0

0

A

A

D

D

T--

T

H

H

C

C

4

5

5

0

0

4

CNC Flame/Plasma Controller

User Manual

ADTECH (SHENZHEN) CNC TECHNOLOGY CO., LTD

5th Floor, 27-29th Building, Tianxia IC Industrial Park, Yiyuan road, Nanshan District,

Shenzhen Post code: 518052

Tel: 0755-26099116 Fax: 0755-26722718

E-mail: sales02@machine-controller.com http://www.machine-controller.com

ADT-HC4500 CNC Flame/Plasma Controller

Copyright

All property rights of this user manual are reserved by Adtech (Shenzhen) CNC Technology Co., Ltd

(ADTECH for short). No institution or person is allowed to counterfeit, copy, transcribe or translate this user

manual without permission of ADTECH. This user manual does not include warranty, standpoint expression,

or other hints in any form. ADTECH does not bear any responsibility for any data outflow, benefit loss or

business termination due to the product info contained or mentioned by this user manual. All products and data

mentioned are for reference only. Contents are subject to change without prior notice.

All Rights Reserved

ADTECH (SHENZHEN) CNC TECHNOLOGY CO., LTD

1

ADT-HC4500 CNC Flame/Plasma Controller

Upgrade Information

Item No. Version No. Revision Date Remark

HC4500

(General)

Note: Meanings of the three numbers in version number are as follows:

0 1 4

Library main version No. Library secondary version No. Reserved

Remark:

0.1.4 2011/02/24 Edition 4

1. This user manual is strictly emended and checked by ADTECH (SHENZHEN) CNC TECHNOLOGY

CO., LTD, however, it is not guaranteed that the user manual has no any mistake or error.

2. ADTECH (SHENZHEN) CNC TECHNOLOGY CO., LTD commits itself to improving the product

functions and the service quality consistently. Therefore, the company reserves the right of changing any

products as described, any software program, and the content of the user manual, without prior notice.

2

ADT-HC4500 CNC Flame/Plasma Controller

Safety Notice

Read this safety notice before operating.

I. Notice

1、 Notice on safety:

Original copy of safety notice should be dispensed to every operator.

Do not open the controller cover without permission; otherwise, it would be out of the range of

guarantee.

Cut off the power supply in case the machine is not used for a long time.

Pay attention not to drop any dust or iron powder into the controller.

Do not pour any liquid into the controller.

Handle with care, and do not cause any damage.

Abide by the accident prevention provision and regulations.

Abide by the accident prevention provision and regulations on Oxygen cutting.

Wear the mask when performing the plasma arc cutting, for the plasma arc will generate UV-b

radiation.

2、 Notice on correct application:

Our control system is capable of anti-interfering, but it is still required that your plasma power

supply have shielding function and the plasma controller have good grounding. Otherwise, it

will bring serious result.

Please set all parameters of the controller strictly according to the user manual; otherwise, it

may lead to failure of control system or even cause serious consequences.

The controller uses the 24V DC power supply. To avoid short circuit, please pay attention to the

voltage, negative or positive electrode of power supply when installing.

Do not insert or pull out any output plug of controller while the power supply is connected;

otherwise, it will damage the inside of controller.

If the output relay is non-solid-state relay, a freewheeling diode should be connected in parallel

on relay coil. Check the applied power supply to see whether it is up to requirements, avoid

burning out the controller.

Controller lifetime has a great relationship with ambient temperature. Install a cooling fan if the

temperature in processing area is too high. The allowable ambient temperature of the controller

is between 0°C and 60°C.

Do some protection measures if the machine is used in high temperature, damp, or dusty

environment, or environment with corrosive gas.

In place with strong vibration, add a rubber anti-vibration pad to weaken the vibration.

3

ADT-HC4500 CNC Flame/Plasma Controller

II. Statement:

We offer one year factory warranty or lifetime maintenance for any malfunction arising under the normal use.

In case of man-made damage or if the warranty expired, ADTECH will charge a certain cost price of parts.

However, the warranty is not applied to the following conditions:

The label of serial number is torn down.

Any damage caused by personal factors

Any damage caused by natural disasters

Disassembly, modification, or repair without permission

III. Maintenance

1. Notice for maintenance and inspection:

Cut off the power supply of major loop before maintaining or repairing the controller.

To prevent the accident, the operator should confirm the power supply is cut off.

2. Inspection item and period:

Under the general operating conditions (Daily average 30°C, load rate 80%, operating ratio 12 hours per

day), carry out the following items to do the route and periodical inspections.

● Check whether the ambient temperature, dust and foreign

Route inspection Daily

matters exceed the criteria

● Check whether there is abnormal vibration or sound

● Check whether the firm parts are loosened

Periodical inspection Half year

● Check whether the terminal board is damaged

4

ADT-HC4500 CNC Flame/Plasma Controller

Content

Upgrade Information..............................................................................................................2

Safety Notice...........................................................................................................................3

Chapter I. Introduction ..........................................................................................................8

1. Function introduction ................................................................................................................................8

2. Features .....................................................................................................................................................8

3. Application environment ...........................................................................................................................9

Chapter II Quick Start..........................................................................................................10

1. Help information .....................................................................................................................................10

2. Restore factory default ............................................................................................................................ 11

3. Figure library........................................................................................................................................... 11

4. Copying processing files .........................................................................................................................12

5. Calling in processing file.........................................................................................................................13

6. Adjustment of cutting speed[Adju] .........................................................................................................13

7. Adjustment of Manual Speed..................................................................................................................15

8. Control of Turning Quality......................................................................................................................15

9. Adjustment of preheating time in flame cutting [Adju] ..........................................................................17

10. Power Failure Treatment .......................................................................................................................19

11. Break point setup................................................................................................................................... 19

12.Change of cutting gun nozzle.............................................................................................................. 19

13. Displacement perforating ......................................................................................................................20

14. Movement of work piece.......................................................................................................................21

15. Line and point selection ........................................................................................................................21

16. Array...................................................................................................................... 错误!未定义书签。

17. Mirror ....................................................................................................................................................24

18. Rotation .................................................................................................................................................25

19. Calibration.............................................................................................................................................26

20.Tool Setting .........................................................................................................................................29

Chapter III Operations and Details.....................................................................................30

1. Auto ......................................................................................................................................................... 30

1.1 Details of program running ...........................................................................................................31

1.2 Details of submenu in auto interface.............................................................................................33

1.3 Basic operations ............................................................................................................................40

2. Figure library........................................................................................................................................... 41

2.1 Operations .....................................................................................................................................41

2.2 Hole-cutting and slicing ................................................................................错误!未定义书签。

2.3 Edge-sharing cut............................................................................................ 错误!未定义书签。

3. Edition ..................................................................................................................................................... 42

3.1 Explanation of sub-menu...............................................................................................................43

3.2 Editing processing file................................................................................................................... 50

3.3 Basic operations ............................................................................................................................53

4. Parameter.................................................................................................................................................54

4.1 System ...........................................................................................................................................54

4.2 Speed .............................................................................................................................................56

5

ADT-HC4500 CNC Flame/Plasma Controller

4.3 Adjustment (Adju) ......................................................................................................................... 58

4.4 Control (Ctrl)................................................................................................................................. 58

4.5 Accuracy (Prec) .............................................................................................................................60

4.6 Save ...............................................................................................................................................62

5. Diagnosis (Diag) .....................................................................................................................................62

5.1 Sub-menu ......................................................................................................................................62

6. Upgrade (Upgd).......................................................................................................................................65

6.1 Description of sub-menu ...............................................................................................................65

6.2 Restoration (Rev) ..........................................................................................................................66

6.3 Upgraded by USB disk (Udsk)...................................................................................................... 69

6.4 Backup/Restoration of HC6500 system files.................................................错误!未定义书签。

6.5 Upgrade via PC .............................................................................................错误!未定义书签。

6.6 Recording program........................................................................................................................ 73

6.7 Upgrade in BIOS interface via PC ................................................................................................74

7. Help system............................................................................................................................................. 76

8. Multi-language operations....................................................................................................................... 77

Chapter IV Instruction System............................................................................................79

1. Explanation of programming symbol .................................................................................................. 79

2. Coordinate explanation .........................................................................................................................79

2.1 Relative coordinate........................................................................................................................ 79

2.2 Absolute coordinate.......................................................................................................................80

3. G instruction............................................................................................................................................80

3.1. G92 reference point setup.............................................................................................................80

3.2. G21/G20 Metric /Imperial setting ................................................................................................80

3.3. G00 idle motion............................................................................................................................ 81

3.4. G01 linear cutting.........................................................................................................................81

3.5. G02/G03 circular arc cutting........................................................................................................ 81

3.6. G04 Pause/Delay instruction........................................................................................................ 82

3.7. G26, G27, G28 Back to reference point....................................................................................... 82

3.8. G22/G80 cycle processing............................................................................................................82

3.9. G81 workpiece counting ..............................................................................................................83

3.10. G91/G90 relative/absolute coordinate programming .................................................................83

3.11. G41/G42/G40 ............................................................................................................................. 83

4. Common M instructions.......................................................................................................................... 84

Chapter V Hardware ............................................................................................................86

1. Overall dimension ...................................................................................................................................86

2. System input/output interface..................................................................................................................87

2.1 Back cover..................................................................................................................................... 87

2.2 Specifications ................................................................................................................................87

2.3 Electrical connection ..................................................................................................................... 88

3. Connection mode of motor...................................................................................................................... 96

3.1 Connection of Differential Driver .................................................................................................96

3.2 Connection of common-anode driver..........................................................................................100

3.3 Connection of Panasonic servo motor .....................................................................................101

4. Key Points for Installation & Test .........................................................................................................101

4.1 NCS’s Requirement on Impulse Equivalent Value ...................................................................... 101

6

ADT-HC4500 CNC Flame/Plasma Controller

4.2 Current adjustment of driver .......................................................................................................102

4.3 Test method of impulse equivalent..............................................................................................102

4.4 Anti-interference measures.......................................................................................................... 102

Chapter VI Troubleshooting...............................................................................................104

1. Why the U-disk cannot be read? ...........................................................................................................104

2. Why there is an error in the cutting? .....................................................................................................104

3. Why the cutting quality of the turning is poor?..................................................................................... 104

4. Why the cutting square is changed to rectangle? .................................................................................. 104

5. Why the cutting circle is changed to ellipse? ........................................................................................104

6. Why there is wave shake in the opposite angles when cutting the circle? ............................................104

7. Why the motor does not work or is similar to death when it is in “Auto” state? ..................................104

8. Why the motor does not work or is similar to death when it is in “Manual” state? ..............................105

9. The processing code has the “Return” instructions. However, why the device does not return to the

home position after having finished the track?..........................................................................................105

10. Why the right angle of the cutting square is not vertical?................................................................... 105

11. Why the anti-interference performance of plasma is poor?.................................................................105

12. Why, one of the solenoid valves cannot work? ...................................................................................105

Annex II Illustration of edition and processing................................................................107

1. Standard circle....................................................................................................................................... 108

2. Square.................................................................................................................................................... 109

3. Triangle ................................................................................................................................................ 110

4. Quincunx .............................................................................................................................................. 111

5. Four figures ........................................................................................................................................... 112

Annex III G Instruction Quick Reference.........................................................................114

Annex IV M Instruction Quick Reference........................................................................115

7

ADT-HC4500 CNC Flame/Plasma Controller

Chapter I. Introduction

1. Function introduction

HC4500 is a newest generation of high-performance flame/plasma controller developed by

ADTECH. The control circuit adopts the ARM9 high-speed microprocessor, large-scale

custom-tailor IC chip, and multi-layer PCB, and the display adopts 7” color display screen. Surface

mount devices are used throughout the entire process. The controller is developed basing on

powerful R&D capacity of ADTECH for many years, and the software integrates advantages of

factories from home and abroad. The hardware of this controller is highly stable in operation, and the

software is perfect in performance, making it a trusted and highly cost-efficient flame/plasma

controller.

2. Features

1) Adopt 32-bit high performance CPU and super-large programmable FPGA, real-time multi-task

control technology and hardware interpolation technology, realizing a fast and stable operation.

2) ARM9 processor technologies, achieving quick running speed of program and refreshing speed

3) Reasonable process structure, combining with all Optocoupler isolation control and powerful plasma

anti-interference capacity

4) 256M storage space for processing files, satisfying the running and processing of all kinds of

complex programs, and capable of handling the running of large program easily

5) Capable of controlling 3 stepper/servo motors at the same time, as well as synchronizing of double

axes or developing the function of third axis in accordance with the actual requirements

6) 7” color display screen, human-friendly operating interface, easy to operate, and the interface

supports display in many languages

7) Support plasma and flame cutting, and the system software contains the perfect cutting processes for

both kinds of cutting

8) Figure library is provided, capable of selecting hole-cutting or slicing of figure in figure library as

required

9) Figure processing function allows it possible to rotate, calibrate, or do X/Y mirror for the processing

figure

10) Provided with array, rectangle edge-sharing cutting functions

11) Delay, preheating, and perforating control

12) Plasma arcing detection, initial positioning, and corner signal speed control, supporting THC

13) Cutting gun nozzle changing, replacement perforating, and part moving

14) Breakpoint restoration, and power-off protection during the processing

15) The functions including idling, testing gragh scope, retroversion etc..

16) Gap compensation and backlash compensation

17) Figure display, real-time track movement display

18) The stepper motor adopts high-subdivision driver, with high accuracy and stable running.

19) Cutting gun can be adjusted up and down as required.

20) Diagnosis function is provided for helping users to solve the machine errors quickly.

21) Capable of copying processing files in NCS to USB disk.

8

ADT-HC4500 CNC Flame/Plasma Controller

22) File name can be displayed in Chinese so that users know clearly the content of files.

23) Users can download the latest upgrade via the USB disk for updating the application.

24) End users can restore the factory default and system files using the one-key backup and restoration

function, which better protects the system parameters and system files.

25) Procedure input has two modes: processing file after USB disk transfers CAD and nests, and on-site

compiling G code manually.

26) USB and RS232 serial port communication control; capable of reading files via USB disk, it is

convenient for the on-site operations

27) Help system makes the operations easier for the primary users.

28) Speed

range : 0---15000MM / MIN , Distance of travel : (+)99999.999—(-)99999.999 mm.

3. Application environment

Power supply: DC 24V 50/60Hz

Power consumption: <4W

Operating temperature: 0°C —60°C

Storage temperature: -20°C —80°C

Operating humidity: 20%—95%

Storage humidity: 0%—95%

9

ADT-HC4500 CNC Flame/Plasma Controller

Chapter II Quick Start

ADT-HC4500 flame/plasma controller can be used in machine tool to control flame or plasma cutting gun

for cutting. This system is displayed with window prompt by grade. In the menu of an interface, you can

press [F1] to [F6] to select the relevant functions, or press [

This chapter introduces the general operating procedures for using the system, allowing users to be able to

use quickly. However, to master every skill or details, you have to read through the user manual.

Once connecting to the power supply and entering into the main interface, a greeting word will be

shown as follows:

] or [ ] to return to the previous menu.

Picture 2 Main interface

Press [F1] to [F6] to enter the interfaces of different functions:

Press [F1] to enter the auto process, manual, figure display and processing interfaces

Press [F2] to enter the figure library.

Press [F3] to enter the interface for calling processing files, manual editing of processing files, and

copying files.

Press [F4] to enter the parameter setting and adjusting interface.

Press [F5] to enter the system diagnosis, version enquiry, and user-defined outlet editing

interfaces.

Press [F6] to enter the system parameter restoration, application upgrade, and help interfaces.

1. Help information

In most interfaces of main menu, you can press [INS] to get the relevant text help information. For

example, in main interface, press [F1] (Auto) to enter the auto interface, where pressing [INS] allows you to

get the help information on this interface.

10

ADT-HC4500 CNC Flame/Plasma Controller

Main menu →Press [F6] to enter the upgrade interface →Press [F6] (Help) to search for the

relevant help information.

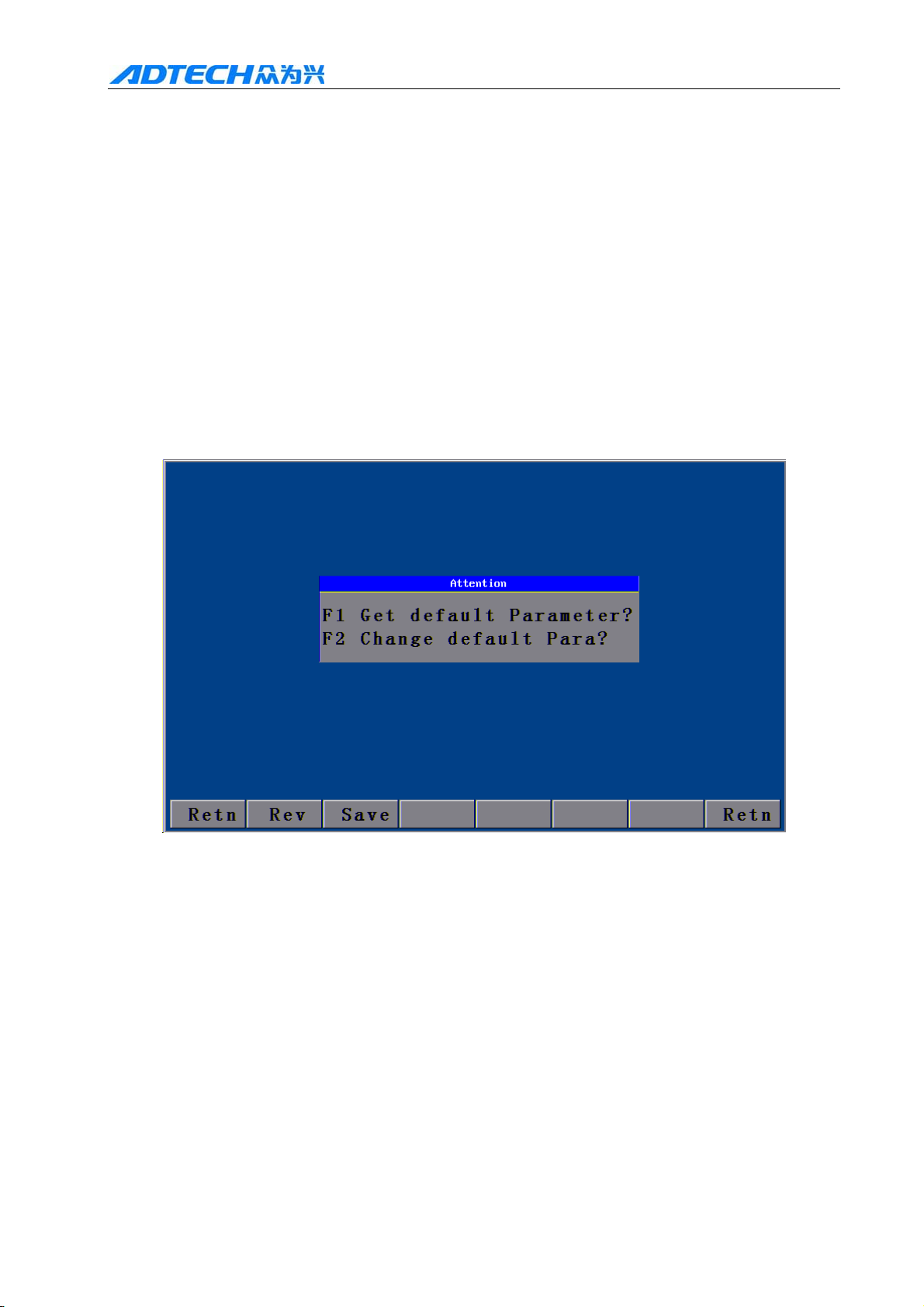

2. Restore factory default

In case there is a condition of abnormal speed or accuracy due to the improper adjustment of system

parameters, you can, in main menu of system, press [F6] (Upgd) →Press [F1] (LEV)→Press [F1]

(LEV)→Press [ENTER] to restore the parameters to factory default.

In HC4500, you can also press [F6] (Upgrade) in main menu→ [F3] (Restore) →Press [F1]

(Restore)→Press [ENTER] to restore the system configuration files, help files, and figure library files.

Note: If the factory has not saved the factory default, it is not allowed to restore the parameters,

and the corresponding dialogue box will be shown.

Picture 2.2 Parameter revert

It can refer to the chape 3 system details operation and specification (6.2) Revert fucntion

3. Figure library

For the convenience of processing and for reducing workload of operators and increasing the usability of

system, the system is provided with 33 common figures of processing part and 1 testing figure. In the main

menu interface, press [F2] (Grap) to enter the figure library interface as follows, and select the corresponding

figure to process.

11

ADT-HC4500 CNC Flame/Plasma Controller

Picture 2.3 Figure library interface

Operation: Press [X+], [X-], [Y+], or [Y-] to move the cursor up, down, left or right. Press [S↑], [S↓] to

page up or down, and press [ENTER] to enter the figure.

4. Copying processing files

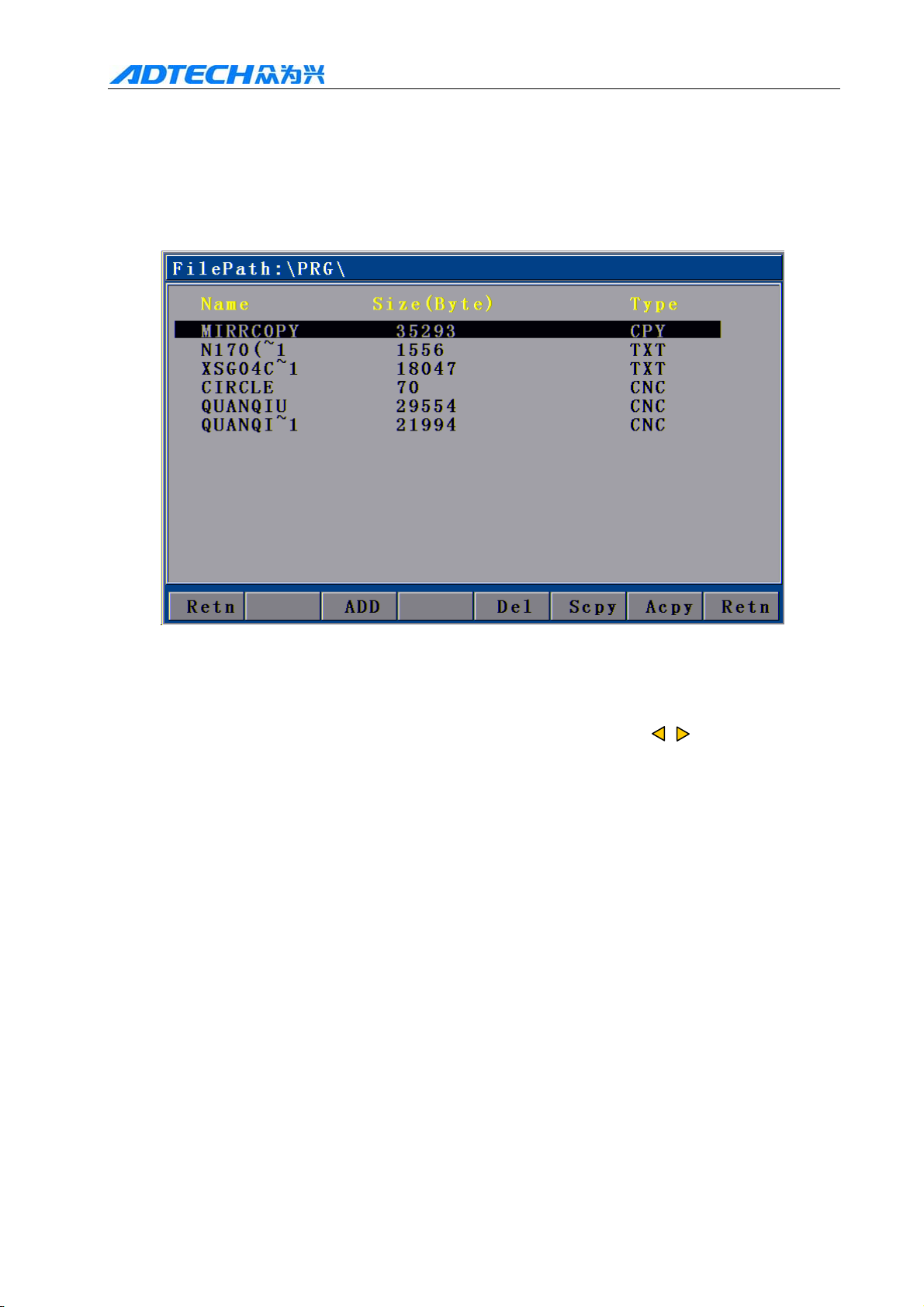

Insert the USB disk with copied processing files into the USB port of control system. In main menu, press

[F3] (Edit) →[F3] (Udsk). If it is connected successfully, the interface will show the file names of files

stored in USB disk, as the following picture shows:

Picture 2.4 Copying processing files

At this time, press [Y+] or [Y-] to select the processing files to be copied, and press [F2] (SCpy) or

[ENTER] to copy. After that, a prompt will pop up when you can press any key to return to the main menu

12

ADT-HC4500 CNC Flame/Plasma Controller

interface.

5. Calling in processing file

In main interface, press [F3] → [F2] to enter the interface for calling in files as follows:

Picture 2.5 File calling interface

After entering the above interface, press [Y+] or [Y-] to select the processing file, and then press [F2] or

[ENTER] to confirm and enter the processing code editing interface. You can press to exit and go back to

the main interface, when you can press [F1] to enter the auto interface to carry out the processing with selected

files.

6. Adjustment of cutting speed[Adju]

In main interface, you can press [F4] (Para) → [F2] (Speed) to enter speed setting interface.

13

ADT-HC4500 CNC Flame/Plasma Controller

2.6.1 Speed setting interface

First, set the processing speed in the interface as above picture. The speed is the max speed that the

actual processing can achieve.

Press [X+], [X-], [Y+], or [Y-] to move the cursor to make the selection, and then press the number key on

left of panel to input the value.

After setting the speed, press to return to main menu. Press [F1] again to enter the auto

processing interface:

2.6.2 Auto processing interface

14

ADT-HC4500 CNC Flame/Plasma Controller

Processing speed is determined by the “CutSpeed” in speed setting interface and the “Speed” rate in

auto processing interface.

Actual Processing Speed =CutSpeed × Speed Rate

Note: Speed rate can be adjusted by pressing [F↑] and [F↓] on the panel, or just the [F] key.

7. Adjustment of Manual Speed

In main interface, press [F4] (Para) → [F2] (Speed) to enter the speed setting interface.

See section “HSpeed” for the interface picture. Set the manual speed with the same method as

setting cutting speed, and exit to the main interface.

In main interface, press [F1] (Auto) → [F2] (Manual) to enter the manual interface:

2.7 Manual interface

Actual Manual Speed = HSpeed × Speed Rate

Note: Speed rate can be adjusted by pressing [F↑] and [F↓] on the panel, or just the [F] key.

8. Control of Turning Quality

During the flame cutting and plasma cutting, there is a process of acceleration and deceleration when

turning. Whether the acceleration or the deceleration is properly set or not, it directly influences the cutting

quality of the turning. Especially when it is flame cutting, the fast speed of turning may easily cause

flameout or halfway cutting; and if the turning speed is too slow, it may easily burn the turning to be

15

ADT-HC4500 CNC Flame/Plasma Controller

circular arc shape.

The system acceleration and deceleration are set as follows: Press [F4] (Para) in main menu interface, and

press [F2] (Speed), then, set the speed in “StrSpeed” and “AddSpeed” (See picture below). Detailed definitions

are as follows:

2.8 Speed settings

1. [StrSpeed]--Start-up speed: Track-Move, a speed of starting up. For example, if the “StrSpeed” is set to be

300, the system speed is 0.3m at the just beginning. The value of start-up speed is determined by the

processing speed. The following list shows the reference value of start-up speed; actual data are subject to

the on-scene cutting effect.

CutSpeed (mm/minute) StrSpeed (mm/minute)

100-200 100

200-500 200

500-700 300

700-800 500

800-1000 600

1000-1300 700

1600-2000 1000

2000-3000 1500

3000-4000 2000

Table 2.8.1

16

ADT-HC4500 CNC Flame/Plasma Controller

2. [AddSpeed]-- Acceleration: It is an average increment of increasing the processing speed from start-up

speed to the highest speed. For example, if the start-up speed is 300, acceleration is 100, and highest

speed is 1000, then, the speed is increased to 300, 400, 500…1000 at 100 intervals; if the acceleration is

50, then, the speed is increased by 50 each time.

The acceleration is determined by the

Precision: refer to the distance the corresponding machine moves when the control system gives an

Precision (In main menu, press [F4] (Para) → [F5] (Prec).

impulse.

The following list shows the reference value of impulse equivalent and the acceleration; the actual data

are subject to the on-scene cutting effect.

Precision Addeleration (mm/minute)

0.001000-0.002000 10

0.002000-0.003000 20

0.003000-0.004000 30

0.004000-0.005000 40

0.005000-0.006000 50

0.006000-0.007000 60

0.007000-0.008000 70

0.008000-0.009000 80

0.009000-0.010000 90

0.010000-0.011000 100

0.011000-0.012000 110

0.012000-0.013000 120

Table 2.8.2

9. Adjustment of preheating time in flame cutting [Adju]

In main menu, press [F4] (Para) → [F4] (Ctrl) to set the “Preheat Delay” in the second row as the

required time.

17

ADT-HC4500 CNC Flame/Plasma Controller

2.9.1 Control interface

In auto cutting interface, it will carry out preheating before perforating. Total preheating time and the

current preheating time will be shown on the right bottom of the interface; on the left bottom there will show

“Record & GO, Press [G]; Stop, press [START]; Go-on, Press [STOP].” As prompted, if you press

[START], the system will stop preheating immediately and go to the next action without saving the preheating

time. If you press [STOP], the preheating time will be extended without limit. Press [G] to stop preheating, and

the system will save the “Current preheating time” automatically as the “Preheating time” for the future.

In main menu, press [F1] (Auto):

2.9.2 Preheating in auto interface

18

ADT-HC4500 CNC Flame/Plasma Controller

10. Powe r Failure Treatment

In order to avoid the waste of raw materials caused by the sudden power failure, the system equips with a

power-off protection function. If the device is powered off during the processing, the system will automatically

save the last processing track as a break point. When the power supply is resumed and you want to resume the

coordinate before power-off, you just have to press [F1] (Auto) in main menu → [F6] (Break point) or [F1]

(Auto) → [F4] (Break point).

Note: Do not move the cutting nozzle when the power is off, and make sure to set the current

coordinate when the power is resumed; otherwise, all the memory coordinate will be wrong.

11. Break point setup

If you exit the automatic processing interface (press [F1] (Auto) to enter) and want to return next time,

you need to resume to the current stop coordinate. This can be made by pressing “Pause” during the automatic

processing and pressing [F6] (Spot), then, the system will automatically save the current processing point

(where the cutting nozzle is located) as a break point. This point is saved forever; no matter it is power off or

on. The coordinate will be the saved break point coordinate when you enter the “Auto” interface next time, as

long as the current program has not changed.

If you restart the device after the power-off, you just have to press [F6] (Spot ) in the “Auto” interface to

restore the break point, and press the [Start] key to resume processing.

12.Change of cutting gun nozzle

If cutting gun nozzle is damaged during the processing, please follow the following steps to change it:

c In main menu, Press [F1] (Auto) → d Press [Stop] key → e Press the corresponding [X+], [X-], [Y+],

and [Y-] keys to move the cutting gun to a proper place for changing the nozzle →f Press [START] → g

select the relevant item in the popped up dialogue box as Picture 2.12 → h Press [ENTER], the coordinate

will be moved to the current break point automatically and proceed the processing of selected item.

19

ADT-HC4500 CNC Flame/Plasma Controller

2.12 Change of cutting gun nozzle

FBack and Cutting : Go back to the

FBack and Stop : Go back to the

CBack and Cutting : Go back to the

interrupt with no cut then cut continue the program.

interrupt with no cut then stop program..

interrupt with cutting then then cut continue program.

Process ringht here : cut continue program right here.

13. Displacement perforating

A

Picture 1 Picture 2

As picture 1, the outer is square steel plate and the inside rectangle is the workpiece to be cut. Assuming

that it is to cut the work piece from point A and the steel plate is of thick materials; then, it will cost a lot of

B

B

time to perforate. However, if it is to cut from the edge of steel plate (point B), the time of preheating

perforating may be saved. Detailed operations are as follows:

c In automatic processing → d Press [STOP] → e Press the corresponding X, and Y keys to move the

cutting gun to the edge of the steel plate →f Press [Start] again →g Select the relevant item in the popped up

dialogue box → h Press [ENTER], the coordinate will be moved to the current break point automatically and

proceed the processing of selected item.

20

14. Movement of work piece

ADT-HC4500 CNC Flame/Plasma Controller

Work piece 2

Work piece 2

Work piece 1

Work piece 1

Picture 1 Picture 2

To save the steels during the processing, you can move the tracks of work piece to a certain place for

processing when cutting some kinds of figures. As shown in above pictures, the out frame is the steel plate,

and the inside frame is the figure to be cut. For example, it may waste many materials if you cut the “work

piece 2” directly after having cut the “work piece 1”, because they are a certain distance away. Therefore, you

can move the track of work piece to a proper place as Picture 2 before cutting, which can save many materials.

Detailed operations are as follows:

Press [STOP] key after you have cut the “work piece 1” → Press [X+], [X-], [Y+], and [Y-] to move

the cutting gun to the proper position.

15. Line and point selection

This function allows you to select any line of G code of the figure for processing.

In main menu, press [F1] (Auto) → [F4] (Grap) → [F4] (Pro) → [F2] (ChoG) to enter the interface

of positioning mode as follows:

21

ADT-HC4500 CNC Flame/Plasma Controller

Picture 2.15.1 Positioning mode of line selection

Direct change coordinate: the cutting gun does not move, but the coordinate is changed to the

coordinate of this line directly.

Auto move Gun: the cutting gun moves from the current position to the coordinate of selected

program line.

You can press [Y+] or [Y-] to change the mode of positioning when selecting line, and press

[ENTER] to select the line number (as Picture 2.15.2 shown below).

Input the line number by pressing the number key and then press [ENTER]. In case of doing fine

adjustment, you can press [X+] or [X-] to select the next line number.

16. Array

When you need to cut a single figure on big steel plate for several times, you can use the array function

to realize the simple array of this repeated figure.

In main menu interface, press [F1] (Auto) → [F4] (Grap) → [F4] (Pro):

22

ADT-HC4500 CNC Flame/Plasma Controller

Picture 2.16.1 before arraying (Processing interface)

The acquiescent deviant is the space usage size as aboce picture, which it means the single graph height

and width. Suitable adjust the width and height can make the arraying more reasonable.

Press the No. key input the parameter value, press 【Y+】、【Y-】select item of paramters, input correct

parameter, press 【Confirm】 enter into the direction seletion of arraying.

In above interface, press [F5] (Arr) to enter the array parameter setting interface.

Picture 2.16.2 Array parameter settings

Press 【X+】、【X-】、【Y+】、【Y-】 select cursor movement to arraying direction, after selected,

press 【Confirm】, finished all of the step of arraying, graph will finished array immideately.

23

ADT-HC4500 CNC Flame/Plasma Controller

Picture 2.16.3 After array graph

Matters need attention when you operate arraying

1) After the array, it will not save the original process file, like stop coordinate etc.

2) After Array, press 【Retn】enter into dealing interface, It can check if the size

suitable the plate or not. Afresh Array press 【F6】(restore)

17. Mirror

If you need to exchange the start point and the final point of the figure horizontally at 180˚ during

the cutting, you can do it by mirror function.

Press [F1] (Auto) → [F4] (Figure) → [F4] (Process) → [F1] (Rotate) → and press [F1] (Y mirror) / [F2]

(X mirror) / [F3] (XY mirror). As shown in the following picture:

24

ADT-HC4500 CNC Flame/Plasma Controller

Picture 2.17.1 Before X mirroring

Picture 2.17.2 After X mirroring

18. Rotation

Sometimes, the position and angle of the steel plate are required to meet the XY axis of the cutting

machine during the cutting. However, in the actual processing, it is hard to avoid the XY axes on steel

plate deviating from the XY axes of cutting machine for an angle.

In virtue of rotation function, it is allowed to achieve the auto calibration of steel plate so that you do not

have to move the steel plate or cutting machine. The operations are as: in main menu, press [F1] (Auto) →

[F4] (Figure) → [F4] (Process) → [F1] (Rotate) → [F4] (Rotate), and then input the rotation parameter to

finish the figure rotation.

25

ADT-HC4500 CNC Flame/Plasma Controller

Picture 2.18 Rotation

19. Calibration

If rotation angle is uncertain when calibrating the steel plate, we can get a correct rotation angle by

calibration function.

First, a reference axis is required, around which the figure is rotated at a certain angle when

calibrating. To select the reference axis, press [F1] (Auto) in main interface → [F4] (Figure) → [F4]

(Process) → [F1] (Rotate) → [F5] (Calibrate), and a dialogue box will show up for selecting the reference axis

(HC4200 can only take X as the reference axis).

Picture 2.19.1 Selection of calibration reference

Reference axis X: the offset angle of steel plate is the angle formed by X axis of steel plate

26

ADT-HC4500 CNC Flame/Plasma Controller

and the X axis of reference coordinate.

Reference axis Y: the offset angle of steel plate is the angle formed by Y axis of steel plate and

the Y axis of reference coordinate.

Press 【X+】【X-】【Y+】【Y- 】to select the move cutting gun, at the same time, the system will

calculate the angel automationly.

The following calibration takes X axis as the reference axis.

The principle of calibration taking X axis as reference axis is as follows:

A

Picture 1 Picture 2

1) In Picture 1, the large frame (Real line) is the steel plate, the small frame (Dashed line) is the

figure to be cut, and point A is the start point of the cutting gun. If it is cut according to Picture 1,

the figure outside may not be cut; and if it is cut when the start point is moved to the middle of

the steel plate as Picture 2, obviously it will waste the steel plate.

2) At this point, without moving the steel plate, you just have to figure out the slope angle of the

plate, and incline the figure to be processed at the corresponding angle before cutting effectively.

27

ADT-HC4500 CNC Flame/Plasma Controller

Way of calibrating the steel plate:

Original position

Position after the move

1) As above picture, point A is the start point of cutting gun. You can figure out the slope angle of

the steel plate by moving the cutting gun to any point of its base line. Press [X+] → [Y-], or [Y-]

→ [X+]; then, press [ENTER] to confirm.

2) Then, the figure displayed on the controller will be rotated at a certain degree. The position of

figure to be processed and the steel plate is shown as follows:

3) If the steel plate is inclined as follows, then, the calibration method is as below:

Original position

Position after the move

28

Press [X+] → [Y+], or [Y+] → [X+], then, press [ENTER] to confirm. The position of

figure to be processed and the steel plate is shown as follows:

20.Tool Setting

Main Interface after power on, press【F1】Auto---【F4】Graph, Enter into Graph track follow

ADT-HC4500 CNC Flame/Plasma Controller

interface, Press key 【G】.

Graph Original start point will turn to position of lower left quarter, Press Key 【G】, The

graph start point will positioned 5 directions like original point, lower left quarter, Lower Right

Corner, top right corner, top left corner.

Picture 2.20

Positioning process Set start to lower right corner

The program will restore automationly when used this fuction.

When you press key of【Start】for processing, cutting gun will start move from “select start” to

program original point, then make the processing

29

ADT-HC4500 CNC Flame/Plasma Controller

Chapter III Operations and Details

1. Auto

In main interface, press [F1] (Auto) to enter the auto processing interface as follows:

Picture 3.1 ① Flame mode

Picture 3.1 ② Plasma mode

30

ADT-HC4500 CNC Flame/Plasma Controller

Picture 3.1① Flame mode interface details:

1) Speed in %: can be adjusted by pressing [F↑] and [F↓]

2) Current moving speed

3) Name of processing file

4) Status of all electrovalves

5) Current The real-time coordinate value of X ,Y,Z

6) Current Gun gas of cutting diameter conpensation

7) Preheating time of preheat oxygen when perforating in flame cutting

8) Current working status of the system

9) Cutting machine model remind

10) System cuttent working status remind

11) System current remind of function mode status

12) Track display of current process graph

For plasma and flame mode interface, the difference is that the plasma mode does not have

preheating time and some electrovalves are different.

1.1 Details of program running

In interface as shown in Picture 3.1① and 3.1②, you can press [Start] to run the current program. Once

you have pressed the [Start] key, in any cutting mode, the cutting gun will start perforating on steel plate (M07

is default as perforating instruction), and then cutting. After the cutting, close the cutting oxygen. For M07

instruction, see section 4 of Chapter IV in this user manual.

If pause key is pressed during the cutting, the interface will be shown as Picture 3.1.1 and [F2] is changed

from [Manual] to [Forward]. If you press [F2] [Forward], the machine will travel forward along the track, and

when you press [◁] or [▷], [Forward] will be changed to [Manual], and the interface operations are of the

same.

31

ADT-HC4500 CNC Flame/Plasma Controller

Picture 3.1.1 Pause in auto mode

Processing in pause (displacement perforating and gun changing)

Picture 3.1.1.2 Pause processing

During the cutting, if [Pause] is pressed, according to whether the cutting gun has been moved manually,

there are the following treatments:

1) If there is no manual movement after the pause, the controller will start perforating once you

press the [Start] button, and then proceed running the program.

2) After the pause, if the cutting gun is moved deviating from the running track of processing

file, when you press the [Start] button, the interface as Picture above will show up.③

[1]. the controller travels back to where the processing program pauses, enables the cutting

32

ADT-HC4500 CNC Flame/Plasma Controller

cycle, and then runs the processing program.

[2]. the controller travels back to where the processing program pauses, and then stops.

[3]. the controller enables the cutting at current position, and then returns to where the

processing program pauses and runs the processing program. The three options can be selected

by pressing [Y+] or [Y-] to move “←” up and down. After that, press [ENTER] to run the

relevant function.

[4]. Proceed running the program code at offset position, and does not return to where the

track is located when paused.

Press [ESC] to cancel, and wait at the current position for the users to decide whether to

continue processing.

3) Perforating instruction will be performed automatically according to the program status.

You can press pause to stop the M07 instruction.

1.2 Details of submenu in auto interface

1.2.1 T r avel

(Auto)→ [F1] (Travel): the system only runs X, and Y tracks, and the switches of preheating

oxygen, acetylene, cutting oxygen, arcing, and cornering are not opened. It is for calculating whether the track

and the size of running steel plate are correct.

(Auto) →【Y】, testing plate function. System will run automation an idling process picture of

min rectangle figure

Travel and TEST speed is the maximum manual speed, and is not controlled by the speed

percentage.

1.2.2 Manual

In main menu → [F1] (Auto) → [F2] (Manual) to enter the manual interface:

33

ADT-HC4500 CNC Flame/Plasma Controller

Picture 3.1.2.2 Manual interface in flame mode

Picture 3.1.2.2 Manual interface in plasma mode

1.2.2.1 Inching

In manual interface as Picture 3.1.2.2, press [F1] (Point), and the above interface will show up

when the “Inching” is highlighted, with an input prompt “Input L value” at the bottom of the screen.

Press the number keys to input the length of inching, unit in mm. Then, you can press [X+], [X-], [Y+]

or [Y-] to allow the motor to run the input length relatively for each time. It’s the same for the plasma

function (Picture is omitted)

34

ADT-HC4500 CNC Flame/Plasma Controller

Picture 3.1.2.2.1 Inching setting interface

If “Inching” is not highlighted, it is default that once [X+], [X-], [Y+], or [Y-] is released, all axes

are doing continuous motion until these keys are pressed again or the [Stop] key is pressed when the

system will decrease and stop moving.

If you press [G] key, the system will be switched between manual and inching. If in inching state,

keep holding [X+], [X-], [Y+], or [Y-] and the related axis will perform the continuous motion until

they are released when the system will decrease and stop moving.

1.2.2.2 Breakpoint

35

ADT-HC4500 CNC Flame/Plasma Controller

Picture 3.1.2.2.2 Breakpoint interface

It is the same as [F6] (spot) in auto interface, please refer to “Breakpoint” in 1.27 in this chapter.

1.2.2.3 Clear

In manual interface, you can press [F5] to clear the parameter in counting. If you press [X] or [Y] → [F5]

(Clear) → [ENTER], it is to clear the entire line of X and Y coordinates. To clear the last digit of value, you

can just press [DEL] on the panel.

1.2.2.4 Back to origin

In manual interface, when you press [F6], the coordinate value of X and Y is returned to 0 coordinate.

1.2.2.5 X, Y coordinate setting

In manual interface, pressing [X] and [Y] keys on panel enables to modify or clear the value of X and Y.

Once [X] or [Y] key is pressed, the interface on the left bottom will show the current coordinate, for

example “Input X value: X=+00123.456”, and at this time you can press [DEL] to clear the coordinate value

or press [F5] (Clear) to clear the entire line of value. After the setting, press [ENTER].

1.2.3 Backward

It is used in auto interface to return along original track due to the incomplete cutting when processing,

and the procedures are:

In auto processing → Press [Stop] to stop → Press [F3] (Backward) to enter backward function → if

the required position is arrived, press [Stop] → If it excesses the required position, press [F1] (Travel) to move

forward → Once the system is stable, you can then press [Start]. The system will run M07 perforating

instruction again directly and process in accordance with the program.

One backward action can only return to the previous perforating point.

1.2.4 Forward

During the processing, travel or backward motion in auto mode, if you press [Stop] to stop, the original

“Manual” displayed in menu will be changed to “Forward”. At this time, if you press [F2], the system will

36

ADT-HC4500 CNC Flame/Plasma Controller

move forward at actual processing speed without running M switching instruction, which is equal to traveling

at processing speed.

1.2.5. Figure processing (Pro)

In figure interface as Picture 3.1.2.5 above, → you can press [F4] (Pro) to enter the figure processing

interface as follows:

Picture 3.1.2.5.1 Interface of figure processing

1.2.5.1.1 Rotation (Turn)

In above processing interface, press [F1] (Turn) to enter the rotation interface.

37

ADT-HC4500 CNC Flame/Plasma Controller

Picture 3.1.2.5.1.1 Interface of figure processing

1.2.5.1.2. X, Y mirror

See “Mirror” in section 17 of chapter II.

1.2.5. 1.3 Rotation (Whir)

See “Calibration” in section 18 of Chapter II.

1.2.5. 1.4 Calibration

See “Calibration” in section 19 of Chapter II.

1.2.5. 1.5 Restoration

In rotation interface, you can press [F6] to restore the current figure to figure before mirroring, rotating or

calibrating.

1.2.5.1.6 Select line

See “Select line” in section 15 of Chapter II.

1.2.5.1.7 Select point (Sdot)

In processing interface as Picture 3.1.2.5.1, press [F3] (Sdot) to enter the interface of selecting point:

Picture 3.1.2.5.1.7 Select point

You can press [Y+] or [Y-] to change the positioning method for selecting perforating point.

38

ADT-HC4500 CNC Flame/Plasma Controller

Direct change coordinate refers to that the cutting gun does not move but the coordinate is changed to

the coordinate of perforating point directly.

Auto move gun refers to that the cutting gun is moved from current position to perforating point.

After that, select any M07 perforating point during the figure processing to process, and input

the perforating point and press [ENTER]. To make fine adjustment, you can press [X+] or [X-] to select

the next perforating point.

1.2.5.1.8 Array

See “Array” in section 16 of Chapter II.

1.2.5.1.9 Restoration (Rev)

In processing interface as Picture 3.1.2.5.1, press [F6] (Rev) to restore the figure after the array,

point/line selection to the shape when loading.

Note: In rotation interface, it can only restore the figure to the state before rotating

Only in processing interface can the figure after the array operation be restored.

1.2.6 Back to origin

In auto interface, press [F5] and the cutting gun will return to origin at the current manual speed.

When in auto running, it’s required to press [Stop] to allow system to be stable before pressing [F5].

1.2.7 Breakpoint (Spot)

Functions of breakpoint:

1) Find the coordinate before power down when the power supply is resumed.

2) Set a breakpoint memory on the current track for changing the cutting nozzle.

3) Set a breakpoint memory on the current track for displacement perforating.

39

ADT-HC4500 CNC Flame/Plasma Controller

In case of manual pause in auto processing, when you press [F6] (breakpoint), the system will save the

current working track (current position of cutting gun) as a breakpoint automatically. This breakpoint is

saved permanently. When you restart the machine or re-enter the auto mode, as long as the current program is

not changed, you can press [F6] (Breakpoint) to restore based on the breakpoint. Once the breakpoint is

found, press [Start] and the system will continue the processing from the breakpoint. It is the same for the

plasma function.

1.3 Basic operations

1) I/O

Flame: Before processing, you can also select the strong electricity key manually to control

the ignition, acetylene, preheating oxygen, cutting oxygen, and cutting gun rising/falling/stop.

Note: when you press the ignition key, if the acetylene is not opened, it will open the acetylene

valve before switching on the ignition switch, and then switch off the ignition switch after an

ignition delay (see Parameter-Control-Ignition Delay). Press [Perforating] and it will perform

preheating perforating (see M07 Fixed Cycle of Preheating Perforating in section 4 of Chapter III).

Pressing [Main switch] is to close all IO outputs.

Plasma: You can use the arcing switch (Cutting Oxygen switch of flame cutting) to control

the arcing before processing and the system gives an arcing signal to the height-adjusting system.

If there is no height-adjusting system, the system will open the arcing switch; press [Perforate] to

starting arcing and perforating (See M07 arcing & perforating cycle in point 4, section 3); press

[Shut down] to shut all the output.

2) [F↑] and [F↓] allows you to increase or decrease the moving speed rate. In standby mode, you

can press and hold this key to increase or decrease the speed continuously. If in the process,

each press would increase or decrease the speed by 1.

3)[Pgup/S↑] and [Pgdn/S↓] are composite keys. Press [Pgup/S↑] (or [Pgdn/S↓]) key, the cutting gun

will move upward (or downward) until it is released. It is to page up or down when editing.

40

ADT-HC4500 CNC Flame/Plasma Controller

4) [F] key allows you to switch the speed ratio swiftly. Press [F] key if the ratio is between

50%--100%, the speed ratio will be switched to 5%; and if the ratio is between 1%--50% when

you press [F], the speed ratio will be switched to 80%.

5)Figure interface operation: You can press the number key to enlarge the figure. 0 –: resume the

figure to original state; 1- Zoom in×1, 2- zoom in×2… and so on. For example, if you press [2],

the figure is enlarged×2, and press [0] to resume to the original size; if you press [2] for twice

successively, the figure is enlarged at 2*2=4 times, and so on.

6)[INS] key is to enable the “Help” of the current interface.

2. Figure library

2.1 Operations

Press [F2] in the system main interface to enter the figure library as Picture 2.1. There are 33 figures

available in the library. You can press [Y+], [Y-], [X+], and [X-] to select the figure, or press [pgup] / [pgdn]

to turn the page to select. When you have selected a figure, you can press [ENTER] to enter the figure library

setup.

Picture 2.1

Take “Convex polygon with hole” for example. Highlight the “w.h.p.p.po.” white on black. (See

Picture 2.2)

41

ADT-HC4500 CNC Flame/Plasma Controller

Picture 2.2

User can get the difference process graph based on the parameter setting.

Parts Type: Hole-cutting and slicing. Related workpiece in the inner of graph when slicing; Related

workpiece in the outside of the graph when hole-cutting.

Lead in/out Line: Lead-in line (arc) is a reserved lead line (Arc) for avoided to over-burnning of point in

the cross the hole. Leads out line (arc) are specal function for plasma cutting, because lead-out line or lead-in

line will happening brake of arc under the plasma cutting. Lead in/out line (arc) hole-cutting is the inner of

graph, but the slicing is in the outside of graph.

Idle line: Idle distance from start point of process to start of cross-hole point.

Parameter setting of graphics library is limited, diameter of round hole can not bigger than diameter of

outside arc and the height from round hole center to botton side of hemline, the length if hemline can not less

than two times of top diameter. Because It can not show the correct composite figures if the the parameter

exceed the related scope. After set parameter, Press 【F5】 for preview, If Parameter exceed the related scope,

system will makte the reminding, then restore parameter as before set. If parameter setting coorect, Press【F6】

leading-in, enter intor auto interface, then Porcess file in the system had been changed to file of graphics

library.

When you set the parameter, Press 【DEL】it can delete the last no of currenct parameter, press key of

number for input value. Press 【CAN】parameter will clear, Press 【Y+】,【Y- 】select parameter setting.

3. Edition

In main interface, press [F3] to enter the window of editing function menu as Picture 3.1, in which shows

42

ADT-HC4500 CNC Flame/Plasma Controller

the code of file being processed. The code can be viewed only, and cannot be edited. If there is more than one

page, you can press [pgup↑] or [pgdn↓] to page up or down.

3.1.1 New

Picture 3.1 Window of editing function menu3.1 Explanation of sub-menu

Picture 3.1.1 Interface of creating new file

In editing interface as Picture 3.1, press [F1] to enter the interface of creating new file as Picture

3.1.1, where you can edit the file name by pressing the number keys directly. After that, press [F5] to save the

settings. You can also press [shift] key to change the input methods between letter input and Pinyin input,

as the following picture shows:

43

ADT-HC4500 CNC Flame/Plasma Controller

Operations of Pinyin input are as follows:

1. Press [ENTER] to select the current character

2. Press [ESC] to delete all the input characters

3. Press [shift] to change the input method

4. Press [DEL] to delete the last character

5. Press [Y+], or [Y-] to select the previous or next character

6. Press [X+] or [X-] to page up or down the listed characters

7. Letters on panel are defined as:

Press [ENTER] key after the input. If the input name exists, there will be a prompt as Picture 3.1.1.2

below as you press [ENTER]. Otherwise, it will enter the file editing interface, as Picture 3.1.1.3.

44

ADT-HC4500 CNC Flame/Plasma Controller

Picture 3.1.1.2 Interface for prompting the exist of input file name

In this prompt interface, you can press [ENTER] to cover the original file and enter the interface

as Picture 3.1.1.2; otherwise, press [ESC] to exit to interface as Picture 3.1.1.

Picture 3.1.1.3 Interface of editing new file

Once a new processing file is created, you can edit the required code of processing file in

editing area. For detailed editing of code, see “3.2 Editing processing file”.

45

ADT-HC4500 CNC Flame/Plasma Controller

3.1.2 Load

1) In window of editing function menu as Picture 3.1, press [F2] to enter the file loading interface

as follows:

Picture 3.1.2

File loading interfaceAfter entering into the above interface, press [F↑] or [F↓] to select the processing

file, and press [F2] or [ENTER] to select, and then enter the processing code editing interface. For file edition,

see “3.2 Editing processing file”.

2) [INS] key: Enable the help system of the current interface.

3.1.2.1Copy

In file loading interface as Picture 3.1.2, you can press [F5] “Copy” to copy the current selected single

processing file in controller to the USB disk, or press [F6] “Copy All” to copy all processing files of controller

to the USB disk.

Note: When copying all files, if you need to quit for some reasons, you can just press and hold the

CANCEL key to exit the interface as Picture 3.1.2.

46

ADT-HC4500 CNC Flame/Plasma Controller

Picture 3.1.2.1 File copy function

3.1.2.2 Delete

In processing file loading interface, you can choose to delete files in system catalog. When deleting the

processing file, the system will ask whether to delete, you can press [ENTER] to delete or [ESC] not to delete

.

Picture 3.1.2.2 Delete interface

47

ADT-HC4500 CNC Flame/Plasma Controller

3.1.3 USB disk

In interface as Picture 3.1, press [F3] to enable the USB disk connecting function. If the USB disk is not

connected well or if the format of USB disk is not compatible with the system, the following interface will

show up:

Picture 3.1.3 USB disk is not connected

If the USB disk is connected, the interface will show the name of file stored in the USB disk, as the

following picture shows:

Picture 3.1.3.1 USB disk is connected successfully

At this time, press [Y+] or [Y-] to select the processing files that need to be copied, and then press [F2]

48

ADT-HC4500 CNC Flame/Plasma Controller

(Copy) or [ENTER]. After the copy, the system will pop up a prompt “Data are completely copied, press any

key to return”, you can then press any key to exit.

3.1.4 Define

3.1.4 Definition interface

As Picture 3.1 shows, in editing interface, press [F4] (Define) to enter the definition interface.

3) In this interface, press [F1] to define the M07 instruction. The system default M07 perforating

instruction is as follows:

Flame:

c Ignition Fixed Cycle, M52

d Cutting gun falling (Fixed Cycle), M71

e Preheating on (Fixed Cycle), M74

f Perforating cutting gun rising (Fixed Cycle), M72

g Cutting oxygen on, M12

h Perforating cutting gun falling (Fixed Cycle), M73

Plasma:

A. With height-adjusting system:

c Enable M22

d Arcing M12

e Waiting for arc voltage detection signal (IN0)

After arcing, the height-adjusting control starts performing initial location (With initial

location function); perforating and perforating delay automatically, and gives a signal of

successful arc voltage detection to the controller.

B. Without height-adjusting system:

49

ADT-HC4500 CNC Flame/Plasma Controller

c Arcing, arcing delay M12

d Perforating, perforating delay

Start the following actions

Users can define the functions of M07 as required.

4) [F2] is used to define the M08 instruction. The system default M08 instruction for closing cutting

oxygen is as follows:

Flame:

c Cutting oxygen off, M13

d Cutting gun rising (Fixed Cycle), M70

Plasma:

c Close striking arc M13

d Close the height-adjusting control M23

Users can define M08 to M80 (close all output) according to their actual demand. All valves will

be closed when performing M08 to save gas.

5) [F3]: Clear the data of current line.

6) [F4]: Add a new line below the current line.

7) [F5]: Delete the current line.

8) [F6]: Save the content.

9) [INS]: Open the help system of the current interface

Note: After you have defined M07 and M08 instructions, you should set [F1] (Configuration) in [F4]

(Parameter) as “user-defined”; otherwise, the instructions would not be effective.

3.2 Editing processing file

As shown in Picture 3.1 at the beginning of this section, in the interface of editing, if you create a new file

or load a file, and enter the edition interface, you can then edit the processing file as follows:

50

ADT-HC4500 CNC Flame/Plasma Controller

Picture 3.2 Processing file editing interface

3.2.1 Figure

In processing file editing interface as above, Press [F1] and the interface will show the preview figure you

are editing for your reference.

3.2.2 Test

In processing file editing interface as Picture 3.2, after enter the code of processing file or loading the

code of nest software, you can press [F2] to detect whether the code of processing file has error. If there is an

error, the error line will be highlighted in the interface and the error type will be shown on the bottom as

follows:

51

ADT-HC4500 CNC Flame/Plasma Controller

Picture 3.2.1.2 Error code detection interface

In case of the interface as above picture, press [ENTER] and the cursor will stop at the error code line,

and you can then modify the error character line. After the modification, you can press [F2] to test the

processing file, while the system will pop up the following dialogue box:

Picture 3.2.1.2.1 Code re-testing interface

In the above interface, press [ENTER] to re-test from the first line, and when you press [ESC], the system

will test beginning from the cursor.

52

ADT-HC4500 CNC Flame/Plasma Controller

3.2.3 Save

3.2.1.3 Saving file

When the processing code is entered or the code is tested, you should press [F3] to save it before exiting

the interface; otherwise, the system cannot memorize the current processing file. Press [F3] and the system

will ask whether to save as other file (as Picture 3.2.1.3). If you press CANCEL], the system will cover the

original file. If you press [ENTER], the system will ask you to input the file name. Once you have entered the

name, press [F5] to save the file.

If there is no need to save the current file, you can press [

] or [ ] to return to the main interface.

3.2.4 New/Delete line

New line: During the editing, you can press [F4] or [ENTER] to add a line of code under the cursor.

Delete line: During the editing, you can press [F5] to delete the code line where the cursor is located.

3.3 Basic operations

1) Keys on panel are divided into two categories, composite key and single function key. Generally, you

are entering the value of lower shift when you press the composite key. If you press [Shift] first and

then a composite key, it becomes the upper shift key. This function is only available in program

editing state.

2) When the cursor is moving up/down, the cursor is located at the end of program automatically. It

moves a line each time you press it.

3) Page Up/Down: You can press [Pagup / S↑] or [Pagdn / S↓] to page up or down.

4) The line number in processing program is generated automatically.

5) You can press [DEL] key on panel to delete a character of instruction where current cursor is located.

6) You can press [INS] on panel to insert a space in the middle of a line.

53

ADT-HC4500 CNC Flame/Plasma Controller

4. Parameter

In main interface, press [F4] to enter the parameter setting function, and the options are as follows:

Picture 4 System parameter setting interface

4.1 System

In system parameter setting interface as above, press [F1] to enter the system parameter setting interface:

Picture 4.1 Configuration interface

M07/M08 instruction: Users can choose the M07 or M08 preheating perforating instruction as system

54

ADT-HC4500 CNC Flame/Plasma Controller

default or user-defined mode. For definition, see “Definition” in section 3.

Language: Choose the language. The system supports operating interface of many languages.

Machine: Two cutting processes are provided, flame cutting or plasma cutting.

Theunit(Metric/Imperial): It is only available before entering into the auto mode or testing the program.

Operation mode: You can press [Y+] or [Y-] to move the cursor up or down, [X+] or [X-] to change the

mode, or [F6] to save the parameters.

4.1.1 Height-adjusting (Pset)

In configuration parameter setting interface as above, you can press [F2] to enter the interface of

height-adjusting parameter settings:

Picture 4.1.1 Height adjusting

Perallow: An extra arc voltage adjustor is added to control when the arc voltage adjusting starts to work

and when it stops.

INITLOCA(Initial positioning): The cutting gun runs a fixed rising height when encountering the steel

plate.

Arc test: A signal is fed back by plasma power supply, with which the system will run the track in case of

successful arcing; otherwise, it will stop running the track.

Operation mode: You can press [Y+] or [Y-] to move the cursor up or down, [X+] or [X-] to change the

mode, or [F6] to save the parameters.

55

ADT-HC4500 CNC Flame/Plasma Controller

4.1. 2 Flame Step Torch Height

Press 【F4】flame in the config parameter setting interface, enter flame step torch height parater

setting interface: press figure input parameter value, Press 【Y+】【Y- 】select parameter.

Picture 4.1.2 Flame step Torch Height

Parameters Details:

1) Z axis Torch height allow: When Status “Open”, Flame cutting of system can accept Z axis make the

gun make adjustment of height

2) Z axis pulse equivalent: Z Axis setting of precision, See 4.5.1 (Pulse equivalent Setting)

3) Z Axis initial speed: See 4.2.1 (speed setting)

4) Z axis acceleration: See 4.2.1 (speed setting)

5) Z axis end speed: See 4.2.1 (speed setting)

6) Gun up-down speed: Distance of first time down to preheat height (Disstance of gun from cutting safe

height up to initial height)

7)Cross hole up-down distance: the distance from cutting height up to safe height (Distance of Gun from

safe height down to cutting height), to avoide the schmelze enter into gun nozzle when high temperature

After related parameter input finished, press 【F6】for save.

4.2 Speed

In system parameter setting interface as Picture 4, press [F2] and the interface will become as the following

56

ADT-HC4500 CNC Flame/Plasma Controller

picture, when you can set all the speed parameters including speed, hand speed and acceleration or

deceleration.

Picture 4.2 Speed parameter settings

4.2.1 Speed settings

Parameter Explanation Unit

Start-up speed Start-up speed of X/Y axis mm/minute

Acceleration the speed increased each time for X/Y axis from the start-up

mm/minute

speed to the maximum speed

Hand speed X/Y axis speed, G00 and the speed of returning back to

mm/minute

origin in hand motion

Processing speed X/Y axis speed, and the speed of G01,G02,G03 during the

mm/minute

processing

Table 4.2.1

Note:

In practical cutting, you need to perform acceleration/deceleration operations at the corner. Too

fast an acceleration/deceleration at the corner would lead to halfway cutting or flame-out, and too slow

the speed may not form a right angle at the corner or lead to circular arc. In this way, the “start-up

speed” and “acceleration” in “Speed” setup should be set for several times according to the current

pulse equivalent to the optimum state.

Reference value:

Processing speed Pulse equivalent Start-up speed Acceleration

500mm/Minute 0.008000 300 80-100 (Adjusted with emphases)

500 mm/Minute 0.001000 300 5-15 (Adjusted with emphases)

Table 4.2.2

57

ADT-HC4500 CNC Flame/Plasma Controller

4.3 Adjustment (Adju)

In system parameter setting interface as Picture 4, press [F3] and the interface will become as the

following picture, when you can set the limit coordinate, origin coordinate, and backlash.

Picture 4.3Adjusting parameter settings

4.3.1 Adjustment settings

Parameter Explanation Unit