Page 1

User

and

Service Guide

Agilent

83446A/B

Lightwave Clock/Data

Receiver

Page 2

Agilent

Edition

1400

Santa

part

1

Printed

F

ountaingrove

Rosa,

95403-1799,

Notice

.

The

without

with

warranties

T

echnologies

notice

regard

of

consequential

of

this

material.

number:

83446-90018

in

US

A

P

arkway

CA

US

A

information

.

to

Agilent

this

T

material,

merchantability

shall

not

be

damages

in

March

2000

,

contained

echnologies

including

and

tness

liable

for

connection

in

this

makes

but

errors

with

document

no

warranty

not

limited

for

a

particular

contained

the

furnishing,

is

subject

to

, the

herein

to

change

of

any

kind

implied

purpose

or

.

for

incidental

performance

Agilent

,

or

or

use

Restricted

Government

of

the

252.227-7013

Commercial

other agencies

c

Copyright Agilent T

Rights

Rights

is

subject

in

T

echnical Data

for

DOD

Computer

.

Legend.

Use

to

restrictions

agencies

Software

echnologies 2000

,

duplication, or

as set

and Computer

,

and

subparagraphs

Restricted

disclosure by

forth in

Software

Rights

subparagraph

clause

(c) (1)

and

clause

at

FAR

the

U

(c)

at

DF

(c)

(2)

52.227-19

.S

ARS

.

(1)

(ii)

of

the

for

All Rights Reserved. Reproduction, adaptation, or translation without prior

written permission is prohibited, except as allowed under the copyright laws

.

Page 3

Printing

History

Agilent

Part

Number

83446-90004 Edition1October

83446-90011 Edition1June

83446-90018 Edition1March

Edition Date

1994

1995

2000

iii

Page 4

C

W

AU

A

Safety

The

following safety

yourself

Symbols

with each

symbols

of

the

are

symbols

used

and

throughout

its

meaning

this

before

manual.

operating

F

amiliarize

this

instrument.

The

TI

O

N

caution

procedure

damage

sign

until

The

R

N

I

N

G

warning

procedure

in

injury

indicated

sign

which, if

to

or

destruction

the

indicated

sign

which, if

or

loss

conditions

denotes a

not correctly

conditions

denotes

not

of

life

.

are

hazard

performed

of

the

instrument.

a

life-threatening

correctly

Do

not

proceed

fully

understood

to

the

instrument.

are

fully

performed

beyond

or

adhered

Do

not

understood

hazard.

or

adhered

a

warning

and

met.

It

calls

to

,

proceed

and

It

calls

attention

could

result

beyond

met.

attention to

to

,

could

sign

to

in

a

caution

result

until the

a

a

iv

L

A

j

CE

ISM1-A

The

instruction

necessary

This

symbol

This

symbol

This

symbol

The

CE

This

symbol

A

product.

The

CSA

for

mark

mark

manual

the

denotes

denotes

denotes

is

a

denotes

is

user

to

that

that

that

registered

that

a

registered

symbol.

refer

the

instrument

the

power

the

power

trademark

the

instrument

trademark

to

The

the

supply

supply

product

instructions

uses

alternating

is

turned

is

turned

of

the

European

is

an

of the

is

marked

with

in

the

manual.

current.

on.

o.

Community

Industrial

Scientic

Canadian Standards

this

.

and

symbol

when

Medical Group

Association.

it

is

1 Class

Page 5

General

This

is

W

A

R

N

I

N

G

ground

inserted

Any

a

incorporated

in

interruption

instrument

interruption

Safety Considerations

Safety

Class

a

socket

is

likely

is

prohibited.

of

I

product

in

the

outlet

the

to

make

(provided

power

provided

protective

the

instrument

cord).

with

conductor

with

a

The

mains

a

protective

inside

dangerous

protective

plug

shall

earth

or

outside

.

Intentional

earthing

only

contact.

of

the

be

W

A

R

N

I

N

G

Before

grounded

socket

of

or disconnection

this

outlet

the

protective

instrument

through the

provided

(grounding)

of the

is

switched

protective

with

protective

on

conductor

conductor

protective earth

,

make

earth

,

inside or

terminal

sure

of

the

contact.

it

has

been

ac

power

Any

outside the

can

result

properly

cable

to

a

interruption

instrument,

in

personal

injury.

If

this

W

A

R

N

I

N

G

equipment

condition

W

A

R

NI

N

G

There

personal

procedures

covers

W

A

R

N

I

N

G

W

A

RN

IN

G

C

A

U

T

I

O

N

No

personnel.

F

same

Always

Failure to ensure adequate earth grounding by not using

instrument

could

(in

are

many

injury

that

removed

operator

T

or

continued protection

type

and ratings

use

the

instrument damage

is

not

be

impaired.

which

all

points in

.

Be extremely

require

should

serviceable

o

prevent

three-prong A

.

used

as

This

means

for

the

instrument

careful.

operation of

be performed

parts

inside

electrical

against re

. The

use of

C

power

specied,

instrument

protection

Any

the instrument

only by

.

Refer

shock,

do

hazard, replace

other fuses

cord

the

protection

must

are

intact)

which

can,

adjustments

trained

servicing

not

remove

or

supplied

provided

be

used

only

.

if

contacted,

or

service

with

protective

service

to

qualied

covers

line fuse

materials

with

is

this

instrument.

this cord may cause

by

the

in

a

normal

cause

personnel.

.

only

with

prohibited.

CAUTION

This product has autoranging

within the specied range

.

line voltage input. Be sure the supply voltage is

v

Page 6

Certication

and Assistance

Agilent

at

certies

National

by

Technologies

the time

that its

Institute of

the Institute's

International

Product

are

F

or

Service

maintenance

available

any

assistance

Oce

of

shipment

certies

from

that

the

calibration measurements

Standards and

calibration facility

Standards

Organization

agreements

for

A

gilent

T

echnologies

,

contact

your

.

this

factory

T

echnology

,

and

members

and

nearest

product

.

Agilent

are

to

the

other

customer

products.

A

gilent

met

its

T

echnologies

traceable

(NIST),

calibration

.

T

echnologies

published

to

the

to

the

extent

facilities

assistance

Sales

specications

further

United

States

allowed

of

other

agreements

and

vi

Page 7

Declaration

of Conformity

vii

Page 8

W

arranty

This

Agilent T

material

During

repair

F

or warranty

facility

charges

charges

charges

another

and workmanship

the warranty

or replace

designated

to

to

, duties

country

echnologies

products which

service or

Agilent

return

,

the

and

.

instrument

for

period, Agilent

repair

by

Agilent

T

echnologies

product

taxes

for

product

a

period

T

echnologies

prove

,

this

product

T

echnologies

and

Agilent

to

Buyer

products

of

one

to

be

must

.

Buyer

T

.

However

returned

is

warranted

year

from

will,

defective

be

returned

.

shall

echnologies

,

Buyer

to

Agilent

against

date

at

its

prepay

shall

shall

T

defects

of

shipment.

option,

to

a

service

either

shipping

pay

shipping

pay

all

shipping

echnologies

in

from

Agilent T

Agilent T

instructions when

does not

rmware

Limit

The

or

interfacing,

environmental

or

NO

TECHNOLOGIES

OF

Ex

THE

REMEDIES

ANY

echnologies warrants

echnologies for

warrant that

will

be uninterrupted

a

tion

of

W

foregoing

inadequate

unauthorized

maintenance

OTHER

W

ARRANTY

MERCHANT

clusive

Remedies

REMEDIES

.

A

GILENT TECHNOLOGIES

DIRECT, INDIRECT

properly installed

arranty

warranty

maintenance

specications

.

SPECIFICALL

ABILITY

PRO

DAMAGES, WHETHER B

LEGAL THEORY

.

use

that its

with

software

an

instrument

on

the

operation

shall

by

or

not

Buyer

of

error-free

apply

modication

for

the

IS

EXPRESSED

Y

DISCLAIMS

AND

FITNESS

VIDED HEREIN

, SPECIAL, INCIDENT

ASED ON CONTRA

and

will

that

instrument.

the

instrument,

.

to

defects

,

Buyer-supplied

or

misuse

product,

OR

,

or

improper

IMPLIED

THE

FOR

A

P

ARTICULAR

ARE BUYER'S

SHALL

NOT

AL, OR CONSEQUENTIAL

CT

, TORT

rmware

execute

designated

its

Agilent

or

software

resulting

from

software

operation

outside

site

.

A

GILENT

IMPLIED

W

ARRANTIES

PURPOSE.

SOLE AND

BE

LIABLE

, OR ANY OTHER

by

programming

T

echnologies

,

or

improper

or

of

the

preparation

EXCLUSIVE

FOR

viii

Page 9

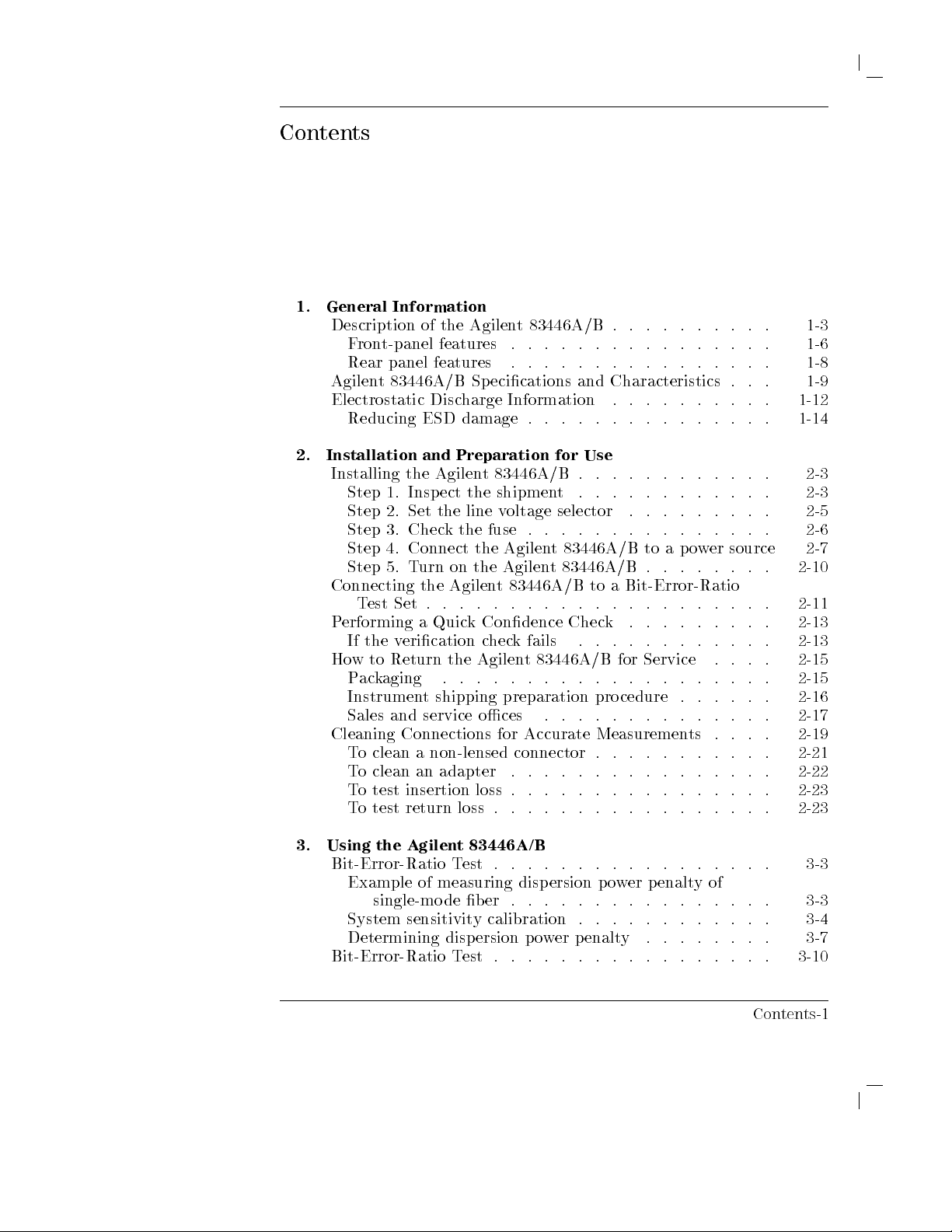

Contents

1.

General

Description

F

ron

Rear

Agilen

Electrostatic

Reducing

2.

Installation

Installing

Step

Step

Step

Step

Step

Connecting

T

P

erforming

If

Ho

w

P

Instrumen

Sales

Cleaning

T

T

T

T

Information

t-panel

panel

t

83446A/B

the

1.

Insp

2.

Set

3.

Chec

4.

Connect

5.

T

urn

est

Set

a

the

v

erication

to

Return the

ac

k

aging

and service

Connections for

o clean

o clean

o test

o

a

an adapter

insertion loss

test

return

of

the

Agilen

features

features

Sp

Disc

harge

ESD

damage

and

Preparation

Agilen

ect

the

the

line

k

the

the

on

the

the

Agilen

.

. .

.

Quic

k

Agilent

.

. .

t

shipping

non-lensed

loss

t

83446A/B

.

.

.

.

.

.

.

.

.

.

ecications

Information

.

t

83446A/B

shipmen

v

oltage

fuse

.

Agilen

Agilen

t

83446A/B

.

.

.

Condence Chec

c

heck

fails

. .

.

preparation

oces

Accurate

connector

.

.

.

.

.

.

.

and

.

.

.

for

Use

.

t

.

selector

.

.

. .

t

83446A/B

t

83446A/B

.

.

.

.

83446A/B for

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Characteristics

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

to

a

.

.

to

a

Bit-Error-Ratio

.

.

.

.

.

k

.

.

.

.

.

.

.

.

Service

.

.

.

.

.

pro

cedure

.

.

.

.

.

Measuremen

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

. .

.

po

. .

.

.

.

.

.

.

ts

.

.

.

. .

.

.

.

.

.

.

.

.

wer

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

source

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

. .

.

.

.

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

1-3

1-6

.

1-8

.

1-9

.

1-12

1-14

2-3

2-3

.

2-5

.

2-6

2-7

.

2-10

.

2-11

.

2-13

.

2-13

.

2-15

.

2-15

.

2-16

.

2-17

.

2-19

.

2-21

.

2-22

.

2-23

2-23

3. Using

the Agilent 83446A/B

Bit-Error-Ratio T

Example of measuring disp

single-mode b er .

System sensitivity calibration .

Determining dispersion po

Bit-Error-Ratio T

est

. . . . . . . . . . . . . . . . .

est .

ersion po

. . . . . . . .

wer penalt

. . . . . . . . . . . .

wer penalt

. . . . . . .

. . . . . . . . .

y . . . . .

yof

. . . .

. .

. . .

Contents-1

3-3

3-3

3-4

3-7

3-10

Page 10

Replaceable

parts

W

4.

Servicing

General

T

Adjustmen

P

Replacemen

Replaceable

Example

aveform

Example

roublesho

P

o

w

Photo

erformance

T

est

T

est

T

est

T

est

T

est

Replacing

Replacing the

Replacing

Replacing

of

T

est

of

signal

the

information

oting

t

er

supply

detector/clo

pro

cedure

1.

Sensitivit

2.

Maximum

3.

Electrical output

4.

Rear-panel

c

hec

k

only)

5.

Input

t

optimizing

.

.

.

measuring

.

.

.

.

Agilent

.

.

Pro

cedures

adjustmen

.

.

T

ests

.

y

.

optical

Pro

cedures

the

RF

ac

cable

the

p

o

w

the

PCDR

parts

.

laser

.

.

.

ey

e

.

.

.

83446A/B

.

.

.

.

.

.

.

t

c

k/data

.

.

. .

.

.

.

.

.

.

operating

input

.

.

.

return

.

cable

or

assem

er

supply

assem

.

.

.

extinction

.

.

.

.

diagram

.

.

.

.

.

.

. .

. .

.

.

.

pro

cedure .

reco

v

ery

. .

.

.

.

.

.

.

input p

signal amplitudes

p

ort

v

erication

.

.

.

loss

.

.

.

the

RF

bly

.

.

bly

.

.

.

ratio

..

..

using

.

.

.

. .

. .

. .

. .

. .

assem

.

.

.

.

. .

.

.

.

o

w

er

.

.

.

.

.

.

.

.

.

connector

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

reco

v

ered

clo

.

. .

. .

. .

. .

. .

.

.

.

.

.

.

.

. .

. .

.

.

. .

. .

.

bly adjustmen

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

(functional

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

. .

.

3-11

.

3-13

c

k

3-13

.

4-3

.

4-5

.

4-8

.

4-8

t

.

4-10

.

4-11

.

4-15

.

4-20

.

4-21

.

4-23

.

4-24

.

4-26

.

4-27

.

4-28

4-30

.

4-31

4-32

Index

Contents-2

Page 11

Figures

1-1.

1-2.

1-3.

1-4.

2-1.

2-2.

2-3.

2-4.

3-1.

3-2.

3-3. Setup

3-4. Setup

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

Agilent 83446A/B

The Agilent

The Agilent

Example of

Opening the

Selecting

A

C

power

Connecting

system.

Setup

Setup

ber.

clock. .

Agilent

Laser

Agilent

Wiring

Wiring

Agilent

Agilent

83446A/B

83446A/B rear

a static-safe

fuse holder

the

line

cables

the

..

for

calibration

to

measure

..

..

for optimizing

for measuring

..

83446A/B block

transmitter

83446A/B

diagram

Diagram

83446A/B

83446A/B

block

front-panel.

voltage

available

Agilent

.

.

.

of

dispersion

.

.

laser

eye

.

.

.

setup

test

equipment

for

the

for

the

assembly

replaceable

diagram.

panel.

work

station.

door

.

value

.

.

.

83446A/B

.

.

.

.

dispersion

power

.

.

.

.

extinction

diagram

.

.

.

.

diagram.

.

.

.

.

line

module

power

supply

level

hardware

.

.

.

.

.

.

.

.

.

.

.

.

.

and

checking

.

.

.

.

to

a

bit

.

.

.

.

power

penalty of

.

.

.

.

ratio

by

triggering

.

.

.

.

.

.

.

.

.

.

.

setup

.

.

.

.

terminals

replaceable

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

the

.

.

.

error

.

.

.

penalty

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

parts

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

fuse

.

.

.

..

ratio

test

.

.

.

.

.

test

system.

single-mode

.

.

.

.

..

.

.

.

.

from

recovered

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

..

.

1-4

.

1-6

.

1-8

.

1-13

.

2-5

.

2-6

. 2-9

.

2-11

3-4

. 3-7

.

3-12

.

3-14

.

4-5

.

4-12

.

4-16

.

4-28

.

4-30

.

4-34

. 4-36

Contents-3

Page 12

T

ables

1-1.

Agilent 83446A/B

1-2.

Static-Safe A

2-1.

Agilent 83446A/B

2-2.

Agilent T

3-1.

Average

4-1.

Required

4-2.

V

oltages

4-3.

Required

4-4.

Laser Transmitter

4-5.

Sensitivity

4-6.

Input

4-7. T

orque V

4-8. Line

4-9. DC

Gating P

Optical

alues .

Module to

Power

4-10. Assembly-Level

4-11.

Replaceable

Specications

ccessories

Power

.

.

Requirements

echnologies Service

eriod

to

A

T

ools

.

.

.

.

.

on

the

DC

P

ower

T

est

Equipment

T

est

Setup

Return

DC

Supply

Setup

.

.

T

erminal

Loss

.

P

ower

.

.

.

.

.

.

Replaceable P

Hardware .

.

and

.

.

.

.

Numbers

chieve

Supply

Supply

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

100

.

T

erminals

.

.

.

..

.

Connections

Connections

arts

.

.

.

.

.

Characteristics

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Errors

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

1-10

.

1-14

.

2-7

.

2-18

.

3-5

. 4-4

. 4-7

4-11

.

4-13

.

4-17

.

4-24

4-27

.

4-29

.

4-30

.

4-35

.

4-37

Contents-4

Page 13

1

General

Information

Page 14

General

What

you'll nd

A

brief

description

A

list

of

options and

Agilent

83446A/B

Information

Information

Information

in this

chapter

of the

Agilent 83446A/B

accessories available

about

about

specications

the

lightwave

avoiding

and characteristics.

receiver's

damage

to

lightwave clock/data

.

serial number

the

instrument

receiver.

label.

from electrostatic

discharge

.

1-2

Page 15

Description

The

Agilent 83446A/B

clock

operate

and data

at the

information

following SONET/SDH

of

the

lightwave

Agilent 83446A/B

from

clock/data

digitally

receivers

modulated

rates:

are

designed

lightwave

to

signals

extract

.

They

Select

optical

electrical

Monitor

the

analog

input

the

quality

eye

Agilent

Agilent

Both

G.958,

ranges

Agilent

An

or

input

electrical

selects

input.

rear

The

of

the

by

the

approximately

not

83446A

83446B

receivers

and

Bellcore

.Outputs

71604B

on

the

signal

between

F

or

best

panel

inputs

auxiliary

analog

A

GC

eye

amplier

gain-limited

:

::

:

:

:

::

:

:

have

been

GR-253-CORE

are

optimized

.

rear

panel

at

the

specied

the

front

sensitivity

simultaneously

output

.

When

on

monitoring

and

0

23

dBm.

so

its

level

:

:

:

:

:

:

:

:

:

:

designed

is

panel

,

signals

the

its

When

is

:

:

:

:

:

:

:

:

:

:

:

:

for

provided

data

optical

.

front

level

monitoring

directly

:

:

:

:

::

:

:

:

:

::

per

the

for

the

use

with

for

rate

input

should

panel

an

optical

is

constant

proportional

::

::

::

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

recommendations

1310/1550

bit-error-ratio

recovering

.

A

slide

switch on

and

the

not

be

applied to

can

be

used

to

signal

this

for

input

an

electrical

to

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

of

nanometer

testers

clock

and

the rear

rear

panel electrical

both the

monitor

output

signals

signal

the

incoming

::

2.48832 Gb/s

::

:

622.08

ITU-T

G.957,

wavelength

,

such

as

data

from

panel

front

the

quality

is

gain-limited

above

this

output

signal

Mb/s

the

an

and

of

is

level.

NO

T

E

This

auxiliary

ouput on

used

for rigorous

not conform to the requirements for e

GR-253-CORE. F

e

ye

the front

mask

panel is

compliance

intended for

testing.

monitoring purposes

The

frequenc

y

response

ye mask testing as described in ITU-T G.957 and Bellcore

or mask testing use an appropriate reference receiver

of

only and

the

should

auxiliary output

not

be

does

, such as the Agilent 83440-series

reference receivers.

1-3

Page 16

General

Information

Description of

F

or

more

Chapter

3.

the Agilent

information

83446A/B

on

using

the

lightwave

clock/data

receiver

refer

to

Learning the

story

.

.

.

inside

The block

The

photodetector

The

single-mode

when

diagram

for

optical-to-electrical

which

optical

used

input

or

multimode

with

uses

62.5

automatic-gain-control

switch,

receiver's

hybrid.

circuit. The

signal.

signal.

interface

is

split

front

The

data

Clock

The

phase

is

maintained

into

panel.

clock

and

two

signal

is

threshhold-detected

data

relationship

the

Agilent

conversion

covers

50

the

m

ber

m

ber

(A

GC)

paths

The

other

is

recovered

outputs

to

approximately

83446A/B

is

performed

1310

and

multimode

inputs

.

.)

The

photodetector

amplier

.

One

path

path

using

are

noninverting

between

1550

ber

(A

slight

and,

provides

goes

and

the

6

0.25

is

shown

by

nm

for

loss

after

to

the

a

phase

re-timed

with

two

outputs

unit

going

in

Figure

a

sensitive

wavelength

compatability

in

sensitivity

output

is

amplied

through

an

auxiliary

clock

and

data

and

frequency-locked

to

the

recovered

respect

at

the

intervals

.

1-1

APD

ranges

with

the

output

to

the

front

.

.

either

results

in

MMIC

on

recovery

clock

incoming

panel

an

the

loop

1-4

Figure 1-1. Agilent 83446A/B block diagram.

Page 17

Description of

General

the Agilent

Information

83446A/B

Accessories

Options

Serial

Numbers

supplied

The

Agilent 83446A/B

P

ower cable

FC/PC

A

gilent 83446A/B

The

following

Option

The

010

Fiber

introduction

Agilent

their

T

echnologies service

Technologies

performance,

changes

Whenever

have

the

complete

A

serial-number

It

contains

receiver

.

information

number

.

(refer to

front-panel connector

option

Optics Handbook

and

to

each

you

contact

complete

and

accurate

the

serial

Whenever

about

lightwave clock/data

Figure 2-3

interfaces

Lightwave Clock/Data

is

available:

Deletes FC/PC

front-panel connector

, Agilent

reference

for

ber-optic measurements

makes frequent

usability,

or reliability

personnel have

type

of

equipment,

Agilent

serial

number

T

echnologies

information

label

is

attached

number

you

your

and

specify

lightwave

the

)

part number

improvements

, and

access to

based

available

possible

to

the

rear

the

options

serial

receiver

,

receiver is

Receiver

User

5952-9654, is

to

to

control

complete records

on

the

equipment's

about

your

to

ensure

obtaining

.

of

the

lightwave

installed

number

be

sure

or

to

shipped with:

and

Service

interface

an

.

its

products

costs

.

Agilent

of

serial

lightwave

the

receiver

in

the

lightwave

refer

to

it

in

use

the

complete

Guide

to

enhance

design

number

receiver

most

.

obtaining

.

.

,

1-5

Page 18

General

Information

Description of

Front-panel features

the Agilent

83446A/B

1-6

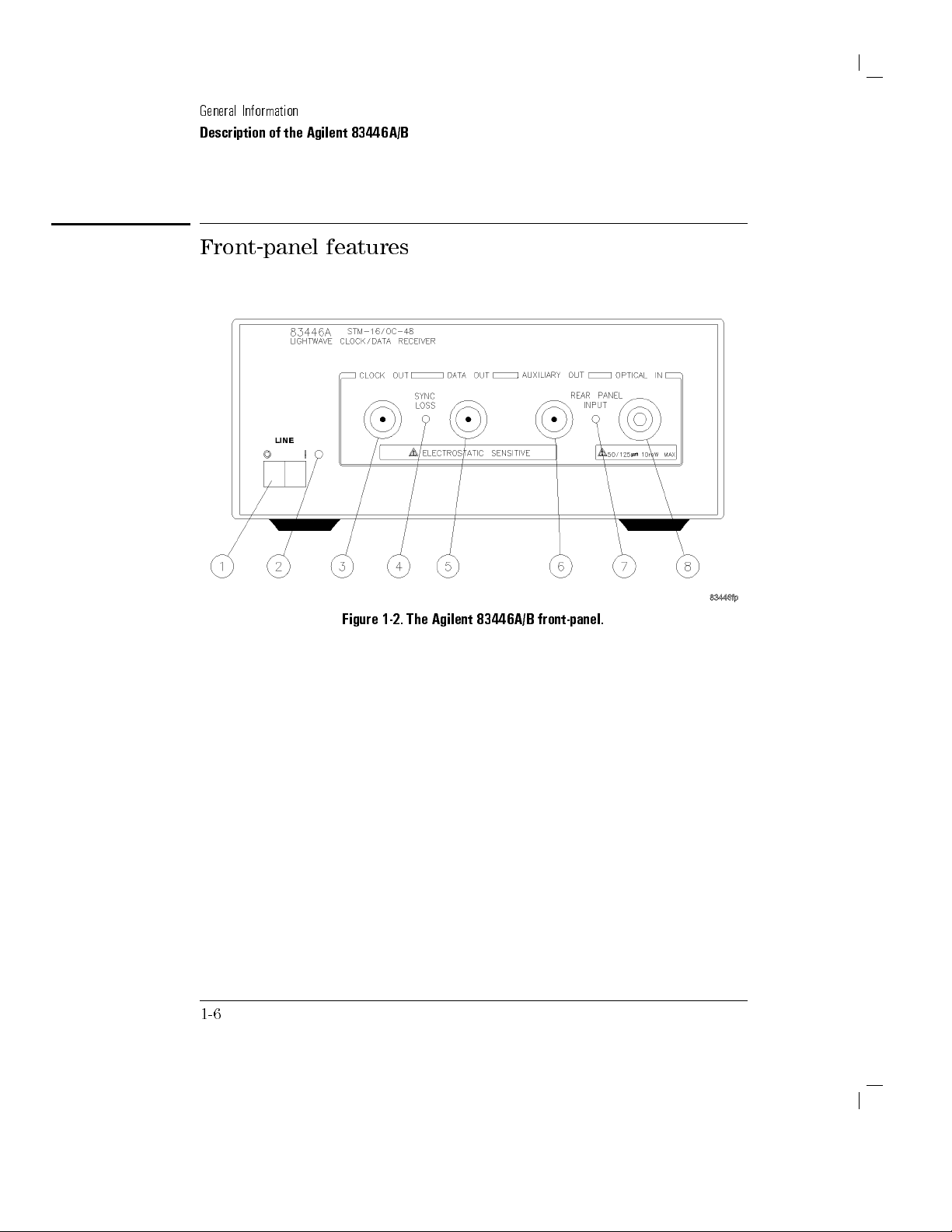

Figure

1-2.

The

Agilent

83446A/B

front-panel.

Page 19

1.

Line

switch.

2.

P

owerline

3.

CLOCK

for

Agilent

output is

synchronized

clock

frequency

4.

SYNC

LOSS

synchronized

remain

at

DATA

5.

DATA

OUT

corresponding

clock

transitions

6.

AUXILIARY

version

is

amplitude

0

23

dBm.

stabilized

of

the

LED

.

OUT

connector

83446B).

synchronized

to

an

.

indicator

to

the

synchronized

OUT.

connector

to

OUT

connector

of

the

input

stabilized

When

so

its

output

incoming

signal.

the

to

used

input

.

6

.

Output

When

with

signal

.

This

bit

rate

to

input

This

incoming

0.25

signal.

for

with

amplitude

the

the

LED

of

signals

output

unit

.

This

When

input

an

is

nominally

SYNC

LOSS

bit

rate

the

output

is

o

whenever

the

input

provides

data

stream.

intervals

output

used

signals

electrical

is

directly

indicator

of

signal.

several

.

provides

with

greater

input

Description of

2.48832

GHz

is

the

input

free-runs

the

clock

Note

dB

below

an

amplied,

Data

transitions

a

non-retimed

an

optical

than

this

output

proportional

General

the Agilent

(622.08

MHz

extinguished

signal.

near

that

the

output

CLOCK

the

onset

retimed

When

nominal

is

signal

are

aligned

analog

input

this port

approximately

is

not

amplitude

to

the

amplitude

Information

83446A/B

this

not

OUT

can

of

errors

to

7.

REAR

switch

8.

OPTICAL

input

adapters

PANEL

on

IN

is

+10

from the

INPUT

the

rear

connector

dBm.

indicator

panel

This

.

This

is

set

to the

.

Maximum

input accepts

LED is

signal

Agilent 81000-series

REAR

input is

any of

.

on

when

position.

0

9

the connector

the

dBm,

input

damage

selector

level

interface

1-7

Page 20

General

Information

Description of

the Agilent

83446A/B

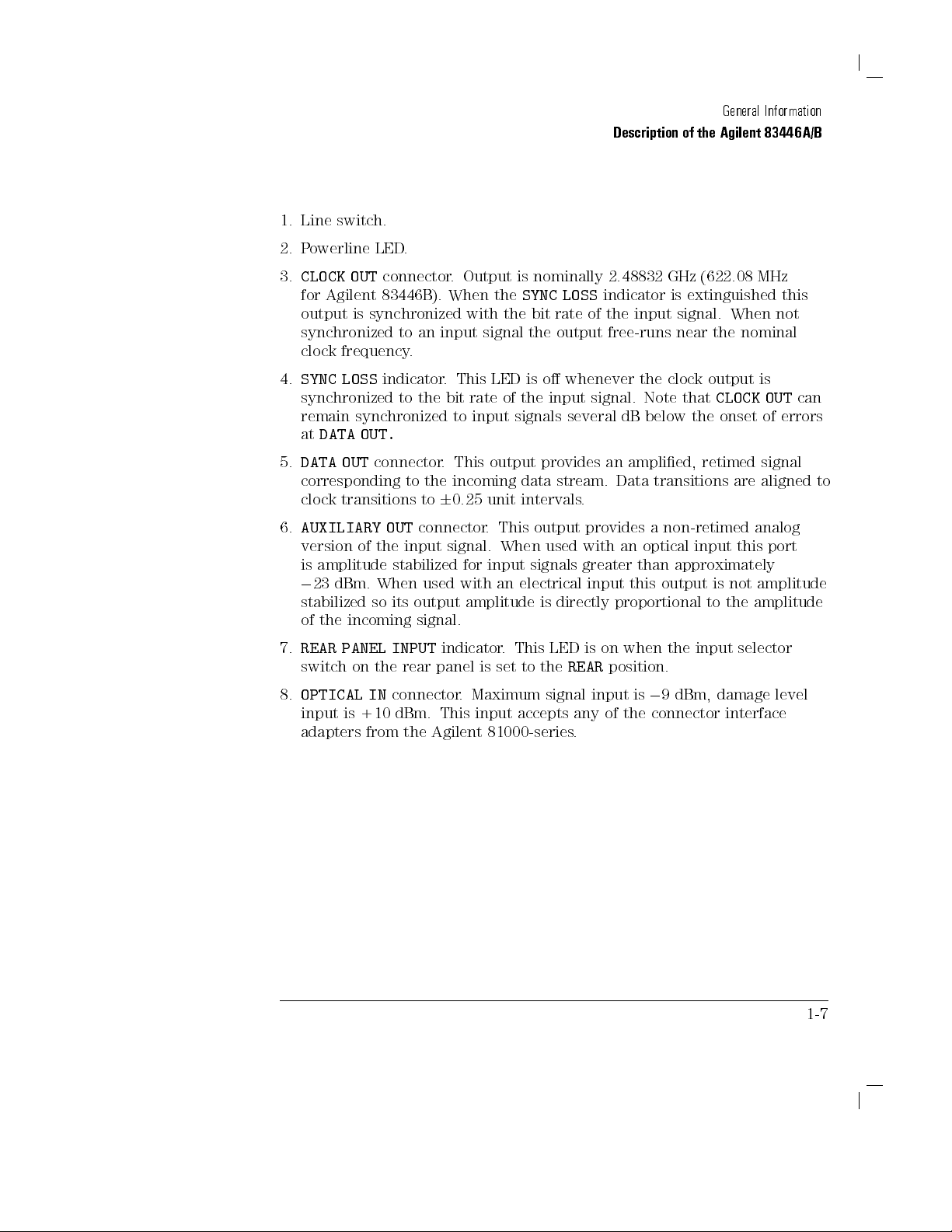

Rear panel

1.

P

ower

line

2.

CLOCK

electrical

RECOVERY

signal.

features

Figure

module

.

INPUT

1-3.

The

connector

Agilent

83446A/B

.

Use

to

recover

rear

panel.

clock

and

data

from an

3.

1-8

CLOCK

optical

RECOVERY

input

and

INPUT

rear

SELECT

electrical

switch.

input.

Use

to

select

between

front

Page 21

Agilent

83446A/B

istics

T

able 1-1

values

Specications describe

range

after

continuous

Characteristics

nonwarranted,

lists

specication,

. The

distinction

C

0

to +55

the instrument's

operation.

provide

performance parameters

italics.

Typical

Performance

performance which

Nominal

Value

indicates

parameter.

Specications

characteristics

between

these

warranted performance

C

(unless otherwise

temperature has

useful

information

,

where

most units

the

listed,

will meet.

expected,

,

typical

terms

noted). All

been

.

Characteristics

is

not

warranted

but

is

described

over

stabilized

by

giving

not

warranted

and Character-

performance

the

specications

functional,

,

but

,

and

as

follows:

temperature

apply

after

30

minutes

but

are

printed

indicates

,

value

of

nominal

in

the

of

1-9

Page 22

General

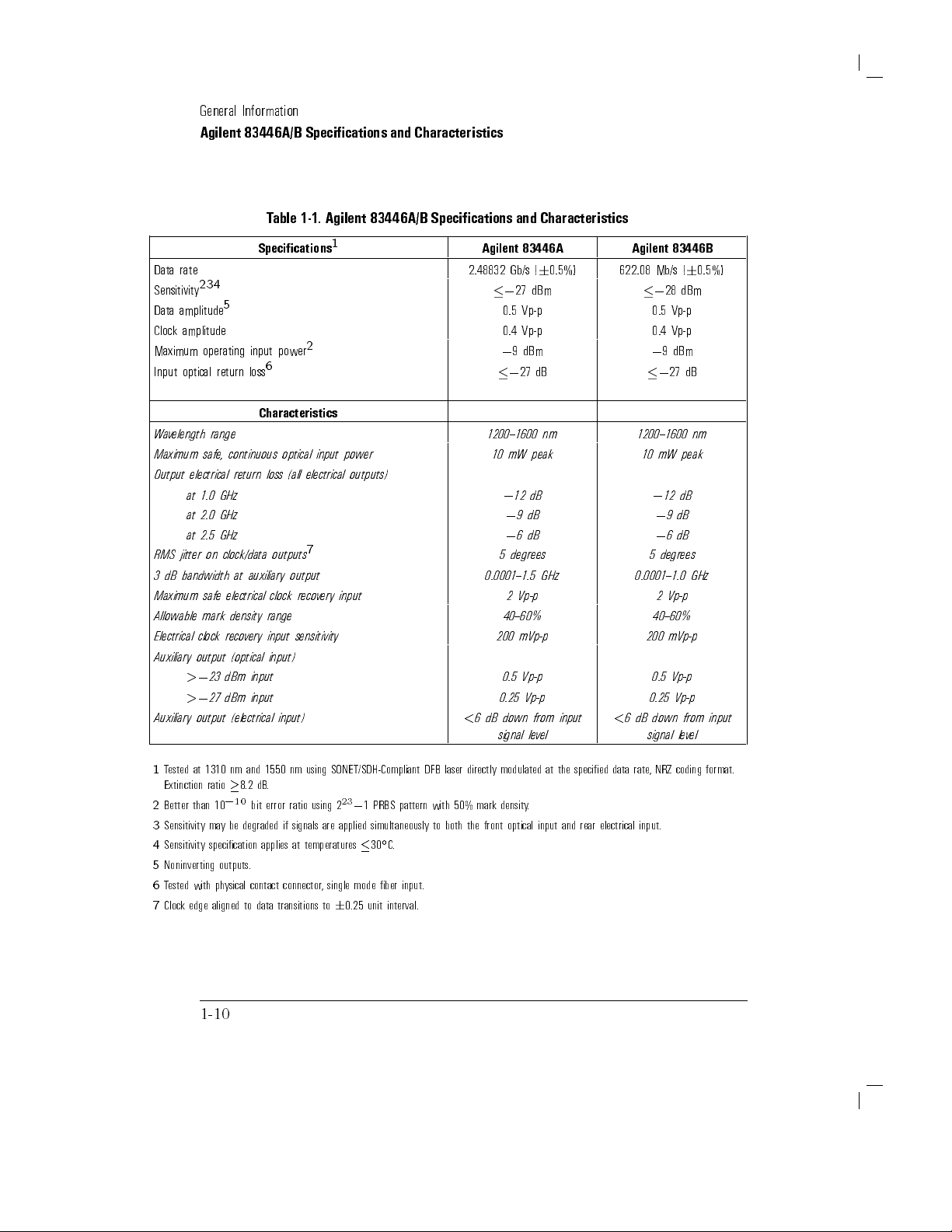

Agilent 83446A/B

Data

rate

2

Sensitivity

3

Data amplitude

Clock

amplitude

Maximum

Input

W

Maximum

Output

RMS

3

Maximum

Allowable

Electrical

a

v

elength

dB

operating

optical

range

safe

electrical

at

1.0

at

2.0

at

2.5

jitter

on

bandwidth

safe

mark

clock

Auxiliary output

>

0

23

>

0

27

Auxiliary

output

Information

4

5

input

return

loss

,

continuous

return

GHz

GHz

GHz

clock/data

at

auxiliary output

electrical

density range

reco

v

ery

(optical

dBm

input

dBm

input

(electrical input)

Specications and

T

able

1-1.

Specications

2

power

6

Characteristics

optical

input

loss

(all

electrical

7

outputs

clock

reco

v

ery

input

sensitivity

input)

Agilent

1

power

outputs)

input

Characteristics

83446A/B

Specications

Agilent

2.48832

0

0

1200{1600

10

0.0001{1.5

200

<

6

dB down

signal

and

Characteristics

83446A

Gb/s

27

(

6

dBm

0.5%)

Agilent

622.08

0

83446B

Mb/s

28

0.5 Vp-p 0.5 Vp-p

0.4

0

mW

0

0

0

5

degrees

2

9

12

Vp-p

dBm

27

9

6

Vp-p

dB

nm

peak

dB

dB

dB

GHz

0.4

Vp-p

0

9

dBm

0

27

1200{1600

10

mW

0

12

0

9

0

6

5

degrees

0.0001{1.0

2

Vp-p

40{60% 40{60%

<

6

dB down

200

0.5

0.25

signal

mVp-p

Vp-p

Vp-p

0.5

0.25

mVp-p

Vp-p

Vp-p

from input

lev

el

(

6

0.5%)

dBm

dB

nm

peak

dB

dB

dB

GHz

from input

lev

el

1

T

ested

at

1310

nm

and

1550

nm using

Extinction ratio

2

Better than

3

Sensitivity

4

Sensitivity specication applies

5

Noninverting outputs.

6

Tested with ph

7

Clock edge aligned to data transitions to

8.2

dB

.

0

10

bit

10

may

error ratio

be degraded

ysical contact connector

if signals

at temperatures

1-10

SONET/SDH-Compliant DFB

23

0

using 2

1 PRBS

are applied

,

simultaneously to

C.

30

single mode ber input.

6

0.25 unit interval.

pattern with

laser directly

50% mark

both

the

front

modulated

density.

optical

input

at

the

specied

data

rate

,

NRZ

coding

format.

and

rear

electrical

input.

Page 23

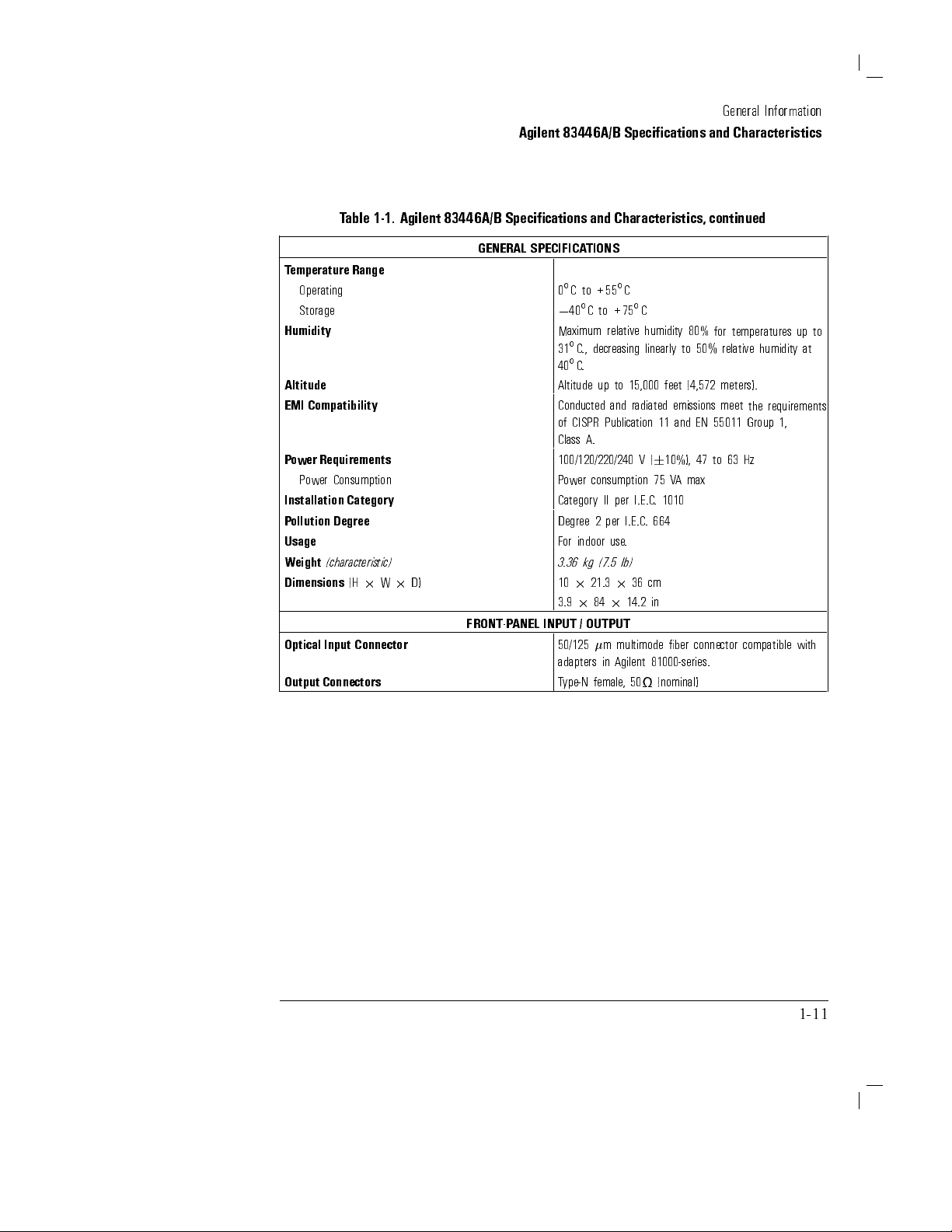

T

able

1-1.

Agilent

83446A/B

Agilent 83446A/B

Specications

Specications and

and

Characteristics,

General

Characteristics

continued

Information

T

emperature

GENERAL

Range

SPECIFICA

Operating 0C

Storage

Humidity

Altitude

EMI

Compatibility

P

ower

Requirements

P

ower

Consumption

Installation

P

ollution

Category

Degree

Usage

Weight

(characteristic)

Dimensions

Optical

Output

(H

2

Input

Connector

Connectors

W

2

D)

FRONT-P

ANEL

TIONS

to

0

40Cto

Maximum

31C

.,

40C

.

Altitude up

Conducted

of

CISPR

Class

A.

100/120/220/240

P

ower

Category

Degree

F

or indoor

3.36

kg

10

2

3.9

2

INPUT

/

OUTPUT

50/125

adapters

T

ype-N

C

+55

+75

relative humidity

decreasing

to 15,000

and radiated

Publication 11

consumption

II

per

I.E.C

2

per

I.E.C

use

.

(7.5

lb)

21.3

2

36

84

2

14.2

m

multimode

in

Agilent

female

,

50

C

linearly

feet (4,572

V

(

6

10%),

75

V

.

1010

.

664

cm

in

ber

81000-series.

(nominal)

80%

to 50%

emissions

and EN

47

A

max

connector

for

temperatures

relative humidity

meters).

meet

the

55011

Group

to

63

Hz

compatible

up

to

at

requirements

1,

with

1-11

Page 24

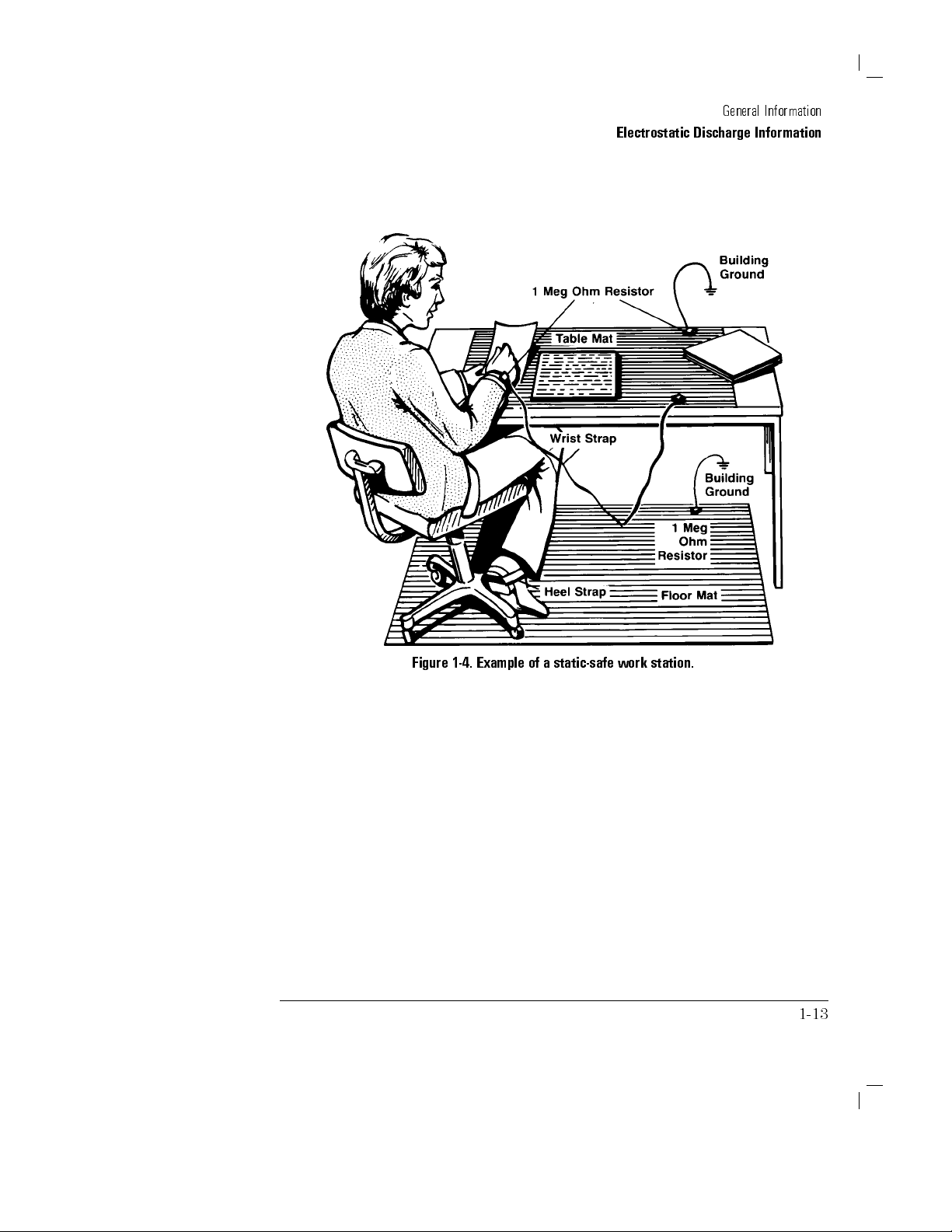

Electrostatic

Discharge

Information

Electrostatic

All

work on

station.

types

of ESD

Conductive table-mat

Conductive

Both

types

Of

the two

ESD

protection

To

ensure user

of isolation

static-safe accessories

W

A

R

N

I

N

G

These

working

discharge (ESD)

electronic

Figure 1-4

protection:

oor-mat

,

when

,

only

when

safety,

from ground.

techniques

on

circuitry

shows an

used

the

table-mat

used

.

for

can

assemblies

example

and wrist-strap

and

heel-strap

together

,

provide

and

alone

.

the

static-safe

Refer

to

a

static-safe

with

a

voltage

damage

should

of

combination.

combination.

wrist-strap

accessories

T

able

1-2

work

potential

or

destroy

be

performed

a

static-safe

a

signicant

combination

for

station

electronic

at

work

level

must

provide

information

should

greater

not

than

components

a

static-safe

station

of

ESD

provides

at

on

ordering

be

used

500

work

using

protection.

adequate

least

1

M

when

volts

.

.

two

1-12

Page 25

General

Electrostatic Discharge

Information

Information

Figure

1-4.

Example

of

a

static-safe

work

station.

1-13

Page 26

General

Information

Electrostatic Discharge

Information

Reducing ESD

The following

testing and

Before

time each

suggestions may

servicing operations

connecting any

day

damage

coaxial cable

,

momentarily

help

.

ground

reduce

to

the

cable.

P

ersonnel

touching

assembly

Be

sure that

buildup of

T

able

1-2 lists

T

echnologies

Agilent

should

the

from

static charge

Part

be

grounded

center

all instruments

the

pin

unit.

of

any

are

.

static-safe accessories

using the

Agilent part

T

able

1-2.

with

a

resistor-isolated

connector

properly

that

numbers

Static-Safe

Number Description

9300-0797 Set

9300-0980 Wrist-strap

wire

includes:

.

(The

3M

static

wrist-strap

cord

1.5

m

control

and

(5

mat

wrist-strap

ft).

0.6

cord

ESD

damage

an

instrument

center

and

and

before

earth-grounded

can

be

obtained

shown.

Accessories

m

2

1.2

m

(2

are not

included. The

outer

removing

ft

2

4

that

occurs

connector

conductors

wrist-strap

to

prevent

from

Agilent

ft)

and

4.6

y

must

be

for

any

cm

(15

ordered

during

the

of

before

a

ft)

separately

rst

the

ground

.)

9300-1383 Wrist-strap

post-type connection.

9300-1169 ESD heel-strap

1-14

,

color

black,

(reusable 6

stainless

to 12

steel, without

months).

cord, has

four adjustable

links and

a

7

mm

Page 27

2

Installation

Preparation for Use

and

Page 28

Installation

What

you'll nd

Installing

Connecting

How

to

How

to

Cleaning

This

instrument

Publication

and

has

been

contains

ensure

safe

in this

the

Agilent

the

Agilent

perform

aquick

return

the

Agilent

connections

has

61010,

supplied

information

operation

and Preparation

chapter

83446A/B.

83446A/B lightwave

condence check

83446A/B for

for

accurate

measurements.

been

designed

Safety

in

and

and

warnings

R

equirements

a

safe

to

maintain

clock/data receiver

of the

Agilent 83446A/B

service.

and tested

for Electronic

condition. The

which

must

the

instrument

for Use

to a

bit-error-ratio tester

.

in accordance

Measuring Apparatus

instruction

be

followed by

in a

.

with

IEC

documentation

the

user

safe

condition.

,

to

2-2

N

O

Clean

T

E

the

cabinet

using

a

damp

cloth

only

.

Page 29

Installing

the

Agilent

83446A/B

C

A

U

T

I

O

N

VENTILA

the

ambient

operating

dissipated

greater

C

A

T

I

O

N

This

Degree

Step

Inspect

If

the

you

lightwave

The lightwave

to

numbers

of

the

lightwave

TION

convection

temperature

temperature

than

product

2per

1.

the

shipping

have

veried

receiver

Return

the

of

Agilent

receiver

REQUIREMENTS:

into

and

out

(outside

of

in

the

cabinet.

800

watts

,

then

is

designed

IEC

1010

and

Inspect the

lightwave

clock/data

container

that

the

mechanically

clock/data

Agilent

the

83446A/B

packaging

83446A/B"

.

When

of

the

the

the

instrument

If

the

total

forced

for

use

in

664

respectively

shipment

receiver

or

cushioning

contents

and

receiver

for

materials

in

Chapter

installing

instrument

cabinet)

by

power

convection

Installation

shipping container

material

are

complete

electrically

is

packed

Service

.

Refer

1,

for

the

must

must

be

C

for

4

dissipated

must

Category

.

is

and

.

within

",

for

the

to

\A

ccessories"

the

accessories

instrument

not

be

less

than

every

in

the

be

used.

II

damaged,

you

have

a

carton.

description

in

restricted.

the

maximum

100

watts

cabinet

and

P

ollution

for

damage

keep

it

tested

Refer

and

in

\Description

shipped

a

cabinet,

The

is

until

the

to

\How

part

with

.

the

If

the

contents

verication

Check"),

container is damaged or

notify the carrier

The Agilent T

are

incomplete

test

(this

procedure

notify

the

nearest

the cushioning material shows signs of stress

.K

eep the shipping materials for the carrier's inspection.

echnologies oce will

or

is

Agilent

if

the

lightwave

provided

Technologies

receiver

in

\Performing

oce.

does

a Quick

If the

not

pass

Condence

shipping

,also

arrange for repair or replacement without

waiting for a claim settlement.

If the shipping materials are in good condition, retain them for possible

future use

.Y

ou may wish to ship the lightwave receiver to another location

the

2-3

Page 30

Installation

Installing the

or

Agilent

and

return

83446A/B

Preparation

Agilent 83446A/B

it

to

for

Agilent

for

Use

T

echnologies

Service

".

for

service

.

Refer

to

\How

to

Return the

2-4

Page 31

Installation

and

Installing the

Preparation

for

Use

Agilent 83446A/B

CA

Step 2.

Use the

selector to

available ac

U

T

I

O

N

Before connecting

the rear-panel

the

power

receiver

1.

Pry

Set the

line

following procedure

the voltage

range (100,

voltage.

the

lightwave

when

open

voltage

source

it is

the

.

An

fuse

selector

improper

turned

holder

voltage

to

set

receiver

correctly

selector

on.

door

the

120,

with

selector

lightwave

220,

or

to

the

to

adapt

setting

a

small

screwdriver

clock/data

240V)

corresponding

power

the

lightwave

can

damage

source

.

receiver's

,

you

must

receiver

the

lightwave

voltage

to

the

set

to

Figure

2-1.

Opening

Y

ou

C

A

U

T

I

O

N

must remove

the

voltage

2.

Remove

the voltage

tumbler while

the

voltage

tumbler

tumbler to

it is

in the

(the

the

fuse

change the

line module

voltage

tumbler

holder

damages

door

.

voltage

is

not

selector

the

line

attached

.

Rotating

module

to the

.

unit).

3. Replace the

through the small

voltage tumbler so the desired line voltage value shows

opening in the fuse holder door

.

2-5

Page 32

Installation

and

Installing the

Preparation

for

Use

Agilent 83446A/B

Step 3.

The recommended

F

or a

Check the

fuse is

listed

100/120V operation:

fuse

T

below:

0.315A,

250V

,

time

delay

,

Agilent

part

number 2110-0449.

F

or

a

220/240V

operation:

T

0.16A,

250V

,

time

delay

,

Agilent

part

number

2110-0448.

F

or

W

A

R

N

I

N

G

continued

same

The

(refer

T

o

check

and

gently

If

the

and

reinsert

type

line

to

fuse

and

fuse

Figure

the

fuse

pull

is

defective

the

protection

ratings

is

housed

2-2

).

The

,

insert

outward

fuse

against

.

The

use

in

a

small

spare

the

tip

to

remove

or

missing,

container

re

of

container

fuse

of

install

.

hazard,

other

fuses

is

stored

a

screwdriver

the

container

a

new

replace

next

below

or

materials

to

the

the

on

.

fuse

line

voltage

line

the

side

in

the proper

fuse

only

is

prohibited.

tumbler

fuse

.

of

the

with

container

position

2-6

Figure 2-2. Selecting the line voltage value and checking the fuse.

Page 33

Installation

Installing the

and

Preparation

Agilent 83446A/B

for

Use

C

P

ower

W

Step 4.

Connect the

Agilent

83446A/B

to

a

power

source

The

lightwave

physical

Do

not

A

U

T

I

O

N

correct,

connect

the

properly

equipment

clock/data

installation

ac

proper

positioned,

could

result.

other

power

fuse

as

T

able

receiver

than

until

you

is

installed,

described

2-1. Agilent

is

a

portable

connection

have

veried

and

the

in

the

following

83446A/B P

instrument

to

a

power

line

that

the

voltage

source

selector

paragraphs

ower Requirements

and

line

requires

.

voltage is

switch

.

Damage

to

no

is

the

Characteristic Requirement

Input

V

oltage

Frequenc

y

P

ower

cable

A

R

N

I

N

G

The

lightwave

accordance

appropriate

F

ailure

injury

to

.

Before

protective

cable

.

Insert

a

protective

by

using

an

protective

receiver

is

equipped

with international

power line

ground

turning

earth

the

earth

extension

ground

outlet,

the

lightwave

on

terminals

main

power

contact.

cable

conductor

the

to

,

safety

this

receiver

lightwave

the

protective

cable

Do

not

power

.

100,

120,

75

with a

standards

cable

grounds

plug

defeat

cable

220,

or

240

V

47

to

63

Hz

V

A

(maximum)

three-wire

.

When

the

properly

receiver

,

you

conductor

only

into

the

earth-grounding

,

or

autotransformer

(

6

10%)

power

connected

instrument

can

result

must

of

a

socket

cable

in

connect

the

main

outlet

without

,

in

to

an

cabinet.

personal

its

power

that

has

protection

a

If

you

are

using

an

autotransformer

connected

to

the

protective

socket.

Various power

types of ac power

cables are available to connect the lightwave receiver to the

outlets unique to specic geographic areas

appropriate for the area to

is included with the unit. Y

,

make

earth

contact

sure its

of

common terminal

the

power source

is

outlet

. The cable

which the lightwave receiver is originally shipped

ou can order additional ac power cables for use in

2-7

Page 34

Installation

and

Installing the

Preparation

for

Use

Agilent 83446A/B

dierent

plug

appropriate

C

A

U

T

I

O

N

Always

F

ailure

instrument

areas

.

Figure

congurations

.

use

the

three-prong

to

ensure

damage

2-3

,

and

identies

adequate

.

lists

ac

earth

the

available

the

power

grounding

ac

geographic

cord

supplied

by

power

area

not

with

using

cables

in

which

this

this

,

illustrates

each

instrument.

cord

may

the

cable

cause

is

2-8

Page 35

Installation

Installing the

and

Preparation

Agilent 83446A/B

for

Use

Figure

2-3.

AC

power

cables

available.

2-9

Page 36

Installation

and

Installing the

Preparation

for

Use

Agilent 83446A/B

Step 5.

With the

receiver on

should light.

Turn on

power cable

by pressing

If the

Condence Check"

the

inserted

the line

LED should

in

this

chapter

Agilent

into

the

switch.

fail

to

light,

.

83446A/B

line

module

The

green

refer

to

,

turn

the

lightwave

light-emitting

\P

erforming

diode

a

Quick

(LED)

2-10

Page 37

Connecting

the

Agilent

83446A/B to

a Bit-

Error-Ratio

The

following procedure

receiver

to a

bit

error

T

est

describes

ratio

Set

test

set

how

to

(BERT).

connect

Refer

the

to

Figure

lightwave

2-4

clock/data

.

Figure

2-4.

Connecting

1. Turn the lightwave clock/data receiver

30 minutes

.

2. Turn the BERT on and let it

3. P

erform any calibrations indicated in the documentaion

the

Agilent

83446A/B

to

a

bit

on. Let it warm up for

warm up according to its specications

error

ratio test

for the BERT

system.

.

.

2-11

Page 38

Installation

and

Connecting the

Preparation

for

Use

Agilent 83446A/B

to

a

Bit-Error-Ratio

T

est

Set

4. Connect

clock

5.

Connect

input

6. Clean

the

for

7.

Connect

the

slot

8.

Connect

interface

9.

Connect

Do

C

A

U

T

I

O

N

not

maximum

10.

If

you

receiver's

a

trigger

Agilent

the

side

a cable

input

a

connector

the

end

glass

ber

A

ccurate

the

connector

of

the

the

.

the

exceed

input

want

AUX

signal

11636A

splitter

of

the

from

the

connector

cable

of

in

from

on

the

the

of

the

the

receiver's

laser

Measurements",

optical

connector

interface

OPTICAL

cable

laser

the

power

to

output

splitter

INPUT

from

source

maximum

is

shown

monitor

OUT

to

the oscilloscope's

to

the

oscilloscope use

,

at

the

to

the

output

CLOCK

the

BERT

DATA

OUT

BERT

.

An

OPTICAL

output

in

Chapter

interface

has

a

small

connector

the

laser

to

the

ber

input

to

on

the

the

analog

clock

output of

oscilloscope's

to

the clock

OUT

connector

.

An

adapter

connector

adapter

cable

.

protrusion.

.

output

optic

the

receiver's

front

eye

on

a

the

input of

on

the

may

on

the

may

be

necessary

INPUT

Refer

2,

to

to

for

instructions

the

OPTICAL

glass

\Cleaning

This

to

the

optical

cable

.

OPTICAL

panel

of

the

an

oscilloscope

vertical

power

input.

splitter

receiver

.

trigger input.

the

BERT

receiver

be

necessary

receiver

to

to

the

.

the

.

ber

and

the

end

Connections

.

INPUT

.

Notice

protrusion

ts

connector

INPUT

.

The

clock/data receiver

, connect

T

o

provide

,

such

Connect

Connect

as

one

the

the

the

side

other

.

in

data

of

the

.

of

2-12

Page 39

P

erforming

T

o verify

procedure

for

1.

2.

3.

4.

5. W

the

. (Clean

Accurate

Turn on

Connect

2.48832

with

The

The

the clock/data

the

Gb/s

Agilent

SYNC

clock

aveforms appear

a

Quick Condence

basic

functionality

all

optical

of

interfaces

Measurements", before

receiver

optical

rate

83446B

LOSS

and

to

LED

data

source

optical

instruments

is

extinguished.

outputs

on these

1200{1600

input.

to an

ports

the

clock/data

as

described

making

and

observe

nm

(Use

a

.)

oscilloscope.

.

Check

receiver

in

\Cleaning

measurements

the

SYNC

>

0

27

dBm

622.08

Mb/s

,

use

.)

LOSS

with

rate

the

following

Connections

LED

lights

modulation

at

>

0

28

.

at

dBm

If

the

verication

If

the

clock/data

review

minutes

the procedure

spent performing

instrument

the

unit for

1.

Is

the

receiver

to be

repaired. Before

service,

rear-panel

does

being

please

voltage

check

not

performed

some

simple

make

selector

pass

calling

the

good?

2.

Does

the

line

socket

3.

Is the

unit

plugged

4. Is the unit turned on? Check

have

in

to

power?

the

proper

that the green light-emitting diode (LED)

next to the line switch is on, indicating

5. If other equipment, cables

clock/data receiver

, are they connected properly and operating

, and connectors are

fails

the

when

checks

following

switch

ac

verication

the

may

Agilent

check,

problem

save

waiting

T

echnologies

you

occurred.

for

or

should

returning

checks:

set

power

correctly?

source?

Is

the

line

that the power supply is on.

being used with the

correctly?

A

few

your

fuse

2-13

Page 40

Installation

Performing

and

a Quick

Preparation

Condence

for

Use

Check

6. Review

appeared.

7.

Are

Measurements"

If the

Return

lightwave

T

echnologies

the

the

Agilent

of

83446A/B

Have

No

W

A

R

N

I

N

G

operator

personnel.

the procedure

the

connectors

clock/data

the

warranty

lightwave

maintenance

the

repair

the

unit

T

Are

all

the

for

receiver