Page 1

ADT-CNC4620

CNC4620 Lathe Control System

Pr ogramming Manual

Adtech (Shenzhen) Technology Co., Ltd.

Add: F/5, Bldg/27-29, Tianxia IC Industrial Park, Yiyuan Rd, Nanshan District, Shenzhen

Postal code: 518052

Tel: 0755-26722719 Fax: 0755-26722718

Email:export@machine-controller.com

http://www.machine-controller.com

Page 2

ADT-CNC4620 Programming Manual

Copyright

Adtech (Shenzhen) Technology Co., Ltd. (Adtech hereafter) is in possession of the

copyright of this manual. Without the permission of Adtech, the imitation, copy,

transcription and translation by any organization or individual are prohibited. This

manual doesn’t contain any assurance, stance or implication in any form. Adtech and

the employees are not responsible for any direct or indirect data disclosure, profits

loss or cause termination caused by this manual or any information about mentioned

products in this manual. In addition, the products and data in this manual are subject

to changes without prior notice.

All rights reserved.

Adtech (Shenzhen) Technology Co., Ltd.

I

Page 3

ADT-CNC4620 Programming Manual

Version History

Item No. First uploaded on Version No. Pages Compiled by Typeset by

XT20101227 2011-5-13 A0101 73 Yang Jipeng

XT20101227 2011-11-15 A0201 61 Shi Tingliang

Revision

Date Version/Page Result Confirmed by

Remark: above table is only for the version update of the Manual.

1. We have collated and checked this Manual strictly, but we can’t ensure that there are no error and

omission in this Manual.

2. Due to constant improvement of product functions and service quality, any products and software described

in this manual and the content of the manual are subject to changes without prior notice.

II

Page 4

ADT-CNC4620 Programming Manual

Precautions

※Transportation and storage

The packaging boxes shouldn’t be stacked more than six layers

Do not climb onto, stand on or put heavy objects on the packaging box

Do not drag or convey the product with a cable connected to the product

Do not impact or scratch the panel and display

Keep the packaging box away from moisture, insulation and rain

※Unpacking and checking

Unpack and check whether the product is the one you ordered

Check whether the product is damaged during transporting

Check whether the parts are complete and intact according to the packing list

If the model doesn’t match, any accessories are missing or damaged, please contact us immediately

※Wire connection

The personnel for wire connection and checking should be qualified

The product must be grounded reliably (resistance < 4Ω) and do not use neutral wire to replace the earth wire

The wires must be connected properly and firmly to avoid failures and accidents

The surge absorption diode must be connected to the product properly, or else it will damage the product

Please cut off the power supply before inserting/removing the plug or opening the enclosure

※Checking and repairing

Please cut off the power supply before repairing or replacing the components

Check the failure if short circuit or overload occurs, and restart after eliminating all failures

Do not connect/cut off the power supply frequently; wait for at least one minute before restarting

※Others

Do not open the enclosure without permission

Please cut off the power supply if it won’t be used for a long time

Prevent dust and iron powder from entering the controller

If non-solid state relay is used for output, please connect freewheeling diode to relay coil in parallel. Check

whether the connected power supply is qualified to avoid burning out the controller

The lifetime of the controller depends on the environment temperature. If the temperature of processing field is

too high, please install cooling fan. The allowable temperature range of the controller is 0℃-60℃

Avoid using in the environment with high temperature, moisture, dust or corrosive gas

Install rubber cushion if the vibration is severe

※Maintenance

Under normal condition (environment: daily average 30 , load rate 80%, running rate 12 hours every d℃ ay),

please perform daily and periodic checking according to the items below.

Confirm environment temperature, humidity and

Daily checking

Periodic checking

Daily

1 year

dust

Whether there is abnormal vibration or sound

Whether the vent hole is blocked by yarn

Whether the fixed parts are loose

Whether the terminal block is damaged

III

Page 5

ADT-CNC4620 Programming Manual

Contents

1. PROGRAMMING BASICS .................................................................................................... - 1 -

1.1. INTRODUCTION OF CNC MACHINE TOOL.............................................................................- 1 -

1.2. DEFINITION OF COORDINATE AXIS .......................................................................................- 2 -

1.3. MACHINE TOOL COORDINATE SYSTEM AND MECHANICAL HOME .........................................- 2 -

1.4. WORKPIECE COORDINATE SYSTEM AND PROGRAM HOME ....................................................- 3 -

1.5. ABSOLUTE/RELATIVE COORDINATE PROGRAMMING ............................................................- 4 -

1.6. CONVERSION BETWEEN IMPERIAL AND METRIC SYSTEM*....................................................- 5 -

1.7. PROGRAM CONSTITUTION ...................................................................................................- 5 -

1.8. GENERAL STRUCTURE OF PROGRAM....................................................................................- 6 -

1.9. MAIN PROGRAM AND SUBROUTINE......................................................................................- 8 -

2. M S F T INSTRUCTION......................................................................................................... - 9 -

2.1. AUXILIARY FUNCTION (M CODE) ........................................................................................- 9 -

2.1.1. Subroutine call M98 ..................................................................................................- 10 -

2.1.2. Return from subroutine and return to main program M99 ........................................- 10 -

2.1.3. Principal axis control M03, M04, M05 .....................................................................- 12 -

2.1.4. Coolant control M08, M09 ........................................................................................- 12 -

2.1.5. Tailstock control M10, M11 ......................................................................................- 13 -

2.1.6. Chuck control M12, M13 ..........................................................................................- 13 -

2.1.7. Lubricant control M32, M33 .....................................................................................- 13 -

2.1.8. Program pause M00...................................................................................................- 14 -

2.1.9. Program running ends and return to program beginning M30 ..................................- 14 -

2.2. PROGRAMMABLE I/O INSTRUCTIONS.................................................................................- 14 -

2.2.1. Programmable input instruction M88........................................................................- 14 -

2.2.2. Programmable output instruction M89......................................................................- 14 -

2.3. PRINCIPAL AXIS FUNCTION (S INSTRUCTION).....................................................................- 14 -

2.3.1. Principal axis rotation switching control ...................................................................- 15 -

2.3.2. Principal axis rotation analog voltage control ...........................................................- 15 -

2.3.3. Principal axis rate ......................................................................................................- 15 -

2.3.4. Constant line speed control G96, constantrotation speed control G97* ...................- 16 -

2.3.5. Principal axis maximum rotation limit* ....................................................................- 16 -

2.4. FAST MOVING AND FEEDING FUNCTION (G98/G99, F INSTRUCTION) .................................- 16 -

2.4.1. Fast moving ...............................................................................................................- 16 -

2.4.2. Cutting feeding instruction F.....................................................................................- 17 -

2.4.3. G98, G99 ...................................................................................................................- 18 -

2.4.4. Manual feeding ..........................................................................................................- 19 -

2.5. TOOL COMPENSATION FUNCTION (T INSTRUCTION)...........................................................- 19 -

3. G INSTRUCTION................................................................................................................. - 21 -

3.1. INTRODUCTION .................................................................................................................- 21 -

3.1.1. Modal, non-modal and initial state ............................................................................- 21 -

3.1.2. Relative definition .....................................................................................................- 21 -

- 1 -

Page 6

ADT-CNC4620 Programming Manual

3.2. INTERPOLATION FUNCTION................................................................................................- 22 -

3.2.1. Fast moving G00 .......................................................................................................- 22 -

3.2.2. Linear interpolation G01 ...........................................................................................- 23 -

3.2.3. Arc interpolation G03, G02 .......................................................................................- 24 -

3.2.4. Pause instruction G04................................................................................................- 26 -

3.2.5. Return to mechanical home G28 ...............................................................................- 26 -

3.3. THREAD CUTTING..............................................................................................................- 27 -

3.3.1. Thread cutting instruction G32..................................................................................- 27 -

3.3.2. Z axis taping cycle G33 .............................................................................................- 30 -

3.4. WORKPIECE COORDINATE SYSTEM SETTING G50 ..............................................................- 30 -

3.5. FIXED CYCLE.....................................................................................................................- 31 -

3.5.1. Axial cutting cycle G90.............................................................................................- 32 -

3.5.2. Thread cutting cycle G92 ..........................................................................................- 34 -

3.5.3. Radial cutting cycle G94 ...........................................................................................- 37 -

3.5.4. Notice for fixed cycle instructions ............................................................................- 38 -

3.6. MULTI-CYCLE INSTRUCTIONS............................................................................................- 39 -

3.6.1. Axial roughing cycle G71 .........................................................................................- 40 -

3.6.2. Radial roughing cycle G72 ........................................................................................- 43 -

3.6.3. Closed cutting cycle G73...........................................................................................- 47 -

3.6.4. Finishing cycle G70...................................................................................................- 52 -

3.6.5. Axial grooving multi-cycle G74................................................................................- 52 -

3.6.6. Radial grooving multi-cycle G75 ..............................................................................- 55 -

4. CNC PROCESS KNOWLEDGE .......................................................................................... - 57 -

- 2 -

Page 7

ADT-CNC4620 Programming Manual

1. Programming Basics

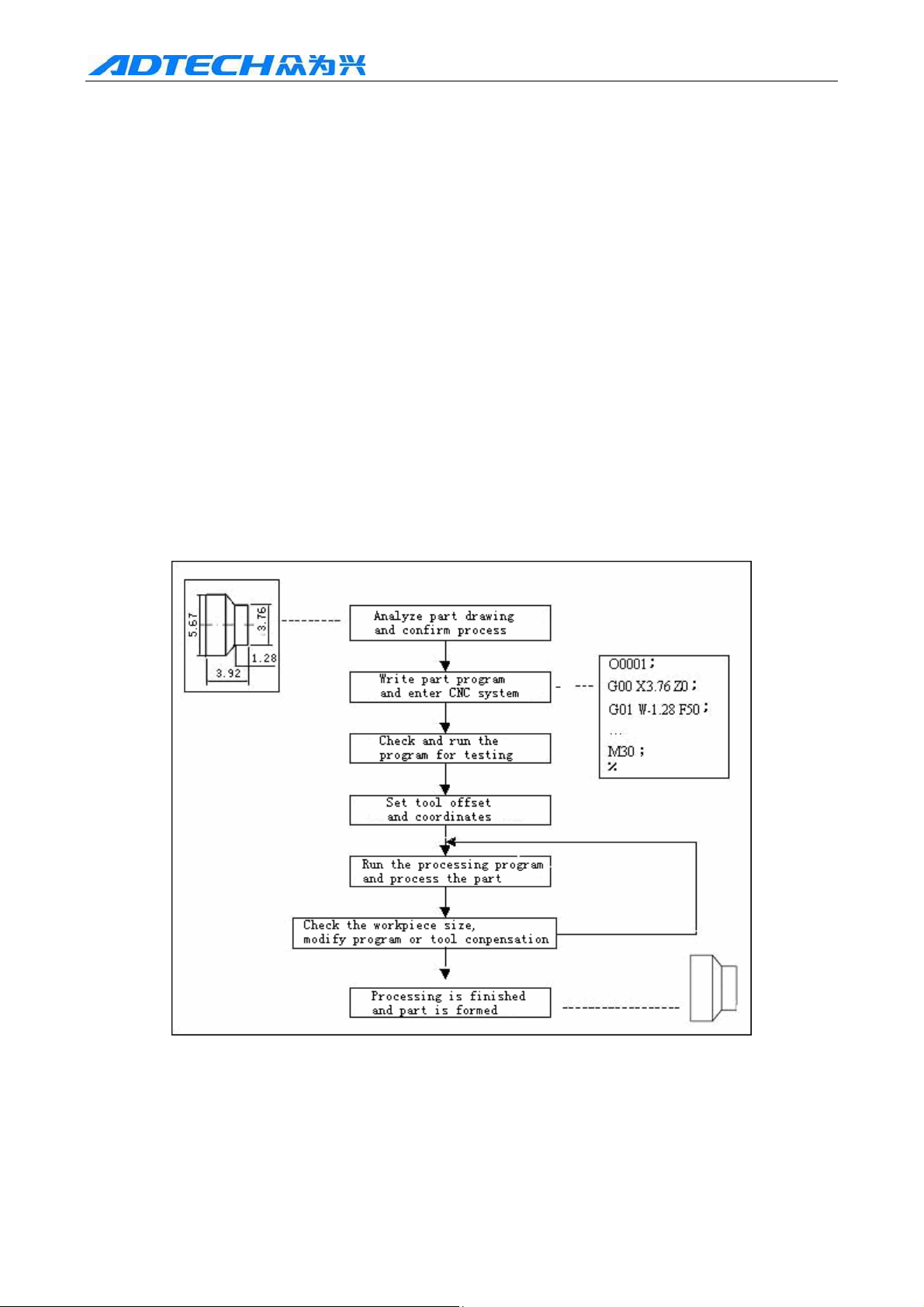

1.1. Introduction of CNC machine tool

CNC (Computer Numerical Controler) machine tool consists of CNC system, servo motor (or step

motor) drive, machine tool (including headstock, feed drive mechanism, worktable, tool holder,

electric control cabinet), etc. After CNC processing, the part program edited by the user will send

motion instructions and control instructions, while motion instructions drive the feeding of machine

tool through motor drive, and control instructions include principal axis start/stop, tool selection,

cooling, lubrication, etc. It achieves parts cutting through relative motion of tool and workpiece.

CNC programming is to write part processing program according to the dedicated programming

instructions of CNC system with the information such as part size, processing process, process

parameters, tool parameters, etc. CNC processing is that the CNC system controls the machine tool

to finish part processing according to the requirement of part processing program. The working

principle of CNC machine tool and the flow of CNC processing are shown in the figure below.

Analyze part drawing and confirm process

Write part program and enter CNC system

Check and run the program for testing

Set tool offset and coordinates

Run the processing program and process the part

Check the workpiece size, modify program or tool conpensation

Processing is finished and part is formed

Fig. 1-1 CNC Processing Flow Chart

- 1 -

Page 8

ADT-CNC4620 Programming Manual

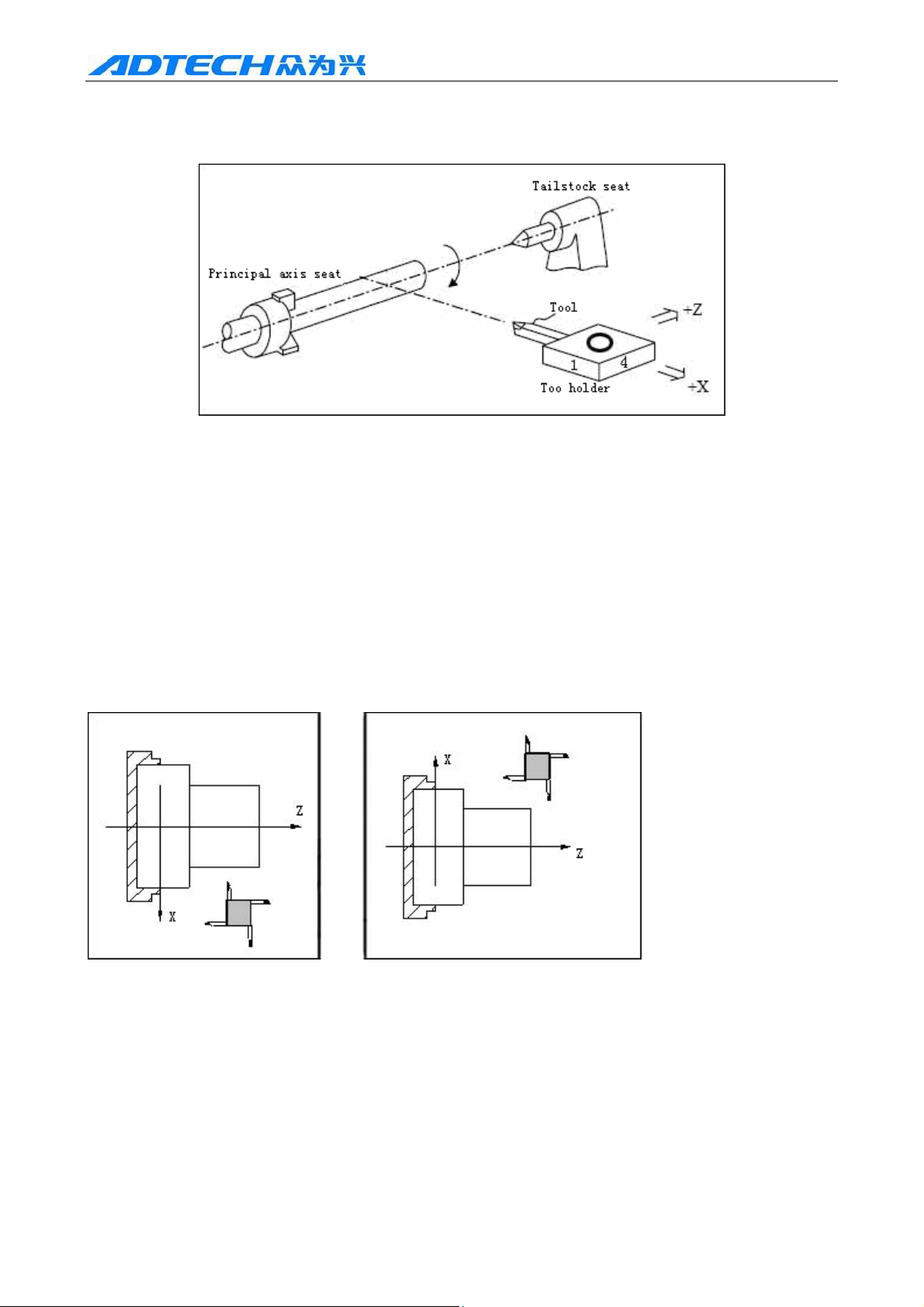

1.2. Definition of coordinate axis

CNC machine tool is shown in Fig. 1-2-1

Tailstock seat Principal axis seat Tool Too holder

Fig. 1-2-1

The system uses the right angle coordinate system constituted with X axis and Z axis. X axis is

vertical to the principal axis, and Z axis is parallel to the principal axis. The direction to the

workpiece is negative, and the direction from the workpiece is positive.

According to the relative position of the tool holder and principal axis of the machine tool, CNC

lathe has front tool holder and rear tool holder. Same programming instruction has different motion

tracks in front tool holder and rear tool holder. This system can be used in the front tool holder and

rear tool holder of the CNC lathe. Seen from the figures below, the X directions of front and rear

tool holder coordinate systems are different, while the Z direction is same. The figures and

examples in this manual use front tool holder coordinate system to describe the application of

programming.

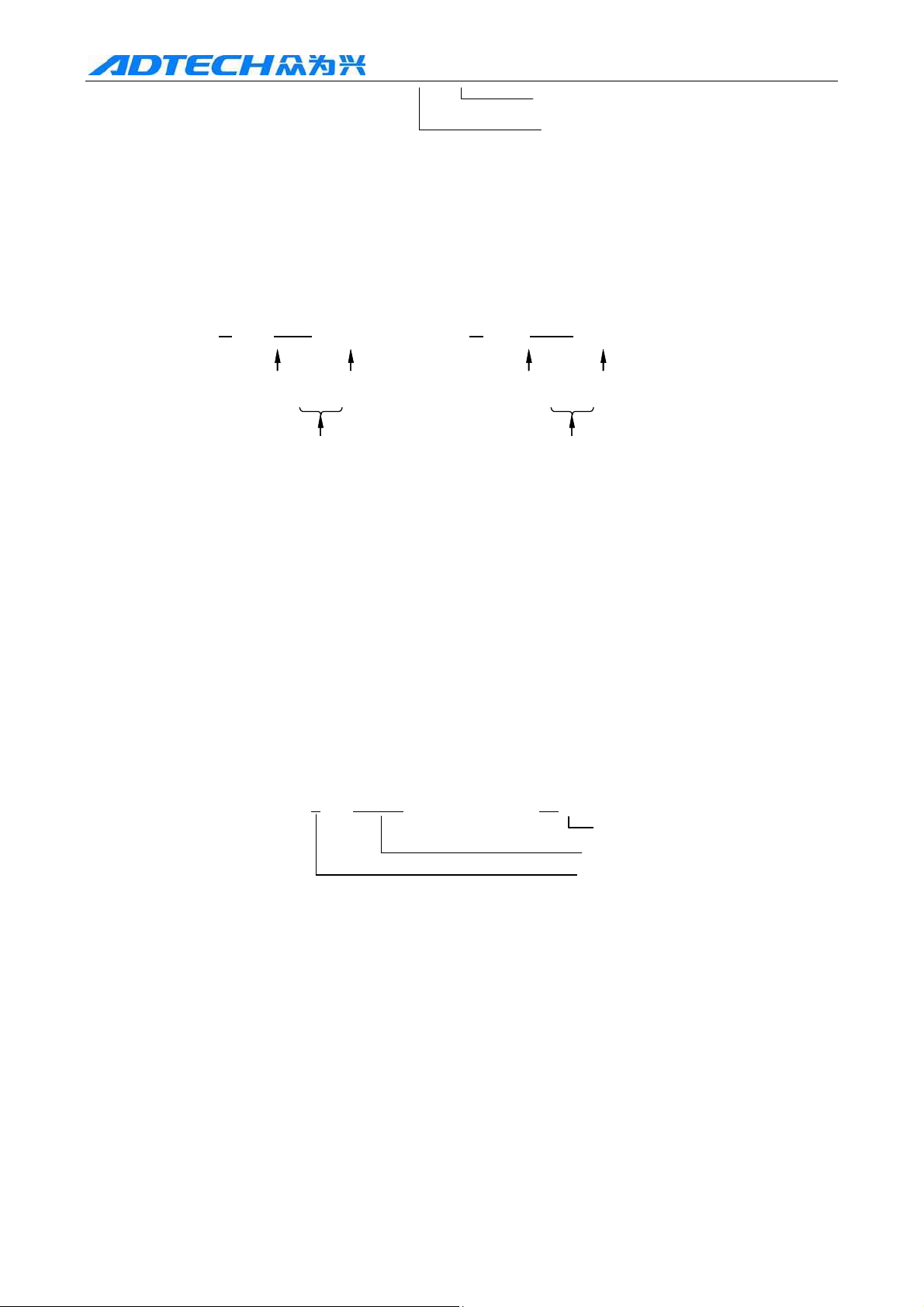

Fig. 1-2-2 Front tool holder coordinate system Fig. 1-2-3 Rear tool holder coordinate system

1.3. Machine tool coordinate system and mechanical home

Machine tool coordinate system is the reference of CNC for coordinate calculation, and is the

intrinsic coordinate system of the machine tool. The origin of the machine tool coordinate system is

mechanical reference or mechanical home.

Mechanical home is determined by the zero switch or home switch on the machine tool, which are

usually installed at the maximum travel in positive direction of X axis and Z axis. For mechanical

home operation, the system will set current machine tool coordinates to 0 after returned to

- 2 -

Page 9

ADT-CNC4620 Programming Manual

mechanical home, and create a machine tool coordinate system with current position as the

coordinate origin.

Note: If the zero switch isn’t installed on the lathe, it isn’t possible to perform home operation.

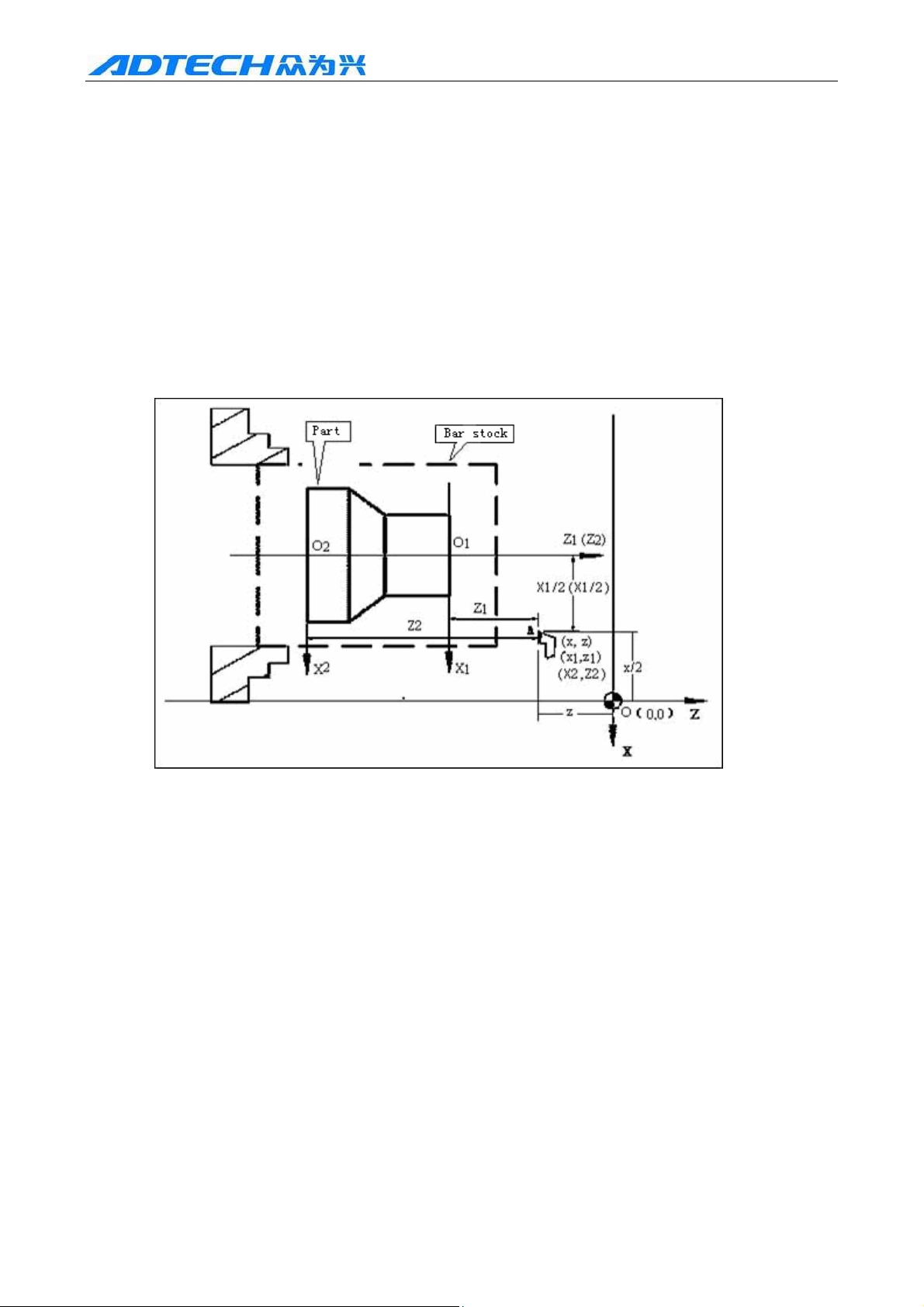

1.4. Workpiece coordinate system and program home

Workpiece coordinate system is the right angle coordinate system set on the part drawing for

programming, which is also called floating coordinate system. When the part is installed on the

machine tool, set the absolue coordinates of the current position of the tool with G50 instruction

according to the relative position of tool and workpiece, and thus create workpiece coordinate

system in the system. The current position of the tool is the program home. Generally, Z axis and

principal axis of the workpiece coordinate system coincide, and X axis is in the head or end of the

part. The workpiece coordinate is always valid once created until replaced by new workpiece

coordinate system.

Part Bar stock

Fig. 1-4

In the figure above, XOZ is machine tool coordinate system, X1O1Z1 is the workpiece coordinate

system of X axis in the head of the workpiece, X2O2Z2 is the workpiece coordinate system of X

axis in the end of the workpiece, O is the mechanical home, A is tool tip, and the coordinates of A

in above three coordinate systems are as follows:

The coordinates of point A in machine tool coordinate system (X, Z);

The coordinates of point A in X1O1Z1 coordinate system (X1, Z1);

The coordinates of point A in X2O2Z2 coordinate system (X2, Z2);

Interpolation function

Interpolation is to control two or several axes to move simultaneously. The motion track complies

with fixed mathematical relationship, constitutes two-dimensional (plane) or three-dimensional

(space) profile, and interpolation is also called profile control. During interpolating, the motion axis

is called joint axis, the movement amount, direction and speed of which are controlled

simultaneously in the entire motion process, to form desired synthetic motion track.

Only control the motion end of one axis or multi-axis, do not control the track in the motion process,

- 3 -

Page 10

ADT-CNC4620 Programming Manual

and the motion control mode is called point-position control.

The X axis and Z axis of this system are linked, which is two axes linked CNC system. This system

has linear, arc and thread interpolation function.

Linear interpolation: the synthetic motion track of X axis and Z axis is the straight line from the

start point to the end point.

Arc interpolation: the synthetic motion track of X axis and Z axis is arc from the start point to the

end point, the radius is specified by R, or the circle center is specified by I, K.

Thread interpolation: X axis, Z axis or two axes motion and principal axis rotation interpolation; F

specifies the pitch of threads, which is the movement (unsigned) of the axis (X or Z) that moves

longer when the principal axis rotates for a circle in the process of thread cutting. This system can

process metric straight thread, taper thread and end thread, and the machine tool must be installed

with principal axis encoder to process threads. If the encoder isn’t installed and it is threading, the

system can’t receive signals from the encoder and can’t perform other operations. (1000 wires

encoder or above is recommended for this system)

1.5. Absolute/relative coordinate programming

Two methods are available for specify the end position of the track during programming:

1: The end position of the track is expressed in absolute coordinates and it is called absolute

coordinate programming (instruction address uses X, Z).

2: The end position of the track is expressed with the coordinate difference of end point relative to

start point and it is called relative coordinate programming (instruction address uses U, W). The

negative value of relative coordinates represents running in negative direction of the axis, while the

positive value of relative coordinates represents running in positive direction of the axis.

This system allows expressing one axis of the end position with absolute coordinates and expressing

the other axis with relative coordinates in the same block. This method is called mixed

programming.

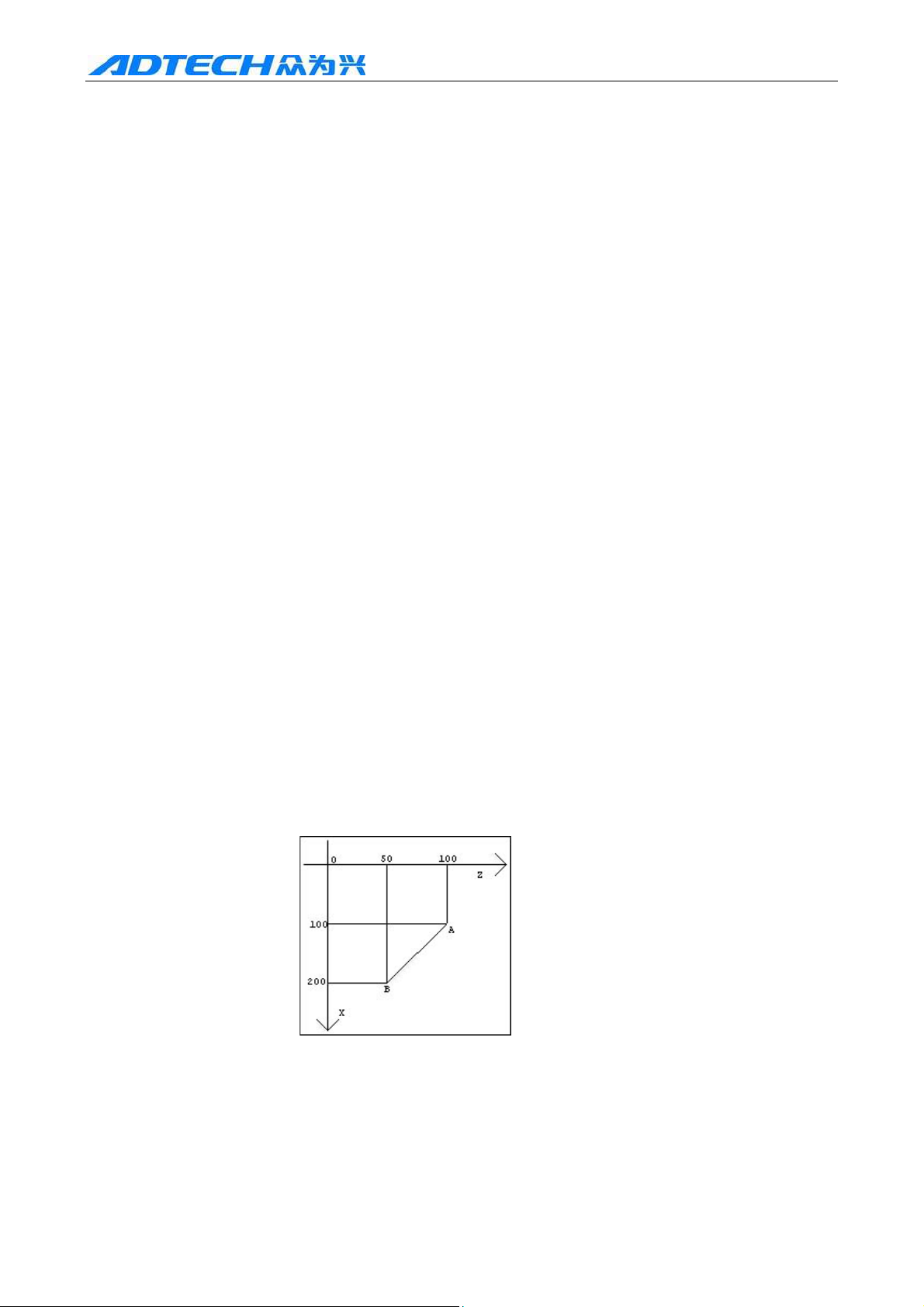

For example: A→B linear interpolation (as in Fig. 1-5)

Fig. 1-2-5

Absolute coordinates programming: G01 X200 Z50;

Relative coordinates programming: G01 U100 W-50;

Mixed coordinates programming: G01 X200 W-50; or G01 U100 Z50;

- 4 -

Page 11

ADT-CNC4620 Programming Manual

1.6. Conversion between imperial and metric system*

Set the unit to imperial or metric with G code (G20, G21).

System G code Minimum unit

Imperial G20 0.0001 inch

Metric G21 0.0001mm

The G code for imperial and metric switch should be placed in front of the program. Use

separate block instruction before setting the coordinate system. The unit system of the

following values changes according to the G code for imperial and metric switch.

(1) Feeding speed instruction value expressed with F.

(2) Instruction value related to position

(3) Compensation

(4) The value of one scale of the Handwheel pulse generator

(5) Movement of single step

(6) Part value of the parameter

Note:

1. When the system is electrified, the G code for imperial and metric switch is same as

before the power supply is cut off

2. In the program, do not change G20, G21

3. If the mechanical unit system is different from the input unit system, the maximum

error would be 0.5 of minimum movement unit, and the error won’t be accumulated.

4. When imperial input (G20) and metric input (21) are switched, the offset should

comply with the new setting of the input unit.

1.7. Program constitution

To complete automatic processing of the part, you need to write the part program (the program)

according to the instruction format of the CNC system, which will execute the program and

complete the controls such as machine tool feeding, principal axis start/stop, tool selection, cooling

and lubrication, and thus finish the part processing.

For example:

Fig. 1-7

- 5 -

Page 12

ADT-CNC4620 Programming Manual

O0001; (program name)

G0 X100 Z50; (quickly locate point A)

M12; (clamp the workpiece)

T0101; (replace tool #1 and execute tool #1 offset)

M3 S600; (start the principal axis, and set the principal axis rotation to 600rpm)

M8 (coolant on)

G1 X50 Z0 F600; (approach point B at the speed of 600mm/min)

W-30 F200; (cut from point B to point C)

X80 W-20 F150; (cut from point C to point D)

G0 X100 Z50; (quickly back to point A)

T0100; (cancel tool offset)

M5 S0; (stop principal axis)

M9; (coolant off)

M13; (release workpiece)

M30; (program ends, principal axis/coolant off)

%

After above program, the tool will have a track of A→B→C→D→A.

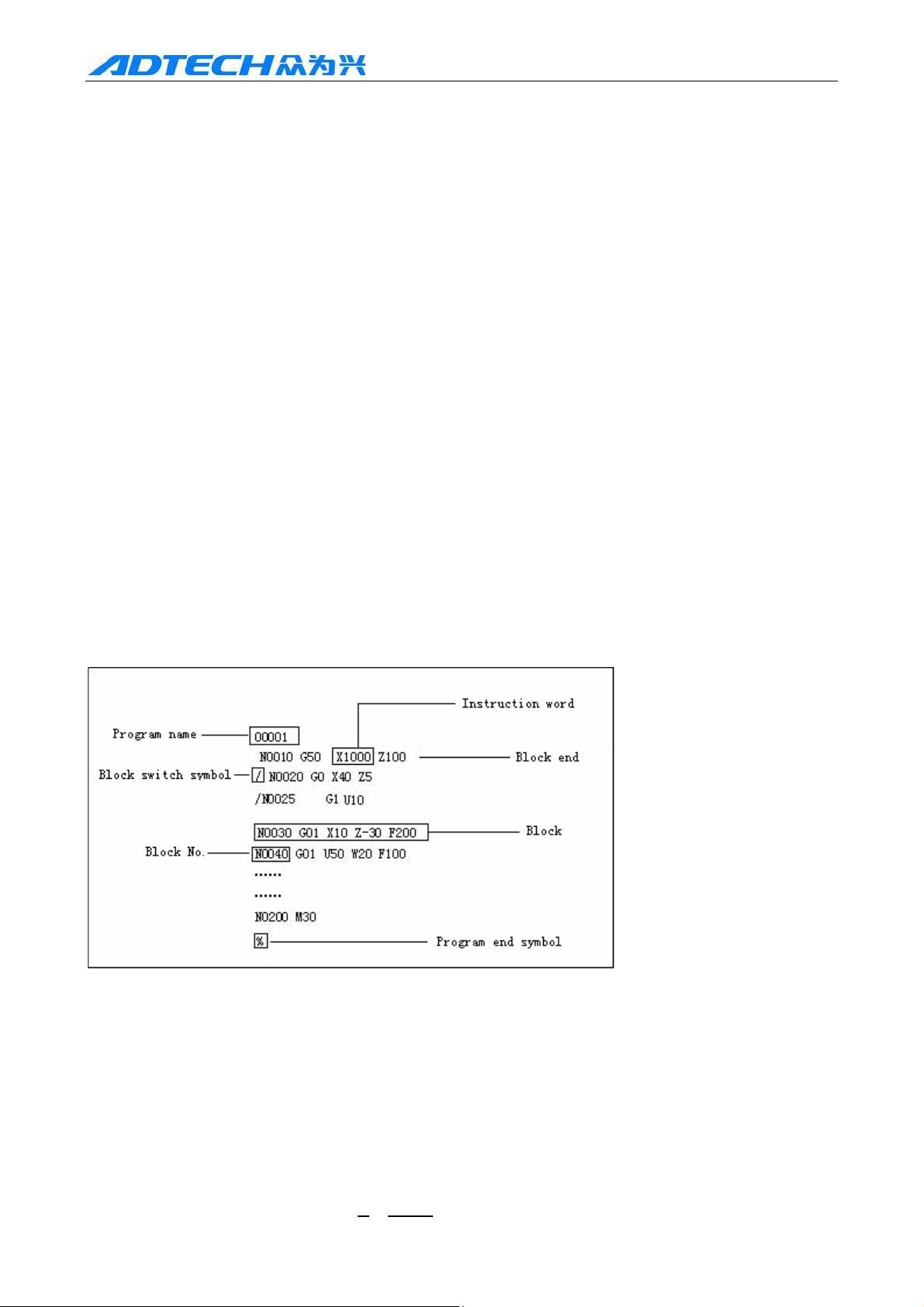

1.8. General structure of program

The program consists of several block started with “OXXXX” (program name) and ended with “%”,

while block consists of several instruction words started with block number (can be omitted),

changed line with “CR” and ended with “LF”. The general structure of a program is shown in Fig.

1-3-2 below:

Instruction word Program name

Block end Block switch symbol

Block No. Block

Program end symbol

Fig. 1-8 General Program Structure

1) Program name

To identify the programs, every program has a name consists of instruction address O and

four digits later in the start of the program. This system can save up to 9999 programs,

and the program names can’t repeat.

□□□□

○

- 6 -

Page 13

ADT-CNC4620 Programming Manual

Program No. (0000~9999, leading zero can’t be

omitted)

Instruction address O

2) Instruction word

Instruction word is the basic instruction unit for CNC system to complete the control

function. Instruction word consists of one English letter (instruction address) and later

digits (instruction value, signed or unsigned). Instruction address regulates the meaning of

following instruction value. In different combinations of instruction word, same

instruction address may have different meanings.

X

1000

X

-1000

Instruction address Instruction value Instruction address Instruction value

Instruction word Instruction word

3) Block switch symbol, block No. and block

A program consists of several blocks and is executed in blocks. Generally, a block is

executed only the previous block has been executed. Blocks are separated with “;” or “*”,

and “;” is used in this manual. A block consists of several instruction words, and is started

with block No. and ended with “;” or “*”.

For example: block may have “/” symbol in the front, which is called block switch symbol

4) When the program is run automatically, if the switch function is enabled, the program will

execute next block automatically when running to this block. If the switch function isn’t

enabled, this block will be executed. The option of switch function is in the auxiliary interface

of main menu. This function won’t be saved after power off, and it is disabled by default after

initialization.

N0100 G0 X200 Z300 ;

/

Block end symbol

Block No.

Block switch symbol

5) Block No.

N0000~N9999; the leading zero can be omitted. Block No. can be omitted, but the target

block for program call and switch must exist. The sequence of block No. may be random,

and the block No. in latter part doesn’t need to be larger than previous number. For the

convenience of reference, the line No. is usually arranged according to certain increment.

During manual editing, it is possible to determine whether insert line No. increment

automatically through No. 47 comprehensive parameter. The initialized value is 0, i.e. do

not insert line No. automatically.

6) Program end symbol

The program is started from program name and ended with “%”, which is the end symbol

of the program file. During communicating, “%” is the end symbol and start symbol.

- 7 -

Page 14

ADT-CNC4620 Programming Manual

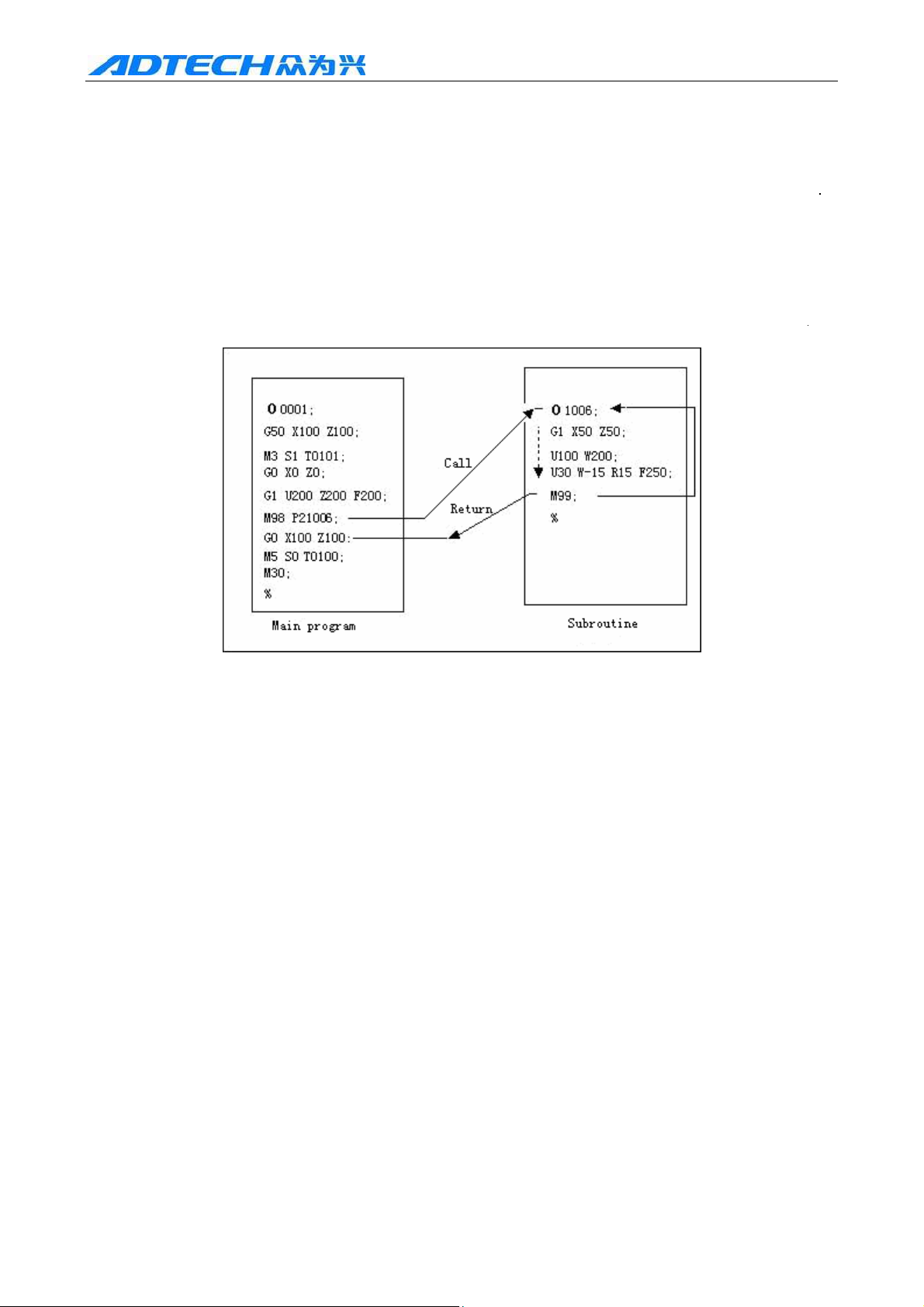

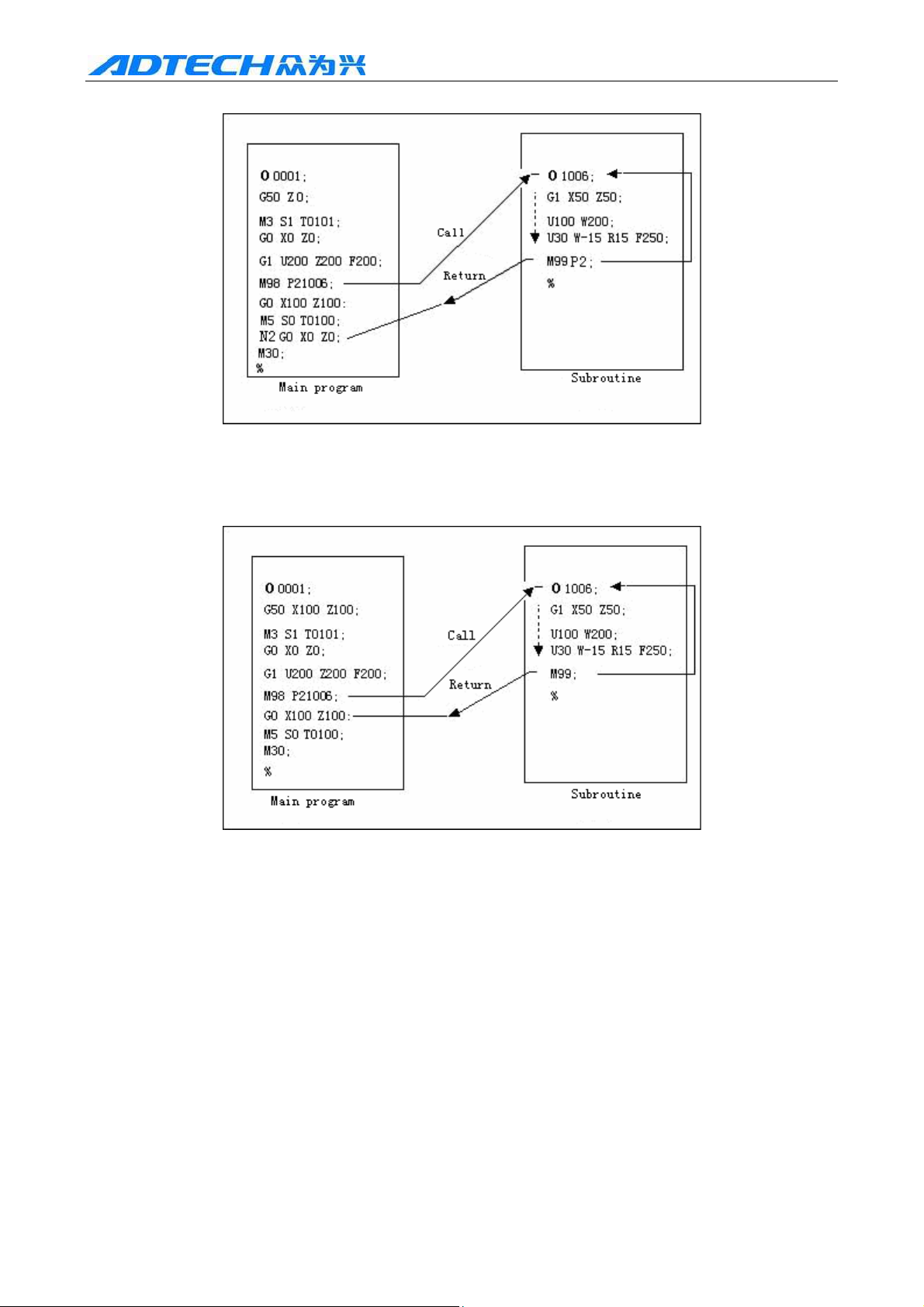

1.9. Main program and subroutine

To simplify the programming, if same or similar processing track and control process need to be

used for several times, the program instructions of this part can be edited to independent program

for calling. The program that calls other programs is called as main program, and the program being

called (ended with M99) is called as subroutine. Both subroutine and main program occupy system

capacity and storage space. Subroutine also must have independent program name, and can be

called by any other main proram or run independently. When subroutine ends, it returns to the main

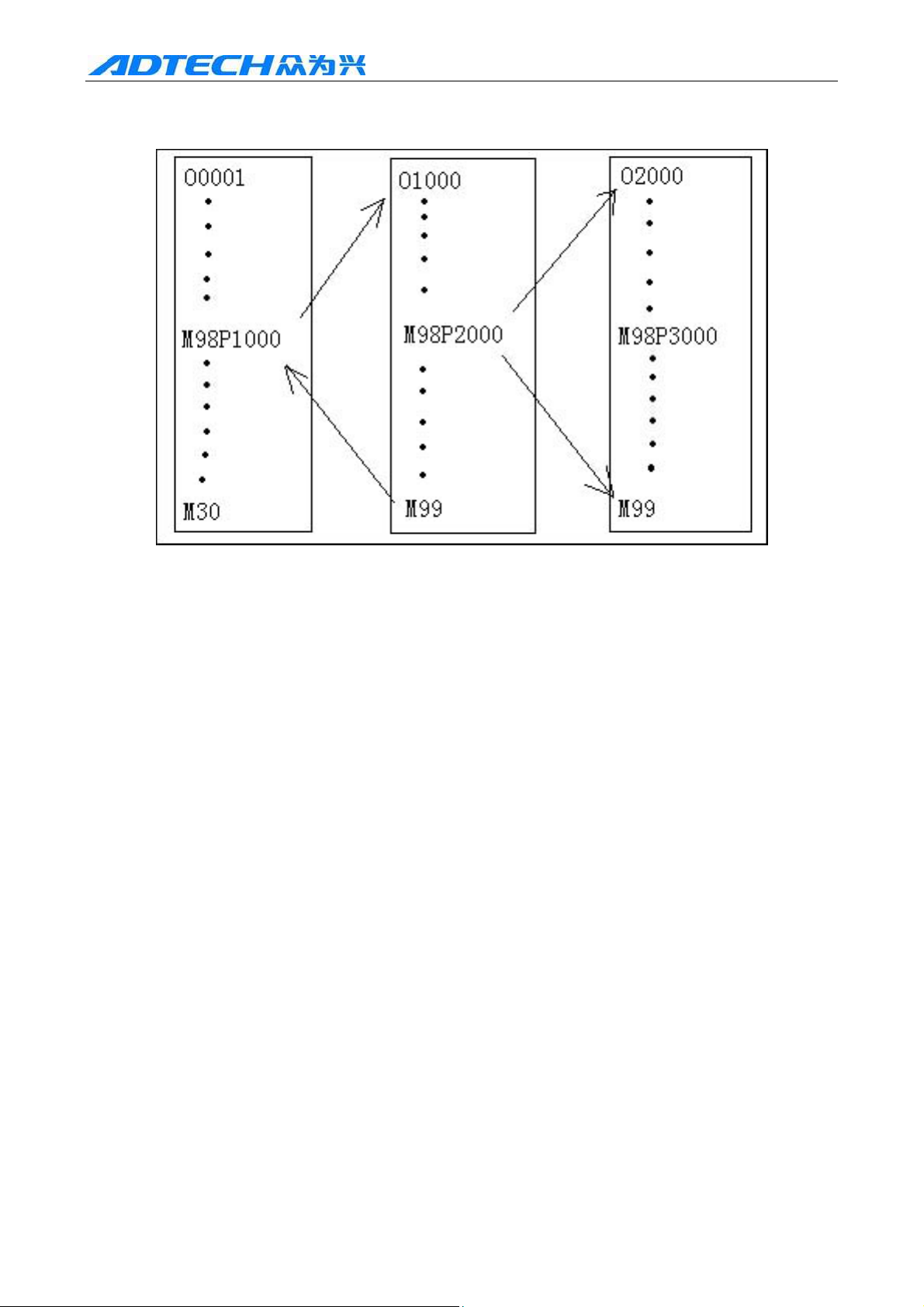

program and continues the execution. The system supports nine layers nesting, i.e. a subroutine can

call other subroutines, as shown in Fig. 1-9 below.

Call Return

Main program Subroutine

Fig. 1-9

- 8 -

Page 15

ADT-CNC4620 Programming Manual

2. M S F T Instruction

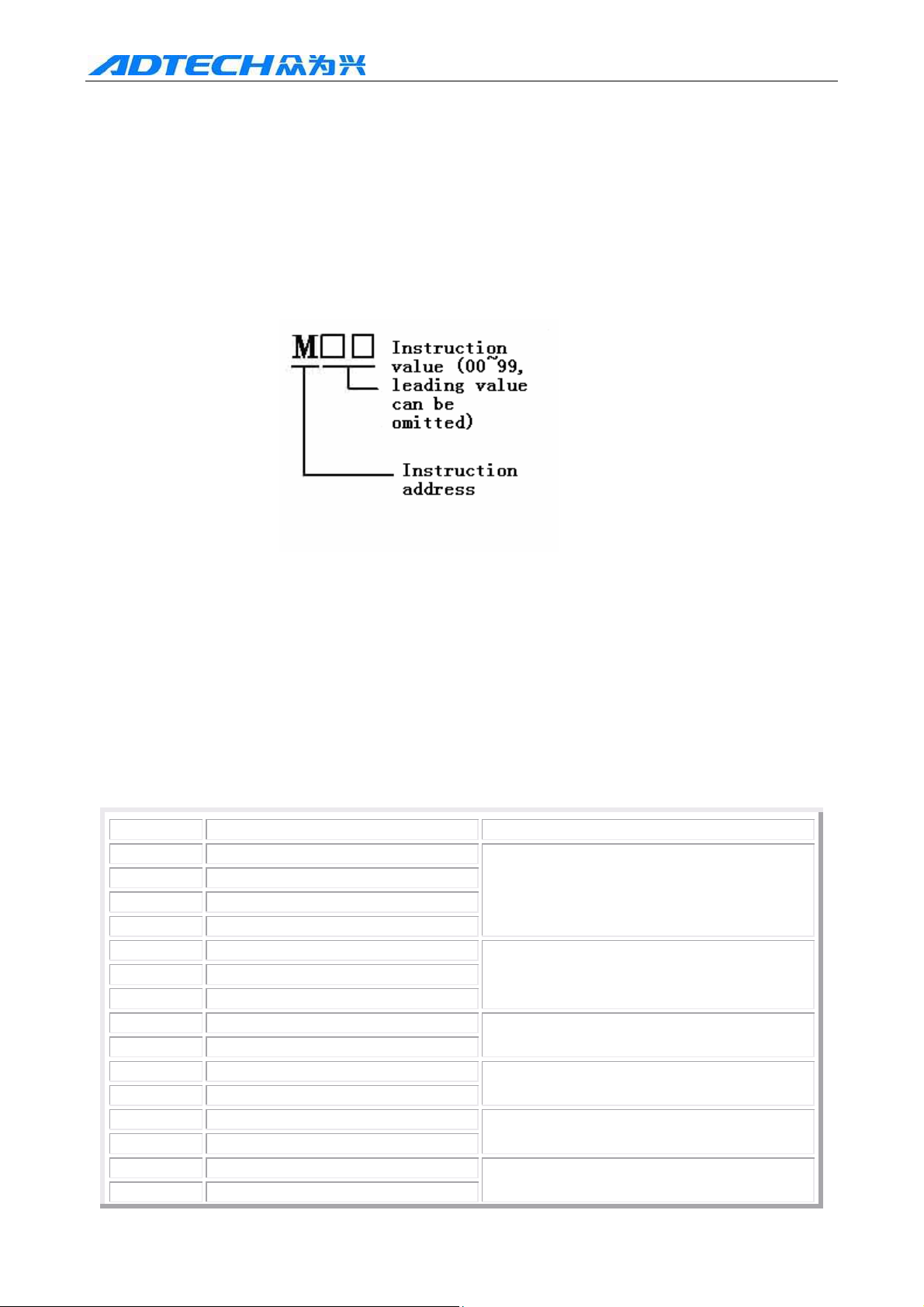

2.1. Auxiliary function (M code)

M instruction consists of instruction address M and later 1~2 digits, and is used to control the flow

of executing program or output signals to machine tool.

Instruction value (00~99, leading value can be omitted)

Instruction address

One block only contains one valid M instruction. If a block has two or more M instructions, the

last M instruction is valid.

If M instruction and the instruction word that executes moving function are in the same block, the

sequence follows:

If M instruction is M00, M30, M98 and M99, execute M instruction after moving;

When M instruction outputs signal to the machine tool, execute M instruction while moving.

M Instructions List

Instruction Function Remark

M00 Program pauses

M30 Program ends

M98 Subroutine calling

M99 Return from subroutine

M03 Principal axis forward rotation

M04 Principal axis reverse rotation

*M05 Principal axis stop

M08 Coolant on

*M09 Coolant off

M10 Tailstock forward

M11 Tailstock backward

M12 Chuck clamped

M13 Chuck released

M32 Lubricant on

*M33 Lubricant off

Functions are interlocked, and state is

Functions are interlocked, and state is

Functions are interlocked, and state is

Functions are interlocked, and state is

Functions are interlocked, and state is

State isn’t retained

maintained

maintained

maintained

maintained

maintained

- 9 -

Page 16

ADT-CNC4620 Programming Manual

M40 Gear position speed setting output off

M41 First gear speed output

M42 Second gear speed output

M43 Third gear speed output

M44 Fourth gear speed output

M88 Check the signa of specified input pin Allow specifying effective input voltage level

M89 Control the switch of specified output

pin

Allow specifying output voltage level

Note: the instructions marked with “*” are valid after electrified.

After the system executed the M instruction that output signal to machine tool, delay for a period

and then execute following instruction word or block. The delay time is set by the system

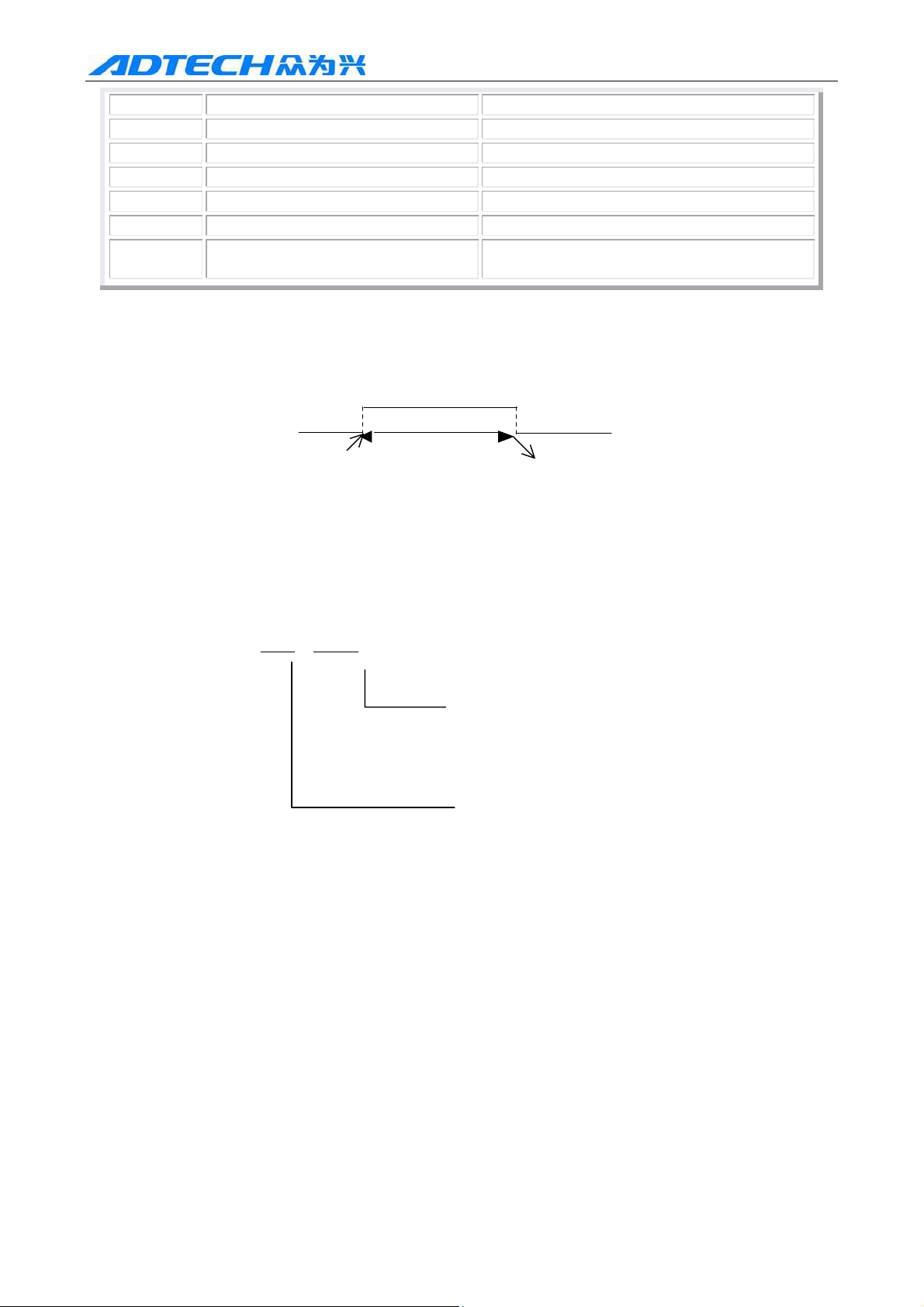

parameter M code waiting time.

M code starts executing

Delay time

Start executing following instruction word or block

2.1.1. Subroutine call M98

Instruction format:

M98 P○○○

□□□□

Subroutine No. (0000~9999) being called. If

the calling time isn’t entered, the leading 0

of the subroutine No. can’t be omitted; if the

calling time is entered, the subroutine No.

must contain four digits.

If the calling time (1-999) is 1, it isn’t required to

enter

Instruction function: after other iinstructions of current block are executed, the system

won’t execute next block, but to execute the subroutine specified by P. The

subroutine can be executed for 999 times at most. In MDI mode, the

subroutine can’t be called.

2.1.2. Return from subroutine and return to main program M99

- 10 -

Instruction format: M99 P○○○ (return from subroutine)

Instruction function: when the called subroutine is finished, return to the block specified

by P in the main program and continue to execution; if P isn’t entered,

return to the next block of M98 instruction that calls current subroutine

in the main program. If M99 is used in the end of the main program (i.e.

current program isn’t called and executed by other programs), current

program will execute repeatedly. M99 iinstruction is invalid in MDI

Page 17

mode.

ADT-CNC4620 Programming Manual

Call Return

Main program Subroutine

Fig. 2-1-1 Returning from Subroutine

Call Return

Main program Subroutine

Fig. 2-1-2 Returning to Main Program

- 11 -

Page 18

ADT-CNC4620 Programming Manual

The system can call nine layers subroutine, i.e. a subroutine can call other subroutines (as

shown in the figure below)

Fig. 2-1-3 Program Nesting Calling

2.1.3. Principal axis control M03, M04, M05

Instruction function: M03 or M3: Principal axis forward rotation;

M04 or M4: Principal axis reverse rotation;

M05 or M5: Principal axis stop

M05 output is valid when the system is electrified, and executes M03 or M04 at this

moment. M03 or M04 output is valid and maintains, and cancels M05 output at the same

time (output is invalid); when M03 or M04 output is valid, execute M05, cancel M03 or

M04 output, M05 output is valid and maintains. The interlocking of principal axis and

chuck can be selected through #022 management parameter. The default setting is

MFUNC(L)1, i.e. not interlocked. MFUNC(L)2 is interlocked, User-Def is user-defined

M code. The parameter setting requires restarting the system.

Note: when the system is stopped in emergency, cancel M03 and M04 output, and M05

output is valid.

2.1.4. Coolant control M08, M09

Instruction function: M08 or M8: cooling pump open;

M09 or M9: cooling pump closed

After the system is electrified, M09 is valid, i.e. M08 output is invalid. Execute M08,

and M08 output is valid, cooling pump opens; execute M09, and cancel M08 output,

- 12 -

Page 19

ADT-CNC4620 Programming Manual

cooling pump closes. Coolant control port is determined by #075 port parameter, and

the initialized value is OUT4.

Note 1: when the system is stopped in emergency, cancel M08 output.

Note 2: M09 doesn’t have corresponding output signal, and M08 output is canceled when

M09 is executed.

2.1.5. Tailstock control M10, M11

Instruction function: M10: tailstock forward.

M11: tailstock backward

After the system is electrified, both M11 and M10 do not have output; execute M10,

M10 output is valid, cancel M11 output, and tailstock forwards; execute M11, M11

output is valid, cancel M10 output and tailstock retreats.

M10 and M11 can’t be valid at the same time.

Note 1: when the system is reset or stopped in emergency, the output states of M10

and M11 won’t change.

2.1.6. Chuck control M12, M13

Instruction function: M12: chuck clamped;

M13: chuck released.

After the system is electrified, both M12 and M13 have no output; execute M12, M12

output is valid, and cancel M13 output; execute M13, M13 output is valid, and cancel

M12 output. M12 and M13 can’t be valid simultaneously. Chuck locking port is

OUT8 by default, and chuck release is OUT9. When chuck is locked, OUT8 output is

valid; when chuck is released, OUT9 output is valid. External input control port is

IN12. The interlocking of chuck and principal axis is selected through #022

management parameter. MFUN(L)1 is not interlocked, and MFUNC(L)2 is

interlocked. M12 and M13 are released through macro program. The user can

customize. After parameter #022 is changed to User-Def, it is realized by writing the

macro program of M code.

Note 1: When the system is reset or stopped in emergency, the output states of M12

and M13 won’t change.

Note 2: chuck can be controlled with external input signal.

2.1.7. Lubricant control M32, M33

Instruction function: M32: lubricant pump open;

M33: lubricant pump closed

After the system is electrified, M33 is valid, i.e. M32 output is invalid. Execute M32,

M32 output is valid, and lubricant pump opens; execute M33, cancel M32 output, and

lubricant pump clodes; lubricant output port is specified by #075 port parameter; the

default option is OUT5.

Note 1: when the system is stopped in emergency, M32 output is invalid;

Note 2: M33 doesn’t have corresponding output signal; cancel M32 output when M33

is executed;

- 13 -

Page 20

ADT-CNC4620 Programming Manual

2.1.8. Program pause M00

Instruction format: M00 or M0

Instruction function: after other instructions of current block are executed, the program

pauses. Press the cycle start key to run next block.

2.1.9. Program running ends and return to program beginning M30

Instruction format: M30

Instruction function: after other instructions of current block are executed, the program

stops automatically, executes M05, M09, and the processing pieces increase by 1.

The cursor returns to the beginning of the program.

2.2. Programmable I/O instructions

2.2.1. Programmable input instruction M88

Instruction function: the user defines the function of standby input point.

Instruction format:M88 Pxx Lx Qxxxx

P is used to specify the value range of output port number 0-23.

L is used to specify the valid input level, “1” is high voltage level and “0” is low voltage level.

Q is used to specify the testing time in the unit of ms.

Note 1: if specified voltage level isn’t detected in the time specified by Q instruction, the alarm

prompts “abnormal program termination error”.

Note 2: if Q instruction isn’t specified, the system will always wait for input signal by default,

and won’t execute next instruction until the signal is valid.

Note 3: if the specified port isn’t in the range 0-23, the alarm prompts “specified port number

error”.

Note 4: if P instruction isn’t written, the alarm prompts “specified port number error”.

2.2.2. Programmable output instruction M89

Instruction function: the user defines the function of standby output point.

Instruction format: M89 Pxx Lx

P is used to specify the value range of output port number 0-23.

L is used to specify the valid output level, “1” is high voltage level and “0” is low voltage level.

Note 1: if the specified port isn’t in the range 0-23, the alarm prompts “specified port number

error”.

Note 2: if P instruction isn’t written, the alarm prompts “specified port number error”.

2.3. Principal axis function (S instruction)

S instruction consists of instruction address S and later digits, and is used to control the

rotation of principal axis.

- 14 -

Page 21

ADT-CNC4620 Programming Manual

Gear position control: S _1~16 principal axis rotation is controlled by switching 16-gear BCD

code. In gear position control mode, #061 comprehensive parameter must be 1, and port

parameters #070~073 specify the output port of gear position.

Analog control: S _0~maximum rotation; in analog control mode, #061 comprehensive

parameter must be 0, and it is required to set the maximum principal axis rotation of parameter #20.

The controller will output 0~10V analog voltage on principal axis port XS8 according to this

parameter. If S instruction and the instruction word that executes moving function are in the same

block, motion instruction and S instruction are executed at the same time.

2.3.1. Principal axis rotation switching control

Instruction format: S_1~16.

Instruction function: 16 gear BCD coding position control.

2.3.2. Principal axis rotation analog voltage control

Instruction format: M03 (M04) S____

Instruction function: set principal axis rotation, the system outputs 0~10V analog voltage to

control principal axis servo or inverter, achieve stepless speed change, and the

value of S instruction is saved after power off.

For example:

Program:

O0001; (program name)

M3 S300; (principal axis forward rotation)

G0 X100 Z50; (quickly move to point A)

G0 X50 Z0; (quickly move to point B)

G1 W-30 F200; (cut from point B to point C)

X80 W-20 F150; (cut from point C to point D)

G0 X100 Z50; (quickly back to point A)

M30; (program ends, principal axis/coolant off)

%

2.3.3. Principal axis rate

If principal axis rotation analog voltage control mode is valid, the actual rotation of the principal axis

can be adjusted in 10%~150% instruction rotation range by 15 levels (change 10% every level) with

- 15 -

Page 22

ADT-CNC4620 Programming Manual

the principal axis ratio adjustment key. In the main menu of the controller, you can press the left/right

key to modify the ratio, or use the principal axis ratio knob on the additional panel to modify

principal axis ration; to modify with the left/right key, the principal axis should be started first.

The actual rotation after the principal axis ratio is adjusted is limited by the maximum rotation of

the current gear position of the principal axis. The principal axis ratio isn’t saved after power off,

and the initial ratio after electrified is 100%.

2.3.4. Constant line speed control G96, constantrotation speed control

G97*

Instruction format: G96 S___; (S0000-S9999, leading 0 can’t be omitted).

Instruction function: constant line speed control is valid, specify cutting line speed (m/min),

and cancel constant rotation control. G96 is mode G instruction. If current mode is

G96, it is not necessary to enter G96.

Instruction format: G97 S__; (S0000-S9999, leading 0 can’t be omitted).

Instruction function: cancel constant line speed control and constant rotation control is valid,

specify principal axis rotation (r/m); G97 is mode G instruction. If current mode is

G97, it is not necessary to enter G97.

When the lathe is shaping workpiece, the workpiece usually rotates around the principal axis.

The cutting point of the tool may be considered as circle motion around the principal axis,

and the instant speed in circumferential tangent direction is called as cutting line speed (line

speed for short).

Constant line speed control function is valid only when principal axis rotation analog voltage

control function is valid. In constant line speed control, the principal axis rotation reduces

along with the change of X axis absolute coordinates of the programming track (neglecting

tool length compensation) and increase of X axis absolute coordinates, and the principal axis

rotation increases along with the decrease of X axis absolute coordinates, making cutting line

speed maintain at S instruction value.

Line speed = principal axis rotation *|X|*л/1000 (m/min)

In constant line speed control, Z coordinate axis of the workpiece coordinate system must

coincide with the principal axis, or else the actual line speed isn’t consistent with the specified

line speed.

2.3.5. Principal axis maximum rotation limit*

Use the value following G50S to specify the maximum principal axis rotation (r/m) of constant

line speed control

G50 S

In constant line speed control, the principal axis rotation is limited to the maximum if it is higher

than the value specified in above program.

;

2.4. Fast moving and feeding function (G98/G99, F instruction)

This system has three axis control modes, i.e. fast moving, cut feeding and manual feeding.

2.4.1. Fast moving

Fast moving: for lathe, X axis direction and Z axis direction move at independent speed, set

through #105 and #107 parameters, and the motion of the two directions doesn’t constitute

- 16 -

Page 23

ADT-CNC4620 Programming Manual

fixed linear or arc track. This system allows G instruction and manual fast moving; X axis

direction and Z axis direction can’t move simultaneously in manual fast moving.

The fast moving speeds of X axis and Z axis are set by X axis fast moving speed and Z axis

fast moving speed respectively. You can adjust the actual fast moving speed with the ratio

adjustment key, and the actual fast moving speed is 25%, 50% or 100% of the set fast moving

speed.

The ratio isn’t saved after power off, and the initial value is 100 after electrified.

2.4.2. Cutting feeding instruction F

Cutting feeding: the system controls the motion of X axis and Z axis simultaneously, making

the motion track of the tool consistent with the track (linear, arc) defined by the instruction,

and the instantaneous speed of the motion track in tangential direction is consistent with F

instruction value, and the process of this motion control is called cutting feeding or

interpolation. The speed of cutting feeding is specified by F instruction word. When the

system is executing interpolation instruction (cutting feeding), it desomposes the cutting

feeding speed specified by F instruction to X axis and Z axis according to the programming

track, the system controls the instantaneous speed of X axis and Z axis simultaneously,

making the vector synthesis speed of the two direction equal to F instruction value.

Remark: use the feeding ratio key on the panel of the machine tool or external ratio switch

to adjust the cutting feeding speed in real time, and the actual cutting feeding speed can be

adjusted in the range of 0~150% of the instruction speed by 16 levels (10% every level). The

adjustment of feeding ratio is invalid for thread cutting.

F is the vector synthesis speed of the instantaneous speed of X axis and Z axis;

dx is the instantaneous (dt period) increment of X axis, and fx is the instantaneous speed of

X axis;

dz is the instantaneous (dt period) increment of Z axis, and fz is the instantaneous speed of Z

axis;

For example: as in Fig. 2-4-1, the values in the brackets are coordinates of the points

(diameter value in X direction).

- 17 -

Page 24

ADT-CNC4620 Programming Manual

Fig. 2-4-1

The program follows:

O0010;

G00 X160 Z80; (move the machine tool to safe position first)

G98;

G0 X50 Z0; (move to point B quickly from point A through point M)

G1 W-30 F250; (B→C)

X100 W-20; (C→D)

X140; (D→E)

G2 W-40 R20; (EFG arc interpolation)

W-10; (G→H)

M30;

%

2.4.3. G98, G99

Instruction format: G98 Fxxxx

speed every minute, mm/min)

Instruction function: specify the cutting feeding speed in the unit mm/min, G98 is mode G

instruction. If current mode is G98, it isn’t required to enter G98.

Instruction format: G99 Fxxxx

Instruction function: specify the cutting feeding speed in the unit mm/r, G99 is mode G instruction.

If current mode is G99, it isn’t required to enter G99. When the system executes G99 Fxxxx, the

product of of F instruction value (mm/r) and current principal axis rotation (r/m) is used as the

instruction feeding speed to control the actual cutting feeding speed. When the principal axis

rotation is changed, the actual cutting feeding speed also changes. Use G99 Fxxxx

cutting feeding every rotation of the principal axis, and form even cutting grain on the surface of the

workpiece. In G99 mode, the machine tool must be installed with principal axis encoder, and set

principal axis encoder wires.

G98 and G99 are in the same group of mode G instruction, and only one is valid at the same time.

G98 is initial G instruction, and G98 is valid by default when the system is electrified.

; (F0001~F8000, the leadin 0 can be omitted, specify the feeding

; (F0.0001~F500, the leadin 0 can be omitted)

to specify the

- 18 -

Page 25

ADT-CNC4620 Programming Manual

2.4.4. Manual feeding

Manual feeding: this system allows X axis or Z axis positive/negative motion at current manual

feeding speed in the manual mode, X axis and Z axis can’t move simultaneously. The actual manual

speeds in X axis direction and Z axis direction are adjusted with the manual ratio adjustment key in

the range 10%~150%. The manual speed of each level is the product of the fixed value set by the

system parameter and manual ratio, and the manual speed of every axis is set by the parameter

independently. When manual fast moving key is valid, manual speed uses the fast moving speed of

every axis, and manual ratio is invalid.

Manual feeding ratio isn’t saved after power off, and the initial ratio is 100% after electrified.

2.5. Tool compensation function (T instruction)

The system allows automatic tool change, and can control the automatic tool holder of position 4~8 to

change tools during the processing, achieving the part processing of multi-process and multi-tool.

The system also allows tool length compensation, which doesn’t need to consider the actual position

of the tool while programming, and only needs to get the position offset data of every tool (tool offset)

through tool setting operation before processing. Before processing with tool, execute tool length

compensation first, i.e. offset the system coordinates according to tool offset to make the motion track

of the tool tip consistent with the programming track. After tool is changed, the user only needs to

reset the tool and modify tool offset, and doesn’t need to modify processing program. If the

processing size has error due to tool abrasion, modify tool offset according to tool offset directly to

eliminate processing size error.

Fig. 2-5-1

Instruction format:

T ○○

Instruction function: automatic tool holder changes tool to target tool No., and executes tool

○○

Tool offset No. (00-16, leading 0 can’t be omitted)

Target tool No. (00-08, leading 0 can’t be omitted)

length compensation according to the tool offset corresponding to the tool offset

No. of the instruction. Tool offset No. may be same to or different from tool No.,

- 19 -

Page 26

ADT-CNC4620 Programming Manual

i.e. one tool can correspond to several offset No. The tool offset corresponding to

tool offset No. 00 is X=0, Z=0, and the system doesn’t have tool compensation

state, i.e. coordinate offset of the system is 0 (without coordinate offset). After

tool length compensation, execute T□□00, the system will offset the system

coordinates reversely according to current tool offset, the state is changed from

tool length compensated to not compensated, the displayed tool offset No. is 00,

and this process is to cancel tool length compensation.

For example: T0101 is to select #1 tool and execute #1 tool offset;

T0102 is to select #1 tool and execute #2 tool offset;

T0301 is to select #3 tool and execute #1 tool offset

After electrified, the tool No. and offset No. displayed by T instruction are the state before

power off.

Only one T instruction is valid in one block; if two or more T instructions are in the block, the

last the valid.

If T instruction and the instruction executing moving function are in the same block, the tool

change instruction is executed before the moving instruction.

This system is suitable for automatic tool holder with 4—8 tool positions; by modifying the

parameters of #2 tool magazine and modifying parameters #17, #18, #19 and #20, tool

position signals (independent) input directly, tool holder forward to change the tool, and

reverse to lock after in position. The control of tool holder is realized through embedded T

code macro program; #023 management parameter is TFUNC(L) by default, and you can

customize T code if this parameter is changed to User-Def.

In manual mode, press the tool change key on the panel of the machine tool to change the

tool manually.

In coordinate menu of the system, tool setting includes setting and compensation. For tool

setting, it is necessary to cut current workpiece for test first, enter actually measured X axis

diameter and Z axis length, and the system will calculate the offset automatically and save in

the parameter. For example, if cut with #1 tool, press the record mode in tool setting interface,

enter X cutting diameter and Z cutting length to #1 parameter and call T0101. Compensation

is to offset current compensation No.

- 20 -

Page 27

ADT-CNC4620 Programming Manual

3. G Instruction

3.1. Introduction

G instruction consists of instruction address G and later 1~2 instruction values. It is used to regulate

the interpolation mode, pause function and coordinate setting of the tool relative to the workpiece.

G □□

Instruction value (00~99, first 0 can be omitted)

Instruction address G

G instruction word is divided into group 00, 01, 02, 03, and 04. In the same block, you can enter G

instruction words of different groups. If two or more G instruction words of same group are entered

in the same block, only the last G instruction word is valid. The G instruction words of different

groups without common parameter (instruction word) may be in the same block, and the functions

are valid simultaneously and are unrelated with the sequence. The system doesn’t support the G

instruction words not in this table, and will alarm if there is.

3.1.1. Modal, non-modal and initial state

The modal function is that a code is always valid once it is specified in current block, until

another code of the same group appears in the block, and it isn’t required to specify if this

instruction is used in next block.

The non-modal function is that a code is only valid in its block, and it should be specified

again if it is used in next block.

After the system is electrified, the mode G instruction word that is valid before the

function or state is executed is called initial G instruction word. If the initial G instruction

word is executed after electrified, it isn’t required to enter this G instruction word. The

initialized instruction word of the system is G01.

3.1.2. Relative definition

This manual has the following description:

Start point: the position when current block is running;

End point: the position after current block ends;

X: absolute coordinates of the end point in X direction;

U: difference between start point and end point in X absolute coordinates;

Z: absolute coordinates of the end point in Z direction;

W: difference between start point and end point in Z absolute coordinates;

F: cutting feeding speed

G instruction word list

Instruction word

G00 Fast moving Initial G instruction

G01 Linear interpolation

G02

Group Function Remakr

01

Modal G instruction

Arc interpolation (CW)

- 21 -

Page 28

ADT-CNC4620 Programming Manual

G03 Arc interpolation (CCW)

G32 Thread cutting

G90 Axial cutting cycle

G33

G92 Thread cutting cycle

G94 Radial cutting cycle

G04 Pause, quasi stop

G31 Jump instruction

G27 Reference point returns

G28 Return to mechanical home

G29 Return instruction from the

G30 Return to second reference

00

G50 Coordimate system setting

G70 Finishing cycle

G71 Axis roughing cycle

Z axis taping cycle

checking instruction

reference point

point instruction

Non-modal G

instruction

G72 Radial roughing cycle

G73 Closed cutting cycle

G74 Axial grooving multi-cycle

G75

G96 Constant line speed on Modal G instruction

02

G97

G98 Feeding every minute Initial G instruction

03

G99

3.2. Interpolation function

3.2.1. Fast moving G00

Instruction format: G00 X(U)Z(W);

Instruction function: X axis and Z axis move to the end point simultaneously from the

start point at the fast moving speed respectively. G00 is initial G instruction.

The two axes move at independent speed respectively. Set the fast moving speed

of X axis and Z axis through comprehensive parameter 009 and 011. The synthetic

track isn’t straight line necessarily, and it should be noted that the two axes may not

Radial grooving multi-cycle

Constant line speed off Initial G instruction

Feeding every revolution Modal G instruction

- 22 -

Page 29

ADT-CNC4620 Programming Manual

reach the end point at the same time.

Either or both instruction addresses X(U) and Z(W) can be omitted. If one is

omitted, the coordinates of the start point and end point of the axis are consistent; if

both are omitted, the start point and end point are in the same position.

The fast moving speed of X axis and Z axis are set by X axis fast moving speed

and Z axis fast moving speed respectively, and the actual moving speed can be adjusted

with the fast ratio key on the panel of the machine tool.

The maximum speed that the machine tool actually can reach depends on the actual

condition of the machine tool and the motor. For detailed parameters, please refer to

the manual of the machine tool.

G00 is modal instruction, and can be omitted if next block is same.

G00 can be abbreviated to G0, which is equivalent to G00.

If X axis and Z axis are moved at the same time, note whether the tool is in safe

area to avoid bump.

For example: the tool moves from point A to point B quickly.

Z axis X axis

G0 X20 Z25; (A coordinates)

G0 U-8 W-14; (A→B)

3.2.2. Linear interpolation G01

Instruction format: G01 X(U)_ Z(W)_F_;

X(U) /Z(W): absolute or relative coordinates of the end point.

F : cutting feeding speed

Instruction function: G01 instruction makes the tool arrive at the position of specified point

along the connection line from current point to the point specified by X(U), Z(W) at

specified speed. The motion track is a straight line from the start point to the end point. F

instruction value is the vector synthetic speed of instantaneous speed of X axis and Z axis,

and the actual cutting feeding speed is the product of feeding ratio and F instruction value.

Once executed, F instruction value is maintained until new F instruction value is executed.

For example:

G01 X60.0 Z-25 F200; (absolute value programming)

G01 U20.0 W-25.0; (relative value programming)

- 23 -

Page 30

ADT-CNC4620 Programming Manual

End point Start point

3.2.3. Arc interpolation G03, G02

Instruction format: G03/ G02 X(U)_ Z(W)_ R_ (I_ K_) F_;

Instruction function: the motion track is the CW arc/CCW arc from the start point to the end

point, and the track is shown in the figure below.

R: arc radius (0~9999.999mm);

I: the difference between X coordinates of the circle center and arc start

(-9999.999~9999.999mm);

K: the difference between Z coordinates of the circle center and arc start

(-9999.999~9999.999mm);

Z axis Z axis End point Start point

Start point End point X axis end point

G03 track G02 track

Fig. 3-2-3-1

For example: as shown in Fig. 3-2-3-2 below

- 24 -

Page 31

ADT-CNC4620 Programming Manual

Start point End point Circle center

Fig. 3-2-3-2

Program:

G02 X63.06 Z-20.0 R19.26 F300;

Or G02 U17.81 W-20.0 R19.26 F300;

Or G02 X63.06 Z-20.0 I35.36 K-6.37 F300;

Or G02 U17.81 W-20.0 I35.36 K-6.37 F300;

Notice:

” In G02/G03 block, it is required to enter at least one of the instruction addresses of I, K

and R, or else the system will alarm; if I, K and R are entered at the same time, R is

valid, while I and K are invalid; if R isn’t entered or R equals to 0, the system alarms;

” If X(U) and Z(W) aren’t entered, and R is used to specify the radius, X axis and Z axis

won’t move when G02/G03 instruction is executed; if R isn’t entered and use I, K

instruction word, the track of executing G02/G03 instruction is a full circle (360°);

” When R instruction is used, it is two arcs larger and smaller than 180° in theory. In this

system, the arc smaller than 180° is valid (as in Fig. 3-4-3 below). If the end point ins’t on

the arc defined with R, the system will alarm;

End point Start point

” In G02/G03 block, if I and K instruction words are used to define the circle center, the

system won’t alarm even if the end point isn’t on the arc. The track of the instruction is:

Fig. 3-4-3

- 25 -

Page 32

in the circle center and arc direction defined by the instruction, X axis and Z axis move

along the arc from the start point at the same time; if the coordinates of X axis or Z axis

are same to the end point, X axis or Z axis stops motion, and the axis (Z axis or X axis)

continues to move to the end point, as shown in Fig. 3-4-4 below

End point Start point

ADT-CNC4620 Programming Manual

Fig. 3-4-4

3.2.4. Pause instruction G04

Instruction format: G04 P__;

Or G04 X__ ;

Instruction function: every axis stops motion, do not change current G instruction mode

and maintained data and state, delay for specified time, and then execute next

block. The delay time is specified with instruction word P__(unit: ms), X__(unit:

sec). G04 is non-modal G instruction.

G04 P1000 delay 1000ms = 1sec

G04 X1 delay 1sec

3.2.5. Return to mechanical home G28

Instruction format: G28 X(U)_ Z(W)_;

Instruction function: from the start point, arrive at the center point specified by X(U), Z(W)

at the fast moving speed and then return to the mechanical home at the same time.

G28 is non-modal G instruction.

One or both instruction addresses X(U) and Z(W) can be omitted; see the table below for

details

- 26 -

Instruction Function

G28 X(U)_

G28 Z(W)_

G28

G28 X(U) Z(W)

X axis returns to mechanical home, Z axis

stays at the original position

Z axis returns to mechanical home, X axis

stays at the original position

Two axes stay at original position, and

continue to execute next block

X and Z axis return to mechanical home

Page 33

ADT-CNC4620 Programming Manual

simultaneously

X: absolute coordinates of center point in X direction; U: the difference of the absolute

coordinates of the center point and start point in X direction;

Z: absolute coordinates of center point in Z direction; W: the difference of the absolute

coordinates of the center point and start point in Z direction.

Process of instruction action (see the figure below):

(1) Move to center point from the start point simultaneously at independent fast

moving speed (point A → point B).

(2) When the two axes reach the center point, move to the mechanical home from the

center point simultaneously at independent fast moving speed (point B →point

R).

(3) If U and W are 0, return to the machine tool home directly, e.g. G28 U0 W0, the

system returns to the reference point directly, and doesn’t pass through the

center point (point A → point R).

Start point Center point Mechanical home

3.3. Thread cutting

3.3.1. Thread cutting instruction G32

Instruction format: G32 X(U)__Z(W)__ F__P__D__V__;

X(U): thread X axis end point coordinates or increment value

Z(W): thread Z axis end point coordinates or increment value

F: metric thread pitch (0.001~500 mm), it is the movement of the long axis when

the principal axis rotates a circle, maintain valid after F instruction value is

executed, until the F instruction word of specified thread pitch is executed again.

P: thread cutting acceleration pitch, the unit is mm, unsigned, the acceleration

length of the long axis during thread cutting; if the program doesn’t specify the P

value, the system calls parameter #109 automatically for calculation; if X is long

axis, P is the radius.

D: thread cutting deceleration pitch, the unit is mm, unsigned, the deceleration

length of the long axis during thread cutting; if the program doesn’t specify the D

value, the system calls parameter #110 automatically for calculation; if X is long

axis, D is the radius.

V: pitch cutting back amount, the unit is mm, signed; the sign relates to the back

direction; it is the back length of the short axis during thread cutting; if the

program doesn’t specify the V value, the system calls parameter #111

- 27 -

Page 34

ADT-CNC4620 Programming Manual

automatically for calculation; if X is short axis, V is the radius.

Instruction function: the motion track of the tool is a straight line from the start point to the end point;

the coordinate axis with larger displacement from the start point to the end point (X

axis depends on the radius value) is the long axis, and the other is the short axis.

During motion, the long axis moves a pitch when the long axis rotates a circle, short

axis and long axis make linear interpolation; when the tool cuts the workpiece, a

spiral grooving with equal pitch is formed on the surface of the workpiece, achieving

thread processing of equal pitch. F instruction word can be used to specify the pitch

of metric thread, and execute G32 instruction to process straight thread, taper thread

and end thread of metric equal pitch:

If the X coordinates of start point and end point are same (do not enter X or U), it is straight

thread cutting;

If the Z coordinates of start point and end point are same (do not enter Z or W), it is end

thread cutting;

If the X coordinates and Z coordinates of start point and end point are different, it is taper

thread cutting, as in Fig. 3-7-1 below

Start point

End point

Fig. 3-7-1

The thread pitch is the displacement of the long axis when the principal axis rotates one circle

(X axis displacement depends on the radius); see Fig. 3-7-2 below for the method to

distinguish the long axis and short axis:

Start point

If Lz ≥ Lx (α≤45°), Z is the long axis;

If Lx ≥ Lz (α>45°), X is the long axis.

Taper thread End point

Fig. 3-7-2

Thread cutting notice:

” The machine tool must be installed with principal axis encoder for thread cutting; the

transmission ration of principal axis encoder and the principal axis is 1:1, modify

#013 principal axis encoder wires, and the system is initialized to 0. When the system

- 28 -

Page 35

ADT-CNC4620 Programming Manual

receives the signals from principal axis encoder Z (origin), it moves X axis or Z axis

and starts thread processing, therefore, the processing of same thread can be finished

through roughing and finishing as long as the principal axis rotation isn’t changed.

” Since X axis and Z axis have acceleration and deceleration process in the beginning

and at the end of thread cutting, the pitch error is large at this moment, and therefore

acceleration pitch P must exist before the long axis start point and deceleration pitch

D (usually called as retreating groove) must exist after the end point of the long axis

during actual thread cutting, i.e. programmed thread length is longer than actual

thread length. Thread cutting length includes P, D; similarly, the end position of the

short axis must have back amount V, i.e. at the end position of thread cutting, the

short axis exits thread cutting in V back amount, as shown in the figure below.

For example:

Thread pitch: 4mm. P = 3.5mm, D = 3.5mm, V=1, total cutting depth 1mm (single side),

cut in two times

G00 X28 Z3; (cut 0.5mm in the first time)

G32 X51 W-77 F4.0 P3.5 D3.5 V1; (taper thread first cutting)

G00 X55;

(tool exits)

W77; (Z returns to the start point)

X27; (cut another 0.5mm in the second time)

G32 X50 W-77 F4.0; (taper thread second cutting)

G00 X55; (tool exits)

W77; (Z returns to the start point)

As in Fig. 3-7-3:

Start point End point

” Under the condition that the start point, end point and thread pitch of G32 are fixed, the

moving speed of X axis and Z axis during thread cutting depends on the principal axis

rotation, and doesn’t relate to cutting feeding ration. During thread cutting, principal

axis ratio control is valid; when principal axis rotation is changed, the pitch error

increases due to acceleration/deceleration of X axis and Z axis, therefore, do not adjust

the principal axis rotation during thread cutting or stop the principal axis (or else the

tool and workpiece will be damaged).

” During thread cutting, the long axis increment should be larger than the value of (P+D),

and the actual thread length of the long axis should be larger than pitch F.

” When the system is reset, stopped in emergency or alarms, thread cutting stops

Fig. 3-7-3

- 29 -

Page 36

ADT-CNC4620 Programming Manual

immediately.

3.3.2. Z axis taping cycle G33

Instruction format: G33 Z(W)__ F__;

Instruction function: the motion track of the tool is from the start point to the end point, and

then returns to the start point. During the motion, Z axis moves a pitch when

principal axis rotates one circle, always keeps consistent with the pitch of the thread,

forms a spiral grooving in the internal hole of the workpiece, and completes the

thread processing of the internal hole after once cutting.

Instruction description: G33 is modal G instruction;

Z(W): do not enter Z or W, the Z coordinates of the start point and end point are

same, and do not execute thread cutting;

F: metric thread pitch, range: 0.001~500 mm;

Cycle process:

Z axis feeding and taping (principal axis must be specified to ON before G33

instruction);

M05 signal outputs after reaching the Z axis coordinate end specified by the program;

Principal axis stops completely;

Principal axis reverse signal output (opposite to original rotation of the principal

axis);

Z axis back to the start point;

Principal axis resumes the turning before G33.

Program:

O0011;

G00 Z90 X0Z0 M03; start the principal axis

G33 -Z50 F1.5; taping cycle

G00 X60 Z10; continue processing

M30

Note 1: before taping, determine the principal axis according to the rotation of the thread, and the

principal axis will resume original rotation after taping.

Note 2: this instruction is rigid taping; when principal axis stop signal is valid, the principal axis

stops rotation after a period of deceleration, and Z axis will feed following the rotation of the

principal axis at this moment, until the principal stops completely, and therefore, the bottom

hole position of the thread is deeper than actual required position during actual processing;

the specific exceeded length depends on the principal axis rotation and principal axis brake

device during taping.

Note 3: during taping cutting, the moving speed of Z axis depends on the principal axis rotation and

pitch, and isn’t related to cutting feeding speed ratio.

Note 4: during single block running or feeding maintenance operation, the system displays “Pause”,

taping cycle doesn’t stop, until taping completes and returns to the start point.

Note 5: when the system is reset, stopped in emergency or alarms, taping cutting decelerates to stop.

3.4. Workpiece coordinate system setting G50

Instruction format: G50 X _ Z _ ;

- 30 -

Page 37

ADT-CNC4620 Programming Manual

X: new X axis absolute coordinates of current position;

Z: new Z axis absolute coordinates of current position;

Instruction function: set the absolute coordinates of current position, and thus create

workpiece coordinate system (also floating coordinate system). After executing this

instruction, the system sets current position as the program home. When workpiece

coordinate system is created, absolute coordinate programming enters the coordinates

according to this coordinate system, until G50 is executed again to create new workpiece

coordinate system. G50 is non-modal G instruction.

X or Z isn’t entered in G50 instruction, the coordinate axis isn’t entered sets the coordinates

according to current absolute coordinates; if both X and Z aren’t entered, current

coordinates won’t be changed. Aslong as G50 is executed, current position will be set as the

program home.

Program home

Before setting coordinate system with G50

After setting coordinate system with G50

As shown in the figure above, after instruction “G50 X100 Z150” is executed, the

workpiece coordinate system as shown in the figure is created, and point (X100, Z150) is

set to program home.

Note: If G50 is executed to set coordinate system in tool length compensation state, the

absolute coordinates displayed by the system are the coordinate value after current

tool offset is modified; program home is the position defined by G50 coordinate value

in workpiece coordinate system. Return to program home in tool length compensation

state, the position of home end is the program home position after tool length

compensation is canceled.

For example:

Current tool

compensation state

T0100 X:20 Z:20 X:12

T0101 X:32 Z:43 Z:23

Coordinates after G50 X20 Z20 is

executed

#01 tool

compensation

3.5. Fixed cycle

To simplfy the programming, the system provides a G instruction of single processing cycle

that only uses one block to complete fast moving positioning, linear/thread cutting, and finally

returns to start point:

G90: axial cutting cycle

G94: radial cutting cycle

G92: thread cutting cycle

- 31 -

Page 38

ADT-CNC4620 Programming Manual

3.5.1. Axial cutting cycle G90

Format: G90 X/U

X/U: cutting end X axis coordinates;

Z/W: cutting end Z axis coordinates;

F: cutting speed

R: cone slope; radial coordinate difference (radius) between cutting start and cutting

end; if R and U do not have same sign, |R| ≤ |U/2| (diameter programming) or |R| ≤

|U/2|(radius programming) is required. If R isn’t specified, the cylinder processing

is shown in the figure below:

Z/W R_ F_ ;

Cutting Fast feeding

Z axis X axis Start point

Execution process:

1) X axis locates (G0) to cutting start quickly from cycle start;

2) Interpolate (G1) to cutting end from cutting start in linear;

3) X axis radially back to radial coordinate position of cycle start in line interpolation

(G1) mode;

4) Z axis quickly locates (G0) and returns to the start point, and cycle ends.

Note:

1) G90 is modal instruction.

2) In single block operation, the system stops at the end position of every block, and pause

and resetting operation are valid in the motion process.

- 32 -

Page 39

ADT-CNC4620 Programming Manual

3) U, W and R reflect the relative position of cutting end and start. G90 has four track

combinations depending on the sign.

During diameter programming, if R and U do not have same sign and |R| > |U/2|, 0792-G90,

G92, G94 program error alarms, and the value of R exceeds allowed range

4) During first tool cutting, if U is 0, current value is the end coordinates by default; W can’t

be 0, or else the system alarms

5) Before executing G90, specify the position of start point, or else the system takes current

point as the start

6) G90 is valid in MDI mode, and modal function is also available.

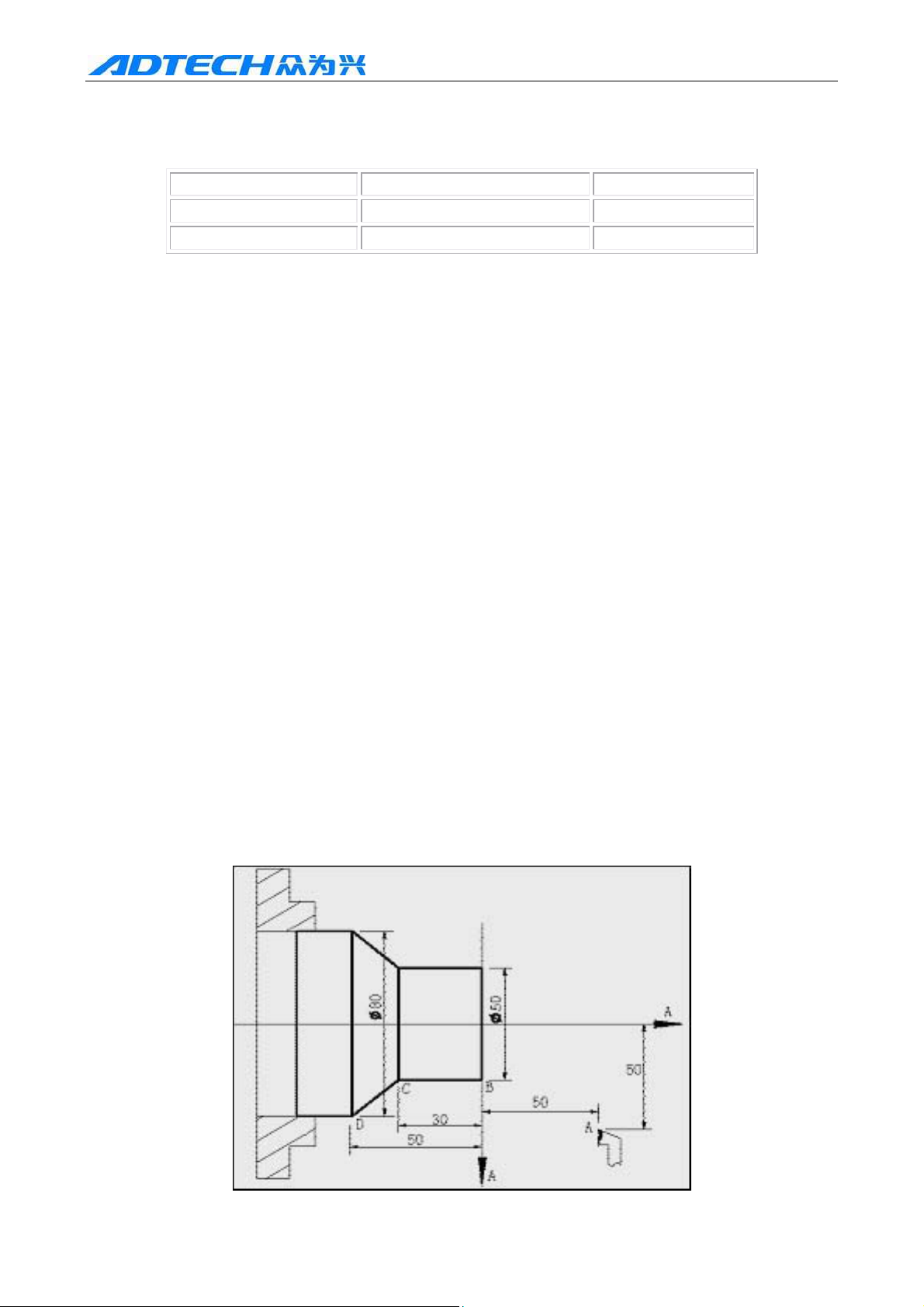

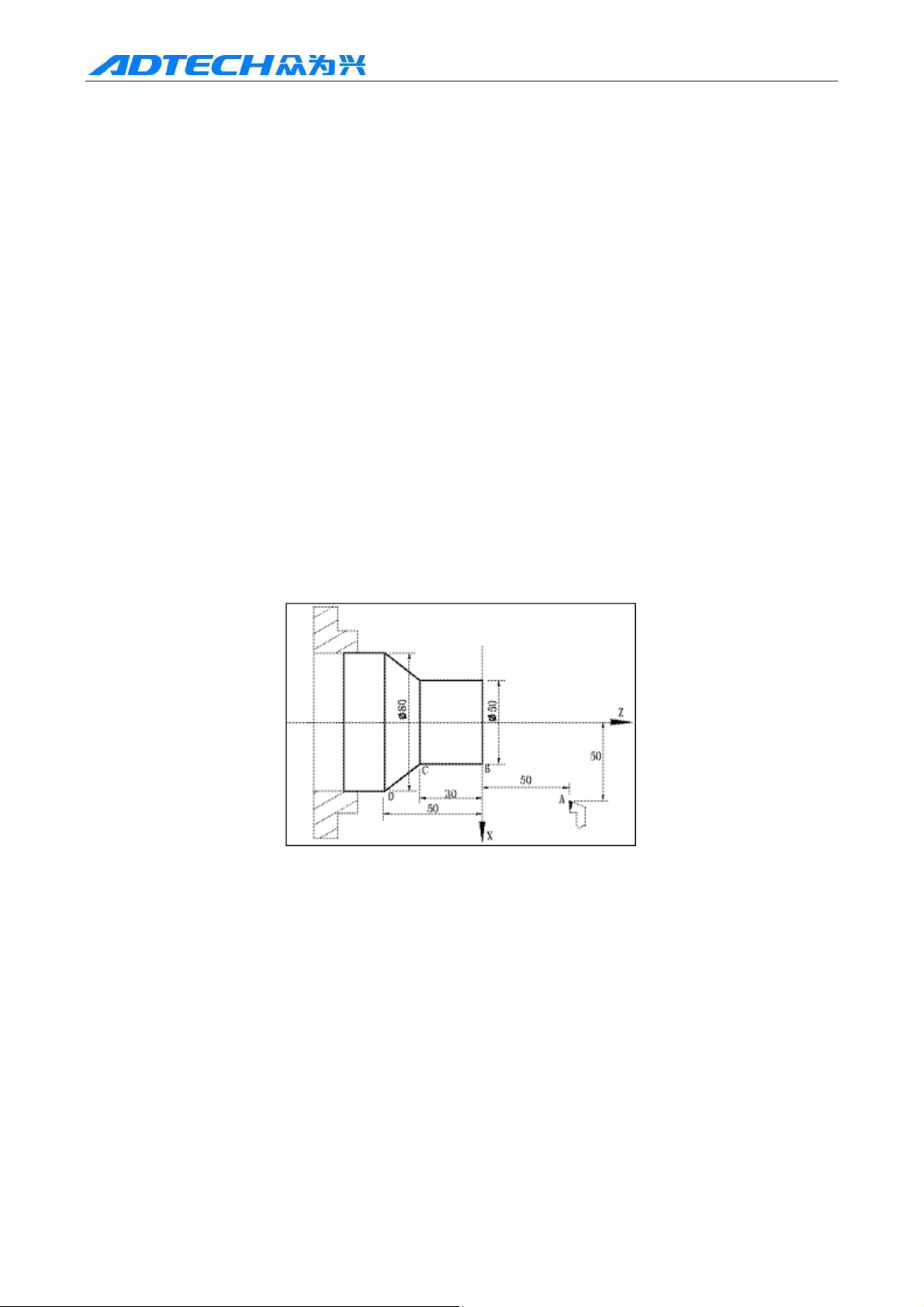

As in Fig. 3-5-1:

Fig. 3-5-1

- 33 -

Page 40

ADT-CNC4620 Programming Manual

O9001

M03 S500T0101

G00 X70 Z2

G90X56Z-60F500

X52

X48

X44

X40

X36

X32

X30

M30

%

3.5.2. Thread cutting cycle G92

Instruction format: G92 X/U

X/U: thread end X axis coordinates;

Z/W: thread end Z axis coordinates;

F: thread pitch

R: thread slope; radial coordinate difference (radius) between cutting start and cutting

end; if R and U do not have same sign, |R| ≤ |U/2| (diameter programming) or |R| ≤

|U|(radius programming) is required. If R isn’t specified, it is straight thread

P, D, V: same to G32 instruction function, but the value of V in G92 is unsigned; the

system retreats the tool according to the direction of the start point automatically,

and G32 needs to check the retreating direction of the specified V sign

Z/W R_ F_ P__ D__ V__;

Thread cutting

Quick feeding

Z axis

X axis

- 34 -

Page 41

ADT-CNC4620 Programming Manual

Thread cutting Quick feeding Z axis X axis

Execution process:

1) X axis locates (G0) to cutting start quickly from cycle start;

2) Interpolate to thread end from cutting start;

3) X axis radially back to radial coordinate position of cycle start in quick positioning (G0)

mode;

4) Z axis quickly locates (G0) and returns to the start point, and cycle ends.

Function description:

1) G92 instruction function is similar to G32 function, and only cycle cutting function is

increased.

2) U, W, and R reflect the relative position of cutting end and start. G92 has four track

combinations depending on the sign.

3) During first tool cutting, if U is 0, current value is the end coordinates by default; W can’t

be 0, or else the system alarms

4) Principal axis ratio control is invalid during thread cutting

5) If the converted feeding speed every minute exceeds the maximum feeding speed, the

system alarms

6) G92 instruction can process one thread in several times of feeding, but the processing of