Page 1

SERVICE MANUAL

AC Power Source/Analyzer

Agilent Models 6814B and 6834B

Regulatory Test Solution (RTS) - formerly called

the Harmonic/Flicker Test System (HFTS)

Agilent Model 6843A

For instruments with Serial Numbers:

Model 6814B: 3601A-00101 through 00272

US36010273 and up

Model 6834B: 3601A-00101 through 00403

US36010404 and up

Model 6843A: 3531A-00101 through 00256

US35310257 and up

Agilent Part No. 5962-0891 Printed in USA

Microfiche Part No. 5962-0892 October, 2000

Page 2

CERTIFICATION

Agilent Technologies certifies that this product met its published specifications at time of shipment from the factory. Agilent

Technologies further certifies that its calibration measurements are traceable to the United States National Bureau of

Standards, to the extent allowed by the Bureau's calibration facility, and to the calibration facilities of other International

Standards Organization members.

WARRANTY

This Agilent Technologies hardware product is warranted against defects in material and workmanship for a period of three

years from date of delivery. Agilent Technologies software and firmware products, which are designated by Agilent

Technologies for use with a hardware product and when properly installed on that hardware product, are warranted not to

fail to execute their programming instructions due to defects in material and workmanship for a period of 90 days from date

of delivery. During the warranty period Agilent Technologies will, at its option, either repair or replace products which

prove to be defective. Agilent Technologies does not warrant that the operation of the software, firmware, or hardware shall

be uninterrupted or error free.

For warranty service, with the exception of warranty options, this product must be returned to a service facility designated

by Agilent Technologies. Customer shall prepay shipping charges by (and shall pay all duty and taxes) for products returned

to Agilent Technologies for warranty service. Except for products returned to Customer from another country, Agilent

Technologies shall pay for return of products to Customer.

Warranty services outside the country of initial purchase are included in Agilent Technologies's product price, only if

Customer pays Agilent Technologies international prices (defined as destination local currency price, or U.S. or Geneva

Export price).

If Agilent Technologies is unable, within a reasonable time to repair or replace any product to condition as warranted, the

Customer shall be entitled to a refund of the purchase price upon return of the product to Agilent Technologies.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by the Customer,

Customer-supplied software or interfacing, unauthorized modification or misuse, operation outside of the environmental

specifications for the product, or improper site preparation and maintenance. NO OTHER WARRANTY IS EXPRESSED

OR IMPLIED. AGILENT TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE THE CUSTOMER'S SOLE AND EXCLUSIVE REMEDIES. AGILENT

TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

ASSISTANCE

The above statements apply only to the standard product warranty. Warranty options, extended support contracts, product

maintenance agreements and customer assistance agreements are also available. Contact your nearest Agilent

Technologies Sales and Service office for further information on Agilent Technologies's full line of Support Programs.

2

Page 3

SAFETY CONSIDERATIONS

GENERAL. This is a Safety Class 1 instrument (provided with terminal for connection to protective earth ground).

OPERATION. BEFORE APPLYING POWER verify that the product is set to match the available line voltage, the correct

line fuse is installed, and all safety precautions (see following warnings) are taken. In addition, note the instrument's external

markings described under "Safety Symbols".

WARNING.

• Servicing instructions are for use by service-trained personnel. To avoid dangerous electrical shock, do not perform any

servicing unless you are qualified to do so.

• BEFORE SWITCHING ON THE INSTRUMENT, the protective earth terminal of the instrument must be connected to

the protective conductor of the (mains) power cord. The mains plug shall be inserted only in an outlet socket that is

provided with a protective earth contact. This protective action must not be negated by the use of an extension cord

(power cable) that is without a protective conductor (grounding). Grounding one conductor of a two-conductor outlet is

not sufficient protection.

• If this instrument is to be energized via an auto-transformer (for voltage change), make sure the common terminal is

connected to the earth terminal of the power source.

• Any interruption of the protective (grounding) conductor (inside or outside the instrument), or disconnecting of the

protective earth terminal will cause a potential shock hazard that could result in personal injury.

• Whenever it is likely that the protective earth connection has been impaired, this instrument must be made inoperative

and be secured against any unintended operation.

• Only fuses with the required rated current, voltage, and specified type (normal blow, time delay, etc.) should be used.

Do not use repaired fuses or short-circuited fuseholders. To do so could cause a shock or fire hazard.

• Do not operate this instrument in the presence of flammable gases or fumes.

• Do not install substitute parts or perform any unauthorized modification to this instrument.

• Some procedures described in this manual are performed with power supplied to the instrument while its protective

covers are removed. If contacted, the energy available at many points may result in personal injury.

• Any adjustment, maintenance, and repair of this instrument while it is opened and under voltage should be avoided as

much as possible. When this is unavoidable, such adjustment, maintenance, and repair should be carried out only by a

skilled person who is aware of the hazard involved.

• Capacitors inside this instrument may hold a hazardous electrical charge even if the instrument has been disconnected

from its power source.

SAFETY SYMBOLS.

Instruction manual symbol. The instrument will be marked with this symbol when it is necessary for you to refer to the

instruction manual in order to protect against damage to the instrument.

This sign indicates hazardous voltages.

This sign indicates an earth terminal (sometimes used in the manual to indicate circuit common connected to a ground

chassis).

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING sign until the

indicated conditions are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which, if not correctly

performed or adhered to, could result in damage to or destruction of part or all of the product. Do not proceed

beyond a CAUTION sign until the indicated conditions are fully understood and met.

.

3

Page 4

Printing History

The current edition of this manual is indicated below. Reprints of this manual containing minor corrections and updates

may have the same printing date. Revised editions are identified by a new printing date. A revised edition incorporates all

new or corrected material since the previous printing date.

Changes to the manual occurring between revisions are covered by change sheets shipped with the manual. In some cases,

the manual change applies only to specific instruments. Instructions provided on the change sheet will indicate if a particular

change applies only to certain instruments.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this document

may be photocopied, reproduced, or translated into another language without the prior consent of Agilent Technologies. The

information contained in this document is subject to change without notice.

Instrument Identification

The power supply is identified by a unique, two-part serial number, such as, 3601A-00101. The items in this serial number

are explained as follows:

Item Description

US The letter suffix indicates the country of manufacture, where US = USA.

3601 This is a code that identifies either the date of manufacture, or the date of a significant design change.

0101 The last five digits of the serial number (0101) is a unique number assigned to each AC Power Source.

Copyright 1996 Agilent Technologies Company Edition 1____________________September, 1996

Update 1_______________________ January 1999

Update 2_______________________ October 2000

4

Page 5

Table of Contents

1. Introduction

Scope ............................................................................................................................................................7

Organization ..............................................................................................................................................7

Safety Considerations...................................................................................................................................7

Related Documents....................................................................................................................................7

Revisions ......................................................................................................................................................7

Manual Revisions......................................................................................................................................7

Firmware Revisions ...................................................................................................................................8

Electrostatic Discharge.................................................................................................................................8

2. Performance Tests

Introduction ..................................................................................................................................................9

Test Equipment Required.............................................................................................................................9

General Measurement Techniques................................................................................................................9

Current-Monitoring Resistor ......................................................................................................................10

Performance Tests ......................................................................................................................................10

Performance Test Record Sheets................................................................................................................10

3. Troubleshooting

Introduction ................................................................................................................................................19

Localizing the Problem...............................................................................................................................19

Test Equipment Required...........................................................................................................................19

List of Equipment .......................................................................................................................................19

Troubleshooting Procedure ........................................................................................................................19

Using the *TST? Query..............................................................................................................................19

Firmware Revisions ....................................................................................................................................20

ROM Replacement or ROM Update ..........................................................................................................20

Calibration Configuration Switch ...............................................................................................................21

Troubleshooting Hints................................................................................................................................22

Switching Amplifier Output Balancing......................................................................................................22

4. Principles of Operation

Introduction ................................................................................................................................................31

General Description....................................................................................................................................31

A1, A2, A3 Switching Amplifier Modules .................................................................................................31

A4 Mother Board Assembly .......................................................................................................................31

A5 Relay Range / Sense Assembly.............................................................................................................32

A6 Servo (Control) Assembly ....................................................................................................................32

A7 IEEE-488 (GPIB) / RS-232 Interface Assembly ..................................................................................32

A8 Digital Signal Processing Assembly .....................................................................................................32

A9 Input Power Assembly (208 Volt Input)...............................................................................................32

A9 Input Power Assembly (400 Volt Input)...............................................................................................32

A10 Auxiliary Power Supply......................................................................................................................33

A11 Front Panel Display Assembly............................................................................................................33

A12 Input Filter Assembly .........................................................................................................................33

A13 Bridge Capacitor Filter Assembly.......................................................................................................33

A14 Bias Power Supply..............................................................................................................................33

5. Replaceable Parts

Introduction ................................................................................................................................................35

5

Page 6

Table of Contents (continued)

6. Diagrams

Introduction ................................................................................................................................................37

General Schematic Notes............................................................................................................................37

Index...............................................................................................................................................53

Figures

2-1. Verification Test Setup.................................................................................................................................... 17

2-2. Verification Test Setup.....................................................................................................................................18

3-1. Bias Voltage to Switching Amplifier Assemblies.............................................................................................28

3-2. AC Programming Signal Path ..........................................................................................................................29

4-1. Agilent Series 665xA/667xA Power Supply, Block Diagram ..........................................................................34

6-1. Mechanical Layouts..........................................................................................................................................38

6-2. Agilent 6814B, 6834B, 6843A Front Frame Assembly....................................................................................39

6-3. A9 208/230V AC Input Board Parts Location .................................................................................................40

6-4. A9 208/230V AC Input Assembly Schematic ..................................................................................................41

6-5. A9 400V AC Input Board Parts Location.........................................................................................................42

6-6. A9 400V AC Input Assembly Schematic .........................................................................................................43

6-7. A10 Auxiliary Power Supply Board Parts Location.........................................................................................44

6-8. A10 Auxiliary Power Supply Assembly Schematic..........................................................................................45

6-9. A14 Bias Power Supply Board Parts Location.................................................................................................46

6-10. A14 Bias Power Supply Assembly Schematic.................................................................................................47

6-11. A5 Range/Output/Phase Relay Schematic.......................................................................................................48

6-12. A5 Range/Output/Phase Relay Driver Schematic............................................................................................49

6-13. A4 Mother Board Parts Location.....................................................................................................................50

6-14. A8 DSP Board Parts Location.........................................................................................................................51

6-15. A6 Servo Board Test Point Locations.............................................................................................................52

Tables

2-1. Test Equipment Required .....................................................................................................................................9

2-2. Performance Tests ..............................................................................................................................................10

2-3. Performance Test Record Form...........................................................................................................................13

2-4. Performance Test Record Agilent 6814B............................................................................................................14

2-4. Performance Test Record Agilent 6834B............................................................................................................15

2-4. Performance Test Record Agilent 6843A............................................................................................................16

3-1. Test Equipment Requirements for Troubleshooting............................................................................................19

3-2. Specific Troubleshooting Procedures..................................................................................................................21

3-3. AC Power Source Troubleshooting Procedure ....................................................................................................23

3-4. A9 208/208 Input Power Supply Troubleshooting..............................................................................................25

3-5. A9 Option 400 (400V) AC Input Power Supply Troubleshooting ......................................................................25

3-6. A10 Auxiliary Power Supply Troubleshooting....................................................................................................26

3-7. Al4 Option 400 Bias Power Supply Troubleshooting .........................................................................................26

3-8. A4 Mother Board Troubleshooting .....................................................................................................................27

3-9. A5 Mother Board Troubleshooting .....................................................................................................................27

5-1. Agilent 68l4B, 6834B, 6843A Replacement .......................................................................................................35

6-1. General Schematic Notes.....................................................................................................................................37

6

Page 7

Introduction

Scope

Organization

This manual contains information for troubleshooting and repairing to the component level Agilent Model 6814B, 6834B

AC Power Source/Analyzers and Agilent Model 6843A Regulatory Test Solution, hereafter referred to as an AC Power

Source. The manual applies to both standard units and units that have Option 400. This manual is organized as follows:

Chapter Description

Chapter 2 Performance tests

Chapter 3 Troubleshooting procedures

Chapter 4 Principles of operation on a block-diagram level

Chapter 5 Replaceable parts

Chapter 6 Diagrams

Safety Considerations

This AC Power Source is a Safety Class I instrument, which means it has a protective earth terminal. This terminal must be

connected to earth ground through a power source equipped with a 4-wire, ground receptacle. Refer to the “Safety

Summary” page at the beginning of this manual for general safety information. Before operation or repair, check the AC

Power Source and review this manual for safety warnings and instructions. Safety warnings for specific procedures are

located at appropriate places in the manual.

Hazardous voltages exist within the AC Power Source chassis, at the output terminals, and at the analog

Related Documents

The following documents are shipped with your ac source:

• Quick Start Guide, to help you quickly get started using the ac source.

• User's Guide, containing detailed installation, checkout, and front panel information.

• Programming Guide, containing detailed GPIB programming information.

• Quick Reference Card, designed as a memory jogger for the experienced user.

programming terminals.

1

Revisions

Manual Revisions

This manual was written for AC Power Sources; that have the same serial prefixes (first part) as those listed on the title page

and whose serial numbers (second part) are equal to or higher than those listed in the title page.

Introduction

7

Page 8

Note 1) If the serial prefix of your unit is higher than that shown in the title page then the unit was made after

the publication of this manual and may have hardware and/or firmware differences not covered in this

manual. If they are significant to the operation and/or servicing of the AC Power Source, those differences

are documented in one or more Manual Change sheets included with this manual.

2) If the serial prefix on the unit; is lower than that shown on the title page, then the unit was made before

the publication of this manual and can be different from that described here. Such differences are covered

in “Appendix A - Manual Backdating Changes” in the User’s Manual.

Firmware Revisions

You can obtain the firmware revision number by either reading the integrated circuit label, or query the AC Power Source;

using the GPIB *IDN query command (see "Chapter 3 -Troubleshooting" ).

Electrostatic Discharge

The power supply has components that can be damaged by ESD (electrostatic discharge). Failure to

observe standard, antistatic practices can result in serious degradation of performance, even when an

actual failure does not occur.

When working on the AC Power Source; observe all standard, antistatic work practices. These include, but are not limited

to:

• working at a static-free station such as a table covered with static-dissipative laminate or with a conductive table mat

(Agilent P/N 9300-0797, or equivalent).

• using a conductive wrist strap, such as Agilent P/N 9300-0969 or 9300-0970.

• grounding all metal equipment at the station to a single common ground.

• connecting low-impedance test equipment to static-sensitive components only when those components have power

applied to them.

• removing power from the AC Power Source before removing or installing printed circuit boards .

8

Introduction

Page 9

Performance Tests

Introduction

This chapter provides test procedures for checking the operation of an Agilent Model 6814B/6834B AC Power

Source/Analyzer or Agilent Model 6843A RTS. The required test equipment is specified and sample performance test

record sheets are included. Instructions are given for performing the tests using the front panel keypad.

Test Equipment Required

Table 2-1 lists the equipment required to perform the verification tests given in this chapter.

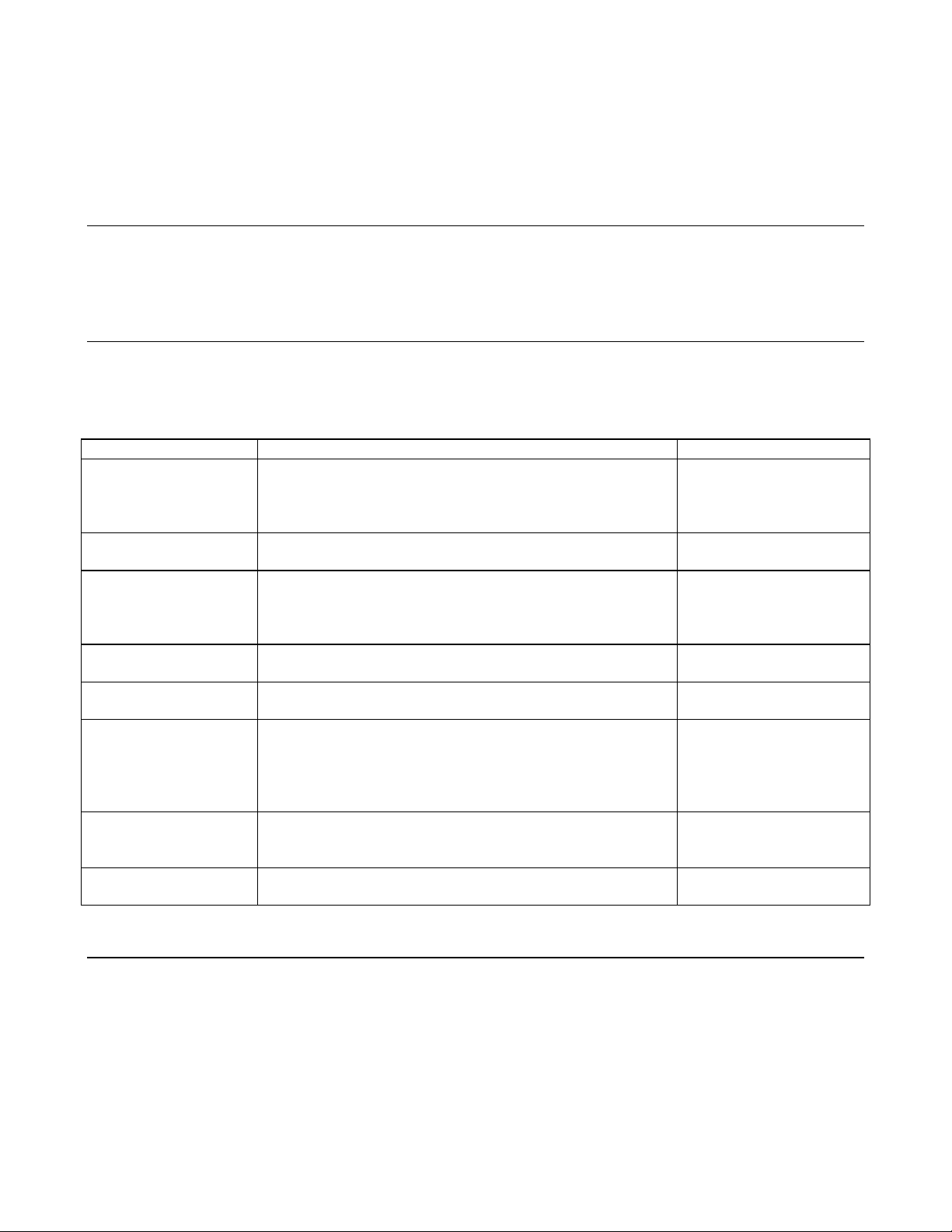

Table 2-1. Test Equipment Required

Equipment Characteristics Recommended Model

Digital Voltmeter* Resolution: 10nV @ 1V

Readout: 81/2 digits

Accuracy: <20ppm

Current Monitor 0.01 ohms +/-200ppm 10W Guildline 7320/0.01

Agilent 3458A

2

Audio Analyzer Input Voltage Range: 50mV to 300 V

Distortion Accuracy: +/-1 db 20Hz to 20KHz

Residual Distortion / Noise: -80db (0.0 1 %) 20Hz to 20KHz

Frequency Counter Accuracy @ 1 KHz < 0.001% Agilent5316B

Ratio Transformer* 30:1 ratio < 50ppm

Variable –Voltage

Transformer

Load Resistors 6814B use 4 ea. 7.5 ohms > 1000W

GPIB Controller Full GPIB capabilities HP Series 200/300

* The 30:1 ratio transformer is not required for a valid MIL-STD 45662A test. The 30:1 ratio transformer is only required when a 4:1

test equipment to specification ratio is desired using a 3458A voltmeter in the 1000 volt range.

Power: 3 phase 24 KVA

Range: 180-254V 47-63 Hz

360-440V 47-63 Hz

6834B use 4 ea. 15 ohm > 1000W

6843A use 4 ea. 5 ohm > 1500W

Agilent8903A

Superior Powerstat

1156DT-3Y

0-280 50A 24.2KVA

or equivalent

General Measurement Techniques

The following chapters provide the test procedures for verifying the Agilent 6814B, 6834B or 6843A's compliance with the

specifications listed in Appendix A of the Users Guide. Please refer to CALIBRATION PROCEDURE or

TROUBLESHOOTING if you observe out-of specification performance. The performance test specifications are listed in

the Performance Test Record Card at the end of this chapter. You can record the actual measured values in the columns

Performance Tests

9

Page 10

provided. Select an adequate gauge wire for load tests using the procedures given in the operating manual for connecting

the load.

Current-Monitoring Resistor

To eliminate output current measurement error caused by voltage drops in the leads and connections, connect the

current-monitoring resistor as a four terminal device.

Performance Tests

Performance tests check all the specifications of the ac source. The various tests are grouped under Table 2-2. If more than

one meter or a meter and an oscilloscope are used, connect each to the sense terminals by separate leads to avoid mutual

coupling effects.

Performance Test Record Sheets

When performing the tests in this chapter, refer to the Performance Test Record sheets ( Table 2-3 and Table 2-4 ) at the

end of this chapter. Table 2-3 is for recording common information, such as test equipment used and environmental

conditions. Table 2-4 is for recording the actual measurements.

Table 2-2. Voltage / Frequency Programming and Readback Accuracy

Step Action Normal Result

This procedure verifies that the voltage programming and GPIB readback and front panel display functions are within

specifications.

1

2

3

4

5

6

7

Turn off ac source. Connect DVM and Ratio Transformer if

used across output terminals as shown in Test Setup Figure 2-1.

Turn on ac source with no load. Press [Shift] [Output], display

reads *RST, press [Enter].

Program VOLT:ALC EXT, VOLT 300, FREQ 45, CURR 10

Enable output press [Output on/off].

Record output voltage / frequency measurements from DVM /

front panel and frequency meter.

Program FREQ 400.

Record output voltage / frequency measurements from DVM /

front panel and frequency meter.

Program FREQ 1000.

*RST resets ac source to known factory

state.

CV annunciator on.

Output voltage at 300 volts.

Output voltage / frequency measurements

within specified limits on test card.

Output voltage / frequency measurements

within specified limits on test card.

8

9

10

11

12

13

14

10

Performance Tests

Record output voltage / frequency measurements from DVM /

front panel and frequency meter.

Program VOLT:RANGE 150, VOLT 150, FREQ 45.

Record output voltage / frequency measurements from DVM /

front panel and frequency meter.

Program FREQ 400.

Record output voltage / frequency measurements from DVM /

front panel and frequency meter.

Program FREQ 1000.

Record output voltage / frequency measurements from DVM /

front panel and frequency meter.

Output voltage / frequency measurements

within specified limits on test card.

CV annunciator on.

Output voltage at 150 volts.

Output voltage / frequency measurements

within specified limits on test card.

Output voltage / frequency measurements

within specified limits on test card.

Output voltage / frequency measurements

within specified limits on test card.

Page 11

Table 2-2. ( Continued ) CV Load Effect

Step Action Normal Result

This test measures the change in output voltage resulting from a change in output current from full-load to no-load or

no-load to full-load.

1

2

3

4

5

6

7

Turn off ac source. Connect DVM across output terminals ( or

ratio transformer if used ) and 7.5 ohm for Agilent 6814B, 15

ohm for 6834B or 5 ohms for 6843A load resistors as shown in

Test Setup Figure 2-1.

Turn on ac source. Press [Shift] [Output] display reads *RST

press [Enter].

Program VOLT:ACL EXT, VOLT:RANGE 150 VOLT 150

CURR 20 for Agilent 6814B, CURR 10 for Agilent 6834B or

CURR 32 for Agilent6843A. Enable output press [Output

on/off].

Record output voltage measurement from DVM.

Open S1 ( S2 or S3 if Agilent 6834B ). Output current near zero.

Record output voltage measurement from DVM.

Check test result.

*RST resets ac source to known factory

default state.

CV annunciator on or reduce voltage until

CV annunciator come on.

Output current near 20A for

Agilent6814B, 10A for Agilent 6834B or

30A for Agilent6843A.

The difference between the DVM

readings in step 4 & 6 are within the

specified load effect limits.

Table 2-2. ( Continued ) CV Source Effect

Step Action Normal Result

This test measures the change in output voltage resulting from a change in ac mains input voltage from the minimum to

maximum value within the line voltage specification.

1

2

3

4

5

6

Turn off ac source. Connect DVM across output terminals ( or

ratio transformer if used ) and 30 ohm for Agilent 6814B, 60

ohm for 6834B or 20 ohm for Agilent6843A load resistors as

shown in Test Setup Figure 2-1.

Turn on ac source. Press [Shift] [Output] display reads *RST

press [Enter].

Program VOLT:ALC EXT, VOLT 300, CURR 10 for Agilent

6814B, CURR 5 for Agilent 6834B or CURR 16 for

Agilent6843A.

Enable output press [Output on/off].

Adjust the variable transformer to low line condition. ( 180 or

360 Vac ).

Record voltage reading of DMM.

Adjust the variable transformer to high line condition. ( 254 or

440 Vac ).

Record voltage reading of DMM.

Check test result.

*RST resets ac source to known factory

default state.

CV annunciator on or reduce voltage until

CV annunciator comes on.

Output current near 10A for

Agilent6814B;

5A for Agilent 6834B or 15A for

Agilent6843A.

The difference between the DVM

readings in step 3 & 5 are within the

specified load effect limits.

Performance Tests

11

Page 12

Table 2-2. ( Continued ) rms Current Accuracy Test

Step Action Normal Result

This test verifies the measurement accuracy of the rms current readback.

1

2

3

4

Step Action Normal Result

1

2

3

4

Turn off ac source. Connect Current Shunt, 7.5 ohm for Agilent

6814B, 15 ohm for Agilent 6834B or 5 ohm for Agilent6843A

load resistors and DVM as shown in Test Setup Figure 2- 2.

Turn on ac source. Press [Shift] [Output] display reads *RST

press [Enter].

Program VOLT 100, CURR 10 for Agilent 6814B, CURR 5

for Agilent6834B or CURR 15 for Agilent6843A.

Enable output press [Output on/off].

Record DMM reading and calculate rms current.

Record front panel reading.

Table 2-2. ( Continued ) Harmonic Distortion Test

This test measures the total harmonic distortion of the output sinewave at full power.

Turn off ac source. Connect Audio Analyzer across output

terminals (or ratio transformer if used) and 7.5 ohm for Agilent

6814B, 15 ohm for Agilent 6834B or 5 ohms for Agilent6843A

load resistors as shown in Test Setup Figure 2-1 .

Turn on ac source. Press [Shift] [Output] display reads *RST

press [Enter].

Program output voltage to VOLT:RANGE 150, VOLT 150,

CURR 20 for Agilent6814B, CURR 10 for Agilent 6834B or

CURR 32 for Agilent6843A.

Record the total harmonic distortion reading from the audio

analyzer and front panel display.

*RST resets ac source to known factory

default state.

CC annunciator on or increase voltage till

CC annuniciator comes on.

Output current near 10A for Agilent6814B;

5A for Agilent 6834B or 15A for

Agilent6843A.

Difference between measured output

current and front panel current reading is

within specified limits.

*RST resets ac source to known factory

default state.

CV annunciator on or reduce voltage until

CV annunciator comes on. Output

current near 20A for Agilent6814B, 10A

for Agilent6834B or 30A for

Agilent6843A

Readings are less than maximum

specified limits.

12

Performance Tests

Page 13

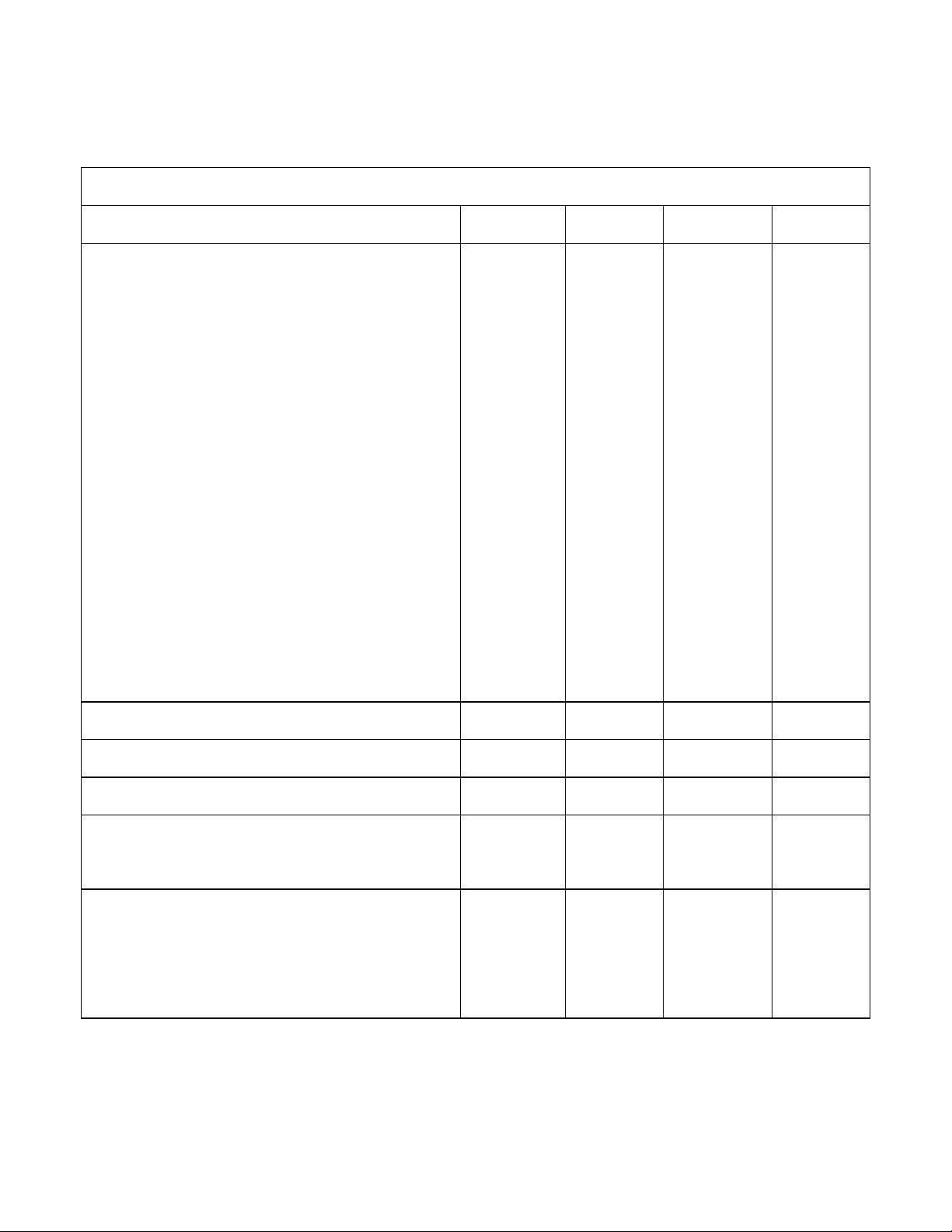

Table 2-3 Performance Test Record Form

Test Facility:

__________________________________________ Report No.__________________________________________

__________________________________________ Date______________________________________________

__________________________________________ Customer___________________________________________

__________________________________________ Tested By___________________________________________

Model_____________________________________ Ambient Temperature

_________________________________________________

Serial No.__________________________________ Relative Humidty

______________________________________ __________

Options__________________________________ Nominal Line Frequency

(Hz) __________________________________ __________

Firmware Revision ___________________________

Special Notes:

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

Test Equipment Used

Description Model No. Trace No. Cal. Due Date

1. Digital Voltmeter ________ ___________ ___________

2. Frequency Meter ________ ___________ ___________

3. Audio Meter ________ ___________ ___________

4. Ratio Transformer ________ ___________ ___________

5. ________ ___________ ___________

Performance Tests

13

Page 14

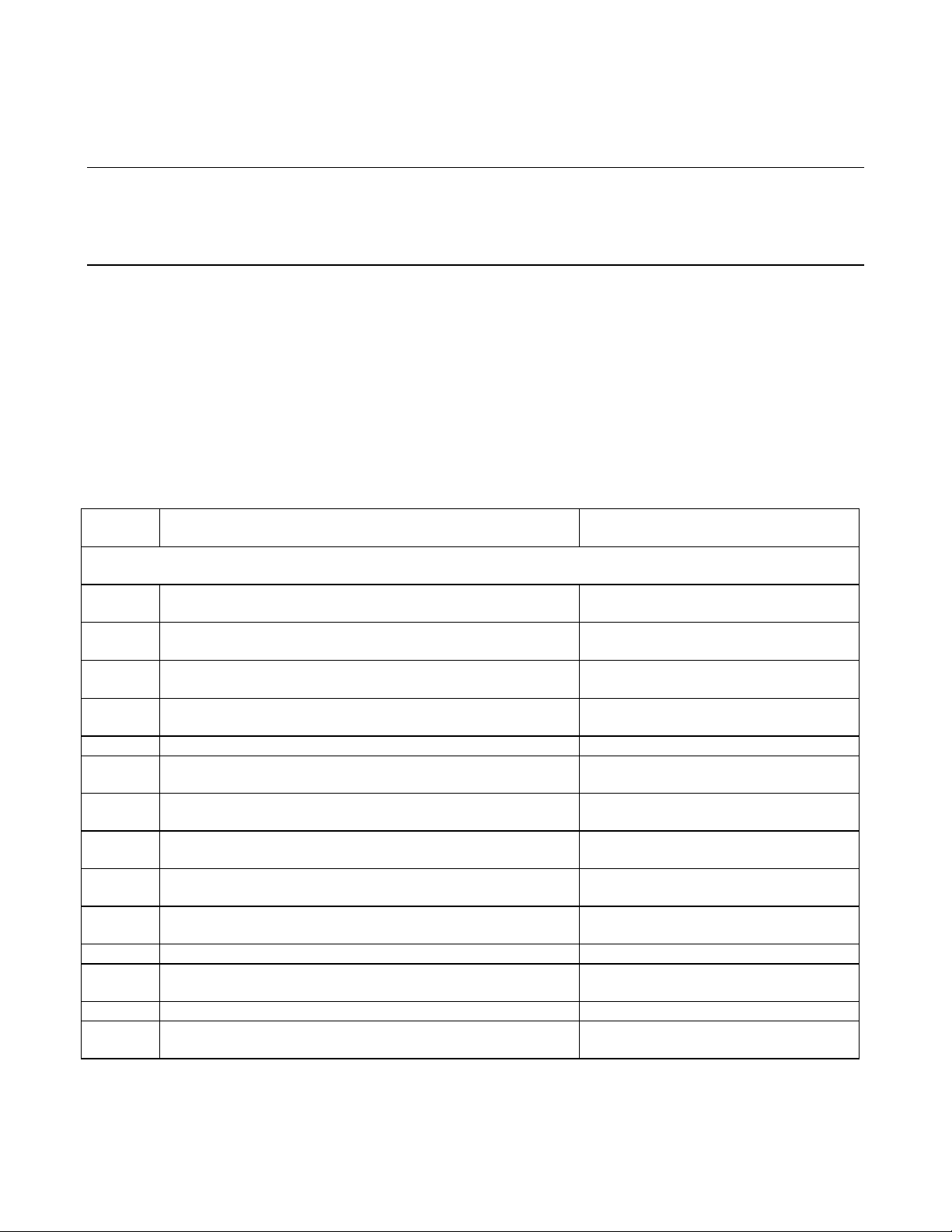

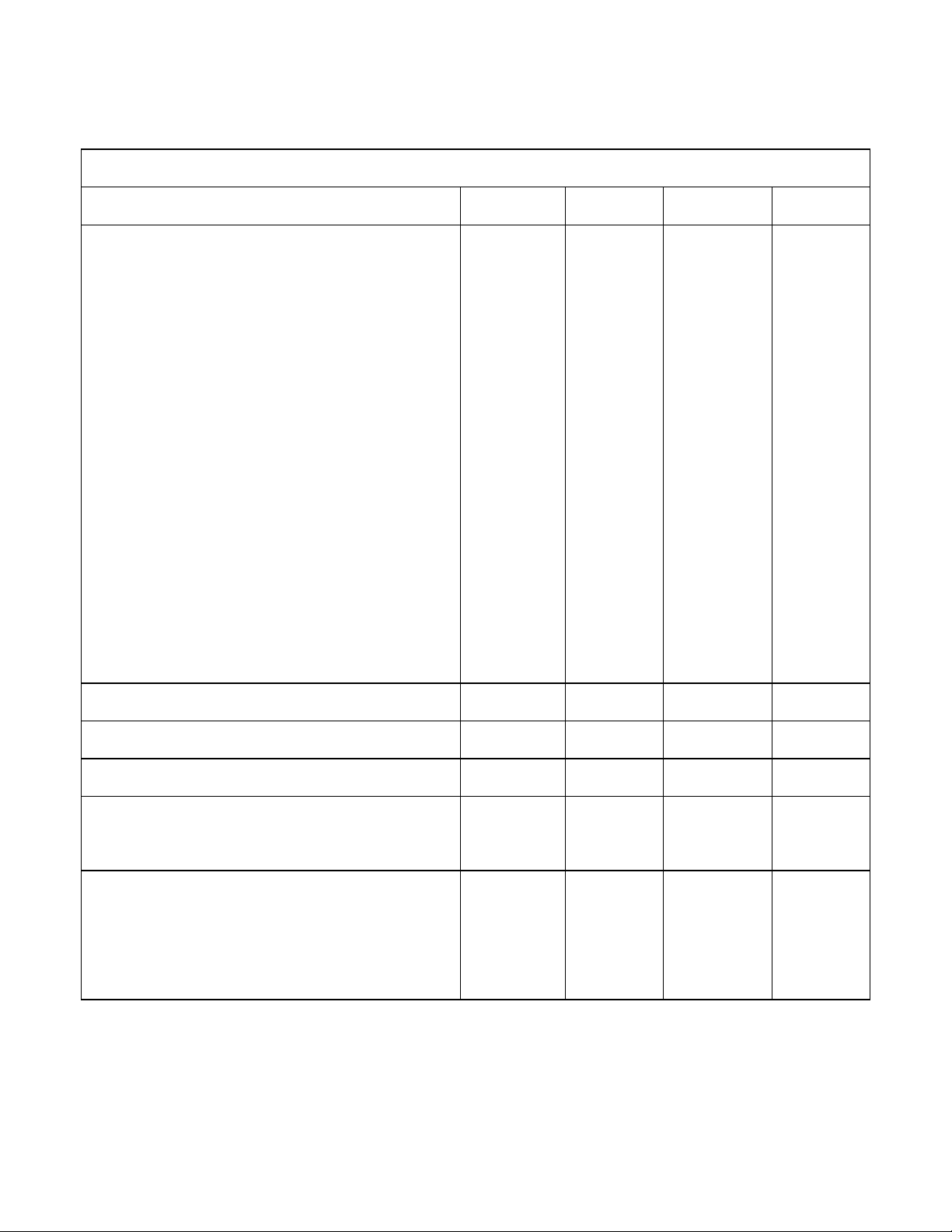

Table 2-4. Performance Test Record - Agilent 6814B AC Power Source

Model: Agilent 6814B Report No.: Date:

Test Description Min Spec Results Max Spec Meas

Voltage Programming & Readback Accuracy

High Range@ 45 Hertz

Program 300V

Front Panel Display

299.250

Vrms-400mV

High Range@ 400 Hertz

Program 300V

Front Panel Display

298.200

Vrms-400mV

High Range@ 1000 Hertz

Program 300V

Front Panel Display

296.700

Vrms-400mV

Low Range@ 45 Hertz

Program 150V

Front Panel Display

149.475

Vrms-325mV

Low Range@ 400 Hertz

Program 150V

Front Panel Display

148.950

Vrms-325mV

______V

______V

______V

______V

______V

______V

______V

______V

______V

______V

300.750

Vrms+400mV

301.800

Vrms+400mV

303.300

Vrms+400mV

150.525

Vrms+325mV

151.050

Vrms+325mV

Uncert **

140mV

( 1.2mV )

140mV

( 1.2mV )

140mV

( 1.2mV )

70mV

( 0.6mV )

70mV

( 0.6mV )

Low Range@ 1000 Hertz

Program 150V

Front Panel Display

148.200

Vrms-325mV

______V

______V

151.800

Vrms+325mV

70mV

( 0.6mV )

CV Load Effect Vo-0.75V ______V Vo+0.75V

CV Line Effect Vo-0.3V ______V Vo+0.3V

Rms Current Readback Io-0.060A ______A Io+0.060A l.lmA

Total Harmonic Distortion

Audio Analyzer

Front Panel Display

0%

0%

______%

______%

1%

1%

Frequency Programming & Readback Accuracy

Program 45Hz 44.985 ______Hz 45.014 0.9mHz

Front Panel Display Fo-0.014Hz ______Hz Fo+0.014Hz

Program 1 KHz 999.89 ______Hz 1000.110 0.010Hz

Front Panel Display Fo-0.110Hz ______Hz Fo+0.110Hz

**Note: 1. Measurement uncertainties are only valid when using test equipment listed in Table 2-1.

2. Voltage Programming and Readback measurements uncertainties are for a 3458A DMM in the 1000 volt range.

3. Measurement uncertainties in parenthesis are only if a 30:1 ratio transformer is used with the 3458A DMM.

14

Performance Tests

Page 15

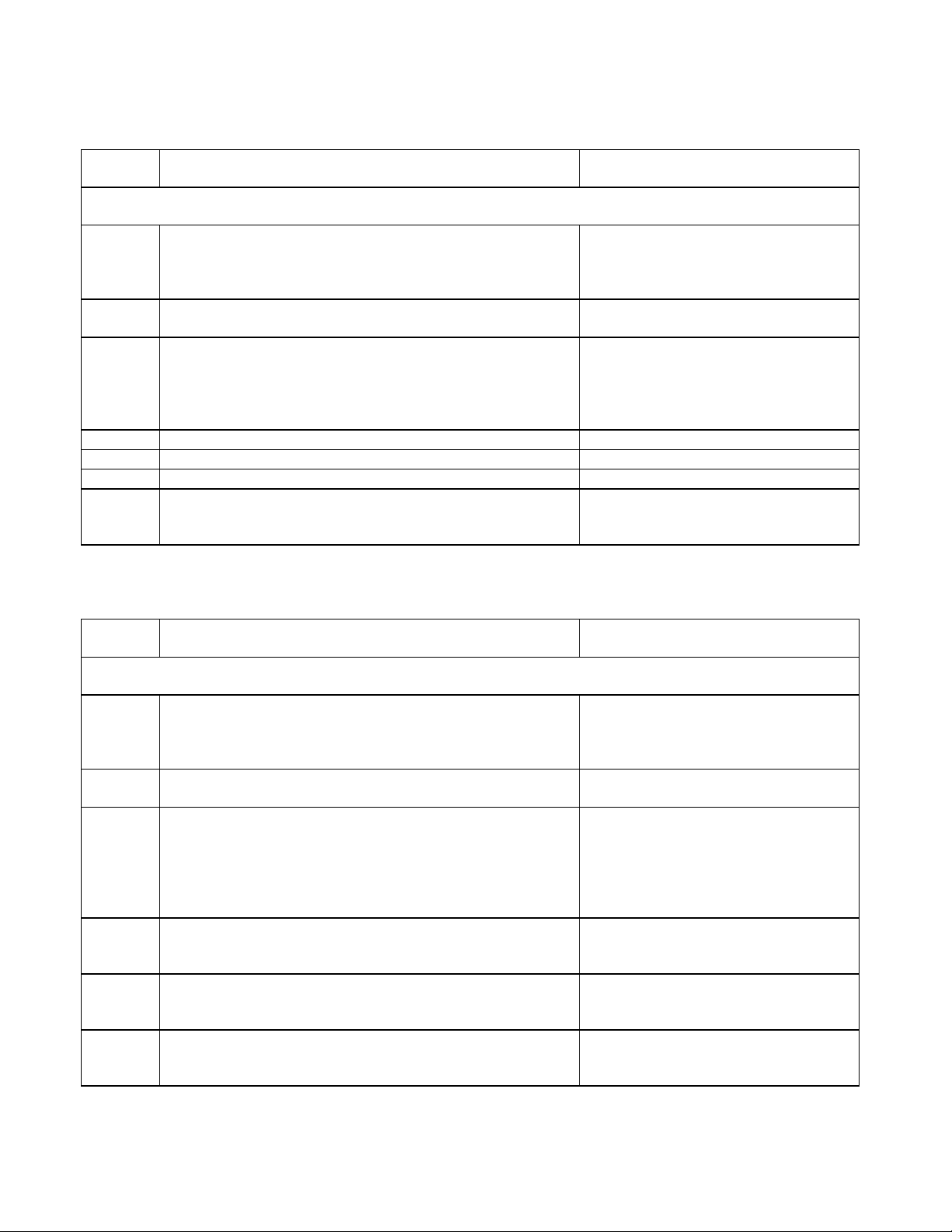

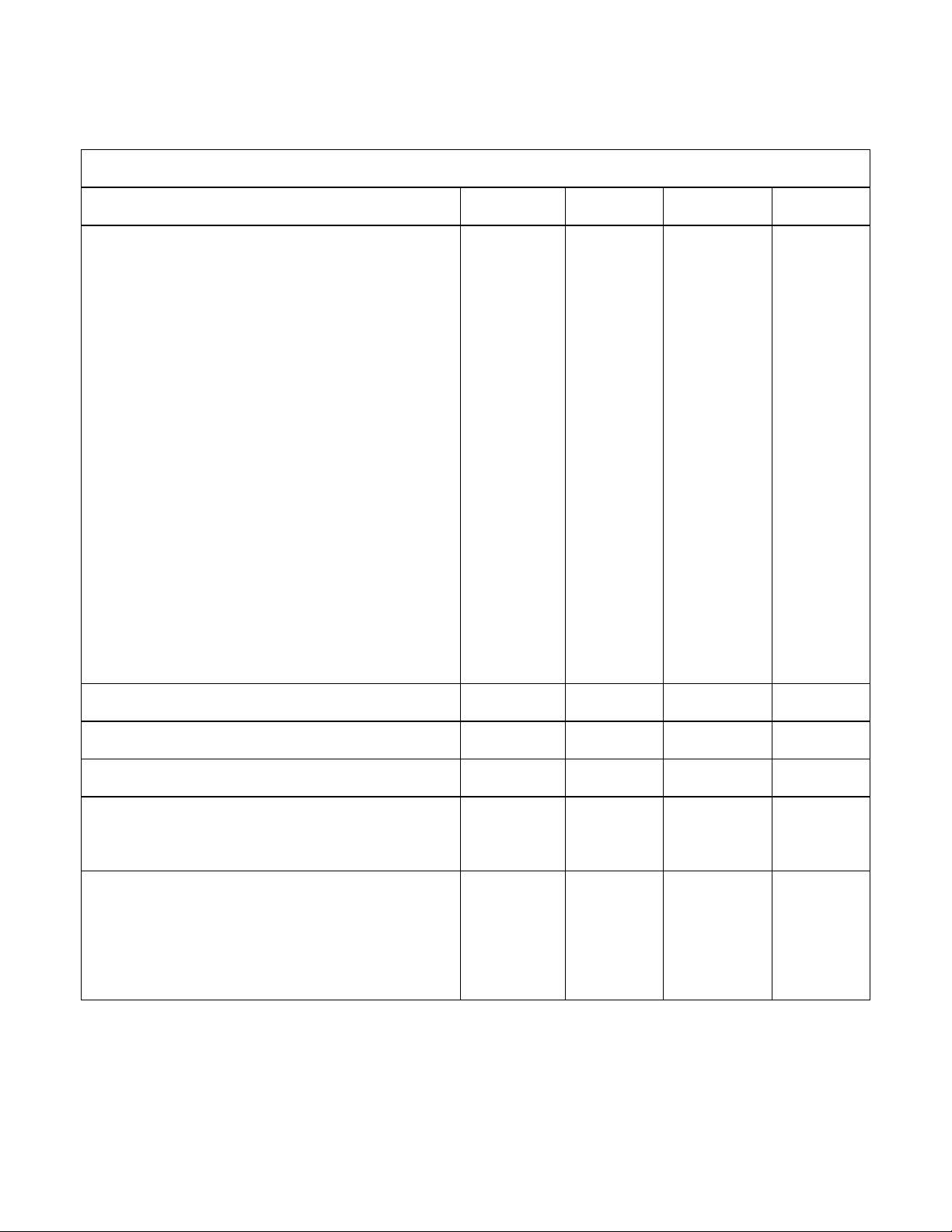

Table 2-4. (Continued) Performance Test Record – Agilent 6834B AC Power Source

Model: Agilent 6843B Report No.: Date:

Test Description Min Spec Results Max Spec Meas

Voltage Programming & Readback Accuracy

High Range@ 45 Hertz

Program 300V

Front Panel Display

299.250

Vrms-400mV

High Range@ 400 Hertz

Program 300V

Front Panel Display

298.200

Vrms-400mV

High Range@ 1000 Hertz

Program 300V

Front Panel Display

296.700

Vrms-400mV

Low Range@ 45 Hertz

Program 150V

Front Panel Display

149.475

Vrms-325mV

Low Range@ 400 Hertz

Program 150V

Front Panel Display

148.950

Vrms-325mV

______V

______V

______V

______V

______V

______V

______V

______V

______V

______V

300.750

Vrms+400mV

301.800

Vrms+400mV

303.300

Vrms+400mV

150.525

Vrms+325mV

151.050

Vrms+325mV

Uncert **

140mV

( 1.2mV )

140mV

( 1.2mV )

140mV

( 1.2mV )

70mv

( 0.6mV )

70mV

( 0.6mV )

Low Range@ 1000 Hertz

Program 150V

Front Panel Display

148.200

Vrms-325mV

______V

______V

151.800

Vrms+325mV

70mV

( 0.6mV )

CV Load Effect Vo-0.75V ______V Vo+0.75V

CV Line Effect Vo-0.3V ______V Vo+0.3V

rms Current Readback Io-0.030A ______A Io+0.030A l.lmA

Total Harmonic Distortion

Audio Analyzer

Front Panel Display

0%

0%

______%

______%

1%

1%

Frequency Programming & Readback Accuracy

Program 45Hz 44.985 ______Hz 45.014 0.9mHz

Front Panel Display Fo-0.014Hz ______Hz Fo+0.014Hz

Program 1 KHz 999.89 ______Hz 1000.110 0.010Hz

Front Panel Display Fo-0.110Hz ______Hz Fo+0.110Hz

**Note: 1. Measurement uncertainties are only valid when using test equipment listed in Table 2-1.

2. Voltage Programming and Readback measurements uncertainties are for a 3458A DMM in the 1000 volt range.

3. Measurement uncertainties in parenthesis are only if a 30:1 ratio transformer is used with the 3458A DMM

Performance Tests

15

Page 16

Table 2-4. Performance Test Record - Agilent 6843A AC Power Source

Model: Agilent 6843A Report No.: Date:

Test Description Min Spec Results Max Spec Meas

Voltage Programming & Readback Accuracy

High Range@ 45 Hertz

Program 300V

Front Panel Display

299.250

Vrms-400mV

High Range@ 400 Hertz

Program 300V

Front Panel Display

298.200

Vrms-400mV

High Range@ 1000 Hertz

Program 300V

Front Panel Display

296.700

Vrms-400mV

Low Range@ 45 Hertz

Program 150V

Front Panel Display

149.475

Vrms-325mV

Low Range@ 400 Hertz

Program 150V

Front Panel Display

148.950

Vrms-325mV

______V

______V

______V

______V

______V

______V

______V

______V

______V

______V

300.750

Vrms+400mV

301.800

Vrms+400mV

303.300

Vrms+400mV

150.525

Vrms+325mV

151.050

Vrms+325mV

Uncert **

140mV

( 1.2mV )

140mV

( 1.2mV )

140mV

( 1.2mV )

70mV

( 0.6mV )

70mV

( 0.6mV )

Low Range@ 1000 Hertz

Program 150V

Front Panel Display

148.200

Vrms-325mV

______V

______V

151.800

Vrms+325mV

70mV

( 0.6mV )

CV Load Effect Vo-0.75V ______V Vo+0.75V

CV Line Effect Vo-0.3V ______V Vo+0.3V

Rms Current Readback Io-0.090A ______A Io+0.090A l.lmA

Total Harmonic Distortion

Audio Analyzer

Front Panel Display

0%

0%

______%

______%

1%

1%

Frequency Programming & Readback Accuracy

Program 45Hz 44.985 ______Hz 45.014 0.9mHz

Front Panel Display Fo-0.014Hz ______Hz Fo+0.014Hz

Program 1 KHz 999.89 ______Hz 1000.110 0.010Hz

Front Panel Display Fo-0.110Hz ______Hz Fo+0.110Hz

**Note: 1. Measurement uncertainties are only valid when using test equipment listed in Table 2-1.

2. Voltage Programming and Readback measurements uncertainties are for a 3458A DMM in the 1000 volt range.

3. Measurement uncertainties in parenthesis are only if a 30:1 ratio transformer is used with the 3458A DMM.

16

Performance Tests

Page 17

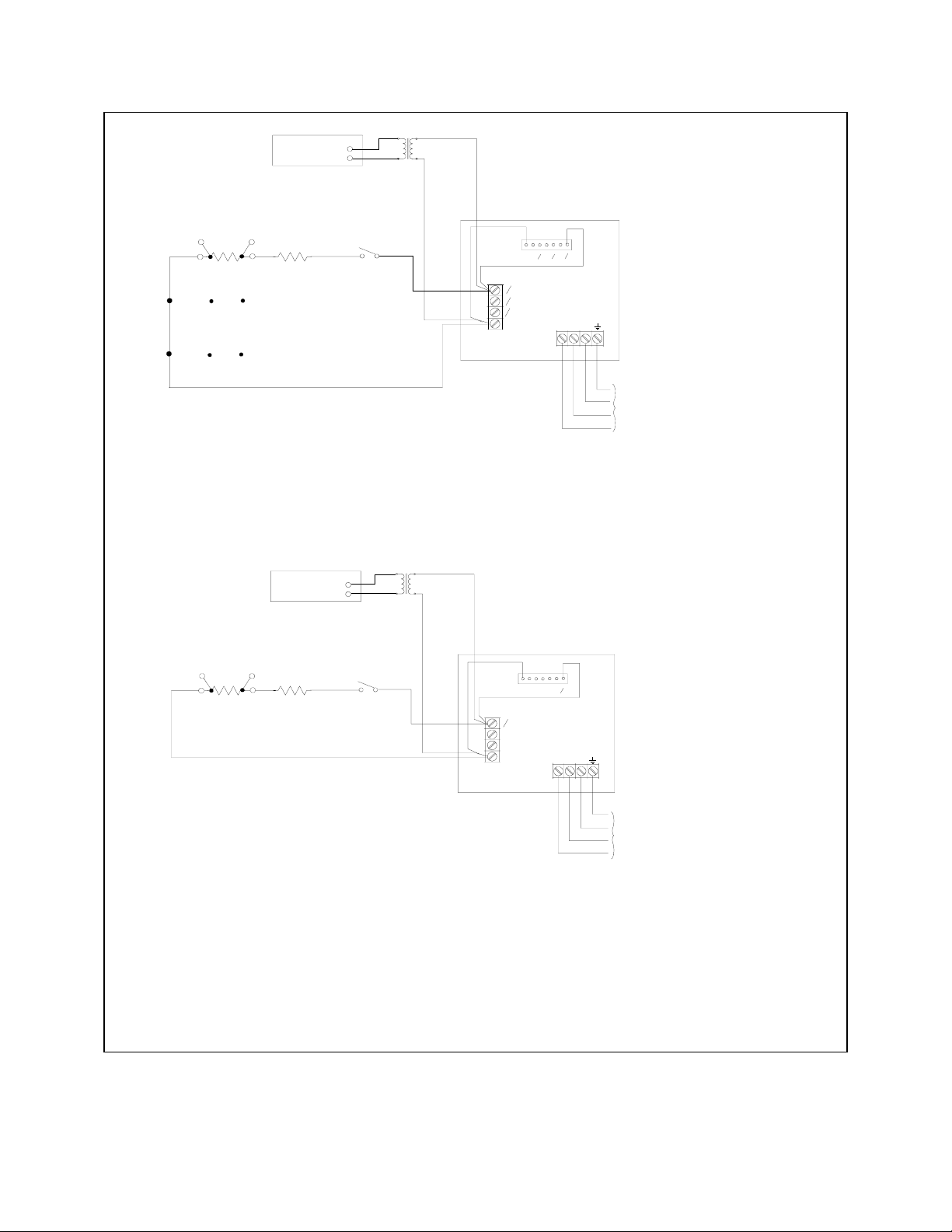

HP3458A

DMM

130

NOTE: Be sure to move sense lead to phase

under test or connect sense leads

to all three phases.

Rs

Rl

S1

Rl = 60 OHM @ 300V OUTPUT >1500W

15 OHM @ 150V OUTPUT >1500W

Rs = Current Monitor resistor - move for

testing current in phase 2 & 3

HP3458A

DMM

l

Rs

Rl

S1

SENSE

O1O2O3

6834B

L1 L2

L3

O1

O2

O3

COM

COM

AC INPUT 3 phase

180-254 VAC line to line

or

360-440 VAC lin e to li ne

TEST SETUP for 6834B

1

30

NOTE: Sense leads connections

reversed on 6843A

SENSE

O1

COM

O1

COM

6814B or

6843A

L1

L2

L3

Rl = 7.5 OHM or 30 OHM for 6814B

5 OHM or 20 OHM for 6843A

see performance test for correct value

Rs = Current Monitor resistor

TEST SETUP for 6814B / 6843A

*Note: Replace HP3458A DMM with HP5316B Counter for frequency test.

Replace HP3458A DMM with HP8903A Harmonic Analyzer for distortion test

Switch is for convience, not required.

Figure 2-1. Verification Test Setup

AC INPUT 3 phase

180-254 VAC line to line

or

360-440 VAC line to line

Performance Tests

17

Page 18

HP3458A

DMM

Rs

Rl

S1

Rl = 60 OHM @ 300V OUTPUT >1500W

15 OHM @ 150V OUTPUT >1500W

Rs = Current Monitor resistor - move for

testing current in phase 2 & 3

HP3458A

DMM

SENSE

O2O3

COM

O1

O2

O3

COM

O1

6834B

L1

L2

L3

TEST SETUP for 6834B

NOTE: Sense lead connections

reversed on 6843A

AC INPUT 3 phase

180-254 VAC line to line

or

360-440 VAC line to line

18

Performance Tests

Rs

Rl

Rl = 7.5 OHM or 30 OHM for 6814B

5 OHM or 20 OHM for 6843A

see perfor mance test for correct v alue

Rs = Current Monitor resistor

S1

SENSE

COM

O1

COM

TEST SETUP for 6814B / 6843A

Figure 2-2 Verification Test Setup

O1

6814B or

6843A

L1

L2

L3

AC INP UT 3 phas e

180-254 VAC line to line

or

360-440 VAC line to line

Page 19

3

Troubleshooting

Shock Hazard. The troubleshooting procedure in this chapter must be performed with power applied and

protective covers removed. These procedures should be done only by trained service personnel aware of

the hazard from electrical shock.

This instrument uses components that can be damaged or suffer serious performance degradation due

to ESD ( electrostatic discharge ). Observe standard antistatic precautions to avoid damage to

components ( see Chapter 1 ).

Introduction

Localizing the Problem

This chapter provides troubleshooting and repair information for the Agilent 6814B, Agilent 6834B AC Power Source and

Agilent 6843A RTS. Before beginning the troubleshooting procedures, make certain the problem is in the AC Power Source

and not with an associated circuit, the GPIB controller, or the ac input lines. Without removing the covers, you can use the

verification tests in chapter 2 to determine if the AC Power Source is operating normally.

Test Equipment Required

List of Equipment

Table 3-1 lists the equipment required to perform the troubleshooting procedures given in this chapter.

Table 3-1. Test Equipment Requirements for Troubleshooting

Equipment Characteristics Model

GPIB Controller Communicate with AC Source via GPIB or

RS232

Digital Voltmeter Check voltages / resistances Agilent 3458A or equivalent

Oscilloscope Observe waveforms Agilent 54504A or equivalent

Current Shunt Check output current 0.01 ohm 10 watt

Logic Probe Check data lines Agilent 545A or equivalent

HP Series 200/300 Controller

or Equivalent.

Troubleshooting Procedure

Table 3-2 gives the troubleshooting procedures to isolate a fault to a circuit board or particular circuit. See figure 6-l for the

location of the circuit boards.

Using *TST? Query

The AC Power Source executes a partial selftest by sending the GPIB selftest query command *TST?. The command

returns a value of zero if all tests pass. Otherwise, the command returns the error code of the first test that failed.

Troubleshooting

19

Page 20

Firmware Revisions

The model number and then the firmware revision is displayed on the front panel for approximately l0 seconds when unit is

first turned on. The firrnware revision is also accessible via the GPIB using the *IDN? query. The following sample

AgilentBASIC program does this.

10 ALLOCATE L$[52]

20 OUTPUT 705;"*IDN?"

30 ENTER 705;L$

40 DISP L$

50 END

The computer will display the string "HEWLETT-PACKARD,<model >,0,<revision>".

ROM Replacement or ROM Update

Instruments that are being initialized for the first time or have suffered non-volatile memory corruption should be initialized

with the front panel EEINIT command. To initialize the unit, perform the following:

1. Turn the unit on, then do the front panel CAL ON command.

2. Press 0 and 9 keys simultaneously. EEINIT <model> should now be displayed.

3. Scroll to the correct model number and press ENTER.

If the command is successful, the front panel display will go through a normal power-on sequence.

It is possible to update to newer ROM versions without destroying the calibration data. To update the unit to newer ROM

revisions, perform the following.

1. Turn input power off, remove the old ROMs and install the new ROMS.

2. Turn the unit on, then do the front panel CAL ON command.

3. Press 0 and 9 keys simultaneously, then scroll to the ROMUPD command.

4. Scroll to the correct model number and press ENTER.

If the command is successful, the front panel display will go through a normal power-on sequence. If "OUT OF RANGE"

error is displayed, then the instrument will have to be re-initialized with the EEINIT command and re-calibrated. This can

occur if the instrument was previously initialized with a QA firmware revision ( QA.xx.xx ), or if non-volatile memory has

become corrupted for any reason.

20

Troubleshooting

Page 21

Calibration Configuration Switch

An internal set of switches control access to calibration commands. The switches are located on the A8 DSP board and are

accessible by removing the top cover. Switches 1 and 2 set the calibration configuration. The three positions are:

Normal Cal This is the default switch position. The calibration functions are accessible after entering a

numeric password. The default password is 0 and is changeable by the user.

Clear Password The calibration password is reset to 0 and the remote programming language is set to SCPI.

This option is useful if the user has forgotten the password.

Inhibit Cal In this position the calibration of the power source cannot be changed. All calibration

commands are disabled. If the CAL ON command is sent with the switch in this position, an

Out Of Range error will be displayed on the front panel. This option is useful in installations

where calibration access is guarded by instrument seals.

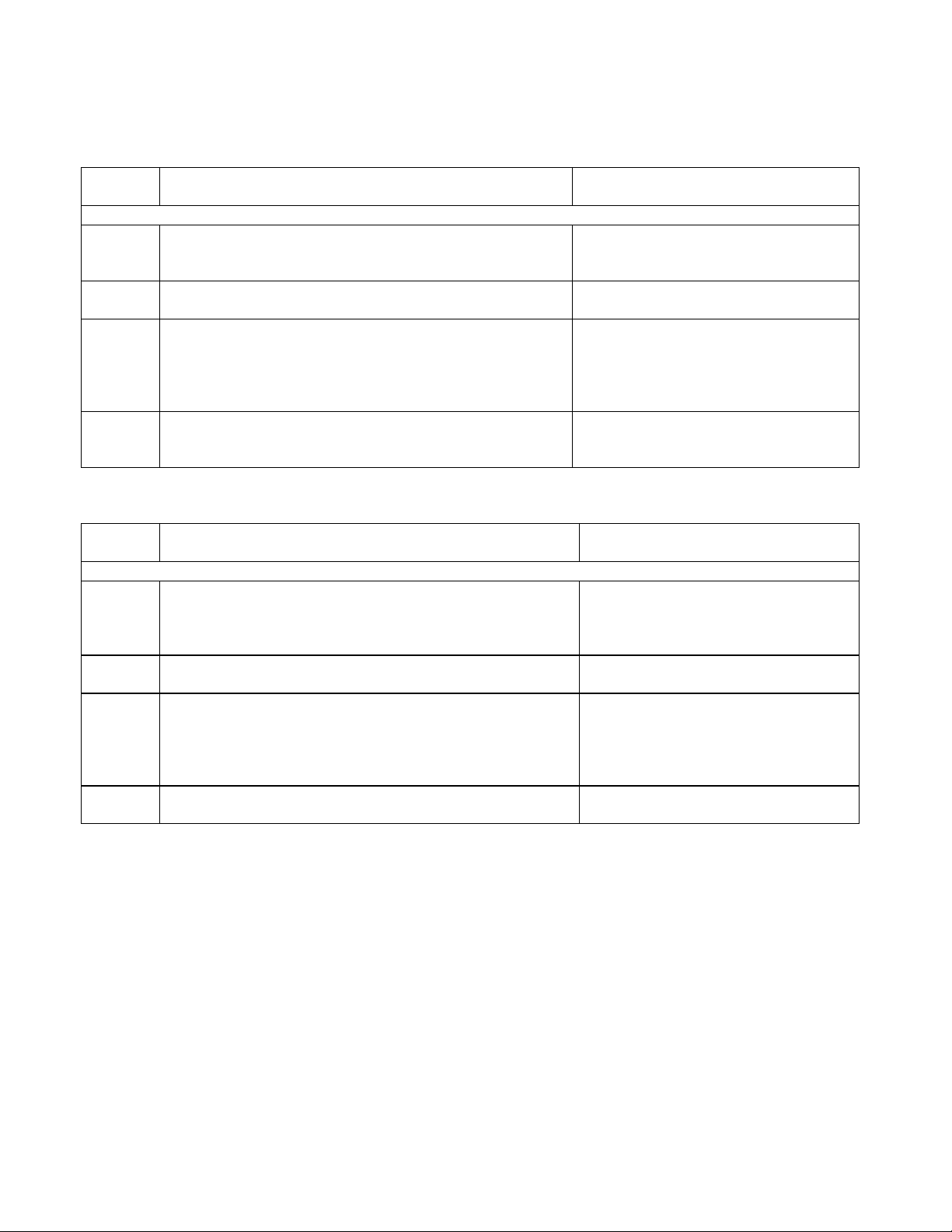

Table 3-2. Specific Troubleshooting Procedures

Step Symptom Corrective Action

1.

2.

3.

rl- Re-initialize unit and re-calibrate. If unit still has RAM error, replace A8 DSP board. To re-initialize unit turn CAL ON,

then press 0 and 9, simultaneously. Press scroll key to model number, then press Enter. When unit is re-initialized all

CAL data, user-defined WAVEFORM data, and LIST data is erased.

r2 -Replace A8 DSP board.

No output voltage / front panel display and fan off go to table 3-3

No or limited output / front panel display and fan on go to figure 3-2

Turn-on Self Test Errors

Error l Non-volatile RAM RD0 section checksum failed Rl

Error 2 Non-volatile RAM CONFIG section checksum failed Rl

Error 3 Non-volatile RAM CAL section checksum failed Rl

Error 4 Non-volatile RAM WAVEFORM section checksum failed Rl

Error 5 Non-volatile RAM STATE section checksum failed Rl

Error 6 Non-volatile RAM LIST STATE section checksum failed Rl

Error l0 RAM selftest r2

Error 11 to 18 DAC self tests, l through 8 r2

Troubleshooting

21

Page 22

Troubleshooting Hints

1. Read all troubleshooting instructions before attempting to troubleshoot the unit.

2. If the AC Power Source operates properly but does not deliver full output power capability, check the ac input mains

fuses located on the rear panel.

3. The amplifiers, ( Al, A2, A3 ) may be interchanged in identical models for troubleshooting purposes. The Agilent

6814A, 6834A, and 6843A models Al, A2, A3 amplifiers cannot be used in the Agilent 6814B or 6834B models. See

Chapter 5, Replaceable Parts, for correct replacement amplifier.

4. The Agilent 6814B uses amplifiers Al and A2 and the 6843A uses amplifiers A1, A2 and A3 connected in parallel at

the output. Drawings show the connections and schematics for the Agilent 6834B 3 phase unit. When troubleshooting

the Agilent 6814B, the A3 amplifier and its associated parts are deleted from specific circuit boards.

5. Troubleshooting the A9 option 400 ( 380 to 460 volt ) Input PS is not recommended at this time. This is a 500 Vdc to

300 Vdc step down switching regulator and contains hazardous voltages.

Switching Amplifier Output Balance Adjustments

If the switching amplifiers ( A1, A2 or A3 ) are replaced phase B and C amplifier gains may require adjustment so they

better match that of phase A and current share equally when paralleled as a single phase output.

6834B Amplifier Balancing

1. With ACS off, temporarily short A5TP1 to A5TP2 on the A5 Relay board (this deactivates the paralleling relays).

2. Turn on ACS, program the output for single-phase operation, 300V, 60Hz, no load.

3. Measure the voltage from phase A output to common and from phase B output to common.

4. Adjust the phase B gain pot, A2A2R104, until phase B output matches phase A output to within 50 millivolts.

5. Measure the phase C output to common.

6. Adjust the phase C gain pot , A3A2R104, until phase C output matches phase A output to within 50 millivolts.

7. Turn off ACS and remove the short from TP1 to TP2.

6814B Amplifier Balancing

1. Turn off ACS, remove phase B amplifier. Turn on ACS. Program output voltage to 300V, 60Hz, no load.

2. Measure and note drive voltage on A6 Servo board at A6TP5 with respect to A6TP1.

3. Turn off ACS, remove phase A amplifier, install phase B amplifier in phase B slot. Turn on ACS. Program output

voltage to 300V, 60Hz, no load.

4. Measure drive voltage at A6TP3 as before. Adjust phase B gain pot A2A2R104 for same drive voltage as noted in step

2, plus or minus 2 millivolts.

5. Turn off ACS, re-install phase A amplifier in phase A slot.

6843A Amplifier Balancing

1. Turn off ACS, remove phase B and C amplifiers. Turn on ACS. Program output voltage to 300V, 60Hz, no load.

2. Measure and note drive voltage on A6 Servo board at A6TP3 with respect to A6TP1.

3. Turn off ACS, remove phase A amplifier, install phase B amplifier in phase B slot. Turn on ACS. Program output

voltage to 300V, 60Hz, no load.

4. Measure drive voltage at A6TP3 as before. Adjust phase B gain pot A2A2R104 for same drive voltage as noted in step

2, plus or minus 2 millivolts.

5. Turn off ACS, remove phase B amplifier, install phase C amplifier in phase C slot. Turn on ACS. Program output

voltage for 300V, 60Hz, no load.

6. Measure drive voltage at A6TP3 as before. Adjust phase C gain pot A3A2R104 for same drive voltage as noted in

step 2, plus or minus 2 millivolts.

7. Turn off ACS, re-install phase A and phase B amplifiers in their respective slots.

22

Troubleshooting

Page 23

Table 3-3. AC Power Source Troubleshooting Procedures

DANGER

Lethal voltages are present when

Instrument covers are removed.

Step Procedure Indication Action

1

Turn off ac mains, disconnect load, and

configure unit for local sensing.

2

3

4

5

Turn on unit and verify that ac power is on

by observing if front panel display is on and

fans are on.

Turn off power supply and remove top cover

as follows:

Remove 9 screws from top and 3 screws from

each side of unit.

Lift cover straight up being careful of lip on

front of cover.

Turn on supply and listen for clicking sound (

relays energizing ) on A9 Input assembly.

** See table 3-7 A14 Option 400 Bias PS

verification

Relays energize but no front panel display

and no fans. 300 Vdc on Cl.

** See table 3-4 A9 200/208 Input PS

verification & table A10 Auxiliary PS

verification.

_______________________________

Option 400 500 Vdc across C9 &

C10 300 Vdc on C1.

** See table 3-5 A9 Option 400 Input PS

verification.

No front panel, no fans, no

relay click ?

No relay click, relays do not

energize?

300 Vdc present ?

_____________________

500 Vdc present ?

300 Vdc present ?

Check F1, F2, F3 on rear

panel.

See fig 6-3 & 6-4

Check A9 1/4 amp fuse.

Check 24 volt bias Option

400 models

See fig 6-6,6-9&6-10 Check

A14 Fl, F2, F3 Check 24

volt bias

No 300 Vdc then

See fig 6-4 Check CR1,

A9F2,F3,F4 A9K1,K2,K3

300 Vdc OK

See fig 6-7 & 6-8

Check A10F1

____________________

No 500 Vdc then

See fig 6-6 Check CR1,

A9F2,F3,F4 A9K1,K2

Check 24 V from A14

assembly

No 300 Vdc then

Check bias voltages from

A14 assembly

Replace A9 assembly

6

Relays energize, fans are on, but no front

panel display.

+5VDC @ A10J6 ? See fig 6-7 & 6-14

Check voltages at A10J6

Check +5V at A8J724-7 to

A8J724-2,4 common

Troubleshooting

23

Page 24

Table 3-3. AC Power Source Troubleshooting Procedures (continued)

Step Procedure Indication Action

7

8

9

Relays energize, fans are on, but no front

panel display. Press the [ Shift ] key a couple

of times.

One or more outputs are missing.

The following procedures will attempt to

isolate the defective assembly by tracking the

bias voltages, ac program signal or ac output

signal.

Front panel display on, fans on.

Program VOLT 100, CURR:LEV 3, Output On using front panel keypad

for following procedures:

Tracking ac program signal.

See figure 3-2 AC Programming Signal Path.

Shift annuniciator on front

panel toggles.

300 Vdc on Cl. Yes

300 Vdc on C1. No

All bias voltage

present see fig 6-7. No

Check A8 DSP assembly.

See figure 6-14

If 1.1 Vrms not present replace

A8DSP assembly

Check +5Vhpib and +/-15V

at A10J1, J2, J3.

Check communication from

A8 DSP to A11 front panel.

A8 DSP assembly may be

defective.

Check A4F1,F2,F3 Fuses

Verify A9 Input PS see

table 3-4 or 3-5. If option

400 model also verify A14

bias see table 3-7.

Verify all bias voltages are

present. See table 3-6.

Measure 1.1 Vrms for

Phase 1 A8U740-9

Phase 2 A8U770-9

Phase 3 A8U774-9

Common is J724-2,4.

10

Tracking AC output signal.

Also see Table 3-9 to verify A5 Relay/Filter

assembly.

CAUTION – HIGH VOLTAGE

To verify amplifier output connect test leads,

Check A6 Servo assembly.

See figure 6-15

If 1.6 Vrms not present replace

A6 Servo assembly.

Check A5 Relay assembly.

Relays A5K5,A5K7 and

A5K8 defective ?

.

A1,A2,A3 amplifier

assemblies are good if voltage

Measure 1.6Vrms at

Phase 1 A6TP-3

Phase 2 A6TP-5

Phase 3 A6TP-7

Common at A6TP-1

Check 100 Vrms at

Phase 1 A5TB1-1

Phase 2 A5TB1-3

Phase 3 A5TB1-4

Common at A5TB1-5

If 100 Vrms not present

Then

Measure 100 Vrms at

Phase 1 A5L1

Phase 2 A5L2

Phase 3 A5L3

Common at A5TP-8

Measure approx. 34 Vrms

between:

24

Troubleshooting

Page 25

One to outside end of C1 and the other to

outside end of C3. ( outside end of capacitor

is end toward edge of heatsink )

is present at C1/C3

connections ( measure 100

Vrms with 300 Vrms

programmed )

A1C1 and A1C3

A2C1 and A2C3

A3C1 and A3C3

With 100 Vrms

programmed.

Verify A4 mother board

Note: See Switching Amplifier Balancing on

page 22.

Table 3-4. A9 208/208 Input Power Supply Troubleshooting

Procedure Action

See figure 6-3 and 6-4 for test points and schematic.

Surge Limit Circuit 1. Measure resistance from Jl-l to Jl-7 or Jl-2 to Jl-8 or Jl-3 to Jl-6.

Resistance must be greater than 100 k ohms.

2. Apply 208 volts 50/60 Hz between E4 and E7.

3. Measure resistance from Jl-l to Jl-7 or Jl-2 to Jl-8 or Jl-3 to Jl-6.

Resistance must be greater than 20 ohms.

Bias Voltages 1. Apply 208 volts 50/60 Hz between E4 and E7.

2. Voltage from ZR1 cathode (+) to TP1 (-) is between 23 and 25.5 Vdc.

3. Voltage from TP3 (+) to TP1 (-) is between +11.5 and 12.5 Vdc.

4. Voltage from ZR2 cathode (+) to TP4 is between 20 and 22 Vdc.

5. Voltage from ZR3 anode (+) to TP4 must be between –20 and -22 Vdc.

UVOV Detector 1. Apply 208 volts 50/60 Hz between E4 and E7.

2. Apply 300 Vdc (+) to El, (-) to E2. Verify voltage from U6-7(+) to TPI(-) is greater

than 9 Vdc.

3. Lower 300 Vdc to 220 Vdc. Verify that voltage at U6-7 is less than 1 Vdc.

4. Raise 300 Vdc to 395 Vdc. Verify that voltage at U6-7 is less than 1 Vdc.

common mode choke

continuity. See figure 6-13 for

location of chokes.

If voltage is present at

amplifier output ( C1/C3

connections) but not on A5

assembly check A5 assy.

Phase Loss Detector 1. Apply 208 volts 50/60 Hz between E4 and E7.

2. Verify that voltage from U4-7(+) to TP1(-) is less than 1 Vdc.

3. Apply 300 Vdc from Jl-l(+) to Jl-2(-). Verify that voltage from U4-7 to TP1(-) is greater

than 9 Vdc. Remove 300 Vdc.

4. Apply 300 Vdc from Jl-2(+) to Jl-3(-). Verify that voltage from U4-7 to TP1(-) is greater

than 9 Vdc. Remove 300 Vdc.

5. Apply 300 Vdc from Jl-3(+) to Jl-l(-). Verify that voltage from U4-7 to TP1(-) is greater

than 9 Vdc. Remove 300 Vdc.

Table 3-5. A9 Option 400 (400V) Input Power Supply Troubleshooting

Caution: A 500Vdc power source plus external capacitors and inductors are required to verify the operation of the A9

option 400 volt AC Input assembly. For safety concerns only check fuses A9F1, A9F2 and A9F3. If this does not resolve

the concern then replace the A9 option 400 AC Input assembly.

Troubleshooting

25

Page 26

Table 3-6. A10 Auxiliary Power Supply Troubleshooting

Procedure Action

See figures 6-7 and 6-8 for test points and schematic.

Control Circuits 1. Apply 20 Vdc between TP7(+) and TP1(-).

2. Verify waveform at TP2 to TP1. 0 V to >15 V at approximately 60 kHz, duty cycle

40% to 50%.

3. Check drive to Ql and Q4 . Connect scope common to CR13 anode, verify waveform

at gate drive resistors R10 and R28 is swinging between +12Vpk and –12Vpk at

approximately 60 kHz, duty cycle 40 to 50%.

Outputs 1. Apply 20 Vdc between TP7(+) and TP1(-). Add a 10 ohm 25 W resistor across R13.

2. Apply 300 Vdc between Jl-1,2 (+) to Jl-5,6 (-).

3. Verify the 15 SW1 voltage across R13 is between 14.5 and 15.5 Vdc.

4. Verify the +5 GPIB voltage across R18 is between 4.8 and 5.2 Vdc.

5. Verify the +5V SEC voltage across R33 is between 4.2 and 5.2 Vdc.

6. Verify the fan voltage from J3-1 (+) to J3-5 (-) is between 14.6 and 15.8 Vdc.

Short J4-6 to J3-5 fan voltage should now be between 17.4 and 18.9 Vdc.

7. Verify the +15 analog supply across R43 is between 14.3 and 15.5 Vdc.

8. Verify the –15 analog supply across R48 is between 14.3 and 15.5 Vdc.

*A lower input voltage ( <300 Vdc ) can be used but the expected output voltages must

be recalculated.

Table 3-7. A14 Option 400 Bias Power Supply Troubleshooting

Procedure Action

See figure 6-9 and 6-10 for test points and schematic.

Outputs 1. Apply 342 V 50/60 Hz between J2-1 and J2-4.

2. From TP1 (Lo) (Jl-7 ) to Jl-8 measure 26 Vdc +/- 2V.

3. From TP1 (Lo) (Jl-7 ) to Jl-6 measure 26 Vdc +/- 2V.

4. From TP2 (Lo) (Jl -3 ) to Jl -4 measure 19.3 Vdc +/- 2V.

5. From TP2 (Lo) (Jl-3 ) to Jl-2 measure -19.3 Vdc +/- 2V.

6. From TP3 (Lo) (J I -11 ) to J1 -1 0 measure 26 Vdc +/- 2V.

7. From TP2 (Lo) (Jl-3 ) to Jl-12 measure -26 Vdc +/- 2V.

*A lower input voltage ( <342 Vac ) can be used, but the expected output voltages must

be recalculated.

26

Troubleshooting

Page 27

Table 3-8. A4 Mother Board Troubleshooting

Procedure Action

See figure 6-13 for test points.

Inputs

Continuity check

Procedure Action

Range relays Program VOLT 50, CURR:LEV 3, Output On.

The following voltage tests verify that the correct input operational voltages are available

to the A4 mother board. To test for these voltages, remove the Al, A2 and A3 amplifier

assemblies.

The +300 Vdc and 300 Vdc return are shown on Fig 6-13.

The following input voltages appear at J2, J4 and J6.

IA phase A high IB phase A common

2A +5V sec 2B *OVT

3A 3B D common

12A common 1 12B common 1

13A -15VSW 13B -15VSW

15A + 15VSW 15B +15VSW

16A + 15VSW1 16B + 15VSW1

Verify common mode inductors ( L1 thru L6 ) continuity. See A4 Mother Board Parts

Location on Figure 6-13.

Table 3-9. A5 Relay / Filter Board Troubleshooting

See figure 6-11 and 6-12 for test points.

Program high range: Measure 25 volts from J2-1 to J2-3, J2-2 to J2-4, J2-5 to J2-7,

J2-6 to J2-8, J2-9 to J2-11 and J2-10 to J2-12.

Program low range: Measure 50 volts from J2-1 to J2-3, J2-2 to J2-4, J2-5 to J2-7,

J2-6 to J2-8, J2-9 to J2-11 and J2-10 to J2-12.

Output enable / disable

Relays

Sense relays Program ACL:INT: Measure greater than 10 megohms from R43 to K5 common, R44 to

Measure 50 volts from TB1-1 to TB1-6, TB1-3 to TB1-6 and TB1-4 to TB1-6. If

voltages are not available, test voltage between relays K5, K7, K8 common terminal to

determine defective relay.

K7 common, R45 to K8 common and R46 to K9 common.

Program ACL:EXT: Measure approximately 105 Kohms from R43 to K5 common, R44

to K7 common, R45 to K8 common and R46 to K9 common.

Troubleshooting

27

Page 28

28

Troubleshooting

Figure 3-1. Bias Voltage to Switching Amplifier Assemblies

Page 29

A8 DSP Assembly

A6 Servo Assembly

A4 Mother Assembly

Remove A1 A2 A3

to access these connections

Phase A U740-9

Phas6 B U770-9

Phase C U774-9

J722-5

J723-11

J723-17

J2-5

J2-11

J2-17

TP1

TP3

TP5

TP7

J4-1 P1-1

J4-5 P1-5

J4-3 P1-3

Figure 3-2. AC Programming Signal Path

J2-1A Sig A Hi

J2-1B

J4-1A Sig B Hi

J4-1B

J6-1A Sig C Hi

J6-1B

Sig A com

Sig B com

Sig C com

Troubleshooting

29

Page 30

Page 31

Principles of Operation

Introduction

Figure 4-1 ( at end of this chapter ) is a block diagram showing the major circuits within the ac source. The ac source

consists of the following modules:

Al, A2, A3 Switching Amplifiers Modules

A4 Mother Board Assembly

A5 Range Relay and Filter Assembly

A6 Servo ( Control ) Assembly

A7 IEEE488 ( GPIB ) & RS232 Interface Assembly

A8 Digital Signal Processing ( DSP ) Assembly

A9 Input Power Assembly

A10 Auxiliary Power Supply Assembly

Al 1 Front panel Assembly

A12 Input Filter PC Assembly

A13 Bridge Capacitor Filter Assembly

A14 Bias Power Supply ( option 400 only )

General Description

4

The 3 phase input power is connected to TBl on the rear panel, then routed through Fl, F2 and F3 to the RFI filter, FLI, to

relay Kl. The 3 phase input power is also connected to the A9 Input power assembly. When relay Kl closes the 3 phase

input is connected to power rectifier CRl, Ll and Cl to create 300 Vdc required by the power amplifiers Al, A2 and A3. The

amplifier assemblies in concert with the output filter and range relays produce the programmed waveform at the

programmed frequency and voltage. The 300 Vdc is also used by the A10 Auxiliary power supply board to produce the bias

voltages required by support circuits.

A1, A2, A3 Switching Amplifier Modules

The switching amplifier modules consist of a heat sink assembly, control board and power board. The 3 amplifier modules

are identical and can be interchanged for troubleshooting assistance. The amplifier assemblies can only be replaced as a

complete assembly, they are not repairable to the component level. The Agilent 6814B uses 2 amplifier assemblies

connected in parallel to provide 3000 watts single phase AC output power. The Agilent 6834B uses 3 amplifier assemblies

connected in a

3-phase configuration with each amplifier providing 1500 watts AC output power per phase. The 6843A uses three

amplifiers connected in parallel to provide 4800 watts single phase AC output power. When an amplifier assembly is

replaced it will be necessary to balance the amplifier, see paragraph on page 3-4 Switching Amplifier Output Balance

Adjustments. Amplifiers from [ 6814A, 6834A ] or [ 6843A ] or [ 6814B, 6834B ] Models are NOT INTERCHANGABLE.

See Chapter 5 Replaceable Parts listing for correct replacement assembly.

A4 Mother Board Assembly

The A4 mother board interconnects the Al, A2 and A3 amplifier assemblies with the A6 servo assembly, the 300 Vdc rail

voltage and the +/-15 Vdc bias supply. There are 10 amp fuses located in the +300 Vdc line to each amplifier assembly. The

Agilent 6814B and 6834B A4 assemblies are not interchangeable.

Principles of Operation

31

Page 32

A5 Relay Range / Sense Assembly

The A5 assembly consists of the output voltage filters, the output voltage range relays A5Kl, A5K2 and A5K3, the output

voltage disconnect relays A5K5, A5K6, A5K8 A5K9 and remote sense relays A5K4, A5K7 and all associated circuits. It

also interconnects the A7 GPIB/RS232 assembly, A11 front panel assembly and A8 DSP assembly with each other and the

trigger and DFI/RI signals. The Agilent 6814B and 6834B A5 assemblies are not interchangeable.

A6 Servo ( Control ) Assembly

The A6 servo or control assembly consists of the gate control circuits for the Al, A2 and A3 power amplifiers where

required. It also contains the voltage and current control amplifiers and receives the voltage and current programming

information from the A8 DSP assembly. It interconnects the range and protection signals between the A5 and A8

assemblies. This assembly is not component level repairable. The Agilent 6814B and 6834B A6 assemblies are not

interchangeable.

A7 IEEE488 (GPIB) / RS232 Interface Assembly

The A7 interface contains the CPU and logic circuits for communicating with either an GPIB or RS232 computer/controller.

This assembly is not component level repairable. This assembly is interchangeable with all AC power sources.

A8 Digital Signal Processing Assembly

The A8 DSP board contains the CPU, ROMs, Digital to Analog and Analog to Digital circuits to control the output voltage

and output current settings. The A8 board also contains all the logic circuits for generating arbitrary waveforms, frequency

changes and phase control. At power on the DSP board performs a self-test and will report a failure via the front panel

display. This assembly is not component level repairable and is not interchangeable between an Agilent 6814B and 6834B.

A9 Input Power Assembly - ( 208 volt input )

The A9 input power assembly provides a current limit circuit to initially charge Cl to 300 Vdc, a phase loss detection

circuit, the undervoltage / overvoltage detection circuits, and +/- l5VSW to the A10 auxiliary power supply assembly. When

S1, on/off switch, is closed a single phase is used to power two bias transformers generating the +/-15 Vdc, 12 Vdc for the

protection circuits and 24 Vdc to the current limit relays Kl, K2 and K3. There are 4 fuses on the A9 board. Fuse A9F1 is in

series with Sl on/off switch, if A9F1 is open the Agilent 6834B will not function in any form. The remaining 3 fuses, A9F2,

A9F3 and A9F4 are in series with the current limit resistors and relays. If all 3 fuses are open the unit will not function and

if 1 or 2 fuses are open the phase loss status bit be true and full output power will not be available. This assembly is not

component level repairable except for fuses. This assembly is interchangeable between an Agilent 6814B and 6834B.

A9 Input Power Assembly - ( 400 volt input )

The A9 input power assembly provides a current limit circuit to initially charge C9 and C10 to 550 Vdc, a step-down

switching regulator to power the +300V on C1, a phase loss detection circuit and the undervoltage / overvoltage detection

circuits. When S1, on/off switch, is closed a single phase is used to power three bias transformers on the A12 Bias board,

The A12 Bias board provides +16 Vdc, +15 Vdc, -5 Vdc, 12 Vdc for the protection circuits and 24 Vdc to the current limit

relays Kl and K2. There are 3 fuses on the A9 board. The 3 fuses, A9F2, A9F3 and A9F4 are in series with the current limit

resistors and relays. If all 3 fuses are open the unit will not function and if 1 or 2 fuses are open the phase loss status bit be

true and full output power will not be available. This assembly is not component level repairable except for fuses. This

assembly is interchangeable between a 6814B and 6834B.

32

Principles of Operation

Page 33

A10 Auxiliary Power Supply

The 300 Vdc is used by the A10 board to generate the bias voltages. The 300 Vdc input line is fused by a 1 ampere

subminiature fuse, A10F1. The A10 supplies an isolated +5 Vdc for the A7 GPIB/RS232 interface board and A11 front

panel board. The + 15 VSW dc to the A4 mother board via J2, the +/-15V and +5Vsec to the A6 servo board via J4 and

+5V sec to the A8 DSP board via J5. It also supplies the 12-24 Vdc for the fan speed control. All secondary bias winding

are fused with 1 ampere subminiature fuses A10F2 through A10F7. This assembly is not component level repairable except

for fuses. This assembly is interchangeable between an Agilent 6814B and 6834B.

A11 Front Panel Display Assembly

The A11 assembly contains the display assembly, keypad, rotary pulse generators (RPG) and digital logic circuits, CPU and

ROM. This assembly is not component level repairable. This assembly is interchangeable between an Agilent 6814B and

6834B.

A12 Input Filter Assembly

The A12 assembly contains resistor / capacitor networks connected line to line to reduce any magnetic noise from being

conducted back into the AC input mains.

A13 Bridge Capacitor Filter Assembly

The A13 assembly contains capacitors and surge protectors connected line to line and a common mode inductor and surge

protector connected in series with the + 300 Vdc bus. The filter is connected to reduce conducted and radiated noise