Page 1

PX71-265WT

USER

MANUAL

EN User Manual

Air conditioner

Gebruikershandleiding

NL

Airconditioner

Manuel d’utilisation

FR

Climatiseur

Benutzerhandbuch

DE

Klimagerät

2

24

48

72

Page 2

www.aeg.com2

CONTENTS

SAFETY INFORMATION ..............................................................................................3

1.

SAFETY INSTRUCTION ...............................................................................................6

2.

UNIT DESCRIPTION ...................................................................................................10

3.

ACCESSORIES INCLUDED .......................................................................................10

4.

INSTALLATION INSTRUCTIONS ...............................................................................11

5.

AIR CONDITIONER FEATURES ................................................................................13

6.

OPERATING INSTRUCTIONS ...................................................................................14

7.

CARE & CLEANING ....................................................................................................17

8.

TROUBLE SHOOTING ...............................................................................................17

9.

ADDITIONAL INFORMATION .....................................................................................18

10.

ENVIRONMENTAL CONCERNS ................................................................................23

11.

FOR PERFECT RESULTS

Thank you for choosing this AEG product. We have created it to give you impeccable

performance for many years, with innovative technologies that help make life simpler

– features you might not find on ordinary appliances. Please spend a few minutes

reading to get the very best from it.

Visit our website for:

Get usage advice, brochures, trouble shooter, service information:

www.aeg.com

Register your product for better service:

www.registeraeg.com

Buy Accessories, Consumables and Original spare parts for your appliance:

www.aeg.com/shop

CUSTOMER CARE AND SERVICE

We recommend the use of original spare parts.

When contacting Service, ensure that you have the following data available.

The information can be found on the rating plate. Model, PNC, Serial Number.

Warning / Caution-Safety information.

General information and tips.

Environmental information.

Subject to change without notice.

Page 3

3

ENGLISH

1.

SAFETY INFORMATION

WARNING!

• This appliance can be used by children aged from

8 years and above and persons with reduced

physical, sensory or mental capabilities or lack

of experience and knowledge if they have been

given supervision or instruction concerning use

of the appliance in a safe way and understand

the hazards involved.

• Children shall not play with the appliance.

• If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualied persons in order to avoid a hazard.

This manual explains the proper use of your new air

conditioner. Please read this manual carefully before

using the product. This manual should be kept in a safe

place for handy reference.

CAUTION!

• Contact authorised service technician for repair or

maintenance of this unit.

• Contact the installer for installation of this unit.

• The air conditioner is not intended for use by young

children of inrmed persons without supervision.

• Young children should be supervised to ensure

that they do not play with the air conditioner.

• There are local council rules regarding maximum

allowable noise levels emitted by air conditioners.

• If the power cord is to be replaced, replacement work

shall be performed by authorised personnel only.

• Installation work must be performed in accordance

with the national wiring standards by authorised

personnel only(if applicable). Incorrect connection

can cause overheating and re.

• Take care not to catch ngers on fan when

adjusting horizontal louvres.

Page 4

4

www.aeg.com

Important notes

1.1

1. Do not operate unit without the air lter.

2. Do not operate unit near any heat source or open re.

3. Do not expose the unit to direct sunlight.

4. Always store or move the unit in an upright position.

5. Do not cover the appliance when in operation

or immediately after use.

6. Always ensure that when the water pump drain hose

is tted that the hose is run to an eective drain point.

7. Always drain condensate before storing unit.

Point to Keep in Mind When Using Your

1.2

Air Conditioner

CAUTION!

Warnings for use

• Do not modify any part of this product.

• Do not insert anything into any part of the unit.

• Ensure the power supply used has an appropriate

voltage rating. Only use a 220V - 240V, 50Hz, 10A

mains electricity supply. Use of a power supply with

an improper voltage rating can result in damage

to the unit an possibly re.

• Always use a circuit breaker or fuse with the proper

amp rating. Do not, under any circumstances, use

wire, pins or other objects in place of a proper fuse.

• In the event of any abnormality with the air

conditioner (eg. a burning smell), turn it o

immediately and disconnect the power supply.

CAUTION!

Warning for power supply cord

• This power plug must only be plugged into an

appropriate wall socket. Do not use in conjunction

with any extension cords.

• Push the power plug securely into the socket and

make sure it is not loose.

Page 5

ENGLISH

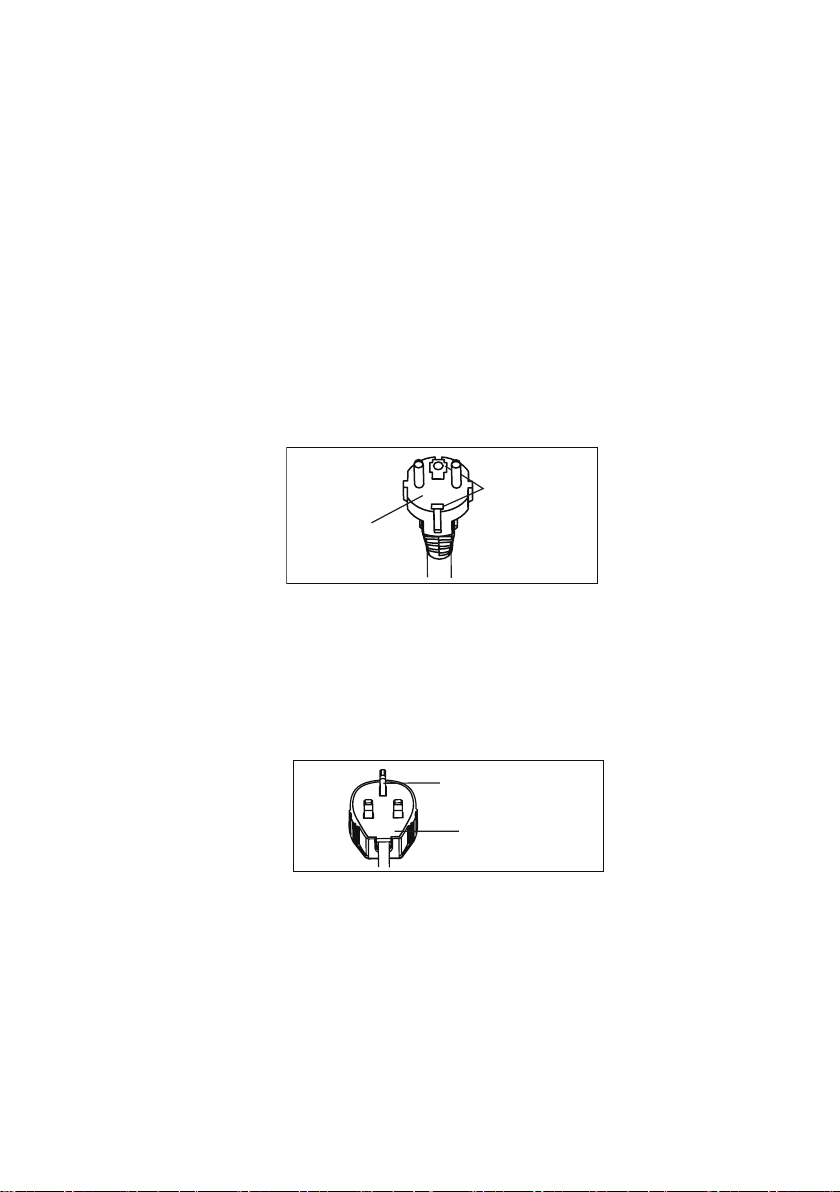

• Do not pull, deform. or modify the power supply

Plug

Grounding tab

cord, or immerse it in water. Pulling or misuse of

the power supply cord can result in damage to the

unit and cause electrical shock.

• If the supply cord is damaged, it must be replaced

by the manufacturer or its service agent or a

similarly qualied person in order to avoid a

hazard. Use only the manufacturer specied power

cord for replacement.

• This appliance must be earthed. This appliance

is equipped with a cord having an earth wire. The

plug must be plugged into an outlet that is properly

installed and earthed.

5

• This appliance is equipped with a cord that has a

earthed wire connected to an earthed pin. The plug

must be plugged into a socket that is properly installed

and earthed. Do not under qny circumstances ccut or

remove the square earthed pin from this plug.

Square earthed pin

Plug

(only for UK)

Usage cautions

1.3

• Be sure to turn the unit o and disconnect the power

supply cord before performing any maintenance or

cleaning.

• Do not splash or pour water directly onto the unit. Water

can cause electrical shock or equipment damage.

• Drainage should be performed whenever moving the

air conditioner (see page 14). If any water remains in

the tank, it may spill out while being moved.

Page 6

6

www.aeg.com

• To ensure proper drainage, the drainage hose must

have no kinks and must not be elevated during

dehumidicatioin mode. If not, the drained water may

spill out into the room.

• The temperature around the drainage hose must not

be below freezing point when used. Drained water may

freeze inside the hose, causing water inside the unit to

overow into the room.

• Do not block the exhaust air outlet with obstacles. Cooling

performance may be reduced or stop completely.

• Provide a residual current device (ROD) in order to

protect against electric shock in accordance with British

Standard and Wiring Rules.

• Exposure to direct airow for an extended period of

time could be hazardous to your health. Do not expose

occupants, pets, or plants to direct airow for extended

periods of time.

• Do not use this air conditioner for non-specied special

purposes (e.g. preserving precision devices, food, pets,

plants, and art objects). Usage in such a manner could

harm such property.

2.

SAFETY INSTRUCTION

2.1 Notes on Operation

• Allow 3 minutes for the compressor

to restart cooling. If you turn the air

conditioner o and immediately restart

it, allow 3 minutes for the compressor

to restart cooling. There is an electronic

device in the unit that keeps the

compressor turned o for 3 minutes

for safety.

• In the event of a power failure during

use, allow 3 minutes before restarting

the unit. After power is reinstated,

restart the air conditioner. If the power

was o for less than three minutes,

be sure to wait at least three minutes

before restarting the unit. if you

restart the air conditioner within three

minutes, a protective device in the unit

may cause the compressor to shut o.

This protective device will prevent

cooling for about 5 minutes. Any

previous setting will be cancelled and

the unit will return to its initial setting.

• Low temperature operation: Is your

unit freezing up? Freezing may occur

when the unit is set close to 18°C in

low ambient temperature conditions,

especially at night. In these conditions,

a further temperature drop may cause

the unit to freeze. Setting the unit to a

higher temperature will prevent it from

freezing.

• Dehumidication mode increases

room temperature. The unit generates

heat during dehumidication mode

and the room temperature will rise.

Warm air will be blown out from the

exhaust air outlet, but this is normal

and does not indicate a problem with

the unit.

• This air conditioner blows the warm air

generated by the unit outside the room

Page 7

7

ENGLISH

via the exhaust hose while in cool mode.

In the mean time, the same amount

of air will enter the room from outside

through any openings of the room.

• Do not use means to accelerate the

defrosting process or to clean, other

than those recommended by the

manufacturer.

• The appliance shall be stored in a

room without continuously operating

ignition sources (for example: open

ames, an operating gas appliance

or an operating electric heater).

• Do not pierce or burn.

• Appliance should be installed,

operated and stored in a room

with a oor area larger than 12 m2.

• Compliance with national gas

regulations shall be observed.

• Keep ventilation openings clear

of obstruction.

• The appliance shall be stored in a

well-ventilated area where the room

size larger than 12 m

2

.

• Any person who is involved with

working on or breaking into a refrigerant

circuit should hold a current valid

certicate from an industry-accredited

assessment authority, which authorises

their competence to handle refrigerants

safely in accordance with an industry

recognised assessment specication.

• Servicing shall only be performed

as recommended by the equipment

manufacturer. Maintenance and repair

requiring the assistance of other skilled

personnel shall be carried out under the

supervision of the person competent in

the use of ammable refrigerants.

• This product contains a lithium button/

coin cell battery. If a new or used lithium

button/coin cell battery is swallowed or

enters the body, it can cause severe

internal burns and can lead to death in

as little as 2 hours. Always completely

secure the battery compartment. If

the battery compartment does not

close securely, stop using the product,

remove the batteries, and keep it away

from children. If you think batteries

might have been swallowed or placed

inside any part of the body, seek

immediate medical attention.

To prevent injury to the user or other

people and property damage, the

following instructions must be followed.

Incorrect operation due to ignoring

instructions may cause harm or damage.

The seriousness is classied by the

following indications:

WARNING!

This symbol indicates the possibility of death or serious injury.

CAUTION!

This symbol indicates the possibility of injury or damage to property.

Meanings of symbols used in this manual

are shown below:

This symbol indicates never

to do this.

This symbol indicates always

do this.

2.2 Warning during usage

WARNING!

Warning during usage

Page 8

8

www.aeg.com

Warning Meaning

Plug in power plug properly Otherwise, it may cause electric shock

or re due to excess heat generation

Do not operate or stop the unit by inserting

or pulling out Die power plug

Do not damage or use an unspecied

power cord

It may cause electric shock or re due

to heat generation

It may cause electric shook or re.

If the power cord is damaged, it must

be replaced by the manufacturer or an

authorised service centre or a similarly

qualied person in order to avoid a hazard

Do not modify power cord length or share

the outlet with other appliances

Do not operate with wet hands or in damp

It may cause electric shock or re due to

heat generation

It may cause electric shock

environment

Do not direct airow at room occupants This could harm your health

Always ensure eective earthing Incorrect earthing may cause electric shock

Do not allow water to run into electric parts It may cause failure of unit or electric shock

Always install circuit breaker and a

dedicated power circuit

Unplug the unit if strange sounds, smell, or

Incorrect installation may cause Are and

electric shock

It may cause re and electric shock

smoke comes from it

Do not use the socket if it is loose or

It may cause re and electric shock

damaged

Do not open the unit during operation It may cause re and electric shock

Keep rearms away It may cause re

Do not use the power cord close to heating

It may cause re and electric shock

appliances

Do not use the power cord near ammable

It may cause an explosion or re

gas or combustibles, such as gasoline,

benzene, thinner, etc.

Ventilate room before operating air

It may cause explosion, re and burns

conditioner if there is a gas leakage from

another appliance

Do not disassemble or modify unit It may cause failure and electric shock

Page 9

ENGLISH

CAUTION!

Caution Meaning

When the air lter is to be removed, do not

It may cause an injury

touch the metal parts of the unit

Do not clean the air conditioner with water Water may enter the unit and degrade the

insulation. It may cause an electric shock

Ventilate the room well when used together

An oxygen shortage may occur

with a stove, etc.

When the unit is to be cleaned, switch o,

and turn o the circuit breaker

Do not clean unit when power is on as it

may cause re and electric shock, it may

cause an injury

Do not place a pet or house plant where

This could injure the pet or plant

it will be exposed to direct air ow

Do not use for special purposes Do not use this air conditioner to

preserve precision devices, food, pets,

plants, and art objects. It may cause

deterioration of quality, etc.

Stop operation and close the window in

storm or cyclone

Operation with windows opened may cause

wetting of indoor and soaking of household

furniture

Hold the plug by the head of the power plug

It may cause electric shock and damage

when taking it out

Turn o the main power switch when not

It may cause failure of product or re

using the unit for a long time

Do not place obstacles around air-inlets

It may cause failure of appliance or accident

or inside of air-outlet

Always insert the lters securely. Clean

Operation without lters may cause failure

lter once every two weeks

Do not use strong detergent such as wax

or thinner - use a soft cloth

Appearance may be deteriorated due to

change of product colour or scratching of

its surface

Do not place heavy object on the power

There is danger of re or electric shock

cord and ensure that the cord is not

compressed

Do not drink water drained from air

conditioner

It contains contaminants and could make

you sick

Use caution when unpacking and installing Sharp edges could cause injury

If water enters the unit, turn the unit o at

It could cause electric shock and damage

the power outlet and switch o the circuit

breaker. Isolate supply by taking the power-

plug out and contact a qualied service

technician

9

Page 10

10

www.aeg.com

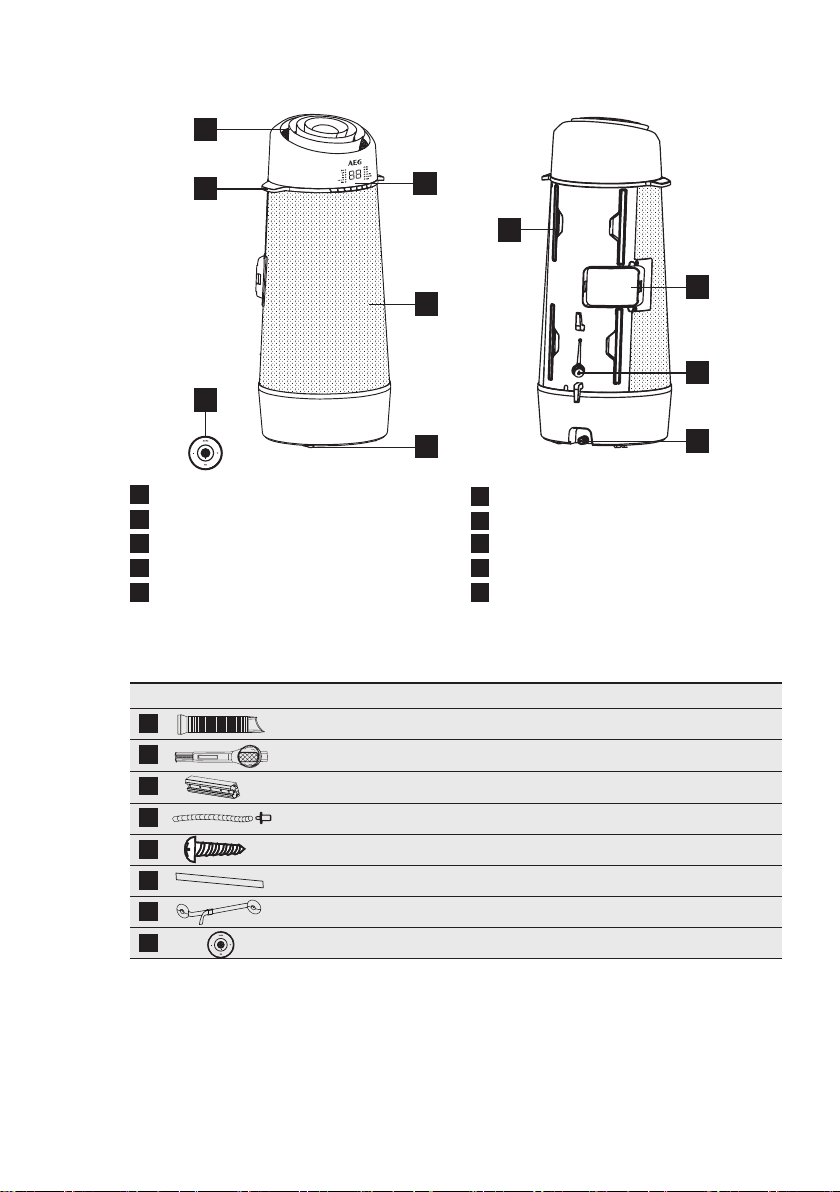

UNIT DESCRIPTION

3.

1

6

5

1

Room air discharge

2

Control panel

3

Room air inlet

4

Castor

5

Remote control

ACCESSORIES INCLUDED

4.

PARTS PARTS NAME: QUANTITY:

1

2

3

4

5

6

7

8

Fig. 2

•

Check all the accessories are included in the package and please refer to the

installation instructions for their usage.

Exhaust hose

Window Sliding Kit

Spared Extend Rod

Drain Hose & Adaptor

3/8" Screw

Decoration lm

Fixing Strap

Remote Control 1 pcs

2

7

8

3

9

4

6

Carrying handle(both sides)

7

Filter

8

Exhaust air outlet

9

Drain outlet

10

Bottom tray drain outlet

10

Fig. 1

1 pcs

1 pcs

1 pcs

1 pcs

2 pcs

1 pcs

1 set

Page 11

ENGLISH

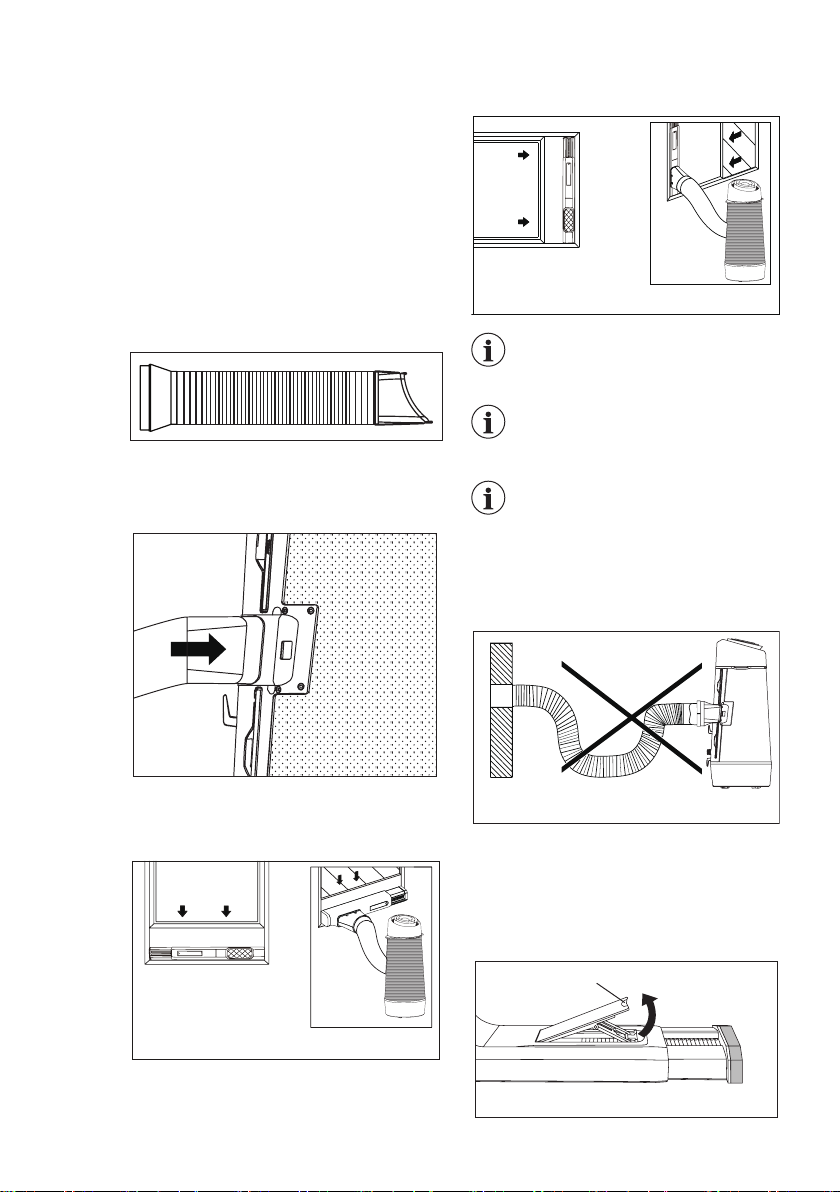

INSTALLATION INSTRUCTIONS

Fig. 4

Fig. 6

Fig. 7

5.

5.1 Exhausting hot air

In the COOLING Mode the appliance

must be placed close to a window or

opening so that the warm exhaust air

can be ducted outside. First position unit

on a at oor and make sure there’s a

minimum of 30cm clearance around the

unit, and is within the vicinity of a single

circuit outlet power source.

Extend either side of the hose (Fig. 3).

1.

Fig. 3

Slide the adaptor A into the exchange

2.

hole of the unit as shown on Fig. 4.

Window Slider Kit

Minimum: 56cm

Maxmum: 112cm

Refer to “

a casement window” about

how to install the window kit.

The hose can be extended from

its original length of 38cm up to

150cm, but it is the best to keep

the length to minimum required.

Also make sure that the hose

does not have any sharp bends

or sags. (Fig. 7)

Installation in

5.2

11

Install the window kit on the window

3.

and slide the adaptor B into the

window slider kit and seal. (Fig. 5 & 6)

Fig. 5

5.2 Installation in a casement

window

Open the window sash and lift the

1.

locking lever of the window slider

kit (Fig. 9)

B

Fig. 9

B: Locking lever

Page 12

12

www.aeg.com

Place the window slider kit on the

2.

window. Adjust the length of the

window slider kit according to the

height of window (Fig. 10).

Fig. 10

The telescopic rod can be

extended, if the window is

too high.

To do that, rst take out the

telescopic rod completely

(Fig.11 A). Then align the 3 hooks

on the extending rod (sold

separately) to the 3 slots on the

end of the telescopic rod and slide

the 3 hooks into the slots, then

press down the extending rod to

lock the slots (Fig.11 B). After that

slide the combined telescopic rod

back into the window kit (Fig.11 C).

Press back the locking lever to x

3.

the length of the window slider kit,

then close the window and pinch

the window kit between the window

and the window frame, to secure the

window kit, peel o the protect lm

in the back of the tabs of the anchor

and attach on the window frame,

then fasten the strap (Fig. 12).

Fig. 12

Cut the decoration lm to an

4.

appropriate length and stick

on the extend rod (Fig. 13).

C

Fig. 11 A

Fig. 13

C: Decoration lm

Fig. 11 B

Fig. 11 C

Page 13

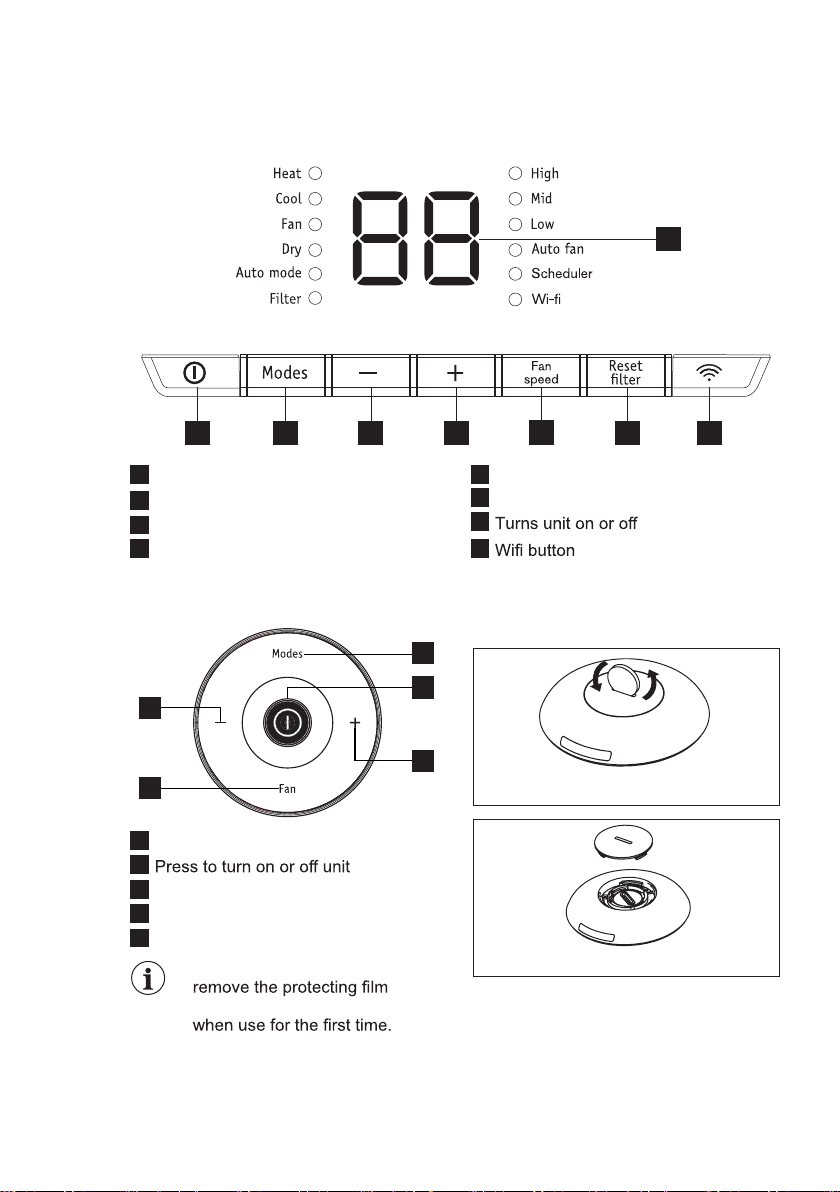

AIR CONDITIONER FEATURES

1

2

3

4

5

2

8

3

4567

6.

6.1 CONTROL PANEL

13ENGLISH

1

1

Displays temperature

2

Filter reset button (hold 3 secs to reset)

3

Sets fan speed

4

Increase temperature

6.2 Remote Control

1

Press to select modes

2

3

Press to increase temperature setting

4

Press to select fan speeds

5

Press to decrease temperature setting

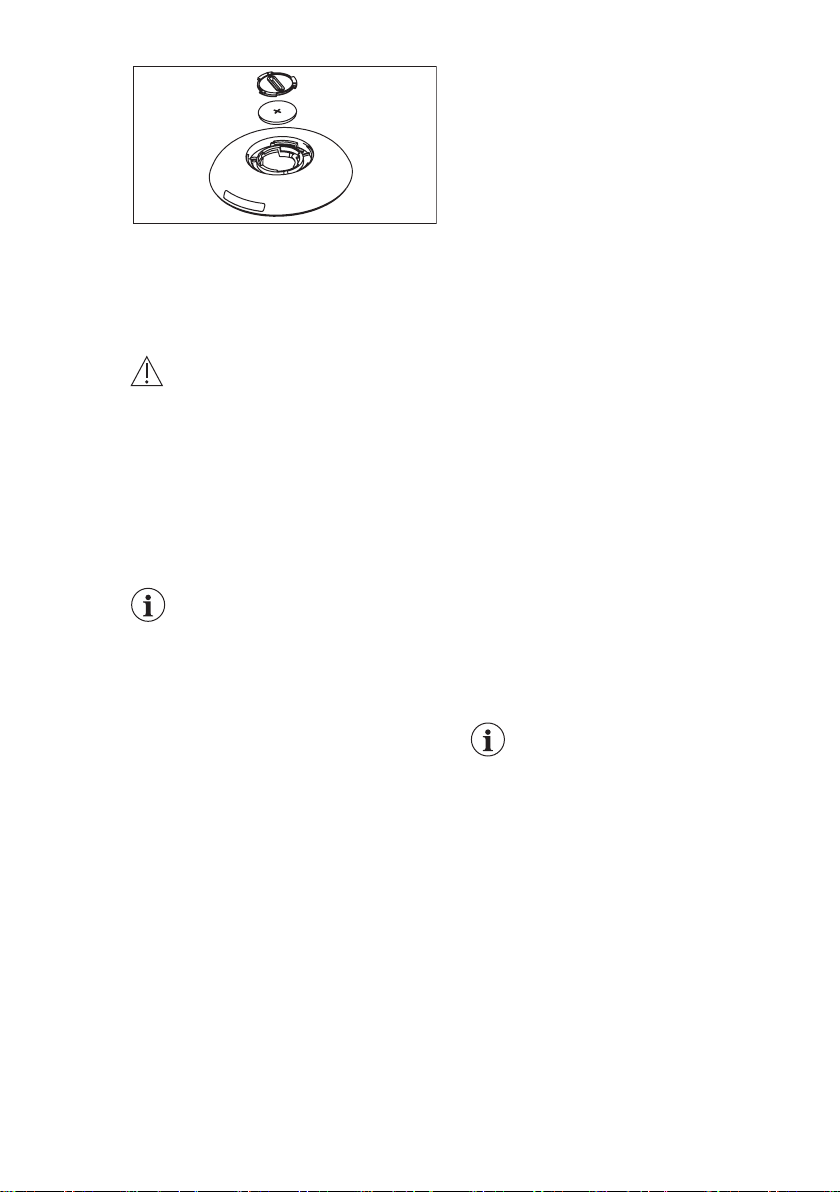

Open the back covers and

to activate the remote control,

To replace the battery

Turn over the remote control. In the

1.

button of the remote control there

is a slot.

5

Decrease temperature

6

Sets mode

7

8

Use a coin or something like that to

2.

rotate the back cover anti-clockwise

to open it. (Fig. 20 & 21)

Fig. 20

Fig. 21

Use the same way to open the

3.

protecting cover inside and take

out the battery. (Fig. 22)

Page 14

14

www.aeg.com

Fig. 22

Replace the battery and reinstall

4.

the inside cover and back cover.

Battery Type: RG15D/E-ELL

(Rated Voltage: 3VDC)

WARNING!

Please use the battery

appropriately

Chemical Burn Hazard. Keep

1.

batteries away from children.

Be sure the batteries are inserted

2.

properly.

OPERATING INSTRUCTIONS

7.

Do not use batteries other than the

3.

type specied.

Do not use old batteries with new

4.

ones.

Do not dispose of batteries in re.

5.

Batteries may explode or leak.

The cells shall be disposed of

6.

properly, including keeping them

away from children and even used

cells may cause injury.

To prevent damage, remove the

7.

batteries when not being used for

a long time.

This device complies with Part 15 of

8.

the FCC Rules. Operation is subject

to the following two conditions: (1)

This device may not cause harmful

interference, and (2) this device must

accept any interference received,

including interference that may cause

undesired operation.

Some of the following instructions

can only be used by using the

Control Panel.

7.1 Usage of the Control Panel

Heating mode (on some models)

In this mode the exhaust adaptor hose

MUST be used.

Press the “Modes” button until the

1.

“Heat” indicator is lit.

Press the “ - ” & “ + ” Temp buttons

2.

for desired setting.

Press the “fan speed” button for

3.

desired fan speed.

Connected drain hose.

4.

See 7.3 Drainage section.

Cooling mode

In this mode the exhaust adaptor hose

MUST be used.

Press the “Modes” button until the

1.

“Cool” indicator lights.

Press the “ - ” & “ + ” Temp buttons

2.

for desired setting.

Press the “Fan speed” button for

3.

desired fan speed.

It is not necessary to use the

drainage hose in the “cool” mode.

Fan mode

In this mode there is no need to use the

exhaust hose or drainage hose.

Press the “Modes” button until the

1.

“Fan” indicator is lit.

Press the “Fan speed” button to

2.

choose the desired fan speed.

The fan will run at the selected speed

3.

and the display will show the room

temperature.

Page 15

Dry mode DEACTIVATE WIFI MODULE:

In this mode you do not need to use the

exhaust adaptor hose, BUT the water

collected must be discharged. See 7.3

Drainage Section.

Press the “Modes” button until the

1.

“Dry” indicator is lit.

The fan will run at low speed and

2.

the display will show the room

temperature.

Keep doors & windows closed

3.

for

Connected drain hose. See Drainage

4.

section.

Auto mode

Always have the exhaust hose attached

in this mode.

When you set the air conditioner in Auto

mode, it will automatically select cooling,

heating (inapplicable for cooling only

models), or fan only operation depending

on what temperature you have selected

and the room temperature. The air

conditioner will control room temperature

automatically round the temperature

point set by you.

Under AUTO mode, you can not select

the fan speed.

1. Press the “Modes” button until the

“Auto mode” indicator lights.

After the “Auto mode” is selected the unit

will run automatically according to the

actual room air temperature.

holding the “Connect button” and “ - ”

synchronously 3 seconds. Press the

“Connect button” again to activate the

10 seconds for the module to initiate again.

7.2 Fault code

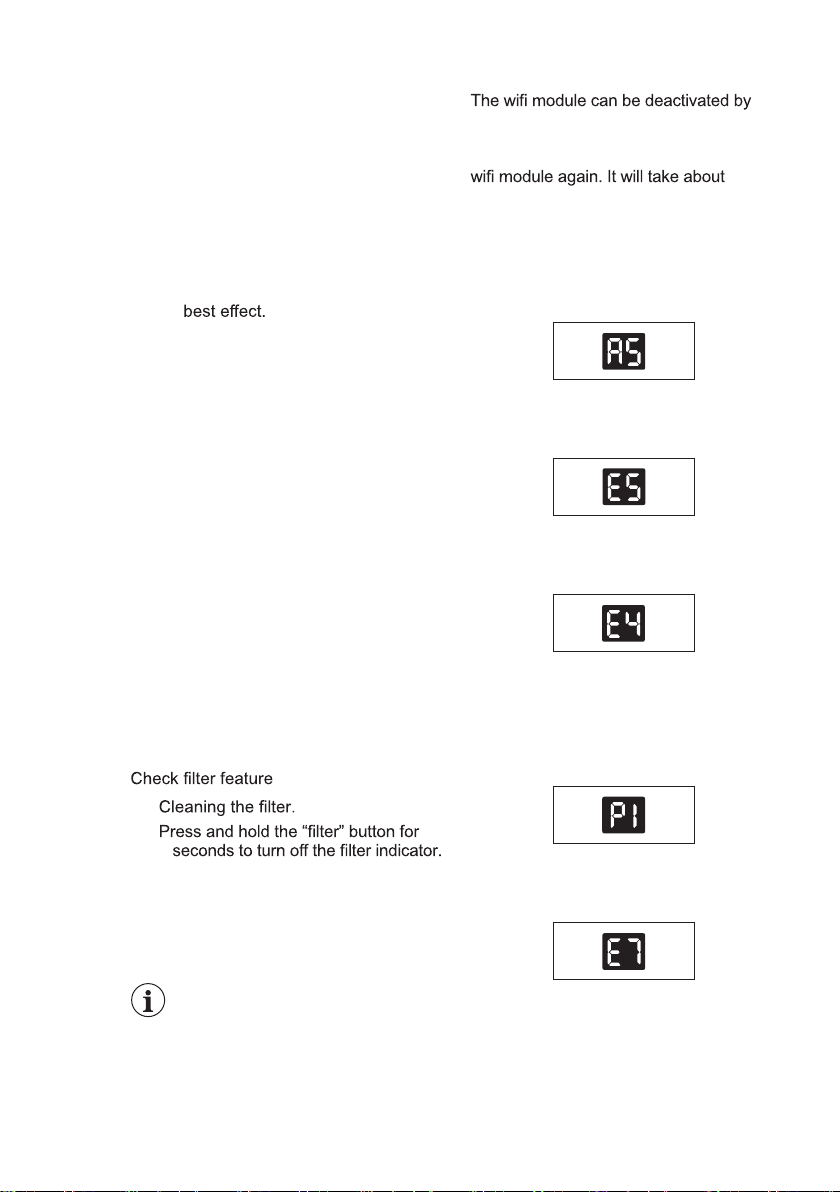

If the display reads “A5”, the room

temperature sensor has failed. Contact

your Authorized AEG Service Centre.

If the display reads “E5”, the evaporator

temperature sensor has failed. Contact

your Authorized AEG Service Centre.

If the display reads “E4”, the display panel

communication has failed. Contact your

Authorized AEG Service Centre.

If the display reads “P1”, bottom tray is full.

Carefully move the unit to a drain location,

remove the bottom drain plug and let the

water drain away. Restart the machine

until the “P1” symbol disappears. If error

repeats, call for service.

15ENGLISH

1.

2.

3

Selecting fan speed

You can select the desired fan speed, by

pressing the “Fan speed” button. The fan

speed will change in the sequence: “Auto

Fan”, “High”, “Mid”, “Low”.

After choosing the fan speed as

“Auto Fan”, “High”, “Mid” or “Low”,

the corresponding fan speed

indicator light will illuminate.

Under Auto and Dry mode, you

can not select the fan speed.

If the display reads “E7”, the indoor motor

has failed. Contact your Authorized

AEG Service Center.

Page 16

16

www.aeg.com

7.3 Drainage 7.4 Operation Tips

During the Heat and dry mode, you need

to connect the drain hose to the drain

outlet in the back of the unit to drain the

condensate from the unit. Otherwise,

the unit may not function normally and

display show “P1”.

A. Discharge into a drain that is lower

than the unit.

B. The unit have a pump to drain the

condensate.

Fig. 23

If necessary you can extend the drain

hose by adapting the drain hose adpator

in the end of the drain hose, then use

a 8-9mm hose to extend.(Fig. 24)

Connect a 8-9mm hose here

to extend the draining hose

Fig. 24

During cooling mode, please replace the

rubber stopper to the hose connector to

reach the maximum performance.

Now that you have mastered the

operating procedure, here are more

features in your control that you should

become familiar with.

•

The “Cool” circuit has an automatic

3 minutes time delayed start if the

unit is turned o and on quickly.

This prevents overheating of the

compressor and possible circuit

breaker tripping. The fan will continue

to run during this time.

•

Temperature can be set between

16°C and 32°C.

•

The control is capable of displaying

temperature in degrees Fahrenheit or

degrees Celsius. To convert from one

to the other and back, press and hold

the “TEMP” Up ( + ) and Down ( - )

buttons together for 3 seconds.

•

There is a 2-Second delay for the

compressor shutting down when

selecting Fan. This is to cover the

possibility of having to roll through

to select another mode.

•

After a power outage, the unit will

memorize the last setting and return

the unit to the same setting once

power is restored.

•

Indoor operating temperature range

for this product is 16°C to 35°C.

•

During normal operation, the unit's

display will show room temperature

but when the room temperature is

over 37°C the display will show “HI”.

•

After 60 seconds of control inactivity

the display and indicator lights will

turn o. Press any button on the

control panel or remote control

and the display will resume.

Page 17

ENGLISH

CARE & CLEANING

8.

17

Clean your air conditioner regularly to

keep it looking new.

8.1 Air lter cleaning

Be sure to unplug the unit before cleaning

to prevent shock or re hazards.

Enter the context of your task here

(optional).

Grasp the lters tab and pull o the

1.

4 lters on the back of the unit one

by one.

Wash the lter using liquid dishwashing

2.

detergent and warm water. Rinse lter

thoroughly. Gently shake excess water

from the lter. Or, instead of washing

you may vacuum the lter clean.

Be sure lter is thoroughly dry

before replacing.

Put back the lter after the lter is dry.

3.

8.2 Cabinet Cleaning

Be sure to unplug the air conditioner

to prevent shock or re hazard.

TROUBLE SHOOTING

9.

Before calling for service, review this list.

It may save you time and expense. This

list includes common occurrences that are

not the result of defective workmanship

or materials in this appliance.

Air conditioner will not operate.

•

Wall plug disconnected. Push plug

rmly into wall outlet.

•

House fuse blown or circuit breaker

tripped. Replace fuse with time delay

type or reset circuit breaker.

•

Control is OFF. Turn Control ON and

set to desired setting.

•

P1 appears in the display window.

Drain water as described in 7.3

Drainage Section.

•

Room Temperature lower than the set

temperature (Cool Mode). Reset the

temperature.

The cabinet and front may be dusted with

an oil-free cloth or washed with a cloth

dampened in a solution of warm water

and mild liquid dishwashing detergent.

Rinse thoroughly and wipe dry.

Caution when cleaning the unit.

•

Never use harsh cleaners, wax

or polish on the cabinet front.

•

Be sure to wring excess water from

the cloth before wiping around the

controls. Excess water in or around

the controls may cause damage

to the air conditioner.

8.3 Winter Storage

If you plan to store the appliance during

the winter, cover it with plastic or return

it to its carton box.

Air from unit does not feel cold

enough.

•

Room temperature below 16°C.

Cooling may not occur until room

temperature rises above 16°C.

•

Reset to a lower temperature.

•

Compressor shut-o by changing

modes. Wait approximately 3 minutes

and listen for compressor to restart

when set in the COOL mode.

Air conditioner cooling, but room is

too warm - NO ice forming on cooling

coil behind decorative front.

•

Outdoor temperature below 16°C.

To defrost the coil, set Fan mode.

•

Air lter may be dirty. Clean lter.

Refer to 8. Care and Cleaning section.

To defrost, set to Fan mode.

•

Temperature is set too low for nighttime

cooling. To defrost the coil, set to Fan

Page 18

18

www.aeg.com

mode. Then, set temperature to a higher

setting.

•

Exhaust duct not connected or blocked.

See 5.1 Exhausting hot air Section.

Air conditioner cooling, but room is

too warm - ice forming on cooling coil

behind decorative front

•

Dirty air lter - air restricted. Clean air

lter. Refer to 8. Care and Cleaning

section.

•

Temperature is set too high. Set

temperature to a lower setting.

•

Air directional louvers positioned

improperly. Position louvers for

better air distribution.

•

Front of unit is blocked by drapes,

blinds, furniture, etc. - restricts air

distribution. Clear blockage in front

of unit.

ADDITIONAL INFORMATION

10.

•

Doors, windows, registers, etc.

open - cool air escapes. Close doors,

windows, registers, etc.

•

Unit recently turned on in hot room.

Allow additional time to remove

“stored heat” from walls, ceiling,

oor and furniture.

Air conditioner turns on and o rapidly.

•

Dirty air lter - air restricted. Clean air

lter.

•

Outside temperature extremely hot.

Set FAN speed to a faster setting to

bring air through cooling coils more

frequently.

Room too cold.

•

Set temperature too low. Increase set

temperature.

Transport of equipment containing

ammable refrigerants

See transport regulations

Marking of equipment using signs

See local regulations

Disposal of equipment using

ammable refrigerants

See national regulations.

Storage of equipment/appliances

The storage of equipment should be

in accordance with the manufacturer’s

instructions.

Storage of packed (unsold) equipment

Storage package protection should be

constructed such that mechanical damage

to the equipment inside the package will

not cause a leak of the refrigerant charge.

The maximum number of pieces of

equipment permitted to be stored together

will be determined by local regulations.

Information on servicing

Checks to the area. Prior to beginning

1.

work on systems containing ammable

refrigerants, safety checks are

necessary to ensure that the risk of

ignition is minimised. For repair to

the refrigerating system, the following

precautions shall be complied with

prior to conducting work on the

system.

Work procedure. Work shall be

2.

undertaken under a controlled

procedure so as to minimise the

risk of a ammable gas or vapour

being present while the work is being

performed.

General work area. All maintenance

3.

sta and others working in the local

area shall be instructed on the nature

of work being carried out. Work in

conned spaces shall be avoided.

The area around the workspace shall

be sectioned o. Ensure that the

conditions within the area have been

made safe by control of ammable

material.

Checking for presence of refrigerant.

4.

The area shall be checked with an

appropriate refrigerant detector prior

to and during work, to ensure the

technician is aware of potentially

ammable atmospheres. Ensure that

the leak detection equipment being

used is suitable for use with ammable

refrigerants, i.e. nonsparking,

adequately sealed or intrinsically safe.

Page 19

19

ENGLISH

Presence of re extinguisher. If

5.

any hot work is to be conducted on

the refrigeration equipment or any

associated parts, appropriate re

extinguishing equipment shall be

available to hand. Have a dry powder

or CO2 re extinguisher adjacent to

the charging area.

No ignition sources. No person carrying

6.

out work in relation to a refrigeration

system which involves exposing

any pipe work that contains or has

contained ammable refrigerant shall

use any sources of ignition in such a

manner that it may lead to the risk of

re or explosion. All possible ignition

sources, including cigarette smoking,

should be kept suciently far away

from the site of installation, repairing,

removing and disposal, during which

ammable refrigerant can possibly

be released to the surrounding

space. Prior to work taking place, the

area around the equipment is to be

surveyed to make sure that there are

no ammable hazards or ignition risks.

“No Smoking” signs shall be displayed.

Ventilated area. Ensure that the area

7.

is in the open or that it is adequately

ventilated before breaking into

the system or conducting any hot

work. A degree of ventilation shall

continue during the period that the

work is carried out. The ventilation

should safely disperse any released

refrigerant and preferably expel it

externally into the atmosphere.

Checks to the refrigeration equipment.

8.

Where electrical components are

being changed, they shall be t for the

purpose and to the correct specication.

At all times the manufacturer’s

maintenance and service guidelines

shall be followed. If in doubt consult the

manufacturer’s technical department

for assistance. The following checks

shall be applied to installations using

ammable refrigerants:

– The charge size is in accordance

with the room size within which

the refrigerant containing parts

are installed;

– The ventilation machinery and

outlets are operating adequately

and are not obstructed;

– If an indirect refrigerating circuit is

being used, the secondary circuit

shall be checked for the presence

of refrigerant;

– Marking to the equipment

continues to be visible and legible.

Markings and signs that are

illegible shall be corrected;

– Refrigeration pipe or components

are installed in a position where

theyare unlikely to be exposed to

any substance which may corrode

refrigerant containing components,

unless the components are

constructed of materials which

are inherently resistant to being

corroded or are suitably protected

against being so corroded.

Checks to electrical devices. Repair

9.

and maintenance to electrical

components shall include initial safety

checks and component inspection

procedures. If a fault exists that could

compromise safety, then no electrical

supply shall be connected to the

circuit until it is satisfactorily dealt

with. If the fault cannot be corrected

immediately but it is necessary to

continue operation, an adequate

temporary solution shall be used.

This shall be reported to the owner

of the equipment so all parties are

advised.

Initial safety checks shall include:

• That capacitors are discharged: this

shall be done in a safe manner to

avoid possibility of sparking;

• That there no live electrical

components and wiring are exposed

while charging, recovering or purging

the system;

• That there is continuity of earth

bonding.

Repairs to sealed components

During repairs to sealed components,

1.

all electrical supplies shall be

disconnected from the equipment

being worked upon prior to any

removal of sealed covers, etc. If

it is absolutely necessary to have

an electrical supply to equipment

during servicing, then a permanently

operating form of leak detection shall

Page 20

20

www.aeg.com

be located at the most critical point

to warn of a potentially hazardous

situation.

Particular attention shall be paid to the

2.

following to ensure that by working on

electrical components, the casing is

not altered in such a way that the level

of protection is aected. This shall

include damage to cables, excessive

number of connections, terminals not

made to original specication, damage

to seals, incorrect tting of glands,

etc. Ensure that apparatus is mounted

securely. Ensure that seals or sealing

materials have not degraded such

that they no longer serve the purpose

of preventing the ingress of ammable

atmospheres. Replacement parts

shall be in accordance with the

manufacturer’s specications.

NOTE: The use of silicon sealant may

inhibit the eectiveness of some types

of leak detection equipment. Intrinsically

safe components do not have to be

isolated prior to working on them.

Repair to intrinsically safe components

Do not apply any permanent inductive or

capacitance loads to the circuit without

ensuring that this will not exceed the

permissible voltage and current permitted

for the equipment in use.

Intrinsically safe components are the only

types that can be worked on while live in

the presence of a ammable atmosphere.

The test apparatus shall be at the correct

rating. Replace components only with

parts specied by the manufacturer.

Other parts may result in the ignition of

refrigerant in the atmosphere from a leak.

Cabling

Check that cabling will not be subject

to wear, corrosion, excessive pressure,

vibration, sharp edges or any other

adverse environmental eects. The check

shall also take into account the eects of

aging or continual vibration from sources

such as compressors or fans.

Detection of ammable refrigerants

Under no circumstances shall potential

sources of ignition be used in the searching

for or detection of refrigerant leaks. A

halide torch (or any other detector using a

naked ame) shall not be used.

Leak detection methods

The following leak detection methods

are deemed acceptable for systems

containing ammable refrigerants.

Electronic leak detectors shall be used

to detect ammable refrigerants, but the

sensitivity may not be adequate, or may

need re-calibration. (Detection equipment

shall be calibrated in a refrigerant-free

area.) Ensure that the detector is not a

potential source of ignition and is suitable

for the refrigerant used. Leak detection

equipment shall be set at a percentage

of the LFL of the refrigerant and shall be

calibrated to the refrigerant employed and

the appropriate percentage of gas (25%

maximum) is conrmed.

Leak detection uids are suitable for

use with most refrigerants but the use

of detergents containing chlorine shall

be avoided as the chlorine may react

with the refrigerant and corrode the

copper pipe-work.

If a leak is suspected, all naked ames

shall be removed/ extinguished.

If a leakage of refrigerant is found which

requires brazing, all of the refrigerant

shall be recovered from the system, or

isolated (by means of shut o valves)

in a part of the system remote from the

leak. Oxygen free nitrogen (OFN) shall

then be purged through the system both

before and during the brazing process.

Removal and evacuation

When breaking into the refrigerant

circuit to make repairs – or for any other

purpose – conventional procedures

shall be used. However, it is important

that best practice is followed since

ammability is a consideration. The

following procedure shall be adhered to:

•

Remove refrigerant;

•

Purge the circuit with inert gas;

•

Evacuate;

•

Purge again with inert gas;

•

Open the circuit by cutting or brazing.

The refrigerant charge shall be recovered

into the correct recovery cylinders. The

system shall be “ushed” with OFN to

render the unit safe. This process may

need to be repeated several times.

Compressed air or oxygen shall not

be used for this task. Flushing shall be

Page 21

ENGLISH

achieved by breaking the vacuum in the

system with OFN and continuing to ll

until the working pressure is achieved,

then venting to atmosphere, and nally

pulling down to a vacuum. This process

shall be repeated until no refrigerant is

within the system. When the nal OFN

charge is used, the system shall be

vented down to atmospheric pressure to

enable work to take place. This operation

is absolutely vital if brazing operations on

the pipework are to take place.

Ensure that the outlet for the vacuum

pump is not close to any ignition sources

and there is ventilation available.

Charging procedures

In addition to conventional charging

procedures, the following requirements

shall be followed.

•

Ensure that contamination of dierent

refrigerants does not occur when

using charging equipment. Hoses or

lines shall be as short as possible to

minimise the amount of refrigerant

contained in them.

•

Cylinders shall be kept upright.

•

Ensure that the refrigeration system is

earthed prior to charging the system

with refrigerant.

•

Label the system when charging is

complete (if not already).

•

Extreme care shall be taken not to

overll the refrigeration system.

Prior to recharging the system it shall be

pressure tested with OFN. The system

shall be leak tested on completion of

charging but prior to commissioning.

A follow up leak test shall be carried

out prior to leaving the site.

Decommissioning

Before carrying out this procedure, it is

essential that the technician is completely

familiar with the equipment and all its

detail. It is recommended good practice

that all refrigerants are recovered safely.

Prior to the task being carried out, an oil

and refrigerant sample shall be taken in

case analysis is required prior to re-use

of reclaimed refrigerant. It is essential

that electrical power is available before

the task is commenced.

21

Become familiar with the equipment

1.

and its operation.

Isolate system electrically.

2.

Before attempting the procedure

3.

ensure that:

• Mechanical handling equipment is

available, if required, for handling

refrigerant cylinders;

• All personal protective equipment is

available and being used correctly;

• The recovery process is supervised

at all times by a competent person;

• Recovery equipment and cylinders

conform to the appropriate

standards.

Pump down refrigerant system,

4.

if possible.

If a vacuum is not possible, make

5.

a manifold so that refrigerant can

be removed from various parts of

the system.

Make sure that cylinder is situated

6.

on the scales before recovery takes

place.

Start the recovery machine and

7.

operate in accordance with

manufacturer's instructions.

Do not overll cylinders. (No more

8.

than 80% volume liquid charge).

Do not exceed the maximum working

9.

pressure of the cylinder, even

temporarily.

When the cylinders have been lled

10.

correctly and the process completed,

make sure that the cylinders and

the equipment are removed from

site promptly and all isolation valves

on the equipment are closed o.

Recovered refrigerant shall not be

11.

charged into another refrigeration

system unless it has been cleaned

and checked.

Labelling

Equipment shall be labelled stating that it

has been de-commissioned and emptied

of refrigerant. The label shall be dated

and signed. Ensure that there are labels

on the equipment stating the equipment

contains ammable refrigerant.

Page 22

22

www.aeg.com

Recovery

When removing refrigerant from a system,

either for servicing or decommissioning,

it is recommended good practice that all

refrigerants are removed safely.

When transferring refrigerant into cylinders,

ensure that only appropriate refrigerant

recovery cylinders are employed. Ensure

that the correct number of cylinders

for holding the total system charge is

available. All cylinders to be used are

designated for the recovered refrigerant

and labelled for that refrigerant (i.e. special

cylinders for the recovery of refrigerant).

Cylinders shall be complete with pressure

relief valve and associated shut-o valves

in good working order. Empty recovery

cylinders are evacuated and, if possible,

cooled before recovery occurs.

The recovery equipment shall be in good

working order with a set of instructions

concerning the equipment that is at

hand and shall be suitable for the

recovery of ammable refrigerants. In

addition, a set of calibrated weighing

scales shall be available and in good

working order. Hoses shall be complete

with leak-free disconnect couplings

and in good condition. Before using

the recovery machine, check that it

is in satisfactory working order, has

been properly maintained and that

any associated electrical components

are sealed to prevent ignition in the

event of a refrigerant release. Consult

manufacturer if in doubt.

The recovered refrigerant shall be

returned to the refrigerant supplier in

the correct recovery cylinder, and the

relevant Waste Transfer Note arranged.

Do not mix refrigerants in recovery units

and especially not in cylinders.

If compressors or compressor oils are

to be removed, ensure that they have

been evacuated to an acceptable level to

make certain that ammable refrigerant

does not remain within the lubricant.

The evacuation process shall be carried

out prior to returning the compressor to

the suppliers. Only electric heating to

the compressor body shall be employed

to accelerate this process. When oil is

drained from a system, it shall be carried

out safely.

WARNING!

•

Do not use means to accelerate the

defrosting process or to clean, other

than those recommended by the

manufacturer.

•

The appliance shall be stored in a

room without continuously operating,

ignition sources (for example: open

ames, an operating gas appliance

or an operating electric heater).

•

Do not pierce or burn.

•

Be aware that the refrigerants may not

contain an odour.

•

Appliance should be installed,

operated and stored in a room with

a oor area larger than 12 m2.

•

The appliance shall be stored so as

to prevent mechanical damage from

occurring a warning that the appliance

shall be stored in a well-ventilated

area where the room size corresponds

to the room area as specied for

operation.

•

Any person who is involved with

working on or breaking into a

refrigerant circuit should hold a

current valid certicate from an

industry-accredited assessment

authority, which authorises their

competence to handle refrigerants

safely in accordance with an industry

recognised assessment specication.

•

Servicing shall only be performed

as recommended by the equipment

manufacturer. Maintenance and repair

requiring the assistance of other

skilled personnel shall be carried out

under the supervision of the person

competent in the use of ammable

refrigerants.

Page 23

ENGLISH

ENVIRONMENTAL CONCERNS

11.

23

Recycle the materials with the symbol.

Put the packaging in applicable

containers to recycle it. Help protect the

environment and human health and to

recycle waste of electrical and electronic

appliances. Do not dispose appliances

marked with the symbol with the

household waste. Return the product

to your local recycling facility or contact

your municipal oce.

Page 24

www.aeg.com24

INHOUD

VEILIGHEIDSINFORMATIE ........................................................................................25

1.

VEILIGHEIDSINSTRUCTIES ......................................................................................29

2.

OMSCHRIJVING .........................................................................................................33

3.

MEEGELEVERDE ACCESSOIRES ............................................................................33

4.

INSTALLATIE-INSTRUCTIES .....................................................................................34

5.

KENMERKEN VAN DE AIRCONDITIONER ...............................................................36

6.

BEDIENINGSINSTRUCTIES ......................................................................................37

7.

ONDERHOUD & REINIGING ......................................................................................40

8.

PROBLEEMOPLOSSING ...........................................................................................40

9.

EXTRA INFORMATIE .................................................................................................41

10.

MILIEUBESCHERMING ..............................................................................................46

11.

VOOR PERFECTE RESULTATEN

Bedankt dat u voor dit AEG-product heeft gekozen. Dit apparaat is ontworpen

om vele jaren uitstekend te presteren, met innovatieve technologieën die het

leven gemakkelijker helpen maken met functies die gewone apparaten wellicht

niet hebben. Neem een paar minuten de tijd om het door te lezen zodat u er

optimaal van kunt profiteren.

Ga naar onze website voor:

Advies over gebruik, brochures, het oplossen van problemen

en onderhoudsinformatie:

www.aeg.com

Registreer uw product voor een betere service:

www.registeraeg.com

Koop accessoires, verbruiksartikelen en originele reserveonderdelen voor

uw apparaat:

www.aeg.com/shop

KLANTENSERVICE

Gebruik altijd originele onderdelen.

Als u contact opneemt met de klantenservice zorg dat u de volgende gegevens bij

de hand hebt: model, productnummer, serienummer.

Deze informatie wordt vermeld op het typeplaatje.

Waarschuwing - Belangrijke veiligheidsinformatie.

Algemene informatie en tips.

Milieu-informatie.

Wijzigingen voorbehouden.

Page 25

25

NEDERLANDS

1.

VEILIGHEIDSINFORMATIE

WAARSCHUWING!

• Dit apparaat mag worden gebruikt door kinderen

vanaf 8 jaar oud en door personen met beperkte

lichamelijke, zintuiglijke of mentale capaciteiten

of een ontoereikende ervaring en kennis, als dit

gebeurt onder toezicht of als ze hiervoor instructies

hebben gekregen met betrekking tot het veilige

gebruik van het apparaat, en als ze begrijpen

welke risico's hieraan zijn verbonden.

• Kinderen mogen niet met het apparaat spelen.

• Als de voedingskabel beschadigd is, moet

de fabrikant of diens technische dienst of

een gekwaliceerd persoon deze vervangen

teneinde gevaarlijke situaties te voorkomen.

Deze handleiding bevat informatie m.b.t. het juiste

gebruik van uw nieuwe airconditioner. Lees deze

handleiding zorgvuldig door alvorens het product

te gebruiken. Deze handleiding moet op een veilige

plaats bewaard worden.

OPGELET!

• Voor reparatie of onderhoud van dit systeem altijd

beroep doen op een erkend monteur.

• Neem contact met de installateur voor montage

van dit systeem.

• Deze airconditioner is niet bedoeld voor gebruik

door jonge kinderen of verstandelijk gehandicapten

zonder toezicht.

• Houd jonge kinderen uit de buurt om te voorkomen

dat ze met de airconditioner spelen.

• Er bestaan plaatselijke richtlijnen m.b.t. maximaal

toelaatbare geluidsniveaus van airconditioners.

• Als het netsnoer moet worden vervangen, mag

deze vervanging enkel gebeuren door bevoegd

personeel.

Page 26

26

www.aeg.com

• Montagewerkzaamheden moeten door bevoegd

personeel worden uitgevoerd in overeenstemming

met de nationale bedradingsnormen (indien van

toepassing). Onjuiste aansluiting kan oververhitting

en brand veroorzaken.

• Zorg ervoor dat uw vingers tijdens het verstellen

van de horizontale lamellen niet gekneld raken

tussen de ventilator.

Belangrijke opmerkingen

1.1

1. Stel het systeem niet in werking zonder het luchtlter.

2. Stel het systeem niet in werking in de nabijheid van

een warmtebron of open vuur.

3. Stel het systeem niet bloot aan direct zonlicht.

4. Bewaar of verplaats het systeem altijd rechtop.

5. Tijdens de werking of net erna het apparaat niet

bedekken.

6. Zorg er altijd voor dat, wanneer er een

waterpompafvoerslang is aangesloten, deze slang

naar een goedwerkende afvoer wordt geleid.

7. Zorg voor opslag altijd dat al het condensatiewater uit

het systeem verwijderd is.

Belangrijke zaken bij het gebruik van

1.2

uw airconditioningsysteem

OPGELET!

Waarschuwingen voor gebruik

• Wijzig geen enkel onderdeel van dit product.

• Steek niets in onderdelen van dit systeem.

• Zorg ervoor dat de stroomtoevoer de gepaste

spanning heeft. Gebruik uitsluitend netstroom van

220 V - 240 V, 50 Hz,10 A. Het gebruik van netstroom

met een onjuiste spanning kan leiden tot schade aan

het apparaat en mogelijk brandgevaar opleveren.

• Gebruik altijd een stroomonderbreker of zekering

met de juiste spanningswaarde. Gebruik in geen

geval draad, pennen of andere objecten in plaats

van een geschikte zekering.

Page 27

NEDERLANDS

• In geval van abnormale werking van het

Stekker

Aarding

airconditioningsysteem (bijvoorbeeld een

brandgeur), schakel het onmiddellijk uit en koppel

het systeem los van het stroomnet.

OPGELET!

Waarschuwing m.b.t. het netsnoer

• Deze stekker mag uitsluitend in een geschikt

wandstopcontact gestoken worden. Niet gebruiken

in combinatie met verlengsnoeren.

• Duw de stekker stevig in het stopcontact en zorg

ervoor dat deze niet los zit.

• Het netsnoer niet vervormen of wijzigen en er niet

aan trekken of het onderdompelen in water. Door

aan het netsnoer te trekken of het niet juist te

gebruiken kan er schade aan het apparaat optreden

en kunnen er elektrische schokken optreden.

• Als het netsnoer beschadigd is, moet de fabrikant

of diens technische dienst of een gekwaliceerd

persoon dit vervangen teneinde gevaarlijke situaties

te voorkomen. Gebruik uitsluitend door de fabrikant

gespeciceerde netsnoeren als vervanging.

• Dit apparaat moet geaard worden Dit apparaat

is uitgerust met een netsnoer met aardingskabel.

De stekker moet verbonden worden met een

stopcontact dat correct gemonteerd en geaard is.

27

• Dit apparaat is uitgerust met een netsnoer met een

geaarde draad die verbonden is met een geaarde

pen. De stekker moet verbonden worden met een

stopcontact dat correct gemonteerd en geaard is.

De vierkante aardingspen van deze stekker mag

in geen geval afgeknipt of verwijderd worden.

Page 28

28

www.aeg.com

Stekker

Vierkante aardingspen

1.3

• Zorg ervoor dat het systeem is uitgeschakeld en

• Gooi of giet geen water rechtstreeks op het apparaat.

• Bij het verplaatsen van het airconditioningsysteem

• Voor een goede afvoer mag de afvoerslang niet geknikt

• Tijdens het gebruik mag de temperatuur rond de

• Blokkeer de luchtuitlaat niet met objecten. De

• Voorzie een lekstroomapparaat (ROD) ter bescherming

• Langdurige blootstelling aan een directe luchtstroming

• Gebruik dit airconditioningsysteem niet voor onbeoogde

(uitsluitend

voor het VK)

Veiligheidsinstructies voor gebruik

losgekoppeld van het stroomnet alvorens enige

onderhoudswerkzaamheden of reiniging worden

uitgevoerd.

Water kan elektrische schokken of schade aan het

apparaat veroorzaken.

moet het water uit het systeem worden afgevoerd

(zie pagina 14). Als er water in het reservoir blijft, kan

dit tijdens het verplaatsen uit het apparaat stromen.

zijn of opgetild worden tijdens de dehumidicatie-

modus. Als dit wel gebeurt, kan er water uit het

apparaat stromen.

afvoerslang niet onder het vriespunt liggen. Afvoerwater

kan dan bevriezen in de slang, waardoor het water in

het systeem uit het apparaat stroomt.

koelingprestaties kunnen dan verminderen of geheel

stoppen.

tegen elektrische schokken, in overeenstemming met

de Britse norm en bedradingsrichtlijnen.

kan schadelijk zijn voor uw gezondheid. Stel bewoners,

huisdieren of planten niet langdurig bloot aan directe

luchtstromen.

bijzondere doeleinden (bijvoorbeeld het bewaren van

precisie-instrumenten, voedsel, huisdieren, planten

en kunstobjecten). Dit kan schadelijk zijn voor zulke

eigendommen.

Page 29

NEDERLANDS

VEILIGHEIDSINSTRUCTIES

2.

29

2.1 Opmerkingen m.b.t.

de bediening/werking

• Wacht 3 minuten tot de compressor

opnieuw start met koelen. Als u het

airconditioningsysteem uitschakelt en

onmiddellijk opnieuw herstart, wacht

dan 3 minuten tot de compressor

de koeling opnieuw inschakelt.

Het airconditioningsysteem bevat

een elektronisch toestel dat, uit

veiligheidsoverwegingen, de

compressor 3 minuten inactief houdt.

• In geval van een stroomstoring tijdens

gebruik, wacht 3 minuten alvorens

het systeem te herstarten. Nadat

de stroom opnieuw is ingeschakeld,

herstart het airconditioningsysteem.

Indien de stroomtoevoer minder dan

drie minuten uitgeschakeld was, wacht

dan ten minste drie minuten alvorens

het systeem opnieuw te herstarten.

Als u het airconditioningsysteem

sneller herstart, zorgt een

beveiligingsapparaat in het

systeem er mogelijk voor dat de

compressor wordt uitgeschakeld. Dit

beveiligingsapparaat zal de koeling

ongeveer 5 minuten verhinderen.

Alle eerdere instelling zullen worden

geannuleerd en het systeem keert

terug naar de startinstellingen.

• Werking bij lage temperaturen:

Bevriest uw systeem? Dit kan

gebeuren wanneer het systeem

bij lage omgevingstemperaturen

wordt ingesteld op een temperatuur

rond 18 °C, met name 's nachts.

In dat geval zal een verdere

temperatuurdaling ervoor zorgen dat

het systeem bevriest. Stel het systeem

in op een hogere temperatuur om te

voorkomen dat het bevriest.

• De dehumicatie-modus verhoogt

de kamertemperatuur. Het

systeem genereert warmte tijdens

de dehumidicatie-modus en de

kamertemperatuur zal stijgen. Er zal

warme lucht uit de luchtuitlaat komen,

maar dat is normaal en wijst niet op

een probleem met het systeem.

• In de afkoelingsmodus blaast het

airconditioningsysteem de warme lucht

die het systeem genereert uit de kamer

via de afvoerslang. Ondertussen

komt dezelfde hoeveelheid lucht van

buitenaf door eventuele openingen in

de kamer binnen.

• Gebruik geen middelen die

het ontdooien versnellen of

reinigingsmiddelen anders dan de

middelen die door de fabrikant worden

aanbevolen.

• Het apparaat moet in een kamer

worden opgeslagen zonder continu te

werken en zonder ontstekingsbronnen

(bijvoorbeeld: open vlammen,

een werkend apparaat op gas

of een werkende elektrische

warmteopwekker).

• Niet doorboren of verbranden.

• Apparaat moet worden geïnstalleerd,

bediend en opgeslagen in een kamer

met een vloeroppervlakte van meer

dan 12 m

• U moet de nationale gasvoorschriften

naleven.

• Houd de ventilatie-openingen altijd vrij

van obstructies.

• Het apparaat moet worden

opgeslagen in een goed-geventileerde

ruimte die groter is dan 12 m

• Enige persoon die is betrokken

bij werken aan of ingebruikstelling

van een koelcircuit moet een

actueel, geldig certicaat van een

in de industrie geaccrediteerde

beoordelingsinstantie bezitten, die zijn/

haar competentie in het veilig hanteren

van koelmiddel in overeenstemming

met een in de industrie erkende

beoordelingsspecicatie autoriseert.

• Onderhoud mag uitsluitend worden

uitgevoerd zoals aanbevolen door

de fabrikant van de apparatuur.

Onderhoud en reparaties waarvoor

de assistentie van ander deskundig

personeel nodig is, moet worden

uitgevoerd onder toezicht van

de persoon die competent is in

het gebruik van ontvlambare

koelmiddelen.

• Dit product bevat een lithium

knoop-/muntcelbatterij. Als een

2

.

2

.

Page 30

30

www.aeg.com

nieuwe of gebruikte lithium knoop-/

muntcelbatterij wordt doorgeslikt

of het lichaam binnenkomt, kan dit

ernstige inwendige brandwonden

veroorzaken en in slechts 2 uur

al leiden tot de dood. Maak het

batterijcompartiment altijd goed vast.

Als het batterijcompartiment niet goed

Om letsel bij de gebruiker of andere

personen en schade aan eigendommen

te vermijden, moeten volgende instructies

strikt worden nageleefd.

Onjuiste werking/bediening wegens het

negeren van instructies kan letsels of

schade veroorzaken.

De ernst hiervan wordt aangeduid d.m.v.

volgende indicaties:

WAARSCHUWING!

Dit symbool duidt op de mogelijkheid van dood of ernstig letsel.

OPGELET!

Dit symbool duidt op een gevaar

voor letsels of schade aan

eigendommen

wordt vastgemaakt, houdt u op met

het gebruik van het product, verwijdert

u de batterijen en houdt u ze uit

de buurt van kinderen. Als u denkt

dat batterijen zijn ingeslikt of in een

deel van het lichaam zijn geplaatst,

raadpleegt u onmiddellijk een arts.

Betekenis van de symbolen in deze handleiding wordt hieronder weergegeven:

Dit symbool geeft aan dit nooit

te doen.

Dit symbool betekent dat u dit

altijd moet doen.

2.2 Waarschuwing tijdens

gebruik

WAARSCHUWING!

Waarschuwing tijdens gebruik

Page 31

NEDERLANDS

Waarschuwing Betekenis

Steek de stekker correct in het stopcontact Gevaar voor elektrische schokken of brand

door oververhitting

Het systeem nooit starten of stoppen door

de stekker in of uit te trekken

Beschadig het netsnoer niet en gebruik

geen onbekende/andere netsnoeren

Gevaar voor elektrische schokken of brand

door oververhitting

Gevaar voor elektrische schokken of brand.

Als de voedingskabel beschadigd is,

moet de fabrikant of diens technische

dienst of een gekwaliceerd persoon deze

vervangen teneinde gevaarlijke situaties te

voorkomen

Pas de lengte van het netsnoer niet aan

en sluit geen andere apparaten aan op

Gevaar voor elektrische schokken of brand

door oververhitting

hetzelfde stopcontact

Gebruik het systeem niet met natte handen

Dit kan een elektrische schok veroorzaken

of in een vochtige omgeving

Richt de luchtstroom niet naar personen Dit kan de gezondheid schaden

Zorg altijd voor een correcte aarding Onjuiste aarding kan leiden tot een

elektrische schok.

Laat geen water in elektrische onderdelen

Dit kan leiden tot storingen of elektrocutie

stromen

Monteer altijd een stroomonderbreker

en een afzonderlijk stroomcircuit

Haal het systeem uit het stopcontact als

er geluiden, geur of rook uit komt

Gebruik het stopcontact niet als dit los

of beschadigd blijkt

Onjuiste montage kan leiden tot brand

en een elektrische schok

Het kan brand en een elektrische schok

veroorzaken

Het kan brand en een elektrische schok

veroorzaken

Open het systeem niet tijdens de werking Het kan brand en een elektrische schok

veroorzaken

Houd vuurwapens uit de buurt Deze kunnen brand veroorzaken

Gebruik het netsnoer niet in de nabijheid

van verwarmingstoestellen

Gebruik het netsnoer niet in de nabijheid

Het kan brand en een elektrische schok

veroorzaken

Gevaar voor elektrische schokken of brand

van brandbare gassen of explosieven,

zoals benzine, benzeen, thinner, enz.

Als er een gaslek is van een ander

apparaat, verlucht de kamer alvorens

Gevaar voor explosie, brand en

brandwonden

de airconditioner in te schakelen

Het systeem nooit demonteren of wijzigen Het kan brand en een elektrische schok

veroorzaken

31

Page 32

32

www.aeg.com

OPGELET!

Waarschuwing Betekenis

Als het luchtlter verwijderd moet worden,

Dit kan letsel veroorzaken

raak dan de metalen onderdelen van het

systeem niet aan

Reinig de airconditioner niet met water Water kan in het systeem terechtkomen

en de isolatie beschadigen. Het kan een

elektrische schok veroorzaken

Verlucht de kamer goed indien het systeem

Er kan een tekort aan zuurstof optreden

gebruikt wordt in combinatie met een

kachel, enz.

Als het systeem moet gereinigd worden,

schakel het uit en zet de stroomonderbreker uit

Reinig de eenheid niet wanneer de

stroom ingeschakeld is; dit kan brand

en elektrische schokken veroorzaken,

alsook letsel

Plaats een huisdier of plant nooit op een

plaats waar ze blootgesteld zijn aan directe

Dit kan schadelijk zijn voor uw huisdier

of planten

luchtstroom

Niet gebruiken voor bijzondere doeleinden Gebruik deze airconditioner niet om

precisie-instrumenten, voedsel, huisdieren,

planten en kunstobjecten te bewaren.

Dit kan nadelig zijn voor de kwaliteit, enz.

Stop onmiddellijk de werking en sluit het

venster bij storm of cyclonen

Neem de stekker op de kop vast wanneer

u deze uit het stopcontact haalt

Schakel de hoofdschakelaar uit wanneer

Het gebruik met geopende vensters zorgt

mogelijk voor een nat interieur of meubilair

Gevaar voor elektrische schokken en

lichamelijk letsel

Er kunnen storingen of brand ontstaan

u het systeem lange tijd niet gebruikt

Plaats geen objecten rond luchtinlaten of

in de luchtafvoer

Plaats de lters altijd stevig terug. Reinig

het lter elke twee weken

Gebruik geen sterke reinigingsmiddelen

zoals was of verdunners - gebruik een

Dit kan schade aan het apparaat of

ongevallen veroorzaken

Werking/bediening zonder lters kan

storingen veroorzaken

De kleuren kunnen verbleken of er kunnen

krassen op het oppervlak ontstaan

zachte doek

Plaats geen zware objecten op het netsnoer

en zorg dat het snoer niet wordt ingedrukt

Drink geen water dat uit de airconditioner

afkomstig is

Wees zorgvuldig bij het uitpakken

Er is gevaar voor brand of elektrische

schokken

Het bevat contaminanten die u ziek kunnen

maken

Scherpe randen kunnen letsels veroorzaken

en monteren

Indien er water in het systeem terecht komt,

schakelt u het systeem uit via de stekker en

Gevaar voor elektrische schokken

en schade

schakelt u de stroomonderbreker uit. Isoleer

de stroomtoevoer door de stekker uit het

stopcontact te halen en neem contact met

een bevoegd monteur

Page 33

NEDERLANDS

OMSCHRIJVING

3.

1

33

6

2

3

5

4

1

Kamerluchtafvoer

2

Controlepaneel

3

Kamerluchttoevoer

4

Zwenkwiel

5

Afstandsbediening

MEEGELEVERDE ACCESSOIRES

4.

ONDERDELEN NAAM VAN HET ONDERDEEL:

1

2

3

4

5

6

7

8

Afb. 2

•

Controleer of alle accessoires in de verpakking zitten en raadpleeg de montageinstructies voor het gebruik ervan.

Uitlaatslang

Vensterschuifkit

Reserveonderdeel uitschuifbare slang

Afvoerslang & adapter

3/8" schroef

Sierfolie

Bevestigingsband

Afstandsbediening 1 stuks

7

6

Handgrepen (beide zijden)

7

Filter

8

Afvoerluchtuitlaat

9

Afvoeruitlaat

10

Afvoerlade onderaan

8

9

10

Afb. 1

HOEVEELHEID:

1 stuks

1 stuks

1 stuks

1 stuks

2 stuks

1 stuks

1 set

Page 34

34

www.aeg.com

Afb. 4

Afb. 6

Afb. 7

INSTALLATIE-INSTRUCTIES

5.

5.1 Warme lucht afvoeren

In de KOEL-modus moet het apparaat

dicht bij een venster of opening worden

geplaatst zodat de warme luchtafvoer

naar buiten kan worden geleid. Plaats

het systeem eerst op een vlakke vloer en

zorg ervoor dat er minimaal 30 cm speling

is rond het systeem, en dat het zich in de

nabijheid van een stopcontact bevindt.

Schuif een van de uiteinden van de

1.

slang uit (afb. 3).

Afb. 3

Schuif de adapter A in het

2.

uitwisselingsgat van de eenheid

(zie afbeelding 4).

Vensterschuifkit

Minimaal: 56 cm

Maximaal: 112 cm

Raadpleeg “

een openslaand raam” voor

informatie over het installeren

van de raamset.

De slang is oorspronkelijk

38 cm lang maar kan verlengd

worden tot 150 cm. Het is echter

aanbevolen om ze niet langer

te maken dan nodig. Zorg er ook

voor dat de slang geen scherpe

bochten maakt. (Afb. 7)

Installatie in

5.2

Installeer de raamset op het raam,

3.

schuif adapter B in de vensterschuifkit

en sluit dit af (afb. 5 & 6).

Afb. 5

5.2 Installatie op een

openslaand raam

Open het raam en hef de

1.

vergrendelingshendel van

de vensterschuifkit op (afb. 9).

B

B: Vergrendelingshendel

Afb. 9

Page 35

35

NEDERLANDS

Plaats de vensterschuifkit op

2.

het raam. Pas de lengte van de

vensterschuifkit aan volgens de

hoogte van het venster (afb. 10).

De uitschuifbare stang kan worden

verlengd als het raam te hoog is.

Verwijder de uitschuifbare

stang hiertoe eerst helemaal

(afb. 11 A). Lijn vervolgens de

3 haken op de uitschuifbare

stang (afzonderlijk verkrijgbaar)

uit met de 3 sleuven op het

uiteinde van de uitschuifbare

stang en schuif de 3 haken in de

sleuven. Druk vervolgens op de