Page 1

MICRO-LINE

Readout Systems

Precision Glass Scales

l l l l l l l l l l l l l l l l l l l l

™

For Turning Applications

REFERENCE MANUAL

Page 2

TABLE OF CONTENTS

Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Packing List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warranty Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installing the Scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing the Readout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Display Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Setup

Parameter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Display Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Linear Error Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How to Determine the Linear Error Compensation . . . . . . . . . 8

Count Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Testing the Scales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation

Radius and Diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting the Datum (Absolute Zero) . . . . . . . . . . . . . . . . . . . . . . . . 13

Example: Setting Up Your Job . . . . . . . . . . . . . . . . . . . . . . . . 15

Incremental Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Example: Incremental Dimensions . . . . . . . . . . . . . . . . . . . . . 17

Tool Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2004-721 Ed B

MICRO-LINE Reference Manual i

Page 3

TABLE OF CONTENTS

Troubleshooting

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Error Messages (General) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Keypad Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reference

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Factory Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DRO Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Count Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Recalling the Last Datum Setting for International Units . . . . 32

General Installation Instructions for the Scale . . . . . . . . . . . . . . . . 33

Installation Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Mounting Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Mounting Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Dimensions for Both Scale Types . . . . . . . . . . . . . . . . . . . . . . 37

Mounting Descriptions for Both Scale Types . . . . . . . . . . . . . 38

Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

MICRO-LINE Reference Manualii

Page 4

I N S TA L L ATION

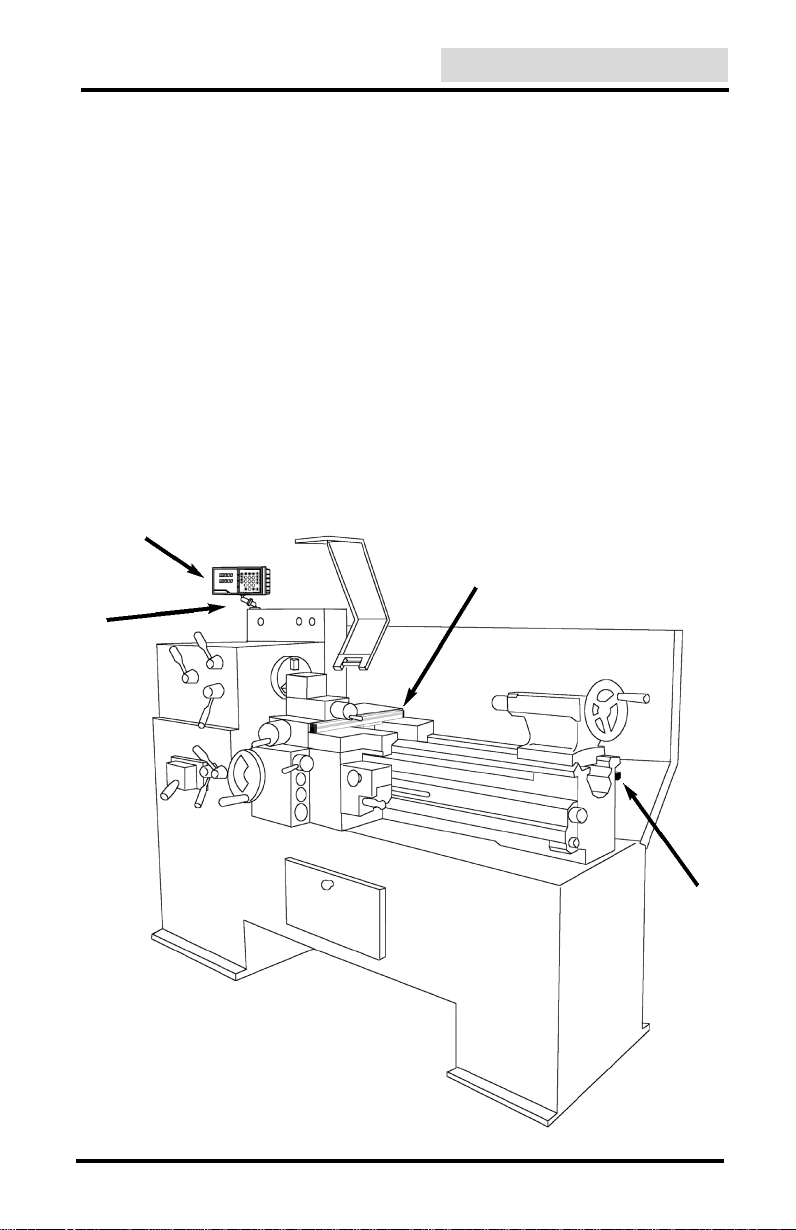

Overview

This manual will guide you through the installation, setup, and operation

of the MICRO-LINE system. Use it to get your system up and running

“out of the box” and as a quick reference guide for your day-to-day

operations.

We recommend installing the scales first, according to the instructions

included with your system. After the scales are in place, install the

readout and then finish setting up the system.

Here’s how a typical machine will look after the installation is complete:

MICRO-LINE

Readout

X-axis Scale

Mounting

Arm

MICRO-LINE Reference Manual

Z-axis Scale

1

Page 5

INSTALLATION

Preparation

Packing List

Before you begin the installation procedure, check that you have

received all of the components for your system:

• Readout & installation instructions

• Mounting arm

• MICRO-LINE scales

- Cable mounting hardware

- Scale mounting hardware

• Warranty card

If a component is missing, contact your MICRO-LINE distributor for

replacement parts.

Warranty Records

For future ordering information or warranty service, please record all

readout and scale information on the warranty card included with your

MICRO-LINE system. The scale catalog number and serial number are

located on the scale assembly tag.

Copy the information here for your own records and then mail the

warranty card as soon as possible.

Distributor: _____________________________________________

Address: _____________________________________________

Telephone: _____________________________________________

Catalog No. Serial No.

Readout ________________ ___________________

Axis #1 ________________ ___________________

Axis #2: ________________ ___________________

Axis #3: ________________ ___________________

Date of Purchase: ____________________________________

2

MICRO-LINE Reference Manual

Page 6

INSTALLATION

Installing the Scales

Install the linear encoders according to installation instructions found

within your Micro-Line system manual. These general installation

instructions are found on page 33. Read these instructions completely

even though bracket kit instructions supersede them.

Installing the Readout

Follow the readout installation instructions that are included with your

mounting arm bracket kit. The electrical specifications for the readout

are listed on pg. 27.

After the installation is complete, proceed to “Power Up.”

MICRO-LINE Reference Manual

3

Page 7

INSTALLATION

Power Up

Press the switch on the back of the readout to power up the system. A

series of tests will check that the display, keypad, and memory are all

working properly.

If a problem is detected, an error code will appear on the screen. (Error

messages and solutions are listed on pgs. 25 - 26.) It is important to

note that the E1 message will appear every time you power up your

system and does not indicate a problem. It merely indicates that the

system had lost power. To acknowledge the message, press the CLEAR

key and proceed to the DRO mode.

Note: If the E1 message appears at any other time during normal

operation, refer to pg. 25 for possible problems and solutions.

Display Saver

When the system is not used for more than 90 minutes, a decimal point

will “scroll” across the X-axis display, indicating that the display saver

has been activated. The display saver, like a screen saver on a computer

monitor, will help prolong the life of your readout.

If the display saver has been activated, press any key on the readout or

move any axis to return to the normal DRO view.

4

MICRO-LINE Reference Manual

Page 8

SETUP

Parameter Setup

There are 3 to 4 parameters that you can define on your system:

• Display resolution (diS)

• Linear error compensation (LEC)

• Scale count directions (Ct dir)

• Input 3 ON/OFF for international units

Establish each setting the first time you power up the system. You can

change the parameters later by returning to Setup and then using the

ENTER key to scroll to the appropriate category.

Anytime you change the linear error compensation, or count direction

for an axis, the absolute and incremental displays for that axis will be

reset to 0. If you change these settings, you’ll need to reestablish the

datum point.

For international units using 5µm (0.0002”) scales with reference

marks, you will need to recall Datum. See page 32.

When in the SetUp mode, use the CLEAR key when you want to backspace, restore the previous value or access the previous parameter.

MICRO-LINE Reference Manual

5

Page 9

SETUP

Display Resolution

The display resolution determines how detailed each scale’s position

will be displayed on the readout. Use the setting that best suits each job.

To change the display resolution:

• Press the SETUP key. (“diS” will show on the display.)

• Press the

For 10µm scales, the display resolution will toggle between 0.01 mm

(0.0005”) and 0.02 mm (0.001”). For 5µm scales, it will toggle

between 0.005 mm (0.0002”) and 0.01 mm (0.0005”).

• After you complete setting your display resolution, press ENTER to

continue with setup or press ENTER then SETUP to return to the normal DRO display.

X or Z key for the display you want to change.

6

MICRO-LINE Reference Manual

Page 10

SETUP

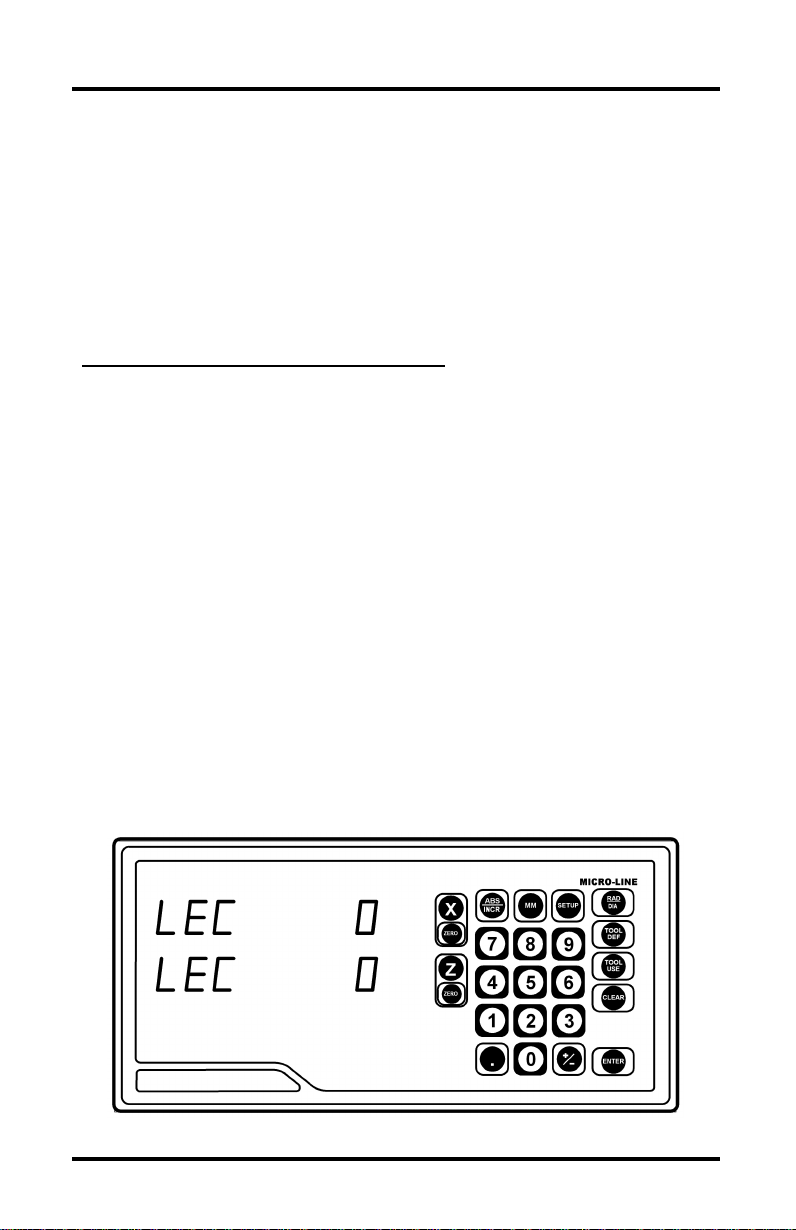

Linear Error Compensation

With MICRO-LINE, you can compensate for machine tool wear. If you

know the linear error compensation (LEC) value in parts-per-million

(PPM), you can enter it directly.

If you don’t know the LEC, use the formula on the next page to determine

the value for each axis.

To change the linear error compensation:

• Move to the “Linear Error Compensation” display in the Setup

mode. (Press SETUP and then the ENTER key until “LEC”

appears).

• Press the

MICRO-LINE will display the current LEC value for that axis.

• Using the keypad, enter the linear error compensation factor

(in PPM), followed by the ± key for negative values. The number

must be within -9999 and 9999 (use whole numbers). The formula for

calculating the value is on the next page.

• After you complete setting your LEC, press ENTER to

continue with setup or press ENTER then SETUP to return to the

normal DRO display.

X or Z key for the axis you want to change.

MICRO-LINE Reference Manual

7

Page 11

SETUP

How to Determine the Linear Error Compensation

Follow this procedure for each axis:

• In the DRO mode.

• Place a standard of known length on the machine. Make sure it’s

parallel with the axis being measured.

• Put the readout in the absolute display mode (ABS/INCR key).

• Using an indicator, locate one end of the standard.

• Press the ZERO key twice for the axis you are measuring.

“0” should appear on the display.

• Move the indicator along the axis until it reaches the opposite

end of the standard.

• Write down the length that is shown on the readout display for

that axis.

• Use the formula below to calculate the LEC for the axis you just

measured. Enter the result in the LEC parameter (previous page).

Note: If the measured length is greater than the standard length the

LEC value will be negative.

Formula

M = Measured length

LEC =

(

S - M

M

)

x 1,000,000S = Standard length

Example

If the length of the

standard you used is

10” and the measured

length is 9.995”, then

the LEC for that axis

is 500 parts-per-million (PPM).

8

LEC =

LEC =

10 - 9.995

(

9.995

500 PPM

(rounded to the nearest

whole number)

MICRO-LINE Reference Manual

x 1,000,000

)

Page 12

SETUP

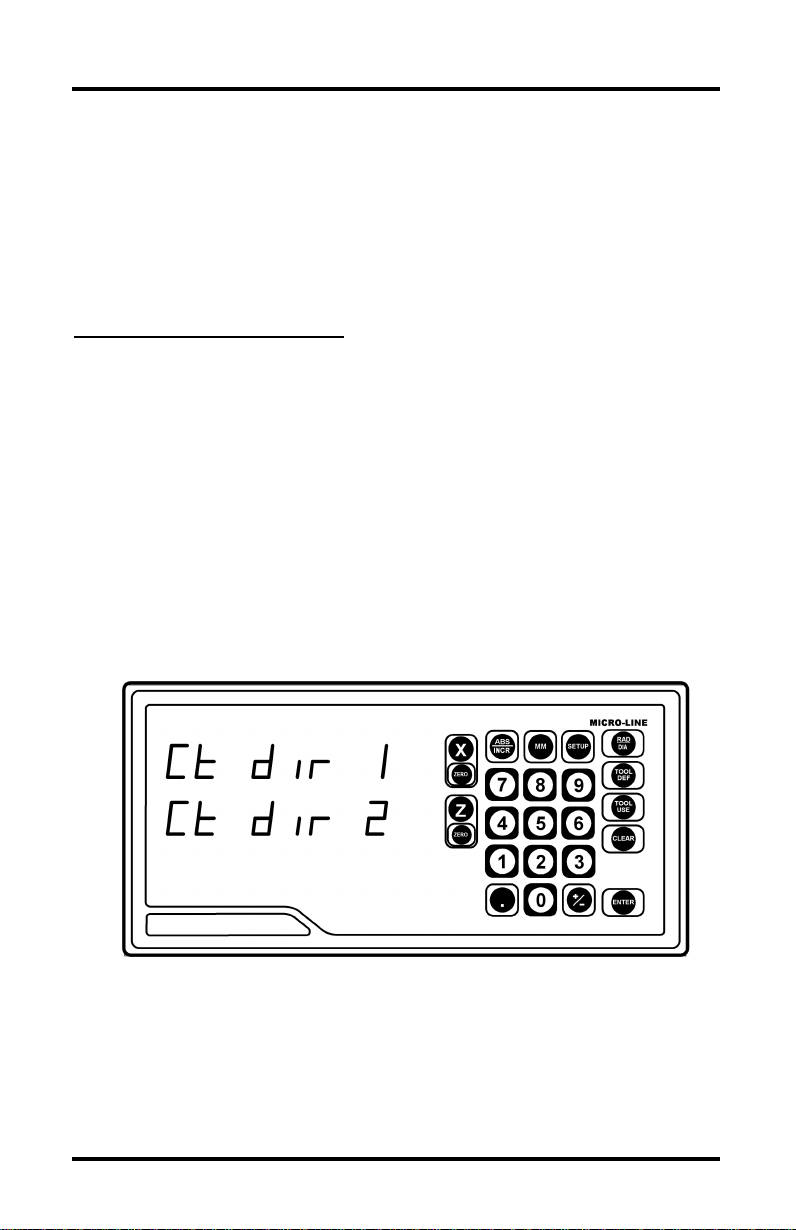

Count Direction

Use the count direction setting to define the positive counting direction

for each scale. The direction will be displayed as a “1” or a “2” (the

numbers are not assigned to a particular direction). You only need to

change the count direction if the scale is counting in the negative

direction during a positive move, or vice versa.

Refer to Conventions (pg. 31) for more guidelines.

To change the count direction:

• Move to the “Count Direction” display in the Setup mode. (Press

SETUP and then the ENTER key until “Ct dir” appears).

• Press the appropriate axis key (

• After you complete setting your count direction, press ENTER to con-

tinue with setup or press ENTER then SETUP to return to the normal

DRO display.

X or Z) to change the count direction.

MICRO-LINE Reference Manual

9

Page 13

SETUP

International Units Only

Input 3 ON/OFF

This parameter allows you to activate the third input. When this input

is enabled, Inputs 2 and 3 will be coupled on the Z-axis (both scales

will count on the Z-axis).

When Input 3 is enabled, additional parameters will need to be setup.

Refer to the procedures on pages 7-9 for setting up the Linear Error

Compensation and Count Direction Setup functions.

10

MICRO-LINE Reference Manual

Page 14

SETUP

Testing the Scales

Follow these steps to confirm that your scales have been installed properly. This test will confirm the scale’s electrical operation, and will also

check the installation integrity.

• Locate a magnetic base on the machine and set the dial indicator

on the scale’s reading head casting. Zero the readout and the

indicator.

• Move the axis through the full travel and return the dial to “0.”

The readout should also read 0 (±.0005” for 10µm scales;

±0.0002” for 5µm scales). If it doesn’t, then the scale cable may

be loose, or the scale, mounting bracket, or reading head may

need to be tightened or realigned.

• Repeat these steps for each scale.

MICRO-LINE Reference Manual

11

Page 15

OPERATION

Radius and Diameter

Pressing the RAD/DIA key lets you view the X-axis dimension either as

a radius or as a diameter.

Display resolution is affected by the RAD/DIA key.

12

MICRO-LINE Reference Manual

Page 16

OPERATION

Setting the Datum (Absolute Zero)

MICRO-LINE allows you to measure both absolute and incremental

dimensions. A dimension measured from the point you define as the

datum is an absolute dimension. A dimension measured from any other

point on your print is an incremental dimension.

Datum, also known as absolute zero or workpiece zero, is the reference

point from which

When the readout is in the ABS mode, it is actually measuring the distance from the datum to the machine axis’current position.

You will need to establish a datum for every job. Your datum may

already be identified on your print; if it isn’t, then establish a datum that

allows you to measure most of your part’s dimensions directly, with the

least number of calculations.

All of the dimensions in the drawing below are based from the datum.

MICRO-LINE will base all of your part’s coordinates.

MICRO-LINE Reference Manual

13

Page 17

OPERATION

If you’re using 5µm (0.0002”) scales (international units only),

MICRO-LINE can recall your last datum position each time you power

up the system (refer to pg. 32 for the proper procedure).

To set the datum at the tool’s current position:

• Position the workpiece in the chuck. Move the tool until

it is positioned at the location where you would like to establish the

datum.

• Using the ABS/INCR key, select the absolute (ABS) mode.

• Press the X-axis ZERO key twice to establish the current X-axis

position as the datum. Repeat for the Z-axis.

To set the datum using an offset:

• Using the ABS/INCR key, select the absolute (ABS) mode. Also

check that the proper measurement (inch or mm) is selected.

• Using RAD/DIA key, select the Radius mode.

• Move the tool to a known point, i.e. the outside diameter of the

workpiece or the face of the workpiece.

• Press the ZERO key once for the axis (X or Z) for which you’re

entering a dimension.

• Using the keypad, enter the distance from your tool’s current

location to the point you want to establish as the datum. Include a

decimal point (.) and minus (-) sign when necessary.

• Press the ZERO key for the other axis, or press ENTER to return

to the DRO display.

14

MICRO-LINE Reference Manual

Page 18

Example:

Setting Up Your Job

1. Place your workpiece into the

chuck.

OPERATION

2. Make a face cut and clear the work

piece by backing the tool off in the

X-axis only. Do not move the Zaxis. (Fig. 2)

3. Zero the Z-axis by pressing the Z-

zero key twice. (Fig. 3)

4. Make a skim cut on the diameter of

the workpiece and clear the work-

piece by backing the tool away in

the Z-axis. Do not move the X-

axis. (Fig. 4)

5. Measure the diameter of the work-

piece. (Fig. 5)

6. Press the X-axis zero key once,

then using the keypad, press the

RAD/DIA key to select diameter

and enter the diameter of the

workpiece, then press

ENTER. (Fig. 6)

2

3

4

6

MICRO-LINE Reference Manual

5

15

Page 19

OPERATION

Incremental Dimensions

As we described earlier, incremental dimensions are measured from the

current tool position. If your tool is currently at 2” and you want to

move an additional 3.125”, you would select the incremental mode,

zero out the axis, and move the axis until the display reads 3.125.

An example of how to measure using incremental dimensions is shown

on page 17.

To use an incremental dimension:

• Move the machine axis to the point from where you want to

measure an incremental distance.

• Use the ABS/INCR key to select the incremental (INCR) mode on

the readout. Also check that the proper measurement (inch or mm)

is selected.

• Press the ZERO key below the axis(es) from which you’re measuring.

• Move the machine axis. MICRO-LINE will display the machine

axis’position in relation to the incremental “0” point(s) for the

axis(es) you chose.

After you’ve reached the position you want and have machined the part,

you can “zero” each axis again and then measure from that location to

the next point on your workpiece or press ABS/INCR to return to the

absolute mode.

16

MICRO-LINE Reference Manual

Page 20

Example: Incremental Dimensions

Let’s say that your print looks like this:

Using Incremental Zero

In order to cut a groove to a depth

of 0.120” from the 1” radius, it is

necessary to establish a zero at 1”.

This can be done using the incremental mode without changing the

Datum. Follow these steps:

1. Move the tool until the readout display

shows that the X-axis = 1.0000” and

the Z-axis = 2.0000” in the absolute mode.

2. Press the ABS/INCR key to switch to the

incremental mode.

3. Press the X-axis ZERO and the Z-axis

ZERO keys.

4. Begin cutting until the X-axis reads -0.1200”.

OPERATION

Using Incremental Presets

In addition to setting incremental zero at the current

tool position, you can also preset the incremental

zero from the current tool position. Enter the distance and direction you wish to move in relation to

your current position. Follow these steps:

1. Move the tool until the readout display shows that the

X-axis = 1.000” and the Z-axis = 2.0000” in the absolute mode.

2. Press the ABS/INCR to switch to the incremental mode.

3. Press the X key and press the following key sequence:

- . 1 2 ENTER then press the Z-axis ZERO key.

4. The X-axis display will show 0.1200”.

5. Begin cutting until the X-axis reads 0.0000”.

MICRO-LINE Reference Manual

17

Page 21

OPERATION

Tool Offset

The MICRO-LINE can store the dimensional offset of an additional tool.

This allows you to use two tools without having to reestablish zero as

you change between them. In order for this feature to work, the tools

must be able to repeat their location when they are changed (Repeatable

tooling). To use this feature you must first select the tool number (either

0 or 1).

1. Place your first tool in the tool holder.

2. Press the TOOL USEkey.

3. Press 0 to select the first tool, then press ENTER.

4. Set the Datum (Absolute Zero) using this tool. See page 13.

5. Change the tool to the second tool you will be using.

6. Press TOOL USE and enter the number 1 for the second tool.

7. Touch this tool to a diameter of known size.

8. Press the TOOL DEF key and press the X key.

9. Press the RAD/DIA key to select diameter if not already selected.

10. Enter the known diameter. Press ENTER.

18

MICRO-LINE Reference Manual

Page 22

OPERATION

11. Move the tool so that it touches a face of known length.

12. Press the TOOL DEF key and press the Z key.

13. Enter 0 if the tool is at Datum or enter the distance the tool is

from Datum by using the ± key if the tool is in the negative

direction. Press ENTER.

Note: Both tools are now set. To switch between them, change

the tool on your lathe, then press the TOOL USE key,

and select the appropriate tool number.

MICRO-LINE Reference Manual

19

Page 23

TROUBLESHOOTING

Troubleshooting Introduction

Refer to this troubleshooting guide whenever you have questions or

concerns about the operation of your MICRO-LINE system.

This guide is arranged in three columns entitled Symptom, Probable

Cause and Recommended Corrective Action. The symptoms are listed

in the order of the most common, easiest to check, and least expensive

to correct.

First locate the symptom that best describes the problem you’re trying

to solve. Then identify the probable cause that most closely matches the

problem and implement the recommended corrective action.

If a problem persists or cannot be resolved using this manual, contact

your MICRO-LINE distributor for further assistance.

20

MICRO-LINE Reference Manual

Page 24

Symptom

Probable Cause

TROUBLESHOOTING

Recommended

Corrective Action

Screen is

blank

Decimal point

scrolls across

display

No power to the

readout

LED failure

System has been idle

for approximately 90

minutes and is in

“display saver”mode

Check that the power

switch on the back of the

console is “on.”

Check that the readout’s

power cord is properly

connected to the power

supply.

Check the fuse. (Located

above the power switch).

Check that the power

source meets the specifications required by your

system (pg. 27).

Contact your MICRO-LINE

distributor for repair/

replacement procedures.

Press any key or move the

cross slide to return to the

previous screen.

Dashes

appear on

screen

MICRO-LINE Reference Manual

Display overflow

The value entered exceeds

the display’s 8-character

capability. Enter a value

with less than 8

characters.

(cont’d next page)

21

Page 25

TROUBLESHOOTING

Symptom

Probable Cause

Recommended

Corrective Action

Dashes

appear on

screen

(cont’d)

Error

message (E1)

appears

Error

messages (E2E56) appear

Display overflow

Power loss occurred

Causes vary

Move the axis toward

the “0” position. As the

scale counts down, the

display will show the

correct position.

This is a normal message at power up. If the

message appears at any

other time during operation, a problem may

have occurred. Refer to

pg. 25 for details.

Turn the system “off”

and then “on” again,

using the switch on the

back of the readout.

If an error (besides E1)

is still detected when the

system is powered up,

contact your MICRO-

LINE distributor for

repair/replacement

procedures. Refer to pgs.

25 - 26 for a list of error

messages.

Keys not

working

properly

22

Invalid keypress

Turn the system “off” and

then “on” again, using the

switch on the back of the

readout. If an error (besides

E1) is detected when the

system is powered up, contact your MICRO-LINE

distributor for

repair/replacement

procedures. Refer to pg. 2526 for a list of error messages.

MICRO-LINE Reference Manual

Page 26

TROUBLESHOOTING

Symptom

Scale won’t

count

Probable Cause

Loose cable

Wrong input

Scale not installed

properly

The scale’s reading

head is not working

properly

Recommended

Corrective Action

Check that the scale cable

is securely connected to

the readout.

Check that the scale cable

is connected to the correct

input on the back of the

readout.

Check the scale and reading head for proper installation (refer to scale installation instructions).

Unplug the scale from the

readout and plug it into an

input for another axis.

If the scale still does not

count, the reading head

may need to be replaced. If

the scale counts on the

other axis then the display

may need to be replaced.

See LED Failure.

Scale counts,

but not

correctly

MICRO-LINE Reference Manual

Wrong count

direction

Scale not installed

properly

Change the count direction

(pg. 9).

Check the scale and reading head for proper installation (refer to scale installation instructions). Clean

the scale, if necessary.

23

Page 27

TROUBLESHOOTING

Symptom

Setup does

not save

values

Numbers

don’t

appear/are

faded on the

display

Probable Cause

Improper procedure

LED failure

Recommended

Corrective Action

Press the ENTER key after

each parameter value is

entered. If you press

another key instead, the

new value may not be

saved. Refer to pgs. 5-10

for proper procedures.

Turn the system “off” and

then “on” again, using the

switch on the back of the

readout. If this does not

correct the problem,

contact your MICRO-LINE

distributor for

repair/replacement

procedures.

24

MICRO-LINE Reference Manual

Page 28

TROUBLESHOOTING

Error Messages (General)

When MICRO-LINE is powered up, it will run a series of tests to ensure

that the software is working properly. If an error message appears, refer

to the charts below for a diagnosis and solution.

E1

E2

E3

E4

A power loss has occurred. This message will appear

every time you power up the system and can be cleared

by pressing the CLEAR key. If the E1 message appears

at any time other than at power up, a power interruption

has occurred and your current position may be lost. Reestablish the datum if necessary. If the problem persists,

contact your distributor for repair/replacement procedures.

An EEPROM memory error has occurred. Press the

CLEAR key to acknowledge the error. The datum and

setup information may be lost. These areas should be

checked and reestablished upon power up. If the problem

persists, contact your distributor for repair/replacement

procedures.

A ROM memory error has occurred. Press the CLEAR

key to acknowledge the error. If the system does not

operate properly, contact your MICRO-LINE distributor

for repair/replacement procedures.

A random access memory (RAM) error has occurred.

Press the CLEAR key to acknowledge the error. If the

system does not operate properly, contact your MICRO-

LINE distributor for repair/replacement procedures.

E9

MICRO-LINE Reference Manual

A scale miscount error (invalid waveform) has occurred.

The E9 message will appear on the axis that has the

error. Press CLEAR to reset the axis(es). Your current

position may be lost. Re-establish the datum if necessary.

If the system does not operate properly, contact your

MICRO-LINE distributor for repair/replacement proce-

dures.

25

Page 29

T R O U B L E S H O O T I N G

Error Messages (Keypad Test)

The messages below indicate that a problem was found during the keypad test at startup. If an error message appears, turn the system off,

press the appropriate key to release it back into position, and then

restart the system. (Or you can press the CLEAR key to clear the error

message.) If the key does not work during normal operation, contact

your distributor for repair/replacement procedures.

E11

E12

E15

E16

E18

E21

E22

E25

E26

E28

SETUP key

RAD/DIA key

MM key

ABS/INCR key

X key

9 key

TOOL DEF key

8 key

7 key

ZERO key for

the X-axis

E35

E36

E38

E41

E45

E46

E48

E51

E54

E55

5 key

4 key

Z key

3 key

2 key

1 key

ZERO key for the

Z-axis

± key

ENTER key

0 key

26

E31

E32

E33

6 key

TOOL USE key

CLEAR key

E56

MICRO-LINE Reference Manual

Decimal point (.)

key

Page 30

REFERENCE

Electrical Specifications

Follow these specifications when installing your MICRO-LINE system.

Characteristic

Operating conditions

Storage conditions

Input requirements:

Voltage

Frequency

Current

Fuse

Scale input

Size 9.875” x 4.679” x 4.75”

Specification

0° to 40°C (32° to 104°F)

25% to 85% relative humidity

-40° to 60°C (-40° to 140°F)

25% to 85% relative humidity

(non-condensing)

115VAC or 230VAC, single phase

47 - 63Hz per channel

300mA @ 115V, 150mA @ 230V

115V operation: 1/2A, 250V, 3AG, slo-blo

230V operation: 1/4A, 250V, 3AG, slo-blo

Position signals: channels A & B

TTL square wave signal in quadrature

(90° nominal phase relationship)

Maximum input rate: 70 kHz

Weight 4 lbs., 2 oz.

Mounting

FCC compliance

CE compliance

ETL compliance

ETLc compliance

MICRO-LINE Reference Manual

Bottom; two 1/4”-20 threaded inserts

Part 15 of FCC rules for a class A

computing device

For Europe

For United States

For Canada

27

Page 31

REFERENCE

Factory Default Settings

Display Resolution

Linear Error

Compensation

Count Direction

Tool Offset

Display Units

Display Mode

High

(0.0005"/0.01 mm for 10µm scale)

(0.0002”/0.005 mm for 5µm scale)

0 parts per million

1

Tool 1 X = 0 , Z = 0

Tool 0 X = 0 , Z = 0

Inches

ABS (absolute dimensions)

Radius/Diameter

28

Radius

MICRO-LINE Reference Manual

Page 32

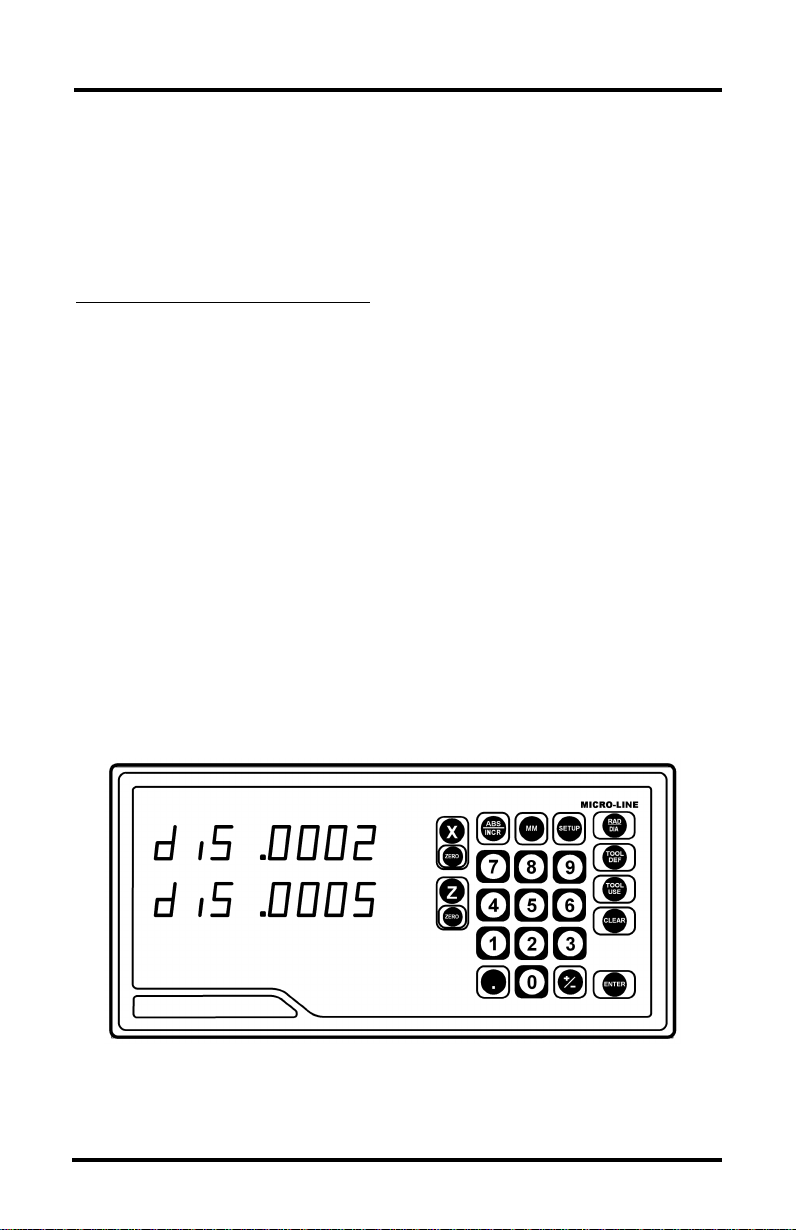

Keypad

Here’s an overview of the MICRO-

LINE keypad. Each key’s function

is described below.

REFERENCE

X, Z

ZERO

ABS/INCR

MM

SETUP

RAD/DIA

Correspond with the scales on the X-,and

Z-axes. Used to specify a change to a particular axis.

These keys reset the incremental or

absolute display position at “0” for the

corresponding axis.

Used to switch between absolute (ABS)

and incremental (INCR) measurements.

The active mode will be displayed at the

top of the DRO display.

Press this key to switch the X and Z displays between English and metric units.

Provides access to the display resolution,

linear error compensation and scale count

direction.

Used to switch between radius (RAD)

and diameter (DIA) dimensions. The

DIA indicator will light up when diameter is displayed.

MICRO-LINE Reference Manual

29

Page 33

REFERENCE

TOOL DEF

TOOL USE

CLEAR

ENTER

±

.

0-9

Used to establish tool offset.

To establish which tool offset will be used.

Acts as backspace key during numeric

entry; otherwise, it clears or cancels the last

operation.

Completes numeric operations; selects next

parameter in SETUP.

Changes the sign of the entered value from

positive (+) to negative (-) or vice versa.

Numbers are positive unless a (-) appears in

front of them.

Decimal point can be used during numeric

entry; also used to access the recall feature

for international units with 5µm (0.0002”)

scales after power up.

Used to enter a distance.

30

MICRO-LINE Reference Manual

Page 34

REFERENCE

Conventions

This section identifies the standard conventions that apply to your

MICRO-LINE system.

DRO Mode

The MICRO-LINE system is considered to be in the DRO (digital readout) mode when the X-axis and Z-axis positions are displayed.

Count Direction

MICRO-LINE uses positive and negative numbers to display the position

of the tool along each axis. The graphic below shows a typical setup for

the positive and negative count directions for the X-and Z-axes on a

lathe. All of the examples in this manual are based upon this setup.

X-axis:

The axis will move away from the

center for a positive count direction.

Z-axis:

The axis will move away from the

spindle for a positive count direction.

MICRO-LINE Reference Manual

31

Page 35

REFERENCE

Recalling the Last Datum Setting For

International Units

If you’re using 5µm MICRO-LINE scales, MICRO-LINE can retrieve

your last datum setting when you power up your system. This feature is

especially useful when you have to shut down the system in the middle

of a job, or if a power interruption occurs. When power is restored,

MICRO-LINE will use Position-Trac

reference marks and recall the datum within seconds.

The recall feature only works after you have completed the initial

system setup and established a datum, so it won’t be accessible the

very first time you turn on the readout. After you’ve completed those

operations, you can recall the datum for every power up thereafter.

To recall your last datum:

• Power up the system.

TM

technology to read the scales’

• Press the CLEAR key to clear the E1 message.

• Press the decimal point (.) on the readout’s keypad. Move the

tool in the positive count direction along the X-axis. Keep

moving it until the system recalls the datum and “found”

flashes on the screen. The system will automatically reset the

X-axis value to reflect the distance from the tool’s current

position to the datum.

Repeat this procedure for the Z-axis, always moving the

tool in the positive count direction.

After you’ve completed the recall procedure, you can move to the datum by

positioning the tool until the display reads “0” for each axis.

Note: If Input 3 is being used, the datum will not be correct until both the

Z-axisand Input 3 scales have been recalled.

32

MICRO-LINE Reference Manual

Page 36

REFERENCE

General Installation Instructions for the Scale

Please do not expose the scale to the following:

Installation Brackets

• Installation brackets and tools are available.

• Your Authorized ACU-RITE Distributor can assist you

in selecting brackets and tools for your installation.

MICRO-LINE Reference Manual

33

Page 37

REFERENCE

Introduction

The Micro-Line precision glass scale provides the accuracy and reliability of an ACU-RITE measuring system. Features and options include:

• Digital resolutions of 5 or 10µm.

• Accuracy Grade of ± 10 µm/1000mm.

• Home reference signals on international units only.

• Braided cables of 10 or 15ft. lengths.

• Two scale case forms:

• Top mounting scale available 2 - 120” measuring length

• End mounting scale available 2 - 22” measuring length

• Mounting Fasteners

• Installation Brackets

See Page 2 to fill out warranty record information.

Scale mounting hardware and cable mounting hardware are

provided with each Micro-Line Scale.

34

MICRO-LINE Reference Manual

Page 38

REFERENCE

Mounting Preparation

• Understand your mounting requirements.

• Mount with lipseals down and away from the work area.

• Brackets should be short and rigid.

• Surfaces must be in good condition, clean and free of dirt

and paint.

• Ensure the correct length scale is being used for the total

machine travel.

Do not remove alignment brackets until instructed.

Never mount with lip seals upward or toward work area.

Limit equipment travel to scale measuring length or less.

MICRO-LINE Reference Manual

35

Page 39

REFERENCE

Mounting Information

• Mount the scale close to machine guide ways to ensure system

accuracy.

• Follow kit instructions when using an ACU-RITE bracket kit.

• Mounting surfaces offset greater than .18” between the

reading head and mounting surface require a spacer or bracket.

• Use reading head leveling set screws to adjust for gap behind

the reading head.

• Tolerances of .010” TIR apply to all mounting dimensions.

36

MICRO-LINE Reference Manual

Page 40

Dimensions for Both Scale Types

End Mounted Scale Form

REFERENCE

Top Mounted Scale Form

MICRO-LINE Reference Manual

37

Page 41

REFERENCE

Mounting Descriptions for Both Scale Types

End Mounted Scale Form

Top Mounted Scale Form

38

MICRO-LINE Reference Manual

Page 42

REFERENCE

Installation Procedure

These steps apply to all mounting conditions. Although this may

not pictorially represent your application, your installation procedure should follow these steps.

ACU-RITE bracket kit instructions supercede this

section.

• Adjust drill depths and fastener lengths as required.

• Contact your authorized ACU-RITE distributor if assistance is

required.

First Steps:

1. Move the machine axis to its center of travel.

2. Mark the machine axis location so that it can be recentered

easily.

3. Slide the reading head with the alignment brackets attached,

along the scale case to the center of the scale case.

4. Locate the bottom of the end cap flush with the axis parting line.

5. Mark one end mounting hole.

6. Drill and tap the first end mounting hole. Drill and tap a

10-32 x 1/2” deep hole for a top mounting form or a

1/4-20 x 1/2” deep hole for an end mounting form. Attach the

scale.

MICRO-LINE Reference Manual

39

Page 43

REFERENCE

7. Align to within .010” TIR to axis of travel and mark the second end mounting hole. Drill and tap.

8. Attach the scale and align to within .010”TIR to axis

of travel.

9. For the top mounting, form indicate to within .010” TIR over

each mounting hole and mark hole location. Drill and tap all

remaining holes. Attach the scale and align to within

.010” TIR to axis of travel.

10. For end mounting form, after scale is attached and

aligned, insert mounting hole covers.

11. Ensure the axis is still at its center of travel and the reading

head is centered on the scale. Mark the reading head

mounting holes.

12. Move the axis and drill and tap for 8-32 (M4).

40

MICRO-LINE Reference Manual

Page 44

REFERENCE

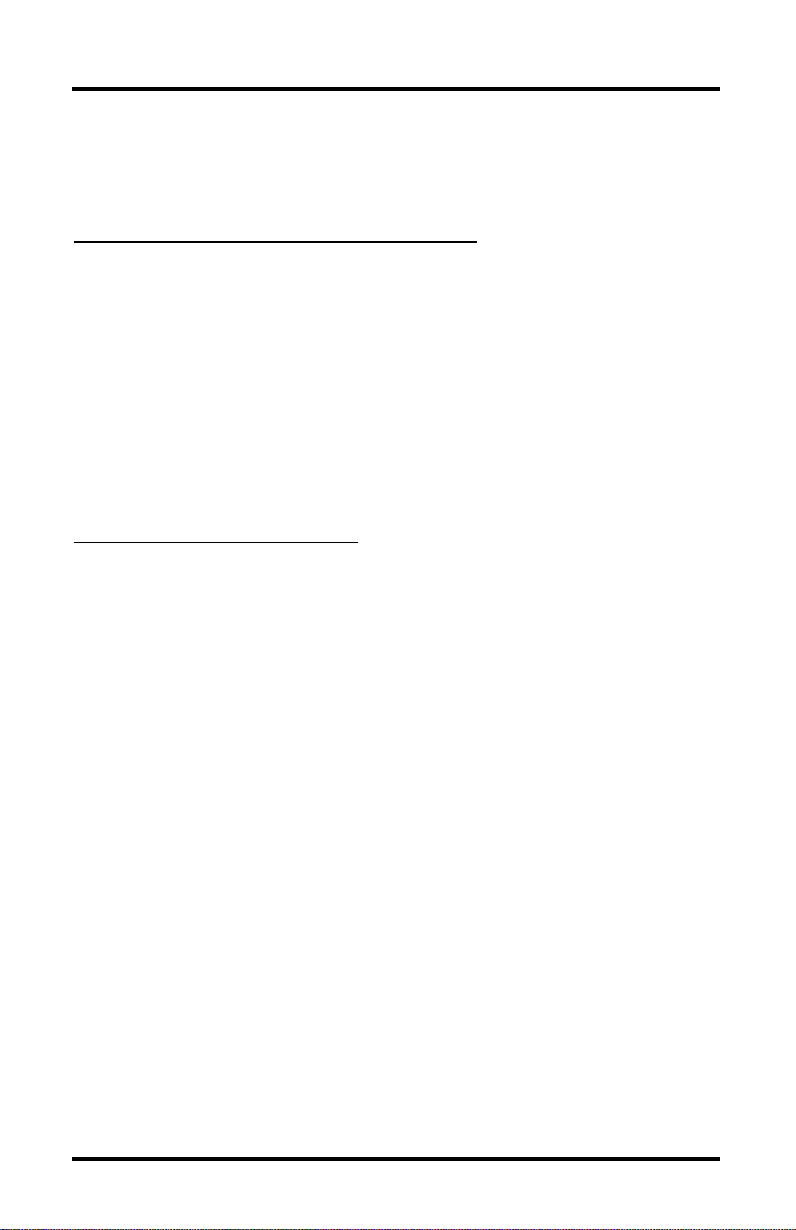

13. Move the axis to align reading head mounting holes.

14. A gap may exist between the reading head and its

mounting surface, requiring leveling screw adjustment.

15. To adjust the leveling screws, place a .001" -.003" feeler

gage (or shim) between one leveling screw and the

mounting surface at a time.

16. Adjust the leveling screw until a slight drag is felt on

the feeler gage. Repeat this for each leveling screw,

3 total.

17. Evenly tighten the two 8-32 SHCS to secure the reading

head.

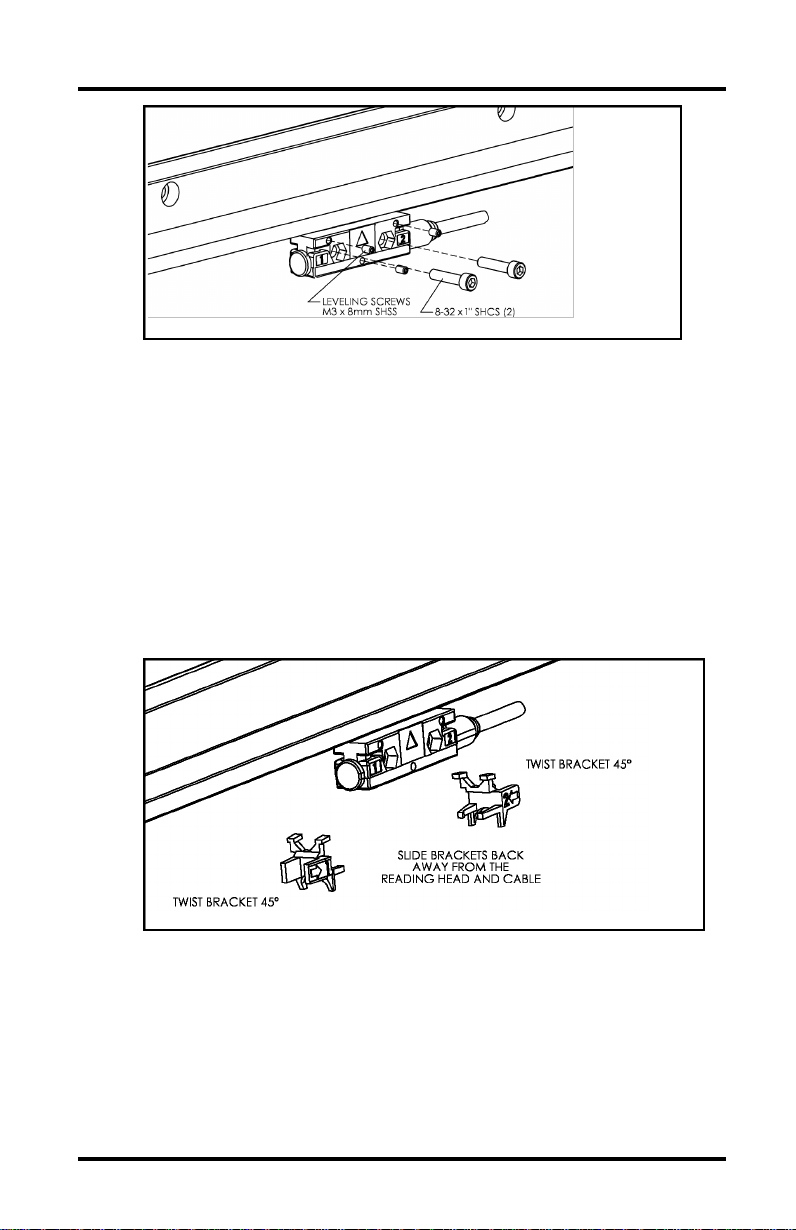

18. Use Allen wrench to slide brackets away from the reading

head.

19. Remove alignment brackets and save for future use.

20. Route cable with slack loops allowing for axis motion.

21. Secure excess cable by fastening with clips and ties.

22. Move the axis through its full travel. Confirm that the

assembly does not interfere with the machine movement.

MICRO-LINE Reference Manual

41

Page 45

REFERENCE

Hassle-Free Warranty

ACU-RITE readouts and precision glass scales are warranted to the

end user against defects in material and workmanship and against any

damage that occurs to the product within three (3) years from the original purchase date. ACU-RITE will, at its discretion and expense, repair

or replace the returned item or any of the item's component(s) as long

as ACU-RITE receives notice of the defect or damage within the three

(3) year warranty period.

The foregoing warranty obligations are in lieu of all expressed

and/or implied warranties of fitness or merchantability or otherwise,

and state ACU-RITE's entire liability and the end user's exclusive

remedy, under any circumstance, for any claim of damage.

In no event shall ACU-RITE be liable for incidental or consequential damages nor shall ACU-RITE's liability for any claims or damage

arising out of or connected with this warranty or the manufacture, sale,

delivery, or use of the products with which this warranty is concerned

exceed the purchase price of said products.

42

MICRO-LINE Reference Manual

Page 46

ACU-RITE INCORPORATED

One Precision Way • Jamestown,NY 14701

Loading...

Loading...