Page 1

ENC 250™ SINGLE SECTION

REFERENCE MANUAL

Acu-Rite Companies Inc.

Page 2

Page 3

ENC 250™ SINGLE SECTION

Table of Contents

Page

Introduction..............................................................................2

Mounting Preparation .............................................................3

Mounting Information ............................................................. 4

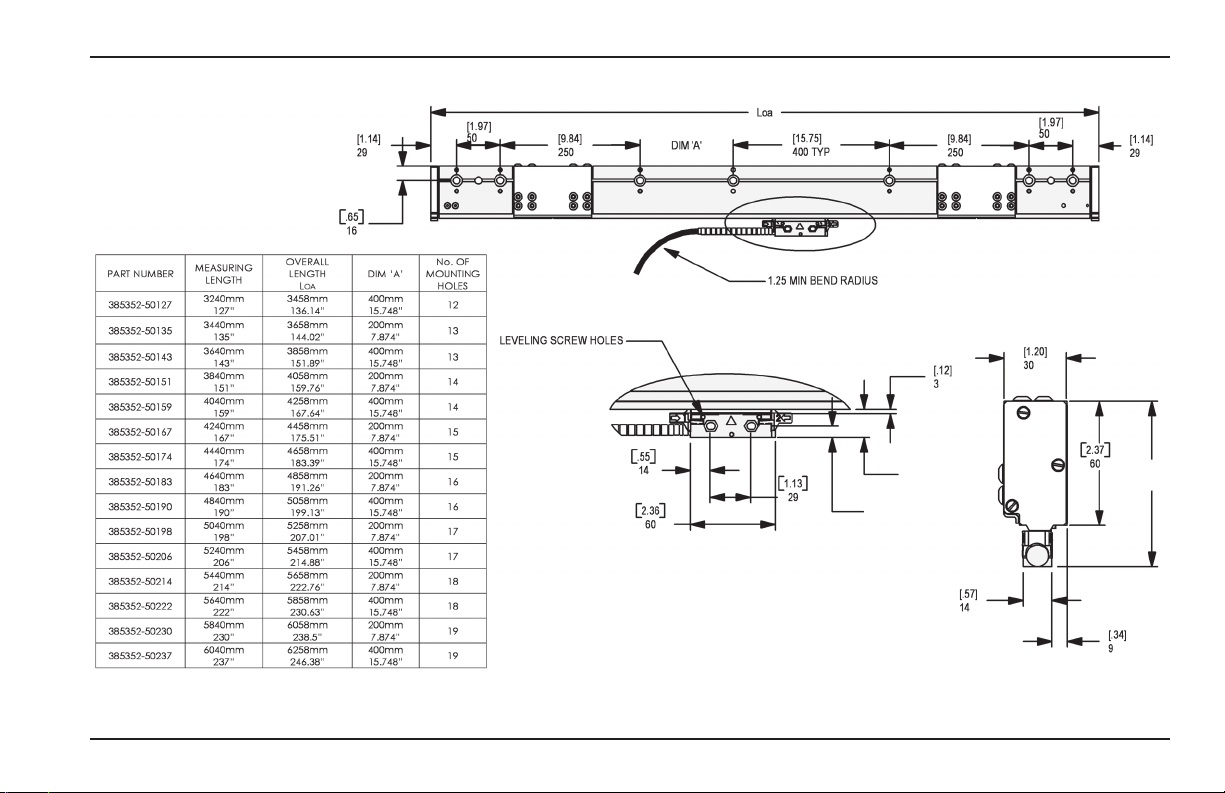

Encoder Dimensions ................................................................5

Mounting Requirements..........................................................6

Installation Procedure .............................................................7

Tape Tensioning.....................................................................10

Electrical Shielding................................................................12

Troubleshooting .....................................................................13

Mechanical Specifications ..................................................... 14

Output Signals and Pin-Outs................................................15

Electrical Specifications ........................................................16

The ACU-RITE Warranty ....................................................17

Tool Requirements .................................................................18

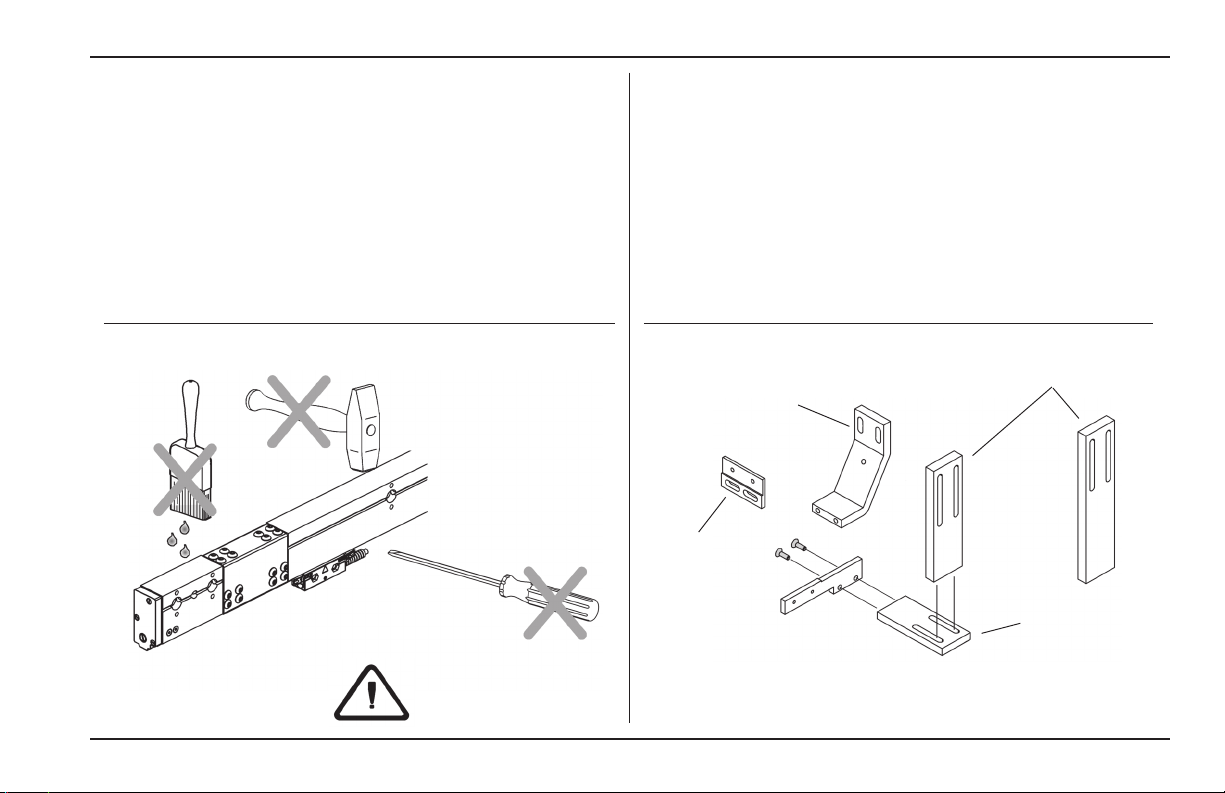

Brackets ...

Off set side

mount bracket

Reading head

mounting plate

Universal side mounting bracket

(Available in different lengths)

Combination

reading head bracket

w/extension

• Installation brackets are available.

• Your authorized distributor can assist you in selecting

brackets for your installation.

1

Acu-Rite Companies Inc.

Page

Page 4

Introduction / Supplied Items

ENC 250™ SINGLE SECTION

The ENC 250 linear encoder provides the accuracy and

reliability of an Acu-Rite Companies Inc. measuring system

with digital output. Features and options include:

• Resolution of [.0002in.] 5µm

• Accuracy grade of +/-15µm/M

• [2 ft.] .61m armor cable and extension cables up to a maximum of

[75 ft.] 22.86m for a VRO; [35 ft.] 10.67m for a DRO

• Mounting hardware

• Brackets and accessories

Contact your Authorized Distributor for a complete list of

other products and accessories.

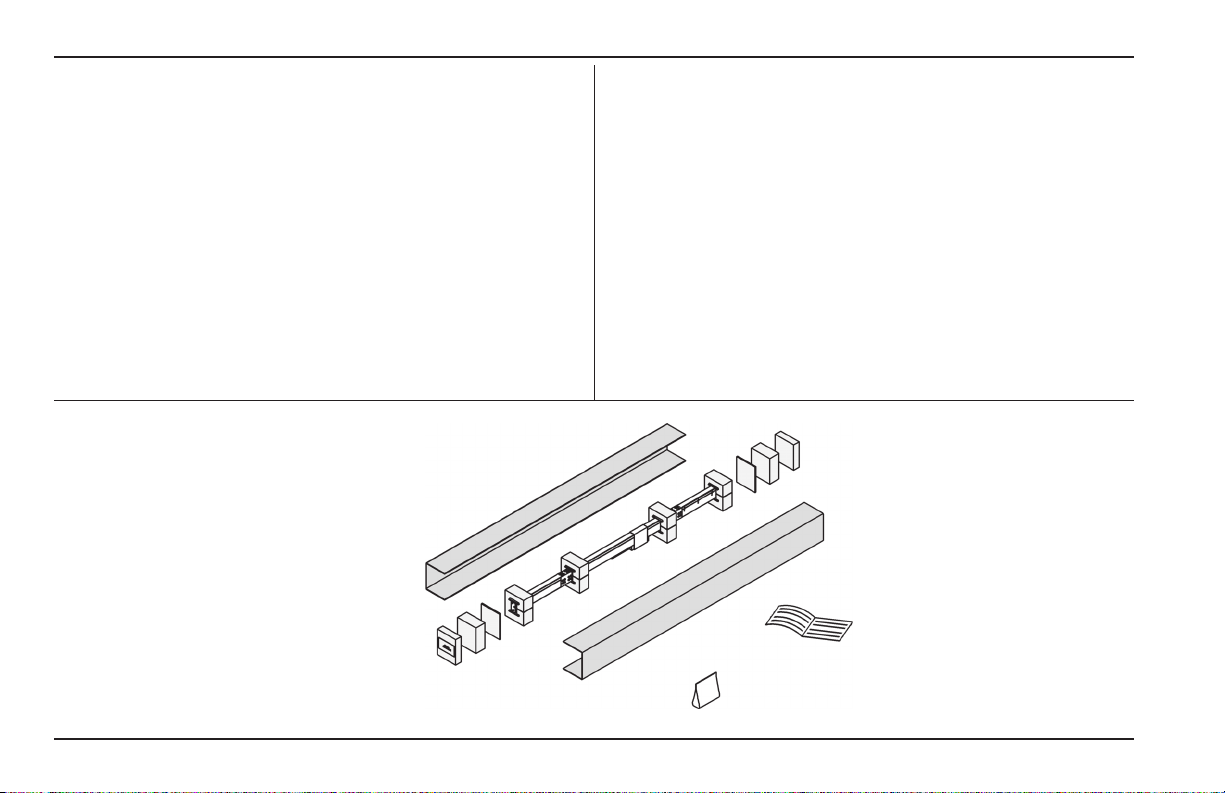

Contents ...

For future ordering information or warranty service, record

the linear encoder catalog number located on the scale

assembly tag, and the serial number from the reading head

tag.

Catalog No. Serial No.

Axis: _______________ __________________

Tape tension value: ___________________________________

Date of purchase: ____________________________________

Distributor: ____________________________________

Address: ____________________________________

Telephone: ____________________________________

A

C

A • ENC 250 Linear Encoder

B • Encoder mounting hardware

C • Reference Manual

Acu-Rite Companies Inc.

B

2

Page 5

ENC 250™ SINGLE SECTION

Mounting Preparation

Please follow these preparation guide lines.

• Understand your mounting requirements.

• Mount with lip seals down and away from the work area.

• Brackets should be kept as short as possible and rigid.

• Surfaces must be in good condition, clean, and free of dirt.

Remove paint from machined mounting surfaces.

Alignment brackets must only be removed as

•

instructed.

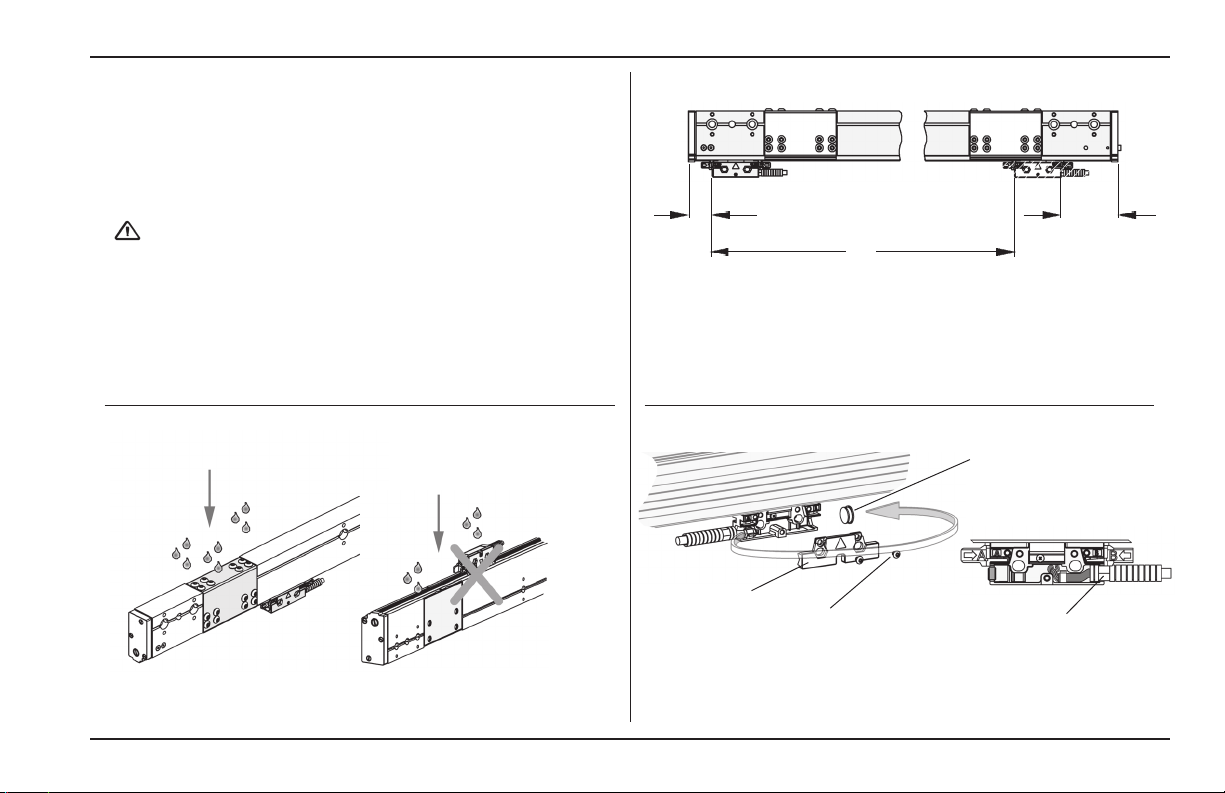

Coolant spray ...

• Encoder lip seals to face away from coolant spray.

Measuring length ...

[1.0”]

25mm

“L”

“L” = Measuring length + [2.0”] 50.8mm nominal over travel

Travel is limited by stops at each end of scale

[2.8”]

71.1mm

• Machine travel can not exceed the encoder measuring length.

• Either limit machine travel or obtain correct length scale.

Changing cable exit direction ...

Plug

Cover plate

T-10 Torx screw (2)

Armor cable hex crimp

• Determine the cable exit direction before installing the encoder.

• To change the cable exit direction; remove the cover plate

and rotate the cable 180°.

3

Acu-Rite Companies Inc.

Page 6

Mounting Information

ENC 250™ SINGLE SECTION

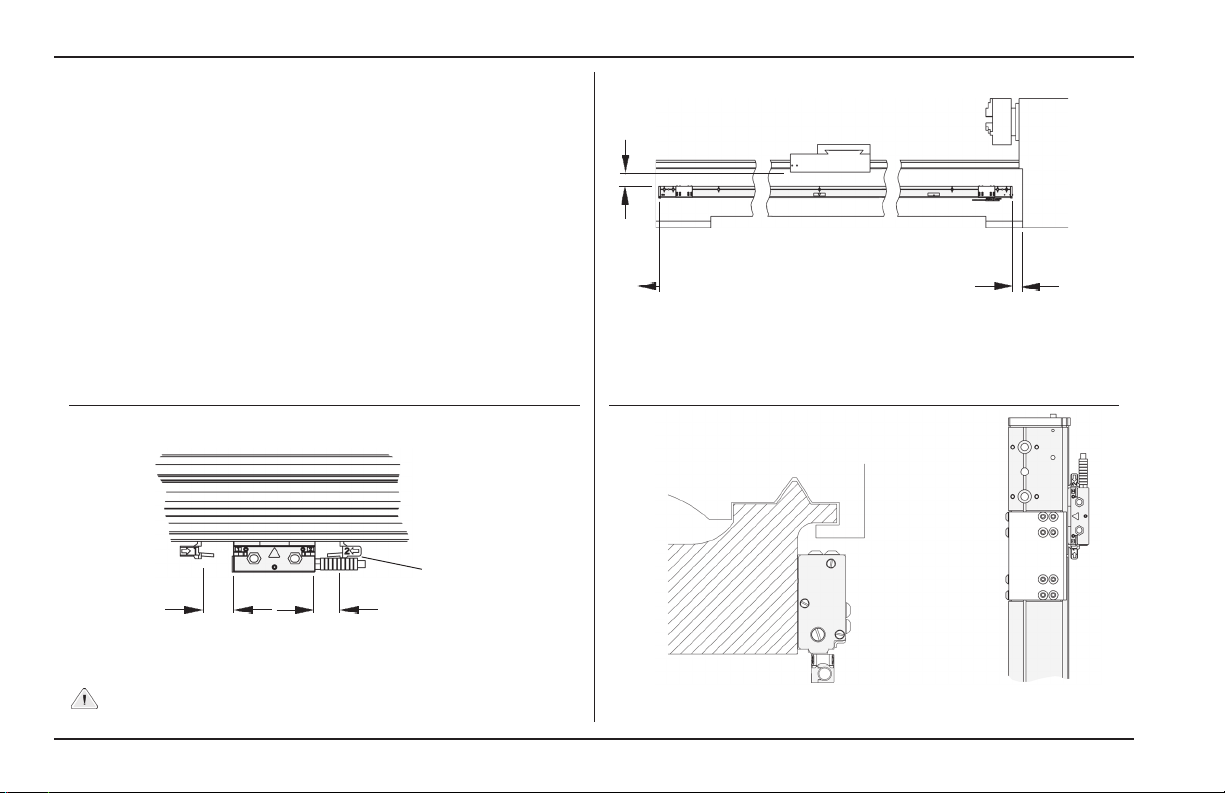

Use this information to plan your Linear Encoder

installation.

• Mount the linear encoders close to machine guide ways to

ensure system accuracy.

• Space between reading head casting and mounting bracket

or surface must not exceed [.188”] 4.7mm.

Alignment bracket removal clearance

Alignment bracket

[1.0]

25mm

[1.0]

25mm

(2)

End of scale clearance requirements

[1.0] 25mm

[5.0]

127mm

[5.0]

127mm

• [1.0] 25mm of clearance is required above the scale case

top surface for access to the expansion cover fasteners.

• A minimum clearance of [5.0] 127mm is required at each

end of the scale case.

Horizontal

mounting

Vertical

mounting

• Allow clearance for alignment bracket removal.

Alignment brackets must not be removed until

•

instructed.

Acu-Rite Companies Inc.

• Mount encoder in a horizontal or vertical position as shown.

• Do not mount flat or inverted.

4

Page 7

ENC 250™ SINGLE SECTION

Encoder Dimensions

[.83]

21.0

[.37]

9.4

5

Acu-Rite Companies Inc.

[3.2]

81.3

Page 8

Mounting Requirements

ENC 250™ SINGLE SECTION

A variety of mounting conditons can be accommodated.

• The machine configuration determimes the brackets

required to install the encoder.

• Two typical mounting conditions are shown; reading head

mounting plate, and a three piece combination assembly for

mounting the reading head to the machine.

• The [8-32] 4mm SHCS for mounting the reading head is a

standard low head style fastener, supplied with the

mounting hardware.

• The shipping bolts (M5 hex head) must be removed from

the expansion covers prior to beginning the installation.

• Tool requirements are listed on page 18.

Three piece combination bracket ...

Machine

axis

Machine

casting

ENC 250 encoder

Combination

bracket

assembly

Encoder reading

head

Reading head mounting plate ...

Machine

axis

ENC 250 encoder

Machine

casting

Encoder reading

head

Mounting plate

• The mounting plate typically applies to surfaces that are

flush, or slightly offset.

Shipping bolts ...

M5 Shipping

bolts (4)

Expansion

cover (2)

• This combination typically applies to a lathe where the

cross feed over hangs the bed mounting surface.

• A wide range of combination lengths are available.

Acu-Rite Companies Inc.

• Remove the M5 shipping bolts prior to encoder

installation.

6

Page 9

ENC 250™ SINGLE SECTION Encoder Installation Procedure

These steps apply to all mounting conditions. Although this

may not pictorially represent your application, your

installation procedure should follow these steps.

• Adjust drill depths and fastener lengths as required.

The stud tool is used

temporarily to support

the encoder while

locating the mounting

holes

• When instructed on page 10, adjust the leveling set screws

as follows:

1. Insert, but do not tighten the [8-32] 4mm reading head

screws.

2. Use a [.001-.003”] .025 - .076mm shim between the

leveling set screws and mounting surface.

3. Adjust each set screw until a slight drag is felt on the

shim.

4. Evenly tighten the [8-32] 4mm reading head mounting screws.

• Contact your Authorized Distributor should you require

additional assistance.

Most centered scale

mounting hole

Encoder

C

L

Movable axis

(carriage)

• Attach the 1/4-20 installation stud tool.

• Slide the scale case onto the stud at the same hole location.

Stud tool

Align to within [.012”] .3mm TIR to the axis

travel measuring over each hole location

Axis Travel

• Move the machine axis to its center of travel.

• Hold the encoder to the intented mounting location, and

position for the required clearances. Allow minimal

distance required for the reading head brackets.

• Mark the “most centered” scale mounting hole location to

the machine with a center punch.

• Remove encoder, drill / tap location for a [1/4-20 x 1/2”] M6

x 12mm deep.

• Align the top of the scale case.

• Transfer punch the furthest right mounting hole location

before the expansion cover.

• Allow the scale to swing down, drill / tap location for a [1/420 x 1/2”] M6 x 12mm deep.

7

Hole location

Right expansion cover

Acu-Rite Companies Inc.

Page 10

Encoder Installation Procedure

Align to within [.012”] .3mm TIR to the axis

travel measuring over each hole location

Axis Travel

ENC 250™ SINGLE SECTION

Align to within [.012”] .3mm TIR to the axis

travel measuring over each hole location

Axis Travel

Starting hole

[1/4-20 x 1-1/4”] M6 x 30mm SHCS & M6 flat washer

• Attach and align the top of the scale case. Secure the

fastener.

Align to within [.012”] .3mm TIR to the axis

travel measuring over each hole location

Axis Travel

Left expansion cover

[1/4-20 x 1-1/4”] M6 x 30mm SHCS & M6 flat washer

• Align the furthest left mounting hole before the expansion

cover with the furthest right attached hole.

• Transfer punch the left hole location.

• Drill / tap location for a [1/4-20 x 1/2”] M6 x 12mm deep.

• Attach the left end, and align the top of the scale case.

Secure the fastener.

Acu-Rite Companies Inc.

[1/4-20 x 1-1/4”] M6 x 30mm SHCS & M6 flat washer

• Starting at the right end, align the top of the scale case,

and transfer punch each remaining hole location.

• Remove scale, drill / tap locations for a [1/4-20 x 1/2”]

M6 x 12mm deep.

• Attach the scale case, align to within [.012”] .3mm TIR, &

secure all fasteners. Note: Replace stud with fastener.

Run an indicator along the front

face to locate the high point.

Mark the location, and set the

indicator to 0.000”

• Align the front face of the scale case to within [.012”] .3mm

TIR of the axis travel following the next steps.

8

Page 11

ENC 250™ SINGLE SECTION

Example:

high point

Encoder Installation Procedure

Align to within [.012”] .3mm TIR to the axis

travel measuring over each hole location

Axis Travel

Loosen next two

fasteners

• Loosen the next two fasteners to the right of the high point.

• Move indicator to the first hole location, insert two M3 x 25mm

SHSS (leveling set screws).

• Use the leveling screws to align the face to within [.012”] .3mm

to the high point along the axis travel and secure the fastener.

Run indicator along the front

face to align scale case to within

[.012”] .3mm to the axis travel

• Move indicator to the next hole location, and loosen the next

fastener to the right of that fastener. Align this location.

• Repeat the previous steps to align the face at each fastener.

• Return to the high point, and use the same procedure working to

the left end.

• Recheck the scale case top alignment, by starting at the

center hole location, and adjust as necessary.

Dowel pin anchoring ...

Scale case holes are

undersized to insure

accurate centering.

BHCS (16) on each

expansion cover

[5/16”] 8mm Dowel

Pin (2)

• Drill a [.302”] 7.7mm diameter hole through the dowel pin hole

locations at each end of the scale case [.375] 9.5mm deep.

• Use a [.312] 8mm reamer to provide a press fit.

• Insert the dowel pins at each end, with the threaded holes facing

outward.

• Loosen the BHCS (16) on each expansion cover, approximately

[1/8”] 3mm turn each.

9

Acu-Rite Companies Inc.

Page 12

Encoder Installation Procedure

Universal brackets are available from ACU-RITE for

mounting the reading head. SENC 150 & SENC 250

encoders use most of the same reading head brackets.

Custom designed brackets by the installer should be solid,

rigidly assembled components, attached to the machine with

[1/4-20] M6 fasteners minimum.

8-32 Low head SHCS

(2)

ENC 250™ SINGLE SECTION

Slide brackets back

away from the

reading head and

cable

Twist brackets

45° to remove

• Follow the procedure on page 7 to attach the reading head

to the bracket.

• Use allen wrench from set screw adjustment to slide

alignment brackets away from the reading head.

• Remove alignment brackets and save with this manual.

• Move the axis through its full travel. Confirm that the

assembly does not interfere with the machine movement.

Tape Tensioning ...

Tape tension location label

Align center marks

• Return the machine axis to its center of travel.

• Align the center marks on the reading head and scale case by

sliding the reading head and brackets along the case.

• Locate and attach the reading head brackets to the machine.

• Align the bracket mounting holes with the reading head holes,

and secure brackets in place.

Insert the [8-32] M4 SHCS, BUT DO NOT TIGHTEN.

Acu-Rite Companies Inc.

Reading head

• Move the reading head to the tape tensioning position.

• Temporarily attach the reading head cable to the readout.

• Follow the readout manual’s instructions for set up, and

set the encoder and display resolution to .005mm. Set the

readout in metric mode.

10

Page 13

ENC 250™ SINGLE SECTION

Encoder Installation Procedure

End Cap

Remove plastic plug

Compession sleeve

Washer

Thumb screw

• Remove red plastic plug.

• Insert the thumb screw through the washer, compression

sleeve, and into the end cap hole.

• Thread the screw into the holder inside the end cap, but do

not tighten.

M5 SHSS

Thumb screw

• Completely loosen the M5 SHSS, but do not remove.

• Position the readout so that it can be seen while adusting

the thumb screw head.

• Insure that the readout is in metric mode.

Thumb screw

• Tighten the screw until the readout display reads

approximately .05mm.

• Back off the screw until the display stops changing.

• Reset readout to zero and repeat the procedure two more

times. This relaxes the tape before setting the tension.

M5 SHSS

Thumb screw

• Refer to the tensioning value listed on the label on the case.

• Slowly tighten the screw until the display reaches the tensioning

value.

• Fully tighten the M5 SHSS [30-lb-in] 3.4N m.

11

Acu-Rite Companies Inc.

Page 14

Encoder Installation Procedure

Apply silicone grease to plug

and reinsert it

• Remove the thumb screw, sleeve, and washer.

• Apply silicone grease to the plug and reinstall it.

ENC 250™ SINGLE SECTION

Electrical shielding ...

• Connect a ground wire from the terminal on the back of

the readout to the machine or earth ground.

• Attach a ground wire from the machine to a solid earth

ground.

• With the encoder attached to the cable connected to the

readout, check shielding by measuring resistance between

connector housing and scale unit.

Desired value: 1 ohm max.

• With the readout properly mounted, route the cable with

sufficient slack loops for machine movement to the readout.

• Secure cables by fastening with clips or ties.

• Attach the encoder connectors to the readout.

Acu-Rite Companies Inc.

12

Page 15

ENC 250™ SINGLE SECTION

Trouble Shooting

If you experience difficulties with your installation, do the

following to determine the problem.

Checking the Readout

Difficulties on more than one axis are usually associated with

the readout. Follow these steps to determine if your

difficulties are associated with the readout:

• Ensure that the linear encoder connectors are correctly

seated.

• Swap linear encoder cables at the readout to see if the

problem is still shown in the same display.

• If the problem remains in the same display, the readout

may be in error. To determine if that is the problem, repeat

above steps with both encoders, but with only one encoder

connected at a time. This should allow you to determine if

the problem is with the readout or the encoder.

• If the problem follows the connection change, the linear

encoder may be in error.

If the Readout is at fault, refer to “What to do” to arrange for

the parts necessary to repair your system. If a linear encoder

appears to be at fault, proceed with “Checking the Linear

Encoders”.

Checking the Linear Encoders

Problems on a single axis are usually associated with the

linear encoder or its installation. Difficulties can be caused

by improper installation, loose or misaligned bracketry, or a

damaged or inoperable encoder.

Follow these steps to determine the cause of your system

difficulties:

• Confirm that your bracketry and installation does not

interfere with other machine structures through the entire

length of the linear encoder travel.

• Check for loose fasteners. If you find loose fasteners, first

confirm that the linear encoder is installed to the

tolerances specified and then retighten the fasteners as

required.

• Confirm that the linear encoder is installed to the specified

alignment tolerances. If the installation does not meet the

tolerances, reinstall the encoder according to the

“Installation Procedure”.

• Do not attempt to repair the reading head or scale

assembly. The ENC 250 is field serviceable by assembly

replacement only. Attempts to repair the encoder can

permanently damage it and void the warranty.

What to do

If an ACU-RITE linear encoder or readout is found to be at

fault, please contact your Authorized Distributor for

instructions prior to removing the encoders or readout.

13

Acu-Rite Companies Inc.

Page 16

ENC 250™ SINGLE SECTIONMechanical Specifications

Mechanical Specifications Digital

Resolution 5µm [0.0002 in.]

Grating pitch 100µm [0.00393 in]

Scale medium Reflective Metal Tape

Accuracy ± 15µm/M [0.00018 in/ft]

Max. slew speed 1 M/sec [40 in/sec.]

Force required to move

reading head ± 3.3 Newtons [0.75 lbs]

Operating Environment:

Temperature 0° to 40° C [32° to 104°F]

Relative Humidity 20% to 95% (non-condensing)

Storage Environment:

Temperature -40° to 60° C [-40° to 140°F]

Humidity 20% to 95% (non-condensing)

Weight w/cable 1 kg + 3.2kg/M [2.2 lbs. + 0.18 lbs/in] of measuring length

Connecting cable: Length = .61m [2 ft]

Armor Connector: DE-9P

Max. cable length 22.9m [75 ft.] VRO / 10.7m [35 ft.] DRO

Measuring length 3240mm [127”] - 6040mm [237”]

Reference Mark Interval 100mm [3.937”] Distance encrypted

Acu-Rite Companies Inc.

14

Page 17

ENC 250™ SINGLE SECTION

Specifications

Output Signals and Pin-Outs

Digital Differential

Pin 1 Pin 2 Pin 3 Pin 4 Pin 5 Pin 6 Pin 7 Pin 8 Pin 9

N/C Green Yellow Blue Red White Brown Pink Gray

N/C Channel Channel Channel Channel Ground Vcc, + 5.1 Channel Channel

A+ A- B+ B- ± 0.1 VDC R+ R-

15

1

5

6

9

Acu-Rite Companies Inc.

Page 18

Parameter Digital

ENC 250™ SINGLE SECTIONElectrical Specifications

Output Signals

Incremental signals

Signal levels

Reference Mark signals

Signal level

Power Supply

IOH=(High level output current) = 20mA

VOH=(High level output voltage) >2.5Vdc

0°

Channel A+

Channel A-

Channel B+

Channel B-

1

0

1

0

90°

1

0

1

0

Square-wave voltage signals.

Channels A and B, in 90°

quadrature relationship

Differential TTL

Square-wave pulse

Differential TTL

5.1 ± 0.1 VDC @ 140 mA max.

360°

Channel R+

Channel R-

1 Count

(Phased)

1

0

1

0

I

=(Low level output current) = 20mA

OL

VOL=(Low level output voltage) < 0.5Vdc

Acu-Rite Companies Inc.

16

Page 19

ENC 250™ SINGLE SECTION

3 Year Warranty ...

Warranty

Acu-Rite Companies Inc. readouts and precision scales are

warranted to the end user against defects in material and

workmanship, and against any damage that occurs to the

product within three (3) years from the original purchase

date. Acu-Rite Companies Inc. will, at its discretion and

expense, repair or replace the returned item or any of the

item’s component(s) as long as Acu-Rite Companies Inc.

receives notice of the defect or damage within the three (3)

year warranty period.

The foregoing warranty obligations are in lieu of all

expressed and/or implied warranties of fitness or

merchantability or otherwise, and state Acu-Rite Companies

Inc. entire liability and the end user’s exclusive remedy,

under any circumstances, for any claim of damage.

In no event shall Acu-Rite Companies Inc. be liable for

incidental or consequential damages nor shall Acu-Rite

Companies Inc. liablility for claims or damage arising out of

or connected with this warranty or the manufacture, sale,

delivery, or use of the products with which this warranty is

concerned exceed the purchase price of said products.

17

Acu-Rite Companies Inc.

Page 20

Tool Requirements

You will need the following tools to complete the installation:

• 0.001” Dial Indicator with Magnetic Base

• English Hex Wrench Set

• Metric Hex Wrench Set

• Dial Calipers

• Feeler Gage

• Hand Drill

• Hand Tap

• Taps(English): 1/4-20 UNC & #8-32 UNC

• Taps(Metric): M6, M4

• Drills(English): #7 (.201”), #29 (.136”), N (.302”)

• Drills(Metric): 5mm, 3.3mm, 7.7mm

• Reamer(English): .312”

• Reamer(Metric): 8mm

• Transfer Punch Set

• Hammer

• Center Punch

• Phillips Screw Driver

• Flat-tip Screw Driver

* NOTE: Both English and metric mounting hardware have

been supplied. The mounting instructions reference to both.

Tools required depend on the fasteners being used.

ENC 250™ SINGLE SECTION

Acu-Rite Companies Inc.

Tools

18

Page 21

Page 22

Acu-Rite Companies Inc.Acu-Rite Companies Inc.

Acu-Rite Companies Inc.

Acu-Rite Companies Inc.Acu-Rite Companies Inc.

IS ANIS AN

IS AN

IS ANIS AN

ISO 9001ISO 9001

ISO 9001

ISO 9001ISO 9001

CERTIFIEDCERTIFIED

CERTIFIED

CERTIFIEDCERTIFIED

MANUFMANUF

ACTURERACTURER

MANUF

ACTURER

MANUFMANUF

ACTURERACTURER

One Precision Way • Jamestown, NY 14701

Acu-Rite Companies Inc.

104000-028 EDITION C 7/07

Loading...

Loading...