AEG-Electrolux EXS12HS2WI, EXS09HS2WE, EXS12HS2WE, EXS18HS2WE, EXS18HS2WI User Manual

[ADD APPLICABLE BRAND HERE]

SPLIT - TYPE

P/No.:

CONTENTS

SAFETY PRECAUTIONS

Warning .........................................................................................................................................

Operating temperature ..................................................................................................................

BEFORE INSTALLATION

Tools needed for installation .......................................................................................................

Items required for installing the unit ..............................................................................................

Typical installation...........................................................................................................................

INSTALLATION

Installation .....................................................................................................................................

REFRIGERANT PIPE CONNECTION

Refrigerant pipe connection ........................................................................................................

ELECTRICAL WORK

Connecting the cable to the indoor unit ......................................................................................

Connecting the cable to the outdoor unit ....................................................................................

CHECKING THE DRAINAGE AND FORMING THE PIPING

Checking the drainage ................................................................................................................

Forming the piping ......................................................................................................................

2

2

3

3

4

5

10

17

18

19

19

AIR PURGING

Air purging ...................................................................................................................................

Safety and leakage check ...........................................................................................................

TEST RUNNING

Test running ...............................................................................................................................

Read This Manual

Inside you will find many helpful hints on how to install and test the air conditioner properly.

CAUTION

!

Contact an authorised service technician for repair or maintenance of this unit.

Contact an authorised installer for installation of this unit.

The air conditioner is not intended for use by young children or infirmed persons without supervision.

Young children should be supervised to ensure that they do not play with the air conditioner.

If the power cord is to be replaced, replacement work shall be performed by authorised personnel only.

Installation work must be performed in accordance with the national wiring Standards by authorised

personnel only.

Take care not to catch fingers on the fan when adjusting vertical louvres.

may use R22, R407C or

This air conditioner R410A refrigerant (Confirmed before installation)

IMPORTANNT NOTES

20

22

22

1

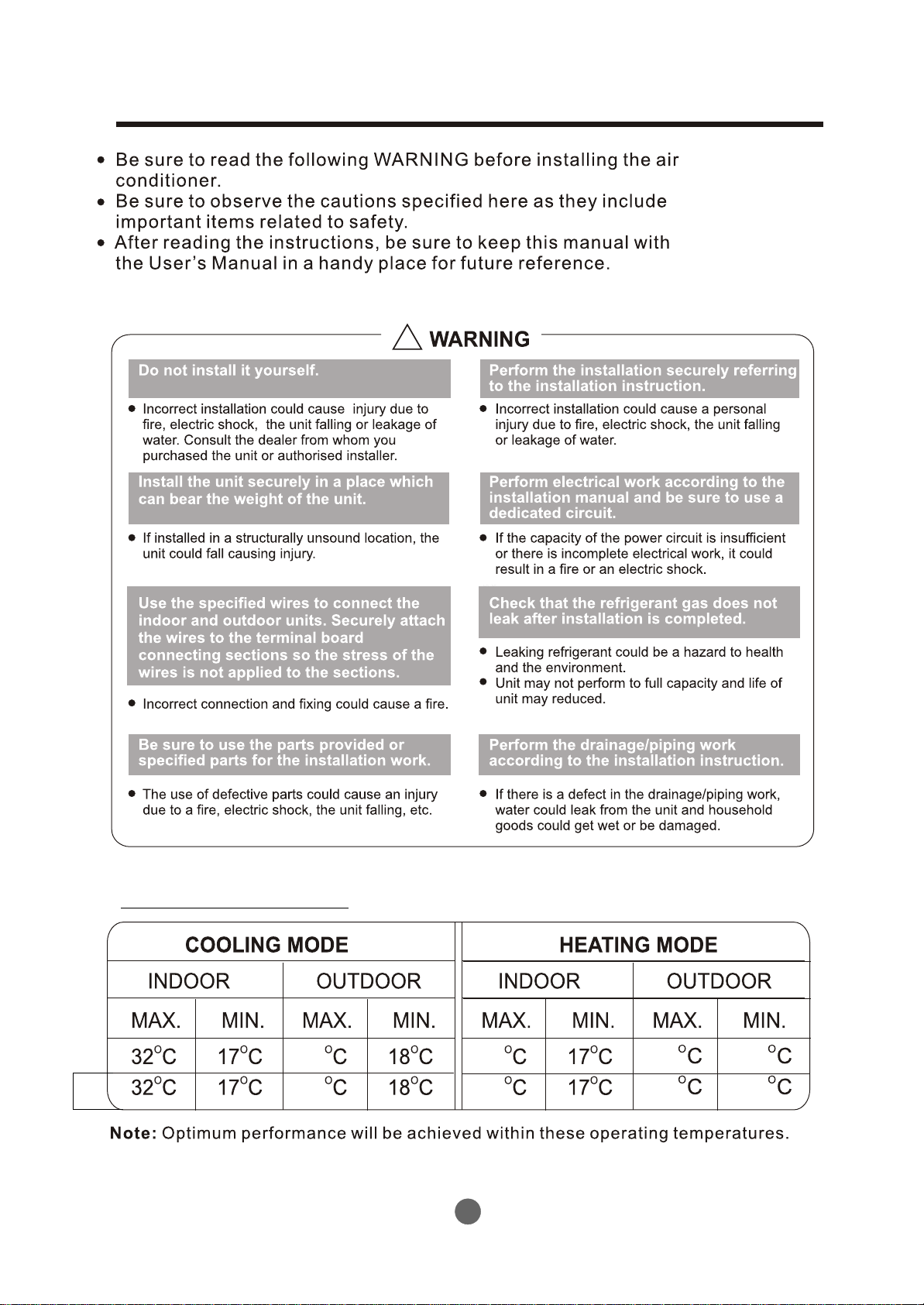

SAFETY PRECAUTIONS

!

OPERATING TEMPERATURE

T3

43

54

2

30

30

24

24

-5

-7

BEFORE INSTALLATION

Tools needed for installation

65mm or 95mm)

Items required for installing the unit

Clip Anchor

Seal (See page 10 for details)

(See page 10 for details)

Insulation materials

Cable Tie (5~10)

7,000 &9,000Btu/h model

12,000 &18,000Btu/h model

>21,000Btu/h model

16.0mm

3

BEFORE INSTALLATION

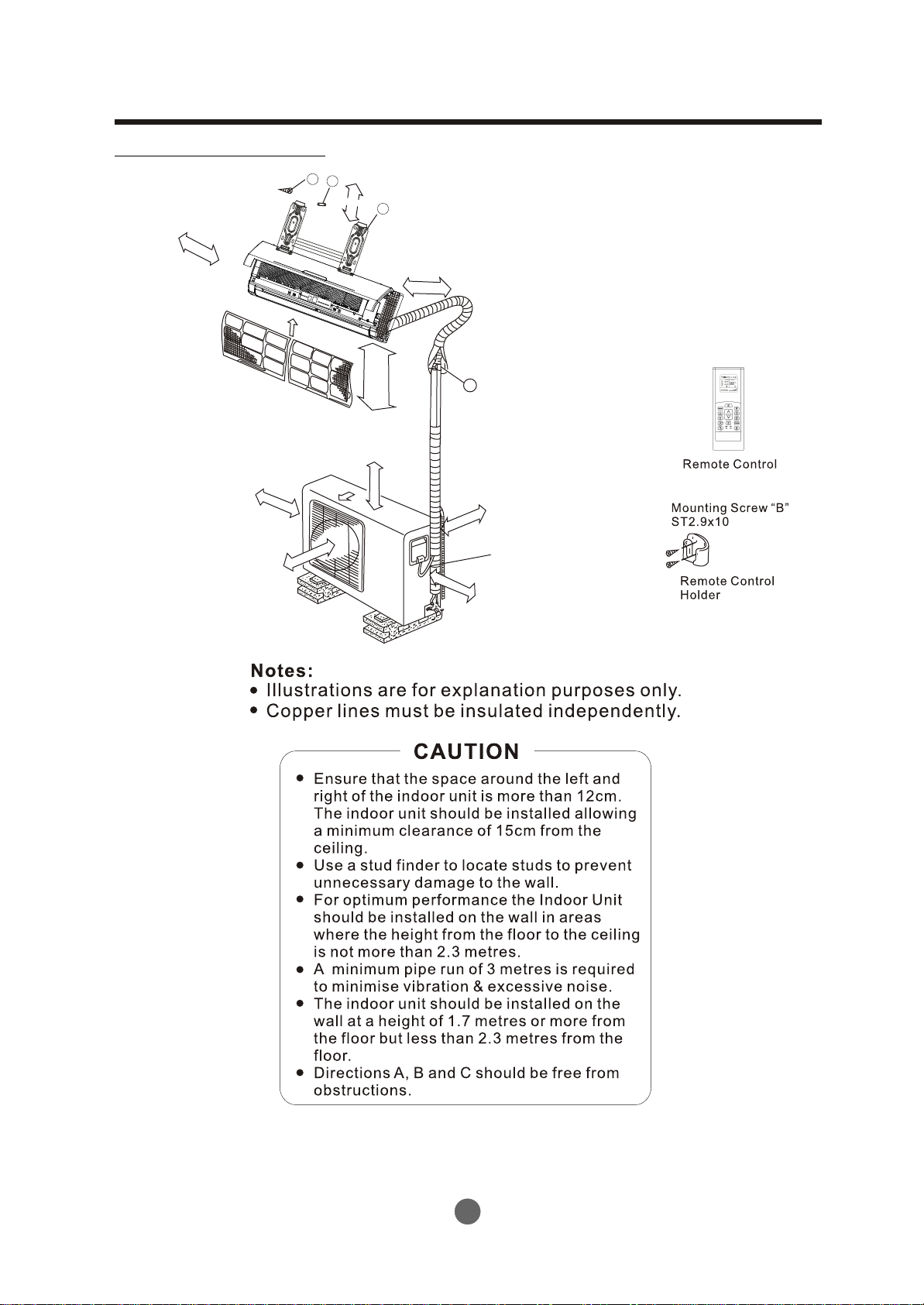

Typical installation

Self-tapping Screw A

12cm

abo

ve

A

10cm abov

B

e

100cm above

3

Air Filter

2

Air Outlet

Clip Anchor

15cm above

Installation Plate

1

12cm above

m

7

.

.3m

1

2

n

an

ha

h

t

t

ess

L

Mole

ve

bo

a

0cm

6

Connecting

6

pipe Assembly

e

abov

20cm

Loop the

connective

60cm

cable.

above

C

(If applicable)

4

INSTALLATION

Installation

Read completely then follow step by step.

Indoor unit

Fig.1

Outdoor unit

Rooftop installatiom

2

2

Fig.2

5

INSTALLATION

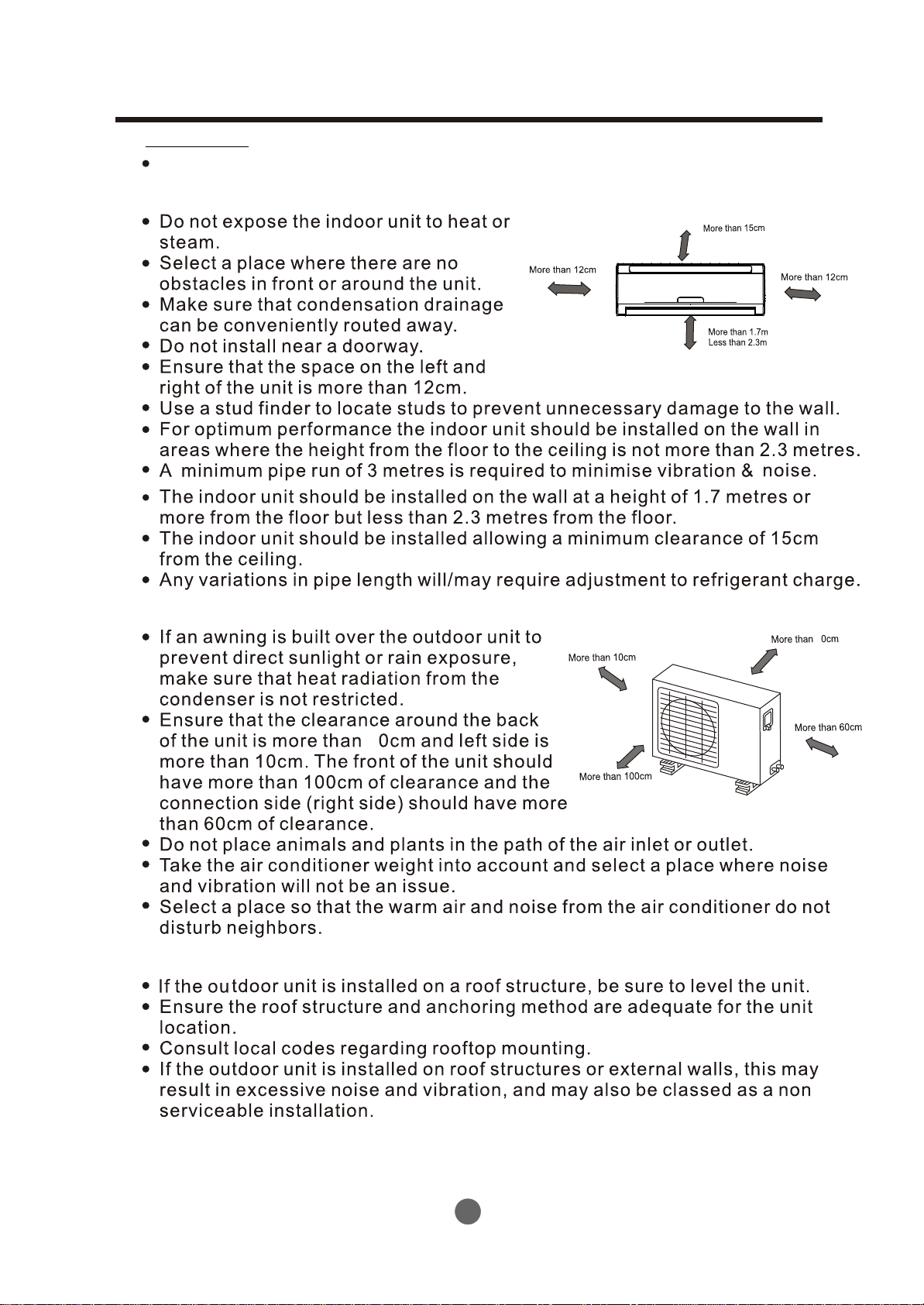

Piping length elevation

8

8

18

21 40

24

30 40

5/8

16.0mm

5/8

16.0mm

5/8

16.0mm

3/8

9.53mm

3/8

9.53mm

3/8

9.53mm

8

10 25

10

10

20

20

20

25

25

15

15

15

40

Capacity is based on standard length and maximum allowance

length is on the basis of reliability.

Oil trap should be installed every 5~7 metres.

When the connecting pipe is longer than 5 metres, additional

refrigerant should be added into the unit according to the

above table through the service port on the “LO” valve on

outdoor unit.

Fig.3

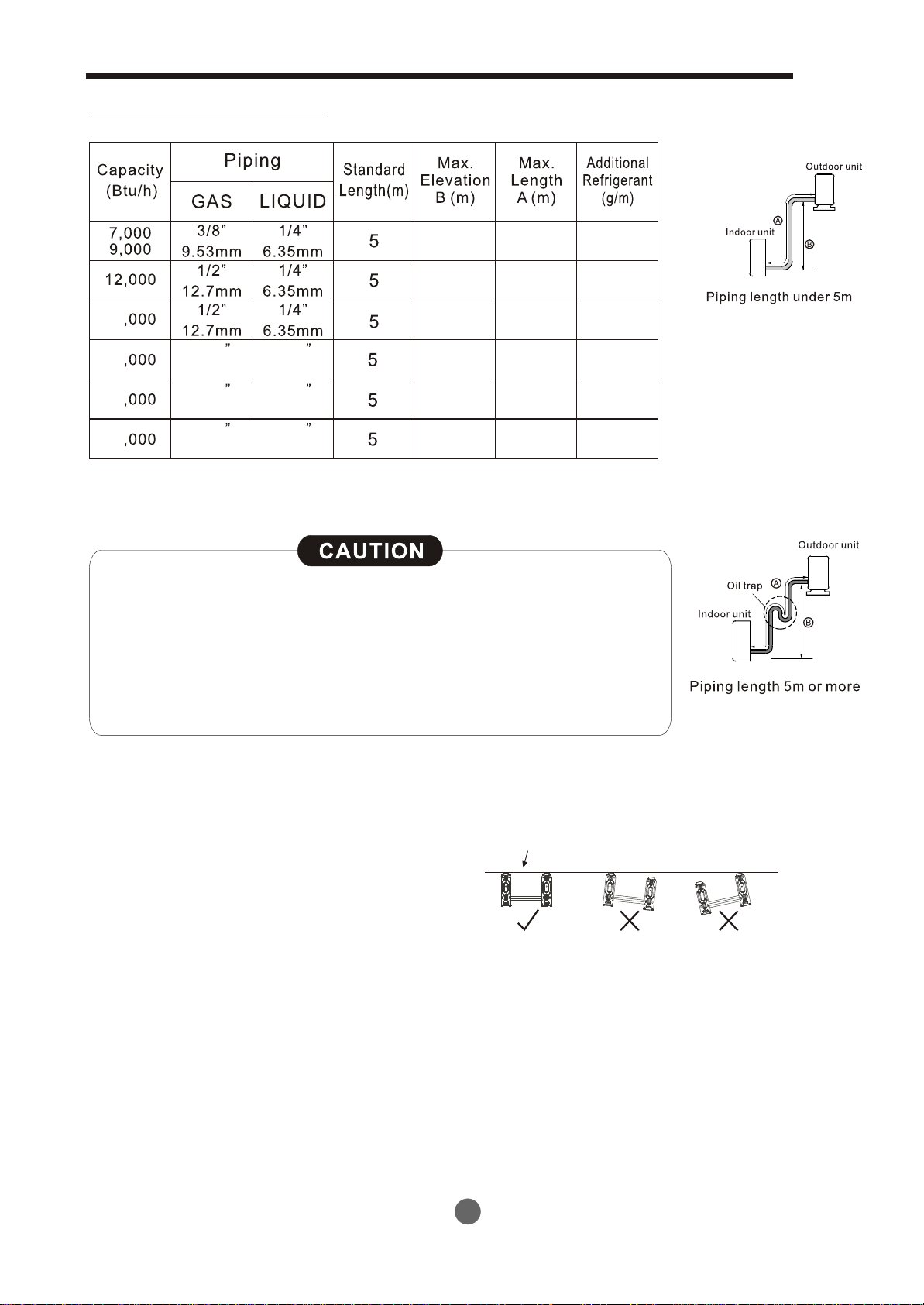

Indoor unit installation

1. Fit the Installation Plate

1). Fit the installation plate horizontally

on structural parts of the wall with

spaces around the installation plate.

2). If the wall is made of brick, concrete or

the like, drill eight (8) 5mm diameter holes

in the wall. Insert Clip anchor for appropriate

mounting screws.

3). Fit the installation plate on the wall with eight

(8) type “A” screws.

Note:

Fit the Installation Plate and drill holes in the wall according to the wall structure and corresponding

mounting points on the installation plate.

(Dimensions are in “mm” unless otherwise stated)

Correct orientation

of Installation Plate

Fig.4

6

INSTALLATION

120mm or more

to wall

Left rear side

refrigerant

pipe hole 65

120mm or more

to wall

Left rear side

refrigerant

pipe hole 65

150mm or more to ceiling

Indoor unit outline

45

40

A

Indoor size:A*B=710*250 or 790*265

150mm or more to ceiling

Indoor unit outline

45

B

45

A

Indoor size:A*B=850*305

Hooked Part

150mm or more from the ceiling

A

380

Installation plate

90

40

Installation plate

380

B

Right rear side

refrigerant

pipe hole 65

120mm or more

to wall

120mm or more

to wall

90

Right rear side

refrigerant

45

pipe hole 65

67

Fig’s 5

120mm or more

from the wall

B

130

65

0

5

Indoor Unit Outline

Indoor size:A*B=998*322

Above 150 from

the ceiling

Hooked Part

A

178

815

Above 120 from

the wall

95

55

Pipe hole

58

Indo

Indoor size:A*B=1250*325

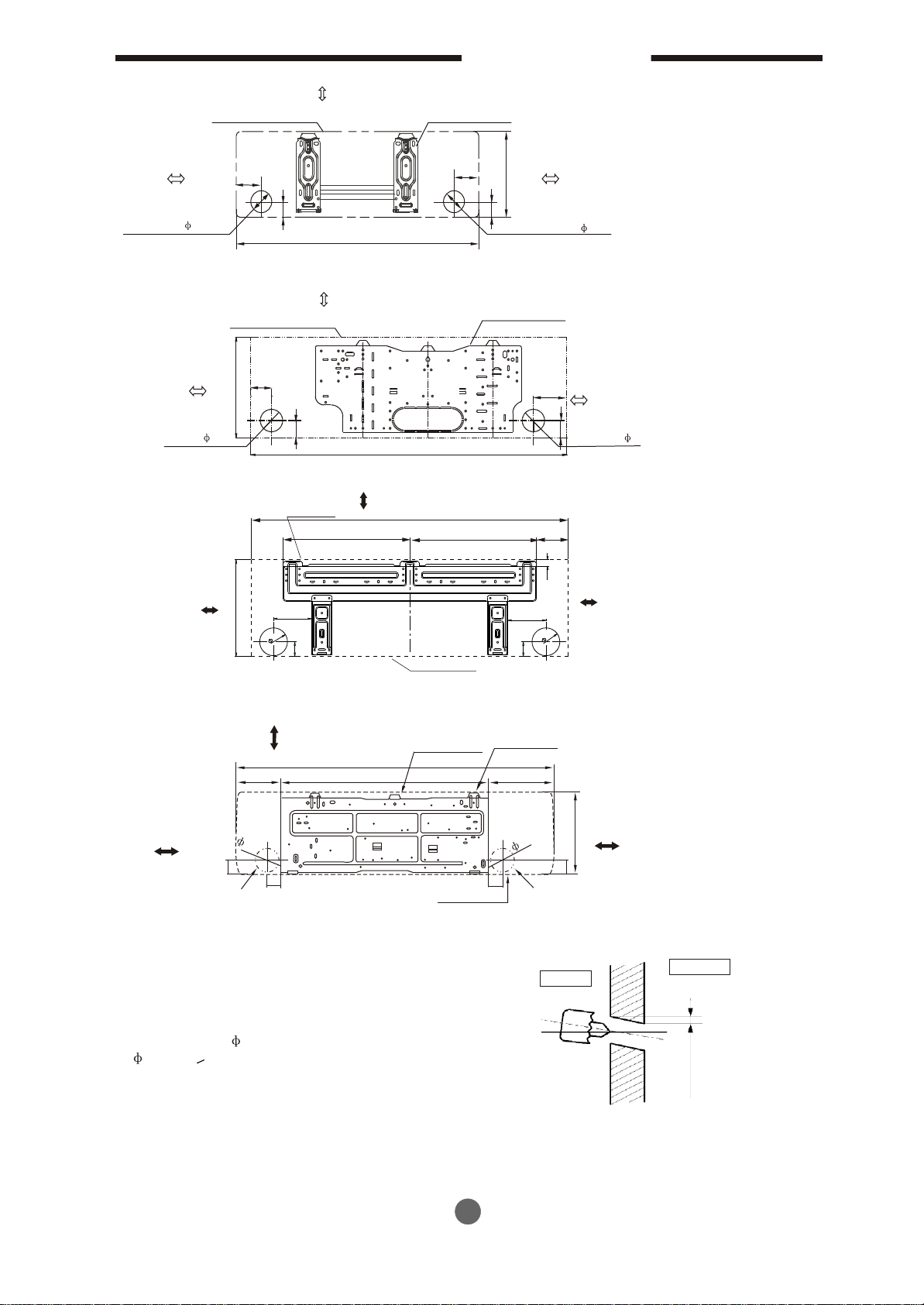

2. Drill a hole in the wall

1. Determine hole positions according to

the diagram detailed in Fig.5. Drill

one (1) hole ( 65mm <998*322 or

95mm >1250*325) slanting slightly

to outdoor side.

2. Always use wall hole conduit when

drilling metal grid, metal plate or the like.

22

120mm or more

from the wall

130

65

0

5

Hooker Part

257

Above 120 from

B

55

ip

e ho

Indoor

the wall

le

Wall

Outdoor

5-7mm

95

55

or

u

ni

t o

utlin

P

e

Fig.6

7

Loading...

Loading...