Page 1

User’s Manual

CSS I/O

English (en)

2/2010

A

®

CU-RITE

Page 2

Page 3

I General Information ..... 4

Connecting the CSS I/O to X101 (turning) ..... 4

I - 1 Execution of Switching Functions ..... 5

Switching inputs ..... 5

Switching outputs ..... 5

I - 2 Spindle Speed Control (RPM) ..... 8

Milling Systems ..... 8

Display ..... 8

Mill Spindle Installation setup ..... 9

Voltage Offset / RPM Source ..... 10

Voltage / RPM Setup ..... 11

Operation / Job Execution ..... 12

Mill Spindle Feature Run ..... 13

Mill Spindle Program Run ..... 13

I - 3 Controlling the Constant Surface Speed (CSS) ..... 14

Configuration of CSS ..... 15

CSS operating mode ..... 16

Activating the DAC output ..... 17

Connecting the CSS I/O to the inverter of the lathe ..... 18

I - 4 Diagnostics ..... 19

General Information ..... 19

Switching I/O functions ..... 19

CSS, and Mill Spindle ..... 20

CSS I/O 1

Page 4

2

Page 5

Operating Instructions

CSS I/O 3

Page 6

General Information

Connecting the CSS I/O to X101 for executing switching functions (milling) or controlling the constant surface speed CSS (turning)

When the CSS I/O is connected to DRO’s that support this feature, the

functionality described above are available. Contact an authorized

Acu-Rite product distributor for more information.

The DRO automatically recognizes when the CSS I/O is connected and

displays the CSS SETUP option or the SWITCHING OUTPUTS option in the

INSTALLATION SETUP menu. These options can be used to configure all

functions of the switching unit.

General Information

4 I Operating Instructions

Page 7

I - 1 Execution of Switching

Functions

If you want to use both the CSS I/O and the KT 130 edge finder at the

same time, or if you want to transmit measured values via the external

switching output, the distribution cable with ID 593761-01 is required.

Switching inputs

The CSS I/O provides four inputs that are used to zero the actual value

of the assigned axis. A low-to-high transition at the input causes the

value for that axis to be set to zero.

Switching outputs

The switching outputs consist of integrated relays available for generic

usage. The number of switching outputs available is dependent on the

configuration options chosen. When the system is configured for a

Mill, and the spindle speed control (RPM) is disabled, 8 switching

outputs are available. If RPM is enabled, then only 5 switching outputs

are available. See "Spindle Speed Control (RPM)" on page 8.

When the system is configured for a Lathe, and the constant surface

speed (CSS) is disabled, 8 switching outputs are available. If CSS is

enabled, then only 5 switching outputs are available. See "Controlling

the Constant Surface Speed (CSS)" on page 14.

I - 1 Execution of Switching Functions

The switching outputs are activated depending on “position”. The

relays can be configured to activate when a position display reaches a

specific value, or within a specified range of zero. The ninth output

relay indicates readiness.

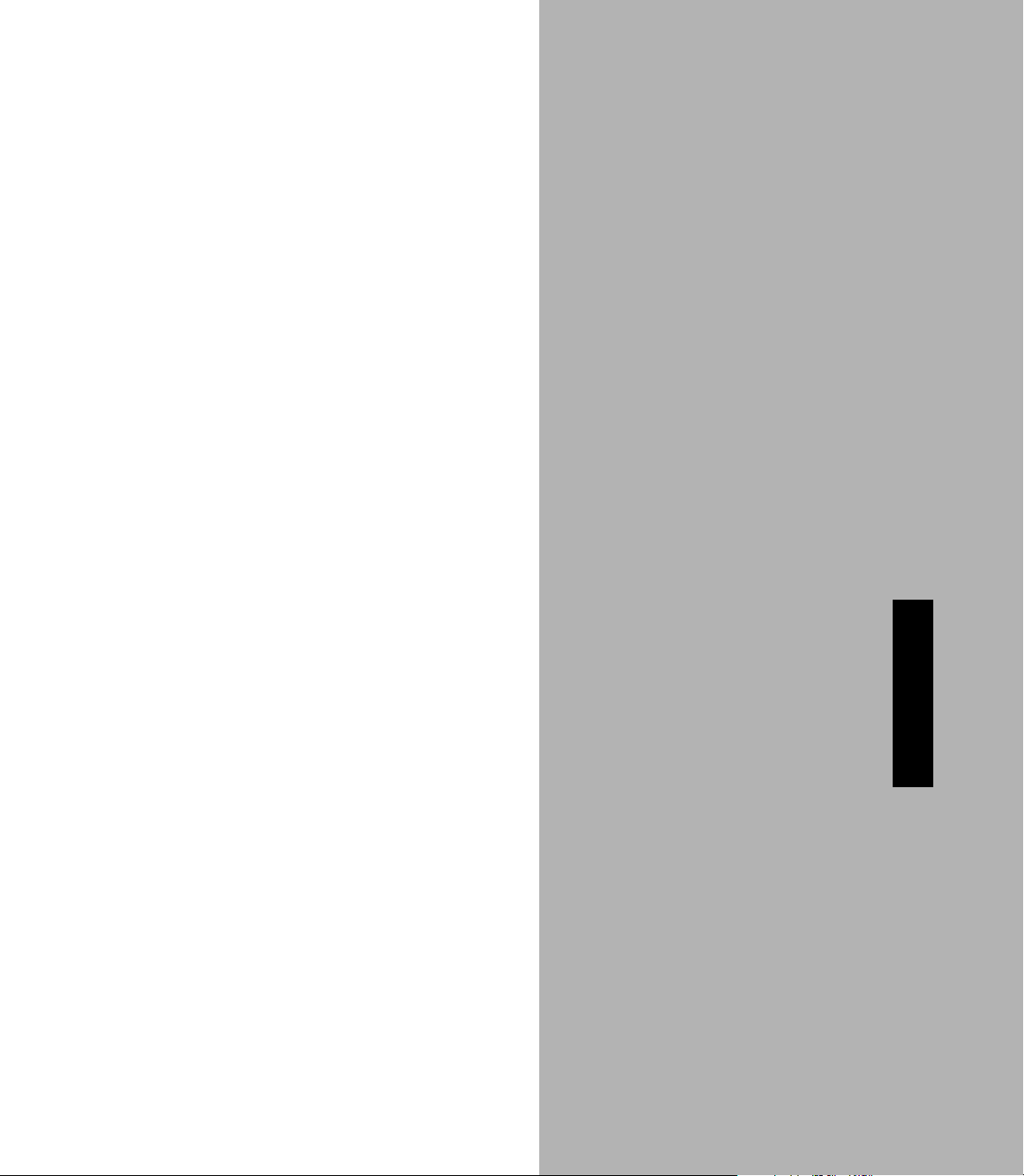

Select SWITCHING OUTPUTS from the INSTALLATION SETUP menu

to open the SWITCHING OUTPUTS table in which the configuration of

the outputs are stored. If you want to change the configuration of an

output, select it with the arrow keys, and press ENTER to confirm your

selection. This opens the OUTPUT SETTINGS form in which you

define the switching conditions. To reset a relay, select the relay in the

table and press the CLEAR RELAY soft key, followed by the YES soft

key for confirmation.

CSS I/O 5

Page 8

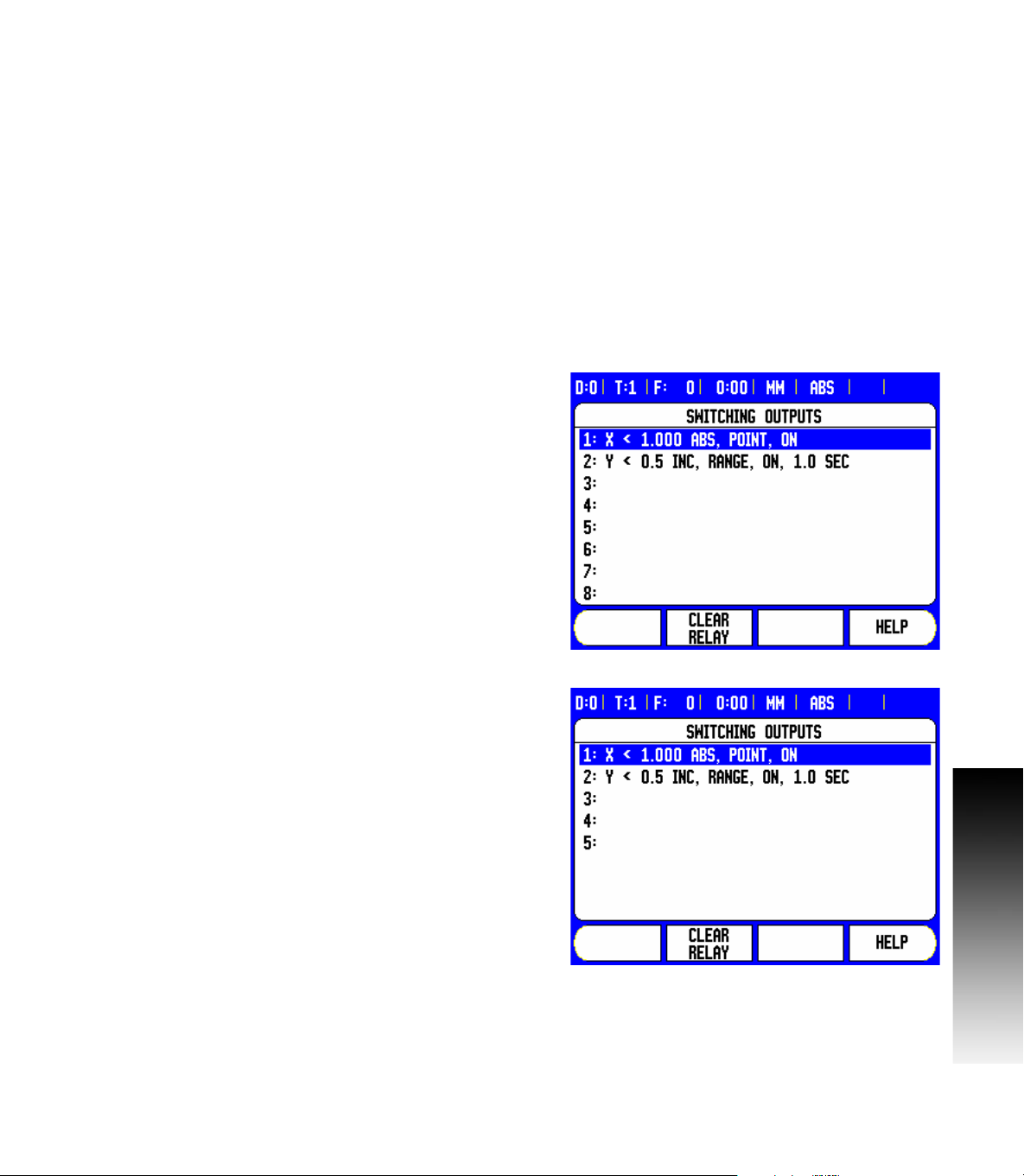

8 The CONDITION field is used to assign an axis to the output and to

specify whether the axis position is an actual-value or distance-to-go

position. You also specify the position display value at which the

relay is activated, and the required condition.

8 The POINT/RANGE field is used to define whether the conditions

refers to a point on the axis or refers to a range about zero.

8 The OUTPUT field is used to specify the relay operation when the

switching condition is met. When the condition is met, the relay is

turned OFF or ON.

If the condition is set to equal, the relay will activate

momentarily even if the switching point is crossed over too

quickly for the value to appear.

Possible switching states of the relays.

I - 1 Execution of Switching Functions

6 I Operating Instructions

Page 9

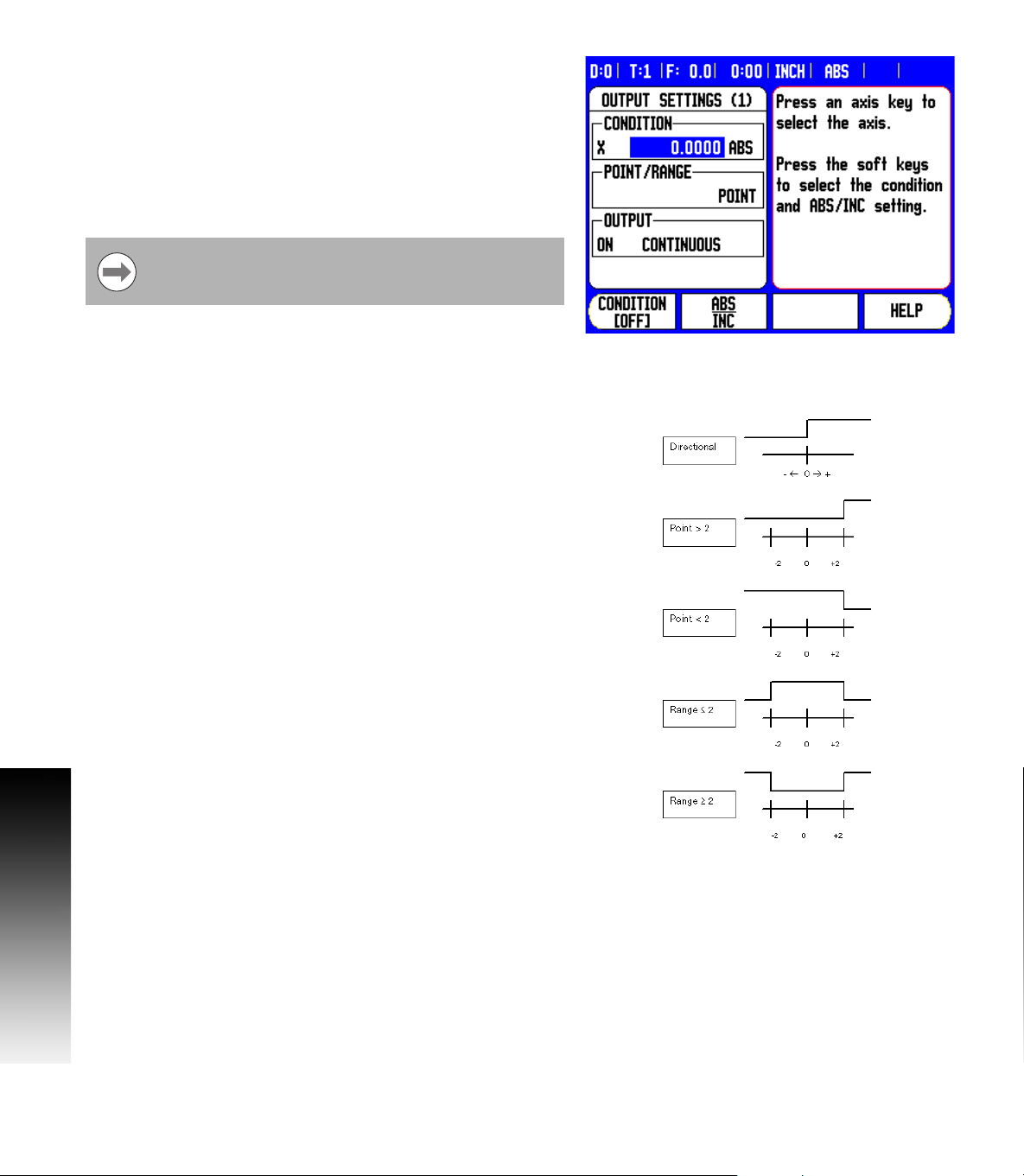

In PULSED mode, the relay is activated (ON or OFF) for a specific

period of time. After the period has timed out, the relay is deactivated.

The pulse time is 0.1 to 999 seconds.

Continuous mode shown:

The time period begins whenever the switching condition

transitions from FALSE to TRUE. If the switching conditions

transitions to TRUE before the period has timed out, the

timer will start over.

The switching functions cannot be used for coupled axes or

for axes with backlash compensation.

Relay

Condition

Pulsed mode shown:

Relay

Condition

I - 1 Execution of Switching Functions

CSS I/O 7

Page 10

I - 2 Spindle Speed Control (RPM)

Milling Systems

The Mill Spindle Speed Control is for milling systems only, and

provides an open loop spindle speed control.

The spindle speed control requires the CSS I/O box.

The spindle speed control is only available for milling

systems. If the DRO is configured for a turning system,

then no Spindle Settings will be displayed.

8 Define the last axis as a rotary encoder axis.

I - 2 Spindle Speed Control (RPM)

Display

8 Define the display as a speed display.

8 I Operating Instructions

Page 11

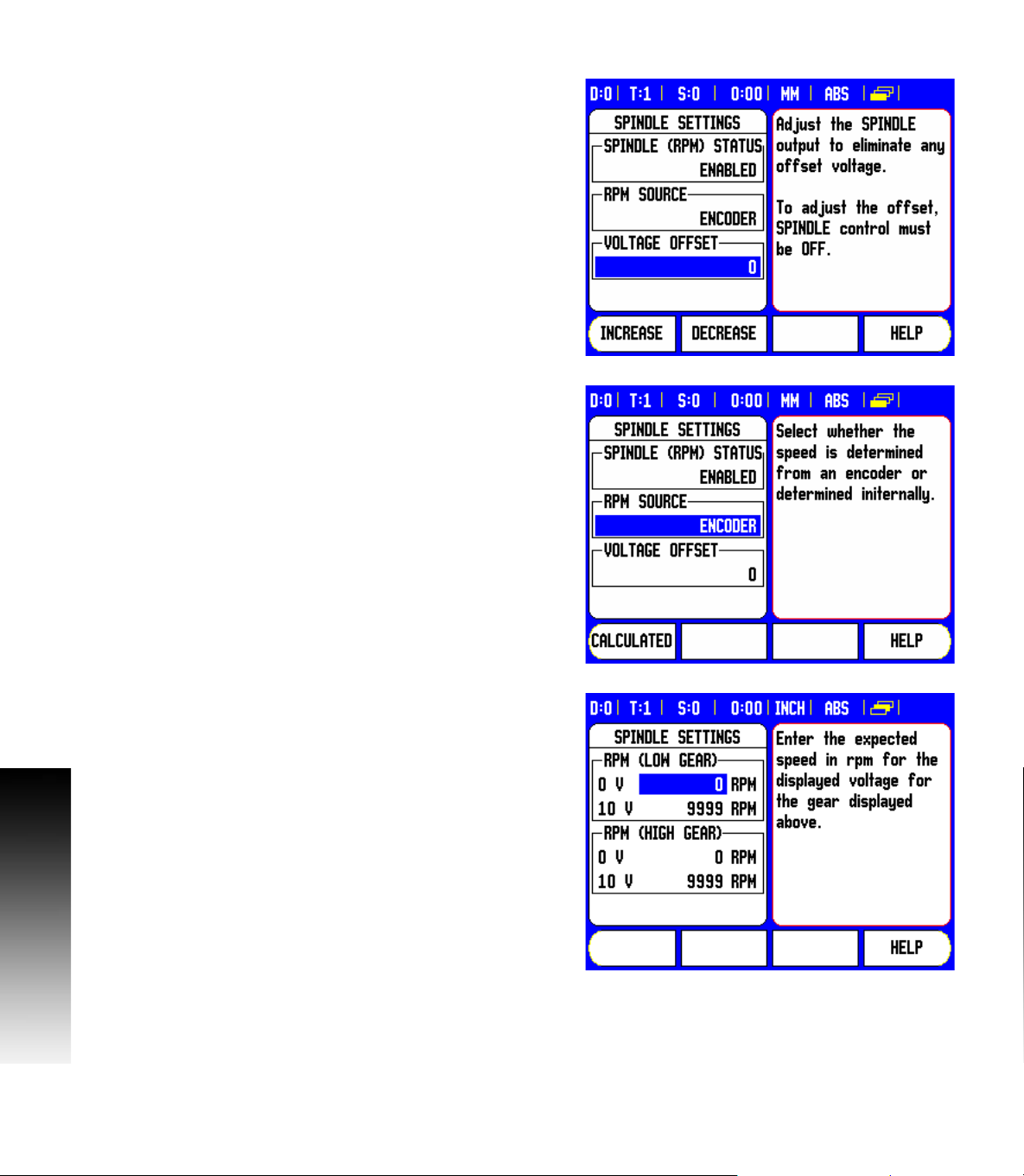

Mill Spindle Installation setup

The configuration parameters are found under Installation Setup. The

Spindle Settings only appear in the list if the CSS I/O box is detected.

8 Select Spindle Settings from the Installation Setup menu, and press

the ENTER key.

The spindle (RPM) status field allows the user to enable, or disable the

spindle (RPM) fuctionality. If it is disabled, then no spindle (RPM)

operations are available for usage. If the spindle (RPM) is enabled,

then all of the following setup must be completed. Six (6) generic

switching outputs will then be available.

I - 2 Spindle Speed Control (RPM)

CSS I/O 9

Page 12

Voltage Offset / RPM Source

The voltage offset field is used to adjust for any inherent offset in the

DAC output. This value is added to the calculated DAC output. Use

a voltmeter to measure the actual voltage at the DAC output. Press

the INCREASE, or DECREASE soft key to adjust the offset until the

output is 0 V. The offset range is limited to 0 - 50, (approximately

0 - 122 mV).

8 Press ENTER to save the settings, and exit the form, or press the C

key to exit without saving the changes.

The RPM source allows the user to define whether the RPM source is

from an actual rotary encoder, or calculated by the software as a

replacement for a rotary encoder.

User speed limits can be established to limit how fast, or slow the

spindle may be run. These are run time limits, and must fit in within

I - 2 Spindle Speed Control (RPM)

the actual hardware limits.

8 Press ENTER to save the settings, and exit the form, or press the C

key to exit without saving the changes.

When in Setup mode, the status bar will display the current spindle

speed in RPM’s shown in the S: field on the status bar.

To set a specific spindle speed, the DAC output S

relationship to determine the corresponding output voltage V

V

= 10 • (S

Out

- S0) / (S10 - S0) + V

Out

Offset

uses this linear

Out

Out

:

Press ENTER to save the parameters and exit the input form. Press

the C key to exit without saving the changes.

These are the physical limits of the machine.

10 I Operating Instructions

Page 13

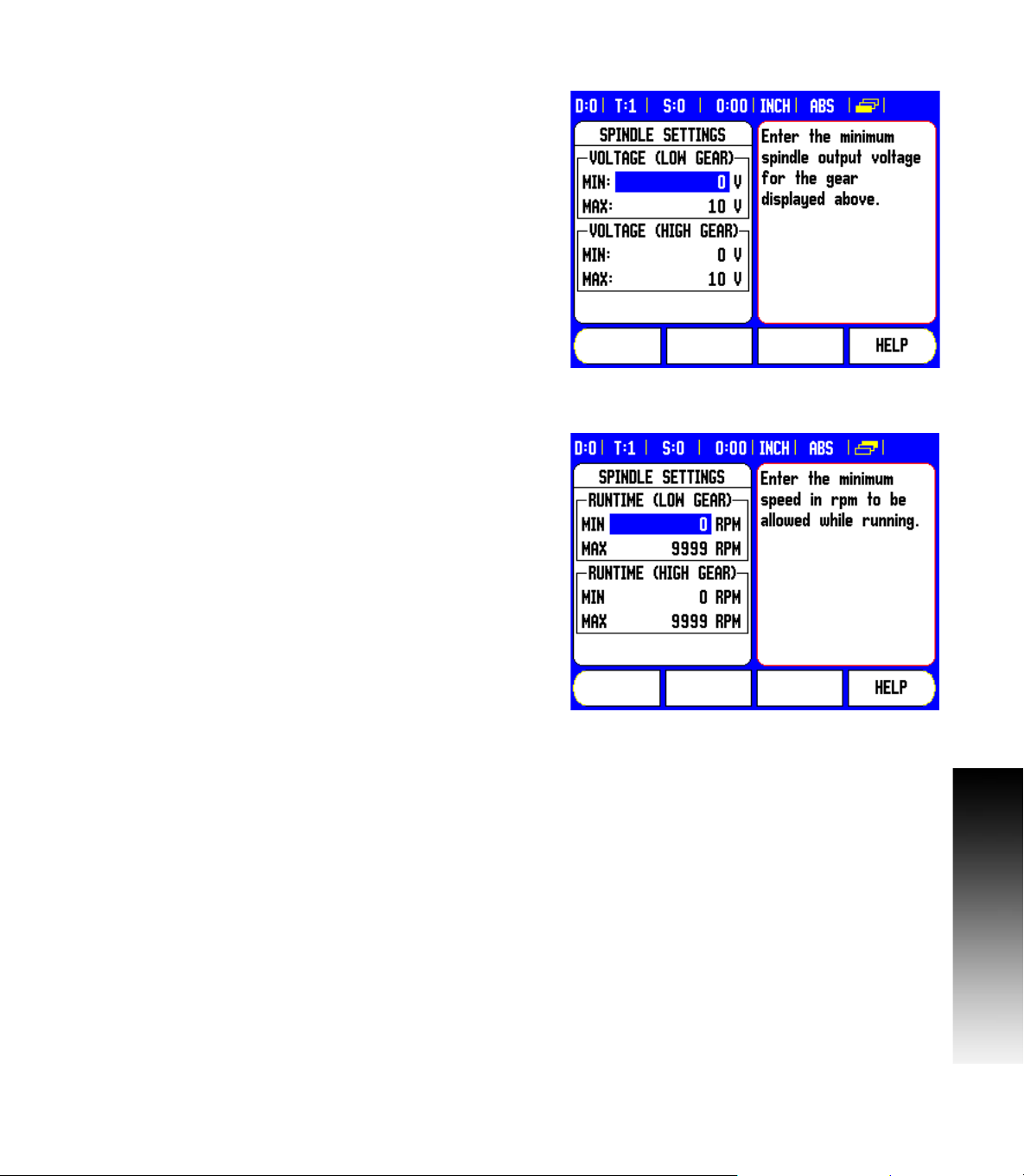

Voltage / RPM Setup

The voltage setup fields are used to establish the relationship

between the DAC output signal (0 - 10 V), and the spindle speed for

each gear.

8 Enter min, and max voltage levels for each gear.

8 Press ENTER to save the settings, and exit the form, or press the C

key to exit without saving the changes.

This screen allows the spindle to have min, and max RPM settings

defined. This limits the spindle not to exceed the limits set at start up.

The spindle speed can then be manually increment above the “Run

Time” limits.

8 After selecting Spindle Settings from the Installation Setup menu,

use the RIGHT or LEFT arrow hard keys to scroll to this menu.

I - 2 Spindle Speed Control (RPM)

CSS I/O 11

Page 14

Operation / Job Execution

The operation of the Mill Spindle is associated with the use of the

selected tool from the tool table, and the spindle parameters for

running the tool.

Refer to the DRO User’s Manual for setting up, and using a tool from

the tool table.

8 Select the desired tool from the tool table.

8 Press ENTER to open the tool setup form.

Press the RPM calc key to specify a surface speed, and get a resultant

RPM spindle speed that is automatically loaded into the tool table

when exiting the RPM calc.

I - 2 Spindle Speed Control (RPM)

12 I Operating Instructions

Page 15

A tool can be run from the tool table, or by pressing enter after defining

the spindle parameters for a tool.

Mill Spindle Feature Run

With all tool, job, and installation setups entered, the Mill Spindle job

can be run by toggling the Spindle ON/OFF soft key.

Select the tool to be used, and the required gear.

The spindle speed can be adjusted using the SPEED +/- soft keys.

Mill Spindle Program Run

Mill Spindle can be used within a program for any program step that

has a mill spindle tool defined for that step.

When in program run, if the SPINDLE: Direction, and Speed fields are

defined for the tool, the operator can use the LEFT, or RIGHT ARROW

keys to display the Spindle control soft keys. When these fields have

not been defined, the Spindle control soft keys are not available.

To go back to the program control screen from the mill spindle control,

press the LEFT, or RIGHT ARROW keys.

The speed of the mill spindle can also be adjusted while in the program

control screen by pressing the SPEED +/- soft keys.

I - 2 Spindle Speed Control (RPM)

CSS I/O 13

Page 16

I - 3 Controlling the Constant

Surface Speed (CSS)

In CSS mode, a constant surface cutting speed can be maintained on

a lathe. The following functions are available:

CSS mode: The DAC output signal provides constant surface speed

by adjusting the spindle speed as the diameter (radius) of the

workpiece changes.

Direct entry of spindle speed: The DAC output signal sets the

spindle speed based on the value entered via the numeric keypad.

Speed limits: The user may set a safe operating range (minimum

and maximum speeds) for spindle speed.

Gear selection: Three different gears can be specified for varying the

relation between the actual speed and the DAC output signal.

The READY output (X103-12) is active when the readout has

recognized the CSS I/O hardware, is monitoring the inputs, and is

controlling the output relays. If the CSS I/O detects a

communications error with the readout, the READY relay will be deenergized.

The CSS setting screen provides a choice between

STANDARD, LIMITED or DISABLED mode. This setting

should always be set to STANDARD mode.

When the CSS status field is set to disabled, then no CSS functionality

is available. Eight (8) generic switching outputs are available for

useage. When STANDARD, or LIMITED is selected, then the

remaining setup options must be completed. Only 5 generic

switching outputs will be available for usage.

I - 3 Controlling the Constant Surface Speed (CSS)

14 I Operating Instructions

Page 17

Configuration of CSS

To use the CSS functionality, the last axis must be defined as a rotary

axis. Define the display as a speed display, and configure them

accordingly. The spindle control configuration parameters are set up

in the INSTALLATION SETUP menu.

8 Select the CSS SETTINGS parameter to open the associated input

form

8 The CSS ON/OFF CONTROL field is used to specify whether the

CSS mode is operated by soft key or by an external hardware signal.

8 The current gear may be selected by local control (MANUAL via

CSS / DIRECT RPM in the JOB SETUP menu) or remote control

(EXTERNAL; via switches in the machine gear). This is defined in the

CSS GEAR SELECT field.

8 The VOLTAGE OFFSET function is used to adjust for any inherent

offset in the DAC signal. Using a voltmeter, measure the actual

voltage at the DAC output. Press INCREASE or DECREASE to adjust

the offset until the output is 0 V. The offset range is limited from 0

to 100 (approximately 0 to 244mV).

8 The VOLTAGE / RPM fields are used to establish the relationship

between the DAC output signal (0 to 10 V) and the spindle speed.

The minimum and maximum limits for each gear are entered.

If the position display of the third axis is configured to be used for the

spindle speed, the rpm in the SETTING field can be set to the current

spindle speed by pressing the TEACH soft key.

To set a specific spindle speed, the DAC output S

relationship to determine the corresponding output voltage V

V

= 10 · (S

Out

- S0) / (S10 - S0) + V

Out

Offset

Press ENTER to save the parameters and exit the input form. Press

the C key to exit without saving the changes you made.

uses this linear

Out

Out

:

CSS I/O 15

I - 3 Controlling the Constant Surface Speed (CSS)

Page 18

CSS operating mode

The operating parameters are set in the CSS / DIRECT RPM form.

8 Press the CSS SETUP soft key to open the form or select the

parameter from the JOB SETUP menu.

The SETTINGS field is used to select the mode of operation and the

control settings. The spindle is controlled by selecting CSS or by

entering the spindle speed directly. The values to be entered depend

on the selected option.

If CSS was selected to maintain a constant surface speed, the surface

speed entered with the numeric keys is maintained. As the diameter

of the part changes, the spindle speed will be adjusted.

8 To set a specific spindle speed, select DIRECT / RPM and enter the

value with the numeric keypad.

8 If the position display of the third axis is configured to be used for

the spindle speed, the rpm in the SETTING field can be set to the

current spindle speed by pressing the TEACH soft key.

8 Select OFF when spindle control is not needed.

8 The GEAR SELECTION field is used to manually enter the operating

gear with the numeric keypad.

If the gear control parameter in INSTALLATION SETUP is

set to EXTERNAL, the field will show the current gear

selection based on the external inputs. The field can then

not be selected and is skipped.

8 The LIMITS field is used to establish the minimum and maximum

limits of the controlled spindle speed. When operating in the CSS or

DIRECT RPM modes, the DAC output will not be set to a speed

above or below these limits.

8 Press ENTER to save the parameters and exit the input form. Press

I - 3 Controlling the Constant Surface Speed (CSS)

the C key to exit without saving the changes you made.

The “Spindle Speed” will default to the OFF position when ever the

Readout power is cycled, and the run mode must be reselected to

use. No settings are lost when power is cycled. The Max RPM field

is discarded between runs in Limited mode only, requiring to teach

a new max RPM each time.

16 I Operating Instructions

Page 19

Activating the DAC output

After selecting the operating mode and entering its parameters, the

DAC output must be enabled to begin controlling the spindle.

The output to the spindle inverter drive is an open loop signal. The

system does not monitor the actual spindle speed. The output signal

is based solely on the inverter's speed input versus the input voltage

profile.

8 Depending on the operating mode selected, the RPM or CSS soft

key is displayed on the fourth page of the soft key menu. If the

current state indicated on the soft key is ON, the DAC output is

active. Press the soft key to OFF to disable the spindle control.

If CSS is active, the CSS icon appears next to the X-axis display. If the

entered surface speed or rpm cannot be maintained because the

speed is outside the range for the current gear or outside the limits

from the CSS/RPM SETTINGS form, an arrow will appear after the

CSS icon ( or ). The direction of the arrow indicates

whether the speed is at the upper or lower limit.

The soft key to enable CSS or RPM control will not appear

if the operating mode is set to OFF.

If the CSS control parameter under INSTALLATION SETUP

is set to EXTERNAL, the CSS or RPM operation cannot be

controlled by soft key. The soft key will show the current

state, but pressing it will have no effect.

The SPEED + and SPEED – soft keys are used to increase or decrease

the current surface speed or spindle speed. The value is increased or

decreased by 5% each time the soft key is pressed.

I - 3 Controlling the Constant Surface Speed (CSS)

CSS I/O 17

Page 20

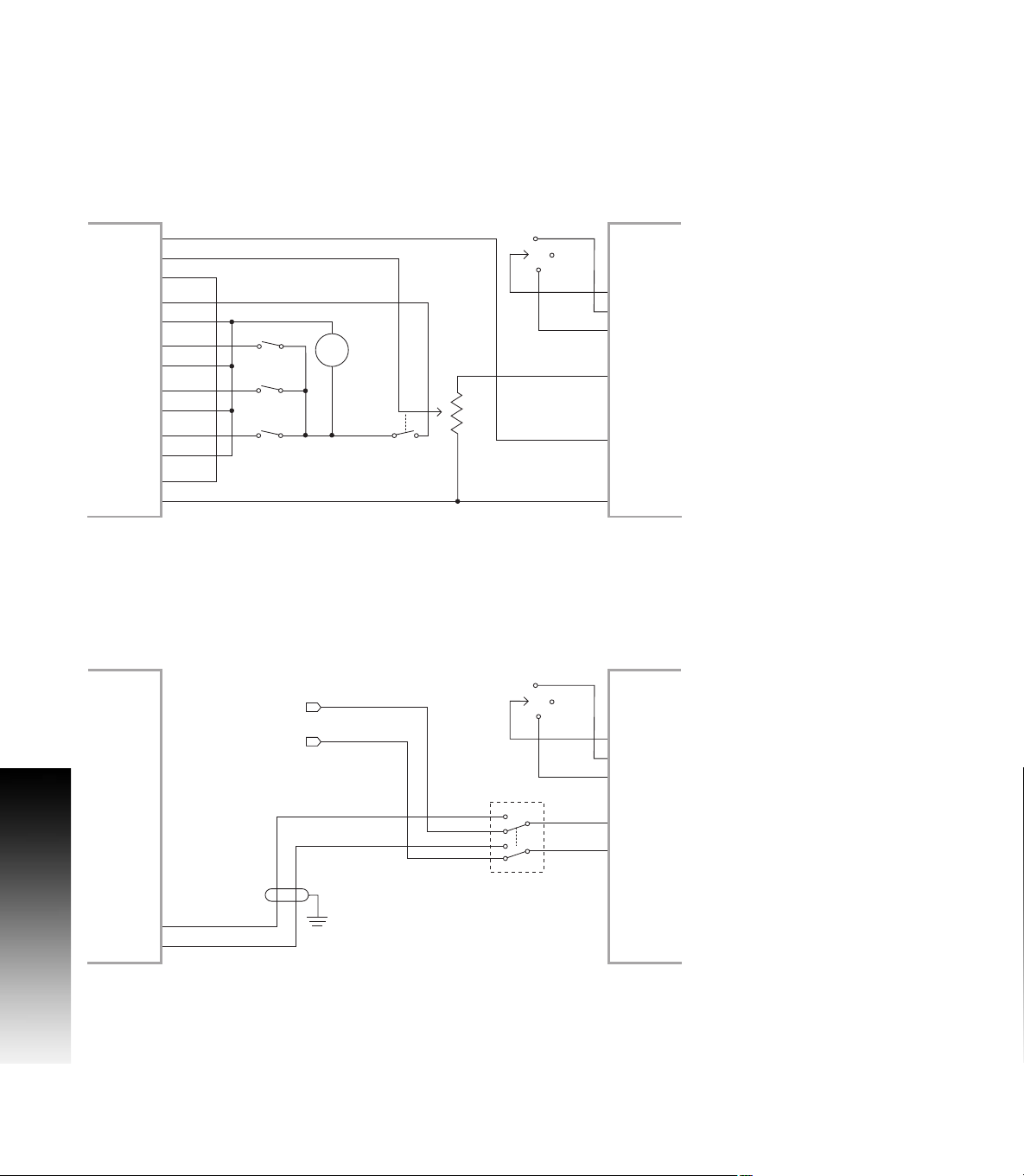

Connecting the CSS I/O to the inverter of the

X1039

X10310

X10311

X1021

X1022

X1023

X1024

X1025

X1026

X1027

X1028

X10211

X10212

MANUAL

RPM

+

1224 VDC

100 mA

OFF

FORWARD

REVERSE

ANALOG SUPPLY

ANALOG INPUT

ANALOG COMMON

TURNING APPLICATION 1Automatic CSS/Pot Control

CSS I/0 INVERTER

DAC OUT

COMMON

GEAR 1

GEAR 2

GEAR 3

OUT 789

OUT 7

OUT 8

IN 0

IN 0+

IN 1

IN 1+

IN 2

IN 2+

IN 3

IN 3+

FWD

REV

INPUT+COMMON

X1039

X10310

X10311

OUT 789

OUT 7

OUT 8

X1021

IN 0

X1022

IN 0+

X1023

IN 1

X1024

IN 1+

X1025

IN 2

X1026

IN 2+

X1027

IN 3

X1028

IN 3+

X10211

X10212

DAC OUT

COMMON

CSS/pot Selector

CSS I/0 INVERTER

FWD

REV

OFF

INPUT+COMMON

FORWARD

REVERSE

ANALOG INPUT

ANALOG COMMON

V ref.+

V ref.

Pot on machine

TURNING APPLICATION 2Manual CSS/Pot Control

lathe

Example of gear detection and switching to manual spindle speed

control

I - 3 Controlling the Constant Surface Speed (CSS)

Example of switching to manual spindle speed control

18 I Operating Instructions

Page 21

I - 4 Diagnostics

General Information

When the CSS I/O box is connected to the DRO, the DIAGNOSTICS

menu under INSTALLATION SETUP provides further diagnostic

possibilities. The information available varies depending on the

configuration of the system, Switching I/O, CSS, or Mill Spindle

functions.

Switching I/O functions

The SWITCHING I/O DIAGNOSTICS shows the status of the

communication via the CAN bus and the state of the switching inputs

and outputs to provide monitoring of the switching functions.

The CAN STATUS field shows the state of the bus communication

between the DRO and the CSS I/O.

The status information has the following meaning:

Information Meaning

NOT PRESENT No communication with hardware

NOR Communication – normal operation

CAL Communication – Hardware in calibration

mode

Wen Watchdog active

Wds Watchdog inactive

Wto Watchdog time-out

Tx Data is transmitted to hardware

Rx Data is received by hardware

I - 4 Diagnostics

The SWITCHING I/O field shows the state of the inputs and the switch

position of the relays.

All currently active inputs (1 to 3) are shown in the ON field.

All currently active relay outputs (1 to 9) are shown in the OFF field.

The CALIBRATE soft key is used to re-synchronize the communication

with the CSS I/O. This, however, is only required if the module is not

detected upon power on.

CSS I/O 19

Page 22

CSS, and Mill Spindle

CSS / MS DIAGNOSTICS shows the status of the communication via

the CAN bus and the state of the DAC output to provide monitoring of

the interfaces for operation with constant surface speed, (or Mill

Spindle). The state of the switching inputs and outputs is also shown.

The CAN STATUS field shows the state of the bus communication

between the DRO, and the CSS I/O, (or Mill Spindle and I/O).

The status information has the following meaning:

I - 4 Diagnostics

Information Meaning

NOT PRESENT No communication with hardware

NOR Communication – normal operation

CAL Communication – Hardware in calibration

mode

Wen Watchdog active

Wds Watchdog inactive

Wto Watchdog time-out

Tx Data is transmitted to hardware

Rx Data is received by hardware

The DAC OUTPUT field shows the current value of the transmitted

voltage. The value is between 0 and 4095, which corresponds to a

voltage of 0 to 10 V at X102-11. The corresponding CSS icon will be

displayed if the spindle speed is at the upper or lower limit ( or

).

The CSS INPUT/OUTPUT field shows the state of the switching

inputs, and relay outputs.

20 I Operating Instructions

Page 23

For CSS only, the MS INPUT/OUTPUT field shows the state relay

outputs. The IN: field of the switching inputs is not used, and will be

blank.

The status information has the following meaning:

Information about

the inputs

EXT External switch is active (X102-12)

G1 Switch for gear 1 is active (X102-3,4)

G2 Switch for gear 2 is active (X102-5,6)

G3 Switch for gear 3 is active (X102-7,8)

The following table applies to both CSS, and RPM.

Information about

the outputs

POT Potentiometer relay is active (X102-10)

DAC DAC output relay is active (X102-11)

The CALIBRATE soft key is used to re-synchronize the communication

with the CSS I/O. This, however, is only required if the module was not

detected at switch-on.

Meaning

Meaning

I - 4 Diagnostics

CSS I/O 21

Page 24

I - 4 Diagnostics

22 I Operating Instructions

Page 25

A

Activating the DAC output ... 17

C

Configuration of CSS ... 9, 15

Connecting the CSS I/O to the inverter

of the lathe ... 18

Connecting the CSS I/O to X101 ... 4

Controlling the constant surface speed

(CSS) ... 8, 14

CSS ... 20

CSS DIAGNOSTICS ... 20

CSS operating mode ... 16

D

Diagnostics ... 19

E

Execution of switching functions ... 5

G

General Information ... 4, 5

M

Mill Spindle Installation setup ... 9

Mill Spindle Job Run ... 13

O

Operation / Job Execution ... 12

Index

R

Relay status ... 6

S

Spindle Speed Control (RPM) ... 8

SWITCHING I/O DIAGNOSTICS ... 19

Switching I/O functions ... 19

Switching inputs ... 5

Switching outputs ... 5

V

Voltage / RPM Setup ... 11

Voltage Offset / RPM Source ... 10

CSS I/O 23

Page 26

Index

Page 27

Page 28

HEIDENHAIN CORPORATION

333 East State Parkway

Schaumburg, IL 60173-5337 USA

+1 (847) 490-1191

+1 (847) 490-3931

E-Mail: info@heidenhain.com

www.heidenhain.com

638296-22 Ver 00 Printed in USA Subject to change without notice 02/2010

Loading...

Loading...