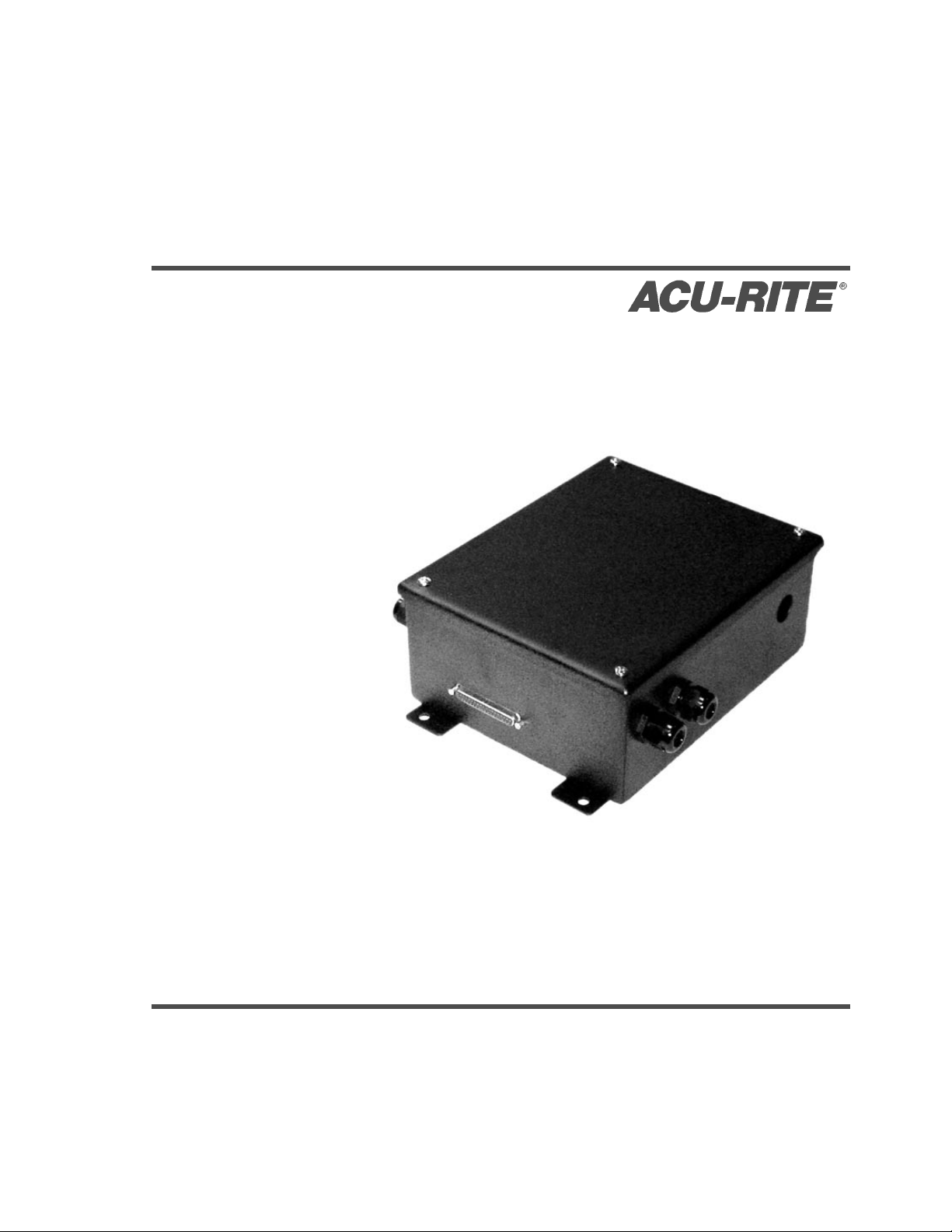

Page 1

REFERENCE MANUAL

A

UXILIARY MACHINE INTERFACE

Page 2

Limited Warranty

The ACU-RITE Auxiliary Machine Interface (AMI) has a limited warranty against

defects in material and workmanship for a period of one (1) year from the original

date of purchase.

ACU-RITE will, at its option and expense, repair or replace any component(s) of

the Auxiliary Machine Interface in question which fails to satisfy this warranty

provided that ACU-RITE shall have received notice of the claimed defect(s) during the limited warranty period.

The limited warranty covers all components and accessories and applies only to

those Auxiliary Machine Interface products which have been installed and operated in accordance with the instructions in the Auxiliary Machine Interface reference

manual(s). ACU-RITE shall have no obligation with respect to any defect(s) or

other condition(s) caused in whole or in part by the end user’s abuse, incorrect use,

improper maintenance, misuse, modification of the product(s), or by the repair or

maintenance of such product(s) by any person except persons deemed qualified to

do so by ACU-RITE.

Responsibility for loss in operating performance or other conditions beyond

ACU-RITE’s control cannot and will not be accepted by ACU-RITE.

The foregoing limited warranty obligations are in lieu of any and all expressed

and/or implied warranties of fitness or merchantability or otherwise, and state

ACU-RITE’s entire liability and the end user’s exclusive remedy, under any circumstance, for any claim of damage.

Page 3

AMI Reference Manual

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

AMI System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Connector Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Input Devices (J2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Output Devices (J18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

AMI Output Device Overview . . . . . . . . . . . . . . . . . . . . . . . 9

Emergency Stop Inputs (J4) . . . . . . . . . . . . . . . . . . . . . . . . . 13

Emergency Stop Output (J17). . . . . . . . . . . . . . . . . . . . . . . . 16

AMI Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting to

MILL

PPWWRR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

General Wiring Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting to a Power Source . . . . . . . . . . . . . . . . . . . . . . . 21

AMI Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Programming Auxiliary Output Devices Wired to J18

(Aux. 1-4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Motor Assembly Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

AMI Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table of Contents

2003-704 Ed D

This symbol alerts you to important information

concerning the installation and/or operation of the

Auxiliary Machine Interface (AMI).

Read these instructions carefully and place them in a

safe and convenient location for future reference.

Page 4

AMI with Spindle Control Reference Manual

1

Introduction

This manual discusses how the Auxiliary Machine Interface (AMI) system works

in conjunction with the ACU-RITE

®

MILLPWR

®

system.

Preparation

Read and understand all instructions in this manual before beginning the installation. Each item has an overview section which will explain their capabilities

and will help ensure that each system is installed properly.

Before you begin, ensure the location where you are planning installation, can

fully support the power supply requirements that are identified in the Electrical

Specifications section at the end of this manual.

Tools

A typical AMI installation will require the following tools:

• Small, flat-tipped screwdriver

• Wire stripper

• Size “F” drill (0.257" diameter)

• 5/16"-18 tap

Page 5

AMI Reference Manual

2

Components

There are two types of AMI systems currently available from ACU-RITE.

One supports 115 volts and the other one supports 230 volts of power. Both

AMIs include a cable for connecting the system to MILLPWR. The 115V AMI

also includes a cord for connecting the system to a

MILLPWR servo motor.

230V AMI

Interface Cable

(included with both

types of AMI)

115V AMI

(includes power cord)

Page 6

AMI Reference Manual

3

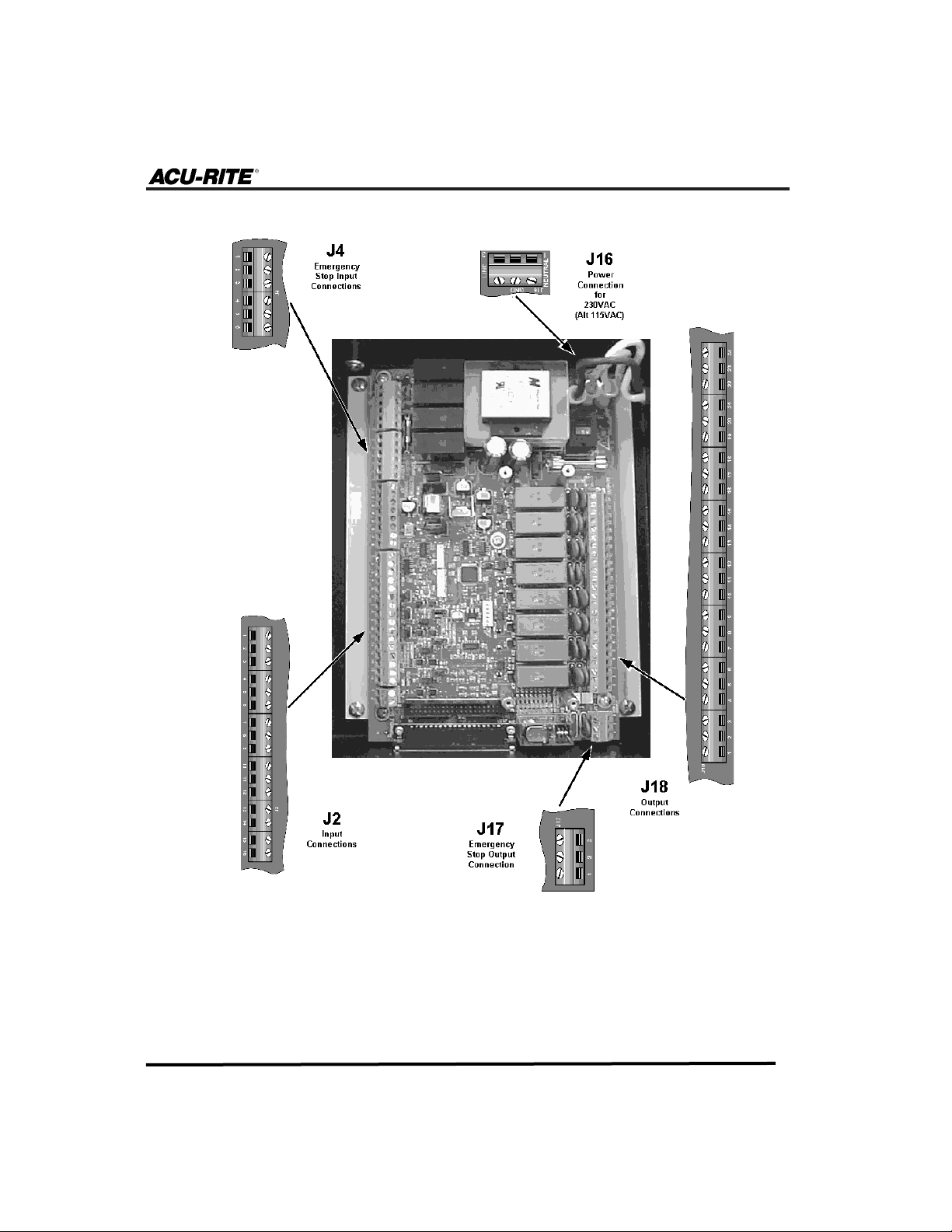

AMI System Overview

The following is a quick reference guide with each connectors name, the page

where its description appears, and their most common uses. Figure 1 on the next

page shows all connector locations.

There are five connectors available. Four of them are to be used for multiple

applications, while the J16 is limited to wiring an external 230V/115V AMI to a

power source. Always identify the correct connector for your particular application and read its description in its entirety before beginning the wiring procedure.

Device Input J2 (refer to page 5):

• Monitor the position of machine guards

• Monitor the oil level of automatic lubrication systems

• Remote Go Input

Device Output J18 (refer to page 8):

• Control up to four devices (i.e., coolant pumps and rotary indexers)

• Activate external devices during hole patterns and position/drill

steps

Emergency Stop Input J4 (refer to page 13):

• Add table limit switches to the emergency stop circuitry

• Add an emergency stop button to the emergency stop circuitry

Emergency Stop Output J17 (refer to page 16):

• Add other controls to the emergency stop circuitry

Power Input J16 (refer to page 21):

• For use with 230V systems or with an alternate 115V power

source—connects AMI to a power source

Connector Descriptions

Page 7

AMI Reference Manual

4

Fig. 1

Page 8

AMI Reference Manual

5

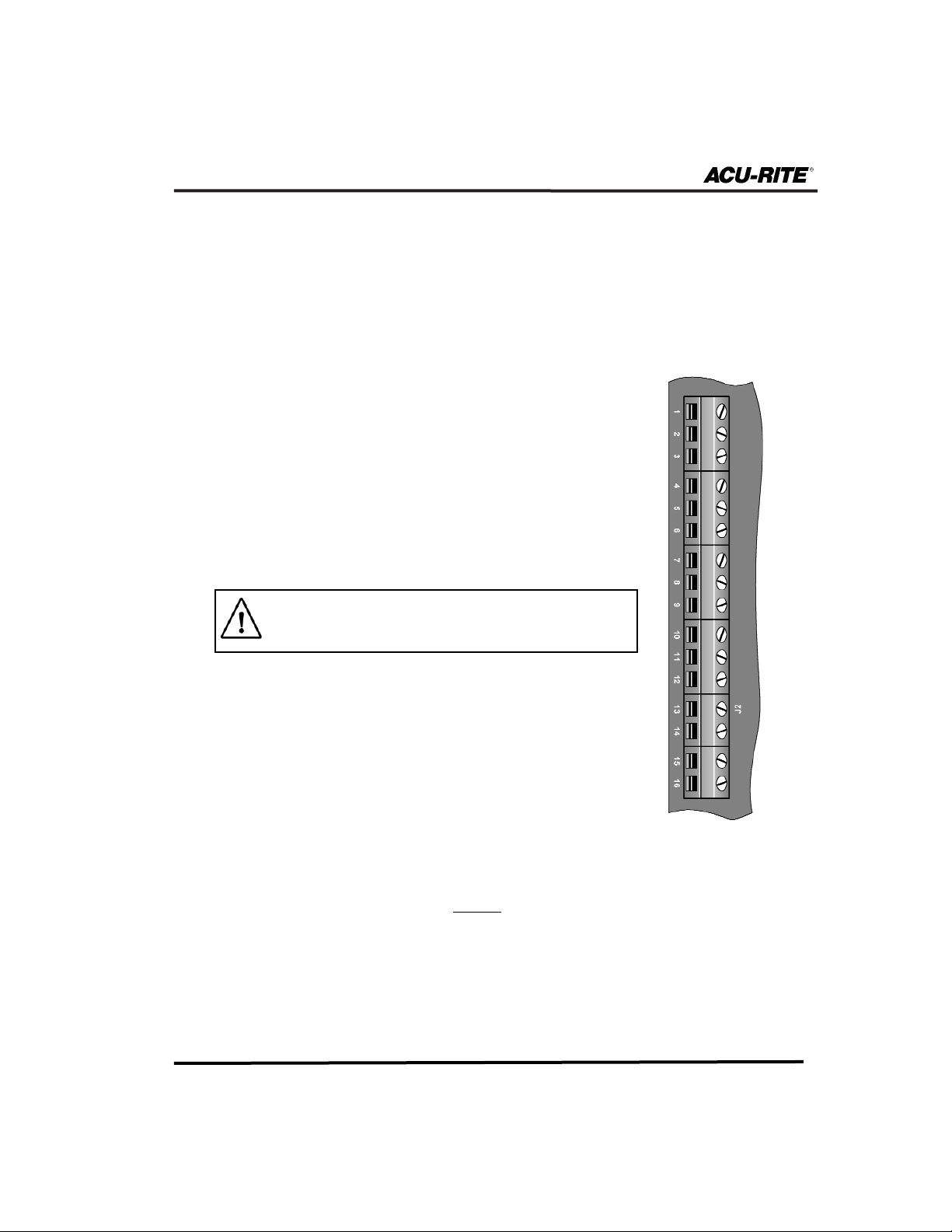

Input Devices (J2)

The J2 input connector is commonly used to:

• Monitor the position of machine guards

• Monitor the oil level of an automatic lubrication system

• Remote Go Input

Do not apply power directly to the AMI

input pins.

Connector Definitions

Machine Guards are safety features that will alter the

activity of certain program functions when they are open.

When guard switches are open:

1) Find Home feature cannot be initiated.

2) Single Cycle cannot be run.

3) A program cannot be run.

4) The table is still able to be moved.

If the guard switches are opened during

these operations:

1) Find Home feature will be aborted.

2) The program currently operating will pause and the table will stop

moving, but the program will not be aborted.

3) Single Cycle will pause.

Table 1 (J2)

Pin #

Description

9

10

11

12

13

14

15

16

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Not active

Pin #

Description

1

2

3

4

5

6

7

8

Machine Guard input

Machine Guard input

Low Oil input

Low Oil input

Remote Go input

Remote Go input

Not active

Not active

Page 9

AMI Reference Manual

6

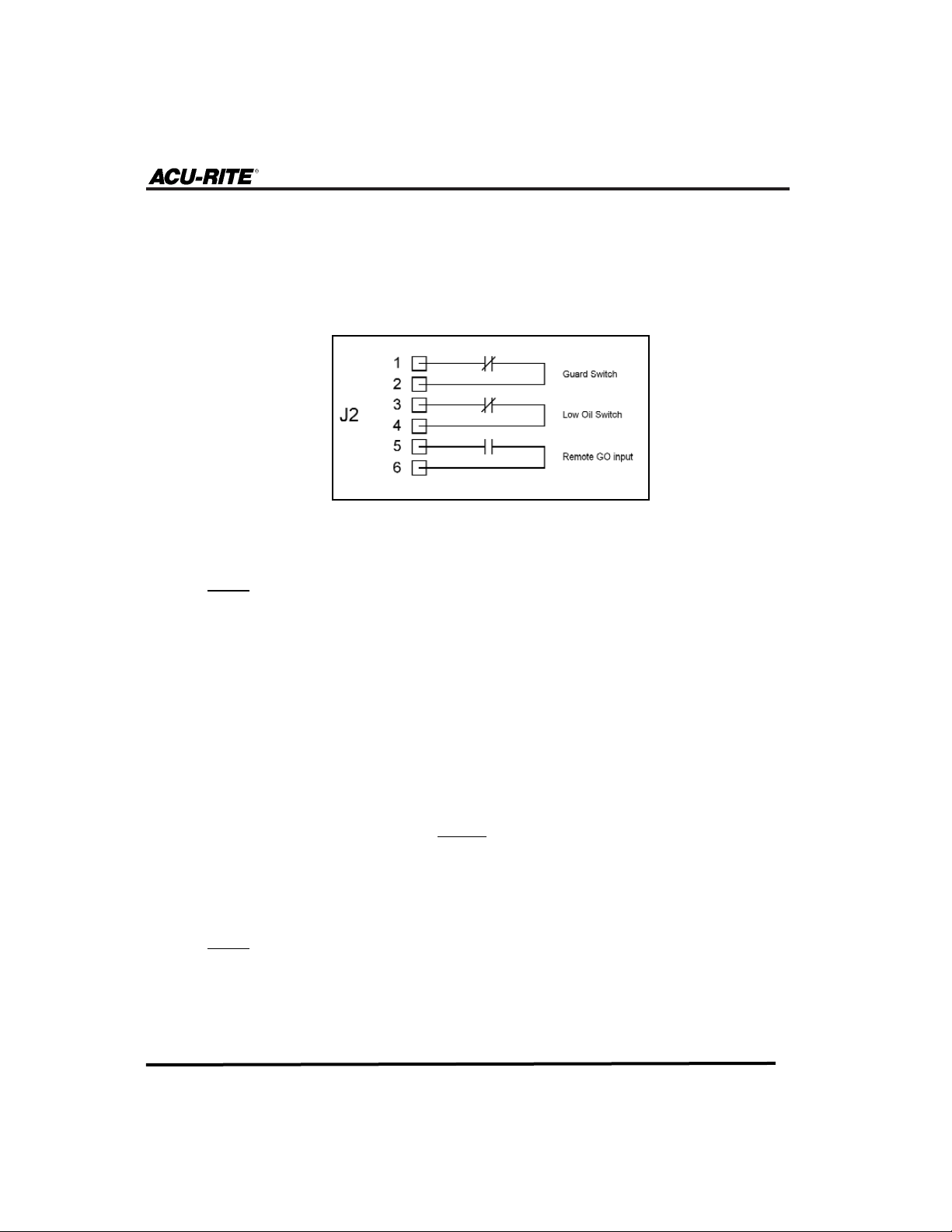

Figure 2 shows a typical wiring diagram for machine guards. As the diagram illustrates, the machine guard switch should be wired to pins 1 and 2.

When the machine guard switches are open, the contacts to those pins will

open, and an Operator Intervention Message (OIM) message will appear on

the MILLPWR screen.

Note:

If guards are not used then pin 1 and pin 2 of J2 must be

jumpered.

Low Oil is a safety feature that will, under certain conditions, stop program

functions when the lubrication pump supply reaches a certain minimum level

of oil. The normally closed low oil switch should be wired to pins 3 and 4.

When the low oil switch opens:

1) Find Home, Move Table, Single Cycle and all program functions

cannot be initiated.

If the low oil feature activates during

these operations:

1) Find Home and Move Table functions will be aborted.

2) Single Cycle and program functions will complete their current

path and then pause.

Note:

If a low oil sensor is not used, then pins 3 and 4 must be

jumpered.

Fig. 2

Page 10

AMI Reference Manual

7

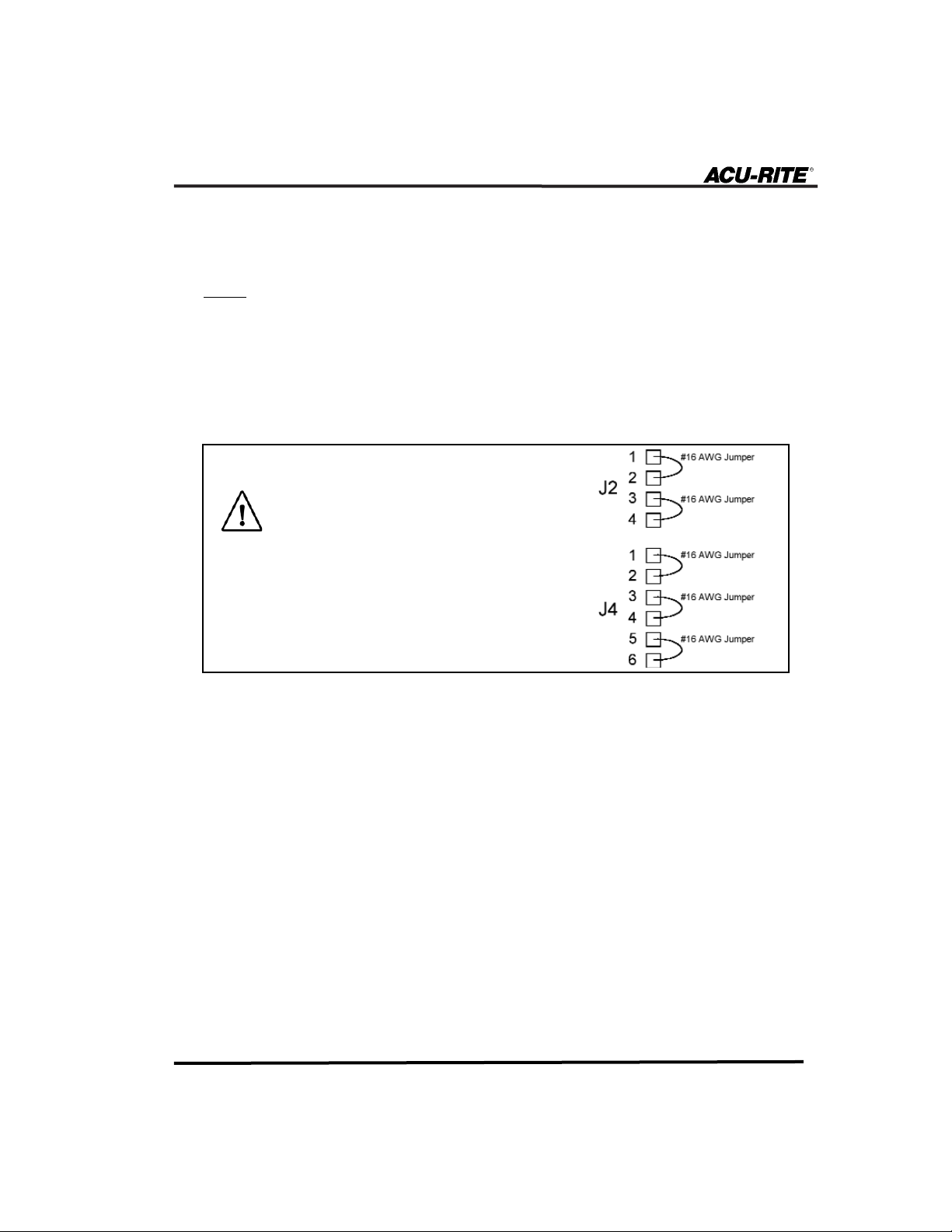

If you are not using the J2 or J4 connec-

tor on the AMI, you must wire a jumper

at this time to close the circuitry.

Otherwise, when you power on

MILLPWR

and the AMI, an emergency stop condi-

tion will automatically occur and

neither system will run.

Remote Go provides a switch input that can be used in place of the operator

pressing the

GO key. Pins 5 and 6 (J2) are reserved for this function.

Note:

The Remote Go input signal must be held for a minimum of

0.2 seconds in either ON or OFF mode in order for it to be recognized by the AMI.

Page 11

AMI Reference Manual

8

Output Devices (J18)

The J18 output connector is commonly used to:

• Control up to five devices (i.e., coolant pumps and rotary indexers)

from within a MILLPWR program.

• Activate external devices during hole patterns and position/drill

steps.

Common relay contact

Normally Open relay contact

Normally Closed relay contact

Common relay contact

Normally Open relay contact

Normally Closed relay contact

Common relay contact

Normally Open relay contact

Normally Closed relay contact

Common relay contact

Normally Open relay contact

Normally Closed relay contact

Common relay contact

Normally Open relay contact

Normally Closed relay contact

Common relay contact

Normally Open relay contact

Normally Closed relay contact

Common relay contact

Normally Open relay contact

Normally Closed relay contact

Common relay contact

Normally Open relay contact

Normally Closed relay contact

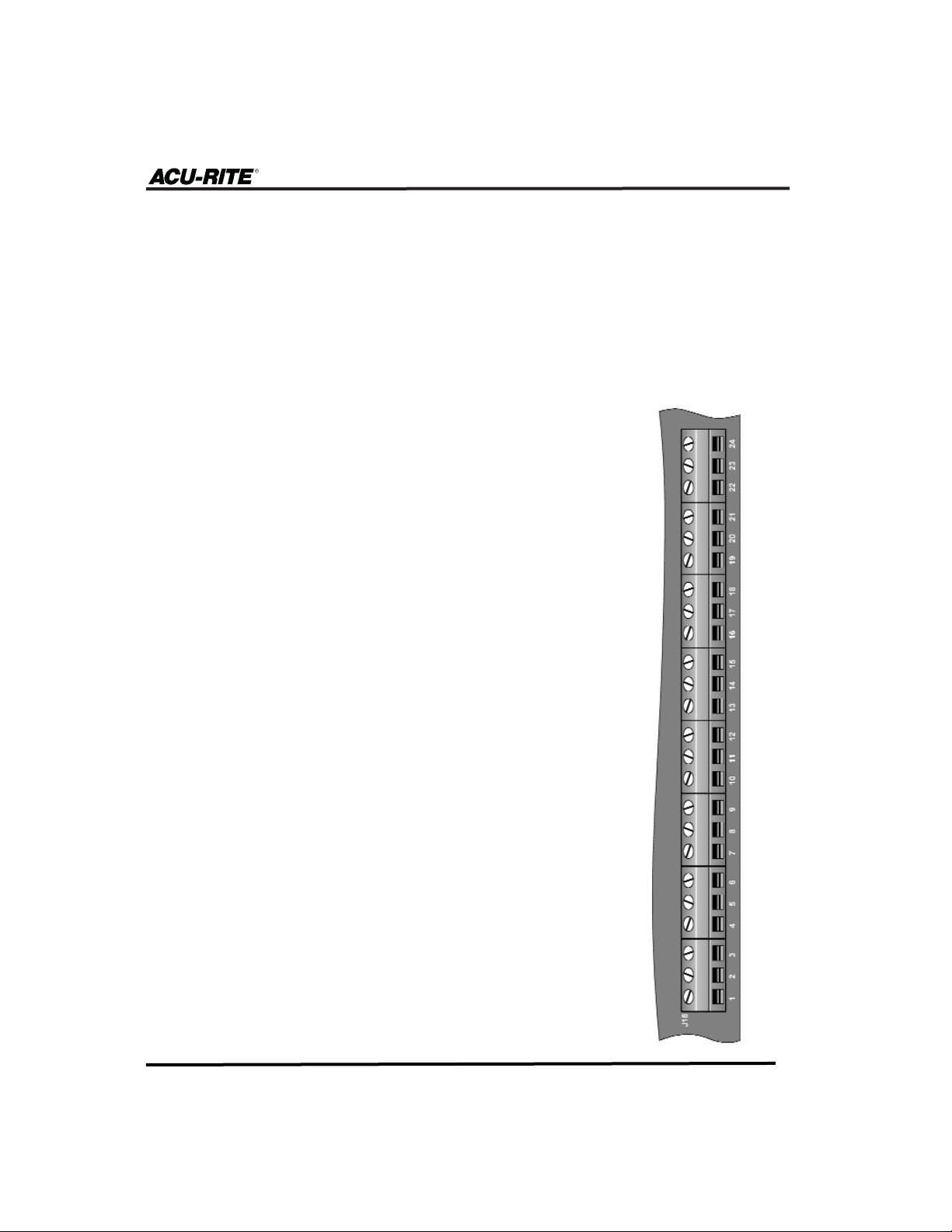

Table 2 (J18)

Pin #

Description

Output Function (Default State)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

AMI output #1

AMI output #1

AMI output #1

AMI output #2

AMI output #2

AMI output #2

AMI output #3

AMI output #3

AMI output #3

AMI output #4

AMI output #4

AMI output #4

AMI output #5

AMI output #5

AMI output #5

AMI output #6

AMI output #6

AMI output #6

AMI output #7

AMI output #7

AMI output #7

AMI output #8

AMI output #8

AMI output #8

Normally = Relay de-energized

Page 12

AMI with Spindle Control Reference Manual

9

AMI Output Device Overview

MILLPWR AMI interface allows it to control four (4) separate functions such as

mist and flood coolant, indexers,etc. There are three (3) programmable options

available when programming an AMI step:

• PULSE - Sends a signal to a device for a programmable length of time.

(The pulse duration can not exceed 999.9 seconds).

• ON - Sends a signal until program signals off, or at the completion of

the program.

• OFF - Sends a signal to turn device off.

Each of the signals listed above can be set to display, or not display an

Operator Intervention Message (OIM) at the auxiliary function step.

• NO - Will signal with no OIM. The signal is sent to the device and the

program continues to run. No operator intervention is required.

• BEFORE - Will signal after an OIM. An OIM indicates that pressing

“GO” will activate the programmed device. Pressing “GO” causes the

signal to be sent, and the program continues to run.

• AFTER - Will signal before an OIM. The signal is sent to the device

prior to displaying an OIM. After a signal has been sent, an OIM will

be displayed prompting the operator to press “GO” and the program

continues to run.

Page 13

AMI with Spindle Control Reference Manual

10

Connection Definitions

Auxiliary Outputs 1-4 are four sets of general purpose relay contacts.

1) These relay contacts can only be controlled through a

MILLPWR pro-

gram.

2) They must be set (programmed) to be either ON, OFF or PULSED.

3) Devices programmed to switch “on” will remain “on” for entire program, unless they are programmed to turn “off” later in the program.

4) Devices set to “pulse” will run for the length of time you define (refer

to page 23 for auxiliary function programming).

5) When the program stops, all relays will turn off.

Auxiliary Output 5 - In Position

In-Position. The Auxiliary Machine Interface (AMI) has the ability to send a

signal when

MILLPWR is “in position” for Position Drill steps and Hole pat-

tern steps which require manual Z-axis operation. This is when the table has

moved to either the X, Y coordinates of the position drill step or to each hole

of a hole pattern.

Output #5 (pins 13 through 15) are used for this function.

The In-Position function is configured through the AMI Outputs field under

Installation Setup. This can be set to ON, OFF or PULSED mode.

Note:

For pulsed outputs, the cycle will complete before the program will continue.

Pausing the program won’t affect the auxiliary functions. Each device will

continue to run normally. However,

MILLPWR, will shut off all relays auto-

matically when the program ends. To shut off a device earlier in the program, insert another auxiliary step with the appropriate relay turned off.

Page 14

AMI Reference Manual

11

Here is an example of how the Auxiliary Output functions work in conjunction with a rotary indexer:

1) Use Aux 3, Output #3 as the Cycle Start relay.

2) When the AMI Output #3 relay is pulsed, pins 7 and 8 of J18 are

momentarily shorted for the amount of pulse time entered. This activity

initiates the “Cycle Start” relay in the rotary indexer control, to start a

cycle or step index.

Note:

The pulse time must not exceed the indexer positioning time

to start the next cycle.

3) Once in position, the rotary indexer sends a “Cycle Finish” signal back

to the AMI. The AMI input interprets this as a “GO” signal and performs the next milling operation (Refer to Remote Go on page 7).

This In-Position activity takes place without any outside intervention from

the operator.

G-code Programs

When using a G-code program that requires coolant commands, certain outputs are configured to specific commands (M7, M8, M9). The following rules

apply while running G-code programs:

1) M7 command turns on the Aux 1 as the coolant flood relay.

2) M8 command turns on Aux 2 as the coolant mist relay.

3) M9 turns off both Aux 1 and 2.

4) Only one output, Aux 1 or Aux 2, is permitted to be on at a time.

5) These outputs will be turned On and Off as defined in the G-code

program.

6) Auxiliary outputs 3 and 4 are not used and are always off.

Page 15

AMI with Spindle Control Reference Manual

12

Devices that are connected to auxiliary outputs 1-4 (pins 1 through 12) on the

AMI’s J18 connector are programmable (refer to Table 2). Figure 3 shows

an example of AMI output wiring that would control a pump.

All of the J18 outputs will automatically return to their default settings (refer

to Table 2) any time the Emergency Stop button on the front of the

MILLPWR

operator console is pressed, when an emergency stop input (via J4) occurs or

when the software detects another emergency stop condition.

Fig. 3

Page 16

AMI Reference Manual

13

Emergency Stop Inputs (J4)

The J4 connector is commonly used to:

• Add table limit switches to the emergency stop circuitry

• Add an Emergency Stop button to the emergency stop circuitry

Table 3 (J4)

Pin #

Description

1

2

3

4

5

6

115V (for E-stop relay coil only)

Auxiliary E-stop relay coil (K1)

Auxiliary E-stop relay coil (K1)

AC Common (for E-stop relay coil only)

Table limit switch contact

Table limit switch contact

An emergency stop condition normally occurs when the system overheats, a

fault occurs, or when the Emergency Stop button on the MILLPWR operator

console is pressed. The AMI gives you the option of adding table limit switches and another Emergency Stop button into the system’s emergency stop circuitry. When an emergency stop is activated,

MILLPWR will immediately shut

off the system’s motors, shut off any external devices that are connected to the

AMI, and stop all machine movement.

If you are not using the J2 or J4 connec-

tor on the AMI, you must wire a jumper

at this time to close the circuitry.

Otherwise, when you power on

MILLPWR

and the AMI, an emergency stop condi-

tion will automatically occur and

neither system will run.

Page 17

AMI Reference Manual

14

Fig. 4

Fig. 5

Figure 4 illustrates how a table

limit switch can be wired into the

emergency stop circuitry. Notice that

the switches have been connected to

pins 5 and 6, which are the table

limit switch contacts (refer to Table

3). Because the table limit connections operate on internal 12V DC

power, it’s important to use a table

limit switch with a 12V DC @

100mA minimum rating. Do not

apply voltage directly to pins 5 or

6 on the J4 connector.

Figure 5 shows how an external

Emergency Stop button can use the

AMI circuit board as its power

source (the table limit switches are

shown for completeness). 115V AC

is provided between pins 1 and 4 of

J4 for the internal emergency stop

relay coil.

Figure 6 shows how the external

emergency stop can be wired directly

into an external 115V AC circuit.

When wiring the Emergency Stop button, use a switch with a 115V AC @

100mA minimum rating. (Do not use this circuit to power any external

devices.)

Fig. 6

There are two options for wiring the additional Emergency Stop button. It can be

wired directly to the AMI’s circuit board as a contact closure, or it can be wired

into an external 115V AC system.

Page 18

AMI with Spindle Control Reference Manual

15

Do not use the 115V AC connection for any other circuitry.

Note: If the existing emergency stop system is any other voltage than

115V AC, you must use the AMI as the power source (described

above) for the AMI emergency stop input.

Table Stop Test

The table stop test shows whether or not an emergency stop (E-stop) condition

has been detected or the internal switch has been pressed.

Reports on whether or not the system detects an emergency stop

condition. An E-stop condition can originate from the operator

console, Z-axis, or optional AMI.

Displays the status of the table stop button (Pressed or Released)

on the operator console.

If Z-axis control is enabled, a “Fault” or “No Fault” message

will appear. A fault indicates that at least one of the limit switches on the spindle has been disengaged.

To display the table stop test:

• From the Job Setup screen, select Installation

Setup and press

ENTER. Then select the

Diagnostics screen and press

ENTER again.

• From the Diagnostics screen, highlight Table

Stop Test and press

ENTER. The test will run

automatically.

• When the test is complete, press the EXIT TEST softkey to close the “Table

Stop Test” screen.

• Continue with Diagnostics or press the USE NEW SETTINGS softkey.

E-Stop

Signal

Status

Table Stop

Button

Z-Limit

Page 19

AMI Reference Manual

16

Whenever an “emergency stop” event occurs—such as when the Table Stop

button on the MILLPWR operator console is pressed or the system detects a

fault—MILLPWR will interrupt the milling machine’s movement and all of the

emergency stop outputs will return to their default state (refer to Table 3).

Figure 7 shows an example of how the AMI emergency stop output might

be used to power down a spindle motor when an emergency stop condition

occurs.

Emergency Stop Output (J17)

The emergency stop outputs are not programmable. Do not wire

external devices that you wish to control (pumps, automatic lubrication systems, etc.) directly into

MILLPWR’s emergency stop cir-

cuitry.

The J17 connector is commonly used to:

• Add other devices to the emergency stop circuitry.

Pin #

Description

1

2

3

Normally closed relay contact

Common relay contact

Normally open relay contact

Table 4 (J17)

Fig. 7

Page 20

AMI Reference Manual

17

AMI Installation

The installation procedure is divided into three sections—Connecting to

MILLPWR, General Wiring Procedure, and Connecting to a Power Source.

Refer to the General Wiring Procedure section anytime you are installing a

new input or output device.

Unless indicated otherwise, each section applies to both AMI versions (115V

and 230V).

• Power down the MILLPWR system and disconnect it from its power source.

• Using four (4) 5/16"-18 machine screws, install the AMI in a convenient

location on or near the machine, within close proximity of the

MILLPWR

operator console. Ensure that both the communication cable and the power

cable, for 115V systems, will reach the MILLPWR. If the AMI is being

installed on the machine, check that both are properly grounded. (Use startoothed washers if necessary).

• Connect one end of the interface cable to the connector located on the

AMI (refer to Figure 8). Tighten the two screws on the connector housing.

• Connect the opposite end of the cable to the AMI connector located on the

rear of the

MILLPWR operator console (refer to Figure 9). Tighten the two

screws on the connector housing.

• Proceed to the General Wiring Procedure section (page 18).

All wiring should be performed by a qualified electrician.

Connecting to MILLPWR

Page 21

AMI Reference Manual

18

Fig. 8

Fig. 9

Page 22

AMI Reference Manual

19

General Wiring Procedure

• Check that the MILLPWR system is powered down and disconnected

from its power source. Check that there is no power to the AMI.

• Remove the cover from the AMI.

• Insert a 0.17" to 0.47" diameter cable (with 24 -16 AWG maximum

wires) through the liquid tight strain relief that’s nearest the connector

you are planning to use (refer to Figure 10).

• Tighten the strain relief until the cable is securely in place.

• Cut the cable to length, then strip approximately 3/8” insulation from the

end of each wire.

• Loosen the appropriate connector screws, then insert the wires into

the connectors (refer to Figure 11).

• Tighten the screws. Ensure the wire has been adequately clamped by

applying a slight “tug”.

• After all of the wires are properly connected, reinstall the AMI cover and

insert rubber plugs into the unused holes.

The steps below explain the general procedure for wiring any device to the

connections on the AMI.

Refer to Figure 1 (page 4) for the location of each AMI and Emergency

Stop (E-Stop) input and output connection. Also refer to the AMI System

Overview section for common applications and descriptions of each connection.

All wiring should be performed by a qualified electrician.

Page 23

AMI Reference Manual

20

Fig. 10

Fig. 11

Page 24

AMI Reference Manual

21

• Check that the MILLPWR system is powered down and disconnected from

its power source.

• Locate the last motor assembly in the series of motors connected to the

MILLPWR system.

• Connect the AMI power cable (it should already be attached to the AMI) to

the last motor assembly’s AC connector (refer to Figure 12).

• Twist the black plastic connector clockwise one-half (1/2) turn (You

should feel the connectors “click”).

115V AMI systems:

Fig. 12

Connecting to a Power Source

The AMI’s electrical specifications determine which power source should be

used. If the AMI is set to run at 115V, it can easily be incorporated into the

MILLPWR servo motor power loop. AMIs that are set up for 230V must be con-

nected directly into an existing electrical circuit using a cable with wires that are

24 -16AWG(max.). Carefully follow the instructions for the type of AMI you

are installing.

• Check that:

1) The AMI power cable

and interface cable are

both properly connected.

2) The voltage selector

switch is set at 115V.

3) The correct fuse is

installed (refer to

Electrical Specifications).

AMI

Power

Cable

115V AC Power

Connection

Servo Motor

Servo Motor

Servo Motor

All wiring should be performed by a qualified electrician.

Page 25

AMI with Spindle Control Reference Manual

22

• After all of the inputs/outputs have been properly wired, power up the

MILLPWR system.

230V AMI systems (via the J16 connector):

• Check the

MILLPWR system is powered down and disconnected from its

power source. Check that there is no power to the AMI.

• Remove the cover from the AMI.

• Insert a 0.17” to 0.47” diameter cable (with 24-16 AWG maximum wires)

through the liquid tight strain relief that’s nearest the power connector.

All wiring should be performed by a qualified electrician.

• Tighten the strain relief until the cable is securely in place.

• Cut the cable to length, then remove approximately 3/8” insulation from the

end of each wire.

• Insert the proper wire into the line, ground and neutral inputs on the J16 connector (refer to Figure 13). Tighten the adjacent screws until each wire is

securely in place.

• Check that:

1) The AMI power cable and interface cable are both properly connected.

2) The voltage selector switch is set at 230V.

3) The correct fuse is installed (refer to Electrical Specifications located at

the end of this manual).

• Reinstall the cover onto the AMI. Insert rubber plugs into the unused holes.

• After all of the inputs/outputs have been properly wired, power up the

MILLPWR system.

Page 26

AMI with Spindle Control Reference Manual

23

Fig. 13

J16

Connectors

Page 27

AMI Reference Manual

24

Programming Auxiliary Output Devices Wired

to J18 (Aux 1-4)

Devices that are connected to pins 1 through 12 of the AMI’s J18 output

connector can be controlled from within any MILLPWR part program.

Simply insert an auxiliary function step at each point in the program

where you want the appropriate device to turn on, off or pulse.

When

MILLPWR reaches an auxiliary function step, an Operator

Intervention Message (OIM) will appear. The OIM will display the status

for each device. Press the

GO key to activate the relays and continue run-

ning the program.

Pausing the program won't affect the auxiliary functions. Each device will

continue to run normally; however,

MILLPWR will shut off all of the

relays automatically when the program ends. To shut off a device earlier

in the program, insert another auxiliary step with the appropriate relay

turned "off."

Devices programmed to switch "on" will run continuously as you

machine; devices set to "pulse" will run for the length of time that you

define.

Modes of Operation

Using Auxiliaries 1-4

• First, check that each device is connected to the Auxiliary outputs

(1-4) of J18, located on the AMI.

• From the PGM screen, highlight a step within the program where

you want to add or insert an auxiliary function step.

• Press the MORE STEPS softkey.

AMI Operation

Page 28

AMI Reference Manual

25

• Press the MORE STEPS softkey two more times.

• Press the AUXILIARY FUNCTIONS softkey.

• Highlight the auxiliary relay(s) that you want to

program. (The “AUX” numbers in each field correspond with the number on the AMI.) Select

from the OFF, ON, and PULSED softkeys for each.

ON The AMI output contacts will

switch to an energized state.

OFF The AMI output contacts will

switch to their default (de-energized) states.

PULSED The AMI output contacts will

switch to an energized state for

the length of time that you define.

Display User Prompt The AMI allows the operator, if desired,

to pause the step before or after the

relays are turned on or off.

• If you selected PULSED, then enter the amount of time (in seconds or

tenths of seconds) that you want the relay to remain on. The maximum

amount of time that a relay can pulse is 999.9 seconds.

Note:

Pulse mode must time out before the steps of the program can

continue.

• Set the Display User Prompt for the step to pause before or after by

pressing either the BEFORE STEP, AFTER STEP. If you choose not to

include a pause, press the NO softkey.

Note:

The auxiliary function relays will not turn off automatically

during an Operator Intervention Message (OIM).

• Pressing YES for the Set Continuous field allows an Auxiliary Function

Step to be entered (e.g. activate coolant) without interrupting the continuous milling path.

• Press the

USE key.

Page 29

AMI Reference Manual

26

G-code Programs

When using a G-code program that requires coolant commands, certain

outputs are configured to specific commands (M7, M8, M9). The following

rules apply while running G-code programs:

1) M7 command turns on the Aux 1 as the coolant flood relay.

2) M8 command turns on Aux 2 as the coolant mist relay.

3) M9 turns off both Auxs 1 and 2.

4) Only one output, Aux 1 or Aux 2, is permitted to be on at a time.

5) These outputs will be turned On and Off as defined in the G-code

program.

6) Auxiliary outputs 3 and 4 are not used and are always off.

Page 30

AMI Reference Manual

27

Using the In-Position Relay

• Press the

SETUP key.

• From the Installation Setup menu, cursor

down to the AMI Outputs field and press

the

ENTER key.

• Along the bottom of the screen the OFF, ON and PULSED softkeys will

also appear.

If ON is selected, the output will be asserted when the desired X/Y

position is reached and will remain on until the X and Y positions

have moved out of position.

If PULSED is selected, the desired pulse time must be entered in seconds. (Time may be entered to tenths of a second.) The In-Position

relay will remain energized when in position and will be de-energized

when the programmed time has elapsed or program step execution is

completed or aborted.

• To save an In-Position configuration, press the USE or the USE NEW

SETTINGS softkey.

Note:

Check that the devices you are using are powered on before

running the program.

Page 31

AMI with Spindle Control Reference Manual

28

Motor Assembly Monitor

When the motor assembly monitor is enabled, it shows the real-time operating status of each axis and the AMI on the DRO screen. Use it to verify the

status of all AMI inputs and outputs.

Reports on the AC power status (On or Off); also reports

system failures and emergency stop conditions when they

occur.

Displays the table’s incremental position (its position relative

to incremental zero).

Displays the table’s absolute position (its position relative to

datum).

Reports on each motor’s operating status (On, Off, Not

Present or Fault).

Shows the internal air temperature for each motor.

Temperatures should not exceed 75° C.

Monitors the DC motor current voltage. An "X" after the

value indicates that the voltage inrush bypass circuit is

active. It can also be seen when the E-Stop button is pressed

and then released. The “X” should disappear within 2 - 3

seconds after the system is powered up.

Top Bar

(Power

Status)

INC

ABS

Status

Temp

Current

Page 32

AMI with Spindle Control Reference Manual

29

T

o enable or disable the motor assembly monitor:

• From the Job Setup screen, select Installation Setup and press ENTER,

enter the passcode. Select the Diagnostics screen and press

ENTER

again

.

• From the Diagnostics screen, highlight Motor Assembly Monitor and

press

ENTER.

• Press either the ENABLED or DISABLED softkey. (If the ENABLED

softkey is selected, the Motor Assembly Monitor display will appear on

the DRO screen.)

• Press the

USE key.

• Continue with Diagnostics or press the USE NEW SETTINGS softkey.

Safety feature that will alter the activity of certain program

functions when they are open.

Safety feature that will, under certain conditions, stop program functions when the lubrication pump supply reaches a

certain minimum level of oil.

Provides a switch input that can be used in place of the

operator pressing the

GO key or the remote Stop/Go switch.

Guards

Closed

Oil Not

Low

No Go Key

Page 33

AMI Reference Manual

30

Symptom

Probable Cause

Recommended

Corrective

Action

No operation or

improper operation

Loose interface cable

No power or incorrect

voltage to AMI

Incorrect voltage setting

Check that the cable is

properly connected to

MILLPWR and that the

screws are secure.

Check that the AMI

is wired at the correct voltage. Also ensure that the

power cables for the

motors are properly daisychained to the

MILLPWR

operator console (refer to

Connecting to a Power

Source, page 20).

Verify that the voltage

selector switch is set correctly—at 115 for 115

volt operation; at 220 for

220 volt operation.

Ribbon connector to J14

is loose (European AMIs

only)

Check the connection.

Tighten or reconnect it as

needed.

AMI Troubleshooting Guide

This troubleshooting guide is arranged in three columns—Symptom, Probable

Cause and Recommended Corrective Action. Begin by locating the symptom

and probable cause that best matches the problem you are experiencing, then follow the directions for each corrective action.

If the suggestions herein do not solve the problem, contact ACU-RITE for repair

and/or replacement procedures.

Page 34

AMI Reference Manual

31

Symptom

Probable Cause

Recommended

Corrective

Action

Improper wiring

Ensure stripped end of the

wire is adequately crimped

by the terminal on the

board (vs. insulation being

crimped).

F3 fuse is loose Check that the F3 fuse is

securely in place.

F3 fuse is blown

Replace the F3 fuse with

one that’s appropriate for

the AMI operation (refer to

Electrical Specifications).

External

emergency stop

button does not

work

Improper voltage

If circuit is wired using

external power, ensure

120VAC (+/- 10%) is being

used.

F1 fuse is blown

Contact ACU-RITE for

repair procedure.

No operation or

improper operation

(cont’d)

Page 35

AMI Reference Manual

32

Symptom

Probable Cause

Recommended

Corrective Action

Machine guards

and low oil messages are reversed

Improper wiring Check the wiring to the

AMI’s J2 connector. The

machine guard switch

should be wired to pins 1

and 2, and the auto lube

system should be wired

to pins 3 and 4 (refer to

Input Devices (J2)).

Table limit switches do not work

Improper wiring

Verify that the wires are

connected to pins 5 and 6

on the AMI’s J4 connector (refer to Emergency

Stop Inputs).

Emergency stop

message is constantly displayed

on MILLPWR operator console.

No External E-Stop is

wired to the J4 connector,

or it may be done so

incorrectly.

This input must be configured. Either connect

an external emergency

stop switch to J4, or use

a wire jumper to defeat

it.

Page 36

AMI Reference Manual

33

Symptom

Probable Cause

Recommended

Corrective Action

No response to oil

or guard switches

Loose interface cable

Check that the interface

cable is properly connected to

MILLPWR and

that the screws are

secure.

"External E-Stop"

and "Table Limits"

messages are

reversed

Incorrect wiring

Verify that the proper

wires are connected to

pins 5 and 6 on the J4

connector (refer to

Emergency Stop

Inputs).

Table limit switches do not work

(cont’d)

Improper wiring (cont’d) Ensure that all of the

table limit switches are

normally closed and

wired in series.

If more than one table

limit switch exists, verify

that they are “normally

closed” and wired in

series.

Improper wiring

Check that the switches

are properly wired to the

J2 connector. The

machine guard switch

should be wired to pins 1

and 2, and the auto lube

system should be wired

to pins 3 and 4 (refer to

Input Devices (J2)).

Page 37

AMI Reference Manual

34

Output devices not

responding/not

responding properly

AMI is not receiving

power.

Check that the AMI is

receiving power (also

refer to probable causes

and corrective actions

under “No operation or

improper operation,”

page 29).

No response to oil

or guards switches

(cont’d)

Symptom

Probable Cause

Recommended

Corrective

Action

Ensure that all of the

wires are secure beneath

the screw(s) on the J2

connector. Disconnect

power to

MILLPWR and

the AMI. Completely

loosen each screw on the

connector. One by one,

reinsert each wire into

the connector, under the

body of the screw.

Tightening each screw as

you do so.

Improper wiring (cont’d)

Page 38

AMI Reference Manual

35

Improper wiring

Compare the wiring to

the "normally closed"

and "normally open" contacts for that connector,

as described in the manual. Rewire as needed.

Symptom

Probable Cause

Recommended

Corrective Action

Each wire must be

secured under the corresponding screw.

Disconnect power to

MILLPWR and the AMI.

Completely loosen each

screw on the connector.

Reinsert each wire one

by one, retightening each

screw as you do so.

One or more wires not

secure in the J2 connector

Output devices not

responding/not

responding properly (cont’d)

Output not functioning

correctly

Check the auxiliary function steps within the program and verify that the

information in each step

is correct.

Page 39

AMI Reference Manual

36

Characteristic Specification

Operating conditions

0° to 40° C (32° to 104° F)

25% to 85% relative humidity (non-condensing)

Storage conditions

-20° to 60° C (-4° to 140° F)

25% to 95% relative humidity (non-condensing)

115VAC ±10%

230VAC ±10%

47-63Hz

124mA (max.) @ 115VAC

62mA (max.) @ 230VAC

Input requirements:

Voltage

Frequency

Current

Fuse

200mA, 3AG, 250V SLO-BLO @ 115VAC

100mA, 3AG, 250V SLO-BLO @ 230VAC

4 Amps max. @ 230V AC

AMI output relay

contact ratings (J18)

FCC compliance

Part 15 of FCC rules for a class A

computing device

Compatibility

Compatible with ACU-RITE

®

MILLPWR

®

systems software versions 2.1.2 and 3.1.2 or later

Electrical Specifications

The installation location must be able to support the AMI operating and

electrical requirements listed below.

E-Stop Output ratings (J17)

14 Amps max. @ 230V AC

SCI Contact Specifications

(J1, J2 & J5)

0.5 Amps max @ 125V AC

Page 40

ACU-RITE INCORPORATED

One Precision Way • Jamestown, NY 14701

ACU-RITE IS AN

ISO 9001

CERTIFIED

MANUFACTURER

fi

Loading...

Loading...