Acco 1400, 4000 ILLUSTRATED PARTS LIST

PAPER SHREDDER 1400 & 4000

PAPER SHREDDER

1400 & 4000

ILLUSTRATED

PARTS LIST

Acco Service Division,

Halesowen Industrial Estate, Hereward Rise, Halesowen, West Midlands B62 8AN

Telephone 0845 658 6600 Fax 0121 501 3991

D Mead Issue 1 Page 1 of 24 December 2005

PAPER SHREDDER 1400 & 4000

TABLE OF CONTENTS

ILLUSTRATED PARTS MANUAL

INTERIM SHREDDERS – 230 VOLTS

Preface Page 3

CUTTING HEADS

Model 1400 S2 Pages 4 - 6

Model 1400 S3, S4 Pages 7 - 9

Model 1400 S5 Pages 10 – 12

Model 4000 S2-4, S2-6 Pages 13 – 15

Model 4000 S3, S4 Pages 16 - 18

CABINETS

Models 1400 Pages 19

Models 4000 Pages 20

ELECTRICAL

Models 1400 Page 21

Models 4000 Page 22

WIRING DIAGRAM Page 23

AMENDMENT SHEET Page 24

D Mead Issue 1 Page 2 of 24 December 2005

PAPER SHREDDER 1400 & 4000

PREFACE

SERVICE PREPARATION

This manual provides the instructions for the replacement of all the components that may become worn or

damaged during normal usage of the machine.

“Illustrated Parts Lists” - For each machine give full details of the replacement part numbers

with supporting diagrams to show the location of the components.

“Service Instructions” - For each machine give the recommended servicing procedure

with supporting pictorial diagrams for added clarity

WARNING

1. Check the machine RATING PLATE DETAILS are compatible with the electrical mains supply.

2. Disconnect the electrical mains supply before removing any covers.

3. The machine MUST have a sound Electrical Earth Connection.

NOTE: THE ELECTRIC MOTOR IS PROTECTED BY AN AUTOMATIC THERMAL

OVERLOAD CUT-OUT

Product Testing after Servicing or Repair.

IMPORTANT. If any electrical component has been changed, an electrical connection broken and remade,

or any wiring disturbed, the product being repaired or serviced must be flash tested or PAT tested. This test

must be carried before a product is handed back or returned to the customer or returned to stock. The test

must be appropriate for the machine being repaired. E.g. double insulated of earthed. A competent person

should conduct the test and keep a log of all machines tested, the serial number of the machine, the details of

the test, the test results and the date the test was carried out.

D Mead Issue 1 Page 3 of 24 December 2005

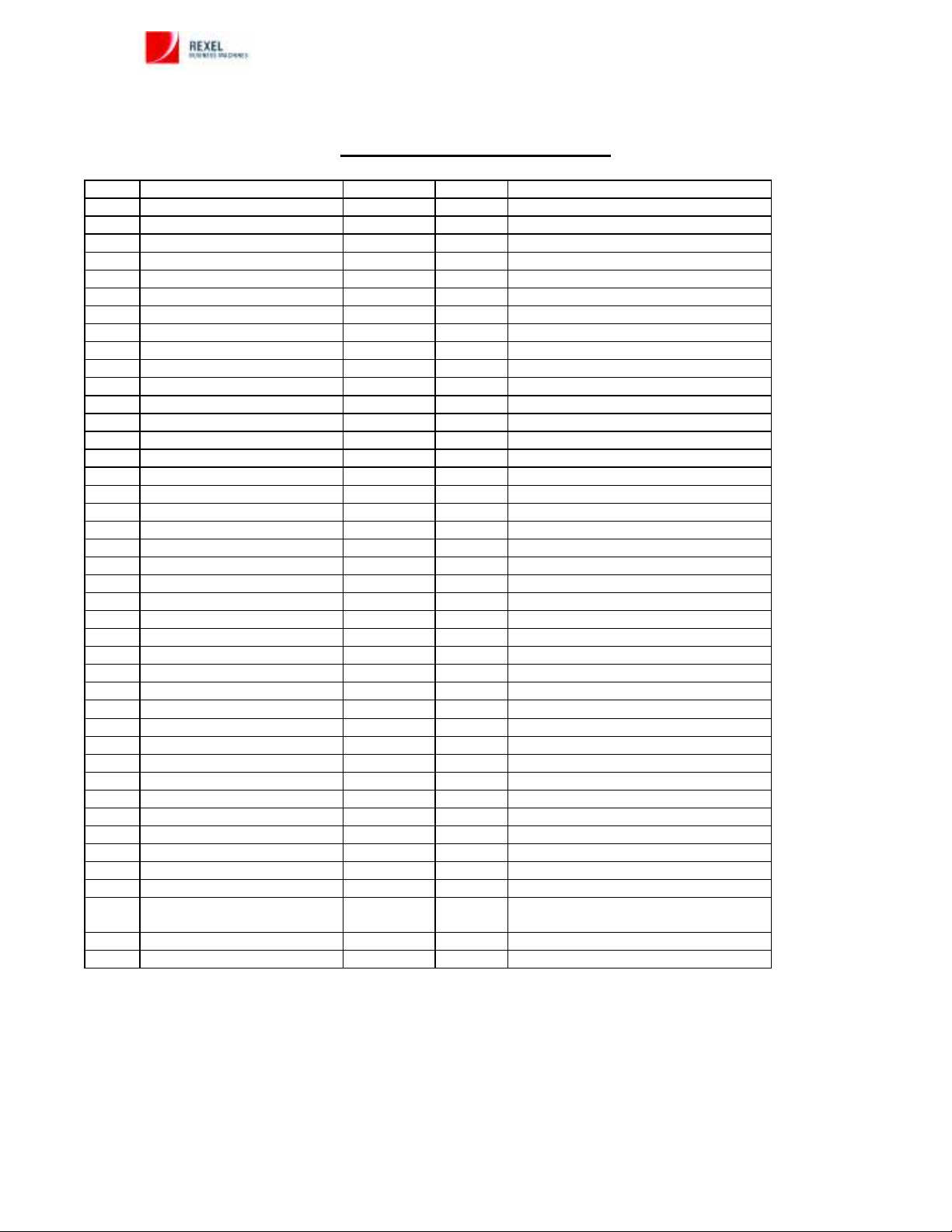

PAPER SHREDDER 1400 & 4000

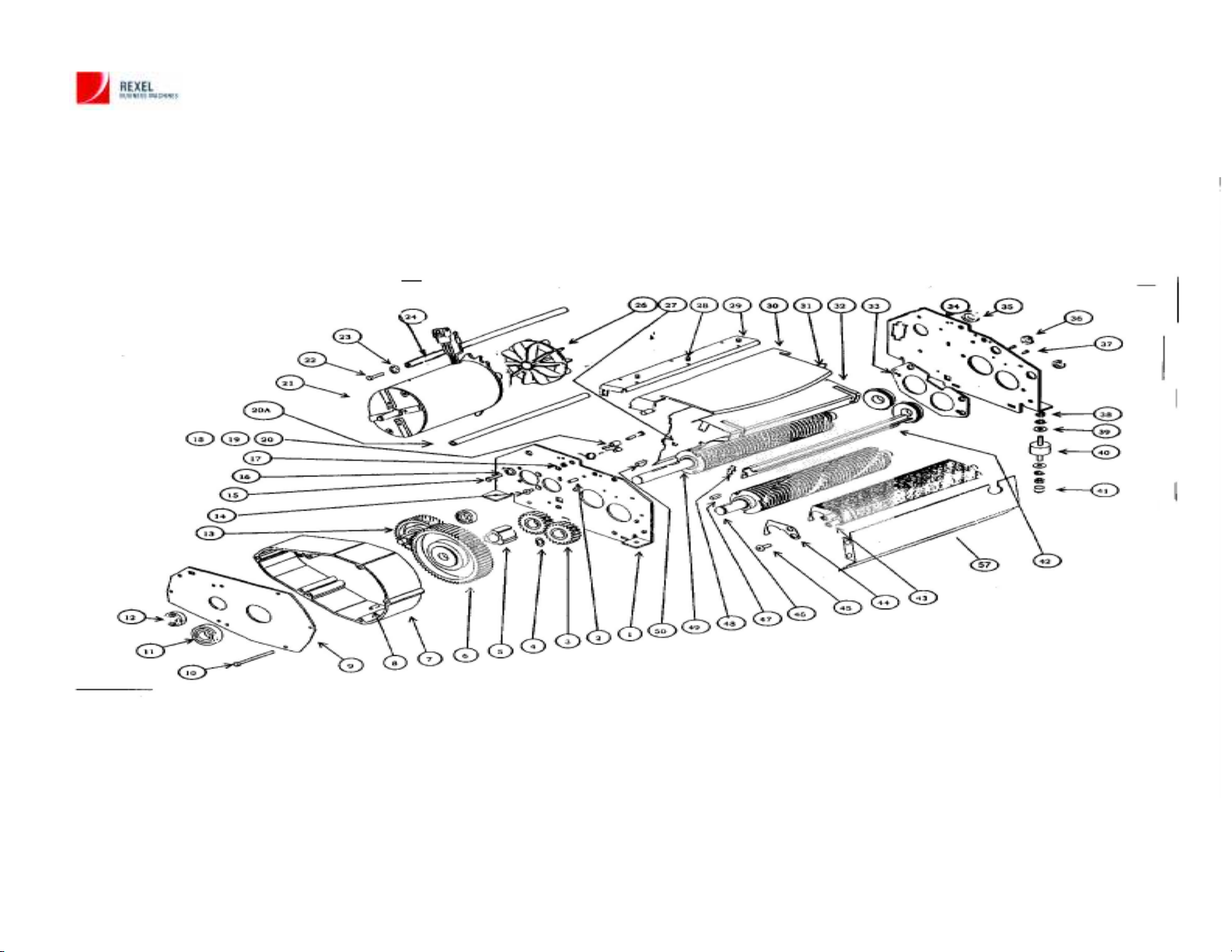

MODEL 1400 S2 CUTTING HEAD

No Description Part 1400 S2 Comments

1 Side Frame (Motor) 1 Part of Side Frame (Motor) Assy.

2 Pin, 20MM long, 5mm dia PEG77 2 Safety Flap Fixing Pin

3 1-1 Gear D53530 2

4 Circlip, 17mm ID TRU88 1

5 Lost Motion Collar D53790 1

6 Spur Gear Assembly A53650 1

7 Gearbox Spacer D53520 1

8 Dowel Pin PEG91 6 Gearbox Spacer to Side Frame

9 End Closing Plate D53065 1

10 Bolt, M5 x 70 MM SCM151 5 End Closing Plate to Side frame

11 Ball bearing BR23 5

12 Ball bearing BR28 2

13 Compound Gear Assembly A53547 1

14 Screw, M5 x 12 CSK Nyloc SCM152 2 Motor to Side Frame

15 Screw, M5 x 10 SCM9 2 Motor to Side Frame

16 Lockwasher, M5 SHK10 2 Motor to Side Frame

17

18

19

20

21 Motor, 550W SL20-307 1

22 Screw, M6 x 12 SCM15 6 Tie Bars to Side Frame

23 Lockwasher, ¼” SHK4 6 Tie Bars to Side Frame

24 Tie Bar (Top Motor) D53636 1

26 Motor fan Supplied with motor

27 Grommet, Blind SL18-140 6

28 Cover Bracing Plate D53648 1

Screw M3 x 16mm SCM78 2 Cover Bracing Plate to Side Frame.

M3 Plain Washer PLN31 2 Cover Bracing Plate to Side Frame.

M3 Shakeproof Washer SHK12 2 Cover Bracing Plate to Side Frame.

M3 Nut NM7 2 Cover Bracing Plate to Side Frame.

29 Active Safety Flap A53583 1

30 Bin Full Flap D53731 1

31 Grommet SL18-333 2 Bill Full Flap Buffers

32 Stripper Location Plate D53554 2

33 Side Frame (Bearing) D53594 1

34 Grommet GRM22 1

35 Snap Bush SL18-369 2 For Sensor Leads.

36 Pop Rivet RTS68 6 Stripper Plates to Side Frame

37 Nut, M6 NM5 8 Vibration Mounts to Side Frame &

Cabinet.

38 Washer, ¼” Plain PLN4 4 Vibration Mounts to Side Frame.

39 Vibration Mount 1000528 4

D Mead Issue 1 Page 4 of 24 December 2005

PAPER SHREDDER 1400 & 4000

No Description Part 1400 S2 Comments

Washer, ¼” x 5/8 Plain PLN4L 2 Vibration Mounts to Cabinet

front.

Washer, ¼” x 11/2 Plain PLN27 2 Vibration Mounts to Cabinet

rear.

M6 Shakeproof Washer SHK4 8 Vibration Mounts

40 Nut Protection Cover SL18-325 2 Front Vibration Mount Nuts

41 Cutter Shaft – Driven D53561 1

42 Tie Bar D53573 2

43 Key, 5X5X16 KEY32 2

44 Stripper plate – front D53556 1

45 Deflector Tab D53641 2

46 Stripper Plate – Rear D53555 1

No 6 x 5/16” Screw SCR496 4 Stripper anti rattle screw.

47 Cutter Shaft – Drive D53562 1

48 Key ‘Woodruff’ 5x9x22 KEY33 1

END PLATE ASSEMBLY A53526SP 1 Comprises 9,11,12

GEARBOX SPACER ASSEMBLY A53531SP 1 Comprises 7,8

SIDE FRAME ASSEMBLY (MOTOR) A53595SP 1 Comprises 1,11,32

SIDE FRAME ASSEMBLY (BRG) A53596SP 1 Comprises 33,32,10

HEAD ASSEMBLY 1000847 1 Comprises all except

21,26,34,35,14,15,16,37,38,

39,40

GREASE C11245 Gearbox

SHREDDER OIL, 500ML 40100 1

D Mead Issue 1 Page 5 of 24 December 2005

PAPER SHREDDER 1400 & 4000

1400 S2 CUTTING HEAD

D Mead Issue 1 Page 6 of 24 December 2005

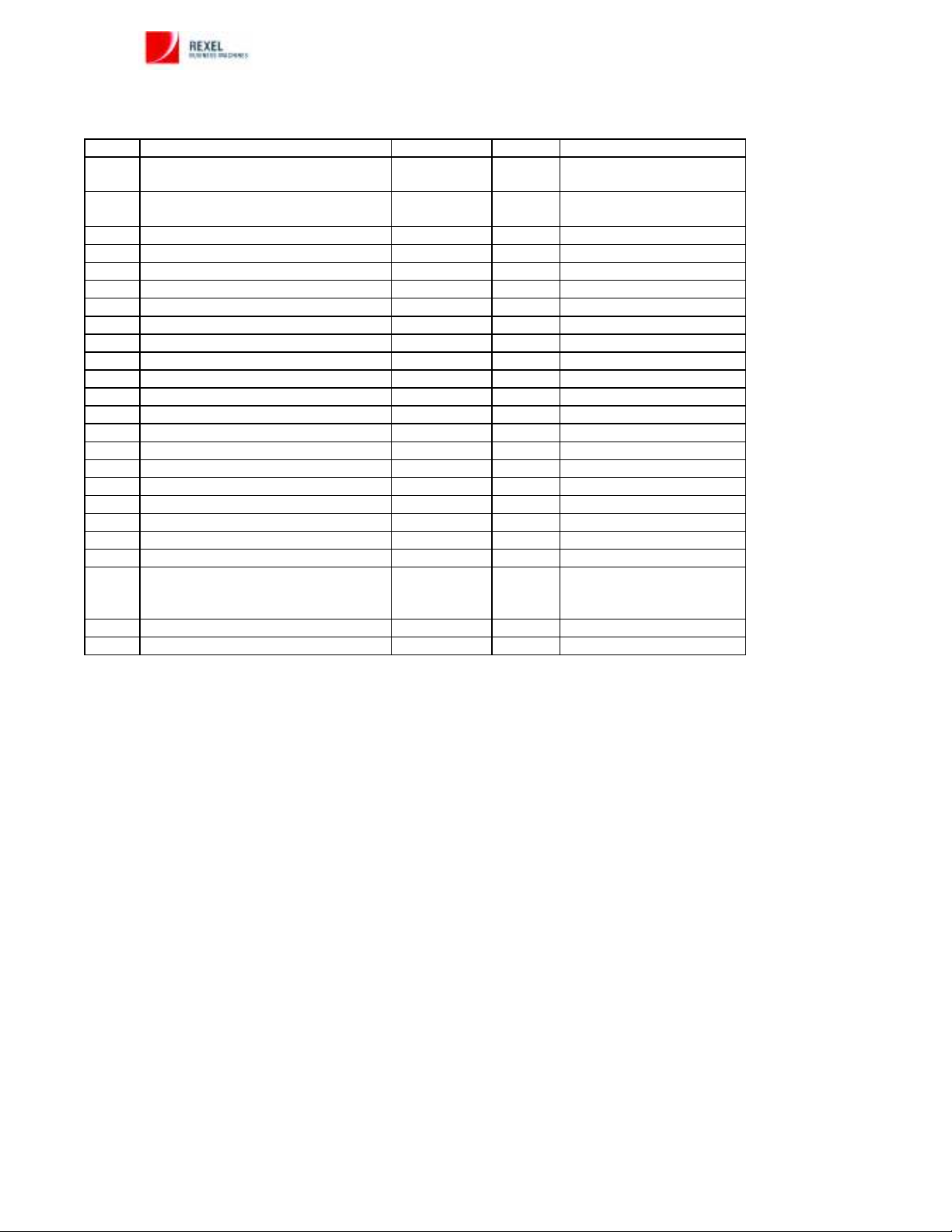

PAPER SHREDDER 1400 & 4000

MODEL 1400 S3 and S4 CUTTING HEAD

No Description Part 1400 S3 1400 S4 Comments

1 Side Frame (Motor) 1 1 Part of Side Frame (Motor) Assy

2 Pin, 20MM long, 5MM dia PEG77 2 2 Safety Flap Fixing Pin.

3 1:1 Gear D53515 2 2

4 Circlip, 17MM ID TRU88 1 1 FOR 1:1 GEAR ON DRIVEN SHAFT

5 Lost Motion Collar D53790 1 1

6 52T Spur Gear Assembly A53650 1 1

7 Gearbox Spacer D53520 1 1

8 Dowel Pin PEG91 6 6 Gearbox Spacer to Side Frame

9 End Closing Plate D53065 1 1

10 Bolt, M5 x 70 SCM151 5 5 End Closing Plate to Side frame

11 Ball Bearing BR23 5 5

12 Ball Bearing BR28 2 2

13 Compound Gear Assembly A53547 1 1

14 Screw, M5 x 12 CSK Nyloc SCM152 2 2 Motor to Side Frame

15 Screw, M5 x 10 SCM9 2 2 Motor to Side Frame

16 Lockwasher, M5 SHK10 2 2 Motor to Side Frame

17

18

19

20

20A Tie/Stripper Bar D53573 1 1

21 Motor, 550W SL20-307 1 1

22 Bolt, M6 x 12 SCM15 5 5 Tie Bars to Side Frame. Also see Item45.

23 Lockwasher ¼” SHK4 5 5 Tie Bars to side frame

24 Tie Bar (Top Motor) D53636 1 1

26 Motor fan Supplied with motor

27 Grommet SL18-333 2 2 For Bin Full Flap

28 Grommet, Blind SL18-140 6 6 For Cover Bracing Plate

29 Cover Bracing plate D53648 1 1

Screw M3 x 16mm SCM78 2 2 Cover bracing Plate to Side Frame

Washer M3 Plain PLN31 2 2 Cover bracing Plate to Side Frame

Washer M3 Shakeproof SHK12 2 2 Cover bracing Plate to Side Frame

Nut M3 NM7 2 2 Cover bracing Plate to Side Frame

30 Active Safety Flap A53583 1 1

31 Bin Full Flap D53588 1 1

32 Infeed Chute – Rear D53680 1 1

33 Stripper Location plate D53682 2 2

34 Side Frame (Bearing) D53687 1 1

35 Grommet GRM22 1 1

D Mead Issue 1 Page 7 of 24 December 2005

PAPER SHREDDER 1400 & 4000

No Description Part 1400

S3

36 Snap Bush SL18-369 2 2

37

38 Nut M6 NM5 8 8 Vibration Mounts to Side

39 Washer, plain PLN4 4 4 Vibration Mounts to Side Frame.

Washer, ¼” x 5/8 Plain PLN4L 2 2 Vibration Mounts to Cabinet

Washer, ¼” x 11/2 Plain PLN27 2 2 Vibration Mounts to Cabinet

Lockwasher ¼” SHK4 8 8 Vibration Mounts to Side Frames

40 Vibration Mount 1000528 4 4

41 Nut Protection Cap SL18-325 2 2 Front Vibration Mount Nuts

42 Infeed chute – Front A53693 1 1

Screw M4 x 12 SCM25 8 8 Infeed Chutes to Side Frames

Washer, Plain 3BA PLN2 8 8 Infeed Chutes to Side Frames

Washer, Shakeproof 3BA SHK2 8 8 Infeed Chutes to Side Frames

43 Stripper Bar D53679 2 2

44 Stripper D53678 144 150

45 Screw, M6 x 16mm CSK Skt Head SCM104 3 3 Tie bars to side frame under

46 Cutter Shaft – Driven D53557 1

46 Cutter Shaft – Driven D53559 1

47 Key KEY32 2 2

48 Deflector Tab D53641 2 2

49 Cutter Shaft – Drive D53558 1

49 Cutter Shaft – Drive D53560 1

50 Key KEY33 1 1

51 Paper Chute D53708 1 1

Bolt, M6 x 16 SCM87 4 4 Paper Chute to Side Frame

Lockwasher ¼” SHK4 4 4 Paper Chute to Side Frame

END PLATE ASS. A53526SP 1 1 Comprises 9,11,12

GEARBOX SPACER ASS. A53531SP 1 1 Comprises 7,8

GREASE C11245 Gearbox

SIDE FRAME ASS (MOTOR) A53689SP 1 1 Comprises 1,11,33

SIDE FRAME ASS (BEARING) A53690SP 1 1 Comprises 11,33,34

HEAD ASSEMBLY 1000848 1 Comprises all except

HEAD ASSEMBLY 1000849 1 Comprises all except

SHREDDER OIL, 500ML 40100

1400

S4

Comments

Frames and Cabinet

front.

rear.

and Cabinet

gearbox spacer.

21,25,26,35,36

21,25,26,35,36

D Mead Issue 1 Page 8 of 24 December 2005

Loading...

Loading...