Page 1

SENC 150

REFERENCE MANUAL

Page 2

Page 3

SENC 150

Page

1 Introduction / Supplied items ........................................ 4

2 Preparing the mounting / Mounting information ........... 5

3 Encoder dimensions ..................................................... 8

4 Backup spar dimensions ............................................. 10

5 Mounting the encoder without backup spar ............... 11

5.1 Mounting the encoder via end holes .......................... 12

5.2 Mounting the encoder via center support .................. 13

6 Mounting the encoder with backup spar .................... 14

7 Mounting the reading head ......................................... 15

8 Checking the mounting .............................................. 16

9 Specifications ............................................................. 17

10 Pin-outs .................................................................... 18

11 Output signals ............................................................ 18

Table of Contents / Warnings

3

Page 4

1 Introduction / Supplied items

SENC 150

The SENC 150 precision glass scale linear encoder provides the

accuracy and reliability of an ACU-RITE

®

measuring system with

digital output. Features and options include:

Resolutions of 0.5, 1, or 5 µm.

Accuracy grades of ± 3, and ± 5 µm/1000 mm.

Vinyl or armor cables of 5, 13, and 19 ft. length.

Distance-coded reference marks.

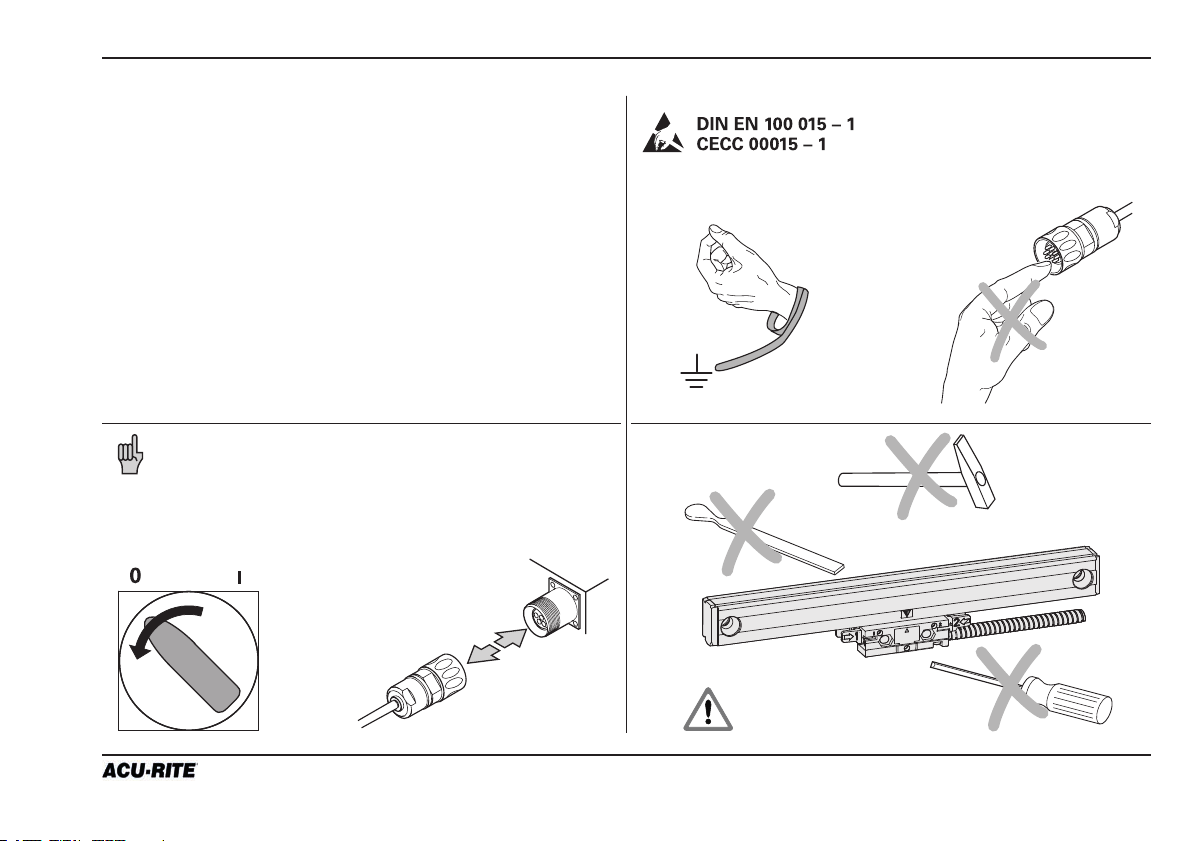

Note: Mounting and commissioning is to be conducted

by a qualified specialist under compliance with local safety

regulations. Do not engage or disengage any connections

while under power. The system must be disconnected from

power.

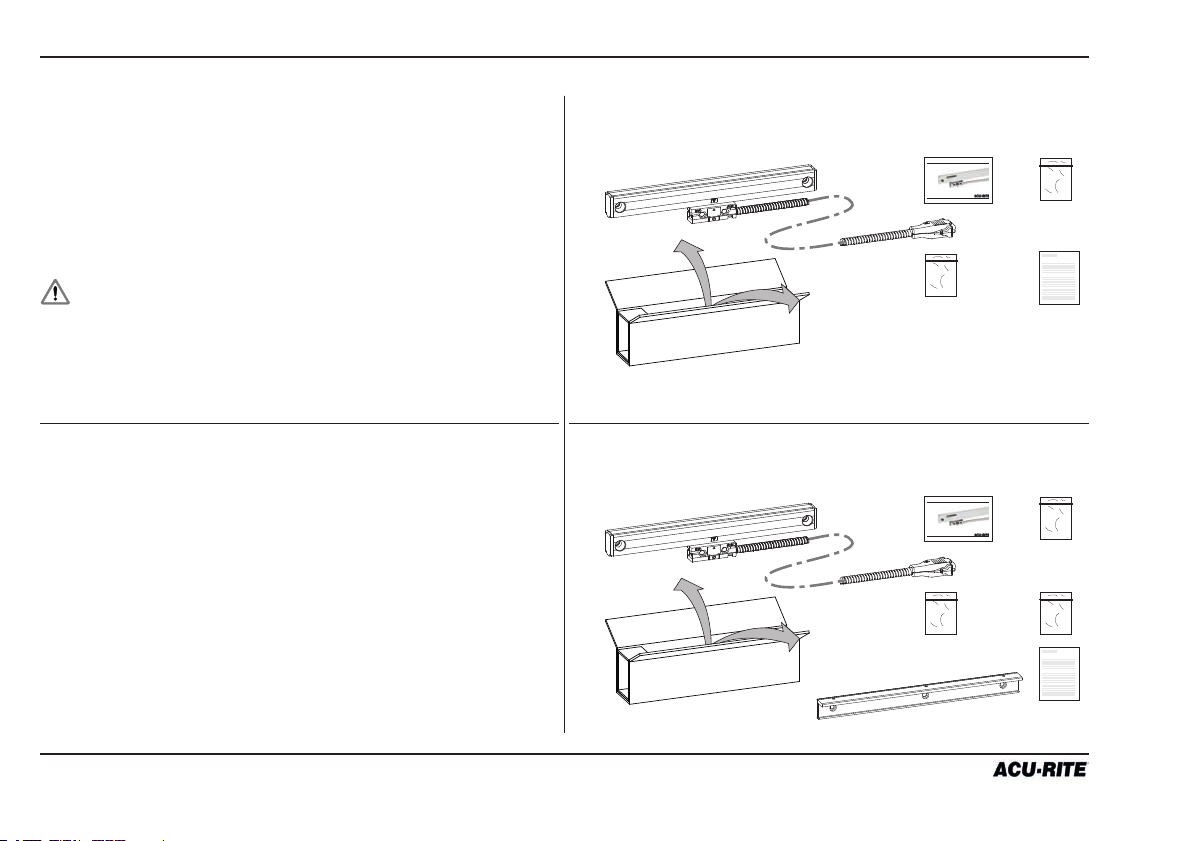

Contents key

A SENC 150 linear encoder

B Backup spar

C Reference manual

D Cable mounting hardware

E Linear encoder mounting hardware

F Backup spar mounting hardware

G Quality test certificate

Contents

ML ≤ 1550 mm (60”)

A

Contents

ML ≥ 1675 mm ( 65”)

A

SENC 150

C

E

SENC 150

C

E

D

REFERENCE MANUAL

G

D

REFERENCE MANUAL

F

G

B

4

Page 5

SENC 150

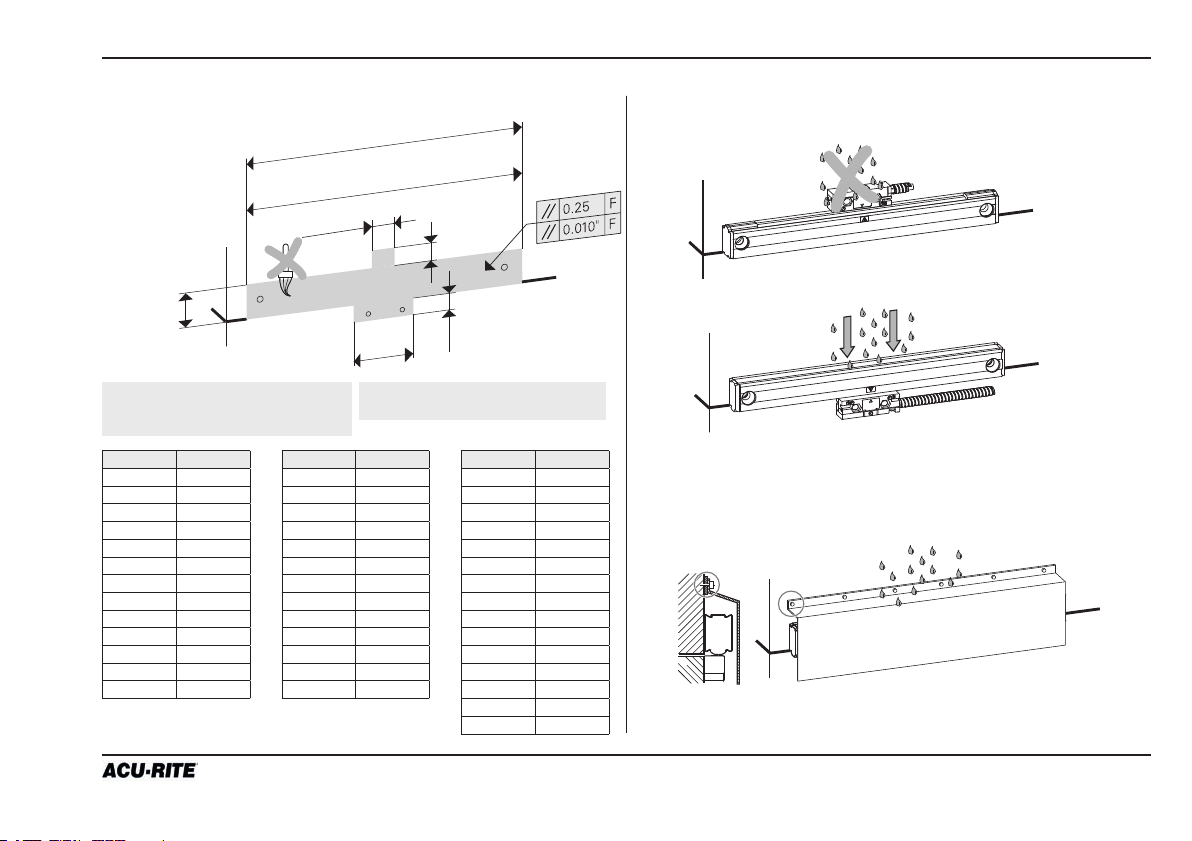

2 Preparing the mounting

Mounting surface clean and free of paint. Protect sealing lips from splash water.

*LL [mm] x 25.4 + 161.6

*LL [“] + 6.362

***L [“] ±0.35

***L [“] ±0.014

**19 mm

**0.748”

* 28.8 mm

* 1.134”

*** 36.6 mm

*** 1.441”

* Linear encoder

** Linear encoder with center support

*** Linear encoder with backup spar

57 mm

2.244”

F = Machine guideway

L = Length of backup spar (page 10)

**19.05 mm

**0.750”

19 mm

0.750”

LL [mm] LL [“]

50 1

75 2

100 3

125 4

150 5

175 6

200 7

225 8

275 10

300 11

125 12

350 13

375 14

LL [mm] LL [“]

400 400

425 16

475 18

525 20

575 22

600 23

625 24

675 26

725 28

775 30

875 33

925 35

950 36

LL [“] LL [“]

1000 38

1050 40

110 0 42

1250 48

1350 52

140 0 54

1550 60

1675 65

1850 72

2000 78

2150 84

2300 90

2575 100

2825 110

3075 120

If there is a risk of severe contamination,

attach a protective cover.

5

Page 6

2 Preparing the mounting / Mounting information

Traverse path

11.75 mm

0.463”

(LL x 25.4 + 138.1)/2 mm

(LL + 5.437”)/2

ML/2 mm

(LL + OT)/2 “

Scale case

C

L

SENC 150

Center marks

ML mm

LL + OT “

ML = Measuring length

OT = Overtravel 1.75”

Center mounting axis

C

L

Mark center of travel

Move the axis to its center of travel.

Mark the axis for quick return to center.

Determine encoder cable exit direction (page 7) and adjust.

6

Alignment brackets (2x)

Cable assembly

Reading head assembly

Align the center marks on the reading head and scale assembly

by sliding the reading head and brackets along the scale.

F = Machine guideway

Locate the scale case so underside of end caps are flush

with the axis parting line.

Mark one end mounting hole location.

Alignment brackets must not be removed until instructed.

Page 7

SENC 150

Mounting possibilities Determining cable direction

2 Mounting information

Flush

mounting

Offset

mounting

Backup spar

mounting

Space of ≤4.5 mm (≤0.18”) use

reading head leveling screws!

Use reading head leveling set screws when surfaces are

not flush.

Detailed information about mounting possibilities on page 11

(Mounting the encoder without backup spar) and on page 14

(Mounting the encoder with backup spar).

Determine cabel exit direction before mounting the encoder.

To change the cable exit direction, remove the cover plate

and rotate it by 180°.

K1 - cable exit right side

Do not pull out the PCB!

1

K2 - cable exit left side

1

1

1

1

T-10 torx screw

Do not clamp the wires!

1

T-10 torx screw

max. 70 Ncm!

7

Page 8

3 Encoder dimensions

SENC 150

8

Page 9

SENC 150

3 Encoder dimensions

ML = Measuring length [mm]

LL = Measuring length [inch]

OT = Overtravel 1.75”

S = Beginning of measuring length

K = required mating dimensions

H1 = for ML ≥ 625 mm to ≤ 1550 mm use mid-point fastening

for ML ≥ 24” to ≤ 60” use mid-point fastening

= Direction of scanning head motion for output signals

in accordance with interface description

F = Machine guideway

9

Page 10

4 Backup spar dimensions

SENC 150

Encoder

ML (mm)

Encoder

LL (inch)L(mm)L(inch)L1(mm)L1(inch)L2(mm)L2(inch)

50 1 185.50 7.303 29.25 1.152 127 52

75 2 211.50 8.327 42.25 1.663 127 52

100 3 236.50 9.311 54.75 2.156 127 52

124 4 261.5 10.295 67.25 2.648 127 52

150 5 287.50 11.319 80.25 3.159 12 7 52

175 6 312.50 12.303 29.25 1.152 254 10 2

200 7 388.50 13.327 42.25 1.663 254 10 2

225 8 363.5 14.311 54.75 2.156 254 10 2

275 10 414.50 16.319 80.25 3.159 254 10 2

300 11 439.50 17.303 92.75 3.652 254 10 2

325 12 465.50 18.327 105.75 4.163 254 10 2

350 13 490.50 19.311 36.60 1.441 417.3 10 2

375 14 515.50 20.295 130.75 5.148 254 10 2

400 15 541.50 21.319 16.75 0.659 254 10 3

425 16 566.50 22.303 29.25 1.152 254 10 3

475 18 617.50 24.311 54.75 2.156 254 10 3

525 20 668.50 26.319 80.25 3.159 254 10 3

575 22 719.50 28.327 105.75 4.163 254 10 3

600 23 744.50 29.311 118.25 4.656 254 10 3

625 24 769.50 30.295 130.75 5.148 254 10 4

675 26 820.50 32.303 29.25 1.152 254 10 4

No.

holes B

Encoder

ML (mm)

Encoder

LL (inch)L(mm)L(inch)L1(mm)L1(inch)L2(mm)L2(inch)

725 28 871.50 34.311 54.75 2.156 254 10 4

775 30 922.50 36.319 80.25 3.159 254 10 4

875 33 998.50 39.311 118.25 4.656 254 10 4

925 35 1049.50 41.319 11.25 0.443 256.75 10.108 5

950 36 1074.50 42.303 29.25 1.152 254 10 5

1000 38 1125.50 44.311 54.75 2.156 254 10 5

1050 40 1176.50 46.319 80.25 3.159 254 10 5

110 0 42 1227.50 48.327 105,75 4.163 254 10 5

1250 48 1379.50 54.311 54.75 2.156 254 10 6

1350 52 1481.50 58.327 105.75 4.163 254 10 6

140 0 54 1531.50 60.295 130.75 5.148 254 10 6

1550 60 1684.50 66.319 80.25 3.159 254 10 7

1675 65 1811.50 71.319 143.75 5.659 254 10 7

1850 72 1989.50 78.327 105.75 4.163 254 10 8

2000 78 2141.50 84.311 54.75 2.156 254 10 9

2150 84 2293.50 90.295 130.75 5.148 254 10 9

2300 90 2446.5 96.319 80.25 3.159 254 10 10

2575 100 2700.50 106.319 80.25 3.159 254 10 11

2825 11 0 2954.50 116.319 80.25 3.159 254 10 12

3075 120 3208.50 126.319 80.25 3.159 254 10 13

H2 for ML ≥1675 mm (65”)

backup spar included

in items supplied

for ML ≤1675 mm (65”)

backup spar optional

B = Number of holes

No.

holes B

10

Page 11

SENC 150

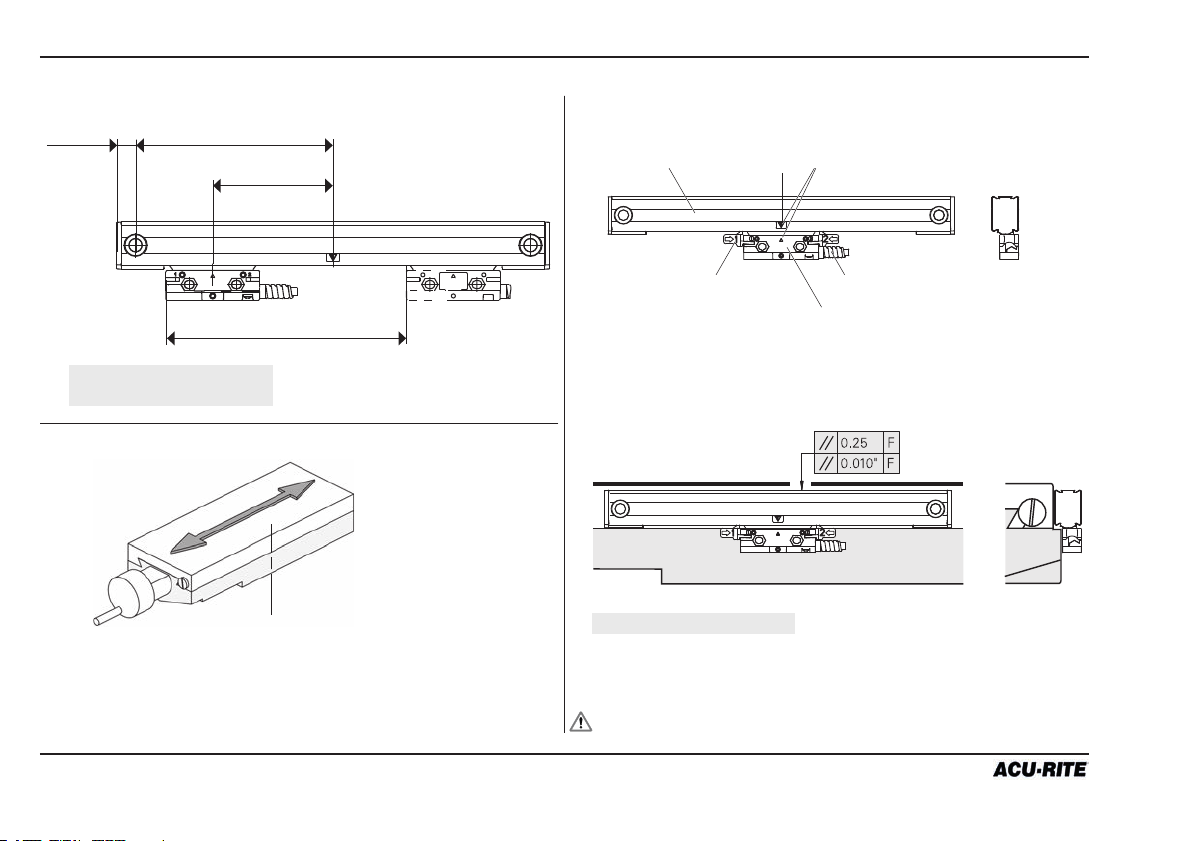

5 Mounting the encoder without backup spar

A variety of mounting conditions can be accomodated.

The machine configuration determines the brackets required

to mount the linear encoder.

Two typical mounting conditions are shown: flush and offset.

All fasteners shown on this page are supplied with the encoder

hardware.

Flush surfaces

1

2

3

M6 x 25 mm BHCS

1 3

(1/4”-20 x 1” BHCS)

M6 flat washer

Mounting surfaces are flush within 0.25 mm (0.010”).

The reading head leveling screws are not required.

M4 x 25 mm SHCS low head

2

(8-32 x 5/8” SHCS low head)

(8-32 x 3/4” SHCS low head)

2

Offset surfaces

1

2

Space of ≤4.5 mm (≤0.18”) use

reading head leveling screws!

2

M4 hex nut

Mounting surfaces are offset.

Mounting without backup spar.

Use leveling screws in place of spacers or shims.

2

2

3

11

Page 12

5.1 Mounting the encoder via end holes

Bore hole pattern

SENC 150

Mounting

LL < 625 mm (24“):

Use end mounting holes.

12

P1

ML/2

1

ML

10

P2

1

2

P = Gauging point

M6 x 25 mm

1

(1/4”-20 x 1” BHCS)

M6 flat washer

M4 x 25 mm SHCS low head

2

(8-32 x 5/8” SHCS low head)

(8-32 x 3/4” SHCS low head)

Page 13

SENC 150

Bore hole pattern

5.2 Mounting the encoder via center support

Mounting

625 mm (24“) † LL

† 1550 mm (60”):

Use end mounting holes

with center support.

P1

ML/2

1

ML

P2

P = Gauging point

10

P3

M6 x 25 mm

1

(1/4”-20 x 1” BHCS)

M6 flat washer

M4 x 25 mm SHCS low head

2

(8-32 x 5/8” SHCS low head)

(8-32 x 3/4” SHCS low head)

1

M6 x 20 mm

3

2

3

(1/4”-20 x 3/4” BHCS)

M6 flat washer

13

Page 14

6 Mounting the encoder with backup spar

SENC 150

MountingMounting possibility

Space of ≤4.5 mm (≤0.18”) use

reading head leveling screws!

Flush or offset mounting with a backup spar.

Bracket used to reduce head to mounting surface gap.

Bore hole pattern

LL > 1550 mm (60”): A backup spar is required.

P1

3

3

3

P2

P3

6

1

1

1

2

M6 x 25 mm

1

(1/4”-20 x 1” BHCS)

M6 flat washer

M4 x 25 mm SHCS low head

2

(8-32 x 5/8” SHCS low head)

(8-32 x 3/4” SHCS low head)

M4 x 8 mm SHSS

3

P = Gauging point

14

Page 15

SENC 150

7 Mounting the reading head

Leveling screws Mounting the reading head with hex nut

M4 hex nut

M3 x 12 mm SHSS

Adjust the leveling set screws as follows:

Insert, but do not tighten 8-32 (M4) reading head screws

as shown on the right side.

Place a 0.025 mm - 0.075 mm (0.001”- 0.003”) shim between

the leveling set screws and mounting surface.

Adjust each set screw until a slight drag is felt on the shim.

Remove the shim before tighten the reading head screws.

Mounting the reading head

M4 x 25 mm SHCS low head

(8-32 x 5/8” SHCS low head)

(8-32 x 3/4” SHCS low head)

M4 x 25 mm SHCS low head

(8-32 x 5/8” SHCS low head)

(8-32 x 3/4” SHCS low head)

Do not tighten prior to adjusting leveling set screws.

Evenly tighten the 8-32 (M4) reading head mounting screws.

Removing the alignment brackets

Slide brackets away from reading head and cable.

Slide the brackets away from the reading head.

Remove the alignment brackets and save for future use.

15

Page 16

8 Checking the mounting

Connecting the encoder

Route the cables with slack loops

to allow for axis motion.

Secure excess cable by fastening

with clips or ties.

Attach the linear encoder connectors

to the readout.

Checking the electrical shielding

Connect a ground wire from the

terminal on the back of the readout to

the machine or earth ground.

Attach a ground wire from the machine

to a solid earth ground.

With the encoder attached to the ma chine and the cable connected to the

readout, check shielding by measuring

resistance between connector housing

and scale unit.

SENC 150

Desired value: 1 Ω max.

16

Page 17

SENC 150

Mechanical specifications Digital

Resolution 0.5 µm 1 µm 5 µm

Grating pitch 20 µm

Scale medium Light transmission reflective off of nickel coated glass

Accuracy (@ 20° C) / 1000 mm ± 3µm, ± 5µm

Max. traversing speed 60 m/min

Force required to move reading head <3.4 N

Operating environment

Temperature

Relative humidity

Storage environment

Temperature

Humidity

Weight w/armor

Connecting cable armored or vinyl Length = 4 m resp. 6 m from ML 1250 mm; connector: DE-9P

Max. cable length

Measuring lengths 50 mm – 3075 mm (1”–120”)

Reference pulse interval distance coded 50 mm

Voltage supply DC 5.1 V ±0.1 V / <220 mA DC 5.1 V ±0.1 V /< 180 mA

Protection EN 60529 IP 53 when mounted as per instructions

0° to 50° C

25 % to 95 % (non-condensing)

-20° to 70° C

20 % to 95 % (non-condensing)

Scale case: 180 g + 0.65 g/mm ML

Reading head: 60 g

Backup spar: 1 g/mm L

Cable: vinyl: 50 g/m

armored: 140 g/m

Connector: 55 g

≤ 9 m

9 Specifications

17

Page 18

10 Pin-outs

11 Output signals

Digital Differential

Pin 1 Pin 2 Pin 3 Pin 4 Pin 5 Pin 6 Pin 7 Pin 8 Pin 9

n/c green yellow blue red white brown pink gray

n/c channel

1

A+

5

channel

A-

channel

B+

channel

B-

ground Vcc, +5.1

±0.1 VDC

channel

R+

SENC 150

channel

R-

6

9

Outout signals

Parameter Digital

Output signals I

Incremental signals

Signal levels

Reference mark signal

Signal level

=(High level output current) = 20 mA

OH

VOH=(High level output voltage) >2.5 Vdc

IOL=(Low level output current) = -20 mA

VOL=(Low level output voltage) < 0.6 Vdc

Square-wave voltage signals. Channels A and B, in 90° quadrature relationship

TTL-level

Square-wave pulse

TTL-level

Channel A+

Channel A-

Channel B+

Channel B-

18

360°

0°

1

0

1

0

90°

1

0

1

0

Channel R+

Channel R-

1

0

1

0

1 count

(phased)

Page 19

SENC 150

19

Page 20

ID: 516291-22 D516291-02-A-01 05/2017

Loading...

Loading...