Page 1

TM

8-6520-002-24&P

UNIT,

DIRECT

MAINTENANCE

(INCLUDING

DENTAL

TECHNICAL

SUPPORT,

REPAIR

SPECIAL

OPERATING

MANUAL

AND

TOOLS

GENERAL

MANUAL

PARTS

LIST)

SUPPORT

AND

AND

'

TREATMENT

ADEC

APPROVED

MODEL

FOR

PUBLIC

UNIT,

6520-01-272-4531

RELEASE;

FIELD,

3406

DISTRIBUTION

PORTA-CART

PORTABLE,

IS

UNLIMITED

HEADQUARTERS,

DEPARTMENT

OF

THE

ARMY

1991

Page 2

TM

8-6520-002-248P

|

|

Throughout

time

to

read

Procedures which

this

manual

these.

They

are

must

are

WARNINGS,

there

be

observed

CAUTIONS,

to

protect

WARNING

to

avoid

you

and

personal

and

the

equipment.

injury,

NOTES.

and

even

loss

Please

of

life.

take

|

|

Procedures

which

must

Essential

observed

be

CAUTION

avoid

to

or

long-term

NOTE

information

that

damage

health

should

eguipment,

to

hazards.

remembered.

be

destruction

eguipment,

of

a/b

blank

Page 3

TM

8-6520-002-24&P

|

TECHNICAL

NO.

8-6520-002-248P

MANUAL

UNIT,

(INCLUDING

FIELD,

You

can

help

prove

procedures,

mended

Changes

Commander,

5001. A reply

Changes

to

DIRECT

DENTAL

PORTABLE,

improve

please

to

Publications

Equipment

U.S.

Army

will

be

furnished

SUPPORT,

MAINTENANCE

REPAIR

OPERATING

6520-01-272-4531

this

manual.

let

us

know.

Technical

Medical

Materiel

directly

AND

PARTS

AND

AND

ADEC

If

you

and

Blank

Publications)

to

find

Mail

Agency,

you.

MODEL

any

your

Forms),

GENERAL

MANUAL

SPECIAL

TREATMENT

3406

mistakes

memorandum,

or

DA

located

ATTN:

in

the

SGMMA-M,

HEADQUARTERS

DEPARTMENT

WASHINGTON,

DC

SUPPORT

TOOLS

UNIT,

PORTA-CART

or

if

you

know a way

DA

Form

2028

Form

2028-2

back

(Recommended

of

this

manual,

Frederick,

OF

THE

LIST)

to

im-

(Recom-

to:

MD

21702-

ARMY

CHAPTER

Section

CHAPTER

Section

CHAPTER

Section

1.

I.

И.

Il.

2.

ll

|.

Ill.

IV.

3.

|.

I.

o

Approved

HOW

TO

USE

INTRODUCTION

General

Equipment

Principles

OPERATING

Operating

Operational

Operation

Operation

UNITLEVEL

General

Service

Information

Description

of

Procedures

of

Under

Information

Upon

for

public

TABLE

THIS

MANUAL...

and

Operation

INSTRUCTIONS

......

Care

Auxiliary

MAINTENANCE

Receiptof

Equipment

Unusual

release;

OF

see

Data

........

еее

Conditions

Eguipment

distribution

is

CONTENTS

нение

..

................

...................

unlimited.

a

инея

as

ser

0...

renen

eee

ee

e

venerne

rr

eee

Page|

iv

2-1

ne

3-1

Page 4

TM

8-6520-002-24&P

Section

CHAPTER

Section

APPENDIX

GLOSSARY

INDEX

Figure

No.

1-1

1-2

1-3

1-4

1-5

16

2-1

3-1

32

E-1

E-2

E-3

E-4

ES

E-6

E-7

E-8

E-9

E-10

E-11

E-12

E-13

E-14

E-15

11.

SEZ

Vil.

Vill.

4.

L

Il

A

B.

C.

D.

E

Lubrication

Preventive

Functional

Troubleshooting

Maintenance

Storage

DIRECT

General

Troubleshooting

REFERENCES

MAINTENANCE

COMPONENTS

EXPENDABLE

REPAIR

Controls

Control

Control

Control

Water

Signal

AVS

Mechanical

Master

Water

Air

filter

Master

Control

Microvalve

Automatic

Foot

Toggle

Needle

SYNGE:

AVS

Air

vacuum

Air

saliva

Water

Frame

Instructions

Maintenance

Testing

Instructions

and

Shipment

SUPPORT

Information

PARTS

and

associated

block

assembly

block

detail

block

front

valve

relay

valve

and

ASE

assemblies

schematic

block

assembly

filt@n

vic

and

regulator

block

assembly

block

assembly

holder

control

handpiece

valve

valve

valve

scan

system

ejector

tank

system

assembly

Checks

......

Procedures

AND

GENERAL

..

.

..

ALLOCATION

OF

END

AND

DURABLE

AND

SPECIAL

LIST

(front

cover

CHART

ITEM

AND

SUPPLIES

TOOLS

OF

ILLUSTRATIONS

components

view)

detail

cms

ancas»

with

chip

blower

rs

assembly

and

Services

SUPPORT

BASIC

Title

(inner

valve

...

..

ISSUE

AND

LIST

surface)

..

MAINTENANCE

ITEMS

MATERIALS

.....................

LIST

LIST

...

ss

41

.

41

„Aj

.B-1

Page

1-6

Page 5

Table

No.

LIST

OF

Title

TABLES

TM

8-6520-002-24&P

1-1

1-2

1-3

14

31

32

33

3-4

35

3-6

3-7

3-8

39

8-10

Nomenclature

Dimensions

Specifications

Miscellaneous

Preventive

Master

Control

Three-way

Foot

Signal

Chip

Three-way

Needle

Air

block

control

relay

blower

regulator

cross-reference

...........

characteristics

maintenance

troubleshooting . ..............................

blocks

microvalve

valve

valve

valve

toggle

valve

troubleshooting

troubleshooting . 2...

list

.........

.

checks

troubleshooting

troubleshooting

troubleshooting

troubleshooting

(tWo-way

valve

microvalve)

troubleshooting

............................

and

services

................

............

..............

..............

troubleshooting

........................

0.

ee

πο

ee

ee

eee

Page 6

TM

8-6520-002-24&P

O

This

manual

functions,

operate,

manual

Lİ

The

manual

appendixes, a glossary,

to

index

O

Multiple

Words

help

locate

will

that

ponents

provides

and

test,

and

before

is

the

help

figures

are

or

words

characteristics

operating

arranged

locate

HOW

all

repair

chapter

more

and

tables

both

capitalized

that

you

TO

USE

the

information

of

the

item.

or

beginning a maintenance

by

chapters,

an

index,

or

section

specific

are

will

actually

THIS

this

equipment.

You

must

sections,

and

DA

Forms

for

subjects.

provided

and

in

see

needed

the

quotation

MANUAL

to

understand

It

familiarize

and

2028-2.

general

for

on

your

the

ease

marks

equipment.

describes

yourself

task.

paragraphs

Use

the

subject

in

area

using

are

the

capabilities,

how

table.of

to

with

the

followed

set

contents

needed.

this

manual.

names

of

up,

entire

by

The

com-

[]

Chapter 3 provides a systematic

ment.

problem

the

detected

Specific

O

cluded.

location

for

measurement,

In this

causing

checks

quickly.

direct

Only

chart

higher

way,

services

and

support

perform

for

levels

and

small

the

unit

maintenance

your

maintenance

of

diagnostic

defects

in

and

level

can

to

fail

same

the

general

of

equipment;

method

be

to

complete

order

of

inspecting

detected

its

each

support

functions

maintenance.

frequently

tools.

or

and

early

time

maintenance

specified

before

mission.

and

Make a habit

anything

in

Maintenance

require

additional

servicing

they

become a major

the

wrong

instructions

maintenance

the

functions

training;

equip-

of

doing

be

will

in-

are

al-

specified

test,

Page 7

TM

8-6520-002-24&P

1-1.

Scope.

This

manual

stallation

information

a.

Type

special

and

b.

Model

Portable.

c.

Purpose

control

1-2.

Special

systems,

Explanation

or

describes

procedures;

follows:

of

manual.

list).

tools

number

of

equipment.

and

work

unique

abbreviations,

the

and

provides

Unit,

and

equipment

surface.

of

INTRODUCTION

Section

dental

unit;

direct

To

abbreviations

acronyms,

I.

GENERAL

provides

operational

support

provide

(DS),

name.

an

and

CHAPTER

maintenance

and

maintenance

and

general

ADEC

3406

Porta-Cart,

integral

and

terms

system

terms.

used

1

INFORMATION

personnel

support

for

within

with

functions,

Dental

dental

this

services,

(GS)

maintenance

Operating

treatment

manual

eguipment

i

with

are

explained

technical

and

actions.

(including

and

Treatment

operating

in

data

and

Additional

repair

Unit,

accessories,

the

glossary.

in-

|

parts

Field,

1-3.

Maintenance

TB

38-750-2

1-4.

Destruction

AR

40-61

publications

ardous.

1-5.

Administrative

a.

Placement

of

maintenance

factors

be

kept.

b.

Army

ance

with

equipment

c.

Inside

1-6.

Preparation

Refer

to

prescribes

contains

provide

as

determined

equipment

the

preventive

is

removed

storage

chapter

forms, records,

of

instructions

periodic

of

the

dental

effort

exists.

by the

placed

maintenance

from

is

preferred

for

3,

section

forms,

Army

for

destruction and

information

storage.

unit

in

Items

should

directing

in

administrative

storage,

for

storage

VIII

for

the

records,

reports,

materiel

and/or

administrative

be

authority.

checks

PMCS

equipment

or

procedures

and

and

to

disposal

instructions

in

mission

During

storage

and

will

be

performed

selected

shipment.

used

reports.

procedures.

prevent

of

Army

on

storage

services

should

readiness

the

storage

will

have

(PMCS)

to

for

administrative

to

prepare

enemy

medical

the

disposal

be

for

condition

period,

preventive

listed

ensure

operational

the

dental

use.

materiel.

of

medical

short

periods

within

24

appropriate

maintenance

in

table

readiness.

storage.

unit

for

storage

Also,

the

SB

materiel

of

time

when a shortage)

hours

or

maintenance

performed

3-1

before

or

shipment.

8-75

series

that

are

haz-

within

the

records

in

accord-

storage.

|

time

will

When

|

1-7.

Quality

TB

740-10/DLAM

assurance

4155.5/AFR

67-43

or

quality

contains

control

QA

or

QC

(QA

or

requirements

QC).

and

procedures.

Page 8

TM

8-6520-002-24&P

1-8.

Nomenclature

Table

1-1

identifies

Common

ASE

AVS

AVS

Dental

1-9.

Reporting

Packing,

improvement

AR

40-61

prescribes

reports

for

the

dental

cross-reference

official

versus

name

handpiece

waste

container

unit

preformed

and

processing

reports.

procedures

unit.

commonly

Table

for

submitting

used

1-1.

Nomenclature

medical

medical

list.

nomenclatures.

cross-reference

Official

Automatic

Air

vacuum

Air

vacuum

Dental

ADEC

O-ring

materiel

materiel

complaints

list.

nomenclature

saliva

ejector

system

handpiece

system

waste

operating

model

3406

and

treatment

porta-cart

complaints

and/or

container

unit, field,

and/or

quality

improvement

—

portable,

quality

1-10.

Awarranty

1-11.

and

1-12.

The

trol

syringe

design

1-13.

The

dimensions,

Warranty

Equipment

a.

The

dental

vacuum

b.

The

unit

Description

dental

block

assemblies.

master

The

a.

flow

which

control

The

b.

Tabulated

tabulated

Dimensions,

a.

information.

is

not

applicable.

Section

characteristics,

unit

is a compact,

to

provide

can use

unit

contains a dual

controls.

permits

block

The

services

block

dental

bottled

assembly

assemblies

data.

provides

data

specifications,

specifications,

II.

EQUIPMENT

portable,

hygiene

gases

of

significant

handpiece

working

without

the

and

and

(nitrogen

contains

components

disconnecting

are

dimensions,

and

miscellaneous

DESCRIPTION

capabilities,

and

self-contained

dental

treatment

or

carbon

components.

control

used

characteristics.

system

coolant

air

the

accessible

are

the

control

to

specifications,

characteristics.

the

unit

that

services.

dioxide)

consisting

flow

tubing.

route

Tables

in

control,

from

water

of

miscellaneous

and

1-2

AND

and

features.

uses

compressed

lieu

of

compressed

of a master

water

the

of

front

the

coolant

air

and

through

block

coolant

the

data

1-4

DATA

air,

air.

assembly

control

and

unit

the

to

the

for

provide

pressurized

and

two con-

valve,

"cartridge"

of

are

handpieces.

dental

unit.

dental

broad

a

water,

and

range

the

of

Table

1-2.

Dimensions.

22

0

1

1/2

in

in

(50.8

1/2

in

(57.2

cm)

cm)

(29.2

cm)

Page 9

TM

8-6520-002-24&P

Table

1-2,

Dimensions - continued.

Unit

Length..

Width

Height.

Tray

Air

Funnel...

Oral

Length..

Width

supply

tube

evacuator

tip

Table

Table

1-3.

1-4.

Miscellaneous

Specifications.

characteristics,

он

3

1/4

in

od

7116

in

od

by

6in

b.

Identification,

of

the

case.

1-14.

Model

semblies,

published

1-15.

water

1-16.

The

components

off

handpieces.

Model

differences

Safety,

Observe

а.

may

Ensure

b.

Follow

с.

Control

dental

Air

a.

when

turned

Water

b.

Water

c.

instruction,

Loosen

this

valve

differences.

not

are

subassemblies,

supply

in

bulletins

care,

WARNING,

each

be

hazardous

that

manufacturer's

the

the

to

air

Section

functions.

operated

is

unit

described

coolant

fully

coolant

coolant

in

control.

flow

clockwise.

"ON-OFF"

flow

and warning

to

equalize

applicable

components

or

and

and

personnel.

supply

since

subsequent

handling.

CAUTION,

shut

is

instructions

III.

controlling

by

subparagraphs

control

This

toggle.

controls.

This

These

plates,

pressure

this

occur

changes

and

or

off

for

decals,

before

manual

periodically.

NOTE

disconnected

use

the

PRINCIPLES

compressed

through

1-16a

adjusts

knob

used

two

is

control

control

or

opening

covers

to

this

this

in

when

chemical

of

and

air

1-16

flow

the

to

knobs

markings.

the

case.

model.

single

a

Information

manual.

manual.

OF

pressurized

|

shut

The

dental

the

cleaning

OPERATION

illustrated

are

coolant

air

of

the

off

adjust

the

flow

An

air

such

on

use

unit

water.

in

of

flow

relief

valve

However,

engineering

compressed

of

in

not

is

solutions

controls

Unit

1-1.

figure

handpieces.

the

to

coolant

water

water

of

is

located

design

changes

air

use.

lubricants.

and

and

to

coolant

on

the

changes

will

pressurized

and

associated

control

The

handpieces.

the

each

to

in

of

end

as-

be

is

the

Page 10

TM

8-6520-002-24&P

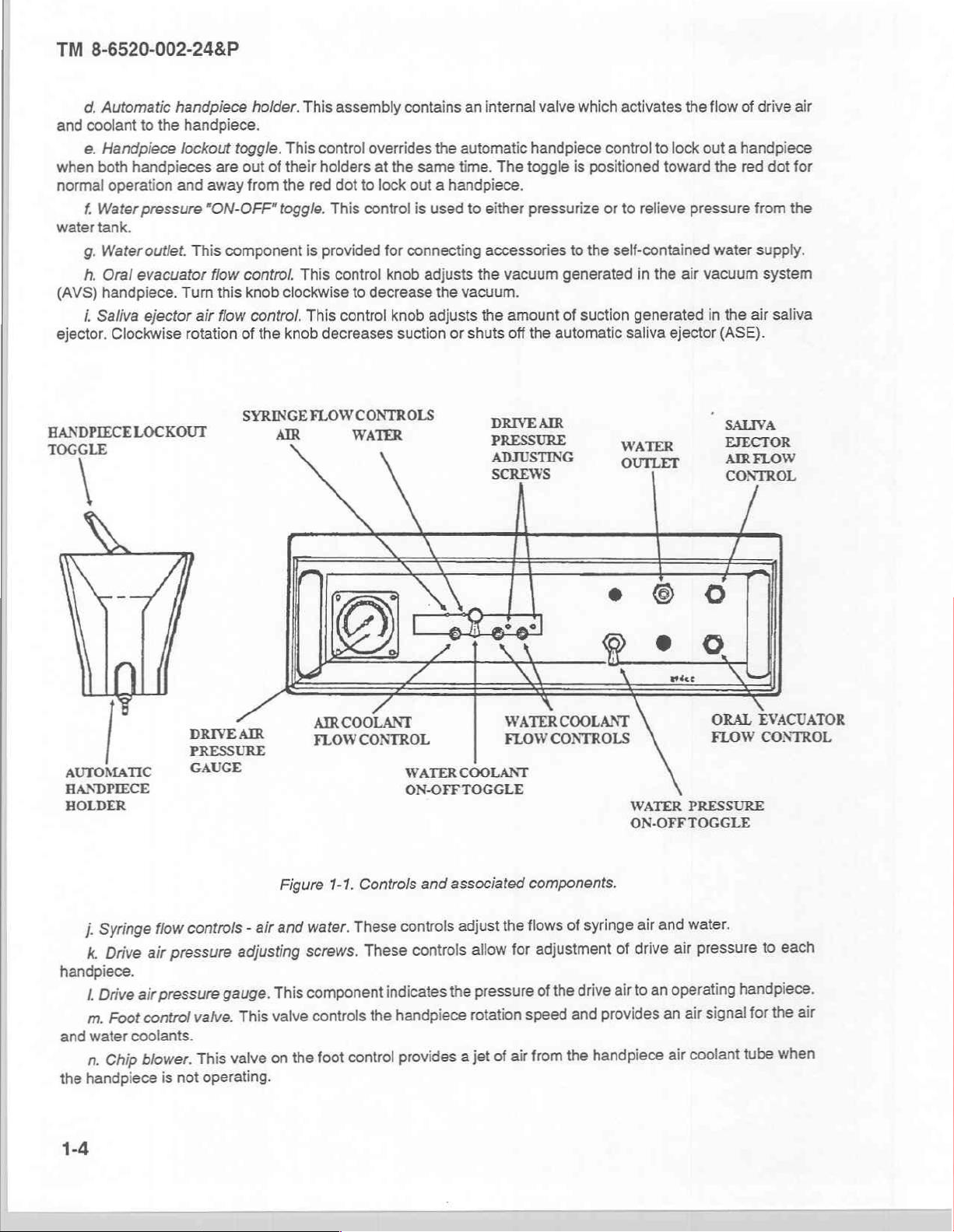

d,

Automatic

and coolant

e.

when

normal

f.

water

g.

h.

(AVS)

i.

ejector.

to

the

Handpiece

both

handpieces

operation and

Water

pressure

tank.

Water

outlet.

Oral

evacuator

handpiece.

Saliva

ejector

Clockwise

handpiece

handpiece.

lockout

Turn

rotation

are

away

"ON-OFF"

This

component

fiow

this

air

flow

toggle.

holder.

This

out

of

their

from

the red

toggle.

control.

knob

clockwise

control.

of

the

knob

This

assembly

control

holders

dot

This

is

provided

This

control

This

control

decreases

overrides

at

the

to

lock

control

for

knob

to

decrease

knob

contains

same

out a handpiece.

is

connecting

suction

an

the

automatic

time.

used

to

adjusts

the

vacuum.

adjusts

or

shuts

internal

either

accessories

the

the

handpiece

The

toggle

pressurize

vacuum

amount

off

the

valve

which

is

to

the

generated

of

suction

automatic

activates

control

positioned

or

to

toward

to

relieve

self-contained

in

the

generated

saliva

the

flow

lock

out a handpiece

the

pressure

water

air

vacuum

in

the

ejector

(ASE).

of

drive

red

dot

from

supply.

system

air

saliva

air

for

the

HANDPIECELOCKOUT

TOGGLE

AIR

DRIVE

PRESSURE

AUTOMATIC

HANDPIECE

HOLDER

GAUGE

SYRINGE

AIR

A

FLOW

CONTROLS

WATER

NN

5

AIRCOOLANT

CONTROL

FLOW

SN

WATER

ON-OFFTOGGLE

DEAR

PRESSURE

ADJUSTING

SCREWS

¿15%

WATER

FLOW

COOLANT

1

Nİ

Sy

CONTROLS

WATER

OUTLET

s

$

\

COOLANT

WATER

ON-OFFTOGGLE

ぁ

る

e

sua

・

SALIVA

EJECTOR

AIR

CONTROL

/

gll

NS

ORAL

FLOW

PRESSURE

FLOW

S

EVACUATOR

CONTROL

Syringe

i.

Drive

k.

handpiece.

air

Drive

I

Foot

m.

and

water

coolants.

Chip

n.

the

handpiece

1-4

controls

flow

pressure

air

pressure

control

blower.

is

not

-

adjusting

gauge.

This

valve.

valve

This

operating.

and

air

This

valve

on the

Figure

water.

screws.

component

controls

foot

1-1.

Controls

These

control

controls

These

indicates

handpiece

the

provides

and

associated

adjust

controls

the

jet

a

flows

the

for

allow

pressure

of

speed

air

rotation

componenits.

syringe

of

air

drive

provides

and

handpiece

of

adjustment

the

of

the

from

and

air

drive

an

to

an

water.

pressure

air

operating

signal

air

coolant

air

each

to

handpiece.

air

the

for

when

tube

Page 11

TM

8-6520-002-24&P

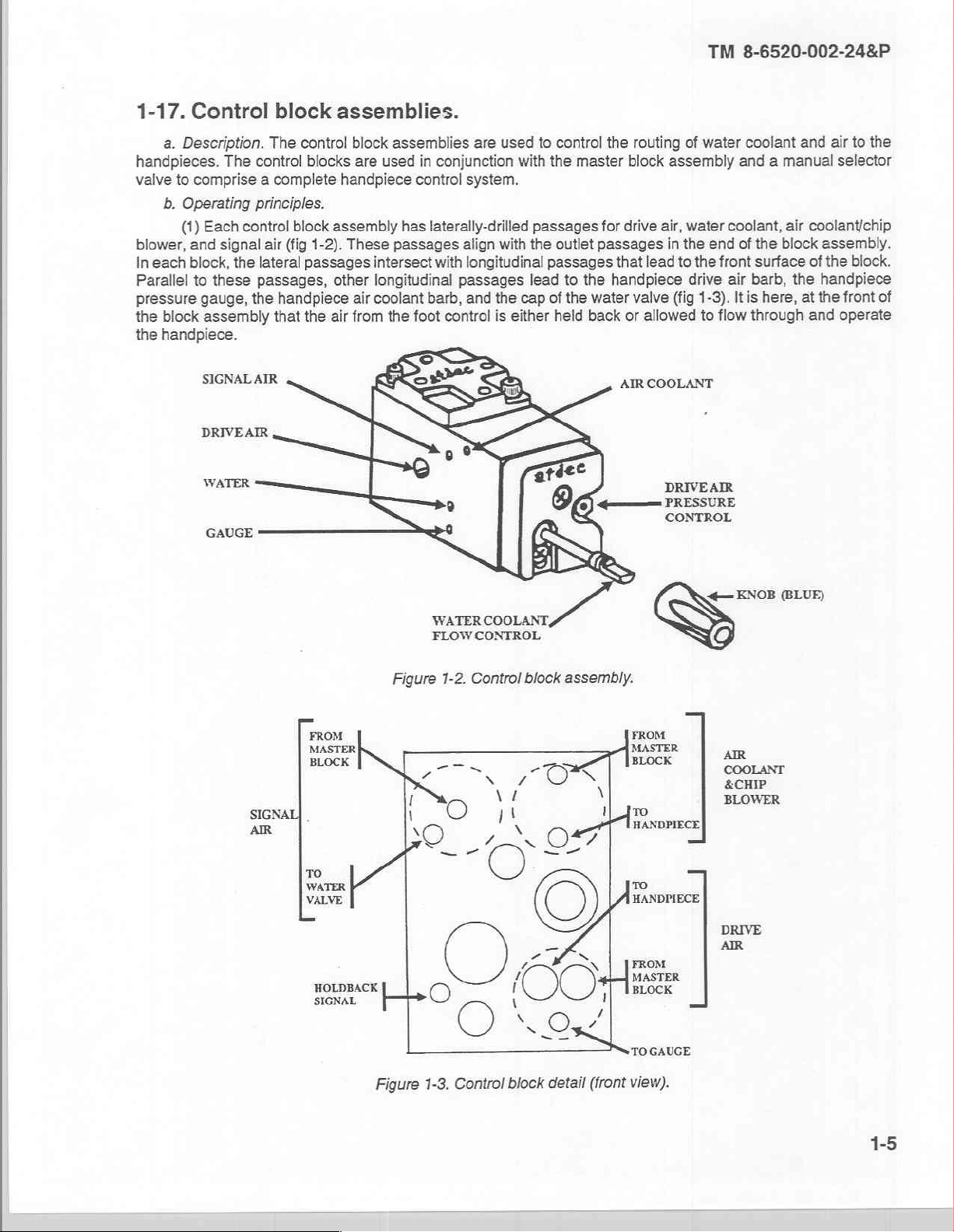

1-17.

handpieces.

valve

blower,

In

Parallel

pressure

the

the

Control

a.

Description.

to

comprise a complete

b.

Operating

(1)

Each

and

each

block,

to

these

gauge,

block

assembly

handpiece.

SIGNABAIR

DRIVEAIR

WATER

GAUGE

block

The

The

control

principles.

control

signal

air

(fig

the

lateral

passages,

the

handpiece

that

assemblies.

control

block

passages

the

blocks

handpiece

assembly

1-2).

These

other

air

block

are

air

from

assemblies

used

in

conjunction

control

has

laterally-drilled

passages

intersect

longitudinal

coolant

the

with

barb,

foot

passages

control

are

used

to

with

system.

passages

align with the

longitudinal

and

the

is

passages

lead

cap

of

either

control

the

master

outlet

to

the

the

water

held

back

the

routing

block

for

drive

passages

that

lead

handpiece

valve

or

allowed

AIR

COOLANT

—

of

water

assembly

air,

water

in

the

end

to

the

front

drive

(fig

1-3).

to

flow

DRIVEAR

PRESSURE

CONTROL

coolant and

and a manual

coolant,

of

air

Itis

air

the

block

surface

barb,

the

here,

through

at

air

to

the

selector

coolant/chip

assembly.

of

the

block.

handpiece

the

front

of

and

operate

FROM

MASTER

BLOCK

WATER

FLOW

Figure

M

I

SIGNAI

AIR

\

x

P

TO

WATER

VALVE

HOLDBACK

SIGNAL

|

>

O

1-2.

—

O

O

COOLANT,

CONTROL

Control

~

Xi

gı

x

O

00;

\

x

block

-

¿O

©

一

一

^

Os

assembly.

№

1

A

Tİ

HANDPIECE

7

x

x

1

/

TO

FROM

MASTER

BLOCK

To

HANDPIECE,

FROM

а

BLOCK

GAUGE

ペー

KNOB

AIR

COOLANT

&CHIP

BLOWER

DRIVE

AIR

(BLUF)

Figure

1-3.

Control

block

detail

(front

view).

1-5

Page 12

TM

8-6520-002-24&P

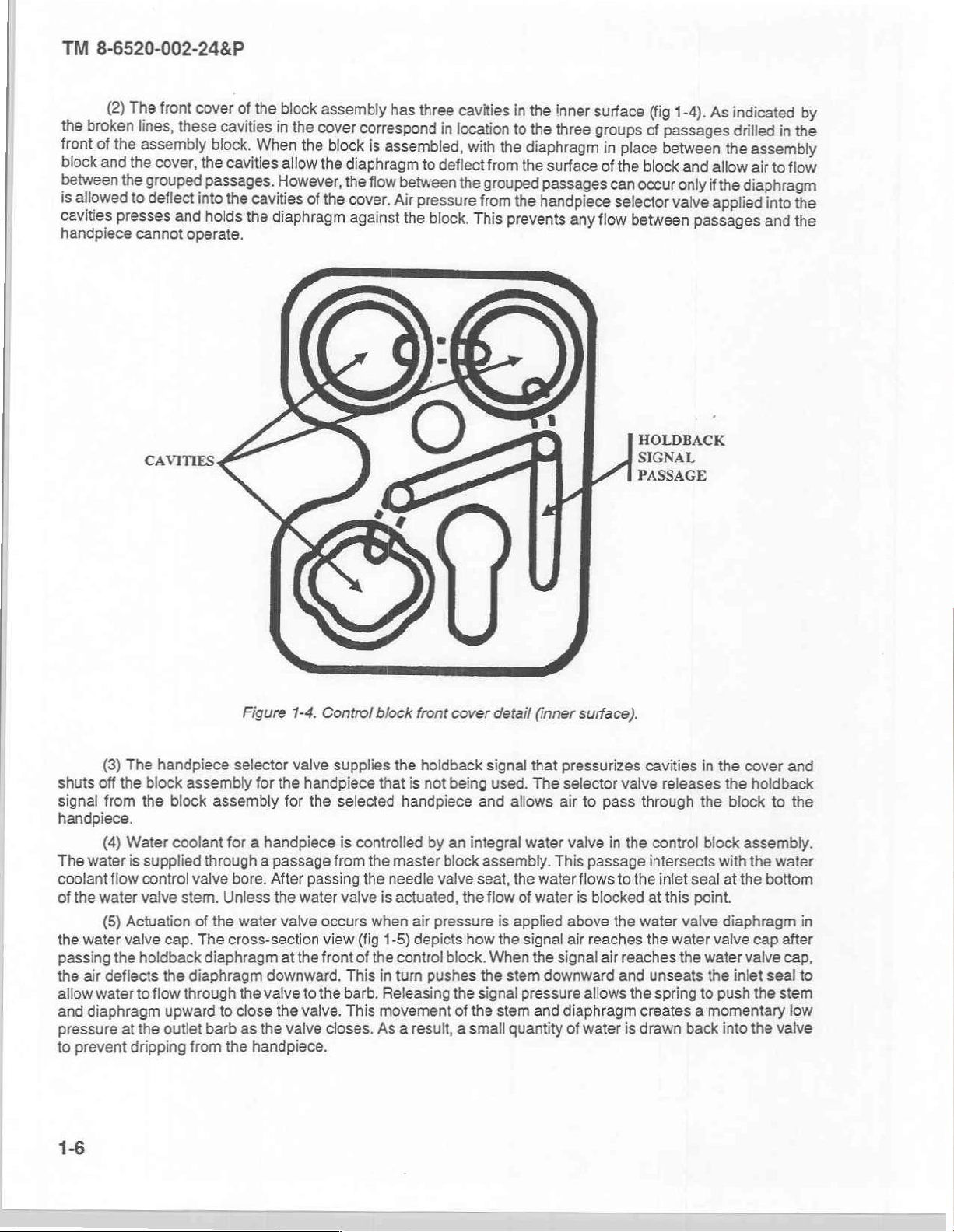

(2)

The

the

broken

front

block

between

is

allowed

cavities

handpiece

of

the

and

the

presses

lines,

assembly

the

cover,

grouped

to

deflect

cannot

front

these

and

operate.

cover

of

cavities

block.

the

cavities

passages.

into

the

holds

the

block

in

the

When

allow

However,

cavities

the

diaphragm

assembly

cover

the

block

the

of

the

has

correspond

is

assembled,

diaphragm

the

flow

between

cover.

Air

against

the

three

cavities

in

location

with

to

deflect

the

pressure

block.

This

in

to

the

from

grouped

from

the

prevents

the

inner

the

three

diaphragm

the

surface

passages

handpiece

any

surface

groups

in

place

of

the

block

can

occur

selector

flow

between

HOLDBACK

SIGNAL

PASSAGE

(fig

1-4).

of

passages

between

and

only

valve

As

indicated

drilled

the

assembly

allow

air

if

the

diaphragm

applied

passages

in

to

flow

into

and

by

the

the

the

(3)

The

handpiece

shuts

off

the

block

signal

from

the

handpiece.

(4)

Water

The

water

is

supplied

coolant

of

the

passing

the

allow

and

pressure

to

flow

the

water

(5)

water

the

air

deflects

water

diaphragm

at

prevent

control

valve

Actuation

valve

cap.

holdback

the

to

flow

upward

the

outlet

dripping

Figure

selector

assembly

block

coolant

through a passage

valve

stem.

of

The

diaphragm

diaphragm

through

barb

from

for

assembly

for a handpiece

bore.

Unless

the

water

cross-section

the

to

close

as the

the

handpiece.

1-4.

Control

valve

the

handpiece

for

the

After

passing

the

water

valve

occurs

view

at

the

front

downward.

valve

to

the

the

valve.

valve

supplies

selected

is

controlled

from

the

the

valve

when

(fig

of

the

This

barb.

This

closes.

block

front

cover

detail

the

holdback

that

is

not

handpiece

by an

master

needle

is

1-5)

in

Releasing

movement

As a result, a small

valve

actuated,

air

pressure

depicts

control

turn

pushes

being

and

integral

block

seat,

the

how

block.

the

the

signal

of

the

signal

used.

assembly.

flow

When

stem

(inner

that

The

allows

water

the

water

of

water

is

applied

the

signal

the

stem

downward

pressure

and

quantity

surface).

pressurizes

selector

air

to

pass

valve

in

This

passage

flows

to

is

blocked

above

air

signal

diaphragm

of

the

reaches

air

allows

water

cavities

valve

through

the

control

intersects

the

at

water

the

reaches

and

unseats

the

spring

creates a momentary

is

drawn

in

releases

the

block

inlet

seal

this

point.

valve

water

valve

the

water

the

to

back

the

the

with

at

diaphragm

push

into

cover

holdback

block

to

assembly.

the

water

the

bottom

cap

valve

inlet

seal

the

stem

the

valve

and

the

in

after

cap,

to

low

Page 13

TM

8-6520-002-24&P

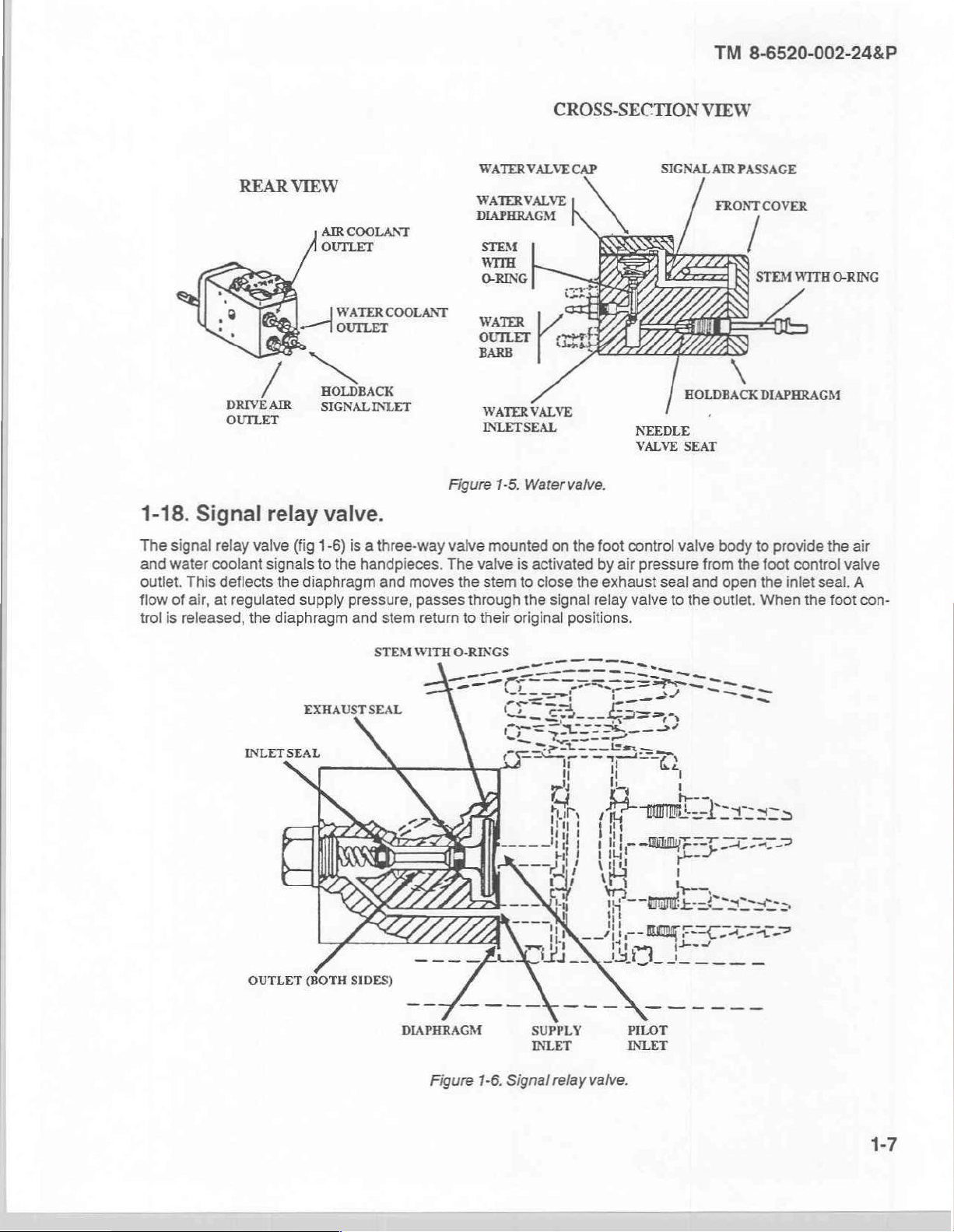

1-18.

The

and water

outlet.

flow

trol

Signal

signal

This

of

air,

is

released,

È

DRIVE

OUTLET

relay

valve

coolant

deflects

at

regulated

the

AIR

relay

(fig

1-6)

signals

to

the

diaphragm

supply

diaphragm

AIR

COOLANT

OUTLET

he

COOLANT

HOLDBACK

SIGNALINLET

valve.

is a three-way

the

handpieces.

and

pressure,

and

stem

moves

passes

return

WATER

‘WATER

DIAPHRAGM

STEM

WITH

O-RING

У,

OUTLET

BARB

‘WATER

INLET

Figure

valve

mounted

The

valve

the

stem

through

to

their

VALVE

VALVE

VALVE

SEAL

1-5.

Watervalve.

is

activated

to

close

the

original

CROSS-SECTION

CAP

SIGNAL

NEEDLE

VALVE

on the foot

the

signal

positions.

control

by

air

exhaust

relay

pressure

seal

valve

VIEW

HOLDBACK

SEAT

valve

from

and

to

the

AIR

PASSAGE

FRONTCOVER

STEM

\

DIAPHRAGM

body

to

the

foot

open

the

outlet.

When

WITH

provide

control

inlet

seal.

the foot

O-RING

the

air

valve

A

con-

INLETSEAL

EXHAUST

STEM WITH

SEAL

DIAPHRAGM

O-RINGS

Figure

1-6.

SUPPLY

INLET

Signal

relay

PILOT

INLET

valve.

Page 14

TM

8-6520-002-24&P

2-1.

Initial

Detailed

procedures

paragraph

a.

Start-up

(1)

(2)

(3)

(4)

(6)

(6)

(7)

(8)

(8)

(10)

amount

flow

of

control

(11)

OPERATING

Section

procedures.

for

unpacking,

3-7.

Procedures

procedures.

Ensure

Depress

Remove

Replace

Install a sterilized

Connect

Turn

Check

Check

suction

Only

the

Check

knob.

Check

that the

sterilize

the

the

generated

the

vent

the

water

the

water

the

air

water

air

water

AVS

the

saliva

the

water

the

supply

pressure

pressure

pressure

for

shutdown

pressure

button

tank

cap and

tank

cap

syringe

two

tips

tubing

gauge

evacuator

oral

the

by

ejector

CHAPTER

|.

OPERATING

assembling,

are

"ON-OFF"

on

the

water

using a funnel,

and

ensure

tip,

an

oral

and

mouthpiece

to a supply

"ON-OFF"

for a reading

gauge

for a reading

by

handpiece

AVS

turning

by

INSTRUCTIONS

and

preparing

provided

toggle

tank

cap

that the

evacuator

NOTE

of

dry,

toggle

to

of

pressing

can

saliva

the

in

paragraph

is

turned

(fig

E-14)

fill

the

vent

tip,

and a saliva

when

patient

filtered

the

"ON"

60

to

80

of

30

AVS

the

increased

be

ejector

2

PROCEDURES

the

dental

unit

2-1c.

"OFF."

to

tank.

button

treatment

air

or

position.

psi.

to

40

psi.

handpiece

flow

air

ensure

or

that

is

not

in

ejector

bottled

button

decreased

control

for

operation

the

tank

the

locked

mouthpiece.

is

involved.

gas

regulated

to

by

vary

to

are

has

position.

from

actuate

turning

amount

the

provided

no

air

80

vacuum.

the

oral

the

of

in

pressure.

to

100

psi.

The

evacuator

suction.

Procedures

b.

technician

с.

Shutdown

Turn

(1)

Insert

(2)

panel.

Turn

(3)

turn

the

toggle

Remove

(4)

Clean

(5)

Empty

(6)

The

or

dentist

Use

of

8

the

the

to

ASE

control

during

during

procedures.

shutdown

the

shuts

patient

patient

hours.

pressure

water

quick-disconnect

the

pressure

water

the

"OFF"

position.

quick-disconnect

the

handpiece

AVS

the

waste

AVS

the

off

the

treatment.

treatment.

procedures

to

toggle

fitting

to

toggle

fitting

ASE

and

container,

suction

when

The

the

when

various

the

"OFF"

(contained

"ON"

the

and

following

by

clean

then

NOTE

turned

functions

NOTE

dental

position.

the

in

position

back

it

put

the

disinfect

and

fully

shut

is

unit

accessory

and

the

in

cleaning

clockwise.

dental

the

of

down

kit)

the

allow

accessory

procedures

it.

unit

any

for

into

water

kit,

will

period

water

the

tank

paragraph

in

controlled

be

excess

in

outlet

completely

to

on

2-2.

dental

a

by

control

the

drain;

then

Page 15

TM

8-6520-002-24&P

(7)

Clean

(8)

Ensure

the

unit

by

depressing

(9)

Clean

and

that

the

external

lubricate

the

the

the

external

syringe

surfaces.

handpieces

air

supply

air

button.

by

following

is

turned

the

off.

Disconnect

lubrication

procedures

the

tube and

in

paragraph

bleed

the

3-8.

air

pressure

from

2-2.

Cleaning,

a.

Cleaning.

(1)

External

detergent.

Abrasive

never

(2)

internal

should

detergent

should

be

thoroughly

solution.

be

flushed

The

a

hot

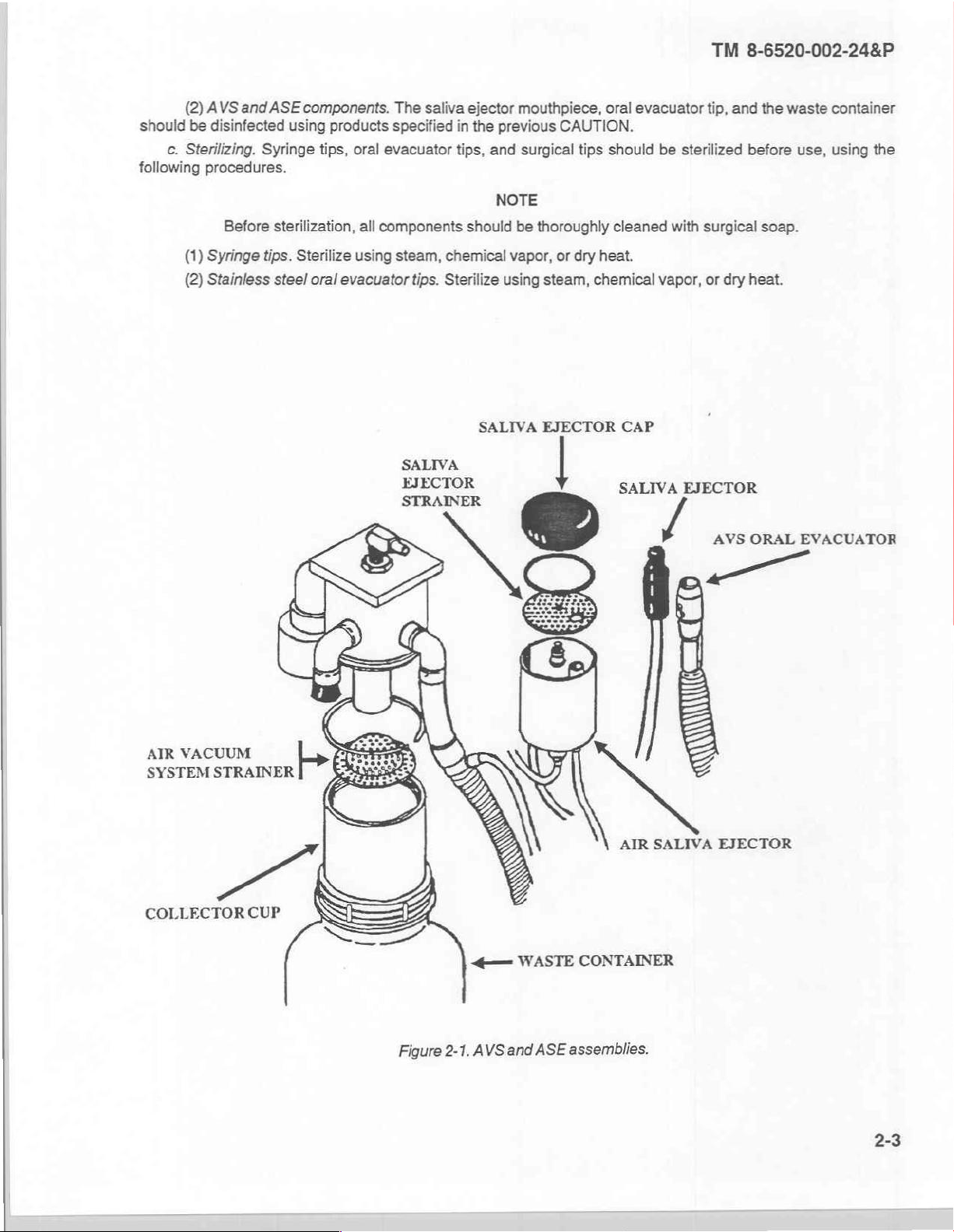

(3)

Air

vacuum

(a)

After

air

through

clean

the

it

with a hot

(b)

system

Daily.

manufacturer's

order

to

clean

the

water

has

been

(c)

Weekly.

removing

strainer,

between

any

debris.

(d)

As required.

(4)

Automatic

(8)

After

(b)

Weekly.

and

removing

b.

Disinfecting.

External

(1)

patients.

disinfecting,

surfaces.

cleansers

be

used.

assemblies

cleaned

Any

wiping

with

clear,

lubricant

detergent

each

detergent

instruction.

lower

purged

each

used

solution

system. The

patient.

for a few

solution.

Clean

the

In

portion.

from

Clean

The

saliva

ejector.

patient.

Clean

any

debris.

surfaces.

Section

All

external

and

scrubbing

and

components.

and

inspected

should

hot

water

in

the

dental

is

AVS

Rinse

seconds

AVS

handpiece

addition,

Then,

the

tubing.

the

strainer

waste

container

The

Remove

the

strainer

external

All

Il.

and

surfaces

be

done

and

then

unitis

the

most

system

the

AVS

to

remove

use

the

rinse

by

ASE

the

by

surfaces

OPERATIONAL

sterilizing

should

CAUTION

pads

will

damage

When

servicing

for

defects

with a soft,

rinsed

largely

effective

(fig

by

using a cleaner

brush

with

removing

should

system

ASE

removing

prior

lint-free

in

isopropyl

NOTE

impervious

cleaner.

2-1)

should

drawing

all

clean

water

provided

clean

water.

the

waste

be

cleaned

should

mouthpiece

the

ASE

dental

the

of

CARE

procedures.

be

cleaned

the

surface

the

dental

to

reassembly.

cloth.

alcohol.

to

chemical

be

cleaned

water

through

from

the

tubes.

with

disinfectant

in

the

accessory

Finally,

be

cleaned

and

cap,

hold

container,

each

as

clean

unscrewing

should

unit

with a solution

finishes

unit,

the

components

The

most

When

the

components

solvents.

as

follows:

the

handpiece

Remove

the

properties

kit

to

insert

the

control

unscrewing

time

it

is

emptied.

follows:

with a hot

be

detergent

the

knurled

carefully

of

hot

water

and

should

of

effective

cleaner

Therefore,

and

oral

evacuator

by

into

the

button

down

the

collector

solution.

screw

with

wiped

and

any

assembly

is a hot

are

clean,

then

drawing

tip

following

handpiece

until

all

cup,

holding

disinfectant

liquid

they

and

the

in

the

and

the

Disinfectants

part

one

phenolics

that

Clorox®

such

will

or

as

Lysol®;

not

damage

Purex©

and

CAUTION

the

surface

parts

ten

to

isopropyl

finishes

water;

of

alcohol.

include--

hypochlorite

gluteraldehyde

solution

solution;

Cydex®,

of

Page 16

(2)

should

following

be

c.

Sterilizing.

(1)

(2)

AVS

and

ASE

disinfected

Syringe

procedures.

Before

Syringe

Stainless

sterilization,

tips.

steel

components.

using

products

tips,

Sterilize

oral

evacuator

The

specified

oral

evacuator

all

components

using

steam,

saliva

chemical

tips.

Sterilize

ejector

in

the

tips,

and

should

mouthpiece,

previous

surgical

NOTE

be

thoroughly

vapor,

using

steam,

oral

CAUTION.

tips

should

or

dry

heat.

chemical

evacuator

be

cleaned

vapor,

TM

tip,

and

sterilized

with

surgical

or

dry

8-6520-002-24&P

the

waste

container

before

heat.

soap.

use,

using

the

AIR

VACUUM

SYSTEM

STRAINER

SALIVA

EJECTOR

EJECTOR

©

CAP

SALIVA

/

EJECTOR

AVS

ORAL

AIR

SALIVA

EJECTOR

EVACUATOR

COLLECTOR

CUP

Figure

==

2-1.

AVS

WASTE

and

ASE

assemblies.

CONTAINER

Page 17

TM

8-6520-002-24&P

2-3.

Operation

The

dental

Stool

Unit,

2-4.

Operation

Operation

quent

intervals

Section

unit

is

used

Dental

Operating;

Section

of

the

dental

of

PMCS.

Ill.

of

auxiliary

with

the

following

and

IV.

OPERATION

under

unit

under

OPERATION

equipment.

items

Compressor,

unusual

unusual

conditions.

conditions,

OF

of

equipment:

Dental

Operating.

UNDER

such

AUXILIARY

Light

Set,

Dental

UNUSUAL

as

in

dusty

environments,

EQUIPMENT.

Operating,

Field;

CONDITIONS

may

require

Chair

more

and

fre-

2-4

Page 18

TM

8-6520-002-24&P

3-1.

Overview.

Maintenance

unit

level

medical

quired

for

cabinet,

3-2.

Common

111

items.

3-3.

Components

and

Tools

tools

of

this

manual.

Components

functions,

the

dental

case.

and

and

of

end

both

equipment

unit

except

This

chapter

test

test

equipment

Refer

to

your

of

item

and

UNIT

Section

preventive

repairer

LEVEL

and

personnel.

for

some

provides

I.

tasks

instructions

equipment.

required

unit's

modified

end

item

basic

issue

items

CHAPTER

MAINTENANCE

GENERAL

corrective,

involving

for

maintenance

table

and

are

that

These

personnel

the

and

information

of

organization

basic issue

listed

in

3

INFORMATION

are

beyond

master

of

the

appendix

will

perform

block

to

dental

and

items.

C,

the

scope

assembly,

aid

in

unit

equipment

sections

of

the

user

the

majority

control

performing

are

listed

in

(MTOE)

II

and

III

are

assigned

of

maintenance

block

the

required

appendix

for

authorized

of

this

manual.

to

re-

assemblies,

tasks.

B,

section

3-4.

Expendable

Expendable

dix

D,

section

3-5.

Repair

Repair

3-6.

Special

3-7.

The

crepancies

case

parts

Special

tools

Inspecting

dental

a.

Unpacking

(1)

Remove

(2)

Loosen

Unlatch

(3)

Lift

(4)

aside.

Open

(5)

and

durable

II

of

this

parts.

reguired

tools.

reguired

Section

will

unit

be

must

the

the

unit

the

the

supplies.

supplies

manual.

for

unit

for

maintenance

and

unpacked,

be

reported

unit.

the

shipping

air

relief

case,

the

from

accessory

and

level

maintenance

II.

SERVICE

servicing

inspected,

accordance

in

container

valve

which

case,

and

kit

the

Also

remove

the

materials

of

the

dental

UPON

the

and

with

if

not

previously

is

located

remove

and

lid,

remove

remove

the

reguired

are

listed

unit

are

RECEIPT

unit.

serviced

instructions

the

on

the

the

waste

the

inch

3/4

for

maintenance

in

appendix

listed

described

as

given

removed.

end

of

protective

container,

open-end

E,

in

appendix

OF

in

in

the

case.

foam

accessory

wrench.

of

the

dental

section

II

E,

section

EQUIPMENT

following

the

40-61.

AR

pad.

kit,

unit

are

of

this

manual.

III

of

subparagraphs.

post

and

listed

in

appen-

this

manual.

assembly.

Dis-

Set

the

3-1

Page 19

TM

8-6520-002-24&P

(6)

Remove

(7)

Fasten

time.

same

foot

(8)

Stand

(9)

Install

(10)

Remove

the foot

the

unit.

performing

procedures.

control

(11)

Set

(12)

Lift

(13)

Loosen

(14)

Locate

(15)

Uncoil

ASE

tip

and

(16)

Feed

(17)

Install

(18)

Screw

(19)

Connect

(20)

Secure

b.

Inspecting

(1)

Perform a visual

(2)

Check

(3)

Perform a thorough

the

(4)

Report

©.

Servicing

For

maximum

pads

the

the

tubing

the

off

the

the

the

initial

the

the

the

Remove

holes,

dental

the top

the

and

the

AVS

the

the

the

the

damage

cap

screw

post

assembly

unit

the

and

secure

into

the

frame

base

unit

on

the

the foot

handpiece

handpieces

the

unit.

unit

procedures

unit.

control

from

inside

unit

upright.

of

the

thumbscrews

install

the

AVS

handpiece

handpiece

AVS

waste

10-foot

accessory

inspection

frame

and/or

that

secures

to

the

mobility,

foot

accessory

upright.

post

unit.

hanger

tubings

container

air

by

inspection

in

the

pads

the

by

tightening

secured

the

unit.

that

and

in

their

and

from

the

supply

kit

and

to

detect any

adjusting

paragraph

discrepancies

the

frame

frame

base

casters

using a 5/32

casters

kit.

secure

bar

case.

for

with

the

on

the

underside

the

assemblies

ASE

tubings and

hangers.

syringe

accessory

onto

tubing

it

to

leaks

2-1.

out

the

to

damage

several

in

base

to

using

the

cap

NOTE

from

the

accessory

inch

hex

wrench,

the

cap

screws

thumbscrews.

of

the

instrument

to

through

kit

onto

bottom

the

quick-disconnect

different

after

components

NOTE

hanger

the

outside

feed

the

their

of

the

which

checking

the

underside

screw

from

unit

with

bar

of

them

out

bottom

tubings.

AVS

assembly.

may

have

heights.

the

control

or

operation

of

and

wrench.

kit

may

be

insert

the

the

foot

an

elastic

assemblies

the

unit.

through

of

the

unit.

on

the

occurred

functions

in

the

unit

using

installed

casters

pads.

Place

cord.

upside

the

bottom

Place

them

short

supply

to

the

in

accordance

the

wrench.

at

this

into

the

the

Carefully

down

in

of

the

in

their

tubing

dental

paragraph

unit.

with

established

draw

the

unit.

unit.

Place

hangers.

under

1-16

and

out

the

Additional

(1)

Syringe.

(a)

(b)

(c)

(2)

Drive

PMCS

A

syringe

table

Change

Pull

the

Insert a replacement

syringe

air

pressure.

servicing

(para

the

syringe

tip

out

tip

that

when

the

instructions

3-9)

or

the

maintenance

tip

by

loosening

with a straight

tip

is

not

air

button

by

pushing

fully

seated

is

motion.

depressed.

and

procedures

the

it

completely

CAUTION

may

may

instructions

nut

approximately

into

cause

the

water

be

incorporated

(para

3-13

1/2

the

syringe

button

through

turn.

seat

to

be

into

either

para

and

tighten

ejected

the

3-23).

the

from

the

nut.

Page 20

at

the

To

preclude

handpiece

The

drive

the

faceplate

(a)

Install a dental

(b)

Operate

The

handpiece

tool

is

completed

(c)

With

maximum

pressure

Turn

counterclockwise

damage

manufacturer.

air

pressure

of

the

handpiece

actually

in

several

the

foot

control

specified

the

drive

to

the

adjusting

the

unit

(fig

tool

in

the

and

should

not

performing

steps

fully

by the

air

pressure

to

increase

unit,

adjust

screws

1-1).

handpiece

observe

be

operated

its

function.

to

prevent

depressed,

manufacturer.

adjusting

pressure.

CAUTION

the

drive

NOTE

are

located

chuck.

the

drive

CAUTION

more

than a few

The

damage

adjust

NOTE

screws

air

air

pressure

drive

to

the

the

drive

clockwise

pressure

next

to

gauge.

seconds

air

pressure

handpiece.

air

adjusting

to

the

the

water

ata

time

adjustment

to

decrease

TM

8-6520-002-24&P

specifications

coolant

unless a dental

screws

of

knobs

should

until

the

pressure

the

on

be

handpiece

or

runs

(3)

Handpiece

(a)

handpiece.

(b)

(c)

(d)

(e)

visible

to

spray

around

(f)

(4)

Syringe

(a)

(b)

increase

(c)

pattern.

Ensure

Operate

Adjust

A

Adjust

The

faceplate

flow.

the

strong

Turn

the

Operate

the

dental

the

flow.

syringe

Depress

Adjust

the

Depress

coolant

that the

the

handpiece

air

coolant

air

coolant

water

coolant

the

handpiece

tool.

second

flow

of

the

unit

the

water

water

both

buttons

flow.

water

coolant

at

medium

flow

flow

is

flow

and

handpiece

adjusting

button.

flow

(fig

1-1).

by

(air

screws

turning

toggle

as

desired.

recommended.

control

turn

by

and

water)

is

speed

NOTE

clockwise

the

water

following

NOTE

are

located

the

adjusting

simultaneously

in

the

while

until

coolant

the

preceding

above

screw

"OFF"

position

observing

it

seats

flow

control

steps.

the

air

clockwise

and

and a dental

the

preceding

softly.

counterclockwise

coolant

adjust

flow

to

decrease

the

air

tool

CAUTION

control

flow

flow

to

is

installed

.

until a fine

on

the

or

counterclockwise

achieve

the

in

mist

desired

the

is

The

syringe

water.

flow

Forcing

adjusting

the

screws

screws

to

turn

CAUTION

are

not

intended

off

the

water

or

to

completely

air

will

damage

stop

the

the

unit.

flow

of

air

and

Page 21

TM

8-6520-002-24&P

3-8.

General.

All

lubrication

internal

tings

to

should

o-rings.

the

moving

also

Section

The

unit.

3-9.

General.

a.

The

dental

at

all

times.

failure.

b.

are

things

observing

c.

each

area

on

Operation, A -

unit.

Inspection

Table

3-1

Preventive

you

for

The

following

column:

(1)

Item

the

Equipment

(2)

Interval.

Section

requirements

parts

of

mechanical

be

coated

should

bores

Seal

IV.

PREVENTIVE

PMCS

should

improper

No.

After

chart

unit

must

will

contains a list

maintenance

do

operational

is a list

This

column

Inspection

This

column

Operation, M -

for

the

before

in

this

be

inspected

allow

defects

of

is

any

time

of

the

shows

shows

III.

LUBRICATION

dental

unit

valves

they

are

lightly

be

also

section

and

to

be

PMCS

not

and

items

limited

you

see

indicators,

PMCS

Monthly, Q -

table

the

sequence

Maintenance

when

can

be

performed

and

controls

installed.

lubricated

should

This

makes

before

MAINTENANCE

NOTE

contains

serviced

discovered

to

performing

they

and

each

all

necessary

systematically

and

to

be

performed

the

need

to

maintaining

column

Quarterly.

headings

in

which

Worksheet,

PMCS

item

be

to

B, D,

INSTRUCTIONS

using

a

high

be

coated

their

inserting

with

installation

stems

CHECKS

unit

level

services

to

ensure

corrected

by

checks

done,

the

do

the

DA

is

to

and A should

before

unit

level

maintenance

and

services

such

as

proper

with a description

be

quantities

PMCS,

Form

and

2404.

serviced; B -

quality

a

light

easier

or

silicone

film

pistons.

AND

for

that the

they

result

listed

checking

of

of

is

used

Before

be

performed

base

of

silicone

and

prevents

SERVICES

the

dental

unit

is

ready

in

serious

personnel.

in

the

PMCS

for

general

operating

the

information

to

identify the

Operation, D -

with

grease.

grease.

damage

for

operation

damage

table.

There

cleanliness,

supplies.

found

equipment

During

daily

use

All

of

O-

or

in

the

When

the

items

that

when

the

(3)

Item

to

be

Inspected

checked

or

ITEM

NO

or

serviced.

(4)

Equipment

unusable.

BIDIA

1

x

is

INTERVAL

| M |Q

x

equipment

Will

equipment

not

x

must

not

disrupt

can

and

Ready/Available

Table

ACCESSORIES.

are

their

a.

b.

be

kept

operation.

be

shut

Procedure.

If..

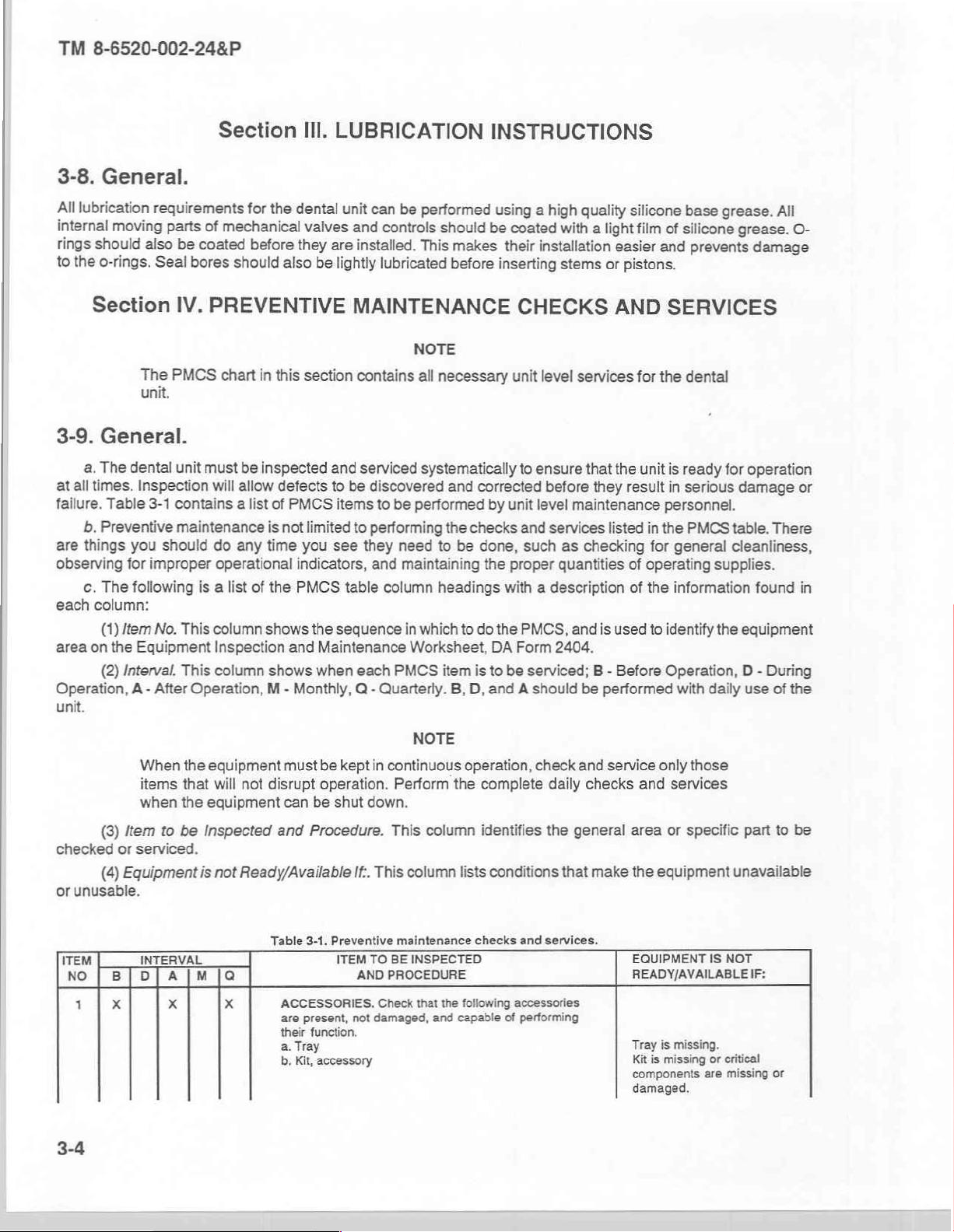

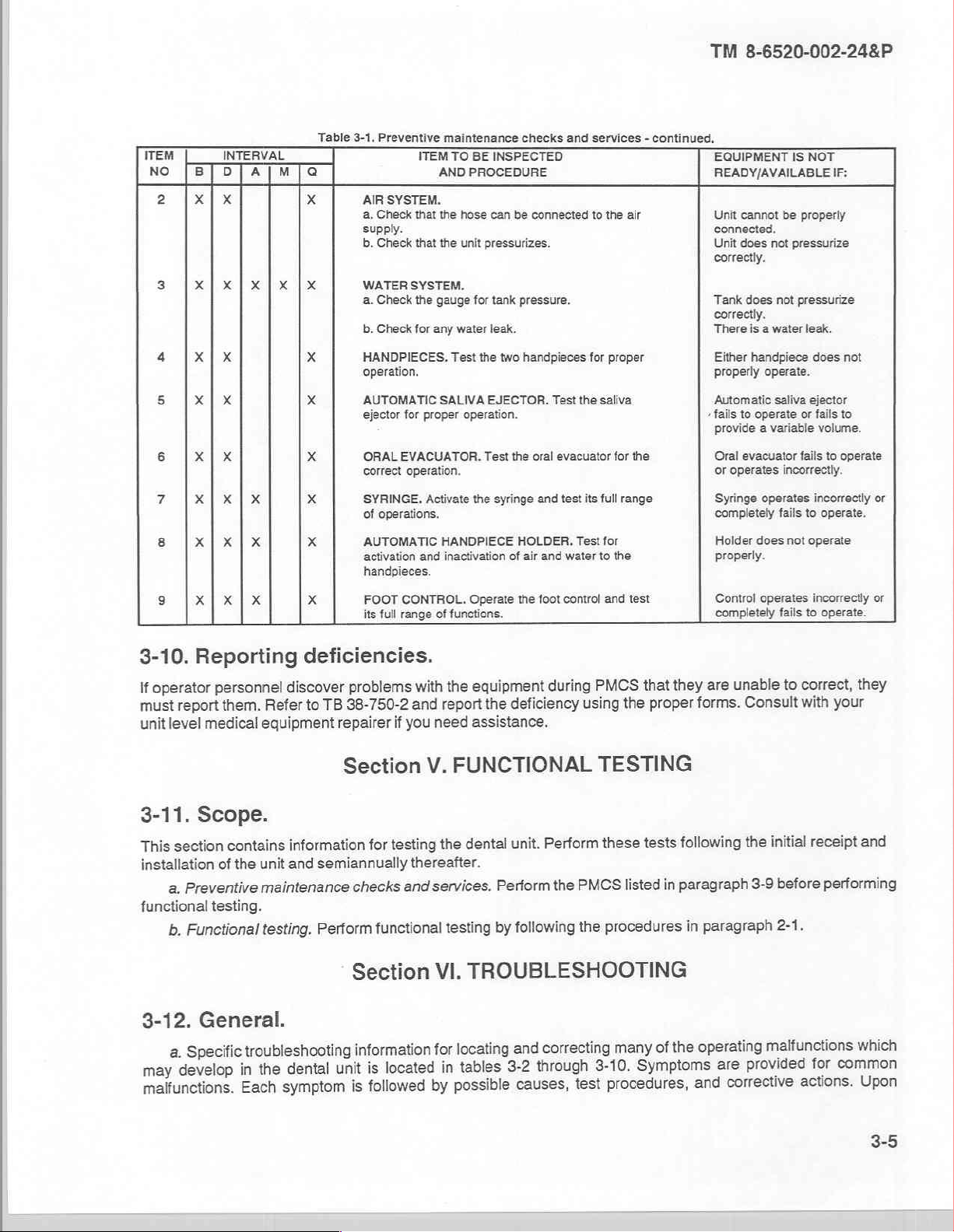

3-1.

Preventive

ITEM

AND

present,

not

function.

Tray

Kit,

accessory

NOTE

in

continuous

Perform

down.

This

This

column

maintenance

TO BE

INSPECTED

PROCEDURE

Check

that

damaged,

operation,

the

column

lists

the

following

and

capable

check

complete

identifies

conditions

checks

and services.

accessories

of

performing

and

daily

the

general

that

service

checks

make

only

those

and

services

area

or

specific

the

equipment

EOUIPMENT

READY/AVAILABLE

IS

-

Tray

is

missing.

Kit

is

missing

components

damaged.

or

are

part

to

be

unavailable

NOT

IF:

critical

missing

or

Page 22

ITEM

no

2

[By]

|x|x

INTERVAL

D]A|M

Table

3-1.

Preventive

AIR

SYSTEM.

a.

Check

supply.

b.

Check

maintenance

ITEM

AND

that

the

that

the

TO

BE

INSPECTED

PROCEDURE

hose

can

be

unit

pressurizes.

checks

and

connected

services - continued.

to

the

air

TM

8-6520-002-24&P

EQUIPMENT

READY/AVAILABLE

Unit

cannot

connected.

Unit

does

correctly.

IS

NOT

IF:

be

properly

not

pressurize

4 X | X

5

X | X

6

X | X

了

X|X|X

3-10.

operator

If

report

must

unit

level

Reporting

personnel

them.

medical

Refer

equipment

deficiencies.

to

TB

problems

38-750-2

repairer

discover

WATER

a.

b.

HANDPIECES.

operation.

AUTOMATIC

ejector

ORAL

correct

SYRINGE.

of

AUTOMATIC

activation

handpieces.

its

SYSTEM.

Check

the

gauge

Check

for

any

water

Test

SALIVA

for

proper

EVACUATOR.

operation.

operations.

FOOT

Activate

and

CONTROL.

full

range

with

and

you

if

HANDPIECE

inactivation

of

functions.

the

report

need

operation.

for

tank

pressure.

leak.

the

two

handpieces

EJECTOR.

Test

the

oral

the

syringe

and

HOLDER.

of

air

and

Operate

the

foot

equipment

the

assistance.

during

deficiency

for

proper

Test

the

saliva

evacuator

test

water

control

its

full

Test

for

to

and

PMCS

using

for

range

the

the

test

that

the

Tank

‘There

+

fails

are

they

forms.

proper

does

not

correctly.

is a water

Either

handpiece

properly operate.

Automatic

to

provide a variable

Oral

evacuator

or

operates

Syringe

completely

Holder

properly.

Control

completely

unable

Consult

pressurize

leak.

does

saliva

operate

operates

does

operates

ejector

or

fails

volume.

fails

incorrectly.

incorrectly

fails

to

not

operate

incorrectly

fails

to

correct,

to

with

to

operate

operate.

operate.

your

not

to

or

or

they

3-11.

This

installation

functional

3-12.

may

maifunctions.

Scope.

section

of

Preventive

a.

testing.

Functional

b.

General.

Specific

a.

develop

contains

the

Section

information

unit

and

semiannually

maintenance

testing.

troubleshooting

the

in

Each

Perform

dental

symptom

unit

V.

testing

for

thereafter.

checks

Section

information

is

and

functional

located

is

followed

FUNCTIONAL

Perform

dental

the

services.

testing

VI.

locating

for

tables

in

possible

by

unit.

Perform

following

by

TROUBLESHOOTING

correcting

and

through

3-2

causes,

the

PMCS

the

test

TESTING

tests

these

in

listed

procedures

of

many

Symptoms

3-10.

procedures,

following

paragraph

paragraph

in

operating

the

are

corrective

and

receipt

initial

the

before

3-9

2-1.

malfunctions

provided

actions.

and

performing

which

common

for

Upon

3-5

Page 23

TM

8-6520-002-24&P

completion

reassembled

b.

This

manual

diagnostic

SYMPTOM

1,

AIR

2.

AIR

procedures,

POSSIBLE

OR

WATER

Defective

LEAKS

Defective

Defective

3.

AIR

LEAKS

Defective

4,

NO

AIR

COOLANT

Obstructed

The

Debris

WATER

NO

5,

No

of

the

corrective

and

the

cannot

CAUSE

TEST

LEAKS

o-ring

Disconnect

bore

for

FROM

THE

exhaust

Isolate

control

o-ring seal

Check

FROM

THE

inlet

seal

Remove

and

the

FROM

air

passage

Refer

air

coolant

Remove

control.

lodged

in

Disassemble

COOLANT

water

supply

Verify

front

action(s),

unit

tested.

list

all

notify

your

PROCEDURE

CORRECTIVE

FROM

AROUND

seal

on

the

stem.

the

air

defects.

Replace

WATER

the

seal

must

COOLANT

in

the

source

be

depressed, A leak

Remove

around

for

leaks

around

Remove

WATER

COOLANT

or

defective

the

valve

bore

in

the

Replace

EITHER

in

the

to

the

instructions

Take

corrective

flow

is

not

getting

coolant

air

the

for

Check

Remove

the

valve.

and

Carefully

EITHER

FROM

to

the

master

is

water

that

the

of

Check

unit.

Remove

the

component

possible

supply,

any defective

valve.

of

the

and

the

the

malfunctions.

appropriate

Table

3-2.

ACTION

THE

SYRINGE

bleed

the

system

parts.

TOGGLE

leak

using a soap

around

disassemble

the

valve.

the

perimeter

valve.

Inspect

TOGGLE

o-ring

seal

around

from

the

master

block

master

block.

any

defective

HANDPIECE

control

in

to

flow

stream

a

obstructions

check

clean

parts.

(WATER

block

next

paragraph

action

as

indicated

the

master

valve

control

coming

air

of

in

the

for

foreign

material

all

passages.

HANDPIECE

block.

try

then

tank,

the

in

obstructions

for

obstructions.

or

If a malfunction

maintenance

Master

block

troubleshooting.

FLOW CONTROLS.

pressure,

VALVE

WHEN

solution.