Page 1

TIMING LIGHT

INSTRUCTIONS

CP7527 INDUCTIVE

CP7528 ADVANCE

CP7529 DIGITAL

Actron, is a Business Unit of SPX Corporation.

Page 2

TABLE OF CONTENTS

SAFETY PRECAUTIONS ............................................................ 2

TIMING LIGHTS........................................................................... 5

HOOKUP PROCEDURE.............................................................. 7

MEASURING ENGINE RPM...................................................... 10

MEASURING INITIAL TIMING.................................................... 11

SETTING INITIAL TIMING ......................................................... 13

CHECKING & MEASURING CENTRIFUGAL ADVANCE ......... 15

MEASURING VACUUM ADVANCE ........................................... 19

DISCONNECTING TIMING LIGHT ............................................ 22

TROUBLESHOOTING AND CARE ........................................... 23

FRANCAIS INSTRUCTIONS ....................................... 26

ESPAÑOL INSTRUCCIONES...................................... 54

1

Page 3

SAFETY PRECAUTIONS

For safety reasons, read this manual thoroughly before operating Timing Light.

Always refer to and follow safety messages and test procedures provided by

manufacturer of vehicle or equipment being tested.

The safety messages presented below and throughout this manual are

reminders to operator to exercise extreme care when using this test instrument.

WARNING

!

IMPORTANT

SAFETY EQUIPMENT

Fire Extinguisher

For gasoline/chemical / electrical fires

Safety Goggles

Protect eyes from Battery Acid / Gasoline / Flying Debris

Protective Gloves

Protect Hands from Battery Acid / Hot Exhaust / Engine Parts / Flying Debris

Indicates a potentially hazardous situation which, if not avoided,

could result in serious injury or death.

Indicates a situation which, if not avoided, may result in damage to

the test equipment or vehicle.

2

Page 4

SAFETY INSTRUCTIONS

Ventilation

Operate vehicle in ventilated area.

Moving Parts

Remove Jewelry

Do Not Wear Loose Clothing

Tie Up Long Hair

Keep Hands Away From Moving Parts

Set Brake

Place Car In:

Park (For Automatic)

Neutral (For Manual)

Set Parking Brake

Disable Automatic Parking Brake Release

Smoking and Open Flames

Never smoke while working on car

Keep sparks, and open flames away from vehicle

Do not use fuel injector cleaning solvents when performing diagnostic tests

3

Page 5

Hot Surfaces

Avoid Contact With:

Exhaust Manifolds

Pipes

Radiator

Mufflers (catalytic converters)

Battery

Do Not Lay Tools on Battery

Do Not Touch Battery Acid

Do Not Create Short Between Terminals

If using an auxiliary battery:

Connect Jumper Wire Between Negative Terminal on Auxiliary Battery

and Ground on Vehicle

Place Battery at least 18 inches Above Floor

High Voltage

30,000 to 50,000 Volts Present At:

Ignition Coil

Distributor Cap

Ignition Wires

Spark Plugs

Use Insulated Pliers

Do Not Use Timing Light if Cords are Damaged

4

Page 6

TIMING LIGHTS

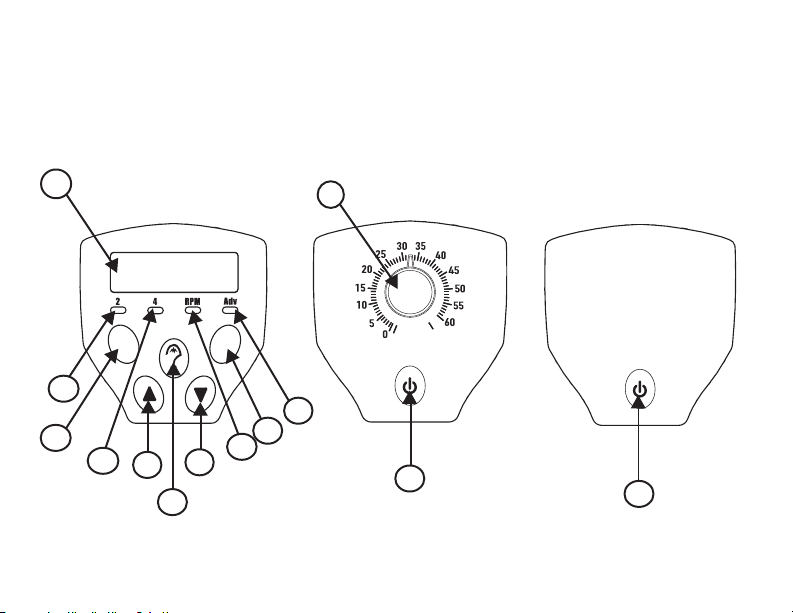

11

6

CP7529

DIGITAL

2/4

Cycle

7

RPM

Adv

CP7528

15

ADVANCE

CP7527

INDUCTIVE

10

13

8

14

12

14

9

5

16

16

Page 7

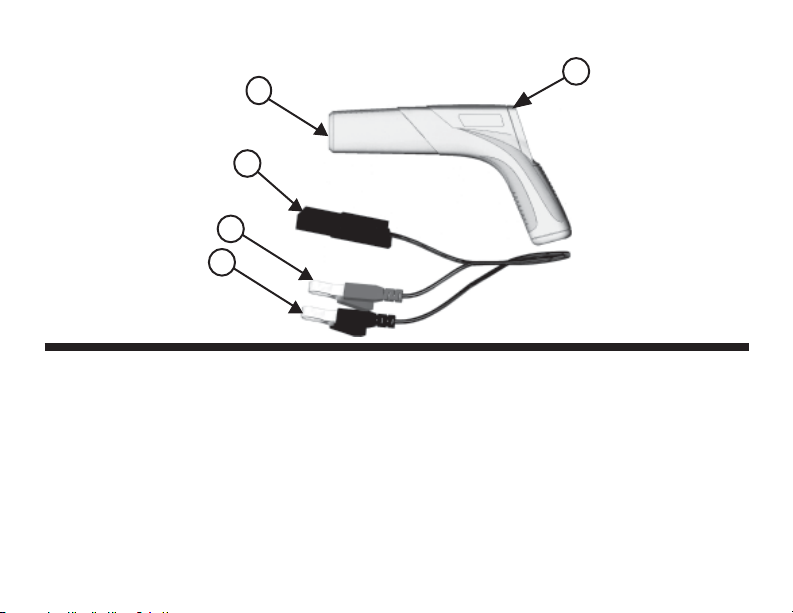

2

3

4

5

1

1. Timing Light

2. Lens

3. Inductive Pickup Clamp

4. RED Clip

5. BLACK Clip

6. 4-digit LED Display

7. 2 Cycle Mode Indicator

8. 4 Cycle Mode Indicator

9. RPM Mode Indicator

10.Advance Mode Indicator

11.2/4 Cycle Mode Button

12. Flashlight Button

13.RPM/Adv Mode Button

14. Increase and Decrease

Advance Buttons

15. Advance Knob

16.ON Button

6

Page 8

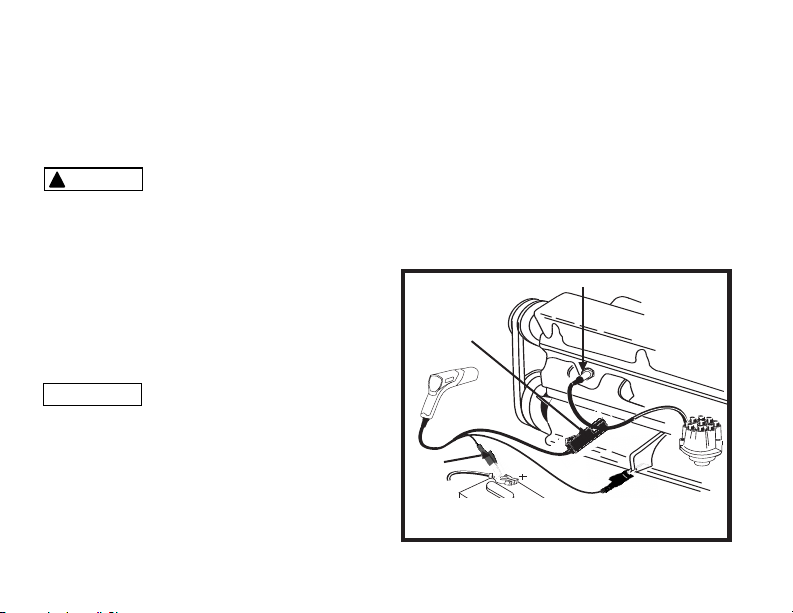

HOOKUP PROCEDURE

1. Turn Vehicle OFF.

WARNING

!

Connecting cables with engine running could result in serious

injury.

2. At distributor, disconnect and plug vacuum line.

3. Attach Inductive Pickup Clamp

· Refer to vehicle service manual.

· Clamp on #1 spark plug wire.

IMPORTANT

Do not allow inductive

Inductive Pickup

Clamp

pickup to touch hot exhaust

manifold or surrounding

parts.

Red

Clip

PO .S

Close the inductive pickup

jaws slowly to prevent

damage.

Connect Inductive Pickup Clamp, Red Clip and Black Clip

7

# 1 Spark Plug Wire

Black Clip

Page 9

4. Connect RED and BLACK Battery Clips on Negative Ground Electrical

Systems.

· Connect RED to positive (+) battery post.

· Connect BLACK to engine ground.

IMPORTANT

On 6-volt electrical systems, use an auxiliary 12-volt battery to

power timing light. Connect BLACK clip to negative (-) post and

RED clip to positive (+) post on auxiliary 12- volt battery. Use 18

AWG or larger wire to connect 12-volt battery negative (-) terminal

to a good engine ground.

On 12-volt Positive Ground electrical systems, connect BLACK clip

to negative (-) battery post and RED clip to engine ground. DO NOT

USE the positive battery post.

On engines equipped with a breaker point ignition system, it will be

necessary to set the point dwell before adjusting the timing. Always

follow the manufacturers specifications and test procedures for

adjusting dwell angle and idle speed.

8

Page 10

TDC

UDC 1-6

16N

OP 1-6

O

A

3

6

10

0

DC

10

10

5. Locate the Timing Marks on the Engine

· The Digital Timing Light is equipped with

a flashlight feature. Press and hold the

button for continuous lighting.

6. Set 2/4 CYCLE OPERATION (Digital

Timing Light Only)

· Use 2-cycle mode on 2-cycle engines and

on vehicles equipped with waste-spark

distributorless ignition systems (DIS).

IMPORTANT

When connected to the battery, the timing light defaults to the 4cycle, tachometer mode.

· Press and release button until correct indicator lights.

9

Page 11

MEASURING ENGINE RPM

(Digital Timing Light Only)

1. Press and Release Button Until RPM Indicator Lights.

IMPORTANT

Always follow test procedures in vehicle service manual or Vehicle

Emission Control Information Label. Instructions given here are for

reference only.

If engine is not running or #1 spark plug is not firing, timing light

display will flash, indicating that no signal is being received.

10

Page 12

MEASURING INITIAL TIMING

1. Follow preparation list for checking

# 1 Spark Plug Wire

timing in vehicle service manual.

2. Start engine and warm to operating

Inductive Pickup

Clamp

temperature.

3. Aim timing light at crankshaft

damper (pulley) or at transmission

bell housing, depending on location

of timing marks.

Red

Clip

PO .S

INDUCTIVE TIMING LIGHT

1. Press and hold down button.

2. Write down initial timing by counting the timing marks

on the engine.

11

Black Clip

Page 13

ADVANCE TIMING LIGHT

1. Press and hold down button.

2. View timing marks. Turn advance knob until

moving mark is aligned with stationary 0 degree

timing mark (Top Dead Center).

3. Write down initial timing from dial on timing light.

DIGITAL TIMING LIGHT

Advance

Knob

IMPORTANT

When connected to the battery, the timing light

defaults to the 4-cycle, tachometer mode.

1. Press and release button until ADV indicator lights.

2. View timing marks. Push and buttons until

moving mark is aligned with stationary 0 degree mark.

3. Write down initial timing from timing light display.

12

2/4

Cycle

RPM

Adv

Page 14

SETTING INITIAL TIMING

INDUCTIVE TIMING LIGHT

1. Press and hold down button.

2. Loosen distributor hold down bolt and turn

distributor as necessary until moving mark is aligned

with correct stationary timing mark.

3. Tighten distributor hold down bolt securely.

ADVANCE TIMING LIGHT

1. Turn advance knob to desired degrees advance

setting.

2. Press and hold down button.

13

Advance

Knob

Page 15

3. View timing marks. Loosen distributor hold down bolt and turn

distributor until moving mark is aligned with stationary 0 degree

mark.

4. Tighten distributor hold down bolt securely.

DIGITAL TIMING LIGHT

1. Push and buttons until display shows

desired degrees advance setting.

2/4

2. View timing marks. Loosen distributor hold down

bolt and turn distributor until moving mark is aligned

with stationary 0 degree mark.

3. Tighten distributor hold down bolt securely.

14

Cycle

RPM

Adv

Page 16

CHECKING & MEASURING

NOTES

ADVANCE READING (RPM NOTED

IN SERVICE MANUAL OR VECI)

TIMING AT IDLE

CENTRIFUGAL ADVANCE

CENTRIFUGAL ADVANCE

INDUCTIVE TIMING LIGHT

1. Leave distributor vacuum line disconnected

and plugged.

2. Press and hold down button. Note

position of timing mark at idle speed.

3. Slowly increase engine speed to 2500 RPM, or other speed specified

by manufacturer. Timing mark should move smoothly in opposite

direction of engine rotation. Note degrees advance at higher RPM.

4. Subtract degrees advance at idle from degrees at higher speed.

Difference is amount of centrifugal advance.

5. Slowly decrease engine speed to idle RPM. Timing mark should move

smoothly in direction of engine rotation, and return to idle position.

15

Page 17

ADVANCE TIMING LIGHT

NOTES

ADVANCE READING (RPM NOTED

IN SERVICE MANUAL OR VECI)

TIMING AT IDLE

CENTRIFUGAL ADVANCE

1. At distributor, leave vacuum line disconnected and plugged.

2. Press and hold down button. View timing marks. Turn advance

knob until moving mark is aligned with stationary 0 degree mark.

Note degrees advance at idle speed.

3. Slowly increase engine speed to 2500 RPM,

or other speed specified by manufacturer.

Timing mark should move smoothly in

opposite direction of engine rotation.

4. Turn advance knob until moving mark is

aligned with stationary 0 degree mark.

5. Subtract degrees advance at idle from

degrees at higher speed. Difference is

amount of centrifugal advance.

6. Slowly decrease engine speed to idle RPM. Timing mark should move

smoothly in direction of engine rotation.

16

Page 18

DIGITAL TIMING LIGHT

NOTES

ADVANCE READING (RPM NOTED

IN SERVICE MANUAL OR VECI)

TIMING AT IDLE

CENTRIFUGAL ADVANCE

1. At distributor, leave vacuum line disconnected and plugged.

2. Push and buttons until moving mark is aligned with the

stationary 0 degree mark. On display, note degrees advance at idle.

3. Slowly increase engine speed to 2500 RPM, or other speed specified

by manufacturer. Timing mark should move smoothly in opposite

direction of engine rotation.

4. Push and buttons until moving

mark is aligned with stationary 0 degree

mark.

5. Subtract degrees advance at idle from

degrees at higher speed. Difference is

amount of centrifugal advance.

6. Slowly decrease engine speed to idle RPM.

Timing mark should move smoothly in direction of engine rotation.

17

Page 19

LEFT BLANK ON PURPOSE

18

Page 20

MEASURING VACUUM ADVANCE

NOTES

RPM XXXX

VACUUM XXXXX

ADV. RPM XX

VACUUM XX

ADVANCE WITH VACUUM

- ADVANCE WITHOUT VACUUM

Contribution of Vacuum

Checking the vacuum advance mechanism requires a vacuum pump with

gauge in addition to the timing light.

INDUCTIVE TIMING LIGHT

1. Leave distributor vacuum line disconnected

and plugged. Connect vacuum pump to

distributor.

2. Increase engine speed to RPM specified by

vehicle manufacturer.

3. Press and hold down button. Note advance at specified RPM.

4. Use pump to apply vacuum specified by manufacturer. Note degrees

advance with vacuum applied.

5. Subtract degrees advance without vacuum from degrees with vacuum

applied. Difference is amount of vacuum advance.

6. Remove vacuum from distributor and return engine speed to idle.

19

Page 21

ADVANCE TIMING LIGHT

NOTES

RPM XXXX

VACUUM XXXXX

ADV. RPM XX

VACUUM XX

ADVANCE WITH VACUUM

- ADVANCE WITHOUT VACUUM

Contribution of Vacuum

1. At distributor, leave vacuum line disconnected and plugged. Connect

vacuum pump to distributor.

2. Increase engine speed to RPM specified by vehicle manufacturer.

3. Use pump to apply vacuum specified by manufacturer.

4. Press and hold down button. Turn

advance knob until moving mark is aligned

with stationary 0 degree mark. Note

advance at specified RPM.

5. Subtract degrees advance without vacuum

from degrees with vacuum applied.

Difference is amount of vacuum advance.

6. Remove vacuum from distributor and return

engine speed to idle.

20

Page 22

DIGITAL TIMING LIGHT

NOTES

RPM XXXX

VACUUM XXXXX

ADV. RPM XX

VACUUM XX

ADVANCE WITH VACUUM

- ADVANCE WITHOUT VACUUM

Contribution of Vacuum

1. At distributor, leave vacuum line disconnected and plugged. Connect

vacuum pump to distributor.

2. Increase engine speed to RPM specified by vehicle manufacturer.

Push and buttons until moving

mark is aligned with stationary 0 degree

mark. Note advance at specified RPM.

3. Use pump to apply vacuum specified by

manufacturer.

4. Push and buttons until moving

mark is aligned with stationary 0 degree

mark. Note degrees advance with vacuum applied.

5. Subtract degrees advance without vacuum from degrees with vacuum

applied. Difference is amount of vacuum advance.

6. Remove vacuum from distributor and return engine speed to idle.

21

Page 23

DISCONNECTING TIMING LIGHT

1. Turn Vehicle OFF.

WARNING

!

2. At distributor, unplug and reconnect vacuum line.

3. Remove Inductive Pickup Clamp.

4. Disconnect RED and BLACK Battery Clips.

Disconnecting cables with vehicle engine running could result

in serious injury.

22

Page 24

TROUBLESHOOTING AND CARE

Timing Light Flashes Randomly

1. Clean Inductive Pickup Clamp

Inside Surfaces with Soft Cloth

IMPORTANT

Do not allow tool to touch

exhaust manifold or

surrounding parts due to

extreme heat.

Do not drop pickup or snap it

shut. Always close jaws

slowly to prevent damage.

23

Clean Areas

Page 25

2. Slide Inductive Pickup Clamp

To new spot on #1 spark plug wire

3. Turn Inductive Pickup Over

To opposite direction on #1 spark

plug wire

4. Replace Spark Plug Wire

If solid copper spark plug wires are

used replace #1 spark plug wire

with a resistive type wire.

Reinstall original spark plug wire

after completing test.

24

Page 26

FULL ONE (1) YEAR WARRANTY

SPX Corporation, 15825 Industrial Parkway, Cleveland, Ohio 44135, warrants to

the user that this unit will be free from defects in materials and workmanship for

a period of one (1) year from the date of original purchase.

Any unit that fails within this period will be repaired or replaced at SPX

Corporations option and without charge when returned to the Factory. SPX

Corporation requests that a copy of the original, dated sales receipt be returned

with the unit to determine if the warranty period is still in effect.

This warranty does not apply to damages caused by accident, alterations, or

improper or unreasonable use. Expendable items, such as fuses, lamp bulbs,

flash tubes are also excluded from this warranty.

SPX CORPORATION DISCLAIMS ANY LIABILITY FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES FOR BREACH OF ANY WRITTEN

WARRANTY ON THE UNIT.

Some states do not allow the disclaimer of liability for incidental or consequential

damages, so the above disclaimer may or may not apply to you. This warranty

gives specific legal rights, and you may also have rights which vary from state to

state.

If you have any questions about the operations of the product, call (800)228-

7667.

© 2005 SPX Corporation All Rights Reserved.

Loading...

Loading...