Page 1

CONGRATULATIONS!

You have just purchased MILLPWR by ACU-RITE , a versatile and flexible 2-axis Control/

3-axis Readout system that effectively combines powerful features and functionality with ease of use at an

affordable price.

MILLPWR satisfies the needs of the milling market where manual and automated operation are both useful

and needed. MILLPWR

other non-productive operations thereby increasing your efficiency, producti vity and profitability.

MILLPWR is designed and manufactured in the United States at ACU-RITE’s ISO-9001 registered facility.

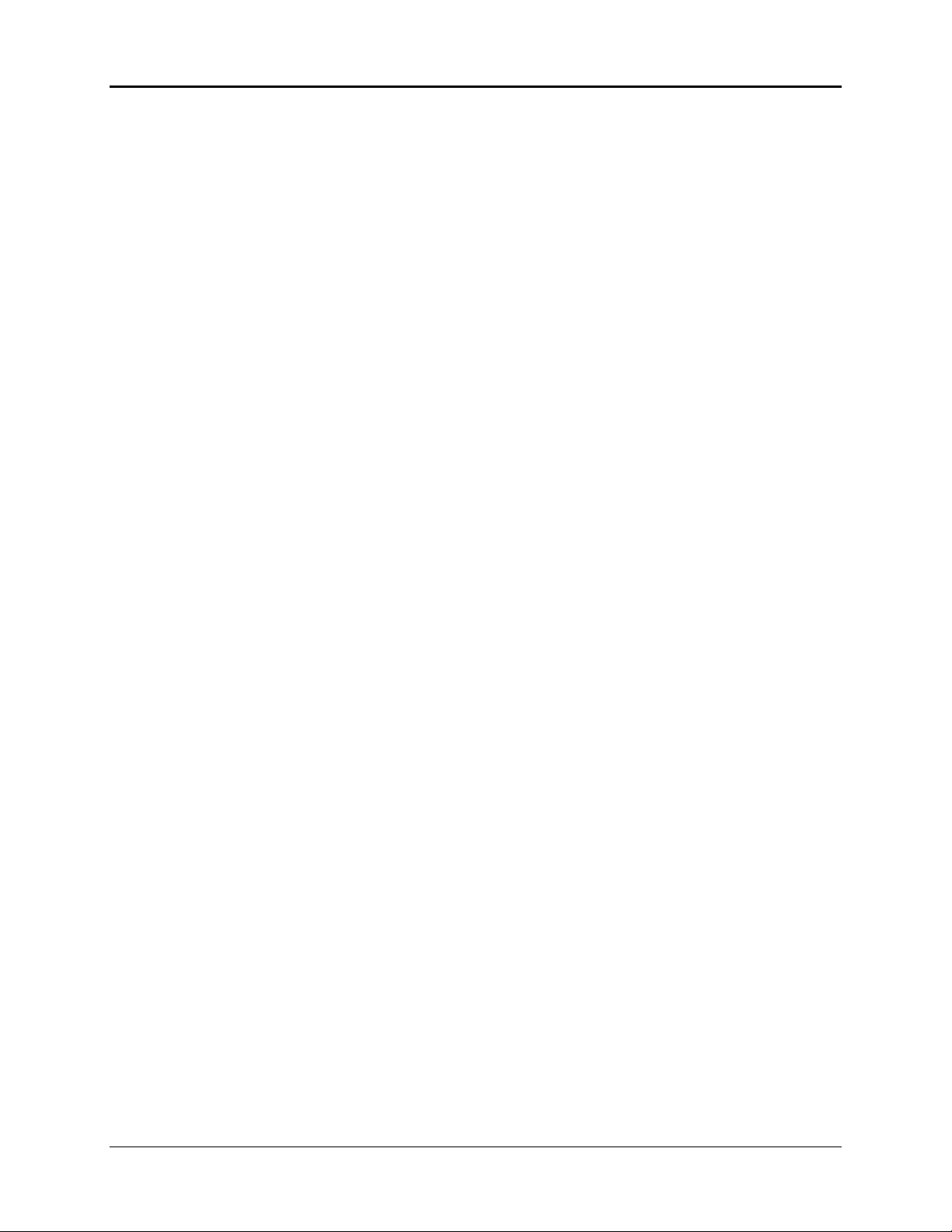

MILLPWR is a complete system that includes ground and hardened ball screws, powerful DC servo motors,

a user friendly operator console with a built-in floppy disk drive, a controller cabinet containing an

electronics module (which includes a large hard disk drive) and a motor control module. The system is

closed-looped with positioning feedback provided by the use of ACU-RITE’s precision glass scales

(2µm/.0001” resolution).

MILLPWR utilizes a conversational, menu prompted format that makes it easy for you to learn and quick for

you to program. No prior programming experience or training is necessary. All you have to do is simpl y

enter part dimensions directly from the print. MILLPWR automatically calculates the tool path... with

immediate part view graphic feedback providing program verification. MILLPWR’s intuitiveness allows you

to learn how to operate MILLPWR and begin making parts, and profits, in a matter of hours.

MILLPWR is backed by a comprehensive 1-year warranty, with nationwide support provided by a factory

trained and certified distribution network.

Thank you for choosing ACU-RITE. We’re confident you’ll be more than glad you did.

Sincerely,

ACU-RITE INC.

also maximizes your throughput by significantly reducing set-up time, scrap and

Page 2

MILLPWR System Setup Access Code

An access code must be entered before the system setup

parameters can be set or changed. This prevents inadvertently

resetting parameters.

IMPORTANT

The access code is 8891

Refer to section 7, “System Setup.”

IMPORTANT

Supervisors may wish to remove this page from the

MILLPWR manual after initially setting up the system

parameters. Keep it in a safe place for future use.

387900-970 Edition E

Page 3

TABLE OF CONTENTS

Section 1. Introduction

System Overview...........................................................................1-1

Machine Layout ...................................................................1-1

Keypad Layout ....................................................................1-3

Screen Layout ......................................................................1-4

Saving, Backing Up, and Creating Directories

For Programs...............................................................1-5

Emergency Table Stop Button ..............................................1-5

Conventions ..................................................................................1-6

Axis Conventions ....................................................................1-6

Absolute/Incremental ...............................................................1-7

Section 2. DRO

Start-up ........................................................................................2-1

Power Up ............................................................................2-1

Finding Home ......................................................................2-2

DRO Functions .............................................................................2-3

Reset an Axis .......................................................................2-3

Inch -Metric ..........................................................................2-3

Move Table .........................................................................2-3

Establishing a Datum ............................................................2-4

Using a Probe ......................................................................2-5

One Time Milling Functions ..................................................2-6

Section 3. Programming

Programming Considerations .........................................................3-1

Depth of Cut ........................................................................3-1

Tool Offset ..........................................................................3-1

“From” and “To” Points .......................................................3-2

Datum Selection ...................................................................3-2

Absolute and Incremental Dimensions ...................................3-2

Operation Manual i MILLPWR

Page 4

TABLE OF CONTENTS

Continuous Milling ................................................................3-3

Creating a Program .......................................................................3-4

The View Key .....................................................................3-6

Running a Program ........................................................................3-6

Setting the Datum .................................................................3-6

Testing Your Program ..........................................................3-7

Pressing the GO Key ...........................................................3-8

Feed Rate Override .............................................................3-9

Machining to Zero ................................................................3-9

Program Functions ......................................................................3-11

Accessing the Load, Save, Delete, and

Backup Options ........................................................3-11

Saving a Program ...............................................................3-12

Directories .........................................................................3-14

Creating a Directory ..................................................3-14

Selecti ng a Directory .................................................3-17

Deleting a Directory ..................................................3-19

Other Program Functions ...................................................3-20

Naming a Program ....................................................3-20

Deleting a Program ....................................................3-21

Backing Up a Program ..............................................3-22

Loading a Program ....................................................3-24

From MILLPWR’s internal hard disk drive ..........3-24

From a 3 ½” floppy disk .....................................3-26

From your PC .....................................................3-27

Section 4. Demonstration

A Demonstration Program .............................................................4-1

Selecting the Datum ..............................................................4-1

Beginning the Program ..........................................................4-1

Selecting a Tool ...................................................................4-2

Milling the Workpiece Contour .............................................4-3

MILLPWR ii Operation Manual

Page 5

TABLE OF CONTENTS

Programming the Bolt Circle ...............................................4-13

Programming the Pocket ....................................................4-15

Saving Your Program .........................................................4-17

Testing Your Program ........................................................4-17

Running the Program ..........................................................4-18

Tool Changes .....................................................................4-20

Clearing the Program ..........................................................4-20

Section 5. Program Steps

Sample Milling and Drilling ............................................................5-1

Set Tool ...............................................................................5-1

Positioning/Drill ....................................................................5-1

Mill Line ..............................................................................5-2

Mill Arc ...............................................................................5-2

Blend ...................................................................................5-3

Rectangular Milling Functions ........................................................5-4

Pocket .................................................................................5-4

Rectangular Frame ...............................................................5-5

Face ....................................................................................5-6

Slot ......................................................................................5-7

Circular Milling Functions ..............................................................5-8

Circular Pocket ....................................................................5-8

Circular Frame .....................................................................5-9

Ring ...................................................................................5-10

Hole Patterns ..............................................................................5-11

Row of Holes .....................................................................5-11

Hole Frame and Hole Array ...............................................5-12

Bolt Circle .........................................................................5-13

More Steps .................................................................................5-14

Repeat ...............................................................................5-14

Rotate ................................................................................5-15

Mirror ................................................................................5-16

Operation Manual iii MILLPWR

Page 6

TABLE OF CONTENTS

Custom Pocket ..................................................................5-17

Engrave .............................................................................5-18

Explode .............................................................................5-20

Section 6. Calculator

Four Function Arithmetic ...............................................................6-1

Trig and Math Functions ................................................................6-1

Geometry Calculator .....................................................................6-4

Why We Need a Geometry Calculator .................................6-4

Working with the Geometry Calculator .................................6-5

Example Problem ..........................................................................6-7

Strategy ...............................................................................6-7

Starting the Program .............................................................6-7

Entering the Lines .................................................................6-8

Finding the Arc ..................................................................6-10

Finding the Points of Tangency ...........................................6-12

Returning Features ..............................................................6-13

Section 7. Setup

Inch or Metric ......................................................................7-1

Operator Setup .............................................................................7-2

Tool Library ..................................................................................7-2

Scale Factor .................................................................................7-3

Display Options ............................................................................7-4

Touch Probe .................................................................................7-5

Feed Rate Settings ........................................................................7-5

System Setup ................................................................................7-6

Protection ............................................................................7-6

Error Compensation .............................................................7-7

Encoder Direction ................................................................7-8

Serial Port ............................................................................7-9

MILLPWR iv Operation Manual

Page 7

TABLE OF CONTENTS

Section 8. Remote Storage

Equipment .....................................................................................8-1

Choosing a Serial Cable ................................................................8-1

Connecting MILLPWR to Your PC ...............................................8-2

Installing the Remote Storage Program ...........................................8-3

Operation Manual v MILLPWR

Page 8

TABLE OF CONTENTS

Setting the PC’s COM Port and BAUD Rates ...............................8-4

Common Error Messages ..............................................................8-5

Section 9. Troubleshooting Guide

Introduction ..................................................................................9-1

Using the Table .............................................................................9-1

Table ............................................................................................9-2

MILLPWR vi Operation Manual

Page 9

TABLE OF CONTENTS

387900-167 Software Version 1.3 Ed G

Operation Manual vii MILLPWR

Page 10

INTRODUCTION

MILLPWR

INTRODUCTION

System Overview

Machine Layout

Operation Manual Page 1-1

Page 11

INTRODUCTION

MILLPWR

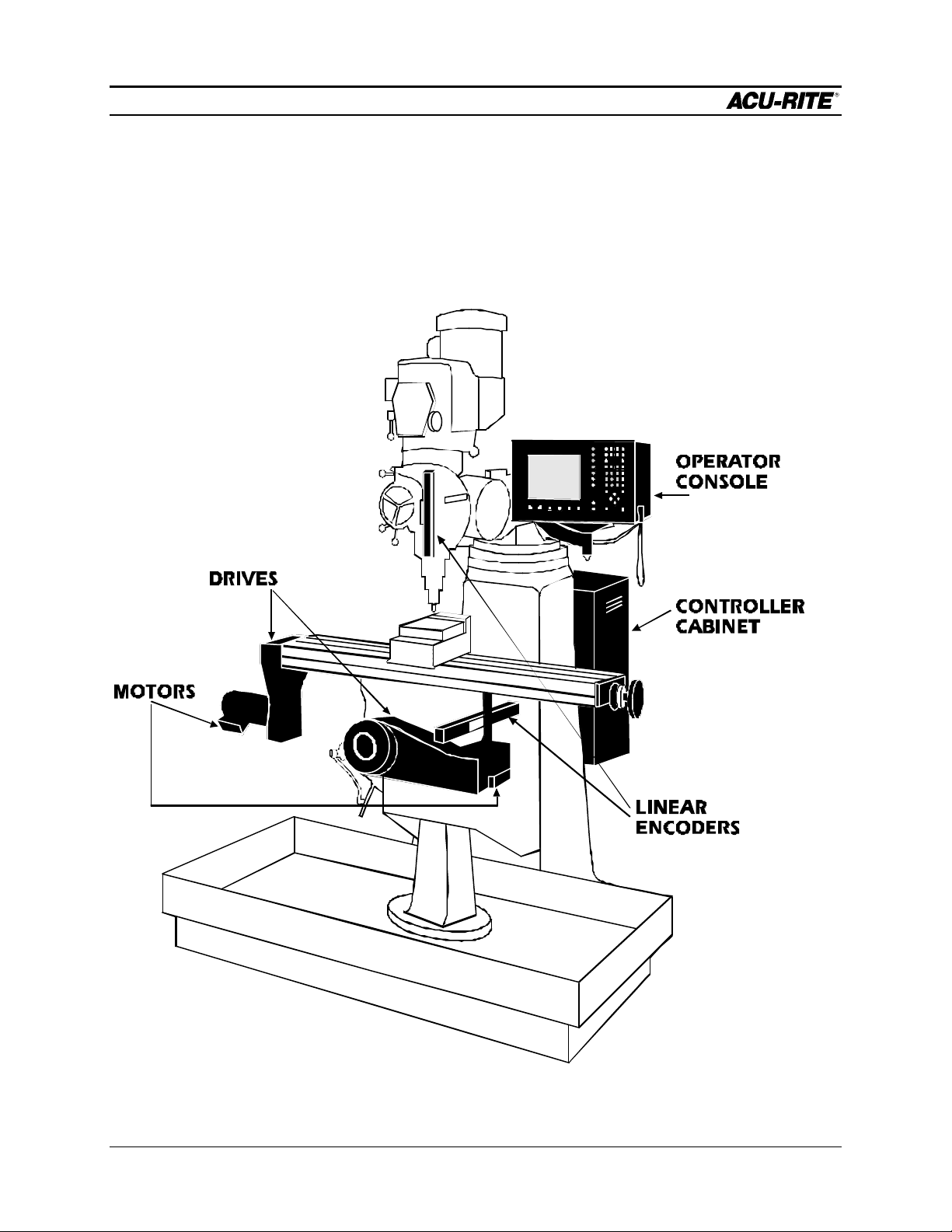

Front View of Operator Console

TABLE

STOP

INFO

SET

UP

TOOL

CIRCLE HOLES

RECT

ARC

LINEPOS BLEND

Floppy

diskette inside

Emergency

Keypad

Softkeys

VIEW

PGM

DRO

CANCEL

USE

ABS

INC

4 5 6

1

2

.

0

CALC

987

3

+/-

TABLE STOP

FEED

FEED

DEL

+

STOP GO

-

ENTER

Rear of Operator Console Side of Controller Cabinet

/

X

-

+

Contrast and

brightness

knobs --adjust

them for best

picture

Main power

switch. Use this

to turn MILLPWR

on and off.

Power

Switch for

console only

(just leave it

on)

Page 1-2 Operation Manual

Page 12

INTRODUCTION

MILLPWR

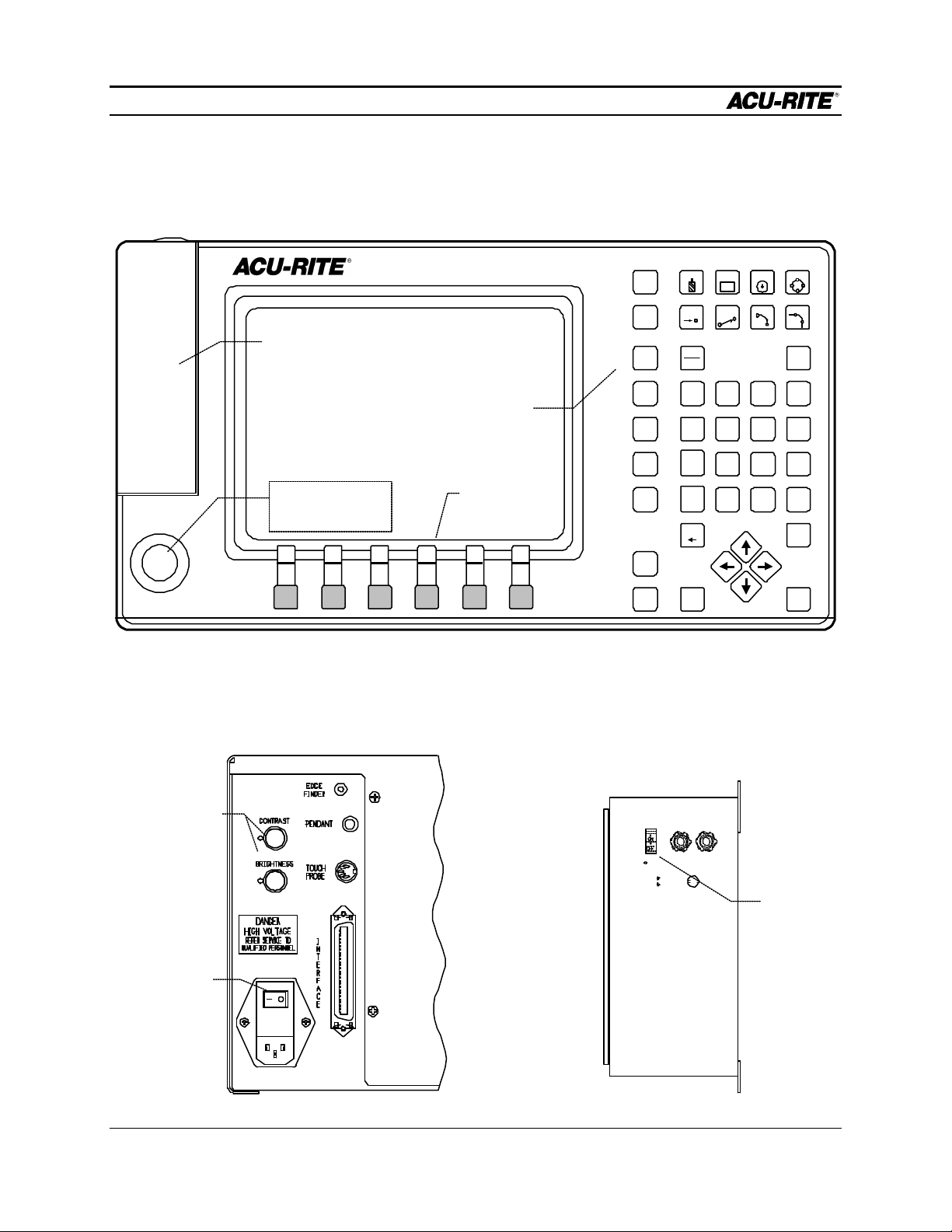

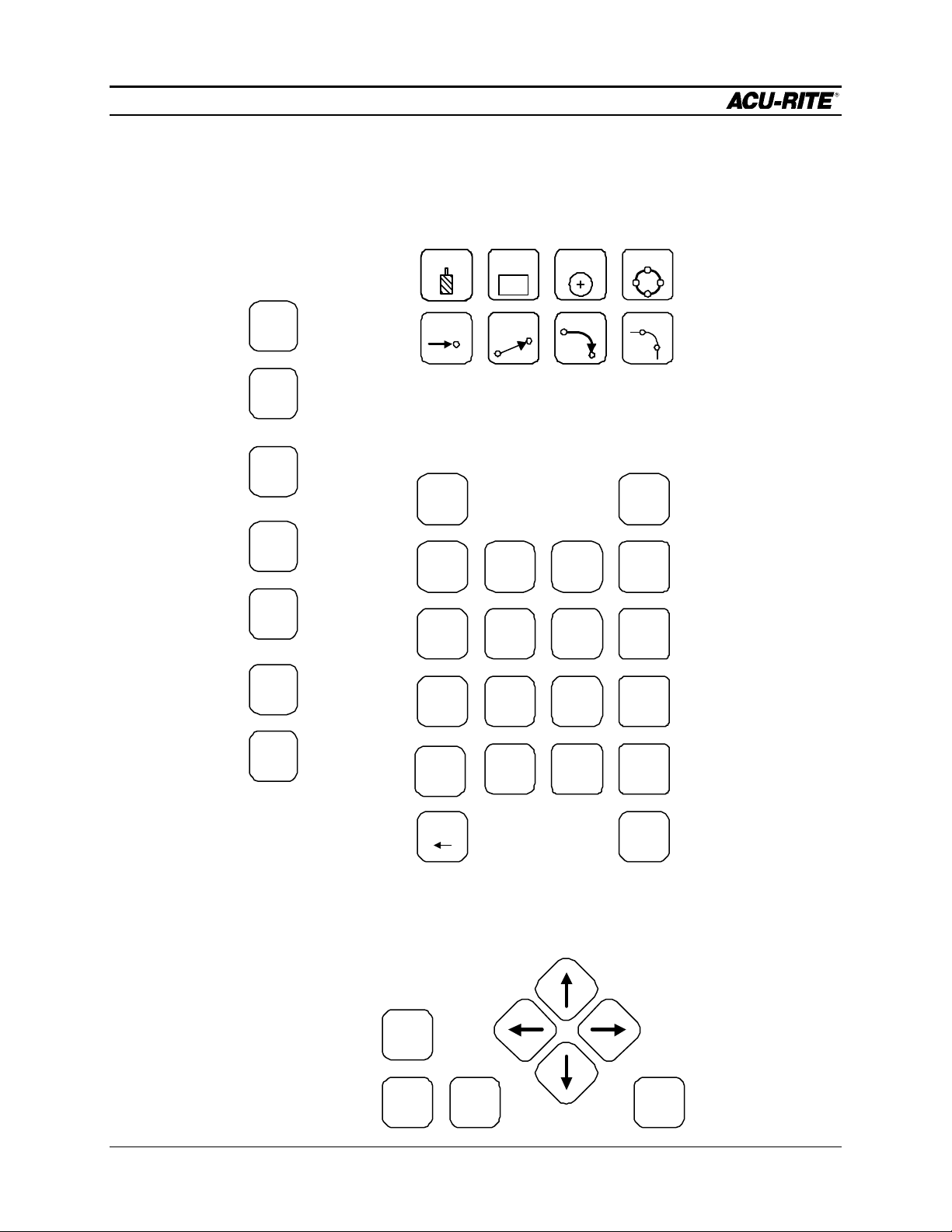

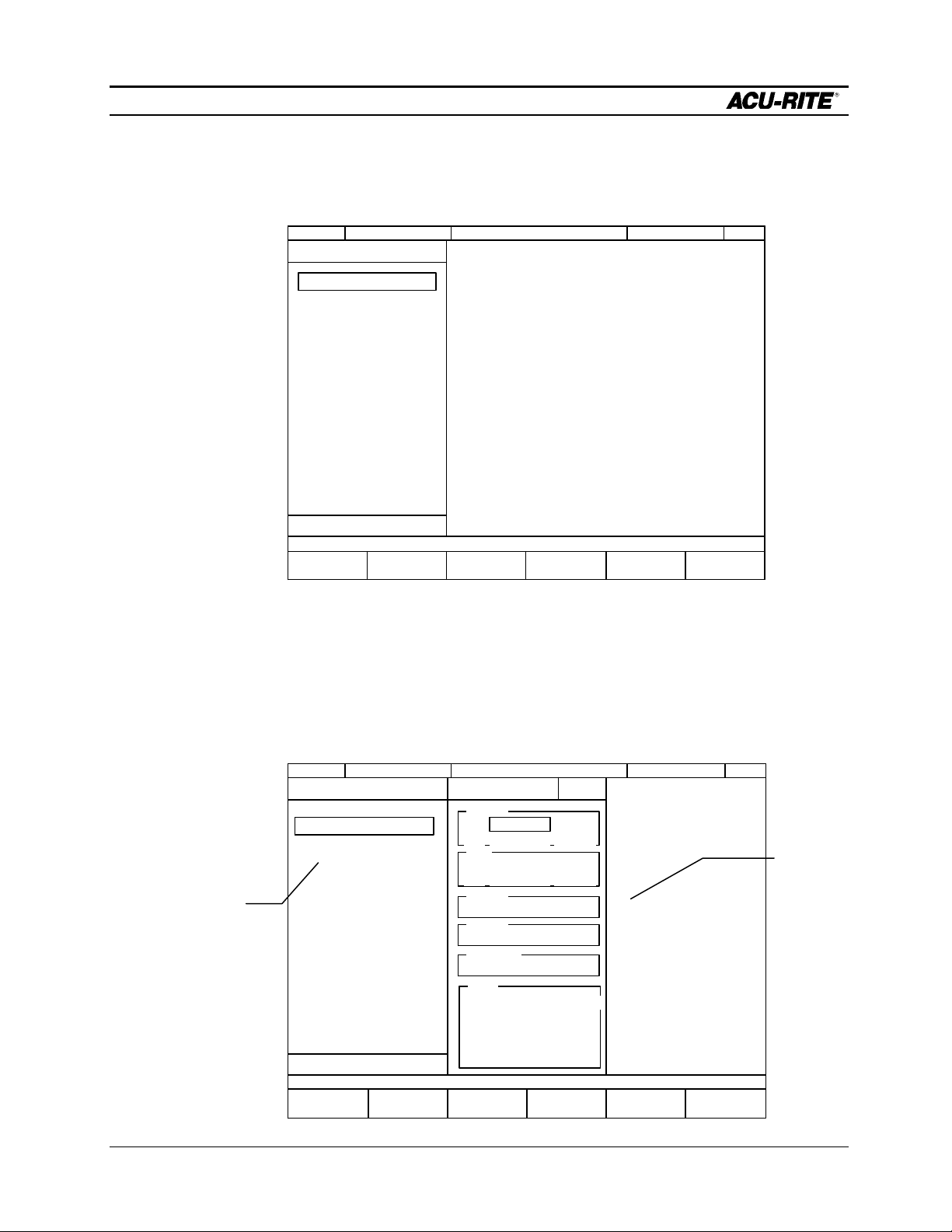

Keypad Layout

These let you set up

the MILLPWR, get

information about

what you are doing,

switch between

program (PGM) and

DRO, and “USE” the

milling functions as

steps in a program.

Main

Function Keys

INFO

SET

UP

VIEW

PGM

Milling Functions

TOOL RECT CIRCLE

POS

LINE

ARC BLEND

Numeric Keypad

and Calculator

ABS

INC

7 8

9

HOLES

CALC

/

With these keys, you define

the operations you want

MILLPWR to perform.

These operations end up

as “steps” in a program, or

you can run just one of

them at any time.

DRO

CANCEL

USE

Press GO to run your program, and

STOP to stop it. The FEED keys let

you adjust the cutting speed on the

fly.

4 5

6

1 2 3

.

DEL

0

Cursor and Motion Control Keys

FEED

+

FEED

-

+/-

ENTER

X

+

Enter all numerical

values with these

keys. When you’re

entering dimensions,

you can specify

absolute or incremental.

-

The handy 4-function

calculator can be used

at any time. Trig and

geometry assistance

is available with a press

of the CALC key.

GOSTOP

Operation Manual Page 1-3

Page 13

INTRODUCTION

MILLPWR

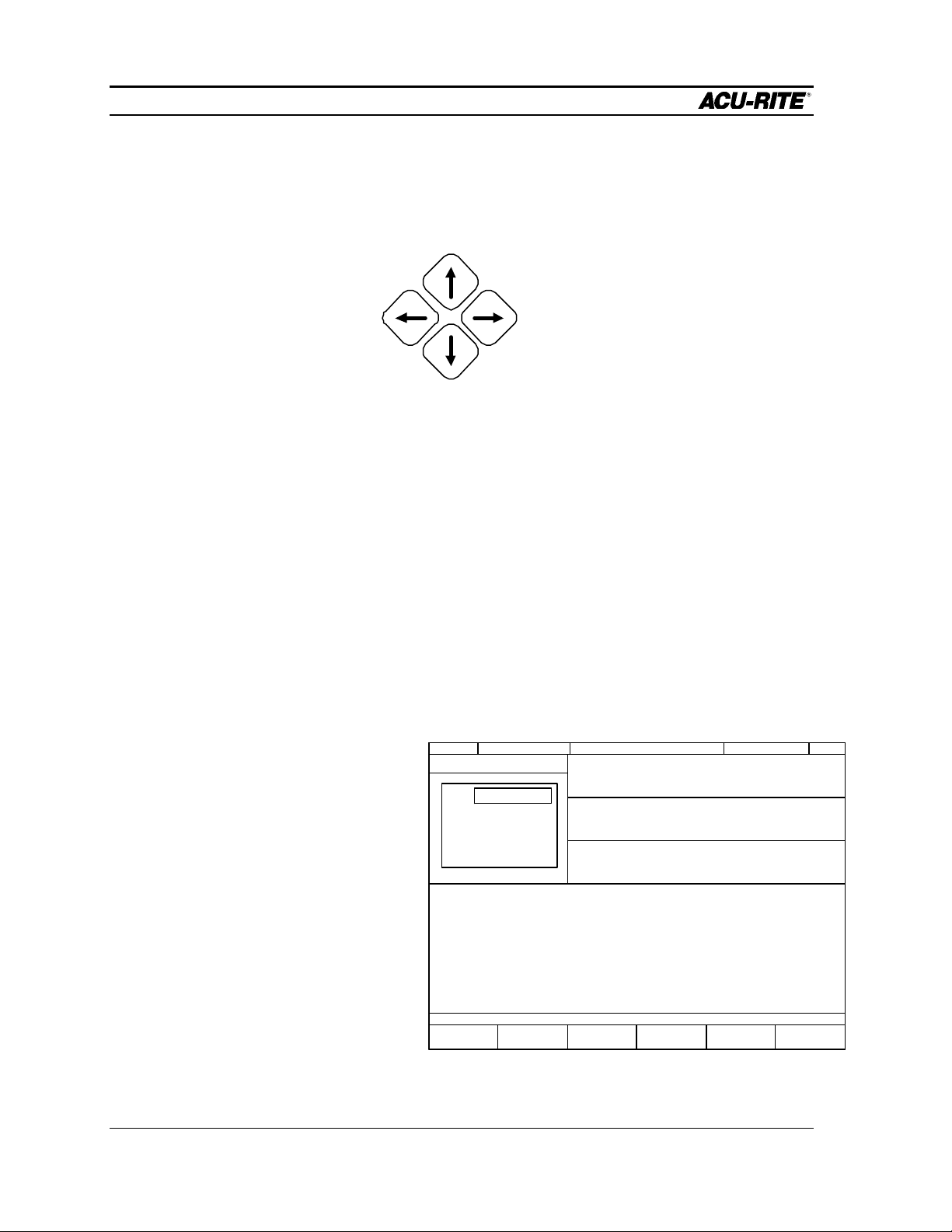

The cursor keys help you

navigate around the screen

while you are using

MILLPWR.

Page 1-4 Operation Manual

Page 14

INTRODUCTION

2 3 4

MILLPWR

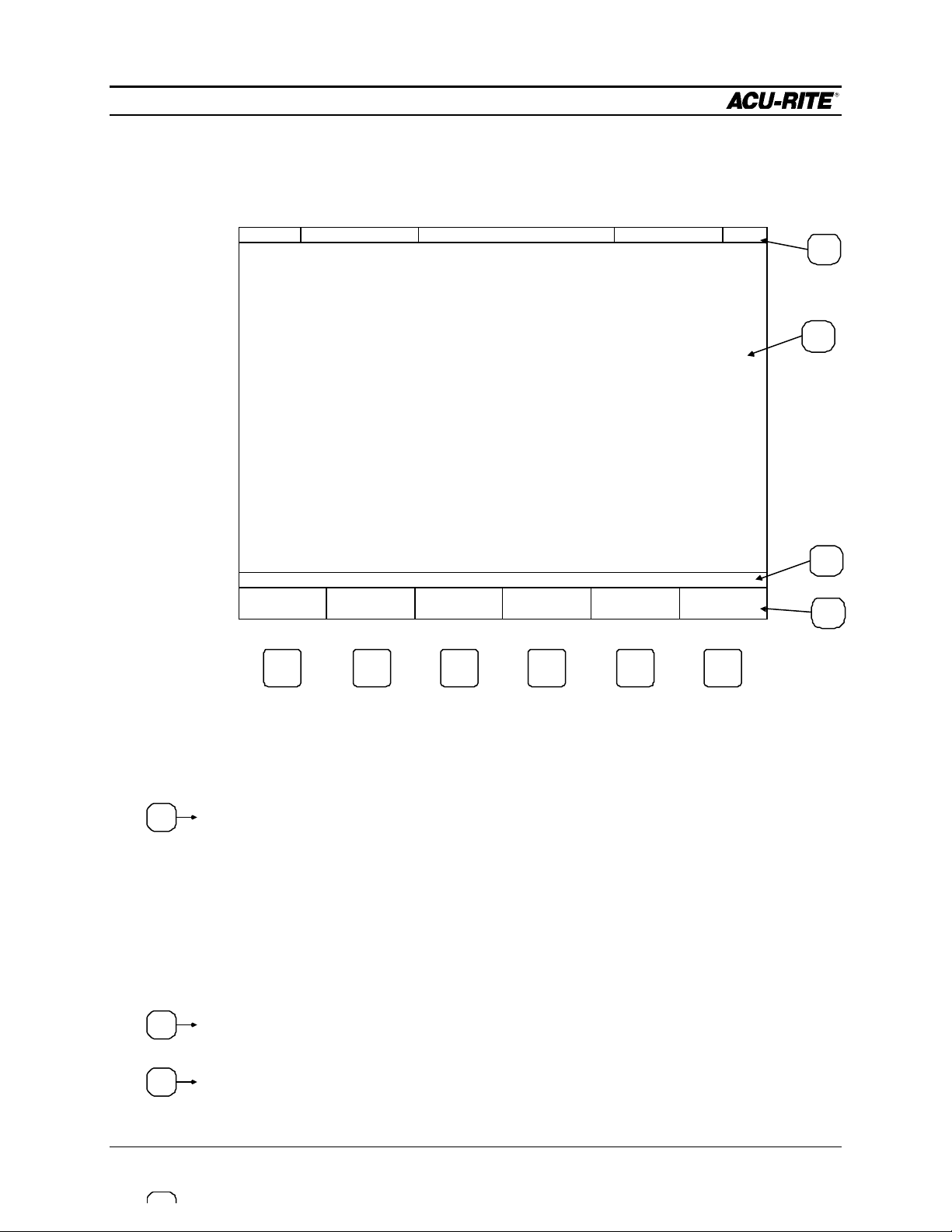

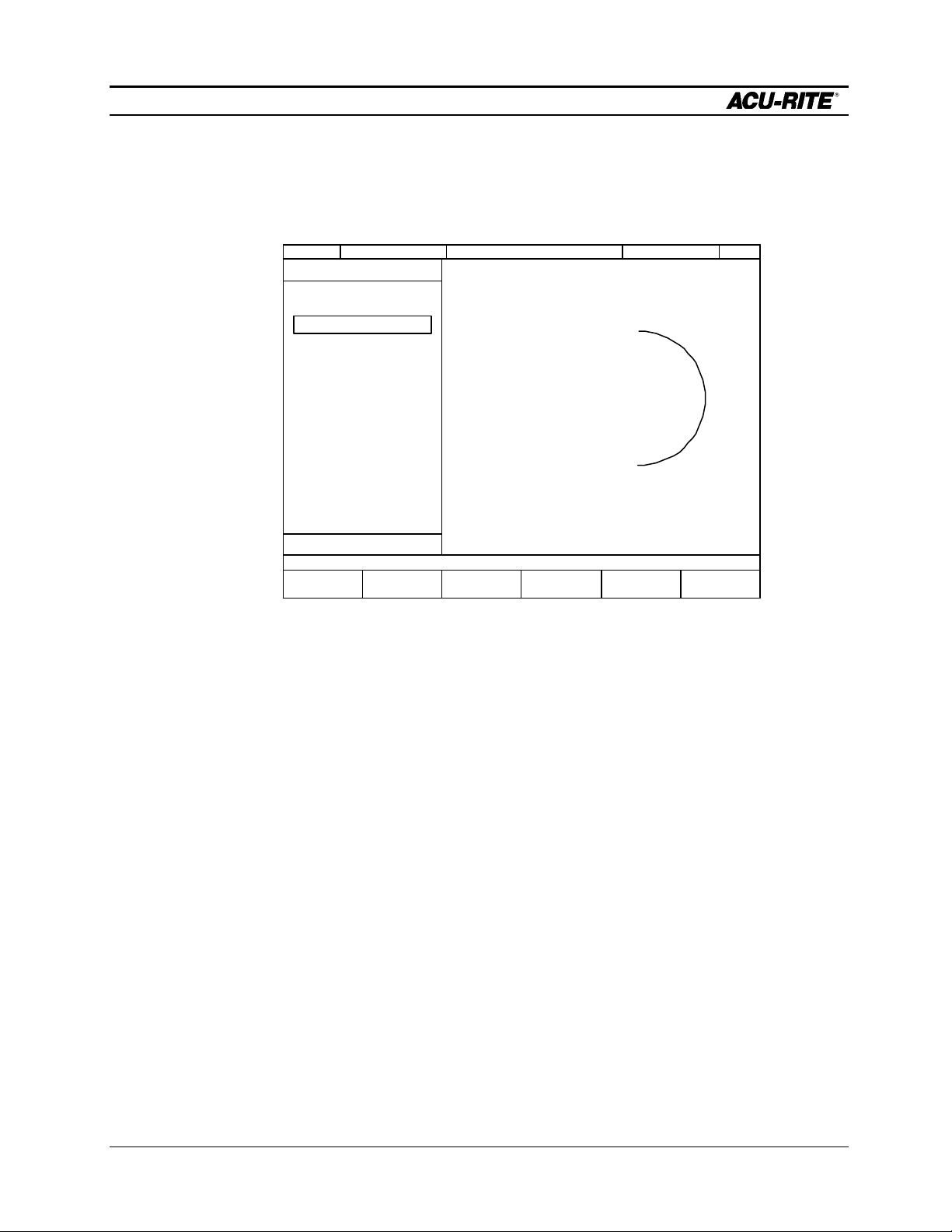

Screen Layout

The MILLPWR display screen is divided into four sections.

SERVO

FEED 0 100%

OFF

ZERO X ZERO Y ZERO Z

SCALE 1.0000TOOL:

DATUM

MOVE

TABLE

INCH

1

2

3

4

Status bar - displays the servo motor status (on/off), feed rate, current tool, scale, and

inch/mm display view.

Information screen - displays information for the job being performed.

• Used as a readout, the screen will display the current location for each axis.

• When programming, a list of milling operations and part view graphics will

be displayed.

• To calculate data geometrically, lines and arcs can be constructed and

displayed.

Message line - operator prompts and messages will appear here.

Softkeys - variable key functions appear here; functions are selected by pressing

the hard key directly below the softkey message.

Operation Manual Page 1-5

Page 15

INTRODUCTION

MILLPWR

Saving, Backing Up, and Cr eating Directories for Programs

When you begin to create programs for your MILLPWR to run, you can save your

If you're writing a

long program,

don't wait until

the end to save

your work.

Frequent saving

reduces the risk

of losing work

due to a power

interruption.

programs in any of three places—on MILLPWR’s internal hard disk drive, on a 3

½” floppy disk, or on your PC’s hard disk drive. Saving your work means it will

not be lost if the MILLPWR is turned off or if there is a power failure.

Your MILLPWR is also equipped with a backup feature that enables you to make

duplicate copies of your saved programs. We recommend backing up your work

as an extra precaution against accidental deletions, hard disk drive failures, or other

problems that may prevent you from recovering your original files. Backing up your

programs takes only a few moments—and will save you valuable time if a problem

does occur.

And as you save and back up your programs, you can neatly organize them in any of

the three default directories (“MILLPWR,” “A:,” and “REMTSTOR”) or in

personalized directories you create on your own.

For more details about how to save programs, back up files, and create directories,

refer to the Programming section.

Note: Before you save or back up programs on your PC’s hard disk drive, refer to the

Remote Storage and System Setup sections for setup instructions.

Emergency Table Stop Button

The large red button on the front of the MILLPWR operator console is the emergency

TABLE STOP. In the event of a malfunction or programming error, press the emergency

TABLE STOP button to disengage the servo motors. Disengaging the servos will

cause all table movement to stop.

WARNING

Pressing the emergency TABLE STOP button will NOT

stop the rotation of the cutting tool unless your machine

has been specifically wired to do so. Therefore, in the

event of an emergency, if your machine has not been

wired to stop the rotation of the cutting tool, be prepared

to raise the quill in addition to pressing the emergency

TABLE STOP button.

Page 1-6 Operation Manual

Page 16

INTRODUCTION

MILLPWR

Conventions

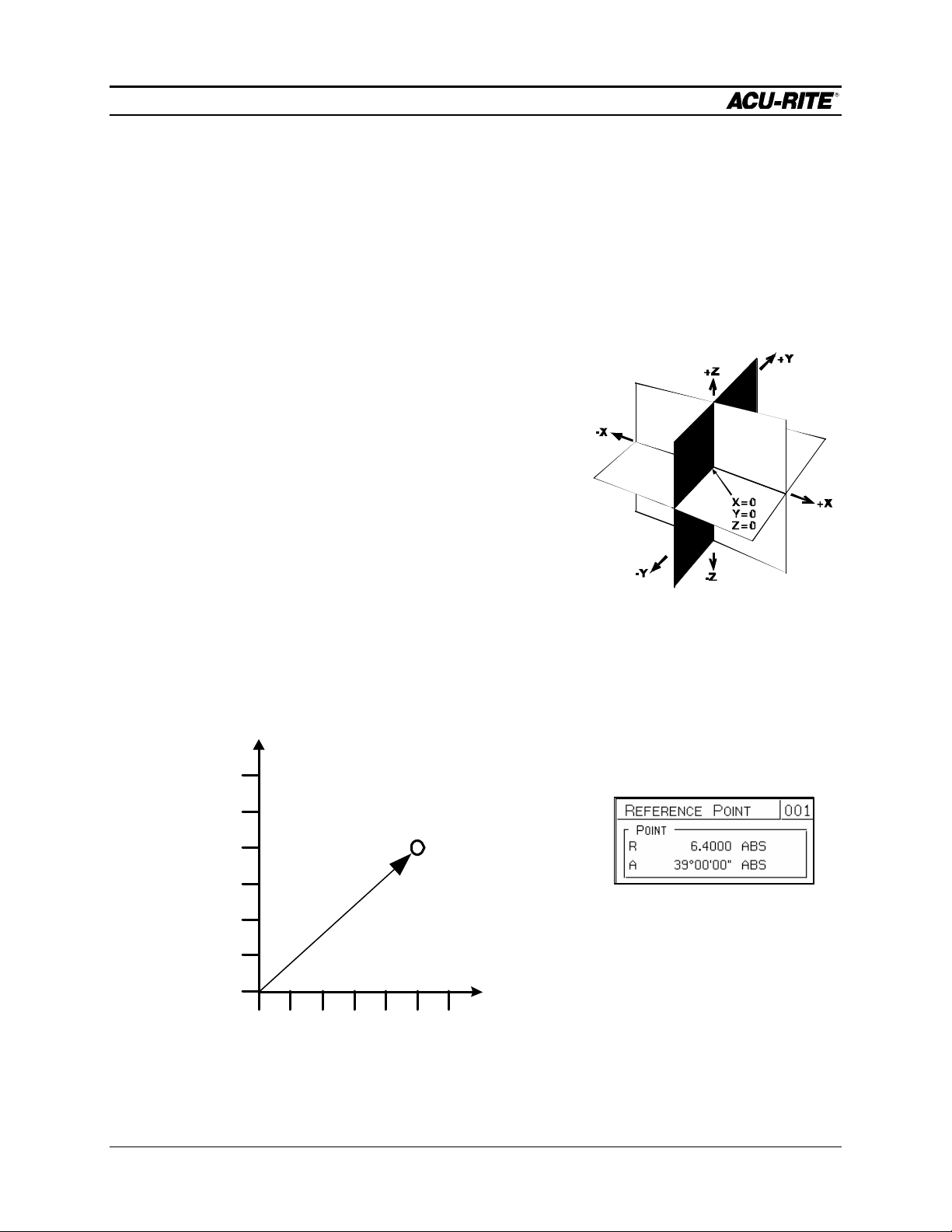

Axis Conventions

Cartesian Coordinates

When programming a part using MILLPWR, table movement and tool motion are

determined by the use of positive or negative numbers. MILLPWR has been factory set

with the following positive and negative directions for X, Y, and Z:

X-axis: the table will move to the left, with tool

motion to the right, for positive positions.

Y-axis: the table will move toward you while tool

motion is away from you for positive positions.

Z-axis: quill movements up (away from the table

surface) are for positive positions.

Polar Coordinates

The polar radius (R), is the distance from datum (absolute zero) to a point. The polar

angle (A), is formed by the X-axis and the radius, positive counter- clockwise. The

angle is always measured from the positive X-axis.

6

5

4

3

2

1

R=6.4

A=39°

0

1 2 3 4 5 60

Operation Manual Page 1-7

Page 17

INTRODUCTION

MILLPWR

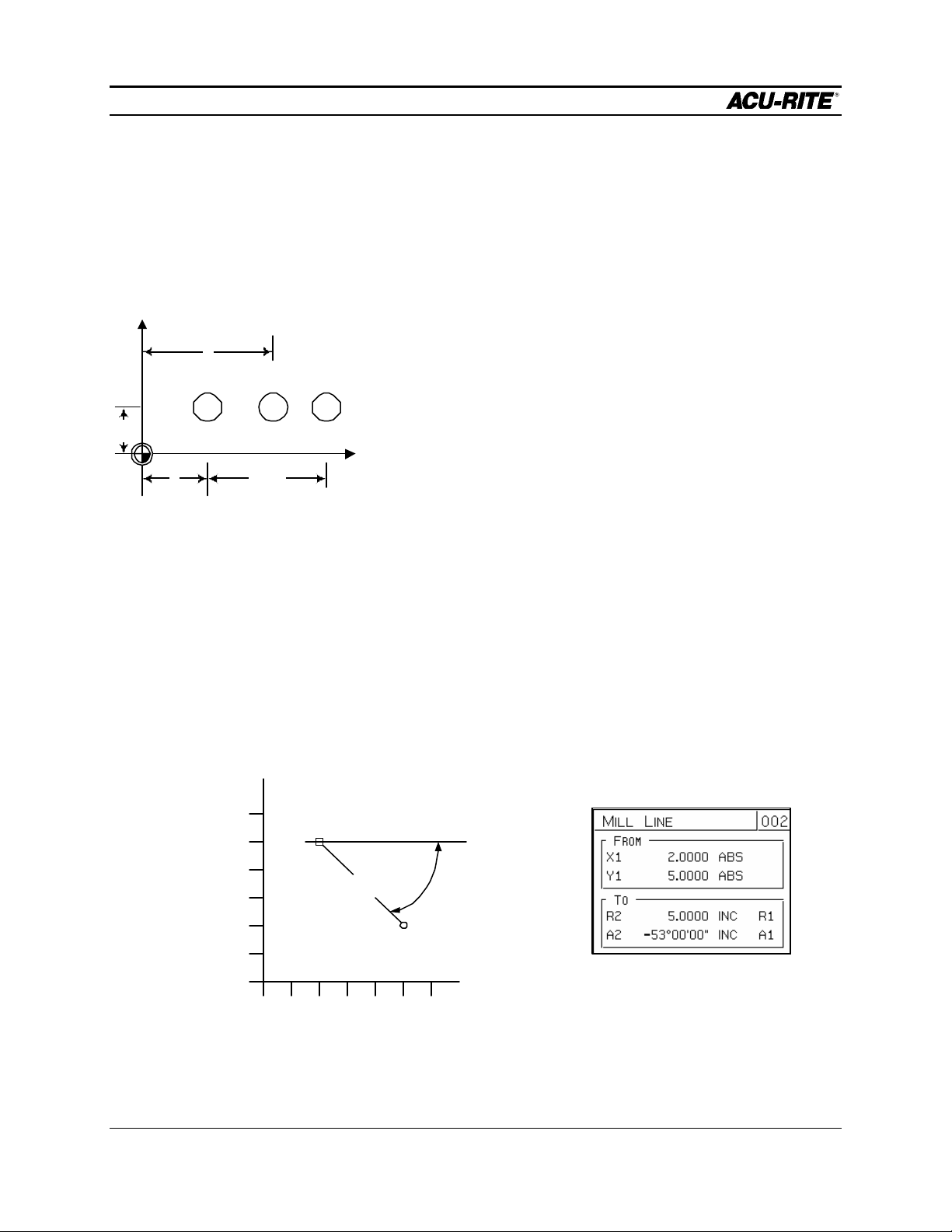

Absolute / Incremental

Dimensions you enter from the print can be either absolute or incremental.

Absolute dimensions are measured from the datum which is the workpiece zero.

Incremental dimensions are measured from one point to another.

+Y

1.5

4

A B C

2

3.625

absolute coordinates of a point.

Both absolute and incremental dimensions can be used on the same workpiece. For

example, Hole C has the dimensions X = 3.625 INC from hole A, Y = 1.5 ABS.

Example: Polar and Incremental

Here is how to enter the angle of a line:

If your drawing provides the angles from one end, you need to use polar and

incremental. The end of the line is measured incrementally from the beginning of the

line.

+X

Holes A and B are dimensioned as absolute, but hole C is

dimensioned incrementally from A.

When entering these dimensions in the MILLPWR, we

would say:

Hole A: X = 2.000 ABS

Hole B: X = 4.000 ABS

Hole C: X = 3.625 INC from hole A

It will often be easier to describe a location in terms of

incremental dimensions than it would be to calculate the

6

5

4

3

2

1

0

P1 (From)

5.0

P2 (To)

0 1 2 3 4 5 6

- 53°

Page 1-8 Operation Manual

Page 18

INTRODUCTION

MILLPWR

Notice that if you don’t use incremental coordinates, Point 2 will be incorrect because it

will be measured from the datum instead of from Point 1.

Operation Manual Page 1-9

Page 19

INTRODUCTION

MILLPWR

BLANK PAGE

Page 1-10 Operation Manual

Page 20

DRO

MILLPWR

DRO FUNCTIONS

Start-Up

Power Up

• Make sure the power switch on the back of the Operator’s Console is on.

• Turn the on/off switch on the side of the controller cabinet ON.

After the program has loaded, the following screen will appear:

SERVO

FEED 0 100%

OFF

SCALE 1.0000TOOL:

INCH

DRO stands

for “digital

readout”.

INC

X

0.0000

INC

Y

0.0000

INC

Z

0.0000

ZERO X ZERO Y ZERO Z DATUM

This is called the “DRO” screen. It shows you the current tool position. Here you

can use several DRO functions to set up your job. In fact, you can use this as a

normal DRO when you use your machine manually.

0.0000

0.0000

0.0000

ABS

ABS

ABS

MOVE

TABLE

Operation Manual Page 2-1

Page 21

DRO

MILLPWR

Finding Home

The ACU-RITE’s ENC150 precision glass scales included with your MILLPWR

system are different from standard ENC150 glass scales because they have only

one reference mark. The reference mark will be located between five and eight

inches from the centerline of your scale. The reference mark will most likely be

found in the positive count direction for both the X and Y axes; however, it may be

found in the negative count direction depending upon how the scale(s) are mounted.

MILLPWR must find these reference marks after power-up in order to establish the

farthest table travel, so you won’t crash the table. You must find home before you

can run a program.

To find home, press the DATUM softkey, then the FIND HOME softkey. The

Once you are

familiar with where

the reference marks

are, you can use the

“MOVE TABLE”

function to get close

to them before you

press "FIND HOME".

table will move, one axis at a time, to find the reference positions.

If the table moves until it hits the hard stops and the servo motor stops, it

means the table was already positioned past the home position. Use the

handcranks to move the table away from the end and press FIND HOME

again. Should the FIND HOME softkey be pressed immediately after home has

been found, the table will move to the hard stops and the servo motors will

disengage.

DATUM is a term

for “workpiece

zero” or “absolute

zero”.

After home has been found, the DRO display will change. The absolute display

shows the tool position from the most recent datum.

Page 2-2 Operation Manual

Page 22

DRO

MILLPWR

DRO Functions

Reset an Axis

Pressing the ZERO X, ZERO Y, or ZERO Z softkey will zero the incremental position

of that axis.

You can’t change

to metric if you

have an “inch”

program active,

and vice versa.

Note that the

arrow keys will

move the table!

Inch - Metric

To change the measurement system between inches and metric units, press the

SETUP key to get the INCH and MM softkeys. Select the system you want, and

press USE NEW SETTINGS.

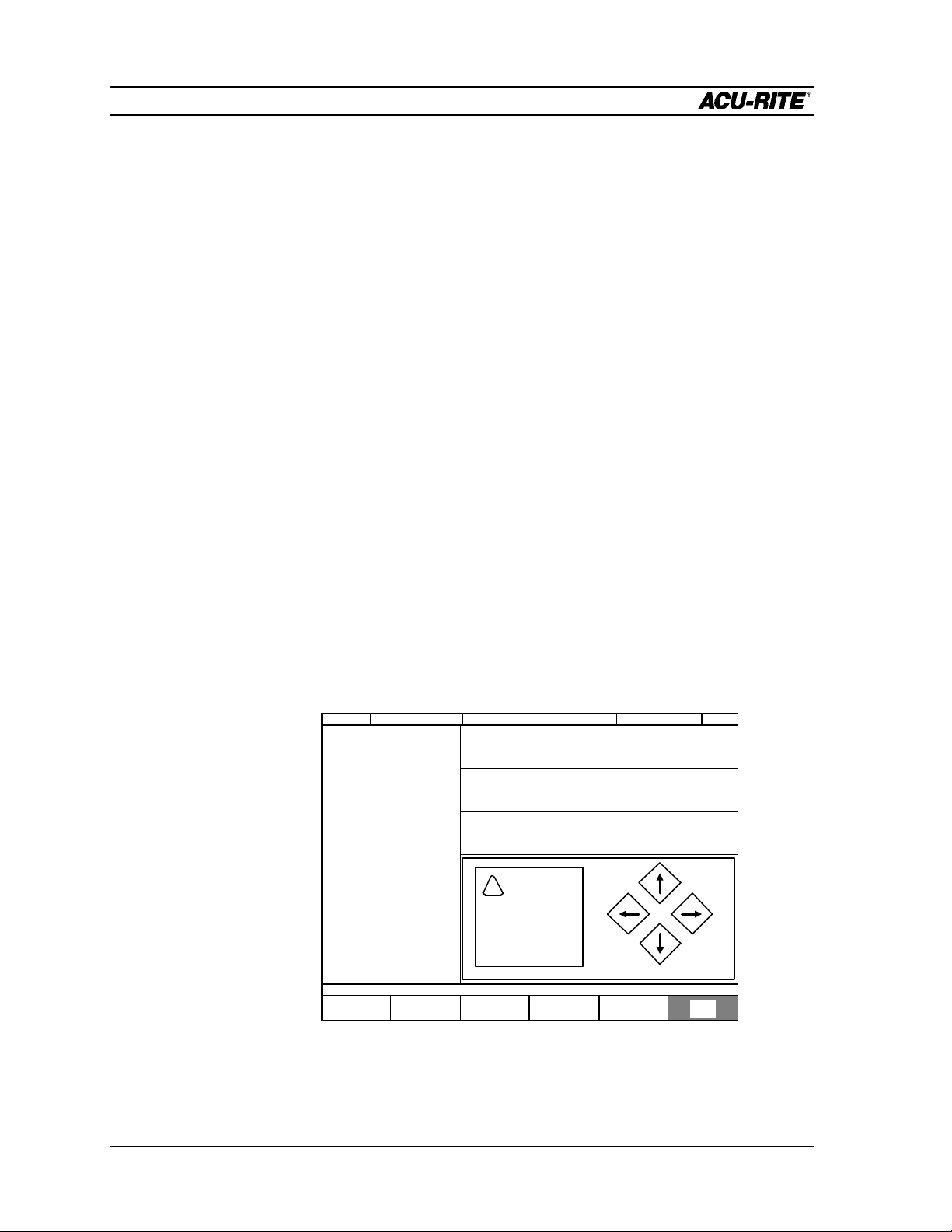

Move Table

This function lets you move the table rapidly using the arrow keys. Pressing the

MOVE TABLE softkey will caution you that the arrow keys no longer move around

the screen, but will instead move the table.

SERVO ONFEED 0 100%

X

Y

Z

INC

0.000

INC

0.000

INC

0.000

SCALE 1.0000TOOL:

0.0000

0.0000

0.0000

INCH

ABS

ABS

ABS

!

CAUTION

ARROW KEYS

WILL MOVE TABLE

PRESS CANCEL WHEN FINISHED MOVING TABLE.

MOVE

TABLE

Operation Manual Page 2-3

Page 23

DRO

MILLPWR

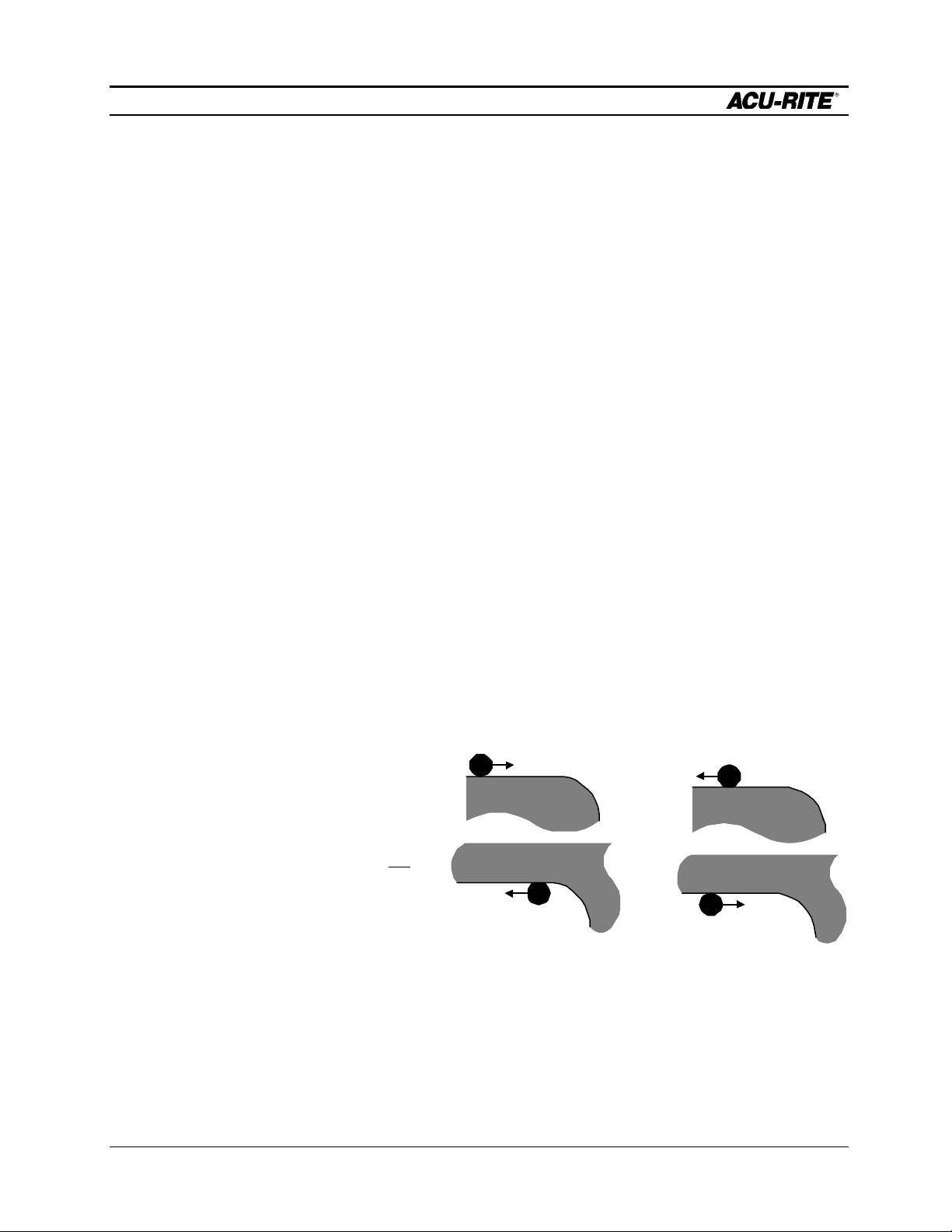

The table moves in the direction of the arrows. You can move in both X and Y at

the same time.

MOVE TABLE AWAY

FROM YOU

While the MOVE TABLE

It’s a REALLY good

idea to fold in the

handcrank handles

before moving the

table!

Establishing a Datum

A datum is a reference point that you establish as the workpiece zero. You need to

set a datum for each job. The location on the workpiece that is to be used as the

datum will be determined by the way the part is dimensioned on the blueprint. In

general, you should select a datum location so that you may enter most dimensions

directly, without calculations.

MOVE

TABLE

LEFT

MOVE

TABLE

RIGHT

MOVE TABLE

TOWARDS YOU

softkey is pressed, the

servo motors are on.

Press it again to turn them

off.

The datum position is not lost at power-down, so you can quit in the middle of a job

at night and easily resume it the next morning.

The simplest datum location to set is where you can position the tool exactly at that

location in all three axes.

• Position the

workpiece so that the

datum point is directly

beneath the tool. This

point might be a

corner, the center of a

bolt hole pattern, etc.

SERVO

X:

Y:

Z:

OFF

FEED 0 100%

SET DATUM

X

Y

Z

INC

0.0000

INC

0.0000

INC

0.0000

SCALE 1.0000TOOL:

0.0000

0.0000

0.0000

• Press the DATUM

softkey and the Set

Datum entry form will

appear.

• Press the X=0, Y=0,

and/or Z=0 softkey(s)

ENTER THE NEW ABSOLUTE POSITION OF THE TOOL CENTER.

X = 0 Y = 0 Z = 0

FIND

HOME

USE

PROBE

MOVE

TABLE

to establish workpiece zero.

INCH

ABS

ABS

ABS

• Press USE to lock in the workpiece zero.

Page 2-4 Operation Manual

Page 24

DRO

MILLPWR

If you can’t position the tool center right at the datum, you’ll need to enter a value

for each axis. The value to use is the absolute position of the tool center from the

new datum. For one axis at a time, position the tool to a known location, such as

the edge of the workpiece. Without moving the tool, enter the desired location of

the tool center and press ENTER. Then move to position the next axis. When all are

entered, press USE.

DISTANCE TO

The MILLPWR

calculator helps a lot

here---To set the

datum for the X axis,

enter:

0.3875/2+.005. Then,

since the tool center is

left of the datum,

change the sign.

.005 SHIM

0.3875

TOOL

ENTER

+

While you are setting the datum, you can use the MOVE TABLE softkey to help you

with long moves.

Using A Probe

You may use a touch probe or edge finder to get very accurate edge locations.

Make sure the diameter of the probe is correct (it’s found in the SET-UP list).

Install the probe and connect it to the back of the Operator Console. Then, for one

axis at a time, enter the absolute position of the edge to be touched into the datum

form, press the USE PROBE softkey, and move the table slowly until the probe

touches the workpiece. When the probe touches, the USE PROBE softkey will

release. Press the USE key to set the absolute position of each axis.

TIP:

Right after you find

home, you

can move quickly to

your previous datum

using the position

function:

POS

GO

Operation Manual Page 2-5

Page 25

DRO

MILLPWR

One Time Milling Functions

Any of the milling functions, except BLEND, can be used “one time” without creating

a program. Press the desired milling function key, fill in the information, and press

GO.

The information for each function will be remembered for the next time you use it.

Each function is described in the Program Steps section.

For many of the milling functions, such as a pocket, you will need to set the proper

tool diameter. You can use the TOOL key as a one-time function to do this.

Page 2-6 Operation Manual

Page 26

PROGRAMMING

MILLPWR

PROGRAMMING

Programming Considerations

Depth of Cut

Since the vertical Z-axis is not controlled by a servo motor, you must make changes to

the depth of cut manually.

You don’t have to program the depth, but if you do, MILLPWR will preset the

programmed value into the DRO for you. Then, when it’s time, MILLPWR will show

you the DRO and ask you to set the depth.

If you are not programming depth, leave it set to 0.

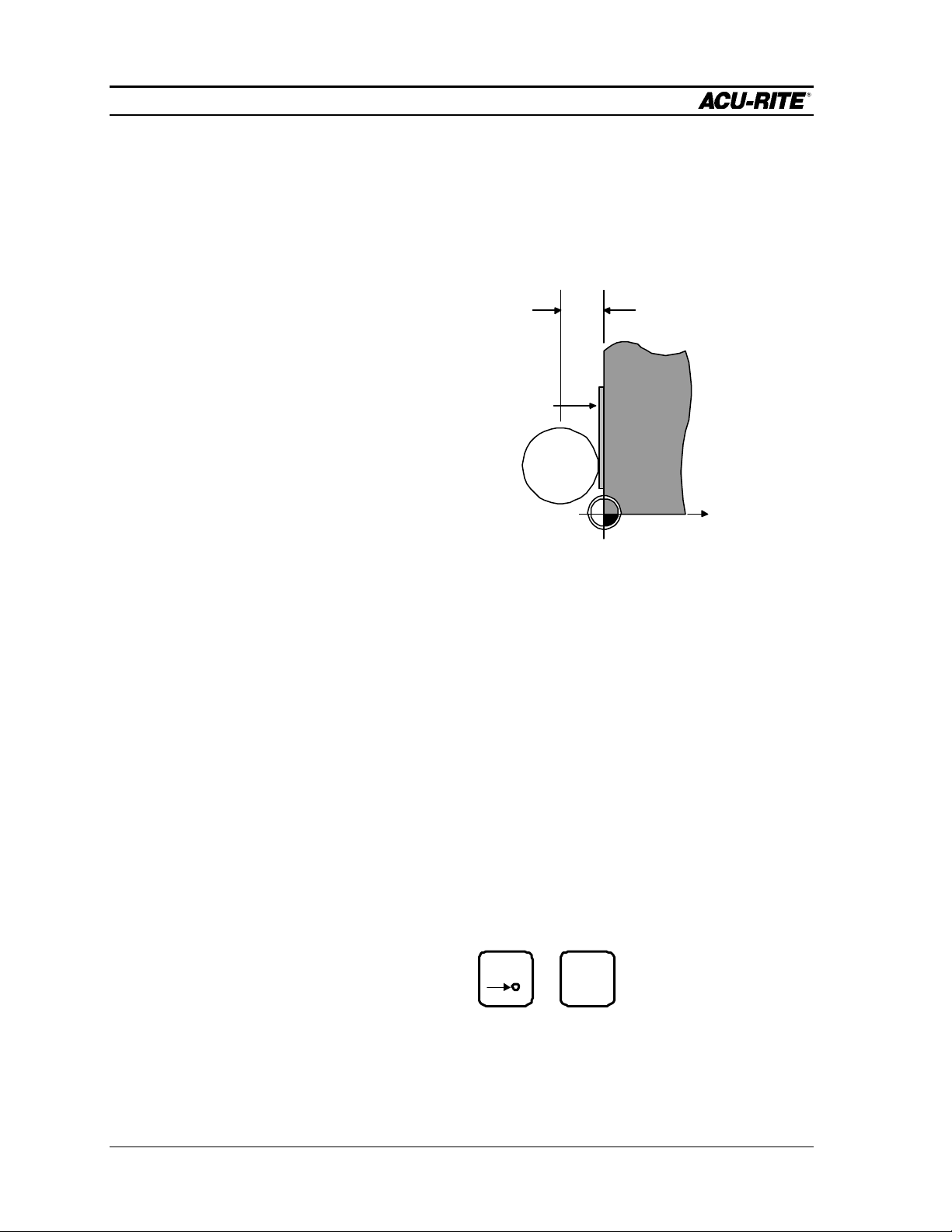

Tool Offset

With MILLPWR, you never have to worry about the actual tool path. Because of

MILLPWR ’s tool radius compensation capability, you program only the actual part

dimensions. When you program a line, arc, or frame, use the TOOL OFFSET field to tell

MILLPWR which side of the cut you want the tool to be on.

Picture yourself standing behind the tool as it is moving. If the tool is on the left of the

workpiece, use “left” offset. If the tool is to the right of the workpiece, use “right” offset.

By using left and right offsets,

you can program the

LEFT OFFSET

RIGHT OFFSET

dimensions of the part as

found on the blueprint.

MILLPWR will take care of

all cutter radius

compensation. You do not

have to program the tool

path.

If you use “center” offset, the

programmed dimensions are

for the center of the tool.

For some milling functions, like Frame and Arc, “inside” and “outside” offsets help you

visualize where the tool is.

Operation Manual Page 3-1

Page 27

PROGRAMMING

MILLPWR

“From” and “To” Points

MILLPWR lines and arcs are defined by both FROM and

TO points. MILLPWR will automatically go to the start

point before it asks you to set the depth.

Datum Selection

The datum is the point where all absolute dimensions are measured from. You must look

at the blueprint of the part and decide what to use as a datum. You should pick a point

which will let you enter most of the dimensions directly, without calculations. However,

any point you select will give the same results.

FROM TO

FROM

X1 ABS

Y1 ABS

TO

X2 ABS

Y2 ABS

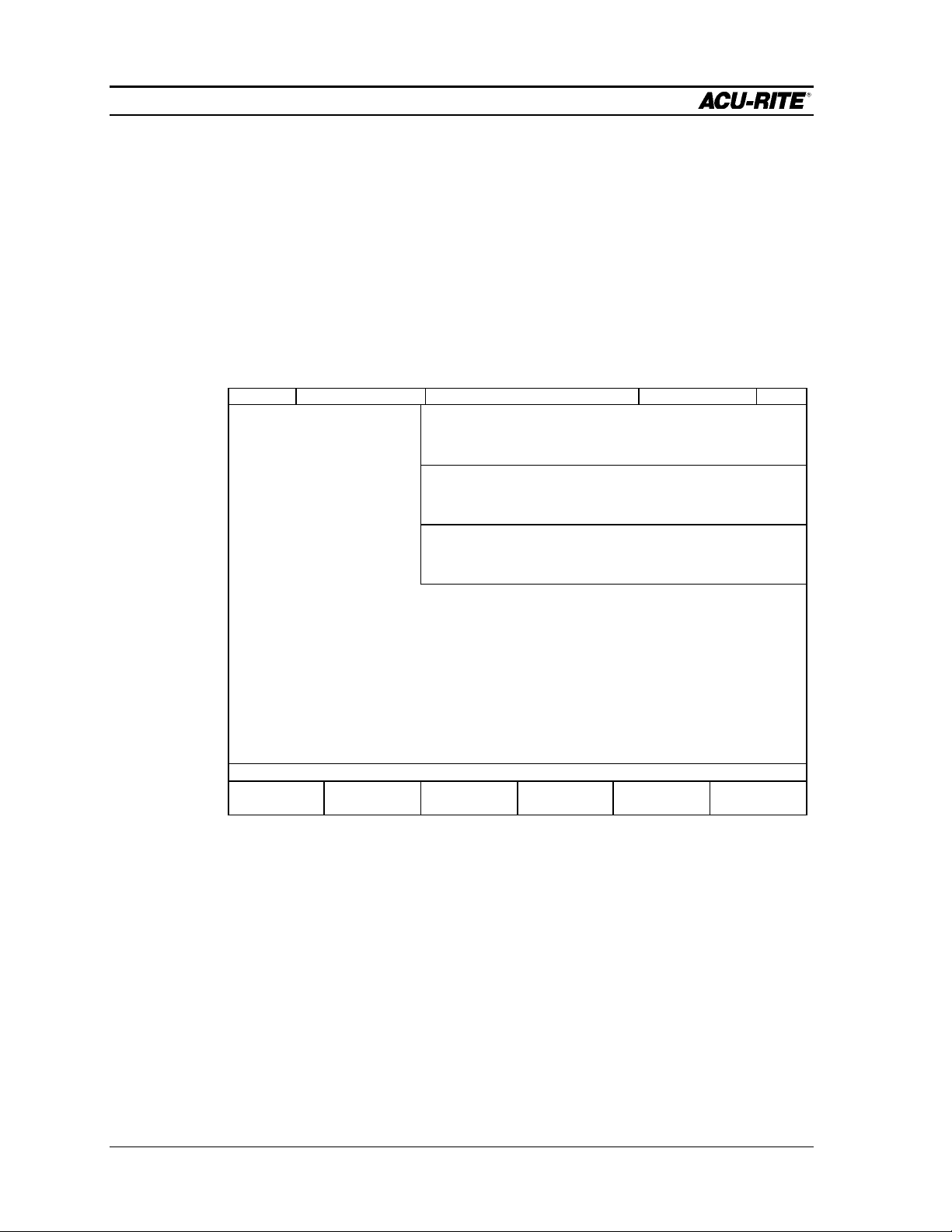

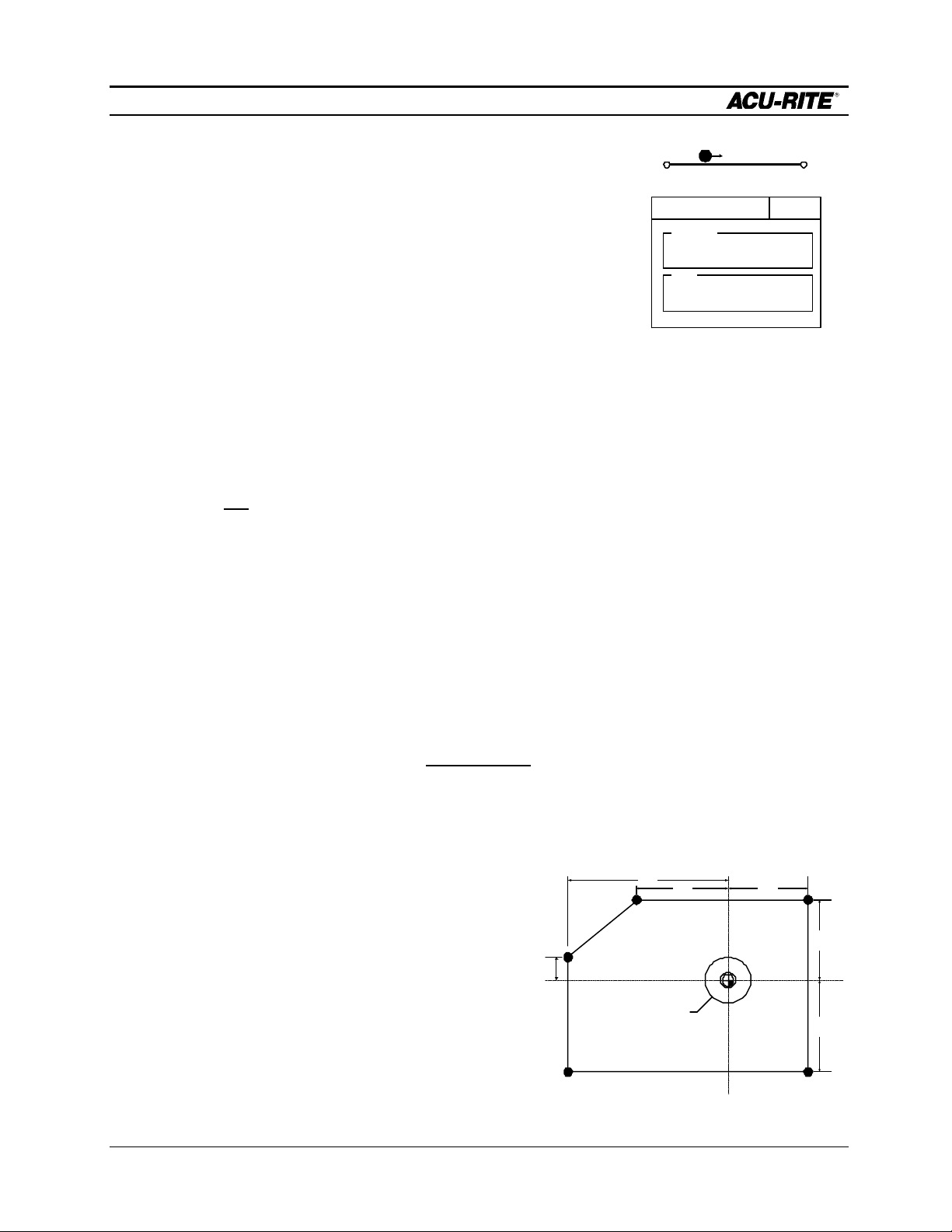

Absolute and Incremental Dimensions

To help you enter dimensions directly from the blueprint, MILLPWR allows direct entry

of both absolute and incremental dimensions. Any dimension measured from the point

you select as the datum is called absolute.

A dimension measured from any other point is called incremental. This “other point” is

called the incremental reference point.

For the part drawn below, if we put the datum in the center of the hole (point F), all

dimensions are absolute.

Point X Y

A -7.123 ABS -3.936 ABS

B 3.421 ABS -3.936 ABS

C 3.421 ABS 3.603 ABS

D -4.893 ABS 3.603 ABS

E -7.123 ABS 1.011 ABS

1.011

7.123

D

E

2.96 DIA

THRU HOLE

3.4214.893

F

C

3.603

3.936

F 0.00 ABS 0.00 ABS

A B

Page 3-2 Operation Manual

Page 28

PROGRAMMING

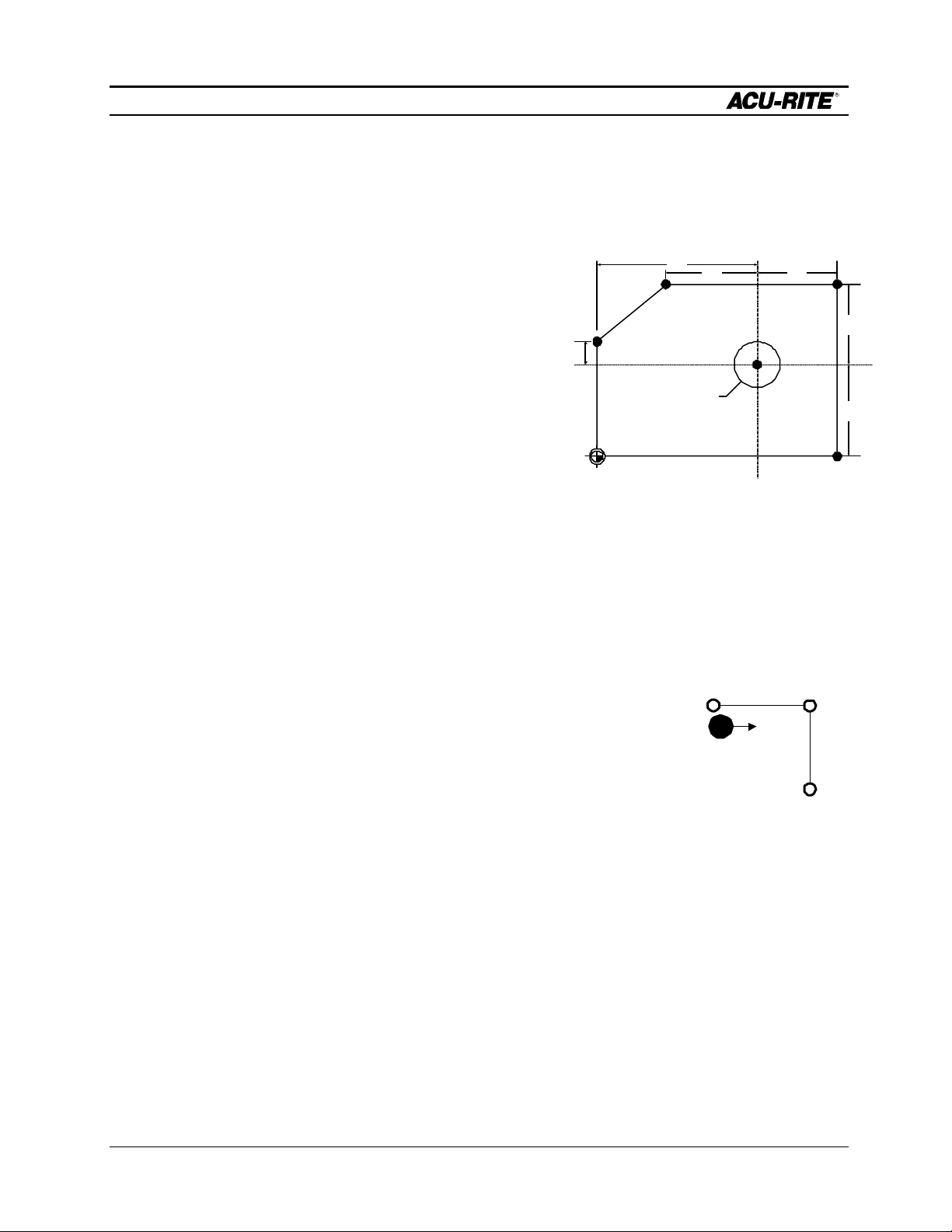

MILLPWR

If we use point A as our datum, many of the given dimensions are incremental because

they are measured from the incremental reference point F and not from the datum.

Point X Y

MILLPWR will

display marks to

the right of each

program step

number for

continuous

contours.

7.123

D

A 0.00 ABS 0.00 ABS

B 3.421 INC F 0.00 ABS

C 3.421 INC F 3.603 INC F

D -4.893 INC F 3.603 INC F

E 0.00 ABS 1.011 INC F

F 7.123 ABS 3.936 ABS

1.011

E

2.96 DIA

THRU HOLE

A

Continuous Milling

When you program a continuous contour made up of lines and arcs, MILLPWR

will mill the contour without stopping. MILLPWR will detect a continuous contour

automatically. There are no special keypresses or different functions to learn.

For lines and arcs to be continuous, they must:

FROM TO

• have the same Z depth,

3.4214.893

F

C

3.603

3.936

B

FROM

• be cut with the same tool,

• be cut on the same side,

TO

• and, of course, they must “touch”--the end of one

must be the same as the start of the next.

When you follow one line (or arc) with another, MILLPWR assumes that you want them

to be connected. It automatically fills in the FROM point, Z depth, and tool offset. All you

have to do is fill in the TO point, and press USE.

You can have different feedrates within a continuous contour by entering the feedrates

you want in each step of the contour.

Operation Manual Page 3-3

Page 29

PROGRAMMING

MILLPWR

Creating a Program

Press the PGM key, and the following program screen appears.

SERVO

OFF

CURRENT PROGRAM

PROGRAM

FUNCTIONS

FEED 0 100%

END OF 0

CLEAR

PROGRAM

EXPLODE

MORE

STEPS

SCALE 1.0000TOOL:

RUN

OPTIONS

INCH

You create a program by creating a list of milling steps to be performed. As you add to

your list, each step will be drawn immediately on the screen so you can see a picture

of your part in progress.

Program

Step

Listing

• To enter a milling step, press the appropriate milling function key. The function

you select will appear in the program listing, and you can enter the information

SERVO

OFF

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

X

FEED 0 100%

2 OF 2

MILL ARC 002

FROM

X1 ABS

Y1 ABS

TO

X2 ABS

Y2 ABS

DEPTH

Z ABS

RADIUS

DIRECTION

CCW

TOOL

0.500 DIAMETER

FL END ML

CENTER OFFSET

10FEED IPM

TEACH

POSITION

TYPE

SCALE 1.0000TOOL:

INCH

Enter

information

about the arc

into this form.

MOREPOLAR

Page 3-4 Operation Manual

Page 30

PROGRAMMING

MILLPWR

describing the step into the form.

• After entering all the data for a step, press the USE key to accept the data. This

updates the picture and moves down for the next step.

SERVO

OFF

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

PROGRAM

FUNCTIONS

FEED 0 100%

END OF 2

CLEAR

PROGRAM

EXPLODE

MORE

STEPS

SCALE 1.0000TOOL:

RUN

OPTIONS

INCH

• To change a step, use the arrow keys to move to the step and press USE or ENTER.

When you have made your changes, press USE to put the changed step back into

the program.

• To delete a step, move to the step and press the DEL key.

• To insert a step, move to where you want the new step to go, and press the new

milling function key.

If you decide not to use a milling function that you have selected, press the CANCEL key.

In addition to the milling functions, the MORE STEPS softkey lets you pick from a

number of other useful steps, such as REPEAT and ROTATE. All steps are described in

the Program Steps section.

Operation Manual Page 3-5

Page 31

PROGRAMMING

MILLPWR

The View Key

If you need to see more detail of the picture, press the VIEW key. This brings up the

following softkeys:

ZOOM

IN

ZOOM

OUT

RESTORE

The ZOOM IN softkey magnifies the picture, and the arrow keys move the picture up,

down, left, and right. The ZOOM OUT softkey will de-magnify the picture, and the

RESTORE softkey brings back the original view.

Press VIEW again (or CANCEL) to see the normal programming softkeys.

Running a Program

When you are ready to run a program, you must make some preparations. This includes

fixturing the workpiece, setting or finding the datum, and deciding on the tools to use.

Setting the Datum

From the DRO, select the DATUM softkey. There are two ways to find the datum:

“touching off” with a tool and using a touch probe or edge finder.

To touch off with a tool:

• Move the tool to touch the edge of the workpiece.

• Key in the new absolute position of the tool center in this axis. Be careful of the

polarity.

• Before you move the table, press ENTER or an arrow key. At this time, MILLPWR

remembers the scale position and will use it to determine the datum for this axis.

• Repeat for the second and, if desired, the third axis. Be sure to press ENTER

For the last axis, you

can press USE

instead of ENTER.

while the tool is in position.

• Press USE to establish the datum.

Page 3-6 Operation Manual

Page 32

PROGRAMMING

same time is

MILLPWR

Testing Your Program

Before you run your program, you might want to test it for things like tool path,

directions, feed rates, and sequence of operations. MILLPWR provides several runtime options to assist you. In the program screen, press RUN OPTIONS to display the

following softkeys.

Using DRY

RUN and

GRAPHICS

ONLY at the

especially

handy.

SINGLE

STEP

DRY

RUN

GRAPHICS

ONLY

MANUAL

POSITIONING

DISABLE

LOOK AHEAD

RUN

OPTIONS

Press any key to activate the option; press it again to release it.

SINGLE STEP

Normally, a continuously milled contour will be cut without stopping. With

single step activated, MILLPWR will stop after each step.

DRY RUN

With this activated, MILLPWR will run your entire program at high speed and

without stopping for anything. You can follow the sequence of steps and see if

the part fits entirely on the workpiece. The dry run speed is determined in

SETUP.

GRAPHICS ONLY

With this activated, the program is run normally, except that the table does not

move. You can see all normal feedrates, tool changes, and so on.

MANUAL POSITIONING

Activate this option if you want to move the table by hand. The MILLPWR acts

just like a programmable DRO. Each target position is preset into the DRO,

and you are prompted to operate the table by hand.

DISABLE LOOK AHEAD

Normally, each cut in a contour is compared to every other cut to determine if

the tool will interfere with the part. This is called look ahead. If you press the

DISABLE LOOK AHEAD key, your program will run without doing this. Except

for custom pockets, selecting this option will make the tool path calculation much

faster.

Operation Manual Page 3-7

Page 33

PROGRAMMING

MILLPWR

Pressing the GO Key

To run a program, with or without any of the run options, move to step 1 and press GO.

Most MILLPWR program steps will cause the tool to move rapidly to the start point of

the step. You then set the tool to the proper depth, press GO, and MILLPWR performs

the action required for the step.

Before any rapid move, MILLPWR will display a warning message that the table is about

to move at high speed and that you should check for tool clearance:

ATTENTION

!

RAPID MOVE

RAISE QUILL

PRESS "GO"

.WARNING

Whenever you are about to run a

program, be sure the handcrank handles

are recessed. Rapid spinning of the

manual handwheels could cause injury.

When the GO key is pressed again, the table will move in a straight line to the new

position where you will be asked to drill or set the tool to the desired depth.

ATTENTION

!

Z AXIS

SET TO

0.0000

PRESS "GO"

Page 3-8 Operation Manual

Page 34

PROGRAMMING

MILLPWR

The remote button

acts as STOP if you

are going and as

GO if you are

stopped.

immediately.

If you use the STOP key, the following prompt will appear:

During any rapid or feed move, you may press the STOP key or the emergency

TABLE STOP button to disengage the power feed for any reason. This will stop

the table motion but will not stop the rotating cutting tool unless your

machine has been specifically wired to do so.

If you press the emergency TABLE STOP button, the program stops running

ATTENTION

!

PAUSE

PRESS "GO"

To move quickly to a

step, key in its number

(look in the message

bar), and press

ENTER.

amount for each keypress.

The override percentage is shown next to the FEED rate in the status bar at the top of the

screen. An override percentage of 100% means that actual feed rates will be at 100% of

the programmed feed rates. If the override percentage is 50%, actual feed rates will be

half of programmed values.

You can press the feedrate override keys at any time, even while the machine is moving.

Machining to Zero

Press GO again when ready to continue running, or STOP to stop running the

program.

To re-start a program, move to the step you wish to start with, and press GO.

MILLPWR will always go to the beginning of a step, even if it had been started.

Feed Rate Override

The FEED+ and FEED- keys will change the override percentage by a certain

MILLPWR is factory set in a distance to go display view. This way, any dimension you

have programmed will be “preset” into the DRO display. Every move will start at the

preset value and end at zero.

Operation Manual Page 3-9

Page 35

PROGRAMMING

SET TO

MILLPWR

If you have programmed a Z depth, when it is time for you to position the Z axis,

MILLPWR will preset the depth value into the DRO Z-axis, and the following Z- axis

prompt will appear:

ATTENTION

!

Z AXIS

SET TO

0.000

PRESS "GO"

Move the quill until the absolute Z display is zero.

If you wish, you can set MILLPWR to the incremental travel display view (see System

Setup). In this view, every move will start at 0.000 and end at the programmed value.

For example, if you have programmed a depth of -0.500, when it’s time to move the

quill, the Z-axis display will show the current tool position, and the prompt will be:

ATTENTION

!

Z AXIS

-0.500

PRESS "GO"

Page 3-10 Operation Manual

Page 36

PROGRAMMING

MILLPWR

Program Functions

Accessing the Load, Save, Delete, and Backup Options

MILLPWR offers you several versatile features for loading, saving, deleting, and backing

up information. Plus, built-in organizational tools make it easy to categorize—and later

retrieve—the programs you’ve stored.

To access these features, press the PROGRAM FUNCTIONS softkey.

SERVO

OFF

FEED 0 100%

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

003 MILL LINE

004 MILL LINE

005 MILL LINE

006 BLEND

007 MILL LINE

008 MILL LINE

009 MILL LINE

010 SET TOOL

011 BOLT CIRCLE

SCALE 1.0000TOOL:

INCH

END OF 11

PROGRAM

FUNCTIONS

CLEAR

PROGRAM

EXPLODE

MORE

STEPS

RUN

OPTIONS

A prompt will ask you to select a program function. You may load a saved file, save the

program you have been working on, delete files, create backup copies, or work with

directories.

SELECT A PROGRAM FUNCTION.

LOAD DELETE DIRECTORYBACKUPSAVE

Operation Manual Page 3-11

Page 37

PROGRAMMING

12

MILLPWR

Saving a Program

You can save your programs in any of three places—on MILLPWR’s internal hard disk

drive, on a 3 ½” floppy disk, or on your PC’s hard disk drive. It is always a good idea

to save your programs for later reference and as a preventative measure against

accidental loss due to a power failure. As a rule of thumb, save your programs often to

avoid losing valuable information.

• After choosing the PROGRAM FUNCTIONS option, select the directory where you

want to save your program. Otherwise, your program will be saved in the last

directory that was selected. (Refer to the Selecting a Directory and/or Creating a

Directory section(s).)

• Return to the “Current Program” screen, then press the SAVE softkey. A “Program

Name” prompt will appear:

SERVO

OFF

FEED 0 100%

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

003 MILL LINE

004 MILL LINE

005 MILL LINE

006 BLEND

007 MILL LINE

008 MILL LINE

009 MILL LINE

010 SET TOOL

011 BOLT CIRCLE

END OF 11

ENTER A NAME FOR THE PROGRAM.

SAVE ALPHABET

SAVE PROGRAM

PROGRAM NAME

TEXT

FORMAT

SCALE 1.0000TOOL:

USE

FLOPPY

REMOTE

STORAGE

INCH

If you want to save your program as a text file, press the TEXT FORMAT softkey.

Note: Information is stored as a numeric file (i.e., program.nsf ) unless you indicate

otherwise. By saving the program as a text file (i.e., program.mpt), you will enjoy

more flexibility later—such as editing the program on a PC or printing a hard copy of

the program steps.

PLATE

• Name the program. (Refer to the Naming a Program section.)

• Press the SAVE softkey. The program’s name should now appear in the left column

above the program steps.

Page 3-12 Operation Manual

Page 38

PROGRAMMING

MILLPWR

Note: If you make any changes, make sure that you save the program again.

Operation Manual Page 3-13

Page 39

PROGRAMMING

MILLPWR

Directories

One of the best ways to keep programs organized is to save them in directories.

Directories are like file folders—they should be clearly labeled and contain closely

related projects. They can be used to categorize programs by job, operator, customer,

or any other method you prefer.

• Press the PROGRAM FUNCTIONS softkey, then press the DIRECTORY softkey.

SELECT A DIRECTORY FUNCTION.

SELECT

DIRECTORY

CREATE

DIRECTORY

DELETE

DIRECTORY

Now you can create a directory, open an existing directory, or delete a directory that

you no longer need.

Creating a Directory

The best approach to take when creating a directory (or “subdirectory”) is to decide

first where to file it. You can file it under a main heading (“MILLPWR,” “A:,” or

“REMTSTOR”) or layer it within subdirectories that you have already created.

Let’s look at an example. The illustration on the next page shows “MILLPWR” and

four subdirectories that we created to keep our programs better organized. In this

case, we designated the MILLPWR directory as our miscellaneous programs folder

and created specific folders for three of our biggest customers.

“COMPANY1,” our largest client, has placed several part orders for a single month.

To help us find those part programs quickly and easily, we save them in subdirectory

“JULY1998.”

When we created the subdirectories COMPANY1, COMPANY2 and

COMPANY3, we selected MILLPWR as the directory we wanted to file each one

under.

When we created the JULY1998 folder, we selected COMPANY1 as the directory

we wanted to file the new subdirectory under. If we want, we can create another

Page 3-14 Operation Manual

Page 40

PROGRAMMING

MILLPWR

subdirectory under JULY1998, layer another one under that, one under that and so

on. How many directories you create and how you layer them is up to you.

Follow the steps below to create directories for your own programs.

• After you have selected the PROGRAM FUNCTIONS and DIRECTORY options,

press the SELECT DIRECTORY softkey.

SERVO

FEED 0 100%

OFF

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

003 MILL LINE

004 MILL LINE

005 MILL LINE

006 BLEND

007 MILL LINE

008 MILL LINE

009 MILL LINE

010 SET TOOL

011 BOLT CIRCLE

END OF 11

SELECT A WORKING DIRECTORY.

SELECT

DIRECTORY

PAGE

UP

DIRECTORY

MILLPWR

COMPANY1

JULY1998

COMPANY2

COMPANY3

1 OF 5

PAGE

DOWN

SCALE 1.0000TOOL:

USE

FLOPPY

• Indicate where you want to store your new subdirectory.

On MILLPWR’s internal hard disk drive:

REMOTE

STORAGE

INCH

Check that the USE FLOPPY and REMOTE STORAGE softkeys are not

selected. “MILLPWR” and any subdirectories should appear under the

“Directory” heading.

On a 3 ½” floppy disk:

Press the USE FLOPPY softkey. “A:” and any subdirectories should

appear under the “Directory” heading.

On your PC’s hard disk drive:

Press the REMOTE STORAGE softkey. “REMTSTOR” and any

subdirectories should appear under the “Directory” heading.

Operation Manual Page 3-15

Page 41

PROGRAMMING

MILLPWR

• Highlight the folder you want to put your new directory in. (In our example, we

highlighted “MILLPWR,” then created a subdirectory “COMPANY1.”)

• Press the SELECT DIRECTORY softkey again to verify your choice. The

“Directory” screen will disappear.

• Now press the DIRECTORY softkey.

• Select the CREATE DI RECTORY softkey. You will be asked to name the

directory.

• Name the directory using the numeric keys on the operator console or by

selecting letters from the ALPHABET option. If you open the alphabet menu, use

the arrow keys to scroll from row to row, then press the ENTER key to make

each selection. All program names are limited to eight characters or less,

consisting of numbers and/or letters.

• After you have named the directory, press the CREATE DIRECTORY softkey

again to verify your choice. The “Directory” screen will disappear.

Additional directories (and subdirectories) may be added at any time.

IMPORTANT!

Creating a directory does not mean the directory is

selected. If you plan to save your current program in the

directory you just created, you must select the new

directory first. Otherwise, your program will be saved in the

last directory that was opened.

To select the directory now, press the DIRECTORY

softkey, then the SELECT DIRECTORY softkey.

Using the arrow keys, highlight the new directory.

Press the SELECT DIRECTORY softkey again to select

the directory and return to your current program.

Page 3-16 Operation Manual

Page 42

PROGRAMMING

MILLPWR

Selecting a Directory

The SELECT DIRECTORY softkey allows you to open any of the established

directories on MILLPWR’s internal hard disk drive, on a 3 ½” floppy disk, or on

your PC’s hard disk drive—whichever one you’ve chosen. You will use this feature

anytime you save or load a program.

• After you have selected the PROGRAM FUNCTIONS and DIRECTORY options,

press the SELECT DIRECTORY softkey. The last directory that was opened will

appear.

SERVO

OFF

FEED 0 100%

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

003 MILL LINE

004 MILL LINE

005 MILL LINE

006 BLEND

007 MILL LINE

008 MILL LINE

009 MILL LINE

010 SET TOOL

011 BOLT CIRCLE

DIRECTORY

MILLPWR

COMPANY1

JULY1998

COMPANY2

COMPANY3

SCALE 1.0000TOOL:

INCH

END OF 11

SELECT A WORKING DIRECTORY.

SELECT

DIRECTORY

PAGE

UP

1 OF 5

PAGE

DOWN

• Indicate where the directory you want to select is located.

On MILLPWR’s internal hard disk drive:

Check that the USE FLOPPY and REMOTE STORAGE softkeys are not

selected. “MILLPWR” and any subdirectories you have created should

appear under the “Directory” heading.

On a 3 ½” floppy disk:

Insert the 3 ½” floppy disk containing the directory into the disk drive

(located in the upper-left corner on the front of the MILLPWR operator

console) and press the USE FLOPPY softkey. “A:” and any

USE

FLOPPY

REMOTE

STORAGE

Operation Manual Page 3-17

Page 43

PROGRAMMING

MILLPWR

subdirectories you have created should appear under the “Directory”

heading.

On your PC:

Press the REMOTE STORAGE softkey. “REMTSTOR” and any

subdirectories you have created should appear under the “Directory”

heading.

• Using the arrow keys, highlight the directory you want to open. (If the list is long,

use the PAGE UP/PAGE DOWN softkeys to scroll through the list more quickly.)

• Press the SELECT DIRECTORY softkey again. The “Directory” list will disappear.

You can now save your current program in the directory you have chosen (refer

to the Saving A Program section); or if no program was running, load an

established program from the directory you selected (refer to the Loading a

Program section).

Page 3-18 Operation Manual

Page 44

PROGRAMMING

MILLPWR

Deleting a Directory

Note: MILLPWR will not delete directories that contain programs. You must delete

each program stored within the directory before continuing. Refer to the Deleting a

Program section.

To delete an empty directory:

• After you have selected the PROGRAM FUNCTIONS and DIRECTORY options,

press the DELETE DIRECTORY softkey.

• Identify where the directory you want to delete is located.

On MILLPWR’s internal hard disk drive:

Check that the USE FLOPPY and REMOTE STORAGE softkeys are not

selected. “MILLPWR” and any subdirectories you have created should

appear under the “Directory” heading.

On a 3 ½” floppy disk:

Insert the 3 ½” floppy disk containing the directory into the disk drive

(located in the upper-left corner on the front of the MILLPWR operator

console) and press the USE FLOPPY softkey. “A:” and any

subdirectories you have created will appear under the “Directory”

heading.

On your PC:

Press the REMOTE STORAGE softkey. “REMTSTOR” and any

subdirectories you have created will appear under the “Directory”

heading.

• Using the arrow keys, highlight the directory you want to delete.

• Press the ENTER key. You will be asked if you are sure that you want to delete

the program. Press the “Yes” softkey to continue or the “No” softkey to cancel

the operation.

Operation Manual Page 3-19

Page 45

PROGRAMMING

MILLPWR

Other Program Functions

Naming a Program

If you have

accidentally

selected the

wrong letter or

number, simply

press the DEL

key and rename

the program.

Before you save a program, MILLPWR

requires that you name it.

S

P

ROGRAM NAME

PLATE

AVE PROGRAM

12

• If you want to use alpha characters, press

the ALPHABET softkey. An alphabet will

appear just below the “Program

Name” area.

A

C

HARACTERS

LPHABET

A B C

E F G HD

J K L MI

O P Q R

N

T U V WS

X Y Z

• Using the arrow keys, you can scroll

from one letter to the next. Press the

ENTER key to make a selection.

• To add numbers to the name, simply

press the number keys on the

operator console. You may choose

up to eight characters, mixing numbers and

letters if you wish.

• Press the SAVE softkey. MILLPWR will store your program in the directory you

have selected for use at a later time.

A message will alert you if the file was not saved properly, or if the name that you

have chosen has already been assigned.

Page 3-20 Operation Manual

Page 46

PROGRAMMING

MILLPWR

Deleting a Program

You can remove any program that has already been saved. To delete a program,

follow these steps:

• Select the directory that contains the program you want to delete. (Refer to the

Selecting a Directory section.)

• After you return to the “Current Program” screen, press the DELETE softkey.

SELECT A PROGRAM FUNCTION.

LOAD DELETE DIRECTORYBACKUPSAVE

• Using the arrow keys, highlight the program you want to delete.

• Press the ENTER key. You will be asked if you are sure that you want to delete

the program. Press the “Yes” softkey to continue or the “No” softkey to cancel

the operation.

IMPORTANT!

By answering “Yes,” you will permanently

erase the highlighted program from memory.

Deleted programs cannot be recovered

unless a backup file was created.

Operation Manual Page 3-21

Page 47

PROGRAMMING

MILLPWR

Backing Up a Program

The BACKUP softkey gives you the opportunity to make backup copies of programs

that you have already saved on MILLPWR’s internal hard disk drive. Remember,

you should keep backup copies on hand in case a program is accidentally deleted,

your hard disk drive fails, or you are unable to recover the original files for any other

reason.

• After you have selected the PROGRAM FUNCTIONS option, select the

It’s best to save

and clear the

final version of a

running program

before creating a

backup copy.

Otherwise, you’ll

have to back up

the program

again after you’ve

made any

changes.

directory containing the program(s) you want to back up. (Refer to the

Selecting a Directory section.)

• Return to the “Current Program” screen, then press the BACKUP softkey.

The following softkey options should appear:

ALL

PROGRAMS

SELECT

PROGRAMS

TEXT

FORMAT

USE

FLOPPY

STORAGE

REMOTE

• Indicate where you want to back up your program(s): onto a floppy disk or

onto your PC. Choose either the USE FLOPPY softkey or the REMOTE

STORAGE softkey.

• If you want to back up text programs, select the TEXT FORMAT softkey.

Otherwise, a list of numeric programs will appear by default.

• Choose the number of program(s) you want to back up.

To back up all of the programs in the directory:

Press the ALL PROGRAMS softkey. MILLPWR will highlight and

store a backup copy of each program in the directory you’ve

selected.

To back up only one or just a few programs:

Press the SELECT PROGRAMS softkey. Highlight each program

you want to back up and press the ENTER key. An arrow will

appear beside each program name you’ve selected.

Page 3-22 Operation Manual

Page 48

PROGRAMMING

MILLPWR

Now press the BACKUP PROGRAMS softkey. MILLPWR will

highlight the program(s) and save a backup copy in the directory

you’ve selected.

Note: If a program with the same name is already stored in the directory

you’ve chosen, MILLPWR will ask you if you want to replace the old

copy with the latest one. Choose the “Yes” softkey to continue or the

“No” softkey to cancel the operation.

• After the backup copies are made, the programs list will disappear.

Operation Manual Page 3-23

Page 49

PROGRAMMING

MILLPWR

Loading a Program

The LOAD softkey allows you to open programs that have already been saved. The

steps below tell you how to retrieve a program from MILLPWR’s internal hard disk

drive, a 3 ½” floppy disk, or your PC’s hard disk drive.

IMPORTANT!

Save and clear any running programs before continuing.

Otherwise, your work will be lost when

another program is loaded.

From MILLPWR’s internal hard disk drive:

• After you have selected the PROGRAM FUNCTIONS option, press the

LOAD softkey. The last directory that was selected and any programs it

contains will appear.

SERVO

OFF

FEED 0 100%

CURRENT PROGRAM

PICK A PROGRAM TO LOAD.

LOAD

PAGE

UP

MILLPWR

MILL1

MILL2

BOLTPRGM

PART242

1 OF 4

PAGE

DOWN

TEXT

FORMAT

SCALE 1.0000TOOL:

USE

FLOPPY

REMOTE

STORAGE

INCH

Page 3-24 Operation Manual

Page 50

PROGRAMMING

MILLPWR

In the sample screen on the previous page, the MILLPWR directory

contains four numeric (i.e., program.mpt) programs. You can retrieve any

text programs (i.e., program.txt) you have saved by pressing the TEXT

FORMAT softkey.

If the program is saved in the MILLPWR directory:

• “MILLPWR” should appear at the top of the left column. If it doesn’t,

check that the USE FLOPPY and REMOTE STORAGE softkeys are not

selected.

• Using the arrow keys, highlight the program you want to load, then press

the LOAD softkey. The program you’ve selected should appear on your

screen.

If the program is saved in another directory on MILLPWR’s hard disk

drive:

• Press the CANCEL softkey to return to the “Current Program” screen.

The right-hand directory column should disappear.

• Press the DIRECTORY softkey.

• Press the SELECT DIRECTORY softkey. The “Directory” screen should

appear.

Operation Manual Page 3-25

Page 51

PROGRAMMING

MILLPWR

SERVO

OFF

FEED 0 100%

CURRENT PROGRAM

SELECT A WORKING DIRECTORY.

SELECT

DIRECTORY

PAGE

UP

DIRECTORY

MILLPWR

COMPANY1

COMPANY2

COMPANY3

PAGE

DOWN

2 OF 4

SCALE 1.0000TOOL:

USE

FLOPPY

REMOTE

STORAGE

INCH

• Using the arrow keys, highlight the directory that contains the program

you want to load.

• Press the SELECT DIRECTORY softkey again. The “Directory” screen

will disappear. Now that you’ve opened the appropriate directory, you

can load your program.

• Press the LOAD softkey. The directory name you chose should appear at

the top of the right-hand column.

• Highlight the program you want to open, then press the LOAD softkey.

The program you selected should now appear on your screen.

From a 3 ½” floppy disk:

• Save and clear any running programs before continuing. (Refer to the

note at the beginning of the Loading a Program section.)

• After you have selected the PROGRAM FUNCTIONS option, press the

LOAD softkey.

Page 3-26 Operation Manual

Page 52

PROGRAMMING

MILLPWR

• Insert the 3 ½” floppy disk containing the file you want to load into the

floppy disk drive (located in the upper left-hand corner of the

MILLPWR operator console).

• Press the USE FLOPPY softkey. The A: directory and any programs it

contains should appear.

Note: If your program is saved as a text file, select the TEXT FORMAT

softkey.

• Using the arrow keys, highlight the program you want to load.

• Press the LOAD softkey. The program you selected should now appear

on your screen.

Operation Manual Page 3-27

Page 53

PROGRAMMING

MILLPWR

From your PC:

• Save and clear any running programs before continuing. (Refer to the

note at the beginning of the Loading a Program section.)

• After you have selected the PROGRAM FUNCTIONS option, press the

LOAD softkey.

• Press the REMOTE STORAGE softkey. A “Programs” directory and any

programs it contains should appear.

If the REMOTE STORAGE softkey does not appear, then it is likely that

MILLPWR and the PC have not been properly set up. (Refer to the

Remote Storage and/or System Setup sections.)

Note: If your program is saved as a text file, select the TEXT FORMAT

softkey.

• Using the arrow keys, highlight the program you want to load.

• Press the LOAD softkey. The program you selected should now appear

on your screen.

Page 3-28 Operation Manual

Page 54

PROGRAMMING

MILLPWR

BLANK PAGE

Operation Manual Page 3-29

Page 55

DEMONSTRATION

MILLPWR

A DEMONSTRATION PROG RAM

The following steps and key stroke sequences will guide you through creating a program to machine the

part illustrated below:

3.00

.750

.838

.838

.250R

1.75

POCKET

.500 X 2.000

.250 DEEP

.125R CORNERS

.750R

1.50R

.250 DIA THRU

TYP (5)

Selecting the Datum

Although there is no clear “zero point” on this drawing, we’re going to use the center of the bolt hole

pattern as our datum. The advantages of using this point include:

• it is the center of the bolt hole pattern,

• it is the center of the large arc, making it easy to calculate the arc’s start and end points,

• the pocket is dimensioned from this point,

• the length of the straight side of the part is dimensioned from this point.

The workpiece can also be correctly programmed using another point (for example, the lower left

corner) as the datum.

When we are ready to run the program, we will actually set the datum.

Beginning The Program

Begin by pressing the program key.

PGM

Operation Manual Page 4-1

Page 56

DEMONSTRATION

MILLPWR

Selecting A Tool

A logical first step for most programs is to choose the tool that you want to start

with. Let’s use a ¼" FLAT END MILL.

Press the TOOL key.

TOOL

SERVO

OFF

FEED 0 100%

CURRENT PROGRAM

001 SET TOOL

1 OF 1

INCH MM

Enter .25 followed by the enter key.

SET TOOL 001

TOOL

INCH

TYPE

SCALE 1.0000TOOL:

INCH

TOOL

LIBRARY

. 2 5

ENTER

You can select a tool

from the Tool Library if

you like.

TOOL

0.250

INCH

TYPE

Press the TOOL TYPES softkey.

TOOL

TYPES

To FLAT END MILL

Arrow down to FLAT END MILL and press enter.

ENTER

USE

Press USE to complete the SET TOOL step.

Page 4-2 Operation Manual

Page 57

DEMONSTRATION

MILLPWR

Milling the Workpiece Contour

This part could be started at several different places. We'll

start at the bottom of the semi-circle on the right end of the

workpiece, and we’ll cut in a counterclockwise (CCW)

direction.

Press the ARC key.

3.00

1.50R

ARC

SERVO

OFF

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

X

Enter the following dimensions:

FROM: X1 = 0

To enter a negative

number, use the +/“CHANGE SIGN”

key, not the

“MINUS” key. The

“MINUS” key will

subtract the number

you enter from the

number that’s

already there.

Y1 = -1.5

FEED 0 100%

2 OF 2

MILL ARC 002

FROM

X1 ABS

Y1 ABS

TO

X2 ABS

Y2 ABS

DEPTH

Z ABS

RADIUS

DIRECTION

CCW

TOOL

0.250 INCH

FL END ML TYPE

CENTER OFFSET

10FEED IPM

TEACH

POSITION

SCALE 1.0000TOOL:

INCH

MOREPOLAR

ENTER

0

+/-

1 5

.

ENTER

Operation Manual Page 4-3

Page 58

DEMONSTRATION

MILLPWR

TO: X2 = 0

Y2 = 1.5

DEPTH: Z = -.25

RADIUS: 1.5

DIRECTION: CCW

+/-

1 5

.

. 2 5

. 51

Since we are starting the arc on the bottom and moving around

to the top, we picked CCW for the direction.

The tool specifications will be filled in automatically based on the

previously selected tool.

ENTER

0

ENTER

ENTER

ENTER

CCW

Now move to OFFSET and select RIGHT or OUTSIDE from the softkey choices.

To OFFSET

RIGHT

Page 4-4 Operation Manual

Pick CCW from the

softkeys that appear

when you’re in the

Page 59

DEMONSTRATION

MILLPWR

Finally, move to FEED and enter the FEED RATE you

would like to use.

To FEED

MILLPWR has

been factory set

with a feed rate of

10 IPM.

1 0

ENTER

USE

SERVO

OFF

FEED 0 100%

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

END OF 2

SCALE 1.0000TOOL:

INCH

PROGRAM

FUNCTIONS

CLEAR

PROGRAM

EXPLODE

MORE

STEPS

RUN

OPTIONS

Operation Manual Page 4-5

Page 60

DEMONSTRATION

MILLPWR

Next, we will enter the 3" line which starts at the

top of the

arc and

goes left.

The FROM point of this line is

automatically set to the end of

the arc programmed before.

SERVO

OFF

FEED 0 100%

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

X

003 MILL LINE

MILL LINE 003

FROM

X1 ABS

TO

X2 ABS

Y2 ABS

DEPTH

TOOL

3 OF 3

0.000

1.500Y1 ABS

0.2500Z ABS

0.250 INCH

FL END ML TYPE

RIGHT OFFSET

10FEED IPM

TEACH

POSITION

SCALE 1.0000TOOL:

POLAR

INCH

3.00

1.50R

LINE

ENTER

+/-

3

Press the LINE key.

1 5.

ENTER

Enter the TO field: TO: X2 = -3.0 ABS

SERVO

OFF

Notice the marks

connecting steps

002 and 003. This

means that the line

FEED 0 100%

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

003 MILL LINE

SCALE 1.0000TOOL:

and arc form a

continuous contour,

and MILLPWR will

cut them without

stopping.

1.5

PROGRAM

FUNCTIONS

END OF 3

CLEAR

PROGRAM

EXPLODE

MORE

STEPS

Page 4-6 Operation Manual

RUN

OPTIONS

INCH

USE

Y

2

=

Page 61

DEMONSTRATION

MILLPWR

Operation Manual Page 4-7

Page 62

DEMONSTRATION

MILLPWR

Press the LINE key to add another line.The FROM

dimensions, DEPTH dimension, and TOOL specifications will

carry forward from the previous line.

.838

3.00

Press the LINE key.

Enter the following TO dimensions:

TO: X2 = -3.0 ABS

Notice that you

don’t have to use

the ENTER key

after the last

value – just

press USE.

Y2 = 0.838 ABS

SERVO

OFF

FEED 0 100%

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

003 MILL LINE

004 MILL LINE

LINE

ENTER

USE

+/-

3

8. 3 8

SCALE 1.0000TOOL:

INCH

END OF 4

PROGRAM

FUNCTIONS

CLEAR

PROGRAM

EXPLODE

MORE

STEPS

RUN

OPTIONS

Page 4-8 Operation Manual

Page 63

DEMONSTRATION

MILLPWR

Now we will program the two diagonal lines. Notice that in the xaxis the end of the first diagonal line is .750 from the beginning of

the line.

FROM (X1, Y1)

3.00

.750

This means we can use

incremental dimensioning.

.838

We say that “X2 is .750

incremental from X1.”

.75

TO (X2, Y2)

Press the LINE key.

LINE

In the TO point, enter

X2 = .750

7. 5

ABS

INC

Then press the ABS/INC key. ABS changes to INC, and

MILLPWR assumes that you want to use the X coordinate

of the FROM point, X1, as your incremental reference.

X2 = 0.750 INC X1

LINE

FROM

TO

Y2 ABS

-3.000X1 ABS

0.838Y1 ABS

0.750X2 INC XI

005

Now finish the TO point:

To Y2

Y2 = 0.000 ABS

0

USE

Operation Manual Page 4-9

Page 64

DEMONSTRATION

MILLPWR

Press the LINE key again for the second diagonal line:

LINE

X2 = -3.000 ABS

Y2 = -0.838 ABS

SERVO

OFF

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

003 MILL LINE

004 MILL LINE

005 MILL LINE

006 MILL LINE

FEED 0 100%

PROGRAM

FUNCTIONS

END OF 6

CLEAR

PROGRAM

EXPLODE

MORE

STEPS

+/-

ENTER

USE

+/-

3

8. 3 8

RUN

OPTIONS

INCH

SCALE 1.0000TOOL:

Page 4-10 Operation Manual

Page 65

DEMONSTRATION

MILLPWR

We can see that lines 005 and 006 should be

connected with an arc. We’ll go back and insert a

BLEND step between them. Using the up arrow key,

select the last step, 006 MILL LINE.

Press the BLEND key.

SERVO

OFF

FEED 0 100%

We could just as

easily have put

the BLEND step

in right after we

did LINE 005.

The BLEND step

would then show

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

003 MILL LINE

004 MILL LINE

005 MILL LINE

006 BLEND

X

007 MILL LINE

BLEND 006

STEPS

RADIUS

FEED RATE

up in the listing,

but it would not

show in the

graphics until we

put in the second

line.

6 OF 7

SCALE 1.0000TOOL:

INCH

5FROM

7TO

10

IPM

CLOSE

CONTOUR

To Step 006

BLEND

Enter a radius of 0.250.

SERVO

OFF

CURRENT PROGRAM

001 SET TOOL

002 MILL ARC

003 MILL LINE

004 MILL LINE

005 MILL LINE

006 BLEND

007 MILL LINE

FEED 0 100%

SCALE 1.0000TOOL:

INCH

2. 5

PROGRAM

FUNCTIONS

7 OF 7

CLEAR

PROGRAM