Page 1

a'dec

"OPERATION

AND

MAINTENANCE

INSTRUCTIONS

-

PORTA-CART

DENTAL

FIELD

FEDERAL

OPERATING

PORTABLE,

NATIONAL

6520-00-140-7663

ITEM

IDENTIFICATION

AND

AIR

STOCK

TREATMENT

NUMBER

3406

UNIT,

OPERATED

Page 2

A-dec

for

one

warranty

have

are

excluded.)

A-dec

resulting

use,

The

by

excessive

warrants

year

from

is

to

no

other

within

the

from

warranty

NO

OTHER

its

products

time

repair,

or

remedy.

Written

warranty

improper

also

or

misuse.

WARRANTIES

OR

WARRANTY

against

of

installation.

at

its

option,

(All

special,

notice

period.

installation

does

not

OTHERWISE

defects

to

incidental,

of

breach

The

and

cover

AS TO

aYdee

in

material

A-dec's

replace

warranty

upholstery

ARE

sole

the

and

of

warranty

does

maintenance,

damaged

MERCHANTABILITY

MADE.

or

workmanship

obligation

unit.

The

buyer

coincidental

must

be

not

cover

accident

or

under

the

shall

damages

given

to

damage

or

mis-

disfigured

9

o

PUBLICATION PRINTED

NUMBER

85-0634-01

ařdec

2601

Crestview

Newberg,

Phone

Telex

Oregon

(503)

538-7478

4970448

Drive

97132

ADEC

(ITT)

U.S.A

IN

U.S.A.

oh

Page 3

aídec

Porta-Cart

3406

OPERATION

THIS

TO

EQUIPMENT

DEFENSE

NATIONAL

NO

OTHER

FEDERAL

2601

CRESTVIEW

DRIVE * POST

AND

INSFRUCTION

PERSONNEL

STOCK

USE

OF

CONTRACT

OFFICE

MAINTENANCE

MANUAL

PURCHASED

NUMBER

THIS

NUMBERS

BOX

APPLIES

BY

THE

SUPPORT

6520-00-140-7663.

MANUAL

111

+»

CENTER

IS

DLA

DLA

NEWBERG,

INSTRUCTIONS

EXCLUSIVELY

UNITED

UNDER

AUTHORIZED

120-87-C-4625

120-87-C-4649

OREGON

97132 * TELEPHONE

STATES

BY

A-DEC.

(503)

538-7678

Page 4

CONTENTS

CONTENTS

Porta-Cart

3406

@idee

INTRODUCTION

General

Description

Equipment

Accessories

Government

Eovipment

Performance

Physical

Safety

EQUIPMENT

버마

Unpaexing

OPERATION

Control

Preparation

Use

Routing

Care

System

PREPARATION

Preliminary

Repacking

MAINTENANCE

General

of

Features

Provided

Furnished

Not

Specifications

Precautions

SETUP

ana

Functions

Air

Coolant

Water

Water

Automatic

Handpiece

Water

Water

Oral

Evacuator

Saliva

Foot

Control

Chip

Blower

For

of

the

Accessories

Soft-Touch

Description

Changing

Tip

Rotation

Air

Vacuum

Description

ANS.

Air

Saliva

Water

Tank

Adjustments

Drive

Air

Handpiece

Syringe

Flow

of

the

Unit

Surface

Cleaning

Surface

Disintecting

Cleaning

Instrument

Parts

Cleaning

Lubrication

A-dec

Special

the

Syringe

Stainless

Gray

Plastic

A-dec

Snut-Down

FOR

Steps

the

Service

Inspections

Internal

Tubing

Tools

Hemostats

Valve

Test

Test

Gauge

Snap

Ring

Tubing

Pocket

O-Ring

ος

the

System

Items

Provided

Characteristics

Assembly

Flow

Coolant

Coolant

Pressure

Outlet

Ejector

Button

Oral

Pressure

Coolant

Surgical

Porta-Cart

Pliers

Magnifier

Installation

Control

On-Off

Toggle

Flow

Handpiece

Use

the

System

Ejector

Sterilization

Tips

Steel

STORAGE

Instrumentation

and

Syringe

Controls

Lockout

Evacuator

Air

Oral

Pliers

Holder

Toggie

On-Off

Toggle

Fiow

Control

Centro!

Vaive

Button

Syringe

Tip

Flow

Vacuum

System

Oral

Evacuator

Evacuator

Tips

OR

Parts

Equipment

Tools

TRANSPORTATION

Tips

Tips

ま

È

2

2

2

2

2

2

3

a

3

ココ

ココ

ココ

ココ

の

gogoogeee

10

Basic

Troubleshooting

Neither

of

the

No

Water

Insufficient

Schematic

Filters

Description

Checking

Air

Filter

Water

Regulators

Pressure

Servicing

Filter

External

Internal

Servicing

Century

Il

Century

Cartridge

Century

Century

Description

Operating

Century

Three-Way

Description

Three-Way

Foot

Contro]

Description

Warning

Foot

Signa!

Relay

Description

Warning

Signal

Chip

Blower

Description

Chip

Three-Way

Description

Three-Way

Needie

Valve

Description

Needle

Syringe

Air

Vacuum

General

AMS.

Button

AMS.

Air

Saliva

SERVICE

PARTS

Min-Fitter

Filter-Reguiator,

Century

II

Century

Il

Three-Way

Foot

Control

Three-Way

Needle

Valves

Syringe,

SoftTouch

Air

Vacuum

ANS.

Hanepiece & Tubing

Air

Saliva

Water

Tank

Porta-Cart

Hanapiece

Porta-Cart

Master

Parts

Miscellaneous

Handpieces

Coolant

Drive

Diagram

the

Filters

Service

Filter

Service

Adjustment

the

Air

Element

Leakage

Leakage

the

Water

Control

System

II

Master

Valve

II

Master

II

Control

Principles

II

Control

Micro-Valve

Micro-Valve

Valve

Control

Valve

Valve

Relay

Valve

Valve

Blower

Valve

Toggle

Valve

Toggle

Valve

System

Oral

Evacuator

Replacement

Air

Tube

Ejector

BREAKDOWN

Air

Master

Block

Control

Block

Micro-Valve

Assembly

Togale

Valves

Button

System

Ejector

System

Frame

Hanger

Assembly

Accessory

List

and

Hardware

Work

from

Either

Air

Regulator

Reguiator

Block

Replacement

Block

Blocks

Block

Valve

Troubleshooting

Replacement

Assembly

Kit

Index

Handpiece.

Pressure

Troubleshooting

Troubleshooting

Troubleshooting

Troubleshooting

Troubleshooting

Troubleshooting

Troubleshooting

16

16

16

16

17

18

A

18

18

18

19

18

19

1

E

19

19

20

20

20

2

22

22

22

24

27

Page 5

a

dy

атаес

INTRODUCTION

GENERAL

The A-dec

the

finest

profession.

of

reliable

amount

sion

instrument,

is

required.

tions

given

the

best

This

manual

troubleshooting,

plus

auxiliary

as

specified

(12-10-79).

DESCRIPTION

The A-dec

mobile

Porta-Cart

units

It

is

performance,

of

attention.

Conscientious

in

this

and

longest service

covers

equipment

under

Porta-Cart

dental

unit

Porta-Cart

3406

dental

of

its

type

available

engineered

As

however, a certain

booklet

the

and

repair

military

OF

THE

designed

to

provide

while

demanding a minimum

is

the

case

adherence

will

ensure

from your

operation,

of

the

A-dec

and

accessories

specification

SYSTEM

(Figure

1) is a self-contained

for

field

3406

system

or

is

to

the

many

with

any

amount

to

the

instruc-

that

you receive

unit.

maintenance,

Porta-Cart,

provided

MIL-D-37945

operatory

one

of

dental

years

preci-

of

care

use.

All

facilities

tistry

assistant.

matic

water

Air

Vacuum

(ASE). A pressurized

for

handpiece

The

only

ply. A ten

purpose.

ering

bottled

80-100

The

entire

packed

portation

required

are

provided

It

is

control

coolant.

dry,

system

System

external

foot

lt

may

filtered

gas

(carbon

psi.

unit

into

its

and

for

built

around

Oral

evacuation

(AVS)

coolant

connection

air

supply hose

be

connected

air

dioxide

can

fiberglass

storage.

for

the

practice

both

the

A-dec's

for

two

handpieces

and

two-quart

and

the

at

80-100

or

be

quickly

carrying

of

general

doctor

is

required

to a compressor

nitrogen)

and

the

Century

with

provided

an

tank

syringe.

is

furnished

psi @ 4

disassembled

case

Air

Saliva

supplies

is

for

the

regulated

by a built-in

cfm,

safe

INTRODUCTION

den-

dental

II

auto-

air

and

Ejector

water

air

sup-

for

this

deliv-

or

to

to

and

trans-

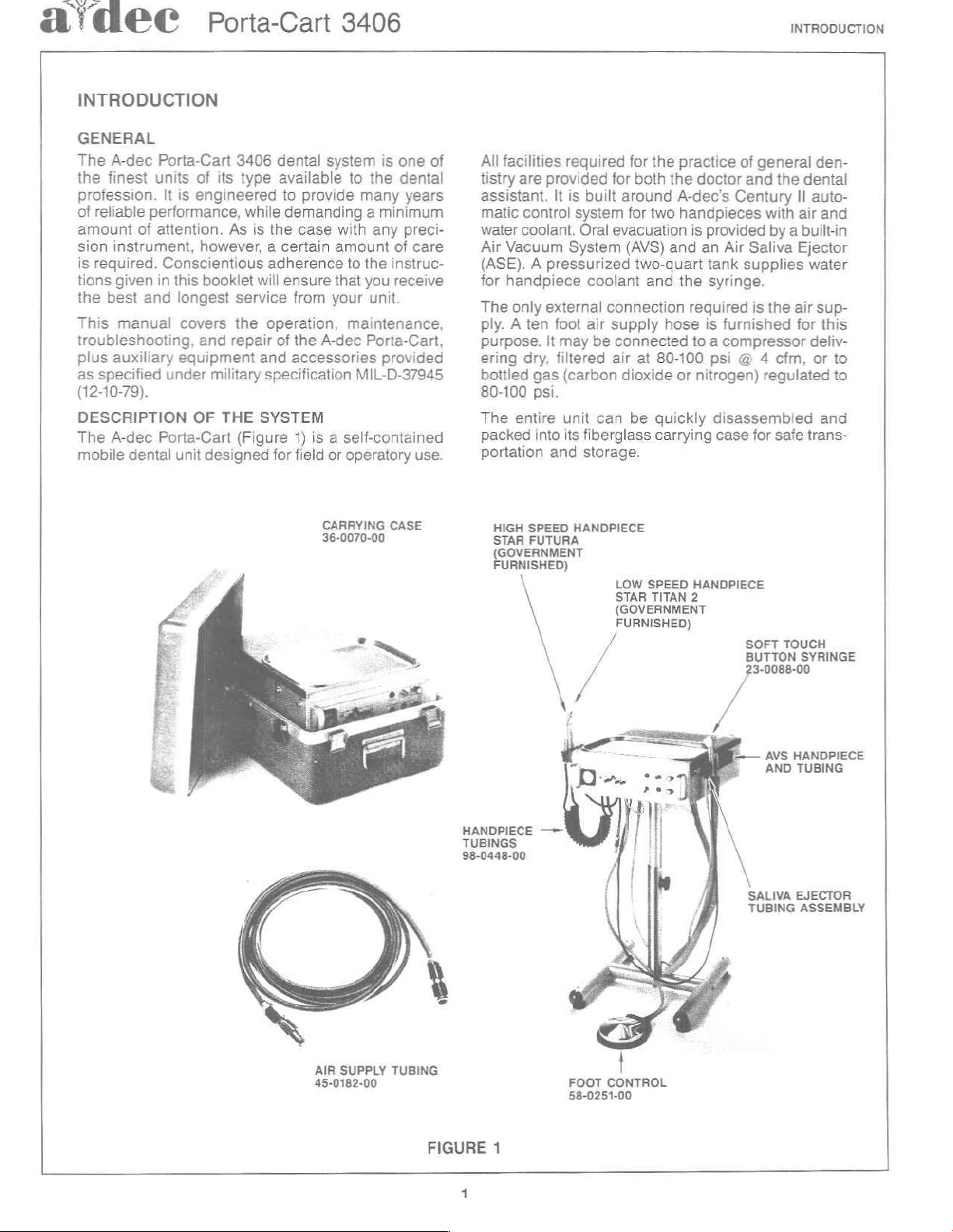

CARRYING

36-0070-00

CASE

HIGH

SPEED

STAR

FUTURA

(GOVERNMENT

FURNISHED)

\

\

HANDPIECE 一 一

TUBINGS

38-0448-00

HANDPIECE

LOW

SPEED

TITAN

HANDPIECE

2

SOFT

BUTTON

'3-0088-00

AVS

AND

STAR

(GOVERNMENT

FURNISHED)

/

SALIVA

TUBING

TOUCH

SYRINGE

HANDPIECE

TUBING

EJECTOR

ASSEMBLY

AIR

SUPPLY

45-0182-00

TUBING

FIGURE

1

FOOT

58-0251-00

CONTROL

Page 6

INTRODUCTION

Porta-Cart

3406

a'dec

EQUIPMENT

*

Century

Handpieces

*

Air

*

Water

+

Individual

Handpiece

*

Individual

Handpiece

*

Drive

*

Disc

*

Self-Contained

*

Water

+

Air

+

Soft

Il

Automatic

Coolant

Coolant

Water

Drive

Air

Pressure

Type

Foot

Pressure

Vacuum

AVS

Handpiece

Oral

Evacuator

Air

Saliva

Polypropylene Waste

Touch

(23-0088-00)

Quick-Disconnect

Adjustable

Fiberglass

Stainless

ACCESSORIES

s

Two

Coiled

nectors

®

10

Foot

Height

Carrying

Steel

Handpiece

(98-0448-00)

Air

Supply

(45-0182-00)

¢

Water

Tank

e

Stainless

®

Stainless

3

Each

®

Porta-Cart

Steel

Steel

Accessory

FEATURES

Flow

Control

On-Off

Coolant

Air

Pressure

Gauge

Control

Two-Quart

On-Off

System,

Assembly

Flow

Ejector

Button

Filler

Syringe

Water

Frame

Tray,

PROVIDED

Tubing

Funnel

Dry

Oral

Control

Toggle

Flow

Adjustment

with

Chip

Water

Toggle

including:

Control

with

Solids

Bottle

with

Outlet

Case

(36-0070-00)

15

1/8”

x10

Tubings

with

(009-003-00)

Oral

Cup

Evacuator

Kit

(36-0089-00)

System

(17-0270-00)

5/8”

with

Quick

(11-0450-00)

Tips

for

Control

Tank

Separator

Coiled

for

for

Blower

Tubing

(043-003-00)

Midwest

Disconnects

(10-0010-00),

Two

Each

Each

Button

Con-

Oral

Evacuator

Package

AVS

Handpiece

(049-001-01)

PERFORMANCE

The

A-dec

with

1.

High

Procedure

2.

Low

Procedure

3.

Vibration,

cedure

STD-810B.

4.

Shock,

dure

Water

Waste

Air

Supply

Gas

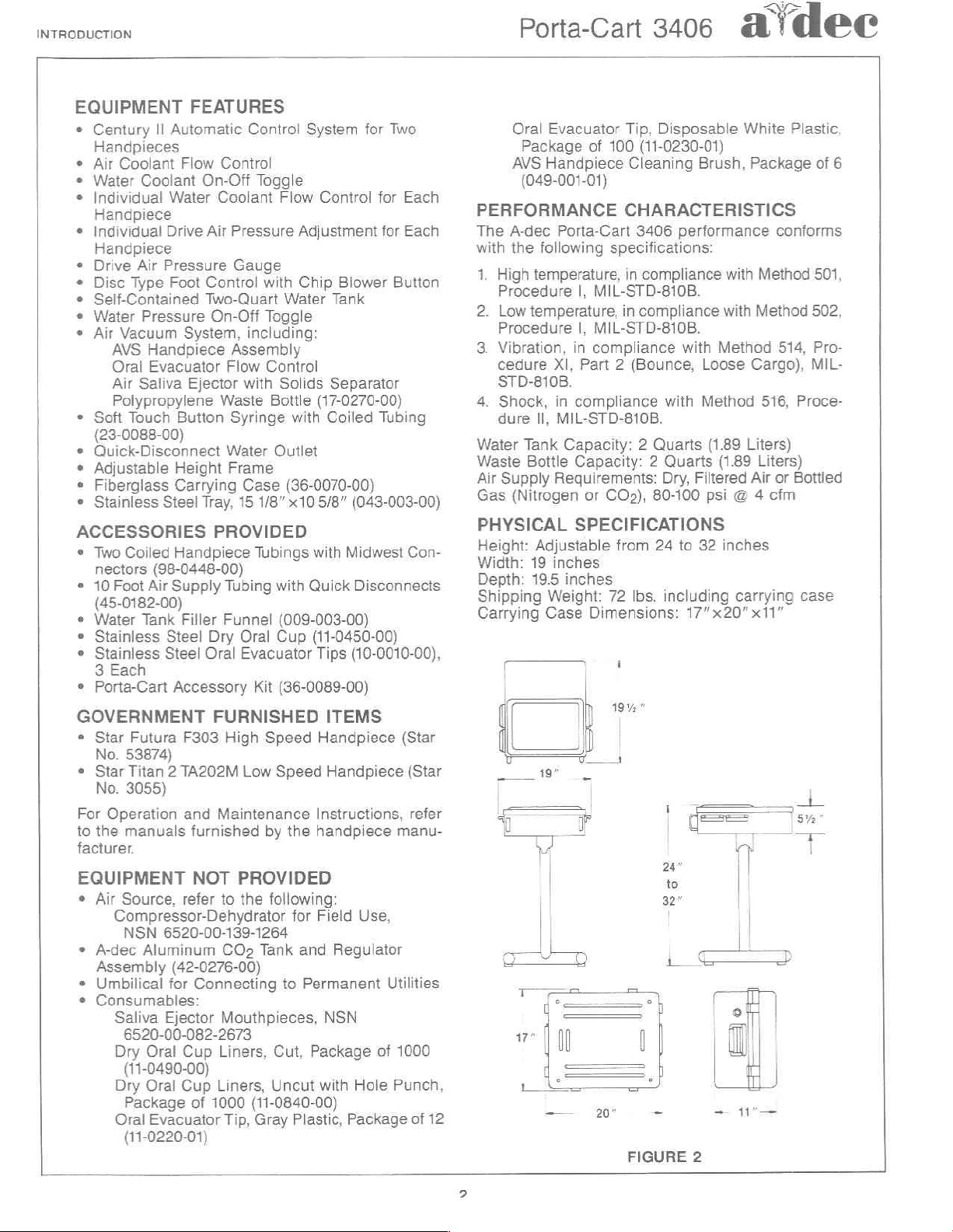

PHYSICAL SPECIFICATIONS

Height:

Width:

Depth:

Shipping

Carrying

Porta-Cart

the

following

temperature,

|,

temperature,

|,

in

XI,

in

compliance

Il,

MIL-STD-810B.

Tank

Capacity: 2 Quarts

Bottle

Capacity: 2 Quarts

Requirements:

(Nitrogen

Adjustable

19

inches

19.5

inches

Weight:

Case

Tip,

Disposable

of

100

(11-0230-01)

Cleaning

CHARACTERISTICS

3406

performance

specifications:

in

compliance

MIL-STD-810B.

in

compliance

MIL-STD-810B.

compliance

Part 2 (Bounce,

with

Dry,

or

CO»),

80-100

from

24

to

72

Ibs.

including

Dimensions:

with

17"x20"

White

Brush,

Loose

Method

Filtered

32

Package

with

with

Method

Cargo),

(1.89

Liters)

(1.89

Air

psi @ 4

inches

carrying

Plastic,

conforms

Method

Method

514,

516,

Proce-

Liters)

or

Bottled

cfm

x11”

of

501,

502,

Pro-

MIL-

case

6

GOVERNMENT

e

Star

Futura

No.

53874)

¢

Star

Titan 2 TA202M

No.

3055)

For

Operation

to

the

manuals

facturer.

EQUIPMENT

e

Air

Source,

Compressor-Dehydrator

NSN

6520-00-139-1264

+

A-dec

Aluminum

Assembly

®

Umbilical

*

Consumables:

Saliva

Dry

Ejector

6520-00-082-2673

Oral

FURNISHED

F303

High

Speed

Low

and

Maintenance

furnished

NOT

refer

by

PROVIDED

to

the

following:

CO:

Tank

(42-0276-00)

for

Connecting

Mouthpieces,

Cup

Liners,

Cut,

Speed

the

for

and

to

Permanent

(11-0490-00)

Dry

Oral

Cup

Package

Oral

Evacuator

of

1000

Liners,

Tip,

Uncut

(11-0840-00)

Gray

Plastic,

(11-0220-01)

ITEMS

Handpiece

Handpiece

Instructions,

handpiece

Field

Use,

Regulator

Utilities

NSN

Package

with

of

Hole

Package

(Star

(Star

refer

manu-

1000

Punch,

of

12

ar

|

Tİ

|

|

|

24"

FIGURE

2

ーー

キー

Ts

e

Page 7

A!

MEC

Porta-Cart

3406

EQUIPMENT

SETUP

SAFETY

Providing

are

followed.

operational

precautions

cautions

and

EQUIPMENT

INSPECTION

1.

During

external

or

2.

Check

vided

page

PRECAUTIONS

that

the

safety

are

associated

procedures.

the

damage

dented

the

and

Government

2.

the

instructions

A-dec

hazards,

required.

with

SETUP

assembly

such

unit.

contents

given

Porta-Cart

and

Observe

standard

of

the

unit,

as

cracked

against

the

Furnished

in

this

manual

3406

presents

no

special

the

normal

dental

check

Accessories

practices

for

obvious

carrying

Items

lists

no

safety

pre-

case

Pro-

on

3.

Inspect

age.

Check

4.

several

Check

5.

hardware.

After

6.

and

a

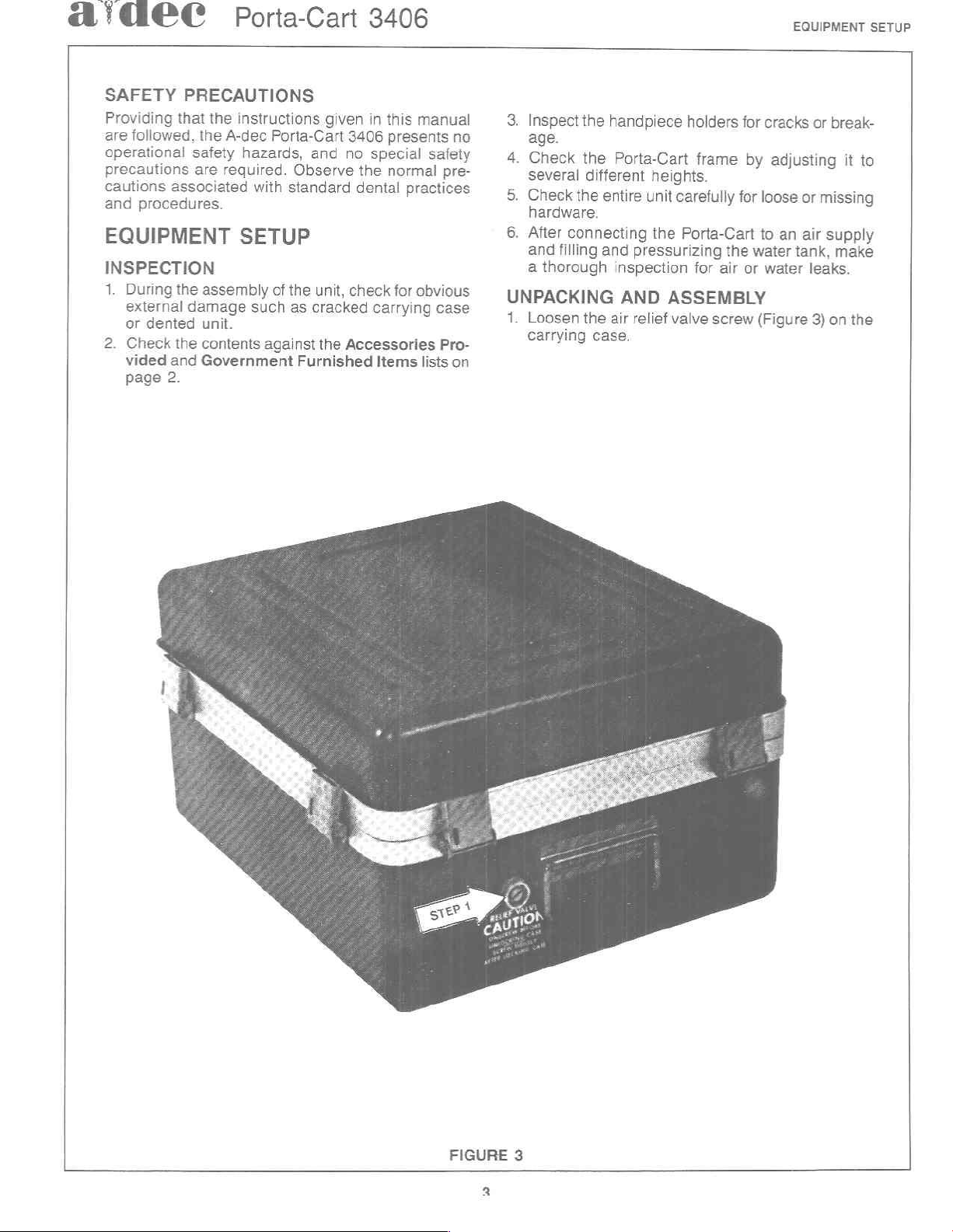

UNPACKING

1.

Loosen

carrying

the

the

different

the

connecting

filling

thorough

the

handpiece

Porta-Cart

entire

pressurizing

and

inspection

AND

air

relief

case.

holders

frame

heights.

carefully

unit

Porta-Cart

the

for

ASSEMBLY

valve

for

by

for

the

or

air

screw

cracks

adjusting

loose

an

to

tank,

water

water

(Figure

or

break-

missing

or

supply

air

make

leaks.

3)

on

it

the

to

FIGURE

3

Page 8

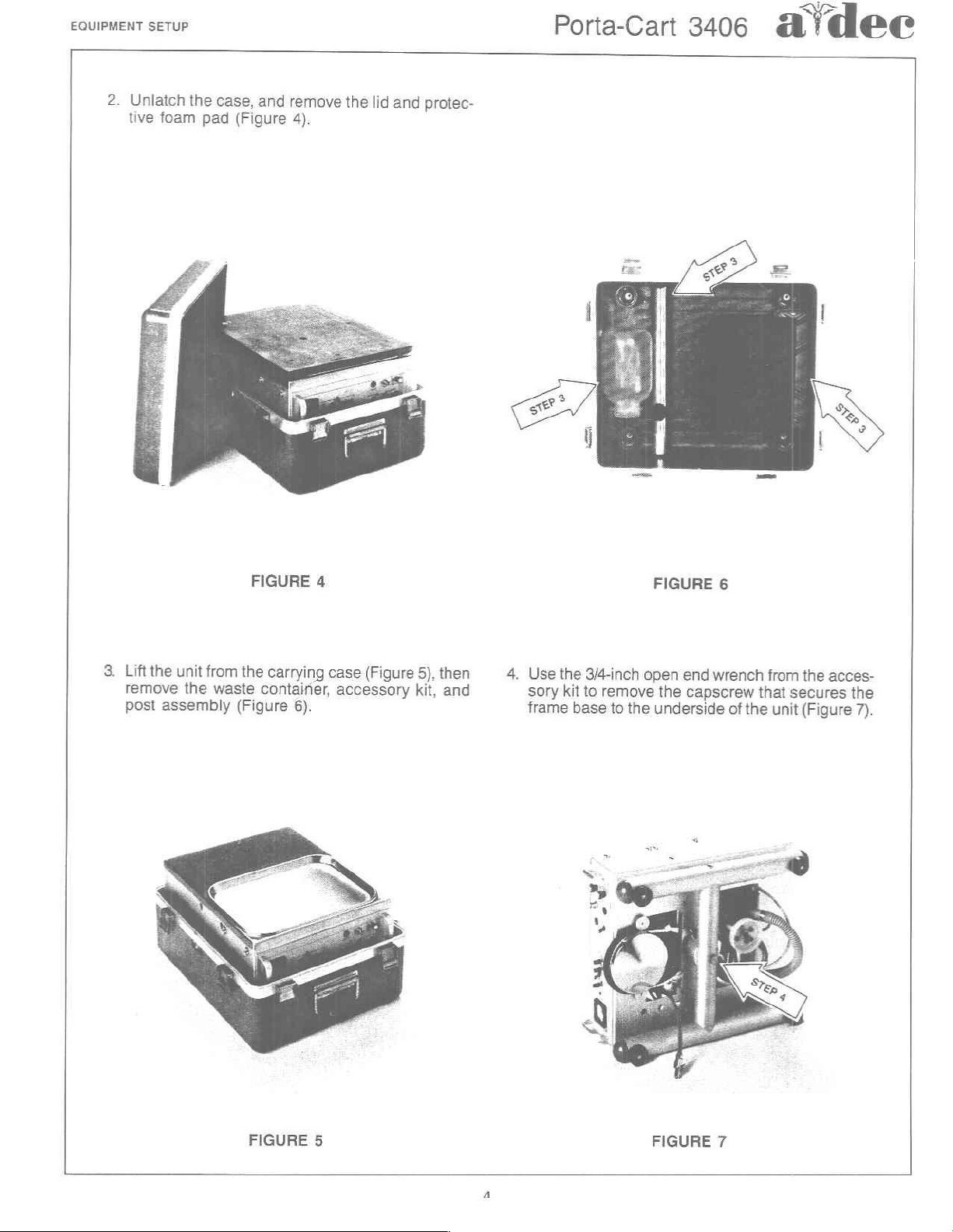

EQUIPMENT

2.

Unlatch

tive

SETUP

foam

the

pad

case,

(Figure

and

remove

4).

the

lid

and

protec-

Porta-Cart

3406

a'dec

3.

Lift

the

remove

post

assembly

unit

the

from

waste

FIGURE

the

carrying

container,

(Figure

6).

4

case

accessory

(Figure

5).

kit,

then

and

4.

Use

the

sory

frame

3/4-inch

kit

to

base

open

remove

to

the

FIGURE

the

underside

6

end

wrench

capscrew

of

that

the

from

secures

unit

the

acces-

the

(Figure

7).

FIGURE

5

FIGURE

7

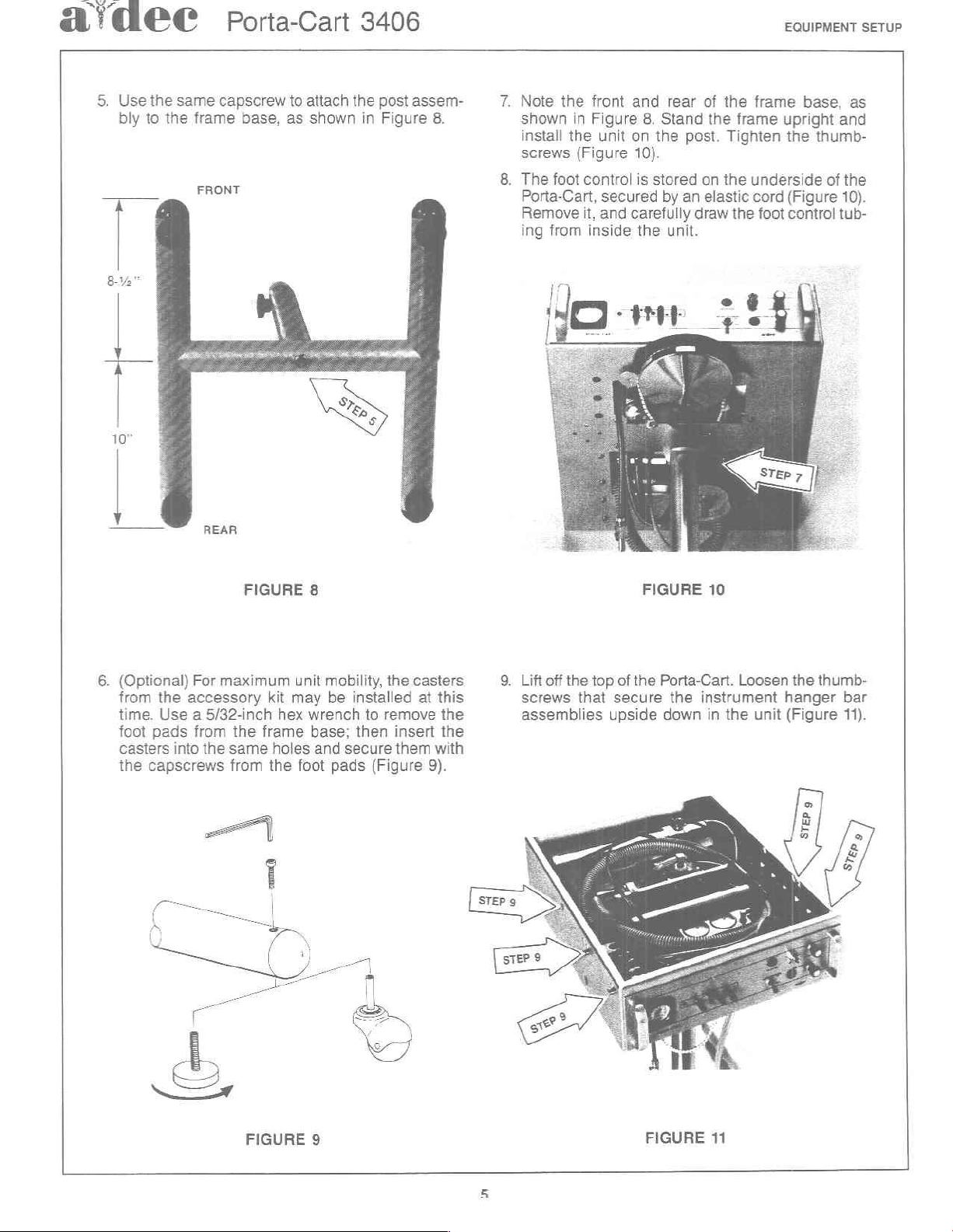

Page 9

a'cdel

5.

Use

the

bly

to

8-2"

À

10”

same

the

Porta-Cart

capscrew

frame

FRONT

base,

to

attach

as

shown

3406

the

post

in

Figure

assem-

8.

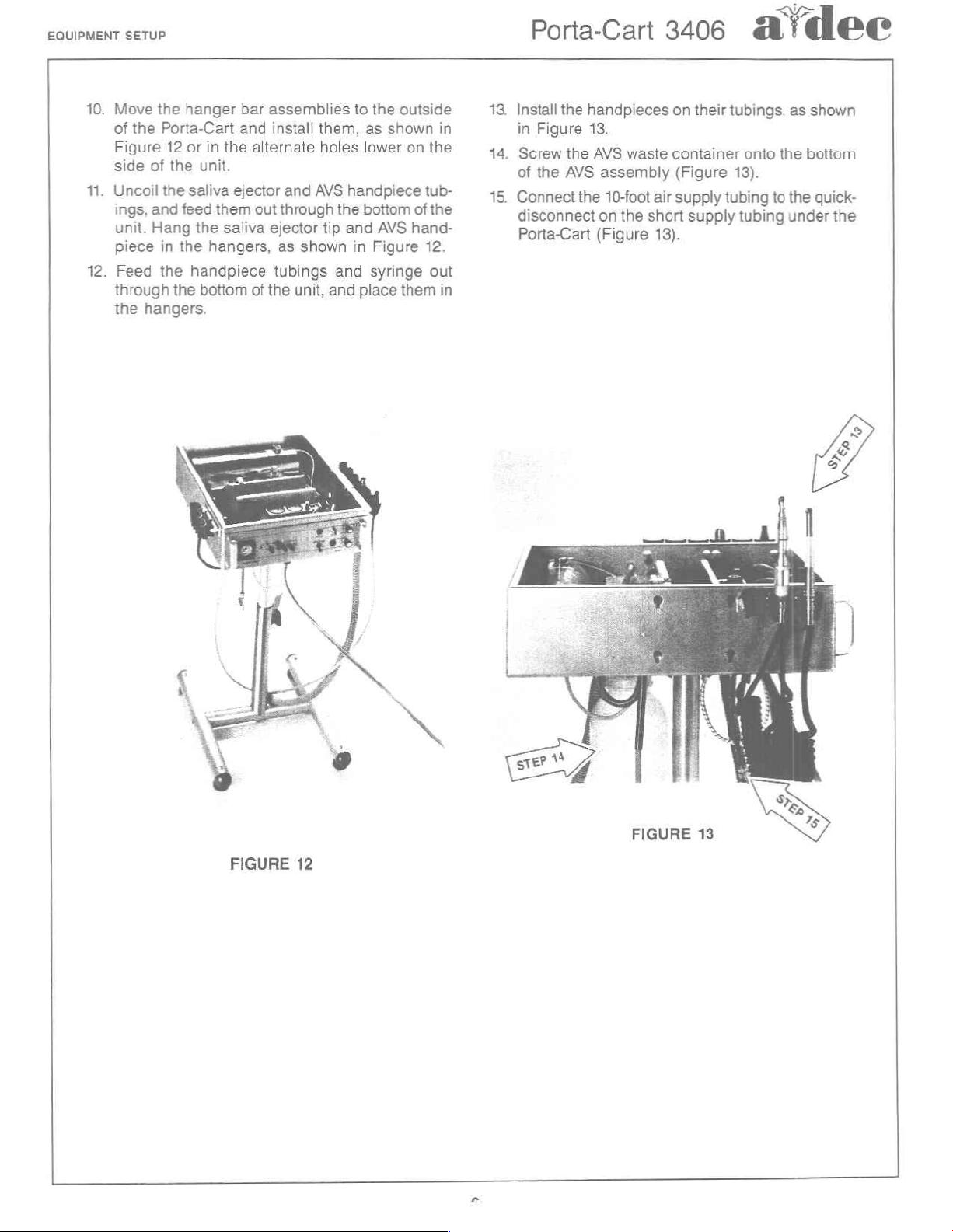

7.

Note

shown

install

screws

8.

The

foot

Porta-Cart,

Remove

ing

from

the

in

the

(Figure

control

it,

inside

front

and

Figure

unit

on

secured

and

carefully

8.

the

10).

is

stored

the

rear

Stand

post.

by

an

draw

unit.

of

the

the

frame

Tighten

on

the

elastic

the

EQUIPMENT

frame

underside

cord

upright

foot

base,

the

thumb-

(Figure

control

and

of

tub-

SETUP

as

the

10).

6.

(Optional)

from

time.

foot

casters

the

REAR

FIGURE

For

maximum

the

accessory

Use a 5/32-inch

pads

from

the

into

the

same

capscrews

from

kit

may

hex

frame

holes

the

8

unit

wrench

base;

and

foot

mobility,

be

installed

to

then

secure

pads

(Figure

the

casters

at

remove

insert

them

this

the

the

with

9).

9.

Liftoff

screws

assemblies

the

that

top

secure

upside

of

the

FIGURE

10

Porta-Cart.

the

down

Loosen

instrument

in

the

unit

the

thumb-

hanger

(Figure

bar

11).

FIGURE

9

FIGURE

11

Page 10

EQUIPMENT

10.

11.

12.

of

side

Uncoil

SETUP

Move

Figure

ings;

unit.

piece

Feed

through

the

the

the

Porta-Cart

12

of

the

the

and

feed

Hang

in

the

the

the

hangers.

hanger

or

saliva

handpiece

in

the

unit.

ejector

them

the

saliva

hangers,

bottom

bar

and

assemblies

install

alternate

out

through

ejector

of

the

them,

holes

and

AVS

tip

as

shown

tubings

unit,

and

to

the

outside

as

shown

lower

on

handpiece

the'battom

and

in

and

place

of

AVS

hand-

Figure

syringe

them

13.

in in

the

tub-

the

12.

out

in

14.

15.

Porta-Cart

Install

the

handpieces

Figure

Screw

of

the

Connect

disconnect

Porta-Cart

13.

the

AVS

AVS

assembly

the

on

(Figure

10-foot

waste

air

the

short

13).

3406

on

their

tubings,

container

(Figure

supply

13).

tubing

supply

tubing

a

onto

to

dee

as

shown

the

bottom

the

under

quick-

the

FIGURE

12

FIGURE

13

Page 11

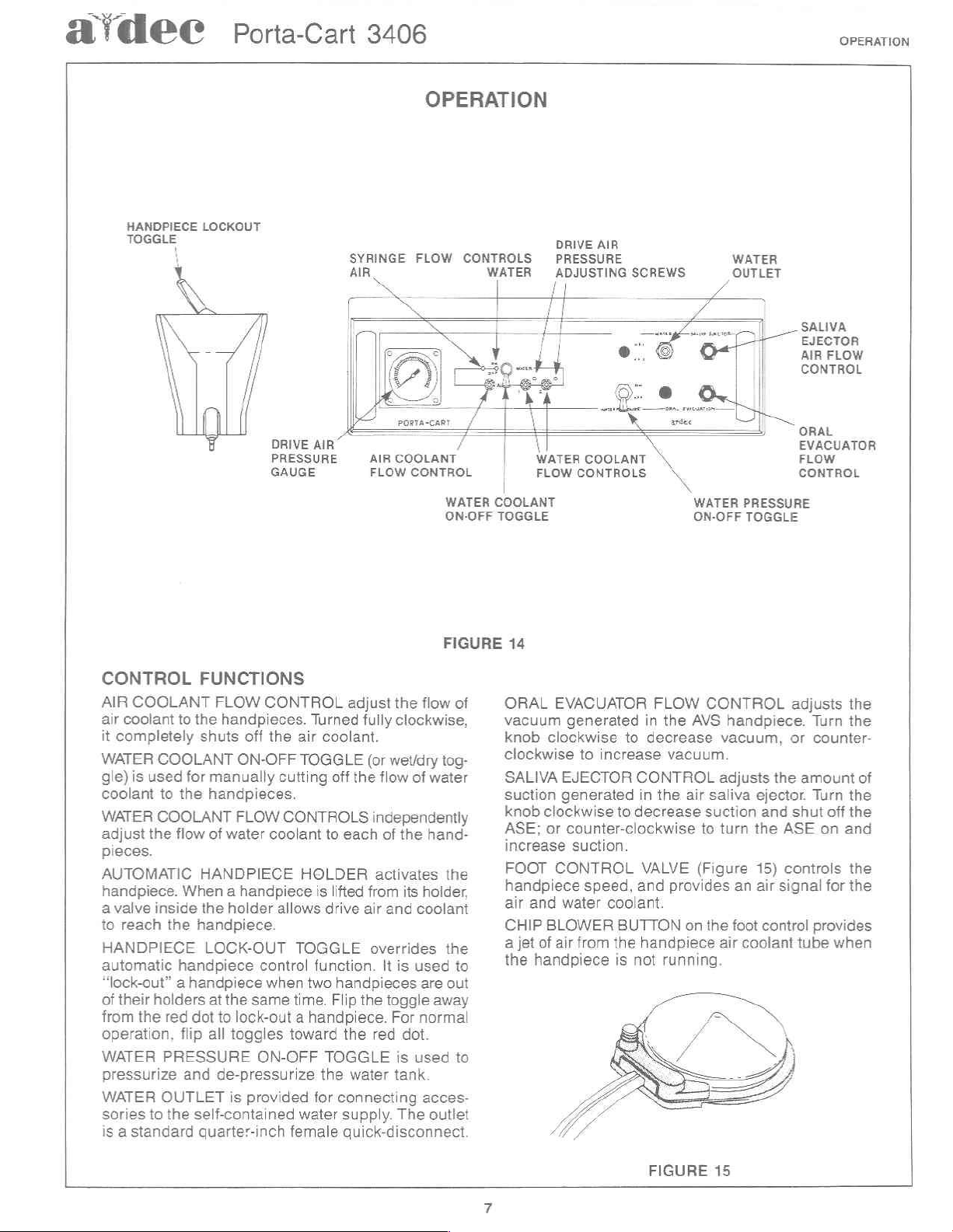

aídeec

Porta-Cart

3406

OPERATION

OPERATION

HANDPIECE

TOGGLE

LOCKOUT

SYRINGE

AIR

X

MOM

DRIVE

PRESSURE © AİR

GAUGE

AIR

FLOW

FLOW

/

COOLANT

CONTROL

WATER

ON-OFF

FIGURE

CONTROLS

WATER

©

1

da

_ i i

/

k

A

|

COOLANT

TOGGLE

14

DRIVE

AIR

PRESSURE

ADJUSTING

/ /

yr

SCREWS

À

Water

FLOW

6ΟΟΙΑΝΤ

CONTROLS

WATER

ON-OFF

WATER

OUTLET

|

PRESSURE

TOGGLE

SALIVA

EJECTOR

AIR

FLOW

CONTROL

GRA:

EVACUATOR

FLOW

CONTROL

CONTROL

AIR

COOLANT

air

coolant

it

completely

WATER

gle)

is

used

coolant

WATER

adjust

the

pieces.

AUTOMATIC

handpiece.

a

valve inside

to

reach

HANDPIECE

automatic

“lock-out” a handpiece when

of

their

holders

from

the

operation,

WATER

pressurize

WATER

sories

to

is a standard

FUNCTIONS

FLOW

to

the

handpieces.

shuts

off

COOLANT

for

to

the

COOLANT

flow

When a handpiece

the

handpiece

red

flip

PRESSURE

and

OUTLET

the

ON-OFF

manually

handpieces.

FLOW

of

water

HANDPIECE

the

holder

handpiece.

LOCK-OUT

at

the

same

dot

to

lock-out a handpiece.

all

toggles

de-pressurize

is

provided

self-contained

quarter-inch

CONTROL

the

cutting

CONTROLS

coolant

allows

control

toward

ON-OFF

Turned

air

coolant.

TOGGLE

off

to

HOLDER

is

lifted

drive

TOGGLE

function.

two

handpieces

time.

Flip

TOGGLE

the

for

connecting

water

female

adjust

each

the

supply.

quick-disconnect.

the

flow

fully

clockwise,

(or

wet/dry

the

flow

of

independently

of

the

activates

from

its

holder,

air

and coolant

overrides

It

is

used

are

the

toggle

For

normal

red

dot.

is

used

water

tank.

acces-

The

of

tog-

water

hand-

the

the

to

out

away

to

outlet

ORAL

vacuum

knob

clockwise

SALIVA

suction

knob clockwise

ASE;

increase

FOOT

handpiece

air

CHIP

a

the

EVACUATOR

clockwise

or

CONTROL

and water

BLOWER

jet

of

air

handpiece

generated

to

increase

EJECTOR

generated

counter-clockwise

suction.

speed,

coolant.

from

in

to

decrease

CONTROL

in

to

decrease

VALVE

and

BUTTON

the

handpiece

is

not

FLOW

the

AVS

vacuum.

the

air

to

(Figure

provides

on

running.

CONTROL

handpiece.

vacuum,

adjusts

saliva

suction and

turn

the

air

ejector.

the

15)

an

air

foot

control

coolant

the

signal

adjusts

Turn

or

counter-

amount

Turn

shut

off

ASE

on

controls

for

provides

tube

when

the

the

of

the

the

and

the

the

FIGURE

15

Page 12

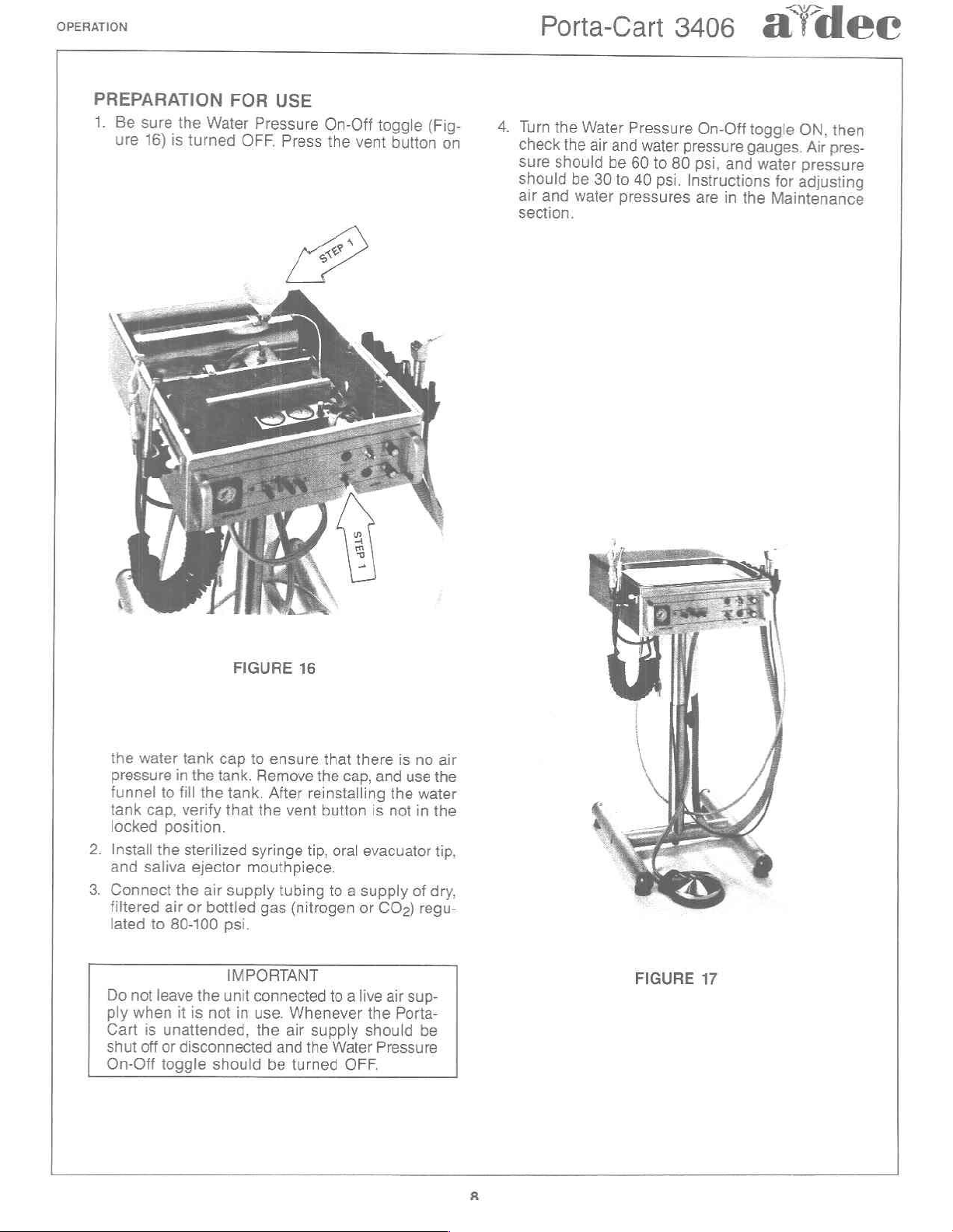

OPERATION

Porta-Cart

34066

d'dec

PREPARATION

1.

Be

sure

the

ure

16)

is

turned

FOR

Water

OFF.

USE

Pressure

Press

On-Off

the

vent

toggle

button

(Fig-

on

4.

Turn

check

Sure

should

air

section.

the

the

should

and

Water

air

30

be

water

Pressure

and

water

be

60

to

psi.

40

to

pressures

On-Off

pressure

80

psi,

and

Instructions

are

in

the

toggle

gauges.

ON,

water

pressure

adjusting

for

Maintenance

Air

then

pres-

the

pressure

funnel

tank

locked

2.

Install

and

3.

Connect

filtered

lated

Do

not

ply

Cart

shut

On-Off

water

tank

in

to

fill

cap,

verify

position.

the

sterilized

saliva

the

air

to

80-100

leave

when

it

is

unattended,

off

or

disconnected

togale

FIGURE

cap

the

tank.

the

tank.

that

ejector

air

supply

or

bottled

psi.

IMPORTANT

the

unit

is

not

should

16

to

ensure

Remove

After

the

vent

syringe

mouthpiece.

tubing

gas

(nitrogen

connected

in

use.

Whenever

the

air

and

be

turned

that

there

the

cap,

and

reinstalling

button

tip,

oral

to a supply

to a live

supply

the

Water

the

is

not

evacuator

or

COs)

air

the

should

Pressure

OFF.

is

no

air

use

the

water

in

the

tip,

of

dry,

regu-

sup-

Porta-

be

FIGURE

17

Page 13

aídee

USE

Soft

DESCRIPTION

is a three-way

change

straightforward

maintenance.

can

be

Maintenance

CHANGING

and

pull

and

push

nut

by

When

sure

way

in

be

is

OF

THE

Touch

the

ejected

pressed.

Button

autoclavable

performed

THE

the

used

it

in

hand

changing

that

the

into

the

syringe

from

Porta-Cart

ACCESSORIES

Syringe

A-dec’s

air

and

design,

Any

service

by

section

TIP

tip

as

far

until

it

the

replacement

syringe. A tip

could

the

Soft

water

syringe

tip.

Because

this

syringe

that

following

of

this

Loosen

straight

as

it

will

is

just

snug.

IMPORTANT

autoclavable

tip

that

cause

syringe

3406

Touch

out.

go,

when

Button

featuring a quick-

of

its

requires

will

ever

be

the

instructions

book.

the nut a half

Insert

the

then

retighten

syringe

is

pushed

is

not

fully

the

water

button

the

air

Syringe

simple,

very

little

required

in

the

turn

new

tip

the

tip,

be

all

the

seated

to

button

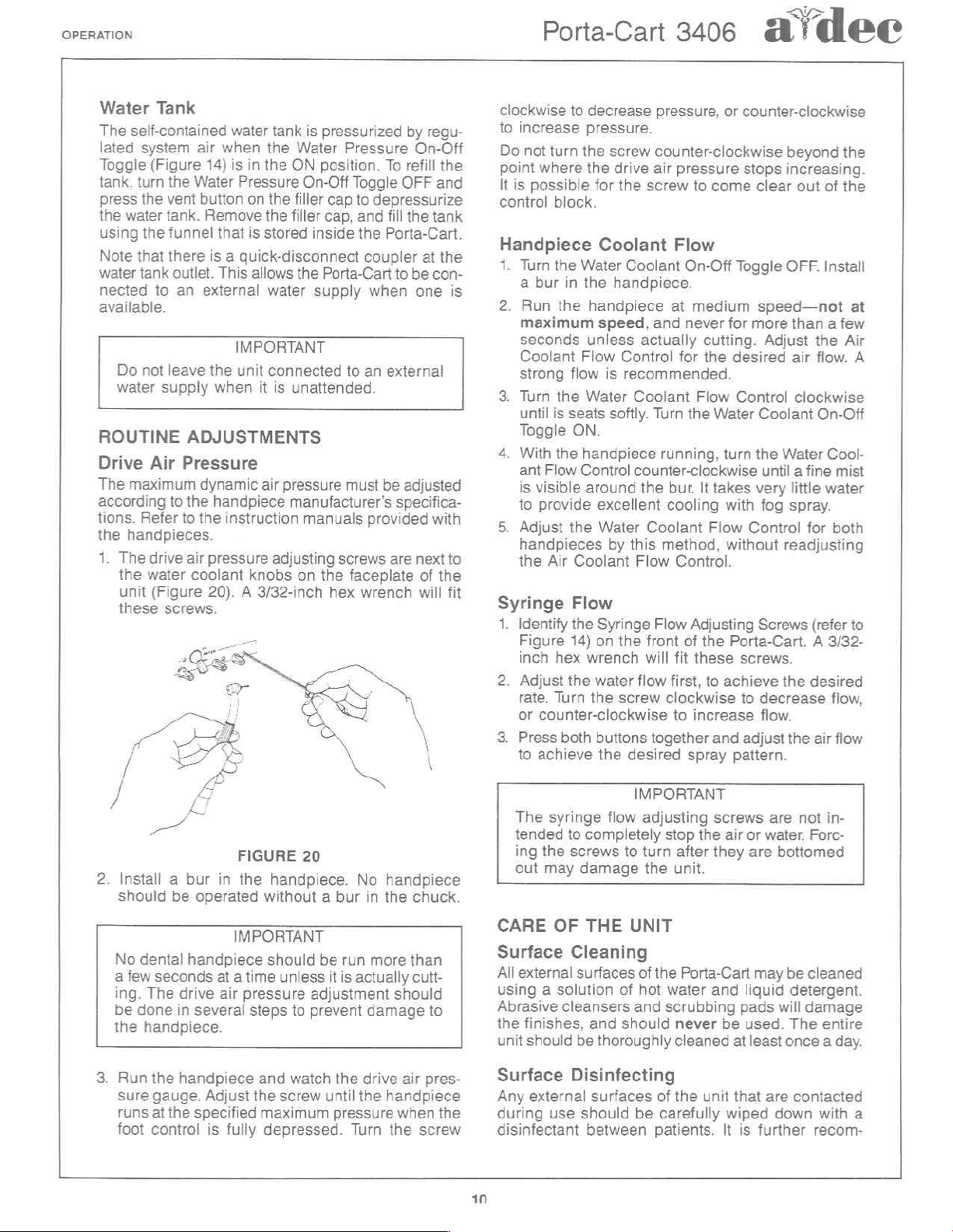

Air

DESCRIPTION

vides

need

cludes

solids

ure

second

Vacuum

assistant’s

for a central

separator,

19).

an

AVS

The

AVS

AVS

HANDPIECE

System

vacuum

Oral

and a waste container

system

Oral

Evacuator

The

A-dec

vacuum

Evacuator,

has

Air

Vacuum

instrumentation

pump.

provisions

assembly

AIR

VACUUM

SYSTEM

Air

System

The

Saliva

(refer

for

(not

AIR

EJECTOR

OPERATION

pro-

without

system

furnished).

Ejector,

to

Fig-

adding

SALIVA

the

in-

a

TIP

ROTATION

of

having

syringe

may

However,

against

nut

For a non-rotating

(23-0887-00),

cessory

is

be

easily

rotation,

and

exchanging

Kit.

You

have

the

either a rotating

assembled

rotated

if

you

which

For a rotating

wish

this

tip,

is

at

the

to

spray

to

have

can

be

sleeves

use

packaged

tip,

option

or

non-rotating

factory

in

different

the

done

(refer

the

white

in

use

(23-0886-00).

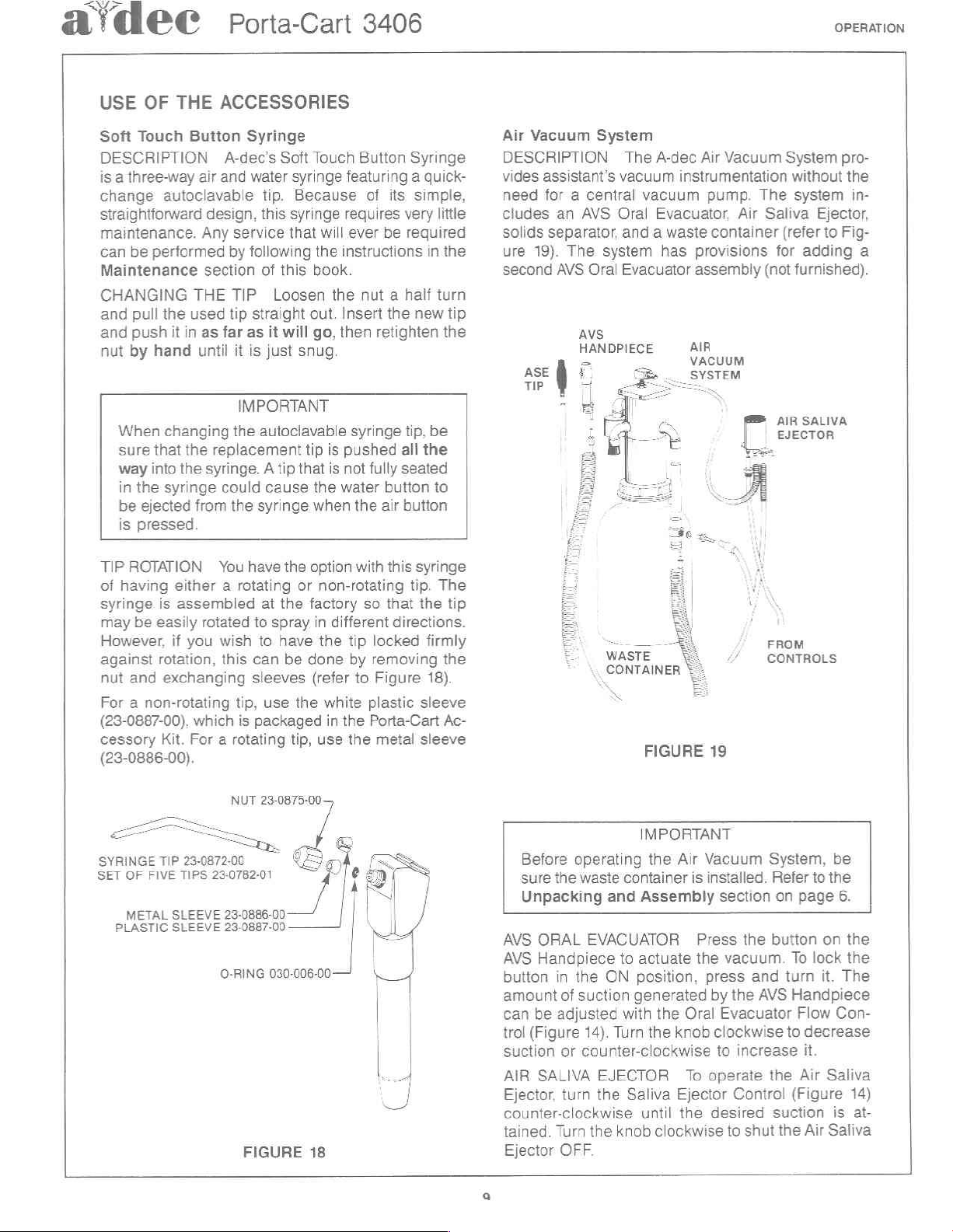

NUT 23-0875-00—

SYRINGE

SET

OF

FIVE TIPS

METAL

PLASTIC

TIP

SLEEVE

SLEEVE

—

23-0872-00

23-0782-01

23-0886-00

23-0887-00

O-RING

030-006-00

FIGURE

18

with

so

that

tip

locked

by

removing

to

Figure

plastic

the

Porta-Cart

the

metal

this

syringe

tip.

The

the

tip

directions.

firmly

the

18).

sleeve

Ac-

sleeve

WASTE

CONTAINER

x

Before

sure

Unpacking

AVS

AVS

button

amount

can

trol

suction

AIR

Ejector,

counter-clockwise

tained.

Ejector

operating

the

waste

ORAL

Handpiece

in

the

of

suction

be

adjusted

(Figure

SALIVA

14).

or

counter-clockwise

turn

Turn

OFF.

container

and

EVACUATOR

to

ON

with

Turn

EJECTOR

the

Saliva

the

knob

FIGURE

IMPORTANT

the

Air

is

Assembly

Press

actuate

position,

generated

the

until

the

the

Oral

knob

To

Ejector

the

clockwise

FROM

и

CONTROLS

19

Vacuum

installed.

section

press and

by

Evacuator

clockwise

to

operate

desired

System,

Refer

the

button

vacuum.

the

AVS

increase

the

Control

suction

to

shut

to

on

page

To

lock

turn

it.

Handpiece

Flow

to

decrease

it.

Air

(Figure

the

Air

be

the

6.

on

the

the

The

Con-

Saliva

14)

is

at-

Saliva

Page 14

OPERATION

Porta-Cart

3406

d

dee

Water

The

lated

Toggle

tank,

press

the

using

Note

water

nected

available.

Tank

self-contained

system

(Figure

turn

the

water

the

that

tank

to

Do

not

water

supply

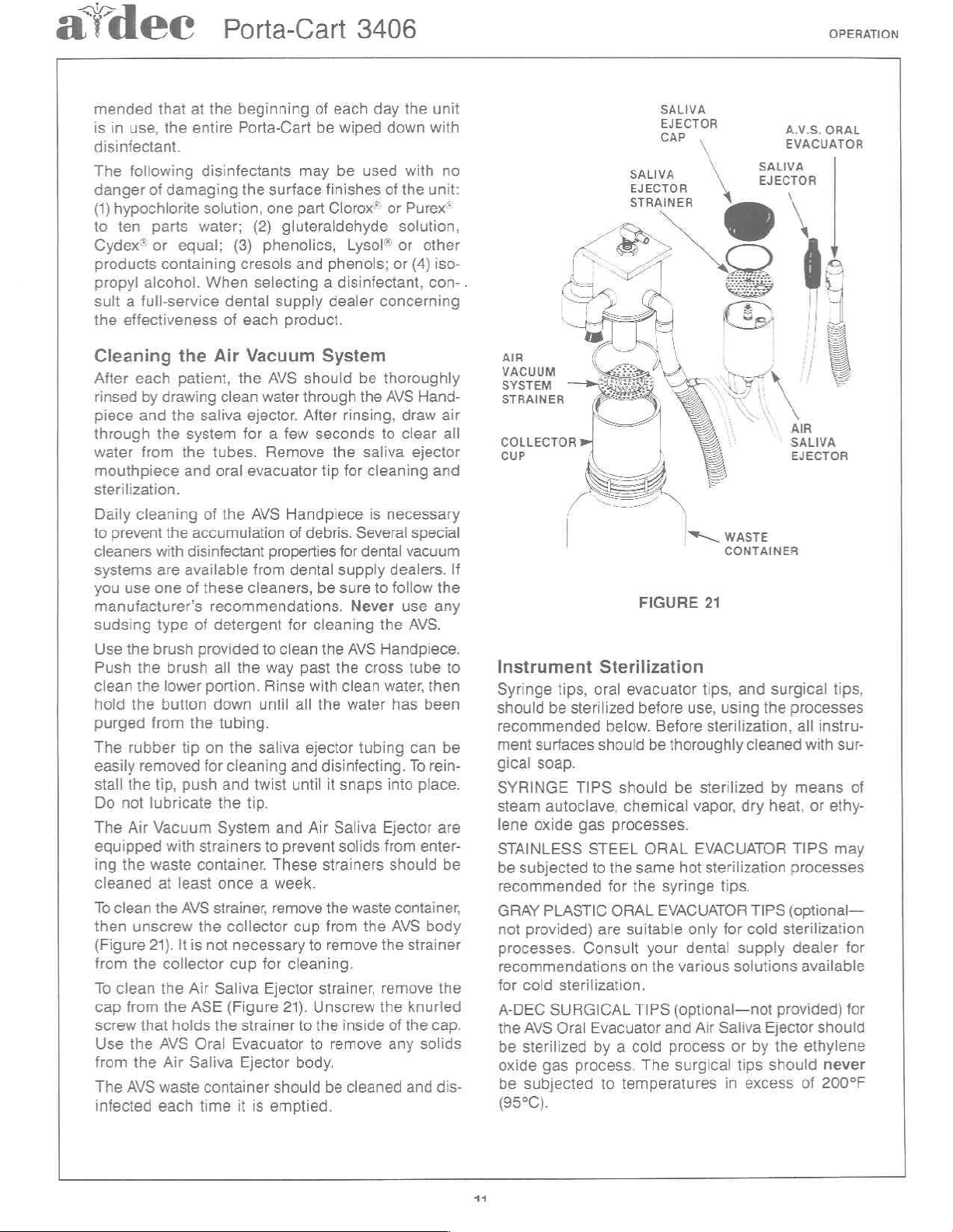

ROUTINE

Drive

The

according

tions.

the

1.

2.

Air

maximum

Refer

handpieces.

The

drive

the

water

unit

(Figure

these

screws.

Install a bur

should

No

dental

a

few

seconds

ing.

The

be

done

the

handpiece.

water

air

when

the

14)

is

in

the

the

Water

Pressure

vent

button

tank.

funnel

there

outlet.

an

leave

on the

Remove

that

is a quick-disconnect

This

external

the

when

the

is

stored

allows

water

IMPORTANT

unit

connected

it

ADJUSTMENTS

Pressure

dynamic

to

the

handpiece

to

the

air

pressure

coolant

20). A 3/32-inch

be

operated

handpiece

drive

in

several

air

instruction

knobs

FIGURE

in

the

without a bur

IMPORTANT

should

at a time

air

pressure

steps

tank

is

pressurized

Water

ON

filler

filler

the

is

unattended.

pressure

manufacturer’s

adjusting

on

handpiece.

unless

to

Pressure

position.

On-Off Toggle

cap

cap,

inside

Porta-Cart

supply

to

must

manuals

screws

the

faceplate

hex

20

be

run

it

is

adjustment

prevent

by

On-Off

To

refill

OFF

to

depressurize

and

fill

the

the

Porta-Cart.

coupler

to

be

when

one

an

external

be

adjusted

specifica-

provided

are

next

wrench

No

handpiece

in

the

chuck.

more

than

actually

cutt-

should

damage

regu-

the

and

tank

at

the

con-

with

of

the

will

to

is

to

fit

clockwise

to

increase

Do

not

point

It

is

control

Handpiece

1.

Turn

a

2.

Run

maximum

seconds

Coolant

strong

.

Turn

until

Toggle

.

With

ant

is

to

.

Adjust

handpieces

the

Syringe

1.

Identify

Figure

inch

.

Adjust

rate.

or

.

Press

to

The

tended

ing

out

CARE

Surface

All

external

using a solution

Abrasive

the

finishes,

unit

to

decrease

pressure.

turn

the

where

possible

the drive

for

block.

Coolant

the

Water

bur

in

the

the

handpiece

speed,

unless

Flow

flow

is

the

Water

is

seats

ON.

the

handpiece

Flow

Control

visible

achieve

around

provide

Air

counter-clockwise

syringe

the

may

the

Coolant

Flow

the

14)

hex

wrench

the

water

Turn

the

both

to

completely

screws

damage

OF

THE

excellent

Water

by

Syringe

on

buttons

the

flow

Cleaning

surfaces

cleansers

and

should

be

thoroughly

pressure,

screw

counter-clockwise

air

pressure

the

screw

to

come

Flow

Coolant

handpiece.

Control

recommended.

Coolant

softly.

counter-clockwise

this

Flow

the

flow

screw

desired

IMPORTANT

to

On-Off

at

medium

and

never

actually

Turn

the

Coolant

Flow Adjusting

front

will

together

adjusting

turn

the

cutting.

for

the

Flow

the

Water

running,

bur.

It

takes

cooling

Flow

method,

Control.

of

the

fit

these

first,

to

clockwise

to

increase

and

spray

screws

stop

the

after

they

unit.

UNIT

of

the

Porta-Cart

of

hot

water and

and

scrubbing

should

never

cleaned

or

counter-clockwise

beyond

stops

increasing.

clear

Toggle

for

desired

Control

turn

with

without

Porta-Cart. A 3/32-

achieve

pattern.

air

be

at

OFF.

speed—not

more

Adjust

Coolant

the

Water

until a fine

very

fog

spray.

Control

readjusting

Screws

screws.

the

to

decrease

flow.

adjust

the

are

or

water.

are

bottomed

may

be

liquid

detergent.

pads

will

used.

The

least

once a day.

than a few

air

clockwise

little

out

of

Install

the

flow.

On-Off

Cool-

water

for

both

(refer

desired

flow,

air

flow

not

in-

Forc-

cleaned

damage

entire

the

the

Air

mist

at

A

to

3.

Run

the

handpiece

sure

gauge.

runs

at

foot

control

Adjust

the

specified

is

and

the

maximum

fully

watch

screw

depressed.

until

the

drive

the

handpiece

pressure

Turn

the

air

when

screw

pres-

the

Surface

Any

external

during

disinfectant

10

Disinfecting

surfaces

use

should

between

of

the

be

carefully

patients.

unit

wiped

It

that

is

further

are

contacted

down

with

a

recom-

Page 15

a

dee

Porta-Cart

3406

OPERATION

mended

is

in

disinfectant.

The

danger

(1)

to

Cydex*

producis containing

propyi

sult a full-service

the

Cleaning

After

rinsed

piece

through

water

mouthpiece

sterilization.

Daily

to

prevent

cleaners

systems

you

manufacturer's

sudsing

Use

Push

clean

hold

purged

The rubber

easily

stall

Do

The

equipped

ing

cleaned

To

then

(Figure

from

To

cap

screw

Use

from

The

infected

that

at

use,

the

entire

following

of

hypochlorite

ten

parts

or

alcohol.

effectiveness

disinfectants

damaging

water;

equal;

the

each

patient,

by

drawing

and

the

saliva

the

system

from

the

and

cleaning

the

accumulation

with

disinfectant

are

available

use

one

of

type

of

the

brush

provided

the

brush

the

lower

the

button

from

the

tip

removed

the

tip,

push

not

lubricate

Air

Vacuum

with

strainers

the

waste

clean

unscrew

21).

the

clean

from

that

the

the

AVS

container.

at

least

the

AVS

the

itis

collector

the

Air

the

ASE

holds

AVS

Oral

Air

Saliva

waste

each

time

the

solution,

When

Air

tubes.

oral

of

these

recommendations.

detergent

all

portion.

down

on

for

strainer,

not

Saliva

the

container

beginning

Porta-Cart

the

one

(2)

(3)

phenolics,

cresols

selecting a disinfectant,

dental

of

each

Vacuum

the

clean water

ejector. After

for a few

Remove

evacuator

the

AVS

from

cleaners,

to

the

way

Rinse

until

tubing.

the

saliva

cleaning

and

twist

the

tip.

System

to

once a week.

collector

necessary

cup

for

Ejector

(Figure

strainer

Evacuator

Ejector

it

is

of

each

be

wiped

may

be

surface

supply

finishes

part

Clorox®

gluteraldehyde

Lysol®

and

phenols;

dealer

product.

System

AVS

should

through

Handpiece

of

debris.

properties

dental

for

clean

past

with

all

ejector

and

until

and

Air

prevent

These

remove

cup

to

cleaning.

21).

to

to

body,

should

emptied.

be

the

rinsing,

seconds

the

tip

for

Several

for

supply

be

sure

Never

cleaning

the

AVS

the

clean

the

water

tubing

disinfecting.

it

snaps

Saliva Ejector

solids

strainers

the

waste

from

remove

strainer,

Unscrew

the

inside

remove

be

cleaned

day

the

down

used

with

of

the

or

Purex*

solution,

or

or

(4)

concerning

thoroughly

AVS Hand-

draw

to

clear

saliva

dental

cross

the

ejector

cleaning

is

necessary

special

vacuum

dealers.

to

follow

use

the

AVS.

Handpiece.

tube

water,

has

can

To rein-

into

from

should

container,

AVS

the

strainer

remove

the

knurled

of

the

any

and

unit

with

no

unit:

other

iso-

con-

air

all

and

If

the

any

to

then

been

be

place.

are

enter-

be

body

the

cap.

solids

dis-

.

AIR

VACUUM

SYSTEM

STRAINER

COLLECTOR

CUP

Instrument

Syringe

should

recommended

ment

gical

SYRINGE

steam

lene

STAINLESS

be

subjected

recommended

GRAY

not

provided)

processes.

recommendations

for

cold sterilization.

A-DEC

the

AVS

be

sterilized

oxide

be

subjected

(95°C).

SALIVA

TOR

SALIVA

EJECTOR

STRAINER

|

tips,

oral

be

sterilized

surfaces

soap.

TIPS

autoclave,

oxide

gas

STEEL

to

PLASTIC

Consult

SURGICAL

Oral

Evacuator

by a cold

gas

process.

Sterilization

evacuator

before

below.

should

should

chemical

processes.

the

same

for

the

ORAL

are

suitable

on the

TIPS

to

temperatures

E

FIGURE

use,

Before

be

thoroughly

be

vapor,

ORAL

your

The

EVACUATOR

hot

syringe

EVACUATOR

only

dental

various

(optional—not

and

Air

process

surgical

ANS.

κ

\

\

EVACUATOR

CR

、

AIR

SALIVA

EJECTOR

WASTE

CONTAINER

21

tips,

and

surgical

using

the

processes

sterilization,

cleaned

sterilized

sterilization

tips.

for

Saliva Ejector

by

means

dry heat,

TIPS

processes

TIPS

(optional

cold

sterilization

supply

solutions available

or

tips

in

excess

dealer

provided)

by

the

should

ORAL

tips,

all

instru-

with

sur-

or

ethy-

may

for

for

should

ethylene

never

of

200°F

of

—

11

Page 16

PREPARATION

OR

TRANSPORTATION

FOR

STORAGE

Porta-Cart

3406

A

dee

SYSTEM

The

following

Cart

is

eight

hours.

1.

Turn

the

quick-disconnect

Accessory

on

the

2.

Turn

allow

the

Water

Off

toggle

fitting.

3.

Clean

tor

by

the

Air

4.

Empty

disinfect

5.

Clean

by

the

6.

Disconnect

sure

button.

7.

Thoroughly

fied

in

SHUT-DOWN

steps

being

shut

down

the

Water

Pressure

Kit

(see

faceplate.

the

Water

the

the

following

Vacuum

the

it.

and

manufacturer.

from

the

Pressure

water

tank

Outlet;

OFF,

and

AVS

Handpiece

the

AVS

waste

lubricate

the

air

the

unit

clean

Care

of

should

then

be

taken

for

any

On-Off

fitting

page

52)

On-Off

to

completely

turn the

remove

and

instructions

System

supply

the

the

section

container,

the

handpieces,

tube,

by

pressing

external

Unit

when

the

period

from

into

Water

the

the

surfaces

section

in

excess

toggle

and

OFF.

the

Porta-Cart

the

Water

toggle

guick-disconnect

in

then

the

drain

Pressure

Air

Saliva

the

Cleaning

on

page

clean

as

specified

bleed

syringe

as

on

page

ON,

through

air

Porta-

of

Insert

Outlet

and

On-

Ejec-

11.

and

pres-

air

speci-

10.

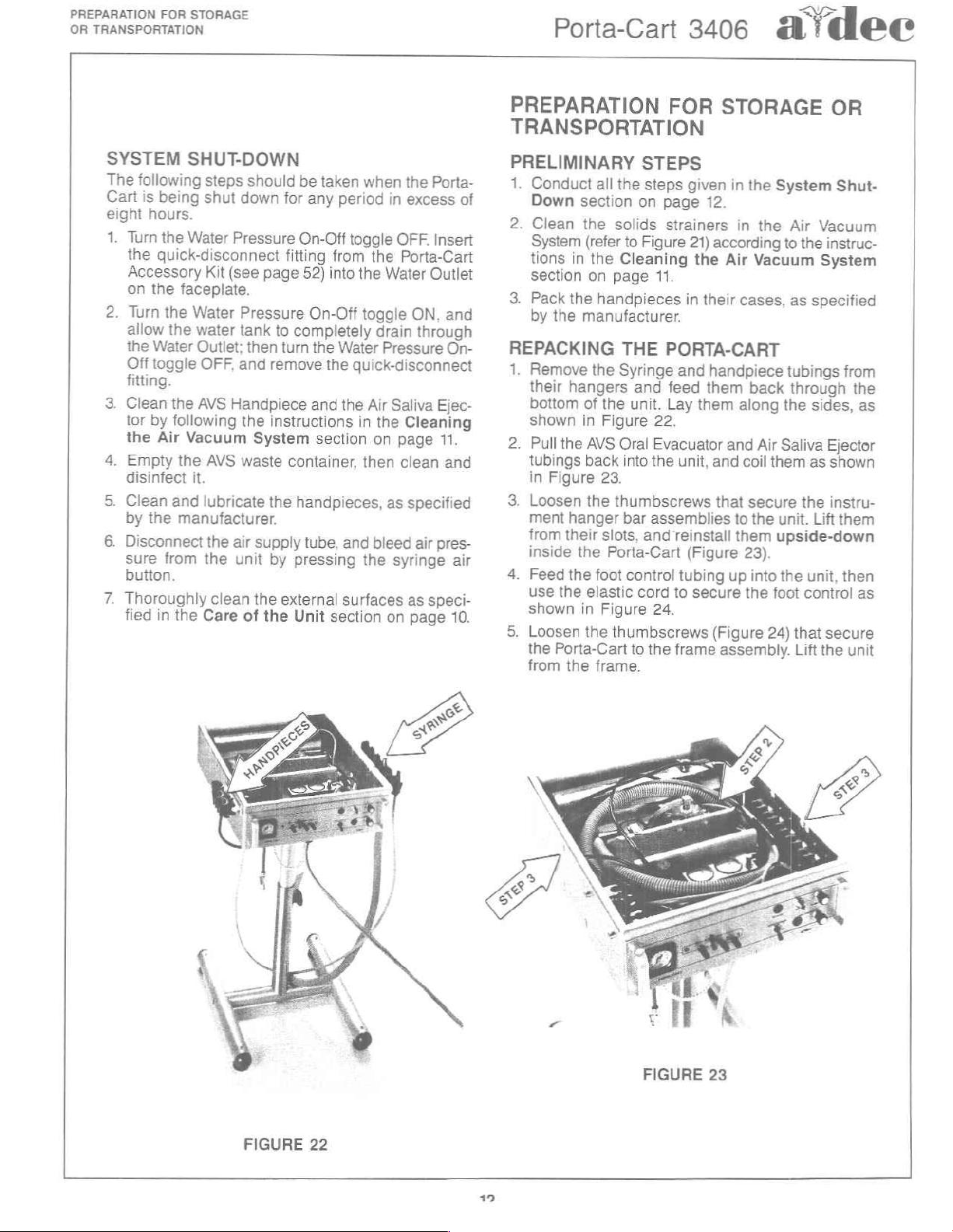

PREPARATION

TRANSPORTATION

PRELIMINARY

1.

Conduct

Down

2.

Clean

System

tions

section

3.

Pack

by

REPACKING

1.

Remove

their

bottom

shown

2.

Pull

tubings

in

3.

Loosen

ment

from

inside

4.

Feed

use

shown

5.

Loosen

the

from

section

the

(refer

in

the

on

the

the

manufacturer.

the

hangers

of

in

the

AVS

back

Figure

the

hanger

their

the

the

foot

the

elastic

in

the

Porta-Cart

the

frame.

STEPS

all

the

steps

on

solids

to

Figure

Cleaning

page

11.

handpieces

THE

Syringe

and

the

unit.

Figure

23.

slots,

Porta-Cart

Figure

22,

Oral

Evacuator

into

the

thumbscrews

bar

assemblies

and

control

cord

24.

thumbscrews

to

the

FOR

page

strainers

PORTA-CART

feed

Lay

STORAGE

given

in

12.

in

21)

according

the

Air

in

their

cases,

and

handpiece

them

them

along

and

unit,

and

that

to

reinstall

(Figure

tubing

to

frame

them

up

secure

(Figure

assembly.

the

System

the

to

Vacuum

tubings

back

the

Air

Saliva

coil

them

secure

the

unit.

upside-down

23).

into

the

the

foot

24)

OR

Shut-

Air

Vacuum

the

instruc-

System

as

specified

through

sides,

Ejector

as

shown

the

instru-

Lift

unit,

control

that

secure

Lift

the

from

the

as

them

then

as

unit

FIGURE

22

FIGURE

23

Page 17

ai

@e@e@

Porta-Cart

3406

PREPARATION

OR

FOR

TRANSPORTATION

STORAGE

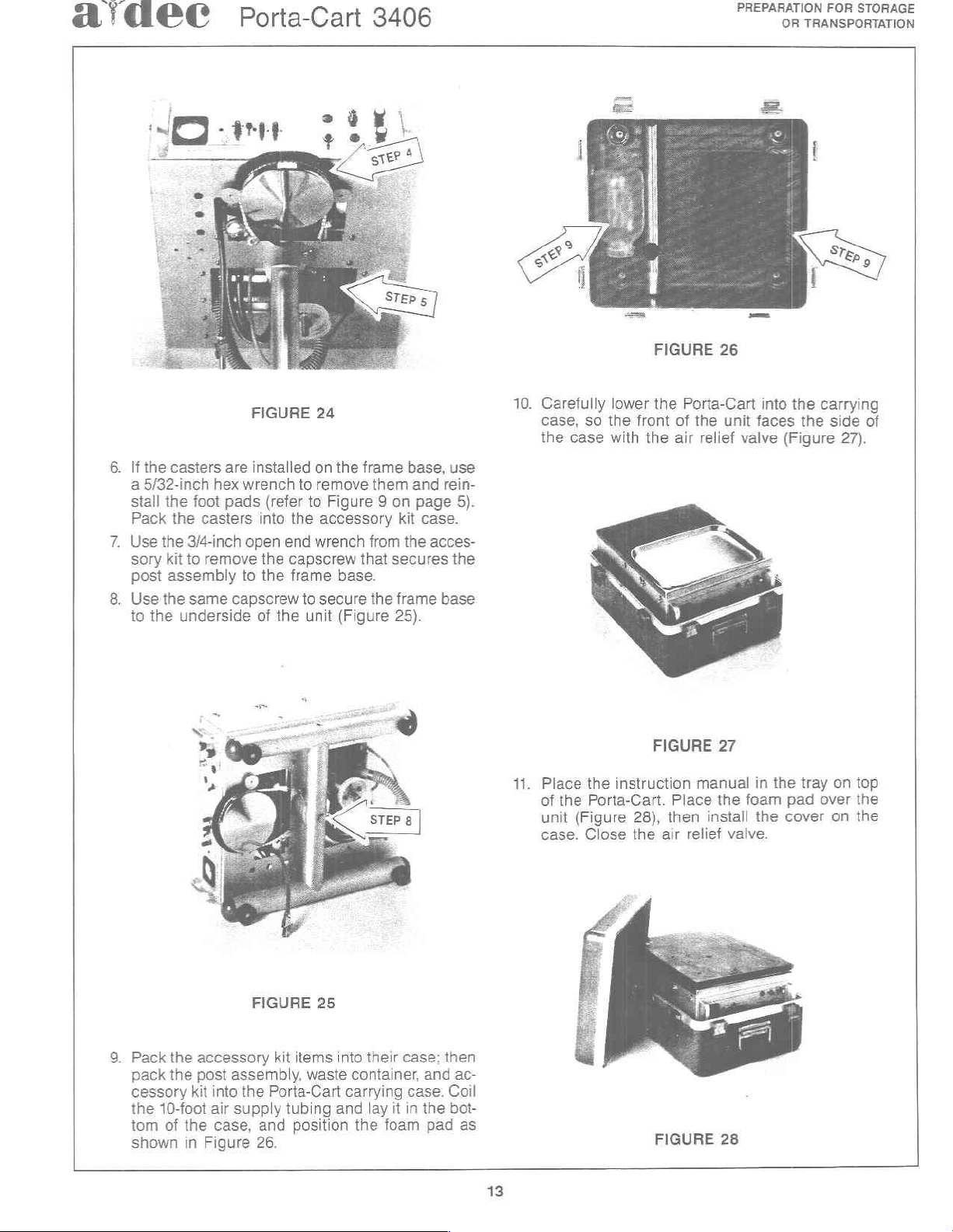

6.

7.

8.

If

a

stall

Pack

Use

sory

post

Use

to

the

casters

5/32-inch

the

foot

the

casters

the

3/4-inch

kit

to

remove

assembly

the

same

the

underside

FIGURE

are

installed

hex

wrench

pads

open

to

capscrew

(refer

into

end

the

capscrew

the

of

the

24

on

to

remove

to

Figure 9 on

the

accessory

wrench

frame

to

secure

unit

the

frame

them

from

that

base.

the

(Figure

base,

and

page

kit

case.

the

acces-

secures

frame

25).

use

rein-

5).

the

base

10.

Carefully

case,

the

Place

11.

of

unit

case.

so

the

case

the

the

Porta-Cart.

(Figure

Close

FIGURE

lower

the

front

with

the

air

FIGURE

instruction

Place

28),

then

the

air

26

Porta-Cart

of

the

unit

relief

valve

27

manual

the

install

relief

valve.

into

faces

in

foam

the

the

carrying

the

(Figure

the tray

pad

over

cover

side

27).

on

on

of

top

the

the

FIGURE

9.

Pack

the

accessory

pack

the

post

assembly,

cessory

the

tom

shown

kit

into

the

Porta-Cart

10-foot

air

of

the

case,

in

Figure

supply

and

26.

kit

items

waste

tubing

position

25

into

and

their

case:

container,

carrying

the

lay

case.

it

in

foam

and

the

pad

then

ac-

Coil

bot-

as

FIGURE

13

28

Page 18

MAINTENANCE

MAINTENANCE

Porta-Cart

3406

a@idee

GENERAL

Parts

In

find

sible

itself

body,

ton.

age,

careful

A

Equipment

that

When

kets

new

old

check

Cleaning

When

ponent

and

lubricant

pervious

cleaner

be

clear,

Inspection

the

Troubleshooting

references

defects.

(usually

and

Defects

so an

examination

magnifier,

are

too

servicing

or

diaphragms,

ones

gasket

for

servicing

disassembled

inspected

recommended

to

is a hot

done

with a soft,

hot

water,

SERVICE

to

the

The

seal

an

O-ring),

the

O-ring

in

any

inspection

as

shown

section,

small

components

when

reassembling

or

diaphragm

pin

holes

Internal

dental

for

chemical

detergent

then

INFORMATION

Guides

“seal

area”

area

the

groove

of

these

of

the

of

all

sealing

in

the

is

essential

to

see

otherwise.

it

is

generally

is

or

cracks.

Parts

systems,

should

defects

lint-free

before

for

these

solvents,

solution.

cloth.

rinse

them

in

this

as

is

comprised

bore

or

in

the

valve

may

result

seal

parts

Special

for

that

have

advisable

the

components.

to

be

reused.

the

parts

be

thoroughly

reassembly.

parts

so

the

Any

Flush

in

isopropyl

manual

location

of

the

seat

in

the

stem

in

seal

area

includes

and

surfaces.

Tools

detecting

rubber

to

carefully

of

any

cleaned

is

largely

most

effective

wiping

all

parts

alcohol.

you

will

of

pos-

seal

valve

or

pis-

leak-

and

flaws

gas-

install

If

the

com-

The

im-

should

with

Lubrication

A-dec

high

lubricating

oral

the

Lubricant.

a

Before

of

will

seal

inserting

A-dec

The

cially

A-dec

When

although

theless

Crimps

short,

Remember

ing

length.

Silicone

quality

evacuator

A-dec

silicone

prevent

bores

silicone

the

lubricant

installing

grease.

the

should

stems

Tubing

tubing

rarely

used

engineered

tubing

troubleshooting

so

this

can

are

that

when

becomes

for

tubing

become

often

it

Lubricant,

base

internal

valves.

O-rings,

O-rings

or

throughout

for

replacement.

is

installing

moving

An

is

Dow-Corning

always

This

makes

from

also

be

pistons.

durability

the

is

resistant

crimped

caused

stretched

crimped,

part

no.

grease

parts,

acceptable

apply a light

installation

being

lightly

A-dec

system,

by

any

and

to

and

the

at

the

tubing

and

lubricated

dental

long

bear

crimping,

obstruct

tubing

barb

98-0090-00,

that

is

ideal

O-rings,

substitute

No.

103

Silicone

coating

easier,

damaged.

before

units

is

life.

Use

in

mind

it

never-

the

being

connection.

that

slack

allow

adequate

is

a

for

and

for

and

The

spe-

only

that

flow.

too

tub-

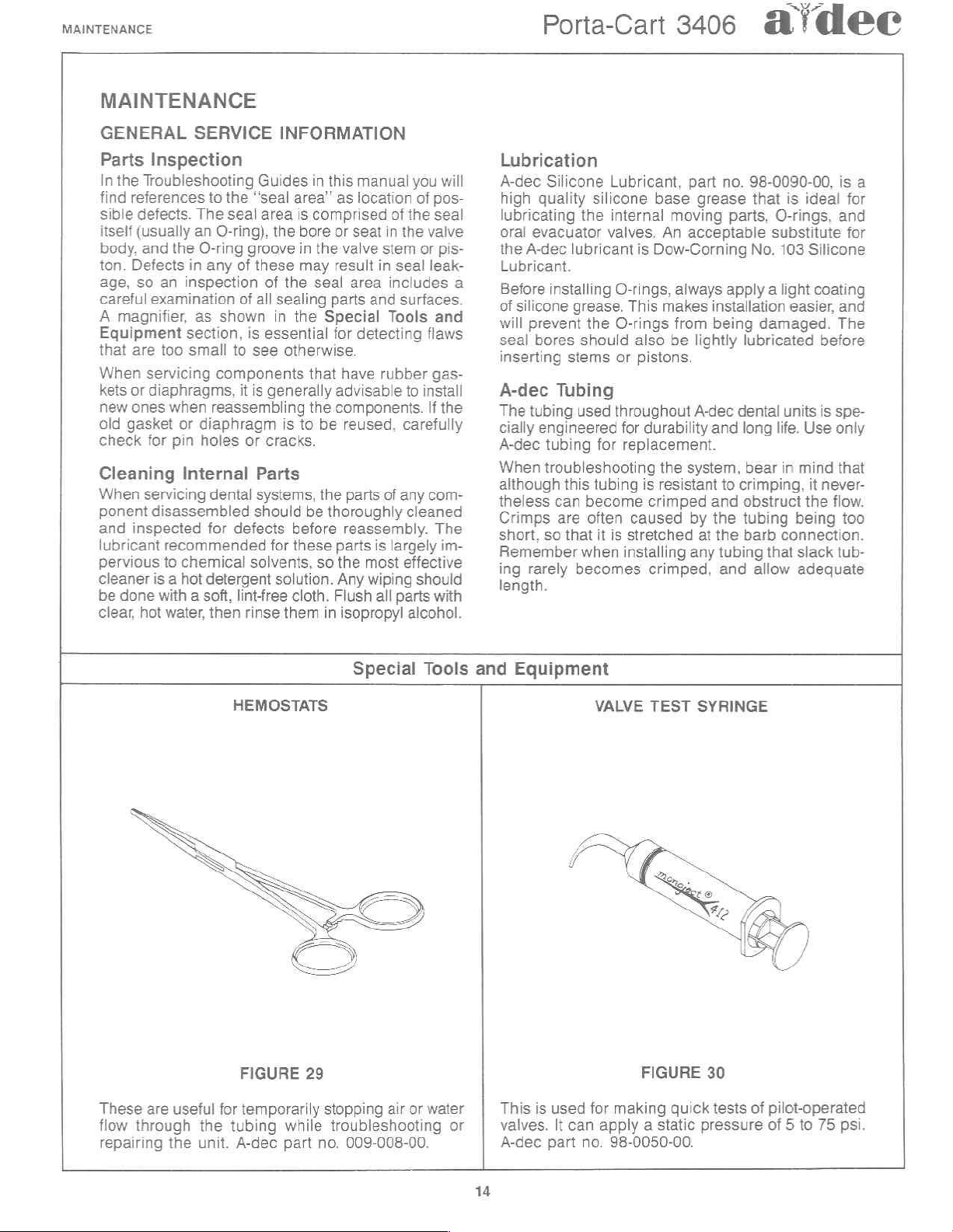

HEMOSTATS

FIGURE

29

Special

Tools

and

Equipment

VALVE

TEST

FIGURE

SYRINGE

30

These

flow

are

through

repairing

useful

the

the

unit.

for

temporarily

tubing

A-dec

stopping

while

troubleshooting

part

no.

air

or

009-008-00.

water

or

This

is

used

valves.

A-dec

It

can

part

no.

14

for

making

apply a static

98-0050-00.

quick

tests

of

pressure

pilot-operated

of 5 to

75

psi.

Page 19

aídeec

Porta-Cart

3406

MAINTENANCE

Use

an

A-dec

range.

points

no.

Barbed

part

A-dec

1/8-inch

This

while

026-078-00.

Fitting,

no.

023-028-00;

part

TEST

FIGURE

air

pressure

is

for

checking

troubleshooting

Also

Washer

Tee

no.

023-014-00;

tubing,

A-dec

GAUGE

It

31

gauge

air

the

required

and

Sleeve

Barb

and a two-foot

part

no.

with a 0-100

pressure

system.

for

use

of

Clamp

and

Sleeve

024-015-00.

at

A-dec

this

Kit,

Clamp

length

psi

various

part

gauge:

A-dec

Kit.

of

These

snap

A-dec

snap

rings,

and

part

SNAP

ring

pliers

fit

no.

009-007-00.

RING

FIGURE

are

all

sizes

PLIERS

for

both

used

33

inside

in

A-dec

and

outside

equipment.

These

tubing

014-00.

modified

onto

the

TUBING

FIGURE

pliers

barbed

PLIERS

32

are

used

fittings.

for

pushing

A-dec

part

no.

O-RING

1/8-inch

009-

INSTALLATION

This

is a 10X

miniature

POCKET

magnifier

valve

parts.

MAGNIFIER

FIGURE

for

A-dec

TOOLS

3

Align

tool

groove

4.

with

tne

O-ring

in

the

stem.

Slide

the

O4

34

inspecting

part

no.

for

defects

009-009-00.

in

These

field,

tools

enable

on

most

A-dec

you

to

make

miniature

quick

components.

repairs,

The

FIGURE

in

the

tools

35

in

this

set

eguipment.

fit

the

four

smallest

A-dec

part

no.

O-ring

009-013-00.

sizes

in

A-dec

Page 20

MAINTENANCE

=

Porta-Cart

3406

4Ÿdec

BASIC

Given

of

go

tells

removing

This

every

so

be

If

the

rect

are

ponents

Neither

(No

1.

2.

3. Is

TROUBLESHOOTING

proper

reliable

wrong

what

troubleshooting

problem

that

you

repaired

procedures

the

problem,

given

in

of

of

Air

or

Does

the

Yes:

Check

tubing.

Control

No:

Proceed

Is

the

air

turned

Yes:

Proceed

No:

Correct

re-test

the

air

Yes:

Refer

No:

Connect

unit.

care,

your

service.

with

can

the

can quickly

the

the

supply

ON

In

the

unit,

be

done

unit

for

that

could

without

the

Water)

syringe

supply

special

given

much

sections

Porta-Cart

Handpieces

for a pinched

If

the

section

to

Step

(compressor

and

operating

with

any

problems

the

unit.

tubing

to

the

Regulators

the

air

Porta-Cart

the

event

this

in

repair.

guide

is

arise.

identify

training

here

do

more

covering

system.

work?

tubing

is

on

2.

Step

3.

properly

supply

will

provide

that

something

troubleshooting

the

operatory,

not

intended

Rather

the

problems

not

identify

detailed

the

to

it

is

designed

that

or

equipment.

and

instructions

individual

Work

or

crimped

okay,

page

or

bottled

properly?

in

the

section

tubing,

foot

refer

to

28.

gas

air

supply.

connected?

on

and

re-test

the

system)

page

years

does

guide

before

isolate

can

cor-

com-

control

Foot

then

19.

the

No

Water

1.

Test

Yes:

No:

2.

Check

Toggle

OPEN?

Yes:

No:

3.

Does

Yes:

No:

Insufficient

1.

Does

Yes:

No:

2.

Check

show a pressure

Yes:

No:

3.

Watch

ing

by

Yes:

the

Proceed

Verify

ne

N.

the

ON?

Proceed

Set the

unit.

the

Refer

tion

Refer

the

Proceed

Refer

cedure

on

the

Proceed

Refer

the

the

syringe

more

Remove

to

the

Coolant

syringe.

Water

handpiece

on

problems

page

system

than

page

No:

Refer

From

Does

with

Step

that

there

is

Pressure

controls.

Are

controls

to

the

page

to

the

Drive

to

the

in

system

to

the

instructions

Is

the

Water

with

Step

Century

20.

Signal

Air

affect

to

Step

Drive

the

Routine

10.

air

of

at

to

Step

Regulators

air

pressure

air

button.

15

psi?

and

inspect

as

air

18.

to

the

Foot

Control

Either

it

spray

2.

water

in

On-Off

the

Water

Coolant

3.

specified

coolant

II

Control

Relay

section

Pressure

both

2.

Air

Pressure

Adjustments

pressure

least

60

3.

secton

gauge

Does

the

air

in

the

Filters

section

Handpiece

water?

the

tank

toggle

Coolant

work?

handpieces?

gauge.

psi?

the

filter

is

Flow

and

re-test

System

on

adjusting

on

while press-

pressure

according

section

on

and

that

turned

On-Off

Controls

the

sec-

page

30.

pro-

section

Does

it

page

19.

drop

on

page

28.

16

Page 21

Porta-Cart

3406

MAINTENANCE

SALIVA

L!

Esecron

see

AIR

Le

AIR

vacuum

SYSTEM

10072900

WASTE-

CONTAİNER

—E

SCHEMATIC

AVS

&

TUBING

@|

‘ость

品 一

DIAGRAM

HANDPIECE

ASSY

NEEDLE

VALVES

(2

EA)

19-0361-00

QUICK-DISCONNECT

925-05-00

e a

26002300

MINEFILTER

19-0100-00

WATER

REGULATOR

24028100

AIR

REGULATOR

02504100

FILTER

026-073-00

026.073

00

CENTURY

CONTROL

56019100

ASSY

AUTOMATIC

HOLDERS

se.0528.00

HANDPIECE

SOFT

TOUCH

BUTTON

SYRINGE

23-0088-00

AIR

IN

17

FOOT

CONTROL

36.025"

06

AIR

WATER

VACUUM

~

B

D>

GAUGE

12610300

Page 22

MAINTENANCE

INLET

AIR

FILTER/REGULATOR

FILTERS

Porta-Cart

IN-LINE

3406

MINI-FILTER

a

dee

SERVICE

BREAKDOWN:

Description

The

entering

be

to

impede

Checking

To

check

the

air

the

water

Watch

the

air

drops

syringe,

Air

The

(97-0280-00)

to

the

PARTS

PAGE

air

and

water

the

serviced

the

a

the

top

of

the

supply.

water

syringe

is

supply

source.

the

15

psi,

by

any

the

ufo

Filter

air

filter

bottom

Be

system

buttons.

element

Service

when

38

supplies

regulators,

flow

the

Filters

condition

Porta-Cart,

sure

and

for

more

>

consists

housed

of

the

The

they

become

to

the

si

of

there

tube

is

pressure

The

maximum

water

than

is

clogged

of a replaceable

in a

regulator.

PURGE

pass

through

filter

elements

sufficiently

regulators.

the

filter

elements,

and

connect

is

water

in

the

connected

gauges

is

10

this

and

transparent

while

pressure

psi.

If

while

must

It

also

FİLTER

ELEMENT

97-0280-00

VALVE

filters

before

should

clogged

remove

the

unit

to

tank

or

to

an

external

pressing

drop

the

pressure

operating

be

serviced.

filter

element

bow!

attached

serves

as

FIGURE

its

that

for

the

a

36

moisture

bowl,

valve.

To

the

by

pressing

tank.

screw

ment

Kit

Water

The

with a reusable

nect

fore

the

ing

disc

the

positioned

separator.

it

should

replace

air

(90-0030-00)

water

servicing

filter

and

with

AVS

a

supply

the

Unscrew

the

filter

is

included

Filter

is

filtered

the

water

housing

remove

isopropyl

handpiece.

when

clogged

tube,

the

element

Service

supply

the

the

When

be

released

air

and

relieve

syringe

porous

button

bowl

from

retainer.

in

the

Air

in

the

Porta-Cart

by

an

disc

tube from

filter.

Remove

together,

filter

disc

alcohol,

Be

assembling

liquid

accumulates

by

pressing

filter

element,

pressure

and

the

A

Filter-Regulator

in-line

Mini-filter

filter

the

then

separate

(19-0220-00).

then

thoroughly

sure

the

the

FILTER

ELEMENT

18022000

SERVICE

BREAKDOWN:

venting

regulator,

replacement

Accessory

element.

the

water

screws

O-ring

filter

PARTS

PAGE

in

the

the

purge

disconnect

from

the

unit

the

water

then

un-

ele-

Service

Kit.

(19-0100-00)

Discon-

tank

be-

that

hold

the

hous-

Clean

the

dry

it

with

is

properly

housing.

37

18

Page 23

a'dec

Porta-Cart

WATER