Page 1

Errata

Title & Document Type: 300A Harmonic Wave Analyzer

Manual Part Number: N/A

Revision Date: 11/30/1955

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that

Hewlett-Packard's former test and measurement, semiconductor products and chemical

analysis businesses are now part of Agilent Technologies. We have made no changes to

this manual copy. The HP XXXX referred to in this document is now the Agilent XXXX.

For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be ideal. If we find a better

copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available product

information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available

Page 2

t

OPERATING

MANUAL

PLUS

SERVICE

MANUAL

MODEL

300A

HARMONIC

WAVE

ANALYZER

This

isacombined

Operation,

Instruction,

and

Service

Manual

for

all

~

Mode1300A

Harmonic

Wave

Analyzers.

This

manual

contains

complete

operation

and

servicing

instructions

for

the

300A

and

may

be

used

in

place

of

thl~

Instruction

and

Operating

Manual

originally

supplied

with

each

ins

trument.

Copyright

1956

by

Hewlett-Packard

Company

The

information

contained

in

this

booklet

is

intended

for

the

operation

and

main-

tenance

of

Hewlett-Packard

equipment

and

is

not

to

be

used

otherwise

or

reproduced

without

the

written

consent

of

the

Hewlett-

Packard

Company.

HEWLETT-PACKARD

COMPANY

PAGE

MILL

ROAD,

PALO

ALTO,

CALIFORNIA,

U.S.A.

Page 3

II

MODEL

300A

HARMONIC

WAVE

ANALYZER

INSTRUCTION

&

OPERATING

MANUAL

TABLE

OF

CONTENTS

SECTION

I

GENERAL

Page

1-1

1-2

GENERAL

DESCRIPTION

SPECIFICATIONS

• • •

· . . .

· .

· .

· .

III

III

SECTION

II

OPERATING

INSTRUCTIONS

2

-1

23D

VOLT

OPERATION.

·

· ·

·

·

·

·

· · · ·

•

III

2

-2

CONTROLS

&

TERMINALS

· · ·

·

·

· · · · ·

•

IV

2

-3

OPERATION.

. . . .

· ·

·

· · · · · · ·

• •

· · · · ·

IV

2-4

CALIBRATION

ADJUSTMENT

PROCEDURE.

·

·

·

• •

IV

2

-5

MEASUREMENT

PROCEDURE.

· · · · ·

•

·

·

·

IV

2

-6

MEASUREMENT

PRECAUTIONS.

·

· · · · · · · ·

•

V

2-7

SELECTIVITY.

. . .

· · · · · · · · · ·

•

V

SECTION

III

CIRCUIT

DESCRIPTION

3-1

GENERAL

••••

· . . . . . . . . . .. . . . .

SECTION

IV

MAINTENANCE

VI

4-1

CABINET

REMOVAL.

· · · · ·

·

· · ·•· ·

•

·

·

VII

4-2

TUBE

REPLACEMENT.

·

· · · · · · ·

·

·

•

·

•

·

•

·

VII

4-3

LOCAL

OSCILLATOR

AMPLITUDE

ADJUSTMENT.

•

·

VII

4-4

VOLTAGE

REGULATOR

ADJUSTMENT.

· ·

• • •

·

•

·

•

VII

4-5

HUM

BALANCE

ADJUSTMENT.

· ·

•

·

• • • • • • • •

·

VII

4-6

BALANCED

MODULATOR

ADJUSTMENT.

•

· ·

• •

·

VII

4-7

SELECTIVE

AMPLIFIER

ADJUSTMENT

· ·

•

· ·

•

·

VII

SECTION

V

TABLE

OF

REPLACEABLE

PARTS

5-1

GENERAL.

. . . . . . . . . . . . . . . . .. . . . .

VII

THE

ATTACHED

300A-2

SERVICE

MANUAL

HASASEPA-

RATE

INDEX

APPEARING

ON

PAGE

1.

..

Page 4

III

INSTRUCTION

&

OPERATING

MANUAL

SECTION

I

GENERAL

1-1

GENERAL

DESCRIPTION

The

Model

300A

Harmonic

Wave

Analyzer

isaselective

voltmeter

designed

to

measure

the

individual

components

of

complex

waves.

The

selectivity

can

be

varied

by

means

of

selective

amplifiers

to

measure

either

closely

or

widely

spaced

harmonics.

The

instrument

coversthe

audio

spectrum

from

30

to

16,000

cps.

It

has

a

wide

voltage

range

so

that

full

scale

readings

may

be

ob-

tained

from

1

millivolt

to

500

volts

0

The

Model

300A

is

well

adapted

to

the

measurement

of

the

harmonic

distortion

in

audio

frequency

equipment

of

all

kinds,

broadcast

receivers,

transmitters;

to

determine

the

harmonic

components

in

ac

machinery

and

power

systems;

to

the

study

of

induced

voltages

on

telephone

lines;

and

to

measurement

of

hum

components

in

rectifier

circuits.

Other

uses

include

the

study

of

noise

by

integrating

portions

of

the

spectrum

with

the

selectivity

control

adjusted

for

a

wide

pass

band

and

the

checking

of

wave

filter

characteristics

with

maximum

selectivity.

The

Model

300A

is

also

useful

asadevice

to

measure

the

amount

of

cross

or

intermodulation

products

generated

by

the

simultaneous

transmis

sion

of

two

frequencies

by

an

audio

system

or

to

measure

demodulation

ofamodulated

wave

applied

through

an

audio

system.

1

-2

SPECIFICATIONS

Complete

specifications

for

the

cEiJ

Model

300A

Harmonic

Wave

Analyzer

will

be

found

on

page

3

of

the

cEiJ

No.

300A-2

Service

Manual.

SECTION

II

OPERATING

INSTRUCTIONS

2-1

230

VOLT

OPERATION

This

instrument

is

shipped

from

the

factory

with

the

power

transformer

pri-

maries

connected

in

parallel

for

operation

from

115

volts.

If

operation

from

a

power

line

of

230

volts

is

desired,

the

power

transformer

primaries

must

be

connected

in

series

as

shown

by

the

"Transformer

Detail"

on

the

schematic

diagram

in

Fig.

3

on

page

39

of

the

No.

300A-2

Service

Manual.

Some

older

instruments

have

a

power

transformer

with

a

single

primary

wind-

ing

for

operation

from

115

volts

only.

The

1.

25

ampere

slo-blo

fuse

required

for

115

volt

operation

must

be

replaced

by

a

0.6

ampere

slo-blo

fuse

after

changing

primary

connections

from

parallel

to

series

for

operation

from

230

vo.lts.

Page 5

IV

2-2

CONTROLS

AND

TERMINALS

All

controls

and

terminals

are

fully

des

cribed

on

pages

4

and

5

of

the

r5j:;

No.

300A-2

Service

ManuaL

CAUTION

THIS

INSTRUMENT

IS

ACCURATE

AT

AMBIENT

TEMPERATURES

OF

APPROXIMATELY

55

TO

95

DEGREES

FAHRENHEIT.

OTHER

AMBI-

ENT

TEMPERATURES

MAY

NECESSITATE

REALIGNMENT

OF

THE

SELECTIVE

AMPLIFIER

SYSTEM.

2-3

OPERATION

The

operation

of

the

Model

300A

is

divided

into

two

parts.

the

calibration

adjustment

procedure

and

the

measurement

procedure.

2-4

CALIBRATION

ADJUSTMENT

PROCEDURE

This

procedure

will

be

found

under

the

heading

of

CALIBRATION

PROCE-

DURE

starting

on

page

11

of

the

r5j:;

No.

300A-2

Service

Manual.

See

the

important

operating

precautions

given

in

step

26

of

CALIBRA

TION

PROCEDURE

in

the

No.

300A-2

manual.

2-5

MEASUREMENT

PROCEDURE

The

instrument

must

be

calibrated

before

attempting

a

measurement.

In

the

following

procedure,

the

voltage

being

analyzed

has

a

fundamental

frequency

of

80

cps

and

an

amplitude

of

20

volts.

The

frequency

and

amplitude

of

this

hypothetical

voltage

have

been

as

sumed

to

simplify

the

instructions.

Any

voltage

between

1

millivolt

and

500

volts

at

any

frequency

between

30

to

16,

000

cps

could

be

similarly

measured.

A

harmonic

frequency

must

not

be

higher

'than

16.

000

cps

if

the

particular

harmonic

voltage

is

to

be

measured.

a.

Calibrate

the

300A

as

previously

described.

b.

Set

the

METER

MULTIPLIER

control

to

50

(XIOO)

and

the

SET

TO

100

FOR

VOLT

AGE

MEASUREMENT

control

to

100.

c.

Set

the

HALF

BAND

WIDTH

control

to

30.

See

step

26B

on

page

12

of

No.

300A-2

Service

Manual

regarding

the

degree

of

selectivity

neces-

sary

for

measuring

voltages

of

various

frequencies.

d.

Set

the

frequency

dial

to

80

cps

and

peak

the

meter

indication

by

adjust-

ing

the

FINE

TUNING

control.

The

METER

SENSITIVITY

control

should

be

adjusted

to

giveareadable

indication

on

the

millivoltmeter.

The

in-

strument

is

now

tuned

to

measure

the

amplitude

of

the

fundamental

fre-

quency

(80

cps)

with

the

harmonics

excluded.

e.

The

actual

value

of

the

funda'mental

voltage

is

found

by

multiplying

the

millivoltmeter

indication

by

the

multiplying

factor

shown

by

the

position

of

the

METER

MULTIPLIER

control.

J

Page 6

Example:

METER

SE.

SITIVITY

at

500

(5.aon

meter

scale)

full

scale

millivolts.

Meter

pointer

at

2.atherefor

e

meter

actually

indicates

200

millivolts.

200

millivolts

x

100

(meter

multiplier

factor)

is

equal

to

20,

000

millivolts

or

20

volts.

2-5

MEASUREMENT

PROCEDURE

(Contld.)

v

..

£.

Turn

the

frequency

dial

to

160

cps

(second

harmonic

of

80

cps)

and

set

the

METER

SEl

SITIVITY

and

METER

MULTIPLIER

controls

to

obtain

a

read-

able

meter

indication.

Use

the

FINE

TUNING

control

to

peak

the

meter

indication.

The

meter

indication

times

the

meter

multiplying

factor

will

give

the

amplitude

of

the

second

harmonic.

g.

Repeat

step

f.

at

as

many

higher

harmonics

as

desired

until

the

harmonic

voltages

become

too

small

to

measure.

In

some

cases,

the

harmonic

fre-

quency

will

be

higher

than

16,

000

cps

which

will

be

outside

the

range

of

the

300A.

2-6

MEASUREMENT

PRECAUTIONS

The

results

obtained

with

the

300A

will

depend

upon

how

clos~ly

the

operator

follows

a few"

simple

but

very

important

operating

precautions.

These

pre-

cautions

are

given

in

step

26

of

PROCEDURE

FOR

CALIBRATION

on

page

12

of

1$

o.

300.1\-2

Service

Manual.

In

addition,

a

20

KC

filter

should

be

used

between

the

voltage

to

be

measured

and

the

input

terminals

of

the

Model

300A

when

voltages

at

frequencies

of5KC

or

10

KC

are

being

measured.

This

filter

will

prevent

the

fourth

harmonic

of

the

5

KC

volt3.ge

or

the

second

harmonic

of

the

10

KC

voltage

from

entering

the

20

KC

seJ.ective

amplifier

and

causing

erroneous

measur~ments.

2-7

SELEC

TIVITY

When

operati.ng

the

Model

300A,

it

should

be

borne

in

mind

that

the

instrument

isafrequency

selective,

wide

range

voltmeter

whose

selectivity

is

variable.

It

is

necessary

during

operation

to

determine

the

degree

of

selectivity

desired

and

to

adjust

the

instrument

correctly

to

obtain

that

degree

of

selectivity.

Determination

of

the

proper

selectivity

to

use

inaparticular

measurement

should

primarily

be

based

on

the

fact

that

unwanted

voltages

must

be

attenu-

ated

by

the

selectivity

of

the

instrument

to

less

than

one

third

of

the

voltage

under

measurement.

This

attenuation

is,

in

turn,

dependent

upon

the

order

of

separation

of

unwanted

voltages

from

the

desired

voltage,

and

the

relative

magnitudes

of

the

various

voltages

involved.

Instrument

selectivity

is

controlled

by

the

HALF

BAND

WIDTH

control

which

is

calibrated

from

"30"

to

"145".

These

calibrations

indicate

the

frequency

separation

fr~m

the

center

frequency

at

which

the

selectivity

characteristics

of

the

instrument

attenuates

by

40

db

(99%).

Another

way

of

saying

the

same

thing

is

that

the

HALF

BAND

WIDTH

calibra-

tions

indicate

the

minimum

frequency

separation

from

a

100%

voltage

which

will

permit

accurate

measurement

ofa3%

voltage.

It

will

often

be

found

convenient

to

use

only

two

degrees

of

selectivity

as

ob-

tained

by

setting

the

HALF

BAND

WIDTH

control

at

"145"

for

minimum

Page 7

VI

2-7

SELECTIVITY

(Contld.)

selectivity

or

at

"30"

for

maximum

selectivity.

Usemlmmum

selectivity

for

voltages

with

a

fundamental

frequency

higher

than

100

to

300

cps.

Use

maximum

selectivity

for

voltages

withafundamental

frequency

lower

than

100

to

300

cps.

This

system

eliminates

the

necessity

of

determining

whether

an

intermediate

degree

of

selectivity

offers

sufficient

attenuation

for

the

case

at

hand.

Occasionally,

however,

it

is

desirable

to

use

degrees

of

selectivity

which

are

intermediate

between

minimum

and

maximum.

An

example

follows

to

illus-

trate

a

typical

case

of

selectivity

determination.

Refer

to

Fig.

2

on

page

38

of

the

No.

300A-2

Service

Manual

which

shows

the

selectivity

characteristics

of

the

300A

for

the

two

extremes

of

the

HALF

BAND

WIDTH

control.

A

convenient

graph

for

converting

attenuation

in

terms

of

decibels

to

percentage

is

given

in

Fig.

9

on

page

45

of

the

No.

300A-2

Service

ManuaL

The

graphs

of

Figs.

2

and9are

used

to

determine

the

setting

of

the

HALF

BAND

WIDTH

control

as

illustrated

in

the

following:

As

sume

that

it

is

desired

to

measure

the

harmonics

of

an

80

cps

funda-

mental

and

that

harmonics

which

are

0.50/0

or

higher

are,of

interest.

Unwanted

voltages

must

be

attenuated

to

less

than

1/3

of

the

voltage

under

measurement

and

for

this

particular

case

it

would

be

1/3

of

1/20/0

or

1/6

of

10/0.

In

other

words,

when

measuring

the

second

harmonic,

the

funda-

mental

must

be

reduced

to

1/6

of

10/0ofits

value

by

the

300A

selectivity

characteristics.

Referring

to

Fig.

9,

we

see

that

1/6

of

1%

is

equivalent

to

approximately

56

decibels.

Therefore,

the

HALF

BAND

WIDTH

con-

trol

must

be

adjusted

so

that

the

instrument

will

attenuate

by

56

decibels

for

a

frequency

separation

of

80

cps.

Refer

to

Fig.

2

and

sketch

inacurve

similar

to

the

two

curves

shown.

The

new

curve

should

pass

through

the

56

db

point

at

80

cps

off

resonance.

Note

the

point

where

the

new

curve

passes

the

40

db

line.

This

point

has

an

abscissa

of

about

50

cycles

off

resonance.

Therefore,

the

HALF

BAND

WIDTH

control

should

be

set

at

"50"

to

obtain

56

db

attenuation

at

80

cps

off

resonance.

The

instrument

must

then

be

calibrated

using

a

HALF

BAND

WIDTH

setting

of

"50"

instead

of

"30"

in

steps

20

through

23

of

PROCEDURE

FOR

CALIBRATION

on

page

12

of

No.

300A-2

Service

Manual.

See

step

26B

on

the

same

page

for

additional

information.

SECTION

III

CIRCUIT

DESCRIPTION

3-

1

GENERAL

The

circuitry

of

the

rFeJ

Model

300A

Harmonic

Wave

Analyzer

is

discussed

on

pages

8,

9,

10,

and

11

of

the

(/!j)

No.

300A-2

Service

Manual.

•

Page 8

VII

SECTION

IV

MAINTENANCE

4-1

CABINET

REMOVAL

To

remove

the

instrument

from

the

cabinet

it

is

necessary

to

unscrew

the

eight

large

Phillips

head

screws

on

~he

control

panel

and

slide

the

instrument

forward

out

of

the

cabinet.

In

some

older

instruments,

it

may

be

necessary

to

remove

the

wire

connect-

ing

the

bottom

chassis

to

the

metal

plate

in

the

bottom

of

the

cabinet.

This

wire

will

be

found

on

the

rear

of

the

instrument.

4-2

TUBE

REPLACEMENT

Refer

to

page

7

of

Service

Manual

No.

300A-2

for

complete

instructions

on

tube

replacements.

4-3

LOCAL

OSCILLATOR

AMPLITUDE

ADJUSTMENT

This

adjustment

can

be

made

at

any

time

as

directed

in

step

2

of

PRELIMI-

NARYTESTS

&

ADJUSTMENTS

on

page

13

of

No.

300A-2

Service

Manual.

4-4

VOLTAGE

REGULATOR

ADJUSTMENT

The

output

of

the

regulated

power

supply

section

in

the

300A

should

be

checked

from

time

to

time

as

directed

in

step1of

PRELIMINARY

TESTS

&

ADJUST-

MENTS

on

page

13

of

No.

300A-2

Service

Manual.

4-5

HUM

BALANCE

ADJUSTMENT

The

hum

balance

control

R159

is

located

on

the

bottom

deck

of

the

instrument

next

to

the

heater

transformer.

The

procedure

for

adjusting

this

control

is

given

in

FINAL

TEST

step

8

on

page

17

of

No.

300A-2

Service

Manual.

•

4-6

4-7

BALANCED

MODULATOR

ADJUSTMENT

The

procedure

for

adjusting

the

balanced

modulator

to

minimize

harmonic

distortion

is

given

on

page

18

of

No.

300A-2

Service

Manual

in

step

10

under

FINAL

TEST.

SELECTIVE

AMPLIFIER

ADJUSTMENT

The

detailed

procedure

for

adjusting

the

selective

amplifier

system

in

the

300A

is

given

on

pages

14

and

15

of

the

No.

300A-2

Service

Manual.

SECTION

V

TABLE

OF

REPLACEABLE

PARTS

5-1

GENERAL

A

table

of

replaceable

parts

which

is

suitable

for

use

with

all

300A

instruments

is

given

in

the

~

No.

300A-2

Service

Manual.

This

table

begins

on

page

51

of

the

manual.

Page 9

I

•

OPERATION

AND

SERVICE

MANUAL

FOR

MODEL

300A

HARMONIC

WAVE

ANALYZER

300A-2A

This

isacombined

Operation

and

Service

Manual

for

all

c5j;

Model

300A

Harmonic

Wave

Analyzers.

This

manual

contains

complete

operation

and

servicing

in-

structions

for

the

300A

and

may

be

used

in

place

of

the

Instruction

and

Operating

Manual

originally

sup-

plied

with

each

instrument

•

Copyright

1955byHewlett-Packard

Company

The

information

containedinthis

booklet

is

intended

for

the

operation

and

main-

tenanceofHewlett-Packard

equipment

and

is

nottobe

used

otherwiseorreproduced

without

the

written

consentofthe

Hewlett-

Packard

Company.

HEWLETT-PACKARD

COMPANY

275

PAGE

MILL

ROAD,

PALO

ALTO,

CALIFORNIA,

U.S.

A.

300A002

Page 10

,

..

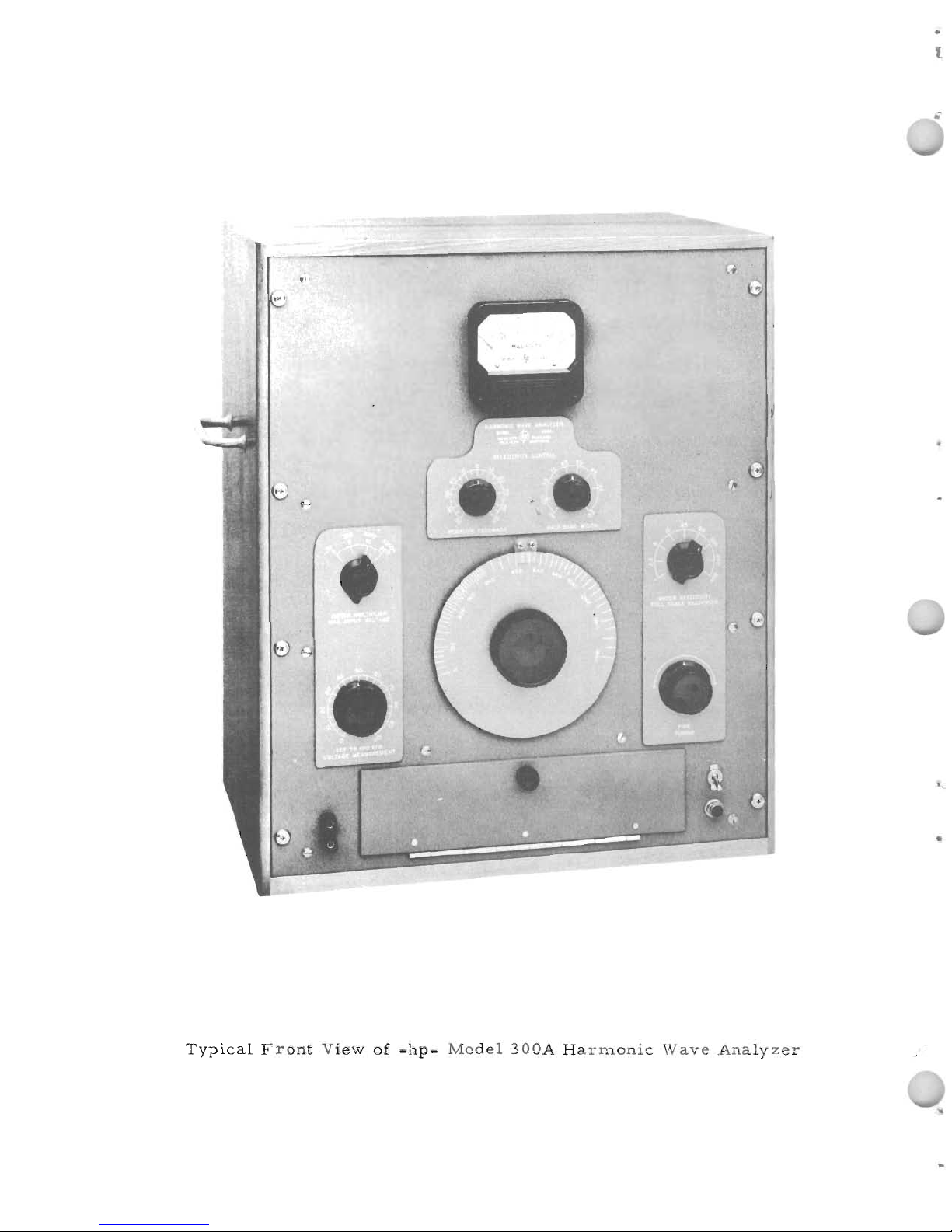

Typical

Front

View

of

-hp-

Model

300A

Harmonic

Wave

Analyzer

'.

Page 11

..

TABLE

OF

CONTENTS

&

INDEX

SPECIFICATIONS.

ACCESSOR'IES

AV

AILAB

LE

CONTROLS

&

TERMINALS.

TUBE

COMPLEMENT

&

TUBE

REPLACEMENTS

1.

PAGE

3

3

4

7

CIRCUIT

DESCRIPTION

General

Input&Phase

Inverter

Circuits.

Modulator

Cir

cuit&Voltage

AInplifier.

Local

Oscillator.

Power

Supply

•

Selective

Amplifier

System.

Voltmeter

Circuit.

CALIBRATION

PROCEDURE

General

Procedure

for

Calibration

.

-'

8

8

9

9

10

10

11

11

11

TEST

PROCEDURE

Instruments

Required

for

Test

Procedure

Preliminary

Tests

&

Adjustments.

1.

Adjustment

of

B+

•

2.

Adjustment

ot:

Local

Oscillator

Injection

Voltage.

3.

Centering

Tuning

Range

of

"F"

Control

•

4.

Check

Os

cillator

Stability

•

S

ele

ctiveAmplifier

Alignment

Heat

Run

Check.

Final

Test

1.

Check&Adjust

Regulated

B+

Voltage.

2.

Check&Adjust

Oscillator

Injection

Voltage

3.

Oscillator

Response

to

Line

Voltage

Change.

4.

Final

Alignment

of

Selective

Amplifier

5.

Adjust

Millivolts

Meter

to

Zero

6.

Centering

Range

of

Control

"C"

7.

Check

for

Carrier

Leakage

•

8.

Check

for

Hum

(Balance

Hum

ControlR159)

•

9.

Check

Resonance

Curves

•

10.Check

Harmonic

Distortion

(Adjust

ControlR117)

11.

Checking

Variable

Selectivity

Contol

12.

Checking

Millivolts

Meter

Tracking.

.13.

Checking

Instrument

Sensitivity

14.

Frequency

Calibration

-

Check&Adjustment

15.

Frequency

Response

Check

16.

Check

Voltage

Calibration.

17.

Checking

Meter

Sensitivity

Control

18.

Checking

Meter

Multiplier

Control

•

19.

Correcting

Unsteady

Millivolts

Meter

Readings

20.

Adding

"CALIBRATION

PROCEDURE"

Labels

21.

Mechanical

Inspection.

22.

Instrument

Bottom

Plate

Replacement.

23.

Completion

of

Final

Test

CIRCUIT

MODIFICATIONS

General

Top

Deck

Modernizing

Procedure.

Parts

Required

for

Complete

Top

Deck

Modernization.

Bottom

Deck

Modification

Procedure

Modification

to

Reduce

Carrier

Leakage.

Power

Supply

Modification

•

Other

Lower

Deck

Modifications

TROUBLE

SHOOTING

General

Trouble

Chart.

13

13

13

13

14

14

14

16

16

16

16

16

16

16

16

16

17

17

18

18

18

18

19

19

20

20

21

21

21

21

21

21

23

23

24

25

25

26

27

29

29

Page 12

2.

TABLE

OF

REPLACEABLE

PARTS

General

..•••.••

Replaceable

Parts

Table

•

List

of

Manufacturers

Code

Letters

for

Replaceable

Parts

Table

;

PAGE

37

38

39

40

41

42

43

44

45

46

47

48

49

51

51

50

..

TABLE

OF

CONTENTS

&

INDEX

(Cont'd.)

Fig.

1•

Fig.

2.

Fig.

3.

Fig.

4.

Fig.

5.

Fig.

6.

Fig.

7.

Fig.

8.

Fig.

9.

Fig.

10.

Fig.

11.

Fig.

12.

Fig.

13.

FIGURES

&

ILLUSTRATIONS

Block

Diagram

of

-hp-

Model

300A

Analyzer.

•

Characteristics

of

Selective

Amplifier

System.

Schematic

Diagram

Serial

No.

1330&Above

-

Selective

Amplifier

(Top

Deck)

•••••

Schematic

Diagram

Serial

No.

1610&Above

-

Modulator,

Oscillator,

Power

Supply

(Lower

Deck).

Typical

Schematic

Diagram,

Serial

No.

1329&Below

-

Selective

Amplifier

(Top

Deck)

••••••••••

Typical

Schematic

Diagram,

Serial

No.

1609&Below

-

Modulator,

Oscillator,

Power

Supply

(Lower

Deck).

Partial

Schematic

Diagrams

Showing

Early

Circuitry.

Chart

for

Plotting

Selectivity

Curves

• • .

Decibel

to

Voltage

Ratio

Conversion

Graph

Top

ViewofTypical

Bottom

Deck

• • • •

Bottom

ViewofTypical

Bottom

Deck

• • • •

Top

ViewofTypical

Top

Deck-Less

Panel.

Bottom

ViewofTypical

Top

Deck-Less

Bottom

Plate

.\

\

Page 13

•

3.

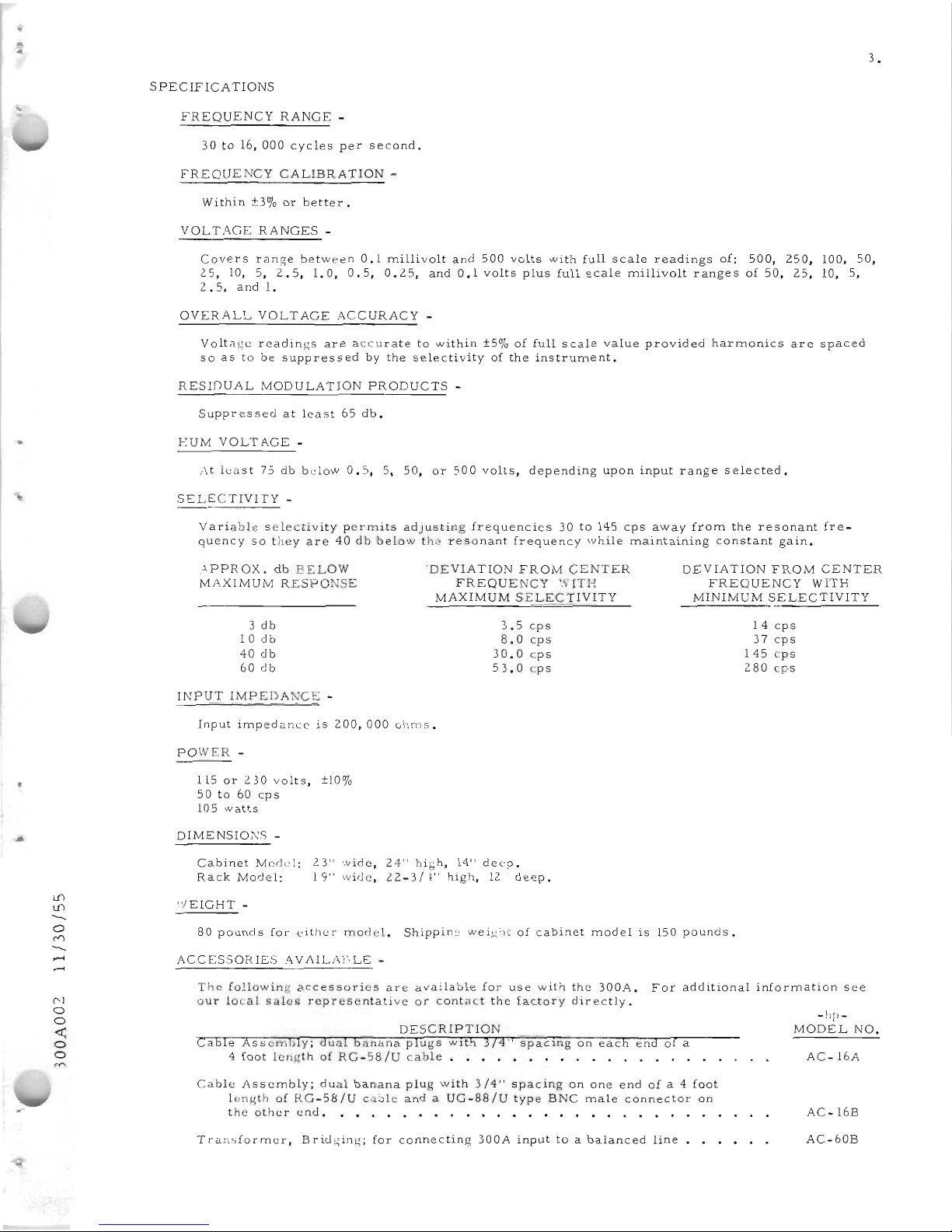

SPECIFICA

TIONS

FREQUENCY

RANGE

-

30to16,000

cycles

per

second.

FREQUENCY

CALIBRATION

-

Within

±3%orbetter.

VOLTAGE

RANGES

-

Covers

range

between

0.1

millivolt

and

500

volts

with

full

scale

readings

of:

500,

250,

100,

50,

25,

10,

5,

2.5,

l.O,

0.5,

0.25,

and

0.1

volts

plus

full

scale

millivolt

ranges

of

50,

25,

10,

5,

2.5,

and

1.

OVERALL

VOLTAGE

ACCURACY

-

Voltage

readings

are

accurate

to

within

±5%offull

scale

value

provided

harmonics

are

spaced

soastobesuppressed

by

the

selectivity

of

the

instrument.

RESIDUAL

MODULATION

PRODUCTS

-

Suppressed

at

least

65

db.

EUM

VOLTAGE

-

l\t

least

73dbbelow

0.5,

:>,

50,

or

500

volts,

depending

upon

input

range

selected.

SELECTIVITY

-

Variable

selectivity

permits

adjusting

frequencies

30to145

cps

away

from

the

resonant

fre-

quency

so

they

are

40dbbelow

th:~

resonant

frequency

while

maintaining

constant

gain.

-\PPROX.

db

BELOW

MAXIMUM

RESPONSE

3

db

10

db

40

db

60

db

INPUT

IMPEDA

TCE -

'DEVIATIO

FROM

CENTER

FREQUENCY

'.'1ITE

MAXIMUM

SELECTIVITY

3.5

cps

8.0

cps

30.0

cps

53.0

cps

DEVIATION

FROM

CENTER

FREQUENCY

WITH

MINIMUM

SELECTIVITY

14

cps

37

cps

145

cps

280

cps

•

Input

impedance

is

200,000

ohms.

POWER

-

115or2.30

volts,

±10%

50to60

cps

105

watts

DIMENSIONS

-

Cabinet

Medel:

Rack

Model:

23"

wide,

24"

high,

14"

deep.

19"

wide,

2.2.-3/1"

high,

12"

deep.

l.1)

l.1)

---

o

<'"'l

---

......

.....

"/EIGHT

-

80

pounds

for

either

model.

Shipping

weight

of

cabinet

model

is

150

pounds.

ACC

ESSOR

IES

,1\

V

IIlLAB

LE

-

The

following

accessories

are

available

for

use

with

the

300A.

For

additional

information

see

our

local

sales

representative

or

contact

the

factory

directly.

l"'J

o

o

«:

o

o

DESCRIPTION

Cable

Assembly;

dual

banana

plugs

wlth

374"

spacmg

on

each

endofa

4

foot

length

of

RG-58/U

cable.

• • • • • • • •

••

•

•••

Cable

Assembly;

dual

banana

plug

with

3/4"

spacing

on

one

endofa 4

foot

length

of

RG-58/U

cilble

andaUG-88/Utype

BNC

male

connector

on

the

other

end.

• • • • • • • • • • • • • • •

Transformer,

Bridging;

for

connecting

300A

inputtoa

balanced

line

-hp-

MODEL

NO.

AC-16A

AC-16B

AC-60B

Page 14

4.

CONTROLS

&

TERMINALS

INPUT

TERMINALS

-

The

two

binding

posts

located

in

the

lower

left

corner

of

the

control

panel

are

the

instrument

input

terminals.

The

lower

binding

post

is

connected

to

the

chassis.

METER

MULTIPLIER

MAX.

INPUT

VOLTAGE

-

This

four

position

rotary

switch

determines

the

maximum

voltages

that

may

be

applied

to

the

in-

strument

without

cir

cuit

overloading.

This

control,

in

conjunction

with

the

METER

SENSITIVITY

control,

indicates

the

multiplication

factor

for

the

MILLIVOLTS

meter

reading.

The

figures

near-

est

the

knob

are

the

maximum

voltages

while

the

outer

figures

are

the

multiplication

factors.

SET

TO

100

FOR

VOLTAGE

MEASUREMENT

-

This

potentiometer

provides

a

control

for

reduCing

the

input

voltage

as

required

for

relative

volt-

age

measurements.

This

control

is

calibrated

from0to

100inarbitrary

units.

OPERATING

PRECAUTION

VOL

TAGE

MEASUREMENTS

ARE

CORRECT

ONLY

WHEN

THE

SET

TO

100

FOR

VOLTAGE

MEAS-

UREMENT

CONTROLISSET

TO

"100"

AND

THE

HALF

BANDWIDTH

CONTROLISSET

TO

THE

SAME

POSITIONS

SELECTED

FOR

CALIBRATION.

NEGATIVE

FEEDBACK

-

This

control

is

used

to

maintain

constant

amplifier

gain

with

different

settings

of

the

HALF

BAND

WIDTH

control

andiscalibrated

50-0-50.in

arbitrary

units.

Instructions

for

setting

this

control

are

given

in

the

PROCEDURE

FOR

CALIBRATION.

Some

older

instruments

in

the

field

are

not

provided

with

this

control.

In

these

instruments,

it

will

be

necessary

to

recalibrate

each

time

the

setting

of

the

HALF

BAND

WIDTH

control

is

changed.

HALF

BAND

WIDTH

-

Instrument

selectivity

is

determined

by

the

setting

of

this

control.

The

calibrations

of30to

145

on

the

scale

around

this

control

knob

indicate

the

number

of

cycles

off

resonance

the

input

signal

must

beinorder

to

be

attenuated

40

db.

Instructions

for

setting

this

control

are

given

in

the

PROCEDURE

FOR

CALIBRATION.

FREQUENCY

DIAL

-

..

;

v;

C

C

>

C

C

r-;

The

frequency

dial

and

internal

tuning

capacitor

are

driven

by

the

vernier

knob

in

the

center

of

the

dial.

The

dial

scale

is

calibrated

from0to16KCinterms

of

the

input

signal

frequency.

METER

SENSITIVITY

-

This

tapped

voltage

divider

controls

the

amplitude

of

the

voltage

supplied

to

the

selective

amplifier

and

the

position

of

the

knob

indicates

the

full

scale

value,

in

millivolts,

of

the

meter

scale

in

use.

MILLIVOLTS

METER-

This

meter

indicates

the

voltage

measured

by

the

instrument.

The

meter

has

three

scale

calibra-

tions.

The

scale

in

use

and

the

scale

multiplication

factor

are

indicated

by

the

position

of

the

METER

SENSITIVITY

FULL

SCALE

MILLIVOLTS

and

the

METER

MULTIPLIER

MAX.

INPUT

VOLTAGE

controls.

FINE

TUNING

-

This

variable

capacitor

provides

an

incremental

adjustment

for

the

frequency

dial.

The

instru-

ment

is

calibrated

with

this

control

rotated

so

that

the

mark

on

the

knob

skirt

is

straight

up

over

the

center

of

the

control.

ON-OFF

SWITCH

-

This

toggle

switch

controls

the

power

supplied

to

the

instrument

from

the

power

line.

When

the

instrument

is

turned

on,

the

indicator

lamp

below

the

toggle

switch

wfll

light.

Page 15

•

U')

U')

-

o

("1"\

-

-

-

N

o

o

~

o

o

("1"\

5.

CONTROLS&TERMINALS

(Contld.)

POWER

CABLE

-

There

are

three

wires

in

the

power

cable.

Twoofthese

wires

(usually

black

and

white)

carry

power

to

the

instrument.

The

remaining

wire

(usually

green)

is

connected

internally

to

the

instru-

ment

chassis

and

protrudes

from

the

power

cable

at

the

plug

end

for

grounding

the

instrument.

FUSE

-

The

fuseholder,

located

on

the

backofthe

lower

chas

sis

or

deck,

containsa1.25

ampere

slo-blo

cartridge

fuse.

The

fuse

may

be

replaced

by

unscrewing

the

fuseholder

cap

and

inserting

a

new

fuse.

Fast

blow2ampere

fuses

were

originally

usedinthese

instruments.

The

1.25

ampere

slo-

blo

fuses

are

recommended

for

replacement

since

they

offer

increased

instrument

protection.

Those

instruments

that

have

been

changed

for

230

volt

operation

require

a

0.6

ampere

slo-blo

fuse

for

replacement.

SUB-PANEL

CONTROLS

-

Controls

C,

F,

G.

R,

S,

andVare

located

behind

the

door

at

the

bottom

of

the

control

panel.

These

are

non-operating

controls

used

for

instrument

calibration.

CONTROL

C -

This

control

is

usedtobalance

the

capacity

across

the

two

modulation

transformer

primaries

•

CONTROL

F -

This

control

provides

an

adjustment

for

setting

the

local

oscillator

fre-

quency

to20KC

when

the

frequency

dial

is

settozero.

CONTROL

G -

Overall

instrument

gainisdetermined

by

the

setting

of

this

control.

CONTROL

R -

This

control

provides

a

resistance

balance

between

the

two

modulation

transformer

primaries.

CONTROL

S -

This

lever

switch

selects

the

input

signal

for

phase

inverter

stage

VIOl.

When

this

switch

istothe

right,

the

internal

calibrating

voltage

is

connected

to

VIOl.

With

this

switch

in

the

remaining

position,

the

input

voltage

is

connected

to

the

gridofVIOl.

CONTROL

V -

This

control

permits

setting

the

internal

calibrating

voltage

to5volts.

A

tentoone

voltage

divider

following

this

control

delivers

0.5

volts

for

instrument

calibration.

VOLTS

METER-This

meter

measures

the

internal

calibrating

voltage

as

adjusted

by

control

V.

Page 16

•

..

U1

U1

-

o

C"'\

-

-

-

N

o

o

<

o

o

C"

7.

TUBE

COMPLEMENT

&:

TUBE

REPLACEMENTS

GENERAL

-

Any

tubes

with

RETMA

standard

characteristics

may

be

used

for

replacement

purposes.

However,

as

notedinthe

instructions

that

follow,

useofa

selected

tube

will

improve

instrument

performance

in

some

cases.

The

300Aisa

high

gain

instrument.

Tubes

that

are

microphonic

or

have

relatively

high

heater

to

cathode

leakage

are

not

desirable.

The

tube type

used

for

some

of

the

stages

in

the

300A

have

varied

with

time.

In

some

cases

use

of

a

later

tube

typeisrecommended

but

not

neces

sary.

Ifindoubt,

replace

tubes

with

the

same

type

foundinthe

instrument.

The

number

of

adjustments

required

will

depend

upon

the

tube

replaced.

The

specific

tests

and/or

adjustments

are

given

in

the

chart

that

follows.

This

chart

also

shows

where

the

procedures

for

these

tests

and

adjustments

can

be

foundinthe

TEST

PROCEDURE

section

of

this

manual.

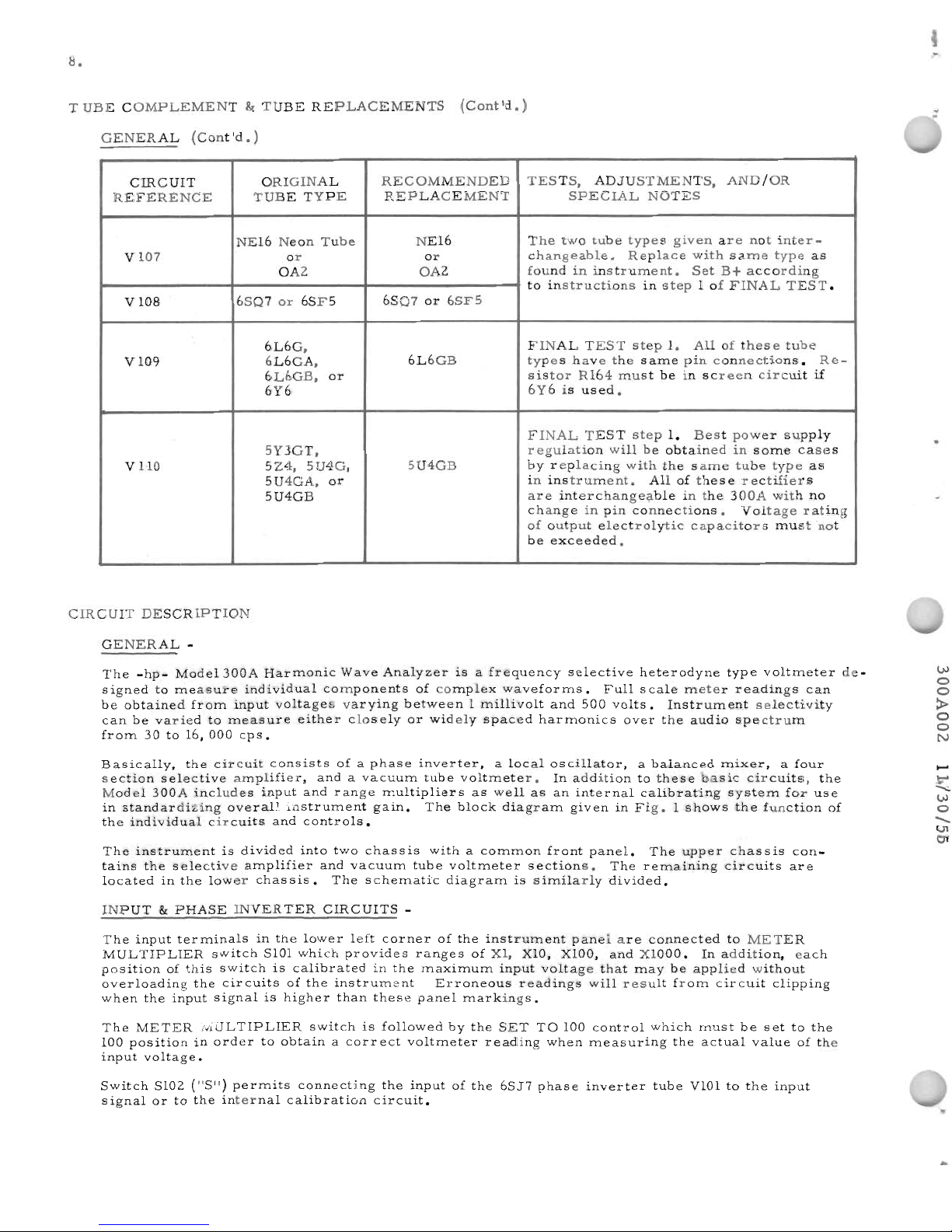

CIRCUIT

ORIGINAL

RECOMMENDED

TESTS,

ADJUSTMENTS,

AND/OR

REFERENCE

TUBE

TYPE

REP

LACEMENT

SPECIAL

NOTES

VI

thru

V8

6SJ7

6SJ7

FINAL

TEST

procedure

steps8and

9.

Low

microphonic

tubes

are

best.

V9

6F8

or

6F8

or

6SN7

Replace

with

same

type

asininstrument.

6SN7

FINAL

TEST

step

3.

VIO

6H6

Aged

6H6

Select

tube

giving

minimum

change

in

zero

setting

between

instrument

on

and

off

with

no

input

signal.

Complete

FINAL

TEST

step

3.

F 101 2

amp

fast

1.

25

amp

Slo-blo

fuse

gives

better

instrument

pro-

blow

or

1.25

slo-blo

tection.

Use

different

fuse

for

230

volt

amp

slo

-blo

operation

as

noted

under

FUSEinthe

for

115

V.

CONTROLS

&:

TERMINALS

section.

operation.

R140

lamp

3

watts,

115

10

watts

FINAL

TEST

step

2.

See

step1of

OTHER

volts

or

230

volts

LOWER

DECK

MODIFICATIONS

under

10

watts,

BOTTOM

DECK

MODIFICATION

PRO-

230

volts

CEDURE

in

CIRCUIT

MODIFICATIONS

section.

VIOl

6SJ7

6SJ7

FINAL

TEST

procedure

steps

3,

6,

8,

&:

10.

Useatube

with

low

microphonics

and

check

fora"hump"

in

the

resonance

V

102

&:

6SJ7

6SJ7

selected

curves

as

directed

in

FINAL

TEST

pro-

V 103

asamatched

cedure

step

9.

pair.

Vl04

6SJ7

6SJ7

FINAL

TEST

step

3.

Check

for

low

microphonics,

hum,

and

60

cps

"hump".

FINAL

TESTstep

9a.

V

105

6J7

6J7

Changing

either

tube

will

not

cause

appre-

ciable

change

in

frequency

oroscillator

inj

ection

voltage.

Check

by

repeating

steps

2,

3,

8,

10,

and14of

FINAL

TEST.

VI06

6F6

6F6

Os

cillator

output

should

be

stable.

Tubes

should

be

non-rnicrophonic.

Page 17

8.

TUBE

COMPLEMENT

lit

TUBE

REPLACEMENTS

(Cont'd.)

GENERAL

(Cont'd.)

CIRCUIT

ORIGINAL

RECOMMENDED

TESTS,

ADJUSTMENTS,

AND/OR

REFERENCE

TUBE

TYPE

REPLACEMENT

SPECIAL

NOTES

NE16

Neon

Tube

NE16

The

two

tube

types

given

are

not

inter-

V

107

or

or

changeable.

Replace

with

same

type

as

OA2

OA2

foundininstrument.

Set

B+

according

to

instructions

in

step1of

FINAL

TEST.

V

108

6SQ7

or

6SF5

6SQ7

or

6SF5

6L6G,

FINAL

TEST

step

1.

Allofthese

tube

V

109

6L6GA,

6L6GB

types

have

the

same

pin

connections.

Re-

6L6GB,

or

sistor

R164

must

beinscreen

circuit

if

6Y6

6Y6isused.

FINAL

TEST

step

1.

Best

power

supply

5Y3GT,

regulation

will

be

obtained

in

some

cases

VUO

5Z4,

5U4G,

5U4GB

by

replacing

with

the

same

tube

type

as

5U4GA,

or

in

instrument.

Allofthese

rectifiers

5U4GB

are

interchange;;ible

in

the

300A

with

no

change

in

pin

connections.

Voltage

rating

of

output

electrolytic

capacitors

must

not

be

exceeded.

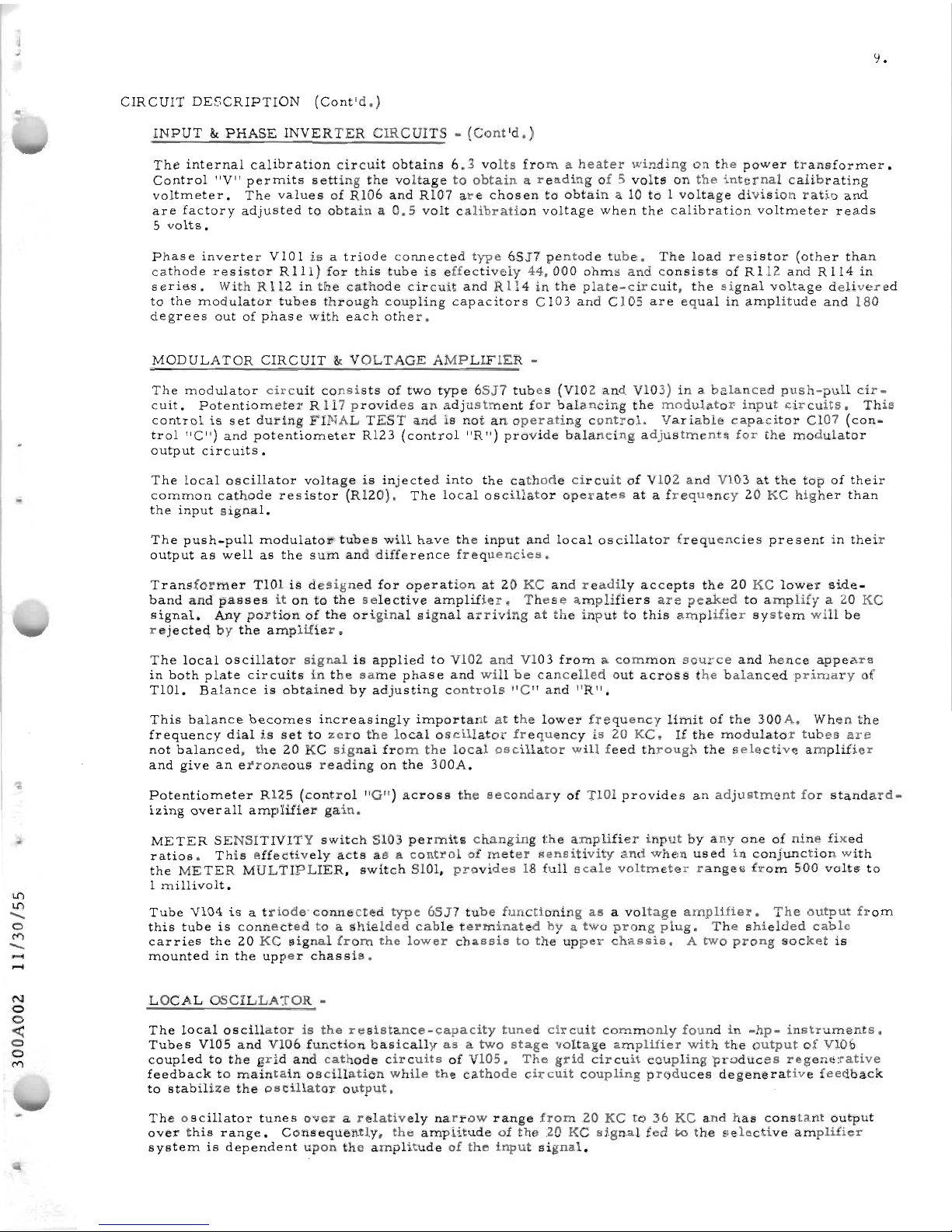

CIRCUIT

DESCRIPTION

GENERAL

-

.

.

The

-hp-

Mode1300A

Harmonic

Wave

Analyzer

isafrequency

selective

heterodyne

type

voltmeter

signed

to

measure

individual

components

of

complex

waveforms.

Full

scale

meter

readings

can

be

obtained

from

input

voltages

varying

between1millivolt

and

500

volts.

Instrument

selectivity

can

be

varied

to

measure

either

closely

or

widely

spaced

harmonics

over

the

audio

spectrum

from

30to16,

000

cps.

Basically,

the

circuit

consists

ofaphase

inverter,

a

local

oscillator,

a

balanced

mixer,

a

four

section

selective

amplifier,

andavacuum

tube

voltmeter.

In

addition

to

these

basic

circuits,

the

Model

300A

includes

input

and

range

multipliers

as

well

as

an

internal

calibrating

system

for

use

in

standardizing

overall

instrument

gain.

The

block

diagram

giveninFig.1shows

the

function

of

the

individual

circuits

and

controls.

The

instrument

is

divided

into

two

chassis

withacommon

front

panel.

The

upper

chassis

con-

tains

the

selective

amplifier

and

vacuum

tube

voltmeter

sections.

The

remalnlng

circuits

are

located

in

the

lower

chassis.

The

schematic

diagram

is

similarly

divided.

INPUT

lit

PHASE

INVERTER

CIRCUITS

-

The

input

terminals

in

the

lower

left

corner

of

the

instrument

panel

are

connected

to

METER

MULTIPLIER

switch

SlOl

which

provides

ranges

of

Xl,

XlO,

XlOO,

and

XlOOO.

In

addition,

each

position

of

this

switch

is

calibrated

in

the

maximum

input

voltage

that

may

be

applied

without

overloading

the

circuits

of

the

instrument.

Erroneous

readings

will

result

from

circuit

clipping

when

the

input

signal

is

higher

than

these

panel

markings.

The

METER

MULTIPLIER

switch

is

followed

by

the

SET

TO

100

control

which

must

be

settothe

100

position

in

order

to

obtainacorr

ect

voltmeter

reading

when

measuring

the

actual

value

of

the

input

voltage.

Switch

5102

("S")

permits

connecting

the

inputofthe

6SJ7

phase

inverter

tube

VIOltothe

input

signal

ortothe

internal

calibration

circuit.

de-

l.U

0

0

~

0

0

N

-

:-

~

l.U

0

-

U1

C11

..

Page 18

lI)

lI)

-

o

l""'I

-

.....

.....

N

o

o

<

o

o

l""'I

9.

CIRCUIT

DESCRIPTION

(Cont'd.)

INPUT&PHASE

INVERTER

CIRCUITS-(Cont'd.)

The

internal

calibration

circuit

obtains

6.3

volts

fromaheater

winding

on

the

power

transformer.

Control

"V"

permits

setting

the

voltage

to

obtainareading

of5volts

on

the

internal

calibrating

voltmeter.

The

values

of

Rl06

and

Rl07

are

chosen

to

obtain

a 10to1

voltage

division

ratio

and

are

factory

adjusted

to

obtaina0.5

volt

calibration

voltage

when

the

calibration

voltmeter

reads

5

volts.

Phase

inverter

VIOlisa

triode

connected

type

6SJ7

pentode

tube.

The

load

resistor

(other

than

cathode

resistor

RIll)

for

this

tubeiseffectively

44,000

ohms

and

consists

of

Rl12

and

Rl14

in

serie-s.

With

Rl12

in

the

cathode

circuit

and

Rll4

in

the

plate-circuit,

the

signal

voltage

delivered

to

the

modulator

tubes

through

coupling

capacitors

CI03

and

Cl05

are

equalinamplitude

and

180

degrees

outofphase

with

each

other.

MODULATOR

CIRCUIT

&

VOLTAGE

AMPLIFIER

-

The

modulator

circuit

consists

of

two

type

6SJ7

tubes

(Vl02

and

Vl03)ina

balanced

push-pull

cir-

cuit.

Potentiometer

R 117

providesan

adjustment

for

balancing

the

modulator

input

circuits.

This

control

is

set

during

FINAL

TEST

andisnotanoperating

control.

Variable

capacitor

CI07

(con-

trol

"C")

and

potentiometer

R123

(control

"R")

provide

balancing

adjustments

for

the

modulator

output

circuits.

The

local

oscillator

voltage

is

injected

into

the

cathode

circuit

of

Vl02

and

Vl03atthe

topoftheir

common

cathode

resistor

(R120).

The

local

oscillator

operates

atafrequency

20

KC

higher

than

the

input

signal.

The

push-pull

modulato1l'

tubes

will

have

the

input

and

local

oscillator

frequencies

present

in

their

output

as

well

as

the

sum

and

difference

frequencies.

Transformer

TlOlisdesigned

for

operation

at20KC

and

readily

accepts

the

20

KC

lower

side-

band

and

passes

itonto

the

selective

amplifier.

These

amplifiers

are

peaked

to

amplifya20

KC

signal.

Any

portion

of

the

original

signal

arriving

at

the

inputtothis

amplifier

system

will

be

rejected

by

the

amplifier.

The

local

oscillator

signal

is

applied

to

Vl02

and

Vl03

fromacommon

source

and

hence

appears

in

both

plate

circuits

in

the

same

phase

and

will

be

cancelled

out

across

the

balanced

primary

of

TlOl.

Balance

is

obtained

by

adjusting

controls

"C"

and

"R".

This

balance

becomes

increasingly

important

at

the

lower

frequency

limit

of

the

300A.

When

the

frequency

dial

is

settozero

the

local

oscillator

frequency

is

20

KC.

If

the

modulator

tubes

are

not

balanced,

the

20

KC

signal

from

the

local

oscillator

will

feed

through

the

selective

amplifier

and

give

an

erroneous

reading

on

the

300A.

Potentiometer

R125

(control

"G")

across

the

secondary

of

TlOl

provides

an

adjustment

for

standard-

izing

overall

amplifier

gain.

METER

SENSITIVITY

switch

Sl03

permits

changing

the

amplifier

input

by

anyone

of

nine

fixed

ratios.

This

effectively

acts

asacontrol

of

meter

sensitivity

and

when

used

in

conjunction

with

the

METER

MULTIPLIER,

switch

SlOl,

provides

18

full

scale

voltmeter

ranges

from

500

volts

to

1

millivolt.

Tube

Vl04isa

triode'

connected

type

6SJ7

tube

functioning

asavoltage

amplifier.

The

output

from

this

tube

is

connected

toashielded

cable

terminated

byatwo

prong

plug.

The

shielded

cable

carries

the

20

KC

signal

from

the

lower

chassis

to

the

upper

chassis.

A

two

prong

socket

is

mounted

in

the

upper

chassis

•

LOCAL

OSCILLATOR

-

The

local

oscillator

is

the

resistance-capacity

tuned

circuit

commonly

foundin-hp-

instruments.

Tubes

Vl05

and

Vl06

function

basically

asatwo

stage

voltage

amplifier

with

the

output

of

Vl06

coupled

to

the

grid

and

cathode

circuits

of

Vl05.

The

grid

cir

cuit

coupling

produces

regenerative

feedback

to

maintain

oscillation

while

the

cathode

circuit

coupling

produces

degenerative

feedback

to

stabilize

the

oscillator

output.

The

oscillator

tunes

overarelatively

narrow

range

from

20

KCto36

KC

and

has

constant

output

over

this

range.

Consequently,

the

amplitude

of

the

20

KC

signal

fedtothe

selective

amplifier

system

is

dependent

upon

the

amplitude

of

the

input

signal.

Page 19

10.

CIHCUIT

DESCrnPTlON

(Cont'd.)

LOCAL

OSCILLATOR

-

(Cont'd.)

The

frequency

dial

is

calibrakd

to

indicate

the

frequency

of

the

input

signal

and

not

the

local

oscil-

lator

frequL'ncy

which

is

lO

KC

high,"r

than

the

dial

indication.

The6to65L,,.,f

trimmer

(C

ll-l

control

"F")

provides

an

acijustment

for

setting

the

local

oscillator

frequency

...

ith

the

frequency

dial

set

to

"0".

control

"F"

is

adjusted

foramaximum

indication

on

the

300A

voltmeter.

This

adjustmr~'1t

tunes

the

local

oscillator

to

the

20

KC

peak

of

the

selec-

tive

amplifiers.

An

accurately

known

external

source

connected

to

the

300A

input

terminals

can

illso

be

used

for

adjusting

the

local

oscillator.

The

300A

frequency

dial

is

set

to

the

same

fre-

quency

as

the

external

source

and

control

"F"

is

adjusted

forama.<:imum

indication

on

the

300A

111eter.

Lo

caloscilla

tor

output

is

obtained

fr

om

VIa6cathodecircuit

and

inj

ected

into

the

cathodecir

cuit

of

VI02

and

VI03.

Injection

voltage

is

set

with

the

frequency

control

dial

at

"a"

by

adjusting

poten-

tiometer

R143

which

controls

negative

feedback

from

VI06tothe

cathode

of

VI05.

The

20

KC

in-

jection

voltage

measured

at

the

top

of

cathode

resistor

Rl20

for

VI02-

and

VI03

should

be2volts.

PO,,'ER

SUPPLY

-

High

voltage

is

obtained

froma5U4G/AB

full

wave

rectifier

followed

byatwo

section

capacity

in-

put

L-C

filter.

This

filtered

dc

output

furnishes

B+

for

all

selective

amplifier

circuits

as

..veIl

as

the

voltmeter

circuit

in

the

upper

chassis.

The

filtered

dcisalso

passed

through

a

voltage

regu-

lator,

the

output

of

which

supplies

VIOl

through

VI06inthe

lower

chassis.

An

OA2

voltage

regulator

tube

VI07

supplies

the

necessary

reference

voltage

for

the

6SQ7

regulator

control

tube

VI08

which

in

turn

controls

the

6L6GB

series

regulator

tube

VI09.

Tube

types

for

VI07, VI08.

and

VI09

may

vary

between

instruments.

Potentiometer

R152isan

adjustment

for

setting

the

output

of

the

regulated

portion

of

the

power

supply

to

+240

volts.

SELECTIVE

AMPLIFIER

SYSTEM

-

The

selective

amplifier

system

consists

ofatotal

of

eight

type

65J7

tubes.

to

give

effectively

four

amplification

stages.

All

four

stages

function

in

the

sequently,

only

the

first

stage

involving

VI

and

V2

will

be

discussed.

These

tubes

are

paired

same

manner.

Con-

The

signal

from

voltage

amplifier

Vl04inthe

lower

chassis

is

fed

through

a

shielded

cable

to

the

grid

circuit

ofVIin

the

upper

chassis.

Coil

LIinthe

grid

circuit

is

tuned

to

20

KC

by

CI

and

C2.

The

resistor

of

830,

000

ohms

in

the

grid

circuit

prevents

the

preceding

stage

from

loading

the

resonant

circuit.

The

amplified

20

KC

signal

is

developed

across

one

section

of

the

HALF

BAND

WIDTH

control.

With

this

control

rotated

full

counterclockwise,

the

control

arm

isatground

potential

and

there

is

no

feedback

from

V2toVI

through

R5, R8,R9,

or

RIO

resistors.

Amplifier

gainisdetermined

by

the

fixed

degenerative

coupling

through

R11and

C37

between

V2

output

and

VI

cathode

circuit.

Amplifier

selectivity

isatminimum

andisprimarily

determined

by

the

resonant

circuit

in

the

grid

circuit

of

VI.

Resistor

R74will

control

the

IIQIIofthe

tuned

circuit

and

hence

also

control

amplifier

selectivity

under

these

conditions.

As

the

HALF

BAND

WIDTH

control

is

rotated

clockwise,

more

and

more

of

the

plate

signal

from

V2isfed

back

to

the

grid

circuit

of

VI.

This

signal

isinphase

with

the

input

signal

and

the

cir-

cuit

becomes

regenerative.

The

selectivity

of

the

two

stages

becomes

progressively

sharper

as

regeneration

increases.

The

positive

feedback

would

also

cause

an

increase

in

gainifit

were

not

for

negative

feedback

through

R5,

R8,

and

RIOtothe

cathode

ofVIfrom