Page 1

DR 400

5520/100

5520/200

User Manual

3231A EN 20150710 1114

Page 2

| DR 400 | Contents

2

Contents

Legal Notice ..........................................................................5

Introduction .......................................................................... 6

Introduction to this Manual ....................................... 7

Scope of this Manual ......................................8

Warnings, Cautions, Instructions and Notes ....

9

Disclaimer ................................................... 10

Introduction to DR 400 ............................................10

Intended Use ............................................... 11

Intended User .............................................. 12

Configuration .............................................. 13

Equipment Classification ............................. 16

Options and Accessories ...............................17

Operation Controls ...................................... 18

System Documentation ................................27

Training .......................................................28

Product Complaints ..................................... 29

Compatibility ...............................................30

Compliance ................................................. 31

Connectivity ................................................ 33

Installation .................................................. 34

Radiation Protection ....................................35

Labels .......................................................... 40

Cleaning and Disinfecting ............................ 46

Patient data security .................................... 49

Maintenance ................................................50

Environmental protection ............................ 53

Safety Directions ..........................................54

Getting started .....................................................................58

Starting the System ..................................................59

Basic workflow using the DR Detector ......................60

Step 1: retrieve the patient info ....................61

Step 2: select the exposure ...........................62

Step 3: prepare the exposure ........................63

Step 4: check the exposure settings .............. 64

Step 5: execute the exposure ........................65

Step 6: perform a quality control ..................66

Basic workflow using a CR cassette .......................... 67

Step 1: retrieve the patient info ....................68

Step 2: select the exposure ...........................69

Step 3: prepare the exposure ........................70

Step 4: check the exposure settings .............. 71

Step 5: execute the exposure ........................72

Step 6: repeat steps 2 to 5 for the next

subexposures ...............................................73

3231A EN 20150710 1114

Page 3

DR 400 | Contents |

Step 7: digitize the image .............................74

Step 8: perform a quality control ..................75

X-Ray System Positioning ........................................ 76

RAD Table Exposures ...................................77

Oblique Exposures ....................................... 78

Lateral Exposures ........................................ 79

RAD Wall Stand Exposures .......................... 80

Guidelines for Pediatric Applications ....................... 81

Stopping the System ................................................ 83

Operation ............................................................................ 84

Tube head display ....................................................85

RAD Table and X-Ray Tube Stand ............................ 86

Positioning the X-Ray Tube Stand ................ 88

Positioning the RAD Table ........................... 91

Positioning the Bucky .................................. 93

RAD Table Accessories .................................94

RAD Wall Stand .......................................................96

Positioning the RAD Wall Stand ...................98

RAD Wall Stand Accessories .......................101

Bucky .................................................................... 104

Bucky configuration ...................................106

Rotating the bucky .....................................109

Loading of the bucky in the RAD Table .......110

Loading of the bucky in the RAD Wall Stand ....

111

Unloading of the bucky in the RAD Table ... 112

Unloading of the bucky in the RAD Wall Stand .

113

Centering and collimating ..........................114

Orientation of DX-D 10C, DX-D 10G in the bucky

........................................................................116

Grids ......................................................................118

Grid focal distance color indication ............119

Grid detection ............................................120

Storage box for DR Detector and grids ................... 121

Automatic Exposure Control (AEC) ........................122

Manual Collimator .................................................123

Dose Area Product Meter (DAP) .................123

Automatic Collimator ............................................ 125

Semi-automatic collimation mode ............. 127

Manual collimation mode .......................... 128

Dose Area Product Meter (DAP) .................129

Effect of SID on patient dose .................................. 130

X-Ray Generator Console .......................................131

Starting and stopping the generator ...........132

X-ray tube start-up modes ..........................133

X-ray generator messages and warning signals .

134

Exposure parameters ................................. 139

Problem solving .................................................................142

3

3231A EN 20150710 1114

Page 4

4 | DR 400 | Contents

System messages ................................................... 143

Restoring connection between generator and NX after

generator failure ....................................................145

Automatic collimation always too wide or too narrow ..

146

Empty Bucky Failure, Double Exposure Failure ...... 147

NX does not connect to the generator due to ID tablet ..

148

No table movement ................................................149

DR Detector is Exceeding the Maximum Working

Temperature ..........................................................150

DR Detector must be Recalibrated ..........................151

Technical Data ...................................................................152

DR 400 Technical Data .......................................... 153

Environmental conditions ..........................154

Generator Technical Data ...................................... 155

RAD Table and X-Ray Tube Stand Technical Data .. 157

Movement ranges ...................................... 158

RAD Wall Stand Technical Data ............................. 160

X-Ray Tube Technical Data .................................... 162

Bucky Unit Technical Data ..................................... 164

Automatic Exposure Control (AEC) Technical Data ....

166

Ralco R221 Collimator Technical Data ...................167

Ralco R225 ACS Collimator Technical Data ........... 168

Dose Area Product Meter (DAP) Technical Data .....169

DX-D Fixed DR Detector Technical Data .................170

Portable DR Detector Technical Data ..................... 172

NX Workstation Technical Data ............................. 173

DR Generator Sync Box Technical Data ..................174

Remarks for HF-emission and immunity ............................ 175

Remarks for HF-emission and immunity ................ 176

Essential performance ........................................... 182

Cables, transducers and accessories ....................... 183

For type 5520/200 only ............................. 185

Optional .................................................... 185

Stray Radiation ..................................................................186

3231A EN 20150710 1114

Page 5

DR 400 | Legal Notice | 5

Legal Notice

0413

Agfa HealthCare NV, Septestraat 27, B-2640 Mortsel - Belgium

For more information on Agfa products and Agfa HealthCare products, please

visit www.agfa.com.

Agfa and the Agfa rhombus are trademarks of Agfa-Gevaert N.V., Belgium or

its affiliates. DR 400 is a trademark of Agfa HealthCare N.V., Belgium or one

of its affiliates. All other trademarks are held by their respective owners and

are used in an editorial fashion with no intention of infringement.

Agfa HealthCare N.V. makes no warranties or representation, expressed or

implied, with respect to the accuracy, completeness or usefulness of the

information contained in this document and specifically disclaims warranties

of suitability for any particular purpose. Products and services may not be

available for your local area. Please contact your local sales representative for

availability information. Agfa HealthCare N.V. diligently strives to provide as

accurate information as possible, but shall not be responsible for any

typographical error. Agfa HealthCare N.V. shall under no circumstances be

liable for any damage arising from the use or inability to use any information,

apparatus, method or process disclosed in this document. Agfa HealthCare

N.V. reserves the right to make changes to this document without prior notice.

The original version of this document is in English.

Copyright 2015 Agfa HealthCare N.V

All rights reserved.

Published by Agfa HealthCare N.V.

B-2640 Mortsel - Belgium.

No part of this document may be reproduced, copied, adapted or transmitted

in any form or by any means without the written permission of Agfa

HealthCare N.V.

3231A EN 20150710 1114

Page 6

6 | DR 400 | Introduction

Introduction

Topics:

• Introduction to this Manual

• Introduction to DR 400

3231A EN 20150710 1114

Page 7

Introduction to this Manual

Topics:

• Scope of this Manual

• Warnings, Cautions, Instructions and Notes

• Disclaimer

DR 400 | Introduction | 7

3231A EN 20150710 1114

Page 8

8 | DR 400 | Introduction

Scope of this Manual

This User Manual describes the features of the DR 400 System, an integrated

X-Ray imaging system. It explains how the different components of the DR

400 System work together.

3231A EN 20150710 1114

Page 9

DR 400 | Introduction | 9

Warnings, Cautions, Instructions and Notes

The following samples show how warnings, cautions, instructions and notes

appear in this document. The text explains their intended use.

Warning: Warnings are directions which, if they are not

followed, can cause fatal or serious injuries to a user,

engineer, patient or any other person or can lead to a

mistreatment.

Caution: Cautions are directions which, if they are not followed,

can cause damage to the equipment described in this manual or

any other equipment or goods and can cause environmental

pollution.

Instruction: This sign is typically used in combination with the

warning sign when providing a specific instruction. If it is followed

exactly, it should avoid the subject of the warning.

Note: Notes provide advice and highlight unusual points. A note is

not intended as an instruction.

3231A EN 20150710 1114

Page 10

| DR 400 | Introduction

10

Disclaimer

Agfa assumes no liability for use of this document if any unauthorized changes

to the content or format have been made.

Every care has been taken to ensure the accuracy of the information in this

document. However, Agfa assumes no responsibility or liability for errors,

inaccuracies or omissions that may appear in this document. To improve

reliability, function or design Agfa reserves the right to change the product

without further notice. This manual is provided without warranty of any kind,

implied or expressed, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Caution: In the United States, Federal law restricts this device to

sale by or on the order of a physician.

Introduction to DR 400

Topics:

• Intended Use

• Intended User

• Configuration

• Equipment Classification

• Options and Accessories

• Operation Controls

• System Documentation

• Training

• Product Complaints

• Compatibility

• Compliance

• Connectivity

• Installation

• Radiation Protection

• Labels

• Cleaning and Disinfecting

• Patient data security

• Maintenance

• Environmental protection

• Safety Directions

3231A EN 20150710 1114

Page 11

DR 400 | Introduction | 11

Intended Use

• The DR 400 system is a General Radiography X-ray imaging system used

in hospitals, clinics and medical practices by physicists, radiographers and

radiologists to make, process and view static X-ray radiographic images of

the skeleton (including skull, spinal column and extremities), chest,

abdomen and other body parts on adult or pediatric patients.

• Applications can be performed with the patient in the sitting, standing or

lying position.

• This device is not intended for mammography applications.

3231A EN 20150710 1114

Page 12

12 | DR 400 | Introduction

Intended User

This manual has been written for trained users of Agfa products and trained

diagnostic X–Ray clinical personnel who have received proper training.

Users are those persons who actually handle the equipment and those who

have authority over the equipment.

Before attempting to work with this equipment, the user must read,

understand, note and strictly observe all warnings, cautions and safety

markings on the equipment.

3231A EN 20150710 1114

Page 13

DR 400 | Introduction |

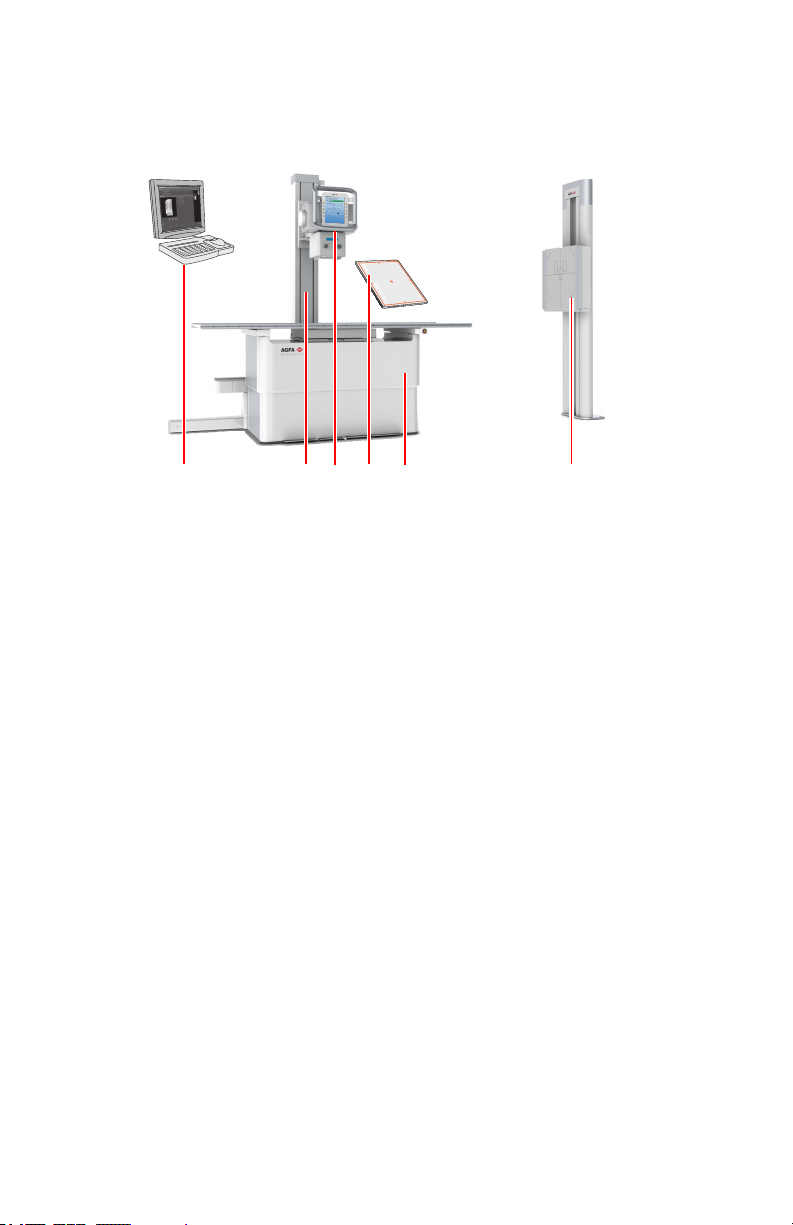

Configuration

DR 400 is a configurable DR (Direct Radiography X-ray system) or CR

(Computed Radiography) X-ray system.

The complete DR 400 consists of the following components:

• RAD Table with an integrated DX-D Fixed DR Detector or with a bucky. In

the bucky a DR Detector or a CR cassette can be inserted.

• RAD Wall Stand with an integrated DX-D Fixed DR Detector or with a

bucky. In the bucky a DR Detector or a CR cassette can be inserted.

• X-ray tube stand mounted on the RAD Table

• X-ray generator integrated in the RAD Table

• X-ray generator console

• X-ray tube with manual or automatic collimator

• NX image processing software on the NX workstation

• DR Generator Sync Box (depending on the configuration)

• Automatic Exposure Control (AEC)

• Dose Area Product Meter (DAP, optional)

Depending on the configuration the following components are also available:

• Portable DR Detector

DR 400 can be used in combination with:

13

• DX-G

• DX-M

• CR 30-X (5175/2XX)

• CR 30-Xm

• CR 10-X

• CR 12-X

• CR 15-X

DR 400 has three main configurations:

1. DR configuration with X-ray exposure parameter control on the NX

workstation.

2. CR configuration with X-ray exposure parameter control on the NX

workstation.

3. Mixed DR and CR configuration with X-ray exposure parameter control on

the NX workstation.

X-ray parameters are controlled using the Software Console on the NX

workstation.

The Software Console is available on the NX workstation, to synchronize the

X-ray exposure parameters between the NX application and the generator.

Other configurable features include:

• Tube head display with controls for X-ray exposure parameters

3231A EN 20150710 1114

Page 14

2

3

6

4

5

1

| DR 400 | Introduction

14

• Position tracking for keeping constand SID on table and wall stand

• Bucky with automatic cassette size sensing (ACSS) and automatic

collimator

NX workstation

1.

X-ray tube stand mounted on RAD Table

2.

X-ray tube with collimator and tube head display

3.

Portable DR Detector

4.

RAD Table with integrated generator

5.

RAD Wall Stand

6.

Figure 1: DR 400 configuration for DR

Topics:

• Applied Parts

Applied Parts

Applied Parts refer to parts of the medical electrical equipment that in normal

use necessarily comes into physical contact with the patient for the equipment

to perform its function. This system includes the following Applied Parts:

Topics:

• RAD Table

• RAD Wall Stand

• DR Detector

RAD Table

• Table top of the RAD Table

• Patient hand grips (optional)

• Lateral cassette holder (optional)

3231A EN 20150710 1114

Page 15

• Mattress (optional)

• Compression belt (optional)

RAD Wall Stand

• Front panel of the RAD Wall Stand

• Overhead arm support (optional)

• Patient hand grips (optional)

DR Detector

• DR Detector

DR 400 | Introduction | 15

3231A EN 20150710 1114

Page 16

16 | DR 400 | Introduction

Equipment Classification

Per EN/IEC 60601-1:2005, EN/IEC 60601-2-54:2009, this device is classified

as following:

Table 1: Equipment classification

Class I equipment Equipment in which protection against electric

Type B equipment A Type B piece of equipment is one that provides a

Water ingress IP10

Cleaning See section on cleaning and disinfecting.

shock does not rely on basic insulation only, but

includes a fixed connection to mains power with

protective earth conductor.

particular degree of protection against electric

shock particularly regarding allowable leakage

current and reliability of the protective earth

protection.

This device does not have protection against

ingress of water.

Disinfection See section on cleaning and disinfecting.

Flammable anesthetics This device is not suitable for use in the presence of

Operation Continuous operation.

Related Links

Cleaning and Disinfecting on page 46

3231A EN 20150710 1114

a flammable anesthetic mixture with air, or in

presence of a flammable anesthetic mixture with

oxygen or nitrous oxide.

Page 17

DR 400 | Introduction | 17

Options and Accessories

The system is delivered with a set of labels. When using multiple DR

Detectors, on the labels a nickname is written to identify the DR Detector. An

identical label is attached to the bucky of the X-ray system to identify the

dedicated workspace of each DR Detector.

For information on options and accessories of the DR Detector, refer to the

user manual of the DR Detector.

Related Links

RAD Table Accessories on page 94

RAD Wall Stand Accessories on page 101

3231A EN 20150710 1114

Page 18

18 | DR 400 | Introduction

Operation Controls

Topics:

• RAD Table

• RAD Wall Stand

• Control Panel of the X-Ray Tube Stand

• NX Application on the NX Workstation

• Software Console

• DR Detector Switch

• X-ray generator mini console

• Manual collimator

• Automatic collimator

• DR Detector

• Emergency stop button

• Emergency shutdown power switch

RAD Table

The RAD Table is used for positioning of the patient lying or sitting over the

detector or the cassette in the bucky for exposure.

The RAD Table supports the patient and the detector or the cassette for free

exposure.

Figure 2: RAD Table

Related Links

RAD Table and X-Ray Tube Stand

RAD Wall Stand

The RAD Wall Stand is used for positioning of patients standing upright or

sitting towards the bucky for exposure.

3231A EN 20150710 1114

Page 19

Figure 3: RAD Wall Stand with vertical bucky

Related Links

RAD Wall Stand on page 96

Control Panel of the X-Ray Tube Stand

DR 400 | Introduction | 19

Figure 4: Control Panel of the X-Ray Tube Stand with tube head display

(controls for X-ray tube position and for X-ray exposure parameters)

Figure 5: Control Panel of the X-Ray Tube Stand with X-ray tube angle

display

Related Links

RAD Table and X-Ray Tube Stand on page 86

3231A EN 20150710 1114

Page 20

Last name, first name

*June 10, 1960, 08154711032,

Chest PA

113 cm 35°

114 kV

+2

0.1 mm Cu

1 mm Al

Detector table

| DR 400 | Introduction

20

Tube head display

The tube head display can be used to control X-ray exposure parameters. It

displays the system status.

Figure 6: Example of the tube head display

Related Links

Tube head display on page 85

NX Application on the NX Workstation

The NX application is used to define patient information, select exposures and

process images.

Figure 7: the NX application

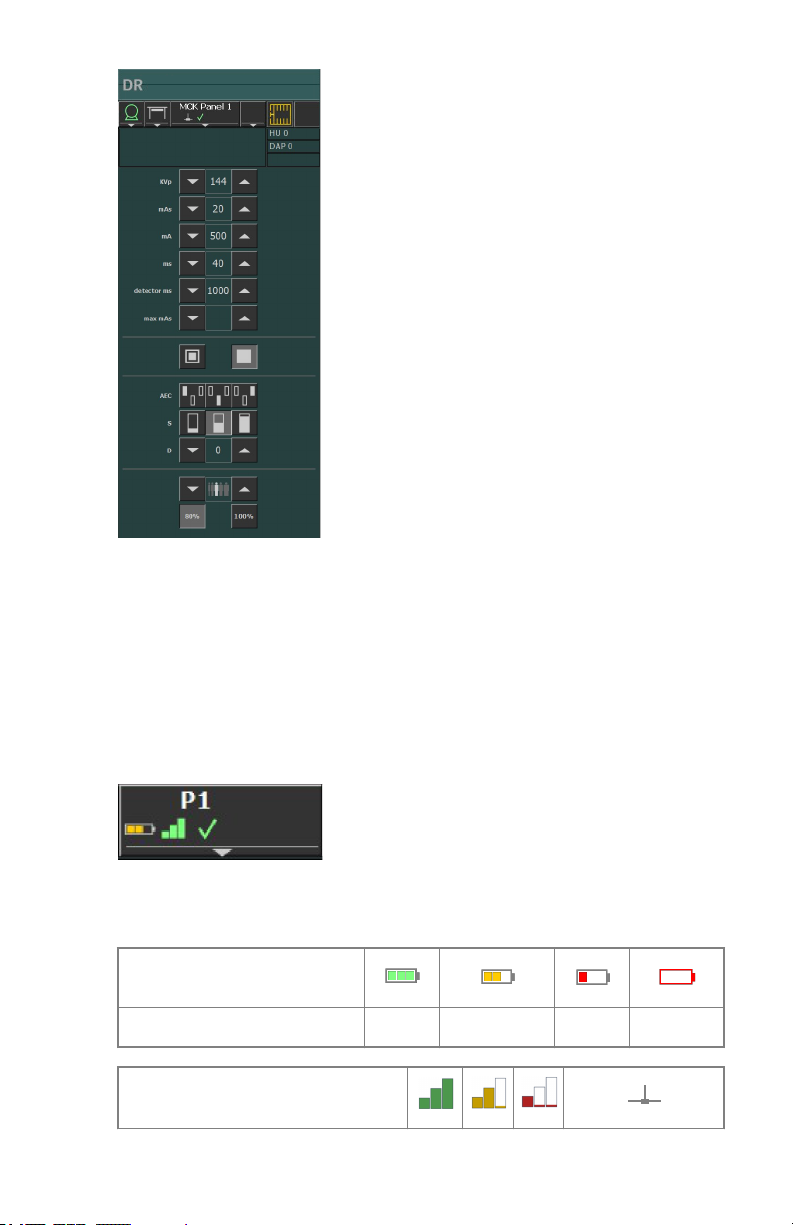

Software Console

The Software Console is available to support X-ray exposure parameter

control on the NX workstation. It is displayed on the NX workstation next to

the NX application.

The Software Console is used to control the X-ray exposure settings.

The Software Console contains the DR Detector Switch.

3231A EN 20150710 1114

Page 21

Figure 8: Software Console

DR 400 | Introduction | 21

DR Detector Switch

The DR Detector Switch is available in the device status frame of the Software

Console.

The DR Detector Switch shows which DR Detector is active and shows its

status. The DR Detector Switch can be used to activate another DR Detector.

The DR Detector Switch can be switched to CR, depending on the

configuration.

Figure 9: DR Detector Switch

DR Detector Status

Battery status icon

Meaning Full Medium Low Empty

Connection status icon (wifi/

wired)

3231A EN 20150710 1114

Page 22

?

4 6

1 32

5

8

7

22 | DR 400 | Introduction

DR detector

status icon

Meaning Good Low Bad Wired DR Detector

(blinking)

Meaning Ready Initializing

exposure

Error Sleep One DR detector

X-ray generator mini console

The X-ray generator mini console is available in the operator room.

Power ON button

1.

Power ON indicator

2.

Power OFF button

3.

Press and hold to prepare for exposure

4.

Prepare ready indicator

5.

Press and hold to start the exposure

6.

Radiation indicator

7.

Exposure button

8.

Figure 10: X-ray generator mini console

must be selected

Exposure button

Preparing for exposure

Press the exposure button down to the first pressure point and hold it for

approximately 0.5 s to 2 s.

3231A EN 20150710 1114

Page 23

DR 400 | Introduction |

The X-ray tube is prepared for performing an exposure.

Starting the exposure

Before starting the exposure:

1. Check if the exposure settings displayed on the console are suitable for the

exposure.

2. Check the Ready for Exposure status.

Press the exposure button down fully and keep it pressed until the exposure

has ended.

The radiation indicator on the control console lights up and a signal sounds to

indicate the exposure.

Note: Letting the exposure button go ends the exposure

immediately and the exposure can be underexposed.

23

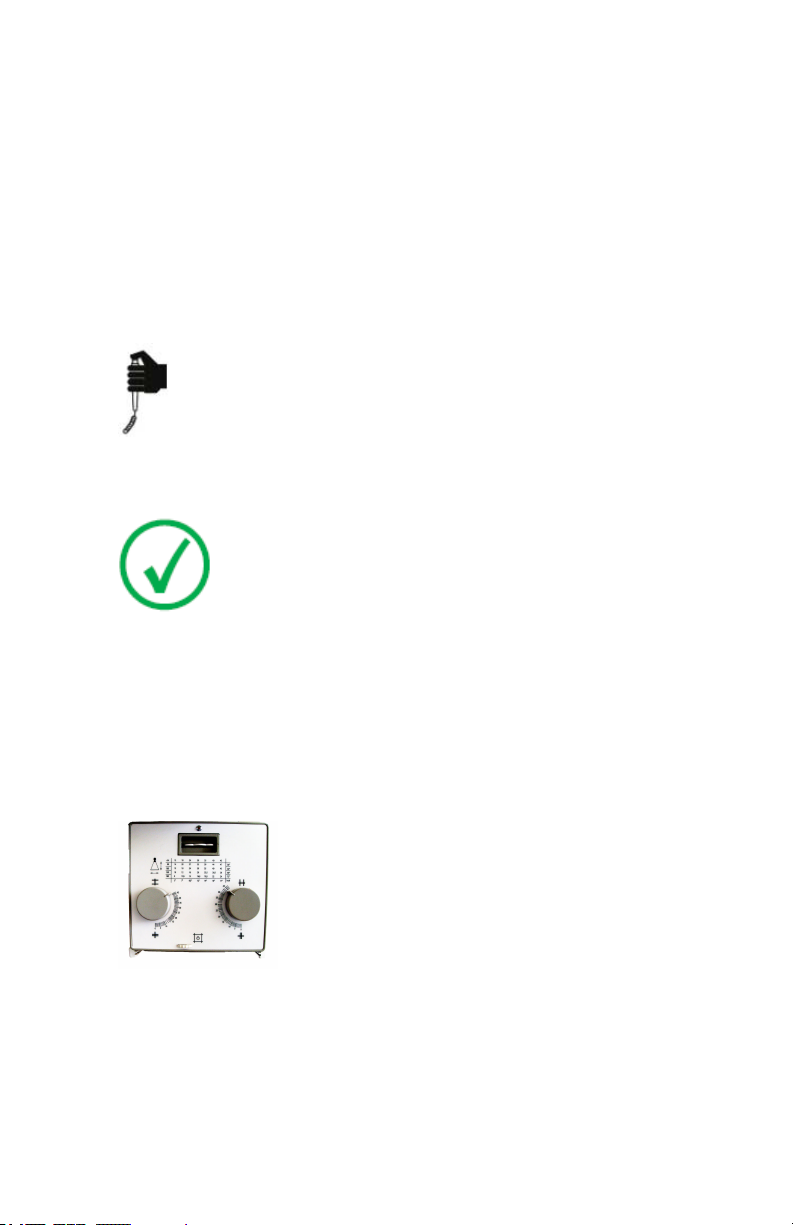

Manual collimator

The collimator sets the exposure field and displays it by means of a light field.

The collimator provides X-ray filtering using the integrated filters or by

inserting a filter in the rails.

A DAP meter (Dose Area Product Meter) can be mounted on the collimator by

inserting it in the rails.

Figure 11: Collimator

Related Links

Ralco R221 Collimator Technical Data on page 167

Automatic collimator

The collimator sets the exposure field and displays it by means of a light field.

3231A EN 20150710 1114

Page 24

24 | DR 400 | Introduction

The collimator provides X-ray filtering using the integrated filters or by

inserting a filter in the rails.

An integrated DAP meter (Dose Area Product Meter) in the collimator is

available as an option.

Figure 12: Collimator

Related Links

Automatic Collimator on page 125

Automatic Cassette Size Sensing on page 114

Ralco R225 ACS Collimator Technical Data on page 168

DR Detector

When performing an exposure, keep in mind the following detector

orientation aids:

1. Tube side

2. Patient orientation marker

For an overview of the operation controls of the DR Detector, refer to the user

manual of the DR Detector.

The DR Detector may come in contact with the patient.

3231A EN 20150710 1114

Note: DR Detectors that operate wireless contain an RF

transmitter. For detailed information, refer to the DR Detector

User Manual.

Page 25

DR 400 | Introduction | 25

Emergency stop button

Figure 13: Emergency stop button

If a system malfunction causes an emergency situation involving the patient,

operating personnel or any system component, activate the emergency stop

on the RAD Table. All motor driven movements will be stopped.

Motor driven movements:

• RAD Table

• RAD Wall Stand

• X-ray tube stand

To allow motorized movements again, turn the cap of the emergency switch in

clockwise direction (default position).

Warning: The emergency stop button does not switch off the

voltage in the X-ray system.

Emergency shutdown power switch

Use the emergency shutdown power switch, if a dangerous situation cannot

be eliminated by pressing the emergency stop button.

Warning: Use the emergency shutdown power switch in

case of danger to patients, operators, third parties, or one of

the units. The entire system will be shut down and the

power supply will be disconnected.

The emergency shutdown power switch for the room is typically located on

the wall and easy to access, often close to the power off switch of the X-ray

system. It is installed and labeled by customer.

3231A EN 20150710 1114

Page 26

26 | DR 400 | Introduction

Warning: It must be ensured that the emergency switches

are always freely accessible.

3231A EN 20150710 1114

Page 27

DR 400 | Introduction | 27

System Documentation

The DR 400 user documentation consists of

• DR 400 User Documentation CD (digital media)

• NX User Documentation CD (digital media)

The DR 400 User Documentation CD contains:

• DR 400 User Manual (this document)

• DX-D Software Console, DR Tube Head Display User Manual, document

0389

• User manuals for the supported DR Detectors

• DX-D DR Detector Calibration Key User manual, document 0134

Other documentation available on the DR 400 User Documentation CD:

• DAP Datasheet

• X-ray Tube Documentation

• Collimator Datasheet

• AEC Datasheet

• X-ray Generator User Manual

• Test Report for IEC60601-1-3

• Test Report for DIN6868-150

3231A EN 20150710 1114

Page 28

28 | DR 400 | Introduction

Training

The user must have received adequate training on the safe and effective use of

the system before attempting to work with it. Training requirements may vary

from country to country. The user must make sure that training is received in

accordance with local laws or regulations that have the force of law. Your

local Agfa or dealer representative can provide further information on

training.

The user must note the following information in the system documentation:

• Intended Use.

• Intended User.

• Safety Directions.

3231A EN 20150710 1114

Page 29

DR 400 | Introduction | 29

Product Complaints

Any health care professional (for example a customer or a user) who has any

complaints or has experienced any dissatisfaction with the quality, durability,

reliability, safety, effectiveness, or performance of this product must notify

Agfa.

If the device malfunctions and may have caused or contributed to a serious

injury, Agfa must be notified immediately by telephone, fax or written

correspondence to the following address:

Agfa Service Support - local support addresses and phone numbers are listed

on www.agfa.com

Agfa - Septestraat 27, 2640 Mortsel, Belgium

Agfa - Fax +32 3 444 7094

3231A EN 20150710 1114

Page 30

30 | DR 400 | Introduction

Compatibility

The system must only be used in combination with other equipment or

components if these are expressly recognized by Agfa as compatible. A list of

such equipment and components is available from Agfa service on request.

Changes or additions to the equipment must only be carried out by persons

authorized to do so by Agfa. Such changes must comply with best engineering

practice and all applicable laws and regulations that have the force of law

within the jurisdiction of the hospital.

3231A EN 20150710 1114

Page 31

Compliance

The system is compliant with specific directives and standards.

Topics:

• General

• Safety

• Electromagnetic Compatibility

• X-Ray Safety

• X-Ray Accuracy

• Environmental Compliance

• Biocompatibility

General

• The product has been designed in accordance with the MEDDEV

Guidelines relating to the application of Medical Devices and have been

tested as part of the conformity assessment procedures required by

93/42/EEC Medical Device Directive (European Council Directive

93/42/EEC on Medical Devices).

• ISO 13485:2003 + Cor. 1:2009

• ISO 14971:2009

DR 400 | Introduction |

31

Safety

• IEC 60601-1: 2005

• IEC 60601-1-6:2006, EN 60601-1-6:2007

• CSA C22.2 60601-1:2008

• AAMI ES 60601-1:2005

Electromagnetic Compatibility

• IEC 60601-1-2:2007, EN 60601-1-2:2007

Topics:

• For USA

• For Canada

For USA

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the installation manual, may cause harmful

3231A EN 20150710 1114

Page 32

32 | DR 400 | Introduction

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense. If required,

contact your local service organization.

For Canada

This class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

X-Ray Safety

• IEC 60601-1-3:2008

• IEC 60601-2-54:2009

• IEC 60601-2-28:2010

For USA

The system conforms to DHHS radiation Standards of 21CFR subchapter J as

of the date of manufacture.

X-Ray Accuracy

The system fulfills the X-ray radiation accuracy according EN IEC 60601-2-54

with a variation of max. 0.05 (5%).

Environmental Compliance

• European Council Directive 1907/2006 (REACH)

• European Council Directive 2011/65/EU (RoHS 2)

• European Council Directive 2012/19/EU (WEEE)

Biocompatibility

• EN ISO 10993-1:2009

3231A EN 20150710 1114

Page 33

DR 400 | Introduction | 33

Connectivity

The NX workstation is connected to the X-ray system to exchange X-ray

exposure parameters.

The NX workstation requires a 100 Mbit ethernet network to exchange

information with a number of other devices.

The NX workstation communicates with other devices in the hospital network

using one of the following protocols:

• DICOM

• IHE

The NX workstation can be connected to a RIS system (input scheduling), a

PACS system (output image/data management) and to a hardcopy device

(output image).

Note: The connections between the components of the system are

separate from the hospital network and should not be disconnected

or modified.

3231A EN 20150710 1114

Page 34

34 | DR 400 | Introduction

Installation

Installation and configuration is performed by an Agfa trained and authorized

service engineer. Contact your local support organization for more

information.

On a configuration with multiple DR Detectors of the same type, it is required

to apply labeling to the DR Detector containing a unique nickname for each

DR Detector. The nicknames must be configured on the NX Workstation. The

DR Detector Switch shows which DR Detector is active and shows its status, by

means of the nickname of the DR Detector.

An identical label is attached to the bucky of the X-ray system to identify the

dedicated workspace of each DR Detector.

HF-emission and immunity

The HF-emission and immunity can be influenced by connected data cables

depending on length and the manner of installation.

A specific installation environment may require special measures to put the

system into operation according to the remarks for HF-emission and

immunity.

Related Links

Cables, transducers and accessories

3231A EN 20150710 1114

Page 35

DR 400 | Introduction |

Radiation Protection

X-ray radiation can cause serious damage to the health, therefore observe

great care and ensure that protection against X-ray exposure is always

applied.

Some of the effects of X-ray radiation are cumulative and may extend over a

period of time. Therefore the X-ray operator should avoid exposure by X-ray

radiation at all times.

Objects in the path of the X-ray beam may produce scattered radiation. The

intensity depends on the energy and intensity of the X-ray exposure and the

material of the object. Protective measures have to be taken to prevent

exposure through scattered radiation.

Protective measures include:

• structural configuration of the X-ray room (e.g. lead shielded rooms)

• radiation protection for the operators (e.g. personal radiation dosimeters,

lead aprons, keep maximum distance from X-ray source, regular training,

etc.)

• protection of patients against unnecessary radiation (e.g. limitation of Xray field by collimation, lead shielding, lead aprons, etc.)

Topics:

35

• Monitoring of Personnel

• Protected area and significant zones of occupancy

Monitoring of Personnel

The monitoring checks the amount of X-ray radiation the personnel has been

exposed to. It determines safety of the operators and it helps checking if safety

measures of the X-ray environment are adequate. Inadequate or improper

protection can lead to serious damage to the health.

To measure radiation, personal radiation dosimeters are typically used. They

are worn on the body at all times during working in an environment where Xray radiation is applied. They provide an indication for the amount of

radiation the operator was exposed to.

Protected area and significant zones of occupancy

If the operator or staff does not need to be close to the patient during the

exposure, the operator and staff use the protected area to control the

following functions:

• selection of mode of operation

• selection of exposure settings (X-ray loading factors)

• actuation of the exposure button

• other necessary controls for the operator during exposure

3231A EN 20150710 1114

Page 36

1

4

3

2

36 | DR 400 | Introduction

X-ray room

1.

Patient environment

2.

Workstation

3.

Operator room: protected area

4.

Figure 14: Protected area and significant zones of occupancy

Warning: The radiation protection has to be applied to the

patient.

If operator or staff needs to be close to the patient during normal use (e.g.

some pediatric examinations or types of examinations for which the patient

requires assistance), the significant zone of occupancy applies for operator

and staff.

Warning: The radiation protection has to be applied to the

patient and to the operator.

Related Links

Radiation Protection on page 35

Topics:

• Significant zones of occupancy at the RAD Table

• Significant zones of occupancy at the RAD Wall Stand

3231A EN 20150710 1114

Page 37

Significant zones of occupancy at the RAD Table

S

SID 100 cm

S3

S4

S5

S

50 cm

4

2

3

1

2

5

2

1

6

8

7

DR 400 | Introduction |

37

X-ray tube

1.

Focal spot label [—]

2.

Significant zone of occupancy.

3.

Minimum area 60x60 cm.

Minimum height above the floor 200 cm.

Dose meter

4.

DR Detector or cassette

5.

Significant zone of occupancy at the left side of the RAD Table

6.

Significant zone of occupancy in front of the RAD Table

7.

Significant zone of occupancy at the right side of the RAD Table

8.

Figure 15: Significant zones of occupancy at the RAD Table

Related Links

3231A EN 20150710 1114

Page 38

140 cm

SID115 cm

Phantom

S1

S2

S

S

50 cm

1

2

3

4

2

5

6

7

2

1

8

9

38 | DR 400 | Introduction

Radiation Protection on page 35

Stray Radiation on page 186

Significant zones of occupancy at the RAD Wall Stand

X-ray tube

1.

Focal spot label [—]

2.

Significant zone of occupancy.

3.

Minimum area 60x60 cm.

Minimum height above the floor 200 cm.

Dose meter

4.

Protective device

5.

Wall

6.

DR Detector or cassette

7.

Significant zone of occupancy at the right side of the RAD Table

8.

3231A EN 20150710 1114

Page 39

Significant zone of occupancy at the left side of the RAD Table

9.

Figure 16: Significant zones of occupancy at the RAD Wall Stand

Warning: The radiation protection has to be applied for the

patient and for the operator.

Related Links

Radiation Protection on page 35

Stray Radiation on page 186

DR 400 | Introduction | 39

3231A EN 20150710 1114

Page 40

| DR 400 | Introduction

40

Labels

Mark Meaning

Label Meaning

This mark shows compliance of the equipment with Directive

93/42/EEC (for European Union).

This mark indicates that this is a Type B Equipment

Serial number

Manufacturer

Date of manufacture

Dangerous voltage

Ionizing radiation

Gaseous disinfectant.

If a disinfectant is used that can form an explosive gaseous

mixture, they must have evaporated and the system must be

aerated before it is switched on again.

Pinch Points.

Risk of stumbling.

Further labels are listed and explained in the relevant modules of the System

Documentation.

Topics:

• Warning labels on the RAD Table

3231A EN 20150710 1114

Page 41

• Warning labels on the RAD Wall Stand

• Type label

• DR Detector identification label

• Additional Labeling of the RAD Table

• Additional Labeling of the RAD Wall Stand

• Labeling of the bucky

• Labeling of the DR Generator Sync Box

Warning labels on the RAD Table

DR 400 | Introduction | 41

Figure 17: Warning labels on the RAD Table

Warning labels on the RAD Wall Stand

Figure 18: Warning labels on the RAD Wall Stand

3231A EN 20150710 1114

Page 42

1

42 | DR 400 | Introduction

Type label

Mark Meaning

(Sample of subtype 5520/100)

Type label positioned on the

lower left hand side of the X-ray

tube stand.

The type label information for

each combination of X-ray tube

and X-ray generator is available

in the technical data.

Note: The CE sign and

safety signs are only

valid at time of product

release.

This mark indicates that this is a

Type B Equipment

Related Links

DR 400 Technical Data on page 153

DR Detector identification label

Label Meaning

3231A EN 20150710 1114

The 21 CFR Subchapter J label is

positioned close to the type label.

Writable label to identify and dedicate a DR Detector to an Xray system bucky.

Page 43

Additional Labeling of the RAD Table

5521/210

Type label on the lower left hand side of the

X-ray tube stand.

The type label information for each

combination of X-ray tube and X-ray

generator is available in the technical data.

(sample of subtype 5521/210)

DR 400 | Introduction | 43

(sample of subtype 5521/410)

This mark indicates that this is a Type B

Equipment

The RAD table is designed for a maximum

patient load of 320 kg.

Related Links

RAD Table and X-Ray Tube Stand Technical Data on page 157

Additional Labeling of the RAD Wall Stand

Type label on the lower right hand side of the

RAD Wall Stand stand

The type label information for each

combination of X-ray tube and X-ray

generator is available in the technical data.

3231A EN 20150710 1114

Page 44

10kg

44 | DR 400 | Introduction

(Sample of subtype

5522/100)

Related Links

RAD Wall Stand Technical Data on page 160

Labeling of the bucky

This mark indicates that this is a Type B

Equipment

Functional earth

The bucky can be tilted to horizontal

position. Do not use the bucky as a seat.

A pinch point label is located on top of the

tilting extension.

The type label is located on the rear cover

of the bucky or on the bucky drawer below

the rotating platform.

The type label information for each bucky

model is available in the technical data.

(Sample of subtype 5523/100)

3231A EN 20150710 1114

Class II equipment.

Pinch Points.

The label is positioned on the lateral cover

of the bucky or on the rotating platform.

Maximum load capacity is 10 kg on the

bucky drawer when it is pulled out. Do not

lean or sit on the bucky.

The label is positioned on the lateral cover

of the bucky or on the rotating platform.

Read the instructions in the user manual.

The label is positioned on the lateral cover

of the bucky or on the rotating platform.

Page 45

Compliance with China RoHS SJ/

T11364-2006. Indication of the

Environment Friendly Use Period (EFUP)

as the period (years) during which the

hazardous substances do not leak or mutate

under normal use.

The label is located on the rear cover of the

bucky or on the bucky drawer below the

rotating platform.

Related Links

Bucky Unit Technical Data on page 164

Labeling of the DR Generator Sync Box

The type label is located on the DR Generator

Sync Box

Functional earth

DR 400 | Introduction | 45

Medical equipotential

3231A EN 20150710 1114

Page 46

46 | DR 400 | Introduction

Cleaning and Disinfecting

All appropriate policies and procedures should be followed to avoid

contamination of the staff, patients and equipment. All existing universal

precautions should be extended to avoid potential contaminations and to

avoid patients coming into (close) contact with the device. The user is

responsible for selecting a disinfection procedure.

Topics:

• Cleaning

• Disinfecting

• Disinfecting safety directions

• Approved disinfectants

Cleaning

To clean the exterior of the equipment:

1. Stop the system

2. Wipe the exterior of the system with a cloth slightly moistened with a

neutral detergent.

Warning: When the equipment is going to be cleaned, be

sure to turn off the main power of the system. Never use

anhydrous or high solvency alcohols, benzine, thinner or

any other flammable cleaning agent. Otherwise, it may

result in fire or electric shock.

Caution: Make sure no liquid gets in the device.

3231A EN 20150710 1114

Caution: Clean the equipment with only a little moisture. Do

not spray disinfectants or detergents directly on the

equipment. Do not pour liquid directly on the equipment.

Caution: Do not use solvents such as anhydrous or high

solvency alcohols, thinner or benzine. Do not use any

corrosive, dissolving or abrasive cleaning or polishing

detergents. Doing so may damage the surface of the

equipment. Using unsuitable cleaning agents or methods can

damage the property when surface becomes dull and brittle.

Page 47

DR 400 | Introduction |

Note: Do not open the equipment for cleaning. No

components inside the device require cleaning by the user.

3. Start up the system.

Cleaning the tube head display during operation

To clean the tube head displayed during operation

1. Press the tools button

Figure 19: Tools button

2. Press the cleaning button

Figure 20: Cleaning button

A black screen hides the screen and shows a number counting down.

3. Clean the display.

The operation is not affected.

4. The display can be used again after the countdown has finished.

47

Disinfecting

To disinfect the device, use only disinfectants and disinfection methods that

are approved by Agfa and that correspond to the national regulation and

guidelines as well as explosion protection. If you plan to use other

disinfectants, approval of Agfa is needed before use, as most disinfectants can

damage the device. UV disinfection is also not allowed.

Perform the procedure following the instructions for use, the disposal

instructions and the safety instructions of the selected disinfectants and tools

and of the hospital.

Disinfecting safety directions

Warning: Using a disinfectant that can form an explosive or

flammable gas mixtures is hazard to life and health because

of explosion risk. Switch the equipment off before

disinfecting. Allow the gas mixture to evaporate before

switching the x-ray system back on.

To disinfect the device:

• Do not use any corrosive, soluble or gaseous disinfectants.

• Use of spray disinfection can cause malfunctions due to ingress of the

disinfectant into the equipment. Disinfect all parts of the unit, including

3231A EN 20150710 1114

Page 48

48 | DR 400 | Introduction

the accessories and connection cables by just wiping them. Switch off the

system and cover the cooled system carefully before performing a room

disinfection using nebuliser.

• Using unsuitable disinfectants can cause discoloration and damage of the

surface of the equipment.

Approved disinfectants

Refer to the Agfa website for specifications on the disinfectants that have been

found compatible with the cover material of the device and can be used on the

outer surface of the device.

http://www.agfahealthcare.com/global/en/main/products_services/

product-info/technology/disinfectants_dx_d_systems.jsp

3231A EN 20150710 1114

Page 49

DR 400 | Introduction | 49

Patient data security

The user must ensure that the patients’ legal requirements are met and that

the security of the patient data is guarded.

The user must define who can access patient data in which situations.

The user must have a strategy available on what to do with patient data in

case of a disaster.

3231A EN 20150710 1114

Page 50

50 | DR 400 | Introduction

Maintenance

Always consult the Agfa Service documentation and an AGFA trained and

authorized Service engineer for complete maintenance schedules.

Topics:

• Maintenance

• Maintenance of the RAD Table, RAD Wall Stand and X-Ray Tube Stand

Maintenance

Always consult the Agfa Service documentation and an Agfa trained and

authorized Service engineer for complete maintenance schedules.

Maintenance of the DR Detector

The DR Detector requires regular calibration. Calibration instructions are

described in the DX-D DR Detector Calibration Key User Manual (doc 0134).

Maintenance of the RAD Table, RAD Wall Stand and X-Ray Tube Stand

The X-ray unit and all components require regular maintenance to ensure the

equipment is safe and reliable for operation.

Warning: Operation in unsafe condition includes the risk of

radiological exposure and injury of the patient and/or the

operator. The customer is responsible to ensure the faultfree condition of the equipment.

3231A EN 20150710 1114

Warning: Improper, irregular or lack of maintenance of the

equipment can lead to injuries to persons (e.g. by radiation

hazard) and property damage as a result of malfunctions

and defects of the equipment.

Warning: Wear of equipment due to excessively long

intervals between service may lead to personal injury and

property damage due to worn and unsafe parts.

Warning: Incorrect or defective spare parts may adversely

affect the safety of the system and lead to damages,

malfunctions or total failure. Use only original spare parts

provided by the manufacturer.

Warning: Improper changes, additions, maintenance or

repair of the system can lead to personal injury and damage

to the equipment. Safety is only guaranteed when changes,

Page 51

DR 400 | Introduction | 51

additions, maintenance or repairs are carried out by an Agfa

certified field service engineer.

Table 2: Lifetime and maintenance

Lifetime

Expected lifetime for the X-ray unit 10 years

Periodic maintenance

The equipment shall have a technical maintenance to

maintain fault-free operation and ensure safety for

patient and operator.

All steel cables of X-ray tube stand and RAD Wall Stand

shall be checked

All steel cables of X-ray tube stand and RAD Wall Stand

shall be exchanged to maintain fault-free operation and

ensure safety for patient and operator

Maintenance by the user

Check constant smooth movements Daily

Check ease of movements Daily

Check secure release and locking of brakes Daily

Check functioning of operating controls Daily

Check markers and warning signs Daily

Warm-up of X-ray tube Daily

Check all electric cables and connections for damage or

broken cables.

Caution: In case of functional defects or other deviations from

normal operation behavior the unit has to be switched off

immediately and the service to be informed. The equipment

must only be put back into operation when the fault has been

repaired.

Caution: The use of spare parts from third party suppliers can

affect the safety of the equipment. If components fail, use only

original spare parts.

Every 12 months

Every 12 months

Every 36 months

Weekly

3231A EN 20150710 1114

Page 52

52 | DR 400 | Introduction

Warming-up of X-ray tube

The X-ray tube needs to be warmed-up before making X-ray exposures at the

start of each day and when the X-ray tube has not been in use for more than an

hour. This extends the X-ray tube lifetime.

To warm-up the X-ray tube

1. Close the collimator blades fully

2. Select 70 kV, 100 mAs, 200 mA and 500 ms exposure settings

3. Ensure that no one will be exposed

4. Make a total of three exposures, 15 seconds apart

This procedure is used for a typical X-ray tube. Consult the X-ray tube

manufacturer instructions for the actual X-ray tube in use and comply with the

instructions if there is conflict with this procedure.

3231A EN 20150710 1114

Page 53

DR 400 | Introduction | 53

Environmental protection

Figure 21: WEEE symbol

Figure 22: Battery symbol

WEEE end user notice

The directive on Waste Electrical and Electronic Equipment (WEEE) aims to

prevent the generation of electric and electronic waste and to promote the

reuse, recycling and other forms of recovery. It therefore requires the

collection of WEEE, recovery and reuse or recycling.

Due to the implementation into national law, specific requirements can be

different within the European Member States. The WEEE symbol on the

products, and/or accompanying documents means that used electrical and

electronic products should not be treated as, or mixed with general household

waste For more detailed information about take-back and recycling of this

product please contact your local service organization and/or dealer. By

ensuring this product is disposed of correctly, you will help prevent potential

negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. The

recycling of materials will help to conserve natural resources.

Battery notice

The battery symbol on the products, and/or accompanying documents means

that the used batteries should not be treated as, or mixed with general

household waste. The battery symbol on batteries or its packaging may be

used in combination with a chemical symbol. In cases where a chemical

symbol is available it indicates the presence of respective chemical substances.

If your equipment or replaced spare parts contain batteries or accumulators

please dispose of them separately according to local regulations.

For battery replacements please contact your local sales organization.

3231A EN 20150710 1114

Page 54

54 | DR 400 | Introduction

Safety Directions

Topics:

• General Safety Directions

• Safety Directions for the X-Ray System

• Safety Directions for the RAD Table

General Safety Directions

Warning: Strictly observe all warnings, cautions, notes and

safety markings within this document and on the product.

Warning: Safety is only guaranteed when an Agfa certified

field service engineer has installed the product.

Warning: The product must only be installed using released

components and in released configurations.

3231A EN 20150710 1114

Warning: To avoid risk of electric shock, this equipment

must only be connected to a supply mains with protective

earth.

Warning: All Agfa medical products must be used by trained

and qualified personnel.

Warning: Ionizing radiation can lead to radiation injuries if

handled incorrectly. When radiation is applied, the required

protective measures must be complied with.

Warning: The operator and end-user must take precautions

to protect themselves against dangerous X-ray exposure

when using the DR Detector in the X-ray beam path of an Xray source.

Warning: The DR Detector is not intended to be used as a

primary barrier to X-rays. The user is responsible for

ensuring the safety of the operator, bystanders, and the

subjects being radiographed.

Page 55

Warning: Operating the equipment when it is faulty

includes the risk of radiological exposure and injury to the

patient and to the operator. Operate the equipment only in

safe and fault-free conditions.

Safety Directions for the X-Ray System

Warning: Avoid unnecessary dose by checking before

exposure if the DR Detector Switch displays the name of the

DR Detector that is being used and if the status of the DR

Detector is ready for exposure.

Warning: Avoid unnecessary dose by checking the

workstation selection on the X-ray generator console before

exposing. In a configuration with a DR Detector configured

on a virtual port, the DR Detector will not be triggered if a

free exposure is selected on the Generator console and yet

the exposure will be allowed.

Warning: Repeated exposures to a patient with high doses

can lead to deterministic effects. Therefore exposure

settings shall be selected carefully and in accordance to the

patient and the object to expose and balanced in such a way

that patient dose is as low as possible while image quality is

usable for diagnosis.

Warning: Even if the generator is switched off, parts on the

inside of the generator cabinet and connected controls are

still powered! Ensure that only trained service personnel

open the generator cabinet and the housing of connected

devices! Improper handling may cause a lethal hazard!

Caution: When operating the DR detector, the calculated

exposure time (ms) or manual overrides should never exceed

the maximum exposure time (Max ms) specified as integration

time of the DR detector.

DR 400 | Introduction | 55

Caution: Damaged grid. Reduced image quality. Please handle

the grids with special care.

Caution: When inserting the scattered radiation grids, it is

essential that the grid corresponds to the intended sourceimage-distance (SID) to which the grid is focussed. Because of

the focussing of the grids, the tube unit must be centered onto

the bucky.

3231A EN 20150710 1114

Page 56

56 | DR 400 | Introduction

Caution: Excessive ambient temperature may impact

performance of DR Detectors and cause permanent damage to

the equipment. If ambient temperature and humidity is outside

the range specified in the technical data, do not operate the

system or use air conditioning. Warranty will be void if it is

obvious that operating conditions are not met.

Caution: To avoid images being lost due to a power failure, the

workstation and the digitizer have to be connected to an

uninterruptable power supply (UPS) or an institutional standby

generator.

Caution: Install the NX workstation and CR digitizer at a

minimum (safe) distance of 2 m from the X-Ray System

components or provide a wall or window to separate both

systems.

Safety Directions for the RAD Table

Warning: The system is not intended for operation in

explosion-prone areas. Such an operation is hazardous to

life and health because of explosion risk. Please note the

applicable regulations on formation of explosive gas

mixtures when cleaning and using in combination with

patients.

Warning: Unauthorized manipulation or opening of the

equipment housing may lead to personal injuries and to

property damage. Take all necessary precautions with

respect to the applicable level of safety.

3231A EN 20150710 1114

Warning: The system is installed with components that emit

radiation or can be triggered to emit radiation. Ionizing

radiation can result in radiation damage or injury if not

handled properly.

Warning: Portable and mobile HF communication devices

may affect medical electrical equipment.

Caution: Using soft covers, sheets, mattresses, etc. may lead to

visual image artifacts. If such shall be used, make sure that they

are x-ray transparent and do not influence image quality.

Page 57

DR 400 | Introduction | 57

Caution: Make sure that the patient hand grips are securely

mounted.

3231A EN 20150710 1114

Page 58

58 | DR 400 | Getting started

Getting started

Topics:

• Starting the System

• Basic workflow using the DR Detector

• Basic workflow using a CR cassette

• X-Ray System Positioning

• Guidelines for Pediatric Applications

• Stopping the System

3231A EN 20150710 1114

Page 59

DR 400 | Getting started | 59

Starting the System

To start the system:

Note: Allow the DR Detector to warm up before the system is used

for clinical purposes. The warming-up time starts as soon as the DR

Detector has been powered on and the NX workstation is running.

To check if a warming-up time is required, refer to the DR Detector

User Manual.

1. Switch on the electrical room switch.

Check that the emergency shutdown power switch for the system and the

emergency stop button for the RAD Table is not activated.

2. Press the Power ON button on the X-ray generator control box to switch on

the system.

3. Start the NX workstation.

The NX application and the software console are available on the NX

workstation.

For detailed information about starting up NX, refer to the NX User

Manual, document 4420.

4. Switch on the DR Generator Sync (if applicable).

5. In a configuration with a wireless DR Detector, power on the DR Detector:

• attach a fully charged battery pack to the DR Detector.

• turn on the DR Detector.

• if needed, register the DR Detector to the NX workstation.

For detailed information about starting up the DR Detector, refer to the

DR Detector User Manual.

6. Switch on the control unit for the DR Detector.

3231A EN 20150710 1114

Page 60

60 | DR 400 | Getting started

Basic workflow using the DR Detector

Topics:

• Step 1: retrieve the patient info

• Step 2: select the exposure

• Step 3: prepare the exposure

• Step 4: check the exposure settings

• Step 5: execute the exposure

• Step 6: perform a quality control

3231A EN 20150710 1114

Page 61

DR 400 | Getting started | 61

Step 1: retrieve the patient info

At the NX workstation:

1. When a new patient comes in, define the patient info for the exam.

2. Start the exam.

3231A EN 20150710 1114

Page 62

62 | DR 400 | Getting started

Step 2: select the exposure

In the operator room:

At the NX workstation, select the thumbnail for the exposure in the Image

Overview pane of the Examination window.

The default X-Ray exposure parameters for the selected exposure are sent

to the modality and displayed on the Software Console.

The selected DR Detector is activated.

The RAD Table or RAD Wall Stand lights up in blue, indicating the

selected modality position.

The DR Detector Switch shows which DR Detector is active and shows its

status.

• Red (flashing): starting up

• Green (constant): ready for exposure

3231A EN 20150710 1114

Page 63

DR 400 | Getting started | 63

Step 3: prepare the exposure

In the examination room:

1. Position the DR Detector.

When using the bucky, check that the identification labels on the DR

Detector and on the bucky match. Do not use a DR Detector that is

dedicated to another bucky.

2. Position the patient.

Apply radiation protective measures for the patient if needed.

3. Check if the X-Ray system position is suitable for the exposure.

4. Position the X-Ray tube with respect to the DR Detector and the patient.

5. Set the correct distance between DR Detector and X-Ray tube.

6. Switch on the light on the collimator. Adapt collimation if required.

Take care that the collimated area is not larger than the detector.

Warning: Monitor the patient position (hands, feet, fingers,

etc.) with special care to avoid injury to the patient caused

by unit movements. Patient hands must be kept away from

mobile components of the unit. Intravenous tubing,

catheters and other patient connected lines should be

routed away from moving equipment.

3231A EN 20150710 1114

Page 64

64 | DR 400 | Getting started

Step 4: check the exposure settings

Related Links

DR Detector Switch on page 21

On the NX application:

1. Check if the DR Detector Switch displays the name of the DR Detector

that's being used

2. If a wrong DR Detector is displayed, select the right DR Detector by

clicking the drop down arrow on the DR Detector Switch.

3. Check if the status of the DR Detector is ready for exposure.

On a DR Detector that has a status indicator:

Check if the status of the DR Detector is ready for exposure. If the status is

not ready for exposure, the DR Detector cannot be used for making an

exposure.

In the operator room on the Software Console:

1. Check if the exposure settings displayed on the console are suitable for the

exposure.

2. Check the Ready for Exposure status.

3231A EN 20150710 1114

Page 65

Step 5: execute the exposure

In the operator room:

Press the exposure button to execute the exposure.

Instruction: Make sure the generator is ready for exposure

before you press the exposure button.

Warning: During exposure ionizing radiation is emitted

by the X-ray system. To indicate the presence of ionizing

radiation, the radiation indicator on the control console

lights up.

Warning: Do not select another thumbnail until the

preview image is visible in the active thumbnail.

In the operator room at the NX workstation:

• While the acquisition is ongoing, the thumbnail status indicator is

flashing green. The image is acquired from the DR detector and

displayed in the thumbnail.

• The actual X-Ray exposure parameters are sent back from the

generator to the NX workstation and are shown in the Image Detail

pane.

• If collimation is applied, the image is automatically cropped at the

collimation borders.

DR 400 | Getting started | 65

3231A EN 20150710 1114

Page 66

66 | DR 400 | Getting started

Step 6: perform a quality control

At the NX workstation:

1. Select the image on which quality control is to be performed.

2. Prepare the image for diagnosis by using e.g. L/R markers or annotations.

3. If the image is OK, send the image to a hardcopy printer and/or PACS

(Picture Archiving and Communication System).

3231A EN 20150710 1114

Page 67

Basic workflow using a CR cassette

Note: Using an ID Tablet to identify cassettes before the exposure

will break the communication of X-ray parameters between the NX

workstation and the X-ray generator console. It is advised to

identify cassettes after the exposure, as described in this workflow.

Topics:

• Step 1: retrieve the patient info

• Step 2: select the exposure

• Step 3: prepare the exposure

• Step 4: check the exposure settings

• Step 5: execute the exposure

• Step 6: repeat steps 2 to 5 for the next subexposures

• Step 7: digitize the image

• Step 8: perform a quality control

DR 400 | Getting started | 67

3231A EN 20150710 1114

Page 68

68 | DR 400 | Getting started

Step 1: retrieve the patient info

At the NX workstation:

1. When a new patient comes in, define the patient info for the exam.

2. Start the exam.

3231A EN 20150710 1114

Page 69

DR 400 | Getting started | 69

Step 2: select the exposure

In the operator room at the NX workstation:

1. Select the thumbnail for the exposure in the Image Overview pane of the

Examination window.

2. Select CR in the Detector Switch.

3. Select the Modality Position (RAD Table, RAD Wall Stand, Free exposure)

in the Software Console.

The default X-Ray exposure parameters for the selected exposure are sent

to the modality and displayed on the software console.

The RAD Table or RAD Wall Stand lights up in blue, indicating the

selected modality position.

4. Select the subexposure if more than one image is required for the same

cassette.

If an image thumbnail is configured for multiple exposures on a single

cassette, another set of thumbnails is shown in the image detail pane. Now

you have to select one of these thumbnails to send the proper default XRay exposure parameters to the modality for each exposure.

Note: When working in a PACS environment, the preferred

workflow is to have only one image per cassette. This is needed

for optimal use of hanging protocols. However, in particular

cases (e.g. printing sites) it is supported to make more than one

exposure per cassette.

3231A EN 20150710 1114

Page 70

70 | DR 400 | Getting started

Step 3: prepare the exposure

In the examination room:

1. Position the cassette.

2. Position the patient.

Apply radiation protective measures for the patient if needed.

3. Check if the X-Ray system position is suitable for the exposure.

4. Position the X-Ray tube with respect to the cassette and the patient.

5. Set the correct distance between cassette and X-Ray tube.

6. Switch on the light on the collimator. Adapt collimation if required.

Take care that the collimated area is not larger than the cassette.

Note: For a free exposure, partial lead covering of the

cassette may be required if multiple images are taken on one

cassette.

Note: For a bucky exposure, always insert an unexposed

cassette in the bucky.

3231A EN 20150710 1114

Warning: Monitor the patient position (hands, feet, fingers,

etc.) with special care to avoid injury to the patient caused

by unit movements. Patient hands must be kept away from

mobile components of the unit. Intravenous tubing,

catheters and other patient connected lines should be

routed away from moving equipment.

Page 71

DR 400 | Getting started | 71

Step 4: check the exposure settings

In the operator room on the Software Console:

1. Check if the exposure settings displayed on the console are suitable for the

exposure.

2. Check the Ready for Exposure status.

3231A EN 20150710 1114

Page 72

72 | DR 400 | Getting started

Step 5: execute the exposure

In the operator room:

Press the exposure button to execute the exposure.

Warning: During exposure ionizing radiation is emitted by

the X-ray system. To indicate the presence of ionizing

radiation, the radiation indicator on the control console

lights up.

• The actual X-Ray exposure parameters are sent back from the generator to

the NX workstation and are shown in the Image Detail pane.

• The actual X-Ray exposure parameters and the Exposure Index (EI) value

on the NX workstation can be used to monitor the performance of the

Automatic Exposure Control of the X-Ray system.

• A green OK mark appears on all thumbnails for which the exposures are

made and for which exposure settings are sent back to the NX workstation.

3231A EN 20150710 1114

Page 73

DR 400 | Getting started | 73

Step 6: repeat steps 2 to 5 for the next subexposures

3231A EN 20150710 1114

Page 74

74 | DR 400 | Getting started

Step 7: digitize the image

In the examination room:

Take the exposed cassette.

In the operator room:

1. Insert the cassette in the digitizer.

2. Click ID in the examination window of NX.

The image will appear in the image overview pane of the examination

window.

Note: You can also use an ID Tablet to identify the cassette

and digitize it using any digitizer.

3231A EN 20150710 1114

Page 75

DR 400 | Getting started | 75

Step 8: perform a quality control

In the operator room at the NX workstation:

1. Select the image on which quality control is to be performed.

2. Prepare the image for diagnosis by using e.g. L/R markers or annotations.

3. If the image is OK, send the image to a hardcopy printer and/or PACS

(Picture Archiving and Communication System).

3231A EN 20150710 1114

Page 76

76 | DR 400 | Getting started

X-Ray System Positioning

Topics:

• RAD Table Exposures

• Oblique Exposures

• Lateral Exposures

• RAD Wall Stand Exposures

3231A EN 20150710 1114

Page 77

DR 400 | Getting started | 77

RAD Table Exposures

1. Position the patient on the RAD table.

2. Position the X-ray tube stand with the X-ray tube over the patient.

The bucky is automatically aligned to the X-ray tube by mechanical

coupling.

3. Center the examined body part over the bucky using the floating table top.

Figure 23: RAD Table Exposures

3231A EN 20150710 1114

Page 78

78 | DR 400 | Getting started

Oblique Exposures

1. Position the patient on the RAD Table.

2. Move the X-ray tube stand out of the coupling range of the bucky.

3. Position the bucky under the patient.

4. Set the required angle of the X-ray tube.

5. Adjust the position of the X-ray tube stand to align the X-ray exposure field

to the center of the bucky using the collimator light and the bucky markers

for orientation.

Figure 24: Oblique Exposures

3231A EN 20150710 1114

Page 79

DR 400 | Getting started | 79

Lateral Exposures

1. Unlock the X-ray tube arm and rotate 90° around.

2. Rotate the X-Ray tube 90° around.

Check the angle on the angle display.

3. Mount the lateral cassette holder on the side rail of the tabletop. Fix it

using the two lower screws. Take care to lift the holders slightly up when

moving it, to protect the tabletop from scratching.

4. Insert a cassette or a DR detector. Fix it using the upper screw.

5. Position the patient on the table between the X-ray tube and the lateral

cassette holder. Adjust the lateral cassette holder to position the cassette

as close as possible to the patient. Fix the position using the middle screw.

Figure 25: Lateral Exposures

3231A EN 20150710 1114

Page 80

80 | DR 400 | Getting started

RAD Wall Stand Exposures

1. Adjust the height of the bucky on the RAD Wall Stand.

2. Position the patient in front of the RAD Wall Stand.

3. Move the table top away from the RAD Wall Stand.

4. Rotate the X-ray tube 90° to face the RAD Wall Stand.

Check the angle on the angle display.

5. Move the X-ray tube stand towards the RAD Wall Stand.

6. Adjust the height of the X-ray tube to center the X-ray exposure field on

the bucky using the collimator light.

Figure 26: RAD Wall Stand Exposures

3231A EN 20150710 1114

Page 81

DR 400 | Getting started |

Guidelines for Pediatric Applications

Caution: Children are more radiosensitive than adults. Adopting

the Image Gently campaign guidelines and reducing dose for

radiographic procedures while maintaining acceptable clinical

image quality will benefit patients.

Please review the following link and reduce pediatric technique factors

accordingly: http://www.pedrad.org/associations/5364/ig/

As a general rule, next recommendations shall be observed in pediatrics:

• X-Ray Generator must have short exposures times.

• ΑΕC must be used carefully, preferably use manual technique setting,

applying lower doses.

• If possible, use high kVp techniques.