Page 1

Agilent 83480A Digital

Communications Analyzer

Agilent 54750A Digitizing

Oscilloscope

Quick Start Guide

Page 2

© Copyright

Agilent Technologies 2000

All Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibited,

except as allowed under copyright laws.

Agilent Part No. 83480-90049

Printed in USA

June 2000

Agilent Technologies

Lightwave Division

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799,

USA

(707) 577-1400

Notice.

The information contained in

this document is subject to

change without notice. Companies, names, and data used

in examples herein are fictitious unless otherwise noted.

Agilent Technologies makes

no warranty of any kind with

regard to this material, including but not limited to, the

implied warranties of merchantability and fitness for a

particular purpose. Agilent

Technologies shall not be liable for errors contained herein

or for incidental or consequential damages in connection with the furnishing,

performance, or use of this

material.

Restricted Rights Legend.

Use, duplication, or disclosure by the U.S. Government

is subject to restrictions as set

forth in subparagraph (c) (1)

(ii) of the Rights in Technical

Data and Computer Software

clause at DFARS 252.227-7013

for DOD agencies, and subparagraphs (c) (1) and (c) (2)

of the Commercial Computer

Software Restricted Rights

clause at FAR 52.227-19 for

other agencies.

Warranty.

This Agilent Technologies

instrument product is warranted against defects in

material and workmanship for

a period of one year from date

of shipment. During the warranty period, Agilent Technologies will, at its option, either

repair or replace products

which prove to be defective.

For warranty service or repair,

this product must be returned

to a service facility designated by Agilent Technologies. Buyer shall prepay

shipping charges to Agilent

Technologies and Agilent

Technologies shall pay shipping charges to return the

product to Buyer. However,

Buyer shall pay all shipping

charges, duties, and taxes for

products returned to Agilent

Technologies from another

country.

Agilent Technologies warrants that its software and

firmware designated by Agilent Technologies for use with

an instrument will execute its

programming instructions

when properly installed on

that instrument. Agilent Technologies does not warrant that

the operation of the instrument, or software, or firmware

will be uninterrupted or errorfree.

Limitation of Warranty.

The foregoing warranty shall

not apply to defects resulting

from improper or inadequate

maintenance by Buyer, Buyersupplied software or interfacing, unauthorized modification or misuse, operation

outside of the environmental

specifications for the product,

or improper site preparation

or maintenance.

No other warranty is

expressed or implied. Agilent

Technologies specifically disclaims the implied warranties

of merchantability and fitness

for a particular purpose.

Exclusive Remedies.

The remedies provided herein

are buyer's sole and exclusive

remedies. Agilent Technolo-

gies shall not be liable for any

direct, indirect, special, incidental, or consequential damages, whether based on

contract, tort, or any other

legal theory.

Safety Symbols.

CAUTION

The

caution

sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in damage to

or destruction of the product.

Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

WAR NING

The

warning

sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in injury or

loss of life. Do not proceed

beyond a warning sign until

the indicated conditions are

fully understood and met.

The instruction manual symbol. The product is marked with this

warning symbol when

it is necessary for the

user to refer to the

instructions in the

manual.

The laser radiation

symbol. This warning

symbol is marked on

products which have a

laser output.

The AC symbol is used

to indicate the

required nature of the

line module input

power.

The ON symbols are

|

used to mark the positions of the instrument

power line switch.

The OFF symbols

❍

are used to mark the

positions of the instrument power line

switch.

The CE mark is a registered trademark of

the European Community.

The CSA mark is a registered trademark of

the Canadian Standards Association.

The C-Tick mark is a

registered trademark

of the Australian Spectrum Management

Agency.

This text denotes the

ISM1-A

instrument is an

Industrial Scientific

and Medical Group 1

Class A product.

Typographical Conventions.

The following conventions are

used in this book:

Key type

for keys or text

located on the keyboard or

instrument.

Softkey type

for key names that

are displayed on the instrument’s screen.

Display type

for words or

characters displayed on the

computer’s screen or instrument’s display.

User type

for words or charac-

ters that you type or enter.

Emphasis

type for words or

characters that emphasize

some point or that are used as

place holders for text that you

type.

ii

Page 3

What You’ll Find in This Book

What You’ll Find in This Book

This book gives you a quick introduction to the instrument. It is not intended

as a comprehensive guide, but rather as a starting point to start using the

instrument quickly. This book is divided into three sections:

Chapter 1 provides a description of the instrument and a quick tour of

the front panel in a descriptive format, with examples that

help to illustrate the text.

Chapter 2 provides several tutorials that show how to get up and

running, how to scale a waveform vertically or horizontally,

and how to use the Help menu.

Chapter 3 provides a few simple hints in case you are experiencing

difficulty in either getting the mainframe or plug-in module

to perform properly.

To best meet your learning needs, you can use this book in one of two ways:

1

Read “A Quick Tour of the Front Panel” on page 1-4 before performing the

exercises.

2

Go straight to the exercises. This method is for users who prefer to learn how

to use the front panel by experimenting with the front-panel controls.

If you are already familiar with the information in this book, you can refer to

the

Agilent 83480A, Agilent 54750A User’s Guide

use the instrument to make many common measurements. It assumes you

have already learned how to use the front panel of the instrument, by first

reading this quick start guide.

All calibration and repair information is contained in the optional

Agilent 83480A, Agilent 54750A Service Guide

information is contained in the

mer’s Guide

.

Agilent 83480A, Agilent 54750A Program-

, which shows you how to

, while all programming

iii

Page 4

General Safety Considerations

General Safety Considerations

This product has been designed and tested in accordance with IEC Publication 61010-1, Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use, and has been supplied in a safe condition. The

instruction documentation contains information and warnings that must be

followed by the user to ensure safe operation and to maintain the product in a

safe condition.

WARNING

WARNING

WARNING

WARNING

WARNING

There are many points in the instrument which can, if contacted, cause

personal injury. Be extremely careful. Any adjustments or service

procedures that require operation of the instrument with protective

covers removed should be performed only by trained service

personnel.

If this instrument is not used as specified, the protection provided by

the equipment could be impaired. This instrument must be used in a

normal condition (in which all means for protection are intact) only.

To prevent electrical shock, disconnect the Agilent (Product variable)

from mains before cleaning. Use a dry cloth or one slightly dampened

with water to clean the external case parts. Do not attempt to clean

internally.

This is a Safety Class 1 product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only be

inserted in a socket outlet provided with a protective earth contact.

Any interruption of the protective conductor inside or outside of the

product is likely to make the product dangerous. Intentional

interruption is prohibited.

No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock, do not remove covers.

WARNING

For continued protection against fire hazard, replace line fuse only

with same type and ratings, (type T 0.315A/250V for 100/120V

operation and 0.16A/250V for 220/240V operation). The use of other

fuses or materials is prohibited. Verify that the value of the linevoltage fuse is correct.

iv

Page 5

General Safety Considerations

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Before this instrument is switched on,

make sure its primary power circuitry

has been adapted to the voltage of the ac power source. Failure to set the ac

power input to the correct voltage could cause damage to the instrument when

the ac power cable is plugged in.

This product is designed for use in Installation Category II and Pollution

Degree 2 per IEC 1010 and 664 respectively.

VENTILATION REQUIREMENTS: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperature of the product by 4°C for every 100 watts dissipated in the

cabinet. If the total power dissipated in the cabinet is greater than 800 watts,

then forced convection must be used.

Always use the three-prong ac power cord supplied with this instrument.

Failure to ensure adequate earth grounding by not using this cord may cause

instrument damage.

connect ac power until you have verified the line voltage is correct.

Do not

Damage to the equipment could result.

This instrument has autoranging line voltage input. Be sure the supply voltage

is within the specified range.

CAUTION

Electrostatic discharge (ESD) on or near input connectors can damage circuits

inside the instrument. Repair of damage due to misuse is

covered under

not

warranty. Before connecting any cable to the electrical input, momentarily

short the center and outer conductors of the cable together. Personnel should

be properly grounded, and should touch the frame of the instrument before

touching any connector.

v

Page 6

Page 7

Contents

General Safety Considerations iiv

1 Introducing the Instrument

The Agilent 83480A, Agilent 54750A—At a Glance 1-2

A Quick Tour of the Front Panel 1-4

2 Operating the Instrument

Operating the Instrument 2-2

Equipment Used in These Exercises 2-3

Exercise 1. Installing a Plug-in Module 2-4

Exercise 2. Turning On the Instrument 2-5

Exercise 3. Connecting a Signal 2-6

Exercise 4. Finding the Signal 2-7

Exercise 5. Modifying the Setup 2-8

Exercise 6. Making Measurements on the Signal 2-13

Exercise 7. Using the Help Menu 2-17

3 In Case of Difficulty

In Case of Difficulty 3-2

If the Mainframe Does Not Operate 3-3

If the Plug-in Does Not Operate 3-4

Contents-1

Page 8

Page 9

1

Entry devices 1-4

Disk drive 1-4

CAL signal 1-4

Hardkeys 1-5

Display 1-5

Softkeys 1-6

Introducing the Instrument

Page 10

Introducing the Instrument

The Agilent 83480A, Agilent 54750A—At a Glance

The Agilent 83480A, Agilent 54750A—At a

Glance

The Agilent 83480A-series digital communications analyzer or

Agilent 54750A-series digitizing oscilloscope are modular, high-performance

mainframes that contain digitizers, timebases, and display circuitry behind

vertical channel plug-in modules containing samplers, IF amplifiers, power

monitoring circuitry and O/E converter (Agilent 83485A).

The Agilent 83480A-series digital communications analyzer include these

unique capabilities:

• A full range of custom and standard telecom and datacom masks and templates with automated conformance and margin testing.

• Automated extinction-ratio and q-factor measurements.

• The ability to set the timebase display to bit period, select the appropriate

telecom bit rate, and enter the number of bits to be displayed.

If you wish to add these capabilities to an Agilent 54750A-series digitizing

oscilloscope, or use the Agilent 83485A optical plug-in module, a firmware

upgrade must first be installed. Order the Agilent 83480K communications

firmware kit and follow the installation instructions.

NOTE

The Agilent 83480A and Agilent 54750A mainframes do

designed for use with the Agilent 54710A and Agilent 54720A.

The instrument also has software modularity by having a 3-1/2 inch disk drive

and flash ROMs to allow for simple firmware upgrades of the firmware features.

The plug-in modules provide optical and electrical signal conditioning for the

A/D converters that are inside the mainframe.

1-2

accept plug-in modules

not

Page 11

Introducing the Instrument

The Agilent 83480A, Agilent 54750A—At a Glance

Certification

Agilent Technologies certifies that this product met its published specifications at the time of shipment from the factory. Agilent Technologies further

certifies that its calibration measurements are traceable to the United States

National Institute of Standards and Technology, to the extent allowed by the

Institute’s calibration facility, and to the calibration facilities of other International Standards Organization members.

1-3

Page 12

Introducing the Instrument

A Quick Tour of the Front Panel

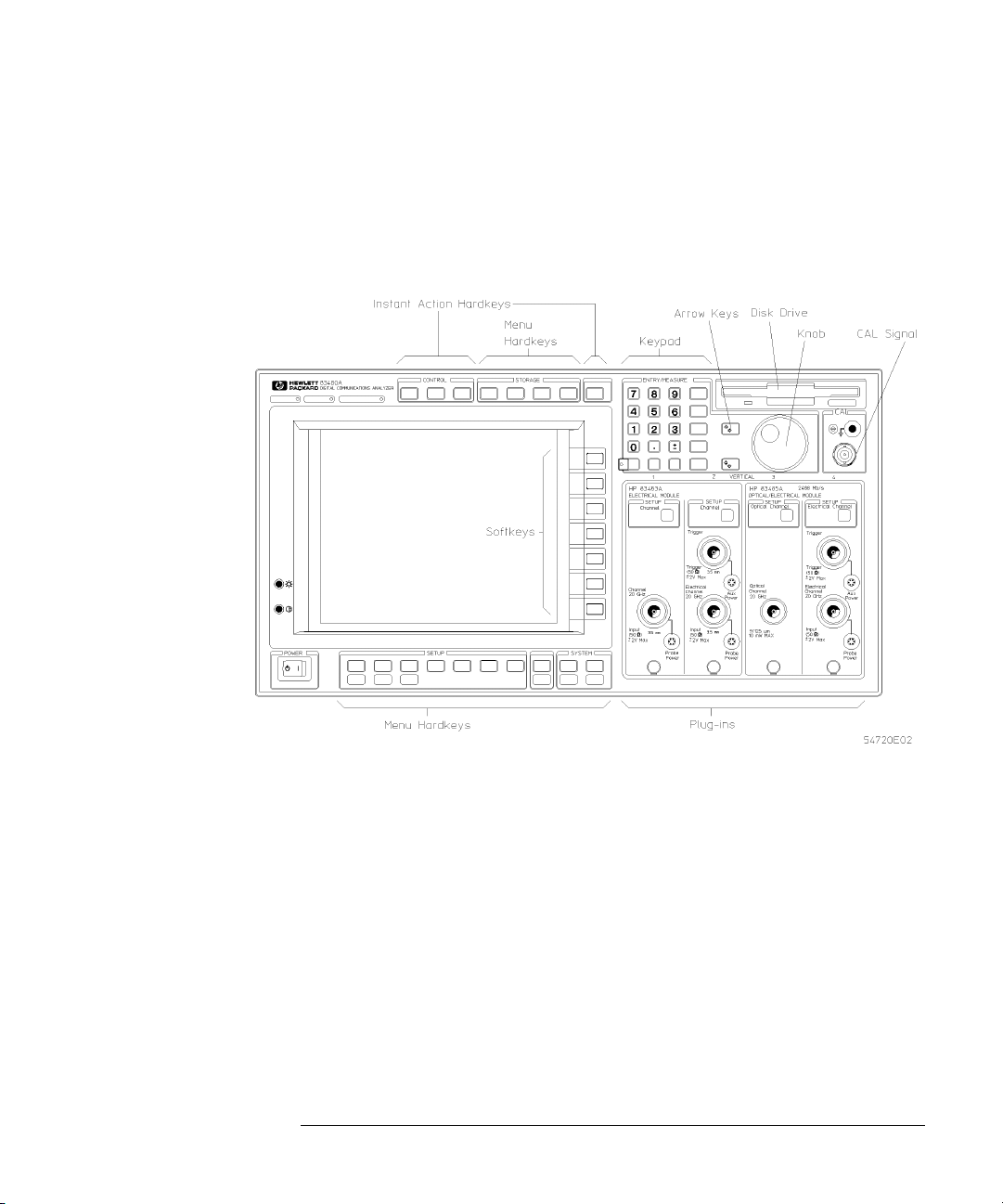

A Quick Tour of the Front Panel

This section describes how to use the front panel. This information will help

you gain the full use of your instrument in the shortest possible time. This section divides the front panel into the following areas:

• Entry devices

• Disk drive

• CAL signal

• Hardkeys

•Display

•Softkeys

Entry devices

Disk drive

CAL signal

The entry devices include the knob, arrow keys, and keypad. The knob provides continuous control, while the arrow keys are step controls. The keypad

allows you to enter specific values.

The disk drive is a 3-1/2 inch, high-density, MS-DOS

®

compatible drive. You

can use the disk drive for loading applications, storing and loading waveforms,

storing and loading instrument setups, printing waveforms to a file, or loading

new system firmware.

MS-DOS

is a registered trademark of Microsoft Corporation.

The CAL signal is a dc voltage level used during the calibration routines. It is

internally generated and only activated during calibration routines. It can be

controlled by the user by pressing:

Utility

Calibrate

,

1-4

Page 13

Introducing the Instrument

A Quick Tour of the Front Panel

Hardkeys

The two types of hardkeys are instant action and menu.

Clear display

and

Run

are examples of instant action keys because as soon as you press them, the

instrument changes operating states.

Time base

and

Trigger

are examples of

menu keys. Pressing them causes softkey menus to come up on the right side

of the display.

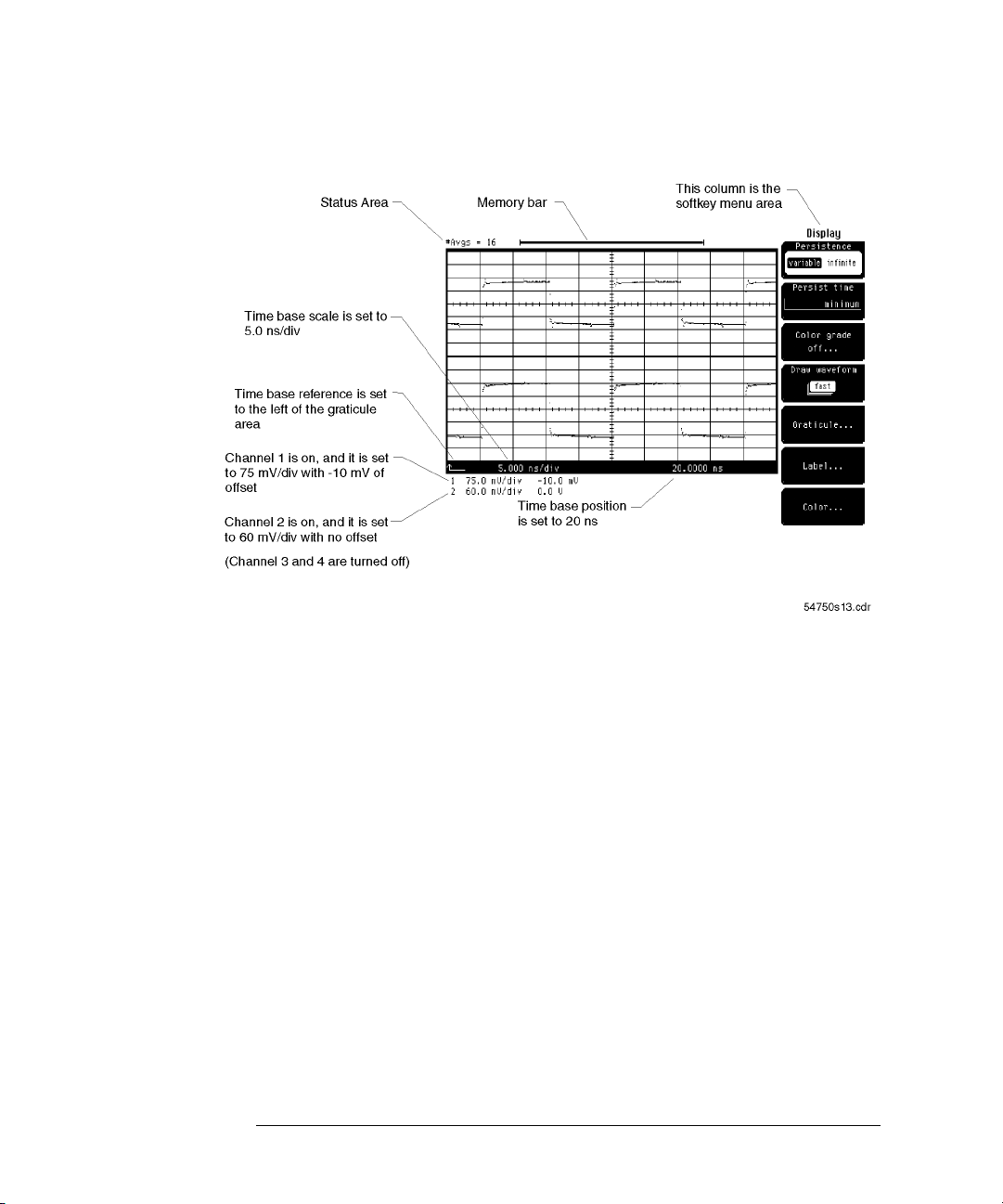

Display

Figure 1-1. The front panel of the instrument

Figure 1-2 shows the main areas of the display, and how you can interpret

some of the instrument’s settings from the display.

1-5

Page 14

Introducing the Instrument

A Quick Tour of the Front Panel

Softkeys

Figure 1-2. The instrument display

The softkeys are to the right of the display, and instead of placing a label on

the softkey itself, the label is actually located on the display next to the softkey. These labels on the display are called menus, and the menu being displayed depends on which key has been pressed. For example, pressing

base

brings up the Time Base menu, while pressing

Trigger

brings up the Trigger

Time

menu.

There are five types of softkeys, and there are some differences on how each

type of softkey operates. The five types of softkeys are toggle, menu, continuous, list, and single choice. Because the Trigger menu contains all five types of

softkeys, it is used over the next few pages to demonstrate the differences

among the softkeys.

When you press the

Trigger

key, the Trigger softkey menu comes up on the

right side of the display as shown in Figure 1-3.

Toggle softkeys

A typical example of the toggle softkeys is

Sweep

. A toggle softkey allows you

to choose between two or more selections, and you change selections by

pressing that same softkey.

1-6

Sweep

has choices of either triggered or freerun.

Page 15

Introducing the Instrument

A Quick Tour of the Front Panel

The highlighted choice is the selection that is currently active. In Figure 1-3,

triggered is highlighted, which indicates that the instrument is set to triggered

sweep.

Figure 1-3. Toggle softkey selection

Menu softkeys

A typical example of the menu softkeys is

External Scale...

(refer to Figure 1-3

on page 1-7). The ellipses after the word "scale" indicate that when you press

this softkey, a new softkey menu comes up on the display that allows you to

make several additional choices (refer to Figure 1-4). To exit this menu, simply press the

Done

softkey. The display returns to the previous menu.

1-7

Page 16

Introducing the Instrument

A Quick Tour of the Front Panel

Figure 1-4. Menu softkey selection

Continuous softkeys

A typical example of the continuous softkeys is

Level

. It has a range of values

that can be changed with the keypad, arrow keys, or knob.

Figure 1-5. Continuous softkey selection

1-8

Page 17

Introducing the Instrument

A Quick Tour of the Front Panel

Because the Trigger menu only has one of this type of softkey, it is active when

the menu comes up on the display. You do not need to press the

Level

softkey

when you want to change the trigger level. However, the Time base menu has

at least two of this type of softkey,

and Position

. In this case, only one of the softkeys is active at a time. To make

Bit Rate

(

Agilent 83480A only

) and

Scale

the other softkey active, you must press the corresponding softkey. You can

tell which softkey is currently active because it has a different colored background from the rest of the softkeys.

When using time base scale or channel scale, the knob and arrow keys operate

in two modes. One mode is a 1-2-5 sequence, while the other mode is a fine

mode that allows you to make smaller incremental changes. You activate the

fine mode by pressing

with the word

Fine

active, you will see the word

You get out of the Fine mode by simply pressing

by pressing the arrow key with the word

Shift

on the keypad, followed by pressing the arrow key

written in blue above that key. When the fine mode is

Fine

at the top-right corner of the graticule area.

Shift

on the keypad, followed

Fine

written above it.

List softkeys

A typical example of the list softkeys is

Hysteresis

. It has several stacked rectangles that represents a list of choices you can choose from. The top rectangle

shows the selection that is currently active. In the example below, normal is

the current selection.

Figure 1-6. List softkey selection

1-9

Page 18

Introducing the Instrument

A Quick Tour of the Front Panel

You change selections by pressing the

Hysteresis

softkey, which brings up a second level softkey menu on the display. Then, you use the softkeys, arrow keys,

or knob to change selections. To activate that selection, press the

then the display returns to the previous softkey menu. If you press the

Enter

softkey,

Cancel

softkey, the instrument returns to the previous selection.

Single choice softkeys

A typical example of the single choice softkeys is

Enter

. There are several variations of this type of softkey throughout the many softkey menus. When you

press the softkey, the instrument executes that softkey command.

Figure 1-7. Single choice softkey selection

1-10

Page 19

2

Equipment Used in These Exercises 2-3

Exercise 1. Installing a Plug-in Module 2-4

Exercise 2. Turning On the Instrument 2-5

Exercise 3. Connecting a Signal 2-6

Exercise 4. Finding the Signal 2-7

Exercise 5. Modifying the Setup 2-8

Exercise 6. Making Measurements on the Signal 2-13

Exercise 7. Using the Help Menu 2-17

Operating the Instrument

Page 20

Operating the Instrument

Operating the Instrument

Operating the Instrument

This chapter contains several exercises that will familiarize you with the operation of the instrument.

Exercises 1–3 show how to get the instrument up and running.

Exercises 4 and 5 demonstrate the vertical, horizontal, and trigger menus by

having you display a signal and then use the channel and

time base menus to expand the signal.

Exercise 6 shows you how to use the markers and automatic

measurement features to make a pulse width and voltage

amplitude measurement.

Exercise 7 introduces you to the Help menu.

You will find it easier to perform these exercises if you are at least a little

familiar with how to use the front panel. The best way to learn how to use the

front panel is to read Chapter 1, “Introducing the Instrument”.

Note

Clean the cabinet using a damp cloth only.

2-2

Page 21

Operating the Instrument

Equipment Used in These Exercises

Equipment Used in These Exercises

All of the pictures of the display in this book were generated using an

Agilent 83480A with an Agilent 83483A, 54751A electrical plug-in module, and

the signal from the Agilent 8133A pulse generator. If you are using a different

plug-in module or signal source, your display and instrument settings may

vary from the pictures in this book.

With the Agilent 83480A, the Agilent 83485A optical/electrical plug-in module

could also have been used. In this case, we would connect the signal to the

electrical input of the Agilent 83485A.

2-3

Page 22

Operating the Instrument

Exercise 1. Installing a Plug-in Module

Exercise 1. Installing a Plug-in Module

The purpose of a plug-in module is to provide measurement channels, including sampling for the mainframe. A plug-in module scales the input signal, sets

the bandwidth of the system, and allows the offset to be adjusted so the signal

can be viewed. The output of the plug-in module is an analog signal that is

applied to the A/D converters inside the mainframe.

1

Slide the plug-in module into either slots 1 and 2 or slots 3 and 4.

Note

The plug-in module will

If the mainframe is already turned on, you do not need to turn it off before you

install or remove a plug-in module. After a plug-in module is installed, the

mainframe identifies the plug-in module and the slot in which it is installed.

Note

In the examples to follow, it is assumed the Agilent 83483A or Agilent 54751A plug-in

module is resident in slots 1 and 2 of the mainframe.

2

Finger-tighten the knurled screw at the bottom of the plug-in module.

The RF connectors on the rear panel of the plug-in module are spring-loaded.

Finger-tighten the knurled screw to ensure there is a good ground connection

between the plug-in module and the mainframe.

3

To remove the module loosen the knurled screws and then pull on the screws

to take out the module. Do

operate if plugged into slots 2 and 3.

not

pull on the cables or connectors.

not

2-4

Page 23

Operating the Instrument

Exercise 2. Turning On the Instrument

Exercise 2. Turning On the Instrument

1

Set the line-voltage switch on the rear panel to the correct voltage selection for

your power source.

2

Connect a power cord from a power source to the rear-panel connector of the

mainframe.

3

Set the rear-panel line switch to the ON position.

CAUTION

When the mainframe is set to the 115 VAC mode, use the supplied power cord.

If you use an alternate power cord that

of the instrument, the power cord may become warm or the instrument may

not operate.

4

Set the front-panel power switch to ON.

After a few seconds, you will see a graticule on the display and a softkey menu

on the right side of the display. If the display is blank or if the message,

Power-On Test Failed

Chapter 3, “In Case of Difficulty” or to the optional

Service Guide

.

, appears at the top of the display, refer to

cannot

handle the power requirements

Agilent 83480A, 54750A

2-5

Page 24

Operating the Instrument

Exercise 3. Connecting a Signal

Exercise 3. Connecting a Signal

CAUTION

CAUTION

Electrostatic discharge (ESD) on or near input connectors can damage circuits

inside the instrument. Repair of damage due to misuse is

warranty. Before connecting any cable to the electrical input, momentarily

short the center and outer conductors of the cable together. Personnel should

be properly grounded, and should touch the frame of the instrument before

touching any connector. For more information regarding ESD, refer to the

Agilent 83480A, 54750A User’s Guide

1

Using the Agilent 8133A pulse generator (or equivalent), set a trigger and

square wave signal to the following:

Trigger level . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 mV (do not exceed 2 Vp-p)

Pulse level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 mV (do not exceed 2 Vp-p)

Pulse frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 MHz

Cables can build up high voltage levels that can discharge into the channel or

trigger inputs and cause damage. Cables should be discharged using a short or

a 50Ω terminator prior to connection.

2

Make sure the trigger and pulse signals are enabled.

3

Connect the trigger to the trigger input (channel 2) on the Agilent 83483A,

54751A electrical plug-in module.

4

Connect the pulse signal to the electrical input (channel 1) on the

Agilent 83483A, 54751A electrical plug-in module.

.

covered under

not

5

Display the Setup menu (on the Agilent 83480A, 54750A) and select the

default setup by pressing:

Setup

Default setup

,

The default setup puts the instrument in a predefined operating condition. This

gives you a known starting point for the following exercises. The default conditions are listed in the setup section of the

.

Guide

2-6

Agilent 83480A, 54750A User’s

Page 25

Operating the Instrument

Exercise 4. Finding the Signal

Exercise 4. Finding the Signal

The purpose of this exercise is to demonstrate the Autoscale function. The

Autoscale function can be used to automatically set up the display for most

input signals.

To activate the Autoscale function, press

Figure 2-1 will be displayed.

When the Autoscale function is enabled, the instrument quickly analyzes the

signal and sets up the vertical, horizontal, and trigger to optimize the display

of the signal. Autoscale can find repetitive signals with:

• a frequency greater than or equal to 50 Hz

• a duty cycle greater than 1%

• an amplitude greater than 50 mV p-p

Autoscale

. A screen similar to

Figure 2-1. Signal displayed using the Autoscale function

If you unintentionally press the

function, press

existed just prior to pressing the

Shift, Undo Autoscale

Autoscale

Autoscale

key or wish to disable the Autoscale

. The instrument is reset to the settings that

key.

2-7

Page 26

Operating the Instrument

Exercise 5. Modifying the Setup

Exercise 5. Modifying the Setup

The purpose of this exercise is to show you the Channel and Time Base

menus.

Changing the vertical scale

1

To display the Channel menu and change the vertical scaling, press:

Channel

(located on the plug-in module),

Change the scaling so the vertical height of the signal is about eight divisions,

using the knob, arrow keys or keypad.

Scale

Selecting Fine mode

When the knob and arrow keys are

ing in a 1-2-5 sequence. You can change the scaling in 1 mV increments by

using the keypad, or by setting the knob and arrow keys to the Fine mode.

2

To set the instrument to the Fine mode, press:

Shift, Fine

The word

fine mode is activated.

FINE

appears at the top-right corner of the display area when the

in the Fine mode, they change the scal-

not

2-8

Page 27

Operating the Instrument

Exercise 5. Modifying the Setup

Using the keypad

When using the Agilent 83483A, 54751A electrical plug-in module, the knob or

arrow key changes the scaling from 50 mV/div to 100 mV/div, in one step. At

50 mV/div the signal is clipped, and at 100 mV/div the signal is

to take advantage of the full vertical size of the display. In this case, you can

use the keypad to set the scaling to 75 mV/div.

3

To set the scaling to 75 mV with the keypad, type the number 75 on the keypad.

Then press

milli

, for millivolts, to select the unit of measure.

expanded

not

When you select a key with a unit of measure written on it, you do

press the

that do

ing on the value you enter with the keypad, the instrument may round the

value up or down. For example, if you try to enter 75.75 mV/div, the instrument will automatically round the entry to 75.8 mV/div.

Enter

key. You only press the Enter key if you are entering numbers

require a unit of measure or that are in volts or seconds. Depend-

not

need to

not

Setting the offset

Offset is similar to the vertical position on analog instruments, except offset is

calibrated. If offset is set to –10 mV, then you know the vertical center of the

display is –10 mV. (For optical channels, offset is referenced two divisions

above the bottom of the display.)

4

To move the waveform vertically on the display, press:

Offset

Readjust the scaling and offset until the signal is expanded vertically and is centered on the display as shown in Figure 2-2.

2-9

Page 28

Operating the Instrument

Exercise 5. Modifying the Setup

Figure 2-2. Signal vertical display

Note — Agilent 83480A only

You can automatically adjust the vertical scale, instead of following the preceding procedure by pressing:

Channel,

Channel autoscale

The amplitude scale is optimized for the input signal while the timebase settings are left

alone.

Changing the time base

5

To display the Time Base menu and change the horizontal scale, press:

Time base

Use the knob, arrow keys or keypad to change the scaling so the horizontal

width of the positive portion of the signal is about eight divisions.

2-10

Scale

,

Page 29

Operating the Instrument

Exercise 5. Modifying the Setup

Using the keypad

6

When the knob and arrow keys are not in the Fine mode, they operate in a 1-2-5

sequence, changing the scale from 5 ns/div to 2 ns/div in one large step. You can

use Fine mode so the knob and arrow keys adjust in smaller increments, or you

can use the keypad to enter a smaller value, like 1.4 ns/div.

Using the Position function

7

To horizontally center the signal on the display, press:

Position

The Position function moves the waveform horizontally on the display. (Position is sometimes referred to as delay.) The reference point is indicated by an

arrow at the bottom of the display as shown in Figure 2-3.

Figure 2-3. Signal horizontal display

2-11

Page 30

Operating the Instrument

Exercise 5. Modifying the Setup

Setting the reference

8

To set the reference to the left or center of the graticule area, press:

Reference

2-12

Page 31

Operating the Instrument

Exercise 6. Making Measurements on the Signal

Exercise 6. Making Measurements on the Signal

The purpose of this exercise is to familiarize you with the Marker menu and

the automatic measurement features of the instrument. You will begin by

using the manual markers to make a pulse width and an amplitude measurement on channel 1. After that, you will make the same measurements using

the automatic measurement features. There are many additional features built

into the instrument. Refer to the

more information on making automatic measurements.

Selecting the manual marker mode

1

To select the manual marker mode, press:

Agilent 83480A, 54750A User’s Guide

for

Marker

Change the mode selection by using the knob, arrow keys, or softkeys.

mode, manual, Enter

,

Setting the X, Y source

In the manual marker mode, there are two X-markers and two Y-markers. You

can position the X-markers horizontally and the Y-markers vertically on the

display. Use the X-markers to make timing measurements and the Y-markers

to make amplitude measurements.

2

To set the X1, Y1 Source to channel 1, press:

X1, Y1 Source, channel 1, Enter

3

To set the X2, Y2 Source to channel 1, press:

X2, Y2 Source, channel 1, Enter

2-13

Page 32

Operating the Instrument

Exercise 6. Making Measurements on the Signal

Positioning the markers

4

To position the X1 marker, press:

X1 Position

Set the X1 marker to the left edge of the pulse.

5

To position the X2 marker, press:

X2 Position

Set the X2 marker to the right edge of the pulse.

6

To position the Y1 marker, press:

Y1 Position

Set the Y1 marker to the bottom of the pulse.

7

To position the Y2 marker, press:

Y2 Position

Set the Y2 marker to the top of the pulse.

The display will be similar to Figure 2-4.

Figure 2-4. Signal custom measurements

2-14

Page 33

Operating the Instrument

Exercise 6. Making Measurements on the Signal

Notice the ∆X and ∆Y at the bottom of the display. The ∆X value is the width

measurement, and the ∆Y value is the amplitude measurement. The markers

allow you to make custom measurements on signals. Remember, they are

tied directly to the waveform data stored in memory, they are just positions on

the display.

Making an automatic +width measurement

8

To make an automatic +width measurement on channel 1, press:

not

Shift, +width

The automatic measurement results are displayed at the bottom left of the

screen.

channel 1, Enter

,

Making an automatic amplitude measurement

9

To make an automatic amplitude measurement on channel 1, press:

Shift, V amptd

The IEEE pulse parameter standards are used for all of the automatic measurements, unless changes are made in the define measurement menu.

Automatic measurements are preferred because they are faster and more

repeatable than manual marker measurements. Automatic measurements use

the waveform data stored in memory for all calculations, and the waveform

data in memory has a higher resolution than the resolution of the display. The

manual markers are

positions on the display.

The automatic measurement results are placed on the display where the vertical scale and offset values are normally displayed as shown in Figure 2-5.

channel 1

,

Enter

,

tied to the waveform data in memory, they are just

not

2-15

Page 34

Operating the Instrument

Exercise 6. Making Measurements on the Signal

Figure 2-5. Signal automatic measurements

Displaying the scale and offset values

10

To redisplay the vertical scale and offset values, press:

Shift, Clr meas

The automatic measurement results are replaced by the vertical scale and offset values.

2-16

Page 35

Exercise 7. Using the Help Menu

Exercise 7. Using the Help Menu

Operating the Instrument

To display the Help menu, press

played.

Figure 2-6. The instrument Help menu

A three-column index appears on the display. The left column lists the features of the instrument, the middle column lists the front-panel key, and (if

needed) the right column lists the softkey you press to find that feature. You

can use either the knob or arrow keys to scroll through the Help menu.

Help

. A screen similar to Figure 2-6 is dis-

2-17

Page 36

Page 37

3

If the Mainframe Does Not Operate 3-3

If the Plug-in Does Not Operate 3-4

In Case of Difficulty

Page 38

In Case of Difficulty

In Case of Difficulty

In Case of Difficulty

This chapter provides suggestions for you to follow if the mainframe or plug-in

module fails to operate. For a complete listing of display messages, refer to the

Agilent 83480A, 54750A User’s Guide

.

CAUTION

For complete service information, refer to the optional

54750A Service Guide

Review the procedure being performed when the problem occurred. A few

minutes spent performing some simple checks, before calling Agilent Technologies or returning the unit for service, may save waiting for your instrument to

be repaired.

Electrostatic discharge (ESD) on or near input connectors can damage circuits

inside the instrument. Repair of damage due to misuse is

warranty. Before connecting any cable to the electrical input, momentarily

short the center and outer conductors of the cable together. Personnel should

be properly grounded, and should touch the frame of the instrument before

touching any connector. Refer to the

for further information regarding ESD.

.

Agilent 83480A, 54750A User’s Guide

Agilent 83480A,

covered under

not

3-2

Page 39

If the Mainframe Does Not Operate

If the Mainframe Does Not Operate

If the mainframe does not operate, check the following:

1

Is the line fuse good?

2

Does the line socket have power?

3

Is the unit plugged in to the proper ac power source?

4

Is the mainframe turned on?

5

Is the rear-panel line switch set to on?

6

Will the mainframe power up

If the mainframe still does not power up, refer to the optional

Agilent 83480A, 54750A Service Guide

fied service department. Refer to the

for a complete listing of Agilent Sales and Service Offices.

without

the plug-in module installed?

or return the mainframe to a quali-

Agilent 83480A, 54750A User’s Guide

In Case of Difficulty

3-3

Page 40

In Case of Difficulty

If the Plug-in Does Not Operate

If the Plug-in Does Not Operate

If the plug-in does not operate:

1

Make the following checks:

• Is the plug-in module firmly seated in the mainframe slot?

• Are the knurled screws at the bottom of the plug-in module finger-tight?

• If other equipment, cables, and connectors are being used with the plug-in

module, are they connected properly and operating correctly?

• Review the procedure for the test being performed when the problem ap-

peared. Are all the settings correct? Can the problem be reproduced?

• Are the connectors clean? Refer to the

for more information about cleaning the connectors.

Guide

• Does the plug-in module work in the other two slots (1,2 or 3,4)?

2

Perform the following procedures:

• Make sure the instrument is ready to acquire data by pressing

• Verify the pulse output is connected to channel 1 on the Agilent 83483A,

54751A electrical plug-in module.

• Verify the trigger output is connected to the trigger input.

• Find any signals on the channel inputs by pressing

• Verify the Agilent 8133A pulse generator is set to:

Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . square wave

Amplitude. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 mV

Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 MHz

Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 mV

Pulse/trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . enabled

• See if any signals are present at the channel inputs by pressing:

Trigger

Sweep, freerun

,

Agilent 83480A, 54750A User’s

Run

.

Autoscale

.

3-4

Page 41

In Case of Difficulty

If the Plug-in Does Not Operate

After viewing the signal, press

triggered

.

• Make sure Channel Display is on by pressing:

Channel

Display on off

,

• Make sure the channel offset is adjusted so the waveform is not clipped off

the display.

• If you are using the plug-in module only as a trigger source, make sure at

least one other channel is turned on.

If all of the channels are turned off, the mainframe will

not

trigger.

• Make sure the mainframe identifies the plug-in module by pressing:

Utility

System config...

,

The calibration status of the plug-in modules is listed near the bottom of the

display, in the box labeled "

Plug-ins

". If the model number of the plug-in

module is listed next to the appropriate slot number, then the mainframe

has identified the plug-in.

~known"

If "

is displayed, instead of the model number of the plug-in

module, remove and reinsert the plug-in module in the same slot. If

~known

"

" is still displayed, then the memory contents of the plug-in module

are corrupt. Refer to the service guide for the plug-in module or contact a

qualified service department. If all of the above steps check out okay, and

the plug-in module still does not operate properly, then the problem is

beyond the scope of this book. Refer to the plug-in module service guide or

return the plug-in to a qualified service department.

3-5

Page 42

Page 43

Index

Symbols

+width key, 2-15

A

amplitude, 2-7

measurement, 2-14

scale, 2-10

analog signal, 2-4

automatic measurement, 2-13, 2-15

Autoscale key, 2-7, 3-4

B

bandwidth, 2-4

Bit Rate softkey, 1-8

C

cabinet, cleaning, iiv

CAL Signal overview, 1-4

Calibrate softkey, 1-4

Cancel softkey, 1-9

care

of cabinet, iiv

Channel autoscale softkey, 2-10

Channel key, 2-8, 3-5

channel scale, 1-9

classification

product, iiv

cleaning

cabinet, iiv

Clear display key, 1-5

Clr meas key, 2-16

connecting a signal, 2-6

continuous softkeys, 1-8

custom measurement, 2-14

D

Default setup softkey, 2-6

description of the instrument, 1-1

disk drive overview, 1-4

display

messages, 3-2

overview, 1-5

Display softkey, 3-5

Done softkey, 1-7

duty cycle, 2-7

E

electrical plug-in module, 2-3, 2-8

Enter softkey, 1-9–1-10, 2-13

entry device overview, 1-4

equipment used for display, 2-3

expanding the signal, 2-8

External Scale softkey, 1-7

F

finding input signals, 2-7

Fine softkey, 1-9, 2-8

freerun softkey, 3-4

front panel, 1-4, 1-10

fuse

values, iiv

H

hardkey overview, 1-5

Help key, 2-17

help menu, 2-17

horizontal

display, 2-7

scale, 2-10

Hysteresis softkey, 1-9

I

IEC Publication 61010-1, iiv

input signal, 2-4, 2-7

installing a plug-in module, 2-4

instant action key, 1-5

instrument

description, 1-1

settings, 1-5

L

Level softkey, 1-8

line voltage switch, 2-5

list softkeys, 1-9

Index-1

Page 44

Index

M

manual marker measurements, 2-15

manual softkey, 2-13

Marker key, 2-13

measuring the signal, 2-13

menu

display, 1-6

key, 1-5

softkeys, 1-7

messages on display, 3-2

milli key, 2-9

mode softkey, 2-13

modifying the setup, 2-8

O

offset, 2-16

adjustment, 2-4

Offset softkey, 2-9

optical/electrical plug-in module, 2-3

P

plug-in module, 2-8

installing, 2-4

Position softkey, 1-8, 2-11

power cord, 2-5

pulse

frequency, 2-6

generator, 2-3, 2-6

level, 2-6

setup modification, 2-8

Shift key, 1-9

signal

connection, 2-6

markers, 2-8

measurement, 2-13

single choice softkeys, 1-10

softkey overview, 1-6

square wave signal, 2-6

Sweep softkey, 1-6, 3-4

System configuration softkey, 3-5

T

Time base key, 1-5

time base scale, 1-9

toggle softkeys, 1-6

trigger

display, 2-7

level, 2-6

signal, 2-6

Trigger key, 1-5–1-6, 3-4

triggered softkey, 3-4

troubleshooting, 3-2–3-5

turning on the instrument, 2-5

U

Undo Autoscale key, 2-7

unit of measure, 2-9

using the front panel, 1-4, 1-10

Utility key, 1-4, 3-5

R

rear panel

connector, 2-5

line switch, 2-5

Reference softkey, 2-12

repetitive signals, 2-7

Run key, 1-5, 3-4

S

safety, iiv

laser classification, iiv

scale increments, 2-8

Scale softkey, 1-8, 2-8, 2-10

Setup key, 2-6

Index-2

V

V amptd key, 2-15

vertical

display, 2-7, 2-9

scale, 2-16

voltage selection, 2-5

W

width measurement, 2-14

X

X1, Y1 Source softkey, 2-13

Page 45

X1/X2 Position softkeys, 2-14

X2, Y2 Source softkey, 2-13

Y

Y1/Y2 Position softkeys, 2-14

Index

Index-3

Page 46

Loading...

Loading...