Page 1

DRO 200T

™

REFERENCE MANUAL

Page 2

Readout Parameter Access Code

An access code must be entered before machine-related parameters can be set or

changed. This prevents inadvertent adjustments to the setup parameters.

IMPORTANT

The access code is 8891

Refer to the Setup section. Begin by pressing the

displayed, press the 8, 8, 9, 1, and

ready for machine parameter setting operations.

SETUP

key. When “SETUP” is

ENTER

keys. The readout is now

IMPORTANT

Supervisors may wish to remove this page from the Reference manual

after initially setting up the readout system. Retain in a safe place

for future use.

Page 3

Page 4

Warranty

ACU-RITE Products and accessories are warranted against defects

in material and workmanship for a period of three years from the

date of purchase. ACU-RITE will, at its option and expense, repair

or replace any part of the ACU-RITE product that fails to meet this

warranty. This warranty covers both materials and factory labor. In

addition, authorized ACU-RITE service representatives will provide

service labor (field service) for a period of one year at no charge.

Notice of the claimed defect must be received by ACU-RITE within

the warranty period.

This warranty applies only to products and accessories installed

and operated in accordance with this reference manual. ACU-RITE

shall have no obligation, with respect to any defect or other

condition caused in whole or part by the customer’s incorrect use,

improper maintenance, modification of the equipment, or by the

repair or maintenance of the product by any person except those

deemed qualified by ACU-RITE.

Responsibility for loss of operation or diminished performance due

to conditions beyond ACU-RITE’s control cannot be accepted by

ACU-RITE.

The foregoing warranty obligations are in lieu of all expressed or

implied warranties. ACU-RITE INCORPORATED shall not be liable

under any circumstances for consequential damages.

30 Day Red Carpet Warranty

All ACU-RITE products are covered by a 30-day Red Carpet

Warranty. If in the first 30 days this product fails for any reason,

repack it in the original packing materials and contact your

Authorized ACU-RITE Distributor for return procedures.

Page 5

Page 6

DRO 200T Table of Contents

Introduction..................................................................................................................... 1

A Tour of the Readout..................................................................................................1

Front and Back Views...............................................................................................1

Keypad .....................................................................................................................2

Displays....................................................................................................................3

Power-On Position Recovery......................................................................................4

Position-Trac ............................................................................................................4

Readout Operations....................................................................................................... 5

Clear Key.......................................................................................................................5

Absolute and Incremental Displays............................................................................5

Absolute Display.......................................................................................................5

Incremental Display..................................................................................................5

Radius/Diameter Display..........................................................................................6

Zeroing the Displays ....................................................................................................7

Absolute Zero...........................................................................................................7

Incremental Zero.....................................................................................................10

Presetting....................................................................................................................11

Absolute and Incremental Presets..........................................................................12

Near Zero Warning .....................................................................................................12

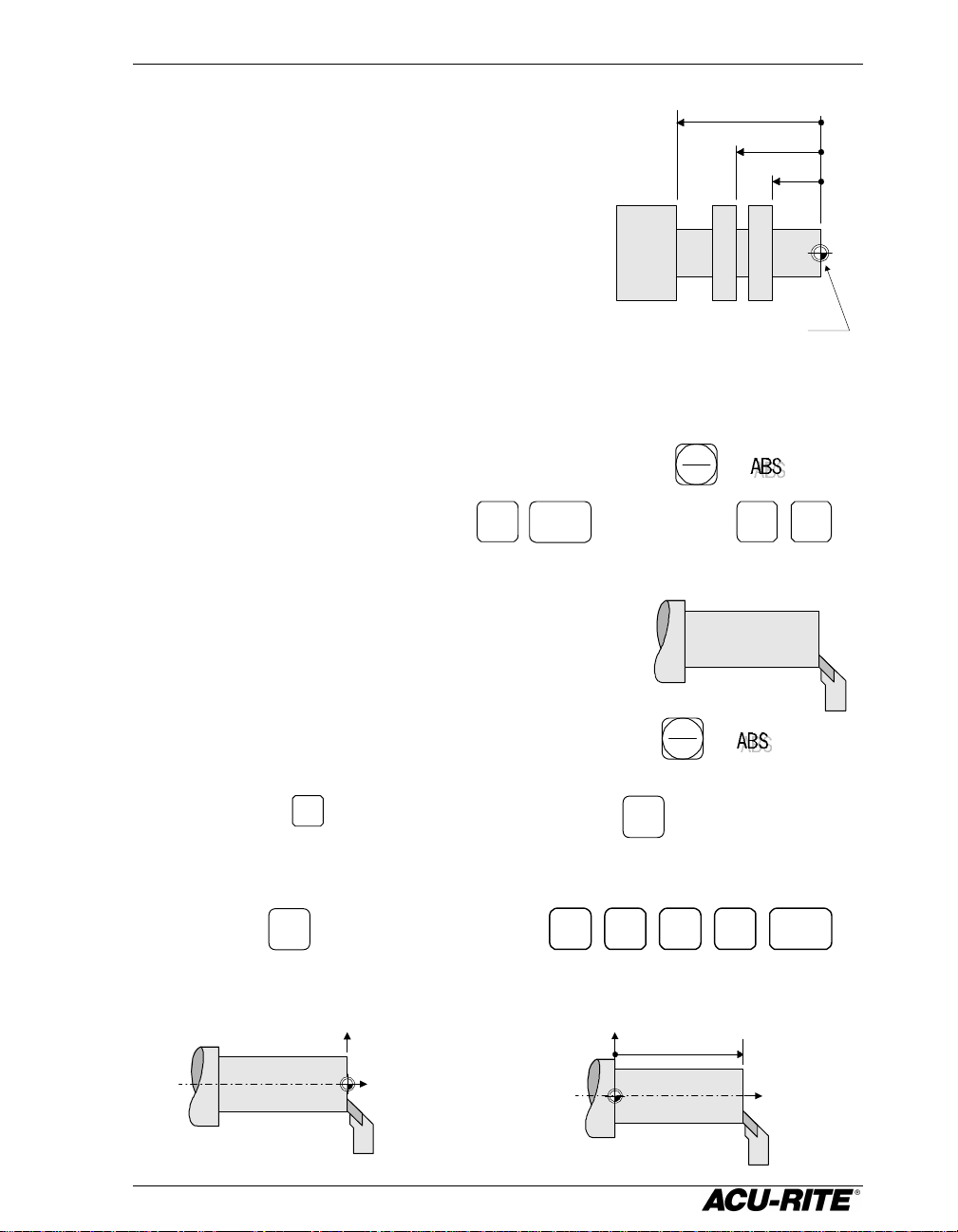

Tool Offset...................................................................................................................13

Defining Tools with the Auto-Offset Calculation Feature.........................................13

Defining Tools with a Tool Presetter.......................................................................15

Setup ..............................................................................................................................16

Machine-Related Setup Parameters .........................................................................16

Count Direction.......................................................................................................16

Encoder Resolution................................................................................................16

Job Setup Parameters................................................................................................17

Display Resolution..................................................................................................17

Scale Factor ...........................................................................................................17

Near Zero Warning.................................................................................................17

Tool Offset Definition..............................................................................................17

Linear Error Compensation.....................................................................................18

Installation .....................................................................................................................19

Readout Specifications ...............................................................................................22

Troubleshooting........................................................................................................... 23

Page 7

!

This symbol alerts you to the fact that

important information concerning the

installation and operation of this readout

has been included in this manual.

DRO 200T

Keep these instructions in a secure place

for future reference.

Page 8

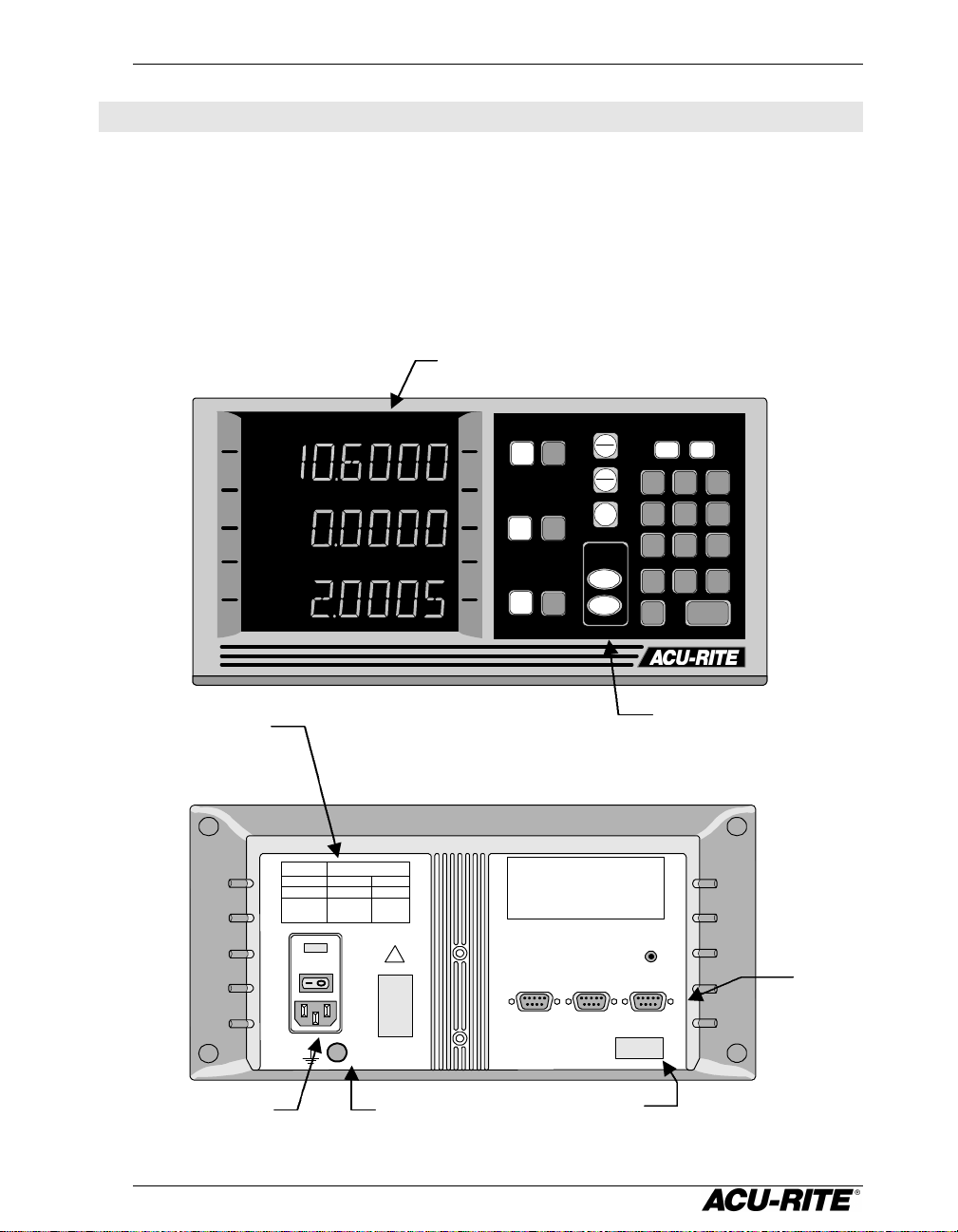

DRO 200T Introduction

Encoder

Electrical &

information

Power switch and

Ground wire

Indicators

Application-specific

Introduction

ACU-RITE’s DRO 200 readout series provides application-specific features

required for you to obtain the most productivity from your manual machine tools.

The DRO 200T is designed specifically for turning applications. Special features

include radius/diameter conversion, a tool offset library, and an axis lock feature.

A Tour of the Readout

Front and Back Views

fuse rating

MM DIA INCR ABS ZERO SET

FREQUENCY

VOLTAGE

CURRENT

FUSE

115V

!

Z1

Z2

ABS

INCR

ZERO

X

RAD

DIA

LOCK

AXIS

ZERO

TOOL

OFFSETS

DEFINE

ZERO

USE

. 0

CLEAR

MM

SETUP

87 9

54 6

21

ENTER

3

+/-

function keys

FCC COMPLIANCE

EDGE

FINDER

INPUT 1INPUT 2INPUT 3

inputs

voltage selector

connection

Model number

and

Serial number

1

3x DRO

PN 2001009

SN 9766554

Page 9

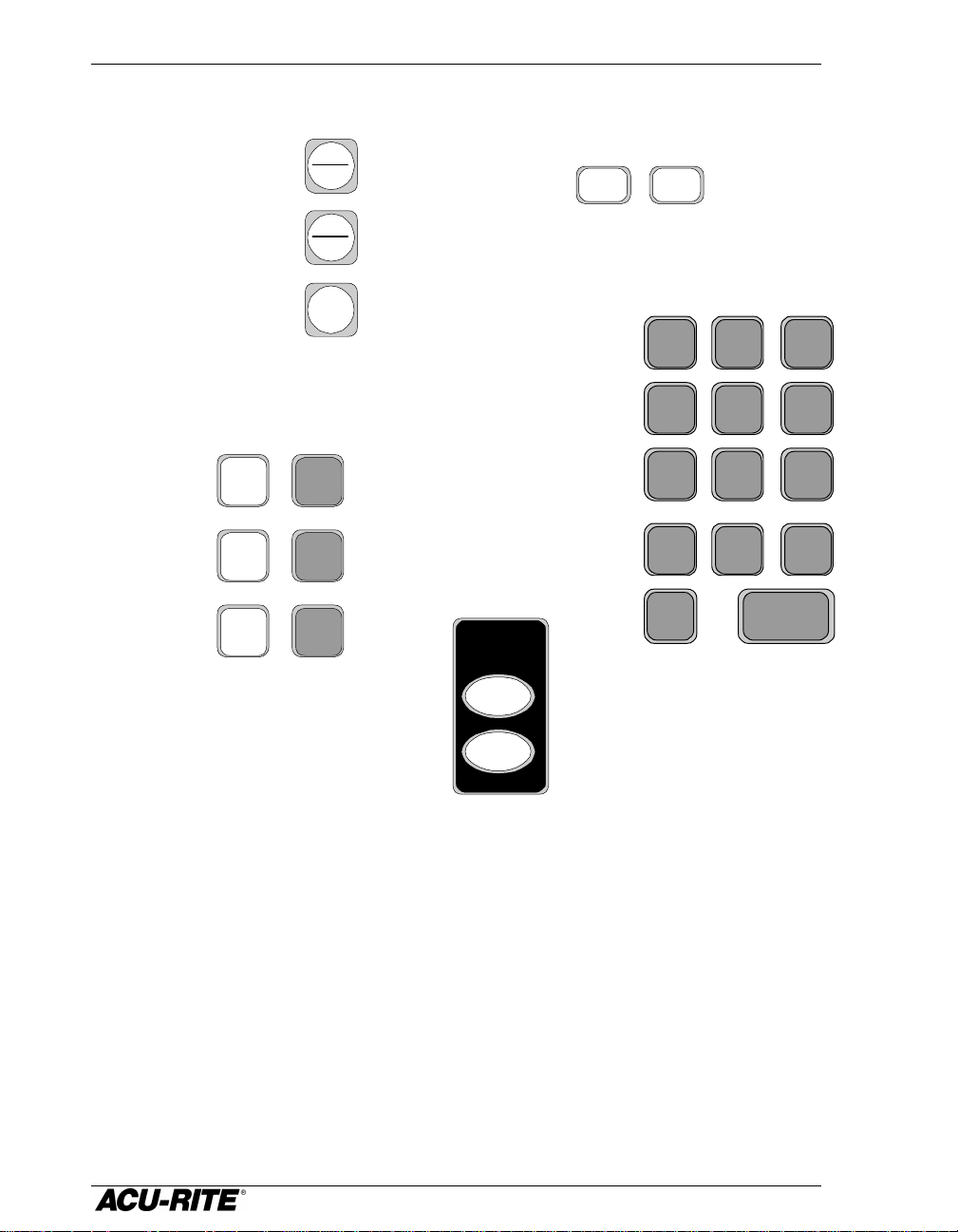

Introduction DRO 200T

Selects absolute or

Selects radius or

Locks the display so you

English / metric

System setup

Enter all numeric values

Lets you define a library of

Begin a preset

Zero an axis display

Keypad

ABS

incremental display

diameter display

INCR

RAD

DIA

conversion

MM

SETUP

parameters

can move the tool without

losing position

X

Z1

Z2

LOCK

AXIS

ZERO

ZERO

ZERO

with these

TOOL

OFFSETS

DEFINE

USE

tool offsets, and select

which offset to use

. 0

CLEAR

87 9

54 6

21

3

+/-

ENTER

2

Page 10

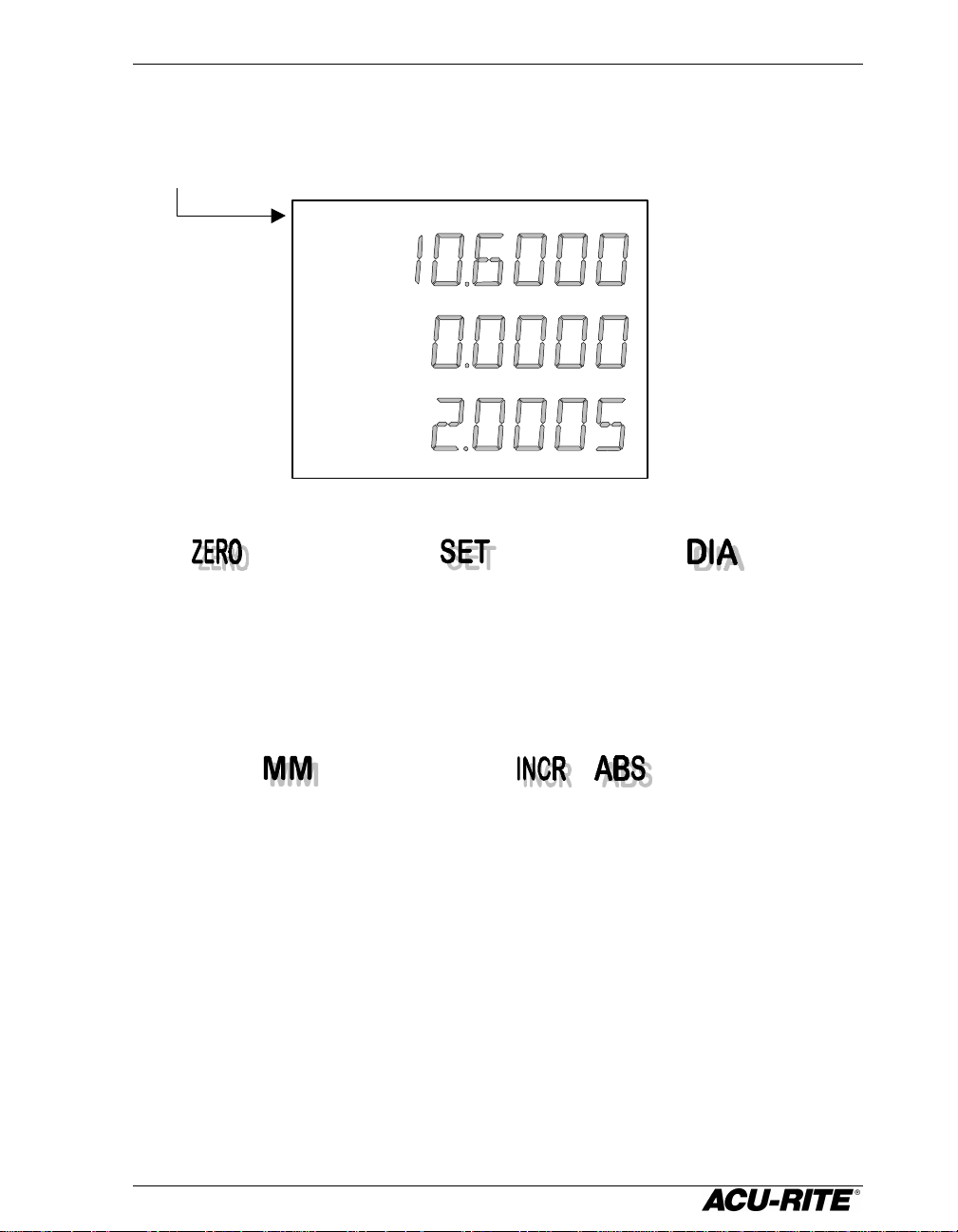

DRO 200T Introduction

Displays

At the top of the display window is a row of indicators. These tell you the current

state of the readout.

MM DIA INCR ABS ZERO SET

Appears when

setting an

absolute zero.

Lets you know when

you are setting a

preset or an absolute

zero.

Tells you when the

crossfeed axis is

displaying the part’s

diameter.

Appears when you’re

positioning in metric,

dark when you’re

positioning in inches.

These tell you if the

position display is

incremental or absolute.

They also refer to the

type of preset.

In addition to the lighted indicators along the top of the display, the top axis

display will scroll longer messages that will help you step through some of the

procedures.

3

Page 11

Introduction DRO 200T

Power-On Position Recovery

Position-Trac

Certain ACU-RITE encoders, such as the ENC 150, contain closely-spaced

reference marks that enable the display to show the correct position after a power

interruption. The readout will indicate when power has been lost, and will prompt

you to move each axis until a reference mark is located. By traversing the

reference marks once in each axis, you will re-establish the display position

relative to the last known zero. The most you will ever have to move an axis is

about one inch. You must move in a positive count direction. A flashing decimal

point will indicate that the last position has not been recalled.

If you use an encoder that does not have the Position-Trac feature, the procedure

for recovering your position is slightly different. Reference marks on these

encoders are about 8” apart. You must find a convenient reference mark and then

use the same mark every time.

1. Move near the desired reference mark.

2. Press and hold the

3. Move slowly past the reference mark until the readout recalls its

ABS

key until the decimal point starts to flash.

INCR

position. You must move in a positive direction.

4

Page 12

DRO 200T Readout Operations

Z -1.000 INCR

Absolute Zero,

Readout Operations

Clear Key

Use the

CLEAR

key to erase digits that you entered by mistake, or to take you back if

you’ve pressed a wrong function key.

Absolute and Incremental Displays

Absolute Display

Shows the distance from your current position to absolute zero.

The tool is positioined at -

1.625 ABS.

-1.625

Z -0.625 ABS

also called datum

or Workpiece

Zero.

Incremental Display

Shows the distance from your current position to incremental zero. An incremental

zero is set when you preset a dimension, or when you zero the incremental

display.

Incremental zero:

the incremental

display will read

0.000 when the

tool is here.

-0.6251.000

Absolute zero

ABS

INCR

-1.625

Z -0.625 ABS

5

Page 13

Readout Operations DRO 200T

Automatic Display Switching

Sometimes the readout will switch from one display to another automatically.

When you enter a preset, for example, the display switches to the incremental

display so you can move to zero. Whenever the readout does an automatic display

switch, INCR will appear in the display.

Radius/Diameter Display

Pressing the

as a diameter.

RAD

key lets you view a workpiece dimension either as a radius or

DIA

1.00

Rad

X 1.000

RAD

X 2.000 DIA

DIA

2.00

Dia

6

Page 14

DRO 200T Readout Operations

Shortcut

If you want the absolute zero to be

If you want the absolute zero to

Zeroing the Displays

Absolute Zero

On many prints, the dimensions are measured from

one or two surfaces of the part. By setting the

readout’s absolute display to zero at a well-chosen

surface, you can enter the part’s dimensions directly

from the print, using absolute presets.

Setting Absolute Zero at the Current Position

1. Move to desired location.

2. Make sure that the absolute position is displayed.

ZERO

3. Zero the appropriate axis.

Setting Absolute Zero with a Tool

Longitudinal Axis

1. Touch the tool to the face of the workpiece.

ENTER

3.00

1.75

1.00

Absolute zero

ABS

INCR

ZERO ZERO

2. Make sure that the absolute position is displayed.

3. Press the

4. Enter the tool position.

be on the face of the workpiece:

ZERO

key for the appropriate axis.

ZERO

X

Z

ABS

INCR

ZERO

1 2 5

.

offset from the face of the workpiece:

X

1.250

7

ENTER

Z

Page 15

Readout Operations DRO 200T

Crossfeed Axis

1. Touch the tool to the diameter of the workpiece.

1.25

2. Make sure that the absolute position is displayed.

3. Press the

ZERO

key for the appropriate axis.

ABS

INCR

ZERO

4. Enter the tool position—either as a radius or as a diameter,

depending on the display.

1 2 5

.

ENTER

8

Page 16

DRO 200T Readout Operations

If you want zero offset from

If you want zero on the

Setting Absolute Zero with the Tool under Load

Longitudinal Axis

1. Make sure that the absolute position is displayed.

2. Machine the face of the workpiece.

3. While the tool is still contacting the

workpiece, press the

LOCK

AXIS

key. The readout will lock this tool position in the display,

ZERO

key for the appropriate axis, then the

ABS

INCR

even if you move the tool.

4. Move the tool away and measure the face location, if required .

5. Enter the face location.

ENTER

0

face of the workpiece

X

.83

8 3

.

the face of the workpiece

9

ENTER

X

Page 17

Readout Operations DRO 200T

This puts the zero on the

Crossfeed Axis

1. Make sure that the absolute position is displayed.

2. Machine the diameter.

3. While the tool is still contacting the

workpiece, press the

appropriate axis, then the

ZERO

key for the

LOCK

AXIS

key. The readout will lock this tool

position in the display, even if you move the tool.

4. Move the tool away and measure the diameter.

Dia = 1.05

5. Enter the diameter.

ABS

INCR

Incremental Zero

From the readout incremental display, press the

incremental display to zero at the current tool position.

1 0 5

.

workpiece centerline

10

ENTER

Z

ZERO

key. This sets the

Page 18

DRO 200T Readout Operations

Presetting

When you preset a dimension, the readout places an incremental zero at the

location you specify. Then, the display automatically switches to the incremental

display so you can move to zero.

Begin a preset by pressing an axis key (X for example). The information from

the previous preset will appear. The display will show you if the preset is absolute

or incremental. Use the

dimension you want to preset.

ABS

key to change from one to the other. Then enter the

INCR

Absolute Zero

The tool is at 0.000 ABS.

To preset the absolute location of the shoulder:

Z

Incremental zero: the

incremental display

will read 0.000 when

the tool is at this

point.

+/-

Z 1.625 INCR

ABS

INCR

Z 0.000 ABS

-1.625

Z -0.000 ABS

2 5

6.1

Display automatically switches to

Absolute display reads zero.

1.625

ENTER

incremental.

Now the tool is

1.625 on the positive

side of the shoulder.

11

Page 19

Readout Operations DRO 200T

When you enter an incremental preset,

Absolute and Incremental Presets

To maintain the best tolerance and to minimize the chance for errors, use

• absolute presets for absolute dimensions

• incremental presets for incremental dimensions.

When you enter an absolute preset, it

does not matter where the tool position

is. The DRO 200T calculates the desired

3.00

1.75

1.00

location automatically.

ABS

Z

INCR

+/-

+/- 1

.1 0

7

.Z 5

ENTER

ENTER

Z

the tool must be positioned at the

location you are dimensioning from.

0.751.25

Z

1.00

Z

Near Zero Warning

When you are moving to zero, the readout

can “warn” you when you are getting close.

This allows you to machine faster and

avoid overshooting your desired location.

You can set the near zero range in Setup.

ABS

INCR

3 . 0

+/-

+/-

+/-

1 . 5

ENTER

.1 0

7

.Z 5

2+/-

ENTER

ENTER

ENTER

Near zero range

The digits displayed to the left

of the decimal point will flash.

12

Page 20

DRO 200T Readout Operations

Tool Offset

The DRO 200T can store the dimensional offsets for up to 10 tools. When you

change a workpiece and establish the absolute zero, all the tools are automatically

referenced from the new zero.

1 2 3 4 9...

0

The offset dimensions can be found using a tool presetter, or you can determine

them using the auto-offset calculation feature of the readout. In Setup you

determine which method you wish to use.

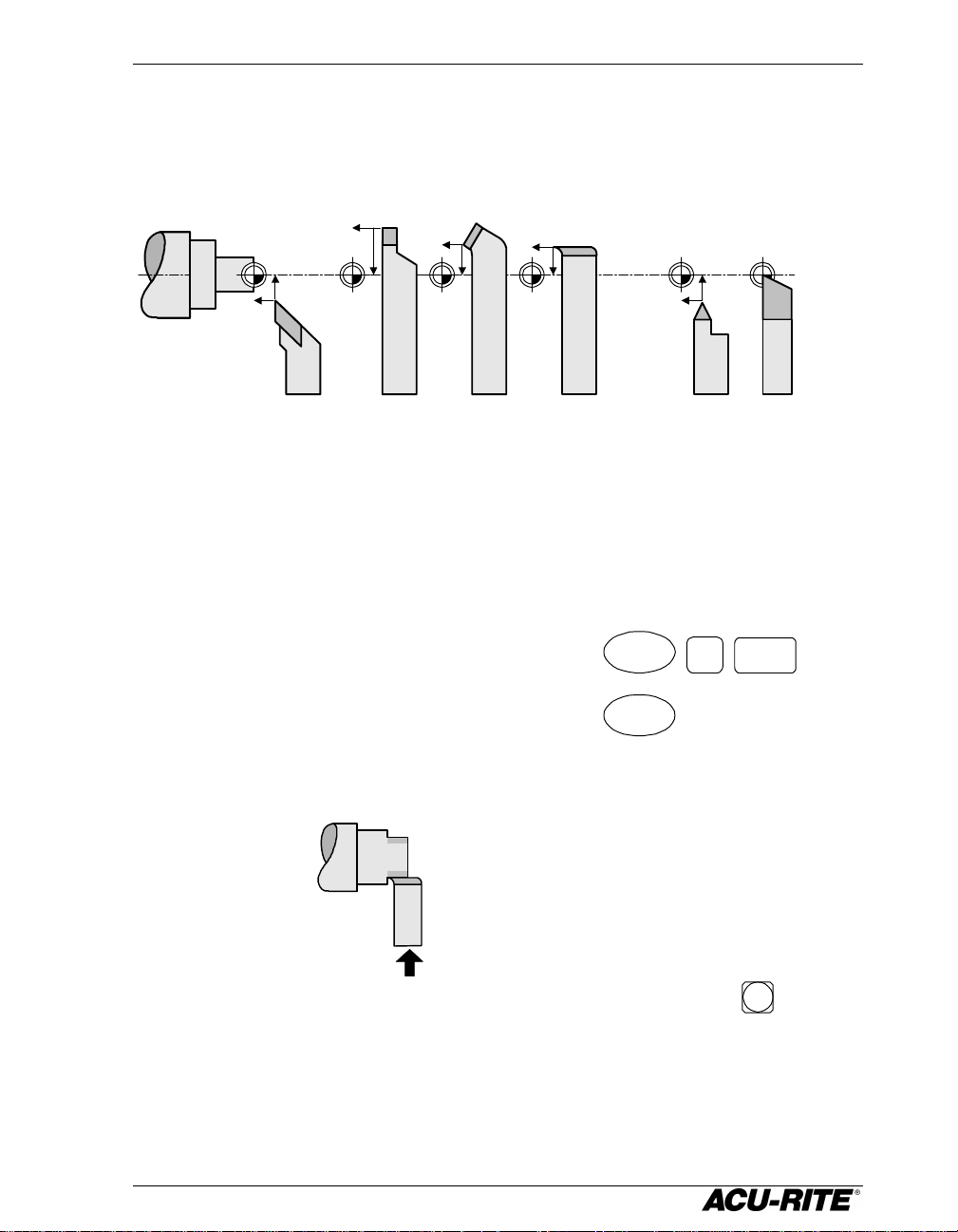

Defining Tools with the Auto-Offset Calculation Feature

1. Install a tool and select its number.

2. Begin the tool offset definition.

3. Machine a diameter.

USE

DEFINE

ENTER

1

4. While the tool is still in contact with the workpiece, press the

key. The readout will lock this tool position into the display, even if

you move the tool.

13

LOCK

AXIS

Page 21

Readout Operations DRO 200T

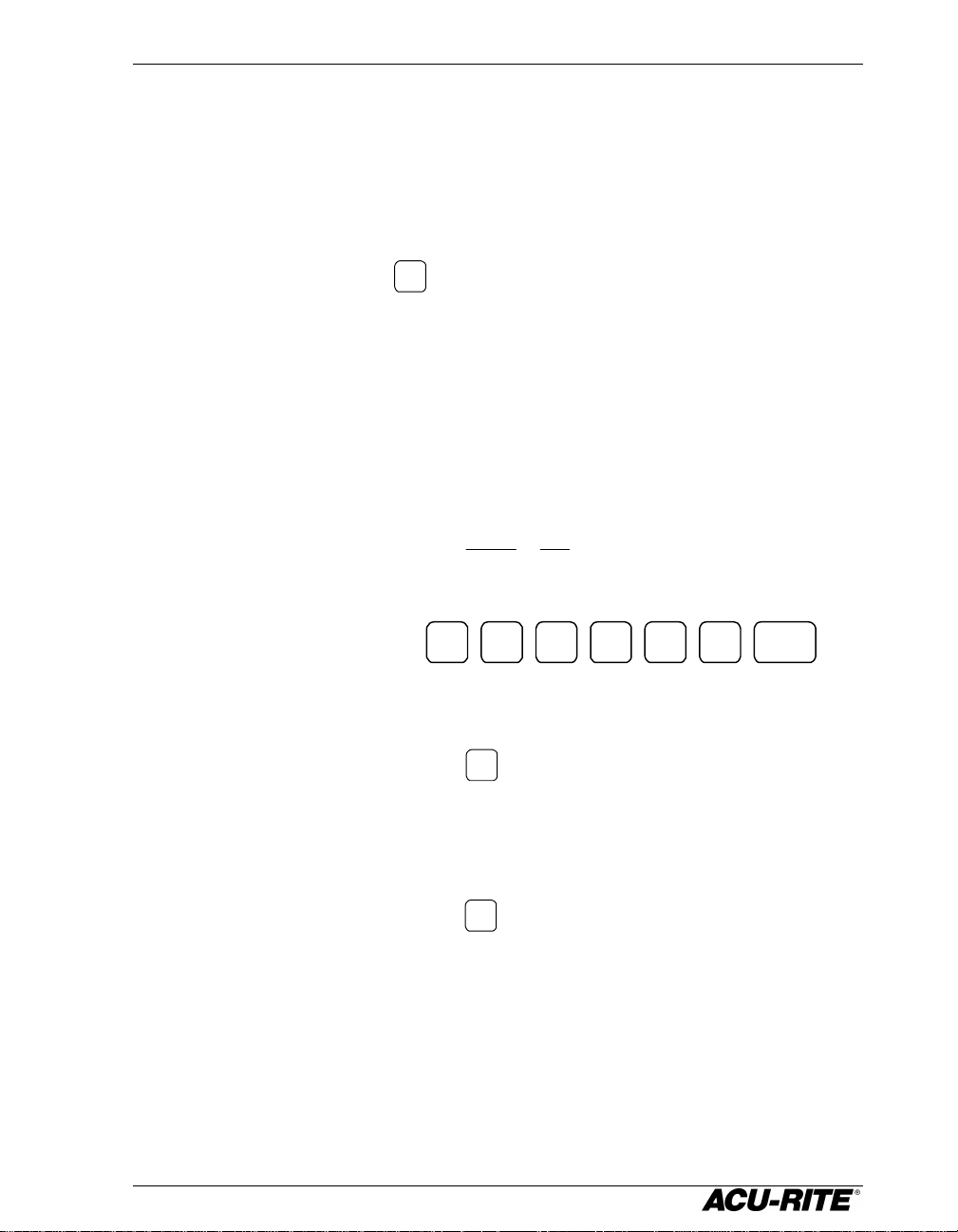

5. Move the tool away from the workpiece and measure the diameter

of the workpiece.

Dia = 1.05

6. Select the axis and enter the measured value.

1 0 5

.X

ENTER

7. Press the define key again, and make a face cut.

DEFINE

.83

LOCK

8. While the tool is still in contact with the workpiece, press the

AXIS

key.

9. Move the tool away from the workpiece, and measure the length of

the shoulder.

.83

10. Select the axis and enter the measured value.

8 3.Z

ENTER

14

Page 22

DRO 200T Readout Operations

The reference tool does not

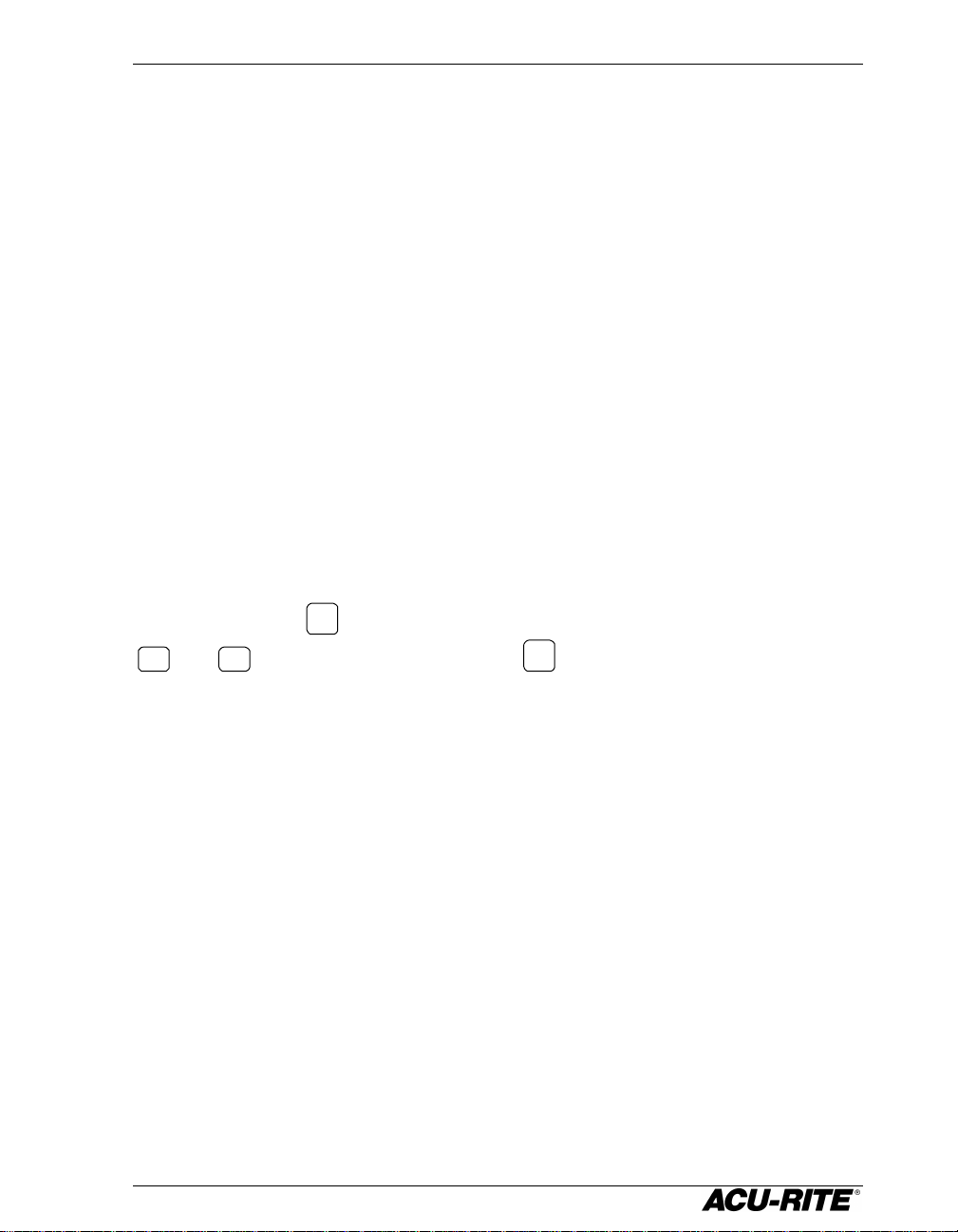

Defining Tools with a Tool Presetter

Use a tool presetter to obtain offsets in X and Z for your tools.

If you wish, you may select a tool to be a reference tool. Then you can use a tool

presetter to obtain the differences, in X and Z, between the reference tool and the

other tools.

Z = 0

have to be Tool 0, and its

X = 0

offset values do not have to

be 0,0

Then, select each tool and define its offset.

USE

USE

DEFINE

1 X +/- . 1 5

Z . 2 3

DEFINE

2 X 1. 6 5

Z . 2 3

1 20

ENTER

ENTER

15

Page 23

Setup DRO 200T

Setup

SETUP

The

are job related, meaning that they may change from job to job. Others are

machine related and should be set as part of the installation. The machine-related

parameters can be accessed by pressing:

key lets you change the system parameters. Some of these parameters

SETUP ENTER

Access Code

Use the X key to move from one parameter to the next. After the last

parameter, the X key ends the setup process and saves any changes. Use the

CLEAR

key to move back to a previous parameter.

Some parameters have choices. Use the Z key cycle through the available

choices.

At any time during setup, pressing the

SETUP

key will end the setup process and

save the changes.

Machine-Related Setup Parameters

Count Direction

This determines which way is positive. Move each axis in the positive count

direction. The display will show a 1 or a 2 depending on count direction. You can

also change the count direction by pressing the Z key.

Encoder Resolution

Move each encoder until the readout senses and displays the resolution. You won’t

have to move more than two inches. For scales without Position-Trac, you need to

enter the encoder resolution. You can press the Z key to select from common

choices, or you can use the keypad to enter the resolution directly.

16

Page 24

DRO 200T Setup

For a scale factor that allows for 3% material shrinkage, use this formula:

.971.03

1

1

Job Setup Parameters

Display Resolution

The display resolution will be the same as the encoder resolution. If the job

tolerance is coarser than the encoder resolution (±0.005 for example), you can

adjust the display resolution so you won’t be tempted to waste time by machining

to a finer resolution. Use the Z key to cycle through all the possible choices. The

choices available depend upon the resolution of the encoders.

Scale Factor

You can define a scale factor for each axis. The typical scale factor is 1.000, which

means that the displayed dimensions are the actual part dimensions. A scale

factor less than 1 causes the part to be smaller than the print dimensions; a scale

factor greater than 1 causes the part to be larger.

Enter the factor by pressing

rScaleFacto ==

=

−

0

1.0309

3 0 9.1

ENTER

Near Zero Warning

Each axis has its own near zero range. You can activate or deactivate the near

zero warning feature by pressing the Z key. When the warning is activated, you

can enter the range. Refer to page 12.

Tool Offset Definition

To determine the relative tool offsets, you can use either a tool presetter or the

readout’s auto offset feature. Use the Z key to select which method you plan to

use.

17

Page 25

Setup DRO 200T

Linear Error Compensation

The DRO 200T includes a linear error

Segment 2Segment 1 Segment 3

compensation feature that enables you to

compensate for machine tool inaccuracies.

You can have up to three different

compensation segments per axis.

Machine bed side view

(slightly exaggerated)

You will need a dial indicator and a measurement standard.

1. Enter the number of segments you will use. If you do not want to

use any error correction, enter 0. Press X to start the first

segment.

2. Position the standard in the center of the segment.

3. Press

4. Enter one edge of the standard.

5. Enter the other edge of the standard.

Z

ENTER

ENTER

ENTER

6. Enter the actual size of the standard, including the probe diameter

if necessary.

If the display shows

all dashes, refer to

“Display Overflow

Errors” on page 27.

1.000

0.875

Opposite sides

Press X for the next segment or, if all segments are done, the next axis.

18

ENTER

Page 26

DRO 200T Installation

IMPORTANT

Installation

Before installing the DRO 200T readout, record the serial

number on the warranty card and return it to ACU-RITE

INCORPORATED. The serial number label is located on the

back of the readout.

Selecting a Location

Selecting a location for the readout is an important consideration for proper

installation. Keep the following points in mind when selecting a safe and

convenient location:

• The readout should be within reach of the operator for easy access to the

keypad.

• The readout should be approximately at eye level.

• Avoid moving components or tools and minimize coolant splash or spray.

• The operating environment must be within the temperature range of 0° to 40°

C (32° to 104°F) with a non-condensing relative humidity of 25% to 85%.

Proper Mounting

ACU-RITE has developed special mounting kits for the readout, which address

the most common mounting requirements. Mounting kits include:

• Column and base machine mountings

• Hardware and mounting instructions

These kits are available from your factory authorized ACU-RITE Distributor or

OEM/OEI.

If you fabricate a support device for the readout, it should be large enough and

strong enough to accommodate the readout. It must also be stiff enough to

minimize any vibration induced by machinery on the shop floor.

19

Page 27

Installation DRO 200T

Connecting the Encoders

Insert the connector from each encoder into the mating connector on the back of

the readout. Fasten it with a small screwdriver.

Encoder input 1 will be displayed in the readout’s top display, input 2 in the next

display, and input 3, if any, in the bottom display.

Provide enough slack in the encoder cables to allow for full travel of all machine

axes. Check that machine movements will not pinch the cables. Use the cable tiedown hardware kits supplied with the encoders to fasten the cables neatly to the

machine.

Connecting a Ground Wire

Connect a ground wire from the terminal on the back of the readout to the

machine. The machine should also be connected to a solid earth ground. If not, be

sure that the readout is.

20

Page 28

DRO 200T Installation

Checking Voltage and Connecting Power

!

CAUTION

Connecting the readout to a power source outside of the

acceptable range, or making an inappropriate setting with the

voltage selector, may damage the readout, the encoders, or

both.

Check that the voltage available at the power source is within specification before

connecting it to the readout. If required, set the voltage selector to match the line

voltage.

1. Remove the caution label from the input

module, and use a thin-blade screwdriver in

Opening

slot

the slot at the top of the power-input module

to open the module cover.

2. Pull the selection block out.

3. Remove the fuse, move the shorting bar to the other

side, install the proper fuse, and push the block

back into place.

4. Close and snap the cover shut.

The voltage setting will show through the window in the voltage selection cover.

Connect the readout to the power source using the power cord supplied.

21

Page 29

Readout Specifications DRO 200T

Readout Specifications

Characteristic Specification

Operating conditions 0° to 40°C (32° to 104°F)

25% to 85% relative humidity (non-condensing)

Storage conditions

Input requirements

Voltage:

Frequency:

Current:

Fuse 115V operation: ½ A, 250V, 3AG, Slo-blo

Encoder input Position signals: channels A & B

Size 12.5”W x 5.125”D x 6.5H”

Weight 7.5 lbs.

-40° to 60°C (-40° to 140°F)

25% to 95% relative humidity (non-condensing)

115VAC or 230VAC (+/-20%), single phase

47-63 Hz

300ma @115V, 150ma @230V

230V operation: ¼ A, 250V, 3AG, Slo-blo

TTL square wave signal in quadrature

(90° nominal phase relationship)

Maximum input rate: 50 kHz

Reference signal: TTL square wave

Mounting Bottom: two ¼ -20 threaded inserts

FCC compliance Class A

22

Page 30

DRO 200T Troubleshooting

NOTICE

Troubleshooting

This section is intended to provide you with some basic troubleshooting assistance

with your readout system. If you cannot correct the problem after following these

instructions, contact your authorized ACU-RITE distributor or OEM/OEI for

repair or replacement procedures.

No Operation

If you turn power off, you must wait at least 5 seconds before

turning it back on, or the readout may not power up. This is

because the power supply, in order to withstand brief power

outages and brownouts, requires several seconds to reset

itself.

If the readout display will not operate, check the following conditions:

• Check AC power source. If the readout cannot be powered up,

line voltage is present at the source and that the line voltage meets the

required specifications.

• Check power cord. Remove the power cord at the electrical input module on

the back of the readout. Determine if line voltage is present at this end of the

cord.

• Check fuse. With the power cord removed, use a thin straight-blade

screwdriver to remove the cover of the electrical input module. Refer to page

21. Slide out the fuse holder and check the fuse. If necessary, replace it.

Replace the input module cover by snapping it back into place, and reconnect

the power cord.

!

Replace fuses only with the specified type. Using incorrect

fuses can present a safety hazard. The readout may also be

permanently damaged. Refer to the Readout Specification

chart on page 22 for the correct fuse.

CAUTION

confirm that

23

Page 31

Troubleshooting DRO 200T

Incorrect Operation

If system positioning does not seem to be repeatable, the problem could be with

the machine tool or with the readout system.

• Check the machine tool. Check that the saddle is not locked. Ensure that the

turret-to-column bolts are properly secured. Check the gib adjustments. Check

spindle run-out.

• Check linear encoders. Check each encoder and reading head for proper

installation. Ensure that the mounting brackets are secure.

If the system seems to be displaying incorrect positions, check the following items.

• Verify presets. Make sure the numbers you enter are correct.

• Verify tool. Check that the correct tool number is being used. Make sure the

correct tool offset has been entered. Check the tool for wear.

• Verify the scale factor. Ensure that the correct scale factor is being used.

• Verify linear error compensation. Make sure that the factors used for linear

error compensation are correct.

Power-On Self Test

There are four tests performed when power is applied to the readout. You will not

notice these tests unless a problem is found, in which case a message will scroll

across the display.

Keypad—a key was detected stuck down. The message will display what row (x)

and column (y) the stuck key is in:

KEY STUCK – RxCy – PRESS CLEAR

Parameter memory—some of the system setup parameters are not valid. You

may be able to check and reset these settings, but it’s possible they will be lost

again. The readout should be serviced as soon as possible.

MEMORY FAILURE [1] – PRESS CLEAR

!

Some working settings are not valid. Proceed with caution.

CAUTION

24

Page 32

DRO 200T Troubleshooting

Working memory—the memory used by the readout for calculations is faulty.

While it may be possible to use the readout, it’s position display and other

information will not be reliable.

MEMORY FAILURE [2] – PRESS CLEAR

!

The readout cannot be relied on for correct operation if any

memory failure is indicated. The readout should be serviced

immediately.

Program memory—the memory used to store the software is faulty. While it

may be possible to operate the readout, some functions will not work properly and

incorrect information may be displayed.

MEMORY FAILURE [3] – PRESS CLEAR

!

The readout cannot be relied on for correct operation if any

memory failure is indicated. The readout should be serviced

immediately.

CAUTION

CAUTION

Internal Testing

Several internal tests may be performed to ensure that the readout is functioning

properly. Tests are available for the internal memory, the keypad, and the

display. In addition, the testing procedure reports the software version of the

readout.

Begin the internal testing by holding down the

The software version will appear in the X-axis display

25

.

key for about 2 seconds.

Page 33

Troubleshooting DRO 200T

Keypad test. Begin by pressing the X key, and then press each key (except

the X key) in turn to verify that it is functioning properly. When a key is

pressed, the X-axis activates a “plus sign” indicator and increments a count. When

you release the key, the plus sign disappears.

Display test. Begin by pressing the X key. All indicators in all displays will

light. Visually check each portion of each display to ensure that they are

functioning properly.

Press X again to test the display electronics. All decimal points on all displays

will light momentarily, and then each segment of all displays will light in turn.

Press X again, and each digit of all displays will light, one digit at a time,

starting with the leftmost digit and moving to the right.

Exit the diagnostics by pressing the X key.

Other Errors

The readout includes built-in test and error-checking circuitry. This circuitry

identifies errors that occur, and reports the problem to the operator. Errors are

reported by scrolling messages in the X-axis display.

Loss of power is indicated by the “Power was off” message. Loss of power means

that power to the readout has been interrupted. Since power to the encoders has

also been interrupted, position information may no longer be accurate. Press the

CLEAR

key to clear the error message. All display measurements will be zeroed.

Refer to page 4 for information about position recovery.

Counting errors are indicated by the “Scale miscount” message, telling you in

which axis the miscount occurred. Counting errors result from distorted electrical

signals from an encoder. These signals can be a result of an encoder malfunction,

misalignment, mounting problems, or electrical interference. Press the

CLEAR

key to

clear the error message. The axis display (for both absolute and incremental

measurements) will be zeroed. Follow these steps to determine if your difficulties

are associated with the readout or with the encoder.

• Ensure that the linear encoder connectors are correctly seated.

• Swap linear encoder cables at the readout to see if the problem still appears in

the same display.

26

Page 34

DRO 200T Troubleshooting

• If the problem remains in the same display, the readout is in error.

• If the problem follows the connection change, the linear encoder may be in

error. Refer to the Checking the Linear Encoders section of your encoder

reference manual.

Display overflow errors are indicated by dashes in all digits in an axis display.

A numeric overflow occurs when the intended measurement is too large for the

eight-digit display. Clear the error by returning the machine table into an area

where measurements can again be displayed, selecting a lower display resolution,

setting a new preset, or zeroing the display.

This error may also occur when using the automatic compensation routine while

setting the LEC parameter. An error indicates that the calculated compensation

factor was outside the acceptable range of -9999 to +9999, and usually is the

result of incorrectly entering data. Clear the error and return to the beginning of

the linear error compensation routine. Refer to page 18.

Data Logging

The readout collects information about itself while it is being used. This

information is stored in memory for review at a later time.

Press and hold the . key until the software version is displayed. Then press the

SETUP

and MM keys simultaneously. Use the X key to cycle through the following

information.

Power on time—displayed in decimal hours.

Scale travel distance—the travel distance for each axis is scrolled one after the

other.

Last 3 errors—the most recent three errors are remembered and messages for

the errors are scrolled one after the other.

27

Page 35

ACU-RITE Readout Systems are

JAMESTOWN, NEW YORK 14701

manufactured in the USA

ACU-RITE IS AN

ISO 9001

CERTIFIED

MANUFACTURER

2001-706 EDITION A PRINTED IN USA

ACU-RITE INCORPORATED

ONE PRECISION WAY

MASON INDUSTRIAL PARK

Loading...

Loading...