Page 1

Lisa

Sterilizer

MB17

Service

Guide

About

the

Lisa

Sterilizer

Section 1 —

About

Characteristics

the

Lisa

Developed,

for

small

Totally

Compact

Patented

-

Low

- 8 to

Quick

5

fractionated

-

Pulsed

Independent

Optimized

Maximum

Interactive

Simple

Entirely

Evolutionary

Single

produced

water

Class B cycles.

sterilizer,

«2CS » pneumatic

water

consumption: 7 to

12

cycles

cycles:

vacuum

steam

energy

absorbed

user-friendly

to

use

controlled

software.

piece

stamped

Sterilizer

and

tested

steam

sterilizers.

without

without

30

minutes

pre-vacuum.

drying.

generator.

management

power:

and

safe.

by

any

system

refilling

(276°F/135.5°C-4

touchscreen.

microprocessor.

stainless-steel

according

external

:

12

oz/cycle

or

draining.

(0.5

2100

W.

chamber.

to

the

European

tank

or

connections.

(.2

to

minutes).

kwh/cycle).

Norm

PrEN

.35

liters/cycle).

13060

85.0815.00

Reversible

or

vertical.

Optional

Refilling

Electric

door

Easy

touchscreen.

the

Warranty:

tray

printers.

and

double

gasket.

accessibility

Up

support: 5 trays

draining

door

to

locking

for

service.

2

years

possible

or

2000

horizontal

during

system

Test

and

functions

cycles

or 3 cassettes

the

cycle.

parallel

whichever

positioning

available

on

comes

horizontal

of

the

first.

Page 2

About

the

Lisa

Sterilizer

Lisa

Sterilizer

MB17

Service

Guide

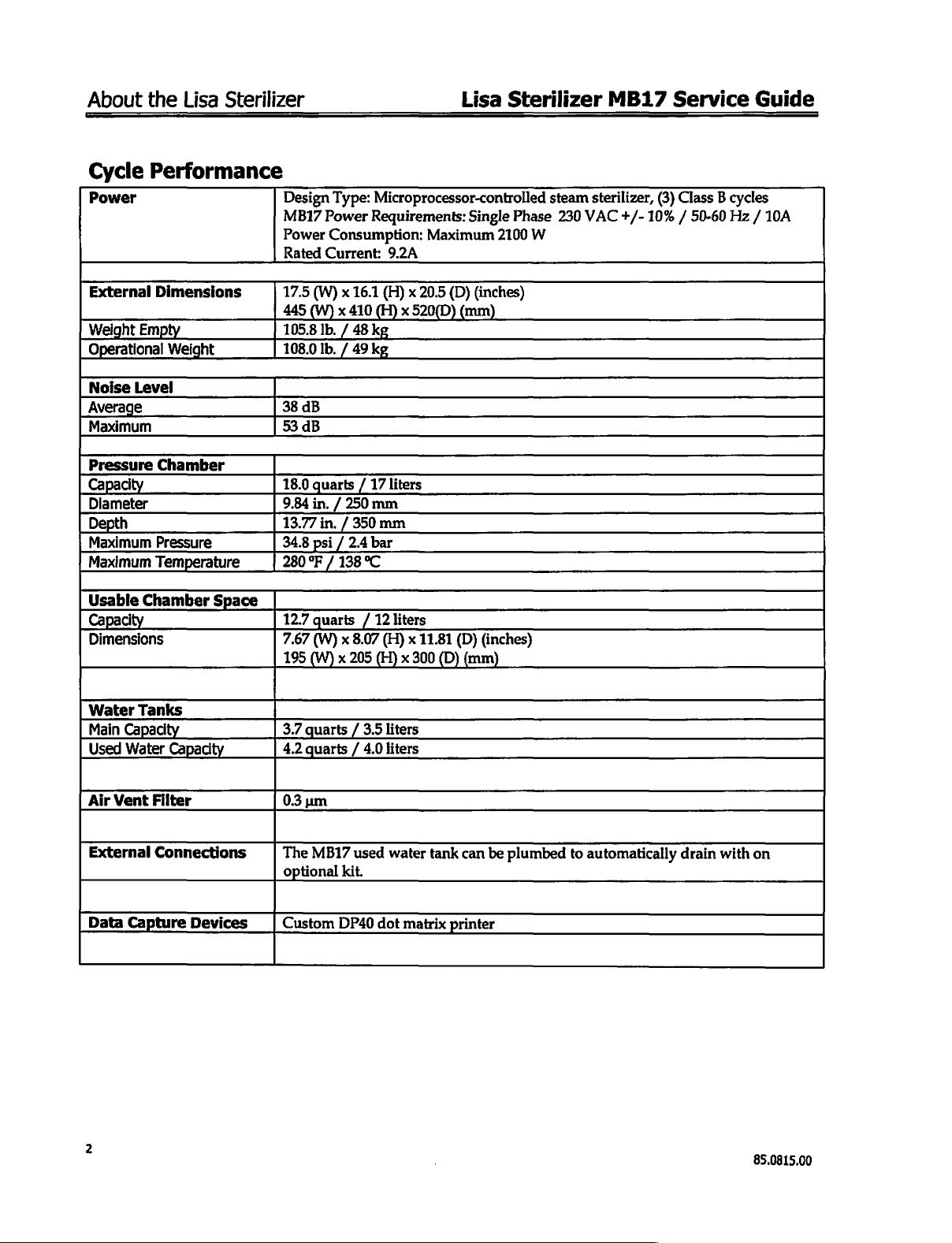

Cycle

Power

External

Weight

Operational

Noise

Average

Maximum

Pressure

Capacity

Diameter

Depth

Maximum

Maximum

Usable

Capacity

Dimensions

Performance

Empty

Level

Chamber

Dimensions

Weight

Chamber

Pressure

Temperature

Space

Design

MB17

Power

Power

Rated

Current:

17.5

(W) x 16.1

445

(W) x 410

105.8

lb. / 48

108.0

lb. / 49

38

dB

53

dB

18.0

quarts / 17

9.84

in. / 250

13.77

in. / 350

34.8

psi / 2.4

280

°F / 138

12.7

quarts / 12

7.67

(W) x 8.07

195

(W) x 205

Type:

Microprocessor-controlled

Requirements:

Consumption:

9.2A

(H) x 20.5

(H) x 520(D)

kg

kg

liters

mm

mm

bar

°C

liters

(H) x 11.81

(H) x 300

Single

Maximum

(D)

(inches)

(mm)

(D)

(D)

(mm)

Phase

2100

W

(inches)

-

steam

230

VAC

sterilizer,

(3)

+/-

10% / 50-60

Class B cycles

Hz / 10A

Water

Main

Used

Air

External

Data

Tanks

Capacity

Water

Vent

Filter

Connections

Capture

Capacity

Devices

3.7

quarts / 3.5

4.2

quarts / 4.0

0.3

um

The

MB17

optional

Custom

used

kit.

DP40

liters

liters

water

dot

matrix

tank

printer

can

be

plumbed

to

automatically

drain

with

on

85,0815.00

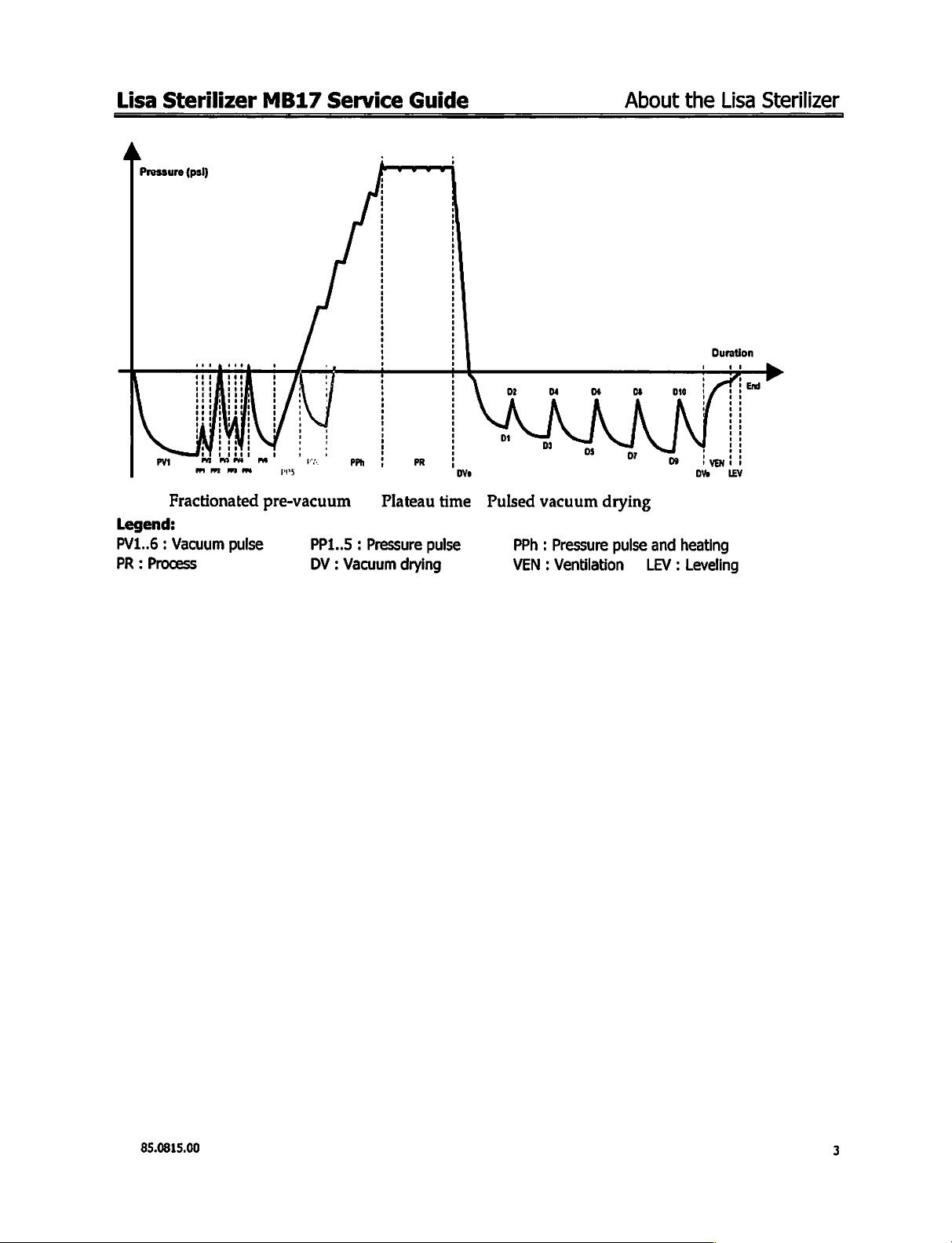

Page 3

Lisa

Sterilizer

A

Pressure

(psi)

MB17

Service

e...

Guide

About

the

Lisa

Sterilizer

2

Fractionated

Legend:

:

PV1..6

PR : Process

Vacuum

pre-vacuum

pulse

Plateau

PP1..5 : Pressure

DV : Vacuum

time

pulse

drying

Pulsed

vacuum

PPh : Pressure

VEN : Ventilation

drying

pulse

and heating

LEV : Leveling

85.0815.00

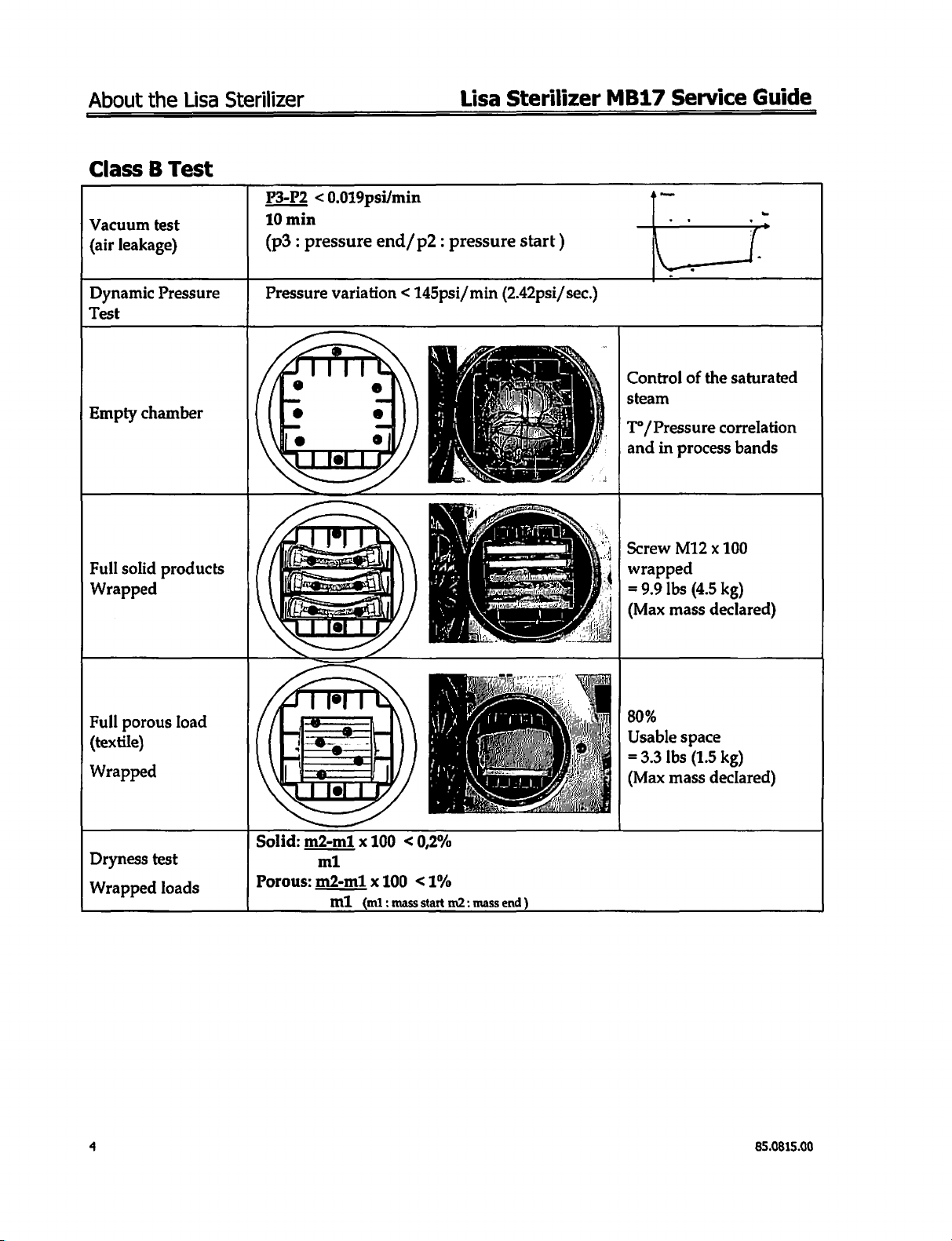

Page 4

About

Class B Test

Vacuum

{air

the

test

leakage)

Lisa

Sterilizer

P3-P2 < 0.019psi/min

10

min

(p3 : pressure

Lisa

Sterilizer

end/p2 : pressure

start)

M

B17

Service

Guide

yr

Dynamic

Test

Empty

Full

Wrapped

Full

(textile)

Wrapped

chamber

solid

porous

Pressure

products

load

Pressure

variation < 145psi/

min

(2.42psi/

sec.)

Control

steam

T°/

and

Screw

wrapped

=

(Max

80%

Usable

=

(Max mass

of

Pressure

in

process

M12 x 100

9.9

Ibs

mass

space

3.3

Ibs

(4.5

(1.5

the

saturated

correlation

bands

kg)

declared)

kg)

declared)

Dryness

Wrapped

test

loads

Solid:

Porous:

m2-m1 x 100 < 0,2%

m1

m2-m1 x 100

ml

(m1:

mass

<1%

start

m2:

mass

end)

85.0815.00

Page 5

Lisa

Sterilizer

MB17

Service

Guide

About

the

Lisa

Sterilizer

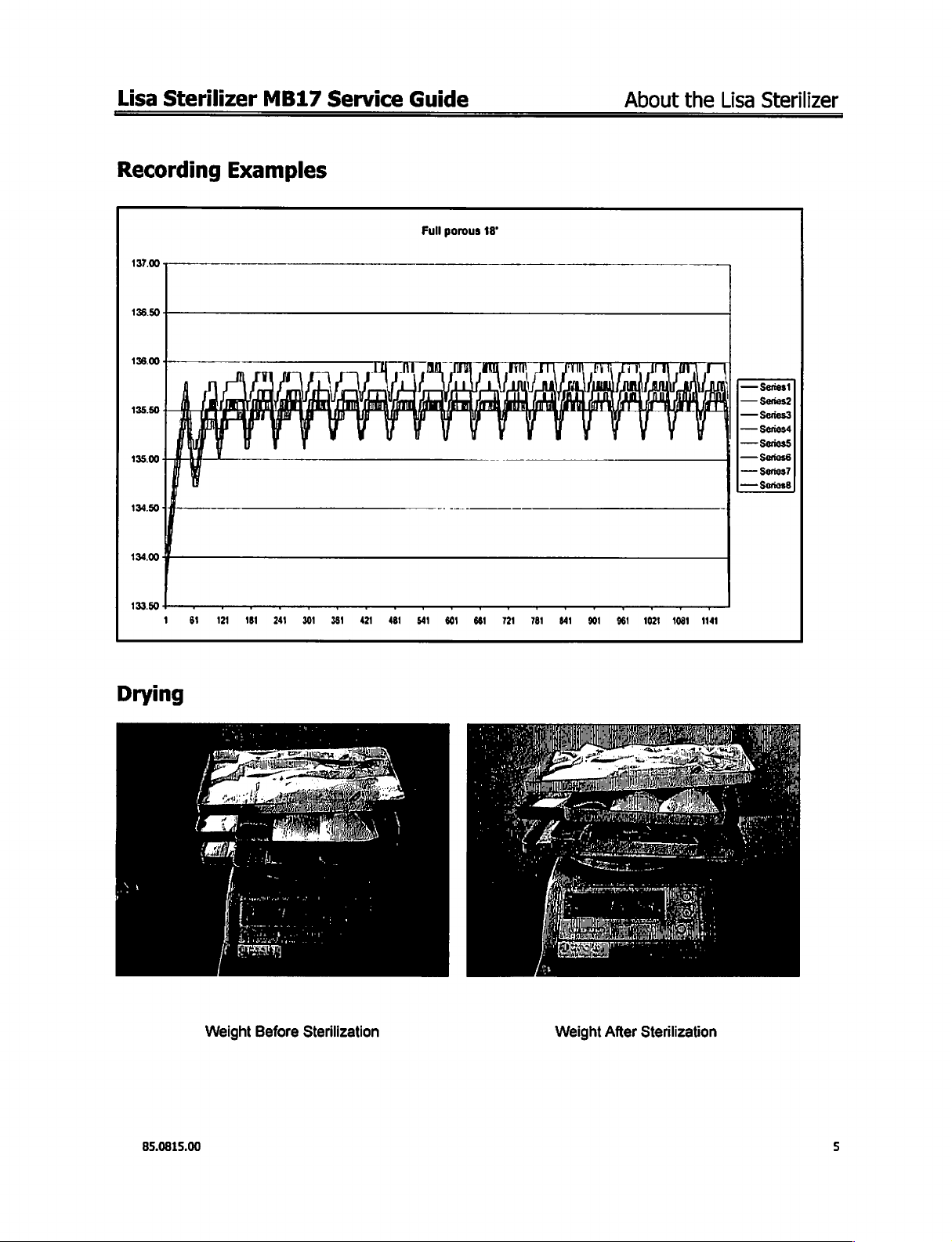

Recording

137.00

434.00

1

6

Examples

121

181

240

301

3581

421

Full

porous

18°

—

Series!

—

$01052

—

561653

—

$67054

—

Seriess

<

—

Serios?

——

$01088

4

541

601

661 721

м

м

901 961

1021

1001

1141

Weight

85.0815.00

Before

Sterilization

Weight

After

Sterilization

5

Page 6

About

the

Lisa

Sterilizer

Lisa

Sterilizer

MB17

Service

Guide

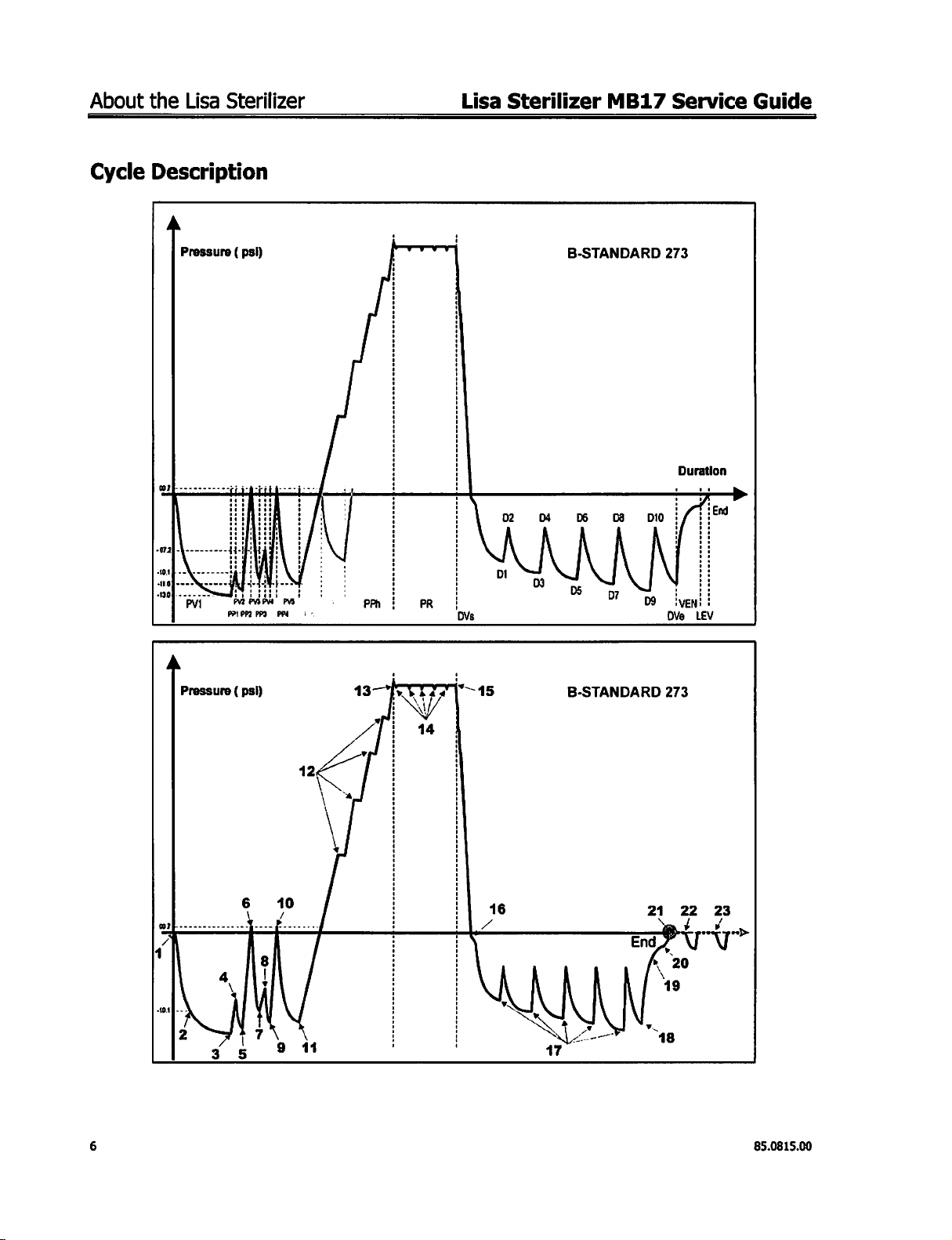

Cycle

Description

A

Pressure ( psi)

mb.

maj-

ot

4116

.

139

GRR

c

ho:

Dvs

02

Di

oq

03

B-STANDARD

pe

os

DS

DI

Do

09

273

Buration

i/

i | :

НОЕ

ivENi

OVe

一

-一

1:99

ii

ii

LEV

>

À

Pressure ( psi)

+

*—

15

16

之

M

SV

B-STANDARD

1

Ş

M

47

End

v

21

273

LA

\

19

18

22

20

23

>

6

85.0815.00

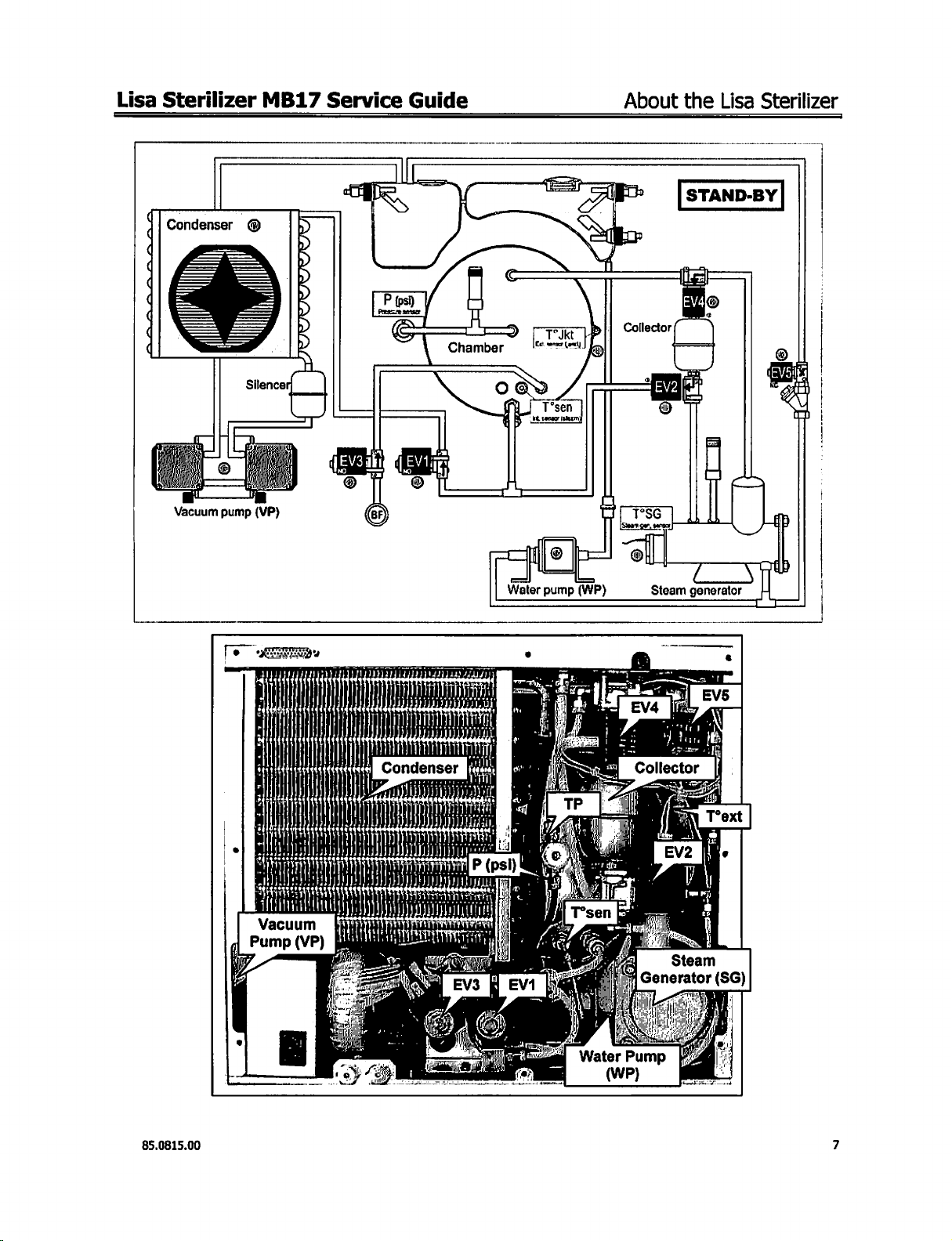

Page 7

Lisa

Sterilizer

MB17

Service

Guide

About

the

Lisa

Sterilizer

Condenser | Φ

(VP)

Vacuum

pump

Water

pump

(WP)

Steam

STAND-BY

generator

1

|

)

Hi

ΙΙ

01

В

ï

Il

Tİ

M

Peo,

00141

fl

|

m

0

NS

Generator

ÉS

(SG

85.0815.00

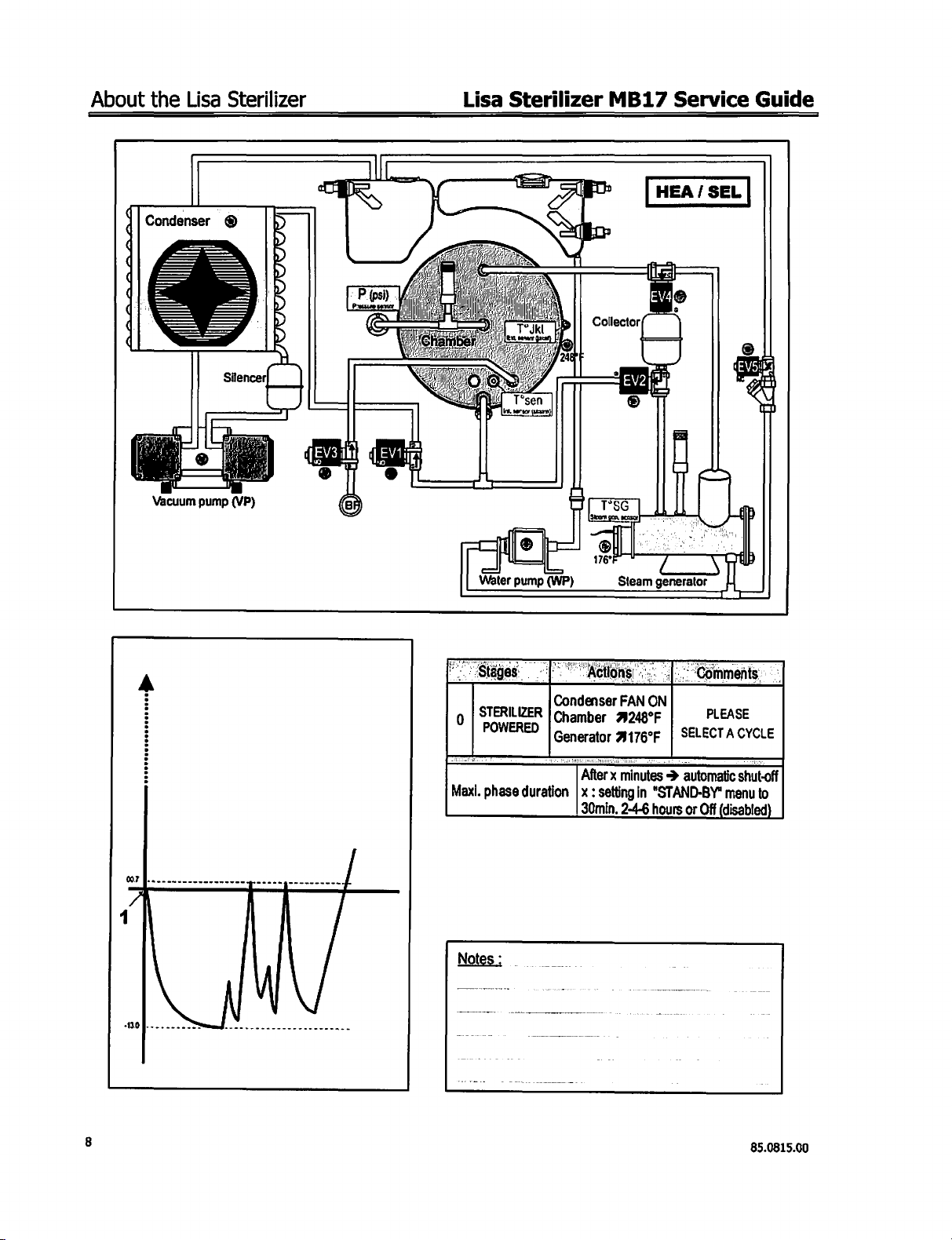

Page 8

About

d

q

di

4

(

the

Lisa

Condenser

|

Vacuum

A

É

Sterilizer

©

Silencer

®

pump

(VP)

Lisa

Sterilizer

E

MB17

Collector

Service

HEA / SEL

iz

3016

一

Guide

"60006

STERILIZER

|

o

POWERED

|

Maxi.

phase

|

duration | x : settingin

AC

ON

Condenser

Chamber

|

Generator

OE

|

FAN

2248ºF

4176°F

After x minutes > automatic

30min.

"STAND-BY"

2-4-6

hours

|

jnments

PLEASE

SELECTA

or

Off

(disabled)

CYCLE

shut-off

menu

to

8

85.0815.00

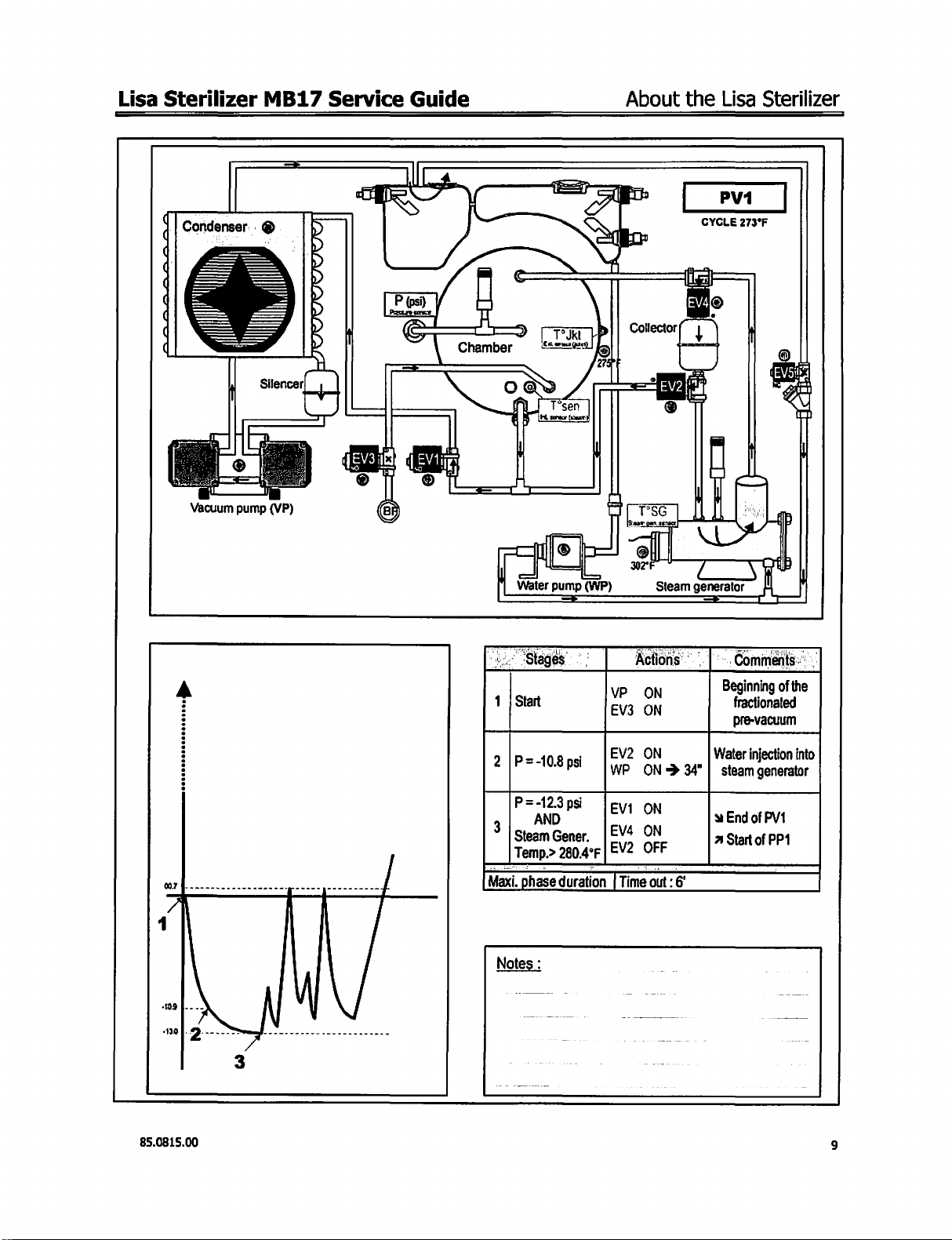

Page 9

Lisa

Sterilizer

|

Condenser.

LS

LS

RS

MB17

@

Service

Guide

About

the

CYCLE

Lisa

Sterilizer

PV1

273°F

dd

Vacuum

©

pump

Silencer

(VP)

1 | Start

=.

2

(P=-10.8psi

P=-12.3

3

|

AND

Steam

Temp.>

Maxi.

phase

VP

EV3

。

|EV2

(wp

psi

vi

Gener.

280.4°F

|

EV2

duration | Time

ON

ON

ON

ON-

ON

OFF

out:

Beginning

fractionated

pre-vacuum

Water

34° | steam

w

End

a

Start

6

of

the

injection

into

generator

of

PV1

of

PP1

85.0815.00

Notes

:

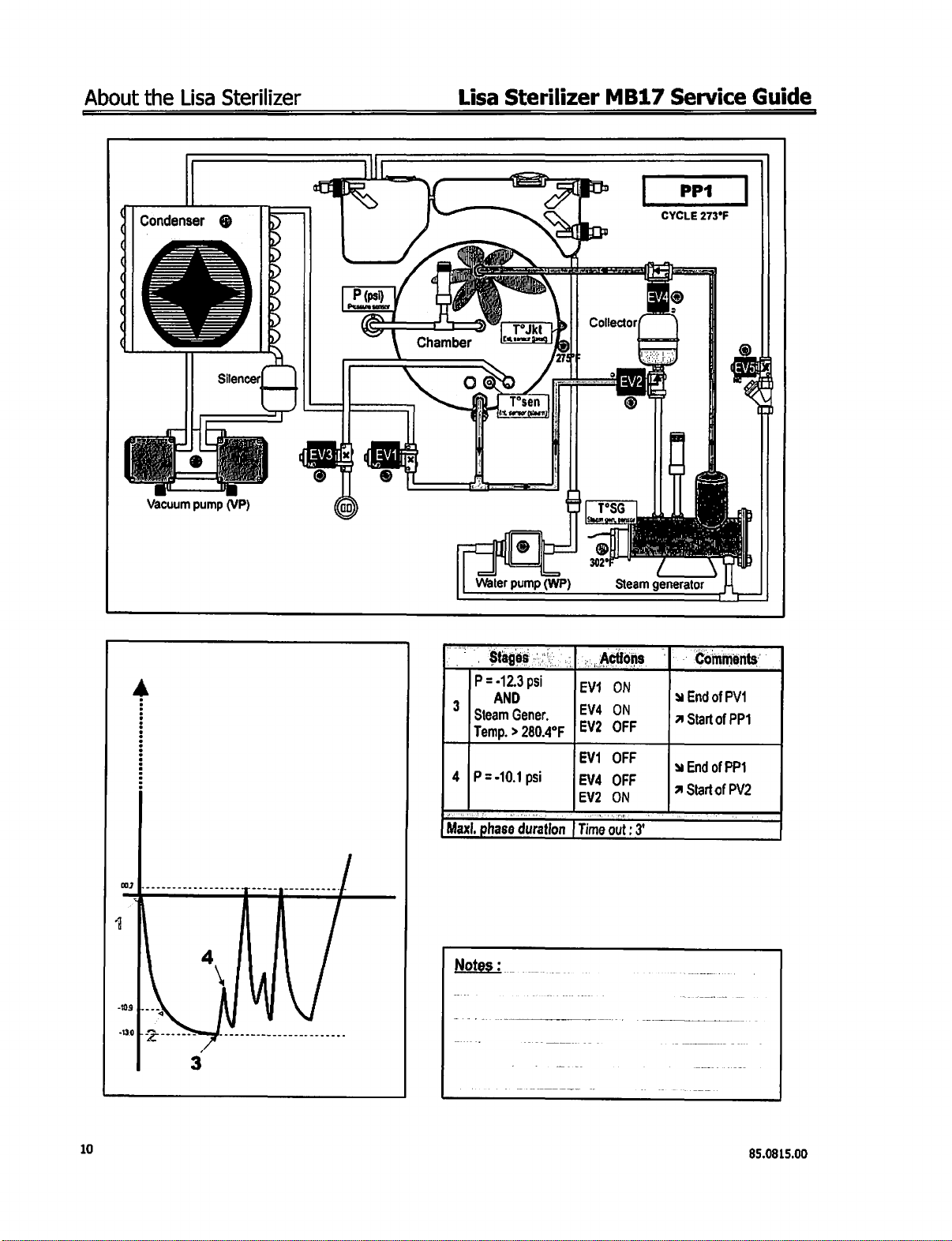

Page 10

About

the

Lisa

Sterilizer

Lisa

Sterilizer

MB17

Service

Guide

(

(

q

(

(

Condenser

Vacuum

A

©

pump

@

Silencer,

(VP)

ea

=

Chamber

TIR

"==

o

ΜΜΕ

|

!

@

|

Water

pump

, . Stages]

P = -12.3

3

|.

Steam

Temp. > 280.4ºF

4

|P=-10.1

Maxl,

phase

psi

AND

Gener.

psi

duration

PP1

CYCLE

273ºF

je

Collector

=

©

TSG

®

Steam

ON

OFF

OFF

OFF

ON

out:

κ

generator

—

à

End

A

Start

à

End

A

Start

of

PV

of

of

PP

of

218

=

|||

|

|

8

302°

(WP)

Actions | Comments’

va

EV2

EV1

EVA

EV2

|

Time

©

내

a

PP4

PV2

Notes:

_

10

_

ーー

85.0815.00

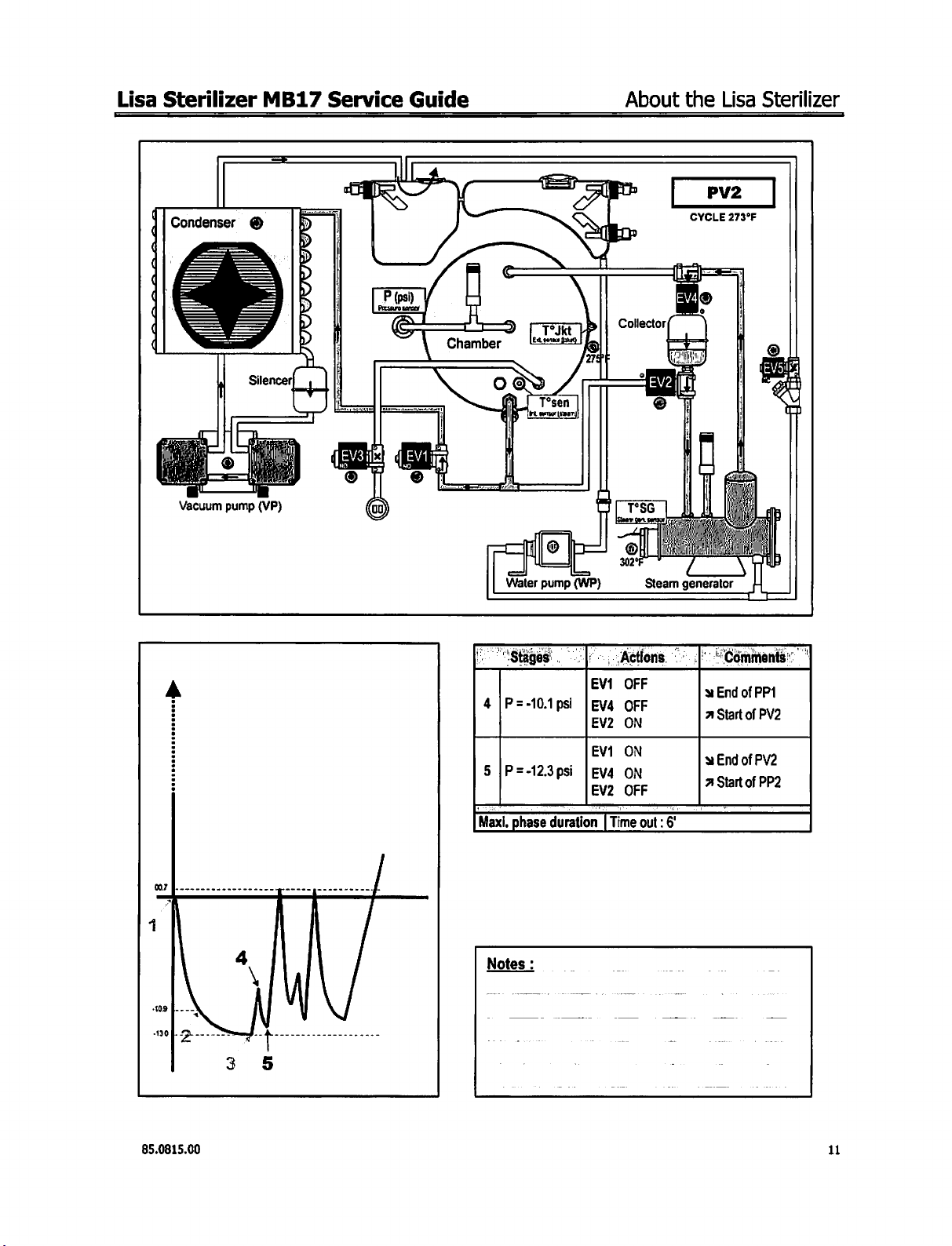

Page 11

Lisa

Sterilizer

MB17

Service

Guide

About

the

Lisa

Sterilizer

Condenser

>

へ

ュー

ュー

ュー

ュー

ヘー

Vacuum

pump

@

(VP)

PV2

CYCLE

273°F

(WP)

Water

O

pump

|

À

60000.

à

|p=

40408 a ore

разра

Maxi,

phase

Actions | Comments

EV2

ON

va

ON

EV2

OFF

duration [ Time

out:

6

w

End

a

Start

w

End

A

Start

of

PP1

of

PV2

of

PV2

of

PP2

|

85.0815.00

il

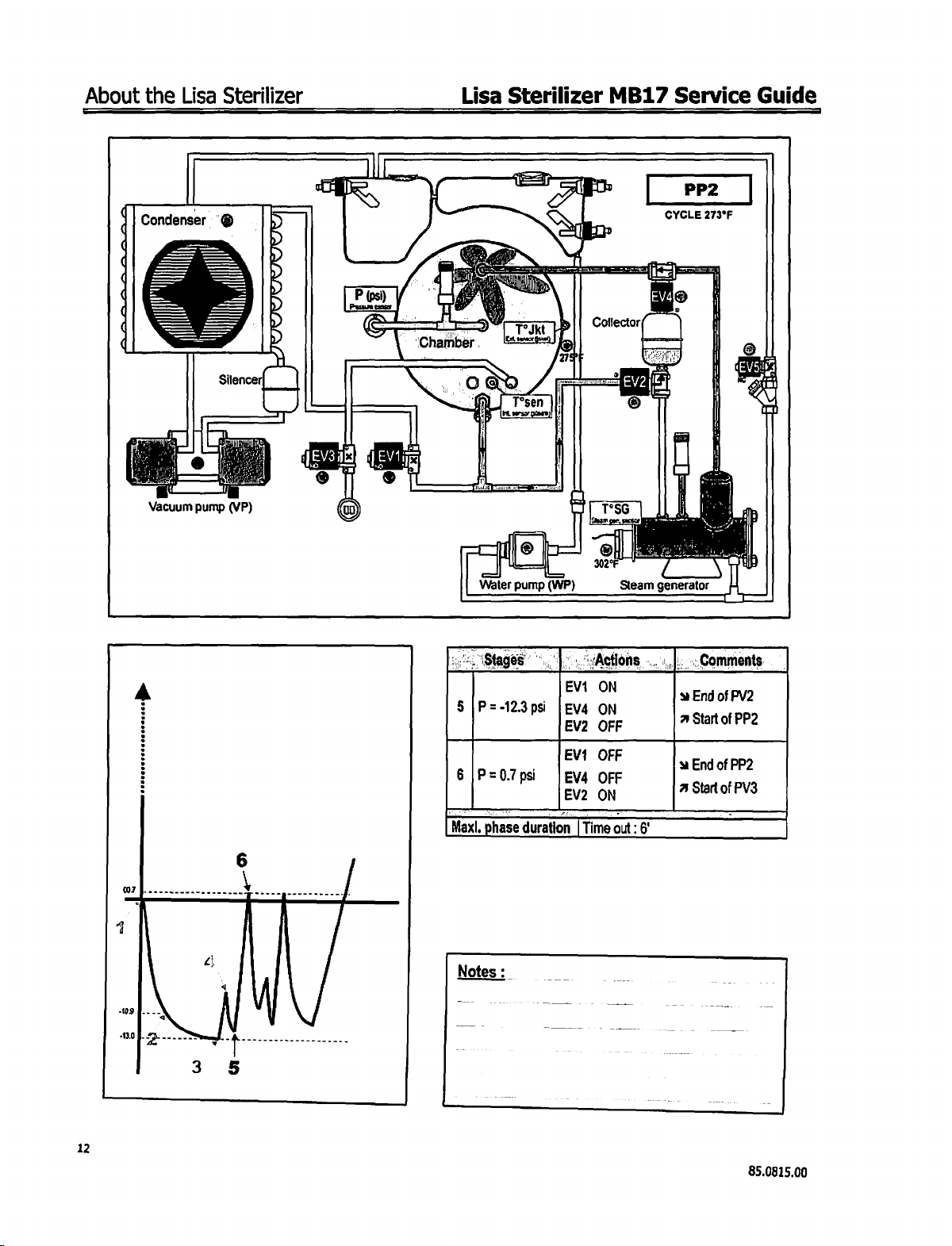

Page 12

About

the

Lisa

Condenser

Sterilizer

"©

.

Lisa

Sterilizer

MB17

CYCLE

Service

PP2

273°F

Guide

q

4

(

Vacuum

A

Silencer|

o

pump

(VP)

Pon Y "UA

|

Pa

==

p

‘Chamber

SEN

x

®

'

|!

T

ОЕ

ο

=

5

6

Мах,

^

A

T

IK

ter

.

Qu

i

Tsen

|

|

A

ehi

Water

pump

|P=-123psi

|P=07

psi

P

phase

duration

.

RU

TT

i

|

(WP)

EV1

|Ev4

EV2

EV1

EVA

Collector

=

©

T°SG

¡Sigan

sen

02°F

Steam

ON

ON

OFF

OFF

one

[Time

out

6

|

on

lo

s

generator

E

à

End

A

Start

à

End

A

Start

of

of

of

of

e

||

LI

1

PV2

PP2

PP2

PV3

12

Notes

:

85.0815.00

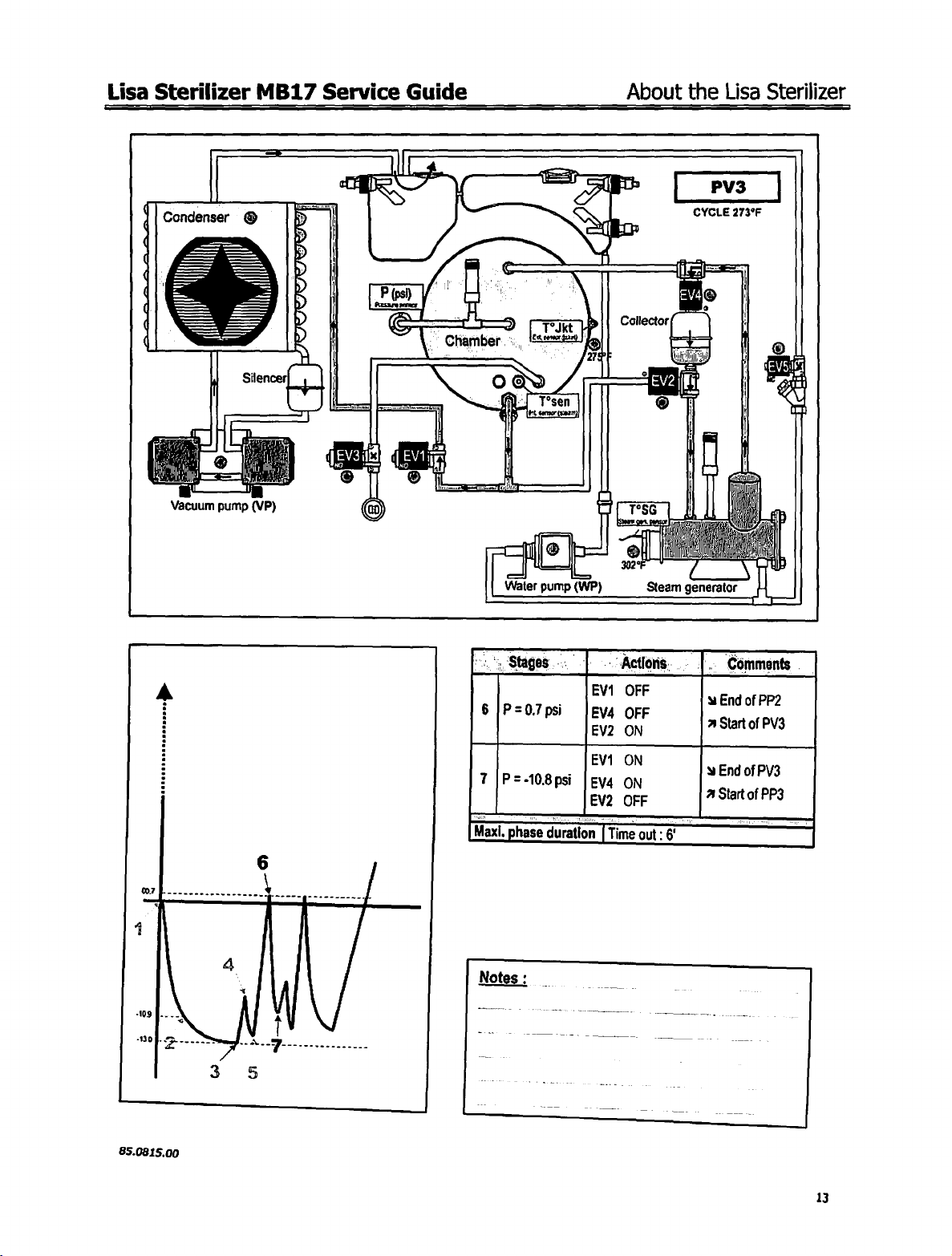

Page 13

Lisa

Sterilizer

MB17

Service

Guide

About

the

Lisa

Sterilizer

Condenser

(

(

q

;

q

.

|

Vacuum

©

pump

ーーーー

:

O

Silence

(VP)

|

y

<

|

|

|

lo

Ped

DO

lo.

há

© ©

(0

ROE

tl

/

7

Chanter

L

OG

è

ie

Water

cs,

Stages o İ

o

。

и

о

I

T°sen

ně

teror

tiež)

ep

pump

(WP)

A)

catador

2

TSG

302°F

Actions...)

©

iz

Steam

PV3

CYCLE

_

©

a

ES

[

i k

la

|

|

generator

273°F

|

|

|

|

Qu

|

|

|

|

=

Comments

=

7

.

À

:

:

85.0815.00

_

6

|P=0.7psi

Cars

7

了

|P=-108psi

Maxi,

phase

、

EV1

|EV4

EV2

EMT

|EV4

duration

T

OFF

OFF

ON

ON

ON

Time

out:

6

©

à

End

a

Start

y

End

of

PP2

of

PV3

of

PV3

13

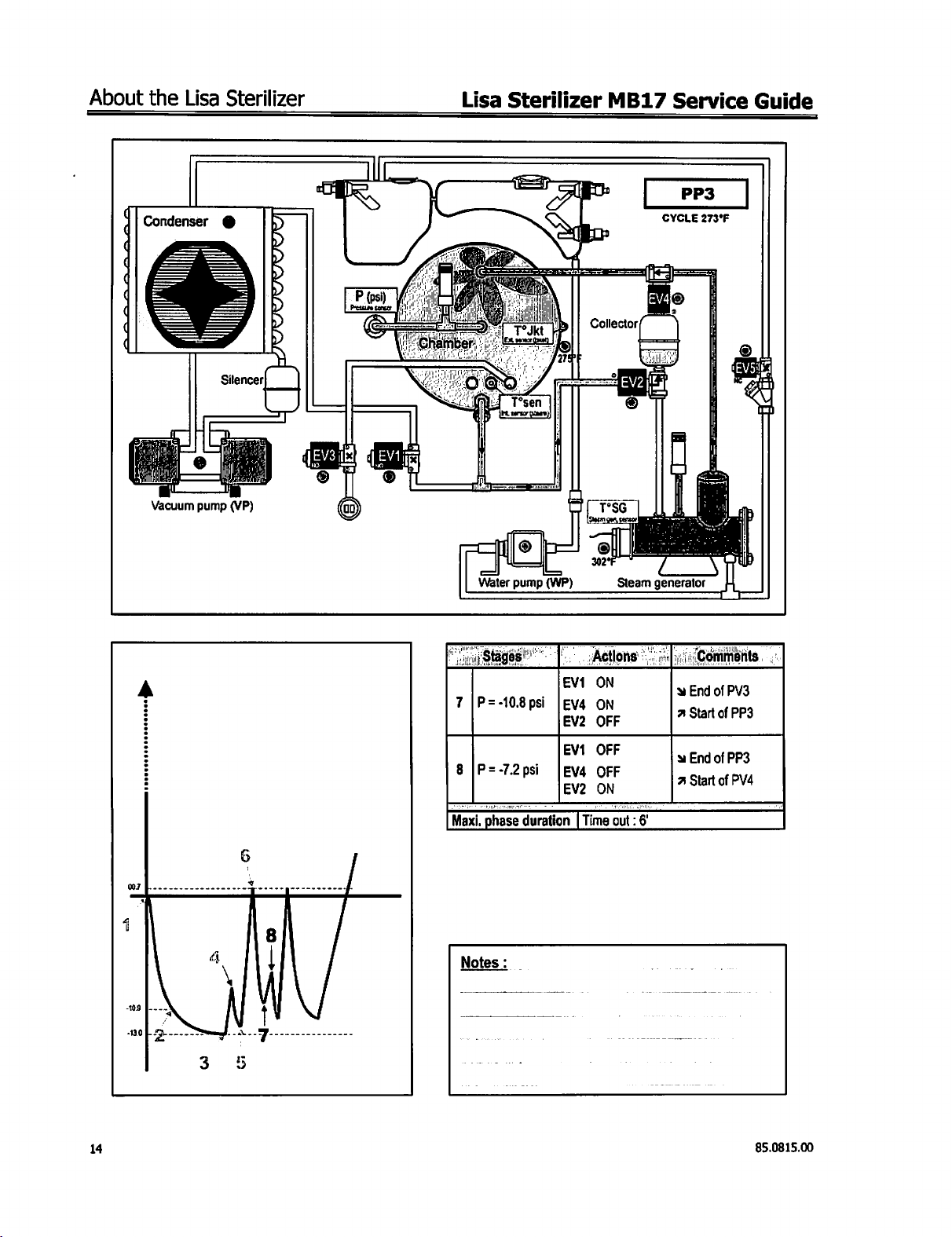

Page 14

About

the

Lisa

Sterilizer

Lisa

Sterilizer

MB17

Service

Guide

¿

(

(

(

|

di

Condenser

|

@

Water

pump

(WP)

Collector

©

1066

Saem

tensor

302

Steam

CYCLE

E)

2

generator

PP3

273°F

©

|

i

A

|

a

Maxi.

ss"

lost

İp-7204

<P

phase

|.

ep

Actions

ES

EV

İnn

Ev

duration | Time

OFF

OFF

ON

out:

6

|

End

of

2

Start

A

End

of

A

Start

PV3

of

PP3

PP3

of

PV4

14

85.0815.00

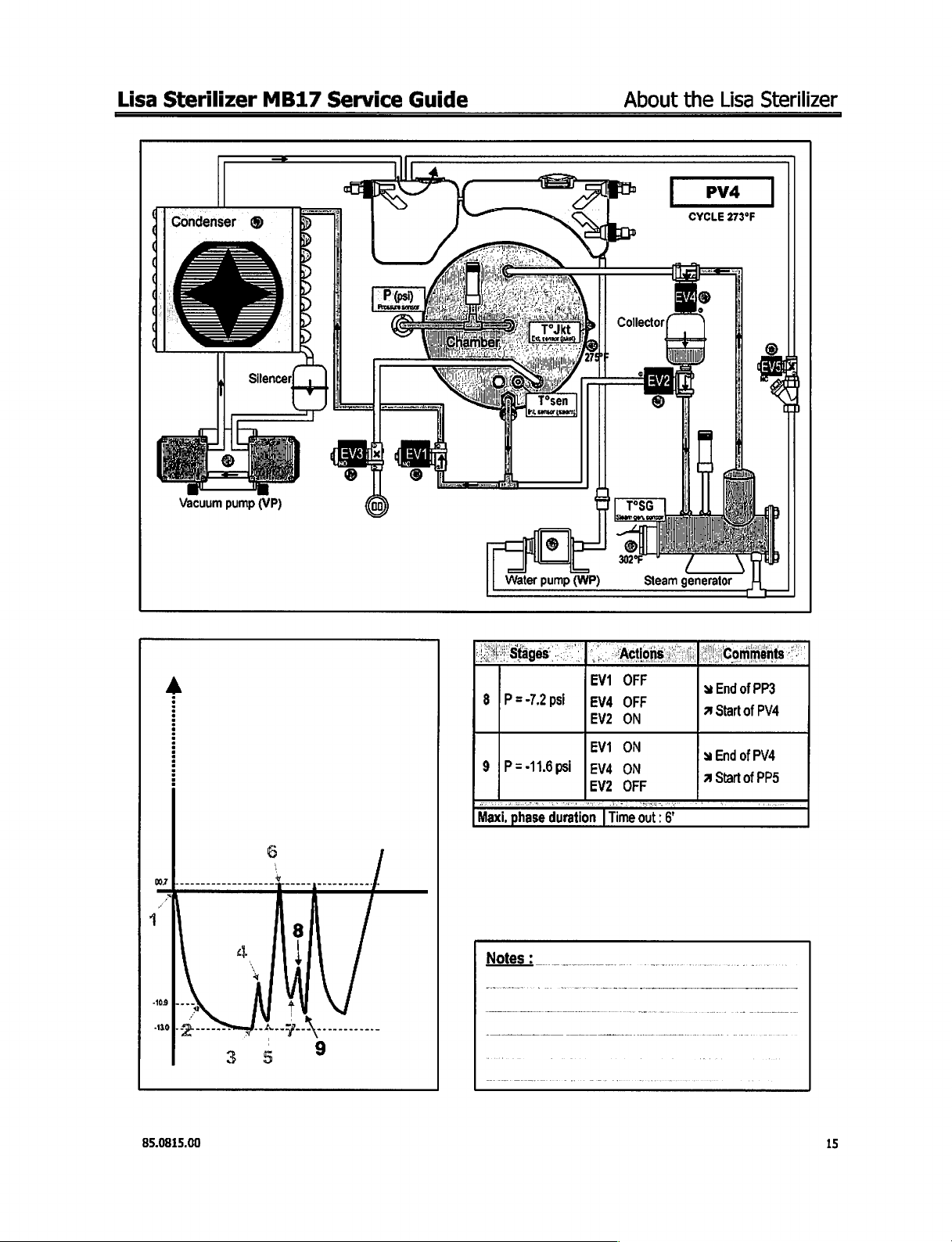

Page 15

Lisa

Sterilizer

MB17

Service

Guide

About

the

Lisa

Sterilizer

Condenser

|

®

|

dl:

dl

|.

Vacuum

pump

(VP)

S

a

il

Water

a

pump

(WP)

=

CYCLE

PV4

273°F

A

ee

a

[p=

2208 a Orr

9

|P=-11.6psi

Maxi,

phase

aa

EV2

ON

EV1

ON

|EV4

ON

EV2

OFF

duration

|

Time

out : 6"

3

EndofPP3

A

Start

of

PV4

à

End

of

PV4

A

Start

of

PP5

85.0815.00

15

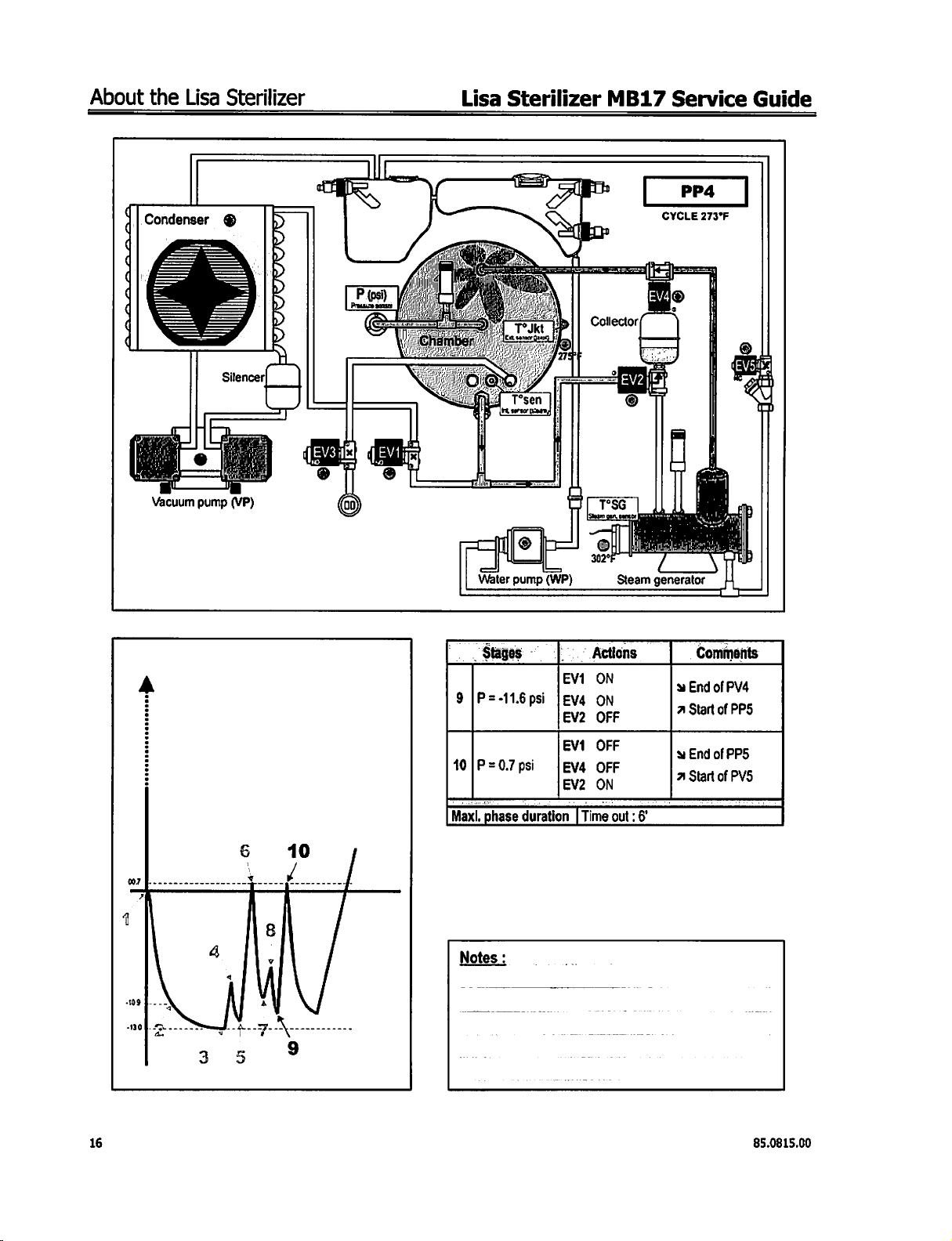

Page 16

About

the

Lisa

Sterilizer

Lisa

Sterilizer

MB17

Service

Guide

|

Condenser

или

и

OO

ジュ

Vacuum

pump

PP4

CYCLE

©

(VP)

Water

@

pump

|

(WP)

273°F

A

Stages

=

41.6

9

|P=-11.6psi E OFF

人

=

ad

Maxi,

phase

|"

Actions

EVI

Eva

ON

on

psi

ps

duration ] Time

out : 5

© _

Comments

y

End

a

Start

s

EndofPP5

a

Start

|

of

PV4

of

of

PPS

PVS

16

85.0815.00

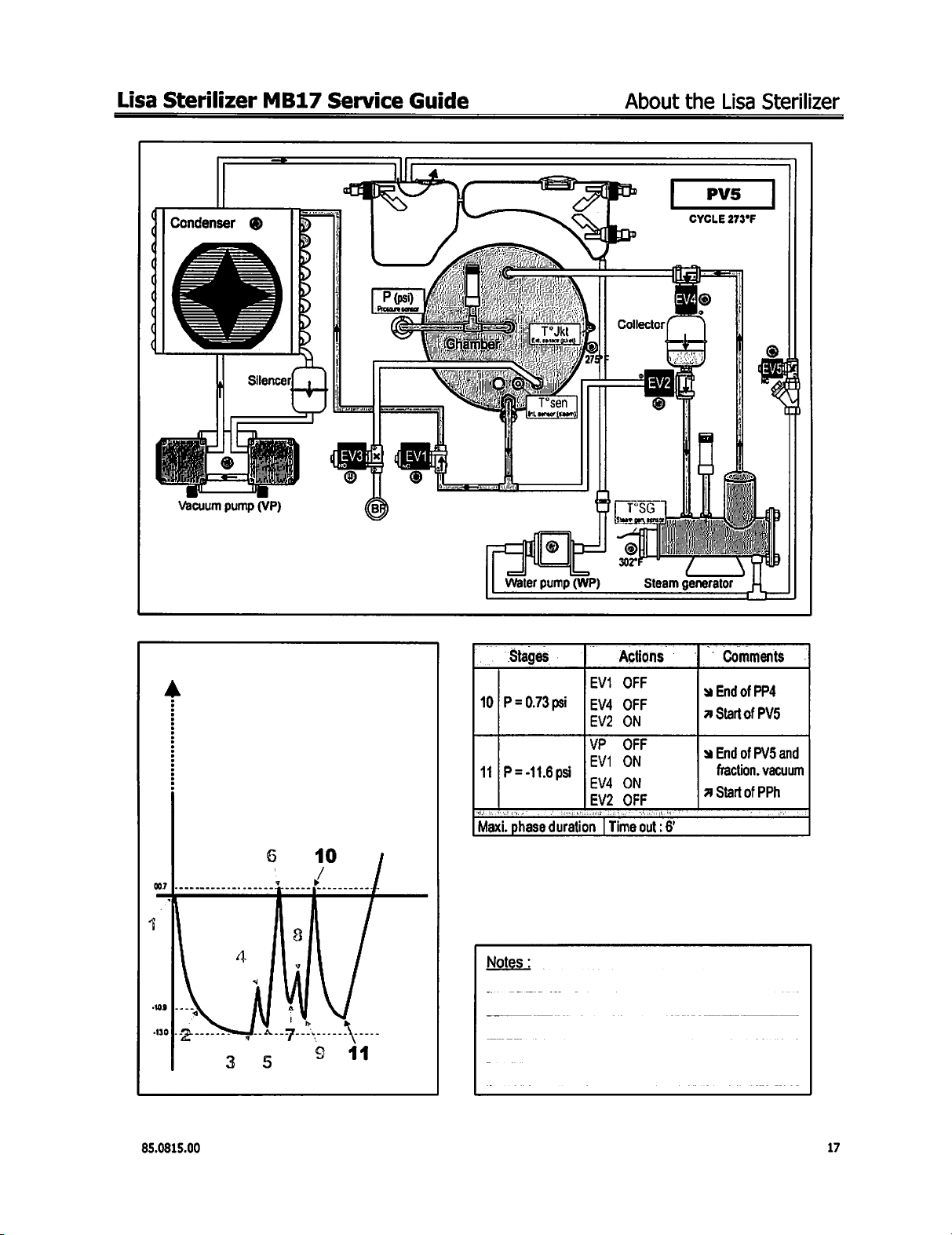

Page 17

Lisa

Sterilizer

MB17

Service

Guide

About

the

Lisa

Sterilizer

Condenser

Vacuum

pump

Y

(VP)

Water

©

pump

(WP)

ol

wd

Steam

CYCLE

le

(M

generator

PVS

273°F

NN

А

Stages

10|P=0.73psi

11 | P=-11.6

Maxi.

phase

-

psi

Actions

EV1

OFF

ΟΕΕ

|EV4

EV2

ON

E

EV4

ON

EV2

OFF

duration

|

Time

out

©

:6

Comments

©

|

End

Endo

v

a

Start

9

End

fraction,

Start

Start

of

of

of

of

of

PP4

ΡΝ5

PVS

and

vacuum

PPh

85.0815.00

17

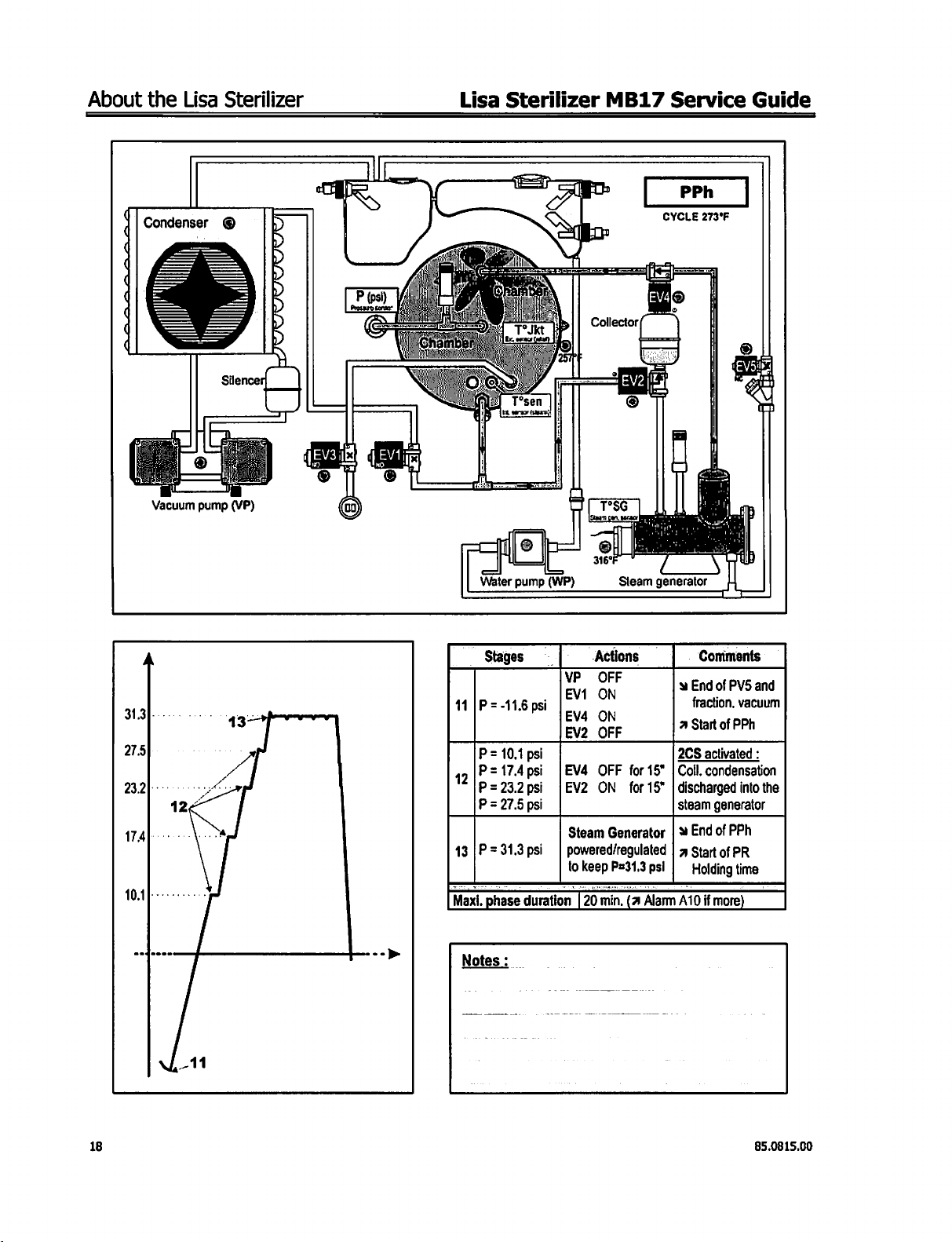

Page 18

About

the

Lisa

Sterilizer

Lisa

Sterilizer

MB17

Service

Guide

A

ュー

うー

ュー

ュー

ュー

トー

ンー

Condenser

Vacuum

pump

@

(VP)

Water

ie

©

pump

|=

(WP)

Collector

SG

9

Steam

PPh

CYCLE

273°F

|

©

o

generator

A

275

232|

174|

他

人

"2

ÃO

11

Stages

11

|P = -11.6

P = 10.1

12

P=174psi

P=23.2

P = 27.5

13

|P

=31.3

Maxi.

phase

Notes:

-|

Actions

Ev 1 on

psi

EV2_OFF

psi

|EV4

OFF

for

15" | Coll.

psi

|EV2

ON

for

15" | discharged

psi

Steam

Generator | End

psi | poweredfregulated | 4

to

keep

P=31,3

duration

||

[20

min

psi | Holding

(4

Alarm

.

Comments

à

End

of

PV5

fraction.

7

Start

o

2CS

aclivated

condensation

steam

generator

of

PPh

Start

of

ATO

if

more)

and

vacuum

:

into

the

PR

time

|

18

85.0815.00

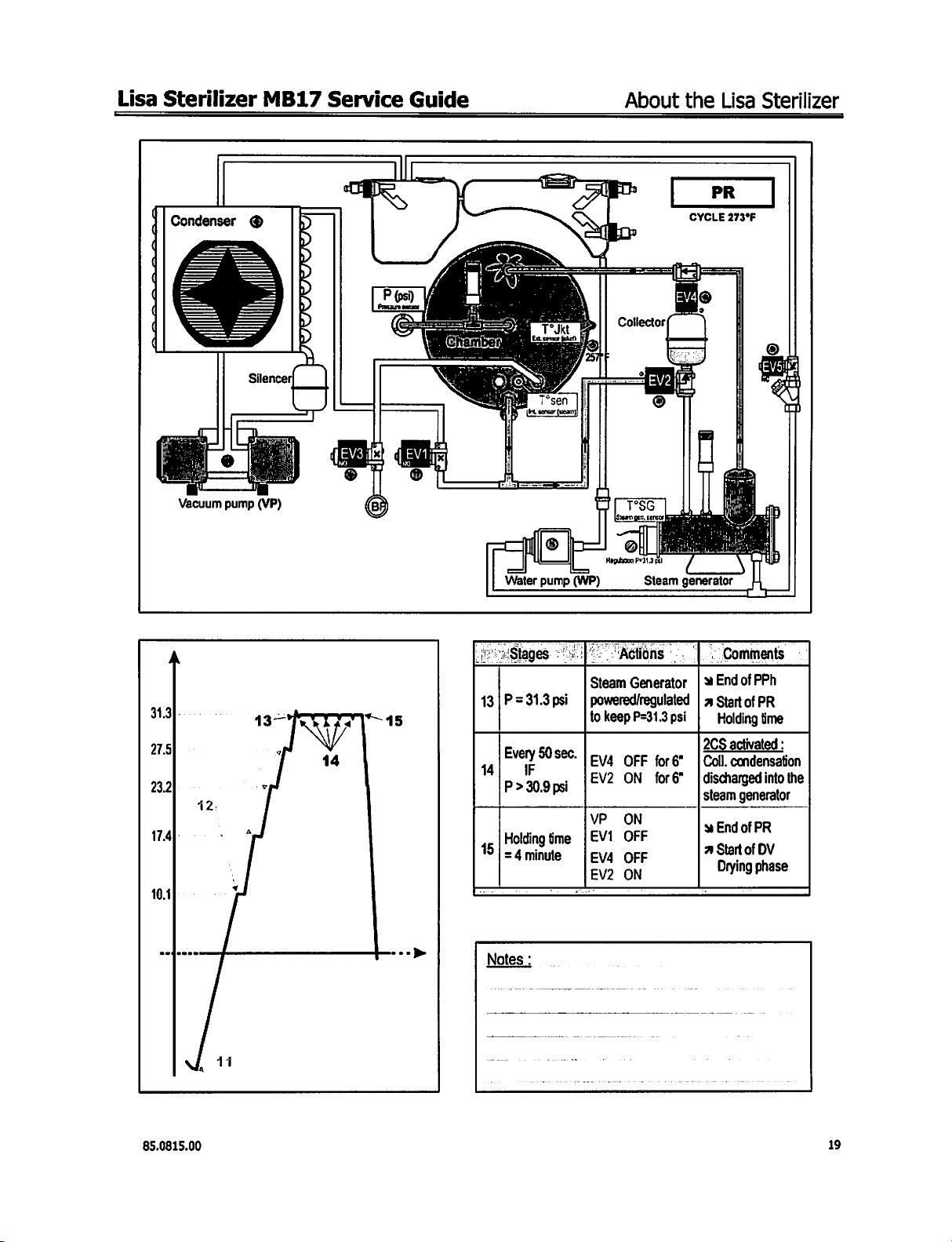

Page 19

Lisa

Sterilizer

MB17

Service

Guide

About

the

Lisa

Sterilizer

Condenser

Vacuum

pump

Y

(VP)

P

(psi)

18627“

©

Water

pump

i

(WP)

Collector

д

可 三 下 SG

su

ger,

gerer

Steam

CYCLE

generator

PR

"©

273°F

A

313|

275

23.2

17.4]:

ㆍ

101

“45

->

13|P=31.3psi

14

Every

90sec.

P

>

Holding

15

|

=

4

Notes

30.9

ime

minute

:

‘Actions

Steam

Generator

|

powered/regulated

to

keepP=31.3psi

|

EV4

OFF

.

[EV2

УР

|

EV1

EV4

EV2

ON

ON

OFF

OFF

ON

一

一

psi

一

-.

|:

|

|

|

2CS

tor6'

|

Coll.

for6”

|

discharged

steam

Comments

a

End

of

4

Start

of

Holding

activated

condensation

generator

send

of

a

Start

of

Drying

PPh

PR

time

into

PR

DV

phase

一

©

:

the

85.0815.00

19

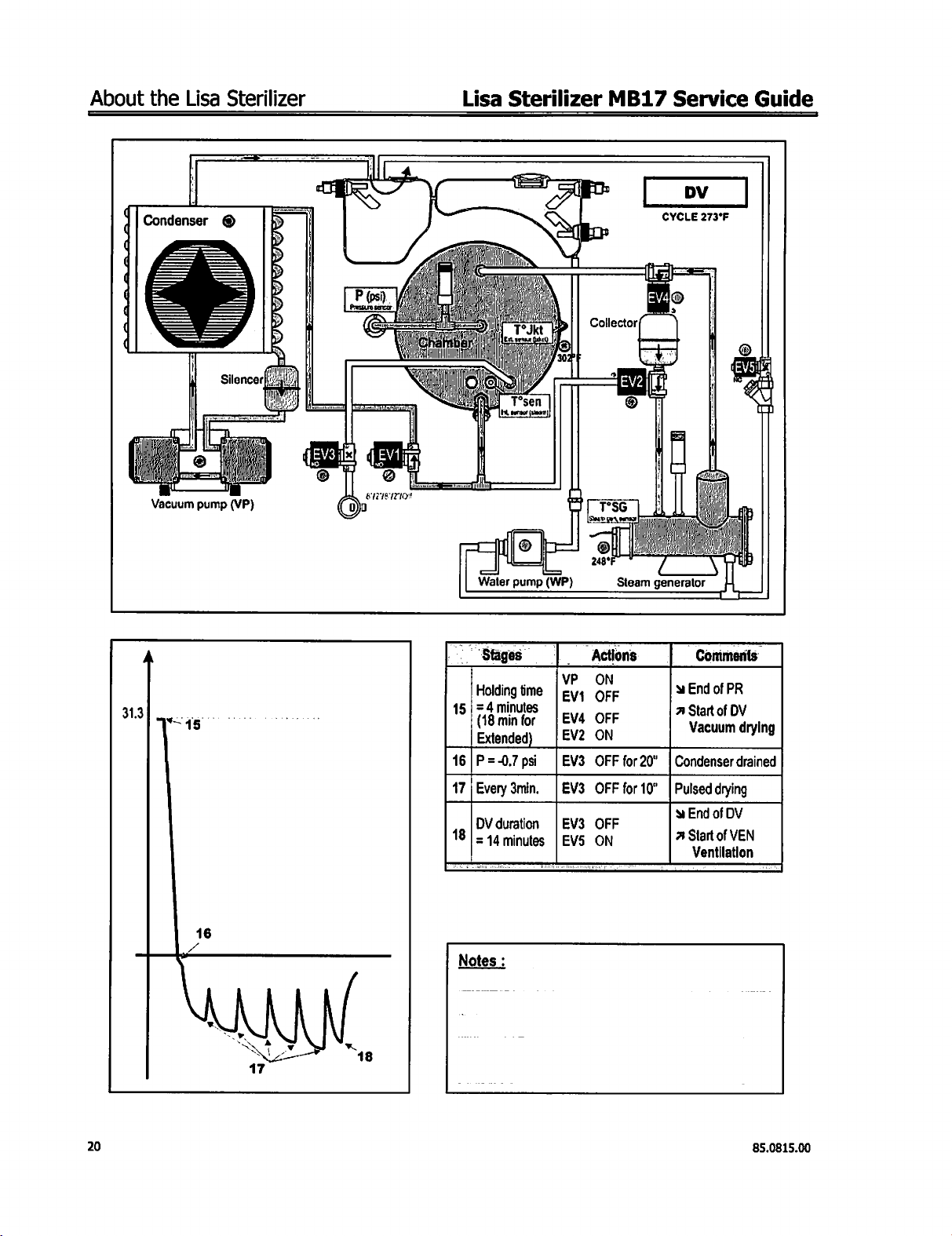

Page 20

About

the

Lisa

Sterilizer

Lisa

Sterilizer

MB17

Service

Guide

Condenser

q

q

(

(

(

q

q

Vacuum

]

pump

=

©

(VP)

Ď

o

>

=

x

|

=

DV

©

MM

Water

pump

|

(WP)

302°

Collector

=

[TSG

Bm

248°

Steam

©

MA

CYCLE

ID

3

i

T

| ;

li

i

3

generator

273°F

|

:

|

|

i

|

ioe

VÁM

|

=

4

313

TS

16

ン

q

BN

Sr

NA

Ne

17

+

ν

18

Stages

Holding

15 | =4

minutes

(18

min

Extended)

16|P=-0.7

17 | Every

DV

duration

18 | = 44

minutes | EV5

Notes

|

time | ey,

for

|

psi

3min.

圖

Actions

VP

N

OFF

EV4

OFF

|EV2

ON

|EV3

OFF

|EV3

OFF

|EV3

OFF

ON

for20"

|Condenser

for

10° | Pulsed

“Comments

à

End

of

PR

A

Start

of

DV

Vacuum

drying

©

End

of

DV

A

Start

of

VEN

Ventilation

drying

drained

20

85.0815.00

Page 21

Lisa

Sterilizer

고

|

Condenser

AE

Vacuum

pump

©-

(VP)

MB17

E

JE

Service

=

>

Y

Guide

=

>

T wa

-一

©

8

AIR

ral I ||

8

i

ИИ

|

=

Toe

|

isa

ir = i

ОНА n |

оаэ)

|

ala

Water

[ΙΙ

TI

T°sen

W

penser

pump

l

st

(staan

e

|

lp

ーー

(WP)

2

About

Collector

。

E

e

LT'SG

m

sul

©

248°

Steam

the

Lisa

See

VEN

CYCLE273F

$

Φ

|

и

RI т A Е

a i |

IM

Ret

generator

Sterilizer

7

{|

|

:

|

©

e

|

à

|

ИН

у |

|

т

|

|}

|

비

A

|

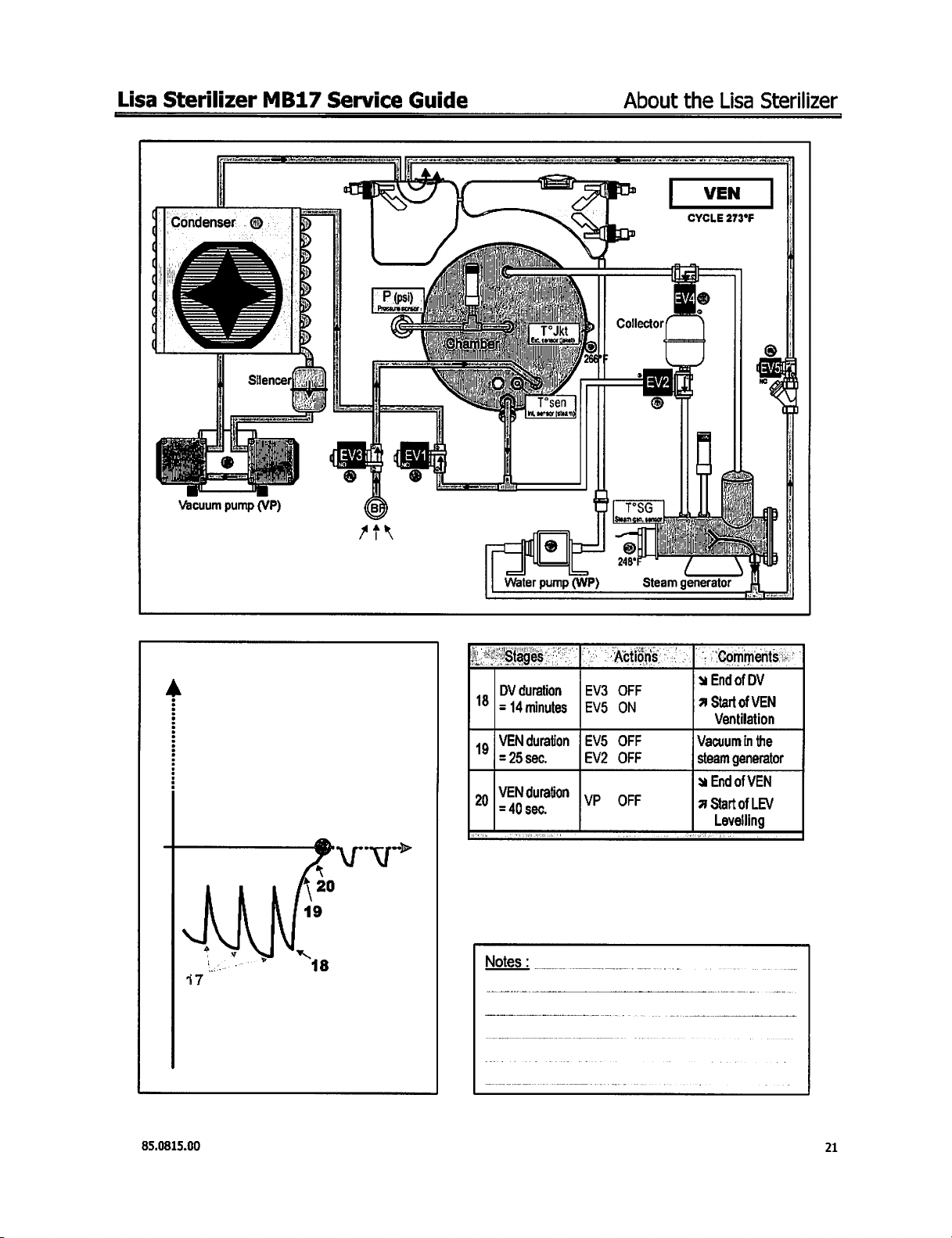

DV

duration

18 | =

44

minutes

19

VEN

duration | EVS

=

25

sec.

İline

=

40

sec.

M

Notes:

Oo...

,

=

Metións

|EV3

OFF

|EV5

ON

OFF

EV2

OFF

[YP

OF

—-

«| - Comments

wEnd

2

Start

Ventilation

Vacuum

steam

generator

à

End

|asmnougy

Levelling

of

DV

of

VEN

in

the

of

VEN

,

>”

85.0815.00

21

Page 22

About

the

Lisa

Sterilizer

Lisa

Sterilizer

MB17

Service

Guide

へ

‘Condenser

ュー

ヘー

T

Vacuum

©

pump

©

Silencerl

(VP)

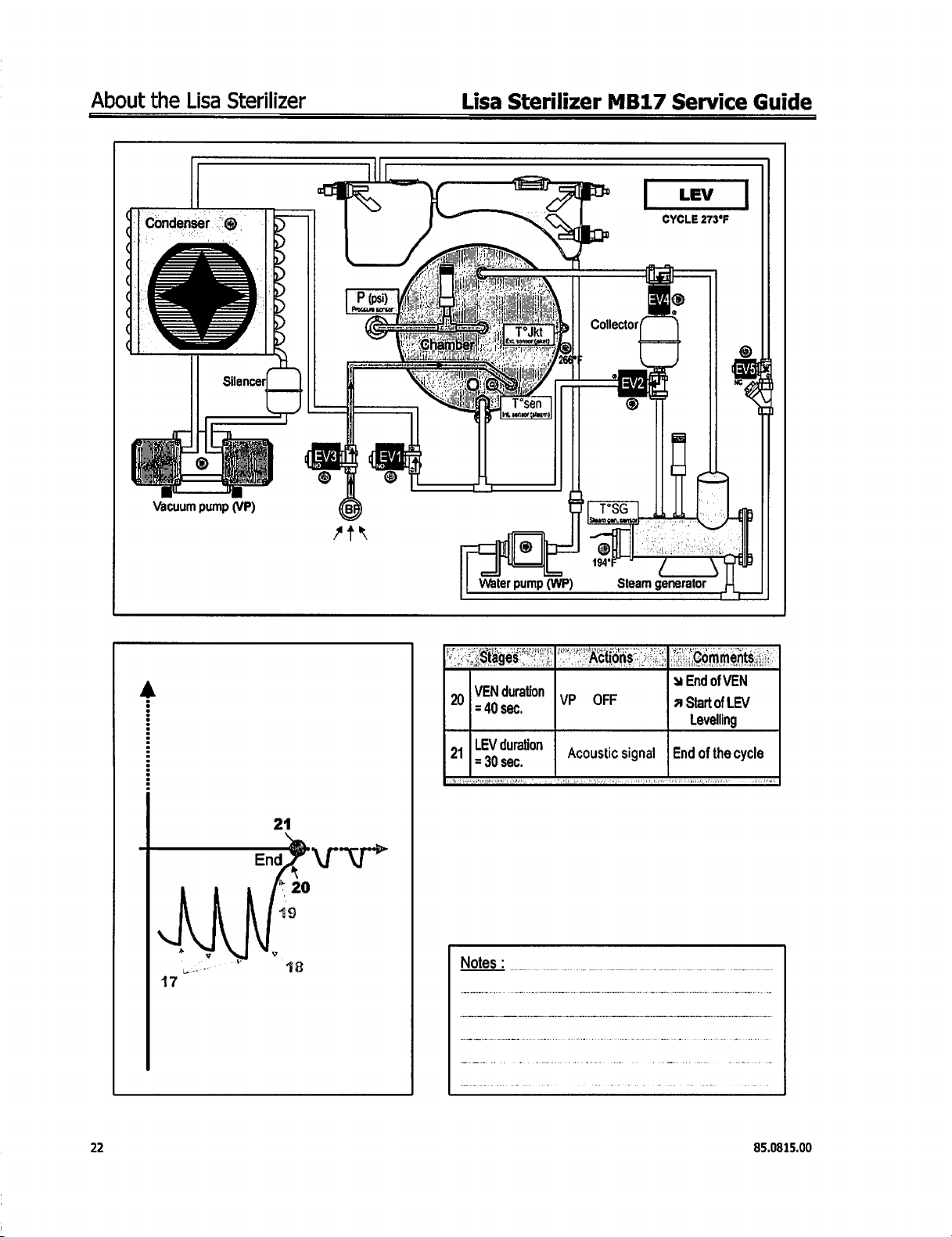

LEV

CYCLE

9

273°F

4

+ +

17

나

18

|

OFF

VP

Acoustic

,

signal | End

duration

A

20

LEV

30

Notes

duration

sec.

:

21 | -

SEndofVEN

Start

a

Levelling

of

LEV

of

the

cycle

22

85.0815.00

Page 23

Lisa

Sterilizer

MB17

Service

Guide

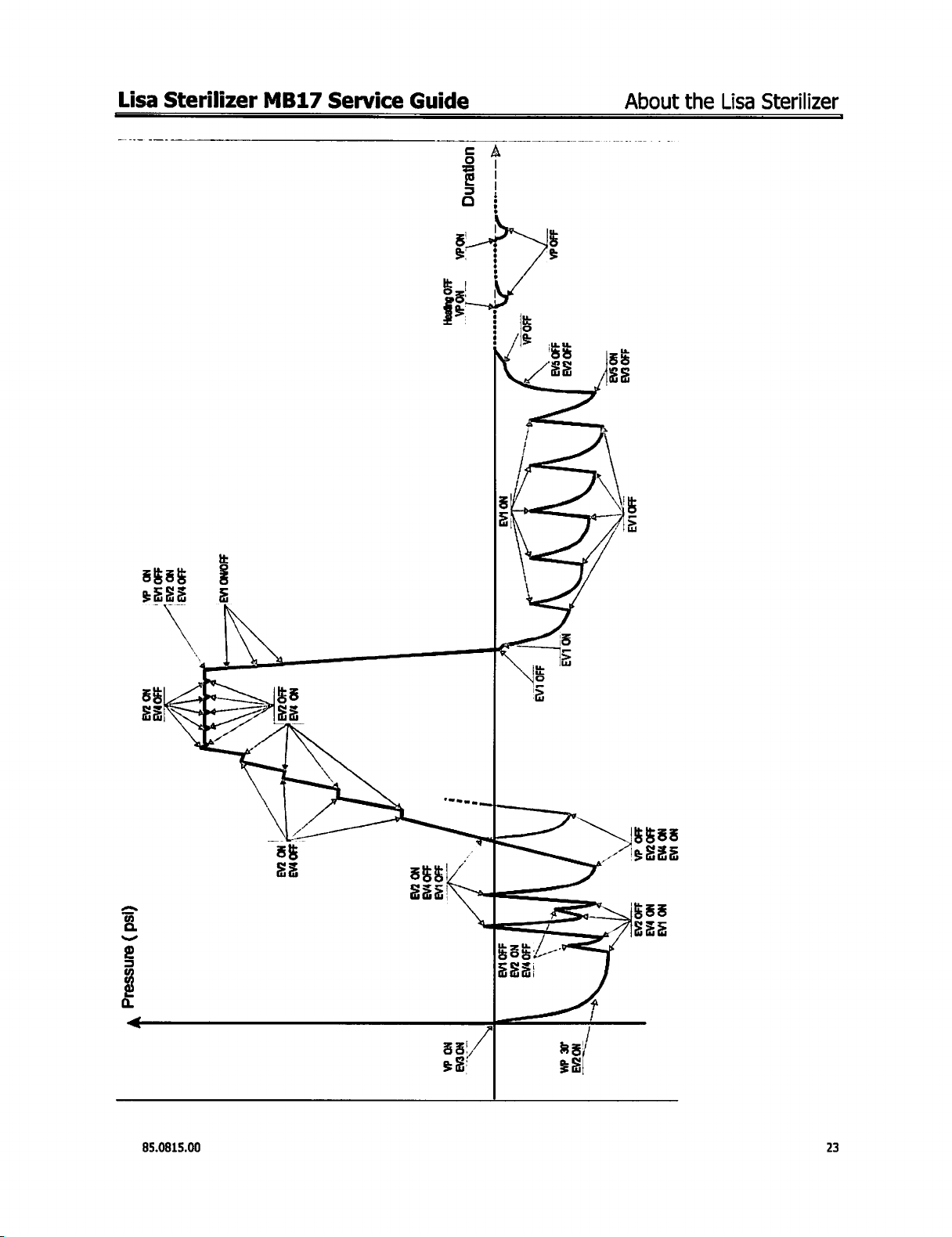

Duration

About

the

Lisa

Sterilizer

5858

haa

\

\

te

3

&

IN

5

ei

Ng

$

人

=

5

Es

EE

8

2

2

ー

<

85.0815.00

LA

‧

N

Es

~

55

Gü

sk

dda

.

5

=

Bee.

585

5888

SEBE

tas

1638

|

Va

eg

BE

bal

23

Page 24

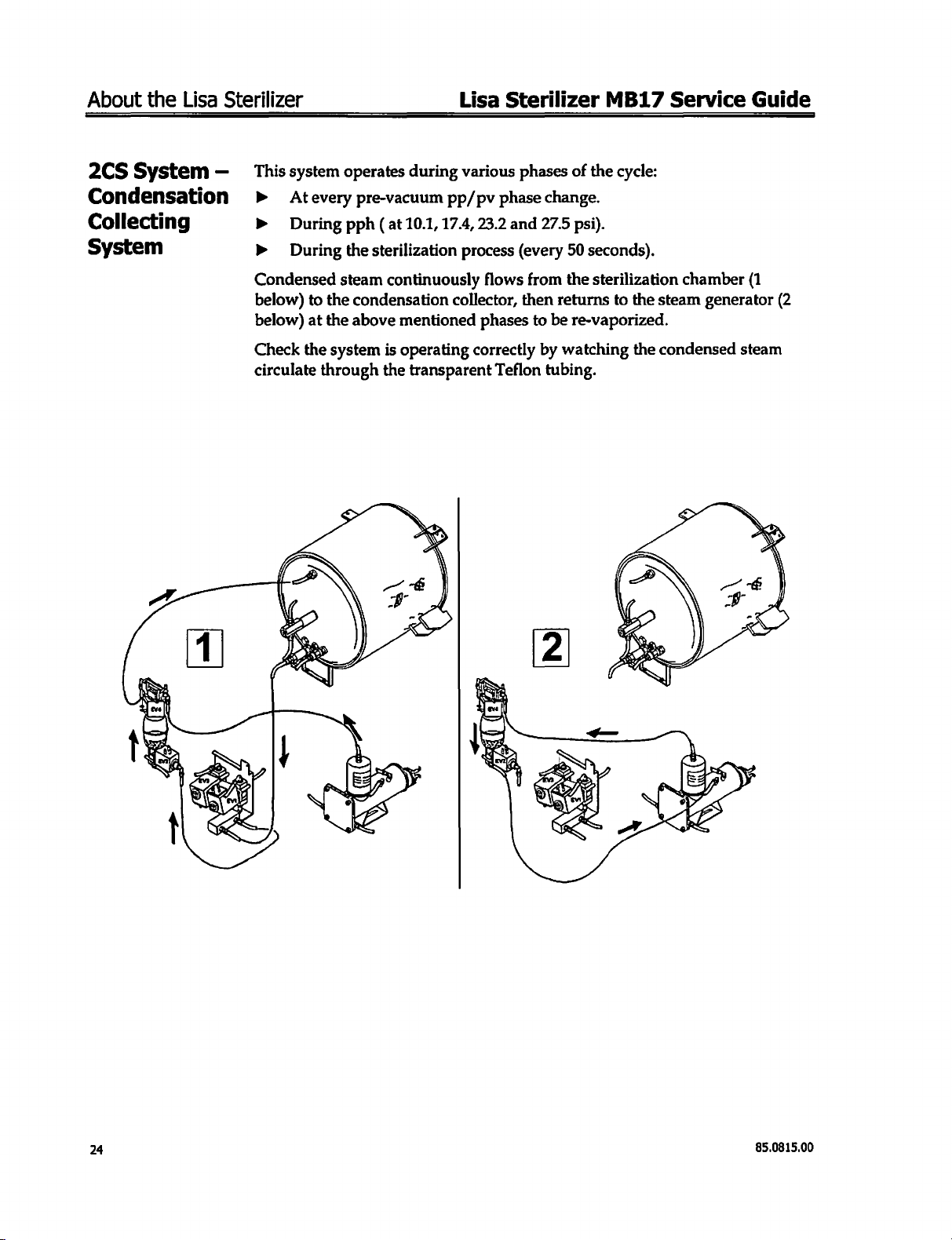

About

2CS

System

the

Lisa

Sterilizer

—

This

system

operates

during

Lisa

Sterilizer

various

phases

of

MB17

the

Service

cycle:

Guide

Condensation

Collecting

System

>

Atevery

>

During

b

During

Condensed

below)

below)

Check

circulate

to

the

at

the

the

through

pre-vacuum

pph

(at

10.1, 17.4,

the

sterilization

steam

continuously

condensation

above

system

mentioned

is

operating

the

pp/pv

phase

23.2

process

flows

collector,

phases

correctly

transparent

Teflon

change.

and

27.5

(every

from

then

to

by

tubing.

psi).

50

seconds).

the

sterilization

returns

be

watching

to

the

re-vaporized.

the

chamber

steam

generator

condensed

(1

(2

steam

24

85.0815.00

Page 25

Lisa

Sterilizer

Technical

Specifications

MB17

Power

Service

Requirements

Sterilizer:

-

Working

-

Storage

(empty)

-

Minimum

-

Nominal

-

Maximum

-

Maximum

-

Dimensions

-

Maximum

-

Clutter

of

-

Weight

-

Max.

mass

fully

loaded

-

Maximum

-

Maximum

Steam

generator:

-

Power/Voltage

-

Max.

pressure/

-

Safety

overpressure

Sterilization

-

Power/

-

Maximum

-

Safety

overpressure

-

Total

volume

-

Usable

space

-

Filter

Distilled

-

-

-

Connections

Miscellaneous

water

Water

quality

Min./Max.

(full

porous

Double

Guide

temperature/

temperature/

atmospheric

voltage

absorbed

current

overall

space

the

empty

in

heat

noise

chamber:

Voltage

pressure/

consumption

tank/

power

required

door

movement

working

output

level

Max.

valve

Max.

valve

(identical

(or

demineralized):

load)

Autonomy

Humidity

Humidity

pressure

condition

temperature

temperature

for

all

cycles)

phase

(0.5

About

230

VAC

bar)

16.1 / D:

410 / D:

Single

-

50/60Hz - 10A

50°-

104°F / 0-90%

10°-

40°C / 0-90%

-4°-

140°F / 0-90%

-20°-

60°C / 0-90%

7.25

psi

230

V

2100

W

9.2

A

W:

17.5 / H:

W:

445 / H:

W:19.1 / H:18.1 / D:

W:

485 / H:

W:

14.2 / H:

W:

360 / H:

106

Ib.

140N/foot

3000

<53

1700

58

psi/302°F

72.5

1000

34.8

36.3

17

liters

Dia.:

12.7

12

liters

0.3

um

Conform

7

to120z

Min 8 cycles

Parallel

Fully

touchscreen

Mains

Programmable

460 / D:

15.8 / D:

400 / D:

(49

kg)

(129.4

N/m?)

KJ/hr

dB

W/230

VAC

(4.0

bar/150°C)

psi (5.0

bar)

W/230

VAC

psi/280°F

psi

9.8

quarts

(2.5

bar)

(18

qt.)

in

(250

W:7.67/H:

W:

195/H:

to

the

(0.2

to

(full

printer

(24

mm)/Depth:

13060-1

0.35

porous

port

micro-processor

filter/2KV

over

stand-by

the

Lisa

+/-

10%

20.5

(in)

520

(mm)

224

(in)

570

(mm)

14.2

(in)

360

(mm)

bar/138°C)

13.8

in

8.07/

D:

11.81

205/

D:

300

(mm)

annex

E

liter)

load)

driven

and

controlled

tension

filter

mode

Sterilizer

(350

mm)

(in)

85.0815.00

25

Page 26

About

the

Lisa

Sterilizer

Technical

Specifications

(continued)

STERILIZER

93/42/EEC

PrEN

13060-1

work

PrEN

13060-2

EN

61010-1

EN

61010-2-041

sterilizer.

EN

50081-2

EN

50082-2

Chamber

Steam

generator

CLASS B conforms

Medical

(11/97)

tests.

(11/97)

(09/94)

(08/97)

(06/97)

(06/97)

Development

Development

Lisa

with

the

devices

Small

Small

Laboratory

Laboratory

Electromagnetic

Electromagnetic

and

and

Sterilizer

following

steam

sterilizer - General

steam

sterilizer - Particular

equipment - Safety

equipment - Specific

testing

conform

testing

conform

MB17

directives

compatibility - Emission.

compatibility - Immunity.

to

pressure

to

steam

and

Service

norms

:

requirements.

requirements

requirements.

instructions

vessel

regulations.

generator

regulations.

Guide

Type

and

for B type.

for

steam

26

85.0815.00

Page 27

Lisa

Sterilizer

MB17

Service

Guide

Maintenance

Section 2 —

User

Maintenance

Maintenance

Program

Maintenance

Note:

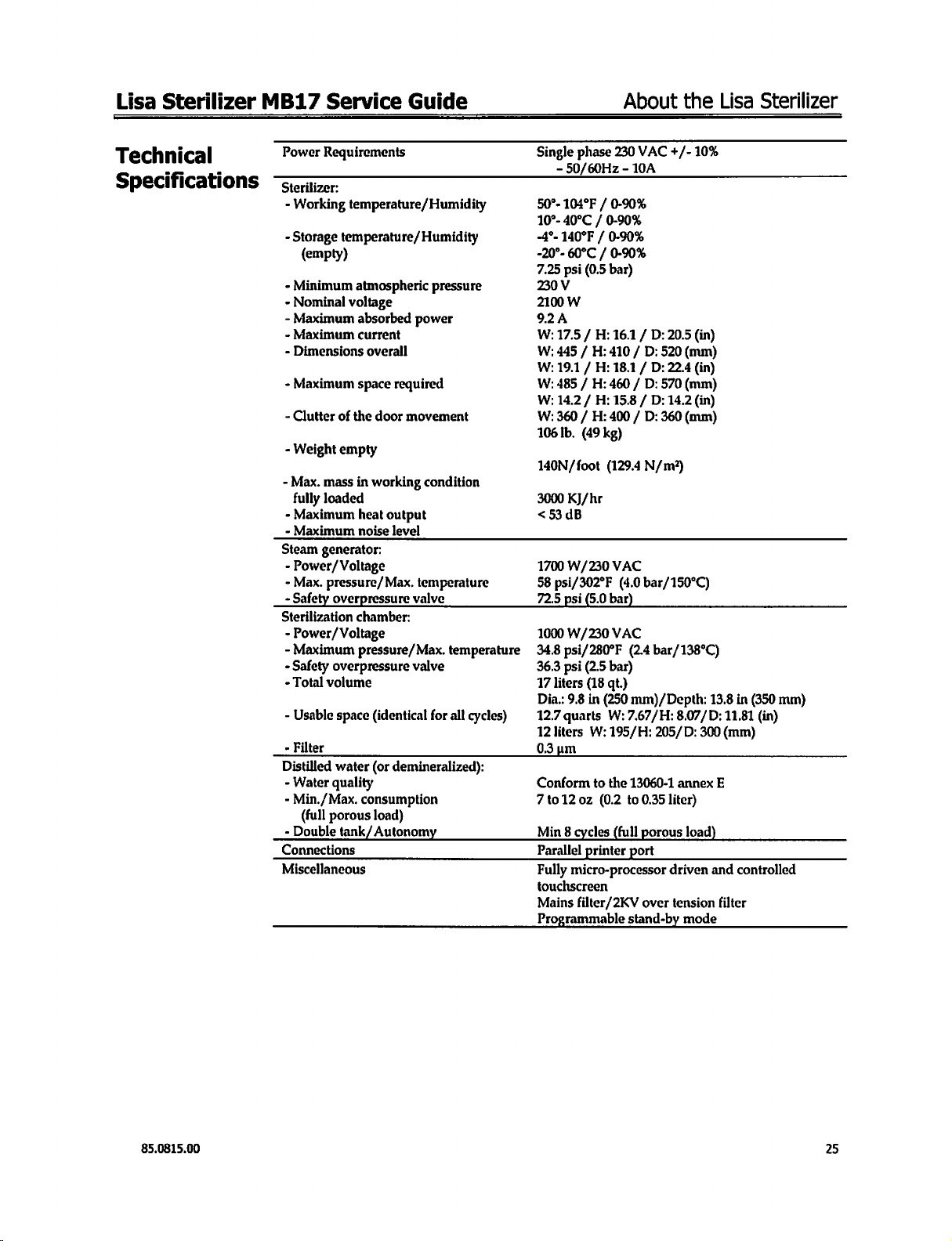

Frequency

Weekly

Every 3 months

Weekly

Every

*

*

Remove

year

Every 3 years

ΤΥ

ΟΥ

Refer

to

medical

the

mains

#

Cycles

50

400

50

1000

4000

device

cable

of

Operation

Clean

Clean

Clean

Replace

Clean

Replace

Service

technician.

regulations

before

the

the

the

the

the

the

by

y

for

examining

door

seal.

chamber,

external

surfaces.

filter.

main

water

door

seal.

an

approved

pp

your

country.

the

sterilizer.

trays

and

tank.

Spare

Number

-

rack.

-

54.0067.00

-

54.0014.00

-

The

maintenance

general

servicing,

required.

The

counters decrease

a

corresponding

the

message

Cycle

Reset

the

counter

and

DOWN

Exit

submenu

and

screen

counter

reaches

icons

of

the

appears.

submenu

replacement

in

value

message

press

appears

OK.

manually

zero.

Place

and

reset

indicates

The

for

the

it

by

the

of

the

filter

after

each

at

the

counter

service

cursor

pressing

remaining

and

cleaning

cycle.

When a counter

bottom

is

that

in

front

of

automatically

has

been

of

the

OK.

number

of

the

the

selection

reset.

completed

operation

of

cycles

door

reaches

screen.

The

before

with

before

seal

are

zero,

Read

Select

a

the

the

UP

85.0815.00

27

Page 28

Maintenance

Cleaning

Door

Cleaning

Chamber,

and

Seal

Tray

the

the

Trays

Holder

Clean

with

alcohol.

The

porthole

1.

Remove

2.

Disconnect

3.

Clean

scouring

Rinse

4.

Clean

Note:

Ensure

>

Do

»

chamber.

»

Never

the

door

can

the

the

chamber

agent

with a damp

the

rack

that

not

bend

use

seal

and

the

also

be

cleaned

trays

from

and

remove

with a damp

if

necessary.

sponge

and

trays

using

you

clean

or

damage

disinfectants

Lisa

Sterilizer

porthole

the

the

all

around

the

to

with a lint

with a non-abrasive

chamber.

rack.

sponge

to

remove

the

same

temperature

clean

all

procedure.

the

sterilizer

the

chamber.

MB17

free

cloth

detergent.

moistened

traces

of

the

chamber.

sensor

at

Service

saturated

with a detergent

cleaning

the

bottom

Guide

or

agent.

of

the

Cleaning

External

Components

Replacing

Filter

the

Clean

the

external

Note:

>

Never

>

Do

damage

>

Take

1.

Open

Unscrew

(counter-clockwise).

Insert

into

use

not

care

the

and

position.

parts

scouring

use

excessive

the

electrical

not

service

the

filter

manually

to

with a damp

agents

amounts

components

scratch

door.

by

the

hand

screw

or

highly

of

plastic

the

new

cloth

abrasive

water

and

film

filter

and

mild

to

wash

safety

in

front

detergent.

products.

the

sterilizer;

mechanisms.

of

the

touchscreen.

this

may

28

85.0815.00

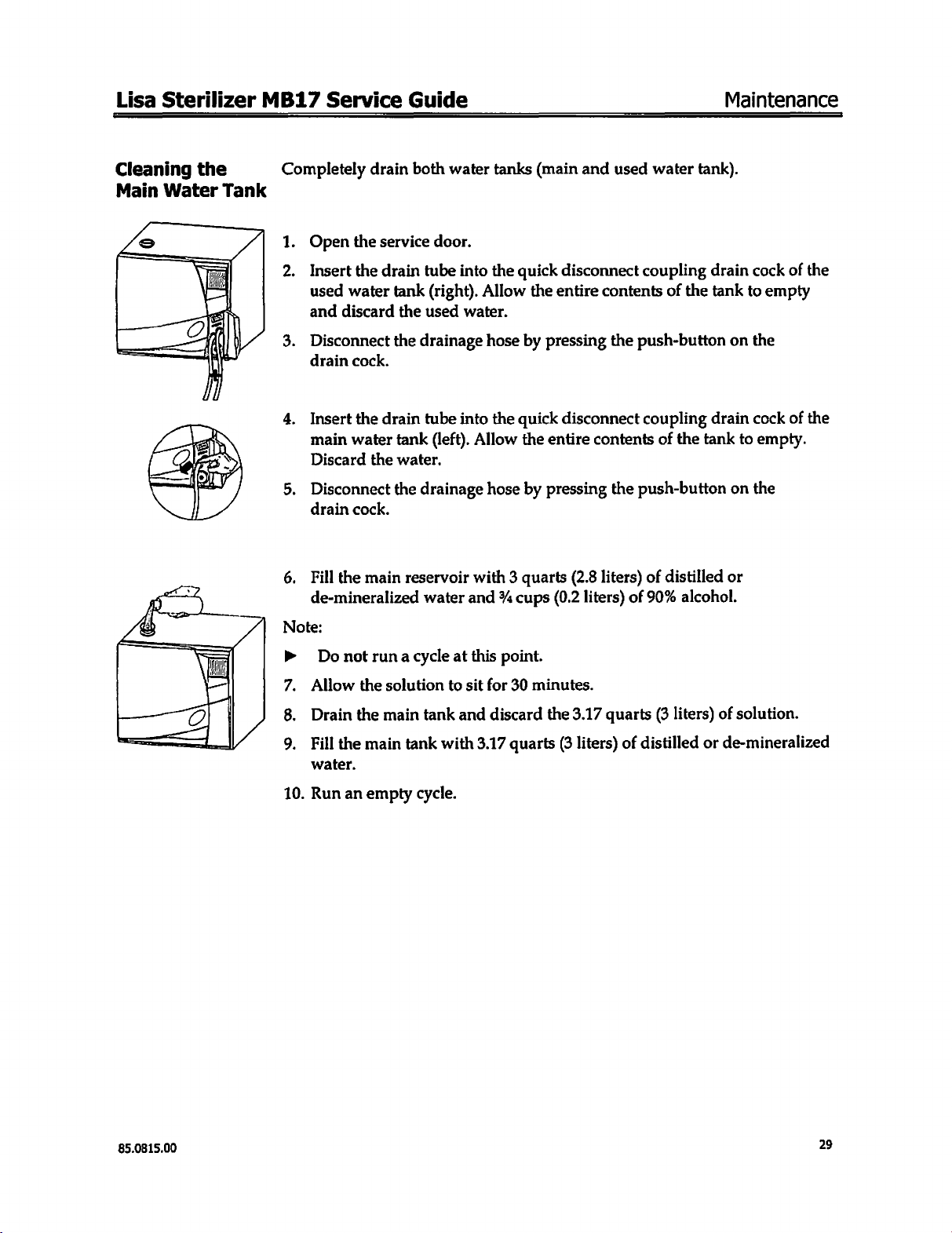

Page 29

Lisa

Sterilizer

MB17

Service

Guide

Maintenance

Cleaning

Main

Water

the

Tank

Completely

1.

Open

2.

Insert

used

and

3.

Disconnect

drain

4.

Insert

main

Discard

5.

Disconnect

drain

6.

Fill

de-mineralized

drain

the

the

water

discard

cock.

the

water

the

cock.

the

main

both

service

drain

drain

door.

tube

tank

(right).

the

used

the

drainage

tube

tank

(left).

water.

the

drainage

reservoir

water

water

tanks

into

the

quick

Allow

water.

hose

by

into

the

quick

Allow

with 3 quarts

and % cups

hose

the

by

(main

and

disconnect

the

entire

pressing

disconnect

entire

pressing

(2.8

(0.2

used

contents

the

push-button

contents

the

push-button

liters)

liters)

of

water

tank).

coupling

of

the

coupling

of

the

tank

of

distilled

90%

alcohol.

drain

tank

to

on

drain

to

on

or

cock

of

empty

the

cock

of

empty.

the

the

the

Note:

>

Do

not

7.

Allow

8.

Drain

9.

10.

Fill

water.

Run

the

the

the

an

main

runa

solution

main

tank

empty

cycle

at

to

tank

with

cycle.

this

sit

and

3.17

point.

for

30

minutes.

discard

quarts

the

(3

3.17

quarts

liters)

of

(3

liters)

distilled

or

of

solution.

de-mineralized

85.0815.00

29

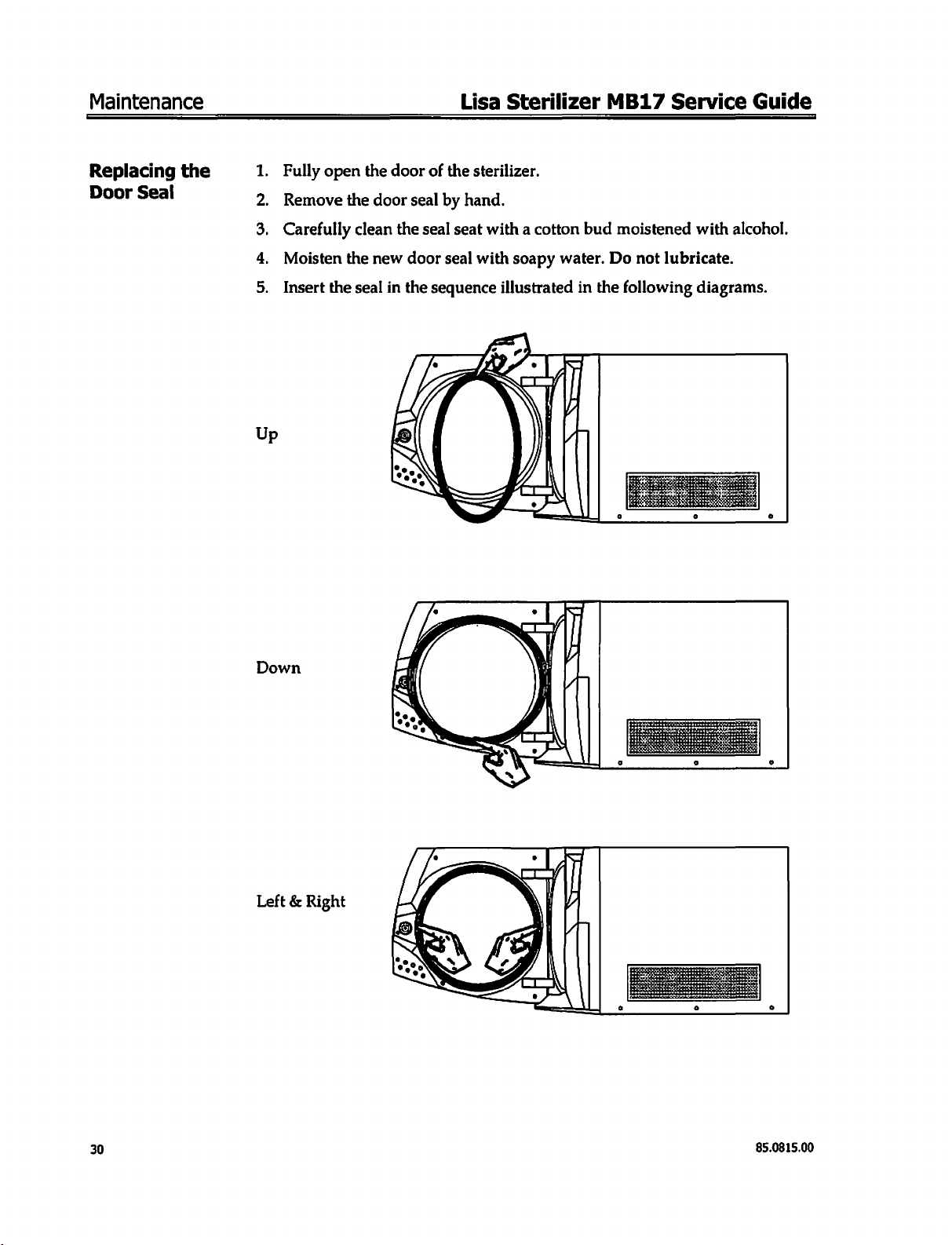

Page 30

Maintenance

Replacing

Door

the

Seal

.

Fully

1

.

Remove

2

3.

Carefully

4.

Moisten

.

Insert

5

open

the

the

the

the

door

door

clean

new

seal

in

seal

the

door

the

seal

Lisa

of

the

sterilizer.

by

hand.

seat

with a cotton

seal

with

sequence

Sterilizer

bud

soapy

water.

illustrated

in

MB17

moistened

Do

not

the

following

Service

with

alcohol.

lubricate.

diagrams.

Guide

Down

Left & Right

30

85.0815.00

Page 31

Lisa

【 一 一 一 一

Sterilizer

一 一 一 一 一 一

MB17

Service

Guide

Maintenance

Service

Checklist

Proper

A-dec

4000

v

maintenance

recommends

cycles.

(Use

assures

service

service

Replace 5 Electro-valves.

e

EV2/EV4/2CS

e

EV1/EV3

e

V5

Replace

e

Vacuum

Replace

<

Replace

e

Steam

e

Viton

Clean

Clean

SOS

Clean

Clean

Electro

vacuum

water

the

generator

steam

the

sterilization

the

sterilization

the

steam

the

condenser.

Collector

subset

valve

pump

pump

membrane

filter.

steam

generator

heating

O-ring

generator

the

Lisa

by

an

approved

kit

54.0152.00.)

subset

membrane

kit

heating

element

chamber.

chamber

filter

continues

technician

kit.

element.

filter.

(EV5).

to

operate

effectively.

every 3 years

or

Check

Check

Check

Check

<

<

Check

<

Check

the

pneumatic

the

electrical

the

door

the

two

the

safety

the

sterilizer

connections.

connections.

locking

pressure

system.

safety

devices.

according

valves.

to

Section 8 of

this

manual.

85.0815.00

31

Page 32

Maintenance

Lisa

Sterilizer

MB17

Service

Guide

32

85.0815.00

Page 33

Lisa

Sterilizer

MB17

Service

Guide

Exploded

Views & Circuit

Diagrams

Section 3 —

Exploded

Views

Accessories

Exploded

Ref.

PartNumber

1

54.0019.00

2

54.0018.00

3

54.0029.00

4

54.0046.00

5

54.0024.00

6

54.0017.00

7

54.0188.00

Views & Circuit

Diagrams

Description

Anodized

Reversible

Drain

Mains

Funnel

Tray

Owner’s

perforated

rack

tubing

cable,

holder

Guide

67

In.

(170

aluminum

cm)

tray

85.0815.00

33

Page 34

Exploded

Views & Circuit

Diagrams

Lisa

Sterilizer

MB17

Service

Guide

External

(1 of

2)

Parts

Ref.

1

2

3

4

5

6

7

8

9

Part

Number

54.0127.00

54.0123.00

54.0138.00

54.0118.00

54.0251.00

54.0037.00

Description

Water

tank

cap

Water

tank / cover

Used

water

tank

Used

water

tank

Housing / cover

Composite

Screws : Pan

Rear

Chassis

washer

housing

foot

Head

plate

grommet

seal

cap

silencer

Phillips

M5 x 6

mm

34

85.0815.00

Page 35

Lisa

Sterilizer

MB17

Service

Guide

Exploded

Views & Circuit

Diagrams

External

(2 of

2)

Parts

Ref.

2

3

4

6

10

11

Part

1

54.0023.00

54.0014.00

54.0022.00

54.0021.00

5

54.0132.00

7

54.0253.00

8

54.0025.00

9

54.0121.00

54.0026.00

Number

Description

Composite

Door

Composite

Composite

Technical

Service

Touchscreen

Touchscreen

EMC

Screw

Composite

door

seal

fascia

technical

door

door

finger

fascia-Cover

pin

complete

external

(carter)

cover

door

sticker

protection

seal

85.0815.00

35

Page 36

Exploded

Views & Circuit

Diagrams

Lisa

Sterilizer

MB17

Service

Guide

Door

Complete

Ref.

20

21

22

23

24

25

26

27

28

29

30

31

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Part

Number

54.0130.00

54.0033.00

54.0036.00

54.0034.00

54.0039.00

54.0005.00

54.0140.00

54.0006.00

54.0009.00

54.0010.00

Description

Door

complete

Lock

clip

Door

locking

Screw,

Washer

Door

arms

Door

locking

Teflon

Spacer

Lock

clip

Door

locking

Screw : Hex

Porthole

Nut

MS

Screw,

Wing

washer

Screw

Spacer

Screw,

Door

hinge

Washer,

Door

locking

Teflon

Lock

clip

Cast

aluminum

Fixed

Screw,

Friction

Rotating

Spacer

Porthole

arm

button

5.3

ID x 20

actuator

pin

guide

washer,

pin

socket

spring

button

M4 x 5mm

washer

hex

socket

mount

5.3

mm

arm

guide

D16

D16

eccentric

button

disc

1mm

door

disc

0.5mm

subset

head

hex

mm

20

mm

seal

cap

head

hex

DS

cap

(door

ID x 15

spring

door

porthole

head

hex

locking

socket

OD

IO x 28

m3 x 10

socket

M8 x 50

side)

mm

disc

socket

disc

MS x 10

mm

mm

m5 x 20

mm

OD

M4 x 6

mm

OD x 0.5

mm

mm

mm

thk

36

85.0815.00

Page 37

Lisa

Sterilizer

MB17

Service

Guide

LR

SUA

Sİ

eA

Exploded

Views & C

ircuit

Diagrams

85.0815.00

37

Page 38

Exploded

Views & Circuit

Diagrams

Lisa

Sterilizer

MB17

Service

Guide

Water

Facade

Tank

/

Ref.

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

PartNumber

1

2

54.0020.00

54.0047.00

54.0145.00

54.0008.00

54.0139.00

54.0064.00

54.0063.00

54.0067.00

Description

Water

tank

complete

Water

tank

only

Water

level

sensor

Water

level

sensor

Pipe

seal

cap

Door

hinge

(chamber

Door

hinge

0.5mm

M10

flat

washer

M10

split

lock

Screw,

Screw,

M6

6

Base

Maln

EMC

Drain

Drain

Filter

Screw

Nut

hex

hex

split

lock

mm

ID

frame

switch

filter 9 pin

fitting,

fitting,

M3.5 x 9.55

MS

socket

socket

washer

flat

washer

(circuit

female

female

seal

spacer

washer

cap

cap

breaker)

(NM

(NM

mm

side)

screw

screw

blue)

grey)

M10 x 20

M6 x 16mm

mm

38

85.0815.00

Page 39

Lisa

Sterilizer

MB17

Service

Guide

Exploded

Views & Circuit

Diagrams

Right

Side

Ref.

10

11

PartNumber

1

54.0150.00

2

54.0031.00

3

4

54.0050.00

5

6

54.0036.00

7

8

54.0053.00

9

54.0051.00

54.0052.00

54.0249.00

Description

Vacuum

CPU

CPU

Vacuum

Internal

Screw,

Screw,

Vacuum

Vacuum

(4x

Vacuum

Clip,

pump

silencer

board

board

metal

pump

lock

washer, 5 mm

button

head

button

head

pump

head

pump

membrane

valve + O-ring + 2x

pump

diaphragm

vacuum

pump

carrier

hex

socket

hex

socket

(1

pce)

diaphragm)

valve

kit

(1

MS x 10

M4

pce)

x 6

mm

mm

85.0815.00

39

Page 40

Exploded

Left

Side

Views & Circuit

Ref.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Diagrams

PartNumber

54.0092.00

54.0070.00

54.0007.00

54.0011.00

54.0054.00

54.0137.00

54.0038.00

54.0149.00

54.0049.00

54.0054.00

54.0012.00

54.0066.01

Lisa

Sterilizer

Description

Steam

generator

Steam

generator

Viton

O-ring

Heating

Fixing

Thermal

element

clip

overload

PT100 D 6x120

Water

pump

Water

pump

Fitting

Spacer 8 mm x 3.2

One-way

Water

PT100

Chamber

Water

Nut

valve

pump

6x40

thermal-overload

filter

Washer

Grower

washer

Nut

Grower

washer

Washer

complete

only

subset

rubber

complete

Class B outside

MB17

support

mm x 1.5

chamber

mm

Service

Guide

40

85.0815.00

Page 41

Lisa

—

Rear

(1

of

Sterilizer

MB17

Side

2)

Ref.

1

mn

[uu

Dun

BIN

Service

Guide

PartNumber

54.0045.00

54.0128.00

54.0015.00

Exploded

Description

Condenser

Condenser

Condenser

Mains

Screw

Washer

Screw

Nylon

subset

fan

filter

box

nipple

230Vac

complete

Views & Circuit

with

transformer

Diagrams

NN

SE _ à

η

RNN

M

κ.

Μι

na]

SAN

a

TS

这

NNN R È

QE

mE M nl

ii x i

a

i

내비

i

NN

SH

o

|]

{

Ч

|

AS

S

NE

s

n

IN

則

85.0815.00

41

Page 42

Exploded

Rear

(2

of

Views & Circuit

Side

2)

Ref.

1

2

3b

4

5

6

7

Diagrams

PartNumber

54.0027.00

54.0028.00

54.0090.00

54.0066.01

54.0055.00

54.0141.00

54.0015.00

0

FI

a

LAI

IS

75

M

ET

È

x

©

at)

ATE

Lisa

Sterilizer

Description

EV2 / EV4 / 2CS

EV1 / EV3

EVS / Filter

Water

filter

PT100

5x100

Chamber

Bi-cone

Teflon

subset

subset

subset

Class A internal

outlet

filter

seal

MB17

Service

Guide

42

85.0815.00

Page 43

Lisa

Sterilizer

Top

Side

MB17

Ref.

1

2

3

4

5

6

7

8

9

10

Service

PartNumber

54,0129.00

54.0062.00

54.0061.00

54.0011.00

Guide

Description

EMC

Printer

Pressure

Safety

Screw

Washer

Pressure

Pressure

Safety

Steam

Exploded

filter

9-pin

flat

cable

safety

valve

manifold

safety

safety

valves

housing

generator

Views & Circuit

EMC

ferrite

valves

subset

valve 5 bar

valve

2.4

bar

thermal-overload

Diagrams

85.0815.00

43

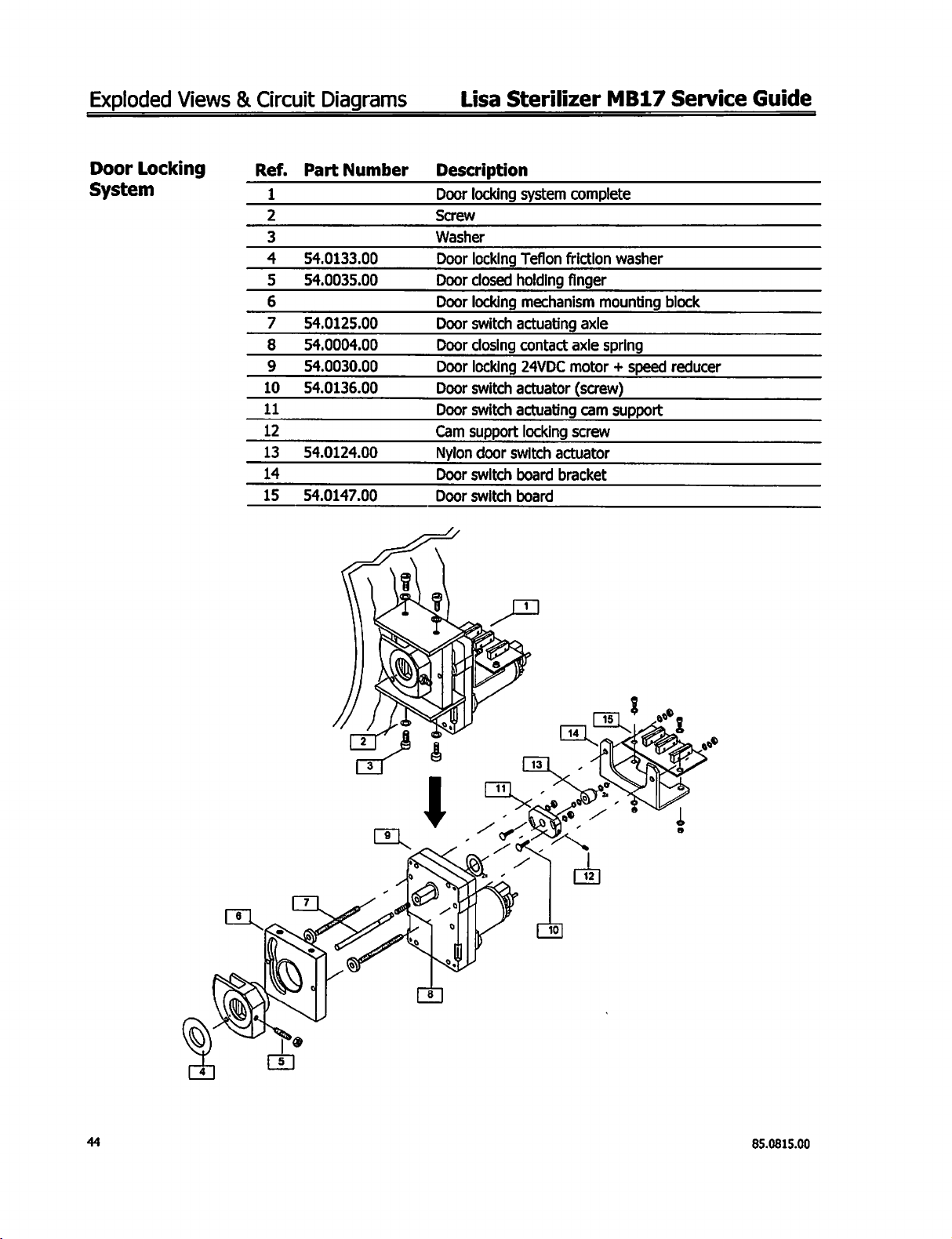

Page 44

Exploded

Views & Circuit

Diagrams

Lisa

Sterilizer

MB17

Service

Guide

Door

System

Locking

Ref.

10

11

12

13

14

15

PartNumber

1

2

3

4

54.0133.00

5

54.0035.00

6

7

54.0125.00

8

54.0004.00

9

54.0030.00

54.0136.00

54.0124.00

54.0147.00

Description

Door

locking

Screw

Washer

Door

Door

closed

Door

locking

Door

switch

Door

closing

Door

Door

switch

Door

switch

Cam

support

Nylon

Door

switch

Door

switch

locking

locking

door

system

Teflon

holding

mechanism

actuating

contact

24VDC

actuator

actuating

locking

switch

board

board

complete

friction

finger

actuator

bracket

washer

mounting

axle

axle

spring

motor + speed

(screw)

cam

support

screw

block

reducer

85.0815.00

Page 45

Lisa

Sterilizer

MB17

Service

Guide

Exploded

Views & Circuit

Diagrams

EV2/EV4/2CS

Collector

(54.0027.00)

Subset

Ref,

1°

alalalejm

Part

Number

54.0126.00

Description

2CS

collector

3

way

3

way

Fitting

Fitting

Fitting

15cc

valve

1/4x2.3

valve

coil

1/4 - 1/8

90°

M1/4

90°

F1/8 T 6/4

T6/4

24VCC

(EV2-EV4)

85.0815.00

45

Page 46

Exploded

Views & Circuit

Diagrams

Lisa

Sterilizer

MB17

Service

Guide

EV1/EV3

(54.0028.00)

Subset

Ref,

bd

ом

A

uloví

[oo

O

Part

Number

54.0250.00

54.0153.00

Description

EV1-EV3

2

way

Solenoid,

Fitting

Fitting

Fitting

(EV1)

Nyton

Fitting

metal

valve

12 volt

90°

M1/4

90°

M1/4

M1/4

3-way

clip

M1/4

NO

T6/4

manifold

T6/4

bracket

1/4x4.5

D7

T6/4

24VCC

(EV1-EV3)

46

85.0815.00

Page 47

Lisa

Sterilizer

EV5/

Filter

Subset

(54.0090.00)

MB17

Ref.

1

jm

jo

jua

Service

Part

Number

54.0141.00

Guide

Exploded

Description

Brass

filter

complete

2

way

valve

NC

Filter

only

(EVS / chamber)

Fitting

M1/8

T6/4

Fitting

M1/8

M1/4

Fitting

M1/8

D7

Views & Circuit

(EV5

/

chamber)

1/8x2

24VCC

(EV5)

Diagrams

85.0815.00

47

Page 48

Exploded

CPU

Board

Fuses

Views & Circuit

Ref.

1

2

3

4

5

Diagrams

PartNumber

54.0040.00

54.0042.00

54.0042.00

54.0041.00

54.0043.00

Lisa

Sterilizer

Description

F1

(230V) : fuse

F2

(9V) : fuse の 5x20

F3

(11V) : fuse の 5x20

F4

(-15V):

F5

(24V):

Door

fuse の 5x20

fuse の 5x20

motor

95x20

2AT

2AT

1AT

6.3AT

MB17

3.15AT

250V — Mains

250V - PT100 - MPX-Analog

250V - 5V-Digital

250V - Touchscreen-analod

250V - Electro-valves

Service

230V

-

Guide

(+)

(-)

[3]

[2]

48

85.0815.00

Page 49

Lisa

Diagrams

Electrical

Sterilizer

Circuit

MB17

Diagram

Service

Rat

Guide

Exploded

QD

©,

Y

に

JL

向

ak

ofre

Views & Circuit

|

때

Diagrams

rs:

学

96

OS

:

E)

;

;

PRESSURI

>EENSOR

e

i

e

MAS

a

ra

BELEK:

AA

a

wr]

Ga

=

°

te

8

28

DE

si

Si

z

こ

AR

85.0815.00

LEGEND

COLOUR

49

Page 50

Exploded

Views & Circuit

Diagrams

Lisa

Sterilizer

MB17

Service

Guide

Hydraulic

Circuit

Diagram

(1

of

2)

50

85.0815.00

Page 51

Lisa

Sterilizer

MB17

Service

Guide

Exploded

Views

& Circuit

Diagrams

Hydraulic

Circuit

Diagram

(2

of

2)

Rear

85.0815.00

51

Page 52

Exploded

Views & Circuit

Diagrams

Lisa

Sterilizer

MB17

Service

Guide

52

85.0815.00

Page 53

Lisa

Sterilizer

MB17

Service

Guide

Testing

Prior

to

Repair

Section 4 —

Vacuum

Test

Testing

Use

this

>

The

>

The

The

profile

>

A

vacuum

>

A

stabilization

> A

testing

Pressure

Prior

test

efficiency

tightness

of

to

to

validate

the

cycle

phase

period

(psi)

of

Repair

the

of

the

vacuum

the

pneumatic

specific

up

to

period

of

16’

performance

pump.

circuit.

to

this

test

P1 = -

12.3

psi.

of

5’

=>

T2.

=>

T'3.

Reading

of

the

sterilizer

includes:

Reading

of

P3.

Duration

T3

of

P2.

in

terms

of

leakage:

SERVICE

85.0815.00

BY.

Select

for

16

Important:

(0.013

0.19

psi/

BURCUYUM

and

start

the

minutes,

bar/

then

According

min)

or

min

(0.013

TEST

DIAGNOSTICO

Vacuum

display a “pass”

greater

bar/

Test

in

the

or

PrEN13060

is

min)

norm, a vacuum

unacceptable. A measurable

will

give a “fail”

un

SERVICE

“fail”

message.

submenu.

leak

message.

of

leak

The

0.19

of

test

psi/

min

I

will

run

53

Page 54

Testing

Bowie

Test

b

È

Pressure

ni

(psi)

oğlu

Prior

&

Dick

to

Repair

The

Bowie & Dick

porous

small

indicator

equipment

type

packet

strip

on

Test

(also

load.

It

comprises

in

the

middle

(physic-chemical

performance

om

四

in

>

b

The

cycles

> a temperature

>

»

> a drying

Lisa

Sterilizer

called

Brown

several

of

which

test).

terms

of

Pre-vacuum

penetration.

Temperature

saturated

cycle

profile

with:

apressureof

asterilization

guaranteeing a security

false

results.

Test)

sheets

there

is a chemical

This

test

textile

load

efficiency

and

steam

is

identical

of

31.3

plateau

time

of 4 min

is

of

paper

is

used

sterilization,

pressure

during

275.9°F

psi.

MB17

representative

and

of 3 min

to

Service

and

foam

heat-sensitive

to

validate

i.e.:

thus

steam

parameters

the

holding

to

that

of

other

(135.5°C).

20

sec

margin.

prevent

Guide

of

the

small

wrapped

the

of

the

time.

ina

To

run

Place

the

chamber,

Select

Note:

Once

the

Caution:

Remove

m

the

test:

Bowie & Dick

with

and

start

the

You

can

number,

cycle

is

the

the

indicator

DBED/HELIX

Test

the

label

B&D

cycle

enter

your

on

each

completed,

packet

VACUUM

will

strip

from

(complete

facing

upwards.

from

the

name,

test

open

be

for

filing

the

very

the

center

the

door

hot.

TEST

TEST

0000

packet)

SERVICE

on

date,

cycle

purposes.

and

of

the

>

the

lower

submenu.

number

remove

packet.

CVCLE

回

|

the

tray

of

and

sterilizer

test.

BED

the

JEST

85.0815.00

Page 55

Lisa

Sterilizer

MB17

Service

Guide

Testing

Prior

to

Repair

The

The

result

excessive

Correct

radial

turned

is

also

temperature).

result:

strips

black.

incorrect,

have

if

the

indicator

is

The

same

gray

Incorrect

central

or

part

color

as

silver

(over-exposure,

result:

is

not

the

edges.

the

i.e.

85.0815.00

55

Page 56

Testing

Prior

to

Repair

Lisa

Sterilizer

MB17

Service

Guide

Accessing

Diagnostic

Screens

the

The

DIAGNOSTIC

sterilizer

troubleshooting.

To

1.

without running a complete

access

Inthe

your

the

DIAGNOSTIC

SERVICE

selection.

B&D / HELIX

VACUUM

DIAGNOSTIC

=

2.

Consecutively

menu

submenu,

press

allows

TEST

1,

you

to

cycle.

menu:

select

DIAGNOSTIC.

TEST

2, 3 and 4 icons.

check

This

The

every

is

useful

first

single

component

during

Press

test

screen

OK

to

confirm

displays.

of

the

56

DIAGNOSTIC

NTER

CODE

85.0815.00

Page 57

Lisa

Sterilizer

Screens

d

and

2

1

MB17

Use

1.

2.

3.

Service

screens 1 and 2 to

Select

the

powered

Select a second

press

OK.

On

screen

to

screen

Guide

item

to

for 8 seconds

item

If

you

2,

select

3,

select

select

be

tested

to

want

the

NEXT

and

and

and

released.

be

tested

to

exit

item

to

and

test

all

press

or

the

test

be

tested

press

Testing

components.

OK.

The

select

NEXT

screens,

OK.

and

press

press

Prior

component

to

go

to

screen 2 and

BACK.

OK.

If

you

to

will

want

Repair

be

to

go

Screen

3

Use

screen 3 to

Select

PRESSURE

press

Select

the

Press

BACK

select

unit

Screen

EVI

EV2

EV3

EVA

EVS

EVO

VACUUM

NEXT

set

OK.

desired

to

go

NEXT

PRESSURE

TEMPERAT.

PUMP

the

UNIT

to

previous

to

go

UNIT

UNIT

1

©

pressure

or

and

to

and

TEMPERATURE

press

screen,

screen 4 and

(8)

temperature

OK.

select a second

press

№

MBAR

ОКРА

gesi

units.

UNIT

OK.

Screen

WATER

PUMP

WATER

PUMP

GENERAT.

CHAMBER

DOOR

DOOR

CONDENSER

>

NEXT___

to

be

parameter

HEATER

HEATER

LOCKING

OPENING

set

and

A

2

1

2

FAN

LY

to

set,

or

85.0815.00

NEXT...

2

57

Page 58

Testing

Prior

to

Repair

Press

previous

Use

»

^

UP

P

OK

screen.

or

DOWN

BCELSIUS

O

FAHARENHEIT

to

confirm

Lisa

to

select

<b>

(9)

your

selection,

Sterilizer

the

temperature

|

or

press

MB17

unit.

BACK

Service

to

return

to

the

Guide

58

85.0815.00

Page 59

Lisa

Sterilizer

Accessing

Screen

4

MB17

The

the

shown

Service

hardware

hardware

below.

Guide

key

is

safety

key

required

to

the

to

modify

serial

functions

port

located

Testing

on

the

4th

behind

the

Prior

to

screen.

service

Repair

Connect

door,

as

Loop

Cycles

Function

Use

the

tanks

»

Select

tested.

Loop

must

be

LOOP

Use a manual

(2

Cycles

function

connected

CYCLES

©

&

LOOP

CYCLES

LOOP

LIMITED

CLEAR

COUNTER

ACTIVE

CYCLE

GAS / TEST

WATER

SUPPLY

HARDWARE

to

run

together

from

stop

to

screen 4 and

to

interrupt

©

22

KEY

unlimited

recycle

the

press

the

consecutive

water.

OK

test.

cycles.

to

run

the

Both

water

cycle

to

be

Loop

Select

Function

85.0815.00

Use

the

cycles.

1.

2.

Both

Select

Set

LOOP

water

LOOP

SELECT

tanks

SELECT

© ®

LOOP

CYCLE

LOOP

SELECT

CLEAR

COUNTER

ACTIVE

CYCLE

GAS / TEST

REV.

OSMOSIS

of

+

^

the

{>

number

function

must

be

from

くめ

cycles

to

to

run a limited

connected

screen 4 and

|

be

run.

number

together

press

to

OK.

of

consecutive

recycle

the

water.

59

Page 60

Testing

Prior

to

Repair

Lisa

=

Sterilizer

MB17

Service

Guide

Clear

Function

Counter

3.

Use

1.

QUANTITY

0002

&

SELECT

Use

the

side

arrow

icon

change

Press

Run

the

Select

the

OK

the

cycle

Clear

CLEAR

(>

number

and

return

to

be

Counter

COUNTER

LOOP

CYCLE

LOOP

SELECT

CLEAR

COUNTER

ACTIVE

CYCLE

GAS / TEST

REV.

OSMOSIS

by

to

tested.

function

くめ

using

to

move

the

the

previous

Use a manual

to

reset

from

screen 4 and

>

the

cursor

arrow

screen.

the

under

keys.

stop

cycle

press

the

to

interrupt

counter.

OK.

desired

the

test.

digit

and

2.

^

Press

and

return

BACK

to

to

the

CLEAR

quit

without

previous

COUNTER

くめ

resetting

screen.

(he

counter.

Press

OK

to

reset

(he

counter

85.0815.00

Page 61

Lisa

Sterilizer

MB17

Service

Guide

Testing

Prior

to

Repair

Active

Function

Cycle

Use

1.

2.

3.

the

ACTIVE

Select

CYCLE

ACTIVE

LOOP

LOOP

CLEAR

B>

ACTIVE

GAS / TEST

REV.

>

On

the

resulting

and

disabled

(P

MB-STAND.

O

B-EXTEND

(C

B-STAND. | 250

>

To

modify a status,

to

go

to

the

previous

function

CYCLE

CYCLE

SELECT

COUNTER

CYCLE

OSMOSIS

Di

screen,

cycles,

respectively.

select

screen.

to

from

screen 4 and

B

the

black

>

273

273

©

the

desired

enable

and

and

white

cycle

disable

press

OK.

squares

then

press

cycles.

show

the

OK.

Press

enabled

BACK

Gas/Test

Function

Rev.

Function

85.0815.00

Osmosis

Use

the

the

PR

to

the

»

Select

ον

Use

the

GAS/TEST

phase,

condensed

to

GAS

LOOP

LOOP

CLEAR

ACTIVE

D>

GAS / TEST

REV.

REV.

OSMOSIS

function

evaluate

steam

volume

TEST

from

CYCLE

SELECT

COUNTER

CYCLE

OSMOSIS

function

to

download

the

proportion

(<3.5%).

screen 4 and

LD,

©

to

the

of

non-condensable

press

configure

chamber

OK.

the

external

steam

water

content

gases

respective

supply.

during

61

Page 62

Testing

Prior

to

Repair

Lisa

Sterilizer

MB17

Service

Guide

62

85.0815.00

Page 63

Lisa

Sterilizer

MB17

Service

Guide

Troubleshooting

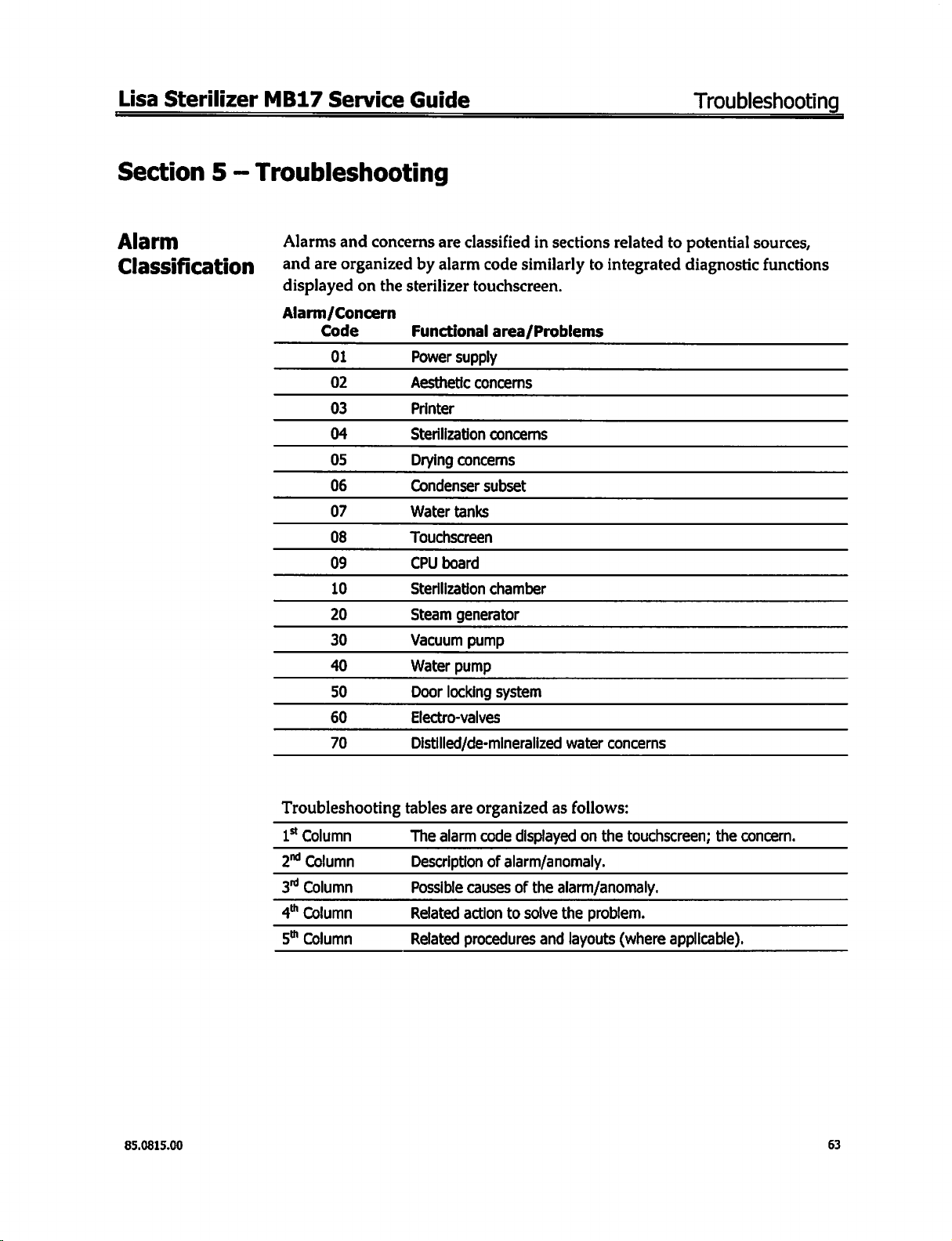

Section 5 —

Alarm

Classification

Troubleshooting

Alarms

and

displayed

Alarm/Concern

and

are

organized

on

Code

01

02

03

04

05

06

07

08

09

10

20

30

40

50

60

70

concerns

by

the

sterilizer

Functional

Power

Aesthetic

Printer

Sterilization

Drying

Condenser

Water

Touchscreen

CPU

Sterilization

Steam

Vacuum

Water

Door

Electro-valves

Distilled/de-mineralized

are

classified

alarm

code

touchscreen.

area/Problems

supply

concerns

concerns

concerns

subset

tanks

board

chamber

generator

pump

pump

locking

system

in

sections

similarly

to

water

related

integrated

to

potential

diagnostic

concerns

sources,

functions

85.0815.00

Troubleshooting

1%

Column

2™

Column

3

Column

4"

Column

5"

Column

tables

are

organized

The

alarm

Description

Possible

Related

Related

causes

action

procedures

as

code

displayed

of

alarm/anomaly.

of

the

alarm/anomaly.

to

solve

the

and

follows:

on the

touchscreen;

problem.

layouts

(where

the

concern.

applicable).

63

Page 64

Troubleshooting

©

DESCRIPTION

CODE

Power

AOL

230°

A10

|

А11

|

А12

A13

A14

CHAMBER

A15

T°

T°

A16

T°

A17

|

A18

A21

|

ATOR_

A22

STEAM

|

GE

A23

A31

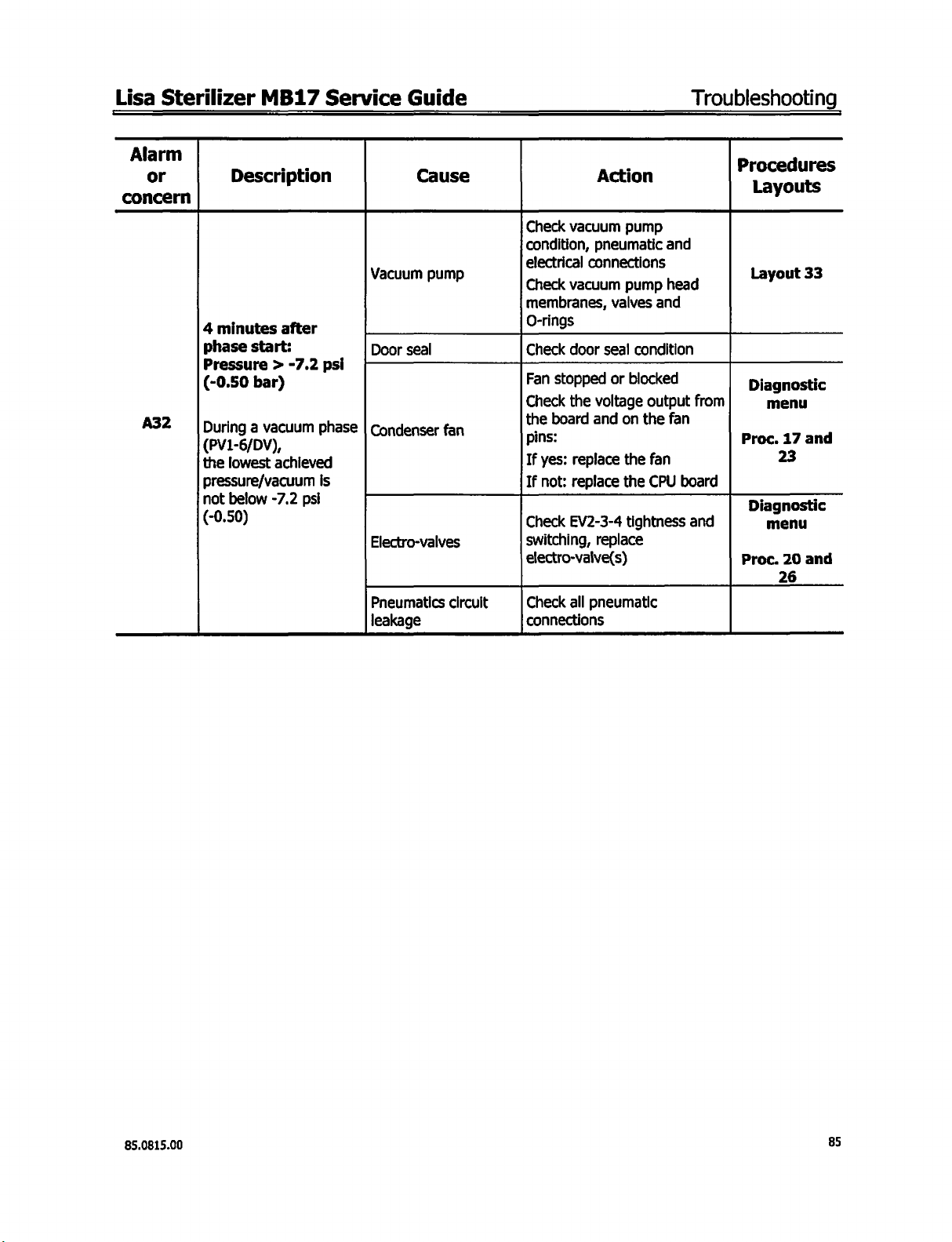

A32

VACUUM

A33

|

A34

A52

DOOR

|

A63

VALVES

failure

If

duration

T°

chamber

T°

chamber

T°

theoretical > 278.6°F

T°

theoretical > 137°C

T°

theoretical < 273.2°F

T°

theoretical > 134°C

T°

sen < 273.2°F/249.8°F

sen < 101°C/121°C

sen > 278.6°F/255.2°F

sen > 137°C/124°C

External

Internal

Steam

Steam

Steam

3

minutes

Pressure > -2.9

4

minutes

Pressure > -7.2

The

<-11.6

The

vacuum

Door

DOOR

2

minutes

Pressure < -10.1

of

heater > Set + 72°F

heater < Set - 72°F

chamber

chamber

generator

generator

generator

after

after

value

of

psi

(-0.8

10

last

cycles

pulse

locking

LOCKED

50

PPh

phase > 20

sensor

sensor

temperature > Set + 126°F

temperature

sensor

beginning

psi

(-0.2

beginning

psi

(-0.5

the

6t

vacuum

bar)

required

problem/

switch

seconds

psi

(-0.7

minutes

(40°C)

(40°C)

(33.4

psi)/255.2°F

(2.3

bar)/124°C

(29.4

psi)/249.8ºF

(2.03

bar)/121°C

(Steam

(Steam

(Steam

(Steam

broken

broken

bar)

bar)

open

after

bar)

temperature)

temperature)

temperature)

temperature)

open

(Jacket

below

of

the

phase:

of

the

phase:

pulse

to

the 6 additional

beginning