Page 1

Drystar 5500

User manual

Software 2.x

Page 2

This product i s registered in China under the registrat ion number:

For more information on Agfa products and Agfa HealthCare produ cts, please visit www.agfa.com, your

Point of Knowledge.

© Agfa-Gevaert N.V. 2004.

No parts of this document may be reproduced, copied, adapted or transmitted in any form or by any means

without the written permission of Agfa-Gevaert N.V.

Agfa-Gevaert N.V. makes no warranties or representation, expressed or implied, wi th respect to the accu-

racy, completeness or usefulne ss of the informa tion contained i n this docu ment and spec ifically di sclaims

warranties of suitability for any particular purpose. Agfa-Gevaert N.V. shall under no circumstances be liable

for any damage arising f rom the u se or inab ility to u se any info rmation , apparatus , me thod o r process disclosed in this document.

Agfa-Gevaert N.V. reserves the right to make changes to this document without prior notice.

Agfa-Gevaert N.V., Septestraat 27, B-2640 Mortsel, Belgium.

Drystar 5500 is a trademark of Agfa-Gevaert N.V., Belgium.

Agfa and Agfa-Rhombus are trademarks of Agfa-Gevaert AG, Germany.

2

2901B EN 20040413

Page 3

Table of contents

Chapter 1: Introducing the Drystar 5500.......................................................... 5

Drystar 5500 features.......................................................................................6

Safety precautions ...........................................................................................8

Security precautions....................................................................................... 12

Safety compliance..........................................................................................13

Privacy and security.......................................................................................15

Operating modes ...........................................................................................17

Control modes (local and remote)................................................................... 19

The user interface..........................................................................................20

Switching on the Drystar 5500........................................................................26

Switching off the Drystar 5500........................................................................28

Chapter 2: Basic operation (operator mode).................................................29

Overview of operator functions....................................................................... 30

Managing the print queue...............................................................................31

Assigning emergency priority..........................................................................33

Deleting print jobs ..........................................................................................34

About Drystar 5500 consumables...................................................................36

Loading films.................................................................................................. 38

Chapter 3: Advanced operati on (key-operator mode)...................................47

Overview of key-operator functions ................................................................48

Prevent ive ma inte nan ce sche du le..................................................................49

Cleaning the exterior......................................................................................50

Cleaning the printhead resistor line ................................................................ 51

Troubleshooting checklist...............................................................................54

Appendix A: Equipment informati on sheet....................................................55

Specifications.................................................................................................56

Options and accessories ................................................................................59

2901B EN 20040413

3

Page 4

4

2901B EN 20040413

Page 5

Chapter

1

Introducing the Drystar 5500

This chapter introduces the Drystar 5500 to the user and

draws attention to important safety precautions.

! Drystar 5500 features

! Safety precautions

! Security precautions

! Safety compliance

! Privacy and security

! Operating modes

! Control modes (local and remote)

! The user interface

! Switching on the Drystar 5500

! Switching off the Drystar5500

Page 6

Drystar 5500 features

The Drystar 5500 is a dry digital printer for producing diagnostic images. It

can print multiple format (8x10” up to 14x17”) blue-based and clear-based

film and offers crisp, dense grayscale images. The Drystar 5500 is designed

for high-throughput and as a central printer.

" The Drystar 5500 is a Dicom-only network printer.

The Drysta r 5500 offers the following features:

# Dry technology for printing diagnostic quality hard copies in full daylight offers

important advantages: no chemistry, no wet processing, simple cleaning

procedures, no time-consuming adjustments, no darkroom and no chemical

disposal costs. The consumables can be loaded in full daylight.

# With its compact design, the Drystar 5500 needs little work space and allows

easy customer access. Maintenance and service activities are reduced to the

minimum.

# The direct thermal printing system provides grayscale images with laser-like

quality: 508 dots per inch resolution, each pixel with 12 bit contrast resolution

and an optical density ranging from 0.2 up to 3.1 (if an X-Rite 310

densitometer is used).

# The built-in image spooling on hard disk assures a high throughput. Printing

time is kept to a minimum.

# Multiple film formats (8x10”, 10x12”, 11x14”, 14x14”, and 14x17”) can be

used. Any combination of two film formats can be used “online”. Both input

trays can be adjusted for all film formats.

# The input trays of the Drystar 5500 are equipped with an RF-tag reader,

which automatically traces the films used in the printer and protects the

printer when detecting non-identified media.

# Number of input trays.

The Drystar 5500 is delivered w ith 2 input tray s. Both input tr ays can use m ultiple

format (8x10” up to 14x1 7”) film s.

6

Introducing the Drystar 5500

2901B EN 20040413

Page 7

# Number of output trays

The Drystar 5500 is delivered with 4 output trays, which can be assigned to

modalities in any combination.

Network features

# The modular design offers optimal application to your specific networking

requirements.

In a network configuration, the Drystar 5500 is fully compatible with Agfa’s

diagnost ic imagin g systems , includin g the ADC Co mpact and ADC Quali ty System

software, the Paxport and the entire line of Impax Review Systems, Storage

Stations and Transmitting Stations.

# The functionality of the Drystar 5500 is completely controlled via the network.

# You can control the working of the Drystar 5500 via the local keypad or via a

remote PC featuring a browser functionality.

Customizable features

# Number of output trays.

The Drystar 5500 is delivered with 4 output trays and a sorter.

# Consumables.

The Drystar 5500 can handle Drystar DT2 B and Drystar DT2 C consumables, both

in multiple formats (8x10” up to 14x17”).

Software license information

# The Drystar 5500 printer uses software developed by the Apache Software

Foundation (http://www.apache.org/licenses/LICENSE).

2901B EN 20040413 Introducing the Drystar5500

7

Page 8

Safety precautions

" The Drystar 5500 must only be operated according to its specifications

and its intended use. Any operation not corresponding to the

specifications or intended use may result in hazards, which in turn may

lead to serious injuries or fatal accidents (for example electric shocks).

AGFA positively will not assume any liability in these cases.

" All images created using any image technology can show artifacts which

could be mixed up with diagnostic relevant information. If there is any

doubt that the diagnostic information could not be absolutely true,

additional investigations must be performed to get a clear diagnostic.

When operating or maintaining the Drystar 5500, always observe the

following safety guidelines:

• Have electrical or mechanical defects repaired by skilled personnel only!

• Do not override or disconnect the integrated safety features.

• Ventilation openings may not be covered.

• Always switch off the Drystar 5500 and disconnect the power cord from the

outlet before carrying out any maintenance work.

" Film jam removal or Cleaning the printer thermal head can be done

without switching the power off. Nevertheless, care should be taken and

the following instructions should be respected:

8

Introducing the Drystar 5500

2901B EN 20040413

Page 9

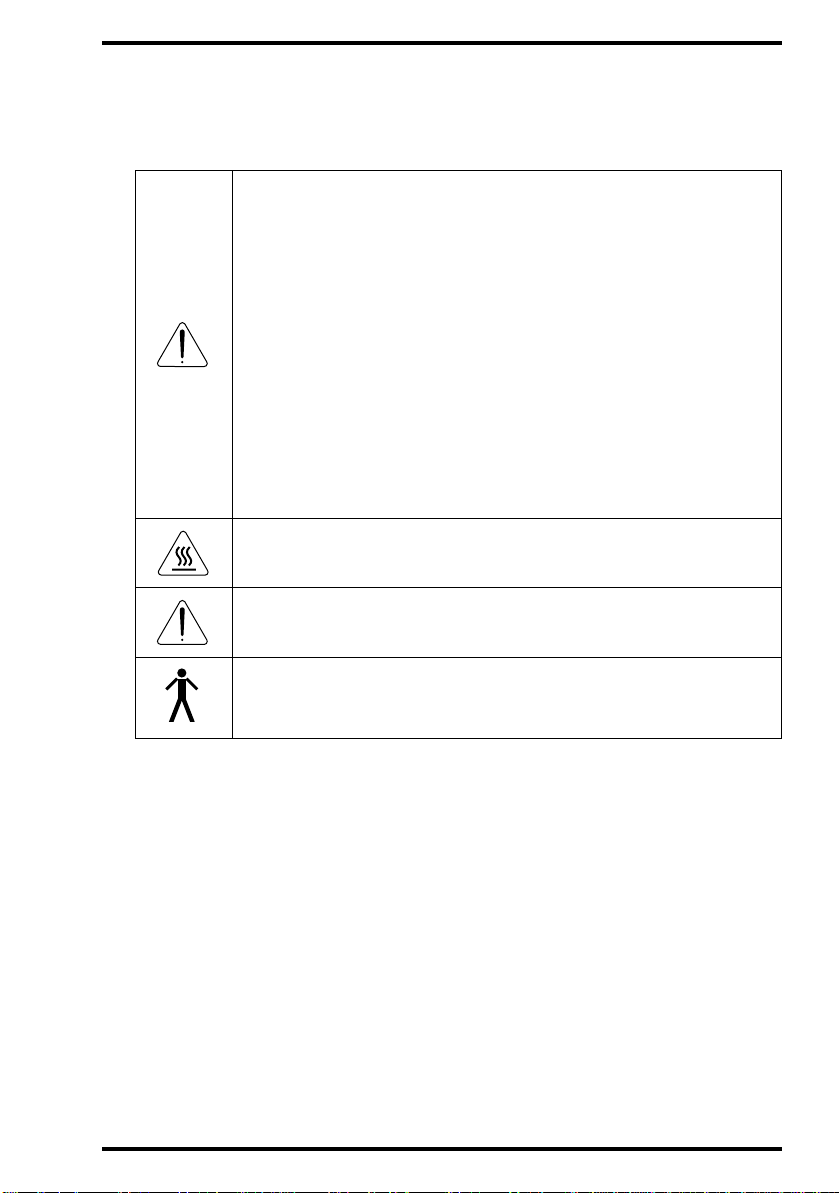

Always take into account the markings provided on the inside and outside of

the printer. A brief overview of these markings and their meaning is given

below.

Safety w arning, indica ting th at the Drystar 550 0 man uals sh ould b e

consulted before making any connectio ns to other equ ipment. The

use of accessory equipment not complying with the equivalent

safety requirements of this printer may lead to a reduc ed level of

safety of the resulting system. Consideration relating to the choice of

accessory equipment shall include:

• Use of the accessory equipment in the patient vicinity,

• Evidenc e that the safe ty cert ifica tion of the access ory equipm en t

has been performed in accordance with the appropriate IEC 601-1

and IEC 601-1-2 harmonized national standard.

In addition all c onf igur atio ns m ust com ply with the med ica l elec tric al

systems standard IEC 601-1-2. The party that makes the

connections acts as system configurator and is responsible for

complying with the systems standard.

If required contact your local service organization.

Caution hot:

Keep hands clear from the thermal printhead.

In order to reduce the risk of electric shock, do not remove any

covers.

Type B equipment:

Indicates that the Dry star 5500 c omplies with th e limits for typ e B

equipment.

2901B EN 20040413 Introducing the Drystar5500

9

Page 10

Supplementary protective earth connector:

Provides a conn ection between the Drystar 550 0 and the potential

equalization busbar of the electrical system as found in medical

environments. This plug should never be unplugged before the

power is turned off and the power plug has been removed.

Intergrounding connector:

Provides a connection between the printer and other equipment

which might exhibit minor ground potential differences. These

differences may degrade the quality of communication between

different equipment. Never remove connections to this terminal.

Protective eart h (grou nd) :

Provides a c onnection b etween the printer and the protectiv e earth

of the ma ins. Do no t r emo ve thi s co nn ecti on, be cau se this wi ll h ave

a negative influence on the leakage current.

Power Button:

Note that the power cord has to be disconnected from the wall outlet

in order to disconnect the unit entirely from the mains.

Precautions for use in USA only:

Make sure that the circuit is single-phase center-tapped, if the printer

is connected to a 240 V/60 Hz source instead of a 120 V/60 Hz

source.

10

Introducing the Drystar 5500

2901B EN 20040413

Page 11

Transport after installation

Before moving the printer, always switch off the machine. The user has to be

very cautious concerning stability, when moving the printer. When doing this,

he has to take into account the condition and the structure of the subsoil,

obstructions and slopes. Also the user has to make sure that the brakes are

loose. The appliance can only be transported with all covers closed. The

appliance may not be transported continuously from one location to the other.

To prevent injuries, lock the brakes when the Drystar 5500 is in place at

the right location.

Waste disposal and environmental regulations

In most countries Drystar film is considered industrial waste and

consequently it is not allowed to dispose of it as household waste. Please

consult your local waste disposal regulations. Agfa recommends to have

waste Drystar film hauled away by a licensed company.

After its life span, do not dispose of the Drystar 5500 without consideration of

local waste disposal regulations. Please consult your local service

organization.

2901B EN 20040413 Introducing the Drystar5500

11

Page 12

Security precautions

CAUTION: U.S. Law restricts this device to sale to or on the order of a

licensed physician.

Printed images should be treated as patient records and should only be

viewed by authorized personnel.

It is good practice not to delete images from the modality, until they are

correctly printed.

12

Introducing the Drystar 5500

2901B EN 20040413

Page 13

Safety compliance

EMC issues

USA: T his equ ipmen t has b een te sted an d foun d to c omply with th e limits f or a

•

class A digital device, pursuant to part 15 of the FCC rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipm ent is oper ate d in a co mm erci al env iron me nt. Th is eq uip men t gen era tes ,

uses, an d can radiate ra dio frequency e nergy and, if no t installed and us ed in

accordance with the Reference manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause h arm ful inte rfer enc e in wh ich cas e th e u ser will be requ ired to cor rect the

interference at its own expense.

If required, contact your local service organization.

• Can ada: This c lass A digi tal appara tus m eets a ll requ iremen ts of t he Ca nadian

Interfere nc e-C aus ing Equ ipm ent Regula tio ns.

• EC: This is a class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate

measures.

Compliances

This equipment complies with:

• the Medical Devices Directive 93/42/EEC

• the standards UL2601-1 of Underwriters Laboratories

• CSA 22.2 No. 601 .1-M 90 of the Canad ian Standards Asso cia tion

• FDA 510k

• FDA Part 820 Good manufacturing Practice for Medical devices

• IEC 601-1 and IEC 601-1-2

• EN 60601-1:1990 + A1:1993 + A2:1995

• EN 606 01- 1-2: 200 1

• GB4943-2001

• GB9254-1998

• GB17625.1-2003

2901B EN 20040413 Introducing the Drystar5500

13

Page 14

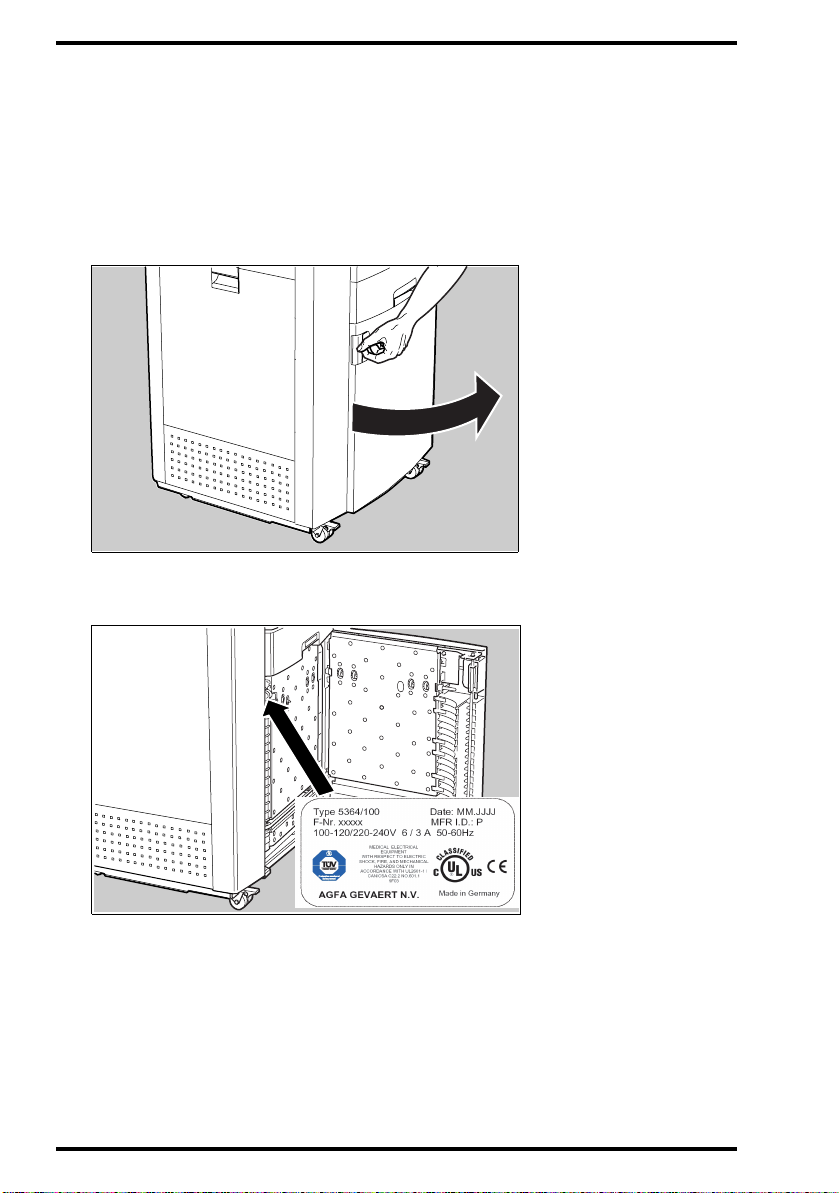

Label

The Drystar 5500 carries the CE, TÜV and the CUL label.

To find the label location

Open the front door.

1

2 The label is visible inside the printer:

14

Introducing the Drystar 5500

2901B EN 20040413

Page 15

Privacy and security

Within the healthcare industry, several standardization efforts are ongoing as

a response to Privacy and Security legislation and regulations. The purpose

of this standardization for hospitals and vendors is to enable information

sharing, interoperability and to support the workflow of hospitals in a multiple

vendor environment.

In order to allow hospitals to comply with HIPAA regulations (Health

Insurance Portability and Accountability Act) and to meet the IHE standards

(Integrated Healthcare Enterprise) some security features are included in the

user interface of the Drystar 5500 (available via the web pages only: under

‘Security tools’. Refer to ‘Controlling the Drystar 5500 via a remote PC (with

browser)’ on page 141 of the D rystar 5500 Reference manual):

• Product Authentication: HIPAA supported products that communicate with

DICOM use the Transport Layer Security (TLS) protocol. The TLS protocol uses

public key certificates for client and server authentication (X.509).

• Product Accountability: HIPAA supported products require some level of user

and system activity to be recorded. As a consequence of these actions, audit

records are be sent to and observed at an Audit Record Repository (ARR).

• Prod uct User Authentic ation: 'User Authentica tion' of HIPAA products involves

password protection for access to User, Key operator, Service Security/

Administrator and other user interfaces that allow access to protected health

information (PHI). These interfaces include all user keypads, front panels

displays and network connections.

The last two functions are available when access to the Administrator is

granted (i.e. when the Administrator password has been correctly entered).

2901B EN 20040413 Introducing the Drystar5500

15

Page 16

Node authen ticat ion, cert ificat es and Cer tifica tio n Auth ority

Each device - connected to a network - will receive a unique identifier: the

X.509 certificate, a digital pass port. Any devi ce on the network is only allow ed

to communicate with another node of which it is holding the certificate in a

‘communication allowed’ table.

A Certification Authority (CA) is responsible for creating a certificate. The CA

can be the hospital, Agfa or a third party.

This CA distributes the certificate to the hospital security responsible or

service technician, who for his part:

• Imports the device certificate, created by the CA.

Imports the c erti fica tes o f al l pe er de vic es w ith whic h c omm un icat ion is au tho rize d,

i.e. creates the list of ‘communication allowed’ device certificates.

16

Introducing the Drystar 5500

2901B EN 20040413

Page 17

Operating modes

The Drystar 5500 can be operated in five modes: operator mode, keyoperator mode, service mode, specialist mode, and administrator mode.

Operator mode

The operator mode groups all basic functions which are aimed at

radiographers without special technical skills:

• Producing diagnostic usable hardcop ies;

• Loading con suma bl es;

• Ensuring norm al operat ion of the printer.

All functions of the operator mode are described in both User and Reference

manuals. Refer to Chapter 2, ‘Basic operation (operator mode)’.

Key-oper ator mod e

The key-operator mode groups advanced functions which are aimed at

technically skilled operators such as X-ray operators, network managers and

service and hospital technicians.

The key-operator mode can be accessed via the Key-operator key on the

keypad and is menu-driven. The key-operator functions are described in the

Reference manual only. Refer to Chapter 3, ‘Advanced operation (key-

operator mode)’.

Service mode

The service mode functions are reserved for trained service personnel. The

service mode is password protected.

Speciali st mode

The specialist mode functions are reserved for trained service personnel of

the Agfa Customer Support Center. The specialist mode is password

protected and is only accessible by browser via a remote PC.

2901B EN 20040413 Introducing the Drystar5500

17

Page 18

Administrator mode

The Administrator mode functions are reserved for the System Administrator.

The Administrator mode is password protected and is only accessible by

browser via a remote PC. Refer to ‘Privacy and security’ on page 15.

18

Introducing the Drystar 5500

2901B EN 20040413

Page 19

Control modes (local an d remot e)

You can control the working of the Drystar 5500 via the local keypad or via a

network remote PC.

The table below gives an overview of the operating modes you can access

locally or via the remote PC.

Local

Operator mode No ––– –––

Key-operator mode No Key-operator mode Yes

Service mode Yes Service mode Yes

––– ––– Specialist mode Yes

––– ––– Administrator mode Yes

Password

protected

Remote

Password

protected

The manual describes the controlling of the Drystar 5500 via the keypad. The

menus for controlling the Drystar 5500 via a remote PC are structured in the

same way. Refer to ‘Controlling the Drystar 5500 via a remote PC (with

browser)’ on page 141 of the D rystar 5500 Reference manual.

2901B EN 20040413 Introducing the Drystar5500

19

Page 20

The user interface

The Drystar 5500 interfaces with the user via the following controls:

• Power button;

• Unlock button;

• a key pad and a displa y;

• a status indicator LED;

• audio signals.

Overview of user interface controls:

1

2

1 Unlock button

2 Power button

3 Display

4 Keypad cover

5 Status indicator LED

6 Film input tray (Upper input tray)

7 Film input tray (Lower input tray)

3

4

5

6

7

20

Introducing the Drystar 5500

Never try to open the printer when the Drystar 5500 is busy printing a

film. Always follow the instructions on the display!

2901B EN 20040413

Page 21

The status indicator LED

At the right side of the display, a LED indicates the status of the Drystar 5500.

Color / Light Statu s Action

Constant

Green

Blinking

Blinking

Red

Constant Error status

Ready (stand-by ) Proceed

Busy or in key-

operator mode

Wait

Warning status Check th e display for messa ges.

Refer to ‘Controlling the

Drystar 5500 via a remote PC

(with browser)’ on page 141 of the

Drystar 5500 Reference manual.

The control buttons

Two control buttons have been provided

Unlock button

• To safely unlock the printer for accessing the

input trays or opening the covers.

Power button • To power on or off the printer.

Do NOT press the Power button without first following the procedure to

stop printing when the Drystar 5500 is busy printing a film. Refer to

‘Switching off the Drystar 5500’ on page 28.

2901B EN 20040413 Introducing the Drystar5500

21

Page 22

Audio signals

The Drystar 5500 gives status information via beeps. The length of the beep

indicates the response of the system to a key command.

• A short beep means tha t Drystar 5500 h as accept ed the key command and is

starting the operation.

• A long beep means that you have pressed a non-active key or that the

Drystar 5500 has rejected the key command.

" Certain conditions can cause an interval beep. An interval beep

accompanies an error or warning message. Refer to ‘Troubleshooting

checklist’ on page 164 of the Drystar 5500 Reference manual.

The keypad

To access the keypad, push the keypad cover backward.

The keypad is located under the keypad cover.

The Drystar 5500 keypad features the following keys:

22

Introducing the Drystar 5500

Emergency

key

Delete key

Keyoperator key

To rearrange the p rint queue: eme rgency jobs can

be place d a t th e to p o f th e q ueu e t o b e p rinte d w ith

priority. Refer to ‘Assigning em ergency priority ’ on

page 33.

To delete print jobs. Jobs that are deleted will not be

printed. Refer to ‘Deleting print jobs’ on page 34.

To access the advanced functions of the keyoperator mode. Refer to Chapter 3, ‘Advanced

operation (key-operator mode)’.

2901B EN 20040413

Page 23

Service key

To access service-level functions. Reserved for

trained service personnel.

Escape key

Confirm key

Up key

Down key

Left key

Right key

To quit the curren t function or e xit a menu wi thout

saving modific atio ns.

(In key-operator mode)

• To select a menu;

• To accept an entry in a menu.

• To move the cursor to the previous entry field.

• To scroll upwards.

• T o increment the number in a(n) (alpha)numerical

entry field.

• To move the cursor to the next entry field.

• To scroll downwards.

• To decrement the number in a(n)

(alpha)numerical entry field.

• To scroll backwards through multiple choices

within a field.

• To move the entry position in a( n)

(alpha)numerical entry field from right to left.

• To toggle between values in a field.

• To scroll forwards through multiple choices within

a field.

• To move the entry position in a( n)

(alpha)numerical entry field from left to right.

• To toggle between values in a field.

" You can press and hold down an arrow key to scroll quickly through a list

or a menu.

2901B EN 20040413 Introducing the Drystar5500

23

Page 24

The display

The Drystar 5500 control panel has a backlit LCD display with 8 lines of

40 characters each. Its lay-out depends on the operating mode.

Operator mode

In operator mode, appropriate information is displayed, in accordance with

the status of the printer.

The operator basic screen looks as follows, indicati ng that the Dryst ar 5500 is

ready for operation and that no job is currently being executed.

READY

During printing, calculation and other processes, as the printer is busy with at

least one job, the Print queue screen is displayed:

Modality name 10:21:34 PRINTING

Modality name 10:21:34 CALCULATING

Modality name 10:23:12 WAITING

Modality name 10:24:45 WAITING

Modality name 10:31:01 WAITING

• The progres s indicato r keeps th e user info rmed of t he progre ss of a pr ocess

(e.g., calculation of a bitmap, printing of a film, copying files). The line is

gradually filled from left to right, from 0% to 100% as the process proceeds.

" On the print queue screen the modality name defined during installation

Refer to ‘Managing the print queue’ on page 31.

24

Introducing the Drystar 5500

film 15 of 22

62%

will be used to refer to the corresponding modality. In case there is also a

nickname (daily used name) defined during installation, the nickname is

used.

2901B EN 20040413

Page 25

Key-operator mode

In key-operator mode, operation is menu driven. The menu displays the

key-operator functions and the active keys.

1 Stop Printing

2 Show settings

3 Change settings

1

4 Print image

5 Save configuration

6 Restore configuration

7 Calibration

8 Installation

1 Key-operator main menu functions

2 Active keys

Key-Operator

Main Menu

quit

ok

select

2

Data entry

When entering numerical or alphanumerical data, always adhere to the

following principles:

• Only (alpha)numerical data can be entered.

• Duri ng the data entr y, the field is displayed in reverse mod e.

• Incr ement the num ber in a(n) (a lpha)numerical e ntry field by p ressing the Up

key. Transition from 9 to 0 of o ne f igur e wil l als o inc rem ent the nex t figu re to the

left, respecting the valid limits of the range.

• Decrement the number in a(n) (alpha)numerical entry field by pressing the Down

key. Transition from 0 to 9 of one figure will also decrement the next figure to the

left, respecting the valid limits of the range.

• Mov e the ent ry position in a(n) (alpha)num erical ent ry field fro m right t o left by

pressing the Left key.

• Mov e the ent ry position in a(n) (alpha)num erical ent ry field fro m left to r ight by

pressing the Right key.

• Press and hold down a key to repeat arrow key actions.

• To accept an entry in a menu, press the Confirm key.

• A short beep acknowledges and terminates the entry.

• The Drystar 5500 will sound a long beep if you press a key that is not to be used

at that moment.

2901B EN 20040413 Introducing the Drystar5500

25

Page 26

Switching on the Drystar 5500

" Before switching on the Drystar 5500, read the safety instructions. Refer

to ‘Security precautions’ on page12.

Follow the procedure below to ensure proper startup of the Drystar 5500 and

to check that everything is working correctly.

1 Check that the power cord is plugged in and then switch on the printer by

pressing the Power button.

On the disp lay, the following messa ge is dis played . After a sh ort whi le, a pro gress

indicator will show the proceeding of the self test.

Please WAIT

Self test proceeding

62%

2 The printer is ready for operation:

• If, on the fr ont pan el dis pla y, the READY mes sag e is sho wn , the status ind ica tor

LED is constant green.

READY

" It takes 13 minutes (starting up of the Drystar 5500 and heating up of the

printhead) before you can start printing. When you send print jobs to the

Drystar 5500 during this period, the display will inform you that the printer

is warming up.

26

Introducing the Drystar 5500

2901B EN 20040413

Page 27

• If, on the front panel display, the Print queue screen is shown, the status

indicator LED is green and blinking.

Modality name 1 0:21 :34 PRINTING

Modality name 10:21:34CALCULATING

Modality name 1 0:23:12 WAITING

Modality name 1 0:24:45 WAITING

Modality name 1 0:31:01 WAITING

film 15 of 22

62%

3 Make sure that the printer is loaded with appropriate consumables.

" Refer to page 38 for detailed information on loading films.

" If the job status holds a warning or error indication: refer to

‘Troubleshooting checklist’ on page 164 of the Drystar 5500 Reference

manual.

2901B EN 20040413 Introducing the Drystar5500

27

Page 28

Switching off the Drystar 5500

When you want to switch off the printer, it is recommended to follow the

procedure as described below, to make sure that any pending jobs are

correctly finished.

1 Make sure that the pending jobs are correctly finished. If necessary, follow

the procedure to stop printing. Refer to ‘Stopping the printing process’ on

page 51 of the Drystar 5500 Reference manual.

2 Press the Power button to switch off the Drystar 5500.

" In case the printer is ready, it shuts down immediately. Otherwise it can

take 20 seconds to power down.

28

Introducing the Drystar 5500

2901B EN 20040413

Page 29

Chapter

2

Basic operation

(operator mode)

This chapter will inform on how to manage the print queue,

how to print films with priority and how to load new films.

! Overview of operator functions

! Managing the print queue

! Assigning emergency priority

! Deleting print jobs

! About Drystar 5500 consumables

! Loading films

Page 30

Overview of operator functions

This section focuses on the basic operating principles of the Drystar5500.

After reading this chapter, the operator should be able to produce diagnostic

usable hardcopies. No special technical skills are required.

All basic operator functions can be activated directly by pressing a single key

on the keypad.

Function / Task Description Page

Jobs that have been received are

‘Managing the print queue’

‘Assigning emergency priority’

‘Deleting print jobs’

‘Loading films’

put in a print queue, waiting to be

printed.

To rearrange the order in which

jobs are waiting to be printed. Jobs

that have emergency priority are

placed on top of the print queue.

To remove print jobs from the print

queue. Print jobs that are deleted

will not be printed.

Instructions for loading new films

on the printer.

31

33

34

38

30

Basic operation (operator mode)

2901B EN 20040413

Page 31

Managing the print queue

You can always check the status of the print jobs.

As long as the jobs are not yet submitted for printing (i.e. they are still in the

‘waiting’ status), you can assign emergency priority and delete individual print

jobs.

" Keep in mind that one print job can hold several films to be printed. In

accordance with the acquisition modality used, and the actual settings,

films can be grouped in a folder to be submitted as one print job for the

Drystar 5500. Refer to the User manual of the acquisition modality for

more information.

Checking the print queue

If jobs have been transmitted from the network to the Drystar 5500, they are

put in the print queue on a first in, first out schedule. New jobs that are added

to the queue get the ‘waiting’ status.

As soon as the last film of a job is ejected in the output tray, the next job that

has been calculated will be put in printing status.

Example of the Print queue screen:

Modality name 10:21:34 PRINTING

film 15 of 22

62%

Modality name 10:21:34 CALCULATING

Modality name 10:23:12 WAITING

Modality name 10:24:45 WAITING

Modality name 10:31:01 WAITING

2901B EN 20040413 Basic operation (operator mode)

31

Page 32

• The first line shows information on the job that is currently being printed:

modality n ame, a nickname (i f defined), time of re ceipt of the job and t he job

status.

• Th e se con d line show s ho w ma ny fi lms a re to b e prin ted for the curr ent job, a nd

also what film from that total is currently being printed.

• On the third line you can watch the progress of the printing process. The

progress in dicator is gradu ally filled from left to right, from 0% to 1 00% as the

process is com pleted . If no job is being prin ted, the pro gress indi cator will sho w

the proceeding of the calculation process of the next job.

The other lines give information on the jobs that are still waiting in the print

queue. A description of the possible status of each job is listed in the table

below:

Status Description Action

Printing

Calculating

Waiting

Media size

indication

Printing of this job is in

progress.

The neces sary calcu lations

are being made before

printing of the job can be

started.

The job has been put in the

print queue, but no

processing is yet being

done.

No compatible media are

loaded for the print job.

Wait.

Wait.

• To put emergency jobs on top of

the queue, refer to ‘Assigning

emergency priority’ on page 33.

• To remove jobs from the queue,

refer to ‘Deleting print jobs’ on

page 34.

Make sure the correct media are

loaded.

" On the print queue screen the modality name defined during installation

will be used to refer to the corresponding modality. In case there is also a

nickname (daily used name) defined during installation, the nickname is

used.

" If the job status holds a warning or error indication: refer to ‘Error

messages while the printer starts up’ on page 186 of the Drystar 5500

Reference manual.

32

Basic operation (operator mode)

2901B EN 20040413

Page 33

Assigning emergency priority

You can assign emergency priority to jobs that need to be printed with

urgency . Jobs that are mar ked for priority handling ar e placed at the top of the

print queue for immediate processing. Emergency jobs will be printed before

other jobs that were received previously. However, any pending jobs that are

already being calculated or scheduled for printing will be finished first.

1 On the keypad, press the Emergency key.

The Emergency printing screen is displayed:

Modality name 10:23:02

Modality name 10:23:34

Modality name 10:24:02

Modality name 10:24:34

Modality name 10:25:34

Modality name 10:26:34

Modality name 10:27:34

!

EMERGENCY

PRINTING

quit

ok

select

" Only the jobs that have the ‘waiting’ status are displayed. Print jobs which

already have an emergency status are blinking.

You can press the Escape key to return to the previous menu without making changes in

the job order (‘Quit’).

2 Press the Down and Up keys to scroll through the jobs and press the Confirm

key to select the job that must be printed with emergency priority.

Printing will be resumed in accordance with the changed queue order.

2901B EN 20040413 Basic operation (operator mode)

33

Page 34

Deleting print jobs

You can remove jobs from the print queue if they are in the ‘waiting status’.

Any pending jobs that are already being calculated or scheduled for printing

will be finished. Such jobs can not be deleted.

1 On the keypad, press the Delete key.

The Delete print job screen is displayed:

Modality name 10:23:02

Modality name 10:24:34

Modality name 10:24:54

Modality name 10:25:34

Modality name 10:26:34

Modality name 10:27:34

Modality name 10:28:34

!

DELETE

PRINT JOB

quit

ok

select

" Only the jobs that have the ‘waiting’ status are displayed.

" The modality name defined during installation will be used to refer to the

corresponding modality. In case there is also a nickname (daily used

name) defined during installation, the nickname is used.

You can press the Escape key to return to the previous menu without deleting print jobs

(‘Quit’).

2 Press the Down and Up keys to scroll through the jobs and press the Confirm

key to select the job that must be deleted.

34

Basic operation (operator mode)

2901B EN 20040413

Page 35

The Confirm delete screen is displayed.

Delete selected job ?

Modality name 10:23:02

DELETE

PRINT JOB

cancel

confirm

You can press the Es cape key to r eturn to the previo us menu w ithout d eleting print jo bs

(‘Cancel’).

3 Press the Confirm key to delete the print job.

Printing will be resumed. The job that has been deleted will not be printed.

2901B EN 20040413 Basic operation (operator mode)

35

Page 36

About Drystar 5500 consumables

The Drystar 5500 can handle blue-transparent and clear-transparent films.

Available film formats are 8x10”, 10x12”, 11x14”, 14x14”, and 14x17”.

Both input tray can use all film formats.

The key-operator can adjust the film size setting for both input trays. Refer to

‘Changing the configuration settings’ on page 61 of the Drystar 5500

Reference manual.

Labeling the input trays

The following film types can be used:

Upper input tray

Lower input tray

Drystar DT2 B 8x10” up to 14x17”

Drystar DT2 C 8x10” up to 14x17”

Drystar DT2 B 8x10” up to 14x17”

Drystar DT2 C 8x10” up to 14x17”

36

Basic operation (operator mode)

2901B EN 20040413

Page 37

Appropriate labels have been applied on the input tray(s) by the service

personnel at installation of the printer, indicating the type of new film to be

loaded when the tray is empty.

2901B EN 20040413 Basic operation (operator mode)

37

Page 38

Loading films

This section describes how to load the Drystar 5500 with appropriate films.

The Drystar 5500 can be loaded with 8x10”, 10x12”, 11x14”, 14x14” and

14x17” films.

" The Drystar 5500 can be loaded with new films in full daylight. Loading

films is easy and can be done in no time. Follow the procedures as

described in this section.

The Drystar 5500 will inform you in several ways that a film tray is empty:

• An audible signal (5 long beeps),

• the Status indicator LED is flashing (red color),

• the Unlock button LED is flashing,

• the display screen shows a message informing you that either the upper or lower

input tray is empty.

The film loading procedure is identical for both input trays. In the examples

below, we will assume that the lower input tray is to be loaded.

" The procedure is slightly different, depending on the fact wether the

Drystar 5500 is printing/calculating or in the ready state.

" When the printer is in the ready state, go to Step 5.

38

Basic operation (operator mode)

Make sure not to load more than one film pack in an input tray. Loading

more than one film pack in an input tray may damage the Drystar 5500.

2901B EN 20040413

Page 39

When the Drystar 5500 is printing or calculating:

The display shows the following message:

1

LOWER INPUT TRAY EMPTY

PRESS THE UNLOCK BUTTON TO

START LOADING PROCEDURE

INPUT TRAY IS LOCKED

2 Press the Unlock button to initiate the loading sequence.

3 Wait while the printer is finishing printing any current jobs.

Modality name 10:21:34 PRINTING

film 15 of 22

62%

LOADING SEQUENCE IS INITIATED

Finishing current print job

DO NOT OPEN THE INPUT TRAY YET !

When the filmpath is cleared, the following message is displayed:

LOWER INPUT TRAY EMPTY

INPUT TRAY IS UNLOCKED

OPEN INPUT TRAY

4 Go to step 7.

Blinking

Blinking

2901B EN 20040413 Basic operation (operator mode)

39

Page 40

When the Drystar 5500 is in the ready state:

The display shows the following message:

5

LOWER INPUT TRAY EMPTY

PRESS THE UNLOCK BUTTON TO

START LOADING PROCEDURE

6 Press the Unlock button to initiate the loading sequence.

From here on, the procedure is identical for the two cases.

7 The pr inter is ready to receive a new film pack when the follow ing message

appears:

LOWER INPUT TRAY EMPTY

INPUT TRAY IS UNLOCKED

OPEN INPUT TRAY

Blinking

" You have 3 seconds to open the input tray. If you do not open the tray

within that time, the first screen (step 1 or 5 respectively) is presented

again, or printing is resumed when a job is received for which media is

available.

40

Basic operation (operator mode)

2901B EN 20040413

Page 41

8 Open the empty input tray.

The display sho ws the followin g mes sag e:

Remove protective sheet from tray

LOAD NEW FILM PACK

Close input tray

9 Remove the white (protective) film sheet.

Blinking

2901B EN 20040413 Basic operation (operator mode)

41

Page 42

10 Take film pack, and open it.

" Verify that the film type on the film pack corresponds with the sticker on

the tray! If you do use an other film type, you are advised to change the

label on the tray.

" You can put the film pack onto a table to make manipulation easier.

Before you do this, make sure that the table is dust-free!

11 Remove the sticker from the film pack.

42

Basic operation (operator mode)

2901B EN 20040413

Page 43

12 Remove the plastic film bag partially.

13 Slide the film pack into the input tray, and remove the plastic film bag

completely.

2901B EN 20040413 Basic operation (operator mode)

43

Page 44

14 Tear the plastic tape from around the film pack.

15 Close the input tray.

" The Drystar 5500 resumes printing as soon as the tray is closed.

" Loading instructions are also available on the input tray cover.

44

Basic operation (operator mode)

2901B EN 20040413

Page 45

Checking the correct position of a film in the input tray

" You can verify that the film is properly loaded by watching the lower right

corner of the films in the input tray. The rounding of this corner should be

smaller than the other three corners. This is also indicated on the sticker

at the right side of the input tray cover.

" When a new film is loaded, the Film Identification tag is read and the

printer settings are automatically adjusted. The Film Identification tag is

located on the protective sheet on the backside of the film pack. The

figure below shows the film pack upside down.

2901B EN 20040413 Basic operation (operator mode)

45

Page 46

46

Basic operation (operator mode)

2901B EN 20040413

Page 47

Chapter

3

Advanced operatio n

(key-operator mode)

This chapter gives an overview of functions for the

advanced user:

! Overview of key-operator functions

! Preventive maintenance schedule

! Cleaning the exterior

! Cleaning the printhead resistor line

! Troubleshooting checklist

Page 48

Overview of key-operator functions

The key-operator menus make it possible to use the Drystar 5500 advanced

functions. The functions are described in detail in the Drystar 5500 Reference

manual.

For general information on the functions of the keys on the Drystar 5500,

refer to ‘The user interface’ on page 20.

Overview

The Drystar 5500 features the following functions on the main menu level of

the key-operator mode:

Menu item Function Page

Stop Printing To halt the printing procedure 51

Show setting s To consult the current settings of the printer. 52

Change settings To change the current settings of the printer. 61

To print one of the standard Drystar 5500 test

Print Image

Save configuration To make a backup of the printer settings. 102

Restore

configuration

Calibration To calibrate the printer. 188

images. To load and print images from a

diskette.

To restore the backup of the printer settings. 105

96

Installation

Refer to the indicated page of the Drystar 5500 Reference manual for an

explanation of the function and the appropriate procedures.

48

Advanced ope ration (key-operator mode)

To install the software with the installation

wizard.

2901B EN 20040413

119

Page 49

Preventive maintenance schedule

Maintenance and cleaning involve only some minor user tasks. Refer to the

following pages for the appropriate cleaning procedure.

Interval What to do? Page

Ad hoc ‘Cl ean ing the exterio r ’ 50

When image quality tends to

degrade. An a ppr opri ate wa rnin g

message is displayed.

When image quality tends to

degrade. An a ppr opri ate wa rnin g

message is displayed

(refer to the Drystar 5500

Reference manual).

Safety guidelines

To prevent damage to the printer while performing maintenance, observe

the following safety precautions:

•

Do not lubricate the printer.

• Do not attempt to disassemble the printer.

• Do not touch the resistor line of the printhead.

• Always switch off the Drystar 5500 and disconnect the power cord from the

outlet before carrying out any maintenance work.

‘Cleaning the printhead resistor

line’

‘Printhead profile calibration’ 116

51

" Film jam removal or cleaning the printer head can be done without

switching the power off.

2901B EN 20040413 Advanced operation (key-operator mode)

49

Page 50

Cleaning the exterior

1 Switch off the Drystar 5500 by following the procedure as described in

‘Switching off the Drystar 5500’ on page 28.

2 Remove the power plug from the socket.

3 Wipe the exterior of the printer with a clean, soft, damp cloth.

Use a mild soap or detergent if required but never use an ammonia–based cleaner.

Be careful not to get any liquid in the power cord port.

4 Plug in the printer and switch it on by following the procedure as described in

‘Switching on the Drystar 5500’ on page 26.

50

Advanced ope ration (key-operator mode)

2901B EN 20040413

Page 51

Cleaning the printhead resistor line

Printhead cleaning must be done when image quality problems occur.

For more information on maintaining image quality: refer to ‘Maintaining

ning

image quality and resolving Image quality problems’ on page 188 of the

Drystar 5500 Reference manual.

To clean the printhead:

1 Press the Key-operator key to enter the key-operator mode.

2 On the Key-operator Main menu, press the Down key six times, followed by

the Confirm key to select ‘Calibration’.

1 Stop printing

2 Show settings

3 Change settings

4 Print image

5 Save configuration

6 Restore configuration

7 Calibration

8 Installation

Key-operator

Main menu

quit

ok

select

The ‘Select Cal ibra tion ’ screen appea rs:

SELECT CALIBRATION

1 Film

2 Prin t head profil e

3 Printhead cleaning

Key-operator

Calibration

quit

ok

select

3 Press the Down key two times to select ‘Printhead cleaning’ and press the

Confirm key. The printer will automatically shut down.

2901B EN 20040413 Advanced operation (key-operator mode)

51

Page 52

4 The ‘Printhead cleaning’ screen will give instructions on what to do:

Printhead cleaning

1. Open TPH Compartment

2. Clean printhead

3. Close the door after cleaning

5 Open the drum compartment door by pulling its handle.

6 Locate and check on sight the printhead resistor line.

" Be careful not to touch the printhead resistor line.

52

Advanced ope ration (key-operator mode)

2901B EN 20040413

Page 53

7 Clean the printhead resistor line.

Gently pass over the resistor line a few times with a lint free cloth, slightly

moistene d with Isopropyl alco hol or Ethanol. Do this only in one direction , i.e.

from left to right, without lifting the cloth.

" Do not apply any pressure on the printhead because this pressure may

cause damage on the interconnections underneath the printhead.

8 Close the drum compartment door.

After you h ave cleaned the printhead res istor line and yo u have closed t he drum

compartment door, the printer will restart automatically.

" If residue dust is present as part of the cleaning procedure it will

disappear after a few prints.

2901B EN 20040413 Advanced operation (key-operator mode)

53

Page 54

Troubleshooting checklist

The table below lists some general problems which can occur when working

with the Drystar 5500. Refer to the appropriate pages of the Drystar 5500

Reference manual.

• The Drystar 5500 does not print.

Action Refer to Page

Check the Drystar 5500

Remove a jammed film

Resolve error messages

• The quality of the printed images is bad (printing remains possible).

‘The Drystar 5500 does not print’ 166

‘Film input tray feed jams’ 169

‘Film transport jams in the front

section’

‘Film transport jams in the print

section’

‘Film transport jams in output

section’

‘Unauthorized opening of the

printer’

‘Check the display messages.’ 166

172

173

177

185

Resolve film quality problems

Resolve war ning messa ges ‘Warning messages’ 192

Have electrical or mechanical defects repaired by skilled personnel only!

54

Advanced ope ration (key-operator mode)

Action Refer to Page

‘White dots or lines appear in the

transport direction’

‘Low frequen cy ban ding ’ 191

‘Scratches appear on film’ 191

191

2901B EN 20040413

Page 55

Appendix

A

Equipment information sheet

Page 56

Specifications

Product des cr iption

Type of product Printer

Commercial name Drystar 5500

Original seller/manufacturer Agfa-Gevaert N.V.

Labeling

TÜV-Certification Ma rk

ULC-listing Mark

Dimensions

• Unpacked: width 75, length 70,

Dimensions (approx. values in cm)

Weight

Hard disk capacity 18 GByte

Floppy disk capacity 2HD 1.44 Mbyte floppy disks

RAM memory 2x256 MB

Floppy disk container Four 2HD 1.44 Mbyte floppy disks

height 141

• Packed: width 90, length 83,

height 160

• Unpacked: approx. 190 kg

• Packed: approx. 235 kg

Electrical connection

Operating voltage 100-120 V; 220-240 V AC

Mains fuse protec tion

220-240 V operation 16/15 A slow blow, max.

100-120 V operation 16/15 A slow blow, max.

Mains frequen cy 50/60 Hz

56

Equipment information sheet

2901B EN 20040413

Page 57

Network connectivity

Ethernet / connectors

RJ45 twisted pair for 10/100Base-TX;

Serial RS232 connection

Network protocols (TCP/IP services) FTP, Telnet, HTTP, SNMP, SMTP, LPD

Image formats

Dicom (Default)

TIFF

Postscript Optional

Power consum ption

During operation 350 W

Maximum 700 W

In standby 140 W

Protection against

Electrical shocks Class 1 (grounded)

Ingress of water IPXØ

Environmental conditions (operation)

Room temperature Between +10°C and +30°C

Relative humidity Between 10% and 80%

Atmospheric pressure 70 kPa - 106 kPa

Environmental conditions (transport and storage)

Room temperature

Relative humidity

Between -25°C and 55°C (storage)

Between -25°C and 70°C (transport)

Between 10% and 100%

: Films may not become wet!

Note

Atmospheric pressure 70 kPa - 106 kPa

Noise emission (method of measurement in accordance with DIN 45635 part 19)

During operation Max. 55 dBA

In standby Max. 45 dBA

2901B EN 20040413 Equipment information sheet

57

Page 58

Consumables

Drystar DT2 B and Drystar DT2 C 8x10” up to 14x17” film sizes

Film thro ugh pu t

14x17” > 100/h

Access time

1 film 14x17” Max. 90 sec.

4 films 14x17” Max. 200 sec.

Print technology

Direct therma l printin g

Reliability

Estimated product life

(if regularly serviced and maintained

> 5 years and > 150 000 films

according to Agfa instructions)

Service interventions Max. 2 interventions / 3 years

Earthquake kit (standard) Meets the CA requirements

58

Equipment information sheet

2901B EN 20040413

Page 59

Options and accessories

Mobile installation kit

The default mobile installation kit allows you to use the printer in a van. Safe

transportation is ensured by a mechanical system blocking the printhead.

Connectivity with Agfa equipment

Paxport

•

• MG3000

• Drystar 2000

• Drystar 3000

• Drystar 4500

• ADC 70

• ADC Compact

• ADC Compact Plus

• ADC Solo

• Impax

• DR-Thorax

Conn ectiv ity wit h no n -A g fa eq ui pm ent

Drystar 5500 is a Dicom printer and can therefore be connected to all

modalities supporting Dicom. Although, to ensure optimal operation and

image quality, Agfa has made the effort to test and release the Drystar 5500

with most of the modalities on the market. For the complete list or if you want

to check on a specific modality, contact your Agfa representative.

2901B EN 20040413 Equipment information sheet

59

Page 60

P

rinted in Belgium

P

2

ublished by Agfa-Gevaert N.V., B-2640 Mortsel-Belgium

901B EN 20040413

Loading...

Loading...