Page 1

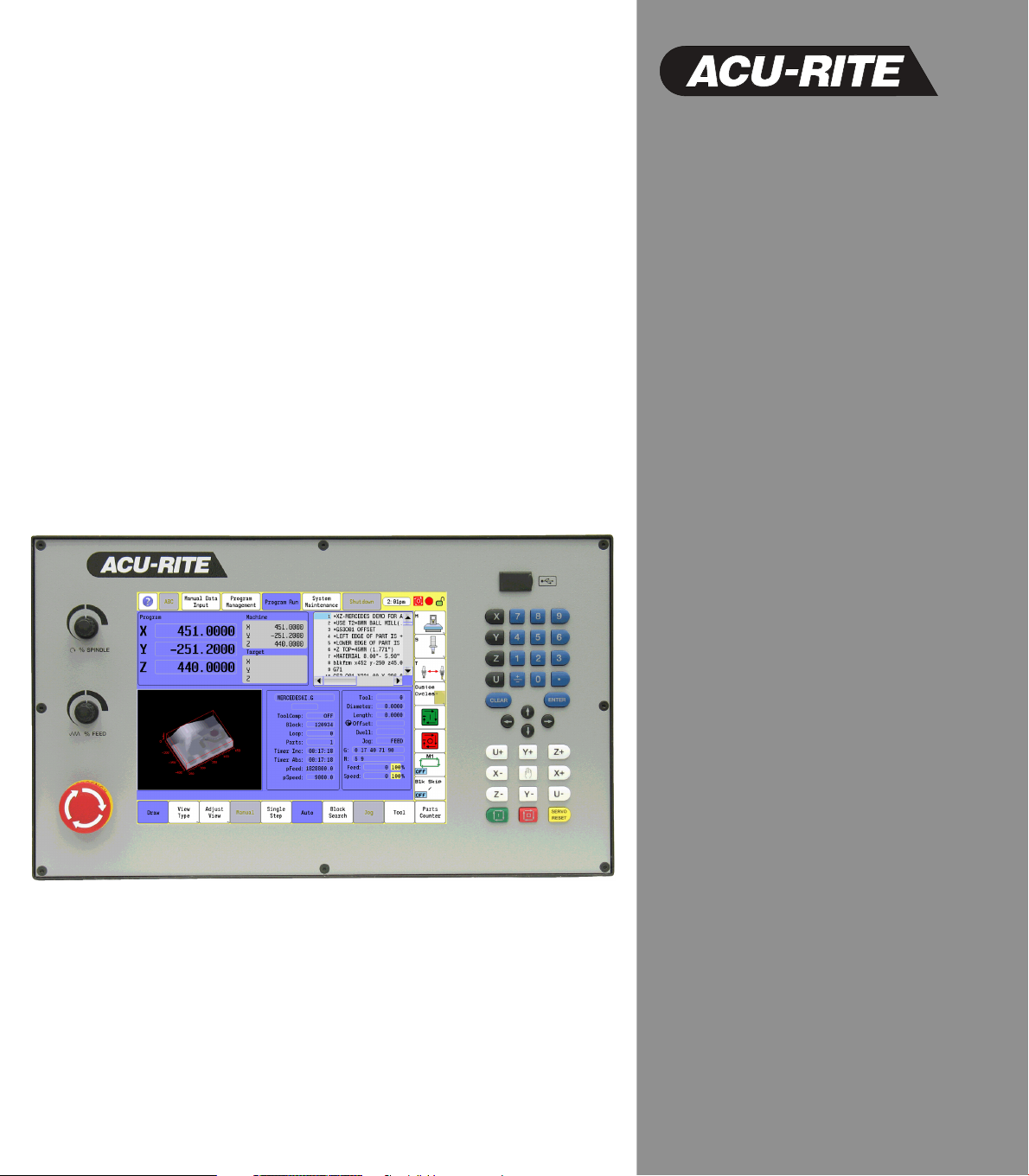

User’s Manual

Conversational and g-code

CNC 3500i

Page 2

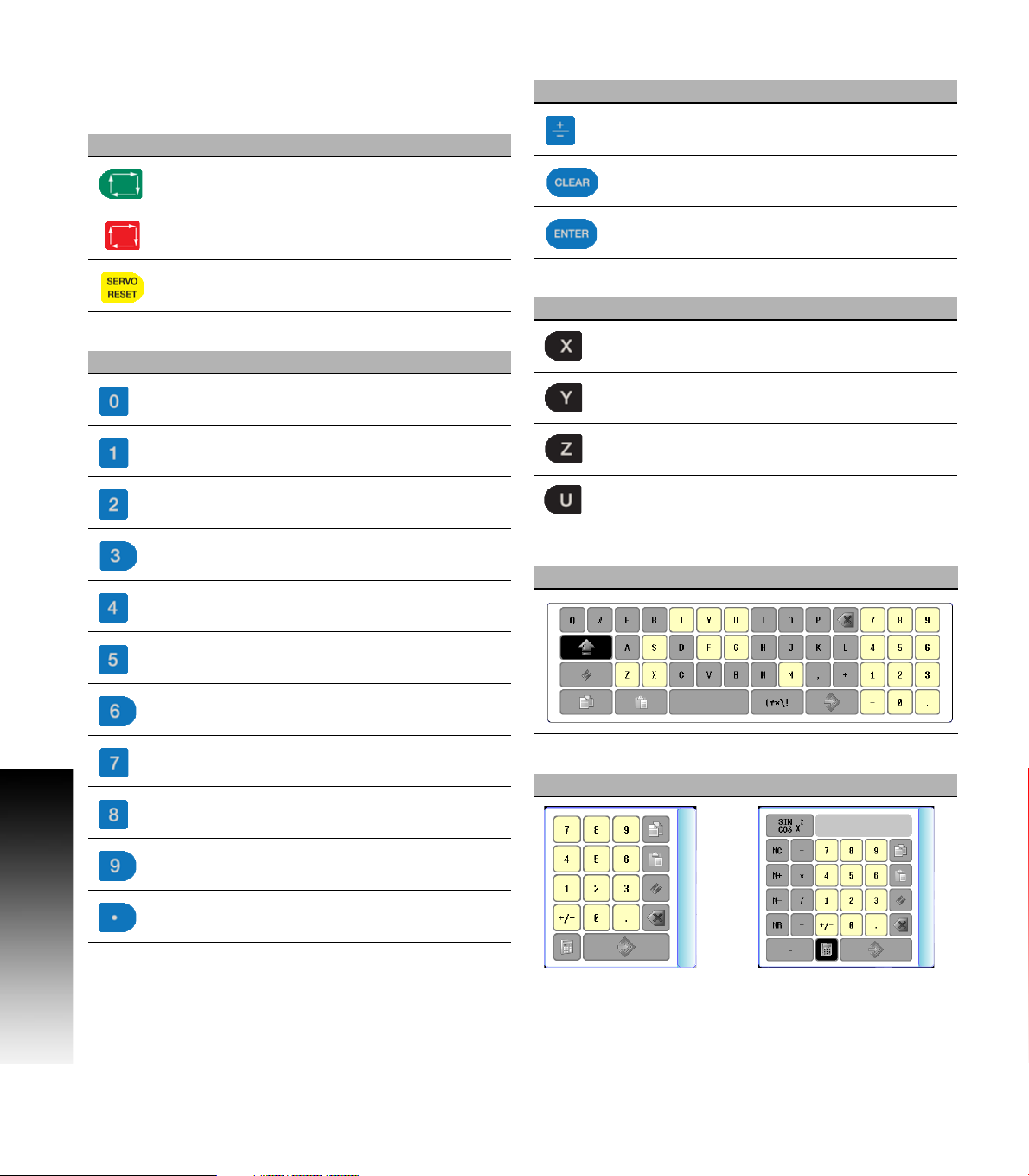

Controls of the 3500i

Keys on visual display unit

Power control keys

Key Function

Data Entry keys

Key Function

Plus - Minus toggle key

Controls of the 3500i

Numerical keys

Key Function

NC Start key (i.e. run a program)

Stop key (i.e. stop a program)

Servo Reset activates servo motors

Zero key

One key

Two key

Three key

Four key

Five key

CLEAR key clears selections, i.e. values,

ENTER key activates selections, and

entries

Axis Keys

Key Function

X Axis

Y Axis

Z Axis

U Axis

Touch QWERTY keyboard

Key Board

Six key

Seven key

Eight key

Nine key

Decimal key

ii

Numeric Touch Pad(s)

Numeric Pad Calculator Pad

Page 3

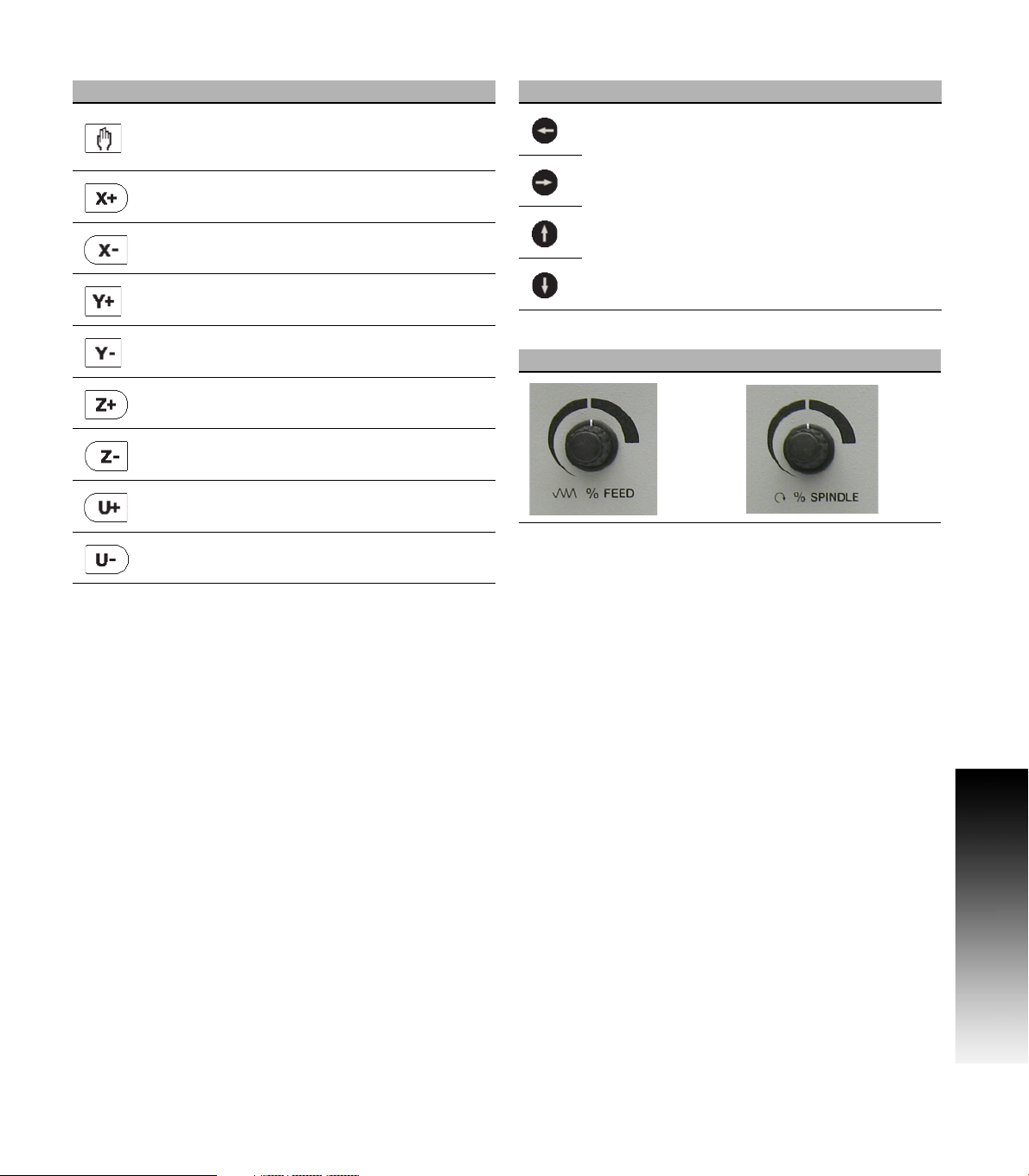

Axis Jog keys Navigation keys

Key Function

JOG Cycles the CNC through manual

movement modes: RAPID JOG, JOG

FEED, JOG @ 100, JOG @ 10, JOG @ 1

Manually moves X+ axis in positive

direction

Manually moves X- axis in negative

direction

Manually moves Y+ axis in positive

direction

Manually moves Y- axis in negative

direction

Manually moves Z+ axis in positive

direction

Manually moves Z- axis in negative

direction

Manually moves U+ axis in positive

direction

Manually moves U- axis in negative

direction

Key Function

ARROW over, up, down to move highlight

Potentiometer for feed rate and spindle speed override

Feed rate Spindle speed

Controls of the 3500i

ACU-RITE 3500i iii

Page 4

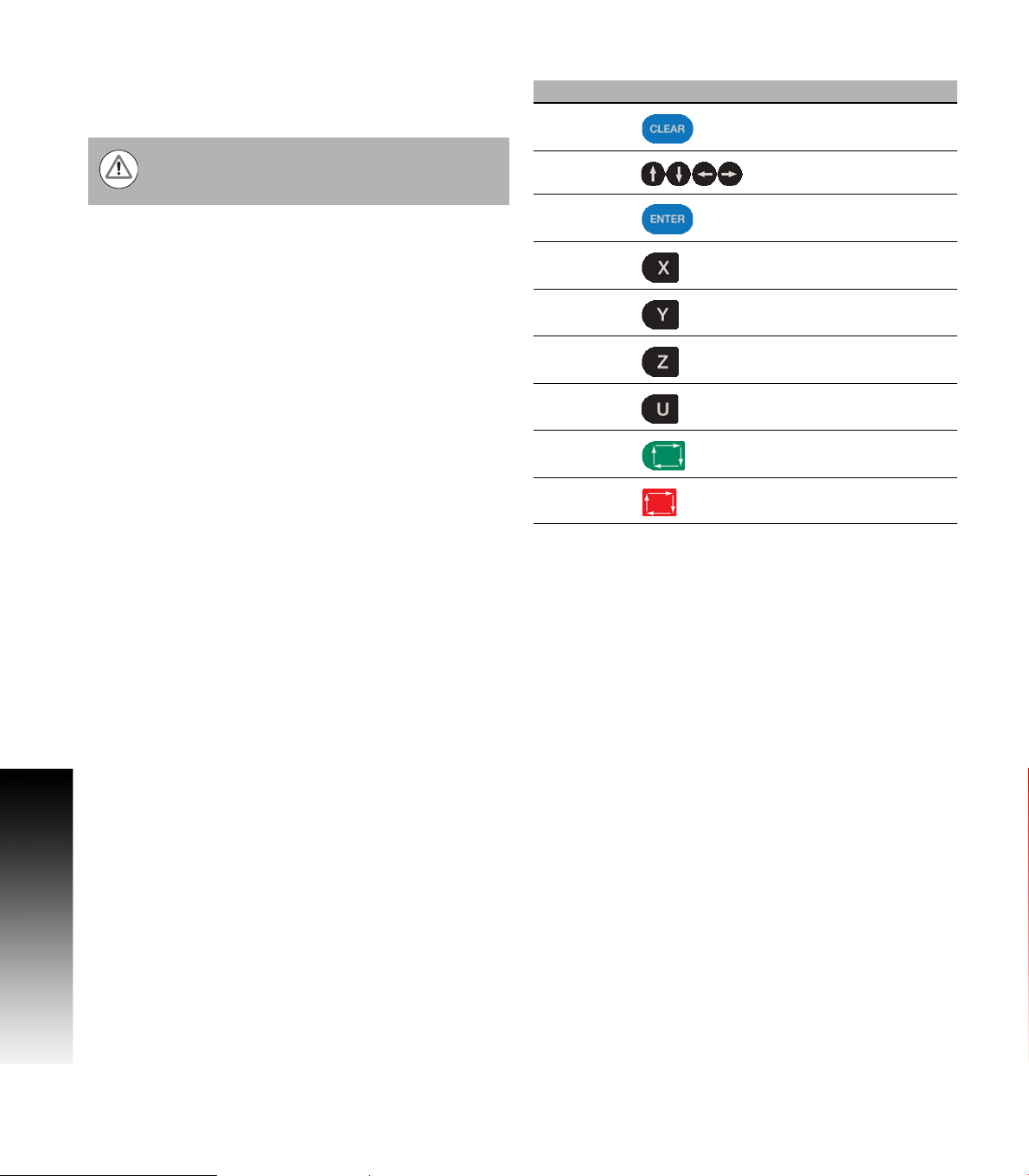

Keyboard Installation

The machine builder determines whether the system

supports a keyboard option. If this option is supported, plug

a USB keyboard into the 3500i.

There is no keyboard equivalent for the E-STOP,

so emergency shutdowns cannot be performed

through the keyboard.

Peripherals Supported:

USB memory devices; e.g. a memory stick.

USB pointing devices; e.g. a mouse.

USB Keyboards.

Controls of the 3500i

Keyboard Equivalent Key Strokes

Key Function

CLEAR Alt + c

ARROWS Arrows

ENTER Enter

X X

Y Y

Z Z

U U

START Alt + s

HOLD Alt + h

iv

Page 5

Manual Information

Message symbols

This symbol indicates that there is one or more of the

following risks when using the described function

Danger to work piece

Danger to fixtures

Danger to tool

Danger to machine

Danger to operators

Damage!

This symbol indicates that there is risk of damage, or

electrical shock if instructions are not adhered to.

Different from machine to machine!

This symbol indicates that instructions may apply

differently from one type of machine to another type of

machine.

Manual Information

Refer to another Manual!

This symbol indicates that information required is located

elsewhere (i.e. Machines Owner Manual).

Advice!

This symbol indicates that an Advice tip is being provided.

Important, and/or additional information about the function

described.

Fonts Used in this manual

3500i reference to the console KEYS

3500i reference to the touch screen Buttons

Changes (errors)

HEIDENHAIN Corporation is continuously striving to improve. Please

help HEIDENHAIN Corporation by sending your request to the

following e-mail address: sales@heidenhain.com

Visit www.acu-rite.com for latest version of this manual.

ACU-RITE 3500i v

Page 6

Model, Software and Features

This manual describes functions and features provided by 3500i as of

the following NC software numbers.

CNC model NC software number

ACU-RITE 3500i CNC Software 689 871-01

The machine tool builder adapts the usable features of the CNC to his

machine by setting machine parameters. Some of the functions

described in this manual may therefore not be among the features

provided by the CNC on your machine tool.

CNC functions that may not be available on your machine include:

Manual Information

Tool measurement with touch probes

The machine tool builder representative can assist with becoming

familiar with the features of the machine.

Many machine manufacturers, as well as HEIDENHAIN Corp., offer

programming courses for the CNC. We recommend these courses as

an effective way of improving your programming skill and sharing

information and ideas with other CNC users.

Intended place of operation

The CNC is intended for use primarily in industrially-zoned areas. Refer

to the respective installation manual for additional information.

vi

Page 7

New Functions of Software

689 871-01-02

CAM now includes a Save button to allow quickly saving progress.

Ctrl-S can now be used as well.

CAM geometry creation dialogs now support copying and pasting

between dialogs.

ARC Help Forms now support all planes. As such, X, Y, and Z

parameters are all available and indicated as optional. User needs to

decide which of these are actually required for the particular

instance.

The Edit Preview Features menu now includes a button to access

the Simulation Tool Table.

Tool and Offset Tables now support copying in both directions; from

Simulation to NC, and from NC to Simulation.

The use of the Sim Tool and Sim Offset tables are now configurable

See "Simulation Tool and Offset Tables" on page 71.

689 871-01-09

Added a new feature for custom OEMTEMPLATE program

template files. See "To create custom program templates:" on page

99.

Manual Information

ACU-RITE 3500i vii

Page 8

Changed Functions of Software

689 871-01-01

Feed & Speed Calculator in MDI was changed; see page 55.

Feeds & Speeds Table functionality and description was expanded;

see page 68.

Additional information for the Repeat blocks feature is being

provided; see page 147.

689 871-01-02

Linear and Arc Engraving cycles now apply active program rotation.

Mirroring and scaling are still cancelled at the start of the cycle. No

Manual Information

rotation, mirroring, or scaling is active after these cycles have run,

and would need to be reprogrammed if desired; see page 110.

Tool Table Teach and Teach Program buttons are now configurable

as to their positions on the menu; see page 66.

The setting to hide or show the on-screen keyboard is now

persistent across machine power cycles; see page 13.

689 871-01-03

Rotation cycles (G68 and RMS) now allow user to specify if the

rotation center is a pivot point for the rotation or not; see page 239.

A circle of the format XYR with start=end now generates an error

because it cannot be properly calculated; see page 134.

The M98 Help Form now includes the previously missing Loop

parameter; see page 238.

689 871-01-04

The Conversational Editor now always ensures that a blank line

exists at the end of programs, in order to make it easy to insert new

blocks at the end of the program; see page 112.

When turning OFF Edit Preview, the active program preview run is

now cancelled. Also, the Preview Features menu is now available

while the program preview is running; see page 116.

689 871-01-05

Added description of estimated machining time in preview image;

see page 93.

Outdated estimated machining times are now displayed on the

preview image in RED colored text; see page 93.

689 871-01-08

Corrected total number of available tools (100); see page 61.

Additional information has been added for islands; see page 192.

Added examples of pockets with islands; see page 241.

689 871-01-09

Pocket cycles now allow changing the direction of the Roughing

Pass, and as such the previous 'FinishDir' parameter has been

superseded by a new 'Direction' parameter, which now applies to

both the Roughing and Finishing passes; see page 171

viii

Page 9

Contents

Introduction

1

Machining Fundamentals

2

Manual Data Input

3

Tool Management

4

Program Management

5

Conversational Editing

6

Programming: Canned Cycles, subprograms

7

Drawing Programs

8

Running a Program on the Machine

9

CAM: Programming

10

G-code Edit, Help, & Advanced Features

11

Software Update

12

ACU-RITE 3500i ix

Page 10

x

Page 11

Table of Contents

Controls of the 3500i

Keys on visual display unit .......................................................................................iv

Numerical keys ........................................................................................................iv

Data Entry keys........................................................................................................iv

Axis Keys .................................................................................................................iv

Touch QWERTY keyboard .......................................................................................iv

Numeric Touch Pad(s)..............................................................................................iv

Axis Jog keys............................................................................................................v

Navigation keys.........................................................................................................v

Potentiometer for feed rate and spindle speed override ..........................................v

Keyboard Installation................................................................................................vi

Keyboard Equivalent Key Strokes ............................................................................vi

Manual Information

Message symbols...................................................................................................vii

Fonts Used in this manual .................................................................................vii

Model, Software and Features .............................................................................. viii

Intended place of operation .............................................................................. viii

New Functions of Software .....................................................................................ix

689 871-01-02.....................................................................................................ix

689 871-01-09.....................................................................................................ix

Changed Functions of Software ...............................................................................x

689 871-01-01......................................................................................................x

689 871-01-02......................................................................................................x

689 871-01-03......................................................................................................x

689 871-01-04......................................................................................................x

689 871-01-05......................................................................................................x

689 871-01-08......................................................................................................x

689 871-01-09......................................................................................................x

Introduction

1.1 The 3500i

ACU-RITE conversational, and G-code formats ....................................................... 2

Powering Up the CNC Machine............................................................................... 3

E-Stop, Servo Reset, and CNC Shutdown ............................................................... 4

Writing Programs..................................................................................................... 5

3500i xi

Page 12

1.2 Visual Display Unit

Operating Panel with Touch Screen display ............................................................ 6

Screen Navigation.................................................................................................... 6

Menus, Dialogues, and Forms ................................................................................. 7

General Operating Guidelines .................................................................................. 8

Main Operating Modes....................................................................................... 8

Sub Modes ......................................................................................................... 9

Upper Menu and Status Information Bar.......................................................... 10

Machine function buttons ................................................................................. 11

Keyboard........................................................................................................... 12

Additional Buttons ............................................................................................ 13

Special Characters ............................................................................................ 13

Programming Sliders ........................................................................................ 14

Numeric touch pad ........................................................................................... 15

Calculator .......................................................................................................... 16

Advanced Function buttons .............................................................................. 16

Context Sensitive Help .......................................................................................... 17

Using Context Sensitive Help ........................................................................... 17

Console Key Pad.................................................................................................... 19

1.3 Main Operating Mode Screens

Display navigation .................................................................................................. 20

Manual Data Input ................................................................................................. 20

Program Management Screen............................................................................... 21

Program Run.......................................................................................................... 22

1.4 Accessories:

Touch probes ......................................................................................................... 23

HR electronic hand wheels.................................................................................... 24

Electronic Edge Finder........................................................................................... 24

Machining Fundamentals

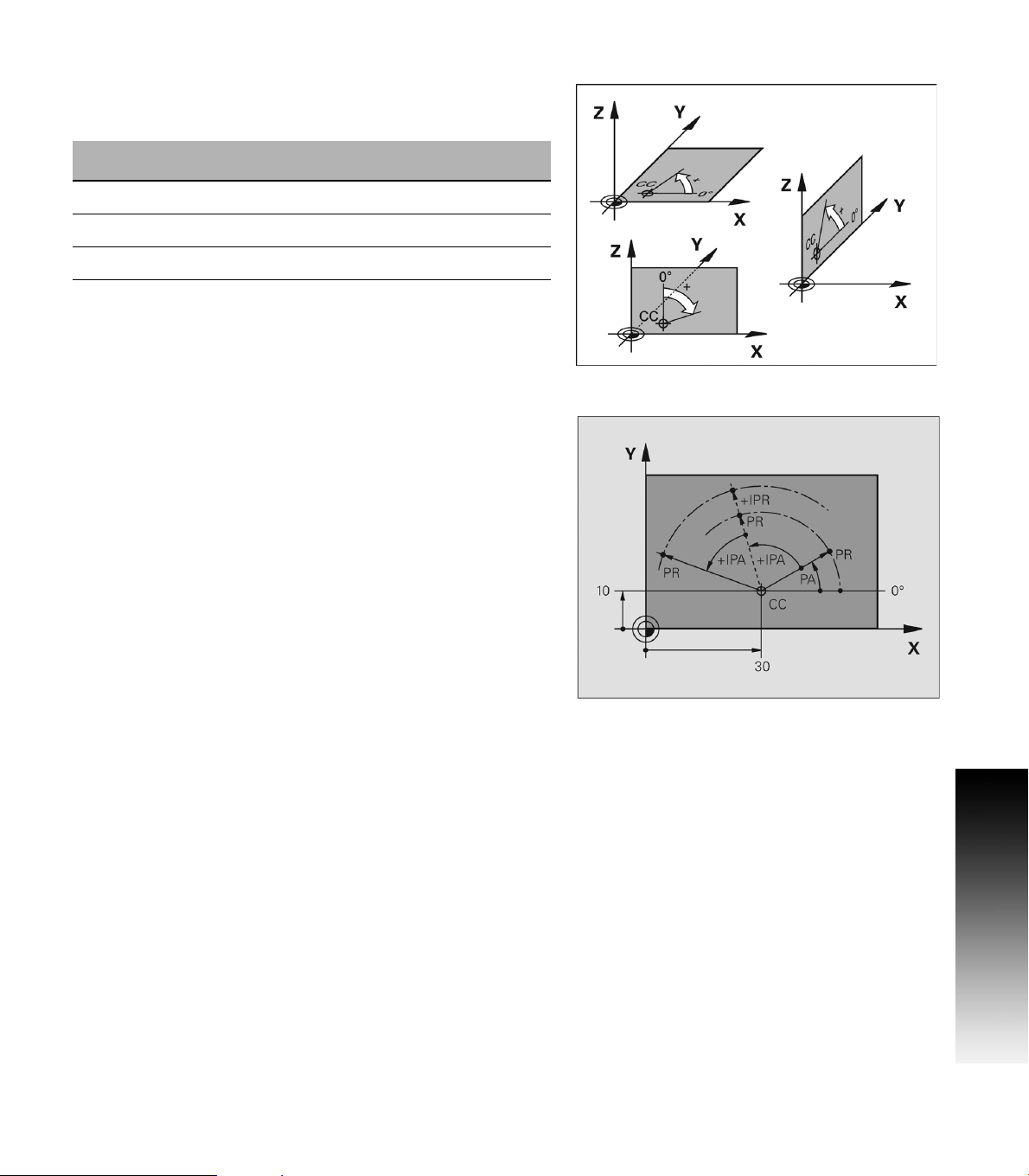

2.1 Fundamentals of Positioning

Position encoders and reference marks ................................................................ 26

Reference system ................................................................................................. 27

Reference system on milling machines................................................................. 27

Designation of the axes on milling machines ........................................................ 28

Polar coordinates ................................................................................................... 28

Setting the pole and the angle reference axis .................................................. 29

Absolute and incremental polar coordinates..................................................... 29

Angle Measurements ....................................................................................... 30

xii

Page 13

Absolute and incremental work piece positions .................................................... 31

Absolute work piece positions.......................................................................... 31

Incremental work piece positions..................................................................... 31

Setting the datum .................................................................................................. 32

Fixture Offsets .................................................................................................. 32

2.2 Manual Machine Positioning

Jog Mode Moves................................................................................................... 34

Changing the Jog Mode.................................................................................... 34

Incremental Moves ........................................................................................... 34

Continuous Moves............................................................................................ 34

Adjusting the Feedrate...................................................................................... 35

Overriding the Spindle RPM .................................................................................. 35

Manual Data Input

3.1 Manual Data Input (MDI)

Overview ............................................................................................................... 38

Manual Data Input Screen ..................................................................................... 38

Manual Data Input Mode Settings......................................................................... 39

Manual Data Input Menu Bar................................................................................. 40

MDI Menu Page two ........................................................................................ 41

Manual Data Input Operations ............................................................................... 42

Manual Data Input Cycles ...................................................................................... 44

Pocket Cycle Example ...................................................................................... 45

Block History.......................................................................................................... 47

G-code MDI .......................................................................................................... 48

MDI Touch Screen Feature Dialogues .................................................................. 49

Zero Axes.......................................................................................................... 49

Program Preset................................................................................................. 50

Move to Target Location................................................................................... 51

Tool ................................................................................................................... 52

Offset................................................................................................................ 53

Basic Modals..................................................................................................... 54

Feed and Speed................................................................................................ 55

MDI Teach ............................................................................................................. 57

3500i xiii

Page 14

Tool Management

4.1 Tool Table

Tool Table / Tool Management .............................................................................. 60

Tool Compensation Required Data ........................................................................ 60

Tool numbers / Tool names ................................................................................... 61

Locating the Tool Table.......................................................................................... 61

Editing the tool table.............................................................................................. 62

Tool Table Menu Bar......................................................................................... 62

Second Menu Bar ............................................................................................. 63

Clearing an entire line of tool data .................................................................... 64

Clearing the current tool table .......................................................................... 64

Find ................................................................................................................... 65

Finding a tool using text.................................................................................... 65

Clear Feature .................................................................................................... 66

Teach, and Teach Program ............................................................................... 66

Tool Table Structure .............................................................................................. 67

Tool table: Standard tool data ........................................................................... 67

Feeds & Speeds Table........................................................................................... 68

Feeds & Speeds Overview ............................................................................... 68

Feeds & Speeds Table Structure ...................................................................... 68

Using the Feeds & Speeds Table ..................................................................... 70

Simulation Tool and Offset Tables......................................................................... 71

4.2 Tool Data

T-Codes, and Tool Activation ................................................................................. 72

Activating Offsets via the Program ........................................................................ 72

Tool-Length Offsets............................................................................................... 73

Entering Tool Length Offsets in the Tool Table ................................................ 73

Diameter Offset in Tool Table................................................................................ 74

Tool Radius Compensation .................................................................................... 75

Contouring without radius compensation......................................................... 75

Contouring with radius compensation .............................................................. 76

Radius compensation: Machining corners........................................................ 77

Ramping into a Compensation Move ............................................................... 78

Line Tangent Entry Move ................................................................................. 78

Line Perpendicular Entry Move......................................................................... 78

Arc Tangent Entry Move................................................................................... 79

Line Arc Tangent Entry Move ........................................................................... 79

Special Code: Temporary Change of Tool Diameter......................................... 80

xiv

Page 15

Tool Compensation Path........................................................................................ 81

Path of Tool During Tool Compensation ........................................................... 81

Intersecting Points ............................................................................................ 82

Compensation Around Acute Angles................................................................ 82

General Precautions............................................................................................... 83

Fixture Offsets - Tool menu................................................................................... 84

Tool Life Management........................................................................................... 84

Activate Tool Life Management........................................................................ 84

Lock, or Unlock a Tool....................................................................................... 85

Replacement Tool (RT)...................................................................................... 85

Program Management

5.1 Program Management Introduction

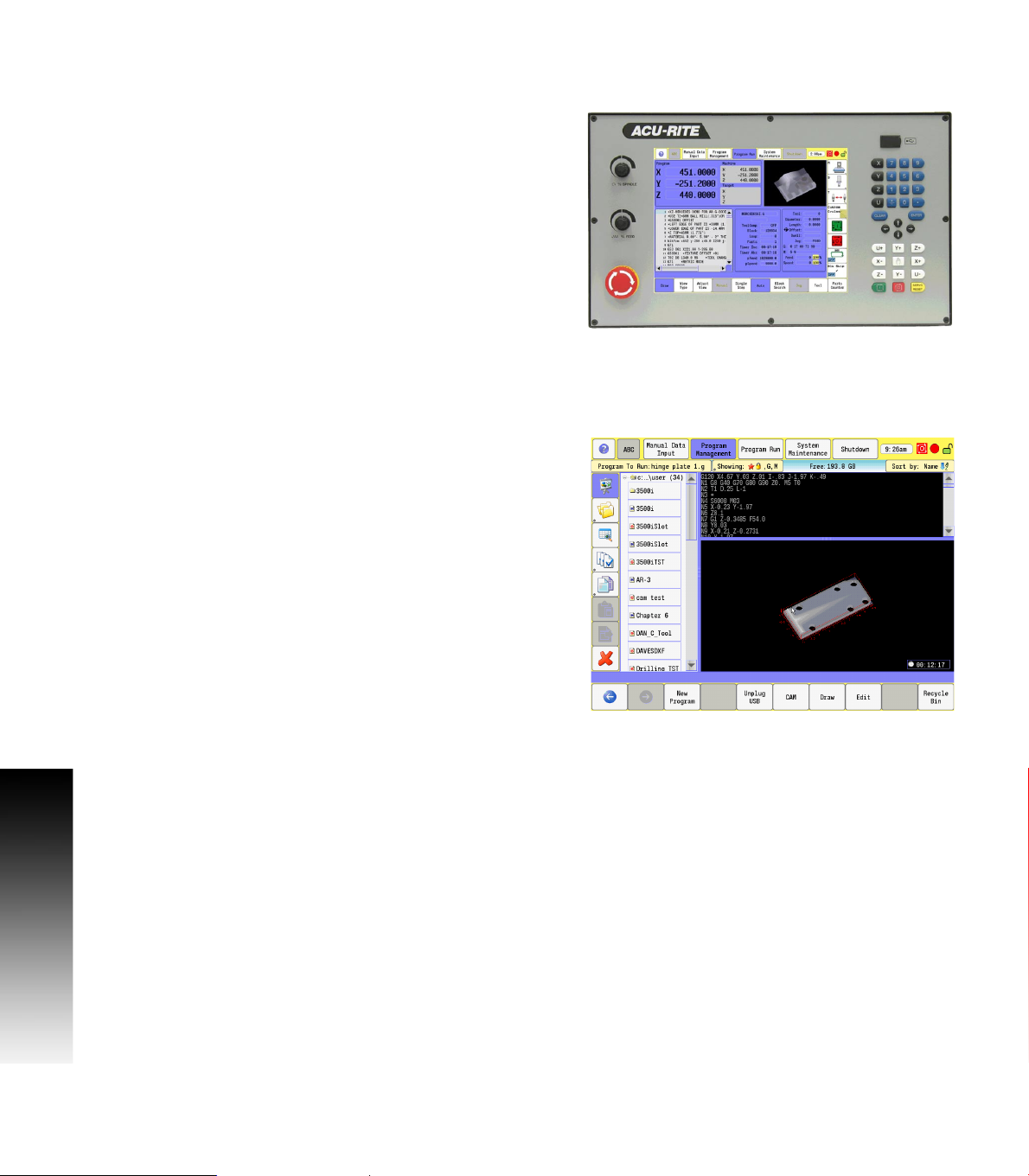

Accessing Program Management ......................................................................... 88

Program Screen Description .................................................................................. 88

Program Manager Menu Bar ................................................................................. 89

Utility Function Buttons ......................................................................................... 90

Display window arrangement ................................................................................ 91

5.2 Program Manager Functions

Folder Filter............................................................................................................ 92

Advanced Folder Filter ........................................................................................... 92

Utility Button Functions ......................................................................................... 93

Sorting Folder Contents......................................................................................... 95

Program Properties................................................................................................ 95

Recycle Bin ............................................................................................................ 96

USB Access ........................................................................................................... 96

5.3 Creating, Editing, & Selecting to Run

Creating a New Part Program ................................................................................ 97

Editing an Existing Part Program ........................................................................... 97

Selecting a Program To Run .................................................................................. 98

Program selection:............................................................................................ 98

Using custom program templates ......................................................................... 99

To create custom program templates:.............................................................. 99

3500i xv

Page 16

Conversational Editing

6.1 Conversational Programming

Getting Started .................................................................................................... 102

Program Edit Screen............................................................................................ 103

Program Edit buttons...................................................................................... 104

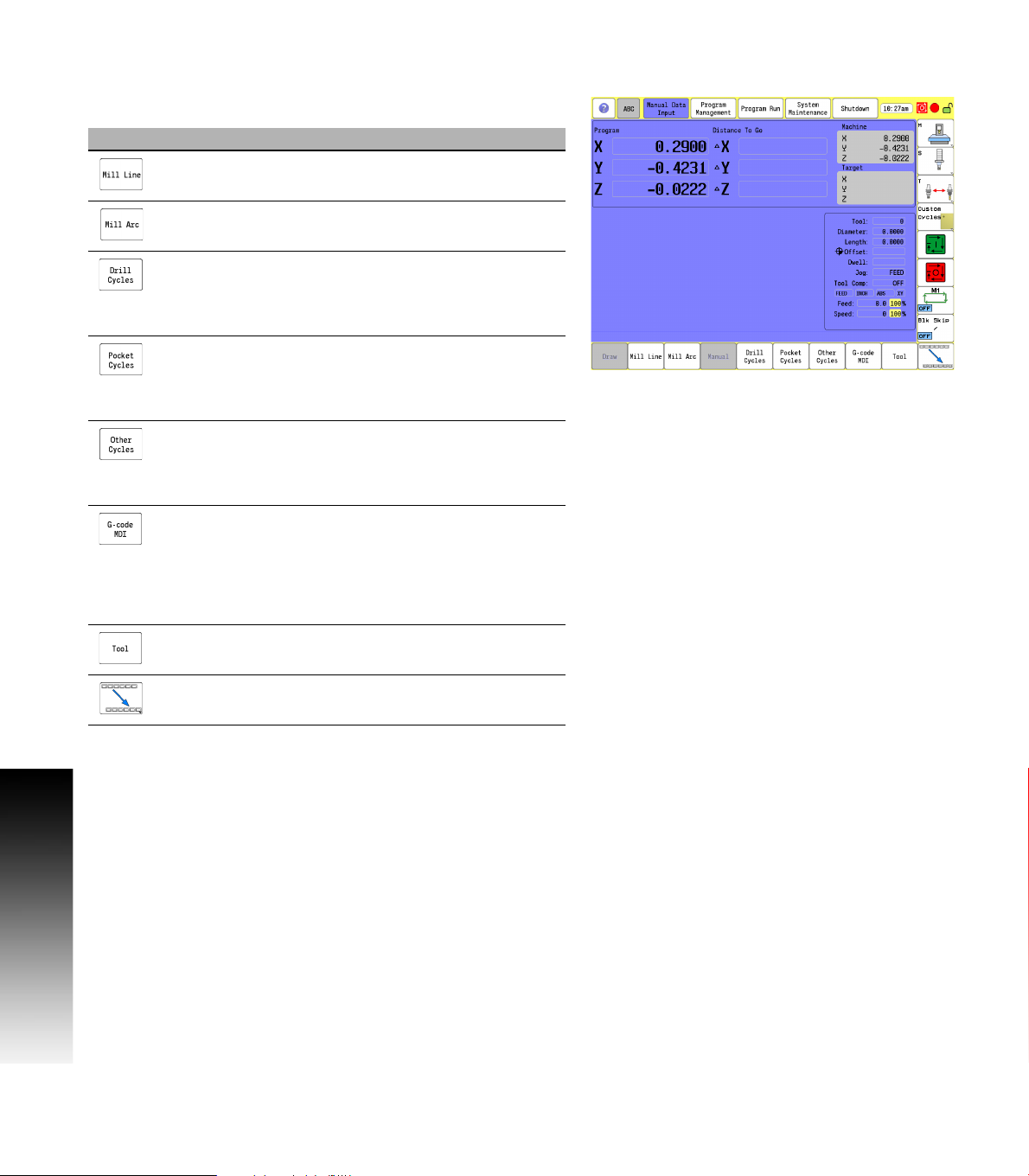

Conversational Data Input Cycles ........................................................................ 105

Milling Button ................................................................................................. 105

Milling Feature Buttons .................................................................................. 106

More Milling Button........................................................................................ 107

Drill Features Button....................................................................................... 108

Pocket Cycles Button ..................................................................................... 109

Other Cycles Button ....................................................................................... 110

Program Editing ................................................................................................... 111

Mark a program block: .................................................................................... 111

Unmark a block, or blocks:.............................................................................. 111

Deleting a program block:............................................................................... 112

Inserting a program block: .............................................................................. 112

Copy/Paste Blocks in a program ..................................................................... 113

Moving Blocks in a program ........................................................................... 113

Canceling edits to a program block:................................................................ 113

Restore edits to a program block:................................................................... 114

Editing an existing block: ................................................................................ 114

Inserting program blocks using keypad hotkeys:............................................ 114

Program Text Editing ........................................................................................... 115

Find: Specific Text or Code in a program........................................................ 115

Program Edit Preview .......................................................................................... 116

Preview Side Bar Menu .................................................................................. 116

Preview Features Menu ................................................................................. 117

Program / Display Relation................................................................................... 118

Programming: Canned Cycles, sub-programs

7.1 Explaining Basic Cycles

Round/Chamfer.................................................................................................... 120

Corner Rounding............................................................................................. 120

Line-to-Line Corner Rounding ......................................................................... 120

Line-to-Arc Corner Rounding .......................................................................... 121

Arc-to-Arc Corner Rounding ............................................................................ 121

Chamfering ..................................................................................................... 121

xvi

Page 17

Rapid.................................................................................................................... 122

Rapid Move..................................................................................................... 122

Rapid Move - EndPoint: .................................................................................. 122

Rapid Move - Angle and Radius:..................................................................... 123

Rapid Move - Angle and X:.............................................................................. 123

Rapid Move - Angle and Y:.............................................................................. 124

Rapid Move - Radius and X: ............................................................................ 124

Rapid Move - Radius and Y: ............................................................................ 125

Line ...................................................................................................................... 125

Line Move:...................................................................................................... 125

Line Move - EndPoint:..................................................................................... 126

Line Move - Angle and Radius: ....................................................................... 127

Line Move - Angle and X:................................................................................ 127

Line Move - Angle and Y:................................................................................ 128

Line Move - Radius and X: .............................................................................. 128

Line Move - Radius and Y: .............................................................................. 129

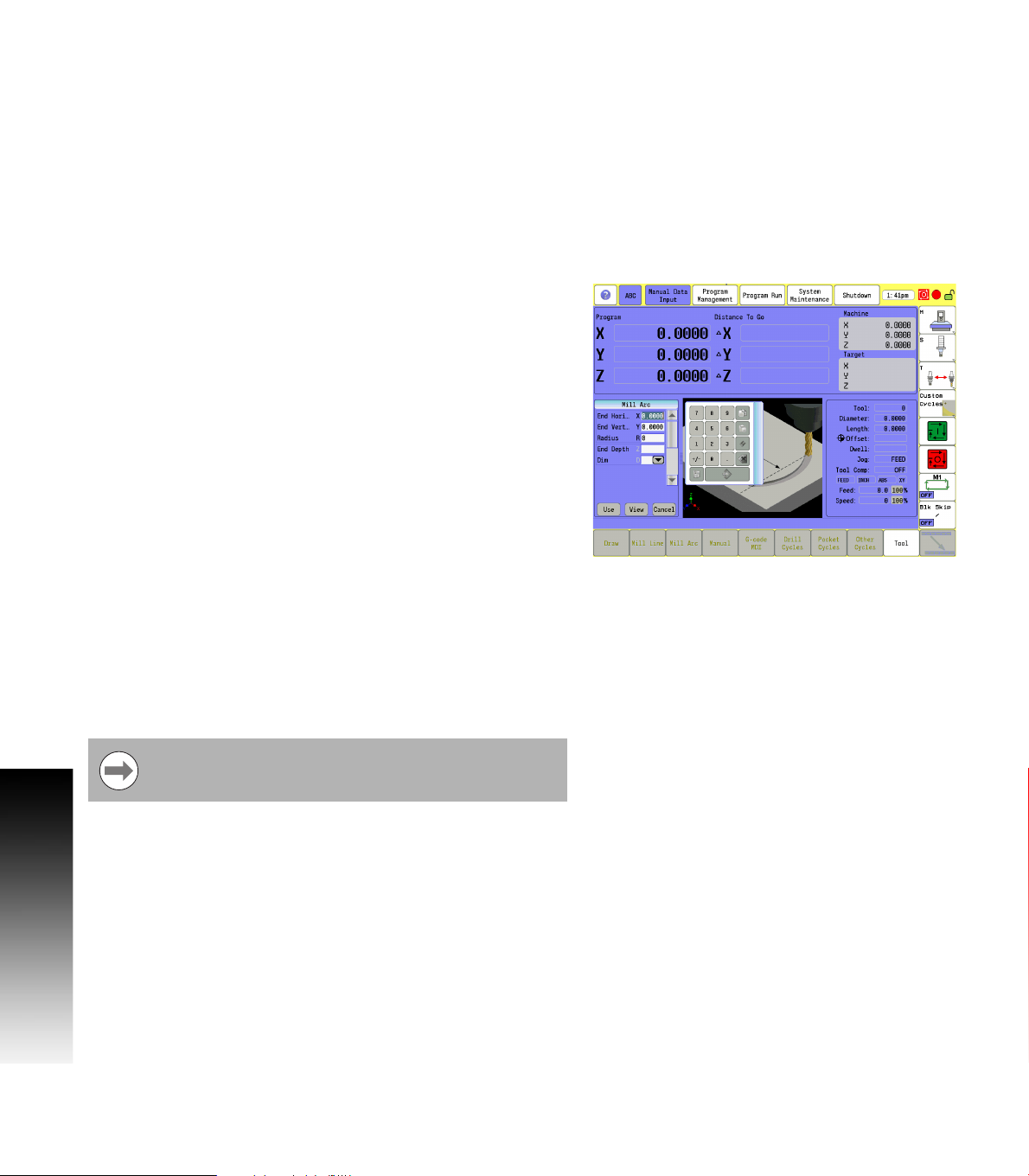

Arc ....................................................................................................................... 130

Arc Move: ....................................................................................................... 130

Arc Move - Radius and EndPoint: ................................................................... 131

Arc Move - Center and EndPoint: ................................................................... 132

Arc Move - Center and Angle:......................................................................... 133

Using Arc Center and EndPoint to create a circle ........................................... 134

Arc Move - Center and Angle, Absolute mode: .............................................. 134

Arc Move - Center and Angle, Incremental mode: ......................................... 134

Dwell:................................................................................................................... 135

Plane Selection .................................................................................................... 136

Reference Point Return: ...................................................................................... 137

Fixture Offset (Work Coordinate System Select):................................................ 138

Unit (Inch/MM)..................................................................................................... 139

Dimension (Abs/Inc)............................................................................................. 139

Absolute Zero Set ................................................................................................ 140

Block Form........................................................................................................... 141

Temporary Path Tolerance ................................................................................... 142

System Data ........................................................................................................ 143

FeedRate ............................................................................................................. 144

FeedRate (4th-Axis) ............................................................................................. 144

Spindle RPM ........................................................................................................ 145

M - Functions....................................................................................................... 145

Tool Definition and Activation .............................................................................. 146

Repeat Blocks...................................................................................................... 147

3500i xvii

Page 18

7.2 Canned Cycles

Canned Cycles ..................................................................................................... 149

Drilling Cycles ...................................................................................................... 150

Drilling, Tapping, and Boring ........................................................................... 150

Basic Drill Cycle .............................................................................................. 150

Counterbore Drill Cycle................................................................................... 151

Peck Drill Cycle ............................................................................................... 151

Tapping Cycle ................................................................................................. 152

Boring Bidirectional Cycle ............................................................................... 153

Boring Unidirectional Cycle ............................................................................. 153

Chip Break Cycle............................................................................................. 154

Flat Bottom Boring Cycle................................................................................ 155

Drill Bolt Hole Cycle ........................................................................................ 156

Drill Pattern Cycle ........................................................................................... 157

Milling Cycles....................................................................................................... 158

Mill Cycle ....................................................................................................... 158

EndMill Cycle .................................................................................................. 160

Face Mill Cycle................................................................................................ 161

Hole Mill Cycle................................................................................................ 163

Thread Mill Cycle ............................................................................................ 164

Circular Profile Cycle....................................................................................... 167

Rectangular Profile Cycle................................................................................ 169

Pocket Cycles ...................................................................................................... 171

Pocket Cycle Overview: ................................................................................. 171

Draft Angle Pocket Cycle................................................................................ 172

Rectangular Pocket Cycle ............................................................................... 174

Circular Pocket Cycle ...................................................................................... 176

Plunge Rectangular Pocket Cycle ................................................................... 178

Plunge Circular Pocket Cycle .......................................................................... 180

Frame Pocket Cycle........................................................................................ 182

Ring Pocket Cycle........................................................................................... 184

Slot Cycle........................................................................................................ 186

Circular Slot Cycle........................................................................................... 188

Irregular Pocket Cycle .................................................................................... 190

Islands............................................................................................................. 192

Bottom Finish ................................................................................................. 193

Side Finish ..................................................................................................... 194

Engraving Cycles ................................................................................................. 195

Programming the Engrave Cycle .................................................................... 195

Programming the Arc Engrave Cycle .............................................................. 197

xviii

Page 19

7.3 Probing Cycles

Tool, and Spindle Probe cycles............................................................................ 199

Tool Probe Cycles ................................................................................................ 200

Tool Probe Calibration Cycle ........................................................................... 201

Tool Length and Diameter Offset Preset........................................................ 203

Manual Tool-Length Offset Preset.................................................................. 210

Manual Tool Diameter Measure for Special Tools.......................................... 213

Tool Breakage, Length and Diameter Wear Detection .................................. 216

Spindle Probe....................................................................................................... 219

Spindle Probe Cycles ...................................................................................... 219

Spindle Probe Settings.................................................................................... 219

Spindle Probe Calibration Cycle ...................................................................... 220

Edge Finding ................................................................................................... 222

Outside Corner Finding .................................................................................. 223

Inside Corner Finding ..................................................................................... 225

Inside/Outside Boss/Hole Finding .................................................................. 227

Inside/Outside Web Finding ........................................................................... 229

Protected Probe Positioning .......................................................................... 231

Skew Compensation ...................................................................................... 232

Using the Z Work Offset Update Feature ....................................................... 235

7.4 Sub-programs

Sub-program information: .................................................................................... 236

Overview......................................................................................................... 236

Ending the Main Program ............................................................................... 236

Defining a sub-program ....................................................................................... 237

Ending a sub-program.......................................................................................... 237

Calling a sub-program .......................................................................................... 237

Looping a sub-program ........................................................................................ 238

Rotate, Mirror, and/or Scale a sub-program......................................................... 239

Pocket and Islands example ................................................................................ 241

Pocket/Island example 1 ................................................................................. 241

Pocket/Island example 2 ................................................................................. 243

Pocket/Island example 3 ................................................................................. 245

Pocket/Island example 4 ................................................................................. 247

Pocket/Island example 5 ................................................................................. 249

Pocket/Island example 6 ................................................................................. 251

3500i xix

Page 20

Drawing Programs

8.1 Draw

Viewing Programs ............................................................................................... 256

Starting Draw....................................................................................................... 257

View Options Menu............................................................................................. 258

Adjust View Menu ............................................................................................... 259

Adjust Block Form ............................................................................................... 260

Zoom.................................................................................................................... 260

Rotate Drawing View........................................................................................... 261

Pan Drawing View ............................................................................................... 261

Line View Adjustments........................................................................................ 262

Draw Options....................................................................................................... 263

Sim Tools ............................................................................................................. 264

Running a Program on the Machine

9.1 Running a program

Modes of Programmed Operation ....................................................................... 266

Auto mode ........................................................................................................... 266

Starting a program .......................................................................................... 267

Pause, or Stop a running program .................................................................. 267

Clearing a Messages ........................................................................................... 267

Single Step........................................................................................................... 268

Block Search ........................................................................................................ 269

Select a Starting Block.................................................................................... 269

Using Draw with running programs..................................................................... 270

Program Status Area............................................................................................ 271

Parts Counter....................................................................................................... 272

Program Run Timers............................................................................................ 273

Accessing the Tool Table..................................................................................... 273

Axis Jog keys....................................................................................................... 274

In-Program Axis Jogging...................................................................................... 275

CAM: Programming

10.1 CAM Programming

CAM Mode .......................................................................................................... 278

Recommended CAM Programming Sequence ................................................... 279

CAM Setup ..................................................................................................... 279

Geometry Data .............................................................................................. 279

Job Setup........................................................................................................ 279

xx

Page 21

CNC Program.................................................................................................. 279

CAM Mode Mouse Operations ........................................................................... 280

CAM Mode Screen .............................................................................................. 281

Activating CAM Mode ......................................................................................... 281

Creating a New Program ..................................................................................... 282

CAM Mode buttons ........................................................................................ 282

Geometry Toolbar buttons: ............................................................................. 282

Point Tool buttons........................................................................................... 283

Point Editing.................................................................................................... 283

Line Tool buttons ............................................................................................ 284

Editing a Line .................................................................................................. 285

Circle Tool buttons .......................................................................................... 286

Circle Editing................................................................................................... 286

Shape Tool buttons......................................................................................... 287

Tool Path Buttons ........................................................................................... 288

Tool Path Data Input ............................................................................................ 289

Quick Coordinate Entry ........................................................................................ 290

Job Setup: Basic tab ............................................................................................ 291

Basic tab Data Entries .................................................................................... 291

Job Setup: Advanced tab .................................................................................... 293

Advanced tab Data Entries.............................................................................. 293

Comment Tab ...................................................................................................... 294

Block Form: Basic tab .......................................................................................... 295

Basic tab Data Entries..................................................................................... 295

Comment Tab ...................................................................................................... 295

Drilling Cycle: ....................................................................................................... 296

Drill Cycle: Basic ............................................................................................ 296

Drill Cycle: Counterbore ................................................................................. 296

Drill Cycle: Peck .............................................................................................. 296

Drill Cycle: Tapping ......................................................................................... 296

Drill Cycle: Boring Bidirectional....................................................................... 296

Drill Cycle: Boring Unidirectional..................................................................... 297

Drill Cycle: Chip Break..................................................................................... 297

Drill Cycle: Flat Bottom Boring........................................................................ 297

Drilling dialogue: .................................................................................................. 298

Basic tab ......................................................................................................... 298

Setup tab:........................................................................................................ 299

Bolt Hole tab: .................................................................................................. 299

Pattern tab: ..................................................................................................... 300

Comment tab:................................................................................................. 300

Mill Cycle ............................................................................................................. 301

Basic tab: ........................................................................................................ 301

Setup tab:........................................................................................................ 302

3500i xxi

Page 22

Pocket Cycle ........................................................................................................ 303

Basic tab: ........................................................................................................ 303

Setup tab: ....................................................................................................... 303

Pocket Finish Cycles............................................................................................ 305

Bottom tab:..................................................................................................... 305

Side tab:.......................................................................................................... 305

Adding a Machining Side: ............................................................................... 306

Engraving Cycle ................................................................................................... 307

Basic tab: ........................................................................................................ 307

Setup tab: ....................................................................................................... 308

Comment tab:................................................................................................. 308

Program Directive ................................................................................................ 308

Adding a Program Directive ............................................................................ 308

Modifying Toolbar ................................................................................................ 309

Modifying Tools Buttons:................................................................................ 309

Viewing Tools ...................................................................................................... 310

Viewing Tool Buttons:..................................................................................... 310

CAM Mode buttons ............................................................................................. 311

CAM Tool Buttons: ......................................................................................... 311

CAM Setup .......................................................................................................... 313

Selection tab: .................................................................................................. 313

Output tab:...................................................................................................... 313

Display tab: ..................................................................................................... 314

Tool Table tab: ................................................................................................ 314

View Buttons: ................................................................................................. 315

Geometry............................................................................................................. 316

Defining Geometry: ........................................................................................ 316

Completing the Geometry: ............................................................................. 317

Finalizing the geometry................................................................................... 319

Creating the shape.......................................................................................... 320

DXF Import Feature ............................................................................................. 321

DXF Entities Supported .................................................................................. 321

DXF Entities Not Supported............................................................................ 321

Importing a DXF File ....................................................................................... 321

Modifying Tools ................................................................................................... 322

Corner Radius (inserting) ................................................................................ 322

Chamfer (inserting) ......................................................................................... 322

Trimming Geometry........................................................................................ 323

Delete button.................................................................................................. 323

Properties button ............................................................................................ 323

Shapes ................................................................................................................. 324

Copying a Shape ............................................................................................. 324

Moving a Shape .............................................................................................. 324

xxii

Page 23

Tool Table ............................................................................................................ 325

Setting up the Tool Table ................................................................................ 327

Importing a Tool Table .................................................................................... 327

Exporting a Tool Table..................................................................................... 327

Tool Paths ............................................................................................................ 328

Creating a Tool Path in CAM Mode ................................................................ 328

Tool Path Verification ...................................................................................... 328

Tool Path Editing............................................................................................. 329

Use Existing Shape......................................................................................... 329

Editing a Tool Path .......................................................................................... 330

Disabling, and Enabling Tool Paths ................................................................. 330

Deleting Tool Paths......................................................................................... 330

Arranging Tool Paths Sequence...................................................................... 330

Smart Programming........................................................................................ 331

Files Created................................................................................................... 331

CAM Example 1................................................................................................... 332

Exercise One:.................................................................................................. 332

Defining Geometry:......................................................................................... 332

Connecting the Geometry:.............................................................................. 334

Finalizing the geometry................................................................................... 335

Creating the shape.......................................................................................... 336

Creating the tool paths:................................................................................... 337

CAM Example 2................................................................................................... 341

Example Two: ................................................................................................. 341

Create Circle Geometry: ................................................................................. 341

Create Line Geometry..................................................................................... 343

Finalizing the geometry................................................................................... 344

Creating the shape.......................................................................................... 345

Creating the tool paths:................................................................................... 346

G-Code Edit, Help, & Advanced Features

11.1 G-Code Program Editing

Activating Edit Mode ........................................................................................... 352

Program Edit Screen............................................................................................ 353

Program Edit buttons ...................................................................................... 354

Edit Features menu......................................................................................... 355

Preview Features menu.................................................................................. 356

Program Editing ................................................................................................... 357

Mark a program block: .................................................................................... 357

Unmark a block, or blocks:.............................................................................. 357

Delete a Character: ......................................................................................... 358

Deleting a program block: ............................................................................... 358

Inserting a program block: .............................................................................. 359

Copy/Paste Blocks in a program ..................................................................... 359

Moving Blocks in a program ........................................................................... 360

3500i xxiii

Page 24

Canceling edits to a program block:................................................................ 360

Restore edits to a program block:................................................................... 360

Program Text Editing ........................................................................................... 361

Inserting Text:................................................................................................. 361

Overwriting Text: ............................................................................................ 361

Find: Specific Text or Code in a program........................................................ 362

Replace: Specific Text, or Code in a program................................................. 363

Preview Features................................................................................................. 364

Edit Features Menu ........................................................................................ 364

Program / Display Relation................................................................................... 365

Edit Help Preview .......................................................................................... 365

11.2 G-Code and M-Code Definitions

G-Code................................................................................................................. 366

M-Code Definition................................................................................................ 370

Typing in Address Words..................................................................................... 371

Typing in M-Codes............................................................................................... 371

11.3 Edit Help

Activating Edit Help ............................................................................................. 372

Help Graphic Screens .......................................................................................... 373

G - Functions........................................................................................................ 374

Basic Modal Functions.................................................................................... 375

Multi -Segment Blocks ................................................................................... 375

Arcs................................................................................................................. 376

Drilling Cycles ................................................................................................. 376

Pocket Cycles ................................................................................................. 377

Milling and Profiles ......................................................................................... 377

Rotation, Scaling, and Mirroring...................................................................... 378

Spindle Probing............................................................................................... 378

Tool Probing.................................................................................................... 379

Tool Radius Compensation ............................................................................. 379

Other G - Functions ........................................................................................ 380

M - Functions....................................................................................................... 381

All M - Functions............................................................................................. 381

Basic M - Functions ........................................................................................ 382

Cooling, Cleaning, and Lubrication.................................................................. 382

Spindle Functions ........................................................................................... 383

Tool Change.................................................................................................... 383

11.4 Advanced Programming

SPEED ................................................................................................................. 384

M - Functions....................................................................................................... 384

Miscellaneous (M-Code) ................................................................................. 384

Control M - Codes........................................................................................... 385

xxiv

Page 25

Order of Execution............................................................................................... 386

Programming Non-modal Exact Stop: ................................................................. 387

In-Position Mode (Exact Stop Check): ................................................................ 387

Contouring Mode (Cutting Mode) : ..................................................................... 387

Setting Stroke Limit: .......................................................................................... 388

Return from Reference Point: ............................................................................. 388

Move Reference from Machine Datum:.............................................................. 388

Modifiers.............................................................................................................. 389

Block Separators.................................................................................................. 389

Tool Offset Modification ...................................................................................... 390

Expressions and Functions .................................................................................. 393

System Variables ................................................................................................. 397

User Variables...................................................................................................... 398

Variable Programming (Parametric Programming) ............................................... 399

Block Skip ....................................................................................................... 399

Select Block Skip ............................................................................................ 400

Parameters and Variable Registers ................................................................. 401

Setting and Direct Transfer Variables.............................................................. 402

Indirect Transfer: ............................................................................................ 403

Storing Result of Computation........................................................................ 404

Variable Programming Examples .................................................................... 405

User Macros (G65, G66, G67)......................................................................... 409

Macro Body Structure..................................................................................... 410

Setting and Passing Parameters ..................................................................... 411

Probe Move (G31)................................................................................................ 422

Conditional Statements ....................................................................................... 423

Unconditional LOOP Repeat ........................................................................... 425

Short Form Addressing........................................................................................ 426

Logical and Comparative Terms .......................................................................... 427

File Inclusion ........................................................................................................ 429

11.5 Four Axis Programming

Axis Type ............................................................................................................. 432

Linear: ............................................................................................................. 432

Rotary:............................................................................................................. 432

Conversion formula: ....................................................................................... 432

Rotary Axis Programming Conventions .......................................................... 433

Programming Examples.................................................................................. 433

3500i xxv

Page 26

Software Update

12.1 Updating System Software

Software Update.................................................................................................. 438

Procedure for updating the software................................................................... 438

Off-Line Software

13.1 3500i Off-Line Software

Off-Line Simulator................................................................................................ 440

System Requirements ......................................................................................... 440

Installation............................................................................................................ 441

Operation ............................................................................................................. 441

Updating .............................................................................................................. 441

xxvi

Page 27

Introduction

Page 28

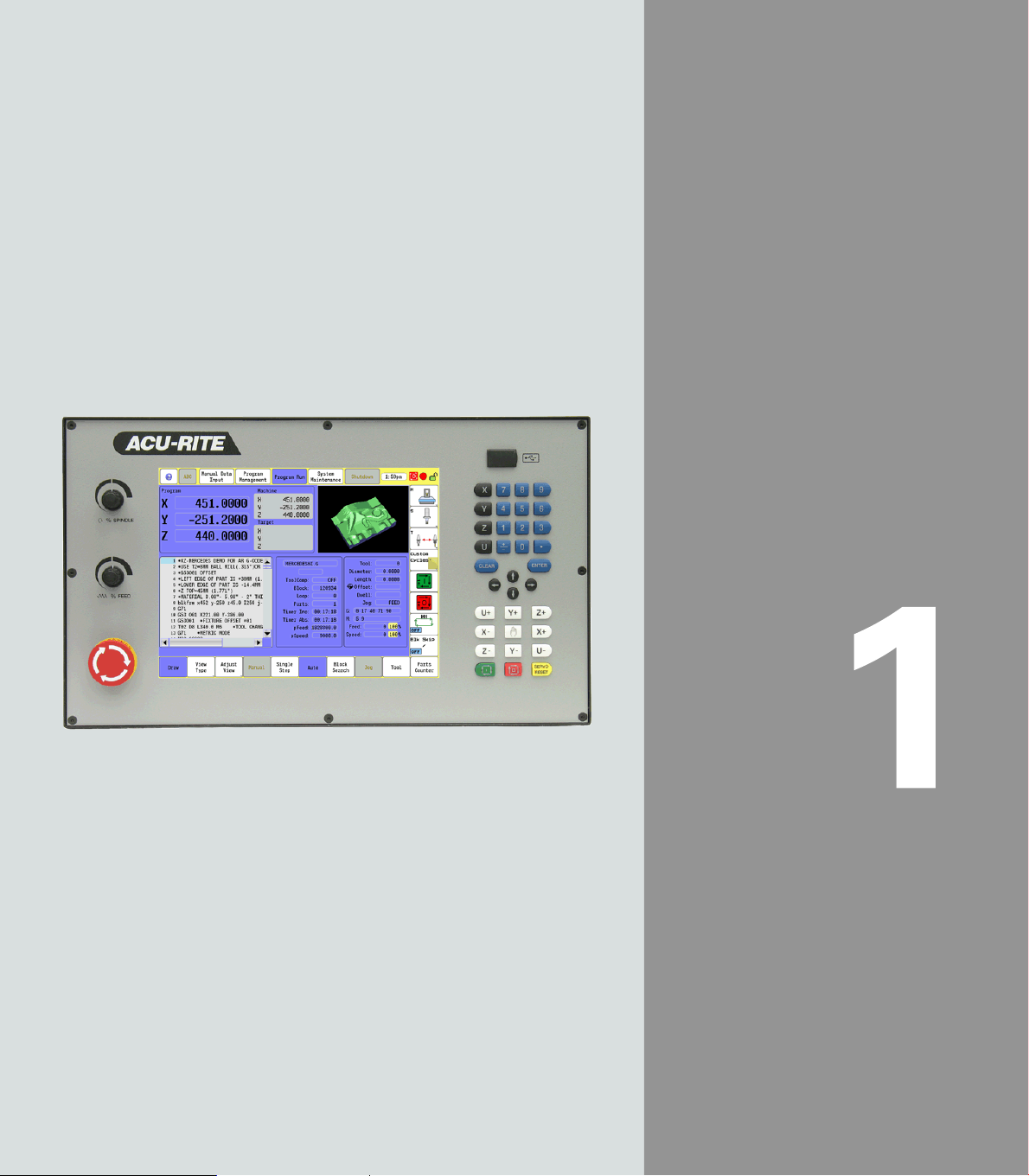

1.1 The 3500i

The ACU-RITE 3500i control is a touch screen workshop-oriented

contouring control that enables you to program conventional

machining operations right at the machine in an easy-to-use

conversational programming language. The control is also capable of

running, and editing g-code (ISO format) programs. It is designed for

milling and drilling machine tools, as well as machining centers, with

1.1 The 3500i

up to four axes. You can also change the angular position of the

spindle under program control.

The 3500i has many powerful features that will improve your

productivity. The touch screen features, and screen layout are clearly

arranged in such a way that the functions are easy to access, fast and

user friendly.

ACU-RITE conversational, and G-code formats

The ACU-RITE conversational programming format is a method of

writing programs; g-code (ISO) programming is also supported.

Preview graphics in the editors illustrate the individual machining

steps for programming the contour as well as the corresponding tool

path generated. If a production drawing is not dimensioned for NC

programming, the CAM can be used to graphically generate a

complete part program. Work piece machining can be graphically

simulated either during or before actual machining.

The conversational and g-code (ISO) formats are the same as that

used in previous CNC products (3000M, 5000M, 6000M and 6000i).

2 1 Introduction

Page 29

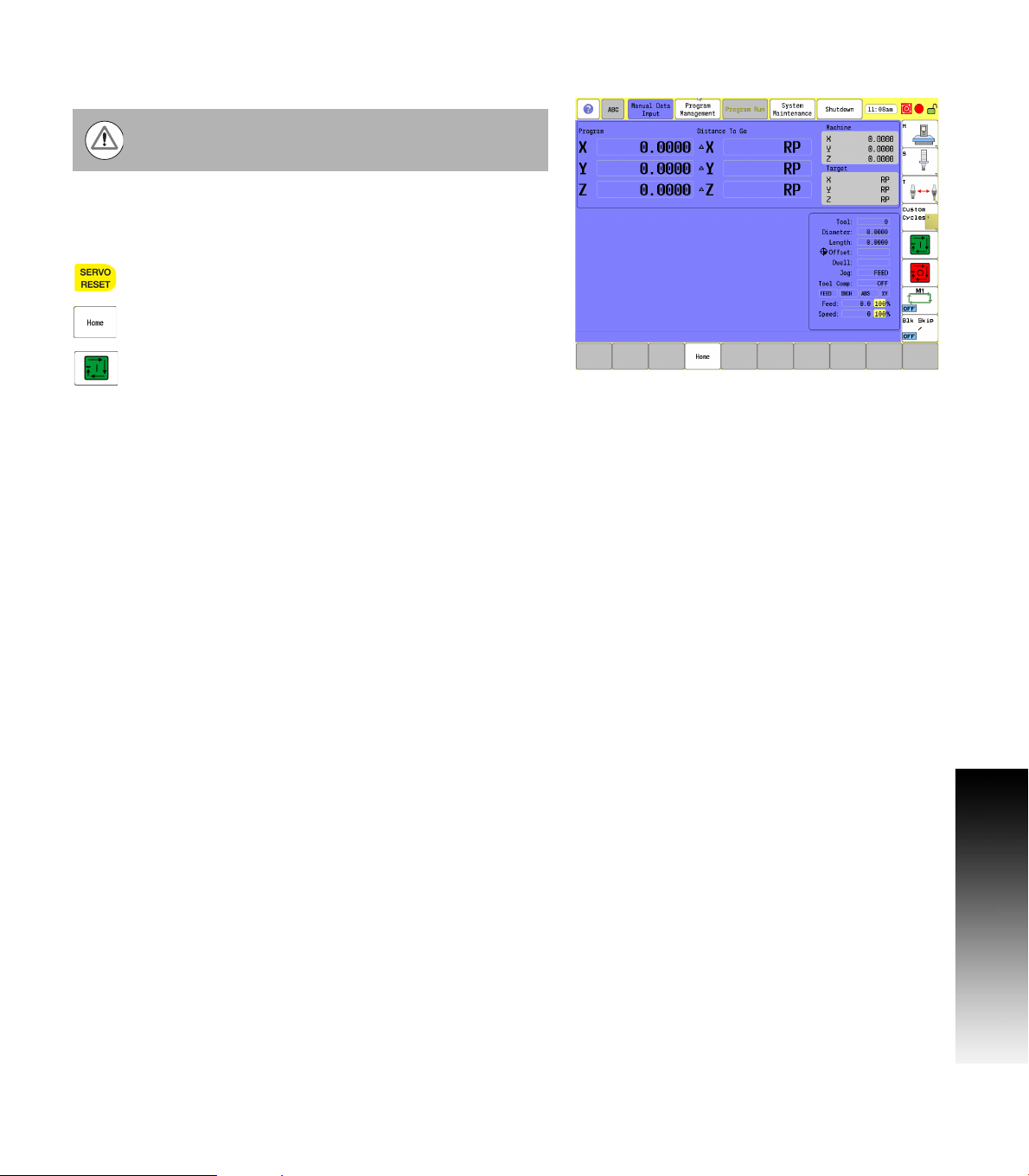

Powering Up the CNC Machine

When you power-on the CNC, ensure that the E-STOP

switch is in the in position.

Turn on the CNC machine according to the builder's instructions. Turn

the power switch on to the 3500i console.

The 3500i completely resets, activating the startup screen.

With the EMERGENCY STOP button out, reset the

servo drive by pressing the SERVO RESET key.

Press the Home button.

Press the Start button. The 3500i default display is

the Manual screen.

1.1 The 3500i

ACU-RITE 3500i 3

Page 30

E-Stop, Servo Reset, and CNC Shutdown

Press E-STOP to disengage the servos and then revert to Manual

Data Input Mode.

Touch Shut Down to display the Shut Down dialogue. Touch Shut Down

to power down the CNC, or touch Cancel to cancel the shut down.

The shutdown takes less than a minute. The 3500i will let you know

when it is safe to turn power off. Or, you can touch Reboot (or press

1.1 The 3500i

the ENTER key) to re-start the 3500i.

Follow the builder's instructions for turning off the machine.

Always shutdown the CNC before turning power off to the

machine.

Emergency Stop (E-STOP)

Press E-STOP to take all axes and spindle servos offline. This ends all

machine movement.

To reset E-STOP, pull out and turn the rotary switch clockwise in the

direction of the arrows. The switch makes a touching sound when

it resets.

Resetting E-STOP does not automatically reactivate the servos.

Activating/Resetting the Servos

For safety reasons, the CNC powers up with the servomotors

disengaged. While the servos are off, the CNC cannot move the

machine.

Reset the servos as follows:

If a limit switch disengaged the servos, manually reposition the

machine inside its normal range of travel.

Press E-STOP to display the message External emergency stop

Rotate the E-STOP switch in the direction of the arrows to reset it.

Press SERVO RESET to reset the servos.

4 1 Introduction

Page 31

Writing Programs

The 3500i allows many features to be used without having to write a

program. But for operations that repeat or complex machining it is best

to write a program. Before you start to write a program, determine the

work-holding device and the location of Part Zero (the point to which

all movement is referenced). Since absolute positions are defined

from Part Zero, try to select a location that directly corresponds to

dimensions provided on the part print, such as the lower left corner of

the work. Then, you can develop a program using a procedure similar

to the one that follows:

The first block of a program is a safe starting position. This is where