Page 1

Readout Parameter Access Code

An access code must be entered before machine-related parameters can be set or

changed. This prevents inadvertent adjustments to the installation related

(machine) setup parameters.

The access code is 8891

IMPORTANT

Supervisors may wish to remove this page from the Reference manual after

initially setting up the readout system. Retain in a safe place for future

use.

IMPORTANT

Refer to the Setup section. Begin by pressing the

S

key. When "Setup" is dis-

played, press the 8, 8, 9, 1, and

E

keys. The readout is now ready

for machine parameter setting operations.

Page 2

Hassle-Free Warranty

AACCUU-RRIITTEE

readouts and precision glass scales are warranted to the end user

against defects in material and workmanship and against any damage that

occurs to the product within three (3) years from the original purchase date.

AACCUU-RRIITTEE

will, at its discretion and expense, repair or replace the returned item

or any of the item's component(s) as long as

AACCUU-RRIITTEE

receives notice of the

defect or damage within the three (3) year warranty period.

The foregoing warranty obligations are in lieu of all expressed and/or

implied warranties of fitness or merchantability or otherwise, and state

AACCUU-

RRIITTEE

's entire liability and the end user's exclusive remedy, under any circum-

stance, for any claim of damage.

In no event shall

AACCUU-RRIITTEE

be liable for incidental or consequential dam-

ages nor shall

AACCUU-RRIITTEE

's liability for any claims or damage arising out of or

connected with this warranty or the manufacture, sale, delivery, or use of the

products with which this warranty is concerned exceed the purchase price of

said products.

Page 3

TABLE OF CONTENTS

DRO 200E

A Tour of the Readout..........................................................................................................................1

Front and Back Views ....................................................................................................................1

Keypad............................................................................................................................................2

Displays...........................................................................................................................................3

Power-On Position Recovery...............................................................................................................4

Position-Trac™...............................................................................................................................4

Machine Conventions......................................................................................................................4

Introduction ..................................................................................................................1

Readout Operations ..............................................................................................................5

DRO View.............................................................................................................................................5

Absolute Display..............................................................................................................................5

Incremental Display.........................................................................................................................5

Automatic Display Switching..........................................................................................................5

Zeroing the Displays............................................................................................................................6

Absolute Zero (Datum)....................................................................................................................6

Setting Absolute Zero (Datum)at the Current Position..................................................................6

Setting Absolute Zero (Datum) Using an Electronic Edge Finder...................................................6

Setting Absolute Zero (Datum) Witha Tool......................................................................................7

Setting Absolute Zero (Datum) Using Center Line..........................................................................7

Incremental Zero.........................................................................................................................8

Presetting..............................................................................................................................................8

Absolute and Incremental Presets................................................................................................9

Center-line Presets........................................................................................................................10

EDM View...........................................................................................................................................11

EDM Display..................................................................................................................................11

Presetting the Cut Depth............................................................................................................11

Setting Absolute Zero (Datum) at Current Position......................................................................12

Setting Absolute Zero (Datum) Using a Preset............................................................................12

Zeroing the Z-axis Using the Spark Detector.............................................................................13

EDM Parameters.................................................................................................................................13

Enable..................................................................................................................................13

R Dist.........................................................................................................................................14

Z Top..........................................................................................................................................14

R Fault.......................................................................................................................................15

Dwell..............................................................................................................................................16

Timed Dwell...................................................................................................................................16

Dwell Until Sparkout......................................................................................................................16

Job Related Setup Parameters........................................................................................................17

Display Resolution........................................................................................................................17

Scale Factor..................................................................................................................................17

Near Zero Warning.......................................................................................................................18

Linear Error Compensation...........................................................................................................19

Machine Related Setup Parameters.................................................................................................21

Count Direction.............................................................................................................................21

Scale Resolution.......................................................................................................................21

Automatic Resolution Detection......................................................................................21

Entering a Scale Resolution Manually....................................................................................22

Setup.....................................................................................................................................17

Page 4

This symbol alerts you to the fact that

important information concerning the

installation and operation of this readout

has been included in this manual.

Keep these instructions in a secure place

for future reference.

Troubleshooting.....................................................................................................................31

Readout Specifications..........................................................................................................30

Installation...............................................................................................................................24

TABLE OF CONTENTS

DRO 200E

Sleep.........................................................................................................................................23

Language..........................................................................................................................................23

Selecting a Location........................................................................................................................24

Proper Mounting..............................................................................................................................24

Connecting the Scales.....................................................................................................................24

Connecting a Ground Wire..............................................................................................................24

Checking Voltage and Connecting Power.......................................................................................25

Connecting the Output Relays.........................................................................................................26

Relay Connections...........................................................................................................................26

Relay Timing Diagrams........................................................................................................................27

No Operation...................................................................................................................................31

Incorrect Operation..........................................................................................................................32

Diagnostics............................................................................................................................................32

Start Up Diagnostics........................................................................................................................32

Operator-Performed Diagnostics.....................................................................................................32

Resetting Factory Defaults..............................................................................................................34

Other Error Messages.....................................................................................................................34

Data Logging....................................................................................................................................35

Page 5

INTRODUCTION

DRO 200E

1

Introduction

ACU-RITE readouts provide application-specific features allowing you to obtain the

most productivity from your manual machine tools. This readout is designed specifically for EDM applications. Specific features include a special EDM display, retract relays,

and dwell capabilities.

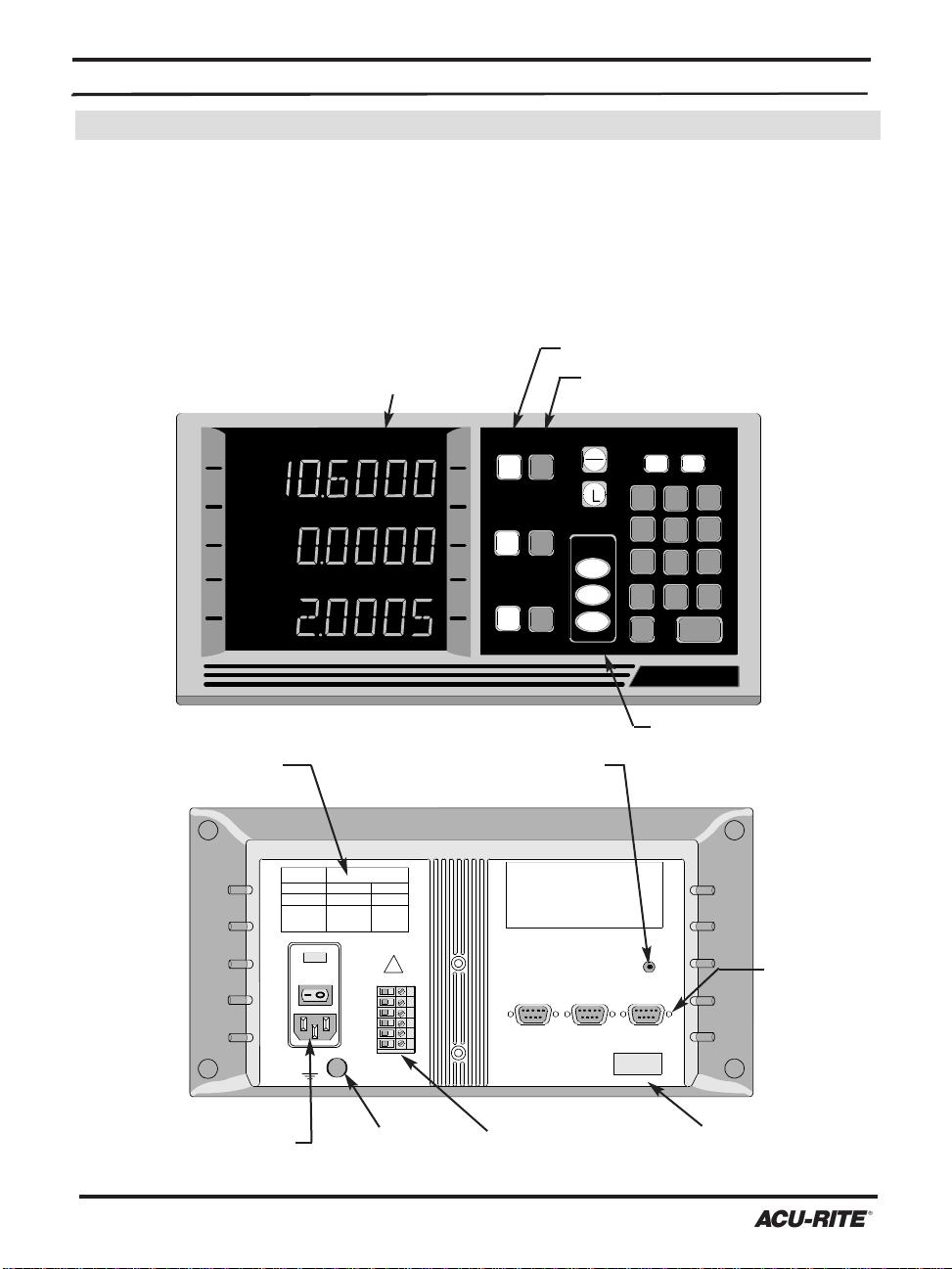

A Tour of the Readout

Front and Back Views

EDM MM INCR ABS ZERO SET C/L

ACU-RITE

CLEAR

+/-

7

8

9

4

5

6

1

2

3

C

ENTER

0

.

MM

SETUP

ABS

INCR

RETRACT

DISPLAY

ENABLE

DWELL

ZERO

ZERO

Z

Y

X

ZERO

3x DRO

PN 2001009

SN 9766554

FCC COMPLIANCE

115V

EDGE

FINDER

INPUT 1INPUT 2INPUT 3

!

FREQUENCY

VOLTAGE

CURRENT

FUSE

2

1

3

4

5

6

Indicators

Axis keys

Zero keys

EDM function keys

Input for electronic edge finder

or spark detector

Electrical & fuse rating

information

Scale

inputs

Power switch &

voltage selector

Ground wire

connection

Output relay

connector

Model number and

Serial number

Page 6

INTRODUCTION

DRO 200E

2

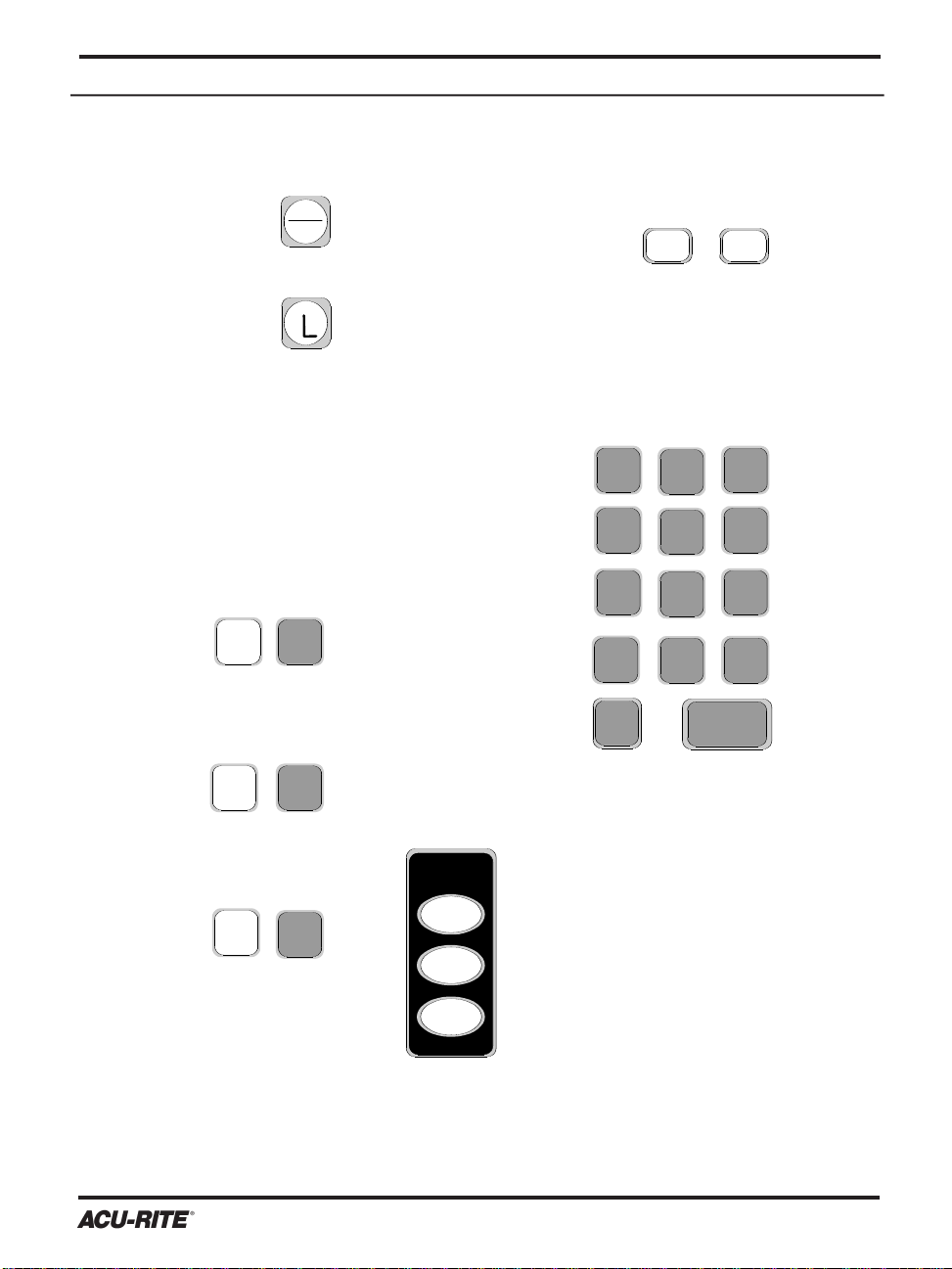

Keypad

Selects

absolute or

incremental

display

Used to

locate

centerlines

English

/metric

conversion

System

setup

parameters

Enter all numeric

values with these

Use to

begin a

preset

ZERO

ZERO

Z

Y

X

ZERO

ABS

INCR

MM

SETUP

CLEAR

+/-

7

8

9

4

5

6

1

2

3

ENTER

0

.

RETRACT

DISPLAY

ENABLE

DWELL

Switches display between

DRO and EDM views.

Program retract and dwell

functions.

C

Use Clear key to

erase digits that

you entered by

mistake, and to

take you back to

a previous para-

meter.

Page 7

INTRODUCTION

DRO 200E

3

Displays

At the top of the display window is a row of indicators. These tell you the current state

of the readout.

EDM MM INCR ABS ZERO SET C/L

Appears

when

setting an

absolute zero.

Appears when

you are setting a

preset or an

absolute zero.

Tells you when the

centerline function

is active.

Appears when EDM

view is displaying

cut depth informa-

tion.

Appears when the

display is in metric,

dark when the display

is in inches.

These tell you if the

position display is

incremental or

absolute. They also

indicate the type of

preset.

In addition to the lighted indicators along the top of the display, the top axis display

will scroll longer messages to assist you with some of the procedures.

In this manual, the text representing key presses, indicators and display text are

shown in their own individual font styles so they are more easily distinguished from

each other and the rest of the manual text.

Key Presses:

EYS

INDICATORS

“DISPLAY TEXT”

ZERO

SET

C/L

EDM

MM

INCR

ABS

Page 8

INTRODUCTION

DRO 200E

4

Power-On Position Recovery

Position-Trac™

Current ACU-RITE precision glass scales, including the ENC 150, contain distanceencrypted reference marks allowing you to quickly recall absolute zero (datum) after

a power interruption. When power is restored, the readout will scroll a message indicating power has been lost, and will prompt you to move each axis until a reference

mark is located. After this message, a flashing decimal point will indicate that

absolute zero has not been recalled for each axis. To recall zero, move each axis

in a positive count direction. By traversing approximately 2 inches on each axis, you

will re-establish and display current position relative to your last set zero.

If you use a scale without Position-Trac™ distance-encrypted reference marks, the

procedure for recovering your position is slightly different. You must find a specific

reference mark and then use the same mark when recalling zero. To setup your display for non-Position-Trac™ scales, refer to page 21, “Machine Related Parameters”.

To recall Zero using non-Position-Trac™ scales:

1. Move near the desired reference mark.

2. Press and hold the

A

key until the decimal point starts to flash.

3. Move slowly past the reference mark until the readout recalls its position.

You must move in the positive count direction.

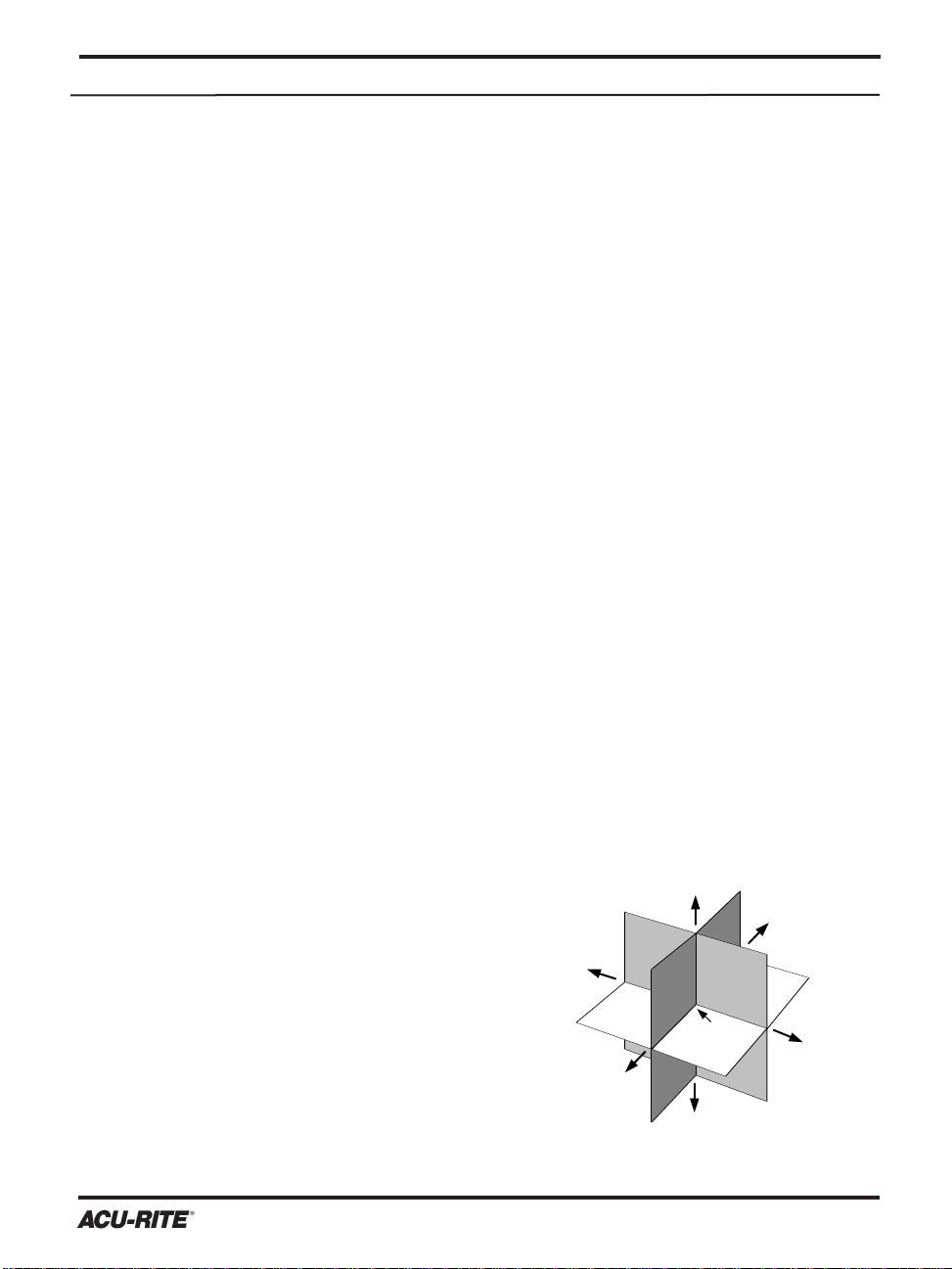

Machine Conventions

For the purposes of this manual, all of the examples are based on the following

conventions.

As you face the machine:

• The tool moving right is X-axis positive

• The tool moving away from you is Y-axis

positive

• The tool moving up is Z-axis positive

+Z

+Y

–Y

–Z

+X

–X

X=0

Y=0

Z=0

Page 9

READOUT OPERATIONS

DRO 200E

5

Readout Operations

DRO View

Absolute Display

Shows the distance from your current position to absolute zero (datum).

1.625

ABS Display will read: 1.6250 in X-Axis

The electrode is

positioned at 1.625

ABS.

Absolute Zero,

also called datum

or Workpiece Zero

Incremental Display

Shows the distance from your current position to incremental zero. An incremental zero is set when you preset a dimension (explained later), or when you zero the

incremental display.

1.625

-0.625

The electrode is 0.625

on the negative side of

the incremental zero.

Incremental zero: the

incremental display will

read 0.0000 when the

electrode is here.

Absolute Zero

(Datum)

INCR Display will read: -0.6250 in X-Axis

ABS Display will read: 1.0000 in X-Axis

ABS

INCR

Location of

Electrode

Pressing the ABS/INCR

key changes the display

Automatic Display Switching

Sometimes the readout will switch from absolute to incremental automatically.

For example, when you enter a preset the readout switches to the incremental

display so you can move to zero. Whenever the readout does an automatic display

switch, “INCR” will appear briefly in the X-axis display.

This section describes the readout’s functions when it is in the DRO view. This includes

a description of absolute and incremental displays, the various methods of setting

absolute zero (datum) and presetting absolute and incremental distances.

Page 10

READOUT OPERATIONS

DRO 200E

6

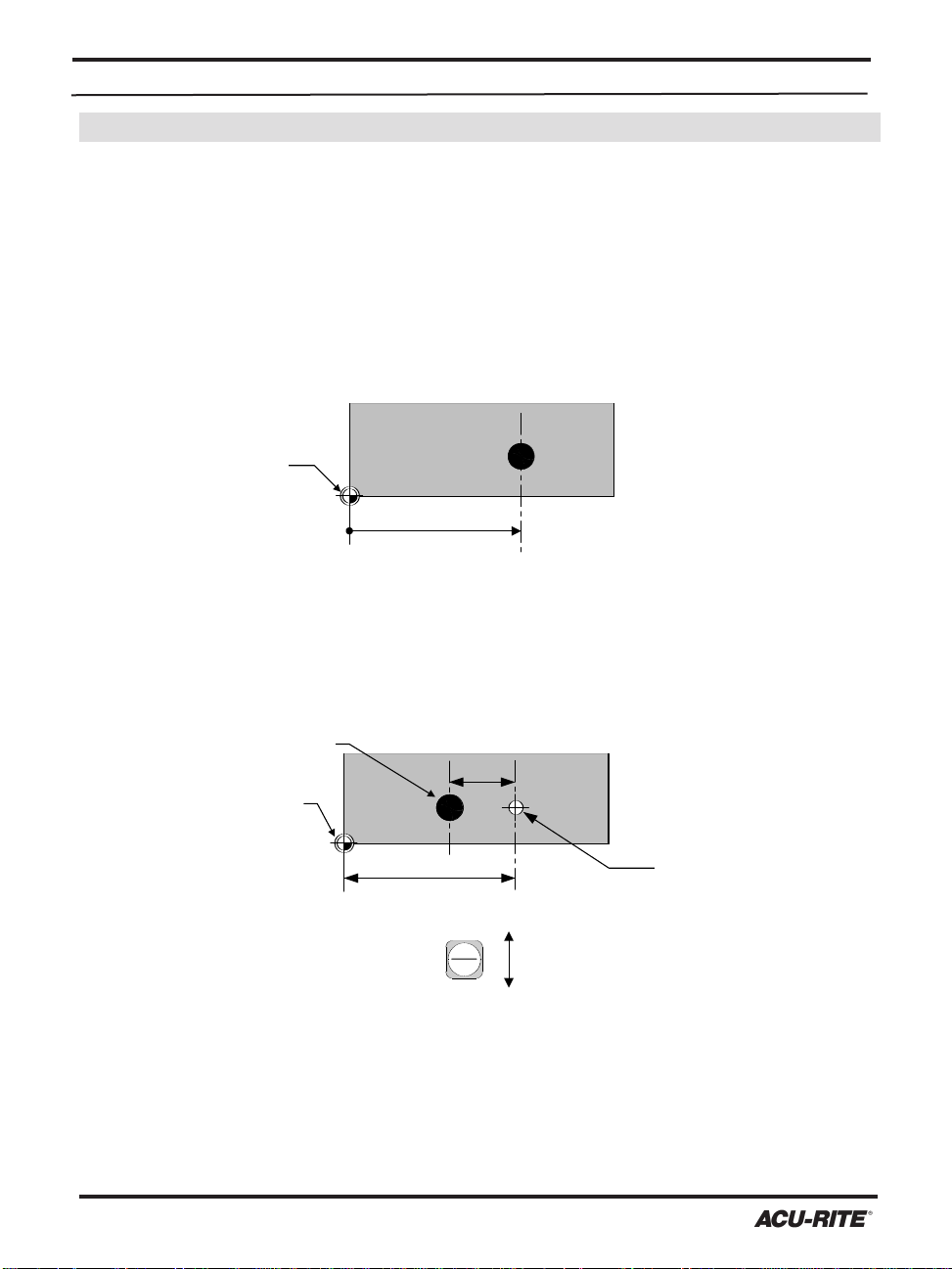

On many prints, dimensions are measured

from a datum. By setting the readout’s

absolute display to zero at a well-chosen

edge, you can position the ram based on

dimensions directly from the print.

Setting Absolute Zero (Datum) at the

Current Position

1. Move to desired location.

2. Make sure that the absolute indicator (ABS) is lit.

Press the

A

key if it is not.

3. Press the

z

key next to the desired axis twice.

Zeroing the Displays

Absolute Zero (Datum)

0.72

1.44

2.44

Absolute Zero

(Datum)

1.25

1. Install the electronic edge finder into the ram and

connect it to the readout.

2. Make sure that the absolute indicator (ABS) is lit.

Press the

A

key if it is not.

3. Press the

z

key for the appropriate axis once.

The readout will display the following; “_ _ _ _ _ _ _ 0”.

4. Move slowly until the edge finder touches

the edge of the workpiece. The absolute

position display will automatically be set to

zero at the edge of the workpiece. Refer to

setup to automatically compensate for the

edge finder’s tip diameter.

Note: You don't have to worry about

overtraveling. The readout

will zero on contact.

Automatic

Radius

Compensation

Setting Absolute Zero (Datum) Using an Electronic Edge Finder

Note: If you are using an electronic edge

finder with your readout, a metallic

surface must be present in order

for the edgefinder to work properly.

Page 11

READOUT OPERATIONS

DRO 200E

7

Setting Absolute Zero (Datum) with a Tool

1. Touch the tool to the edge of the workpiece.

2. Make sure that the absolute indicator (ABS) is lit.

Press the

A

key if it is not.

3. Press the

z

key for the appropriate axis.

The readout will display these indicators: ABS ZERO SET

4. Enter the position of the tool center and press

E

.

.25 Inch

Tool

-.125

Setting Absolute Zero (Datum) Using Center Line

You can set absolute zero (datum) at the center of your workpiece or in the center of

a hole. To set absolute zero using centerline:

1. Verify the readout is in ABS mode. The ABS indicator will be displayed.

If not press the

A

key to select the absolute mode.

2. Press the

z

key for the appropriate axis.

3. Press the

L

key. A message will ask you to

“ENTER FIRST EDGE”. Move to the first edge.

4. Press the

E

key.

Note: The closer you are to the

center of the feature the

more accurate your centerline calculation will be.

5. A message will ask you to “ENTER

SECOND EDGE”. Move to the second edge.

6. Press

E

key.

Absolute zero (datum) is now set at

the center between the two points.

The display will change showing

you the distance to center line on

that axis.

Repeat this procedure to set absolute zero center line in the other axis.

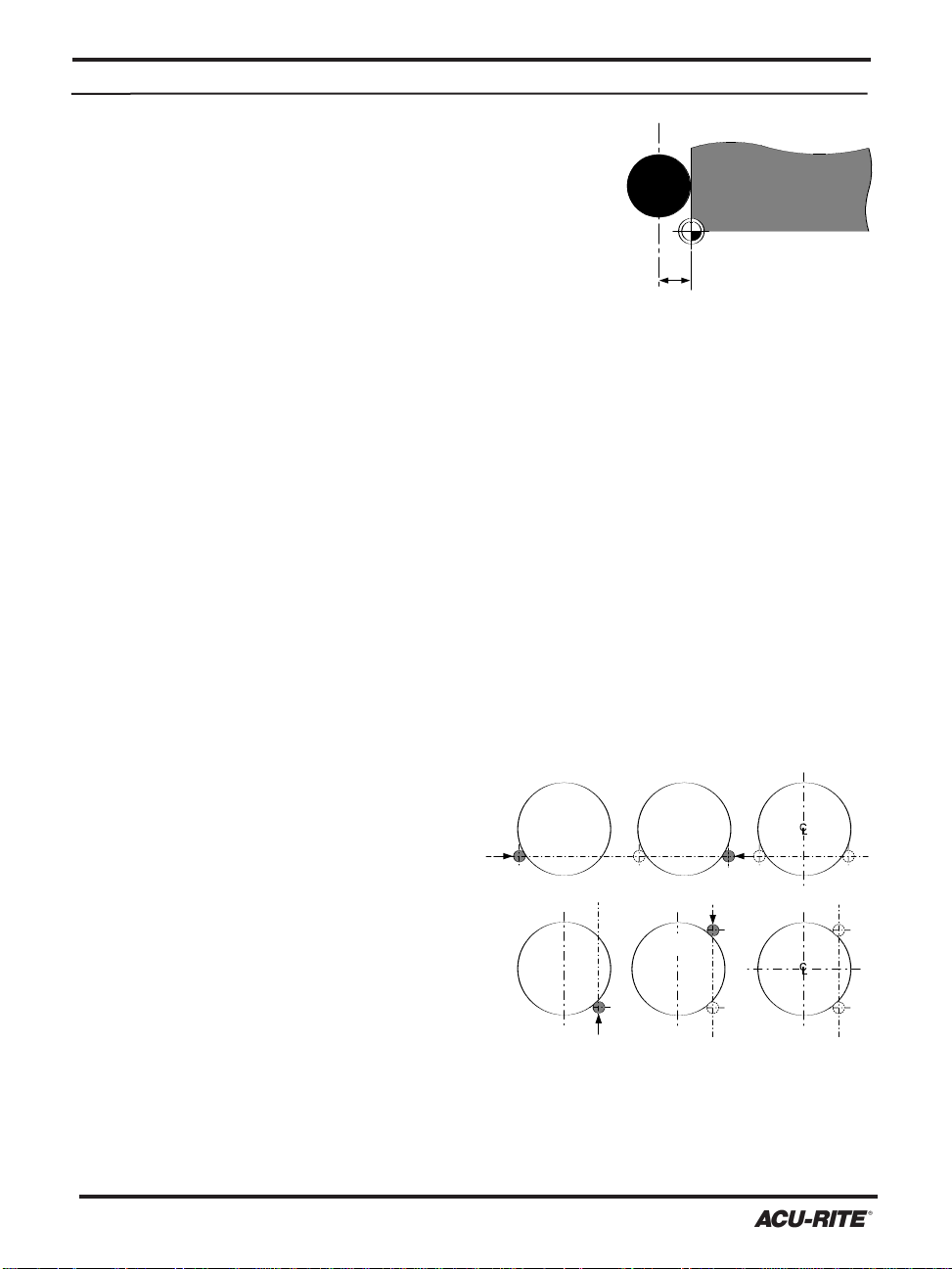

First

Point

First

Point

Second

Point

Second

Point

Absolute zero is now set in the center on both X and Y-axes.

Page 12

READOUT OPERATIONS

DRO 200E

8

Incremental Zero

From the incremental display (INCR), press the

z

key next to the appropriate axis.

This sets the display to zero at the current tool position.

Presetting

Absolute

The absolute preset is based on datum. When an absolute preset is entered, the readout calculates the incremental distance to the preset position. In the example below,

the current position is 1.0000” and the desired position is 1.5000” as measured from

datum. The key press sequence is

X

,

A

(ABS indicator is lit),

1,.,5

,

and

E

. The readout will automatically shift to incremental display mode and show the

distance remaining to the preset position.

An absolute (ABS) preset

is based on Absolute Zero

(Datum).

Absolute

Zero

(Datum)

X

ABS

INCR

.

1 5

ENTER

1.50

Current

Position

INCR

X

ABS

INCR

ABS

.

1 5

ENTER

1.50

Absolute Preset

Incrementel Preset

An incrementel (INCR)

preset is based on current

position.

INCR Display will read: -0.5000 in X-Axis

1.00

INCR Display will read: -1.5000 in X-Axis

Incremental

The incremental preset is based on current position. When an incremental preset is

entered, the readout displays the length of preset value. In the above example, the

current position is 1.0000” and the desired position is 1.5000” from current position.

The key press sequence is

X

,

A

(INCR indicator is lit)

,

1,.,5,E

. The

readout will automatically shift to incremental mode and show the distance to move.

Page 13

READOUT OPERATIONS

DRO 200E

9

Absolute and Incremental Presets

To maintain the best tolerance and to minimize the chance of errors, use

• absolute presets for absolute dimensions.

• incremental presets for incremental dimensions.

The following examples, shows how to make the identical part using absolute

presetting or incremental presetting.

Absolute Example:

.72

1.44

2.44

Note: When you enter an absolute preset,

it does not matter where the tool

position is. This system calculates

the desired location from absolute zero

(datum).

1. Verify the readout is in ABS mode. If not press A.

2. Press, in order, Xkey, then type in

.,7,2

,

then

E

.

3. Repeat for dimensions 1.44 and 2.44.

0.72

0.72

1.00

Absolute

Incremental

Incremental

Note: When you enter an incremental

preset, the tool must be positioned at the location you are

dimensioning from.

Incremental Example:

1. Verify the readout is in ABS mode. If not

press A.

2. Enter the key sequence:

X,.,7,2,E

.

3. Display will automatically shift to incremental. Move the X-axis until “0.0000” is

displayed.

4. Enter the key sequence:

X

,

A

, to select incremental (

IINNCCRR

)

.,7,2,E

.

5. Move the X-axis until “0.0000” is displayed.

6. Repeat steps 4 & 5 for incremental dimension 1.00.

Page 14

READOUT OPERATIONS

DRO 200E

10

Center-line Presets

You can set a preset at the center of

a workpiece, or in the center of a hole.

To preset incremental zero on a centerline:

1. Press the axis key you wish to find

center with.

2. Press the centerline

L

key. The

SET C/L indicator will be lit.

3. A message will ask you to “ENTER

FIRST EDGE”.

4. Move to first edge and press the

E

key.

5. A message will ask you to “ENTER SECOND EDGE.” Move to the second

edge and press

E

key.

6. The display will automatically change to show you the incremental distance

to the center between the two entered points.

7. Repeat this procedure for each axis as needed.

Second

Point

Second

Point

First

Point

First

Point

Page 15

READOUT OPERATIONS

DRO 200E

11

The cut depth is the point at which you want the cut to end. At this point, you can

program the ram to dwell and or retract. You need to preset the cut depth when

using the ram retract, dwell, sparkout and reverse fault features. The cut depth can

be set prior to, or after, setting datum.

To preset the cut depth:

1. Press the

D

key to switch to the EDM

display.

2. Verify the readout is in ABS mode. If not

press A.

3. Press the

Z

key.

4. Enter the desired cut depth and press

E

.

EDM View

This readout provides a very flexible dwell and retract capability which can be configured to a wide variety of EDM control schemes. Your particular EDM machine may not

have the ability to use all of these features described in this section.

EDM Display

To help you monitor the progress of a cut, press the

D

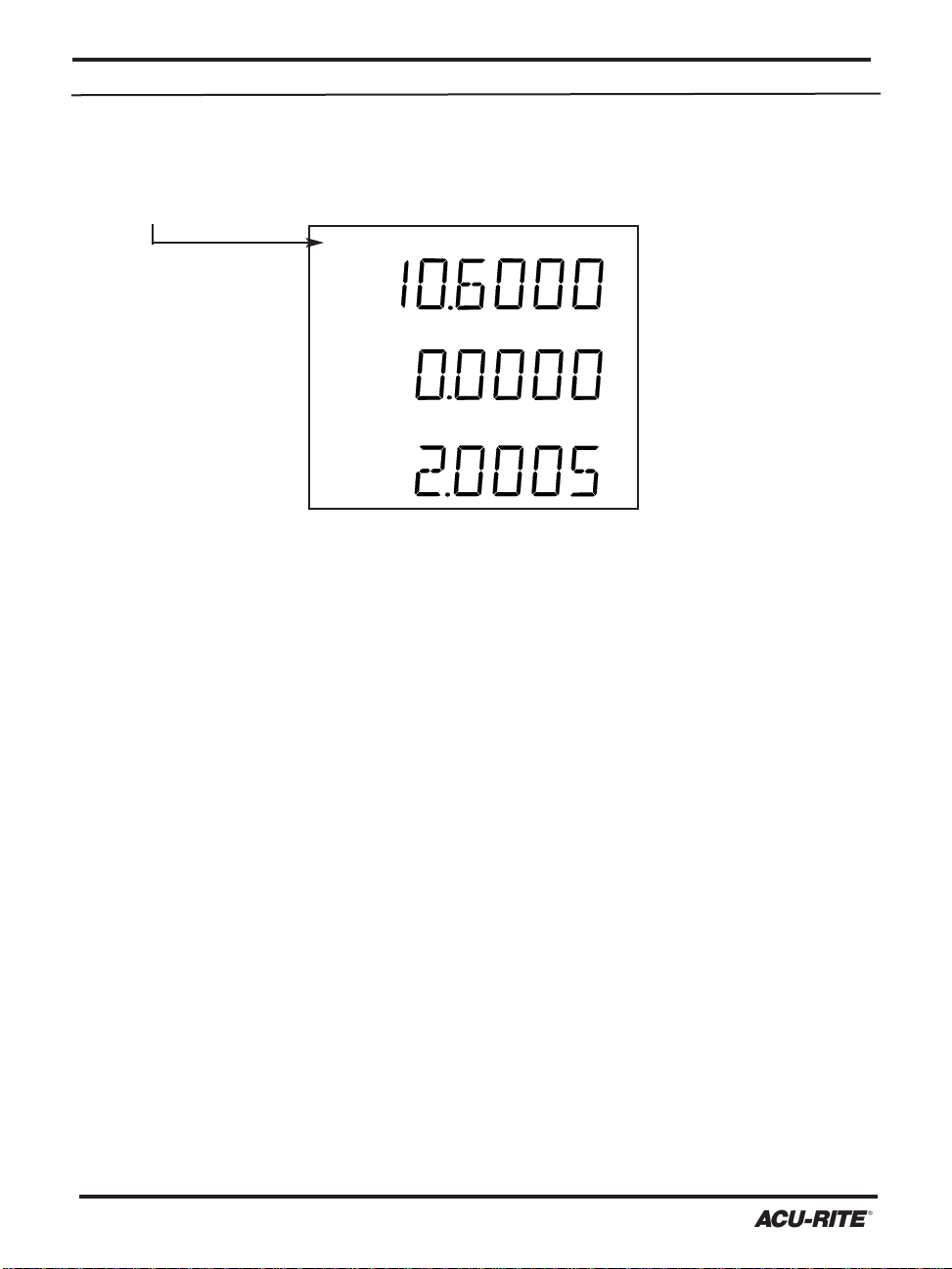

key. The EDM indicator

will light up. All three displays show you something about the Z-axis.

• The top display shows the current position of the electrode.

• The center display shows the progress depth.

• The bottom display shows the programmed cut depth.

Press

D

key again to return to X-Y-Z display.

Z

Programmed cut depth

Lowest progress depth

Current Z-Axis position

Oscillating Ram

Presetting the Cut Depth

ACU-RITE

CLEAR

+/-

7

8

9

4

5

6

1

2

3

C

ENTER

0

.

MM

SETUP

ABS

INCR

RETRACT

DISPLAY

ENABLE

DWELL

ZERO

ZERO

Z

Y

X

ZERO

Current

Position

Progress

Depth

Programmed

Cut Depth

EDM ABS

Page 16

READOUT OPERATIONS

DRO 200E

12

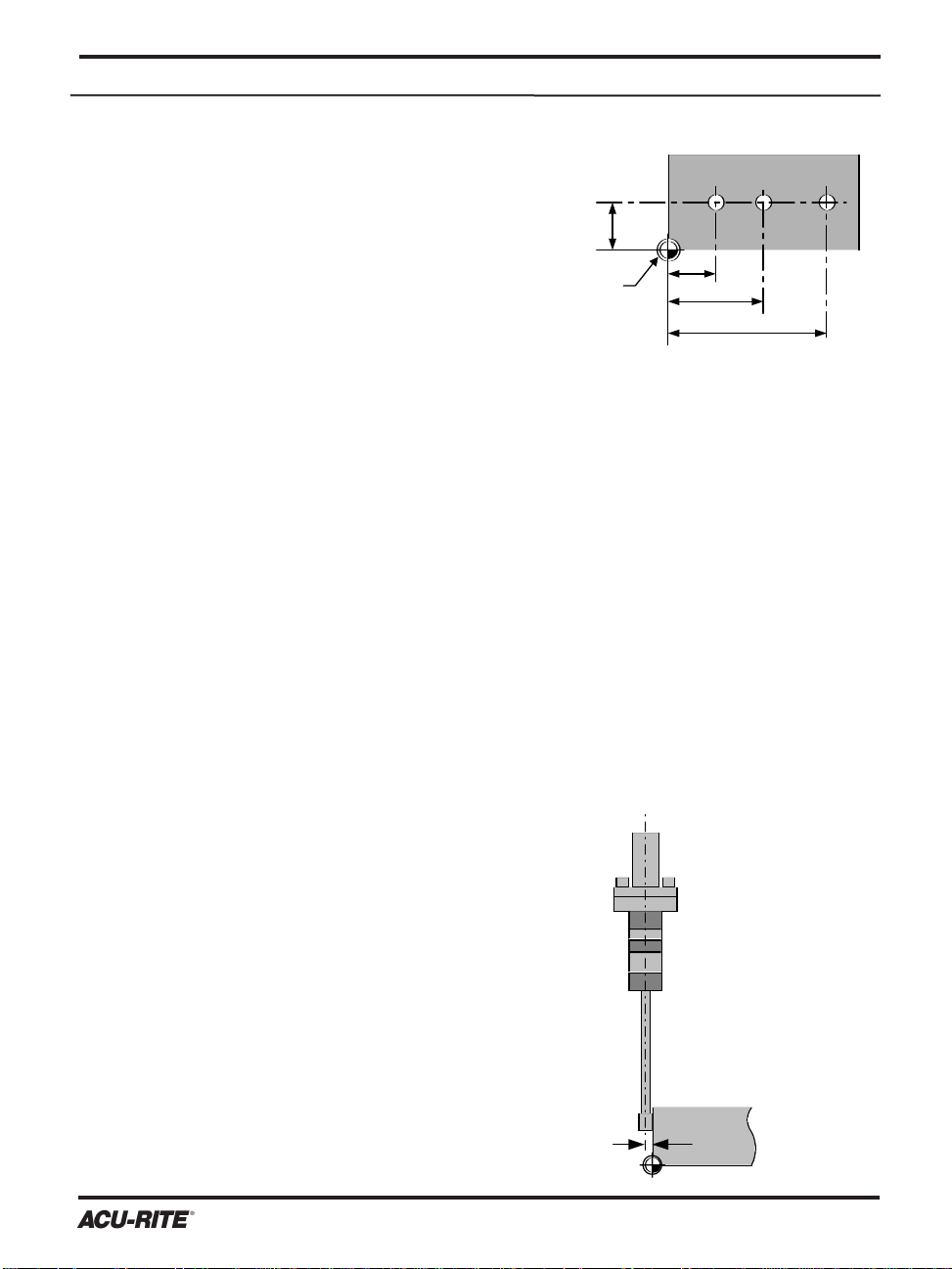

Setting Absolute Zero (Datum) Using a Preset

Presetting absolute zero (datum) allows the operator to

establish absolute zero at a point other than the current

position. To preset absolute zero:

1. Verify the readout is in ABS mode. If not press A.

2. Position the ram to a known location.

3. Press the

z

key next to the

Z

key once.

4. Enter the distance to the desired zero location.

Example:

The desired absolute zero (datum) is at the top of the work-

piece. The electrode is known to be 2.5 inches long and is

too fragile to be used to set zero.

1. Verify the readout is in ABS mode. If not press

A

.

2. Position the electrode clamp at the top of the workpiece.

3. Press the

z

key next to the

Z

key once. The

display will show; “ _ _ _ _ _ _ _ 0”.

4. Press ±±

2, ., 5

and then the

E

key. The dis-

play will show “-2.5000” in the Z-axis.

With the electrode installed, the Z-axis absolute zero is

now set at the top of the workpiece.

Work Piece

2.500

electrode

length

ABS Display shows

0.0000 in Z-Axis

With Electrode

Setting Absolute Zero (Datum) at Current Position

1. In either DRO or EDM view, verify the readout is in

ABS mode. If not press

A

.

2. Position the ram to the point where 1st

spark will occur.

3. Press the

z

key next to the Zkey twice.

Work Piece

Electrode

Clamp

ABS Display shows

-2.5000 in Z-Axis

Without Electrode

Work Piece

Spark

Gap

Position Ram

Here, then set

Z-zero

(Datum)

Preset at -2.5 inches

Page 17

READOUT OPERATIONS

DRO 200E

13

1. Press the

e

key.

2. Press the

Y

key to toggle between “ON” and “OFF”.

3. Press the

X

key to continue to the next parameter or press the

e

key to

return to EDM/DRO view.

Zeroing the Z-axis Using the Spark Detector

If you set zero using the optional ACU-RITE spark detector, you can easily compensate for spark gap and electrode erosion from one cut to the next.

1. Preset the depth of the cut (explained on page 11).

2. Verify the readout is in ABS mode. If not pressA.

3. Press the

z

key next to the Zkey once.

The Z-AXIS display will look like this;

“_ _ _ _ _ _ _ 0”.

4. Start the cut. When the first spark is detected,

the readout sets the top of the workpiece to zero.

5. When the retract point is reached, any programmed dwell and/or retract will

occur.

EDM Parameters

Pressing the

e

key allows the operator to access four EDM function parameters.

When

e

is pressed, “EDM” is displayed along with a flashing dash. A flashing dash

indicates that the key to the right of it has a function. Pressing the Xkey will

advance you to the next parameter. Pressing the Ykey will allow you to change the

parameter setting. Pressing the Ckey will clear information entered or take you back

to the normal display.

Enable

This parameter allows you to suspend all EDM functions. When “ON” the Dwell,

Retract and Position Hold relays are active. When “OFF”, all relays remain in their

relaxed states. Turning off all functions allows you to setup a job without the concern

of activating the retract or dwell functions accidentally. To indicate all functions are

off, the entire Z-axis display will blink.

Work Piece

Z-zero

(Datum) set

when first

spark occurs

Page 18

READOUT OPERATIONS

DRO 200E

14

R DIST

R DIST, or Retract Distance, allows you to establish an incremental distance above

the cut depth where the Retract relay will relax, stopping retraction movement.

When used, the Retract relay will activate when the cut depth is reached and after

any dwell cycle has completed. Retract ends when the current Z position equals RDIST or Z-TOP whichever occurs first.

To establish a retract distance:

1. Press the

e

key then the Xkey. The display will read “R DIST”.

2. Press the

Y

key to toggle the R-DIST function “OFF” or to begin entering a dis

tance.

3. Enter the retract distance. For example,

type in

2,.,5

and press the

E

key.

Pressing

E

saves the information entered

and advances you to the next parameter.

4. Press the

X

key to continue to the next

parameter or press the

e

key to return

to the EDM/DRO display.

Z TOP

Similar to R DIST, Z TOP allows the operator to establish a distance above absolute

zero (datum) where the Retract relay will relax, stopping retraction movement.

To establish a Z TOP position:

1. Press the

e

key then the

X

key twice. The display will read “Z TOP”.

2. Press the

Y

key to toggle the Z TOP function “OFF” or to begin entering the Z

TOP parameter.

3. Enter the Z TOP distance. For example, type in

2,.,5

and press the

E

key. Pressing

E

saves the information entered and advances you to the next

parameter.

4. Press the

X

key to continue to the next parameter or press the

e

key to

return to the EDM/DRO view.

Page 19

READOUT OPERATIONS

DRO 200E

15

R FAULT

To establish an R FAULT point:

1. Press the

e

key then the

X

key three times. The display will read

“R FAULT”.

2. Press the

Y

key to toggle

between the R FAULT function “OFF” or to begin entering a distance.

3. Enter the retract fault distance as a real number (positive value). For example,

type in

2,.,5

then press the

E

key.

4. Pressing

E

key will save the information entered and return to the

EDM/DRO view.

R FAULT, or Retract Fault, stops a cut in the event that the ram drifts above a

pre-set range from the lowest progress depth. When the R FAULT distance is

reached the retract relay is actuated for 1/10th of a second to halt the cutting cycle.

Page 20

READOUT OPERATIONS

DRO 200E

16

Dwell

The two DWELL parameters tell the EDM control to hold at the cut depth to obtain a

better finish or to allow an orbiter to operate. Press the

d

key to view or change the

parameters.

Timed Dwell

The D-TIME, or Dwell Time parameter causes the ram to hold a cut depth for the

number of minutes that you enter.

To enter or change the dwell time use the keypad to enter the minutes you would

like the EDM to dwell. The time is displayed in minutes and fractions of minutes

(i. e. 1.0167 = 1 minute, 1 second, or 1.5 = 1 minute 30 seconds).

To set a Dwell time:

1. Press the

d

key. The display will read “DWELL TIME MINUTES” and then

“D TIME”.

2. Press the

Y

key to toggle the D-TIME function “ON” or “OFF”, and use the key

pad to enter or change the Dwell time, then press

E

. (Pressing

E

saves the

information and advances you to the next parameter.)

3. Set Sparkout condition, as shown below, or press the

d

key to return to the

EDM/DRO display.

Dwell Until Sparkout

With the optional ACU-RITE spark detector connected to the readout, you can set the

dwell to last until sparkout is detected. The sparkout condition is determined by

measuring the time between sparks. When this time becomes long enough (greater

than the S-TIME parameter), the dwell cycle ends and the ram retracts. Use the

Y

key to turn the S-TIME parameter on or off. When it’s on, the number of minutes can

be entered that defines sparkout

1. Press the

d

key then the

X

key the display will read “Sparkout time

minutes” and then “S-TIME”.

2. Press the

Y

key to toggle this parameter “ON” or“OFF”, and use the keypad to

enter the time between sparks you wish to monitor. For example: .0167 = 1 second, .5 = 30 seconds, then press

E

. (Pressing

E

saves the information and

advances you to the next parameter.)

Both timed dwell and sparkout can be enabled at the same time. Whichever occurs

first will terminate the dwell cycle.

Page 21

SETUP

DRO 200E

17

Setup

The

S

key lets you access the many readout configuration parameters. Some of these

parameters are “job related”, meaning that they may change from job to job. Others are

“machine related” and are only set when the readout is installed or maintained.

Press the

S

key to access these parameters. Use the

X

key to move from one para-

meter to the next. After the last parameter, the

X

key ends the setup process and

saves any changes. Use the

C

key to return to a previous parameter. Some parameters

have several possible selections. A flashing dash by the

Y

key indicates that the

Y

key can be used to cycle through the available choices. At any time during setup, pressing the

S

key will end the setup process, and save changes.

“Job Related” Setup Parameters

These parameters are used to adjust the readout display to suit specific job requirements. You can access the job parameters by pressing the

S

key. Then press the

X

or

E

key. Use the

X

key to advance to the next parameter. Use the Ckey to

return to a previous parameter. A flashing dash next to an axis key indicates that the

key has a function.

Display Resolution

The display resolution parameter allows you to adjust the increment by which the

display counts for each axis. Press the

X

key to advance to the next parameter.

Press the Ykey to change the numeric value of the parameter:

“X DISP” indicates the display resolution for the X-axis.

“Y DISP” indicates the display resolution for the Y-axis.

“Z DISP” indicates the display resolution for the Z-axis.

Press the

X

key to continue with Setup or the

S

key to save changes and exit Setup.

Scale Factor

This function allows the operator to adjust the display to automatically compensate

for material shrinkage or expansion so you can quickly and easily finish a job with

out the need to calculate each dimension. If the print has a shrinkage/expansion factor you can enter this value here and proceed to machine to nominal dimensions.

Press the

X

key to advance to the next parameter. Use the keypad to change the

display value.

“X FACTOR” indicates the scale factor for the X-axis.

“Y FACTOR” indicates the scale factor for the Y-axis.

“Z FACTOR” indicates the scale factor for the Z-axis.

When power is turned off or power is interrupted scale factors will return to 1.000.

Press the

X

key to continue with Setup or the

S

key to save changes and exit

Setup.

Page 22

SETUP

DRO 200E

18

Near Zero Warning

When used with presets, Near Zero Warning allows you to establish a distance from

zero where the display will indicate you are nearing the end of your cut (zero).

When the established point is reached while approaching zero, the digit(s) to the left

of the decimal will flash. The range is, in effect, on both the positive and negative

side of zero. When zero is reached the flashing digits stop. Near Zero Warning will

not reset until you preset or move a distance greater than the established range.

.2500 Near Zero Warning Range

Display Begins

Flashing

Display Stops

Flashing

Near Zero

Resets

Display Begins

Flashing

Display Stops

Flashing

Near Zero

Resets

Digits Left of the decimal

flash when you are within

the Near Zero range.

0-1/2 1/2

When you are in the Near Zero parameter for the X-axis “X NEAR 0”will be displayed. “OFF” will be displayed if the parameter is currently off. A numeric value

will be displayed if the parameter is already on. Press the

Y

key to turn the Near

Zero parameter on or off. Use the keypad to change the value displayed.

Press the

X

key to cycle through the remaining axis factors:

“X NEAR 0” indicates the near zero setting for the X-axis.

“Y NEAR 0” indicates the near zero setting for the Y-axis.

“Z NEAR 0” indicates the near zero setting for the Z-axis.

Press the

X

key to continue with Setup or the

S

key to save changes and exit

Setup.

Page 23

SETUP

DRO 200E

19

Linear Error Compensation

This readout includes a linear error compensation (LEC) feature that enables you to

compensate for machine tool inaccuracies by using a simple measuring standard.

You can have up to three different compensation segments per axis. For linear error

compensation to be effective, the error must repeat. If the error is different each

time it is measured, check and adjust the machine ways and lead screws. Also check

scale mounting bracketry.

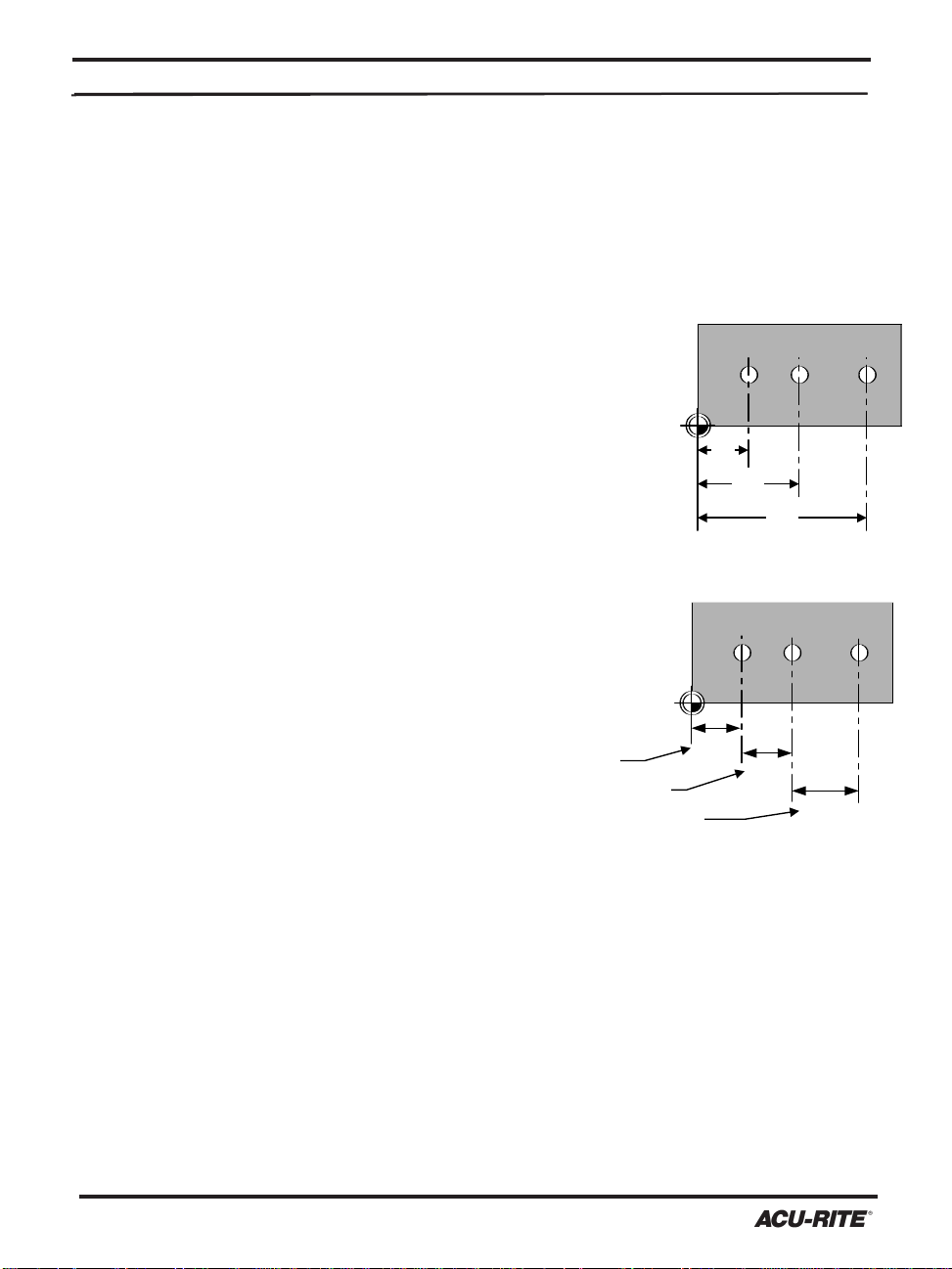

If only one segment per axis is

being used, the correction factor

will be applied along the entire

length of the scale.

To use two or three segments you

must first find home using the

Power On Position Recovery (page

4). The segments must be

sequenced in order from negative

to positive without overlapping.

Segment centers will be located

midway between the two ends of

the standard. Segment boundaries

will be located midway between

the segment centers.

The standard must be parallel

with the axis of travel. Use an

indicator to insure this. If you

approach the ends of the standard

from opposite sides, you must add

the indicator tip diameter to the

length of the standard.

Order segments from Negative to Positive

DISTANCE

BETWEEN

CENTERS

MIDPOINT

BETWEEN

CENTERS

FIRST

SEGMENT

BOUNDARIES

THIRD

SEGMENT

BOUNDARIES

SECOND

SEGMENT

BOUNDARIES

MIDPOINT

BETWEEN

CENTERS

3 SEGMENT

LEC

ONE SEGMENT

COVERS THE

ENTIRE TRAVEL

1 SEGMENT

LEC

DISTANCE

BETWEEN

CENTERS

MIDPOINT

BETWEEN

CENTERS

FIRST

SEGMENT

BOUNDARIES

SECOND

SEGMENT

BOUNDARIES

2 SEGMENT

LEC

Order segments from Negative to Positive

When the LEC parameter is reached a message will prompt you to “ENTER NUMBER

OF ERROR COMPENSATION INTERVALS (0-3)”, then “X-INT” and the number of

intervals previ-ously selected will be displayed.

• Using the keypad, press

1,2

,

or

3

to select the number of LEC segments.

Press

0

if no LEC is indicated for this axis.

• Press

X

to begin the first interval.

To automatically calculate the LEC, press the

Y

key.

A message will prompt you to “MOVE TO FIRST SIDE OF GAUGE – PRESS ENTER”.

Page 24

SETUP

DRO 200E

20

3. When prompted, use the keypad to enter the actual length of the standard and press

E

. “X LEC 1” and the “LEC” value are displayed.

You can press the

Y

key to repeat this process for the same segment to

verify if the error is repeatable.

4. Press the Xkey to begin the next segment or, if all segments are complete, to advance to the next axis.

Repeat this procedure for each segment of each axis.

(

S - M

M

LEC =

)

x 1,000,000

S = Standard

length

M = Measured

length

Formula

Example

If the length of the standard you used is

10” and the measured length along the Xaxis is 9.995”, then the LEC for the Xaxis is 500 parts per million (PPM).

(

10 - 9.995

9.995

LEC =

)

x 1,000,000

LEC =

500 PPM

(rounded to the nearest

whole number)

8.1250

Opposite sides

1. Move to the first side of the

standard and press

E

.

2. When prompted, move to the

second side of the standard

and press

E

.

8.0000

Same side

ENTER

ENTER

To calculate linear error compensation use this formula:

Page 25

SETUP

DRO 200E

21

“Machine Related” Setup Parameters

Count Direction

After entering the access code, the operator will be prompted to “MOVE EACH

SCALE IN A POSITIVE COUNT DIRECTION”. Then the display will read “X

DIRECT” and a number will show in the Y-axis. This is the X-axis count direction

and is used to determine which direction is positive.

• Move the X-axis in the direction you would like to be positive. The display will

show a 1 or a 2 depending on the direction you move. The operator can also change

the count direction by pressing the

Y

key. Count direction settings for each addi-

tional axis will follow and are set in the same manner. Press the

X

key to access

each additional axis. Refer to page 4 to review “Machine Conventions” assumed in

this manual.

• Press the

X

key to continue with setup, or press the

S

key to save changes

and exit setup.

Scale Resolution

In order for the readout to count correctly each scale resolution must be entered.

Factory default settings are 10µm (0.01mm).

Automatic Resolution Detection

Scales with Position-Trac™, a distance encrypted reference system, allow the

readout to automatically detect and record the scale’s resolution. You will be

prompted to “MOVE EACH SCALE UNTIL RESOLUTION DECTECTED”, then

“X SCALE” will be displayed.

Machine related setup parameters are generally set during installation or when

maintenance is performed. These parameters affect the readout performance in dramatic ways and are protected by an access code to prevent accidental modifications.

The machine related parameters can be accessed by pressing

S

, entering the 4-digit

access code and then pressing

E

.

The access code number is given on a tear-out sheet on the first page of this manual.

Use the

X

key to move from one parameter to the next. After the last parameter, the

X

key ends the setup process and saves any changes. Use the

C

key to return to a

previous parameter. A flashing dash by the Ykey indicates that the

Y

key can be

used to select an optional setting and to cycle through the available choices. At any

time during setup, pressing the

S

key will end the setup process and save your

changes.

Page 26

SETUP

DRO 200E

22

To automatically detect the scale resolution:

• Move the X-axis scale in a positive direction until the displayed resolution

blanks continue moving axis until a resolution value appears in the Y-axis

display field. Scale Resolution settings for each additional axis will follow and

are set in the same manner.

• Press the

X

key to continue or, press the

S

key to save changes and

exit setup.

Entering A Scale Resolution Manually

To establish the resolution for scales without Position-Trac™, or to disable the

Position-Trac™ Power-on Position Recovery routine described on page 4, you need

to enter the scale resolution manually.

When you first enter this parameter, you will be prompted to “MOVE EACH

SCALE UNTIL RESOLUTION DETECTED”, then “X SCALE” will be displayed.

This is the X-axis scale resolution parameter.

To establish the scale resolution for non-Position-Trac™ scales:

• Press the

Y

key to cancel the automatic resolution detection routine. “Scale

does not have Position-Trac Feature” will scroll across the X-axis display.

• Continue to press the

Y

key to select from common resolution choices, OR

use the keypad, to enter the resolution in millimeters (Enter inches for

English resolution scales. Press the

M

key to toggle to English, then press

E

when entering these values.)

• Press the

X

key to continue or, press the

S

key to save changes and exit

setup.

The chart below will help to determine the resolution value to enter.

Resolution on Scale Label

Metric Resolutions

10µm (.0005”)

5µm (.0002”)

2µm (.0001”)

1µm (.00005”)

.5µm (.00002”)

English Resolutions

.0005” (10µm)

.00025” (5µm)

.0001” (2µm)

Resolution value to enter

MM indicator will be lit

.01mm

.005mm

.002mm

.001mm

.0005mm

Press the MM key to toggle to English

MM indicator will “not” be lit.

.0005”

.00025”

.0001”

Page 27

SETUP

DRO 200E

23

Sleep

In order to prolong the life of the vacuum fluorescent display the readout will go to

“sleep” after being idle for approximately 30 minutes. When the display is sleeping,

a dot will scroll along the X-axis indicating that the readout is still active. To wake

the readout, either press any key, or move any axis. The display will instantly

return to normal. If you wish to prevent your display from going to sleep, press the

Y

key until “0” is displayed. To reactivate sleep, press the

Y

key until a “1” is

displayed.

To change the SLEEP parameter:

• Press the

Y

key to select your option.

0 = OFF

1 = ON

• Press the

X

key to continue or, press the

S

key to save changes and exit

setup.

Language

The readout is capable of displaying several languages.

To change the language displayed:

• Press the

Y

key to scroll through the options.

DISPLAY

ENGLISH

F

S

D

IT

DK

PL

CZ

TK

NL

LANGUAGE

English

French

Spanish

German

Italian

Danish

Polish

Czechoslovakian

Turkish

Dutch

• Press the

X

key to continue or, the

S

key to save changes and exit setup.

Page 28

INSTALLATION

DRO 200E

24

Installation

IMPORTANT

Before installing the readout, record the serial number

on the warranty card and return it to ACU-RITE

INCORPORATED. The serial number label is located

on the back of the readout.

Selecting a location for the readout is an important consideration for proper installation. Keep the following points in mind when selecting a safe and convenient location:

• The readout should be within reach of the operator for easy access to the keypad.

• The readout should be approximately at eye level.

• Avoid moving components and tools.

• Minimize coolant splash or spray.

• The operating environment must be within the temperature range of 0°C to 40°C

(32°F to 104°F) with a non-condensing relative humidity of 25% to 85%.

Selecting a Location

Proper Mounting

ACU-RITE has developed special mounting kits for the readout, which address the

most common mounting requirements. Mounting kits include:

• Column and base machine mountings

• Hardware and mounting instructions

These kits are available from your factory authorized ACU-RITE Distributor or

OEM/OEI. If you fabricate a support device for the readout, it should be large enough

and strong enough to accommodate the readout. It must also be stiff enough to minimize any vibration induced by the machinery.

Connecting the Scales

Insert the connector from each scale into the mating connector on the back of the

readout. Fasten it with a small screwdriver.

Scale input 1 will be displayed in the readout's top display, input 2 in the next

display, and input 3 in the bottom display.

Provide enough slack in the scale cables to allow for full travel of all machine axes.

Check that machine movements will not pinch the cables. Use the cable tiedown

hardware kits supplied with the scales to fasten the cables neatly to the machine.

Connecting a Ground Wire

Connect a ground wire from the terminal on the back of the readout to the machine.

The machine should also be connected to a solid earth ground. If not, be sure that

the readout is grounded.

Page 29

INSTALLATION

DRO 200E

25

Checking Voltage and Connecting Power

Check that the voltage available at the power source is within specification before

connecting it to the readout. If required, set the voltage selector to match the line

voltage.

CAUTION

Connecting the readout to a power source outside

of the acceptable range, or making an inappropri-

ate setting with the voltage selector, may damage

the readout, the scales, or both.

1. Remove the caution label from the

input module, and use a thin-blade

screwdriver in the slot at the top of

the power-input module to open the

module cover.

2. Pull the selection block out.

Rotate the block 180° so the

proper voltage setting will be

seen through the window of

the cover.

3. Remove the fuse, move the shorting

bar to the other side, install the proper fuse, and push the block back into

place.

4. Close and snap the cover shut.

Opening Slot

The voltage setting will show through the window in the voltage selection cover.

Connect the readout to the power source using the power cord supplied.

Page 30

INSTALLATION

DRO 200E

26

The readout has three output relays:

• The Retract relay indicates to the control that the ram has reached the target

depth. The operator can define how far the ram will retract from the target

depth. The ram can be raised to a pre-determined position or a preset distance

from the target depth. The characteristics of your particular control and work

piece setup will determine how the operator should set the Retract relay.

• The Dwell relay tells the control to hold at the target depth (the bottom or top of

the burn) in order to obtain a better finish or to allow an orbiter to operate. The

operator can set this dwell to a specified time period, or with the optional Spark

Detector, it can be set for a sparkout condition.

• The Position Hold relay is active only while the Dwell relay is de-energized. It

maintains the relative position of the ram with respect to the target depth. If

the ram position is above the target depth, the relay is de-energized (contacts

open). If the ram position moves below target depth, the relay is energized (contacts closed). Refer to the Relay Timing Diagrams on pgs. 27-29.

The optional Spark Detector can be connected so that the readout can determine the

sparkout condition. Sparkout occurs when no spark is detected for a predetermined

period of time. The Spark Detector connects to the Electronic Edge Finder input on

the back of the readout.

Relay Connections

The Retract and Dwell relay contact are rated at 1 amp at 30 VDC, 0.5 amp at 125

VAC. The Position Hold relay contact rating is 0.10 amp at 30 VDC, 0.10 amp at

125 VAC.

Connecting the Output Relays

2

1

3

4

5

6

Retract

Relay

Dwell

Relay

.35"

9 mm

14 - 22 AWG wire, solid or stranded

insulation rating: 600V/80

o

C min.

8

7

Position

Hold

Relay

CAUTION

Connecting the relays improperly or exceeding the specified

limits may result in damage to the readout system or to external equipment. Equipment connecting to the CFI relays is to

have no live parts that are accessible.

Page 31

INSTALLATION

DRO 200E

27

Relay Timing Diagrams

The readout's

e

key lets the operator:

• turn all EDM functions “ON” and “OFF”.

• change the distance (R-DIST) that the retract relay is de-energized, or

• enter a Z-Top position. When a Z-Top position has been entered, the Retract

relay will energize at the preset retract depth, and will stay energized until the

ram reaches the Z-Top position. The relay will relax if the RAM stops before the

Z-Top position is reached.

Retract Without Dwell

Fig. 1

Spark

Dwell

Relay

Retract

Relay

Active

Relaxed

Active

Relaxed

Active

Relaxed

Retract begins

when cut depth

is reached.

Retract ends when

Z = R-DIST or Z-TOP

which ever occurs first.

Electrode is de-energized*

No dwell is programmed

Not Active

Spark

No Spark

Position

Hold Relay

There are three control function relay (CFI) outputs on the readout. When power

is on the Retract and Dwell outputs are energized. The Position Hold relay energizes when ram is at or below programmed cut depth.

The Retract and Dwell relays can be wired normally open or normally closed. The

Position Hold relay is always normally open.

In the event of a power failure to the readout all CFI outputs revert to a relaxed

state.

The following figures show the state of each relay while under the given conditions;

Retract Without Dwell, Retract After Dwell and Retract After Sparkout.

* The machine must be properly configured for the electrode to de-energize.

Page 32

INSTALLATION

DRO 200E

28

Retract After Dwell

Fig. 2

Spark

Dwell

Relay

Retract

Relay

Active

Relaxed

Active

Relaxed

Active

Relaxed

Retract ends when

Z = R-DIST or Z-TOP

which ever occurs first.

Electrode is de-energized*

Retract begins when

dwell time expires plus a

short delay of 100 ms.

Dwell time begins

when cut depth is

reached.

Dwell Time

Ram position is

monitored until retract.

Position

Hold Relay

Spark

No Spark

Ram Position

Monitoring Begins

Active when ram is at

or below target depth.

* The machine must be properly configured for the electrode to de-energize.

Page 33

INSTALLATION

DRO 200E

29

Dwell Time

Retract After Sparkout

Fig. 3

Spark

No Spark

Spark

Dwell

Relay

Retract

Relay

Position

Hold Relay

Active

Relaxed

Active

Relaxed

Active

Relaxed

Retract ends when

Z = R-DIST or Z-TOP

which ever occurs first.

Electrode is de-energized*

Dwell time begins

when cut depth is

reached.

Active when ram is at

or below target depth.

Ram position is

monitored until retract.

The spark timer is

reset with each spark.

Sparkout time expires

Dwell time is interrupted

by sparkout condition.

Ram Position

Monitoring Begins

Retract begins when Spark

out time expires plus a

short delay of 100 ms.

Spark timer

begins when cut

depth is reached.

* The machine must be properly configured for the electrode to de-energize.

Page 34

READOUT SPECIFICATIONS

DRO 200E

30

Characteristic Specification

Operating conditions 0° to 40°C (32° to 104°F)

25% to 85% relative humidity (non-condensing)

Storage conditions -40° to 60°C (-40° to 140°F)

25% to 95% relative humidity (non-condensing)

Input requirements

Voltage: 115VAC or 230VAC (+/-20%), single phase

Frequency: 47-63 Hz

Current: 300ma @115V, 150ma @230V

Fuse 115V operation: ½ A, 250V, 3AG, Slo-blo

230V operation: ¼ A, 250V, 3AG, Slo-blo

Scale input Position signals: channels A& B

TTL square wave signal in quadrature

(90° nominal phase relationship)

Maximum input rate: 50 kHz

Reference signal: TTL square wave

Edge finder input Compatible with ACU-RITE Electronic Edge

Finder and First Spark Detector

Size 12.5"W x 5.125"D x 6.5H"

Weight 7.5 lbs.

Mounting Bottom: two ¼ -20 threaded inserts

Compliance FCC Class A

ETL

CSA

CE

Readout Specifications

Page 35

TROUBLESHOOTING

DRO 200E

31

Troubleshooting

This section is intended to provide you with some basic troubleshooting assistance with

your readout system. If you cannot correct the problem after following these instructions,

contact your authorized ACU-RITE distributor for repair or replacement procedures.

No Operation

If the readout display will not operate, check the following conditions:

• Check AC power source. If the readout cannot be powered up, confirm that line

voltage is present at the source and that the line voltage meets the required

specifications.

• Check power cord. Remove the power cord at the electrical input module on the

back of the readout. Determine if line voltage is present at this end of the cord.

• Check fuse. With the power cord removed, use a thin straight-blade screwdriver

to open the cover of the electrical input module. Refer to page 25. Slide out the

fuse holder and check the fuse. If necessary, replace it. Close the input module

cover by snapping it back into place, and reconnect the power cord.

NOTICE

If you turn power off, you must wait at least 5 seconds before

turning it back on, or the readout may not power up. This is

because the power supply, in order to withstand brief power

outages and brownouts, requires several seconds to reset

itself.

CAUTION

Only replace fuses with the specified type. Using

incorrect fuses can present a safety hazard. The

readout may also be permanently damaged. Refer

to the Readout Specification chart on page 30 for

the correct fuse.

Page 36

TROUBLESHOOTING

DRO 200E

32

Incorrect Operation

If system positioning does not seem to be repeatable, the problem could be with the

machine tool or with the readout system.

• Check linear scales. Check each scale and reading head for proper installation.

Ensure that the mounting brackets are secure. Verify repeatability of the reading head.

If the system seems to be displaying incorrect positions, check the following items.

• Verify presets. Make sure the numbers you enter are correct.

• Verify tool. Check that the correct electrode is being used. Check the electrode

for wear.

• Verify the scale factor. Ensure that the correct scale factor is being used.

• Verify linear error compensation. Make sure that the factors used for linear

error compensation are correct.

Diagnostics

Start Up Diagnostics

There are four diagnostic tests performed each time the readout is powered up.

These tests run without indication unless a problem is detected. If a problem is

detected, a message will be displayed at start up. The messages are as follows:

If you experience any of these error messages please contact your ACU-RITE distributor for assistance.

Operator-Performed Diagnostics

There are four operator-performed diagnostic tests to evaluate your readout. The

tests can be operated by holding the decimal key for two seconds. When the software version is displayed, you are in the Diagnostics mode.

Test

Key Pad Test

EEPROM Test

RAM Test

ROM Test

Error Message

“KEY STUCK R(#) N(#) - PRESS CLEAR

MEMORY FAILURE [1] - PRESS CLEAR

MEMORY FAILURE [2] - PRESS CLEAR

MEMORY FAILURE [3] - PRESS CLEAR

CAUTION

If any memory failure is indicated the readout cannot

be relied on for correct operation. The readout should

be serviced immediately.

Page 37

TROUBLESHOOTING

DRO 200E

33

To run the diagnostics:

• Press and hold the

.

key until the software version is displayed (i.e.

“V1.2.0”).

• Press the

X

key to continue.

Key Pad Test

As a key is held a “+” is displayed on the left side of the X-axis. When the key is

released the “+” will disappear. A count of the number of keys pressed will be displayed on the right side of the X-axis.

• Press any key, but

X

and observe the “+” to verify proper functioning.

• Press the

X

key to continue.

Display Test 1

All segments of the display are turned on. Carefully observe the display, checking

for any missing segments.

• Press the

X

key to continue.

Display Test 2

All decimal points on all displays are lit momentarily, then all “a” segments, then

all “b” segments. etc. This test allows you to look for segments that may have

shorted to those not in the same location as all of the others.

• Press the

X

key to continue.

Display Test 3

All segments of all 3 displays are lit one digit at a time starting from left to right.

This test allows you to look for digits that may have shorted together or for digits

that are not in the same location as all of the others.

• Press the

X

key to exit diagnostics and return to normal DRO functions.

Page 38

TROUBLESHOOTING

DRO 200E

34

Resetting Factory Defaults

In some cases, it may be advantageous to reset the readout factory default settings.

Doing this will cause all parameters to revert to the state they were in when the

readout left the factory. Once accomplished, it may be necessary to re-establish

certain parameters as needed for proper EDM functions.

To reset factory default settings:

1. Turn power off to the readout, wait 5 seconds and turn power on.

2. While the power off message is being displayed, press and hold the

M

key for

two seconds.

3. Press the

3

key.

4. Turn power off to your readout, wait 5 seconds and turn power on again.

Factory default settings have now been reset.

Other Error Messages

The readout includes built-in test and error-checking circuitry. This circuitry identifies errors that occur, and reports the problem to the operator. Errors are reported

by scrolling messages in the X-axis display.

Loss of power is indicated by the "POWER WAS OFF" message. Loss of power

means that power to the readout has been interrupted. Since power to the encoders

has also been interrupted, positioning information may no longer be accurate. Press

the

C

key to clear the error message. All display measurements will be zeroed.

Refer to page 4 for information about position recovery.

Counting errors are indicated by the "SCALE MISCOUNT" message, telling you

in which axis the miscount occurred. Counting errors result from distorted electrical

signals from a scale. These signals can be a result of an scale malfunction,

mis-alignment, mounting problems, or electrical interference. Press the Ckey

to clear the error message. The axis display (for both absolute and incremental measurements) will be zeroed. Follow these steps to determine if your difficulties are

associated with the readout or with the scale.

• Ensure that the linear scale connectors are correctly seated.

• Swap linear scale cables at the readout to see if the problem still appears in

the same display.

Page 39

TROUBLESHOOTING

DRO 200E

35

• If the problem remains in the same display, the readout is in error.

• If the problem follows the connection change, the linear scale may be in error.

Refer to the Checking the Linear Scales section of your scale reference manual.

Display overflow errors are indicated by dashes in all digits in an axis display. A

numeric overflow occurs when the intended measurement is too large for the eightdigit display. Clear the error by returning the machine table into an area where

measurements can again be displayed, selecting a lower display resolution, setting a

new preset, or zeroing the display.

This error may also occur when using the automatic compensation routine while

setting the LEC parameter. An error indicates that the calculated compensation factor was outside the acceptable range of -9999 to +9999, and usually is the result of

incorrectly entering data. Clear the error and return to the beginning of the linear

error compensation routine. Refer to page 19.

Data Logging

The readout collects information about itself while it is being used. This information

is stored in memory for review at a later time.

Press and hold the

.

key until the software version is displayed. Then press

the

S

and

M

keys simultaneously. Use the

X

key to cycle through the follow-

ing information.

Power on time - displayed in decimal hours.

Scale travel distance - the travel distance for each axis is scrolled one after the

other.

Last 3 errors - the most recent three errors are remembered and messages for the

errors are scrolled one after the other.

Page 40

Page 41

Loading...

Loading...