Acco Arctic Titan 165 Operation manual

ARCTIC TITAN 165 OPERATION

& MAINTENANCE MANUAL

© October 2000 GBC Films Group

Do not duplicate without written permission.

GBC Pro - T ech

4151 Anderson Road

DeForest, WI 53532

Revision : A Ph: ( 608 ) 246 - 8844

Part number : 930 - 052

Fx: ( 608 ) 246 - 8645

Arctic Titan 165 Operation and Maintenance Manual

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS .................................................................. 2

IMPORTANT SAFEGUARDS ...................................................................................... 3

GENERAL ...................................................................................................................... 3

ELECTRICAL ................................................................................................................ 3

SERVICE ........................................................................................................................ 4

INSTALLATION ............................................................................................................. 4

FEATURE GUIDE ......................................................................................................... 5

OPERATING INSTRUCTIONS ................................................................................... 8

FILM LOADING AND THREADING ......................................................................... 8

BEGIN LAMINATING .................................................................................................. 13

MOUNTING ................................................................................................................... 14

CLEARING A FILM JAM ........................................................................................... 16

CARING FOR THE ARCTIC TITAN ........................................................................ 17

CLEANING THE ROLLERS ....................................................................................... 18

SPECIFICATIONS ....................................................................................................... 19

Page 1 © GBC Films Group October 2000

Arctic Titan 165 Operation and Maintenance Manual

Important Safety Instructions

YOUR SAFETY AS WELL AS THE SAFETY OF OTHERS IS IMPOR TANT T O GBC. IN THIS INSTRUCTION

MANUAL AND ON THE PRODUCT , YOU WILL FIND IMPOR T ANT SAFETY MESSAGES REGARDING

THE PRODUCT . READ THESE MESSAGES CAREFULL Y. READ ALL OF THE INSTRUCTIONS AND

SAVE THESE INSTRUCTIONS FOR LATER USE.

THE SAFETY ALER T SYMBOL PRECEDES EACH SAFETY MESSAGE IN THIS

INSTRUCTION MANUAL. THE SYMBOL INDICA TES A POTENTIAL PERSONAL SAFETY

HAZARD TO YOU OR OTHERS, AS WELL AS PRODUCT OR PROPER TY DAMAGE.

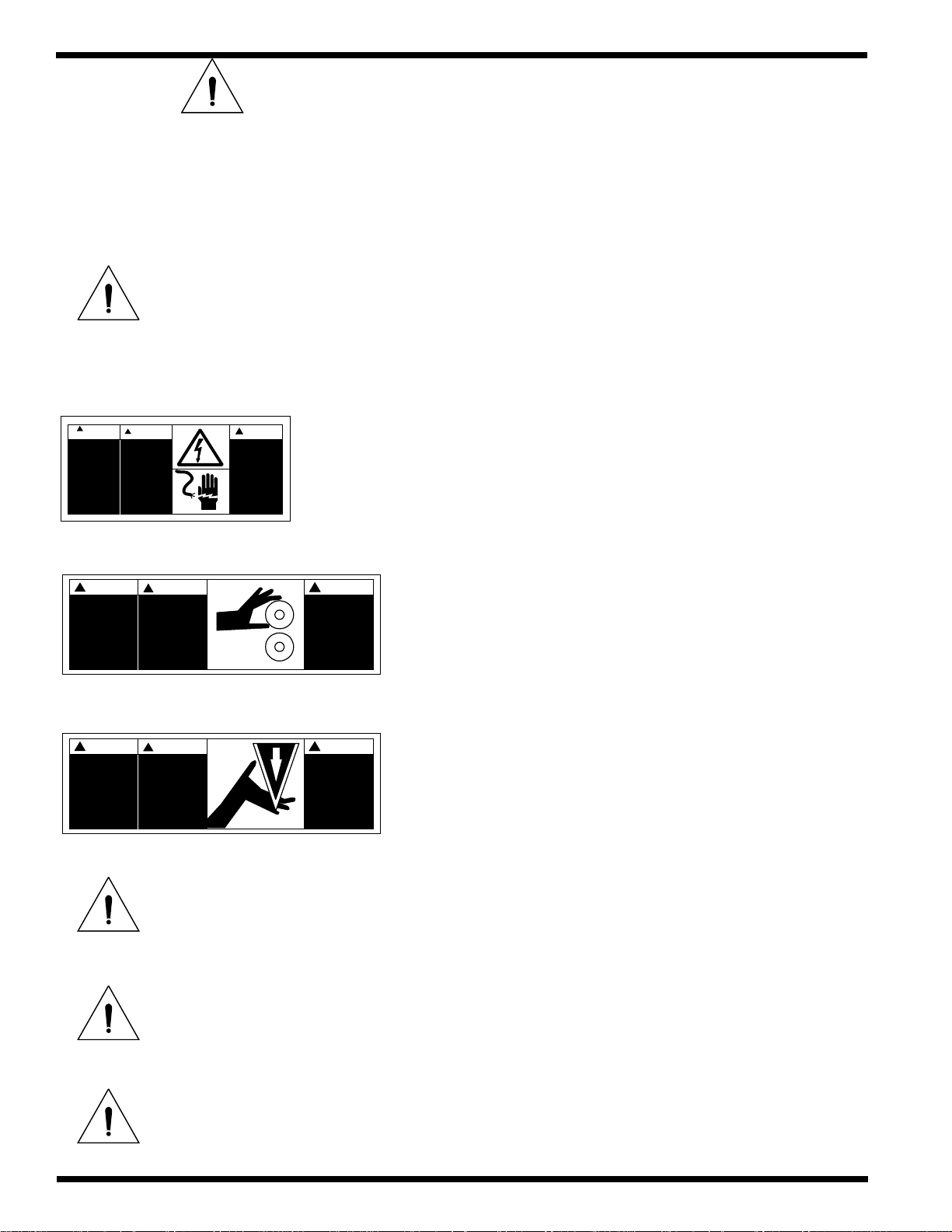

THE FOLLOWING W ARNINGS ARE FOUND UPON THE ARCTIC TITAN 165:

MUCH O

!

CUIDADO

Riesgo de choque

electrico

No abra

Adentro, no hay

piezas reparables

para el usuario.

Mantenimiento

solamente para

persona l c a lificado

!

ATTENTION

Risque de secousse

electrique.

Ne p a s o uvri r.

Pas de pieces

reparables par

l'utilisateur.

Entretien par

personnel qualifie.

!

WARNING

Electrical shock

hazard.

Do not open.

No user serviceable

parts inside.

Refer servicing to

qualified service

personnel.

THIS SAFETY MESSAGE MEANS THA T YOU COULD BE

SERIOUSL Y HUR T OR KILLED IF YOU OPEN THE PRODUCT AND

EXPOSE YOURSELF TO HAZARDOUS VOL T AGE.

!

CUIDADO

RODILLOS

CALIENTES.

PUNTO DE

PINCHAMIENTO.

Mantener manos y

ropa a distancia.

!

CUIDADO

NAVAJA FILOSA.

Mantener manos y

dedos a distancia.

ATTENTION

!

ROULEAUX

CHAUDS.

POINT DE

PINCEMENT.

Tenir mains et

vetements a l'ecant.

ATTENTION

!

LAME COUPANTE .

Tenir mains et

doigts a l'ecant.

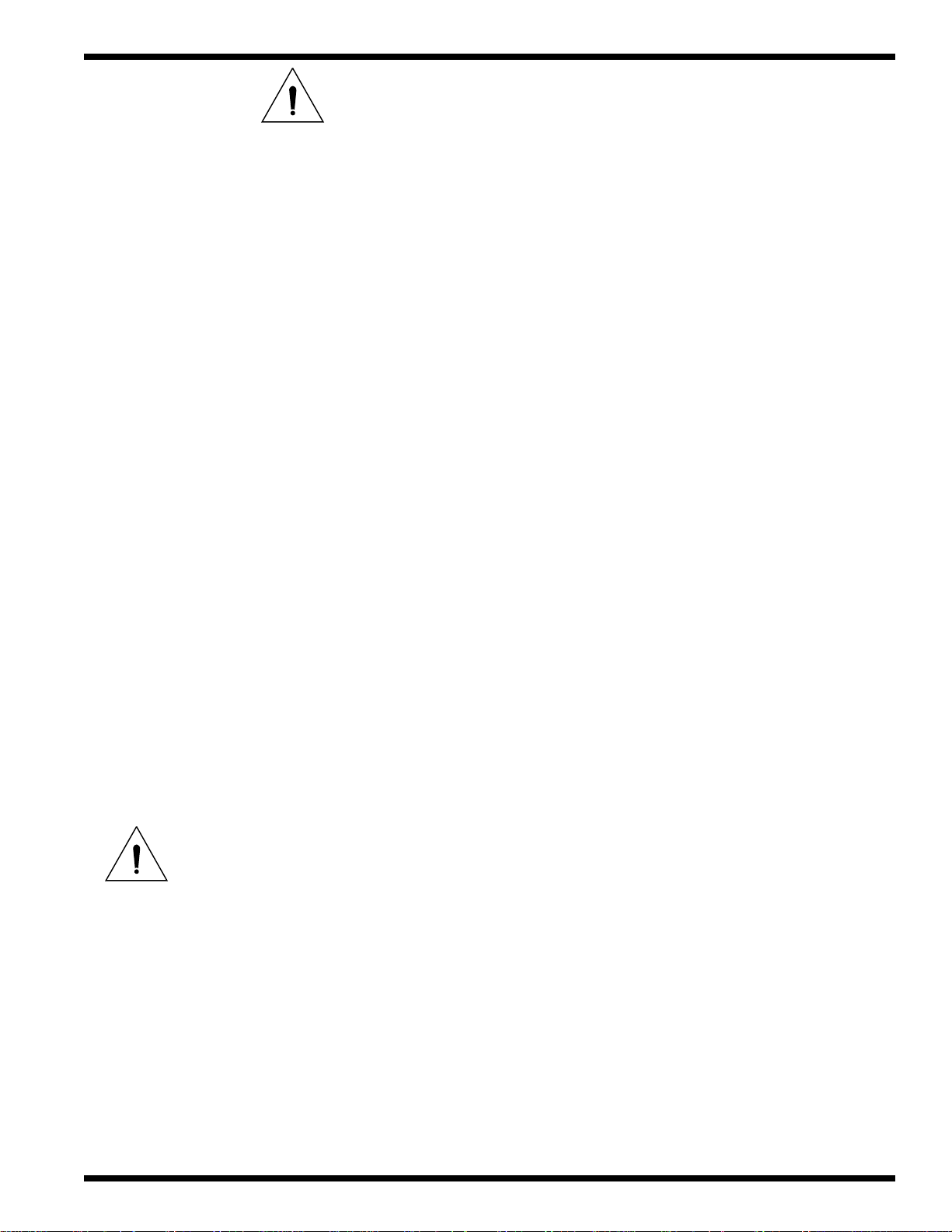

CAUTION

!

PINCH POINT.

Keep hands and

clothing away.

CAUTION

!

SHARP BLADE.

Keep hands and

clothing away.

THIS SAFETY MESSAGE MEANS THA T HANDS COULD BE

TRAPPED AND CRUSHED IN THE ROLLERS. CLOTHING,

JEWELRY AND LONG HAIR COULD BE CAUGHT IN THE

ROLLERS AND PULL YOU INTO THEM.

THIS SAFETY MESSAGE MEANS THA T YOU COULD CUT

YOURSELF IF YOU ARE NOT CAREFUL.

W ARNING DO NOT ATTEMPT TO SER VICE OR REP AIR THE ARCTIC TIT AN

LAMINA TOR.

W ARNING DO NOT CONNECT THE ARCTIC TIT AN LAMINATOR TO AN ELECTRICAL

SUPPL Y OR A TTEMPT T O OPERA TE THE LAMINA TOR UNTIL YOU HAVE COMPLETEL Y

READ THESE INSTRUCTIONS. MAINT AIN THESE INSTRUCTIONS IN A CONVENIENT

LOCA TION FOR FUTURE REFERENCE.

W ARNING TO GUARD AGAINST INJUR Y, THE FOLLOWING SAFETY PRECAUTIONS

MUST BE OBSER VED IN THE INST ALLATION AND USE OF THE LAMINA TOR.

Page 2 © GBC Films Group October 2000

Arctic Titan 165 Operation and Maintenance Manual

Important Safeguards

General

Keep hands, long hair, loose clothing, and articles such as necklaces or ties away from the front

rollers to avoid entanglement and entrapment.

Do not use the laminator for other than its intended purpose.

Do not place the laminator on an unstable car, stand or table. An unstable surface may cause

the laminator to fall resulting in serious bodily injury. Avoid quick stops, excessive force and

uneven floor surfaces when moving the laminator on a cart or stand.

Do not defeat or remove electrical and mechanical safety equipment such as interlocks, shields

and guards.

Do not insert objects unsuitable for lamination or expose the equipment to liquids.

Electrical

The laminator should be connected only to a source of power as indicated in these instructions

and on the serial plate located on the rear of the laminator. Contact an electrician should the

attachment plug provided with the laminator not match the receptacles at your location.

CAUTION: The receptacle must be located near the equipment and easily

accessible.

Disconnect the attachment plug from the receptacle to which it is connected and keep the

power supply cord in your possession while moving the laminator .

Do not operate the laminator with a damaged power supply cord or attachment plug, upon

occurrence of a malfunction, or after the laminator has been damaged. Contact GBC’ s Technical

Service Department or your dealer/distributor for assistance.

Page 3 © GBC Films Group October 2000

Arctic Titan 165 Operation and Maintenance Manual

Service

Perform only the routine maintenance procedures referred to in these instructions.

WARNING: Do not attempt to service or repair the laminator. Disconnect the

plug from the receptacle and contact GBC’ s T echnical Department or your dealer/

distributor when one or more of the following has occurred.

• The power supply cord or attachment plug is damaged.

• Liquid has been spilled into the laminator

• The laminator is malfunctioning after being mishandled

• The laminator does not operate as described in these instructions.

Installation

1. Shipping damage should be brought to the immediate attention of the delivering carrier .

2. The Arctic Titan 165 comes fully assembled on a stand. If another stand is preferred, it

must be able to support 285 pounds.

3. A void locating the laminator near sources of heat or cold. A void locating the laminator in

the direct path of forced, heated or cooled air.

4. Connect the attachment plug provided with the laminator to a suitably grounded outlet

only . Avoid connecting other equipment to the same branch circuit to which the

laminator is connected, as this may result in nuisance tripping of circuit breakers

or blowing fuses.

Page 4 © GBC Films Group October 2000

Arctic Titan 165 Operation and Maintenance Manual

Feature Guide

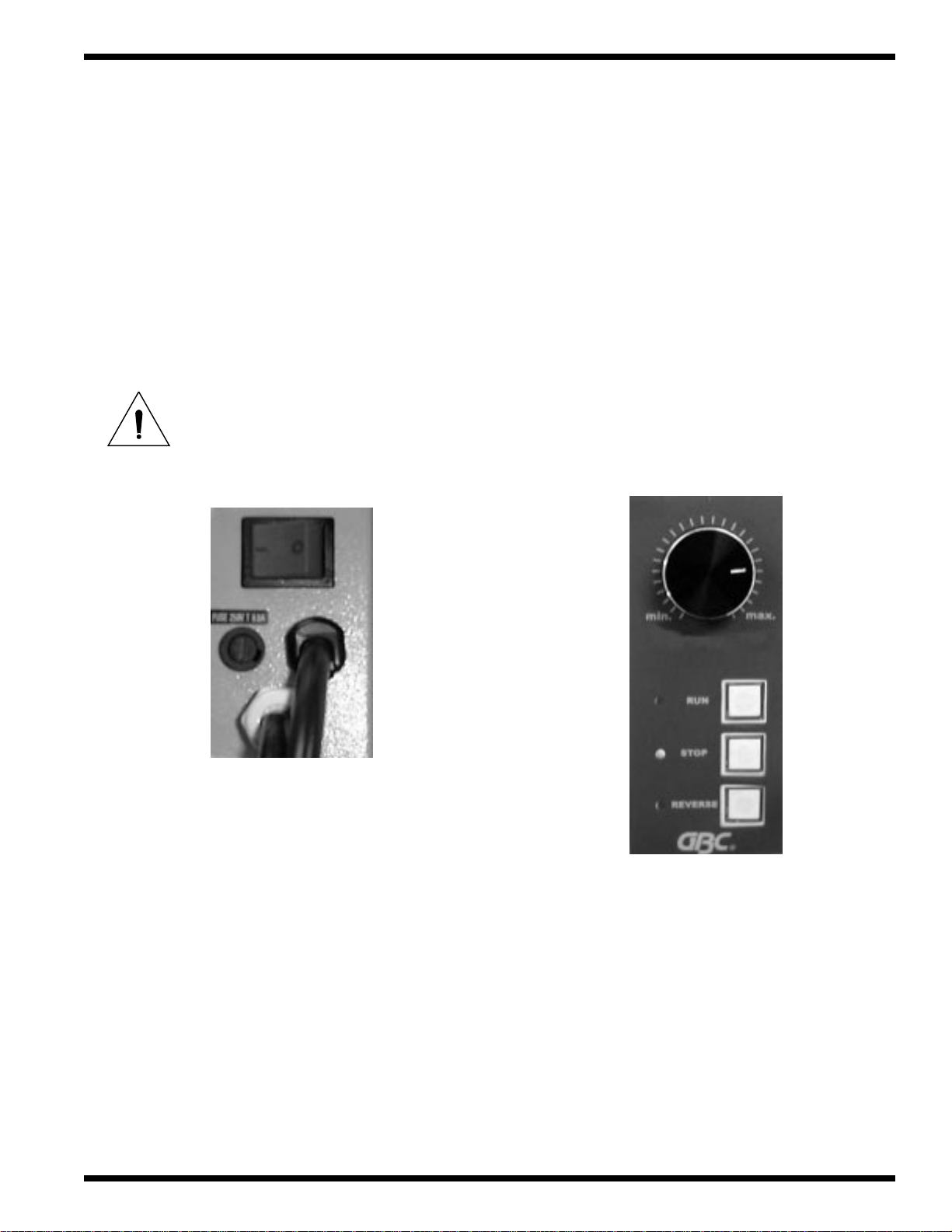

A. Power Switch: Fig (1). Located in the rear of the machine and applies power to the

laminator .

B. Fuse: Fig (1). Electrical safety device, located near on the rear of the machine near the

power cord, that can be replaced by the operator if necessary. The Arctic Titan 165

requires a 10A, 250V fuse.

WARNING: If the fuse opens a second time after being replaced, contact your

local GBC Technical Representative or dealer/distributor for assistance.

Figure 1

Figure 2

C . Control Panel: Fig (2).

Run: Activates rollers for normal operation

Stop: Deactivates rotation of the rollers.

Speed Control: Variable speed control up to 3 ft./min

D. Top Pressure Plate: Helps prints remain against the feed table while being fed into the

rollers. This plate may be removed for mounting boards.

Page 5 © GBC Films Group October 2000

Arctic Titan 165 Operation and Maintenance Manual

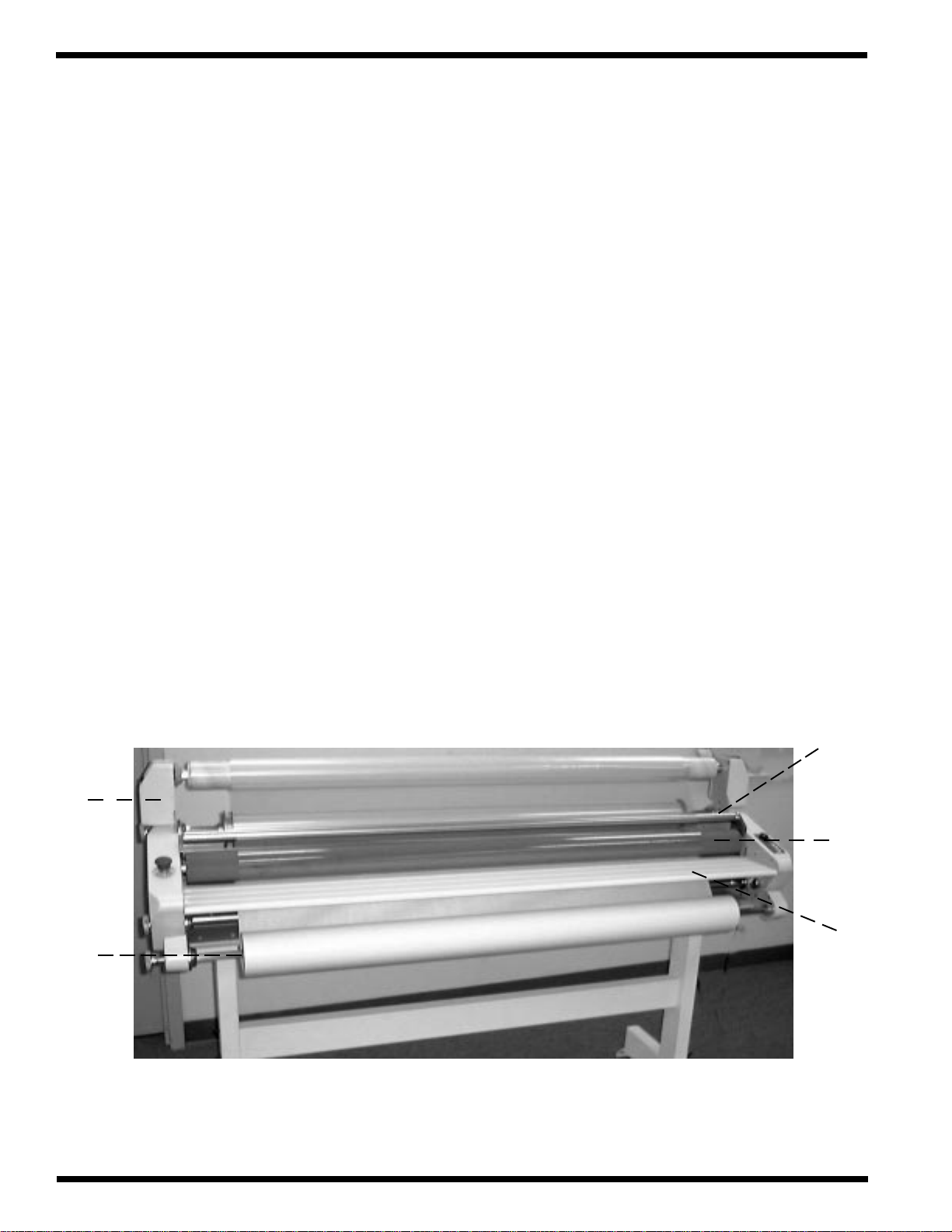

E. Feed Table: Fig (3). The feed table is has a safety interlock switch. When the table is

removed, power to the motors is also removed.

F . Front Rollers: Fig (3). Prints are fed into the roller so that pressure sensitive materials

may be applied to prints.

G. Idler Bar: Fig (3). The idler bar located near the supply roll is used to direct the film to

the heat rollers and helps to release the liner from pressure sensitive films.

H. Film Shafts and Core Adapters: Fig (3). The core adapters are inserted into the ends

of the film cores. The film shaft is inserted through the centers of the core adapters then

placed on the laminator . Four 3” and four 2 ¼” cores are included with the Arctic T itan.

I. Rewind Unit: Fig (3). Located on the top of the unit, the rewind is designed to take up

the release liner as the print is being laminated.

G

I

F

E

H

Figure 3

Page 6 © GBC Films Group October 2000

Loading...

Loading...