Page 1

ENC 250TM MULTI-SECTION

REFERENCE MANUAL

Acu-Rite Companies Inc.

Page 2

™

ENC 250

MULTI-SECTION

Table of Contents

Introduction

Bracket availability ...........................................................1

Components supplied .........................................................2

Tool requirements ..............................................................2

Mounting Preparation

Measuring length ................................................................2

Cable exit ............................................................................2

Mounting information ........................................................3

Encoder Dimensions ...........................................................3

Mounting Requirements ....................................................4

Installation

Left end section ...................................................................4

Center section(s).................................................................5

Right end section ................................................................6

Dowel pin anchoring ...........................................................6

Page

Page

Tape .....................................................................................7

Lip seal ................................................................................7

Reading head.......................................................................8

Completing the installation

Tape tensioning................................................................... 9

Specifications

Electrical shielding ...........................................................10

Trouble Shooting ...............................................................10

Mechanical ........................................................................11

Electrical ...........................................................................11

Pin out ...............................................................................12

Hassle-Free Warranty .......................................................12

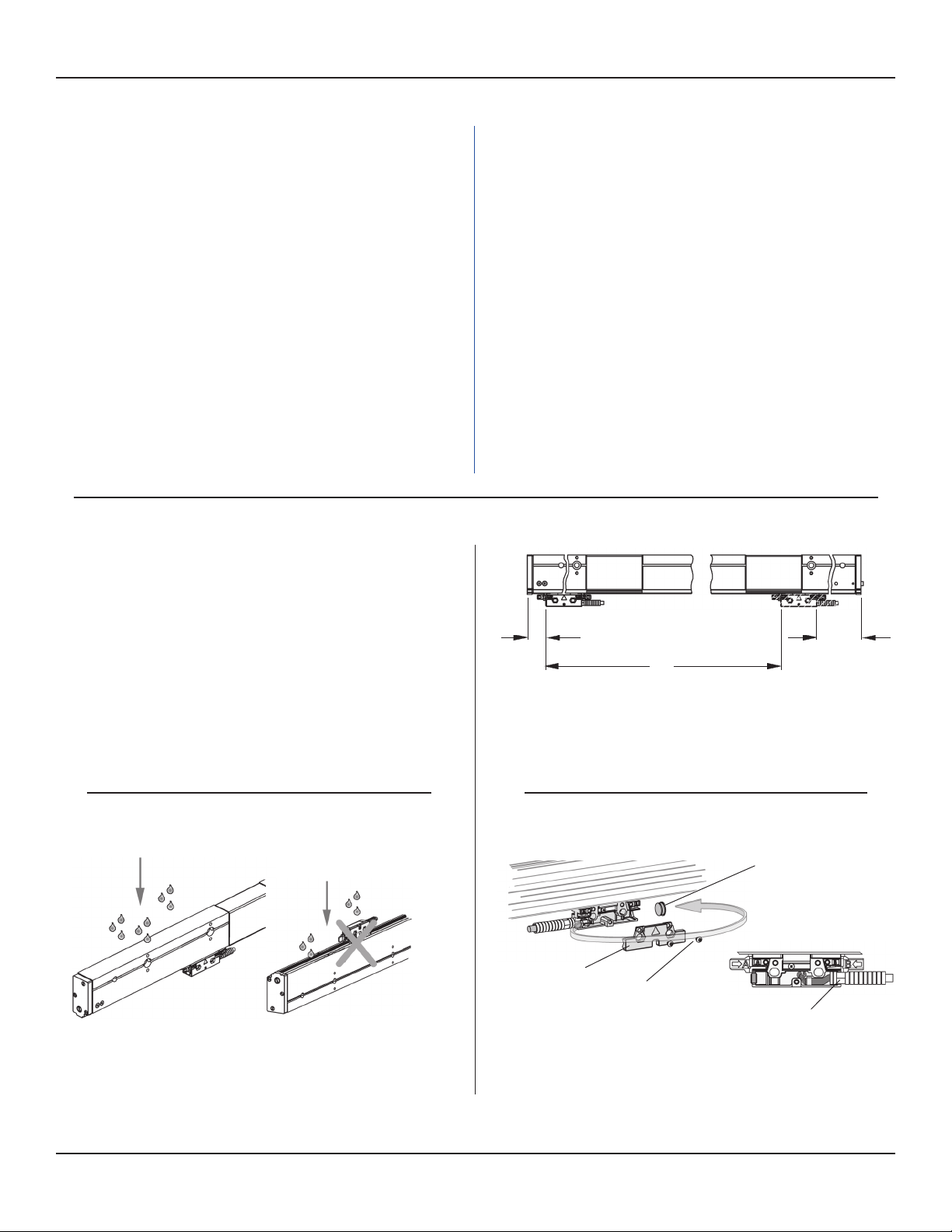

Brackets ...

Off set side

mount bracket

Universal side mounting bracket

(Available in different lengths)

Introduction

The ENC 250 linear encoder provides the accuracy and

reliability of an Acu-Rite Companies Inc. measuring system

with digital output. Features and options include:

• Resolution of [.0002in.] 5µm

• Accuracy grade of [.00018 in/ft] +/-15µm/M

• [2 ft.] .61m armor cable and extension cables up to a

maximum of [75 ft.] 22.9m for a VRO; [35 ft.] 10.7m for a

DRO

• Mounting hardware

• Brackets and accessories

Contact your Authorized Distributor for a complete list of

other products and accessories.

Reading head

mounting plate

Combination

reading head bracket

w/extension

• Installation brackets are available.

• Your authorized distributor can assist you in selecting

brackets for your installation.

For future ordering information or warranty service, record

the linear encoder catalog number located on the scale

assembly tag, and the serial number from the reading head

tag.

Catalog No. Serial No.

Axis: _______________ _________________

Tape tension value: __________________________________

Date of purchase: ___________________________________

Distributor: ___________________________________

Address: ___________________________________

Telephone: ___________________________________

1

Acu-Rite Companies Inc.

Page 3

ENC 250

™

MULTI-SECTION

Components

Each unit should consist of the following boxes:

Scale Section Boxes:

• Right End Section

• Left End Section

• Center Sections (One or more boxes depending on length)

Common Components Box:

• Scale Measuring Tape (Coiled On Spool)

• Lipseals (Coiled On Spool)

• Reading Head

• Mounting Hardware with RTV and Silicone Grease

• Reference Manual

* NOTE: Both English and metric mounting hardware have

been supplied. The mounting instructions reference to both.

Tools required depend on the fasteners being used.

Mounting Preparation

Tools

You will need the following tools to complete the

installation:

• 0.001” Dial Indicator with Magnetic Base

• English Hex Wrench Set

• Metric Hex Wrench Set

• Dial Calipers

• Feeler Gage

• Hand Drill

• Hand Tap

• Taps (English): 1/4-20 UNC & #8-32 UNC

• Taps (Metric): M6, M4

• Drills (English): #7 (.201”), #29 (.136”), N (.302”)

• Drills (Metric): 5mm, 3.3mm, 7.7mm

• Reamer (English): .312”

• Reamer (Metric): 8mm

• Transfer Punch Set

• Hammer

• Center Punch

• Phillips Screw Driver

• Flat-tip Screw Driver

• Torque Wrench

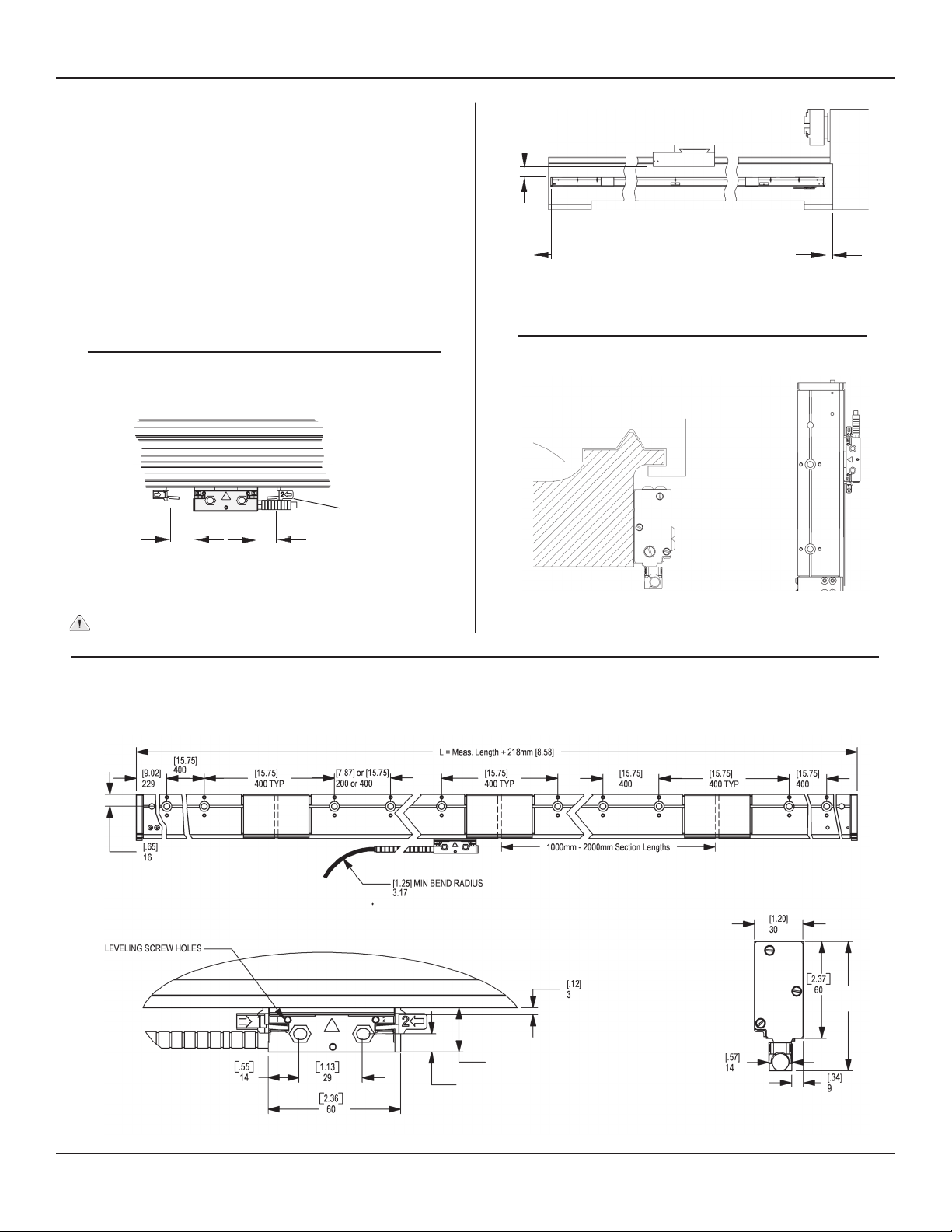

Measuring length ...

Please follow these preparation guide lines.

• Understand your mounting requirements.

• Mount with lip seals down and away from the work area.

• Brackets should be kept as short as possible and rigid.

• Surfaces must be in good condition, clean, and free of dirt.

Remove paint from machined mounting surfaces.

• Locate the machine’s center of travel on the axis that

the encoder will be mounted to. Move the axis to the

center of travel prior to installing the encoder. Mark

a reference line on the axis so that it can easily be

returned to the center of travel.

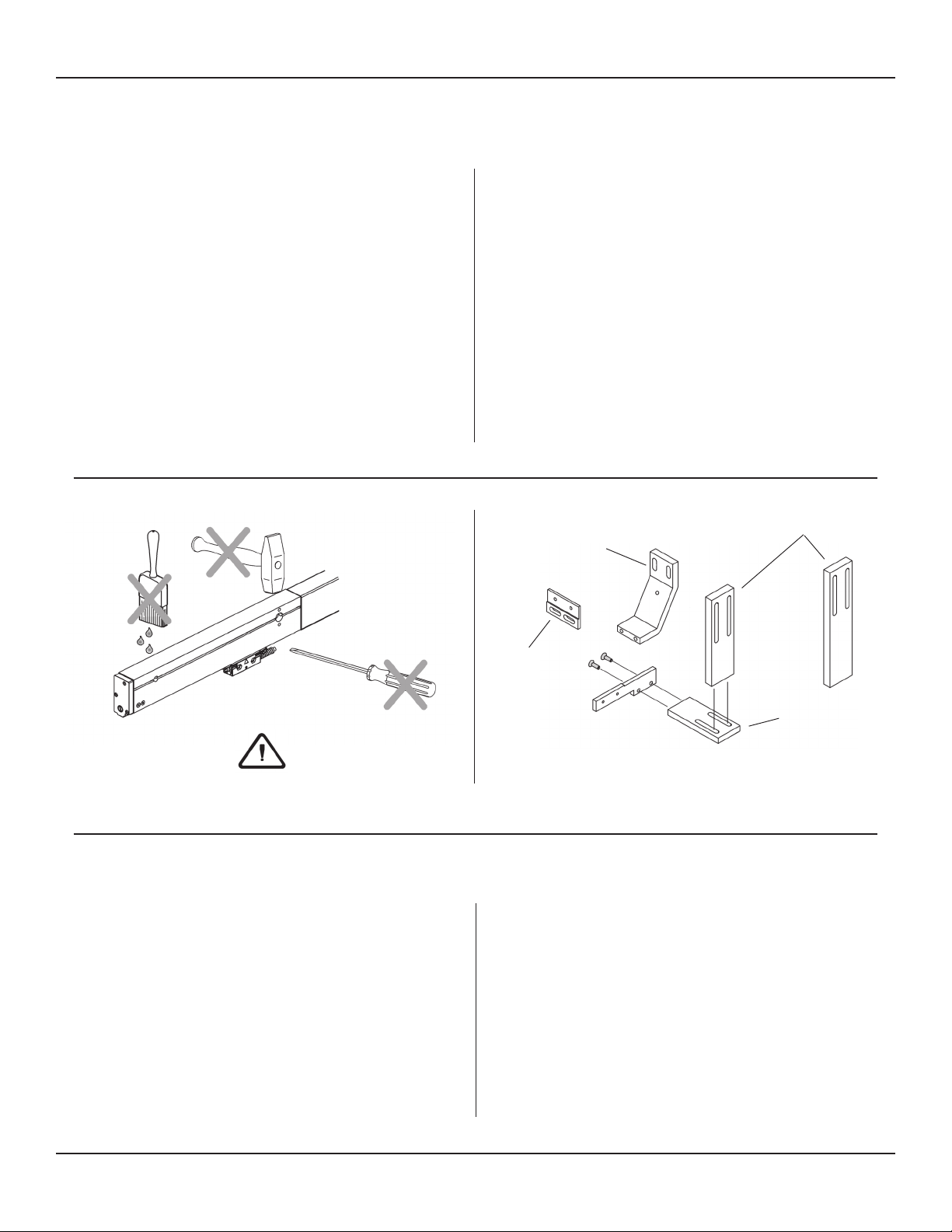

Coolant spray ...

[1.0”]

25mm

“L”

“L” = Measuring length + [2.0”] 50.8mm nominal over travel

Travel is limited by stops at each end of scale

[2.8”]

71.1mm

• Machine travel can not exceed the encoder measuring

length.

• Either limit machine travel or obtain correct length scale.

Changing cable exit direction ...

Plug

Cover plate

T-10 Torx screw (2)

• Encoder lip seals to face away from coolant spray.

Armor cable hex crimp

• Determine the cable exit direction before installing the reading

head.

• To change the cable exit direction; remove the cover plate

and rotate the cable 180°.

2

Acu-Rite Companies Inc.

Page 4

ENC 250

™

MULTI-SECTION

Mounting Information

Use this information to plan your Linear Encoder installation.

• Mount the linear encoders close to machine guide ways to

ensure system accuracy.

• Space between reading head casting and mounting bracket

or surface must not exceed [.188”] 4.7mm.

Alignment bracket removal clearance

Alignment bracket

[1.0]

25mm

[1.0]

25mm

(2)

End of scale clearance requirements ...

[1.0] 25mm

[5.0]

127mm

[5.0]

127mm

• Minimum clearance is required above the scale case top.

• A minimum clearance of [5.0] 127mm is required at each

end of the scale case.

Positioning ...

Horizontal

mounting

Vertical

mounting

• Allow clearance for alignment bracket removal.

Alignment brackets must not be removed until

•

instructed.

Encoder Dimensions

• Mount encoder in a horizontal or vertical position as shown.

• Do not mount flat or inverted.

[.83]

21.0

[.37]

9.4

[3.2]

81.3

3

Acu-Rite Companies Inc.

Page 5

ENC 250

™

MULTI-SECTION

Mounting Requirements

A variety of mounting conditions can be accommodated.

• The machine configuration determines the brackets

required to install the encoder.

• Two typical mounting conditions are shown; reading head

mounting plate, and a three piece combination assembly for

mounting the reading head to the machine.

• The [8-32] 4mm SHCS for mounting the reading head is a

standard low head style fastener, supplied with the

mounting hardware.

• Tool requirements are listed on page 2.

• Due to the long length of the encoder sections, the

installation illustrations have been modified.

In most cases, the sections have been shorten to

accommodate the information that they are presenting.

Please keep this in mind as the encoder is being installed.

Three piece combination bracket ...

Machine

axis

Machine

casting

• This combination typically applies to a lathe where the

cross feed over hangs the bed mounting surface.

• A wide range of combination lengths are available.

ENC 250 encoder

Combination

bracket

assembly

Encoder reading

head

Scale Case Installation Procedure

Left end section installation

Roll Pin

Left end section

Insert roll pin with open slot

• Tap two roll pins into the extruded slots in the “left end

section” as shown. Pins should protrude approximately [5/8”]

15.87mm.

• The seams on the roll pins face towards the inside of the

scale case.

• Repeat this step for all middle scale sections, inserting the

roll pins into the right end of each.

Left end

section

• Hold the left end section against the selected mounting

surface and transfer punch one mounting hole.

• Remove section, drill and tap the location for a

[1/4-20 x 1/2”] M6 x12mm deep minimum.

• Attach the section to the machine, and align the top

surface to within [.012”] .3mm of the axis travel.

Measuring directly over each mounting hole location.

• Transfer punch the second mounting hole. Remove the

section; drill and tap second hole location for a

[1/4-20 x 1/2”] M6 x12mm deep.

Enlarged end

view

facing in as shown

Transfer punch (1)

mounting hole location to

the machine surface

Reading head mounting plate ...

Machine

axis

ENC 250 encoder

Machine

casting

Encoder reading

head

Mounting plate

• The mounting plate typically applies to surfaces that are

flush, or slightly offset.

RTV

Scale clip

Seated end of pin

Sealant groves (2)

• Apply RTV Silicone Rubber to the two sealant grooves in

the left end section. The sealant must be applied on all

three sides of the case. Seal the seated ends of the spring

pins. Keep the end and inside of the section free of

sealant.

• Slide the scale clip over the end of the scale section to the

stop machined in the scale case. There is sufficient spring

in the clip to clamp it securely around the case.

• Clean off any excess RTV on the outside of the case.

4

Acu-Rite Companies Inc.

Page 6

™

ENC 250

MULTI-SECTION

[1/4-20 x 1-1/4”]

M6 x 30mm

SHCS and washer

• Attach this section to the machine using two [1/4-20 x

1-1/4”] M6 x 30mm SHCS and washers provided in the

hardware kit.

• Align the top of the section parallel to the axis travel to

within [.012”] .3mm and secure the fasteners.

Center section installation

Center scale

section

2mm Spacer

Scale clip

2mm Spacer

Roll pins installed

Transfer punch

furthest mounting

hole

RTV

This end first

Center section(s)

• Apply RTV to the two sealant grooves in the right end on

all three sides as done previously. Seal the seated ends of

the spring pins, keeping the end and inside of the section

free of sealant.

• Slide the scale clip over the end of the scale section up to

the stop in the scale case.

• Clean off any excess RTV on the outside of the case.

• Now apply RTV Silicone Rubber to the sealant grooves in

the left end keeping the end and inside of the section free

of sealant.

• Center sections can be mounted in random order.

• Place the 2mm spacer provided in the hardware kit into

the scale clip as shown.

• With the roll pins already installed, insert the left end of

the center section into the scale clip and butt it to the

mounted end section. Tap the end of the center section

with a soft hammer to seat it against the 2mm spacer.

• Align the top of the section parallel to the axis travel to

within [.012”] .3mm. Transfer punch the furthest right

end mounting hole to the mounting surface.

• Remove the center section, drill and tap the location for

an [1/4-20 x 1/2 “] M6 x12mm deep.

[1/4-20 x 1/2 “]

M6 x12mm SHCS

and washer

• Re-insert the center section back into the scale clip as

done previously, seating it against the 2mm spacer.

• Attach the right end to the machine but do not tighten.

• Transfer punch remaining mounting holes by aligning the

top surface to within [.012”] .3mm to the axis travel over

each mounting hole. Remove the center section, drill and

tap the locations for an [1/4-20 x 1/2 “] M6 x12mm deep.

• Reinsert the center section back into the scale clip as done

previously, seating it against the 2mm spacer.

• Attach the right end to the machine but do not tighten.

Clean off any excessive RTV sealant.

To be within [.012”] .3mm to the

axis travel

End

section

Center section

[1/4-20 x 1/2 “]

M6 x12mm SHCS

and washer

• Align the top surface to within [.012”] .3mm to the axis

travel measuring over each mounting hole. Secure the

scale case in place maintaining the alignment.

• Turn the handle of the 2mm spacer forward and remove it

through the bottom of the scale clip.

Remaining section(s) installation

• Mount any remaining center sections and the right end

section to the machine repeating this procedure. Use the

2mm spacer each time to set the required gap between

each section. Complete the next step prior to drilling and

tapping the right end mounting holes.

5

Acu-Rite Companies Inc.

Page 7

ENC 250

™

MULTI-SECTION

End to end distance must be

xx40mm ± 2mm

Suggested second location

• Check for proper spacing between sections. Using a tape

measure, record the over all length of the mounted scale

sections (no end caps). Convert the length to millimeters

by multiplying by 25.4. If the sections are mounted

correctly, the last two digits of your measurement should

be very close to 40 mm; (e.g. 6640 mm, 8040 mm, 10840

mm etc.). If this distance is off by more than two

millimeters from nominal (e.g. 6637 mm, 6643 mm) shift

the location of the right end section to bring it within the

nominal distance.

Scale face alignment

Run an indicator along the front

face to locate the high point.

Mark the location, and set the

indicator to 0.000” [0.0mm]

• To align the front face of the scale case to the axis travel,

first locate the high point. This is the TIR point furthest

away from the mounting surface along the axis travel.

Suggested first location

Move the indicator to a different

location on the face of the scale case

• Recheck the scale face alignment at a second location to

insure the encoder is parallel. Use the leveling screws for

further alignment if necessary.

Top surface

• Following the face alignment procedure, the top alignment

must be rechecked. Follow the previous steps placing the

indicator over each mounting hole.

Dowel pin anchoring ...

[5/16”] 8mm Dowel

Pin (2)

Loosen next two

Example:

high point

fasteners

• Loosen the next two fasteners to the right of the high point.

• Move indicator to the first hole location, insert two M3 x 25mm

SHSS (leveling set screws).

• Use the leveling screws to align the face to within [.012”]

.3mm to the high point along the axis travel and secure the

fastener.

• Move indicator to the next hole location, then loosen the

next fastener to the right. Align this location to within

[.012”] .3mm. Continue alignment with the remaining

fasteners.

• Return to the high point, and use the same procedure

working out to the left end.

Threaded hole

Scale case holes are undersized to

insure accurate centering.

• Drill a [.302”] 7.7mm diameter hole through the dowel pin

hole locations at each end of the scale case [3/8”] 9.5mm

deep.

• Use a [.312] 8mm reamer to provide a press fit.

• Insert the dowel pins at each end, with the threaded hole

facing outward.

6

Acu-Rite Companies Inc.

Page 8

™

ENC 250

MULTI-SECTION

Scale Tape Installation

End view of

tee slot

Scale Tape

• Apply a small amount of silicone grease – as a sealant - to

the two M3 x 8mm FHSS.

• Insert the screws through the scale case and thread into

the anchor block. Tighten fasteners completely.

Scale Tensioner

• Place the Scale Tensioner into the tee slot on the left end

of the scale case.

• Retrieve the scale tape from the carton. The scale tape is

shipped in a protective plastic coil. Do not uncoil the tape.

It should be uncoiled as it is inserted into the case. The

tape must be kept free of fingerprints and contaminants.

It is best to wear clean cotton gloves when handling it. If

necessary, the scale tape may be cleaned with cotton cloth

soaked in alcohol or acetone.

• Hook the boss on the scale tensioner through the square

hole in the scale tape to capture the tape and slide the

scale tensioner into the scale case. Note – the gold

rulings on the scale tape must face into the scale

cavity.

End view of

tee slot

Left end of

travel mark

[0.65”] 16.5mm

Center of

travel mark

Equal Equal

Right end of

travel mark

[2.46”] 62.5mm

• Draw a line onto the front of the scale case at a distance of

[0.65”] 16.5mm from the left end. Similarly draw a line

onto the front of the scale case at a distance of [2.46”]

62.5mm from the right end. These are the end-of-travel

marks. The ends of the reading head must not travel

beyond those lines.

• Find the center distance between the two lines and draw

another line onto the front of the scale case. This line

represents the center of travel. The reading head must be

mounted so that it is centered under this line when the

machine carriage is located at the center of its axis travel.

Retainer clip

0.XXX mm

Tape tension value

Anchor block

• Before inserting the tape completely into the case, check

the tension value on the backside of the scale tape at the

anchor end. Check the value on the label attached to the

right end section, and verify that it is correct.

• The two M3 x 8mm Flat Head Socket Screws must be

removed from the scale anchor block. Continue pushing

the scale tape into the case until the anchor end is flush

with the left side of the case. Make sure that all the

scale tape retainer clips go into the T-slot. If the scale

tape can not be inserted completely by pushing at one end,

the scale tensioner may be pulled along the case with a

small steel ruler from the bottom of the scale case.

Lip seal keying feature

• Insert a lip seal into the front keyhole slot (the one closest

to the scale tape) until it protrudes at least 1/2” [12mm]

from the far side. Lip seals must be installed with the

keying features opposing each other.

This view shows lip seal orientation.

It is not required for them to be inter

locked during installation.

• Similarly, insert the rear lip seal. Make sure that the lip

seals are not under excessive tension in the case.

Normally, the lip seal can be pulled through completely

with a pair of needle-nose pliers.

7

Acu-Rite Companies Inc.

Page 9

™

ENC 250

Insert straight pins here

to fasten ends of lip seals

MULTI-SECTION

Approximately [1/8”]

3mm over hang

Straight pin

If necessary pull the lip seal along at different points

along the inserted length. Insert the 4 straight pins from

the hardware kit into the ends of the lip seal grooves to

keep the lip seals from pulling away from the ends of the

scale case. Trim the lip seals ends with a pair of scissors

so that there is an overhang of approximately [1/8”] 3mm

at each end.

M3 x 12 CHMS

• Attach the right end cap with M3 x 12 CHM screws

provided in the hardware kit. Tighten these screws

securely to compress the end cap gasket.

Changing cable exit direction ...

Plug

• Support the reading head by hand, and remove the

alignment brackets by sliding them away from the reading

head and twisting them 45° to remove them from the

scale case. Gently pry them away from the reading head

with a small screw driver if needed.

Reading head

• Slide the reading head onto the scale case to the center of

travel mark on the case.

Cover plate

T-10 Torx screw (2)

Armor cable hex crimp

• Determine the cable exit direction before installing the

reading head.

• To change the cable exit direction; remove the cover plate

and rotate the cable 180°.

Numbers on reading head

casting

• The reading head is shipped attached to the installation

tool. Push the protruding roll pins of the reading head

installation tool assembly into the left end of the scale

case. Push on securely to close the gap between the scale

sections. The number indicators of the reading head

are always facing out.

• Reinstall the alignment brackets by inserting each at 45°

and twist to insert them into grooves on the bottom of

scale case. Slide brackets against the reading head until

they clip into place. Numbers and letters on reading head

casting and alignment brackets must correspond.

• Align the triangle on the reading head with the center-oftravel mark previous placed on the scale.

• Return the axis back to its center of travel, and

lock in place.

8

Acu-Rite Companies Inc.

Page 10

™

ENC 250

MULTI-SECTION

Installing the reading head

The reading head must be mounted in the same location as

it is held by the alignment brackets. To attach the reading

head to the mounting surface, follow these steps:

• Custom designed brackets by the installer should be solid,

and rigidly assembled. Attach brackets to the machine

with [1/4-20] M6 fasteners minimum. Allow clearance for

removing alignment brackets once the reading head has

been installed. Also, allow a small amount of clearance

between the reading head and its mounting surface for

setting the leveling screws. For custom brackets, transfer

punch the two head mounting holes on the bracket and tap

these holes for [8-32 x 1/2”] M4 x 12mm deep minimum.

To mount the reading head proceed as follows:

• Insert, but do not tighten the [8-32] M4 reading head

screws.

• Place a [.001 - .003”] .025 - .076mm shim between the

leveling set screws and mounting bracket.

• Adjust each screw until a slight drag is felt on the shim.

• Evenly tighten the [8-32] M4 reading head mounting

screws so that the head does not shift or twist. Remove

the alignment brackets as done previously.

• Verify the reading head is able to move through the entire

length of machine travel without interference.

• Move the axis so that the reading head is at the tape

tensioning position indicated by the tension label on the

right side of the scale.

• Set the readout’s display and encoder resolution to .005

mm. See readout reference manual for setting resolution.

Polyurethane

compression spring

Flat washer

M4

Thumbscrew

Tensioning hole

• Remove tensioning hole plug from the right end cap.

• Insert the M4 thumbscrew from the hardware kit through

the washer and polyurethane compression spring into the

tensioning hole. Turn the thumbscrew until it engages the

scale tensioner inside the scale case.

M4

Thumbscrew

Completing the

installation

M3 x 12 CHMS

• Remove the Reading Head shipping tool from the end of

the scale case. Attach the left end cap with M3 x 12 CHM

screws provided in the hardware kit. Tighten these screws

securely to compress the end cap gasket.

M5 SHSS

• Turn the thumbscrew clockwise to tension the tape until

the display has changed approximately .050mm.

Carefully back off the thumbscrew until the display stops

changing. Reset the display to zero.

• Repeat this procedure two to three times to put the tape

in a relaxed, slack-free position.

• Slowly tighten the thumbscrew until the display reaches

the tensioning value shown on the scale label.

• Tighten the M5 SHSS on the right side of the case to

30 in-lb. [3.4Nm]

• THE M5 SHSS MUST BE TIGHTENED SECURELY

AFTER TENSIONING TO PREVENT TAPE

SLIPPAGE.

• Unscrew and remove the knurled tensioning screw

assembly from the scale case.

9

Acu-Rite Companies Inc.

Page 11

ENC 250

™

MULTI-SECTION

Trouble Shooting

Apply silicone grease to plug

and reinsert it

• Coat the plastic plug with silicone grease and install it

into the tensioning hole.

• This completes the installation of the ENC 250.

• With the readout properly mounted, route the cable with

sufficient slack loops for machine movement to the readout.

• Secure cables by fastening with clips or ties.

• Attach the encoder connectors to the readout.

If you experience difficulties with your installation, do the

following to determine the problem.

Checking the Readout

Difficulties on more than one axis are usually associated

with the readout. Follow these steps to determine if your

difficulties are associated with the readout:

• Ensure that the linear encoder connectors are correctly

seated.

• Swap linear encoder cables at the readout to see if the

problem is still shown in the same display.

• If the problem remains in the same display, the readout

may be in error. To determine if that is the problem,

repeat above steps with both encoders, but with only one

encoder connected at a time. This should allow you to

determine if the problem is with the readout or the

encoder.

• If the problem follows the connection change, the linear

encoder may be in error.

If the Readout is at fault, refer to “What to do” to arrange

for the parts necessary to repair your system. If a linear

encoder appears to be at fault, proceed with “Checking the

Linear Encoders”.

Checking the Linear Encoders

Problems on a single axis are usually associated with the

linear encoder or its installation. Difficulties can be caused

by improper installation, loose or misaligned bracketry, or

a damaged or inoperable encoder.

Electrical shielding ...

• Connect a ground wire from the terminal on the back of

the readout to the machine or earth ground.

• Attach a ground wire from the machine to a solid earth

ground.

• With the encoder attached to the cable connected to the

readout, check shielding by measuring resistance

between connector housing and scale unit.

Desired value: 1 ohm max.

Follow these steps to determine the cause of your system

difficulties:

• Confirm that your bracketry and installation does not

interfere with other machine structures through the

entire length of the linear encoder travel.

• Check for loose fasteners. If you find loose fasteners, first

confirm that the linear encoder is installed to the

tolerances specified and then retighten the fasteners as

required.

• Confirm that the linear encoder is installed to the

specified alignment tolerances. If the installation does

not meet the tolerances, reinstall the encoder according to

the “Installation Procedure”.

• Do not attempt to repair the reading head or scale

assembly. The ENC 250 is field serviceable by assembly

replacement only. Attempts to repair the encoder can

permanently damage it and void the warranty.

What to do

If an ACU-RITE linear encoder or readout is found to be at

fault, please contact your Authorized Distributor for

instructions prior to removing the encoders or readout.

10

Acu-Rite Companies Inc.

Page 12

™

ENC 250

MULTI-SECTION

Mechanical Specifications

Mechanical Specifications Digital

Resolution 5µm [0.0002 in.]

Grating pitch 100µm [0.00393 in]

Scale medium Reflective Metal Tape

Accuracy @ 20° C ± 15µm/M [0.00018 in/ft]

Max. slew speed 1 M/sec [40 in/sec.]

Force required to move

reading head ± 3.3 Newtons [0.75 lbs]

Operating Environment:

Temperature 0° to 40° C [32° to 104°F]

Relative Humidity 20% to 95% (non-condensing)

Storage Environment:

Temperature -40° to 60° C [-40° to 140°F]

Humidity 20% to 95% (non-condensing)

Weight w/cable 1 kg + 3.2kg/m [2.2 lbs. + 0.18 lbs/in] of measuring length

Connecting cable: Length = .61m [2 ft]

Armor Connector: DE-9P

Max. cable length 22.9m [75 ft.] VRO / 10.7m [35 ft.] DRO

Measuring length 6240mm [246”] - 19,640mm [773”]

Reference Mark Interval 100mm [3.937”] Distance encrypted

Electrical Specifications

Parameter Digital

Output Signals

Incremental signals

Signal levels

Reference Mark signals

IOH=(High level output current) = 20mA

VOH=(High level output voltage) >2.5Vdc

0°

Channel

A+

Channel A-

Channel

B+

Channel B-

1

0

1

0

90°

1

0

1

0

Square-wave voltage signals.

Channels A and B, in 90°

quadrature relationship

Differential - TTL

Square-wave pulse

360°

Channel R+

Channel R-

1

0

1

0

1 Count

(Phased)

I

=(Low level output current) = -20mA

OL

VOL=(Low level output voltage) < 0.5Vdc

Signal level

Power Supply

Differential - TTL

5.1 ± 0.1 VDC @ 140 mA max.

11

Acu-Rite Companies Inc.

Page 13

™

ENC 250

MULTI-SECTION

Digital Differential

Pin 1 Pin 2 Pin 3 Pin 4 Pin 5 Pin 6 Pin 7 Pin 8 Pin 9

N/C Green Yellow Blue Red White Brown Pink Gray

N/C Channel Channel Channel Channel Ground Vcc, + 5.1 Channel Channel

A+ A- B+ B - ± 0.1 VDC R+ R-

1

6

5

9

Hassle-Free Warranty

Acu-Rite Companies Inc. readouts and precision scales are warranted to the end user against defects in material and workmanship and

against any damage that occurs to the product within three (3) years from the original purchase date. Acu-Rite Companies Inc. will, at

its discretion and expense, repair or replace the returned item or any of the item’s component(s) as long as Acu-Rite Companies Inc.

receives notice of the defect or damage within the three (3) year warranty period.

The foregoing warranty obligations are in lieu of all expressed and/or implied warranties of fitness or merchantability or otherwise, and

state Acu-Rite Companies Inc.’s entire liability and the end user’s exclusive remedy, under any circumstances, for any claim of damage.

In no event shall Acu-Rite Companies Inc. be liable for incidental or consequential damages nor shall Acu-Rite Companies Inc.’s liability

for claims or damage arising out of or connected with this warranty or the manufacture, sale, delivery, or use of the products with which

this warranty is concerned exceed the purchase price of said products.

Acu-Rite Companies Inc.Acu-Rite Companies Inc.

Acu-Rite Companies Inc.

Acu-Rite Companies Inc.Acu-Rite Companies Inc.

IS ANIS AN

IS AN

IS ANIS AN

ISO 9001ISO 9001

ISO 9001

ISO 9001ISO 9001

CERTIFIEDCERTIFIED

CERTIFIED

CERTIFIEDCERTIFIED

MANUFMANUF

ACTURERACTURER

MANUF

ACTURER

MANUFMANUF

ACTURERACTURER

One Precision Way • Jamestown, NY 14701

Acu-Rite Companies Inc.

104001-115 EDITION C 7/07

12

Acu-Rite Companies Inc.

Loading...

Loading...