Page 1

ADT-CNC4640

CNC4640M Milling Machine Control System

Programming Manual

Adtech (Shenzhen) Technology Co., Ltd.

Add: F/5, Bldg/27-29, Tianxia IC Industrial Park, Yiyuan Rd, Nanshan District,

Shenzhen Postal code: 518052

Tel: 0755-26722719 Fax: 0755-26722718

E-mail:

adtcnc@machine-controller.com http://www.machine-controller.com

Page 2

CNC4640 Programming Manual

Copyright

Adtech (Shenzhen) Technology Co., Ltd. (Adtech hereafter) is

in possession of the copyright of this manual. Without the

permission of Adtech, the imitation, copy, transcription and

translation by any organization or individual are prohibited. This

manual doesn’t contain any assurance, stance or implication in

any form. Adtech and the employees are not responsible for any

direct or indirect data disclosure, profits loss or cause

termination caused by this manual or any information about

mentioned products in this manual. In addition, the products and

data in this manual are subject to changes without prior notice.

All rights reserved.

Adtech (Shenzhen) Technology Co., Ltd.

II

Page 3

Version History

Item No. First uploaded on Version No. Pages Compiled by Typeset by

XT20100819 2011-3-01 A0101 81 Yang Jipeng Yang Jipeng

XT20100819 2011-10-12 A0201 91 Yang Jipeng Yang Jipeng

Revision

Date Version/Page Result Confirmed by

III

Page 4

CNC4640 Programming Manual

Remark:

We have collated and checked this Manual strictly, but we can’t ensure that there are no error and omission in

this Manual.

Due to constant improvement of product functions and service quality, any products and software described in

this manual and the content of the manual are subject to changes without prior notice.

IV

Page 5

Adtech (Shenzhen) Technology Co., Ltd. Contents

Contents

1. Operating procedures of CNC machine tool ....................................................................1-1

2. Identifying the machine tool...............................................................................................2-2

2.1 Motion direction naming of control axes......................................................................................................................... 2-2

2.2 Coordinate systems of machine tool and workpiece........................................................................................................ 2-3

3. Preparation functions..........................................................................................................3-4

3.1 Modal and non-modal function ....................................................................................................................................... 3-4

3.2 Standard G codes list....................................................................................................................................................... 3-4

4. CNC program structure .....................................................................................................4-1

4.1 Program structure ............................................................................................................................................................ 4-1

4.2 Main program and subroutine.......................................................................................................................................... 4-3

5. Position instructions............................................................................................................5-1

5.1 Programming mode instruction ....................................................................................................................................... 5-1

6. Feeding, rapid traverse, interpolation function (G00-G03, G17-G19)...........................6-2

6.1 Feeding............................................................................................................................................................................ 6-2

6.2 Rapid positioning (G00).................................................................................................................................................. 6-2

6.3 Linear interpolation (G01)............................................................................................................................................... 6-3

6.4 Plane selection (G17-G19) .............................................................................................................................................. 6-3

6.5 Arc interpolation (G02, G03)........................................................................................................................................... 6-4

7. Pause instruction (G04) ......................................................................................................7-7

8. Coordinate system setting function (G52-G59, G591-G599, G92)..................................8-2

8.1 Machine tool coordinate system (G53)............................................................................................................................ 8-2

8.2 Workpiece coordinate system.......................................................................................................................................... 8-2

8.2.1 Programmable workpiece coordinate system (G92) ............................................................................................. 8-3

8.2.2 Using preset workpiece coordinate system (G54~G59, G591~G599).................................................................. 8-3

8.3 Local coordinate system (G52)........................................................................................................................................ 8-4

8.4 Operation related to reference point ................................................................................................................................ 8-5

8.4.1 Auto return to reference point (G28) .................................................................................................................... 8-5

8.4.2 Auto return from reference point (G29)................................................................................................................ 8-6

8.4.3 Reference point return checking (G27)................................................................................................................. 8-7

9. Tool compensation function................................................................................................9-1

9.1 Tool compensation........................................................................................................................................................... 9-1

9.2 Tool length compensation................................................................................................................................................ 9-1

9.3 Tool radius compensation................................................................................................................................................ 9-2

9.3.1 Tool radius compensation action .......................................................................................................................... 9-3

9.3.2 Other instructions and actions during tool radius compensation........................................................................... 9-8

9.3.3 G41/G42 instruction and I, J, K designation....................................................................................................... 9-14

9.3.4 Insertion treatment during tool radius compensation.......................................................................................... 9-18

9.3.5 Notes for tool radius compensation.................................................................................................................... 9-20

9.3.6 Compensation number change in compensation mode....................................................................................... 9-21

9.3.7 Tool radius compensation start and axis Z cut-in action ..................................................................................... 9-22

10. Hole processing function...................................................................................................10-1

10.1 Standard fixed cycle .................................................................................................................................................... 10-1

10.2 High-speed deep-hole drilling cycle (G73).................................................................................................................. 10-3

10.3 Reverse-threading cycle (G74).................................................................................................................................... 10-5

10.4 Cancel fixed cycle (G80)............................................................................................................................................. 10-5

10.5 Drilling cycle (G81) .................................................................................................................................................... 10-5

10.6 Drilling cycle, rough boring cycle (G82)..................................................................................................................... 10-6

10.7 Deep-hole drilling cycle (G83).................................................................................................................................... 10-7

10.8 Tapping cycle (G84).................................................................................................................................................... 10-7

10.9 Boring cycle (G85)...................................................................................................................................................... 10-8

10.10 Boring cycle (G86).................................................................................................................................................... 10-9

10.11 Boring cycle (G88).................................................................................................................................................... 10-9

10.12 Boring cycle (G89).................................................................................................................................................... 10-9

10.13 Notes for using hole processing fixed cycle ............................................................................................................ 10-10

10.14 Examples of using tool length compensation and fixed cycle ................................................................................. 10-11

11. Auxiliary function .............................................................................................................11-1

11.1 M code......................................................................................................................................................................... 11-1

11.2 Principal axis speed function....................................................................................................................................... 11-2

11.3 Tool function................................................................................................................................................................ 11-3

12. Category B macro function..............................................................................................12-1

12.1 Variable instruction...................................................................................................................................................... 12-1

12.2 Macro program call ..................................................................................................................................................... 12-2

12.2.1 Using macro calling function............................................................................................................................ 12-2

12.2.2 Macro program calling command............................................................................................................................. 12-2

I

Page 6

Contents Adtech (Shenzhen) Technology Co., Ltd.

12.3 Variable........................................................................................................................................................................ 12-6

12.4 Types of variables........................................................................................................................................................ 12-6

12.5 Calculus instruction ..................................................................................................................................................... 12-8

12.6 Control instruction..................................................................................................................................................... 12-12

12.6.1 Conditional instruction ...................................................................................................................................12-12

12.6.2 Cycle conditional instruction.......................................................................................................................... 12-12

12.7 Notes of using macro................................................................................................................................................. 12-14

12.8 Macro variable user parameters system configuration............................................................................................... 12-14

13. CAD function...................................................................................................................13-16

13.1 Function..................................................................................................................................................................... 13-16

13.2 Keywords description................................................................................................................................................ 13-17

13.3 Example..................................................................................................................................................................... 13-17

14. Automatic tool change (ATC) ..........................................................................................14-1

II

Page 7

Adtech (Shenzhen) Technology Co., Ltd. 4. CNC Programming Structure

1. Operating procedures of CNC machine tool

The step of CNC processing follows:

Fig. 1.1 CNC System Operation Flow

Programming:

Draw part drawing and write processing program (manual or CAM software)

Operating machine tool:

Read the program into CNC system, install the workpiece and the tool properly, and operate the tool to

complete the processing task of preset track.

Therefore, programming is the first step of CNC operating, and also the main content of the manual. The

details are in the chapters below.

1-1

Page 8

4. CNC Programming Structure Adtech (Shenzhen) Technology Co., Ltd.

2. Identifying the machine tool

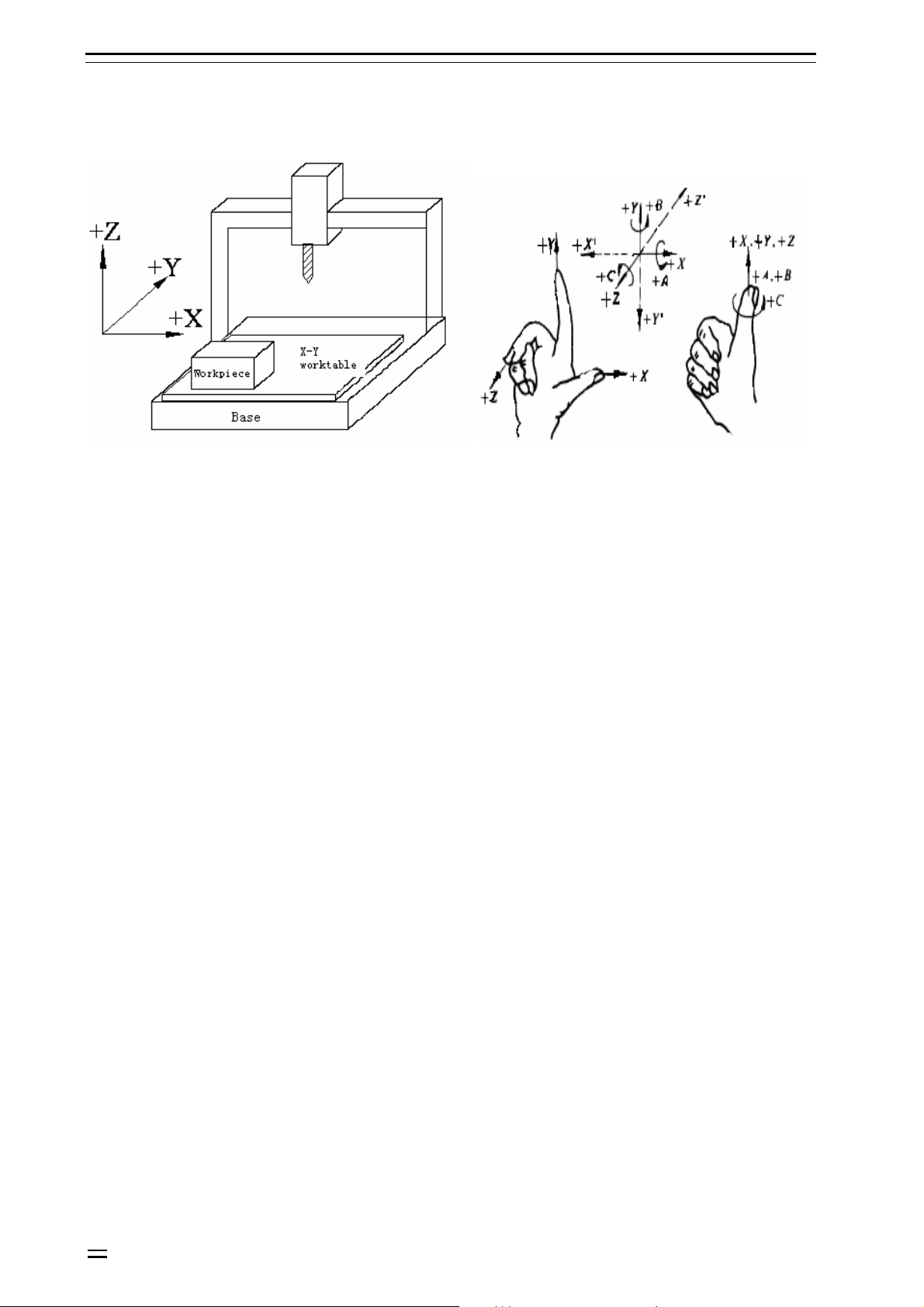

2.1 Motion direction naming of control axes

Fig. 2.1 Name of the machine tool coordinate axis Fig. 2.2 Rotation axis direction determination of the

machine tool

This system can control the rapid traverse, feeding and interpolation of four axes. The axis direction is defined

in Cartesian coordinate system, as shown below (facing to the machine tool):

Z axis:

The up and down movement of the tool relative to the workpiece is Z axis motion, with the upward movement

the positive motion and the downward movement the negative motion.

X axis:

The left and right movement of the tool relative to the workpiece is X axis motion, with the rightward

movement the positive motion and the leftward movement the negative motion.

Y axis:

The forward and backward movement of the tool relative to the workpiece is Y axis motion, with the forward

movement the positive motion and the backward movement the negative motion.

Principal axis:

Look down to the workpiece, the clockwise rotation is principal axis positive rotation and the

counterclockwise rotation is negative rotation.

A, B, C axes:

The positive directions of rotation axes correspond to the positive directions of X, Y, Z axis, which are

determined according to the forward direction of right hand screw.

O Notice:

The X, Y, Z, A, B, C axis motion described in this manual is the tool’s motion relative to the workpiece, i.e. it is assumed

that the workpiece coordinate system has been set.

2-2

Page 9

Adtech (Shenzhen) Technology Co., Ltd. 4. CNC Programming Structure

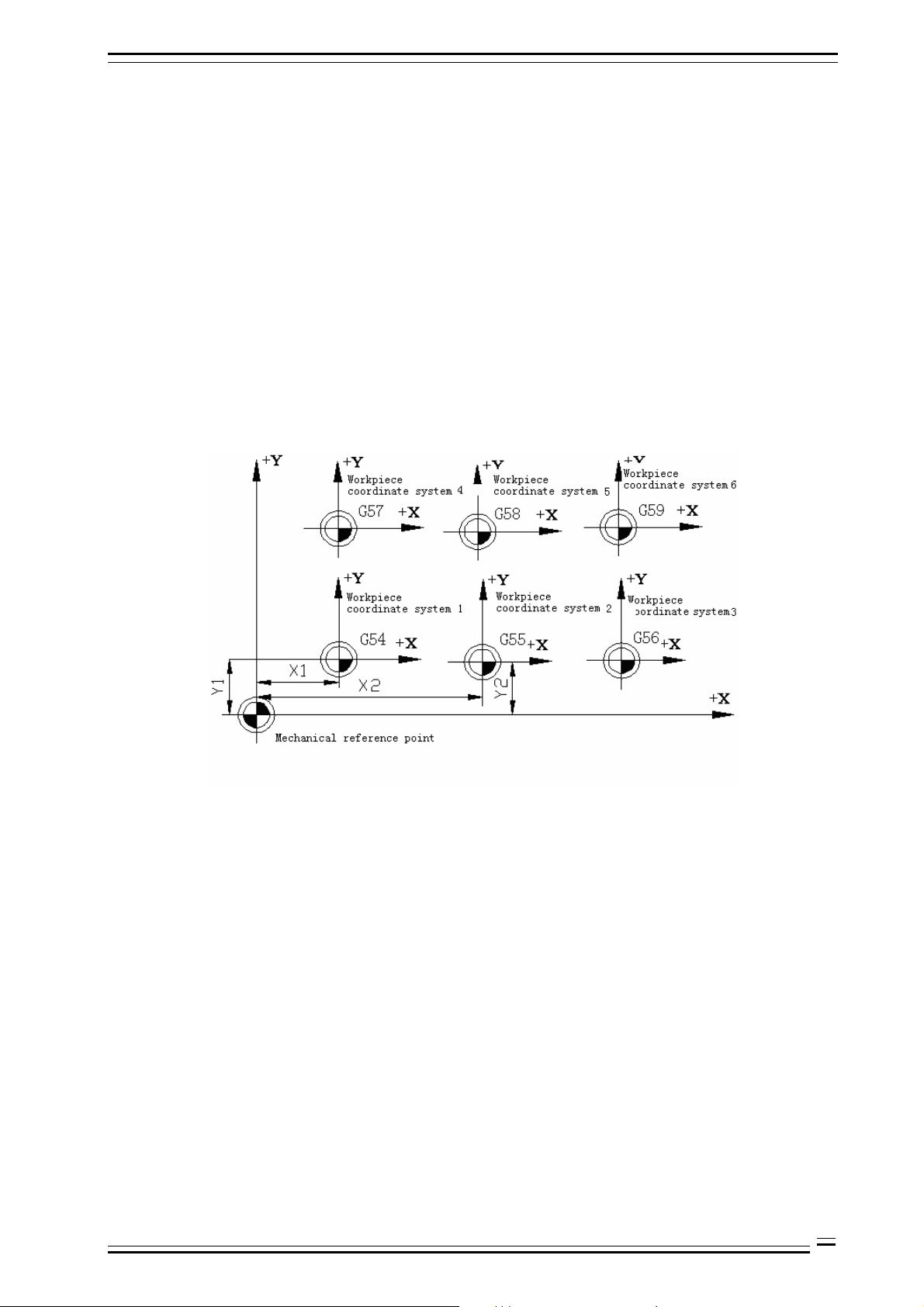

2.2 Coordinate systems of machine tool and workpiece

Machine tool coordinate system:

The coordinate system fixed on the machine tool is created through returning to reference point after NC is

electrified every time. To select machine tool coordinate system, use G53 instruction.

Workpiece coordinate system:

When start programming, the programmer doesn’t know the position of the workpiece on the machine tool,

and usually uses a point on the workpiece as the reference point to write processing program. The coordinate

system created with this reference point is the workpiece coordinate system. When the workpiece is fixed on

the worktable of the machine tool, move the tool to specified workpiece reference point and set the coordinate

value of this point as the origin of workpiece coordinate system, and the tool will use this workpiece

coordinate system as the reference system and process according to program instruction when the system

executes the machining program. Therefore, the origin offset function of coordinate system is very important

to CNC machine tool.

This system can preset six workpiece coordinate systems (nine extended coordinate systems G591-G599 are

added in new version). Set the offset of every workpiece coordinate system origin relative to machine tool

coordinate system origin, and then use G5X (5X is the specific workpiece coordinate system number, the same

below) instruction to select. G5X are nodal instructions, corresponding to 1#~6# preset workpiece coordinate

system respectively.

Fig. 2.3 Workpiece Coordinate System Diagram

2-3

Page 10

4. CNC Programming Structure Adtech (Shenzhen) Technology Co., Ltd.

3. Preparation functions

3.1 Modal and non-modal function

G code determines the function of the command and can be classified into two types:

Non-modal G code:

G code is only valid in defined program segment

Modal G code:

G code is always valid, until next G code of same group appears.

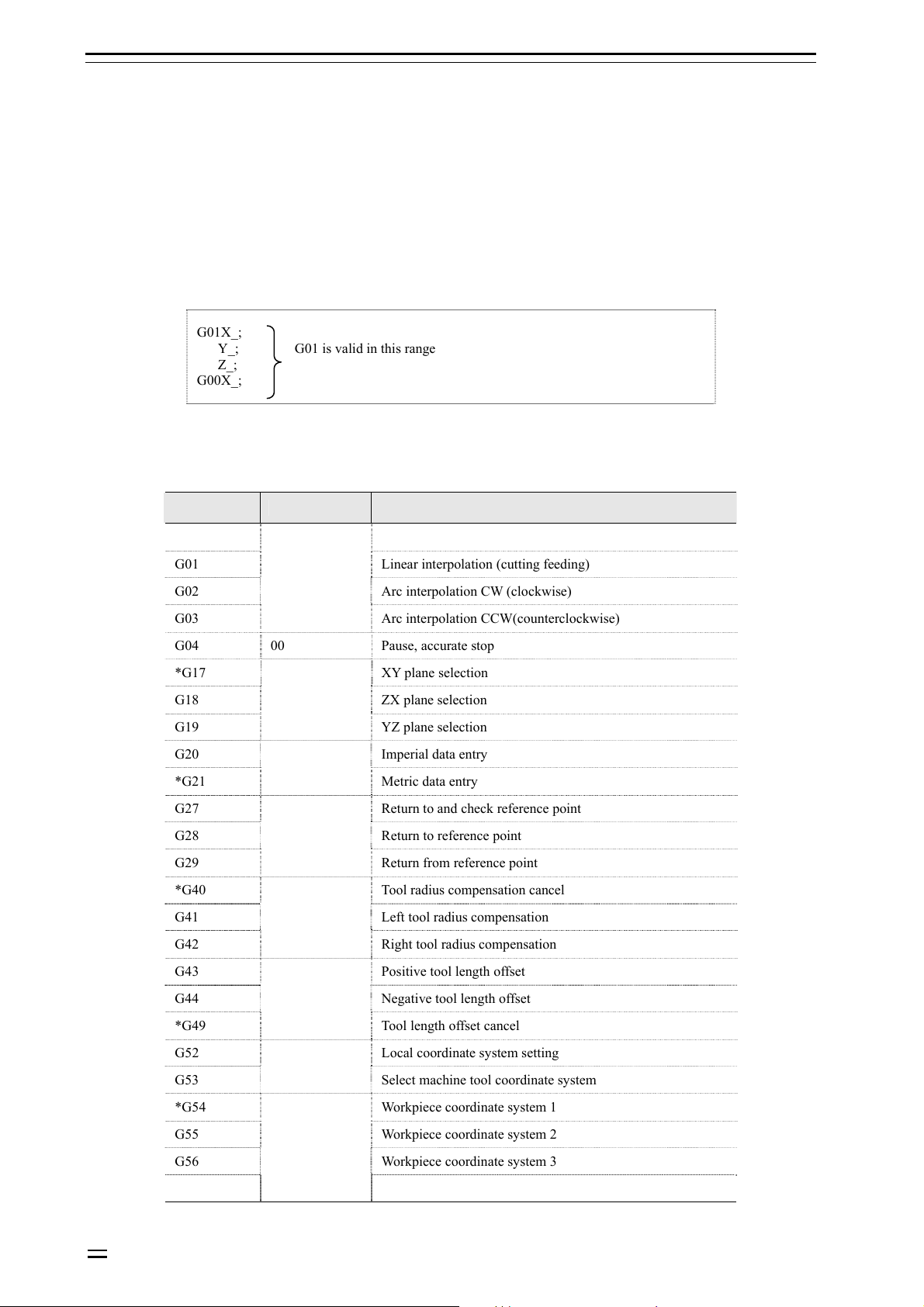

B Example: G01 and G00 are modal G codes

G01X_;

Y_; G01 is valid in this range

Z_;

G00X_;

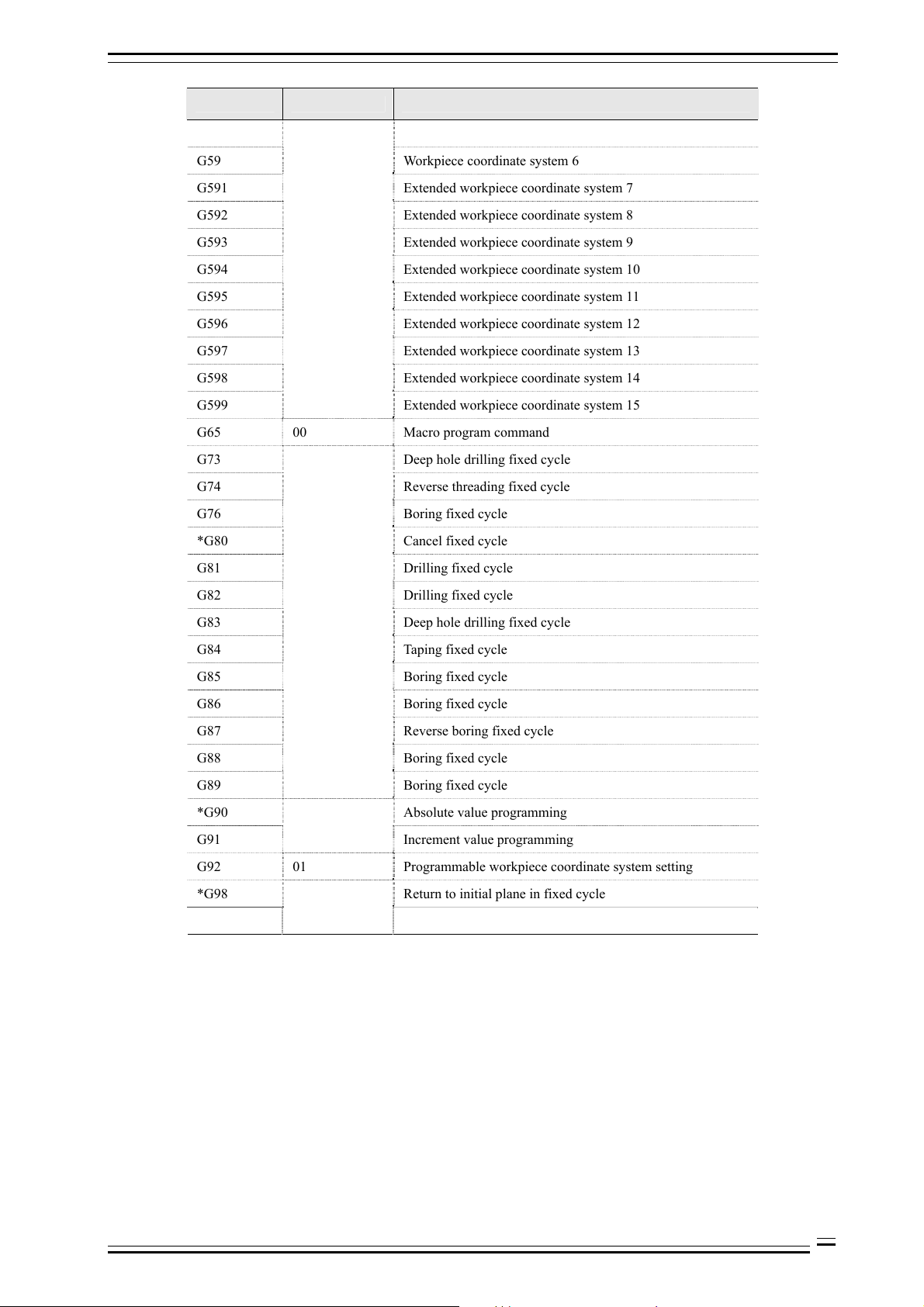

3.2 Standard G codes list

G code Group Function

*G00 Positioning (rapid traverse)

G01 Linear interpolation (cutting feeding)

G02 Arc interpolation CW (clockwise)

G03

G04 00 Pause, accurate stop

*G17 XY plane selection

G18 ZX plane selection

G19

G20 Imperial data entry

*G21

G27 Return to and check reference point

G28 Return to reference point

G29

*G40 Tool radius compensation cancel

G41 Left tool radius compensation

G42

G43 Positive tool length offset

01

Arc interpolation CCW(counterclockwise)

02

YZ plane selection

06

Metric data entry

00

Return from reference point

07

Right tool radius compensation

3-4

G44 Negative tool length offset

*G49

G52 Local coordinate system setting

G53

*G54 Workpiece coordinate system 1

G55 Workpiece coordinate system 2

G56 Workpiece coordinate system 3

G57

08

Tool length offset cancel

00

Select machine tool coordinate system

05

Workpiece coordinate system 4

Page 11

Adtech (Shenzhen) Technology Co., Ltd. 4. CNC Programming Structure

G code Group Function

G58 Workpiece coordinate system 5

G59 Workpiece coordinate system 6

G591 Extended workpiece coordinate system 7

G592 Extended workpiece coordinate system 8

G593 Extended workpiece coordinate system 9

G594 Extended workpiece coordinate system 10

G595 Extended workpiece coordinate system 11

G596 Extended workpiece coordinate system 12

G597 Extended workpiece coordinate system 13

G598 Extended workpiece coordinate system 14

G599 Extended workpiece coordinate system 15

G65 00 Macro program command

G73 Deep hole drilling fixed cycle

G74 Reverse threading fixed cycle

G76 Boring fixed cycle

*G80 Cancel fixed cycle

G81 Drilling fixed cycle

G82 Drilling fixed cycle

G83 Deep hole drilling fixed cycle

G84 Taping fixed cycle

G85 Boring fixed cycle

G86 Boring fixed cycle

G87 Reverse boring fixed cycle

G88 Boring fixed cycle

G89

*G90 Absolute value programming

G91

G92 01 Programmable workpiece coordinate system setting

*G98 Return to initial plane in fixed cycle

G99

09

Boring fixed cycle

03

Increment value programming

10

Return to point R plane in fixed cycle

O Notice:

The items marked with * are the default modal values of G codes of the system;

3-5

Page 12

Adtech (Shenzhen) Technology Co., Ltd. 4. CNC Programming Structure

4. CNC program structure

4.1 Program structure

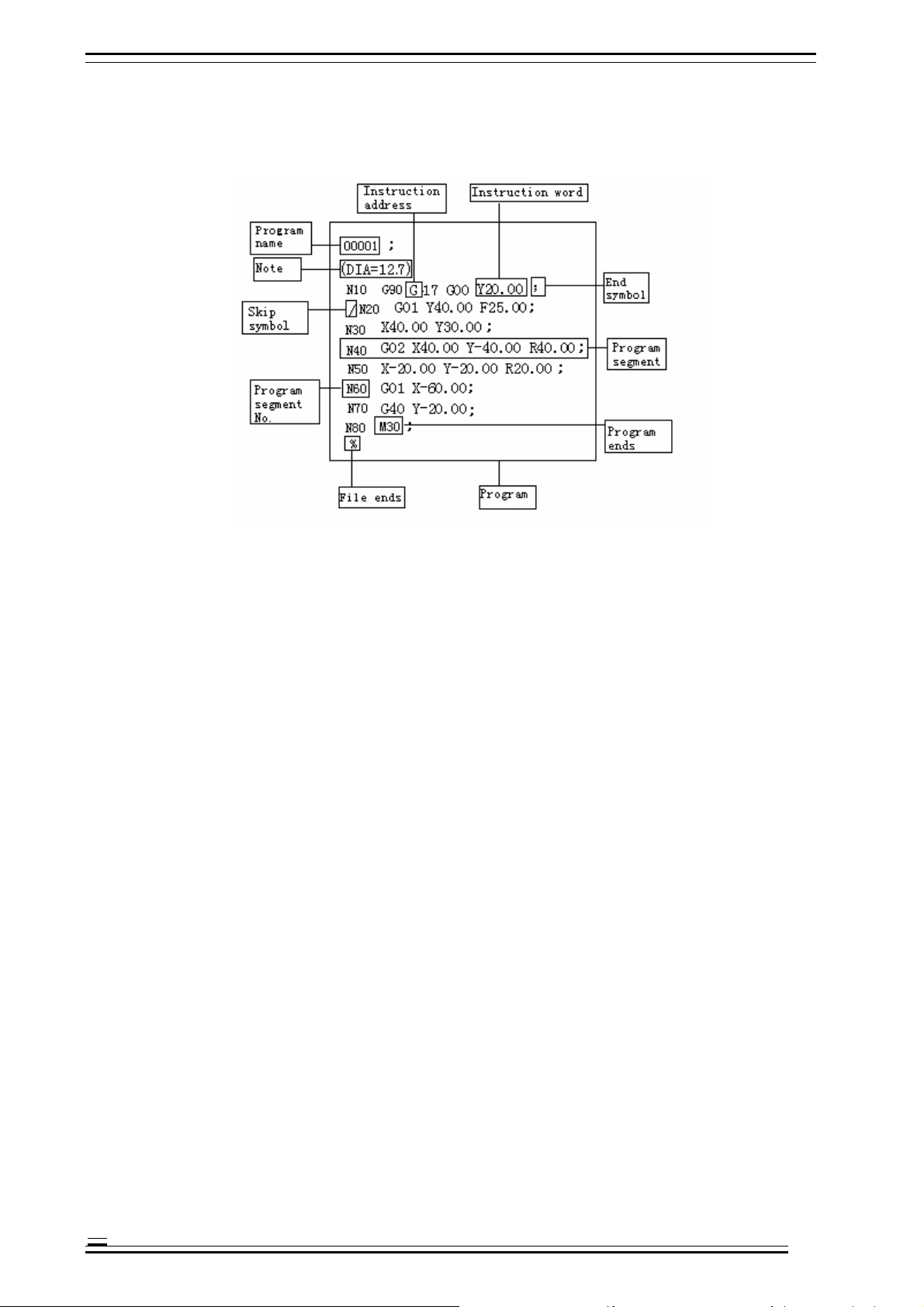

CNC processing program consists of the following parts:

Fig. 4.1 CNC Program Structure Diagram

Program name:

Used to mark different programs, and consists of O and four digits.

Ü If the start of the program doesn’t have program name, the program segment No. of the program start will be

considered as the program name by default;

Ü If the program segment No. contains five digits, the latter four digits will be used as the program name;

Ü If the latter four digits are 0, add 1 automatically to use as the program name;

Ü N0 can’t be used as program name;

Ü When saving the program, if both program name and program segment No. don’t exist, it is necessary to make a

program name through MDI panel.

Note:

The content in the parentheses, in which the user can specify notes, guide, etc.:

Ü The note doesn’t have limit on length; if the program has a long note, the axis motion will pause for a while; therefore,

if a long note is required, please put it at the place that motion pauses or without motion;

Ü If there is only one “)” without “(”, “)” will be ignored;

Ü The note may have multiple lines and are separated with space;

Ü During processing, the note can’t be executed.

Instruction address:

One English letter in the text of the processing program (“Address” hereinafter)

Instruction word:

Adding a number after the instruction address will constitute an instruction word.

Program segment No.:

Consist of letter N and number (≤5 digits), and can be randomly arranged.

Ü The sequence of executing program segments only related to the storage position rather than program segment No.;

Ü If program segment N20 appears before program segment N10, N20 shall be executed first.

Program segment:

A program segment consists of one or several instruction word and ends with “;”;

4-1

Page 13

4. CNC Programming Structure Adtech (Shenzhen) Technology Co., Ltd.

N_ G_ X_ Z_ F_ S_ T_ M_ ;

Program segment No. Preparation Size definition Feeding speed Principal axis rotation Tool change Auxiliary

function

Skip symbol:

If the first character of a program segment is “/”, this program segment is conditional, i.e. skip switch. In upper

position, this program segment isn’t executed; when the skip switch is in lower position, this program segment

is executed.

Program end:

Generally, the following codes are used when program ends:

Code Action

M30 End main program

M99 End subroutine

H Note:

After M30 is executed, CNC stops executing and returns to program start;

After M99 is executed, CNC returns to the program that calls this subroutine and continues executing.

File end:

If the program end doesn’t have %, CNC is reset.

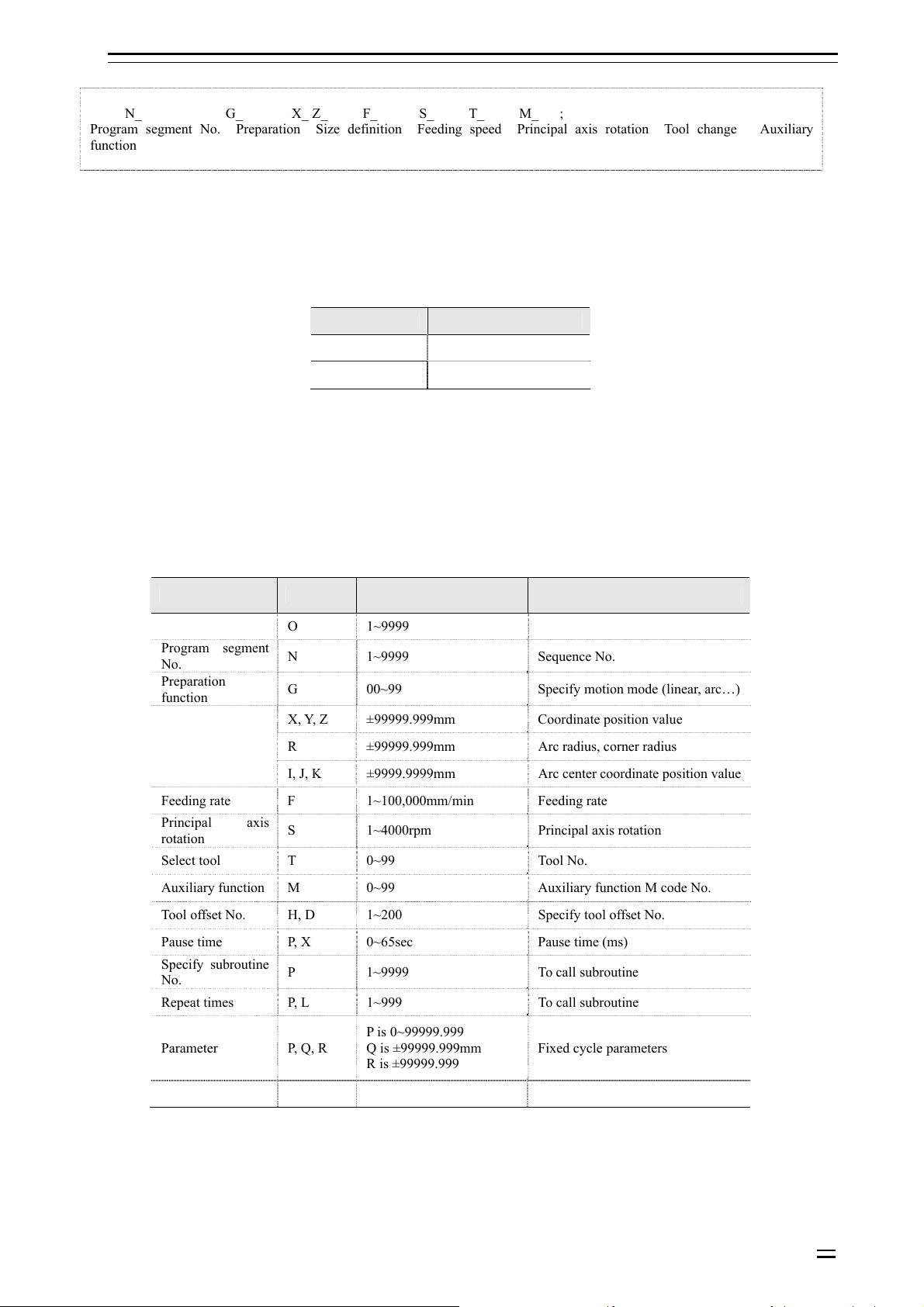

Instruction word is the basic unit of program segment. Every address has unique meaning, and the following

values also have different formats and ranges, as in the Table below:

Table 4.1 Instruction Address and Range of Command Value

Function Address Range Meaning

Program name O 1~9999 Program No.

Program segment

No.

Preparation

function

Size definition

Feeding rate F 1~100,000mm/min Feeding rate

Principal axis

rotation

Select tool T 0~99 Tool No.

Auxiliary function M 0~99 Auxiliary function M code No.

Tool offset No. H, D 1~200 Specify tool offset No.

Pause time P, X 0~65sec Pause time (ms)

Specify subroutine

No.

Repeat times P, L 1~999 To call subroutine

Parameter P, Q, R

N 1~9999 Sequence No.

G 00~99 Specify motion mode (linear, arc…)

X, Y, Z ±99999.999mm Coordinate position value

R ±99999.999mm Arc radius, corner radius

I, J, K ±9999.9999mm Arc center coordinate position value

S 1~4000rpm Principal axis rotation

P 1~9999 To call subroutine

P is 0~99999.999

Q is ±99999.999mm

R is ±99999.999

Fixed cycle parameters

4-2

Page 14

Adtech (Shenzhen) Technology Co., Ltd. 4. CNC Programming Structure

4.2 Main program and subroutine

The processing programs include main programs and subroutines. Generally, NC executes the instructions of

main program; however, NC will turn to execute subroutine when executes a subroutine calling instruction,

and will return to the main program when executes the return instruction in subroutine.

When the processing program needs to run same track for several times, edit this track into the subroutine and

save in the program memory of the machine tool, and this subroutine can be called when this track should be

executed in the program.

When the main program calls a subroutine, this subroutine can call another subroutine, which is called double

nesting. Generally, the machine tool allows up to quadruple subroutine nesting. In calling subroutine

instruction, the subroutine can be repeated for 999 times.

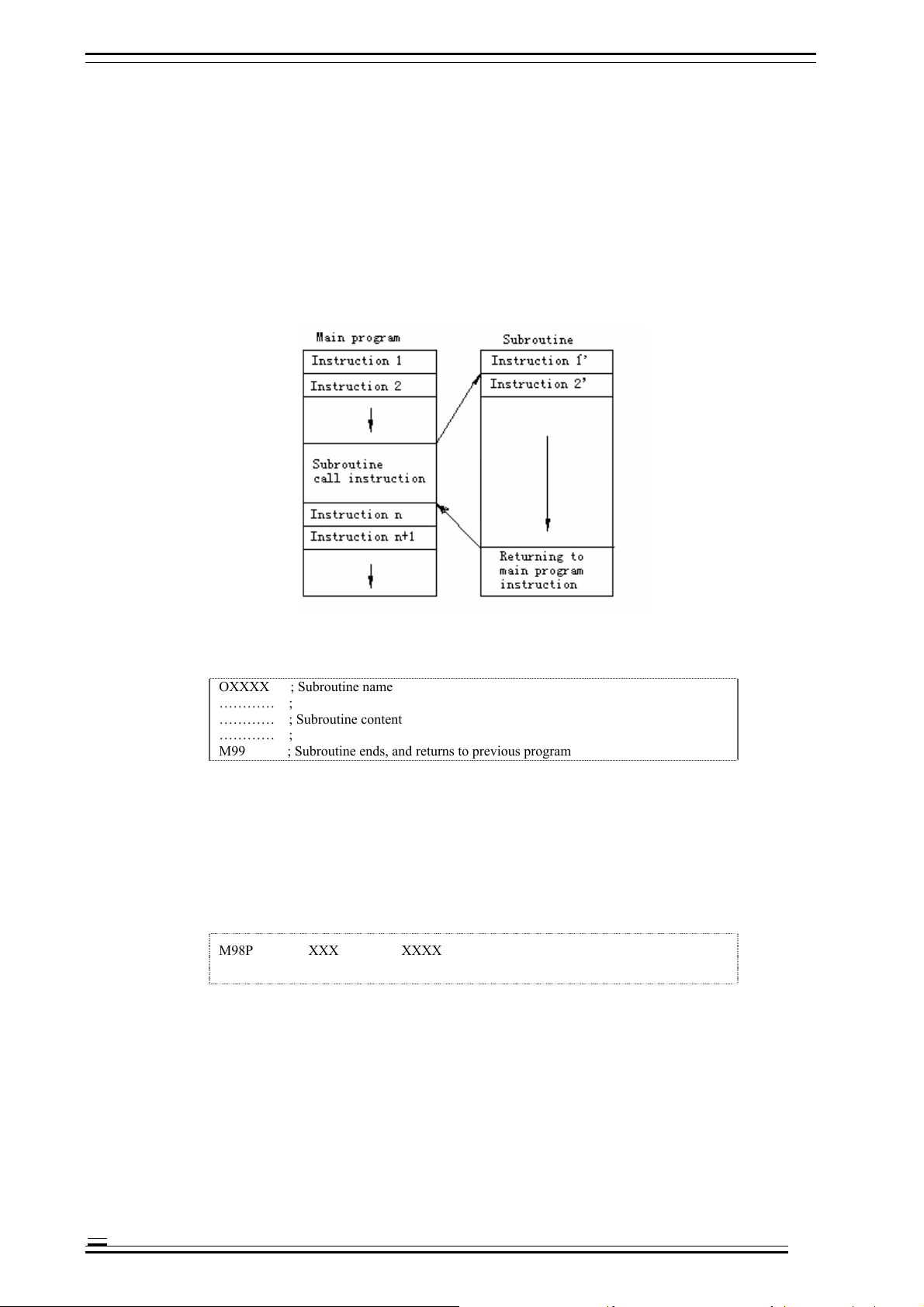

Fig. 4.2 Main Program and Subroutine

Subroutine format:

OXXXX ; Subroutine name

………… ;

………… ; Subroutine content

………… ;

M99 ; Subroutine ends, and returns to previous program

B Example: X100.0 Y100.0 M99;

H Note:

Program start should have a subroutine name specified by address O

M99 doesn’t need to appear in a program segment separately.

Subroutine call format:

M98P XXX XXXX

H Note:

In the number following address P, the latter four digits are used to specify the program No. of called subroutine, and the

4-3

former three digits are used to specify the repeat times of calling.

B Example:

M98 P41005; call subroutine 1005, repeat four times

Page 15

4. CNC Programming Structure Adtech (Shenzhen) Technology Co., Ltd.

G90 G00 X-75. Y50. Z53. M98 P40035; this program segment specifies the X, Y, Z axis to fast locate the instruction

position, and then call subroutine 0035 for four times.

H Note:

Ü If the calling time isn’t specified, the subroutine will be called only once;

Ü M98 doesn’t need to appear in a program segment separately;

Ü Different from other M codes, M98 and M99 won’t send signal to the machine tool when executing;

Ü NC gives an alarm if can’t find the program No. specified by address P;

Ü Subroutine call instruction M98 can’t be executed in MDI mode; to execute a subroutine separately, please edit the

following program in the editing mode, and execute in automatic running mode.

O×××;

M98 P××××;

M30;

4-4

Page 16

Page 17

Adtech (Shenzhen) Technology Co., Ltd. 7. Pause Instruction

5. Position instructions

5.1 Programming mode instruction

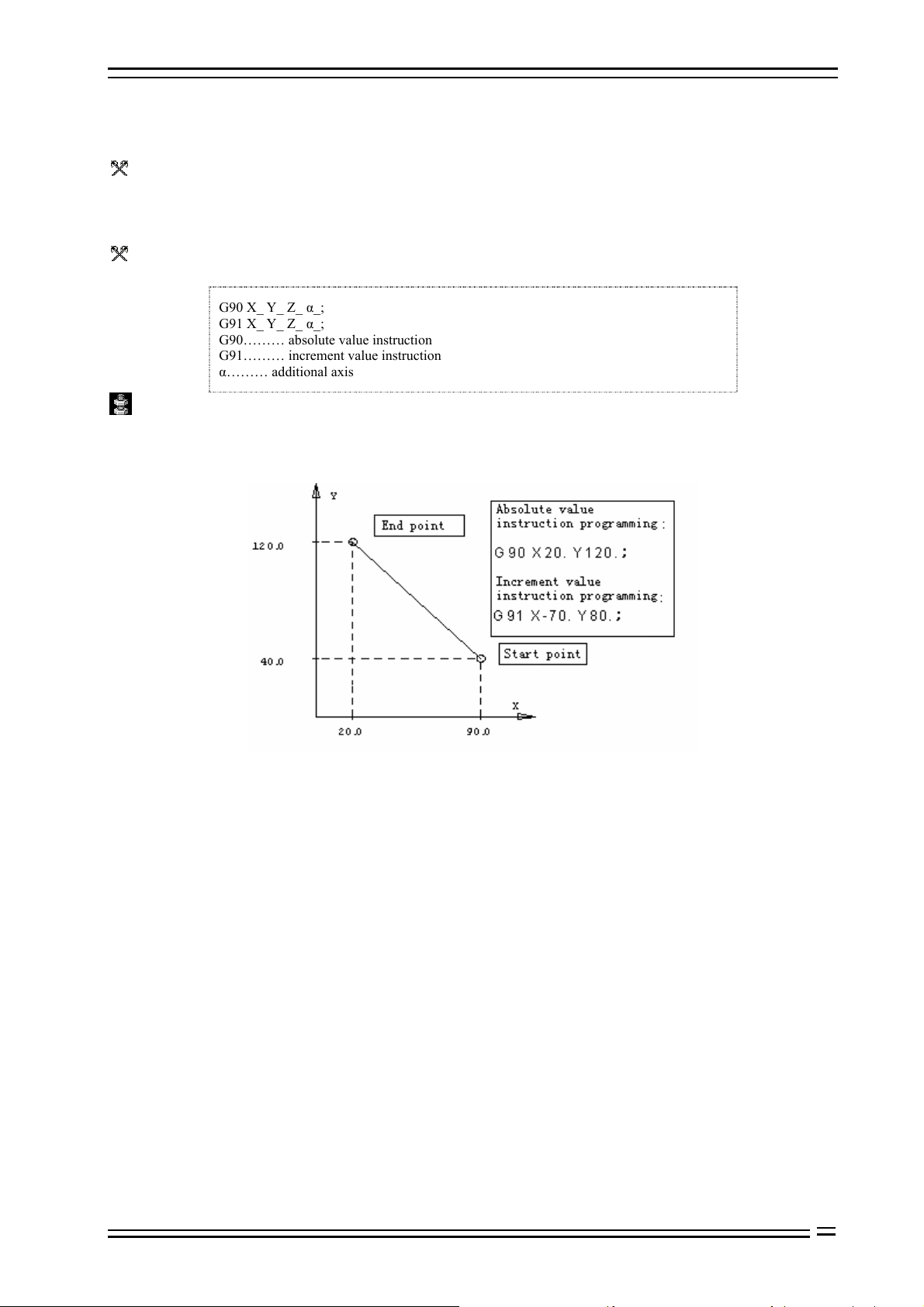

Function:

Tool motion instructions include absolute value instruction and increment value instruction. In absolute value

instruction mode, the coordinate value of the motion end in current coordinate system is specified; in

increment value instruction, the distance of every coordinate axis relative to the start point motion is specified.

Format:

G90 X_ Y_ Z_ α_;

G91 X_ Y_ Z_ α_;

G90……… absolute value instruction

G91……… increment value instruction

α……… additional axis

Details:

In absolute value instruction mode, the tool motion is unrelated to current position, and moves according to the

position of specified workpiece coordinate system;

In increment value instruction, the current position is the start point;

Fig. 1.1 Graphic Description Text

For the instructions from workpiece coordinate system home, absolute value or increment value coordinate instructions are same;

G90 and G91 are modal instructions, and are always valid until next new setting of G90 and G91.

5-1

Page 18

7. Pause Instruction Adtech (Shenzhen) Technology Co., Ltd.

6. Feeding, rapid traverse, interpolation function (G00-G03, G17-G19)

6.1 Feeding

The feeding of CNC machine tool is classified into quick positioning and cutting feeding.

The quick positioning feeding appears in the motion between quick feeding and positioning during manual

rapid traverse and fixed cycle of instruction G00. The speed of quick positioning feeding is specified by

machine tool parameters. During quick positioning feeding, the motions among feeding axes are disrelated,

and move at the rapid traverse speed set by the parameters respectively. Generally, tool track is a broken line or

straight line.

Cutting feeding appears in the processing feeding in G01, G02/03 and fixed cycle, and cutting feeding speed is

specified by address F (unit: mm/min). In processing program, F is a modal value, i.e. original programmed F

value is always valid before a new F value is specified. When CNC system is just electrified, F value is

specified by system parameter. The axes of feeding are in interpolation relation, and the composition of their

motions is cutting feeding motion.

The maximum value of F is controlled by system parameter; if the programmed F value is larger than this

value, the actual feeding cutting speed is also this value.

The cutting feeding speed also can be controlled by the feeding rate switch on the operation panel, and the

actual cutting feeding speed is the product of specified F value and feeding rate. The range of rate is

10%-150%.

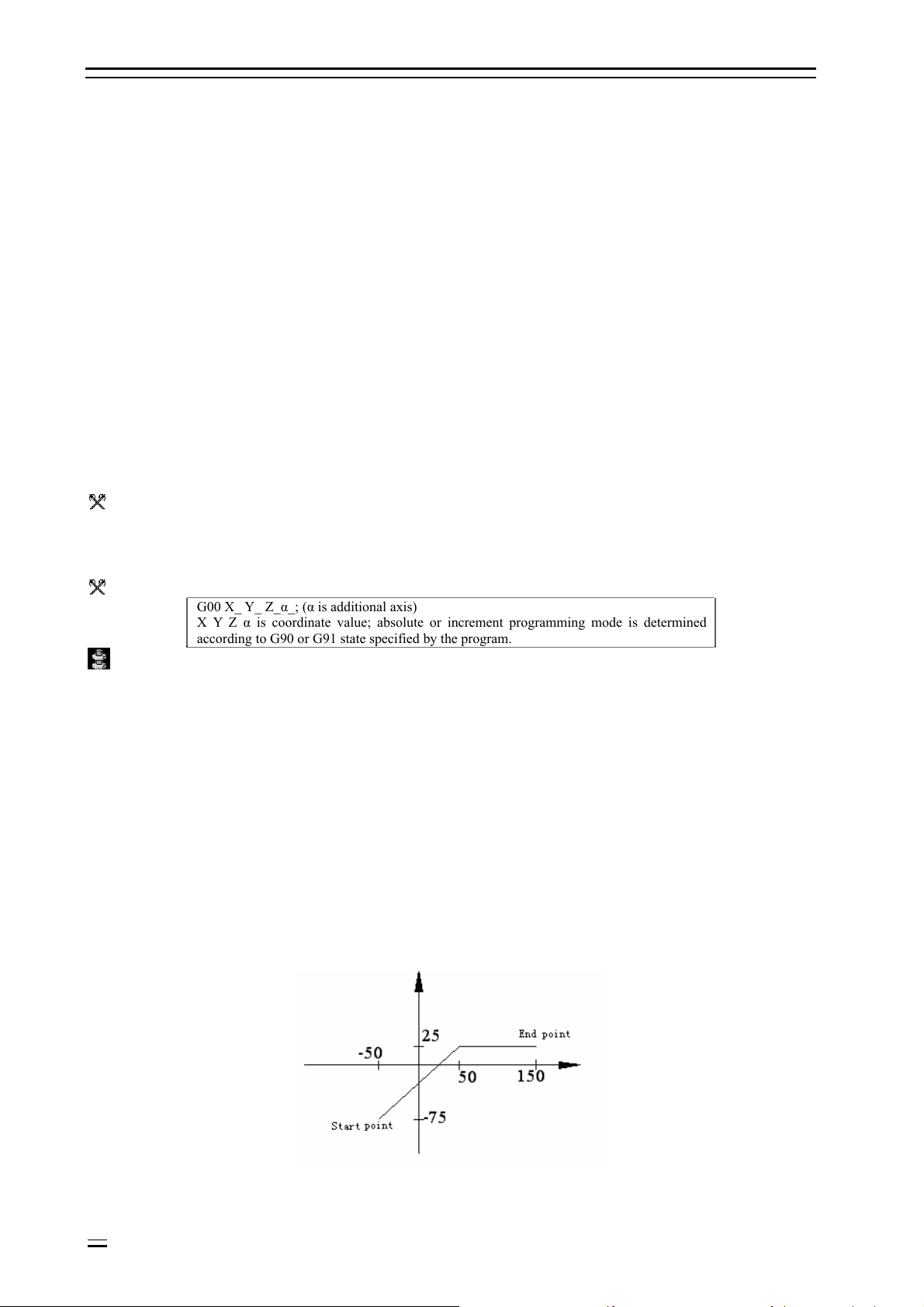

6.2 Rapid positioning (G00)

Function:

Every axis moves to specified position at specified fast traverse speed respectively; in absolute coordinate

system, the specified motion end is the coordinate value in current coordinate system; in increment coordinate

system, the motion distance of every coordinate axis relative to start point is specified.

Format:

G00 X_ Y_ Z_α_; (α is additional axis)

X Y Z α is coordinate value; absolute or increment programming mode is determined

according to G90 or G91 state specified by the program.

Details:

This instruction changes other G functions; G00 is always valid until the G01, G02 and G03 instructions of same group (01)

appears; when G00 mode is valid, the latter instructions only need to specify coordinate X, Y, Z.

In G00 mode, the tool always accelerates at the start point and decelerates at the end point of every path. It will execute next path

only after the in-place state is confirmed.

When every motion axis reaches the end point, CNC considers that this program segment has ended and turns to next program

segment.

When G00 instruction is valid, the G code function of group 09 (G73-G89) turns into cancellation state (G80).

The motions among different axes are disrelated, i.e. tool path is straight line or broken line (confirmed by selected parameters),

but the positioning time doesn’t change.

Straight line path: same as linear interpolation (G01) mode, the speed is limited by the fast feeding speed of every axis.

Broken line path: every axis is independent and moves for positioning at the maximum speed.

O Notice:

If there is no following number, G will be treated as G00.

B Example:

The position of start point is X-50, Y-75; instruction G00 X150. Y25.; the tool will have the track shown in the

figure below.

6-2

Fig. 6.1 G00 Programming Diagram

Page 19

Adtech (Shenzhen) Technology Co., Ltd. 7. Pause Instruction

6.3 Linear interpolation (G01)

Function:

G01 changes current interpolation state into linear interpolation, tool moves to specified position from current

position, and the track is a straight line from start point to end point.

Format:

G01 X_ Y_ Z_ α_ F_; (α is additional axis)

X Y Z α is coordinate value; absolute or increment programming mode is determined

according to G90 or G91 state specified by the program.

F indicates the speed of linear motion (unit: mm/min)

Details:

This instruction changes other G functions, and G01 is always valid until G00, G02 or G03 instruction of same

group (01) appears. If the next instruction is still G01 and the feeding speed is same, G01 can be ignored. If the

program segment in which G01 instruction appears for the first time doesn’t have F instruction, there will be

error.

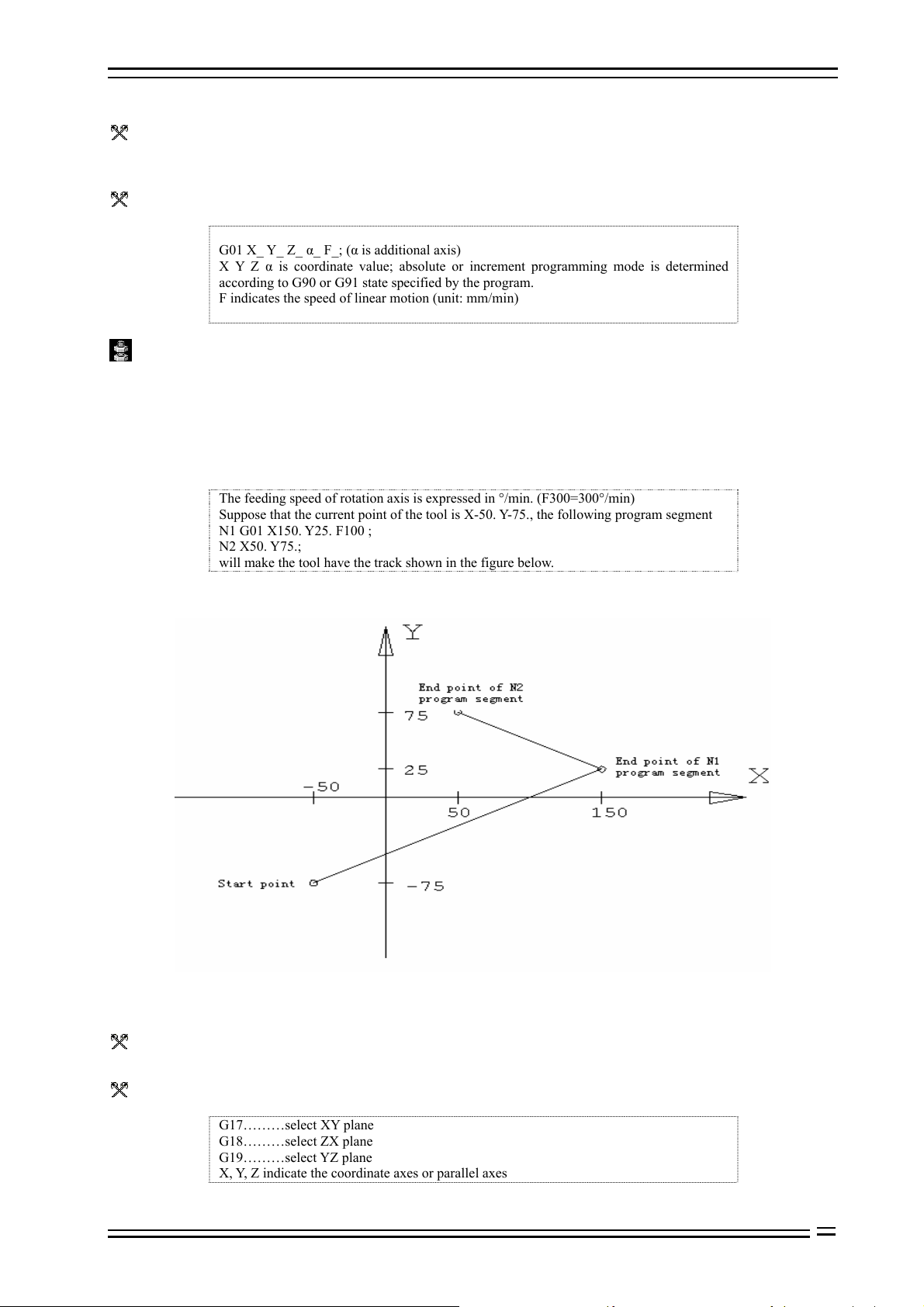

B Example:

The feeding speed of rotation axis is expressed in °/min. (F300=300°/min)

Suppose that the current point of the tool is X-50. Y-75., the following program segment

N1 G01 X150. Y25. F100 ;

N2 X50. Y75.;

will make the tool have the track shown in the figure below.

Fig 6.2 G01 Programming Diagram

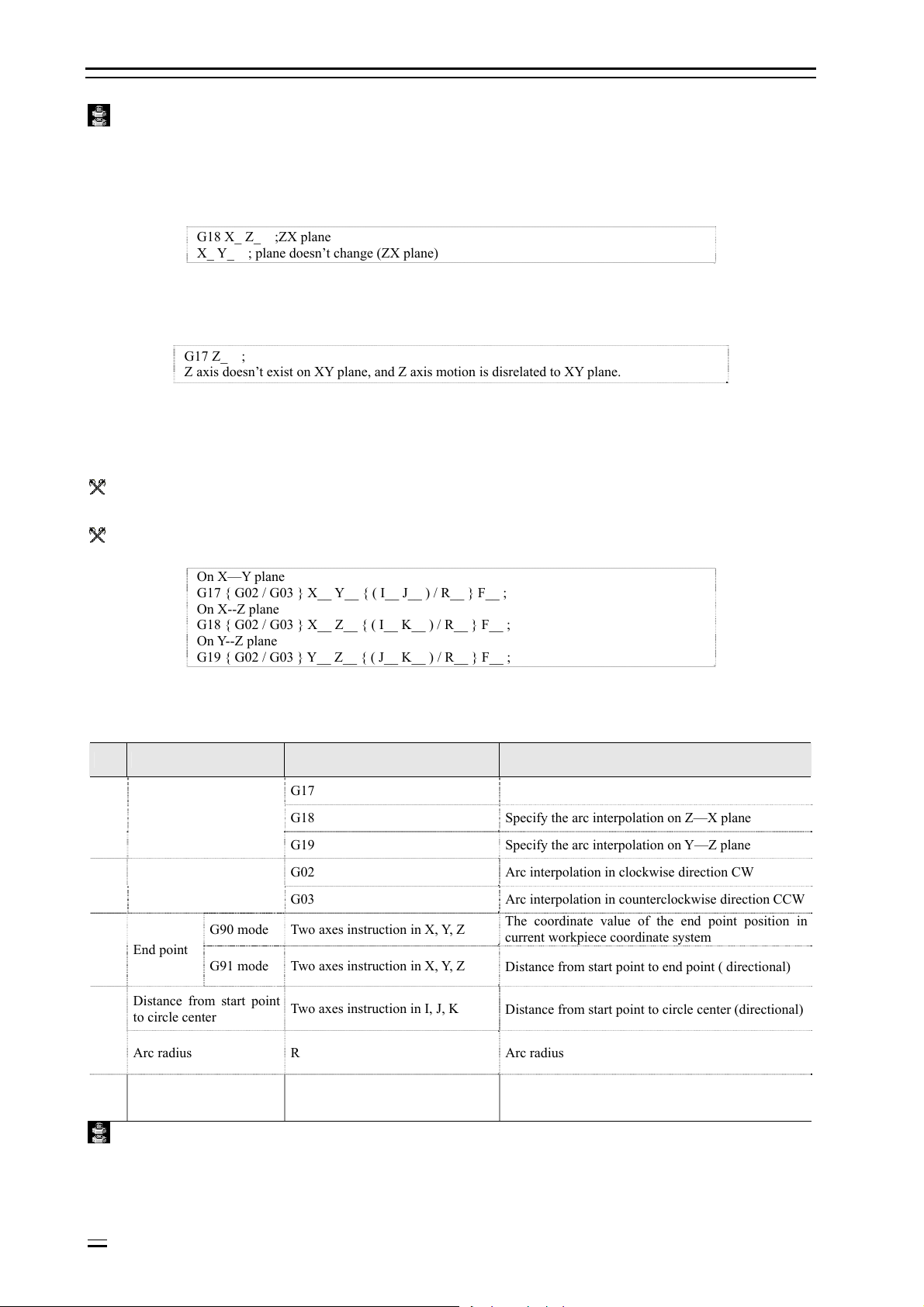

6.4 Plane selection (G17-G19)

Function:

This group of instruction is used to select the plane of arc interpolation and tool radius compensation.

Format:

G17………select XY plane

G18………select ZX plane

G19………select YZ plane

X, Y, Z indicate the coordinate axes or parallel axes

6-3

Page 20

7. Pause Instruction Adtech (Shenzhen) Technology Co., Ltd.

Details:

When the system is electrified, plane XY is selected by default.

In the program segment without instruction G17, G18 or G19, the plane doesn’t have any change.

B Example:

B

G18 X_ Z_ ;ZX plane

X_ Y_ ; plane doesn’t change (ZX plane)

Motion instruction is disrelated to plane selection.

B Example:

Under the following instruction,

G17 Z_ ;

Z axis doesn’t exist on XY plane, and Z axis motion is disrelated to XY plane.

About the instructions related to plane selection, please refer to the content related to arc interpolation and tool

compensation instructions.

6.5 Arc interpolation (G02, G03)

Function:

Used to move the tool in arc track

Format:

On X—Y plane

G17 { G02 / G03 } X__ Y__ { ( I__ J__ ) / R__ } F__ ;

On X--Z plane

G18 { G02 / G03 } X__ Z__ { ( I__ K__ ) / R__ } F__ ;

On Y--Z plane

G19 { G02 / G03 } Y__ Z__ { ( J__ K__ ) / R__ } F__ ;

Table 6.1 Arc Interpolation Command Format Description

S/N Data content Instruction Meaning

G17 Specify the arc interpolation on X—Y plane

1 Plane selection

2 Arc direction

G90 mode Two axes instruction in X, Y, Z

3 End point

G91 mode Two axes instruction in X, Y, Z

G18 Specify the arc interpolation on Z—X plane

G19 Specify the arc interpolation on Y—Z plane

G02 Arc interpolation in clockwise direction CW

G03 Arc interpolation in counterclockwise direction CCW

The coordinate value of the end point position in

current workpiece coordinate system

Distance from start point to end point ( directional)

Distance from start point

to circle center

4

Arc radius R Arc radius

5 Feeding rate F The speed of arc motion

Two axes instruction in I, J, K

Distance from start point to circle center (directional)

Details:

G02 (G03) is modal instruction.

The arc crossing multiple quadrants can be specified in one program segment.

6-4

Page 21

Adtech (Shenzhen) Technology Co., Ltd. 7. Pause Instruction

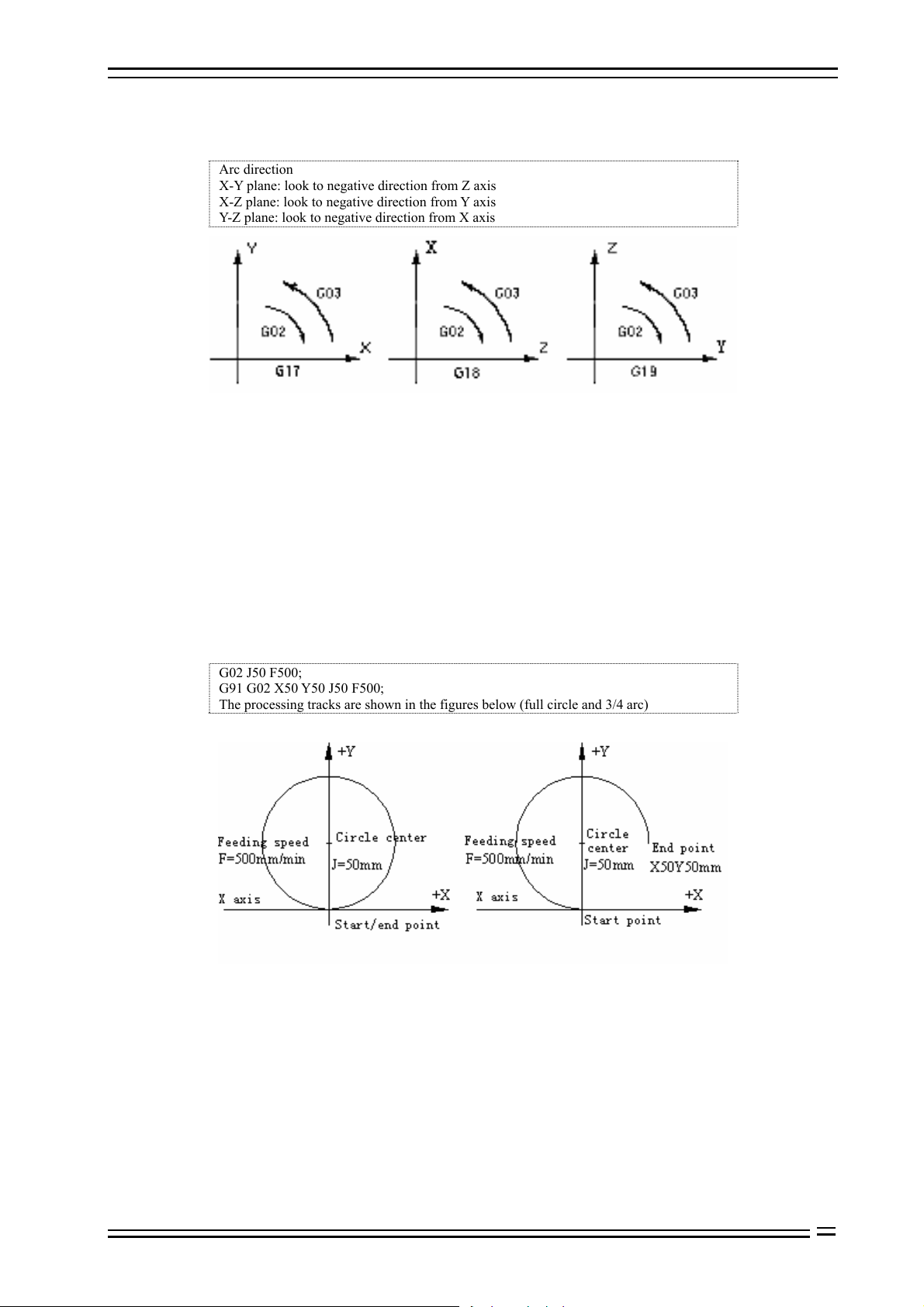

H Note:

Arc direction

X-Y plane: look to negative direction from Z axis

X-Z plane: look to negative direction from Y axis

Y-Z plane: look to negative direction from X axis

Fig. 6.3 Arc Interpolation Plane Definition Diagram

The end point of the arc is determined by address X, Y and Z. In G90 mode, i.e. absolute value mode, address

X, Y and Z specify the coordinate value of arc end in current coordinate system; in G91 mode, i.e. increment

value mode, address X, Y and Z specify the distance from the point of current tool to the end point in the

direction of every axis.

In X, Y and Z direction, the distance from the point of current point to the circle center is specified by address I,

J and K respectively, the symbols of which are determined by their motion directions.

The coordinate value of arc end can be either in absolute value or increment value, while the coordinate value

of arc center must be increment instruction from the start point.

When X, Y and Z are ignored (the start point coincides with the end point), I, J and K define the circle center,

and the track will be a full circle.

B Example:

G02 J50 F500;

G91 G02 X50 Y50 J50 F500;

The processing tracks are shown in the figures below (full circle and 3/4 arc)

Fig. 6.4 Instruction Diagram of Processing Full Circle

To program a segment of arc, in addition to specifying end point and circle center position, it is also possible

by specifying radius and end point position. If the radius is specified with address R, the value of R can be

either positive or negative; a positive R value can be used to determine an arc smaller than 180°, and a

negative value can be used to determine an arc larger than 180°. Programming a full circle is only possible by

specifying circle center.

6-5

Page 22

7. Pause Instruction Adtech (Shenzhen) Technology Co., Ltd.

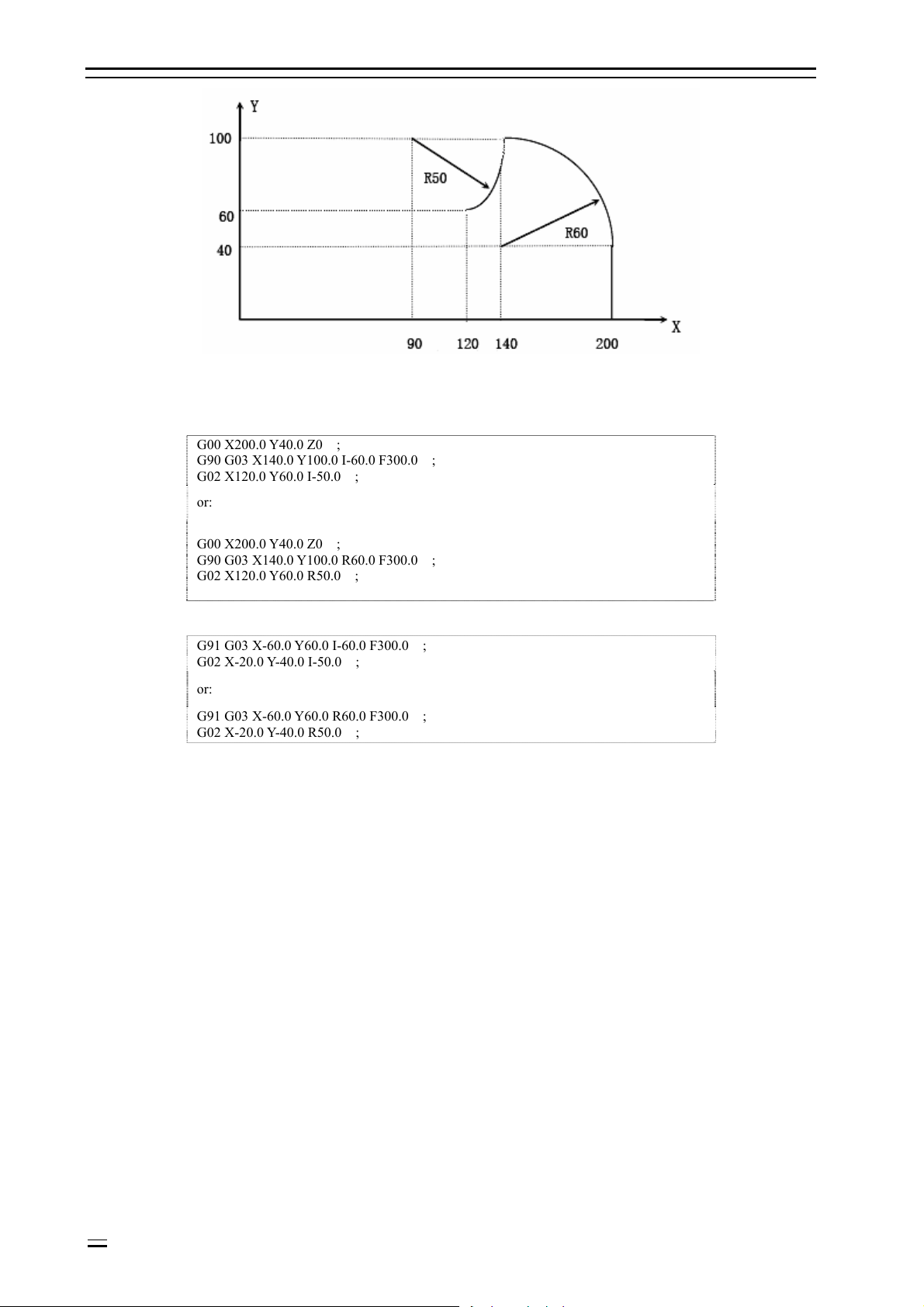

Fig. 6.5 Absolute/Increment Programming Diagram

Above tracks are programmed in absolute value and increment value mode as follows:

Ü Absolute value mode

G00 X200.0 Y40.0 Z0 ;

G90 G03 X140.0 Y100.0 I-60.0 F300.0 ;

G02 X120.0 Y60.0 I-50.0 ;

or:

G00 X200.0 Y40.0 Z0 ;

G90 G03 X140.0 Y100.0 R60.0 F300.0 ;

G02 X120.0 Y60.0 R50.0 ;

Ü Increment mode

G91 G03 X-60.0 Y60.0 I-60.0 F300.0 ;

G02 X-20.0 Y-40.0 I-50.0 ;

or:

G91 G03 X-60.0 Y60.0 R60.0 F300.0 ;

G02 X-20.0 Y-40.0 R50.0 ;

The feeding speed of arc interpolation is specified with F, which is the speed of tool in arc tangent direction.

6-6

Page 23

Adtech (Shenzhen) Technology Co., Ltd. 7. Pause Instruction

7. Pause instruction (G04)

Function:

Pause for a period of time between two program segments.

Format:

G04 P_ or G04 X_

Address P specifies the pause time, and the minimum unit of its instruction is 0.001 second

if there is no radix point.

Address X specifies the pause time, and the minimum unit of its instruction is 1 second if

there is no radix point.

B Example:

G04 P 1000 : pause for 1000ms, equal to 1sec

G04 X 1 : pause for 1sec

7-7

Page 24

8. Coordinate System Setting Function Adtech (Shenzhen) Technology Co., Ltd.

8. Coordinate system setting function (G52-G59, G591-G599,

G92)

8.1 Machine tool coordinate system (G53)

Machine tool coordinate system:

The coordinate system fixed on the machine tool is created through returning to reference point after NC is

electrified every time. To select machine tool coordinate system, use G53 instruction.

Format (machine tool coordinate system):

G53 X_Y_Z_;

X_Y_Z_; The coordinate absolute value of every axis

Details:

When the machine tool is electrified, it must be reset in auto or manual mode, and the coordinate system is

created basing on reset reference origin.

The machine tool coordinate system won’t change before the power supply is cut off after created.

The machine tool coordinate system won’t be changed due to G92 instruction.

G53 instruction only can be used in absolute value mode (G90).

G53 is non-modal instruction, and is only valid in current program segment.

If G53 instruction and G28 instruction appear in the same program segment at the same time, the latter

instruction is valid.

When G53 instruction is created, cancel tool radius compensation and tool offset.

All G53 instructions move in quick feeding mode.

The distance between machine tool coordinate system home and machine tool reference point is determined by

the parameters; unless otherwise specified, the reference point of every axis coincides with machine tool

coordinate system home.

8.2 Workpiece coordinate system

Workpiece coordinate system:

When start programming, the programmer doesn’t know the position of the workpiece on the machine tool,

and usually uses a point on the workpiece as the reference point to write processing program. The coordinate

system created with this reference point is the workpiece coordinate system. When the workpiece is fixed on

the worktable of the machine tool, move the tool to specified workpiece reference point and set the coordinate

value of this point as the origin of workpiece coordinate system, and the tool will use this workpiece

coordinate system as the reference system and process according to program instruction when the system

executes the machining program. Therefore, the origin offset function of coordinate system is very important

to CNC machine tool.

8-2

Page 25

Adtech (Shenzhen) Technology Co., Ltd. 7. Pause Instruction

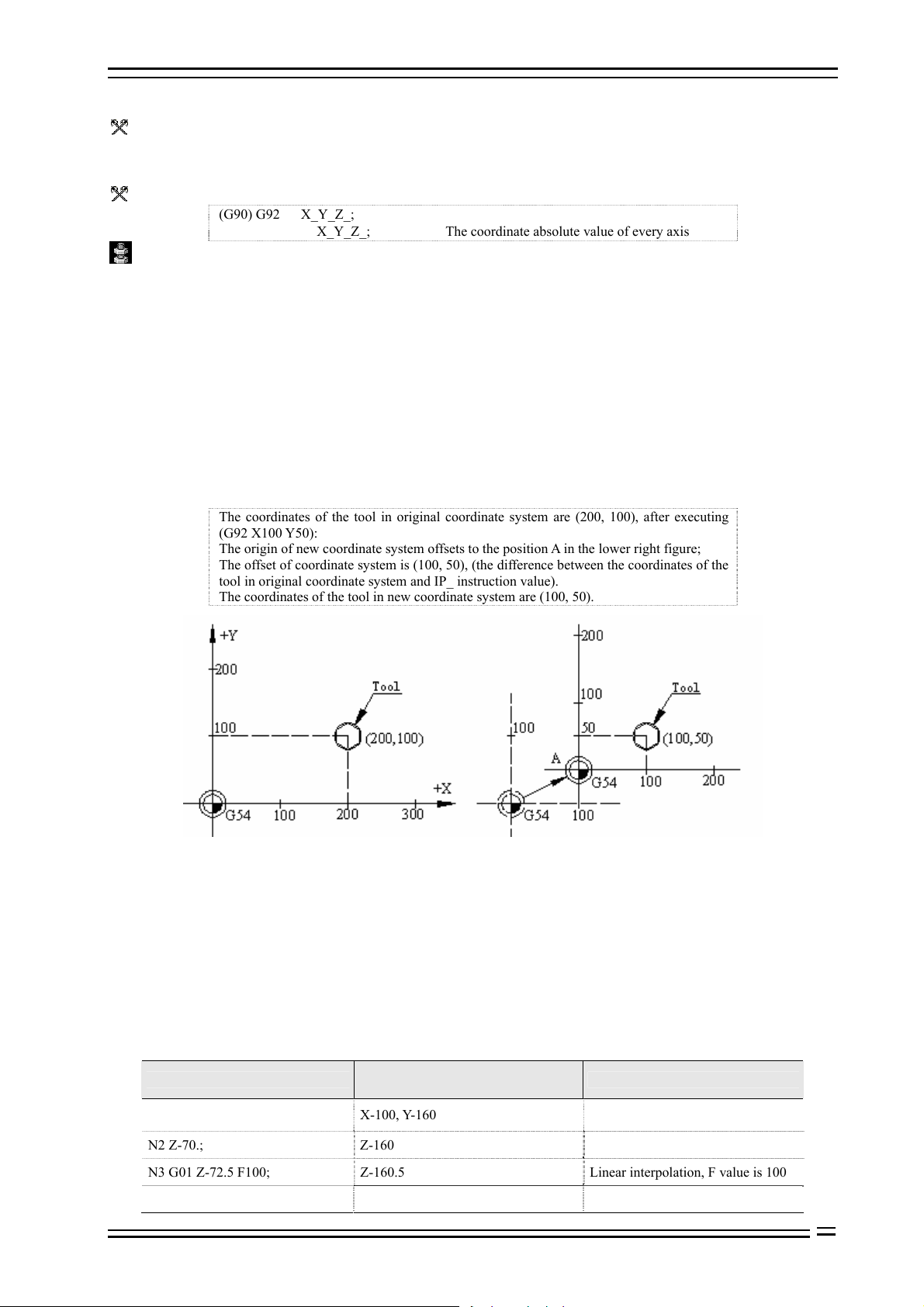

8.2.1 Programmable workpiece coordinate system (G92)

Function:

This instruction creates a new workpiece coordinate system, so that the coordinate value of the point where

current tool locate is the value of IP_ instruction in this workpiece coordinate system. (as shown in Fig. 8.1)

Format:

(G90) G92 X_Y_Z_;

X_Y_Z_; The coordinate absolute value of every axis

Details:

G92 instruction is a non-modal instruction, but the workpiece coordinate system created with this instruction is

modal.

Actually, this instruction also specifies an offset, which is specified indirectly. It is the coordinate value of new

workpiece coordinate system origin in original workpiece coordinate system; seen from G92 function, this

offset is the difference between the coordinate value of the tool in original workpiece coordinate system and

IP_ instruction value. ( as shown in Fig. 8.1)

If G92 instruction is used for several times, the offset specified by G92 instruction will superpose. For every

preset workpiece coordinate system (G54-G59), the superposed offset is valid.

New coordinate system of the part is set in above instruction, e.g. the coordinate value of tool tip is IP_. Once

the coordinates are confirmed, the position of the absolute value instruction is the coordinates in this

coordinate system.

B Example:

The coordinates of the tool in original coordinate system are (200, 100), after executing

(G92 X100 Y50):

The origin of new coordinate system offsets to the position A in the lower right figure;

The offset of coordinate system is (100, 50), (the difference between the coordinates of the

tool in original coordinate system and IP_ instruction value).

The coordinates of the tool in new coordinate system are (100, 50).

Fig. 8.1 G92 Instruction Function Diagram

8.2.2 Using preset workpiece coordinate system (G54~G59, G591~G599)

According to the loading position of the workpiece in the machine tool, this system can preset six coordinate

systems (nine extended in new version); through the operation on LCD panel, set the offset of the origin of

every workpiece coordinate system relative to the origin of machine tool coordinate system, and then use

G54~G59, G591~G599 to select, which are modal instructions, corresponding to 1#~15# preset workpiece

coordinate systems respectively.

B Example:

Preset 1# workpiece coordinate system offset: X-150.000 Y-210.000 Z-90.000

Preset 4# workpiece coordinate system offset: X-430.000 Y-330.000 Z-120.000

Program segment content

N1 G90 G54 G00 X50. Y50.; X-100, Y-160

N2 Z-70.; Z-160

N3 G01 Z-72.5 F100; Z-160.5 Linear interpolation, F value is 100

N4 X37.4; X-112.6 (Linear interpolation)

Coordinates of end point in machine

tool coordinate system

Note

Select 1# coordinate system, quick

positioning

8-3

Page 26

8. Coordinate System Setting Function Adtech (Shenzhen) Technology Co., Ltd.

N5 G00 Z0; Z-90 Quick positioning

N6 X0 Y0 A0; X-150, Y-210

N7 G53 X0 Y0 Z0; X0, Y0, Z0

N8 G57 X50. Y50. ; X-380, Y-280 Select 4# coordinate system

N9 Z-70.; Z-190

N10 G01 Z-72.5; Z-192.5

N11 X37.4; X392.6

N12 G00 Z0; Z-120

N13 G00 X0 Y0 ; X-430, Y-330

Select to use machine tool coordinate

system

Linear interpolation, F value is 100

(modal value)

Seen from above samples, the function of G54~G59 instruction is to move the coordinate origin used by NC to

the point that the coordinates in machine tool coordinate system are preset value; please refer to the operation

section in this manual for the method of presetting.

After returning to the home of machine tool, coordinate systems 1~6 of the workpiece are created. G54 is the

initial mode after electrified. The absolute position of the position screen is the coordinates in current

coordinate system.

In CNC programming of machine tool, unless otherwise specified, the IP of interpolation instruction and other

instructions related to coordinates are the coordinate position in current coordinate system (the coordinate

system used when the instruction is executed). In most cases, the current coordinate system is one of G54~G59,

and machine tool coordinate system are seldom used directly.

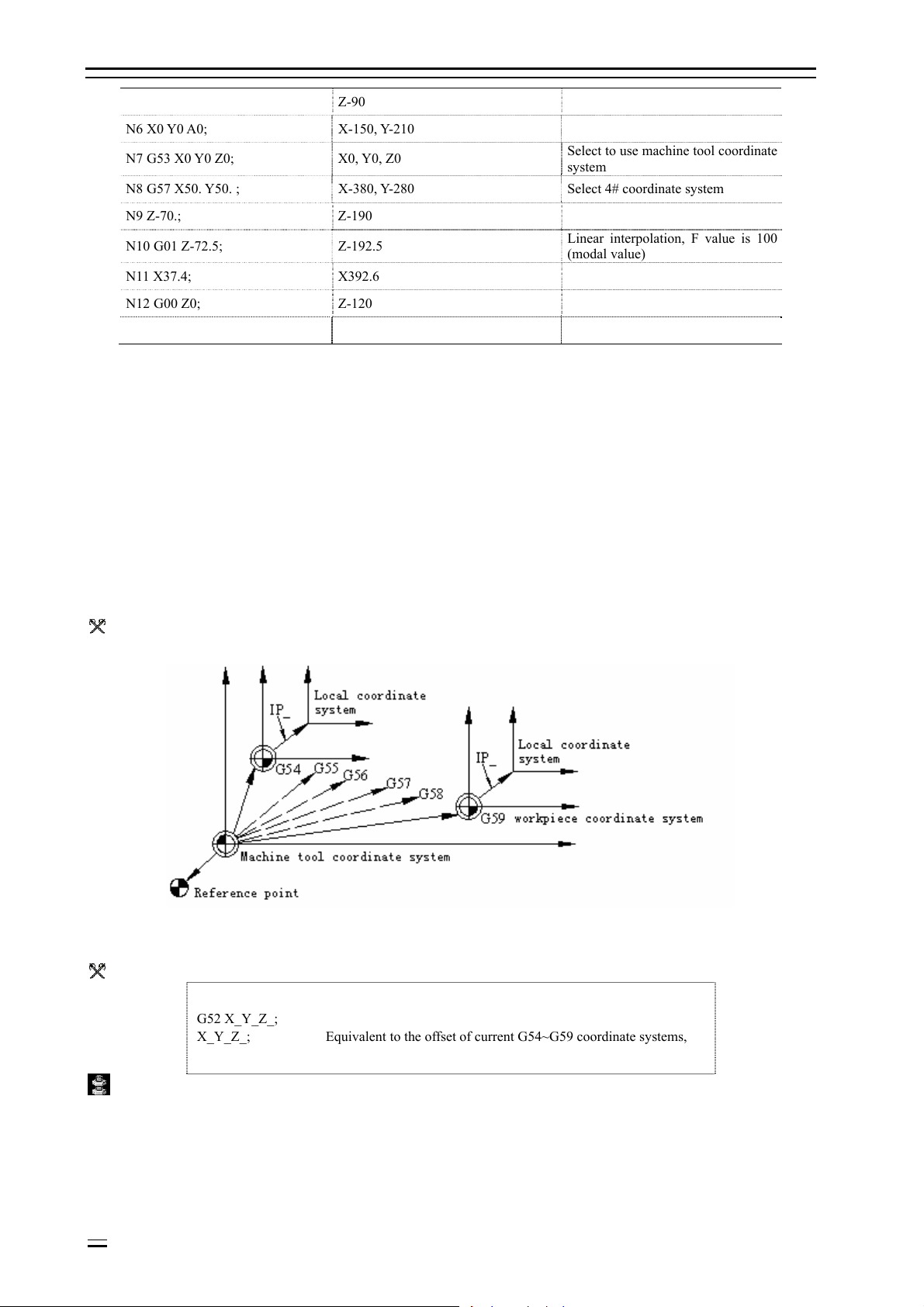

8.3 Local coordinate system (G52)

Function:

G52 can create a local coordinate system, which is a sub-coordinate system equivalent to G54~G59.

Fig. 8.2 Local Coordinate System Diagram

Format:

G52 X_Y_Z_;

X_Y_Z_; Equivalent to the offset of current G54~G59 coordinate systems,

Details:

In this instruction, IP_ specifies the offset equivalent to current G54~G59 coordinate systems, i.e. IP_ specifies

the position coordinates of local coordinate system origin in current G54~G59 coordinate system.

G52 instruction is always valid after specified until next G52 instruction is specified.

G52 instruction can set the processing coordinate system without changing the workpiece coordinate system.

G52 IP0 (G52 X0 Y0 Z 0 α0) can be used to cancel local coordinate system.

8-4

Page 27

Adtech (Shenzhen) Technology Co., Ltd. 7. Pause Instruction

The setting of local coordinate system doesn’t change the machine tool coordinate and workpiece coordinate

system.

G52 instruction can replace G92 instruction to specify the offset between the origin of processing program and

workpiece origin.

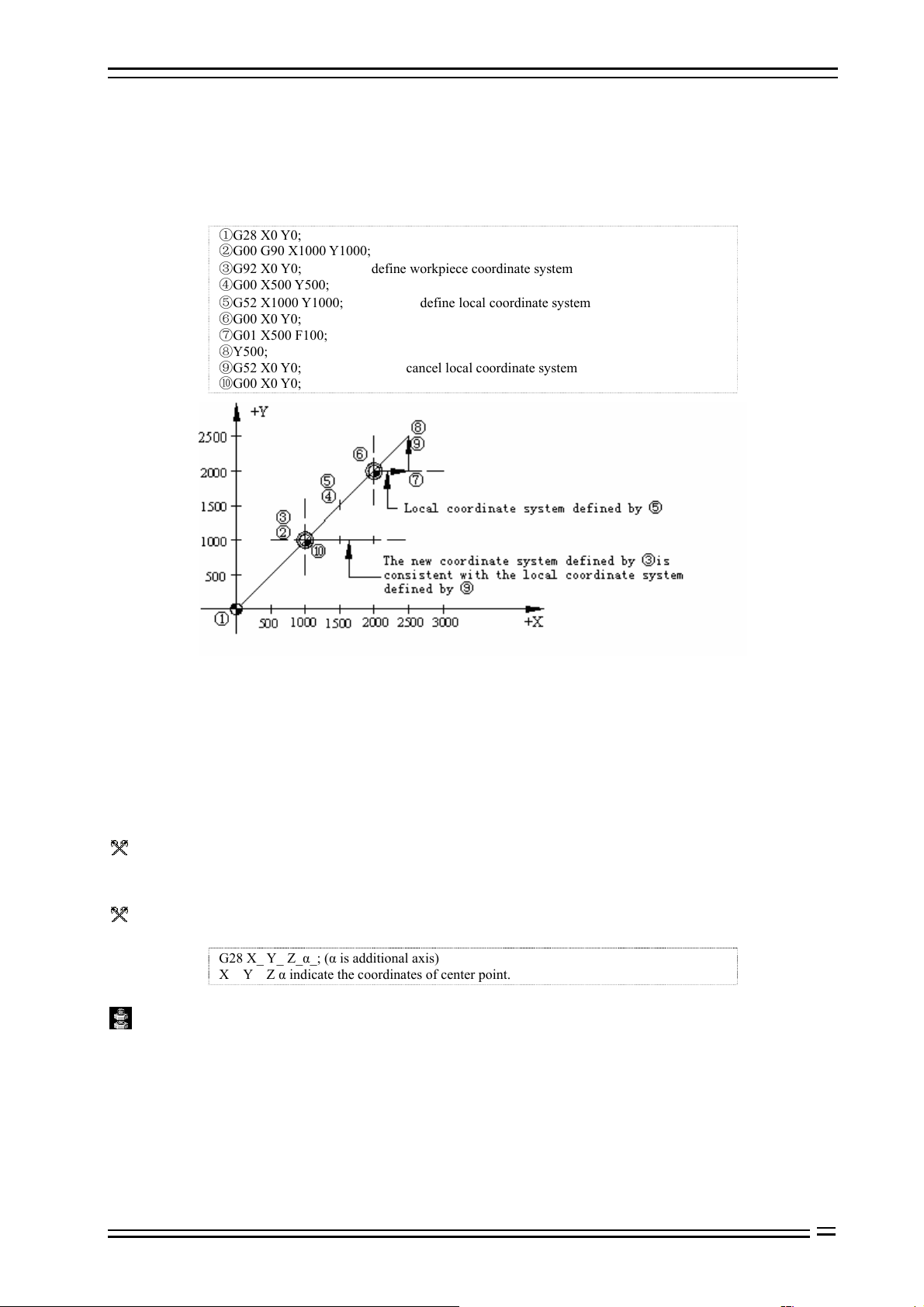

B Example:

Local coordinate system in absolute value mode

G28 X0 Y0;

G00 G90 X1000 Y1000;

③G92 X0 Y0; define workpiece coordinate system

G00 X500 Y500;

⑤G52 X1000 Y1000; define local coordinate system

G00 X0 Y0;

G01 X500 F100;

Y500;

G52 X0 Y0; cancel local coordinate system

G00 X0 Y0;

Fig. 8.3 Local Coordinate System Usage Diagram in Absolute Value Mode

8.4 Operation related to reference point

The machine tool coordinate system is created through returning to reference point after NC is electrified every

time. The reference point is a fixed point on the machine tool, and its position is determined by the installation

position of stopper switch of every axis and the home position of the servo motor of every axis. When this

machine tool returns to the reference point, the coordinates of the reference point in the machine tool

coordinate system is X0, Y0, Z0.

8.4.1 Auto return to reference point (G28)

Function:

This instruction makes the axis return to reference point of the machine tool through the center point specified

by IP at the feeding speed of quick positioning.

Format:

G28 X_ Y_ Z_α_; (α is additional axis)

X Y Z α indicate the coordinates of center point.

Details:

The center point may be specified either in absolute value mode or increment value mode, which depends on

current mode.

Generally, this instruction is used to move the workpiece out of the processing area when the entire processing

program ends, so as to unload processed parts and load the parts to be processed.

When execute G28 instruction before returning to reference point manually, the motion of every started from

center point is same as returning to reference point manually, and the motion direction started from the center

point is positive.

8-5

Page 28

8. Coordinate System Setting Function Adtech (Shenzhen) Technology Co., Ltd.

The coordinates in G28 instruction is saved as center point by NC; on another hand, if an axis isn’t contained

in G28 instruction, the coordinates of the center pointed saved by NC will use the value G28 instruction

specified previously.

B Example:

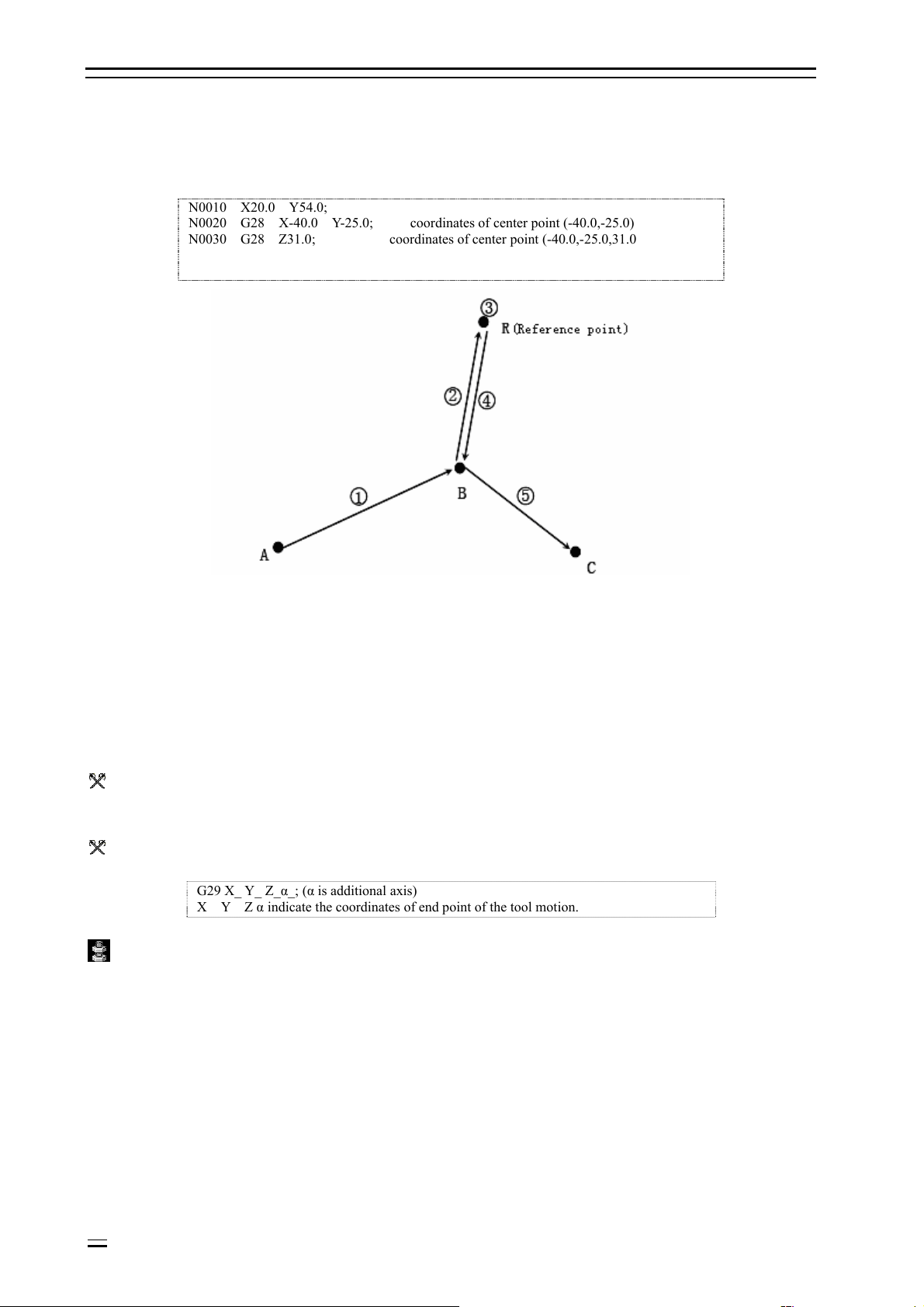

N0010 X20.0 Y54.0;

N0020 G28 X-40.0 Y-25.0; coordinates of center point (-40.0,-25.0)

N0030 G28 Z31.0; coordinates of center point (-40.0,-25.0,31.0

Fig. 8.2 Diagram of Automatically Returning to Reference Point

O Notice:

The coordinates of this center point are mainly used by G28 instruction.

In tool offset mode, tool offset is also valid for G27; for safety reasons, tool offset should be disabled before executing G28

instruction (radius offset and length offset).

8.4.2 Auto return from reference point (G29)

Function:

This instruction makes the axis move from reference point to instruction position through center point at the

feeding speed of quick positioning; the position of center point is confirmed by previous G28 instruction.

Format:

G29 X_ Y_ Z_α_; (α is additional axis)

X Y Z α indicate the coordinates of end point of the tool motion.

Details:

Generally, after this instruction is used for G28, the instructed axis is on reference point or second reference

point.

In increment value mode, the instruction value is the distance from center point to end point (instruction

position).

In program, the specific movement amount from center point to reference point doesn’t need to be calculated.

B G28, G29 example:

8-6

Page 29

Adtech (Shenzhen) Technology Co., Ltd. 7. Pause Instruction

Fig. 8.3 G28, G29 Usage Diagram

G28 X1300.0 Y700.0; (A→B program)

………………………

G29 X1800.0 Y300.0 ; (B→C program)

O Notice:

When change part coordinate system after moving to reference point through center point with G28 instruction, the center

point also moves to new coordinate system; when instruct G29 later, positioning at instructed position through center point

in new coordinate system.

8.4.3 Reference point return checking (G27)

Function:

This instruction makes the axis move to the position of IP instruction at the feeding speed of quick positioning,

and then checks whether this point is reference point; if yes, sends the finishing signal that this axis returns to

reference point (reference point arriving indicator of this axis is lighted); if not, gives an alarm and interrupts

the running program.

Format:

G27 X_ Y_ Z_ P_;

X Y Z indicate that reference point returns to control axis.

P reference point returns number (the first reference point by default)

Details:

The axes of simultaneous reference point return check are same to simultaneously controlled axes.

If the reference point isn’t reached after instruction is executed, the program alarms.

8-7

Page 30

Page 31

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

9. Tool compensation function

9.1 Tool compensation

CNC programming is considered as the motion track of a point; however, the tool has certain length or radius,

and therefore the motion track of tool point during part contour machining isn’t the actual contour of the part;

they have the difference of a tool length or radius; to make the motion track of tool point coincide with the

actual contour, it must offset a distance, which is called tool compensation.

Tool compensation consists of length compensation and radius compensation. The tool length is different or

wears due to long time cutting, and thus the length compensation is required. Radius compensation is required

because the actual processing tool always has certain tool radius or tip arc radius, and therefore there is a

difference of tool radius between tool point motion track and the actual contour of the part during part contour

processing. To make the motion track of tool point coincide with the actual contour, it is necessary to offset a

tool radius, which is tool radius compensation.

9.2 Tool length compensation

Function:

Assume the difference between tool length and actual tool length when correct the programming.

Format:

G43 Z_ H_; positive offset

G44 Z_ H_; negative offset

G49 Z_; (or H00) tool length compensation cancel

Move the end point position of Z axis instruction for an offset according to above instruction, and preset the

difference between tool length and the tool length of actual processing assumed during programming in offset

memory, and therefore the operator only needs to change the tool compensation to process parts with tools of

different lengths without changing the program.

Details:

In either absolute value or increment value mode, for G43, add the offset specified by H code (set in offset

memory) to Z axis motion instruction end point coordinates in the program; for G44, subtract the offset

specified by H code, and use the calculated coordinates as the end point coordinates.

When Z axis motion is omitted, if the offset is positive, G43 instruction will move an offset in positive

direction and G44 will move an offset in negative direction. If the offset is negative, it moves to reverse

direction.

G43 and G44 are modal G codes, which are always valid before the G codes of same group appear.

Specifying offset:

H code specifies the offset No., the corresponding offset will add or subtract Z axis motion instruction when

the program is running, and thus creates new motion instruction of Z axis. Offset No. can be specified between

H00 and H18, while the offset corresponding to H00 can’t be set to static 0.

Enter tool compensation menu, and preset the offset to corresponding offset No. in the offset memory.

mm inch

Offset 0-±999.999 0-±99.9999

Cancel tool length compensation:

Cancel tool length compensation with G49 or H00.

B Example:

Tool compensation processing (hole #1, #2, #3)

9-1

Page 32

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

Fig. 9.1 Tool Compensation Processing Hole Example

N1 G91 G00 X120.0 Y80.0;……………… (1)

N2 G43 Z-32.0 H01;……………………… (2)

N3 G01 Z-21.0; ………………………… (3)

N4 G04 P2000; …………………………… (4)

N5 G00 Z21.0; …………………………… (5)

N6 X30.0 Y-50.0;………………………… (6)

N7 G01 Z-41.0; ………………………… (7)

N8 G00 Z41.0; …………………………… (8)

N9 X50.0 Y30.0;……………… ………… (9)

N10 G01 Z-25.0; ……………………… (10)

N11 G04 P2000; ……………………… (11)

N12 G00 Z57.0 H00; …………………… (12)

N13 X-200.0 Y-60.0;…………………… (13)

N14 M30;

O Notice:

When the offset No. is changed, it only changes to new offset, rather than adding the new offset to the old offset.

H01……………………… offset 20.0

H02………………………offset 30.0

G90 G43 Z100 0 H01………Z moves to 120.0

G90 G43 Z100 0 H02………Z moves to 130.0

9.3 Tool radius compensation

Tool radius compensation function:

Tool radius compensation is expressed with G instruction (G40-G42) and D instruction, and the radius of

selected tool can be compensated in any vector direction.

Format:

Cancel or carry through tool radius compensation vector with G40, G41 and G42 instruction. They combine

with G00, G01, G02 and G03 instructions, define a mode and confirm the value of compensation vector,

direction and tool motion direction.

G code Function

G40 X_ Y_ ; Tool radius compensation cancel

9-2

Page 33

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

G41 X_ Y_ ; Tool radius left compensation

G42 X_ Y_ ; Tool radius right compensation

Details:

Tool radius compensation is specified by D instruction, and H instruction is invalid.

The plane selection of tool radius compensation can be compensated according to D instruction or in the plane

specified by two axes; the axis instructions out of selected plane won’t be compensated; for the usage of G

instruction plane selection, please refer to the instructions of plane selection.

9.3.1 Tool radius compensation action

Start action of tool radius compensation

(1) Occasions inside of the corner

(2) Occasions out of the corner (obtuse angle) [

oo

90 180

θ

≤<

]

(3) Occasions out of the corner (acute angle) [

o

90

θ

<

]

9-3

Page 34

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

Note: In the program segment that compensation starts, there shouldn’t be arc instruction G02, G03, else it will

alarm (P/S69).

Action in compensation mode

In compensation mode, the same compensation instructions (G41/G42) do not require new setting; over cutting

or insufficient may occur if four or more continuous segments do not have motion instructions.

(1) Occasions that outer corner rotates

9-4

Page 35

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

(2) Occasions that inner corner rotates

9-5

Page 36

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

Cancelling tool radius compensation

(1) Occasions inside the corner

9-6

Page 37

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

(2) Occasions out of corner (obtuse angle)

(3) Occasions out of corner (acute angle)

9-7

Page 38

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

Note: In the program segment that cancelling compensation starts, there shouldn’t be arc instruction G02, G03,

or else it will alarm (P/S70).

9.3.2 Other instructions and actions during tool radius compensation

Inserting corner arc

When G39 (corner arc) instruction is specified, the node at the workpiece corner calculates compensation and

inserts automatically.

Corner vector changes/maintains

According to G38 instruction, the compensation vector in tool radius compensation can be changed or

maintained.

9-8

Page 39

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

(1) Maintain vector: when G38 instruction is moving single segment instruction, the end point of this single

segment isn’t calculated as the node, and maintains the vector same to migration segment.

(2) Change vector: the new compensation vector direction is specified by I, J and K, and the compensation is

specified by D.

Changing compensation direction in tool radius compensation

The compensation direction follows the tool radius compensation instruction (G41, G42) and compensation

symbol.

In compensation mode, the compensation instruction and direction can be changed without compensating

cancellation instruction. However, the compensation start segment and next segment can’t be changed.

When compensation direction is changed, and there is no intersection

9-9

Page 40

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

Instruction of canceling compensation vector temporarily

If the following instructions are used in compensation mode, the compensation vector will be invalid

temporarily. Later, the compensation mode will resume automatically. In this case, the compensation

cancellation action is invalid, the tool moves from intersection to the instruction point of compensation vector

directly, i.e. moving to program instruction point; when compensation mode resumes, the tool moves to the

intersection directly.

(1) Instruction of returning to reference point

9-10

Page 41

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

(2) If G53 instruction is used, basic mechanical coordinate system selection will become temporary

compensation vector.

When the coordinate system sets (G92) instruction, the compensation vector doesn’t change.

Details

In the following segments, the tool doesn’t have motion

M03;…………………………………M instruction

S12;………………………………...S instruction

T45;………………………………….T instruction

G04X500;……………………………Pause

G22X200 Y150 Z100;……………………Restricted processing area setting

G10 L10 P01 R50;………………………..Compensation setting

G92 X600 Y400 Z500;……………………Coordinate system setting

(G17)Z40;……………………………..Compensation the motion out of the plane

G90;……………………………………..G instruction only

G91 X0;…………………………………… 0 is moved

M00, M01, M02, M03 stop M instruction

(1) Instructions when compensation starts

Then, move the segment to compensate in vertical direction.

If four segments without motion are specified consecutively, the compensation vector can’t be accomplished.

9-11

Page 42

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

(2) In compensation mode, the occasions specified by instruction

In compensation mode, if the segments without motion aren’t specified consecutively for four and M

instruction isn’t restricted in advance, the intersection vector of usual path can be calculated.

If four segments without motion are specified consecutively and M instruction is restricted in advance, the

compensation vector is made in the vertical direction of the end point of previous segment.

(3) Occasions that have instructions same to compensation cancellation instruction

Occasions specified by I, J, K in G40

(1) In the four segments before G40 segment, if the last motion instruction segment is in G41 or G42 mode,

the compensation cancels and the compensation direction doesn’t change after the compensating from the last

motion instruction end point to the intersection of tool center path of assumed motion instruction in I, J, K

direction.

9-12

Page 43

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

In this case, the compensation direction is shown in the figure below; although the compensation direction is

different from the instruction direction, the intersection still can be calculated, and therefore attention is

required.

Secondly, if the compensation of intersection calculation is high, vertical vector occurs in the program before

G40.

⑵ After the arc instruction, according to I, J, K vector of G40, if the arc path exceeds 360°, the uncut part

occurs, and attention is required.

Corner motion

When the connection between motion instruction segments has several compensation vectors, the tool will

move on the linear direction of the vectors, and this motion is called as corner rotation.

9-13

Page 44

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

If these vectors are inconsistent, to move the corner, the motion action is executed in subsegment; therefore, in

single segment mode, it will execute previous segment + corner motion of previous segment and keep

connection motion + the secondary segment executes the corner motion of the other half in following

operation.

9.3.3 G41/G42 instruction and I, J, K designation

Function and purpose

If G41/G42 and I, J, K are specified in same segment, the compensation direction can be changed.

Format

G17 (XY plane)G41/G42 X_Y_I_J_;

G18 (ZX plane)G41/G42 X_Z_I_K_;

G19 (YZ plane)G41/G42 Y_Z_J_K_;

Then, the motion mode is used as linear instruction.

I, J vector (G17XY plane selection)

Now, using this instruction to generate new I, J vector (G17 plane) is described; similar description is also

suitable for vector KI (G18 plane) and JK (G19 plane).

As shown in the figure below, I, J vector isn’t related to the intersection calculation of program specified path,

and only uses the vector in I, J specified direction and having same compensation. I, J vector can be specified

when the compensation starts or in compensation mode.

(1) I, J compensation specified occasion

(2) Compensation without motion instruction

9-14

Page 45

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

(3) I, J specified (G17) occasions in G41/G42 mode

9-15

Page 46

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

G18 plane

G19 plane

(4) If I, J is specified in the segment without motion

Direction of compensation vector

(1) In G41 mode

In the direction specified by I, J, rotate 90° to the left in the positive direction of Z axis.

(2) In G42 mode

In the direction specified by I, J, rotate 90° to the right in the positive direction of Z axis.

9-16

Page 47

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

Switching compensation mode

In compensation mode, G41/G42 mode can be switched at any moment.

Compensation value of compensation vector

The compensation value is determined by I, J specified segment compensation No. (or mode).

The compensation value of vector O equals to the value recorded on compensation No. mode D1 of N100

segment.

The compensation value of vector P equals to the value recorded on compensation No. mode D2 of N200

segment.

Other precautions

(1) If I, J vector is used, the compensation starts in linear mode (G00, G01). In arc mode, the program will

alarm. In compensation mode, the IJ instruction in arc mode is the arc center.

(2) After I, J vector is made, the vector won’t disappear even there is interference (no interference avoidance).

Therefore, over cutting may occur sometimes.

9-17

Page 48

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

(3) G38 I_J_(K_) instruction and G41/G42 I_J_(K_) instruction specified different vectors.

(4) According to the combination of G41/G42 and I, J, K instructions, the compensation method follows:

G41/G42 I,J,K Compensation method

No No Intersection calculation vector

No Yes Intersection calculation vector

Yes No Intersection calculation vector

Yes Yes I, J vector, no segment inserted

9.3.4 Insertion treatment during tool radius compensation

MDI insertion

(1) Insertion treatment when there is no motion (tool track doesn’t change)

9-18

Page 49

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

(2) Insertion treatment when there is motion

Insert the treated motion segment, and then the compensation vector calculates automatically.

Manual insertion

9-19

Page 50

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

9.3.5 Notes for tool radius compensation

(1) Specifying the compensation

The compensation is specified by D instruction and compensation No. Once D instruction is specified, this

instruction is always valid until new D instruction is specified. P170 error occurs if specified with H

instruction.

In addition to specifying the compensation of tool radius compensation, D instruction also can be used as the

compensation value of tool position compensation.

(2) Changing compensation

The compensation is usually changed after radius compensation mode is canceled and another tool is selected;

in compensation mode, when the compensation is changed, the vector of segment end point is calculated

according to the compensation specified by the segment.

(3) Compensation symbol and tool center path

If the compensation is negative (-), it is same to G41 and G42 switched circles; but the rotation outside of

workpiece turns into inside rotation, and the inside rotation turns into outside rotation.

Generally, the compensation is made into program with positive (+) symbol. In the figure below, the tool

center path in the left will be as in the right if the compensation turns to negative. Therefore, the processing

shown in the figure below only needs to select the tolerance of them, adds in appropriate compensation, and

then cut into two shapes with one program.

9-20

Page 51

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

9.3.6 Compensation number change in compensation mode

In compensation mode, the compensation No. shouldn’t be changed in principle. To change, the motion is

shown in the figure below:

G41 G01………………………………….Dr1;

α=0,1,2,3

N101 G00 α Xx1 Yy1;

N102 G00 α Xx2 Yy2 Dr2;…………. compensation No. change

N103 Xx3 Yy3;

9-21

Page 52

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

9.3.7 Tool radius compensation start and axis Z cut-in action

Function

Before cutting starts, make tool radius compensation (usually XY plane) action at the position before leaving

the workpiece, and then Z axis can execute cutting; at this moment, Z axis motion can approach the workpiece

quickly, and then executes cutting action, which contains two sections; please pay attention to the description

below:

B Example:

When programming as below

If above program, i.e. N1 compensation starts, pre-read to N6 segment, and then determine the relation

between N1 and N6, and compensate appropriately as shown above.

Then, divide N4 segment into two in above program.

9-22

Page 53

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

At this moment, there is no instruction segment of XY plane in the four continuous segments N2-N5,

pre-reading isn’t allowed from N1 to N6, and overcutting as above occurs.

Basic execution compensation is made with N1 only, but correct compensation vector can’t be made, and thus

overcutting occurs.

In this case, considering the calculation in NC, in the cutting direction after Z axis descends, before Z axis

descending and cutting, and add the instruction of same direction to prevent overcutting.

N2 and N6 have same direction, and thus the compensation can be executed properly.

9-23

Page 54

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

10. Hole processing function

10.1 Standard fixed cycle

With hole processing fixed cycle, the functions that require several segments in other method can be finished

in one segment. Table 10.1 lists all hole processing fixed cycles.

Table 10.1: Hole Processing Fixed Cycle

G code

G73 Sub, cutting feeding -

G80 - - - Cancel fixed cycle

G81 Cutting feeding -

G82 Cutting feeding Pause

G83 Sub, cutting feeding -

G84 Cutting feeding

G85 Cutting feeding - Cutting feeding Boring cycle

G86 Cutting feeding Principal axis stop

Processing motion

(Z axis negative)

Hole bottom action

Pause - Principal

axis reverse rotation

Return motion

(Z axis positive)

Quick positioning

feeding

Quick positioning

feeding

Quick positioning

feeding

Quick positioning

feeding

Cutting feeding Right thread taping

Quick positioning

feeding

Application

High speed deep hole

drilling

Common drilling cycle

Drilling to rough boring

Deep hole drilling cycle

Boring cycle

G88 Cutting feeding

G89 Cutting feeding Pause Cutting feeding Boring cycle

Pause- Principal

axis stop

Manual Boring cycle

Format:

After G73/G74/G76/G81~G89, give hole processing parameters,

The format follows: (See Table 10.2 for details)

G××X_ Y_ Z_ R_ Q_ P_ F_ K_ ;

G×× : hole processing method

X_ Y_ Z_ : position parameters of hole being processed

R_ Q_ P_ F_ : hole processing parameters

K_ : repeat times

Details:

Generally, one hole processing fixed cycle completes the following six steps (see Fig. 10.1):

G73/G74/G76/G81~G89,

1. X, Y axis quick positioning. 2. Z axis quickly positions to point R. 3. Hole processing.

4. Hole bottom action. 5. Z axis returns to point R. 6. Z axis quickly returns to the start

point.

10-1

Page 55

10. Hole Processing Cycle Function Adtech (Shenzhen) Technology Co., Ltd.

Fig. 10.1 Six Steps of Hole Processing Fixed Cycle

The instructions that have influence on the execution of hole processing fixed cycle instruction include

G90/G91 and G98/G99. Fig. 10.2 shows the effect of G90/G91 on hole processing fixed cycle instruction.

Fig. 10.2 Effect of G90/G91 on Hole Processing

G98/G99 determines fixed cycle returns to point R or the start point after hole processing; in G98 mode, Z axis

returns to the start point after hole processing; in G99 mode, it returns to point R.

Generally, if the holes being processed are on a flat plane, we can use G99 instruction, because it will position

next hole after returning to point R in G99 mode; in general programming, point R is close to workpiece

surface, it will shorten part processing time; but if the workpiece surface has convex platform or tendon, the

tool and workpiece may collide if G99 is used; at this moment, G98 should be used to return Z axis to the start

point and then position next hole to ensure the safety. See the figure below.

10.3 Effect of G98/G99 on Hole Processing

10-2

Page 56

Adtech (Shenzhen) Technology Co., Ltd. 10. Hole Processing Cycle Function

Table 10.2 Meaning of Every Address in Hole Processing Fixed Cycle

Address Meaning

Position parameter X,

Y of holes being

processed

Position parameter Z of

holes being processed

Hole processing

parameter R

Hole processing

parameter Q

Hole processing

parameter P

Hole processing

parameter F

Repeat times K

Specify the position of the hole being processing in increment or absolute mode; the track and

speed of the tool moving to processed hole are same to G00

In absolute value mode, specify the position of hole bottom in Z axis direction; in increment

value mode, specify the distance from point R to hole bottom

In absolute value mode, specify the position of point R in Z axis direction; in increment value

mode, specify the distance from the start point to point R

Used to specify the tool feeding of deep hole drilling cycle G73 and G83, and the offset of fine

boring cycle G76 and reverse boring cycle G87 (always increment value instruction no matter

G90 or G91 mode)

Used to specify the pause time (unit: sec) in the fixed cycle that hole bottom action has pause

Used to specify the cutting feeding speed in fixed cycle; in the fixed cycle, the motion from

start point to point R and from point R to start point executes in the speed of quick feeding, the