Page 1

85.0812.00, 2003 i

Contents

Identifying A-dec Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-2

Identifying Tubing Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-3

Locating Serial/Model Number Labels . . . . . . . . . . . . . . . . . . . . .PR-7

Troubleshooting Performer I Chair . . . . . . . . . . . . . . . . . . . . . . . . .PR-13

Troubleshooting Performer II Chair . . . . . . . . . . . . . . . . . . . . . . . .PR-19

Adjusting the Hydraulic Manifold . . . . . . . . . . . . . . . . . . . . . . . . .PR-25

Installing a Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-26

Correcting Hydrostatic Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-28

Testing and Programming the Circuit Board . . . . . . . . . . . . . . . .PR-34

Testing Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-35

Identifying New Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-38

Using the Headrest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-44

Removing the Helical Drive Shaft . . . . . . . . . . . . . . . . . . . . . . . . .PR-47

Adjusting the Base Positioning Potentiometer . . . . . . . . . . . . . . .PR-49

Adjusting the Base Up Limit Switch . . . . . . . . . . . . . . . . . . . . . . .PR-50

Programming the Chair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-51

Programming Function 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-52

Troubleshooting Foot Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-73

Troubleshooting the Control Block . . . . . . . . . . . . . . . . . . . . . . . . .PR-79

Troubleshooting Syringes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-83

Working with the Holder Valve Assembly . . . . . . . . . . . . . . . . . .PR-84

Activating the Holder Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-87

Adjusting the Accessory Tray Holder Height . . . . . . . . . . . . . . . .PR-88

Adjusting the Accessory Tray Holder Arm Tension . . . . . . . . . .PR-88

Adjusting the Light Head Vertical Tension . . . . . . . . . . . . . . . . . .PR-91

Adjusting the Light Head Horizontal Tension . . . . . . . . . . . . . . .PR-91

Focusing the Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-91

Adjusting the Flexarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-92

Troubleshooting Dental Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-93

Troubleshooting Cuspidors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-99

Troubleshooting Air Vacuum Generator . . . . . . . . . . . . . . . . . . . .PR-103

Troubleshooting Water Saliva Ejectors . . . . . . . . . . . . . . . . . . . . . .PR-111

Adjusting Holder Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PR-120

Adjusting Tension on the Assistant’s Arm . . . . . . . . . . . . . . . . . .PR-120

Troubleshooting Assistant’s Instrumentation . . . . . . . . . . . . . . . .PR-121

Page 2

85.0812.00, 2003 PR-1

Performer Overview

This section provides descriptions, service, maintenance, adjustment, and troubleshooting detail on

the Performer product line.

Page 3

85.0812.00, 2003 PR-2

Performer Tubing

Identifying

A-dec Tubing

Using

Suggested Fittings

Identifying Detail

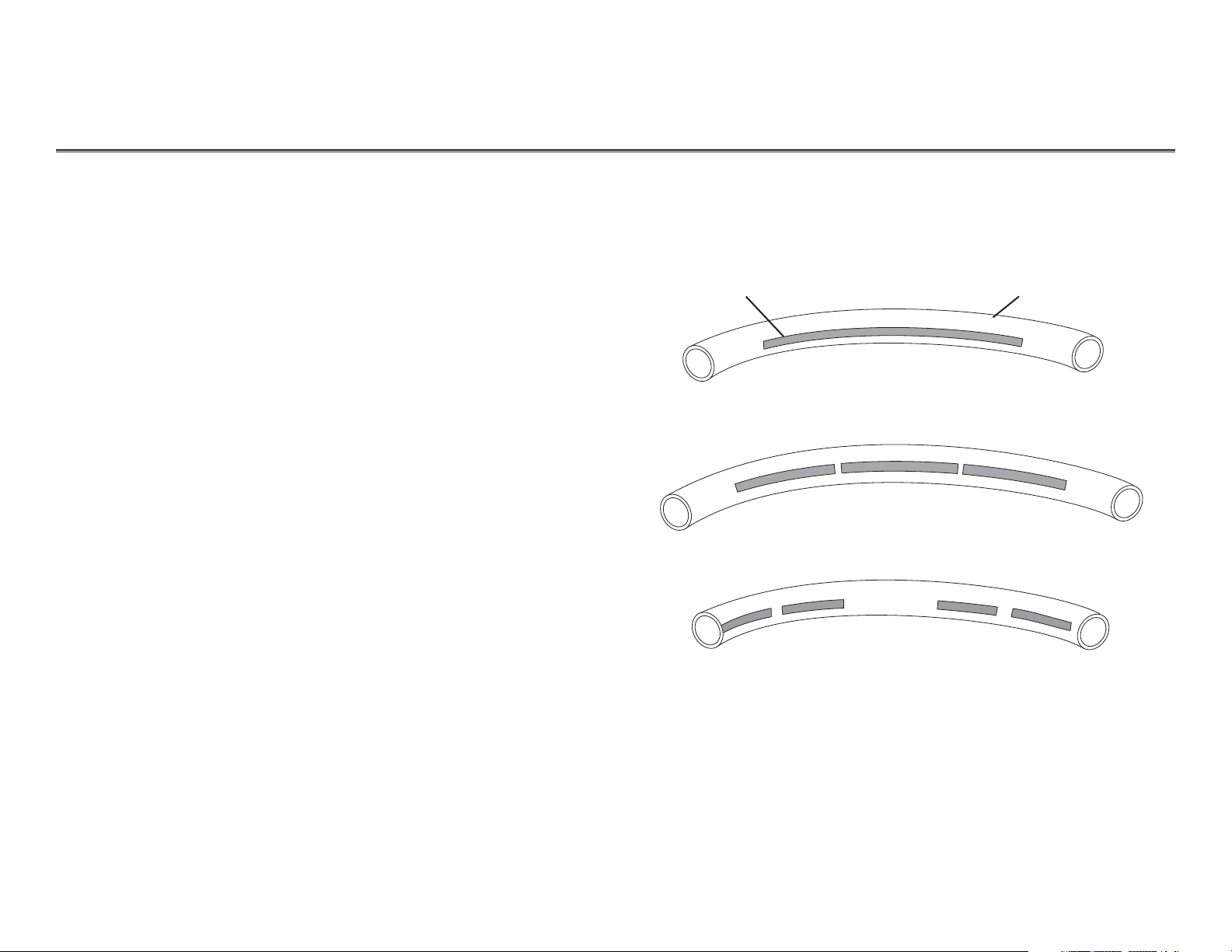

This section identifies the tubing type

used when servicing A-dec products.

Allow adequate length when installing

to avoid crimping or bending of

tubing. The use of the appropriate

tools can improve the ease of tubing

installation or replacement.

Unit-clamps or tubing sleeves must be

used to ensure a good seal and to

prevent tubing from coming off barbs.

For 1/4" polyurethane tubing,

use 1/4" barbs with sleeves and 1/4"

Poly-Flo fittings.

For 3/8" Polyurethane tubing,

use 3/8" Poly-Flo fittings.

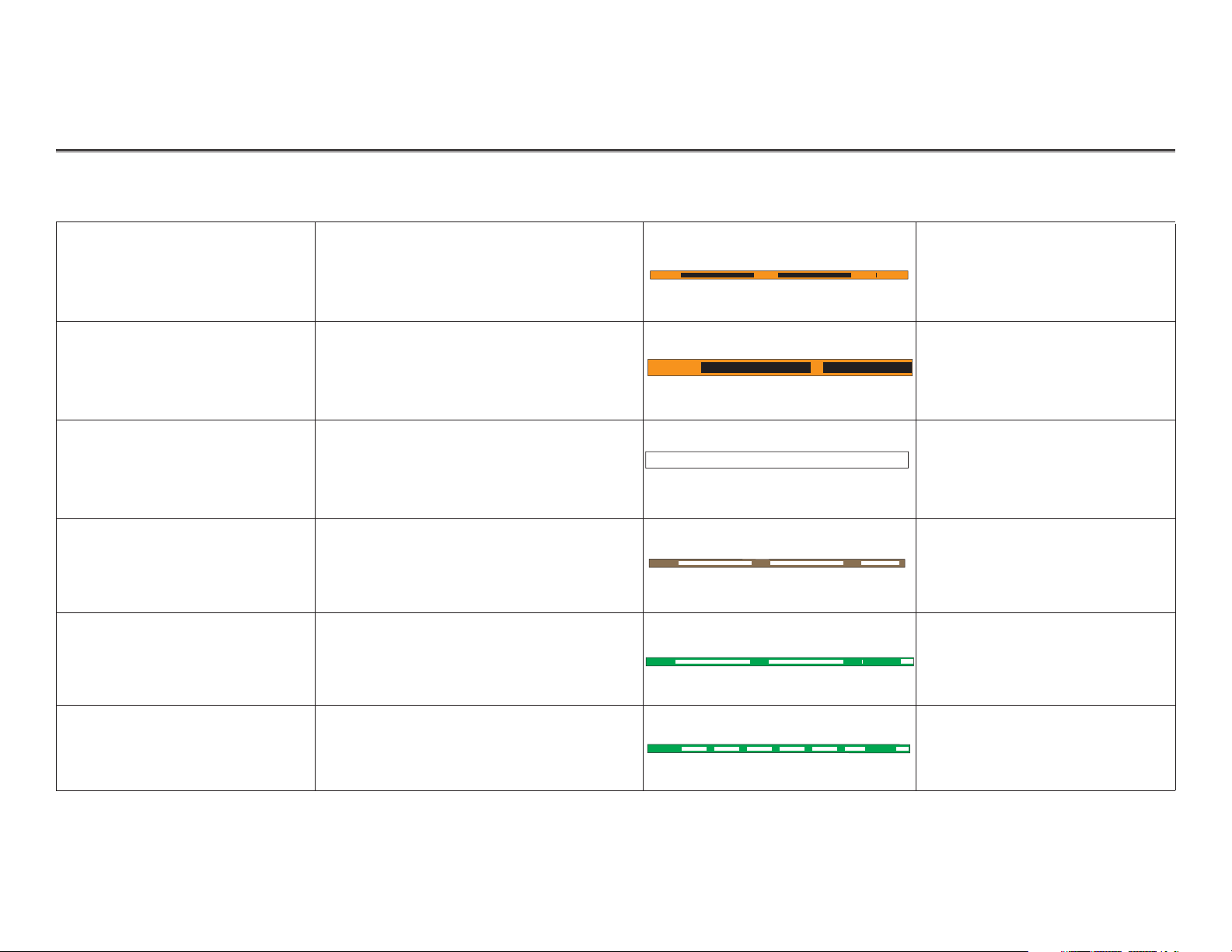

When identifying tubing, the body

color of the tubing is the “tubing

color”. The line and/or the A-dec

name printed on the tubing are the

“tracer markings”. These two details

will identify the type of tubing you

will need and its use.

Color of tubing

Tracer marking

Tubing with stripe tracer

Tubing with long dash tracer

Tubing with short dash tracer

Tubing Identification Details

A-DEC

A-DEC

A-DEC

A-DEC

A-DEC

Page 4

85.0812.00, 2003 PR-3

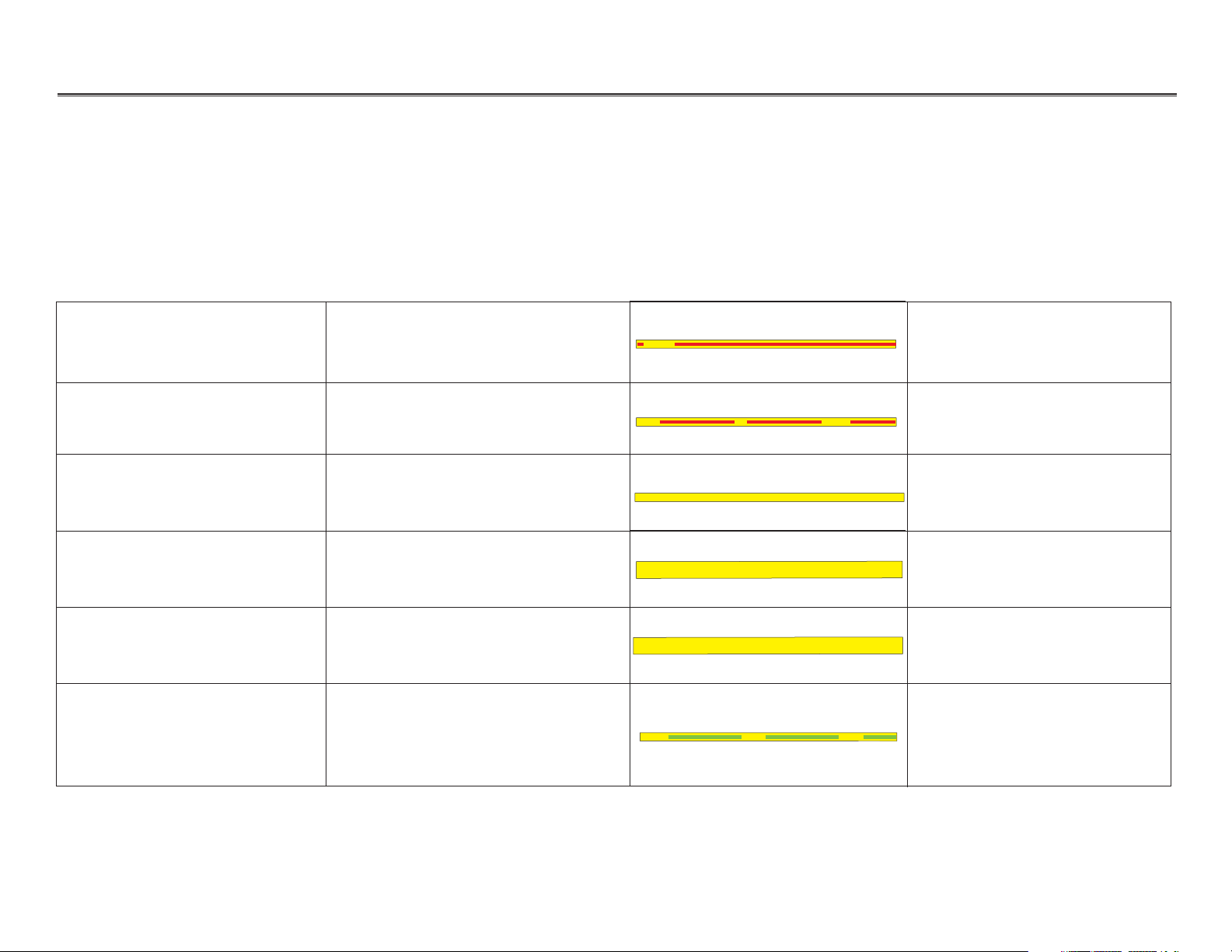

Performer Tubing

Tubing Function

Description Part NumberTubing Color

When installing or replacing tubing, allow enough length to avoid crimping or bending. Unit-clamps or

tubing sleeves must be used to ensure a good seal and to prevent tubing from coming off barbs.

The following table lists the different types of tubing and its function.

Identifying

Tubing Functions

Unregulated Air Continuous, filtered, unregulated air

— 1/8" OD from the air

regulator to On/Off toggle

036.013.03

Pilot Air Filtered unregulated air controlled by

Master On/Off toggle —1/8" OD

036.009.04

Regulated Air Supply Continuous, filtered, regulated air

—1/8" OD

036.003.03

Regulated Air Supply Regulated air — 3/8" OD 036.103.03

Regulated Air Supply Regulated air — 3/8" OD 036.031.02

Regulated Air (40 psi) Regulated air at 40 psi to pressurize

the water bottle — 1/8" OD

036.044.03

A-DEC

A-DEC A-DEC

A-DEC

A-DEC

A-DEC

A-DEC

Page 5

036.006.03

Signal air/air coolant from foot control,

signal air for cuspidor cup filler and

vacuum actuator — 1/8" OD

Signal Air, Coolant Air

85.0812.00, 2003 PR-4

Performer Tubing

Tubing Function

Description

Part Number

Tubing Color

Drive Air Drive air for pressure gauge — 1/8" OD 036.010.03

Drive Air Drive air for foot control — 1/4" OD 036.052.03

Drive Air Handpiece drive air (clear) — 1/4" OD 036.066.03

Chip Blower Air Air for chip blower — 1/8" OD 036.014.02

Signal Air, Water Coolant Signal air/water coolant from foot

control, signal air for cuspidor bowl rinse

— 1/8" OD Signal

036.018.03

A-DEC A-DEC

A-DEC

A-DEC A-DEC

A-DEC

A-DEC A-DEC

A-DEC

A-DEC

Page 6

85.0812.00, 2003 PR-5

Performer Tubing

Tubing Function

Description

Part Number

Tubing Color

Signal Air, Coolant Water Signal air (clear) from foot control relay to

wet/dry toggle — 1/8" OD

024.015.04

Water Supply Coolant water supply, handpiece water

— 1/8" OD

036.004.03

Oral Cavity Water Oral cavity water — 1/8" OD 036.005.03

Water Supply Regulated water, water to bowl rinse

— 1/4" OD

036.053.03

Water Supply

Unregulated water

— 3/8" OD

036.033.02

Return Water Return water, tank water heater, water to gravity

drain drip tube from syringes — 1/8" OD

036.011.03

A-DEC A-DEC

A-DEC A-DEC

A-DEC

A-DEC A-DEC

Page 7

85.0812.00, 2003 PR-6

Performer Tubing

Tubing Function

Description Part NumberTubing Color

Miscellaneous Miscellaneous line (white) for use with

A-dec authorized accessories — 1/8" OD

036.019.03

Hydraulic System Supply Low pressure hydraulic system supply for

chair (clear) — 3/8" OD

036.035.00

A-DEC A-DEC

A-DEC A-DEC

Page 8

85.0812.00, 2003 PR-7

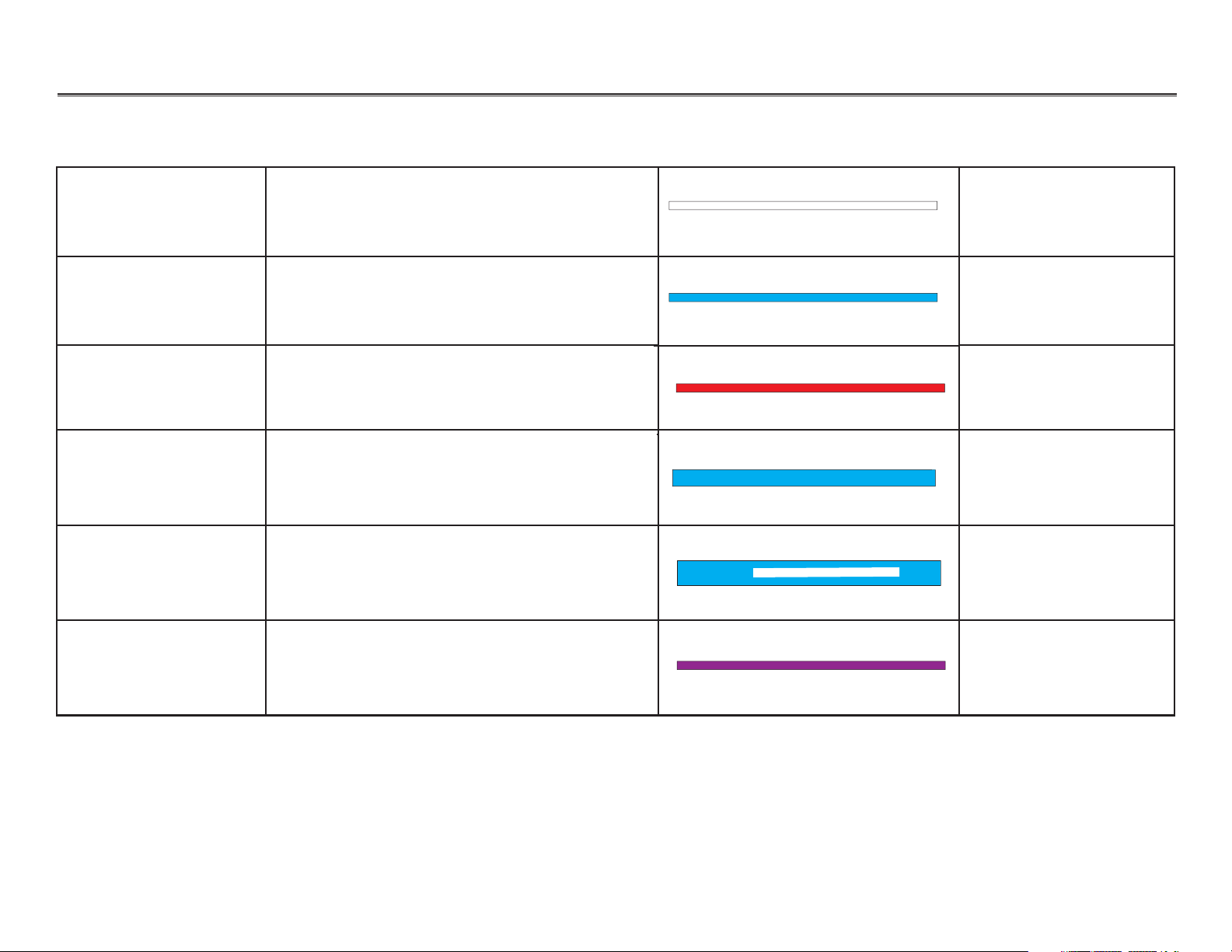

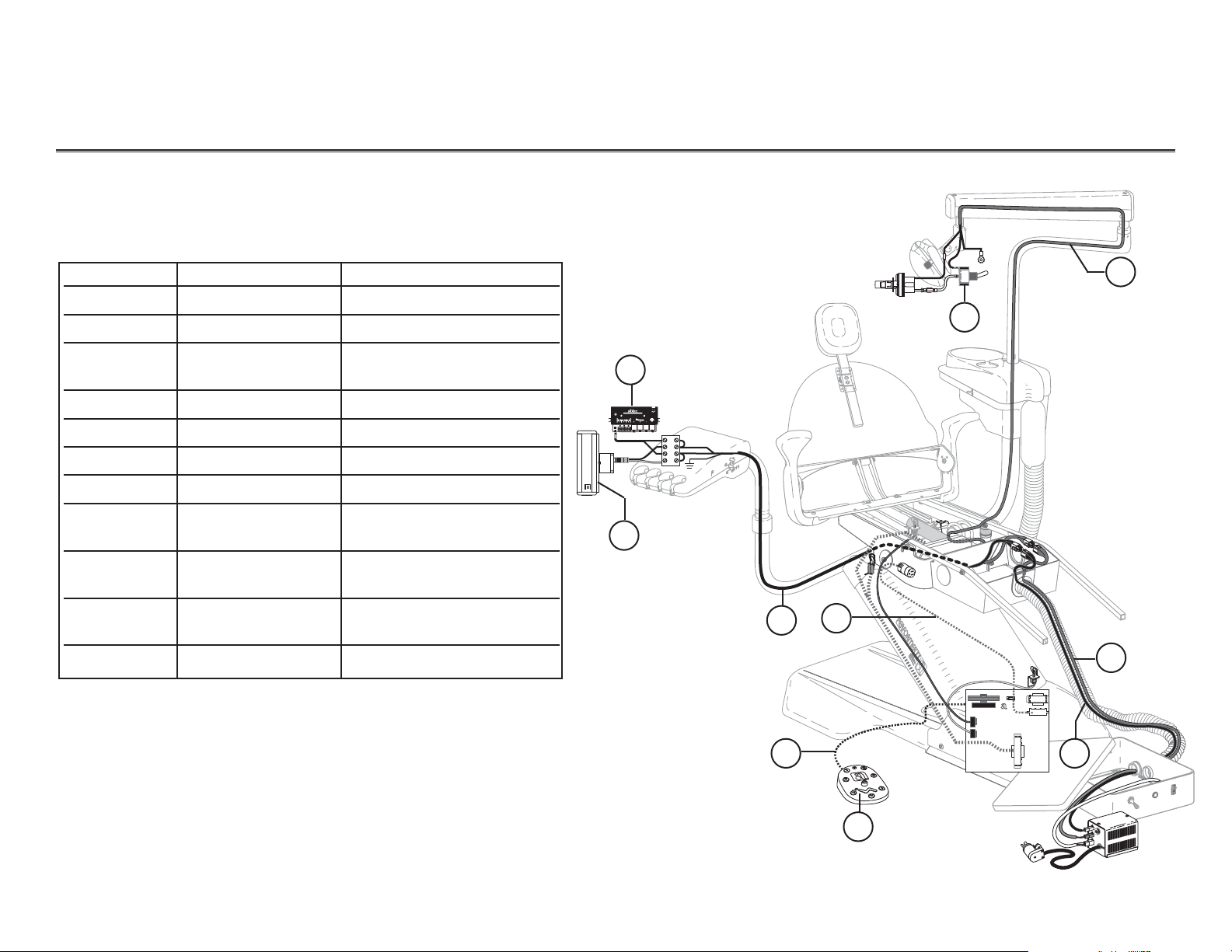

Performer Serial/Model Number Label

Locating Serial/Model

Number Labels

Item # Description

1 Month of manufacture

The first letter of the serial number indicates the month

the product was manufactured; e.g., A is January.

2 Last digit of the year manufacture

1

2

Serial/model number

tag (at base of arm)

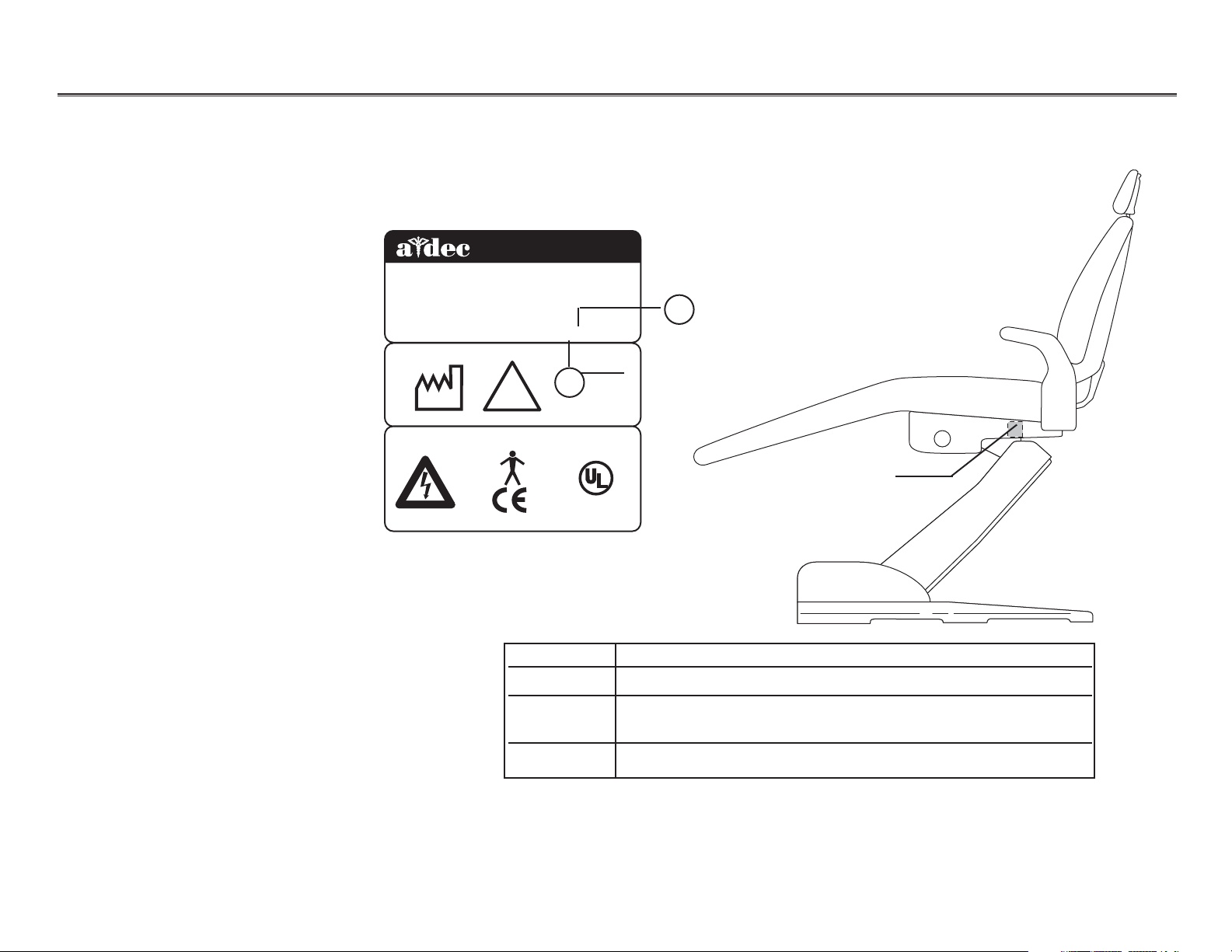

The serial/model number label identifies the chair model and the month and year in

which the chair was manufactured. This label is located on the underside of the righthand arm rest support.

2601 CRESTVIEW DRIVE

®

BERG, OREGON 97132 USA

NEW

Designated EU Representative: A-dec Dental U.K., Ltd.

Austin House, 11 Liberty Way, Attleborough Fields,

Nuneaton, Warwickshire, England CV 116RZ

DENTAL

CHAIR

MADE IN

USA

2001

CAUTION!

Tele: (44) 1203-350901

REF: 8000

!

DENTAL CHAIR

LABEL P/N: 051.515.02 REV L

S/N: J167856

INPUTS

-

120 V

10 AMPS MAX

50-60 Hz

C

®

LISTE

D

15VJ

U

S

Page 9

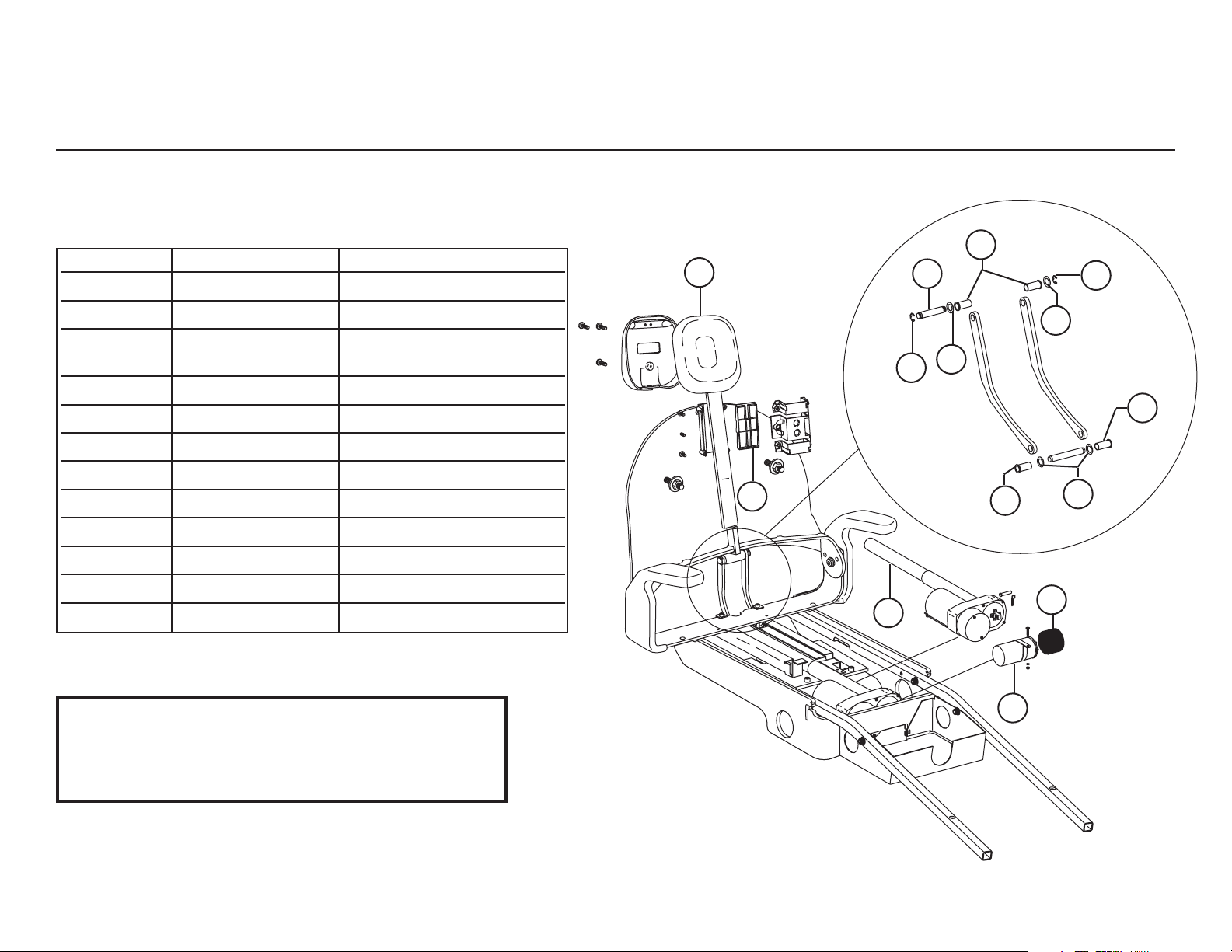

85.0812.00, 2003 PR-8

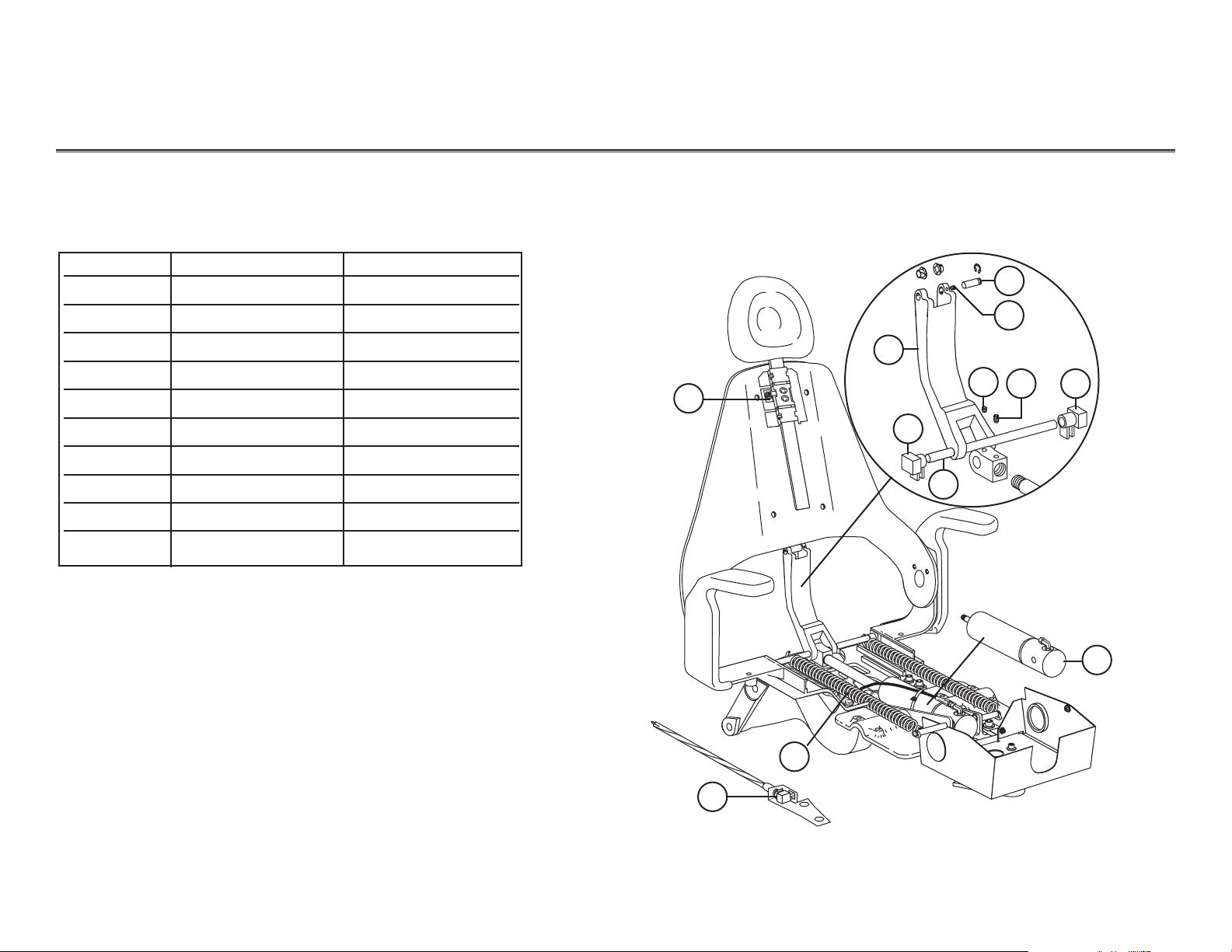

Performer Performer I

WARNING.

DO NOT

USE THE

HEADREST

IF THE

LINE IS

VISABLE.

Item # Part Number Description

1 (Obsolete) Single articulating headrest

61.2116.XX Double articulating headrest

2 61.1569.00 Wear pad, sliding

wedge molded

3 61.2409.00 115V tilt actuator

3 61.2410.00 230V tilt actuator

4. 041.529.00 Capacitor boot

5 90.1035.00 115V tilt actuator capacitor

90.1036.00 230V tilt actuator capacitor

6 61.2181.00 Bearing, flanged

7 004.035.00 Washer, flat, nylatron

8 010.040.01 E-ring, retaining

10 61.2425.00 Pivot pin, back link

Performer I Upper Structure

1

2

8

7

6

4

5

3

7

8

9

6

7

6

WARNING

High voltages are present at motor and limit switch

connections. Unplug the chair before servicing. Failure

to do so could result in serious injury.

WARNING.

DO NOT

USE THE

HEADREST

IF THE

LINE IS

VISABLE.

Page 10

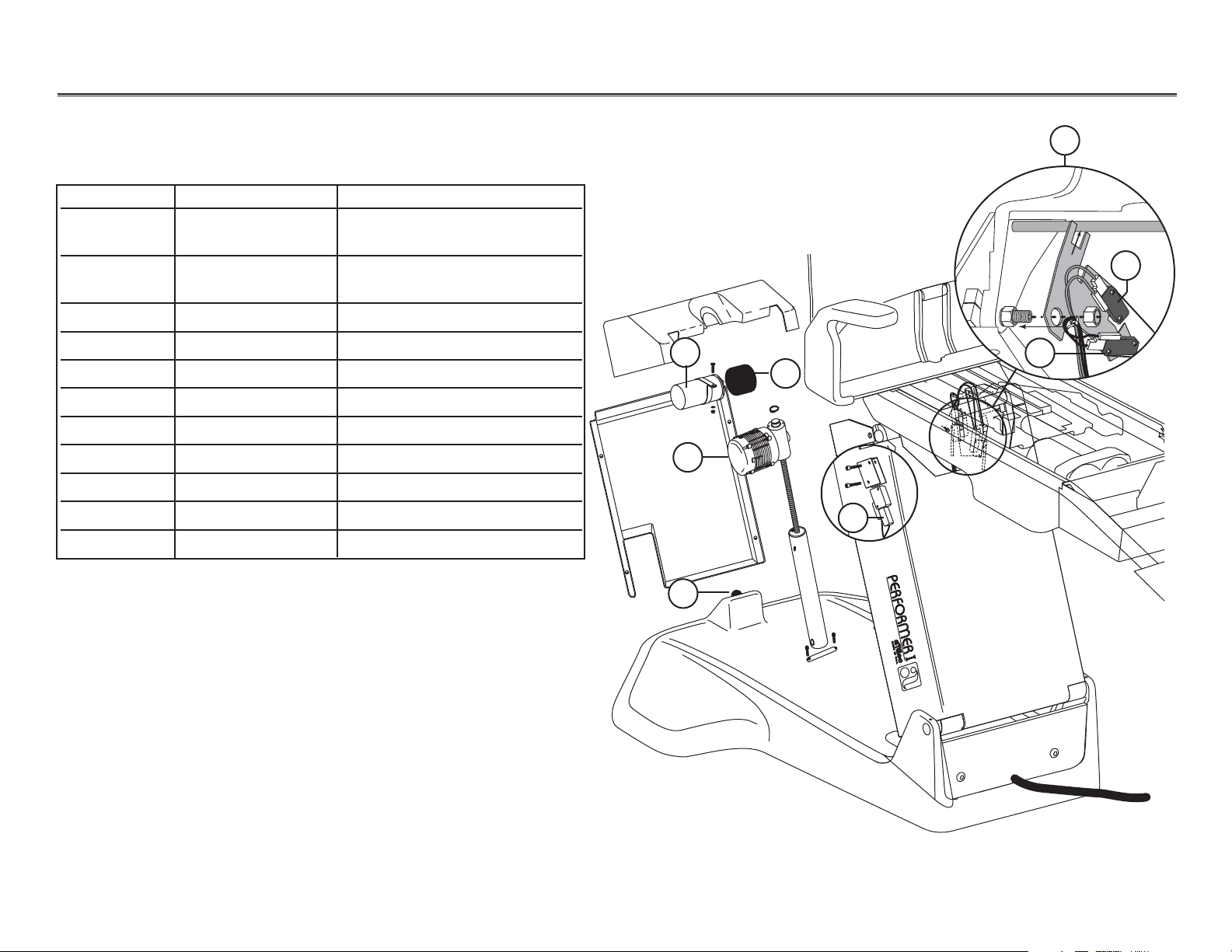

85.0812.00, 2003 PR-9

Performer Performer I

Performer I Base Structure

TM

TM

TM

TM

TM

1

3

4

2

6

8

7

NOTE: If the chair limit switch bracket assembly is not located in the

upper lift arm of the chair, it will need to be replaced with a

base limit switch kit, P/N 90.1000.00.

5

Item # Part Number Description

1 041.583.00 240V base capacitor

(after June 1998)

— 041.517.00 240V base capacitor

(before June 1998)

— 041.504.00 440V base capacitor

2 041.529.00 115V capacitor boot

3 61.2469.00 115V base actuator

— 61.2470.00 230V actuator

4 61.2483.00 Joystick chair control

5 90.1000.00 Base limit switch kit

6 044.183.00 Base down, shutoff switch

7 044.184.00 Base up limit switch (Red)

8 044.184.00 Base down limit switch (Black)

T

T

M

M

T

M

T

T

M

M

Page 11

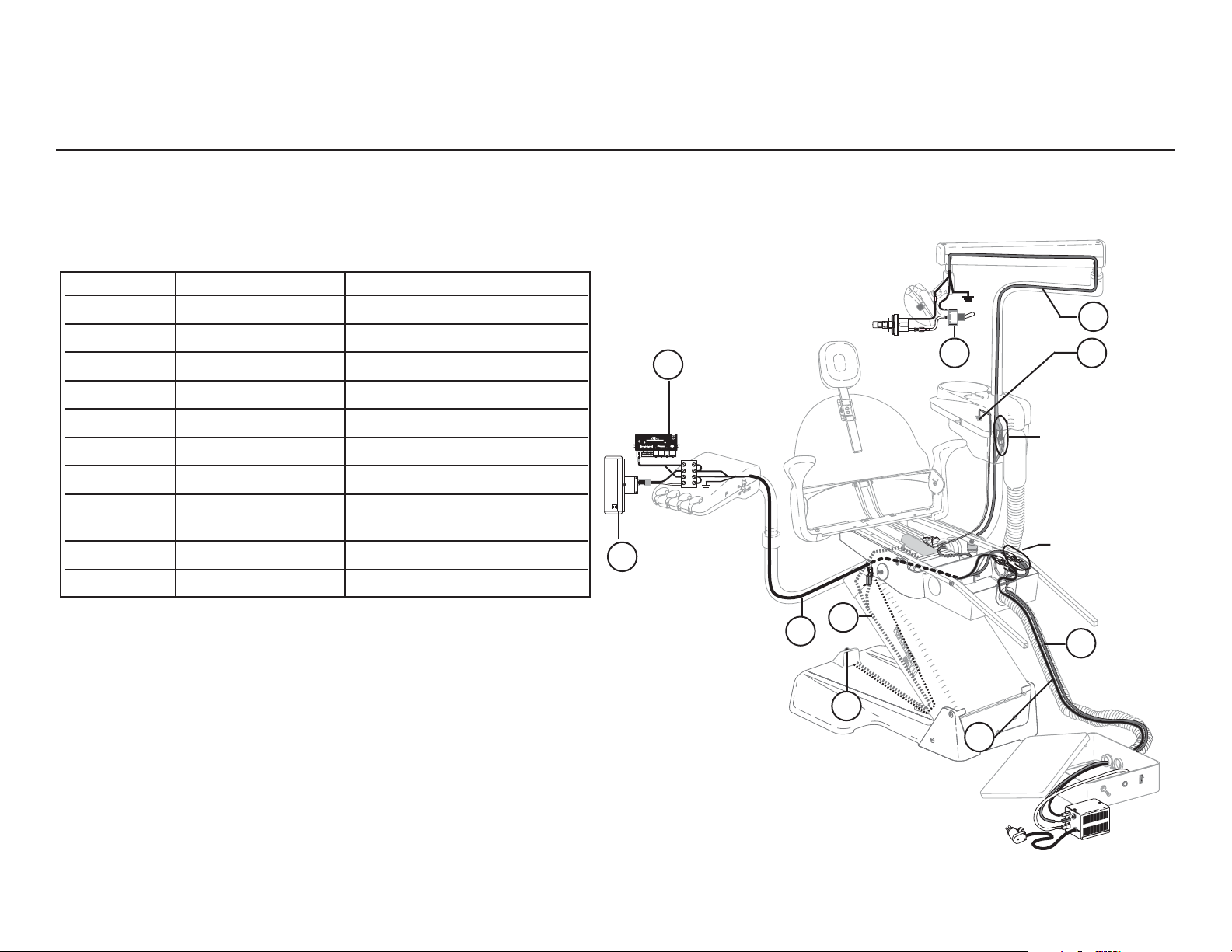

85.0812.00, 2003

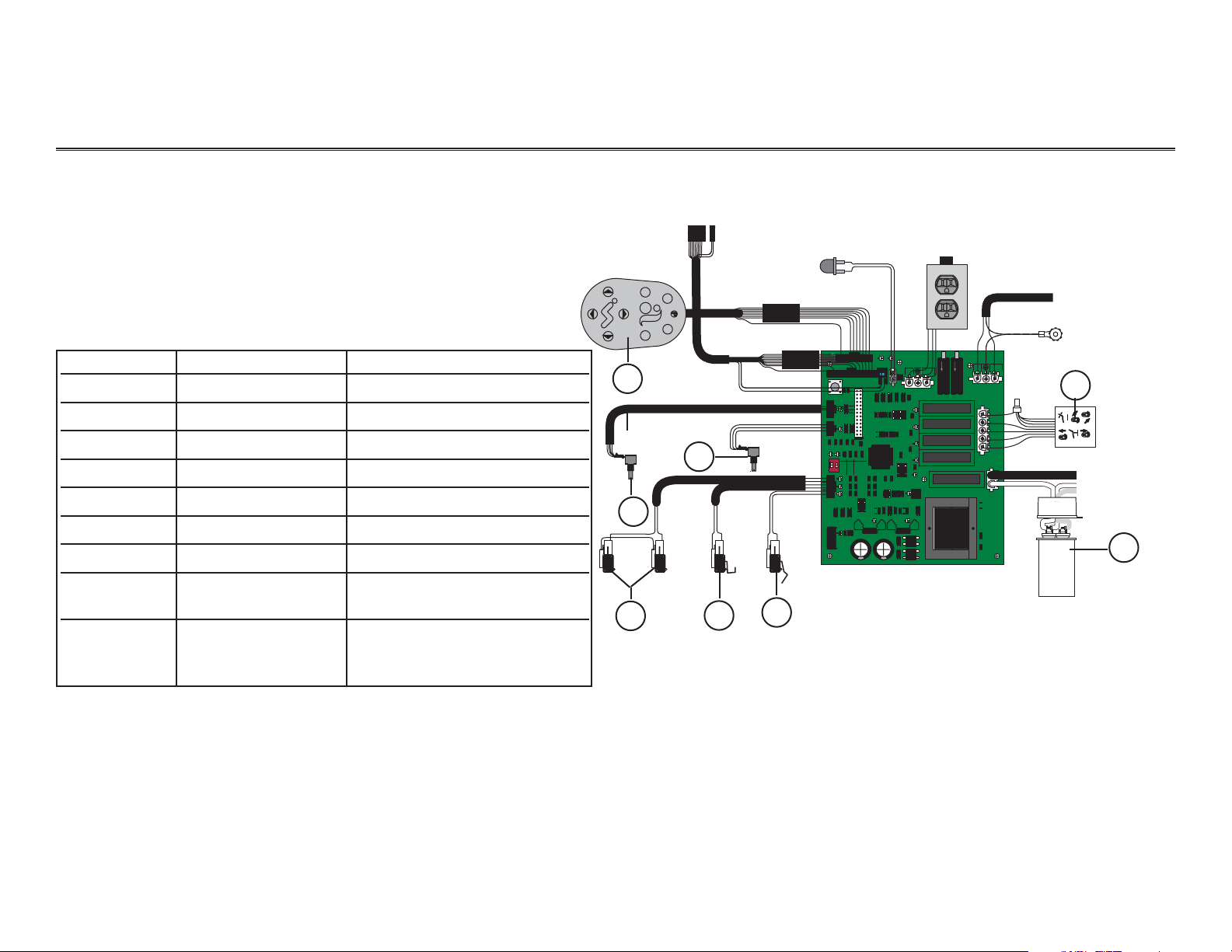

Performer Performer I Electrical Flow Diagram

INTRA OR AL

Item # Part Number Description

1 76.1005.00 Intra-oral light source kit

2 76.8000.00 Bitewing x-ray viewer

3 35.1673.00 Cable assembly

4 61.2582.00 Wire harness assembly

5 61.2483.00 Joystick, auto exit

6 35.1567.00 Cable assembly

7 28.1244.00 Cable assembly, dental light

8 41.1444.00 Ground wire assembly

(after April 1999)

9 90.1054.00 Cable assembly

10 90.1039.00 On/Off switch

1

2

3

4

5

6

7

8

9

10

Before January 1996,

dental light cable

assembly connected in

cuspidor housing.

After January 1996,

dental light cable

assembly connected

in the junction box.

Performer I Electronics

PR-10

ADJUST ONLY

PN 34-0064-00

WHEN BRIGHT

DANGER

INTRA ORAL

LIGHT SOURCE

2.9 - 4.25VDC .8AMP

POWER

24V

BRIGHT

/DC

AC

4321

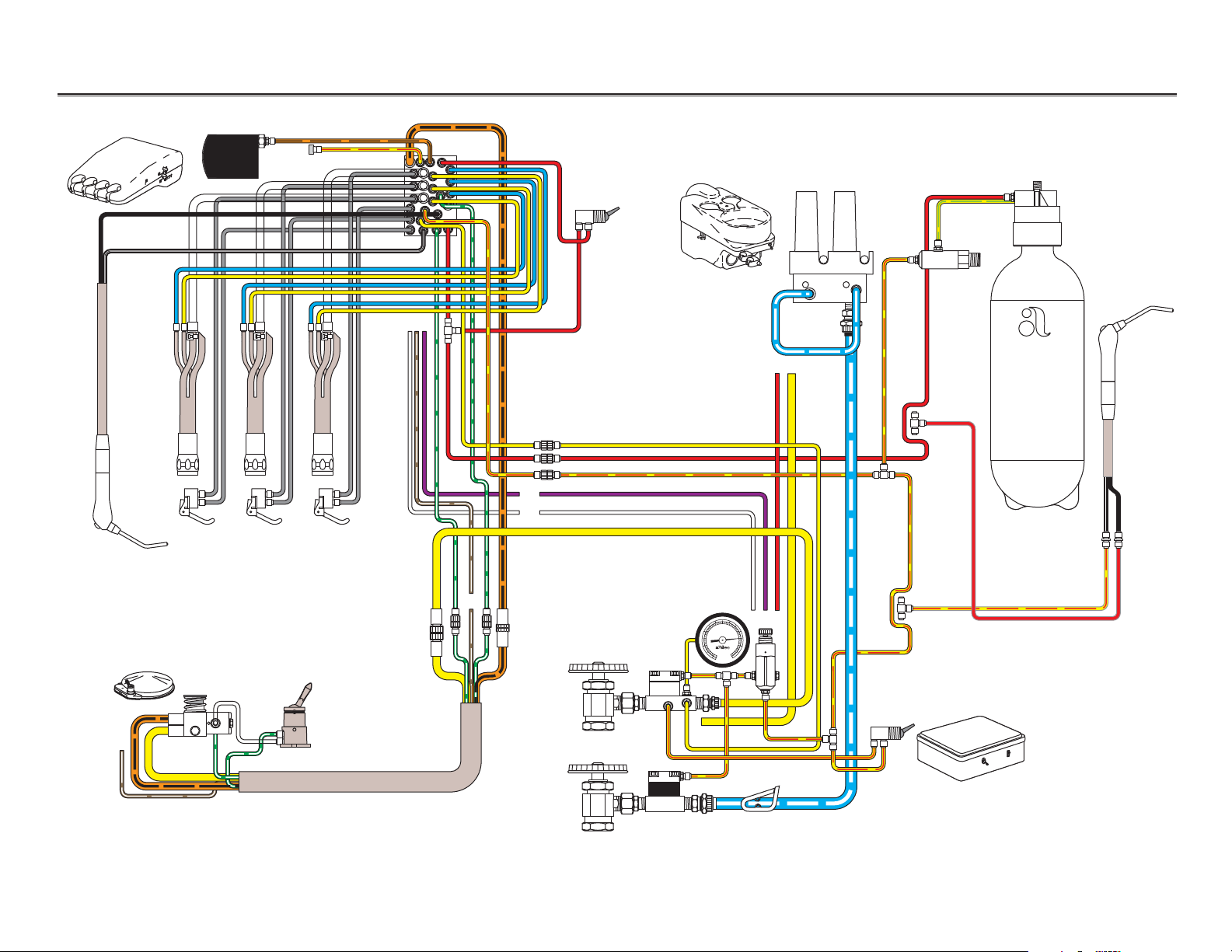

Page 12

85.0812.00, 2003 PR-11

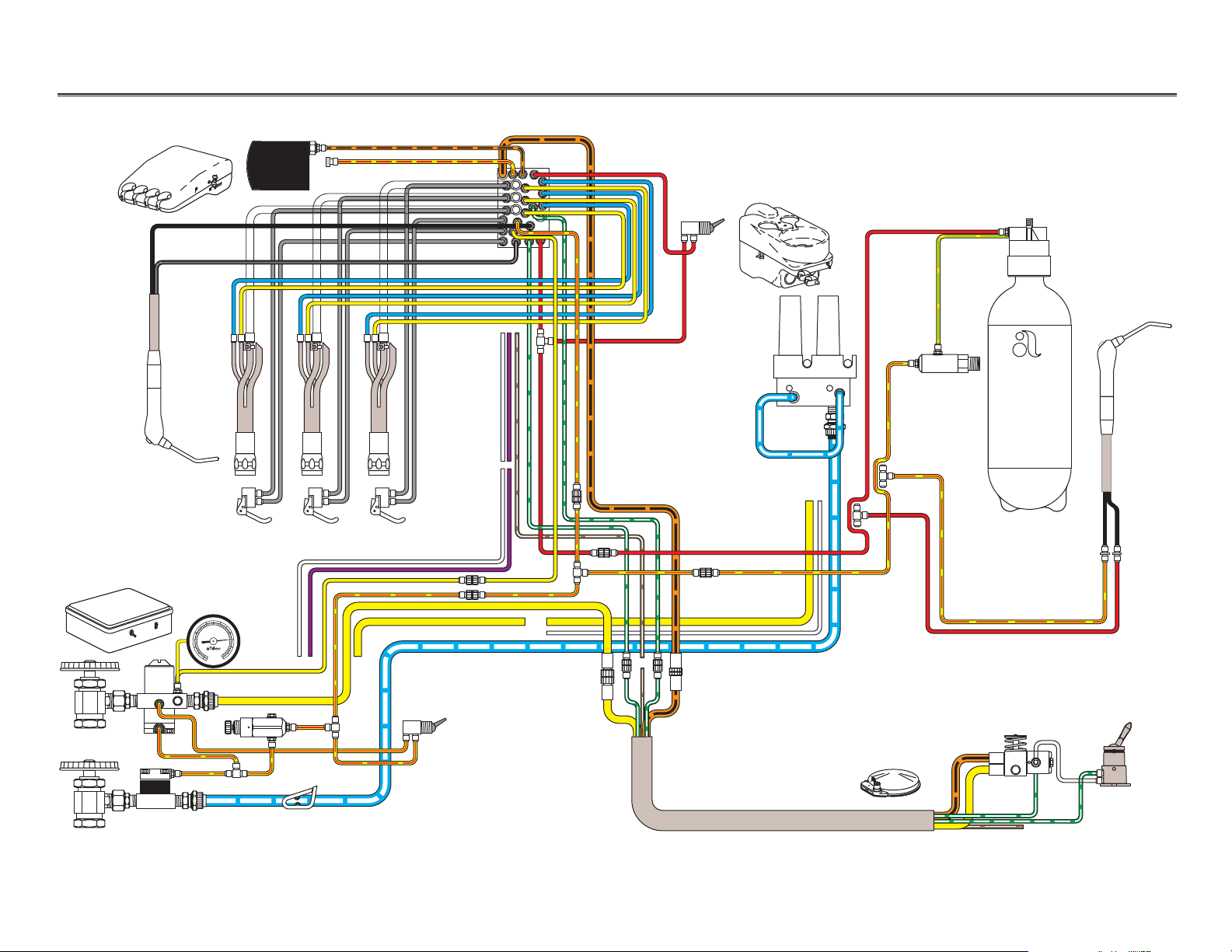

Performer Performer I Flow Diagram

Control head

Foot control

Cuspidor and Assistant’s instrumentation

Optional

assistant’s

syringe

Floor box

34

50

40

60

5

2

30

70

20

80

1

6

90

10

100

0

psi

2

7

0

kg/cm

Page 13

85.0812.00, 2003 PR-12

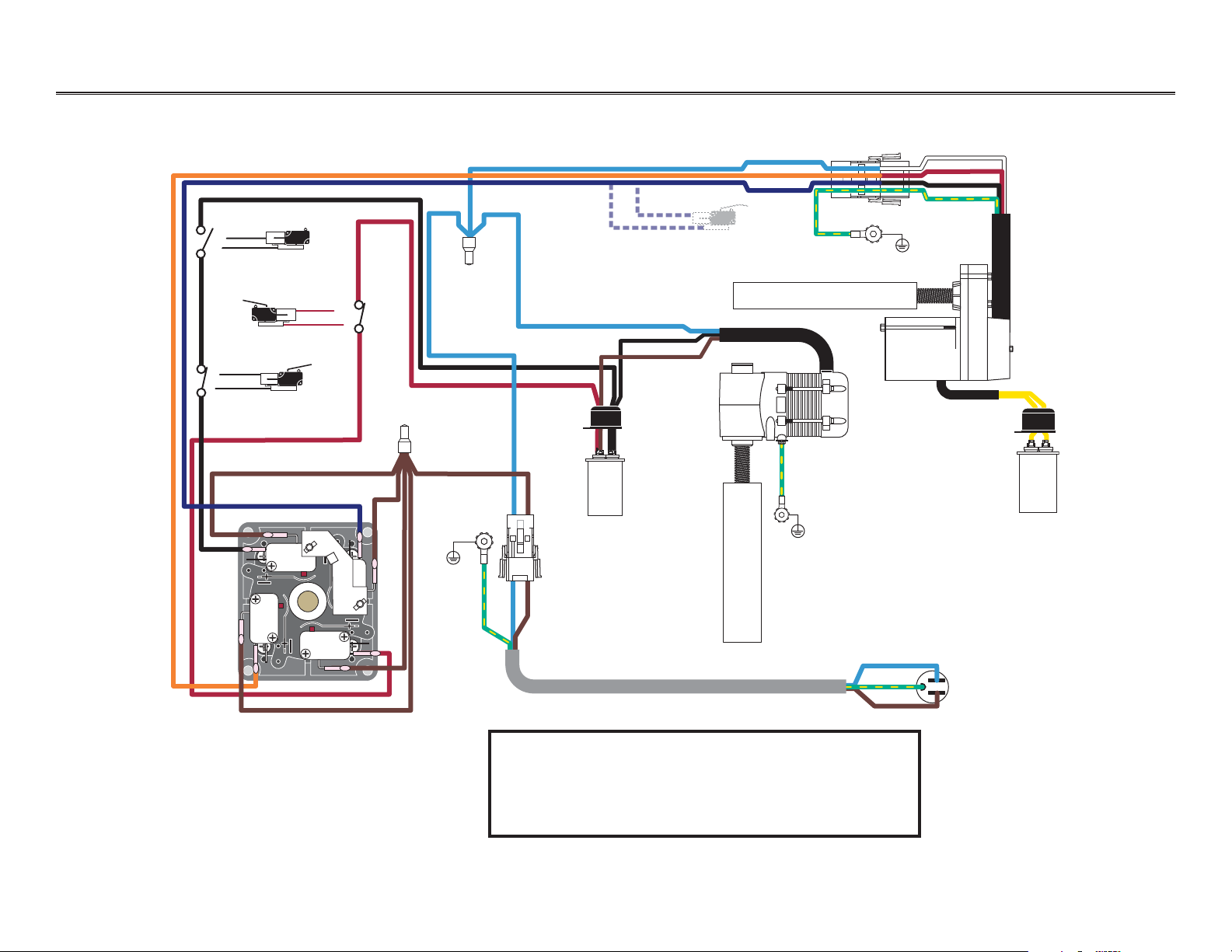

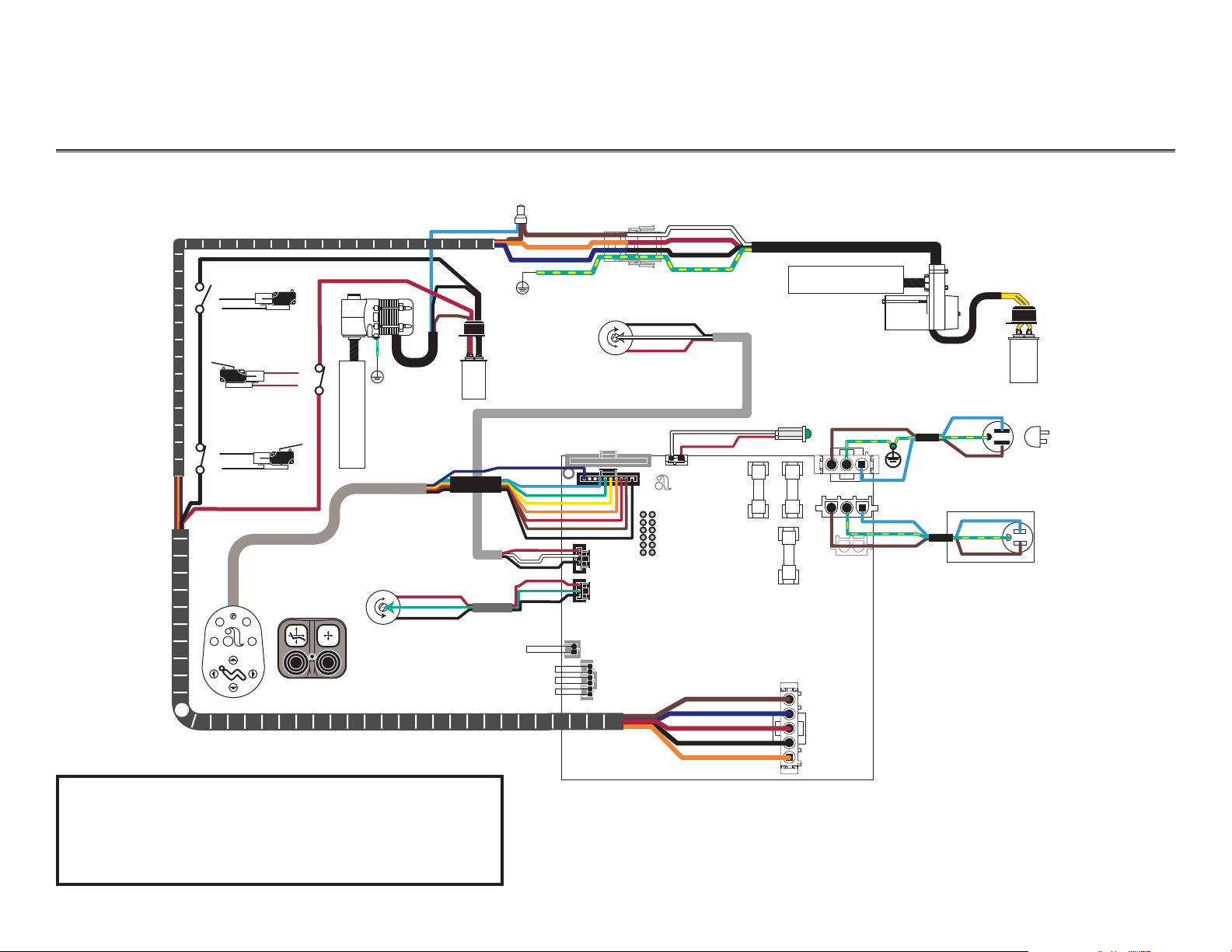

Performer Performer I Electrical Flow Diagram

Tilt actuator

Lift actuator

Tilt capacitor

Lift capacitor

Ground

Ground

BS

DN

BS

UP

BK

DN

BK

UP

Joystick (viewed from the bottom)

Base down

limit switch

Base down

shutoff switch

Base up

limit switch

AC plug

Ground

(NO)

(COM)

(NO)

(COM)

(NO)

(COM)

(NO)

(COM)

WARNING

High voltages are present at motor and limit switch

connections. Unplug the chair before servicing.

Failure to do so could result in serious injury.

Page 14

85.0812.00, 2003

Performer Troubleshooting

Problem

Action

Chair back is inoperative

Chair base is inoperative

Noisy motor

Follow these steps to determine the problem with the chair back.

Task Description

1Make sure system power is ON.

2 Check power and connections.

3 Check for bad capacitors.

Follow these steps to determine the problem with the chair base.

1Make sure system power is ON.

2 Check power and connections.

3 Check for bad capacitors.

Follow these steps to check the motor.

1 Check for loose mounts.

2 Adjust base screw drive nut.

3 Replace motor.

Tips and troubleshooting information are listed to assist in distinguishing Performer I chair problems.

Troubleshooting

Performer I Chair

PR-13

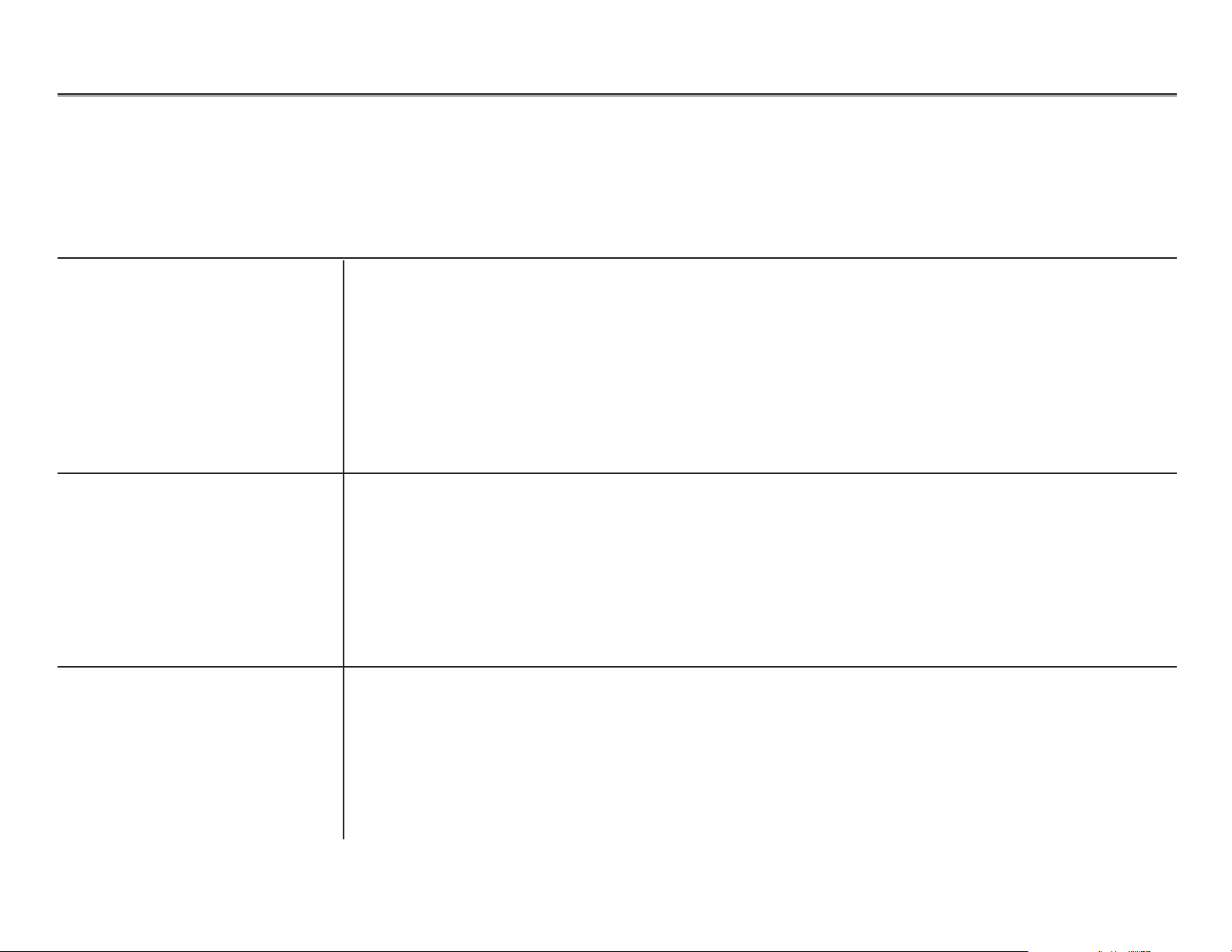

Page 15

85.0812.00, 2003 PR-14

Item # Part Number Description

1— Single articulating headrest

2 61.1569.00 Wear pad, sliding

wedge molded

3 61.2409.00 115V tilt actuator

61.2410.00 230V tilt actuator

4 041.529.00 Capacitor boot

5 90.1035.00 115V tilt actuator capacitor

90.1036.00 230V tilt actuator capacitor

6 041.372.00 Potentiometer, back up

7 61.2181.00 Bearing, flanged

8 004.035.00 Washer, flat, nylatron

9 010.040.01 E-ring, retaining

10 61.2425.00 Pivot pin, back link

Performer II Upper Structure

1

2

9

8

7

4

5

6

3

8

9

10

7

8

7

WARNING

High voltages are present at motor and limit switch

connections. Unplug the chair before servicing.

Failure to do so could result in serious injury.

Holder

Tubing, 3/8" OD

Helical drive shaft

Performer Performer II

ARNING.

W

DO NOT

USE THE

REST

HEAD

IF THE

LINE IS

VISABLE.

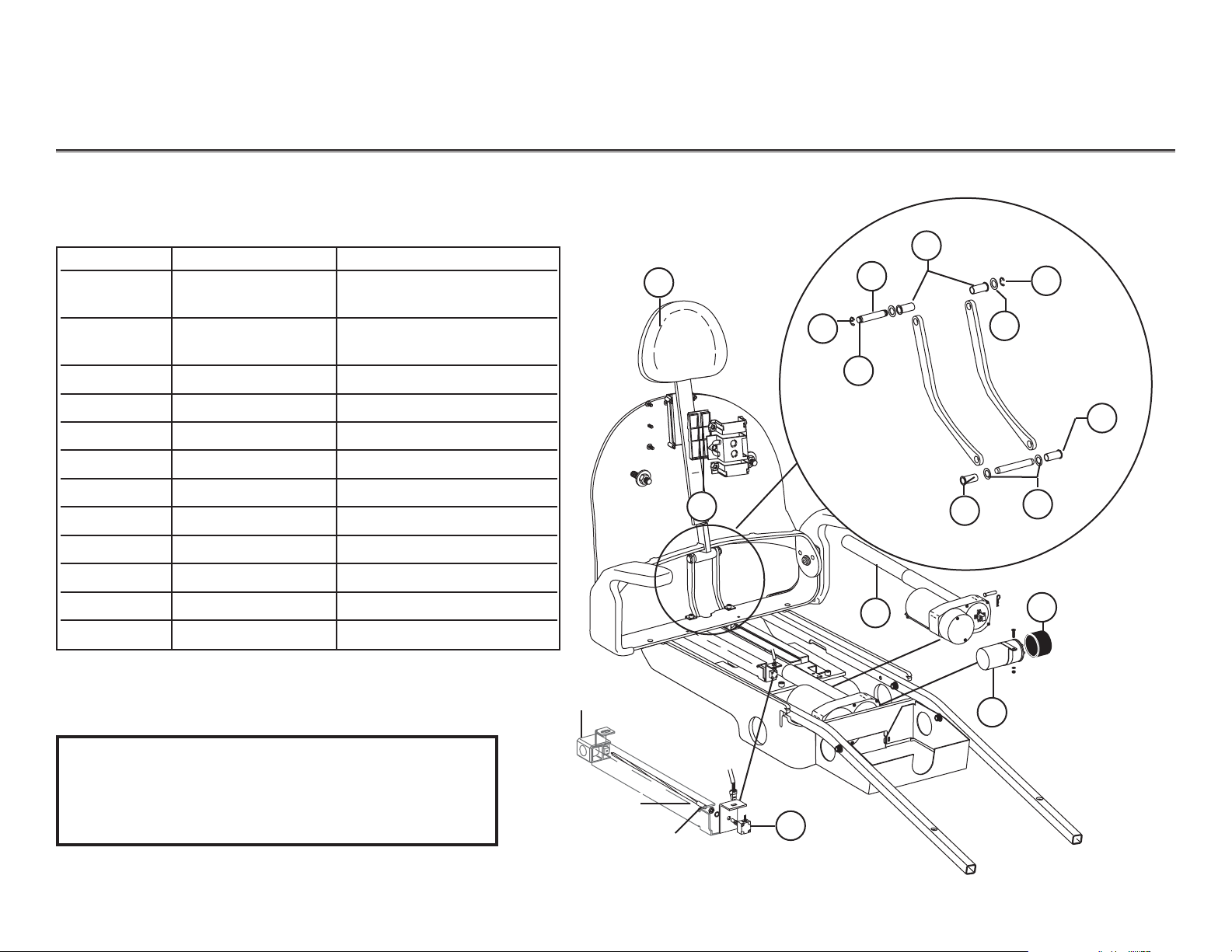

Page 16

85.0812.00, 2003

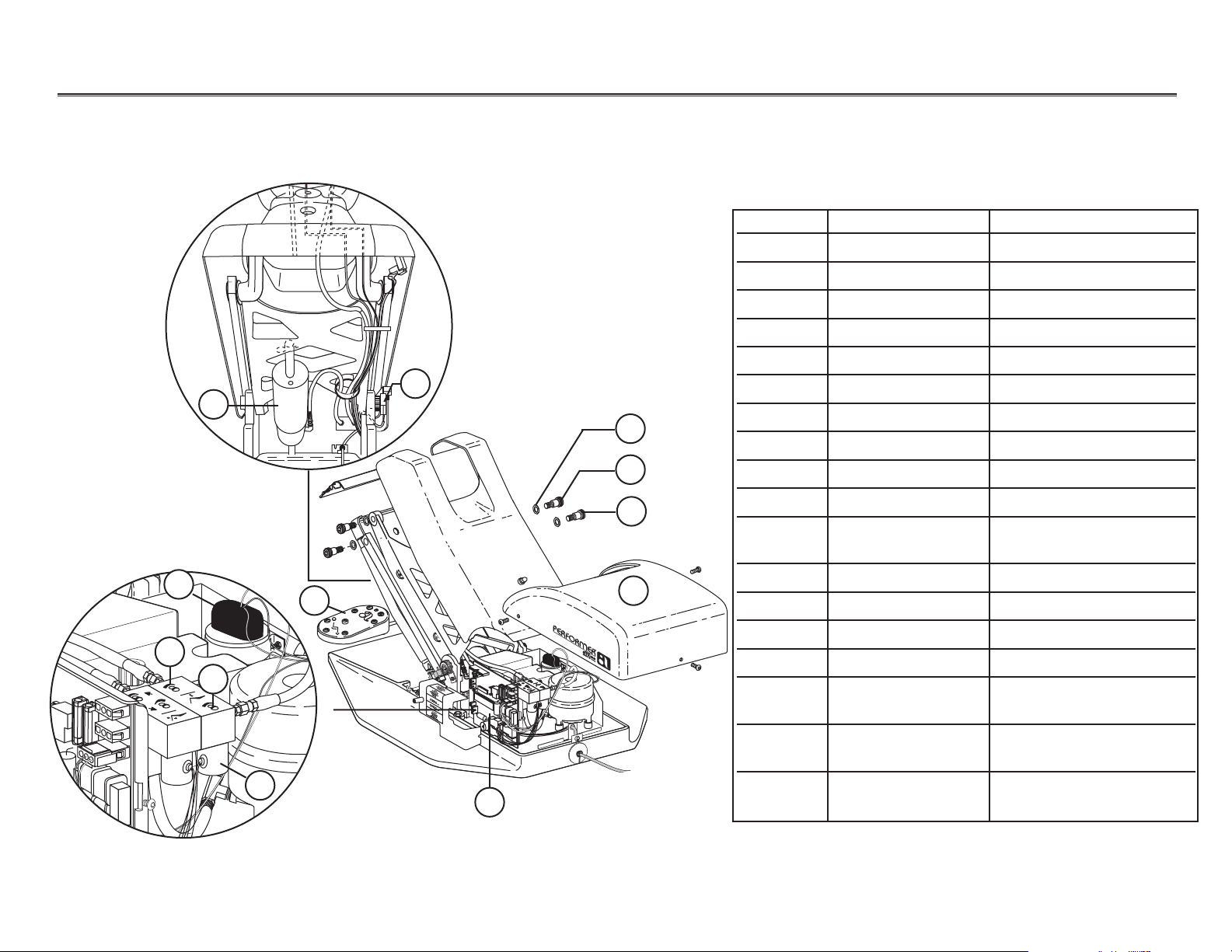

Performer Performer II

Item # Part Number Description

1 041.583.00 240V base capacitor

(after June 1998)

041.517.00 240V base capacitor

(before June 1998)

041.504.00 440V base capacitor

2 041.529.00 115V capacitor boot

(after June 1998)

041.529.00 115V capacitor boot

(before June 1998)

3 61.2469.00 115V base actuator

61.2470.00 230V base actuator

4— Base down shutoff switch

5 041.372.00 Potentiometer, base up

6 90.1000.00 Base limit switch kit

7 90.1029.00 100V/120V, PCB, chair

90.1029.01 220V/240V, PCB, chair

8 044.184.00 Base up limit switch (Red)

9 044.184.00 Base down limit

switch (Black)

Performer II, Base Structure

1

3

4

5

2

7

9

8

WARNING

High voltages are present at motor and limit switch connections. Unplug

the chair before servicing. Failure to do so could result in serious injury.

NOTE: If the chair limit switch bracket

assembly is not located in the

upper lift arm of the chair, it will

need to be replaced with a limit

switch bracket assembly kit,

P/N 90.1000.00.

6

PR-15

TMTMTMT

M

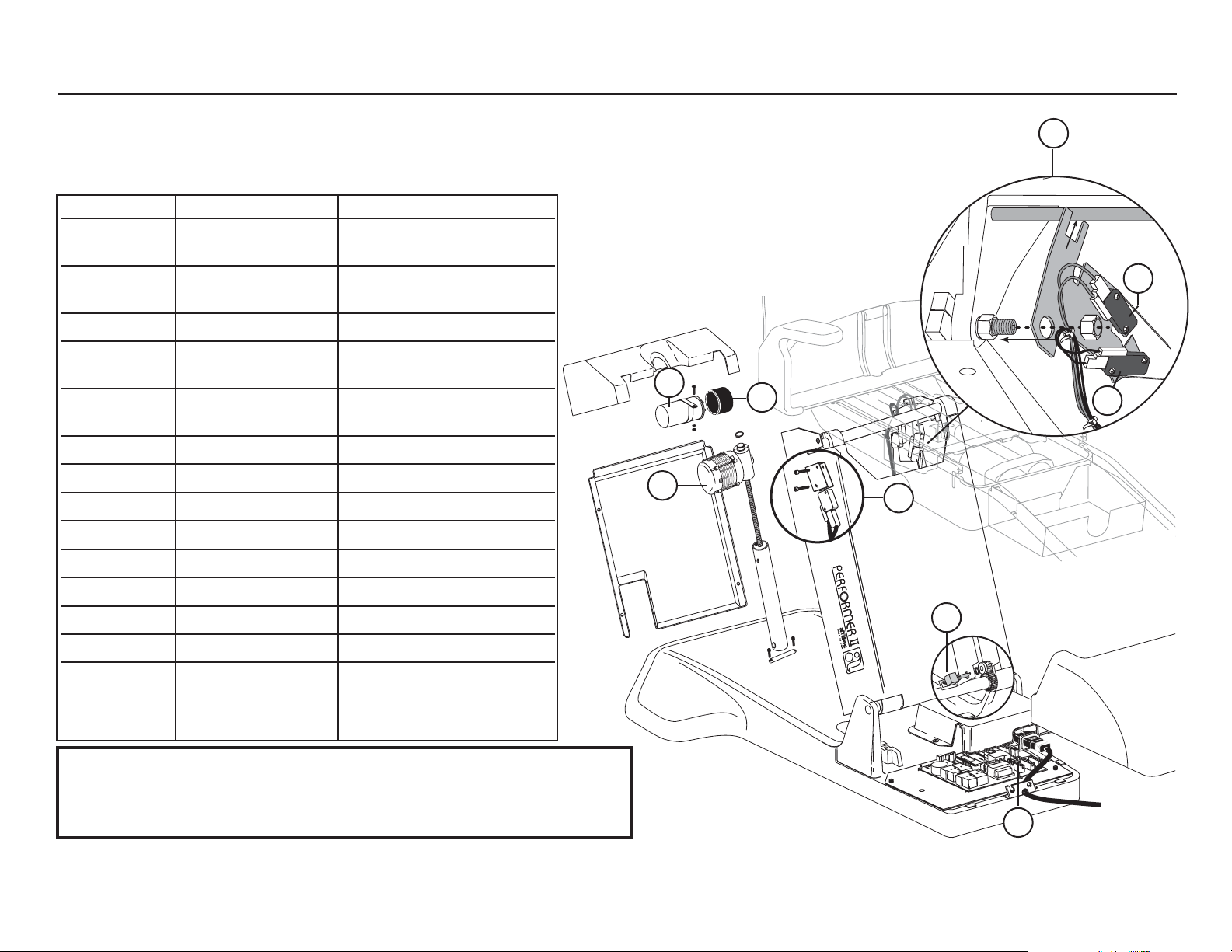

Page 17

85.0812.00, 2003 PR-16

Performer Performer II Flow Diagram

INTR A ORA L

Item # Part Number Description

1 76.1005.00 Intra-oral light source kit

2 76.8000.00 Bitewing x-ray viewer

3 35.1673.00 Cable assembly,

control head

3 28.1264.00 Power cord, 115V

4 28.1276.00 Power cord, 230V

5 61.2108.00 Cable assembly, footswitch

6 61.3043.00 Button footswitch

7 35.1567.00 Cable assembly,

accessory power

8 28.1244.00 Cable assembly,

dental light lower

9 90.1054.00 Cable assembly,

dental light upper

10 90.1039.00 On/Off switch

3

4

8

9

10

75

Performer II Electronics

2

1

NOTE:Performer II chair discontinued in April 1999.

6

ADJUST ONLY

PN 34-0064-00

WHEN BRIGHT

DANGER

INTRA ORAL

LIGHT SOURCE

2.9 - 4.25VDC .8AMP

POWER

24V

BRIGHT

/DC

AC

4321

P9

Page 18

85.0812.00, 2003 PR-17

Performer Performer II Flow Diagram

Control head

Foot control

Cuspidor and Assistant’s instrumentation

Optional

assistant’s

syringe

Floor box

NOTE: The Performer II was discontinued

in April 1999.

34

50

40

60

5

2

30

70

20

80

1

6

90

10

100

0

psi

2

7

0

kg/cm

Page 19

85.0812.00, 2003 PR-18

Performer Performer II Electrical Flow Diagram

Tilt actuator

Lift actuator

Tilt

capacitor

Lift

capacitor

Base down

limit switch

Base down

shutoff switch

Base up

limit switch

AC plug

Ground

Tilt (back) potentiometer

back up = clockwise

Lift (base) potentiometer

base up = counterclockwise

(NO)

(COM)

(COM)

WARNING

High voltages are present at motor and limit switch

connections. Unplug the chair before servicing.

Failure to do so could result in serious injury.

(NO)

(NO)

(COM)

2

1

3

0

210

3

P1

TEST POINTS

P5

P4

P14 CUSP

JUMPER

JUMPERS

P6

P2

IND. LAMP

ENT

EXT

DN

BS UP

BK DN

BK UP

P16

P11

F2

F1

P12

P9

F3

P10

Page 20

85.0812.00, 2003 PR-19

Performer Troubleshooting

Problem

Action

Chair back or base is inoperative

Noisy motor

Automatic positions erratic

Follow these steps.

Task Description

1Make sure system power is ON.

2 Check power and connections.

3Check for bad fuses on the circuit board.

4 Operate chair from printed circuit board test points.

5 Check for bad capacitors.

Follow these steps.

1 Check for loose mounts.

2 Adjust base screw drive nut.

3 Replace motor.

• Check potentiometers and wiring

• Replace the circuit board

Troubleshooting

Performer II Chair

Tips and troubleshooting information are listed to assist in distinguishing Performer II

chair problems.

Page 21

85.0812.00, 2003 PR-20

Performer Performer III

Item # Part Number Description

1 006.122.01 Retainer nut

2 61.2740.00 Pin

3 007.069.00 Setscrew

4 61.2741.01 Back link

5 007.042.00 Setscrew

6 61.2082.00 Slide

7 61.2693.00 Tilt rod

8 61.2050.01 Tilt cylinder

9 013.054.00 Spring

10 041.372.00 Potentiometer

Performer III Upper Structure

1

3

2

3

5

4

6

6

7

8

10

9

Page 22

85.0812.00, 2003 PR-21

Performer Performer III

Performer III Lower Structure

1

2

5

4

3

6

8

12

10

9

11

7

Item # Part Number Description

1 61.1287.00 Lift cylinder

2 044.184.01 Base up limit switch

3 004.148.00 Flat washer

4 001.165.00 Socket shoulder screw

5 001.164.00 Socket shoulder screw

6 61.3043.00 Button foot switch

7 61.2142.00 Pump cover

8 90.1029.00 PCB, 120V

90.1029.01 PCB, 240V

9 90.1032.00 Capacitor (after 6/1/98)

90.1033.00 Capacitor

(before 6/1/98)

90.1034.00 Base capacitor

10 61.0460.00 Flow adjustment screw

11 001.002.01 Truss head screw

002.118.02 Button head screw

12 61.1335.00 Solenoid, 100V,

Yellow wires

61.1336.00 Solenoid, 120V,

Black wires

61.1337.00 Solenoid, 240V,

Red wires

Page 23

85.0812.00, 2003 PR-22

Performer Performer III Flow Diagram

BRIGHT

POWER

ADJUST ONLY

2.9 - 4.25 VDC .8AMP

PN 34-0064-00

WHEN BRIGHT

DANGER

24V

AC

DC

INTRA ORAL

LIGHT SOURCE

ON

CB2

CB1

"STATIC SENSITIVE

"

P

17

P5

P2

P1

S1

P4

S2

P6

B

S

P

O

T

BK

P

O

T

BKUP

PRGM

B

EE

P

E

R

PUMP

(

100

-

120

V

~

)

N/L2

DS3

DS5

DS12

DS8

P14

CUSP

STATUS

P16

P12

P11

DS15

BK UP

DS14

DS7

DS13

DS4

BS UP

BK UP

BS UP

BS DN

BK DN

N/L2

BS DN

BK DN

PUMP

K5

PUMP

P9

LOCKOUT

P13

DS1

DS16

DS17

DS2

DS11

DS6

DS9

DS10

+12V

+5V

BSU

P

BSDN

BK

DN

PRGM

0

PRGM

1

PRGM

2

PRGM

3

EN/DIS TP/F

S

FACT DEFAU

LT

BK POT

BS PO

T

SPAR

E

SPAR

E

TEST POINTS

P10

N/L2

N/L2

AUXILIARY

OUTPUT POWE

R

(2A MAX

)

MAINS

INPUT POWER

R74

R72

R73

SET

S

O

FF

O

N

O

FF

O

N

O

FF

O

FF

O

N

O

N

CUSP/RET

LAST POST

PRGM

3

NOT USE

D

B

S

BK

SP

(

220

-

240

V

~

)

P

A

R

T

#

1

3

12

15

16

10

2

5

11

6

4

7

8

9

14

13

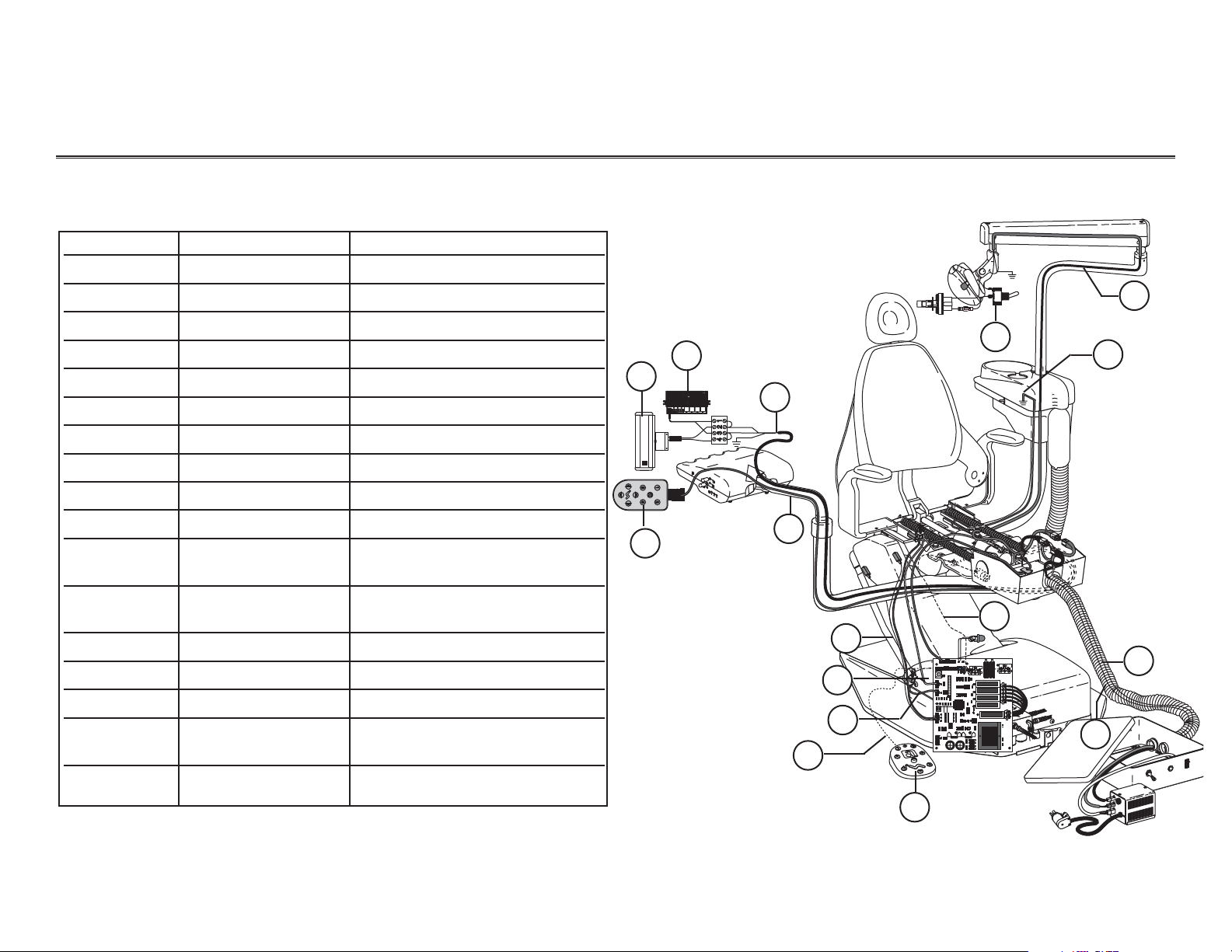

Performer III Electronics

Item # Part Number Description

1 35.1673.00 Cable assembly, control head

2 76.1005.00 Single volt intra-oral light source

3 76.8100.00 Bitewing viewer

4 39.1385.00 Touchpad

5 76.0144.00 Cable assembly, touchpad

6 61.2099.00 Limit switch, back up

7 61.1503.00 Back electric wiring cable

8 61.1502.00 Base electric wiring cable

9 61.2108.00 Cable assembly, foot switch

10 61.3043.00 Button footswitch

11 35.1567.00 Cable assembly,

accessory power

12 28.1244.00 Cable assembly,

dental light, lower

13 28.1264.00 Power cord, 115V

13 28.1276.00 Power cord, 230V

14 41.1444.00 Ground wire assembly

15 90.1054.00 Cable assembly,

dental light, upper

16 90.1039.00 On/Off switch, dental light

ADJUST ONLY

PN 34-0064-00

WHEN BRIGHT

DANGER

INTRA ORAL

LIGHT SOURCE

2.9 - 4.25VDC .8AMP

POWER

24V

BRIGHT

AC

/DC

P1

P2

S1

PRGM

P5

T

O

P

BK

P4

T

O

P

S

B

DS1

DS2

ON

S2

1 2

P6

SP

BK

S

B

R

E

P

EE

B

DS8

DS15

AUXILIARY

CB2

CB1

MAINS

OUTPUT POWE

R

INPUT POWER

P14

P16

(2A MAX

)

CUSP

STATUS

L1L1N/L2

L1L1N/L2

P11

P12

P

17

TEST POINTS

BKUP

BSU

P

BSDN

BK

DN

DS3

PRGM

0

PRGM

1

PRGM

2

PRGM

3

EN/DIS TP/F

FACT DEFAU

DS5

BK POT

BS PO

T

SPAR

E

SPAR

E

"STATIC SENSITIVE

#1#1#2#2SET

S

O

FF

O

FF

CUSP/RET

O

N

O

FF

LAST POST

O

FF

O

N

PRGM

3

O

N

O

N

NOT USE

D

DS6

DS9

DS10

DS17

+12V

P10

BK UP

DS12

S

LT

"

N/L2

BK UP

BS UP

DS14

BS UP

BS DN

BS DN

DS7

BK DN

BK DN

DS13

P9

PUMP

K5

PUMP

DS11

PUMP

P13

N/L2

LOCKOUT

DS4

)

~

V

R73

240

220

(

DS16

+5V

#

)

~

T

V

R72

R

A

120

-

P

R74

100

(

Page 24

85.0812.00, 2003 PR-23

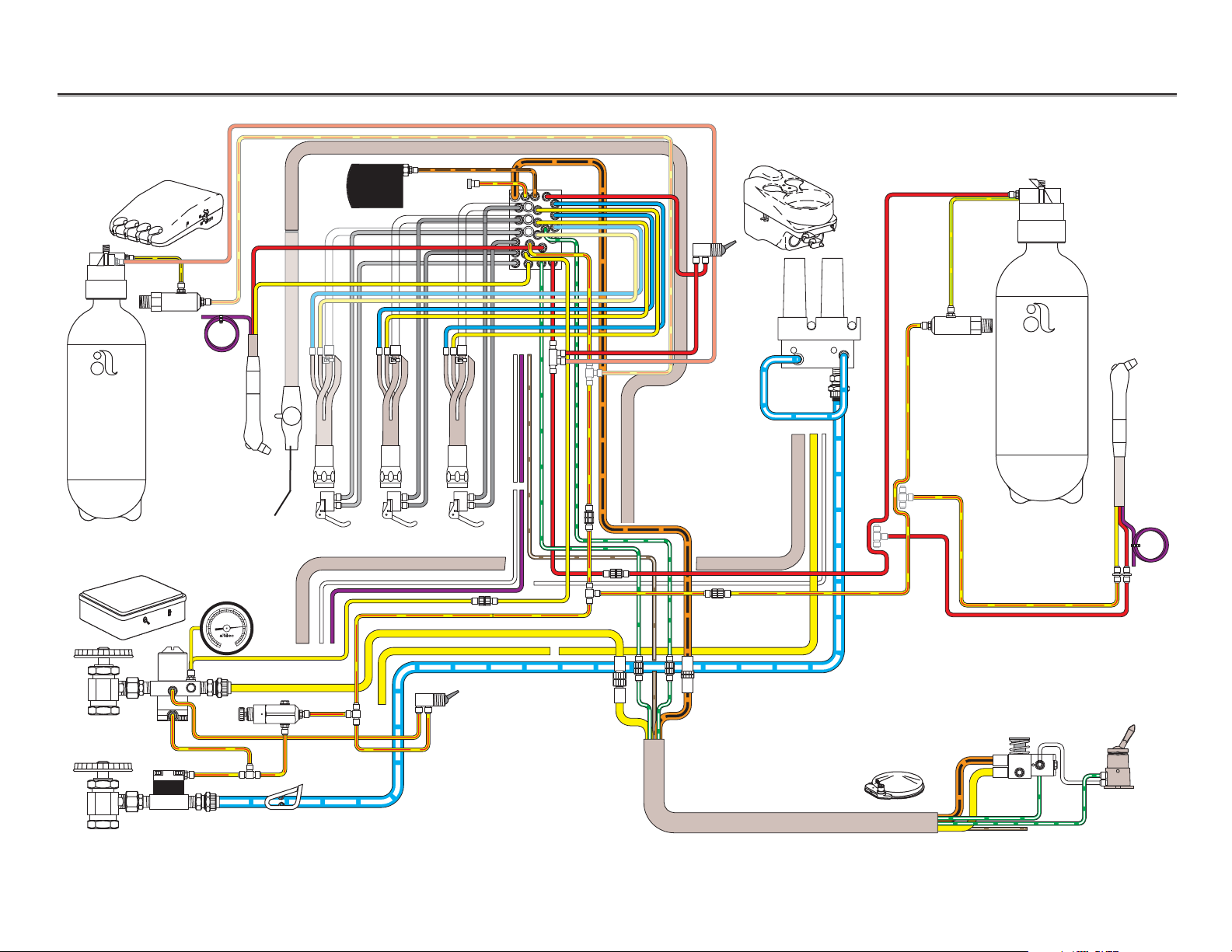

Performer Performer III Flow Diagram

Control head

Foot control

Optional

assistant’s

syringe

Cuspidor and Assistant’s instrumentation

Floor box

Optional

control head

mounted selfcontained

water (for

systems without cuspidor)

Optional control

head saliva ejector

34

50

40

60

5

2

30

70

20

80

1

6

90

10

100

0

psi

2

7

0

kg/cm

Page 25

85.0812.00, 2003 PR-24

Performer Performer III Electrical Flow Diagram

PUMP

N/L2

P14

CUSP

STATUS

P16

DS4

DS6

DS9

DS10

ON

CB2

CB1

"STATIC SENSITIVE"

Performer III (LEDs)

3

2

4

5

6

8

7

1

To post box

Led light

Optical duplex

100V and 120V only

From electrical

outlet

Ground

To hydraulic

motor pump

Item # Part Number Description

1 61.3043.00 8-function footswitch

2 041.372.00 Positioning potentiometer, back

3 041.372.00 Positioning potentiometer, base

3 28.1264.00 Power cord, 115V

4— Safety stop limit switch

5 61.2065.00 Back up limit switch (1040 only)

6 044.184.01 Base up limit switch (1040 only)

7 90.1031.00 Capacitor with boot (100-120V)

90.1034.00 Capacitor with boot (240V)

8 61.1332.00 Manifold assembly, hyd, 100V

61.1333.00 Manifold assembly, hyd, 120V

61.1334.00 Manifold assembly, hyd, 240V

0

1

2

3

DS8

#1 #2 SETS

OFF

ON

OFF

ON

DS6

DS9

DS10

TEST POINTS

OFF

OFF

ON

ON

P17

CUSP/RET

LAST POST

PRGM 3

NOT USED

P14

CUSP

BKUP

BSUP

BSDN

BKDN

PRGM 0

PRGM 1

PRGM 2

PRGM 3

EN/DIS TP/FS

FACT DEFAULT

BK POT

BS POT

SPARE

SPARE

"STATIC SENSITIVE"

+12V +5V

DS15

P16

STATUS

AUXILIARY

OUTPUT POWER

(2A MAX)

L1

N/L2

BK UP

DS12

BS UP

DS14

BS DN

DS7

BK DN

DS13

K5

PUMP

DS11

P13

LOCKOUT

DS4

DS16DS17

CB2

CB1

MAINS

INPUT POWER

L1 N/L2

P11

P12

P10

N/L2

BK UP

BS UP

BS DN

BK DN

P9

PUMP

PUMP

N/L2

(220-240V~)

PART #

R74 R72 R73

(100-120V~)

P1

P2

S1

PRGM

P5

DS3DS5

BK POT

P4

BS POT

DS1

DS2

ON

S2

1 2

P6

BS BK SP

BEEPER

Page 26

85.0812.00, 2003 PR-25

Performer Adjustments

Adjusting the

Hydraulic Manifold

Base down

control valve

Base up

control valve

Back down

control valve

Back up

control

valve

CAUTION

Do not remove retaining screw from the manifold.

Do not completely close a speed control valve. The

motor/pump could overheat and become damaged

from pumping against a closed valve.

Retaining

screws

To adjust... Do this...

Base up speed Turn base up control valve:

clockwise to decrease speed, or

counterclockwise to increase speed.

Base down speed Turn base down control valve:

clockwise to decrease speed,

or counterclockwise to increase speed

Back up speed Turn back up control valve counterclockwise to decrease

speed, or clockwise to increase speed. Back down speed.

Turn the back down control valve, clockwise to decrease

speed, or counterclockwise to increase speed.

The hydraulic manifold incorporates four speed control valves which restrict or divert the flow of

hydraulic fluid to and from the lift and tilt cylinders.

NOTE: The speed control valves are hex drive.

NOTE: This is opposite of the other three control valves.

Turning the back up valve counterclockwise too

far may disable this function.

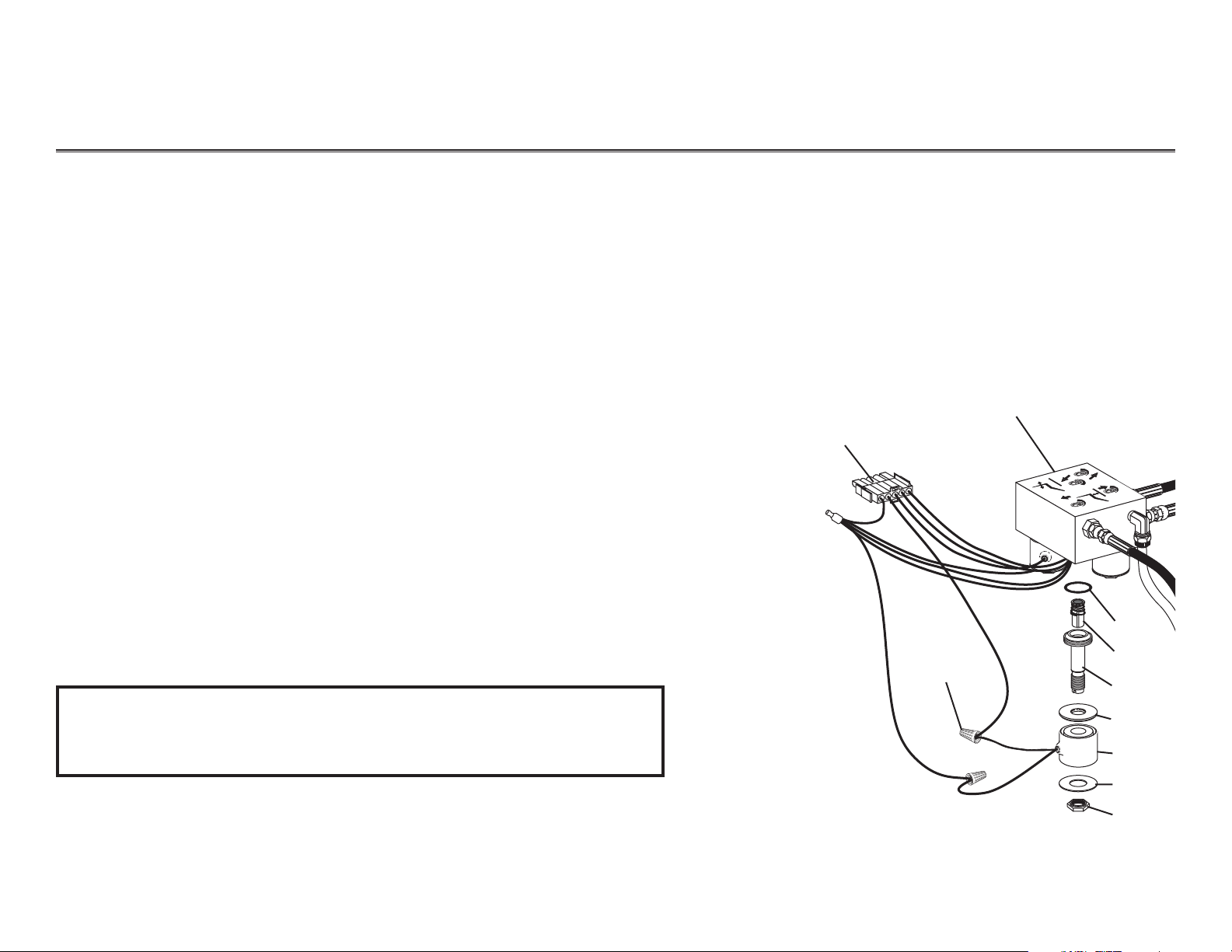

Page 27

85.0812.00, 2003 PR-26

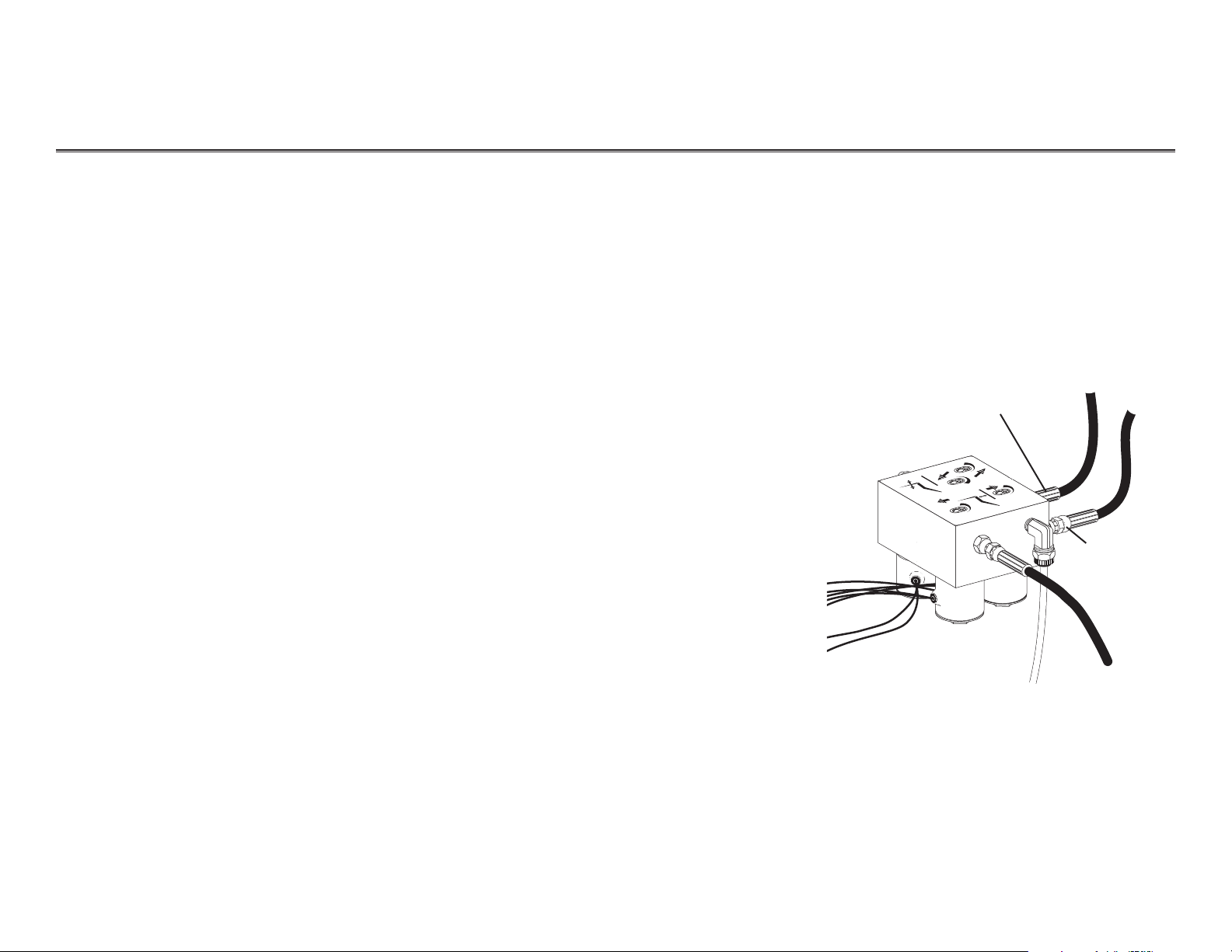

Performer Hydraulic Manifold

Removing a

Solenoid

Installing

a Solenoid

To remove a solenoid:

1 Lower the chair base and back to the full down position to depressurize the

hydraulic system. Remove the motor pump cover, then unplug the chair.

2 If necessary, remove the two mounting screws that secure the manifold

to the hydraulic tray. Rotate that manifold so the solenoids

are accessible.

3Using a flat blade screwdriver and a 9/16" wrench, remove

the defective solenoid.

4 Cut the defective solenoid wires 3" (74mm) from the coil

and discard.

5Remove the old o-ring from the solenoid cavity and clean

out any excess oil. Replace the o-ring with the correct o-ring

provided in the kit.

Hydraulic manifold

O-ring

Poppet sleeve

Washer

ID washer

Retaining

nut

Poppet

Coil

Wire nut

J10

WARNING

The solenoid coils are powered by line voltage (100, 120, or 240V AC).

Failure to unplug the chair may result in serious injury from electrical shock.

The following steps will guide you through the procedure for installing a solenoid.

Page 28

85.0812.00, 2003 PR-27

Performer Hydraulic Manifold

Replacing a

Solenoid

To replace a solenoid:

1 Install the new solenoid stem and poppet into the manifold and tighten to 35-40 in lb

(.11985–.2284 Nm). Position the remaining solenoid parts on the stem and secure by

tightening the retaining nut to 25-30 in lb (.14275–.1713 Nm).

2 Cut the solenoid wires 3" (75 mm) from the coil. Install the stripped wires from the

solenoid and the connector housing into a wire nut. Repeat for the remaining wire.

3Using the mounting screws, secure the manifold to the hydraulic tray.

4. Plug in the chair. Test the chair functions to ensure proper operation and that no

fluid leakage occurs. Reinstall the motor pump cover.

Page 29

85.0812.00, 2003 PR-28

Performer Troubleshooting

Task Description

1 Remove the motor/pump cover from the chair.

2 Fit a 5/8" wrench to the high pressure outlet port

(either lift or tilt, whichever is in hydrostatic lock) of

the hydraulic manifold. Hold the port still and use a

9/16" wrench to loosen the hose fitting.

3 Place a shop rag around the fitting to absorb

the fluid.

4 Carefully loosen the fitting counterclockwise until

oil begins to leak from the fitting. Retighten the

fitting. Operate the down function. A second release

of hydraulic fluid may be required.

5 Adjust the limit switch that caused the hydrostatic

lock (refer to Adjusting the Base Up Limit Switch). In

some cases it may be necessary to remove and

replace the limit switch. Adjust the new limit switch

as needed. Also ensure that the large gear/actuator

is securely installed and not slipping.

6Cycle the chair a couple of times to verify it is no

longer in hydrostatic lock.

Tilt cylinder

high pressure

fitting

Lift cylinder

high pressure

fitting

Correcting

Hydrostatic

Lock

Hydraulic lock occurs based on the following conditions:

•chair base or back is stuck in full up position

• limit switch not activated, or

• down solenoid poppet is unable to open based on excess hydraulic pressure.

Correcting Hydrostatic Lock

Page 30

85.0812.00, 2003 PR-29

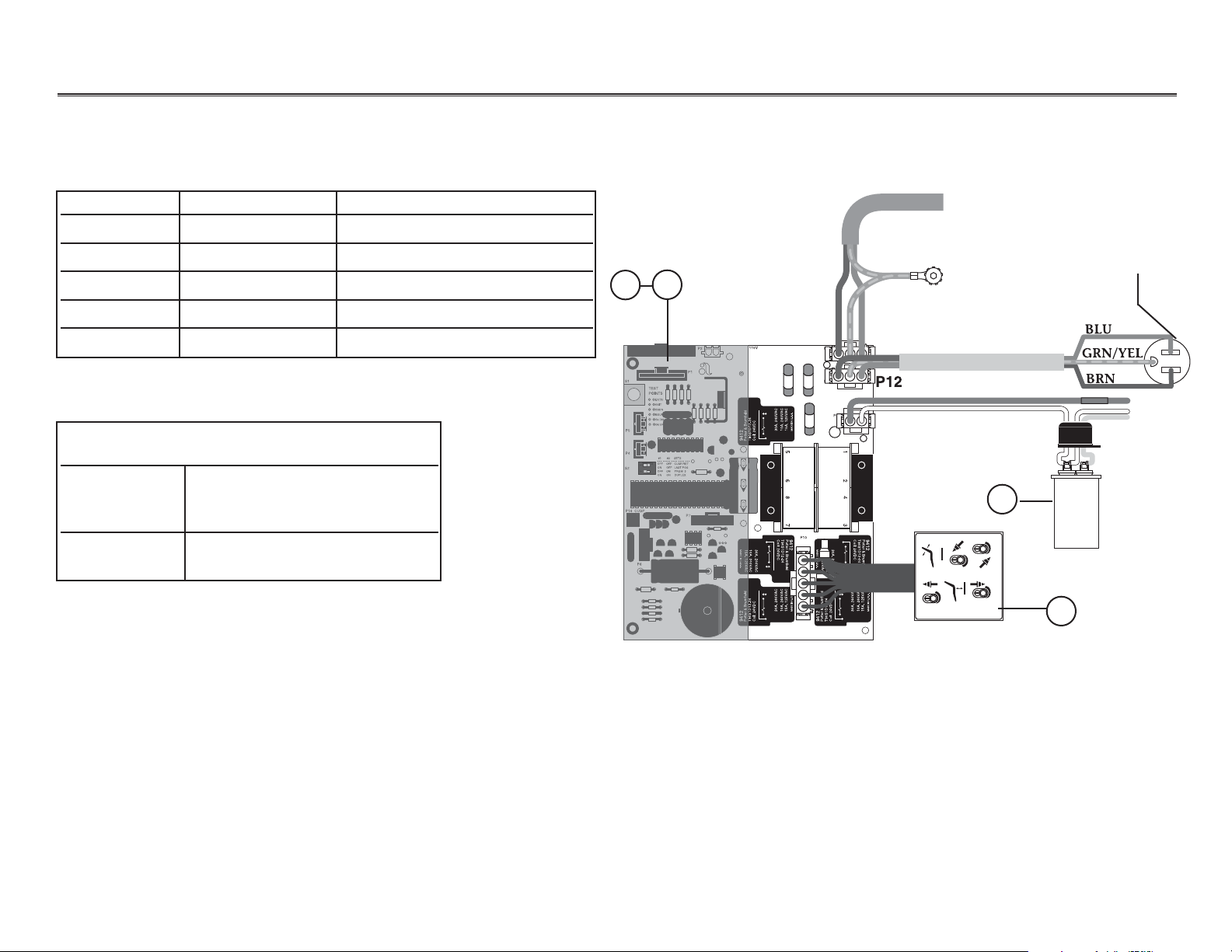

Performer Performer III Electrical Diagram

Performer III (No LEDs)

1

2

3

4

Item # Part Number Description

1 61.2512.00 Printed circuit board, 240V

2 61.2510.00 Printed circuit board, 100-120V

3 61.1333.00 Hydraulic manifold, 120V

3 61.1334.00 Hydraulic manifold, 240V

4 90.1031.00 Capacitor

From electrical outlet

Optional accessory

power cord

Ground

NOTE: P12 should be used for

the optional accessory

power cord.

NOTE:Solenoid wire color

varies with voltage.

To Replace Circuit Board

Part Number Order this kit

61.2510.00 90.1029.00 (100-120V)

61.1214.01

61.1373.01

61.2512.00 90.1029.01(220-240V)

61.1217.01

S1

P5

P4

S2

P14 CUSP

TEST

POINTS

ENTR

EXIT

BSDN

BSUP

Bk DN

Bk UP

#1 #2 SETS

- - - - - - - - - - - - - - - - - - -

ON

12

OFF OFF sCUSP/RET

ON OFF LAST POS

OFF ON PRGM 3

ON ON DUPLEX

P6

100 - 120 V

P2

P1

9412

P7

MADE IN U.S.A.

9412

A-DEC 61-1215-00 REV L ASSY 61-1214-01 REV E

Page 31

85.0812.00, 2003 PR-30

Performer Performer III Electrical Diagram

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

30A, 240VAC

MADE IN U.S.A.

30A, 240VAC

MADE IN U.S.A.

10A, 240VAC

15A, 125VAC

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

30A, 240VAC

MADE IN U.S.A.

10A, 240VAC

15A, 125VAC

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

30A, 240VAC

MADE IN U.S.A.

10A, 240VAC

15A, 125VAC

1243

5687

P9

P12

P11

P1

P5

P4

P14 CUSP

P7

P10

P6

S1

S2

12

ON

- - - - - - - - - - - - - - - - - - -

#1 #2 SETS

OFF OFF sCUSP/RET

ON OFF LAST POS

OFF ON PRGM 3

ENTR

TEST

POINTS

EXIT

BSDN

BSUP

Bk DN

Bk UP

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

30A, 240VAC

MADE IN U.S.A.

10A, 240VAC

15A, 125VAC

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

30A, 240VAC

MADE IN U.S.A.

10A, 240VAC

15A, 125VAC

9412

30A, 240VAC

MADE IN U.S.A.

10A, 240VAC

15A, 125VAC

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

30A, 240VAC

MADE IN U.S.A.

10A, 240VAC

15A, 125VAC

1243

5687

T90S1D12-24

Coil: 24VDC

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

1

2

3

0

1

2

3

4

6

7

9

10

12

11

5

8

To chair touchpad

Printed circuit

board assembly

Performer III

(No LEDs)

Item # Part Number Description

1 39.1385.00 Chair touchpad kit

2 041.582.00 LED light

3 61.2108.00 Cable assembly,

button footswitch

4 61.1503.00 Cable assembly,

potentiometer, back up

5 61.1502.00 Cable Assembly,

potentiometer, base up

6 041.372.00 Potentiometer, back

7 041.372.00 Potentiometer, base

8 61.3043.00 Button footswitch

8 61.3048.00 Button footswitch,

membrane

8 61.3049.00 Button footswitch, boot

9 Limit switch, safety

10 044.184.00 Limit switch, back up

11 044.184.01 Limit switch, base up

12 61.2099.00 Cable assembly,

limit switch

Page 32

85.0812.00, 2003 PR-31

Performer Performer III Electrical Diagram

Performer III (No LEDs)

1

Item # Part Number Description

1 90.1029.00 Circuit board assembly, 100V-120V

90.1029.01 Circuit board assembly, 240V

2 044.192.00 Fuse, 10 A, 5x20 mm time lag,

240V (61.2510.00 CBA, 120V)

044.147.00 Fuse, 6.3 A (61.2512.00 CBA, 240V)

3 044.193.00 Fuse, .063 A, 5x20MM, time lag,

250V (61.2510.00 CBA, 120V)

044.194.00 Fuse, .040A (61.2512.00 CBA, 240V)

2

3

NOTE:Refer to the

Genuine A-dec Service Parts Catalog

for information

on fuses that worked on previous styles of printed circuit boards.

There are no replacement fuses on the following circuit boards:

61.2774.00 (100-120V) and 61.2774.01 (220-240V).

Page 33

85.0812.00, 2003 PR-32

Performer Performer III Diagnostic LEDs for the Circuit Board

LEDs

NOTE: Refer to

Testing Factory Defaults

for more details.

DS1

DS2

DS3

DS7

DS8

DS9

DS10

DS11

DS12

DS13

DS4

DS5

DS6

DS14

DS15

DS16

DS17

R73

R72

R74

Page 34

85.0812.00, 2003 PR-33

Performer Performer III Diagnostic LEDs for the Circuit Board

LED Description Information Communicated

DS1 S2 (red DIP switch) is ON Switch is ON

DS2

DS3 Back Potentiometer LED ON Back potentiometer is functioning normally when the chair back is moving

DS4 Handpiece Lockout LED ON Lockout enabled

DS5 Base Potentiometer LED ON Base potentiometer is functioning normally when the chair base is moving

DS6 Chair Stop Plate Limit Switch LED ON Chair stop plate limit switch activated

DS7 Base Down LED Relay is ON when LED is ON and the function is moving

DS11 Pump LED

DS12 Back Up LED

DS13 Back Down LED

DS14 Base Up LED

DS8 Cuspidor Limit Switch LED ON Cuspidor limit switch activated, or jumper is missing

DS9 Back Up Limit Switch LED ON Back Up limit switch activated

DS10 Base Up Limit Switch LED ON Base Up limit switch activated

DS15 Status LED ON ON: Normal operation

Off: Microcontroller is not functioning. Verify voltage regulator LEDs

(DS16 and DS17) are ON. Is the chair plugged in? Circuit breaker tripped?

Slow Blink: Check cuspidor (DS8) and stop plate (DS6) limit switch LEDs

Fast Blink: Check handpiece lockout (DS4) LED

Double Blink: A SPARE jumper is in the FACT DEFAULT position

DS16 5V Regulator LED OFF 1 Power to circuit board is OFF, or

2 There is a short in the cable to the base or back potentiometer. Disconnect all cables

except the power cable. Plug the cables in one at a time (the LED will turn ON when the

problem is fixed).

DS17 12V Regulator LED OFF 1 1 Power to circuit board is OFF, or

2. There is a short in the cable to the status light or limit switch (the LED will turn ON when

the problem is fixed).

Page 35

85.0812.00, 2003 PR-34

Performer Performer III Printed Circuit Board (PCB)

Testing and

Programming

the Circuit Board

Follow these steps to test and program the chair circuit board.

Task Description

1 Insert the SPARE jumper into the FACT DEFAULT location (on P17).

Result: The chair will cycle the base and back movements and automatically

reprogram the memory positions to the factory settings

(position 0 to entry/exit; 1 and 2 to the same pre-programmed positions;

and 3 to cuspidor/return).

If the circuit board beeps three times, continue with step two.

If the circuit board beeps just once, the chair cycle has been interrupted. Diagnose

and correct any errors, then press either circuit breaker for five seconds to restart

the cycle (refer to Testing Factory Defaults).

2Move the jumper from the FACT DEFAULT location (on P17) back to the

SPARE location.

NOTE: The jumper must be in the SPARE position for normal chair functions and

safe operation.

3Press “1” on the touchpad or footswitch or green position on the 8-function

footswitch.

Result: The chair will move to the operating position.

4Press “0” on the touchpad or footswitch, or the red button on the 8-function

footswitch.

Result: The chair will move to the entry/exit position.

NOTE: The chair programmable position buttons can be reprogrammed to the

desired positions as specified by the dental team.

WARNING

The chair will begin to move

automatically during this

test; to avoid injury or

equipment damage, remove

all possible obstructions and

maintain a safe distance

from the chair. To interrupt

the chair cycle, press any

button on the touchpad or

footswitch, or activate the

chair stop plate.

Page 36

85.0812.00, 2003 PR-35

Performer Tests

Problem Action

Factory Default test will not start

(LEDs DS15, DS16 and DS17

are Off)

Factory Default test will not start

(LED DS15 is Off; DS16 and DS17

are ON)

Factory Default test will not start

(LED DS15 is blinking; DS16 and

DS17 are ON)

If . . .

Then . . .

Transformer thermal limiter is open

Circuit breaker is tripped

Wait for transformer to cool off.

Reset circuit breaker (short circuit fault currents

may damage the circuit breaker and prevent it

from resetting).

If . . .

Then . . .

Input voltage is too low or is outside the

required range

Microcontroller is not functioning

Ve rify input voltage and voltage selection

resistors (100-120VAC=R72 and R74)

(220-240VAC=R73).

Replace the circuit board.

If . . .

Then . . .

Input voltage is too low or is outside the

required range

Microcontroller is not functioning

Ve rify input voltage and voltage selection

resistors (100-120VAC=R72 and R74)

(220-240VAC=R73).

Replace the circuit board.

Testing Factory Defaults

The table lists conditions and corrective actions for testing the factory defaults for LEDs.

Page 37

85.0812.00, 2003 PR-36

Performer Tests

Problem Action

Factory Default test halts during

the BASE UP test and the PCB

board beeps one time

Factory Default test halts during

the BACK DOWN test and PCB

board beeps one time

If . . .

Then . . .

Input voltage is too low or is outside the

required range

Base Up limit switch is activated

Motor thermal limiter is open, motor is hot

Motor capacitor is defective

Base Up solenoid is defective

Base is in hydrostatic lock

Potentiometer is not changing voltage

Ve rify input voltage and voltage selection

resistors (100-120VAC=R72 and

R74 (220-240VAC=R73).

Verify switch operation.

Wait for motor to cool off.

Test capacitor and replace, if needed.

Test solenoid and replace, if needed

Refer to Correcting Hydrostatic Lock.

Ve rify potentiometer LED comes ON when base

is moving.

Check potentiometer mechanical drive and

electrical connections.

If . . .

Then . . .

Stop plate limit switch is activated

Stop plate is jammed

Back Down solenoid is defective

Back is in hydrostatic lock

Potentiometer is not changing voltage

Verify switch operation.

Remove and reinstall the stop plate.

Test solenoid and replace, if needed

Refer to Correcting Hydrostatic Lock.

Ve rify potentiometer LED is ON when back

is moving.

Check potentiometer mechanical drive and

electrical connections.

Page 38

85.0812.00, 2003

Performer Tests

PR-37

Problem Action

Factory Default test halts during

the BACK UP test

Factory Default test halts during

the BASE DOWN test

Chair moves by itself when power

is turned ON

If . . .

Then . . .

Back up limit switch is activated

Back Up solenoid is defective

Back is in hydrostatic lock

Potentiometer is not changing voltage

Verify switch operation.

Test solenoid and replace, if needed.

Refer to the Correcting Hydraulic Lock.

Ve rify potentiometer LED is ON when back

is moving.

Check potentiometer mechanical drive and

electrical connections.

If . . .

Then . . .

Stop plate limit switch is activated

Base Down solenoid is defective

Base is in hydrostatic lock

Potentiometer is not changing voltage

Verify switch operation.

Test solenoid and replace, if needed.

Refer to Correcting Hydraulic Lock.

Ve rify potentiometer LED is ON when base

is moving.

Check potentiometer mechanical drive and

electrical connections.

If . . .

Then . . .

The jumper is in FACT DEFAULT position

Short circuit in touchpad or footswitch

Short circuit on circuit board

Verify that the jumper is in the

SPARE position.

Unplug the touchpad and footswitch; reset the

circuit breaker. If the problem isn’t repeated, the

touchpad or footswitch may have shorted.

Replace the circuit board.

Page 39

85.0812.00, 2003 PR-38

Performer Performer III Printed Circuit Board (PCB)

Raise the chair with the

stop plate limit switch

Enable and disable touchpad

and footswitch buttons

Handpiece lockout

Plug the chair into an electrical outlet.

Tap the chair stop plate three times within five seconds and hold on the third tap.

Result: The chair base will continue to rise as long as the stop plate is held in. This function is

automatically disabled after five minutes but is re-enabled upon each power up. To reset the

five-minute timer, depress either circuit breaker until the LEDs turn OFF, then release the

circuit breaker.

Place the SPARE jumper in the EN/DIS TP/FS position of the Test Points header P17.

Push the buttons to be Enabled or Disabled (PRGM, PRGM 0, PRGM 1, PRGM 2, PRGM 3).

Result: One beep indicates the button is disabled. Three beeps indicate the button in enabled.

Place the SPARE jumper back into the SPARE position of the Test Points header P17.

Plumb a normally open air-electric switch (kit P/N 61.1384.00) to the air-coolant tubing (green with

long white dashes).

Insert the two position connector from the air-electric switch into P13 Lockout (next to the transformer).

Feature Programming

The chart provides information on new features and associated programming on the PCB.

Identifying

New Features

Page 40

85.0812.00, 2003 PR-39

Performer Performer III Printed Circuit Board (PCB)

Diagnostic LEDs

Test Points Header

See Performer III Diagnostic LEDs for the Circuit Board.

Use a SPARE jumper to test the chair manual functions (BKUP, BSUP, BSDN, BKDN).

BK POT and BS POT points allow test meter check of potentiometer voltages and measurement of the

analog DC voltage from pin 2 of the potentiometer.

Feature Programming

Page 41

85.0812.00, 2003 PR-40

Performer Headrests

Single-Articulating Headrest

(Discontinued)

Item # Part Number Description

1 61.2355.XX Formed headrest upholstery assy

2 Not a serviceable part

3 61.2350.00 Headrest cover

NOTE:For upholstery color availability, refer to the current

A-dec Standard Upholstery Guide

.

1

2

3

Page 42

85.0812.00, 2003 PR-41

Performer Headrests

Double-Articulating Headrest

NOTE:For upholstery color availability, refer to the current

A-dec Standard Upholstery Guide

.

1

2

Item # Part Number Description

1 61.2116.XX Formed headrest upholstery assy

2 027.035.01 Height adjustment knob, Gray

027.035.00 Height adjustment knob, Black

Page 43

85.0812.00, 2003 PR-42

Performer Headrests

Headrest Instrument Holder

(For single-articulating headrest)

1

2

3

Item # Part Number Description

1 99.0584.00 Cascade individual assistant’s holder

(includes friction pad and setscrew)

2 45.0403.00 Friction pad, Black

3 007.042.00 Set screw, socket cup point

Page 44

Performer Headrests

Headrest Instrument Holder Kit

(For double-articulating headrest)

1

2

3

Item # Part Number Description

1 99.0584.00 Cascade individual assistant’s holder

(includes friction pad and setscrew)

2 45.0403.00 Friction pad, Black

3 007.042.00 Set screw, socket cup point

PR-4385.0812.00, 2003

Page 45

85.0812.00, 2003 PR-44

Performer Adjustments

Using the Headrest

Adjusting

Headrest Position

Adjusting Headrest Glide

Bar Tension

The double articulating headrest offers complete

versatility in head positioning. This headrest

allows the doctor/assistant to position the headrest

to fit the nape of the patient’s neck, and to tilt to

the head to almost any position.

Loosen the knob on the back of the headrest. Move

the headrest into the desired position. Tighten the

headrest knob.

The headrest should move freely while positioning

yet maintain its position when set. Turn the tension

adjustment screw clockwise to increase friction and

hold the headrest more securely. Turn the tension

adjustment screw counterclockwise to decrease

friction and allow the headrest to move up and

down more freely.

1/8" hex key

Page 46

85.0812.00, 2003 PR-45

Performer Hydraulic Manifold

Hydraulic Manifold

Item # Part Number Description

1 61.1335.00 Solenoid, 8-watt, 100V, Yellow wires

61.1336.00 Solenoid, 8-watt, 120 V, Black wires

61.1337.00 Solenoid, 8-watt, 240 V, Red wires

2 030.015.02 O-ring pkg 10

3 030.004.02 O-ring, AS568-004 pkg 10

4 61.0460.00 Flow adjust screw with o-ring

5 002.118.01 Screw, button-head, socket

6. 61.1333.00 Manifold assy, hyd, 120V

61.1334.00 Manifold assy, hyd, 240V

3

4

5

2

6

1

3

After January 1999

Page 47

85.0812.00, 2003 PR-46

Performer Hydraulic Flow Diagram

From motor/pump

start capacitor

{

Hydraulic

manifold

assembly

Tilt cylinder

Lift cylinder

Vent lines

Pickup tube

Hydraulic fluid reservoir

(check fluid level with

base and back full up)

Hydraulic

pump

motor

NOTE: Use only A-dec fluid P/N 61.0197.00.

MAX

MIN

Page 48

85.0812.00, 2003 PR-47

Performer Potentiometers

Removing the

Helical Drive Shaft

Potentiometer shaft

Back positioning

potentiometer

Clockwise

Follow these steps to remove the limit switch and the

helical drive shaft from the potentiometer shaft.

Task Description

1 Position the chair back full down, loosen the

four screws under the toeboard and remove the

seat upholstery.

2Raise the toeboard assembly and disconnect the

limit switch wiring harness from the limit switch.

3Remove the limit switch mounting screws

and limit switch from the bracket. Lower the

toeboard, if necessary, to access the rear mounting

screw. Do not bend the switch arm.

4Remove the bracket mounting screws. Manually

raise or lower the toeboard for access if necessary.

5Remove helical drive shaft from potentiometer

shaft. While holding the helical shaft, reach

underneath the chair to the base of the backrest.

Grasp the bracket and pull away from the

helical shaft.

6Remove the helical drive shaft from the chair by

moving it toward the chair backrest and then

slightly to the side to dislodge it from the holder

and guide.

Limit switch

mounting screws

Potentiometer shaft

Urethane tubing 3/8" OD

Helical drive shaft

Page 49

85.0812.00, 2003 PR-48

Performer Potentiometers

Base Positioning Potentiometer and Limit Switch

2

1

3

Item # Part Number Description

1 041.372.00 Potentiometer,

5K Ohm, +20%, 1W, w/nut

2 044.049.01 Limit switch, modified

3. 61.1295.00 Gear, 24 pitch, 30 tooth

Replacing Base Positioning Potentiometer,

Limit Switch and Gear

CAUTION

Ensure that the large drive gear is secure (does not

turn) on the head of the bolt. Do not over tighten

(or “bottom” out) the setscrew.

Page 50

85.0812.00, 2003 PR-49

Performer Potentiometers

Follow these steps to adjust the base positioning potentiometer.

Task Description

1 Remove the motor/pump cover and position

the chair base down.

2Remove the mounting screw.

3Turn the potentiometer gear clockwise until

it stops.

4Align the potentiometer assembly, then

turn the potentiometer gear counterclockwise

two teeth (relative to one tooth on the large

drive gear).

5 Ensure all electrical connections to the limit

switch and positioning potentiometer are complete.

6Raise the chair base while observing the two gears for binding.

Adjusting the

Base Positioning

Potentiometer

Limit

switch

Large drive gear

Potentiometer gear

Positioning

potentiometer

Mounting screw

Clockwise

Counterclockwise

Adjusting the Base Positioning Potentiometer

NOTE: Do not raise the base to full up until you have

checked the base up limit switch for proper

adjustment (see

Adjusting the Base Up Limit Switch

).

CAUTION

Ensure that the large drive gear is secure (does not

turn) on the head of the bolt. Do not over tighten

(or “bottom” out) the setscrew.

Page 51

85.0812.00, 2003 PR-50

Performer Potentiometers

Adjusting the

Base up

Limit Switch

Limit switch

Switch arm

Actuator

Clamping

screws

Mounting bracket

NOTE:Positioning potentiometer omitted for clarity.

23"

584mm

To adjust the base up limit switch, do the following.

Task Description

1 Remove the motor/pump cover.

2 Loosen the two screws clamping the limit

switch to the mounting bracket.

3 Position the chair base up until the distance

from the floor to the base of the upper chair

casting is 23" (584mm).

4 Push the limit switch against the

actuator on the drive gear until the switch

opens (clicks).

NOTE:For correct limit switch actuation, the

actuator tab on the large gear should be at

the 5:30 clock position when the chair is full

base down.

5Tighten the clamping screws, making sure they

do not hit the gear.

6Lower the chair base down until the limit

switch has closed, then raise the chair full base

up. Check the distance from the floor to the base

of the chair casting to ensure it is 23" (584mm).

Page 52

85.0812.00, 2003 PR-51

Performer Auto-Positioning

Programming

the Chair

Follow these steps to set the auto-positioning for the chair.

Task Description

1Use the footswitch or touchpad to set the chair at the desired position

for base and back.

2Press and release the program button.

Result: You will hear a single beep.

3Within four seconds, press an automatic position button (0, 1, 2, or 3)

on the footswitch or touchpad to store the chair position. On an

8-function footswitch, move the actuator to the desired position.

Result: You will hear three beeps confirming that

the function has been programmed.

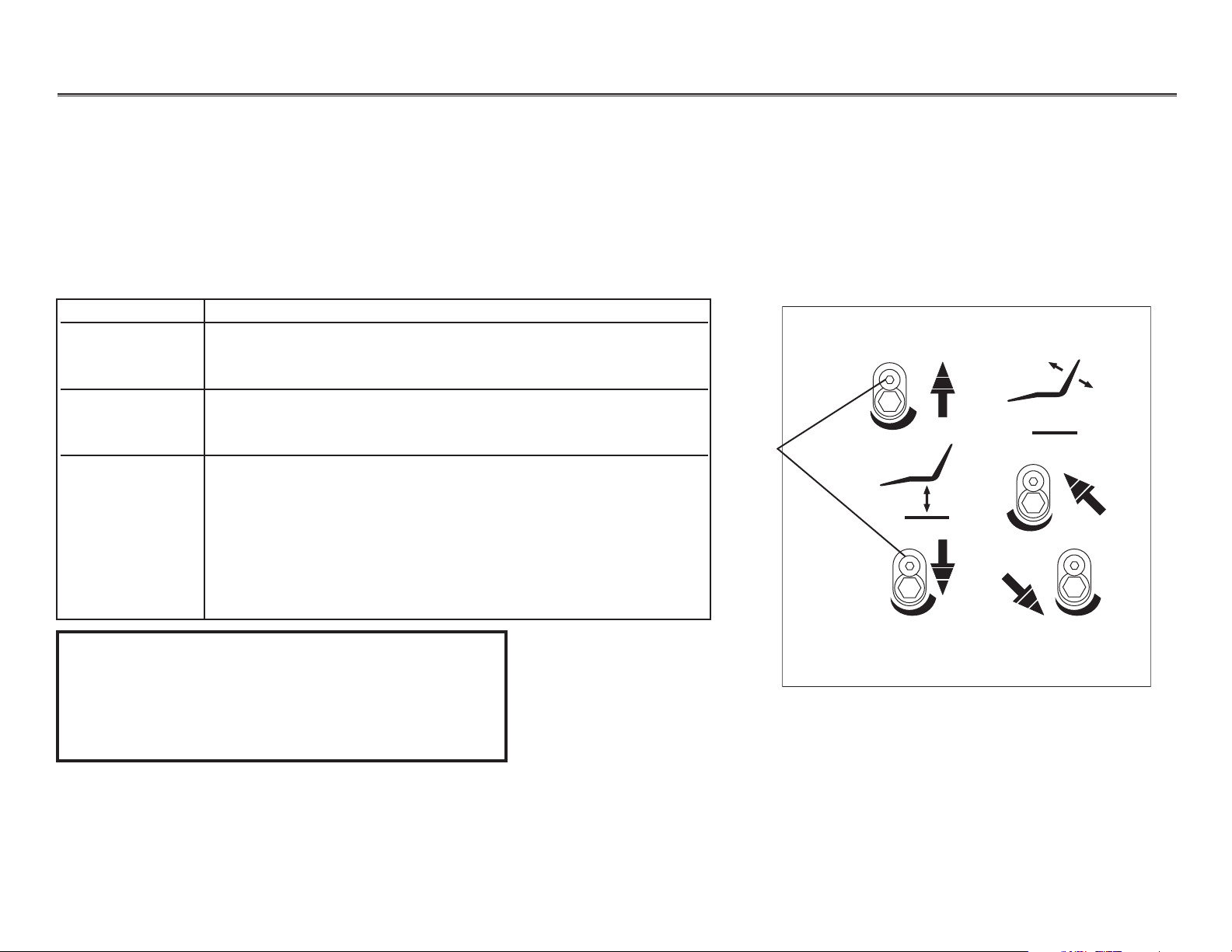

Performer III Touchpad

8-Button Footswitch

Pre-position (1)

Pre-position (2)

Entry/Exit (0)

Cuspidor/return,

last position, or

pre-position (3)

Program

button

Program

button

Base up

Back down

Back up

Base down

Programmable

position (1)

Programmable

entry/exit (0)

Programmable

position (2)

Cuspidor

return (3)

Base up

Back up

Base down

Back down

Replacement membrane P/N 61.3048.00

NOTE: PCBs manufactured before 1994, do not beep.

Test the programming by trying it.

2

3

1

0

Page 53

85.0812.00, 2003 PR-52

Performer Function 3 Programming

Programming

Function 3

Function

Programming

Cuspidor/Return

NOTE: Chairs with S/N J467728

and later are factory set with

function 3 as cuspidor/return

Last Position

Programmable Position

NOTE: Chairs up to S/N J467727

are factory set with function 3

as a programmable position

Description

Switches 1 and 2 are OFF.

Switch 1 is ON and switch 2 is OFF.

Go back and forth between two

positions by momentarily moving the

righthand actuator on the 8-function

footswitch to position 3 or pressing

number 3 on the touchpad or 8-button

footswitch.

Switch 1 is OFF and switch 2 is ON.

Move the chair to the desired position.

Press and release the program button.

After the beep, push button 3 on the

touchpad or 8-button footswitch or

move the actuator to position 3 on the

8-function footswitch. The single beep

confirms the position is programmed.

Used to raise the chair back to a

programmable upright position

providing the patient access to the

cuspidor. Momentarily pushing button 3

on the touchpad or 8-button footswitch,

or moving the actuator to position three

on the 8-function footswitch, returns the

back to the previous position.

Anon-programmable position that

simply moves the chair base and back to

their previous positions.

This option is used to set the base and

back to a predesignated

position. It allows this function to be

programmed like 0, 1, and 2.

ON

Switch 2

Function 3 DIP Switch

before 2000

Switch 1

Before 2000

1 2

ON

Page 54

85.0812.00, 2003 PR-53

Performer Function 3 Programming

Switch 1

Switch 2

Function 3 DIP Switch

after 2000

Programming

Function 3

Function

Programming

Cuspidor/Return

Last Position

Programmable Position

Description

Both switches 1 and 2 are OFF.

Switch 1 is ON and switch 2 is OFF.

Go back and forth between two

positions by momentarily pushing the

right hand rocker button to position 3

or pressing number 3 on the touchpad.

Switch 1 is OFF and switch 2 is ON.

Move the chair to the desired position.

Press and release the program button.

After the tone, push button 3 on the

touchpad or footswitch or move the

actuator to position 3 on the 8-function

footswitch. The audible tone confirms

the position is programmed.

Used to raise the chair back to a

programmable upright position

providing the patient access to the

cuspidor. Momentarily pushing button 3

on the touchpad or 8-button footswitch,

or the actuator to position 3 on the

8-function footswitch will return the

back to the previous position.

Anon-programmable position that

simply moves the chair base and back to

their previous positions.

Used to set the base and back to a

predesignated position.

After 2000

Page 55

85.0812.00, 2003 PR-54

Performer Floor Box

Floor Box

1

2

3

Item # Part Number Description

1 33.0048.03 Master On/Off (3-way) toggle valve

2 041.582.00 12 volt green light; not installed on all floor boxes

(replace as a complete assembly)

3 041.512.00 Light intensity rocker switch

(replace as a complete assembly)

90.1045.00 Kit, intensity light switch cable.

Page 56

85.0812.00, 2003 PR-55

Performer Flow Diagram

Item # Part Number Description

1 24.0469.00 Air filter/regulator valve

2 34.0033.00 Water shutoff valve, air operated

3 025.052.00 Pinch clamp

4. 33.0048.03 Master On/Off (3-way) toggle valve

Floor Box

1

2

Handpiece

control

Cuspidor/

Assistant’s

Foot control

Air manual shutoff valve

Water manual shutoff valve

NOTE: Do not connect the water shutoff valve

(34.0033.00) when the unit does not include a

cuspidor or a water quick disconnect.

After December 1995

3

4

2

30

20

1

10

0

34

50

40

60

70

90

100

0

psi

2

kg/cm

5

80

6

Page 57

85.0812.00, 2003 PR-56

Performer Flow Diagram

Item # Part Number Description

1 24.0372.00 Air regulator valve

2 34.0033.00 Water shutoff valve, air operated

3 025.052.00 Pinch clamp

4 33.0048.03 Master On/Off (3-way) toggle valve

Floor Box

1

2

Handpiece control

Cuspidor/

Assistant’s

Foot control

Air manual shutoff valve

Water manual shutoff valve

NOTE: Do not connect the water shutoff valve (34.0033.00) when the

unit does not include a cuspidor or a water quick disconnect.

After December 1995

(only with the International Performer I chair)

3

4

34

50

40

60

2

20

1

5

30

70

80

6

90

10

100

0

psi

2

7

0

kg/cm

Page 58

85.0812.00, 2003

Performer Flow Diagram

Item # Part Number Description

1 90.1027.03 Automatic moisture separator

2 24.0469.00 Air filter/regulator valve

3 34.0037.00 Air shutoff valve, air operated

4 34.0033.00 Water shutoff valve, air operated

5 025.052.00 Pinch clamp

6 33.0048.03 Master On/Off (3-way) toggle valve

Floor Box with Automatic Moisture Separator

1

2

Handpiece control

Cuspidor/

Assistant’s

Gravity drain

Dump tube

Air manual shutoff valve

Foot

control

Water manual shutoff valve

NOTE: Do not connect the water shutoff valve (34.0033.00) when the

unit does not include a cuspidor or a water quick disconnect.

After December 1995

3

6

4

5

Moisture

separator

PR-57

34

50

40

60

2

30

70

20

1

90

10

100

0

psi

2

7

0

kg/cm

5

80

6

Page 59

85.0812.00, 2003 PR-58

Performer Flow Diagram

Item # Part Number Description

1Moisture separator

2 24.0469.00 Air filter/regulator assembly

3 34.0033.00 Water shutoff valve, air operated

4 025.052.00 Pinch clamp

5 33.0048.03 Master On/Off (3-way) toggle valve

Floor Box with Manual Moisture Separator

1

2

Handpiece control

Cuspidor/

Assistant’s

Air manual shutoff valve

Water manual

shutoff valve

Foot control

NOTE: Do not connect the water shutoff valve (34.0033.00) when the

unit does not include a cuspidor or a water quick disconnect.

After December 1995

3

5

4

Moisture

separator

34

50

40

60

2

30

20

1

10

100

0

psi

0

kg/cm

5

70

80

6

90

2

7

Page 60

85.0812.00, 2003 PR-59

Performer Flow Diagram

Item # Part Number Description

1 24.0372.00 Air regulator valve

2 34.0033.00 Water shutoff valve, air operated

3 025.052.00 Pinch clamp

4 33.0080.01 Master On/Off (3-way) toggle valve

with 4" barbs

Floor Box

1

2

Handpiece control

Cuspidor/

Assistant’s

Air manual shutoff valve

Water manual shutoff valve

Foot control

NOTE: The 1/4" ID pilot air tubing (yellow with red dashes)

was changed to 1/8" ID pilot air tubing (yellow with

red stripe) in all units built after December 1995.

Before January 1996

3

4

34

50

40

60

2

30

20

1

10

0

5

70

80

6

90

100

0

psi

2

7

kg/cm

Page 61

85.0812.00, 2003 PR-60

Performer Floor Boxes

Item # Part Number Description

1 90.1027.03 Automatic moisture separator

2 24.0469.00 Air regulator assembly

3 34.0037.00 Air shutoff valve assembly,

air operated

4 34.0033.00 Water shutoff valve assembly,

air operated

5 025.052.00 Pinch clamp

6 33.0080.01 Master On/Off (3-way)

toggle valve with 4" barbs

Floor Box with Automatic Moisture Separator

1

2

Handpiece

control

Cuspidor/

Assistant’s

Gravity drain

Dump tube

Air manual shutoff valve

Foot

control

Water manual

shutoff valve

Before January 1996

3

6

4

5

NOTE: The 1/4" ID pilot air tubing (yellow with red dashes) was changed

to 1/8" ID pilot air tubing (yellow with red stripe) in all units built

after December 1995.

Automatic

moisture

separator

34

50

40

60

5

2

30

70

20

80

1

6

90

10

100

0

psi

2

7

0

kg/cm

Page 62

85.0812.00, 2003 PR-61

Performer Floor Boxes

Item # Part Number Description

1 22.0040.00 Spring

2 33.0031.01 Gray toggle and pin

3 29.0840.00 Stem with o-rings, 3-way

4 030.001.02 O-ring pkg 10

8 33.0048.03 Master On/Off toggle, 3-way

Master On/Off Toggles with Valve, 3-way

Item # Part Number Description

1 023.001.03 Barb, 1/4" pkg 10

2 023.004.03 Barb, 1/8" pkg 10

3 004.005.02 Washer pkg 10

4 004.005.02 Washer pkg 10

5 22.0040.00 Spring

6 29.0840.00 Stem with O-ring, 3-way

7 33.0031.01 Gray toggle with pin

8 33.0080.01 Master On/Off Toggle, 3-way

After December 1995

After January 1996

1

5

6

4

7

1

2

3

2

3

4

5

8

Page 63

85.0812.00, 2003 PR-62

Performer Floor Boxes

Item # Part Number Description

1 026.118.00 Gauge, 0-100 psi

2 24.0182.02 Pre-regulator, 80 psi, relieving

3 030.019.03 O-ring pkg 10

4 24.0234.01 Filter element pkg 6

5 24.0137.01 Gasket, 9-hole pkg 10

6 22.0460.00 Spring conical

7 22.0440.02 Diaphragm pkg 10

8 24.0132.00 Piston with o-ring

9 030.003.02 O-ring pkg 10

Air Filter/Regulator Valve

20

50

10

30

40

60

70

80

90

100

psi

kg/cm

1

9

2

3

24.0469.00

4

5

6

7

8

10

1

0

2

10

20

0

30

40

3

50

kg/cm

psi

100

60

2

7

4

90

70

80

5

6

Page 64

85.0812.00, 2003 PR-63

Performer Floor Boxes

Item # Part Number Description

1 026.118.00 Gauge, 0-100 psi

2 24.0182.02 Pre-regulator, 80 psi, relieving

3 24.0137.01 Gasket, 9-hole pkg 10

4 22.0460.00 Spring conical

5 22.0440.02 Diaphragm pkg 10

6 24.0132.00 Piston with o-ring

7 030.003.02 O-ring pkg 10

Air Regulator Valve

20

50

10

30

40

60

70

80

90

100

psi

kg/cm

1

6

2

3

24.0363.04

4

5

7

1

0

2

10

20

0

30

40

kg/cm

2

7

3

50

psi

100

60

4

90

70

80

5

6

Page 65

85.0812.00, 2003 PR-64

Performer Floor Boxes

Water Shutoff Valve, Air Operated

34.0033.00

5

1

3

2

4

Item # Part Number Description

1 22.0440.02 Diaphragm pkg 10

2 013.032.00 Spring conical

3 24.0132.00 Piston with O-ring

4 030.003.02 O-ring pkg 10

5 24.0137.01 Gasket, 9-hole pkg 10

Page 66

85.0812.00, 2003 PR-65

Performer Floor Boxes

Air Shutoff Valve, Air Operated

5

1

3

2

4

Item # Part Number Description

1 22.0440.02 Diaphragm pkg 10

2 22.0460.00 Spring conical

3 24.0132.00 Piston with o-ring

4 030.003.02 O-ring pkg 10

5 24.0137.01 Gasket, 9-hole pkg10

Page 67

85.0812.00, 2003 PR-66

Performer Floor Boxes

Automatic Moisture Separator

3

1

2

Item # Part Number Description

1 22.0440.02 Diaphragm pkg 10

2 97.0280.02 Filter element pkg 6, 5 micron filtration

(not a bacterial filter)

3 97.0290.00 Bowl with seal

90.1027.30

R

Page 68

85.0812.00, 2003 PR-67

Performer Floor Boxes

Manual Moisture Separator

1

2

Item # Part Number Description

1 97.0280.02 Filter element pkg 6, 5 micron filtration

(not a bacterial filter)

2 97.0290.00 Bowl with seal

Page 69

Wire Voltage Wire

Before Feb 98 After Feb 98

1 Grn/Yel Ground 1 Grn/Yel

2 White 0 VAC 2 Black

3 Orange 10.8/12.1 V 3 White

4 Yellow 10.8 V 4 Orange

5 Violet 12.1 Volts 5 Yellow

6 Red 12.1 Volts 6 Yellow

85.0812.00, 2003

Performer Power Supplies

Wire Voltage Wire

Before Feb 98 After Feb 98

1 Grn/Yel Ground 1 Grn/Yel

2 Black 0 VAC 2 Black

3 Red 24 Volts 3 Gray

4 Orange Not used 4 Open

Front view before

February 1998

Front view before

February 1998

Front side —

test voltage

Wire side —

power supply

White 4-Pin Connector

Wire Voltage Wire

Before Feb 98 After Feb 98

1 Grn/Yel Ground 1 Grn/Yel

2 Brown 0 VAC 2 Black

3 Open Not used 3 Open

4 Open 10.8/12.1 4 White

Front view before

February 1998

Front view before

February 1998

Front side —

test voltage

Wire side —

power supply

Red 4-Pin Connector

Front view before

February 1998

Front view before

February 1998

Front side —

test voltage

Wire side —

power supply

White 6-Pin Connector

80-Watt Power Supply

After January 1998

28.1345.00 115 VAC .80A, 50-60Hz

47.2030.00 100 VAC, .90A, 50-60Hz

47.2031.00 230 VAC, .40A, 50-60Hz

Line voltage selector switch (115V or 230V)

Before February 1998

80-Watt, 115/230 Volt Switchable

Selector Switch Voltage/Fuse Table

Mains Voltage Part Number Description

115 VAC 044.191.00 1.25 A Time Lag Fuse, 5 x 20 mm

Replaces 044.148.00.

230 VAC 044.190.00 630 mA Time Lag Fuse, 5 x 20 mm

Replaces 044.185.00.

WARNING

Make sure the line voltage selector switch is set

on the correct voltage (115V or 230V).

Fuses (see table)

NOTE: No serviceable parts. Replace as a complete assembly.

PR-68

10

A

M

P

230

115

2

30

5

1

1

Page 70

85.0812.00, 2003 PR-69

Performer Foot Control

Foot Control III

9

2

3

6

7

4

8

5

10

1

11

12

Item# Part number Description

1 38.0320.02 Foot control housing

2 38.0075.03 Toggle and pin, dark surf

3 22.0040.00 Spring

4011.016.00 Pin

5 38.0072.03 Valve holder, dark surf

6 38.0066.00 Cap

7 010.056.00 Retainer

8 007.002.00 Setscrew pkg 10

9 33.0138.00 Micro-valve

10 003.078.00 Screws, valve mounting

11 38.0237.00 Retaining ring, internal

*12 38.0760.00 FC3 piston

NOTE:* Parts included in Foot Control III service kit.

** Parts not used in foot controls after 12/96. All parts in the

38.0607.01 are included in Foot Control II service kit.

Page 71

85.0812.00, 2003 PR-70

Performer Foot Control

Foot Control III Valve

Foot Control II Valve

1

2

4

5

6

7

9

8

3

10

11

3

2

12

7

9

8

13

14

NOTE:* Parts included in Foot Control III service kit.

** Parts not used in foot controls after 12/96. All parts in the

38.0607.01 are included in Foot Control II service kit.

*

*

*

*

*

*

*

**

**

Item# Part number Description

*1 38.0760.00 FC3 piston

*2 013.011.00 Spring

*3 10.0440.00 Spring

*4 22.0060.00 Poppet

*5 22.0580.00 Spring

6 22.0050.00 Spring cap

*7 030.012.02 O-ring

*8 22.0778.00 Stem with o-rings

*9 38.0054.02 Diaphragm pkg 10

10 38.0246.00 Stem with E-ring

11 38.0552.00 Ring return, valve stem

12 030.008.02 O-ring pkg 10

**13 023.040.00 Check valve barb, slotted

**14 013.053.00 Spring

Foot Control II &III Valves

*

Page 72

85.0812.00, 2003 PR-71

Performer Flow Diagram

Optional chip blower

or scaler valve

Foot Control II valve

Wet/dry

toggle valve

From air

regulator

To control

head

Foot Control II Cross View

Signal

relay valve

Diaphragm

Foot Control II Valve Assembly

Foot Control II

valve

Signal

relay valve

Exhaust hole

Foot Control I and II were used on A-dec equipment before October 1999. These units are no

longer available.

WARNING

When working on Foot Control II, move the master On/Off toggle to the OFF position and

bleed the system of air pressure. Do this before removing the foot control disc to prevent the

foot control stem from being forcefully ejected from the foot control valve.

Foot Control II

Page 73

85.0812.00, 2003 PR-72

Performer Flow Diagram

Use of Foot Control III began in March 1999. A service kit, P/N 90.0593.00, and an

international conversion kit, P/N 38.1764.00, are available for Foot Control III.

Optional chip blower

or scaler valve

Foot Control III valve

Wet/dry

toggle valve

From air

regulator

To control

head

Foot Control III Cross View

Signal relay

valve

Diaphragm