

TEO

CSO

RFL

FEO

V20

V1P4

V2P8

CB34

0.1u

PWMOUT2

HTRC

FOSO

TRSO

TROPEN

V1P4

C5 10p

C6 390p

Z6

TEO

Z9

FEO

RVCC

R9 27k

C2 27p

Z5

C4 0.015uL?

HTRC

R10 100k

C9

C8

Z7

CSO

0.033u

470p

Z8

RFL

CB25

CB27

+

C11

+

C12

CB26

0.1u

0.1u

10u

10u

0.1u

HTRC

Z11

V2P8

+

C26

CB37

47u

0.1u

AV33

R29

4.7

CB40

+

C39

C40

C41

0.1u

47u

100p

1u

Z17

LPFON

Z18

LPFOP

Z19

JITFO

C51

C50

C49

330p

330p

C

R14 0

C42

10n

C47 100p

C52

0.015u

Z10

RFRPC

Z13

RFON

C45 10n

Z12

ADIN

Z14

RFOP

R33 8.2k

C43 10n

R36 750k

R39 20k

R40 18k

R41 0

R42 10k

R43 15k

CB45

0.1u

V33

AV33

+

C18

47u

CSO

FEO

RFL

RFRP

RFZC

RFRPC

TEO

V2P8

ADIN

C27 20p

C28 20p

RFON

C30 1000p

RFOP

C34 1000p

LPIOP

C44 10n

C46 10n

V25

GND

GND

DV33

V25

R47

AV33

4.7

R137 4.7k

VCC

R51 4.7k

VCC

CB47

0.1u

MT1336E/MT1369E with

SANYO HD60 PUH

CB30

CB29

0.1u

R15 R

LPION

A8

A9

A10

A11

A12

A13

A14

A15

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

A0

A1

A2

A3

A4

A5

A6

A7

A16

A17

A18

A19

C53

2.2u,0805

0.1u

2.7u, DIP

C29

150p

RFIN

RFIP

U3

1

IREF

2

PLLVSS

3

LPIOP

4

LPION

5

LPFON

6

LPFIP

7

LPFIN

8

LPFOP

9

JITFO

10

JITFN

11

PLLVDD3

12

FOO

13

TRO

14

TROPENPWN

15

PWMOUT2

16

DVDD2

17

DMO

18

FMO

19

FG

20

DVSS

21

HIGHA0

22

HIGHA1

23

HIGHA2

24

HIGHA3

25

HIGHA4

26

HIGHA5

27

DVSS

28

HIGHA6

29

HIGHA7

30

AD7

31

AD6

32

AD5

33

AD4

34

DVDD3

35

AD3

36

AD2

37

AD1

38

AD0

39

IOA0

40

IOA1

41

DVDD2

42

IOA2

43

IOA3

44

IOA4

45

IOA5

46

IOA6

47

IOA7

48

A16

49

A17

50

IOA18

51

IOA19

52

DMVSS

L24

C56

1000p

V1P4

208

207

RFIP

RFIN

R13 100k

206

205

204

SCOP

RFDTSLVN

CB32

0.1u

R16

C22

18k

1000p

C24

1000p

C31

150p

203

202

201

200

199

198

197

196

195

194

193

192

191

190

189

188

FEI

TEI

CSO

ADIN

SCON

HRFZC

RFSUBI

TEZISLV

ADCVSS

PDMVSS

RFLEVEL

RFRPSLV

RFRP_AC

ADCVDD3

RFRP_DC

RFDTSLVP

MT1369E_208

DMVDD3

ALE

IOOE#

IOWR#

IOCS#

DVSS

UP1_2

UP1_3

UP1_4

UP1_5

UP1_6

DVDD3

UP1_7

UP3_0

UP3_1

INT0#IRDVDD2

UP3_4

VSDA

VSCK

1 2

R54 100k

UP3_5

TxD

IR

RxD

MUTE

SCL

SDA

MIC_EN#

PWR_STBY

V25

DV33

U5A

74HC04

Y1

27MHz

C57

22p

5354555657585960616263646566676869707172737475767778798081828384858687888990919293949596979899

VSTB

PRD#

PCE#

PWR#

GND

DIP

C121

22p

CB33

0.1u

DV33

187

186

185

PDMVDD3

PWMVREF

PWM2VREF

UWR#

URD#

XTALI

U5B

3 4

74HC04

VCC [ 1,3,4,5 ]

VCC

RVCC

RVCC [ 1 ]

AVCC [ 1 ]

AVCC

V33 [ 1,3,4 ]

V33

AV33

AV33 [ 1 ]

V25

V25 [ 1 ]

DV33

DV33 [ 1,3,4 ]

GND [ 1,3,4,5 ]

GND

SGND

27MHZ

PWR_STBY

URST

Y[0..7]