A

D

T

-

C

N

C

4

2

2

0

A

D

T

-

C

N

C

4

2

2

0

CNC Lathe Control System

User Manual

Operation&Test

Adtech (Shenzhen) CNC Technology Co., LTD

Address: F/5, 36th Building, MaJiaLong Industrial Park, Nanshan District, Shenzhen City, China

P.C: 518052

TEL:+86-755-2672 2719 (20 lines) FAX:+86-755-2672 2718

Website://www.adtechen.com

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Copyright Warning

The property right in work regarding all the contents of this manual is owned by Adtech (Shenzhen)

CNC Technology Co., LTD (hereinafter referred to as Adtech), without the permission of Adtech, any

company or individual is not allowed to imitate, copy, reproduce or translate this manual. Our company

makes no warranty, express representation or other imply regarding the contents of this manual. Adtech

and its employees assume no responsibility for any direct or indirect information disclosure, benefit loss

or business termination due to this manual or the products information described in it. In addition, the

products and their information described in this manual are only for the purpose of reference, we

reserve the right to amend the manual without prior notice.

All Rights Reserved, Reprint Not Allowed .

Adtech (Shenzhen) CNC Technology Co., LTD

1

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Version Upgrading Instruction

Version

Program No.

Number

XT20061225

Remarks: the meanings of the three numbers in the version number are as follows:

Bank Main Version Number/ Bank Secondary Version Number/ Reservation

Notes:

1. This user manual is strictly emended and checked by ADTECH (SHENZHEN) CNC TECHNOLOGY CO., LTD,

however, it is not guaranteed that the user manual has no any mistake or error.

2. ADTECH (SHENZHEN) CNC TECHNOLOGY CO., LTD commits itself to improve the product functions and the

service quality consistently. Therefore, the company reserves the right of changing any products as described, any

software program, and the content of the user manual, without prior notice.

9.0 2010/2/23 The Ninth Version

Modification

Instruction

Date

2

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Contents

1. OPERATION MODES AND DISPLAY INTERFACES..................................................................7

1.1. DESCRIPTION OF EDITING KEYPAD.............................................................................................8

1.2. DISPLAY MENUS.........................................................................................................................9

1.3. CNC PANEL...............................................................................................................................9

1.4. OPERATION MODES..................................................................................................................10

1.5. DISPLAY INTERFACE.................................................................................................................11

1.5.1 Position interface..................................................................................................................13

1.5.2 Program display....................................................................................................................15

1.5.3 MDI......................................................................................................................................15

1.5.4 Program directory.................................................................................................................16

1.5.5 KNIFE COMPENSATION INTERFACE.............................................................................16

1.5.6 aLARM INTERFACE..........................................................................................................17

1.5.7 sETTINGS INTERFACE......................................................................................................17

1.5.8 gRAPH INTERFACE...........................................................................................................18

1.5.9 GRAPH PARAMETERS......................................................................................................18

1.5.10 gRAPH DISPLAY..............................................................................................................18

1.5.11 pARAMETER INTERFACE..............................................................................................19

1.5.12 Diagnosis INTERFACE......................................................................................................19

2. SAFE OPERATION......................................................................................................................21

2.1 HARDWARE OVERTRAVEL PROTECTION.....................................................................................21

2.2 SOFTWARE OVERTRAVEL PROTECTION ......................................................................................21

2.3 EMERGENCY OPERATION..........................................................................................................22

2.4 RESET.....................................................................................................................................22

2.5 EMERGENCY STOP....................................................................................................................22

2.6 FEEDING MAINTAINING............................................................................................................22

2.7 CUTTING OFF POWER SUPPLY....................................................................................................22

2.8 TURNING OFF ..........................................................................................................................23

3. MANUAL OPERATION...............................................................................................................23

3.1 MANUAL FEEDING...................................................................................................................23

3.2 QUICK MOVING........................................................................................................................23

3.3 MANUAL MAGNIFICATION SELECTION.......................................................................................23

3.4 QUICK MAGNIFICATION SELECTION...........................................................................................23

3.5 COORDINATES RESET...............................................................................................................24

3.5.1 Relative position reset...........................................................................................................24

3.5.2 CNC coordinates reset..........................................................................................................24

3.6 OTHER MANUAL OPERATIONS...................................................................................................24

3.6.1 Main axis control..................................................................................................................24

3.6.2 Cooling liquid control...........................................................................................................25

3.6.3 Chuck control.......................................................................................................................25

3.6.4 Manually replacing knife......................................................................................................25

3.6.5 Regulation of main axis magnification..................................................................................25

4. SINGLE STEP/HANDWHEEL OPERATION..............................................................................25

3

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

4.1. SINGLE STEP FEEDING ..............................................................................................................25

4.2. INCREMENT SELECTION............................................................................................................26

4.3. MOTION DIRECTION SELECTION................................................................................................26

4.4. HANDWHEEL FEEDING .............................................................................................................26

4.5. INCREMENT SELECTION............................................................................................................27

4.6. MOTION AXIS AND DIRECTION SELECTION.................................................................................27

4.7. OTHER AVAILABLE OPERATIONS IN HANDWHEEL/SINGLE STEP MODE..........................................27

4.8. DESCRIPTION...........................................................................................................................28

5. MDI OPERATION........................................................................................................................28

5.1. INPUT AND EXECUTION OF MDI INSTRUCTION WORDS...............................................................28

5.2. PARAMETER EDITING AND SETTING...........................................................................................29

6. PROGRAM EDITING AND MANAGEMENT............................................................................29

6.1. CREATING PROGRAM................................................................................................................29

6.1.1 program content Input...........................................................................................................29

6.1.2 Searching instructions words................................................................................................30

6.1.3 Inserting instruction word.....................................................................................................33

6.1.4 Deleting instruction word......................................................................................................33

6.2. DELETING PROGRAM................................................................................................................34

6.2.1 Deleting single program........................................................................................................34

6.2.2 Deleting lines from the program...........................................................................................34

6.2.3 Deleting all programs............................................................................................................35

6.3. PROGRAM SELECTION ..............................................................................................................35

6.3.1 Searching..............................................................................................................................36

6.3.2 Scanning...............................................................................................................................36

6.3.3 Cursor confirmation..............................................................................................................36

6.4. PROGRAM MANAGEMENT.........................................................................................................36

6.4.1 Program directory.................................................................................................................36

6.4.2 locking Program...................................................................................................................36

7. KNIFE BIAS AND ALIGNMENT................................................................................................37

7.1. FIXED KNIFE ALIGNMENT.........................................................................................................37

7.2. TEST CUTTING KNIFE ALIGNMENT.............................................................................................38

7.3. KNIFE ALIGNMENT IN MECHANICAL ORIGIN ..............................................................................39

7.4. EDITING THE BIAS VALUE .........................................................................................................41

7.4.1 Absolute value input of knife compensation..........................................................................42

7.4.2 Increment input of knife compensation.................................................................................42

8. AUTOMATIC OPERATION.........................................................................................................42

8.1 AUTOMATIC RUNNING ..................................................................................................................42

8.1.1 Automatic running start.........................................................................................................43

8.1.2 Automatic running stop.........................................................................................................43

8.1.3 Automatic running in any section..........................................................................................44

8.1.4 Feeding magnification regulation..........................................................................................44

8.1.5 Main axis speed regulation...................................................................................................45

8.1.6 Single section running..........................................................................................................45

8.1.7 Program section skip.............................................................................................................46

8.1.8 Other operations...................................................................................................................46

4

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

9. ORIGIN OPERATION..................................................................................................................46

9.1. PROGRAM ORIGIN ....................................................................................................................46

9.1.1 Program origin......................................................................................................................46

9.1.2 Procedures of program origin................................................................................................46

9.2. MECHANICAL ORIGIN...............................................................................................................47

9.2.1 Procedures of mechanical origin...........................................................................................47

9.2.2 Other operations in origin mode............................................................................................48

10. DATA SETTING AND SAVING................................................................................................48

10.1. DATA SETTING......................................................................................................................48

10.1.1 Options in setting interface.................................................................................................48

10.1.2 Settings in graph interface...................................................................................................49

10.1.3 System/diagnosis parameters setting...................................................................................49

11. FILE MANAGER......................................................................................................................50

11.1. CONNECTING USB DISK TO PC.............................................................................................50

12. PROCESSING EXAMPLES......................................................................................................53

12.1. CREATING NEW PROGRAMS...................................................................................................54

12.2. PROGRAM VERIFICATION ......................................................................................................56

12.2.1 Graph parameter setting......................................................................................................56

12.2.2 Program running.................................................................................................................58

13. CONNECTION TEST...............................................................................................................59

13.1. MOTOR DRIVE CONNECTION TEST .........................................................................................61

13.1.1 Connection of motor, drive and controller...........................................................................62

13.1.2 Setting and calculation of eletronic gear ratio......................................................................64

13.1.3 Acceleration/deceleration features adjustment.....................................................................65

13.1.4 Troubleshooting for motor drive.........................................................................................65

13.2. HARD LIMIT FUNCTION.........................................................................................................66

13.2.1 Enabling hard limit function...............................................................................................66

13.2.2 Troubleshooting for hard limit............................................................................................67

13.3. MECHANICAL ORIGIN ADJUSTMENT.......................................................................................67

13.3.1 Origin parameter setting......................................................................................................67

13.3.2 Troubleshooting for mechanical origin................................................................................69

13.4. REVERSE CLEARANCE COMPENSATION ..................................................................................69

13.5. DRIVE PROTECTION SETTINGS AND CHECKING .......................................................................70

13.6. MAIN AXIS ENCODER............................................................................................................71

13.6.1 Troubleshooting for main axis encoder................................................................................71

13.7. MAIN AXIS CONTROL............................................................................................................72

13.7.1 Wiring diagram...................................................................................................................72

13.7.2 Main axis parameter setting................................................................................................74

13.7.3 Calibration of analog voltage..............................................................................................74

13.7.4 Time sequence and V/S characteristic diagram....................................................................75

13.7.5 table of Multi-section speed regulation states......................................................................75

13.7.6 Troubleshooting for main axis control.................................................................................76

13.8. CHUCK CONTROL .................................................................................................................76

13.8.1 Wiring diagram...................................................................................................................76

13.8.2 Chuck parameter setting......................................................................................................76

5

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

13.8.3 Troubleshooting for chuck control......................................................................................77

13.9. TAILSTOCK CONTROL...........................................................................................................78

13.9.1 Tailstock wiring diagram.....................................................................................................78

13.9.2 Parameter settings...............................................................................................................79

13.10. KNIFE REPLACING CONTROL.................................................................................................79

13.10.1 Wiring diagram of electric knife rack................................................................................79

13.10.2 Knife replacing parameter setting......................................................................................81

13.10.3 Troubleshooting for knife replacing..................................................................................81

13.11. HANDHELD BOX AND ADDITIONAL PANEL INTERFACE XS7.....................................................81

13.11.1 Internal wiring diagram of the handheld box.....................................................................81

13.11.2 Pin function of handheld box interfaces.............................................................................81

13.11.3 Wiring diagram of additional panel...................................................................................83

13.11.4 Precautions and parameter setting for handheld box..........................................................83

13.11.5 Troubleshooting for handheld box.....................................................................................83

13.12. WIRING DIAGRAM OF COOLING AND LUBRICATION CONTROL..................................................84

13.13. WIRING DIAGRAM OF WORKING INDICATORS.........................................................................84

13.14. PROGRAMMABLE I/O PORT ...................................................................................................85

13.14.1 Wiring diagram of programable i/o port............................................................................85

13.14.2 Wiring diagram of programable input and certain control ports.........................................85

13.15. WIRING DIAGRAM OF MAIN POWER SUPPLY ...........................................................................86

13.16. SYSTEM PARAMETERS TABLE ................................................................................................87

13.17. ALARM INFO REFERENCE TABLE............................................................................................90

13.18. MAIN FUNCTIONS AND PARAMETERS REFERENCE TABLE.........................................................93

13.19. SYSTEM WIRING DIAGRAMS..................................................................................................95

13.19.1 Servo drive wiring diagram...............................................................................................95

13.19.2 Step drive wiring diagram.................................................................................................95

13.19.3 Main axis encoder wiring diagram....................................................................................96

13.19.4 Hard limit wiring diagram.................................................................................................97

13.19.5 Mechanical origin wiring diagram.....................................................................................97

13.19.6 Main axis control wiring diagram......................................................................................98

13.19.7 Chuck control wiring diagram...........................................................................................99

13.19.8 Tailstock control wiring diagram.....................................................................................100

13.19.9 Electric knife rack wiring diagram..................................................................................101

13.19.10 Additional panel wiring diagram...................................................................................103

13.19.11 Cooling and lubrication wiring diagram........................................................................103

13.19.12 Power supply wiring diagram........................................................................................104

13.19.13 Indicator wiring diagram...............................................................................................105

13.19.14 Installation dimensions.................................................................................................105

6

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

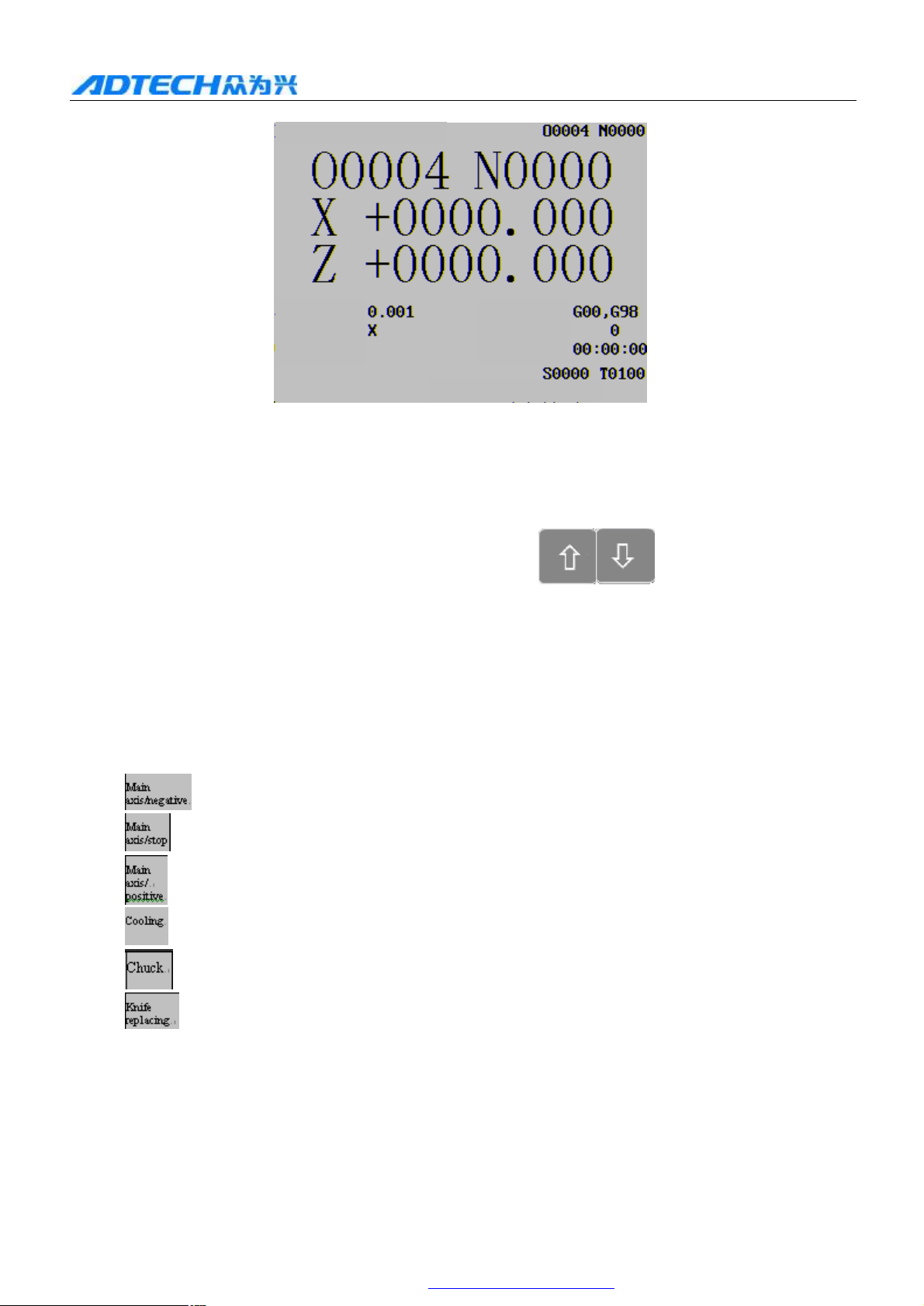

axis/negative

axis/stop

positive

replacing

compensation

1. Operation modes and display interfaces

Product appearance

The appearance and deployment of the operation panel are shown below:

Parameter settings 00004 N0000

1. Multiplying ratio of

instructions in X axis

2. Frequency division coefficient

of instructions in X axis

3. Multiplying ratio of

instructions in Z axis

4. Frequency division coefficient

of instructions in Z axis

5. Feeding speed 4000 (mm/min)

6. Start speed of feeding 300 (mm/min)

7. Feeding acceleration time 200 (ms/min)

Multiplying ratio of instructions in X axis

S0000 T0100

System parameters Page 1

Manual mode

1

1

1

1

Insert

Delete Cancel

Edit Auto

Main

Main

Manual

Main

axis/

MDI

Cooling

Reset

Chuck

Single

Knife

State indicators

Edit To indicate the edit mode Manual

Auto To indicate the auto mode

Skip

Single

Pause Start

Single

step

Position Program

Settings Parameters Diagnosis

Magnification

To indicate the manual

mode

To indicate the single

step mode

Knife

Reset

7

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Single

segment

To indicate the single

segment mode

1.1. Description of editing keypad

Keys Name Function description

Reset Reset key System reset, feeding, output stop, etc.

Address

keys

Input address

Reset

To indicate the reset

mode

Cancel

Double

address

key

Press the keys repeatedly to switch between

the letters

Input numbers

Number

keys

The number keys 8, 2, 6 and 4 are X-, X+, Zand Z+ in manual mode and single step

mode respectively; the direction key 5 is the

quick switch in manual mode

Minus

sign key

Radix

point

Cancel

key

Input the minus sign

Input radix point

Clear the contents in input line

Insert/Delete

8

Editing

keys

Insert or delete programs or fields while

editing

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

single step

1.2. Display menus

Menu keys Remark

Position

EOB key

Cursor

moving

keys

Page

turning

keys

Enter the position interface, which consists of relative

coordinate, absolute coordinate, comprehensive coordinate,

and position/program.

Input the end symbol of program segment, or

edit the option

Control the moving of cursor in program

editing mode and parameter interface

Adjust the feeding and magnification quickly

in auto mode

Single step mode: Adjust the increment in

Turn pages in same display mode

Program

Knife

compensation

Settings

Parameters Enter the parameter interface, display the system parameters

Diagnosis

Enter the program interface, which consists of program, MDI

and program directory.

Enter knife bias interface, which includes knife compensation

data and macro variable

Enter the setting interface and graph interface (press

repeatedly to switch); the setting interface includes code

setting and switch setting; the graph interface includes graph

parameters and graph display

View alarm info when there is alarm

Enter the diagnosis interface and machine tool panel (press

repeatedly to switch); the diagnosis interface and diagnosis

parameters; the soft keypad operation can be performed on the

machine tool panel

1.3. Machine tool panel

The keys are described in the table below:

Keys Name Function description

Pause

Start Loop start key

9

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Feeding

maintaining key

Pause program, MDI instruction

running

Start program, MDI instruction

running

Magnification

Mechanical reset

CNC4220 Machine Tool Operation and Test

Feeding rate /

Rapid

magnification /

Main axis

magnification

Automatic or manual feeding speed /

fast-moving magnification / Main

axis speed regulation

switch key

Knife replacing

Chuck

Cooling

Main axis/positive

Main axis/stop

Main axis/negative

Single section

Manual knife

replacing key

Switch key of

lubricant

Switch key of

cooling liquid

Replace the knife manually

Lubricant on/off of the machine tool

Cooling liquid on/off

Forward rotating of main axis

Main axis control

key

Manual feeding

key

Main axis stops

Reverse rotating of main axis

X axis and Z axis move in

positive/negative direction in manual

and single step operation modes

Quick switch Switch quick/manual feeding speed

Switch running state between single

Single section

switch

section and continuous for the

program; if single section is valid,

the single section indicator is on.

Edit

Auto

MDI

Reset

Editing mode

selection key

Auto mode

selection key

Data input mode

selection key

mode selection key

Enter editing mode

Enter auto mode

Enter MDI operation mode, enter

program reset operation mode

Enter mechanical reset mode

Single step/

Single step

handwheel mode

Switch single step/ handwheel mode

selection key

Manual

Manual mode

selection key

Enter manual operation mode

1.4. Operation modes

This system allows seven operation modes, which are edit, auto, MDI, mechanical reset, single

step/handwheel, manual and program reset.

l Editing operation mod

In editing mode, you can create, delete and modify the processing program.

l Auto operation mode

10

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

In auto mode, the program runs automatically

l MDI operation mode

In MDI mode, input the parameters, and insert and execute instruction segment.

l Mechanical reset operation mode

In mechanical reset mode, perform the mechanical reset operation for X axis and Z axis

respectively

l Handwheel/single step operation mode

In single step/handwheel feeding mode, the system moves in selected increment

l Manual operation mode

In manual mode, perform the operations such as manual feeding, manual speed, feeding

rate regulation, quick rate regulation, main axis start/stop, cooling liquid switch, lubricant

switch and manual knife switch.

l Program reset operation mode

In program reset mode, perform the program reset operation for X axis and Z axis

respectively.

1.5. Display interface

This system contains six interfaces, including position and program. Each interface contains several

pages. Press the display menu key to switch interfaces, and press the Up/Down key to turn pages. The

interfaces (pages) are independent to the operation modes.

11

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Setting

Settings

interfa

ce

Graph

interface

Program

Position

Knife

Knife bias

Knife alignment value

Diagnosis

Handheld box and main axis

Absolute position

Position

Program

Relative position

Position/program

Comprehensive coordinates

Program display

MDI

Program directory

Knife bias interface

Macro variable display

Diagnosis

Parameter switch

File manager

Graph parameters

Graph display

Input point state

Output point state

Keypad test

Alarm info display

12

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

1.5.1 POSITION INTERFACE

Press the position key to enter the position interface, which consists of absolute, relative,

comprehensive and position/program pages. You can press the Up/Down key to

view.

Absolute coordinates

The X coordinate and Z coordinate are the absolute position of the knife in current work piece

coordinates system, which is specified by G50.

Programming speed: the speed specified by F code in the program (unit: mm/min).

Actual speed: the actual processing speed (unit: mm/min) after the magnification has been adjusted in

the actual processing.

Feeding magnification: the current feeding magnification

Quick magnification: the current quick magnification

G function code: current valid G code processing pieces in Group 01 and 03: when the program has

executed M30, the processing pieces are increased by 1.

Cutting time: the cumulative time when the program and MDI are running; the time format is: Hour:

Minute: Second. The cutting time is 0 when the system is electrified.

T: current tool number

S: current main axis rotation speed

Note: The main axis encoder is necessary to display the actual rotation of the main axis.

Current position (absolute coordinates)

Manual rate: G code:

Actual rate: Processing pieces:

Manual magnification: Cutting time:

Main axis magnification:

Manual mode

Fig. 1-3-1

Relative coordinates

The U coordinate and W coordinate, which are 0 when the system is electrified, are the relative

coordinates of current position relative to the reference point. In manual mode, press the letter key

or , and the U or W flashes in the page; press the Cancel key to reset the U or

W coordinate.

13

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Manual mode

Current position (relative coordinates)

Manual rate: G code:

Actual rate: Processing pieces:

Manual magnification: Cutting time:

Main axis magnification:

Fig. 1-3-2

Comprehensive coordinates

In comprehensive position page, relative coordinates, absolute coordinates, machine tool

coordinates and remaining movement are displayed at the same time. The value of machine tool

coordinates is the coordinates of current position in machine tool coordinates, which is created

through mechanical reset. The remaining movement is the difference between the target

coordinates of program section or MDI instruction and the current absolute coordinates.

The page follows:

Current position

(machine tool coordinates) (Absolute coordinates)

(Relative coordinates) (Remaining movement)

Manual mode

Fig. 1-3-3

Position/program

In position/program page, the absolute coordinates and relative coordinates of current

position and program line of current program are displayed at the same time. When the program

is running, the displayed program line refreshes dynamically.

Current position

(machine tool coordinates) (Absolute coordinates)

Manual mode

Fig. 1-3-4

14

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Manual mode

Manual mode

Program interface

Press the Program key to enter the interface, which consists of program, MDI and program

directory pages in non-editing operation mode. Press the Up/Down key to view.

1.5.2 PROGRAM DISPLAY

In the program page, display the contents of the program, including current program section. In

editing mode, press the Up/Down key to view the contents of the program.

Program

Data

Fig. 1-3-5

1.5.3 MDI

In MDI page, display the current instruction states of G, M, S, T and F, and display the contents of

current program section in auto and MDI modes.

Program section value Mode state value

Data

Fig. 1-3-6

15

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Program directory

Manual mode

1.5.4 PROGRAM DIRECTORY

The contents in program directory page:

(a) System version number: display the current version number of the system

(b) Saved programs: the saved programs number (including sub-programs); remaining: the

programs number that still can be saved

(c) Occupied memory: the memory occupied by the saved programs; Remaining: available

memory

(d) Program directory: display the numbers saved programs in sequence

Version: Hardware version:

Current work area: Library version:

Saved programs: Remaining:

Used storage: Remaining:

Fig. 1-3-7

1.5.5 KNIFE COMPENSATION INTERFACE

Press the Knife compensation key to enter the bias interface, and press the Up/Down key

to display knife bias and macro variable.

Knife bias display

Measurement value Fixed knife alignment

S/N

Data =

Position:

Fig. 1-3-8

16

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

1.5.6 ALARM INTERFACE

When the system alarms, press the Diagnosis key to enter the alarm interface and view the alarm

information.

Alarm info

41-Main axis control logical error

Alarm

Manual mode

Fig. 1-3-10

Settings interface

The Setting key is composite, and you can press it repeatedly to switch the setting/graph interface.

1.5.7 SETTINGS INTERFACE

The settings interface contains two pages, and you can press the Up/Down key to view.

Settings

Parameter switch (W): OFF ON

Program switch (H): OFF ON

Manual mode

Fig. 1-3-12

Parameter switch: when the parameter switch is on, you can edit the parameters; when it is off, you

can’t edit; press the key to switch the state in MDI mode

Program switch: when the program switch is on, you can edit the program; when it is off, you can’t

edit; press the key to switch the state in MDI mode

17

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Manual mode

1.5.8 GRAPH INTERFACE

The graph interface contains graph parameters and graph display pages, and you can press the

Up/Down key to view.

1.5.9 GRAPH PARAMETERS

In graph parameters page, you can select coordinates system of graph, scaling and range.

Graph parameters

Coordinates selection(0:XZ,1:ZX)

Scaling +

Graph center X (work piece coordinates) (mm)

Graph center Z (work piece coordinates) (mm)

Maximum X (mm)

Minimum X (mm)

Maximum Z (mm)

Minimum Z (mm)

X origin bias of graph (mm)

Z origin bias of graph (mm)

Data =

Manual mode

Fig. 1-3-13

1.5.10 GRAPH DISPLAY

In graph display page, the motion track (referring to absolute coordinates) of the processing

program is displayed. Press the S key in this page to start drawing, press the T key

to stop and press the R key to clear.

Graph

Start drawing S * End drawing T

Fig. 1-3-14

18

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

1.5.11 PARAMETER INTERFACE

Press the Parameter key to enter the interface, which consists of system parameters and

data parameters. You can press the Up/Down key to view. In parameters display page, the

prompt line of parameter contents displays the contents of the parameter that the cursor points to. The

parameters can be edited in MDI mode. Input the target parameter number and press the EOB key to

go to the specified parameters.

Parameter settings

1. Axis X instruction magnification

2. Axis X instruction frequency conversion coefficient

3. Axis Z instruction magnification

4. Axis Z instruction frequency conversion coefficient

5. Feeding speed

6. Start feeding speed

7. Feeding acceleration time

System parameters Page 1

1. Axis X instruction magnification

Manual mode

Fig. 1-3-15

(mm/min)

(mm/min)

(mm/min)

1.5.12 DIAGNOSIS INTERFACE

The Diagnosis key is composite, and you can press it repeatedly to switch between diagnosis

interface and machine tool panel interface.

Diagnosis interface display

Press the Up/Down key to view the I/O signal state and system state of the diagnosis

display system and machine tool

Input point status interface

Input point state

19

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Keypad test

Main axis encoder and handheld box interface

Main axis encoder test

Main axis encoder

Handheld box test

Handwheel

Output point status interface

Output point state

Keypad test interface

Press Cancel to return

20

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Axis Z positive limit travel switch

2. Safe operation

2.1 Hardware overtravel protection

The overtravel protection is the necessary measure for the machine tool to prevent damage caused

when the X axis and Z axis exceed the travel. The hardware overtravel protection function is enabled

and controlled by system parameter 22 --- hard limit, which is enabled if the parameter is set to “1”.

The effective level of hardware limit is controlled by system parameter 23 --- effective level of hard

limit. Set the above two parameters according to the actual connection of the machine tool to realize

overtravel protection. Install travel limit switch in the position of maximum travel in positive and

negative directions of axis X and axis Z respectively, and connect the wires according to the figure

below. When overtravel occurs, the travel limit switch acts, and the system stops moving and displays

the alarm of not ready. It indicates that the hard limit enable control parameter can only control the

limit function of motion chip, and the limit response of the motion chip features high speed and low

delay. The hard limit function is still valid in this system when the hard limit parameter is disabled.

The software will execute the limit function instead. Comparing with the limit by the chip, the delay is

increased, but the immunity is much better.

Digital input wiring board

XS5 interface

xis Z negative limit travel switch

Axis X positive limit travel switch

xis X negative limit travel switch

2.2 Software overtravel protection

The software limit function is enabled and controlled by system parameters --- software limit,

which is enabled if the parameter is set to “1” and disabled if set to “0”.

The software travel range is set by system parameters: positive soft limit in X axis, negative soft

limit in X axis, positive soft limit in Z axis and negative soft limit in Z axis, and refers to the

coordinates of the machine tool. As shown in the figure below, X and Z are two axes of the

coordinates of the machine tool, 25 and 26 are the maximum travels of X axis in positive and negative

directions, 27 and 28 are the maximum travels of Z axis in positive and negative directions, and the

area inside the dashed frame is the range of software travel.

21

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Axis X negative soft limit

Axis Z negative soft limit Axis Z positive soft limit

Axis X positive soft limit

2.3 Emergency operation

During the processing, due to user programming, operation and product failures, certain

unexpected events may occur. At this moment, please stop the system immediately. This section

involves the treatment that the system can perform under emergency conditions. Please refer to the

instructions of machine tool for the treatment that the machine tool can perform under emergency

conditions.

2.4 Reset

When the system output or coordinates action is abnormal, press the Reset key to reset the

system:

1. The motion of all axes stops;

2. M, S function output is invalid (it is possible to set whether disable main axis positive/negative

rotation, lubricant and cooling signals automatically after pressing the Reset key );

3. Automatic running stops, and mode function and state maintain.

2.5 Emergency stop

When the machine tool is running, press the Emergency stop button (when external emergency

stop signal is valid) if there is any danger or emergency, and the system will enter the emergency stop

state immediately. At this moment, the machine tool stops moving immediately, and all outputs (e.g.

rotation of main axis, cooling liquid, etc.) are off. Release the button to relieve the alarm, and then the

system enters reset state.

Note 1: Please make sure that the failure has been eliminated before relieving the alarm;

Note 2: Before turning on/off the machine, press the emergency stop button to reduce the electric

impact to the equipment;

Note 3: After relieving the alarm, please re-execute the mechanical reset operation to ensure the

accuracy of the coordinates (if the machine tool doesn’t have mechanical origin, do not perform this

operation);

The emergency stop function is controlled by system parameters ---- emergency stop function. The

function is valid only when the value is set to 1.

The level of emergency stop signal is controlled and set by system parameters ---- emergency stop

signal level.

2.6 Feeding maintaining

When the machine tool is running, press the Pause key to hold the running. Please note

that the running can’t be stopped immediately during screw thread cutting and circle instruction

running.

2.7 Cutting off power supply

If any danger or emergency occurs when the machine tool is running, please cut off the power

supply immediately to prevent accidents. Please note that the system coordinates may be significantly

different from the actual position when the power supply is cut off. Please align the knife again.

22

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

2.8 Turning off

Before turning off, please make sure:

1. Axis X and axis Z of machine tool are stopped;

2. The auxiliary functions (e.g. main axis, water pump, etc.) are disabled;

3. Please cut off the machine tool power supply and then the machine tool power supply

4. When the machine tool is electrified, the position is (X +00000.000, Z +00000.000), please

perform the mechanical reset operation first.

3. Manual operation

Press the Manual key to enter the manual operation mode, in which you can perform

operations like manual feeding and main axis control.

3.1 Manual feeding

Press the or key to feed axis X in negative or positive direction, and release the

key to stop the axis motion. At this moment, you can adjust the manual magnification to change the

speed of manual feeding; press the or key to feed axis Z in negative or positive

direction, and release the key to stop the axis motion. At this moment, you can adjust the manual

magnification to change the speed of manual feeding.

In manual feeding mode, press the key to enter manual quick moving state.

Note: The manual feeding can be adjusted only in position interface and manual mode.

3.2 Quick moving

Press the key, and then press the or key to move the axis X in negative or

positive direction quickly, release the key to stop the motion of the axis, and you can adjust the quick

magnification to change the moving speed; press the or key to move the axis Z in

negative or positive direction quickly, release the key to stop the motion of the axis, and you can

adjust the quick magnification to change the moving speed.

During manual quick moving, press the key to disable the quick moving and move in

manual feeding speed.

Note 1: The speed, time constant, acceleration/deceleration mode during quick moving are same to

the quick moving (G00 orientation) of program instruction;

Note 2: Only one axis is valid in manual mode.

3.3 Manual magnification selection

In manual feeding and cutting, press the magnification key, and then press the

/ key when the quick magnification appears in the lower left corner of the position

interface to decrease or increase the manual feeding magnification, which contains 16 levels and

10% each level.

3.4 Quick magnification selection

In manual quick moving state, press the magnification key to switch to the regulation

23

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

mode of quick moving magnification; when the quick magnification appears in the lower left

corner of the position interface, press the and key to decrease or increase the

manual quick moving magnification respectively, and switch among F0, 25%, 50% and 100%.

Press the key once to increase the quick moving magnification by one grade, until 100%;

Press the key once to decrease the quick moving magnification by one grade, until F0

Note 1: system parameters 10 and 11 set the quick moving speeds of axis X and axis Z

respectively; actual quick moving speed of axis X = the value set by system parameter 10 *

quick magnification; actual quick moving speed of axis Z = the value set by system

parameter 11 * quick magnification

Note 2: the quick moving can be adjusted only in position interface and manual mode.

Note 3: the quick magnification is valid in the following conditions

(1) G00 orientation

(2) Quick moving in fixed circle

(3) Quick moving at G28

(4) Manual quick moving

(5) Quick moving of returning to mechanical origin manually: e.g. if the speed of quick

moving is 6m/min and the magnification is 50%, then, the speed is 3m/min.

3.5 Coordinates reset

3.5.1 RELATIVE POSITION RESET

1) Press the Position key (press the Up key or key if necessary) to enter the

page of relative coordinates;

2) Press the key to make the U flash in the page, and then press the Cancel key to

clear the relative coordinates of axis X;

3) Press the key to make the W flash in the page, and then press the Cancel key to

clear the relative coordinates of axis Z;

3.5.2 MACHINE TOOL COORDINATES RESET

Press the Position key (press the Up key or key if necessary) to enter the page

of comprehensive coordinates,

Press the Cancel key and then press to clear the machine tool coordinates of

axis X;

At the same time, press the Cancel key and then press to clear the machine

tool coordinates of axis Z

3.6 Other manual operations

3.6.1 MAIN AXIS CONTROL

Main axis/positive: In manual operation mode, press this key, and the main axis rotates

in positive direction;

24

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Main axis/stop: In manual operation mode, press this key, and the main axis stops rotating;

Main axis/reverse: In manual operation mode, press this key, and the main axis rotates in

reverse direction.

3.6.2 COOLING LIQUID CONTROL

Cooling: In manual operation mode, press this key to switch the cooling liquid

3.6.3 CHUCK CONTROL

Chuck: In manual operation mode, press this key to switch the chuck of the machine tool

3.6.4 MANUALLY REPLACING KNIFE

Replace knife: In manual operation mode, press this key to replace the knife manually (if

the first knife is being used, press this key to switch to the second knife; if it is the maximum

knife value set by current parameters, press this key to switch to the first knife).

3.6.5 REGULATION OF MAIN AXIS MAGNIFICATION

During automatic running, the analog voltage output can be used to control the speed of main axis.

Press the or key to adjust the magnification of the main axis and change the speed.

The magnification of main axis has eight levels, which are from 50% to 120%.

4. Single step/handwheel operation

In single step/handwheel operation mode, the machine tool moves in the increment value set by the

system.

The Single step key is the switch of single step and handwheel functions. Press the Single step key

to enter single step mode, press it again to enter handwheel mode, and press it for another time to return to single

step mode.

4.1. SINGLE STEP FEEDING

Press the Single step key to enter single step operation mode, which is shown in the figure

below:

25

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Current position (absolute coordinates)

See the description in

Section 1.1, and the

value varies

according to the

selection

Single step G code:

increment: Processing pieces:

4.2. Increment selection

Cutting time:

Fig. 4-1-1

Single step mode

Press the key to adjust the increment of single step: if the current increment is 0.01, press

the key to change the increment to 0.1, and press it again to change the increment to 1. To reduce

the increment, press the key.

4.3. Motion direction selection

Press the or key once to feed once the axis X in single step increment in negative or

positive direction; press the or key once to feed once the axis Z in single step

increment in negative or positive direction.

4.4. Handwheel feeding

Press the Single step key to enter handwheel operation mode, which is shown in the figure below:

26

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Current position (absolute coordinates)

Handwheel increment: G code:

Current axis:

Processing pieces:

Cutting time:

Handwheel mode

Fig. 4-1-2

4.5. Increment selection

Move the increment selection lever on the handheld box to select desired increment.

If additional panel is used, please select the increment with the key.

4.6. Motion axis and direction selection

Move the axis number selection lever on the handheld box to selected required motion axis. If additional

panel is used, please select the axis number through key X and Z.

4.7. Other available operations in handwheel/single step mode

Main axis/positive: press this key to rotate the main axis in positive direction;

Main axis/stop: press this key to stop the rotation of the main axis;

Main axis/reverse: press this key to rotate the main axis in reverse direction.

Cooling: press this key to switch the cooling liquid.

Chuck: press this key to switch the chuck of the machine tool.

Replace knife: press this key to replace the knife manually

In addition, it is possible to regulate the magnification of main axis in handwheel/single step

mode.

27

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

(Program section value) (Mode state value)

4.8. Description

1

. See the table below for the relationship between handwheel scale and machine tool motion:

Motion of every scale on the handwheel

Handwheel

increment

Specified value

of coordinates

0.001 0.01 0.1

0.001mm 0.01mm 0.1mm

2. The rotation speed of the handwheel can’t exceed 3r/s, or else, the scale and motion won’t be

consistent;

3. If the system uses step motor, the rotation speed of the handwheel shouldn’t exceed 5r/s or the single

step position that can disable 0.1mm and 1mm.

5. MDI operation

In MDI operation mode, you can set the parameters, input and execute instruction words.

5.1. Input and execution of MDI instruction words

Select the MDI mode to enter the MDI page, input a program section G50 X50 Z100, and the

operation follows:

A. Press the MDI key to enter MDI operation mode;

B. Press the Program key (and then press the key or key if necessary) to

enter the MDI page;

C. Type X50 in sequence and then press the Insert key, type G50 and press the Insert key, type

Z100 and press the Insert key (if any error appears when type the fields, please press the

Reset key to clear all contents, and then type new data). As in the figure below:

Data=

MDI mode

D. After inserting the instruction words, press the Start key to execute the MDI

instruction words. During running, you can press the Pause key, Reset key and

Emergency stop button to stop the running of MDI instruction words.

28

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

P

rogram

MDI mod

e

Note: Subroutine call instruction (M98 P___ ;) and composite cutting cycle instruction (G70, G71,

G72, G73, G74, G75, G76, etc.) are invalid in MDI.

5.2. Parameter editing and setting

You can edit and set the parameters only in MDI mode.

6. Program editing and management

In the editing mode, you can create, select, edit and delete programs. To prevent the program

from unexpected modification and deletion, the system integrates program switch. Before editing

the program, please turn on the program switch.

6.1. Creating program

6.1.1 PROGRAM CONTENT INPUT

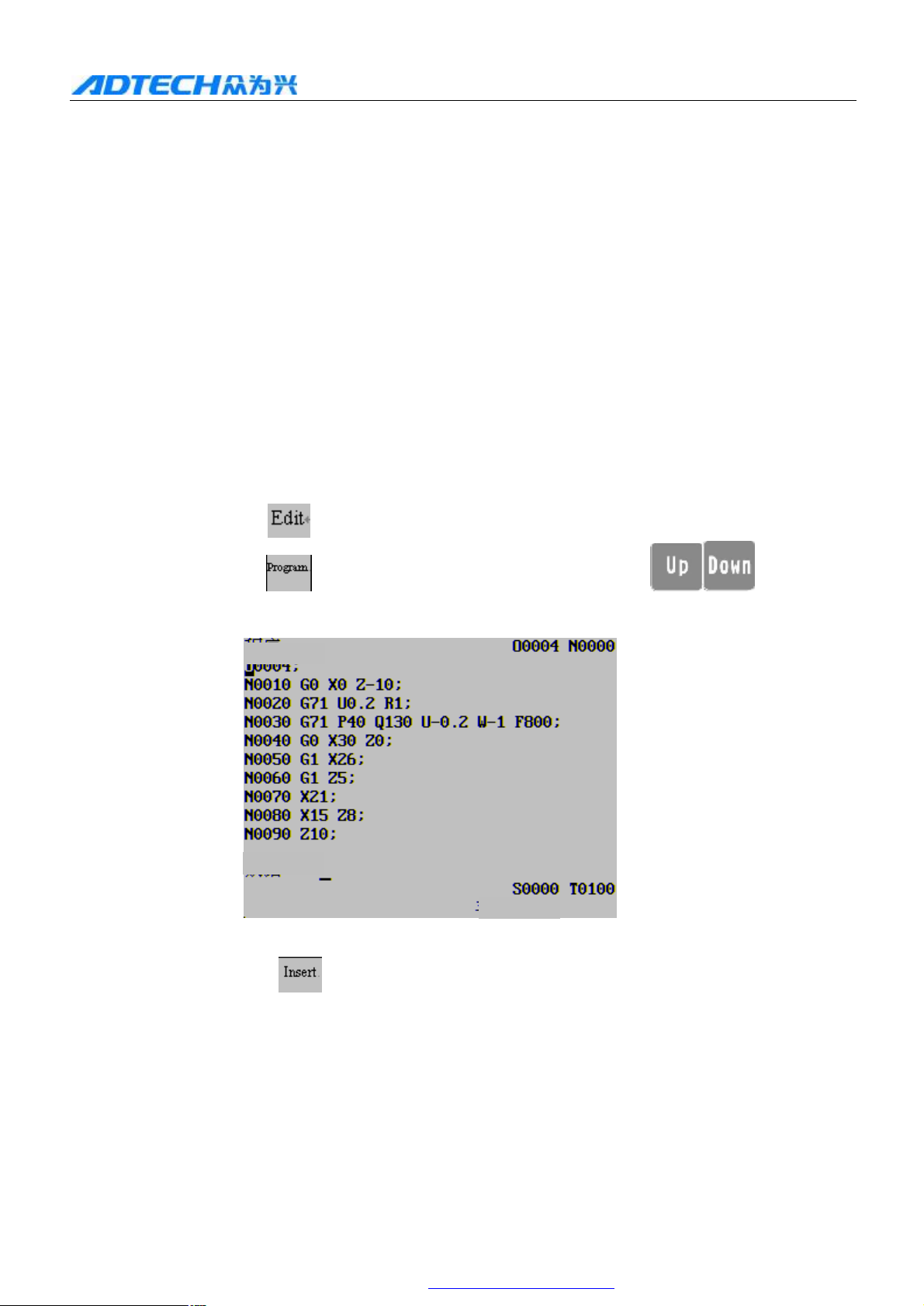

1) Press the Edit key to enter the editing mode;

2) Press the Program key to enter the program page, and press the key to

select program editing interface if necessary.

Data=

3) Type the address key O and number key 0001 in sequence (to create program O0001).

4) Press the Insert key to create new program, as shown in the figure:

29

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Program

MDI mod

e

Program

MDI mod

e

Data=

5) To edit the program content, please input the address and then the number (If the program

section contains several instruction words, please input all instruction words in the above

mentioned method), and then press the Insert key to complete the input of the program

section. (If the input buffer contains the input characters, press the key at the line end to

insert the data in buffer and start a new line. If it is in the line, please edit current instructions.)

Press the key and the cursor goes to the program section in next line.

6) Input other sections of the program in the method in step 5.

6.1.2 SEARCHING INSTRUCTIONS WORDS

◆Scanning: the cursor scans every instruction word in sequence

1) Press the key, and the cursor moves upwards or downwards by instruction word.

Press the key once, the cursor moves to next instruction word; press and hold the key,

the cursor moves downwards by instruction word consecutively; press the Up/Down key, the

cursor moves in opposite direction.

Data=

30

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Program

Editing

mod

e

Program

Editing

mod

e

2) Press the key to display the previous page of the program (when the program is in

the first page, the key is invalid), the cursor locates the start of previous page; press

the key to display the next page of the program (when the program is in the first page,

the key is invalid), the cursor locates the start of next page. Press and hold the key

to turn pages consecutively.

◆ Searching (instruction word): search for specified instruction word upwards or downwards from

the cursor position. The current position of the cursor is N0030, now move the cursor to Z9.5;

Data=

Searched!

The operation method follows:

1) Press the address key , number key and in sequence;

2) Press the key and the system starts searching downwards; after that, the cursor locates

address Z9.5. If you press the key to search upwards, the system can’t find instruction word

Z9.5, and alarms.

Data=

Not searched!

Note: to search for Z9.5, please input Z9.5 exactly; if you input Z9.50 only, the system can’t find

Z9.5.

◆

Searching (address): search specified address upwards or downwards starting from current position.

The current position of the cursor is N0030, now move the cursor to Z14;

31

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Program

Manual mode

1

Program

Editing

mod

e

Data=

The operation follows:

1) Input Z14.

2) Press the key and the system starts searching downwards; after that, the cursor locates

address Z. If you press the key to search upwards, the system can’t find instruction word

Z14, and alarms.

Data=

Not searched!

◆

To return to the start of the program

Method

In editing mode and program display page, press the Reset key and the cursor returns to the

start of the program.

Method 2: Searching

(a) Select the editing mode;

(b) Press the Program key to enter the program display interface;

(c) Type address key and number key (the current program is

number 5);

(d) Press the key and the cursor returns to the start of the program

Method 3: scanning

(1) Select the editing mode to enter the program display interface;

32

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Program

Manual mode

Program

Manual mode

(2) Press the address key and then the key, and the cursor returns to the start of

the program.

6.1.3 INSERTING INSTRUCTION WORD

Insert G01 instruction before address X40 in the steps below:

Locate the cursor at X40, type G01 and then press the Insert key , as shown below:

Data=

6.1.4 DELETING INSTRUCTION WORD

To delete instruction word G01:

1) Locate the cursor at G01

Data=

2) Press the Delete key to delete G01 (the instruction word that current cursor points at), as

shown below

33

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Program

Manual mode

Program

Editing

mode

Data=

3) To delete the characters in input buffer: If X1000 has been input in the input buffer, press the Delete key to delete

the last character, then, the character in the input buffer is X100, and press again to input X10.

6.2. Deleting program

6.2.1 DELETING SINGLE PROGRAM

The operation follows:

1) Select the editing mode to enter program page;

Data=

2) Type address key and number keys in sequence,

3) Press the Delete key to delete program O0001.

6.2.2 DELETING LINES FROM THE PROGRAM

Delete from the character where the cursor locates to %semicolon. The operation is invalid if the cursor locates the

name of current program.

The operation follows:

1) Select the editing mode, and move the cursor to the start N character to delete

34

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Program

Editing

mode

Program

Editing

mode

Data=

2) Input characters and

3) Press the Delete key to delete from the cursor to the line end, as in the figure below:

Data=

6.2.3 DELETING ALL PROGRAMS

The operation follows:

1) Select the editing mode to enter the program page

2) Type the address key , symbol key , number keys , , and

in sequence;

3) Press the Delete key to delete all programs.

6.3. Program selection

If the system has several programs, you can select a program by searching.

35

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

6.3.1 SEARCHING

Take O0005 for an example,

(a) Select the editing mode;

(b) Press the Program key to enter program display interface;

(c) Type the address key and number keys in

sequence;

(d) Press the key, and the searched programs appear on the LCD (the system alarms if the

program doesn’t exist).

6.3.2 SCANNING

(a) Select the editing mode;

(b) Press the Program key to enter the program display interface;

(c) Press the address key ;

(d) Press the key to display next program;

(e) Repeat step c and d to display the saved programs one by one.

6.3.3 CURSOR CONFIRMATION

1) Select the auto mode;

Program

2) Press the Program key to enter program directory page;

3) Press the , , or key to move the cursor to desired program name;

press the key to move cursor leftwards and press the key to move rightwards;

6.4. Program management

6.4.1 PROGRAM DIRECTORY

In non-editing mode, press the Program key (and then press if necessary) to

enter program directory page. In this page, the saved program names in the system are displayed in

directory; each page displays up to 36 program names; if the number of saved programs exceeds 36,

press the key to display other program names.

6.4.2 LOCKING PROGRAM

To prevent the program from unexpected modification and deletion, the system integrates

program switch. After editing the program, please turn off the switch (see the figure below) to lock

the program.

36

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ肀 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Setting

Parameter switch (W): OFF ON

Program switch (H): OFF ON

Manual mode

To set the program switch: Press Settings to switch to setting switch page, and press the key to

switch the state to off.

7. Knife bias and alignment

7.1. Fixed knife alignment

The fixed knife alignment is valid if the system parameter 45 is 0. The operation follows:

1) Select a knife as the reference, and set the bias number in the knife to 0 (e.g. T0100, T0300);

2) Locate the tip of the reference knife to a point (the knife alignment point), and measure the diameter "α" (suppose

α=10), as Fig. A;

Fig. A Fig. B

37

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Surface B

Surface A

3) Press the MDI key to enter the MDI mode, and press the Program key (press if

necessary) to enter the MDI page; type , , , , , , ,

and Insert key in sequence, and then press the Start key to set the actual values of axis X

and Z to the value to work piece coordinates

4) Clear the relative coordinates (U, W) (press the Position → turn page to relative position → →

Cancel → → Cancel );

4) Press the Knife compensation key to enter the bias interface, press the / key to move

cursor to select the corresponding bias number of the reference knife;

5) Press the address key , number key , and then press the Insert key to set the bias of axis X

of reference knife to 0;

6) Press the address key , number key , and then press the Insert key to set the bias of axis Z

of reference knife to 0;

7) Move the knife to safe position, select another knife (set the bias number in the knife to 0) and move to the

alignment point, as Fig. B;

8) Press the knife compensation key, and move the cursor to select the corresponding bias number of

the knife;

9) Press the address key and then press the Insert key to set the knife compensation value of axis

X to the corresponding bias number;

10) Press the address key and then press the Insert key to set the knife compensation value of axis

Z to the corresponding bias number;

11) Repeat step 7~10 to align other knives.

7.2. Test cutting knife alignment

The test cutting knife alignment is valid if the system parameter 45 is 1. The operation follows

(create work piece coordinates with surfaces of the work piece):

1) Select knife 1 as the reference to make the knife cut along surface A;

2) Take out the knife along axis X when axis Z is still, and stop the rotation of main axis;

38

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

3) Press the Knife compensation key to enter the bias interface, and press the key to

move the cursor and select bias number (the bias number corresponding to this knife is 101);

4) Type the address key , number key and Insert key to set the knife bias in direction Z

to 0 and the current coordinates are Z0;

5) Cut along surface B with the knife;

6) Take out the knife along axis Z when axis X is still, and stop the rotation of main axis;

7) Measure the diameter "α" (suppose α=15) ;

8) Press the Knife compensation key to enter the bias interface, and press the key to

move the cursor and select bias number (the bias number corresponding to this knife is 101);

9) Type the address key , number key , and Insert key to set the knife bias in

direction Z to 0 and the current coordinates are X15;

10) Move the knife to a safe position and change the knife;

11) Cut along the surface A in manual mode;

12) Take out the knife along axis X when axis Z is still, and stop the rotation of main axis;

13) Measure the distance "β "ˊ between surface A and origin of work piece coordinates (suppose β =ˊ 1)

1 14) Press the Knife compensation key to enter the bias interface, and press the key to

move the cursor and select bias number (the bias number corresponding to this knife is +100);

15) Press the address key , symbol key , number key and Insert key in sequence

to set the knife bias of axis Z;

16) Cut along the surface B in manual mode;

17) Take out the knife along axis Z when axis X is still, and stop the rotation of main axis;

18) Measure distance "α "ˊ (suppose αˊ=10);

19) Press the knife compensation to enter the bias interface, and press the and key to

move the cursor to select bias number (the bias number corresponding to this knife is +100);

20) Type the address key , number key , and Insert key in sequence to set the bias

of axis X;

21) Repeat step 10-20 to align other knives.

7.3. Knife alignment in mechanical origin

The knife alignment in mechanical origin is valid when the system parameter 45 is 2. The

operation follows:

39

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

Surface B1

Surface A1

Surface B

Surface A

1) Press the Reset key to enter mechanical reset mode and return the two axes to the mechanical origin;

2) Select a knife and set the bias number in the knife to 0 (e.g. T0100, T0300)

3) Cut along surface A with the knife;

4) Press the Knife compensation key to enter the bias interface, and press the key to

move the cursor and select bias number;

5) Press the address key , number key and Insert key to set the bias of axis Z;

6) Cut along surface B with the knife;

7) Take out the knife along axis Z when axis X is still, and stop the rotation of main axis;

8) Measure distance "α "ˊ (suppose αˊ=15);

9) Press the Knife compensation key to enter the bias interface, and press the key to

move the cursor and select bias number;

10) Press the address key , number key , and Insert key to set the bias of axis X;

11) Move the knife to safe position;

12) Change another knife and set the bias number to 0 (e.g. T0100, T0300);

13) Cut along surface A1 with the knife;

14) Take out the knife along axis X when axis Z is still, and stop the rotation of main axis; measure the distance

"β" (suppose=1) between surface A1 and work piece origin;

40

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

S/N

15) Press the knife compensation key to enter the bias interface, and then press the

key to move the cursor and select bias number;

16) Press the address key , symbol key , number key and Insert key to set the

bias of axis Z;

17) Cut along surface B1 with the knife;

18) Take out the knife along axis Z when axis X is still, and stop the rotation of main axis;

19) Measure distance "α1" (suppose α1=10);

20) Press the Knife compensation key to enter the bias interface, and then press the

key to move cursor and select the bias number;

21) Press the address key , number key , and Insert key to set the bias of axis X;

22) Move the knife to safe position;

23) Repeat step 14-22 to align other knives.

Note 1: the machine tool should have mechanical origin switch to perform the knife alignment

operation in mechanical origin.

Note 2: after knife alignment in mechanical origin, it is not possible to execute the G50

instruction to set the coordinates of the work piece

As shown below:

CNC4220 Machine Tool Operation and Test

7.4. Editing the bias value

Press the Knife compensation key to enter the bias interface, and then press the

key to display bias 001~016

Knife compensation parameters Fixed knife alignment

Data

Position:

41

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn

CNC4220 Machine Tool Operation and Test

S/N

7.4.1 ABSOLUTE VALUE INPUT OF KNIFE COMPENSATION

1. Enter the bias interface, move the cursor to the compensation number to edit the bias value and

press the MDI key to enter the MDI mode;

1 Press the address key or , and then input the compensation value (allows radix point)

2 Press the key to display the compensation on the LCD.

For example: Input -20 in the X value of bias number T0202, and the operation follows:

In the MDI mode, type X-20 and then press the key to have the following page:

Knife compensation parameters Fixed knife alignment

Data

Position:

MDI mode

7.4.2 INCREMENT INPUT OF KNIFE COMPENSATION

1. Enter the bias interface, move the cursor to the compensation number to edit the bias value and

press the MDI key to enter the MDI mode;

2. Press the address key or , and then input the compensation value (allows radix point)

3. Press the key to display the increased value of the increment.

8. Automatic operation

8.1 Automatic running

Select the program with searching or scanning method

l Searching (take searching program O0001 as an example)

A. Select the Auto mode;

B. Press the Program key to enter the program page;

C. Press the address key and number keys 0, 0, 0, 1 in sequence;

D. Press the key to display the searched programs on the LCD (the system alarms if the

program doesn’t exist).

l Scanning

42

PDF 文件使用 "pdfFactory Pro" 试用版本创建 À www.fineprint.com.cn