Page 1

G2

ACU-RITE

®

MILLPWR

User’s Manual

Page 2

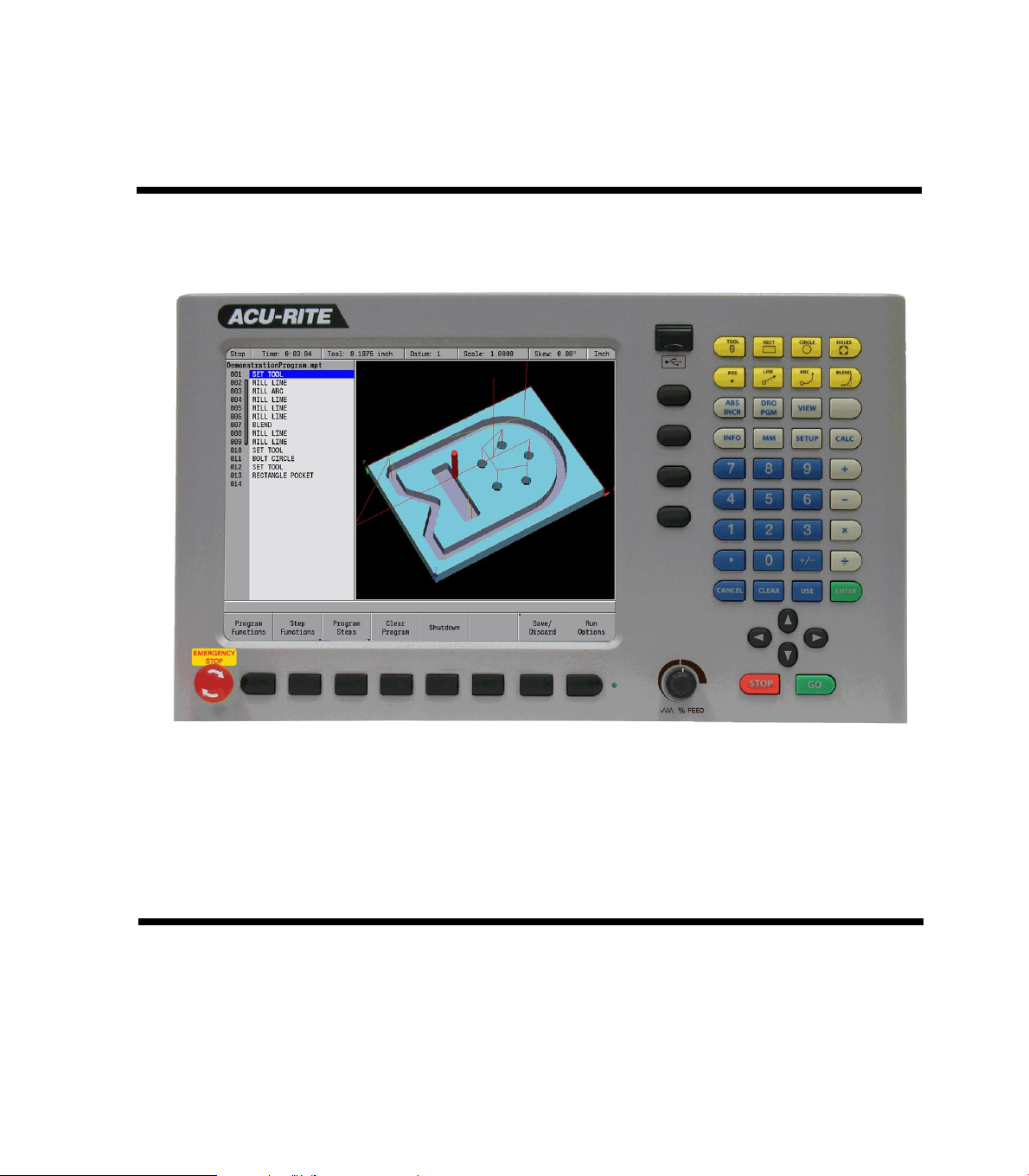

Controls of the MILLPWR

G2

Keys on console

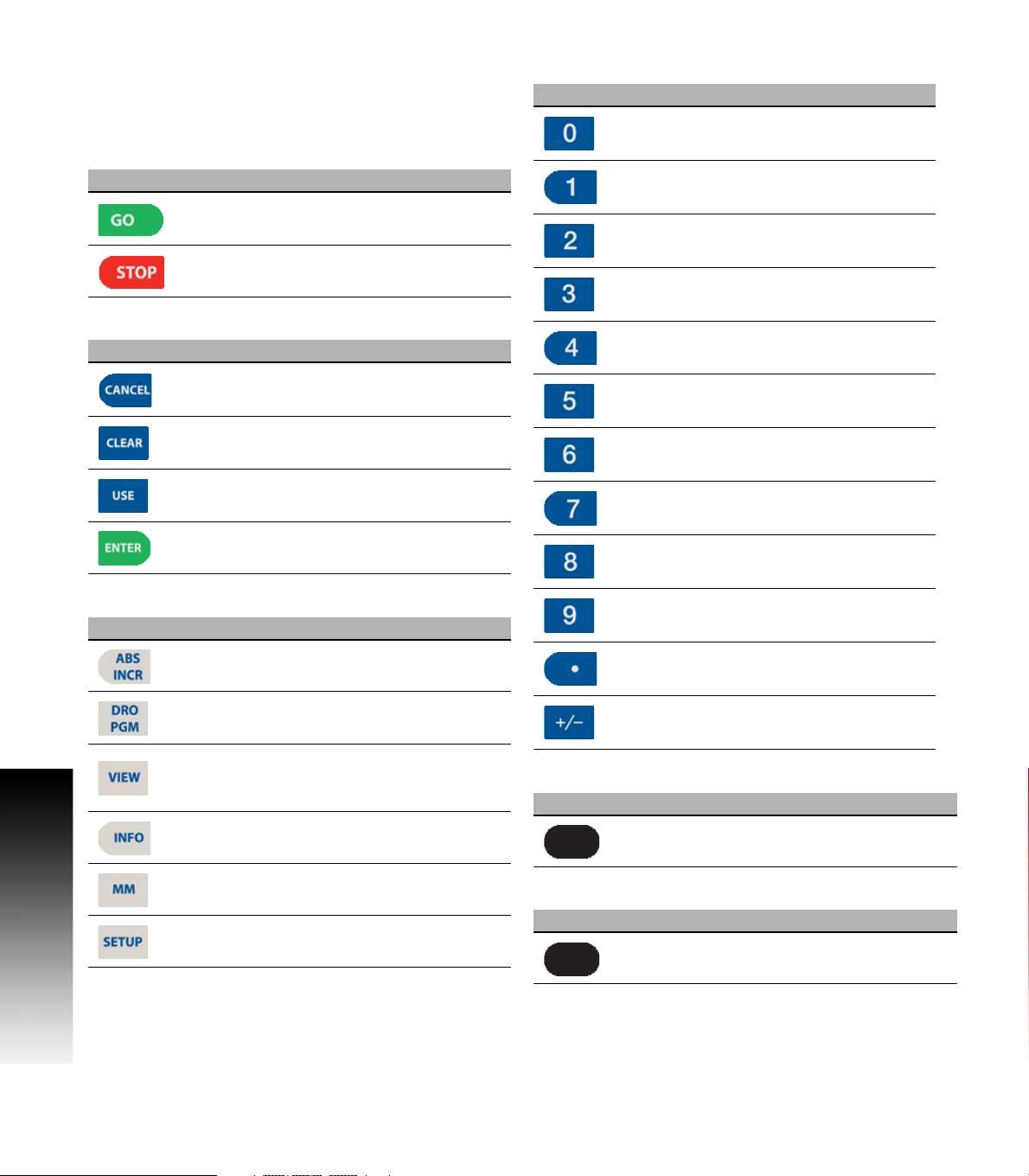

Motion control keys

G2

Numerical keys

Key Function

ZERO key.

Key Function

GO key (e.g. run a program).

STOP key (duel function: press once to

pause, press twice to stop a program).

Data Entry keys

Key Function

CANCEL key cancels operation, i.e. form.

Controls of the MILLPWR

Function keys

Key Function

CLEAR key clears selections, i.e. values in

a field, a program step.

USE key completes operation, i.e. data

entered in a form.

ENTER key completes selection, i.e.

values entered in a field.

ABS/INCR key toggles between Absolute

or Incremental positioning.

ONE key.

TWO key.

THREE key.

FOUR key.

FIVE key.

SIX key.

SEVEN key.

EIGHT key.

NINE key.

DECIMAL key.

DRO/PGM key toggles between the DRO

display or Program mode display.

VIEW key opens menu for setting part

graphic display parameters, i.e. type,

orientation.

INFO key opens on-screen manual.

MM key toggles between INCH or MM

mode.

SETUP key opens configuration menu.

ii

Axis Keys

Key Function

Soft Keys

Key Function

PLUS / MINUS key.

AXIS keys open the datum, or preset

form.

SOFT KEYS performs the function directly

above it.

Page 3

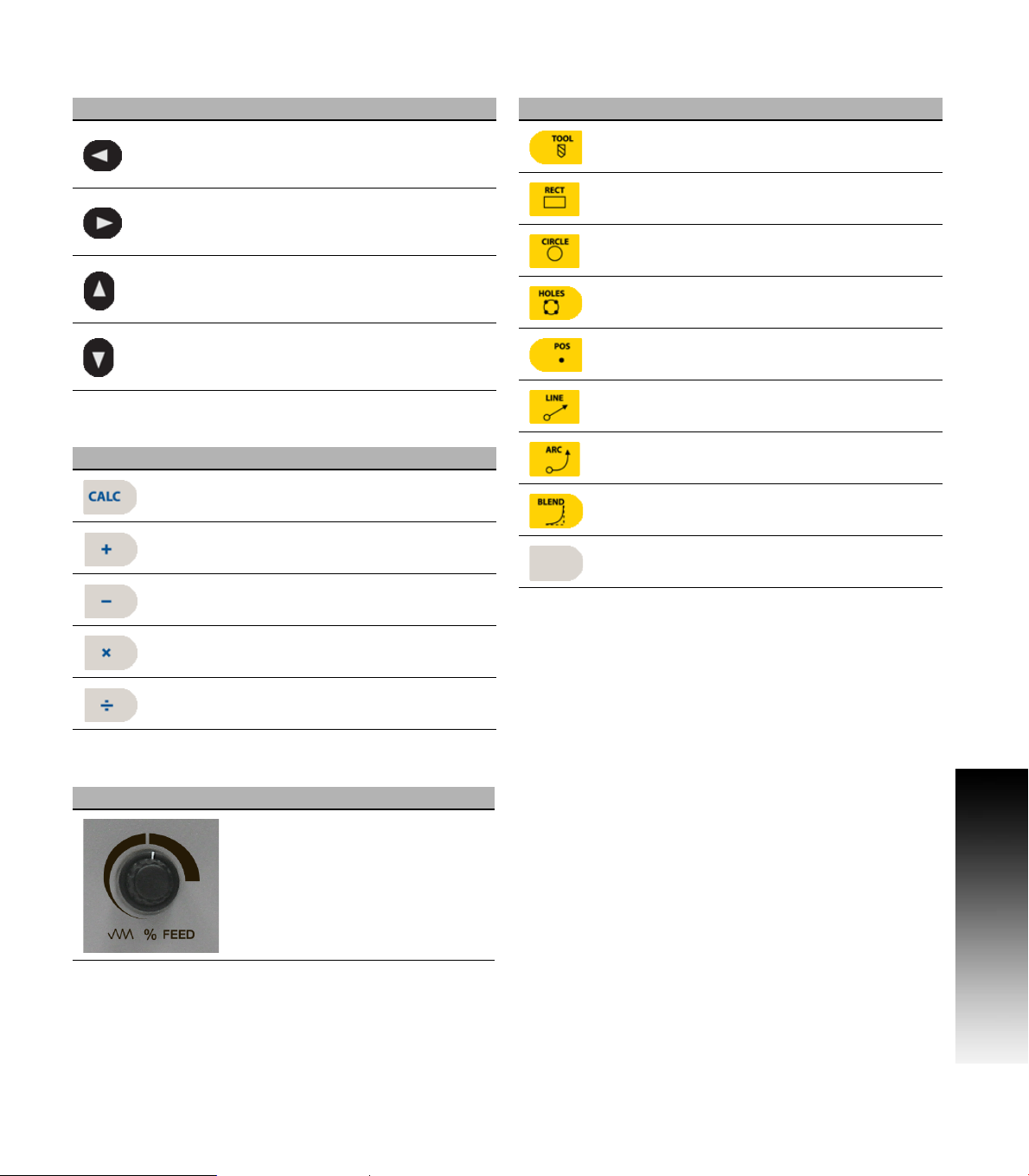

Move Table and Navigation keys

Key Function

LEFT ARROW key will move the table or

display cursor depending on the function

selected.

RIGHT ARROW key will move the table or

display cursor depending on the function

selected.

UP ARROW key will move the table or

display cursor depending on the function

selected.

DOWN ARROW key will move the table or

display cursor depending on the function

selected.

Calculator Function keys

Key Function

CALC key opens the calculator.

PLUS key.

MINUS key.

Milling Function keys

Key Function

TOOL key opens the SET TOOL

Dialogue.

RECT key opens the Rectangle milling

popup menu.

CIRCLE key opens the Circle milling

popup menu.

HOLES key opens the Hole pattern popup

menu.

POS key opens the POSITION / DRILL

data input dialogue.

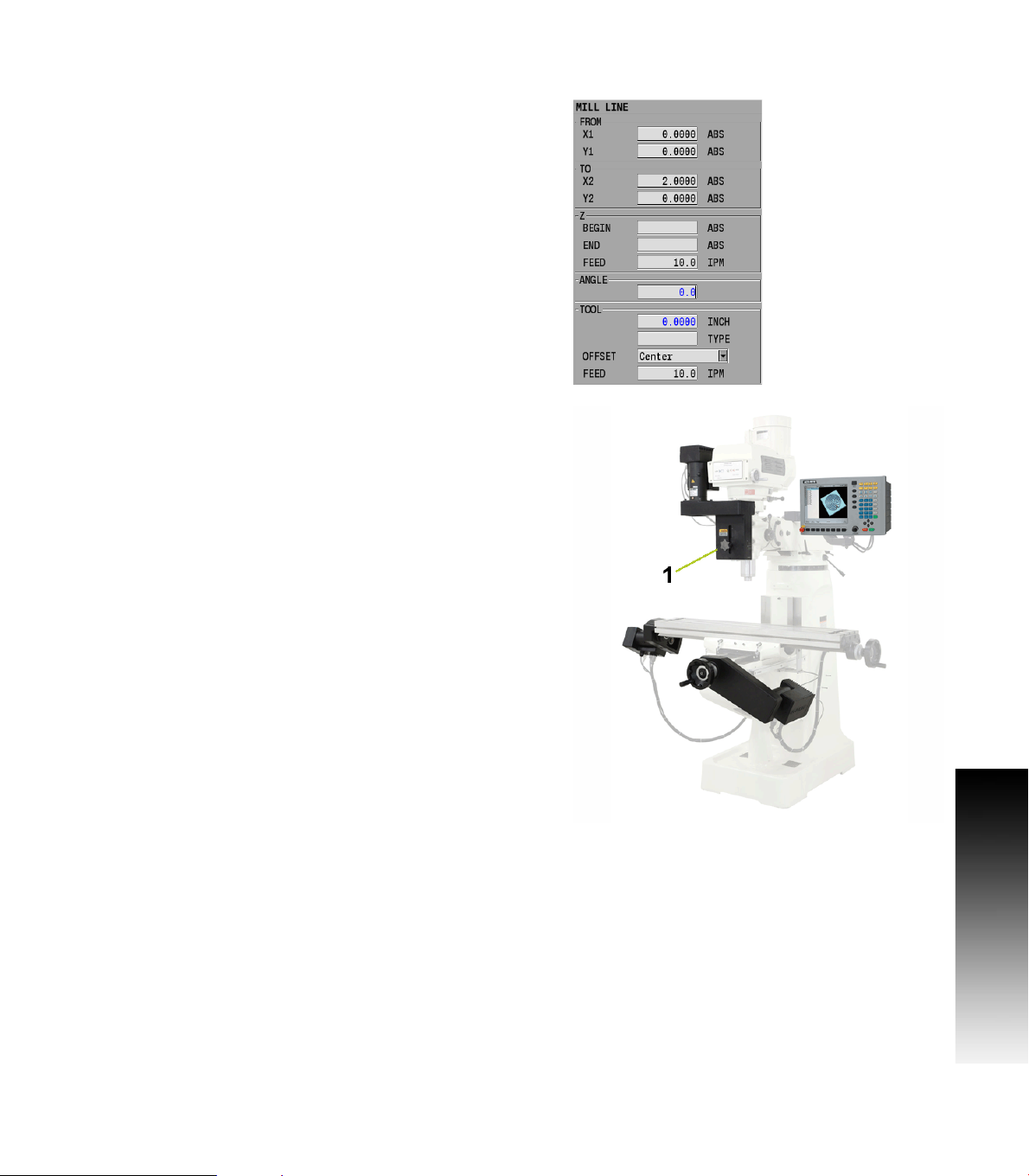

LINE key opens the MILL LINE data

input dialogue.

ARC key opens the MILL ARC data input

dialogue.

BLEND key opens the BLEND \

CHAMFER data input dialogue.

BLANK key opens the user defined milling

function data input form.

G2

Controls of the MILLPWR

MULTIPLIER key

DIVIDE key.

Peripherals Supported:

USB memory devices; e.g. a memory stick.

Networking, USB pointing devices; e.g. a mouse, USB

keyboard.

Potentiometer for feed rate override

Feed rate override

ACU-RITE MILLPWRG2 iii

Page 4

G2

Controls of the MILLPWR

iv

Page 5

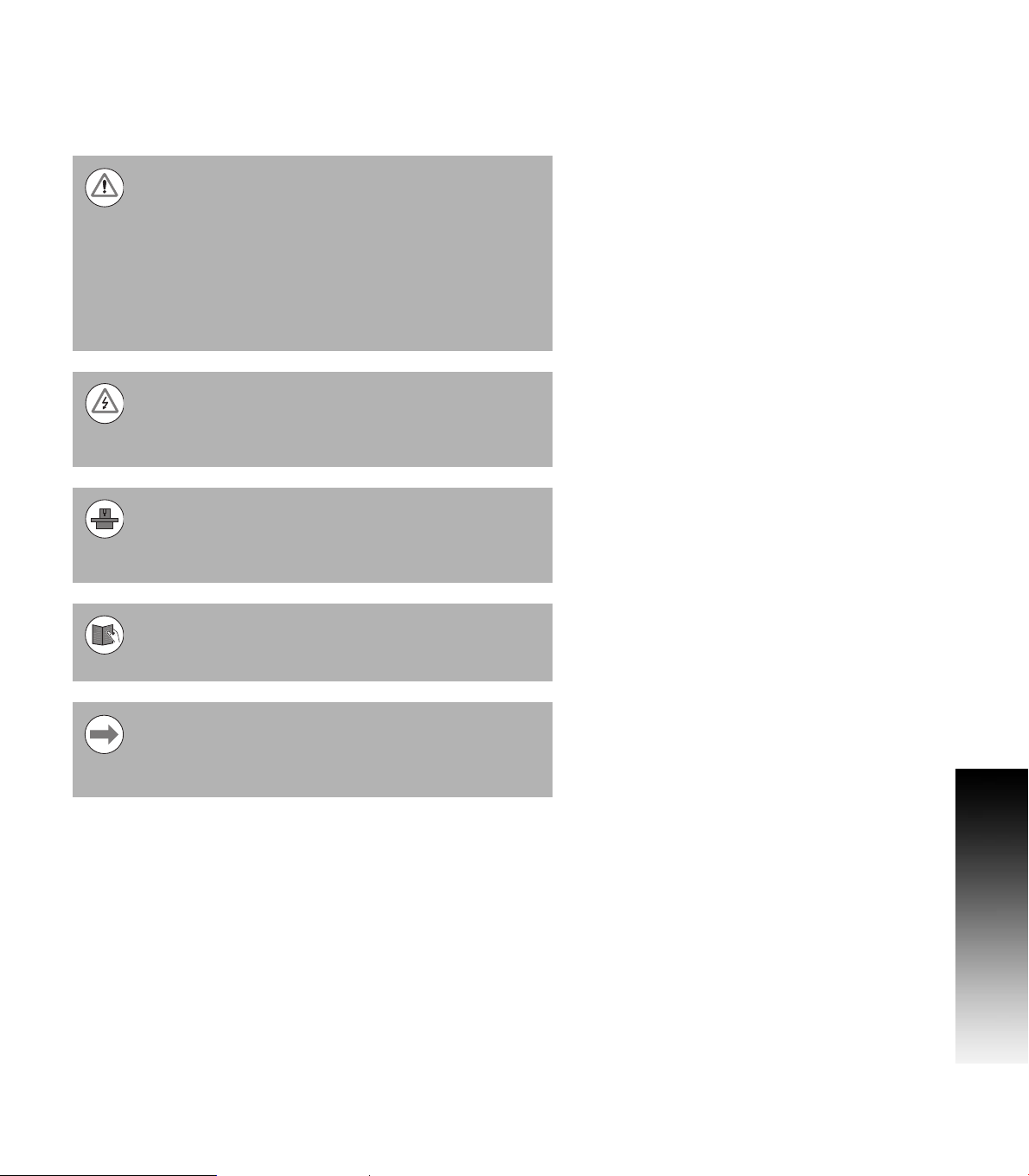

Manual Information

Message symbols

Attention!

This symbol indicates that there is one or more of the

following risks when using the described function

Danger to work piece

Danger to fixtures

Danger to tool

Danger to machine

Danger to operators

Damage!

This symbol indicates that there is risk of MILLPWRG2

damage, or electrical shock if instructions are not adhered

to.

Different from machine to machine!

This symbol indicates that instructions may apply

differently from one type of machine to another type of

machine.

Manual Information

Refer to another Manual!

This symbol indicates that information required is located

elsewhere (i.e. Machines Owner Manual).

Advice!

This symbol indicates that an Advice tip is being provided.

Important, and/or additional information about the function

described.

ACU-RITE MILLPWRG2 v

Page 6

Fonts Used in this manual

Reference to the: Console HARD KEYS.

Reference to the: Display Screen Soft Keys.

Reference to the: Display Screen DIALOGUES.

Reference to the: Display Screen FIELDS.

Changes (errors)

HEIDENHAIN CORPORATION is continuously striving to improve.

Please help HEIDENHAIN CORPORATION by sending your request to

the following e-mail address: sales@heidenhain.com

Visit www.ACU-RITE.com for latest version of this manual.

Manual Information

Model, Software and Features

This manual describes functions and features provided by

MILLPWR

Console model NC software number

ACU-RITE MILLPWRG2 Software 751005-01

The machine tool builder may not allow some of the functions

described in this manual, therefore they may not be among the

features provided by the MILLPWR

The machine tool builder representative can assist with becoming

familiar with the features of the machine.

Many machine manufacturers, as well as HEIDENHAIN Corp., offer

programming courses for the MILLPWRG2. We recommend these

courses as an effective way of improving your programming skill and

sharing information and ideas with other MILLPWRG2 users.

Intended place of operation

The MILLPWR

areas. Refer to the respective installation manual for additional

information.

G2

as of the following NC software number.

G2

on your machine tool.

G2

is intended for use primarily in industrially-zoned

vi

Page 7

New Functions of Software

751005-01-01

Zero Incremental was added to Section 2.2.

Manual Information

ACU-RITE MILLPWRG2 vii

Page 8

Changed Functions of Software

751005-01-01

Blend/Chamfer information input in Section 8.1 has been redefined.

Preset Moves information input in Section 2.2 has been redefined.

Display:Peck\Pass in Section 9.1 has a note added that the limit of

pecks or passes is 9999.

751005-01-02

The off-line software described in Section 11.1now requires the

purchase of a USB Protection Module for operation.

Custom Pocket: The tool path for custom pockets and islands,

Manual Information

described in Section 8.2, has changed to use the programmed

cutting convention.

751005-01-03

A message box warning that the table limits are not established prior

to homing was added to Section 1.1.

751005-01-04

Part Graphics: The show tool path and show step number options

were removed from the graphics view in Section 5.1.

Probing examples were added to Section 6.1.

viii

Page 9

MILLPWRG2 Access Code

Access Code

Attention!

The parameter access code is 8891

Access to Machine Parameter Operations

The access code must be entered before the installation setup

parameters can be accessed or changed.

Press the SETUP key to enter the Job Setup dialogue.

Press the Config Data soft key, and enter the access

code in the yellow message bar.

Attention!

To prevent setup parameters from being changed, remove

this page from the manual after initial system setup.

Retain this information in a safe place for future use.

Access Code

G2

MILLPWR

ACU-RITE MILLPWRG2 ix

Page 10

Access Code

G2

MILLPWR

x

Page 11

Table of Contents

Controls of the MILLPWR

Keys on console........................................................................................................ii

Motion control keys .............................................................................................ii

Data Entry keys....................................................................................................ii

Function keys.......................................................................................................ii

Numerical keys ....................................................................................................ii

Axis Keys .............................................................................................................ii

Soft Keys..............................................................................................................ii

Move Table and Navigation keys .............................................................................iii

Calculator Function keys.......................................................................................... iii

Potentiometer for feed rate override ....................................................................... iii

Milling Function keys ............................................................................................... iii

Peripherals Supported: ............................................................................................ iii

G2

Manual Information

Message symbols.....................................................................................................v

Fonts Used in this manual ..................................................................................vi

Model, Software and Features ................................................................................vi

Intended place of operation ................................................................................vi

MILLPWRG2 Access Code

Access Code............................................................................................................ix

Access to Machine Parameter Operations ..............................................................ix

1.1 MILLPWR

ACU-RITE conversational, and G-code format ......................................................... 2

Powering Up ............................................................................................................ 3

E-STOP and Shutdown ............................................................................................ 4

Find Home ............................................................................................................... 6

Disengage Z Axis feature......................................................................................... 7

Disengaging the Z axis drive:.............................................................................. 7

Re-engaging the Z axis drive............................................................................... 7

Writing Programs..................................................................................................... 8

Overview............................................................................................................. 8

G2

1.2 Operating in 2 Axes and 3 Axes Modes

Overview ................................................................................................................. 9

Program Steps in 2 Axis Mode ................................................................................ 9

Selecting 2 Axis Mode on 3 Axis Systems ............................................................ 10

ACU-RITE MILLPWRG2 xi

Page 12

1.3 Console

Operating Console ................................................................................................. 11

Rear Panel.............................................................................................................. 11

Screen Navigation.................................................................................................. 12

DRO Mode display............................................................................................ 12

PGM Mode display ........................................................................................... 12

Dialogues, and Drop Down Menus........................................................................ 13

Operator Prompts ............................................................................................. 13

Cursor ............................................................................................................... 13

General Operating Guidelines ................................................................................ 14

Operating Modes.............................................................................................. 15

Popup Menus ................................................................................................... 16

Keyboard........................................................................................................... 17

Special Characters ............................................................................................ 17

Navigational Soft keys ...................................................................................... 17

Editing Keys ...................................................................................................... 18

Calculator ............................................................................................................... 18

Numeric Keypad ............................................................................................... 18

Context Sensitive Help .......................................................................................... 19

Using Context Sensitive Help ........................................................................... 19

Console Keypad ..................................................................................................... 20

1.4 Operating Mode Screens

Display navigation .................................................................................................. 21

DRO display screen ............................................................................................... 21

Program Display Screen ........................................................................................ 22

1.5 Accessories

Electronic Edge Finder........................................................................................... 22

2.1 Conventions

Axis Conventions ................................................................................................... 24

Count Direction................................................................................................. 24

X axis ................................................................................................................ 24

Y axis ................................................................................................................ 24

Z axis................................................................................................................. 24

Cartesian Coordinates............................................................................................ 24

Polar Coordinates................................................................................................... 24

Absolute and incremental work piece positions .................................................... 25

Absolute work piece positions.......................................................................... 25

Incremental work piece positions..................................................................... 25

Setting the datum .................................................................................................. 26

Overview .......................................................................................................... 26

xii

Page 13

2.2 Manual Machine Positioning

Move Table ............................................................................................................ 27

Changing the Mode .......................................................................................... 27

Incremental Moves ........................................................................................... 27

Continuous Moves............................................................................................ 27

Adjusting the Feedrate...................................................................................... 28

Preset Moves.................................................................................................... 28

Zero Incremental............................................................................................... 28

3.1 DRO Manual Data Input

Overview ............................................................................................................... 30

DRO Screen........................................................................................................... 31

Status Bar Display.................................................................................................. 32

Move Table ............................................................................................................ 33

Milling Function ..................................................................................................... 33

Zeroing an Axis ...................................................................................................... 34

Teach Position ....................................................................................................... 34

Electronic Edge Finder........................................................................................... 35

Skewing ................................................................................................................. 36

Milling Function Keys............................................................................................. 37

DRO Operations .................................................................................................... 38

Rectangle milling............................................................................................... 38

Rectangle milling example................................................................................ 38

Circle milling...................................................................................................... 39

Circle milling example....................................................................................... 39

DRO Mill Cycles..................................................................................................... 40

3.2 Calculator

Accessing the calculator ........................................................................................ 41

Using the calculator to insert data .................................................................... 42

Trig Functions ................................................................................................... 42

4.1 Tool Table

Overview ............................................................................................................... 44

Tool Compensation Required Data ........................................................................ 44

Tool numbers / Tool names ................................................................................... 45

Locating the Tool Table.......................................................................................... 45

Tool Table .............................................................................................................. 46

Editing the tool table ......................................................................................... 46

Editing an existing tool...................................................................................... 47

Tool Table Structure .............................................................................................. 47

Tool table: Standard tool data ........................................................................... 47

ACU-RITE MILLPWRG2 xiii

Page 14

4.2 Tool Data

Tool-Length Offsets............................................................................................... 48

Teaching Tool Length Offsets in the Tool Table ............................................... 48

Diameter Offset in Tool Table................................................................................ 49

Tool Radius Offset ................................................................................................. 50

Moving without radius offset............................................................................ 50

Machining with radius offset ............................................................................ 51

Radius offset: Machining corners ..................................................................... 52

5.1 Programming Introduction

Program Display mode .......................................................................................... 54

Display area ...................................................................................................... 54

Program Function Screen ...................................................................................... 55

Folder View....................................................................................................... 55

Program Drawing View.......................................................................................... 56

Program Screen Display ........................................................................................ 57

Program Mode Soft Keys ...................................................................................... 58

Program Functions................................................................................................. 59

Program Functions soft keys ............................................................................ 59

View hard key ........................................................................................................ 62

Step Functions soft keys ....................................................................................... 63

Program Steps soft keys ....................................................................................... 64

Clear Program soft key .......................................................................................... 65

Save/Discard soft key ............................................................................................ 65

Run Options soft keys ........................................................................................... 66

Program Saving...................................................................................................... 67

Saving a Program.............................................................................................. 67

5.2 Program Mode Functions

Program Type Filter ............................................................................................... 68

USB Access ........................................................................................................... 68

5.3 Creating programs overview

New Part Program ................................................................................................. 69

xiv

Page 15

6.1 Conversational Programming

Programming Considerations ................................................................................ 72

“From” and “To” points ................................................................................... 72

Depth of Cut ..................................................................................................... 72

Pass .................................................................................................................. 72

Tool Offset........................................................................................................ 73

Datum Selection ............................................................................................... 73

Absolute vs. Incremental Dimensions .............................................................. 74

Continuous Milling ............................................................................................ 74

Fundamentals for Creating a Program ................................................................... 75

Entering milling steps ....................................................................................... 75

Adding/Inserting milling steps........................................................................... 76

Editing or Deleting a milling step ...................................................................... 76

Program Errors.................................................................................................. 77

Program Edited ................................................................................................. 77

Running a Program ................................................................................................ 78

Skewing a Part.................................................................................................. 78

Establishing a Datum ............................................................................................. 80

Overview........................................................................................................... 80

Steps to Establish the datum............................................................................ 81

X Axis Datum: ................................................................................................... 82

Y Axis Datum .................................................................................................... 82

Z Axis Datum .................................................................................................... 82

Retract Z ........................................................................................................... 83

Using an electronic edge finder ........................................................................ 83

Setting the datum on an edge .......................................................................... 84

Setting the datum at the centerline .................................................................. 85

Setting the datum at the center of a circle ....................................................... 85

Test the Datum Setting..................................................................................... 86

Testing a MILLPWR

Single Step........................................................................................................ 88

Dry Run............................................................................................................. 88

Graphics Only.................................................................................................... 88

Machining Your Part .............................................................................................. 89

Potentiometer for Feedrate Override .................................................................... 90

Manually Positioning the Quill .............................................................................. 91

G2

Program ....................................................................... 87

6.2 Folders

Folder Functions .................................................................................................... 92

Folders .............................................................................................................. 92

Creating a Folder............................................................................................... 92

Naming a new folder......................................................................................... 93

Deleting a Folder............................................................................................... 93

Saving a Program.............................................................................................. 93

Naming a Program ............................................................................................ 94

Deleting a Program ........................................................................................... 94

ACU-RITE MILLPWRG2 xv

Page 16

Loading a MILLPWRG2 (MPT) Program ............................................................ 95

Importing a DXF drawing .................................................................................. 96

G-code Programs ................................................................................................... 97

Loading a G-code Program ............................................................................... 97

Running a G-Code Program .............................................................................. 98

Starting or Stopping a G-code Program ........................................................... 98

G-code and M-Code Definitions............................................................................. 99

G-code .............................................................................................................. 99

M-Code Definition........................................................................................... 103

Additional G-code Conventions for MILLPWR

G2

............................................ 106

Backing Up a Program ......................................................................................... 107

Copy and Paste programs............................................................................... 107

Program Errors................................................................................................ 108

7.1 Demonstration Program

Overview ............................................................................................................. 110

Selecting Datum ............................................................................................. 110

Begin Programming ............................................................................................. 111

Selecting A Tool.............................................................................................. 111

Programming a line......................................................................................... 112

Programming an Arc ....................................................................................... 113

Programming the connecting Line.................................................................. 114

Programming the lower vertical Line .............................................................. 115

Programming the lower angle Line................................................................. 116

Programming the upper angle Line ................................................................ 117

Programming a Blend ..................................................................................... 118

Closing the contour......................................................................................... 119

Tool Change for the Bolt hole Pattern ............................................................ 120

Programming the Bolt circle ........................................................................... 121

Tool Change for the Rectangular Pocket ........................................................ 122

Programming the Rectangular Pocket ............................................................ 123

Testing the Program ............................................................................................ 124

Graphics only .................................................................................................. 124

Dry Run with table movement........................................................................ 124

Running the Program........................................................................................... 125

Tool Changes ....................................................................................................... 126

Clearing the Program ........................................................................................... 126

xvi

Page 17

8.1 Milling and Drilling

Overview ............................................................................................................. 128

Selecting A Tool.............................................................................................. 129

Repeatable Tool Length Offsets.......................................................................... 131

Programming a Tool........................................................................................ 131

Changing to a Tool of unknown length in DRO mode .................................... 131

Changing to a Tool of unknown length in a program ...................................... 133

Position / Drill....................................................................................................... 134

Line ...................................................................................................................... 135

Arc ....................................................................................................................... 136

Blend/Chamfer..................................................................................................... 137

Rectangular Milling Functions.............................................................................. 140

Rectangle Pocket............................................................................................ 140

Tool Path Description:..................................................................................... 141

Rectangle Frame............................................................................................. 142

Rectangle Face ............................................................................................... 144

Rectangle Slot................................................................................................. 146

Circular Milling Functions..................................................................................... 148

Circle Pocket................................................................................................... 148

Circle Frame.................................................................................................... 150

Circle Ring....................................................................................................... 152

Circle Helix...................................................................................................... 154

Hole Patterns ....................................................................................................... 155

Row of Holes .................................................................................................. 155

Hole Frame and Array ..................................................................................... 157

Bolt Circle Patterns ......................................................................................... 159

8.2 Additional Milling Functions

Step Functions soft key ....................................................................................... 160

Explode ........................................................................................................... 160

Reverse Step .................................................................................................. 161

Reverse Path................................................................................................... 161

Change Steps.................................................................................................. 162

Shift Steps ...................................................................................................... 162

Delete Steps ................................................................................................... 163

Copy/Move Steps ........................................................................................... 163

Custom Pockets .................................................................................................. 164

Custom Pocket ............................................................................................... 164

Island............................................................................................................... 165

Tool Path Description for Custom Pocket, and Islands................................... 165

Contour ........................................................................................................... 166

Repeat, Rotate, ................................................................................................... 168

Repeat............................................................................................................. 168

Rotate ............................................................................................................. 168

Mirror .............................................................................................................. 169

ACU-RITE MILLPWRG2 xvii

Page 18

Other Steps ......................................................................................................... 169

Engrave Line ................................................................................................... 170

Engrave Arc .................................................................................................... 171

Comment Step ............................................................................................... 172

Dwell............................................................................................................... 173

Reference Point .............................................................................................. 173

9.1 Setup

Overview ............................................................................................................. 176

Setup .............................................................................................................. 176

Tool Table ....................................................................................................... 176

Error Log ......................................................................................................... 176

Job Setup............................................................................................................. 177

Job Setup........................................................................................................ 177

Scale Factor .................................................................................................... 178

Feed Rate ...................................................................................................... 178

Display: Peck\Pass.......................................................................................... 178

Job Clock - Parts Counter ............................................................................... 179

Probing............................................................................................................ 179

Display Grid..................................................................................................... 180

Travel Limits ................................................................................................... 180

Tool Table ............................................................................................................ 183

Error Log .............................................................................................................. 183

Service Files.................................................................................................... 184

10.1 Updating System Software

Software Update.................................................................................................. 186

Procedure for updating the software................................................................... 186

11.1 MILLPWR Off-Line Software

Off-Line Simulator................................................................................................ 188

System Requirements ......................................................................................... 188

Installation............................................................................................................ 189

Operation ............................................................................................................. 189

On Screen Keypad ............................................................................................... 190

Keyboard Shortcuts ............................................................................................. 190

Updating .............................................................................................................. 192

xviii

Page 19

Introduction

Page 20

1.1 MILLPWR

G2

The ACU-RITE MILLPWRG2 control is a workshop-oriented contouring

control that enables you to program conventional machining

operations right at the machine in an easy-to-use conversational

programming language. It is designed for milling and drilling machine

tools, with up to 3 axes.

MILLPWR

and die makers and other machinists where manual and automated

1.1 MILLPWR

operation are both useful and needed. MILLPWR

maximize your throughput by significantly reducing set-up time, scrap,

and other non-productive operations, thereby increasing your

efficiency, productivity and profitability.

The MILLPWR

productivity. The screen layout is clearly arranged in such a way that

the functions are easy to access, fast and user friendly.

MILLPWRG2 is a closed-looped system with positioning feedback

provided by ACU-RITE precision glass scales (1µm/0.00005"

resolution). MILLPWR

unique feature that enables you to easily, quickly and accurately

re-establish work piece zero after shutting down, or power loss.

G2

was developed to satisfy the wants and needs of tool

G2

has many powerful features that will improve your

G2

G2

will enable you to

G2

also includes Position-Trac™, an advanced,

ACU-RITE conversational, and G-code format

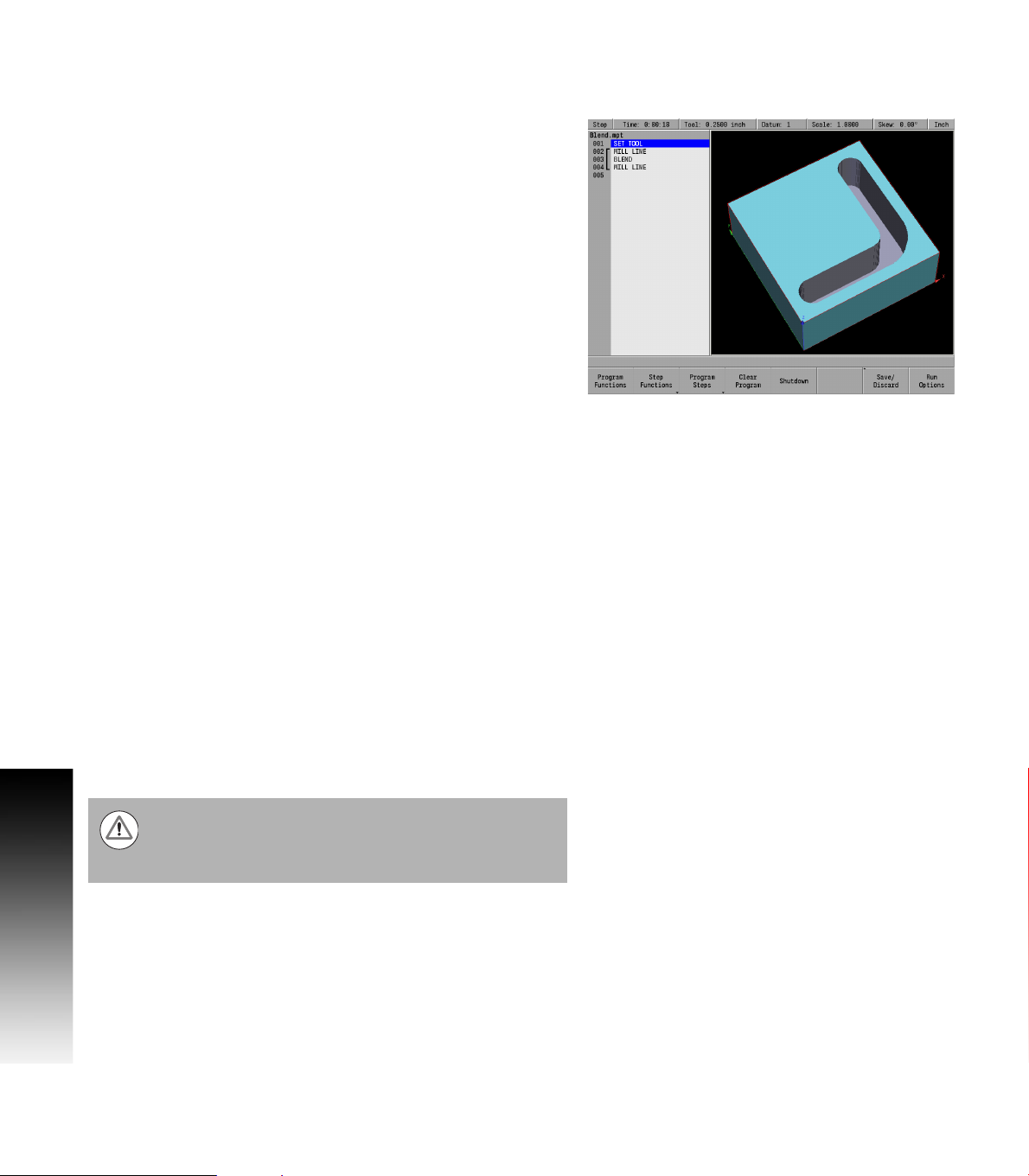

The ACU-RITE conversational programming format is a method of

writing programs; g-code (ISO) programming can be used, and run, but

can not be edited. Preview graphics in the editor illustrate the

individual machining steps for programming the contour as well as the

corresponding tool path generated. A production drawing does not

need to be dimensioned for NC programming, the MILLPWR

programmed using the dimensions directly from the production

drawing. The programming format is the same as used in previous

MILLPWR products. Always verify old programs before machining

with MILLPWRG2.

G2

can be

2 1 Introduction

Page 21

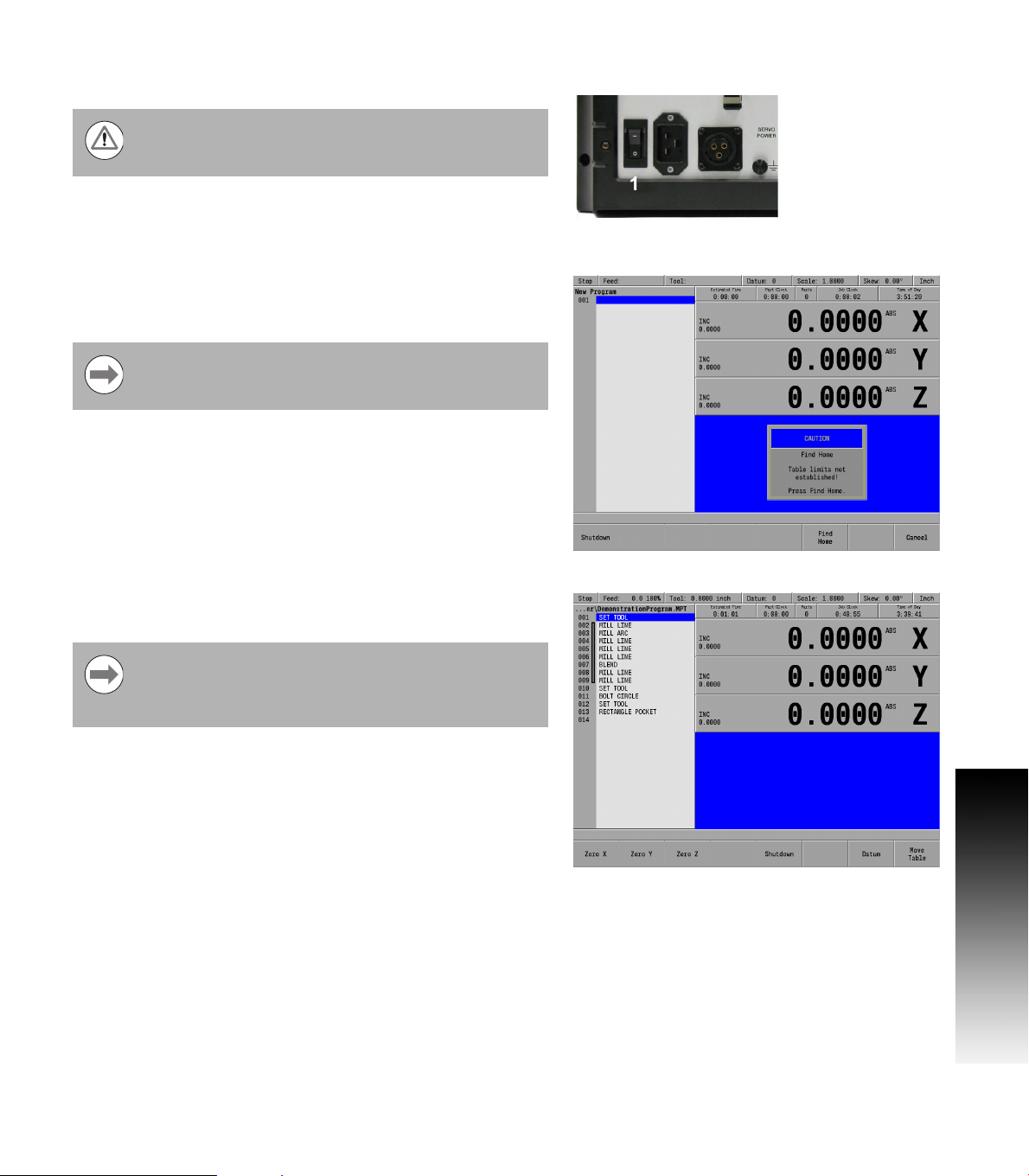

Powering Up

The MILLPWRG2 console does not disconnect the power

supply to the spindle motor. It can only be disconnected

by turning off the main power supply.

G2

Turn the power switch On [1], (to the I position) on the MILLPWR

console which is located on the back of the unit.

Follow the builder’s instructions to turn off the machine.

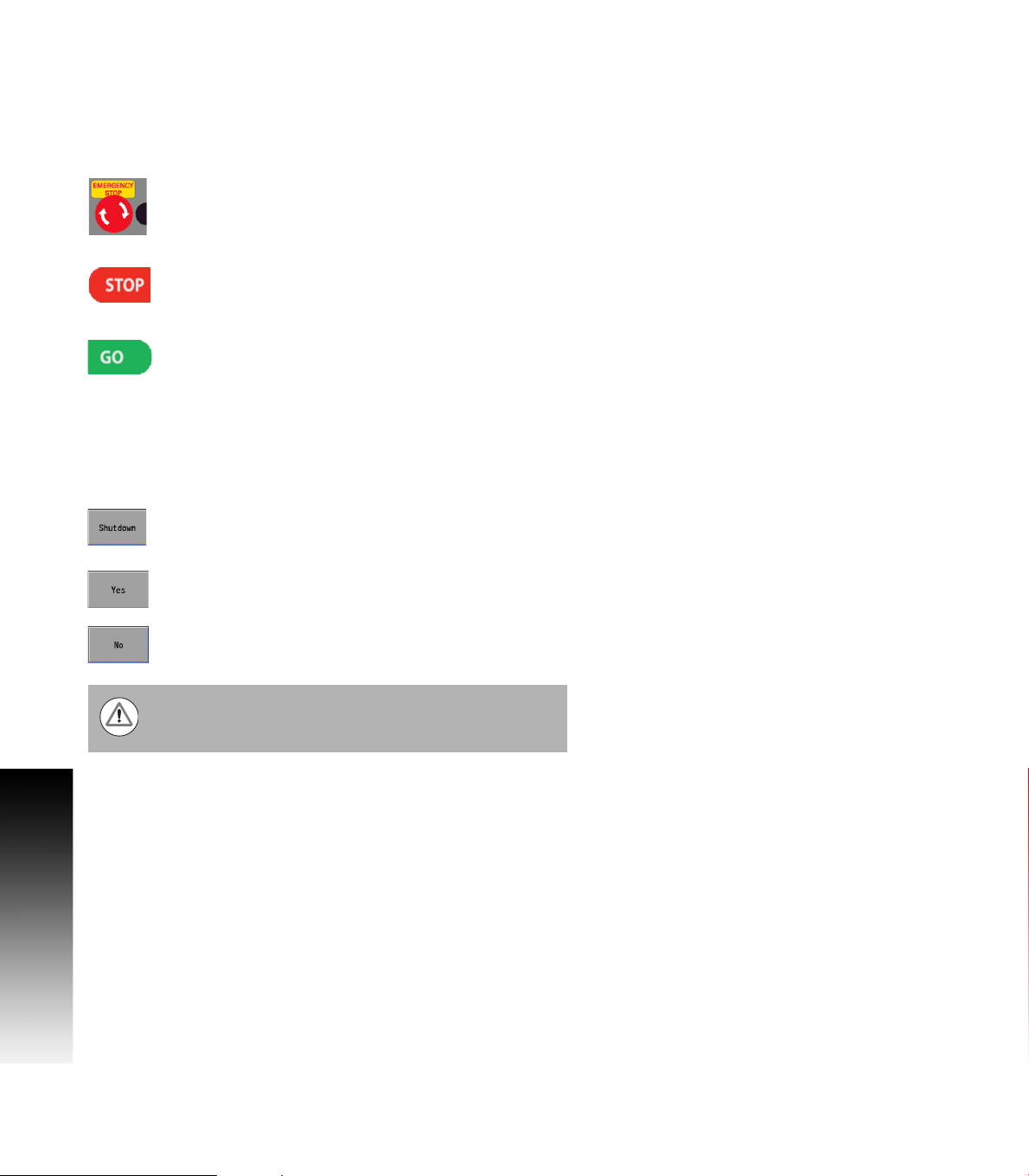

The start up screen with 3 soft keys will be displayed; Shut Down,

Find Home, and Cancel. After pressing either the Find Home, or

Cancel soft key, the default DRO screen will be displayed.

It is strongly recommended that the MILLPWRG2

performs the Find Home feature at start up, prior to any

other action taken.

If a program was loaded when the MILLPWR

same program will be reloaded when the unit is powered up again.

If the MILLPWRG2 did not perform the Find Home feature

at start up, press the Datum soft key from the default DRO

screen to display the Home soft key. Press the Home soft

key then the Find Home soft key will be displayed.

G2

was shut down, that

G2

1.1 MILLPWR

ACU-RITE MILLPWRG2 3

Page 22

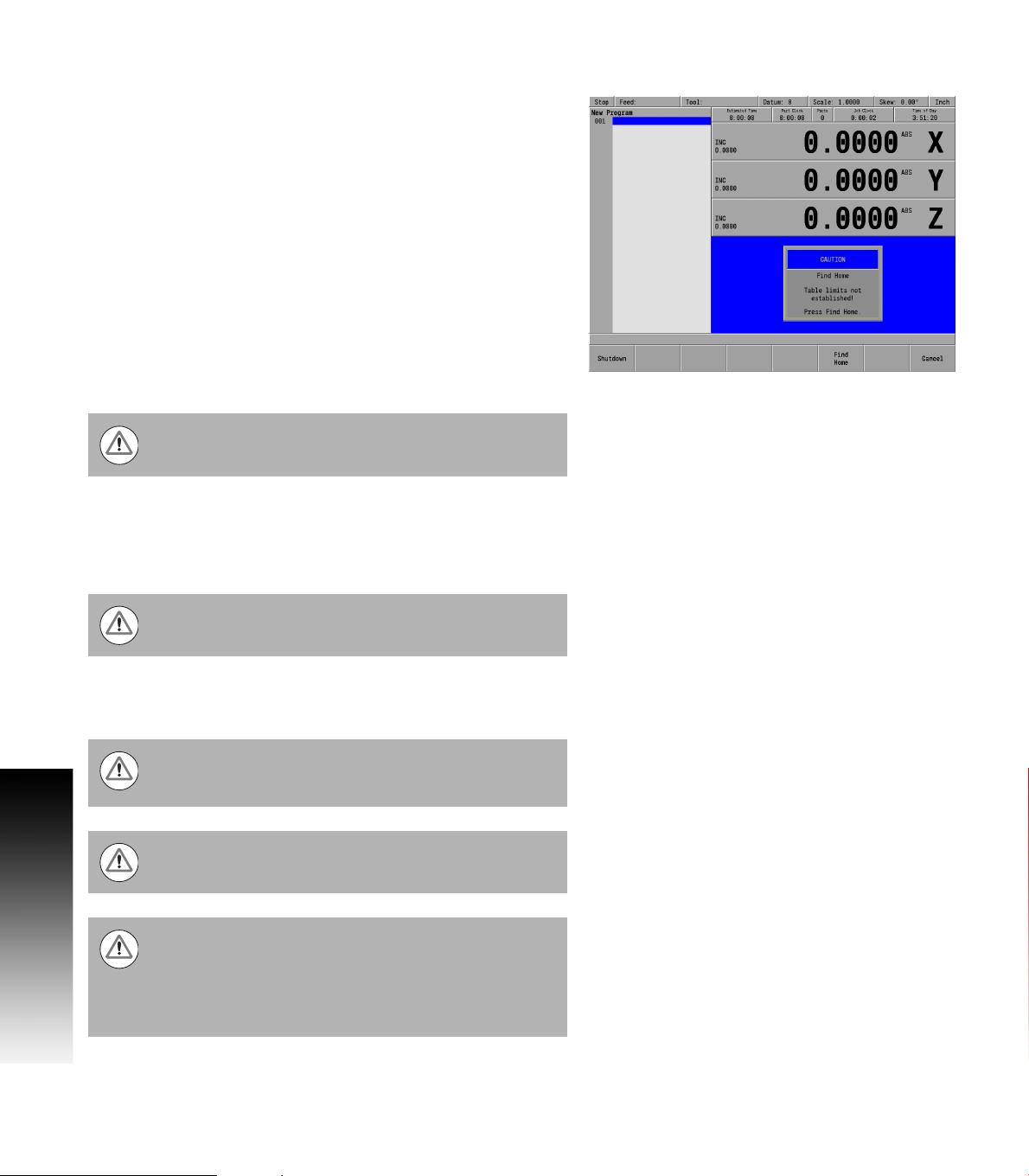

E-STOP and Shutdown

G2

The E-STOP is used for emergency program shut down by turning off

the servo motors. It does not shut down the spindle motor. The

spindle motor must always be manually stopped using the spindle

switch to stop the motor, and the cutting tool.

When the E-STOP button is pressed, the servo motors

are stopped, and the quill can be raised.

1.1 MILLPWR

When the STOP key is pressed once, the servo motors

pause, but are still active. All axes are locked, and can

not be moved.

The program can now either continue by pressing the

GO key, or stopped by pressing the STOP key a second

time.

If the STOP key is pressed a second time canceling the

program, the spindle motor must be stopped, and the

tool raised before moving any of the remaining axes.

Shutting down the MILLPWR

soft key.

Press the Shutdown soft key to shut down the

MILLPWR

DRO and PGM mode.

Confirm the shut down by pressing the Yes soft key.

G2

system is done by using the Shutdown

G2

system. This soft key is available in both

Press the No soft key to cancel and exit the shut down

procedure.

Always shutdown the MILLPWRG2 before turning power

off to the machine. Refer to the builder's instructions for

for additional information on turning power off.

4 1 Introduction

Page 23

Emergency Stop (E-STOP)

Press E-STOP to take all axes servos offline. This ends

all machine movement, and allows the quill to be

raised to move the tool out of the way.

To reset the E-STOP, turn the rotary switch clockwise in the direction

of the arrows. The switch pops outward, and is reset.

Resetting E-STOP does not reactivate the servos.

Activating/Resetting the Servos

For safety reasons, the mill powers up with the servomotors

disengaged. While the servos are disengaged the mill axes cannot

move under servo power. The axes can be manually positioned if

necessary.

Reset the servos as follows:

If a limit switch disengaged the servos, manually reposition the

machine inside its normal range of travel.

If a miscount occurs, press the Find Home soft key to reset the

servos and return all axes to their home position.

G2

1.1 MILLPWR

ACU-RITE MILLPWRG2 5

Page 24

Find Home

G2

You should find home before a program is run, or immediately after

startup.

During start up, the Find Home soft key is provided on the start up

screen soft key area.

If the find home step is not performed at initial start up, it can be

initiated at any time during operation. Press the Datum soft key, then

press the Home soft key, and then press the Find Home soft key.

A 3 axes system will move the table and quill. They will

1.1 MILLPWR

automatically move a few inches along the Z, Y, and then X to find

home. If a W axis exists (i.e. coupling knee to quill) then the control

will prompt you to move the W manually to home it.

A 2 axes system will move the table. The table will automatically

move a few inches along the Y, and then X to find home. Then the

control will prompt you to move the Z quill manually to home it. If a

W axis exists (i.e. coupling knee to quill) then the control will prompt

you to move the W manually also to home it.

Before finding home with a 2 axes system, the quill must

be fully raised first.

When finding home, the MILLPWR

with ACU-RITE glass scales), the Position-Trac™ distance-encrypted

reference mark line pattern. This line pattern allows MILLPWRG2 to

accurately find home and re-establish workpiece zero from any

position.

Finding home applies to the X, Y, Z, and W axes.

Position-Trac will accurately re-establish workpiece zero after power

loss, or shut down. After home has been found, the tool’s position

(relative to the most recent datum set) will be displayed.

Not finding home before moving the table will risk

exceeding the table's travel limits, and possible damage to

the machine, and the MILLPWRG2 system.

Programs will not be allowed to run if the homing process

does not complete successfully.

The Find Home soft key is not available if there is an error,

and the front panel LED indicator is flashing.

The error must be corrected, and then cleared from the

error log. Then homing is allowed.

Refer to Chapter 9 "Error Log" on page 183 for information

on opening the error log and deleting errors.

G2

will use (on machines equipped

6 1 Introduction

Page 25

Disengage Z Axis feature

MILLPWRG2 provides the flexibility to switch between 2 axes and

3 axes operation.

Disengaging the Z axis drive:

Leave the Z BEGIN field blank when programming a step, or a one

time milling operation.

Raise the quill, then loosen the quick release knob [1] on the front of

the the Z axis drive system.

When a program step, or milling operation is then performed, the

operator is prompted to manually position the quill.

Re-engaging the Z axis drive

Raise the quill handle to seat the ball screw into the nut block (e.g.

this would be similar to hitting a dead stop).

Tighten the quick release knob [1].

G2

1.1 MILLPWR

ACU-RITE MILLPWRG2 7

Page 26

Writing Programs

G2

Overview

The MILLPWR

write a program. For operations that repeat, or complex machining it

is best to write a program. Before writing a program, determine the

work-holding device and the location of Part Zero (the point to which

all movement is referenced). Since absolute positions are defined

from Part Zero, try to select a location that directly corresponds to

dimensions provided on the part print, such as the lower left corner of

the work. Then you can develop a program. The following is a general

1.1 MILLPWR

approach to programming:

First, select the unit of measurement (Inch/MM) using the MM key.

This will place the DRO in the required unit of measure, and all

dialogues will use the selection. If the selection is changed after

data has been entered, the MILLPWR

new unit of measure.

The first step in a program selects the tool that is to be used. It’s size

can be entered in either Inch or MM regardless of the unit of

measure selected in the DRO. The Tool dialogue provides fields for

data input for the tool position. This is a tool change position, a

location away from the work area where the axes can return for safe

tool changing. TOOL POSITION will use the unit of measure that has

been selected for the DRO.

The remaining steps in the program describe the required moves,

single cycles, and Tool changes to complete the machining.

The next to the last step in the program returns the axes to the Tool

change position and ends the program.

After writing a program, verify it. Run it to troubleshoot for errors.

Verify that all programmed moves are safe, and accurate to the part

print dimensions.

Setup the work piece into the intended holding device.

First run the program in Single-Step Mode to verify that both the

program and the setting of Tool Offsets are correct. Single-Step

Mode allows you to run the program step-by-step. Make any

necessary corrections. Once verified, the program can be run in

Auto Mode.

When the finished program is ready for production, back it up on a

USB memory device.

G2

allows many features to be used without having to

G2

will convert the data to the

If there is an interruption to the power supply, the program

is not lost. The program is periodically saved. Verify that

the most recent steps (prior to the power failure) are in the

program. The fixture zero location is also remembered.

8 1 Introduction

Page 27

1.2 Operating in 2 Axes and 3 Axes Modes

Overview

The MILLPWRG2 is capable of running a 2 axes machine (manual Z) or

a 3 axes machine with the Z being switched to manual as needed. This

User's Manual covers 2 axes and 3 axes operation. This section

provides some general guidelines. In 2 axes mode, all Z moves must

be made manually.

When running a program, the system will pause and provide a prompt

whenever a Z move is required.

The incremental DRO display will show the distance to the Z axis

target position.

Press the ABS/INCR key to toggle between absolute and incremental

display modes.

In incremental mode, a bar graph is displayed below each axis

position. A small blue indicator moves toward the center of the bar

as the incremental position approaches 0. When at 0, the blue

indicator will be centered.

After moving the Z axis to the programmed position, press the GO

key to continue running the program.

Program Steps in 2 Axis Mode

When running a program step in 2 axis mode, not all information in the

program step is used. Values may be programmed for Z Pass, Z Peck,

and Tool Retract, but they will not be used when running in 2 axis

mode.

When prompted to set Z, the incremental display will show the

distance to the Z end depth.

After drilling to depth, raise the quill and press the GO key to continue

running the program.

For pocket steps, raise the quill and press GO when prompted.

If an additional pass is needed for a step, press STOP to end

the program and run the step again.

It may also be necessary to repeat a set of steps for each

pass in a program.

ACU-RITE MILLPWRG2 9

1.2 Operating in 2 Axes and 3 Axes Modes

Page 28

Selecting 2 Axis Mode on 3 Axis Systems

To run a program in 2 axis mode, disengage the quill assembly

before pressing the GO key.

A prompt will appear indicating that the quill is disengaged.

If this is intentional, press GO and the program will run in 2 axis

mode.

To program a specific step to run in 2 axis mode:

Select POSITION for the Z operation type (drill steps).

For pockets, clear the Z begin depth field.

When the step is run, the Z axis servo motor will be turned off to

allow manual movement.

Follow all manual Z motion prompts. See "Tool Table" on

page 44 for a complete description about using the Tool

Table.

1.2 Operating in 2 Axes and 3 Axes Modes

10 1 Introduction

Page 29

1.3 Console

Operating Console

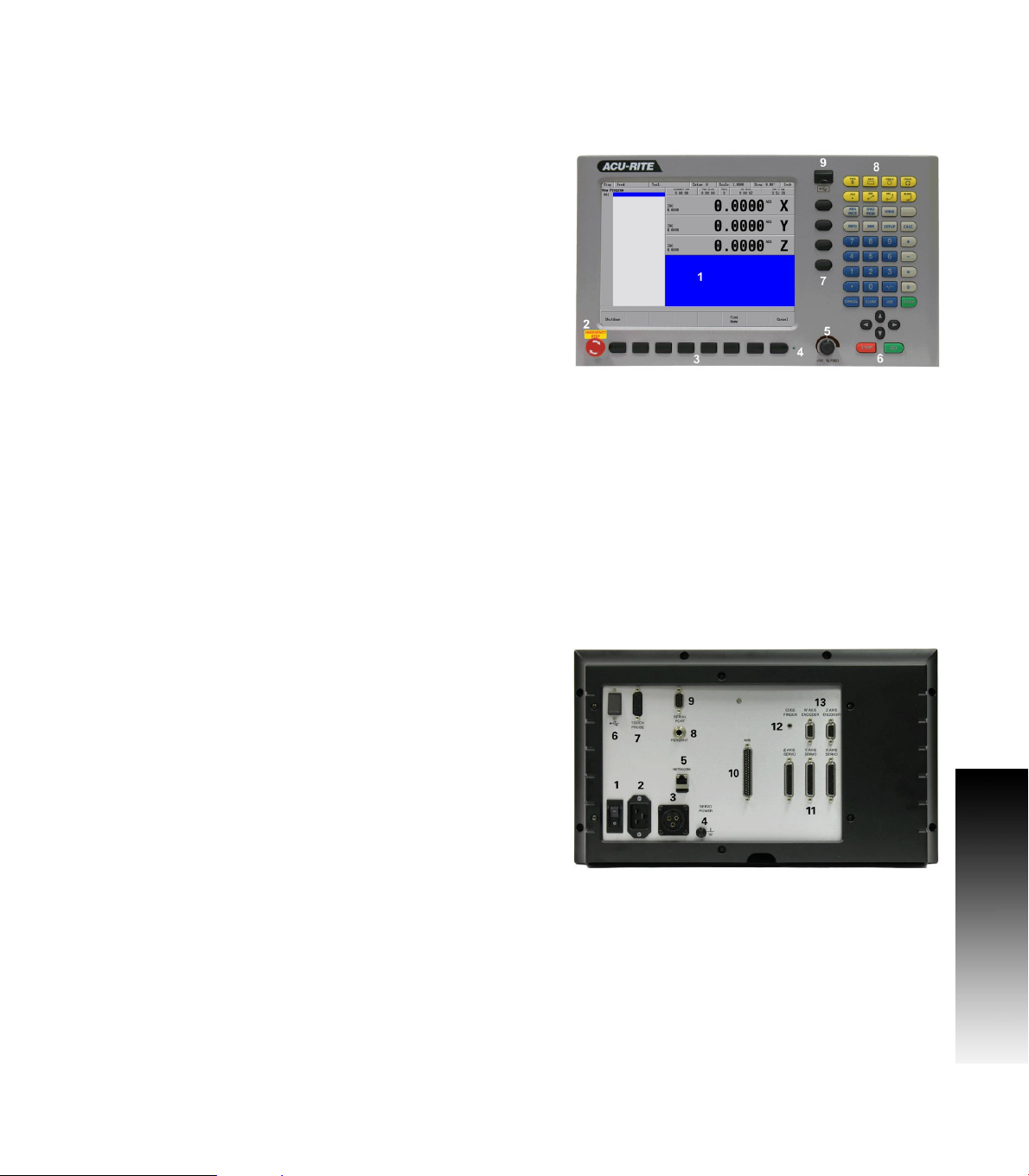

The ACU-RITE MILLPWRG2 Console has a 12.1-inch Flat-Panel Color

Screen Display. The following list of items are located on the front

panel.

See "DRO display screen" on page 21 for mapping information of the

start up screen.

See "Console Keypad" on page 20 for a full description of the console

keypad layout. The individual keys are fully described on page ii of the

inside front cover.

The following features are located on the front panel of the console:

1 Color flat panel screen display.

2 Emergency “E” Stop

3 Soft keys

4 Power On indicator light / Error indicator light

5 Potentiometer for feed rate override

6 Go, Pause/Stop, Navigation keys, and Move Table keys

7 Axis keys

8 Console keypad

9 USB Port

See "Calculator" on page 18 for a full description of the calculator

keypad.

1.3 Console

Rear Panel

The ACU-RITE MILLPWRG2 DRO rear panel has the following list of

items located on the panel.

1 Power switch

2 Power connector

3 Servo Power connector

4 Earth (ground) terminal

5 Ethernet port

6 USB port

7 KT 130 Edge Finder

8 Pendant (Remote switch)

9 RS-232-C connector

10 Auxiliary Machine Interface (AMI); for future expansion.

11 Servo connector (X, Y, and Z)

12 Grounding Edger Finder

13 Encoder Inputs (W and Z axis)

ACU-RITE MILLPWRG2 11

Page 30

Screen Navigation

The MILLPWRG2 display layout changes between DRO Mode and

PGM (Program) Mode by pressing the DRO/PGM key. The following

illustrates the differences between the two screen modes.

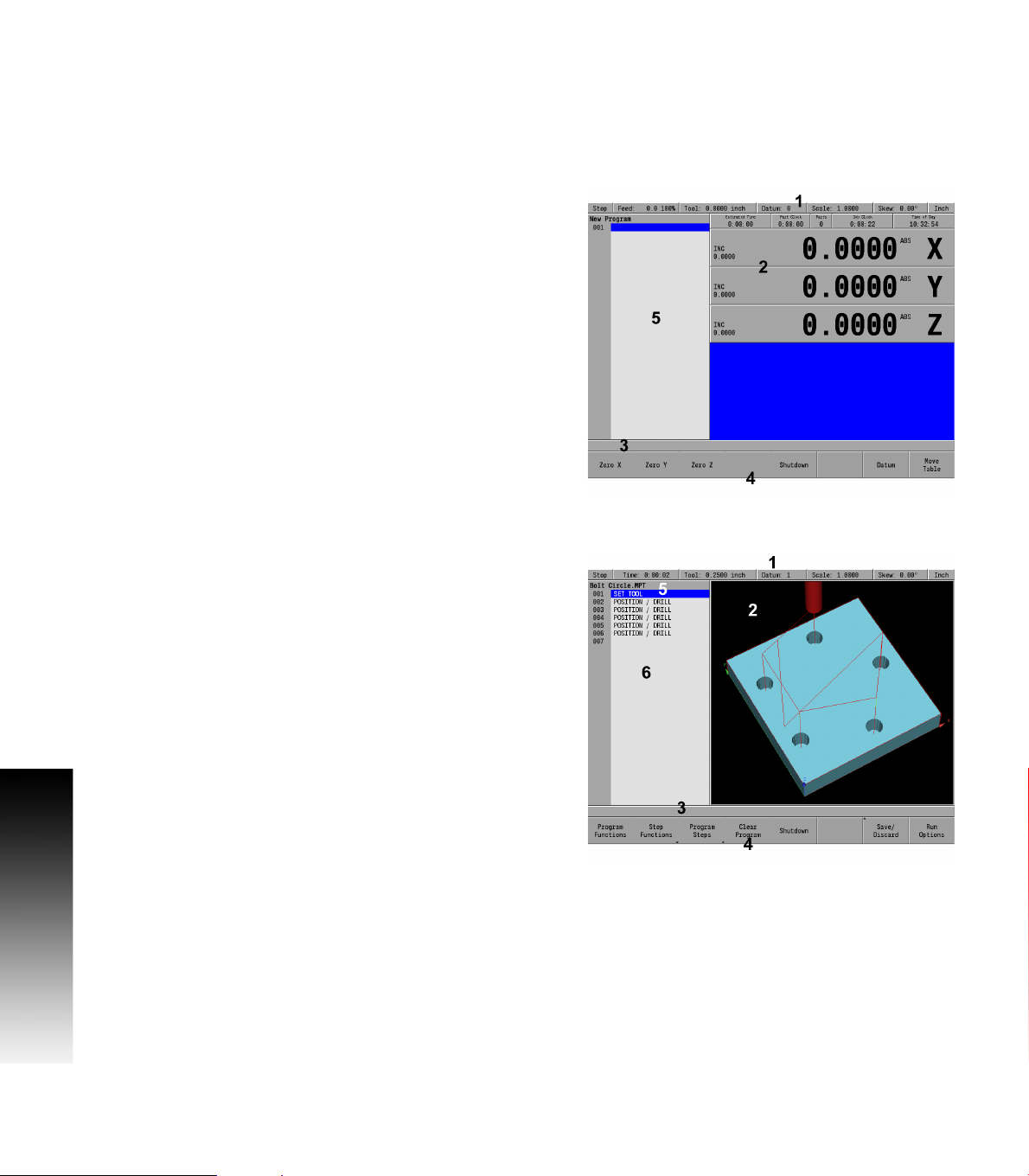

DRO Mode display

In general, the display changes as different functions are activated.

1.3 Console

Soft keys in the lower display area change per the function selected.

Soft keys perform their associated function by pressing the key

directly below it. Basic procedures and features remain the same

regardless of which mode is selected. For a complete description of

the display areas see "DRO Screen" on page 31.

1 Status Bar display for Servo Motor Status, Feed rate, Tool,

Datum, Scale, Skew, (Inch/MM), Estimated Time, Part Clock,

Parts (run), Job Clock, and Time of Day. See "Status Bar Display"

on page 32.

2 Axes Display (current position).

3 Operator Intervention Message line (OIM).

4 Soft keys display area.

5 Dialogue box display area for milling functions.

PGM Mode display

When PGM mode is selected, the display changes from DRO mode to

display program functions and graphics. Soft keys change to

programming functions. All soft keys are run by pressing the

corresponding hard key located directly below it. See "Status Bar

Display" on page 32 for complete descriptions.

1 Status Bar display for Servo Motor Status, Estimated Time, Tool,

Datum, Scale, Skew, (Inch/MM).

See "Status Bar Display" on page 32.

2 Display window of graph simulation.

3 Operator Intervention Message (OIM).

4 Soft keys display area.

5 Program name.

6 Program steps.

12 1 Introduction

Page 31

Dialogues, and Drop Down Menus

This manual provides complete information where specific examples

of actions are being explained.

As a general overview of the dialogues provided by the MILLPWR

several fields are likely to be provided for input. To navigate a dialogue,

use the ARROW keys to select the desired field. After entering the data

into a field, press either the ENTER key, or the UP or DOWN ARROW keys to

move to the next field. Exiting a field with one of these key methods

will retain the entered data in that field.

When the required data has been entered, press the USE key to accept

the data entered for use in that specific function.

Most dialogues contain Drop Down menus. Specific milling functions

may require additional information. The choices available are provided

in a drop down menu. In most cases, they are also provided as soft

keys. The choices can be selected from either location.

Operator Prompts

For actions that require immediate input to continue the operation an

operator prompt will be displayed by the MILLPWR

bar. The required data can be entered with the numerical keypad, and

in some instances using the alphanumeric on screen keyboard.

Cursor

The MILLPWRG2 uses a highlighted cursor to mark a field for selection

or editing. In some instances, the cursor will default to a field without

highlighting the field. Use the ARROWS keys to move the cursor. The UP,

and DOWN ARROWS move the cursor through the fields available. The

RIGHT ARROW will open a field that contains more choices, or subfolders

in the folder tree. The LEFT ARROW will close the menu, or subfolders.

The cursor will also change from a highlighted bar to a text cursor

when a field selected is having data entered.

G2

in the message

G2

,

1.3 Console

ACU-RITE MILLPWRG2 13

Page 32

General Operating Guidelines

General operating guidelines for the MILLPWRG2.

Additional operation soft keys are located in the soft key area along

with task selection, and dialogue. The soft keys change in relation

to the task being performed.

Selection of a particular soft key that requires additional information

1.3 Console

may open a popup menu [1].

A soft key may open a dialogue menu that requires input necessary

to continue with the operation selected.

The status bar in the top of the display is constant, and reflects only

what has been selected for the current program.

Use the Context Sensitive Help (INFO key) feature when assistance

is desired. This is an intuitive feature that aids the user by going

directly to the section in the manual in relation to the feature, or key

that has been selected to obtain assistance with.

14 1 Introduction

Page 33

Operating Modes

The MILLPWR

(Program). These are accessed from the front panel hard key. This is a

toggle key.

A USB pointing device e.g. mouse, trackball, etc. may also be used.

If a pointing device is being used, the action of clicking on a soft key

button is the same as pressing the corresponding soft key. A USB

keyboard can also be used for data entry and cursor control.

G2

has two main operating modes: DRO, and PGM

DRO mode shows the current position of each axis

relative to current datum. In DRO mode, manual

machining, and Single Cycles can be performed. Tool

selection, units, along with most setup features can

be accessed.

Program mode PGM, displays the list of program steps

and part-view graphics. New programs can be

created as well as editing existing programs.

Programs, new or existing, can be saved, deleted, or

copied using program functions.

1.3 Console

ACU-RITE MILLPWRG2 15

Page 34

Popup Menus

Within the soft keys, additional features may be available in program

mode. A soft key that has a down arrow in the lower right hand corner

indicates that additional soft keys are available for that feature.

As an example, pressing the Program Steps soft key (in PGM mode)

opens another set of soft keys available for this function. Then you will

notice an up arrow on most of the soft keys. This indicates a popup

menu will open when that key is pressed.

1.3 Console

Soft keys for PGM provide access to edit existing programs, or

create a new program. Sub menus provide dialogue for machining

operations such as milling a line, an arc, engraving, drilling and

creating pockets.

Pressing the required operation step soft key will open a popup menu

to further define the machining operation required.

A selection for a popup can occur in one of two ways:

Use the shortcut number to the left of the feature; for example,

pressing 9 on the numeric keypad will select the Circle Ring

dialogue.

Or use the Up and Down arrow keys to highlight the feature to be

used, then press ENTER.

When the type of machining operation has been selected, the

corresponding dialogue opens so that the required data can be

entered.

A dialogue in DRO mode will retain the previous data entered making it

possible to re-run the previous operation without having to re-enter all

the data.

At anytime when entering data into a dialogue the calculator can be

accessed by pressing the CALC key.

Soft keys for CALC provide access to additional math functions such

as trig functions.

When a dialogue is activated, it is not possible to change

to another dialogue. The current dialogue must be exited

by pressing USE to save the data in the dialogue or pressing

CANCEL to discard the data.

16 1 Introduction

Page 35

Keyboard

An on screen QWERTY keyboard will automatically popup when you

enter a field that requires text information input.

The keyboard becomes visible (popup) when text, and numerical

information is required for an action (e.g. saving a program, or

entering text for engraving).

Use the ARROW keys for navigation of the cursor to go to the desired

character and press ENTER to select the character.

When the information has been entered using the keyboard, press

the Save soft key. The keyboard will disappear from the screen. The

keyboard will also be removed from the screen when the CANCEL key

is pressed.

When using a USB keyboard, the on screen keyboard can be

disabled by pressing the Keyboard soft key. The on screen keyboard

will remain disabled untill it is enabled by pressing the Keyboard soft

key again. When the console goes through a power cycle, the key

board will retain its setting prior to the power cycle.

Special Characters

The keyboard also provides a “Special Characters” display which is

accessed by the “(#*\!...” key.

Arrow over to the “(#*\!...” key to highlight the key, and press the

the ENTER key.

1.3 Console

Navigational Soft keys

The following navigational soft keys are always available on the

keyboard.

The “Up Arrow” key switches the keyboard from

upper to lower case letter mode, or from lower to

upper case letter mode depending on the current

keyboard mode.

The “Abc” key switches the keyboard from the

special character key mode to the alpha numeric key

mode.

The “(#*\!...” key switches the keyboard from the

alpha numeric key mode to the special character key

mode.

ACU-RITE MILLPWRG2 17

Page 36

Editing Keys

The following keys are available for editing text on the keyboard.

The Copy key will copy the highlighted text in the text

field.

The Paste key will paste to the text field text that was

previously highlighted, and copied.

1.3 Console

The Clear key will remove all text in the text field.

The back space key will delete text in the text field one

character at a time.

Calculator

Numeric Keypad

The numeric keypad on the front of the console resembles a standard

calculator with keys for numbers 0 through 9, four math function

symbols (+, -, x, and ÷), a decimal point, and a positive/negative sign

(+/-).

The calculator is accessible from nearly any screen or

field. Press the CALC key to access the “stand-alone”

calculator. The math function soft keys are displayed

in the soft key area. Calculations can be entered

directly into a highlighted field.

Using the calculator in an entry field in a dialogue requires

the operator to press the ENTER key to run the calculation.

To move to the next field using the ENTER key requires the

operator to press ENTER a second time.

Anytime data is entered into an entry field in a dialogue

and the value is changed using the +/- key, the operator is

required to press the ENTER key to use the value change.

Moving to the next field using the ENTER key requires the

operator to press ENTER a second time.

18 1 Introduction

Page 37

Context Sensitive Help

The MILLPWRG2 uses an intuitive method to aid the user when

assistance is required. When assistance is needed with a feature, the

User Manual can be displayed directly at the point which describes the

feature.

To use this help, in this example, the console is in PGM mode, and a

Linear Engraving cycle is being programed. It is desired to see

descriptions of the cycle parameters, and the cycle itself. The

following steps describe the actions needed to take.

Using Context Sensitive Help

Press the INFO key to open the on screen User

Manual.

This will display a new window containing the section in the User

Manual, opened directly to the description of the desired feature.

This is the active window when Context Sensitive Help is activated.

To activate the Contents View on the left side of the display, press

the Contents View soft key. This allows the user to see all available

topics from the User Manual. The Forward and Back soft keys will

navigate the users previous history. The Previous Topic and

Next Topic soft keys will select the previous and next topic in the

manual contents (shown in the Contents View on the left hand side).

These soft keys allow the user to select other sections of the User

Manual while in Context Sensitive Help. Using these keys will

navigate the User Manual even if the Contents View is hidden.

The following describes the action, and use of the soft keys:

The Back soft key navigates one page back per key

press to a previous page that was viewed from the

history. History is not cleared when the Help Screen

is exited.

The Forward soft key navigates one page forward per

key press from the viewed pages in history.

The Previous Topic soft key navigates one Topic up

in the contents window per key press.

The Next Topic soft key navigates one Topic Down in

the contents window per key press.

The Contents View soft key is a toggle key to show/

hide the contents view on the left hand side of the

display.

To close, press the Exit soft key.

1.3 Console

ACU-RITE MILLPWRG2 19

Page 38

Console Keypad

The following keys are located on the console keypad. There is also a

quick reference guide located at the beginning of this manual on page

ii of the inside front cover.

1 Axis keys, use to select the required axis.

2 Numeric keys, use to enter numeric data.

1.3 Console

3 CANCEL key, use to cancel current action.

4 CLEAR key, use to clear selections such as values entered in a

field.

5 ARROW keys, use to navigate around the screen, and highlight

dialogue fields. Also used to move the table axes.

6 STOP key, use to pause, or stop a program that is running, or a

machine operation.

7 GO key, use to start, or resume a program.

8 USE key, use to complete an operation, i.e. data values entered in

a dialogue.

9 ENTER key, use to activate selections, and entries.

10 +/- key, use to toggle key for “Plus/Minus” data entry.

11 CALC key, opens the fully functional calculator.

12 Function keys, select appropriate key for quick access to the

function and data entry.

13 Milling function keys. Selection of appropriate key provides direct

access to the milling function dialogue.

20 1 Introduction

Page 39

1.4 Operating Mode Screens

Display navigation

The DRO mode is the default start up mode, and PGM mode can be

selected from the front panel key after start up. A condensed

description of these has been provided here on how to navigate, and

become familiar with the information that is being provided.

Complete descriptions, and details of these are provided later in this

manual, see "DRO Screen" on page 31.

DRO display screen

The MILLPWRG2 display screen provides the information required to

monitor the machine, it’s movement, programming, and more.

The default screen, or home screen, displays two main windows, and

soft keys in the soft key display area. When the console is first turned

on, the unit defaults to this screen. See "Screen Navigation" on page

12.

The DRO screen displays information per the current operation. DRO

mode allows the use of the milling function keys, or can be used as a

DRO in manual machining operations.

The system Shutdown soft key is located here as well as in PGM mode.

1.4 Operating Mode Screens

ACU-RITE MILLPWRG2 21

Page 40

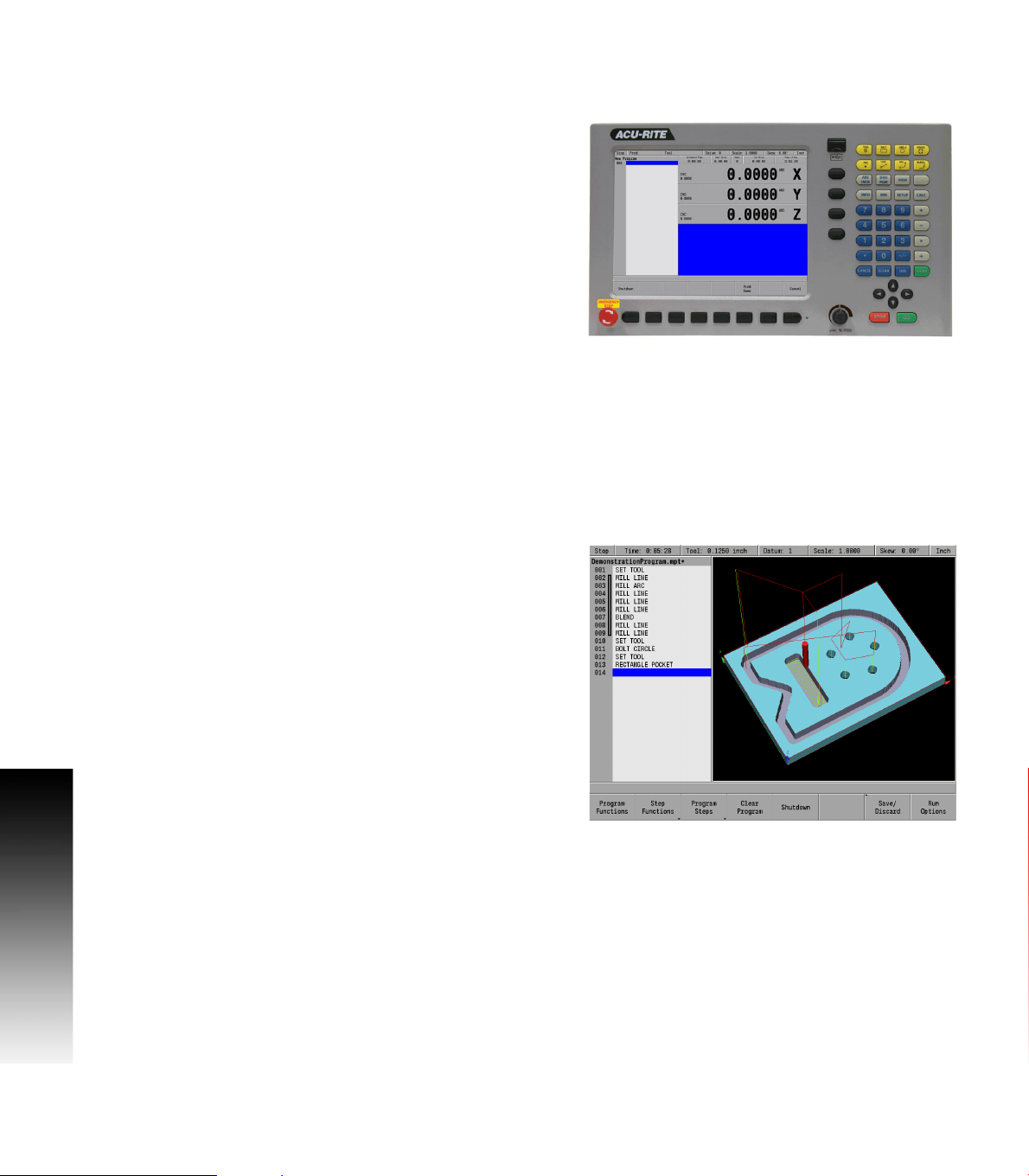

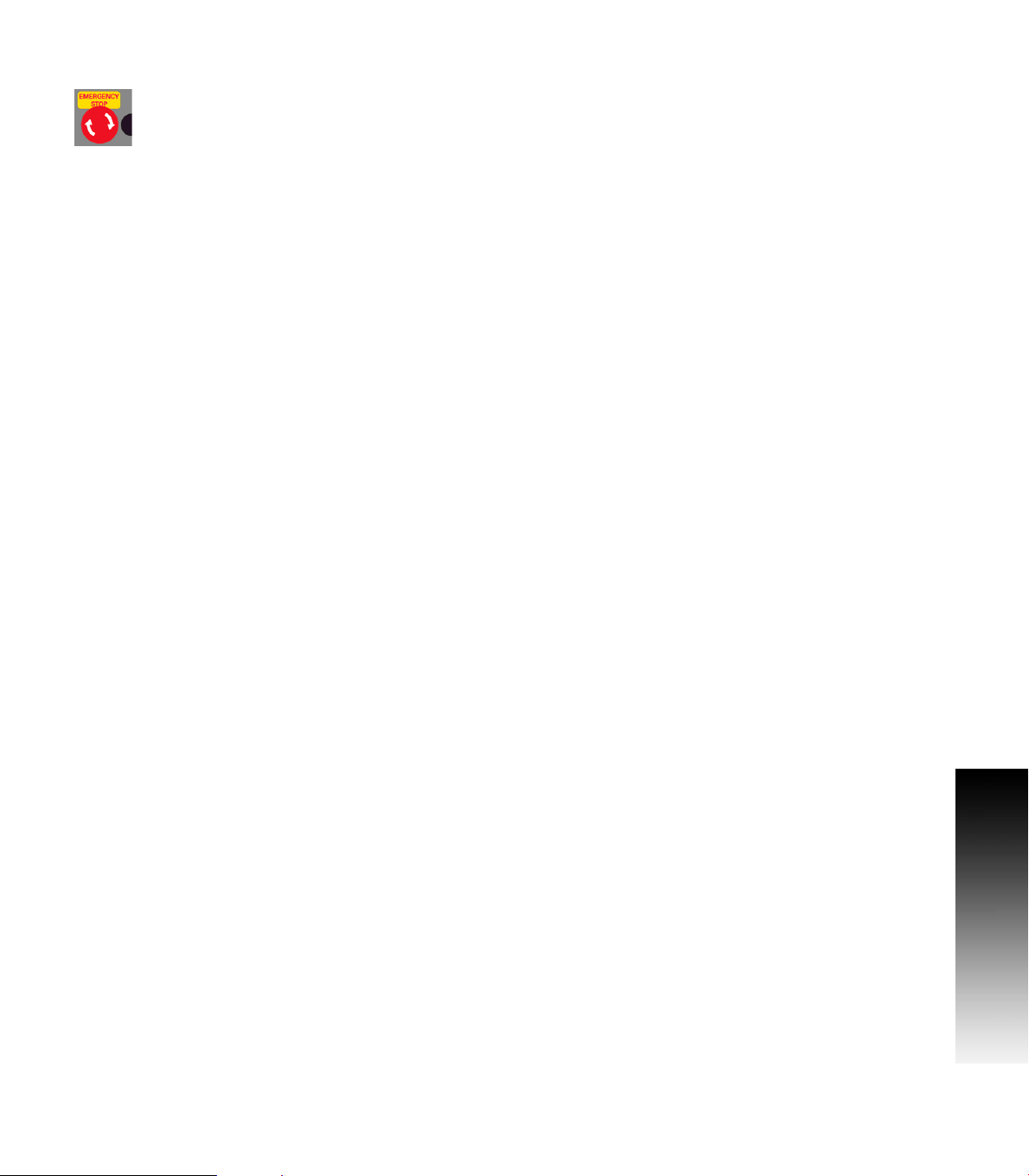

Program Display Screen

From the DRO mode, press the DRO/PGM key, and the

display changes to program mode showing the

currently selected or loaded program.

When Programing a job, the display activates a graphic view of the

program. While the program is running, the operation that is being

performed is graphically shown as well. The VIEW key provides

features to configure the graphic area.

For more information, see "Program Function Screen" on page 55.

1.5 Accessories

1.5 Accessories

Electronic Edge Finder

The Electronic Edge Finder KT 3D enables the ability to teach

positions, find the center point of a circle, or locate datum (work piece

zero) by touching off on the part. Advantage of an electronic edge

finder is that it instantly senses when contact is made with the point

(even if the axis over traveled).

22 1 Introduction

Page 41

Machining Fundamentals

Page 42

2.1 Conventions

Axis Conventions

Count Direction

When programming a part using MILLPWR

tool movement are determined by the use of positive or negative

numbers. MILLPWR

positive and negative count directions for the X, Y and Z-axes:

2.1 Conventions

X axis

The table will move to the left and the tool will move to the right for

a positive count direction.

Y axis

The table will move toward you while the tool moves away from you

for a positive count direction.

Z axis

The quill will move up (away from the table surface) for a positive

count direction.

G2

has been factory set with the following

G2

, table movement and

Cartesian Coordinates

A cartesian coordinate is a position that can be measured from the

X- and Y-axes.

Polar Coordinates

A polar coordinate is a position that is defined by an angle and a

radius.

24 2 Machining Fundamentals

Page 43

Absolute and incremental work piece positions

Absolute work piece positions

Absolute coordinates are position coordinates that are referenced to

the datum of the coordinate system (origin). Each position on the work

piece is uniquely defined by its absolute coordinates.

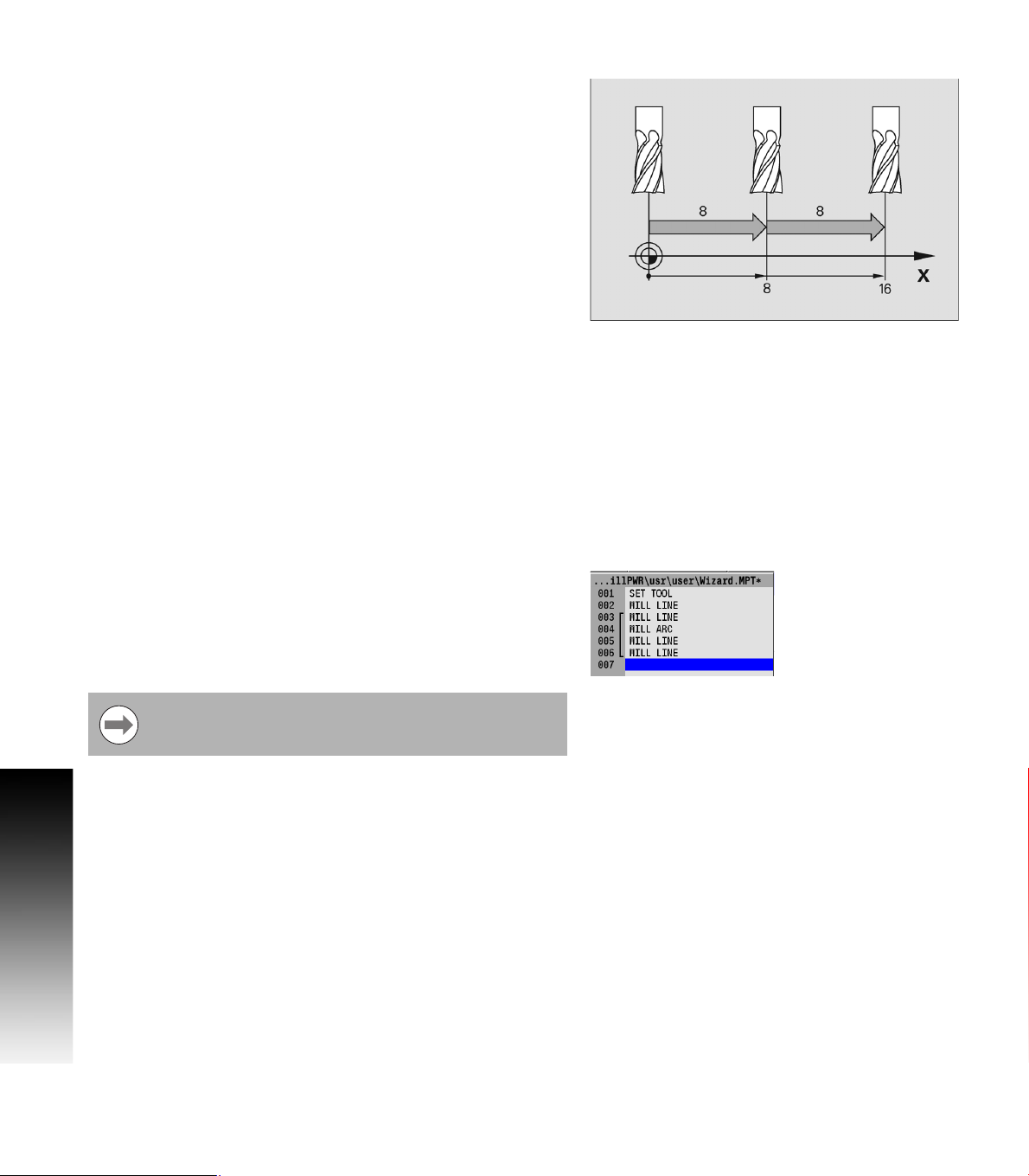

Example 1: Holes dimensioned in absolute coordinates

Hole 1 Hole 2 Hole 3

X = 10 mm X = 30 mm X = 50 mm

Y = 10 mm Y = 20 mm Y = 30 mm

Incremental work piece positions

Incremental coordinates are referenced to a previous step within the

program, which serves as the relative (imaginary) datum. When you

write a part program in incremental coordinates, you thus program the

tool to move by the distance between the previous and the

subsequent nominal positions. Incremental coordinates are therefore

also referred to as chain dimensions.

Example 2: Holes dimensioned in incremental coordinates

Absolute coordinates of hole 4

X = 10 mm

Y = 10 mm

Hole 5, with respect to 4 Hole 6, with respect to 5

X = 20 mm X = 20 mm

Y = 10 mm Y = 10 mm

2.1 Conventions

ACU-RITE MILLPWRG2 25

Page 44

Setting the datum

Overview

Datum is the workpiece zero or absolute zero, and is a point of

reference that the MILLPWR

from.

A datum must be established for every job. Datum's location may be

indicated on the print; or the operator may establish a datum that

allows most of the part's dimensions be entered directly using the

least amount of calculations.

2.1 Conventions

When establishing datum, it may be easiest to locate a known point

on each axis, such as the corner of the part, or a location on a vise or

fixture.

Datum can be set at a point on the top surface, a position beneath the

surface, or at a point where there's no material present (such as in the

center of a circular part). Touching off the edge of a work piece using

a tool, or an edge finder can be used when establishing a datum. See

"Steps to Establish the datum" on page 81.

G2

bases all of the part's coordinates

26 2 Machining Fundamentals

Page 45

2.2 Manual Machine Positioning

Move Table

Non Cutting Mode

You can make or change jog moves when in DRO mode with the servos

on.

Jog Mode Description

Rapid Default rapid speed for continuous jogs. Actual

speed determined at machine setup, and can be

over ridden using the potentiometer.

Jog: 0.1 Conventional Jog increment set at 0.100”.

Jog: 0.01 Conventional Jog increment set at 0.010”.

Jog: 0.001 Conventional Jog increment set at 0.001”.

In mm units the jog increment is 20 microns, 200 microns and 2000

microns respectively.

Changing the Mode

Jog move modes are performed at the currently active feedrate. The

active Jog is selected by pressing the appropriate soft key, then

pressing the appropriate ARROW key to move the table in the direction

required. The up and down arrows move the table in the Y axis. The