ABB ACS55 Users Manual

ACS55

User's Guide

for type ACS55

AC Drives

from 0.18 to 2.2 kW

English EN

Dansk DA

Deutsch DE

Español ES

Suomi FI

Français FR

Italiano IT

Nederlands NL

Português PT

Русский RU

Svenska SV

中文 CN

한국어 KR

Table of contents

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Dansk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Suomi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Italiano . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Nederlands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Português . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

Русский . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Svenska . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

中文 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

3

한국어 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .249

3AFE68929300 Rev B

EN, DA, DE, ES, FI, FR, IT, NL, PT, RU, SV, CN, KR

Effective: 25.02.2008

© 2008 ABB Oy. All Rights reserved.

4

EN 5

User's Guide

for type ACS55

AC Drives

from 0.18 to 2.2 kW

English EN

6 EN

Product and service inquiries

Address any inquiries about the product to your local ABB representative, quoting the type code and serial number of the unit in question.

A listing of ABB sales, support and service contacts can be found by navigating to www.abb.com/drives

Support and Service network on the right pane.

and selecting Drives – Sales,

Product training

For information on ABB product training, navigate to www.abb.com/drives and select Drives – Training courses on the right pane.

Providing feedback on ABB Drives manuals

Your comments on our manuals are welcome. Go to www.abb.com/drives, then select successively Drives – Document Library –

Manuals feedback form (LV AC drives) on the right pane.

3AFE68929300 Rev B

EN

Effective: 25.02.2008

© 2008 ABB Oy. All Rights reserved.

ABB Oy

AC Drives

P.O. Box 184

FI-00381 HELSINKI

FINLAND

Telephone +358 10 22 11

Fax +358 10 22 22681

Internet www.abb.com

EN 7

8

I

,

8

I

,

$&6($

,3

61<::5;;;;

$)(;;;;;;;;

3QPRWRUN:+3

a9

+]

$

a8

+]

$

5R+6

Safety instructions

Read the following instructions carefully before proceeding with the

installation.

Warning! Dangerous voltage!

Only a competent electrician may install ACS55.

Never work on the drive, the motor cable or the motor when main

power is applied. After switching off the input power, always wait at

least for 5 minutes to let the intermediate circuit capacitors

discharge before you start working on the drive.

Warning! If the heat sink is not earthed properly, you can get an

electric shock if you touch the heat sink.

Note: DIP switches are at a dangerous voltage.

Note: Even when the motor is stopped, dangerous voltages are

present at power circuit terminals L/R, N/S, T1/U, T2/V and T3/W.

Note: Even when the unit is powered down, there may be

dangerous external voltages connected from outside to the relay

output terminals.

Warning! Hot surfaces!

During operation, the cooling element may reach high temperature

(>80°C). Make sure to follow the installation instructions.

General safety instructions

ACS55 starts the motor automatically after a supply break if the

external start signal is on.

Altering the DIP switches will affect the function and performance

of ACS55. Check that the changes will not cause any risk to

persons or property.

About this manual

This guide provides information necessary to install and start-up

the unit.

Delivery check

The delivery includes:

1. ACS55

2. User’s guide

3. Two clamps for the control cable (EMC units

only).

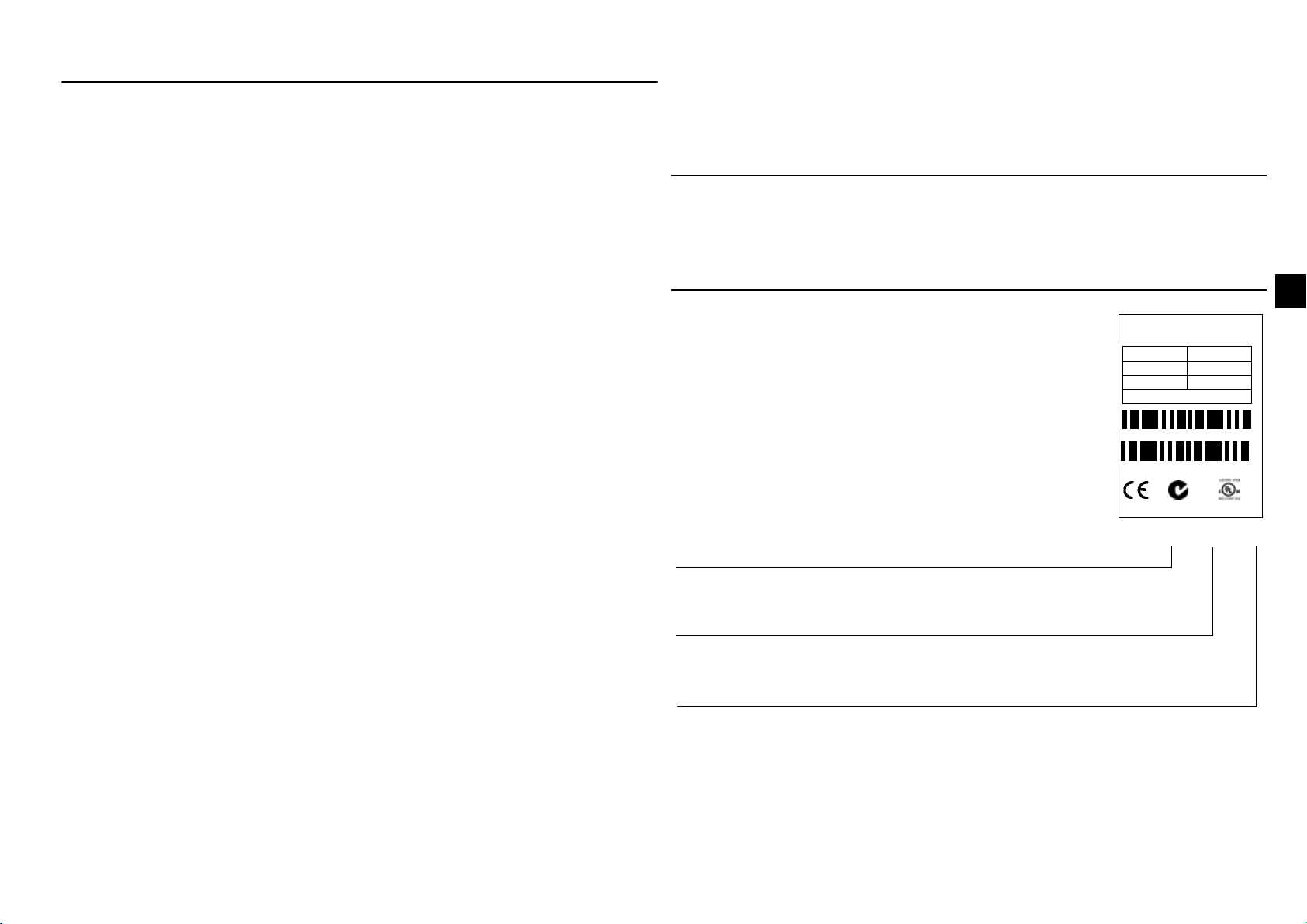

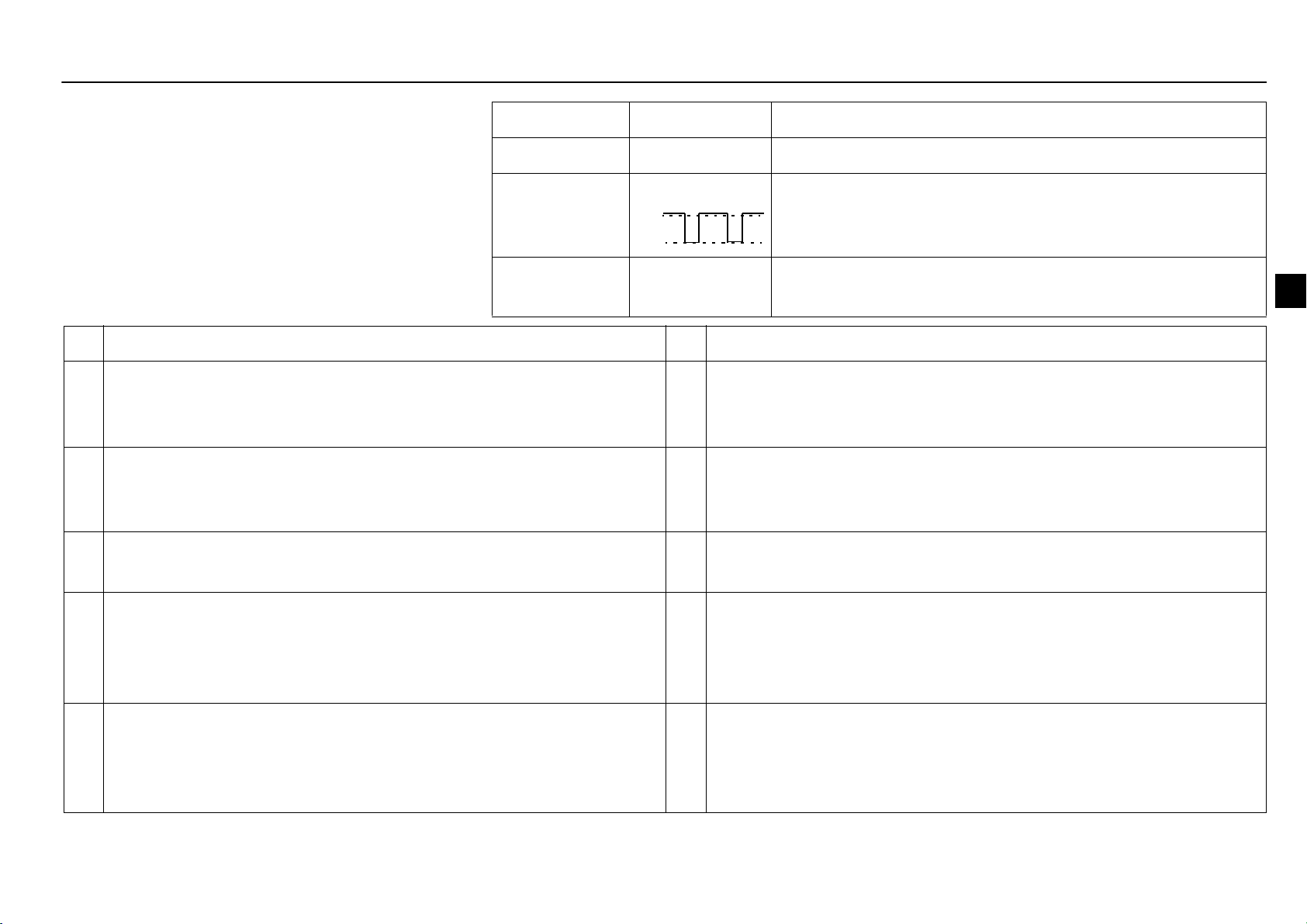

Check the rating plate and ensure that the

delivered device corresponds to the order.

EMC filter: E = Built in, N = No

Max. continuous output current (I

):

2

01A4 = 1.4 A, 02A2 = 2.2 A, 04A3 = 4.3 A,

07A6 = 7.6 A, 09A8 = 9.8 A

Supply voltage (U

):

1

1 = 110…120 VAC +10%/-15%

2 = 200…240 VAC +10%/-15%

ACS55-01_-____-_

Never attempt to repair a broken unit. ACS55 is not a field

repairable unit. Contact the supplier for replacement.

Install ACS55 in a locked or tool-openable space.

Do not connect input power to the unit more than once every three

minutes.

Serial number (S/N) is printed on the rating plate.

(Y = manufacturing year, WW = manufacturing week)

8 EN

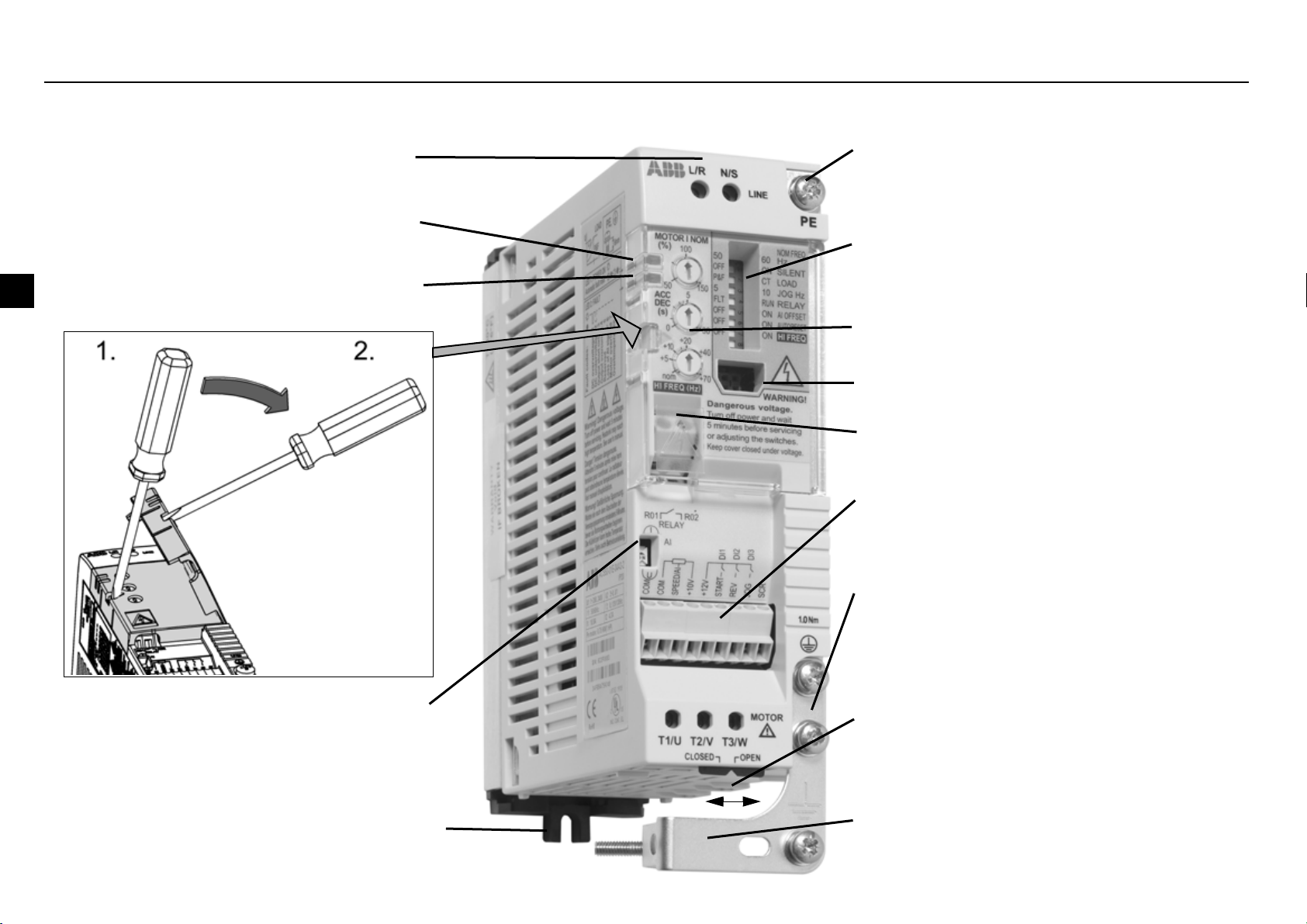

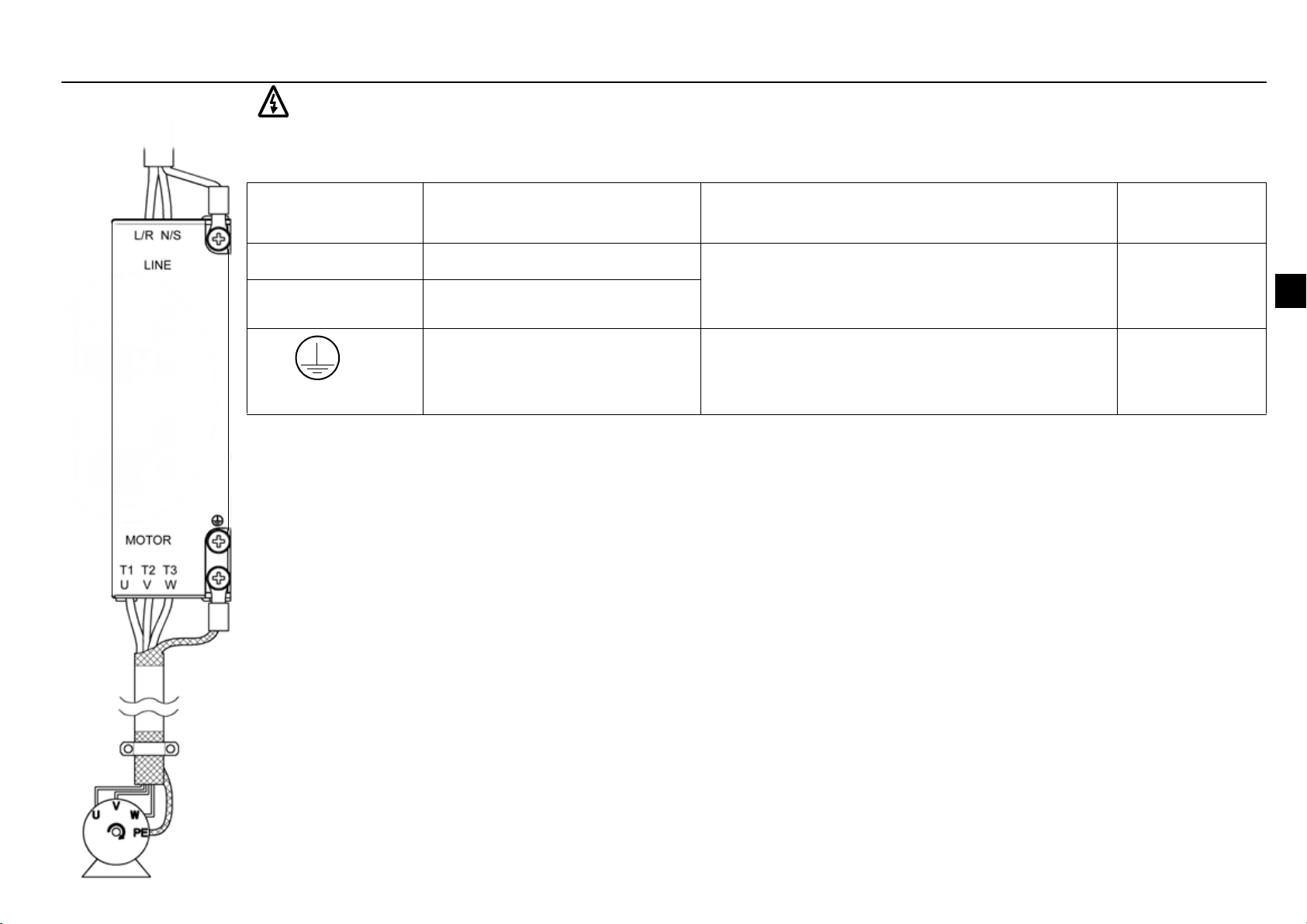

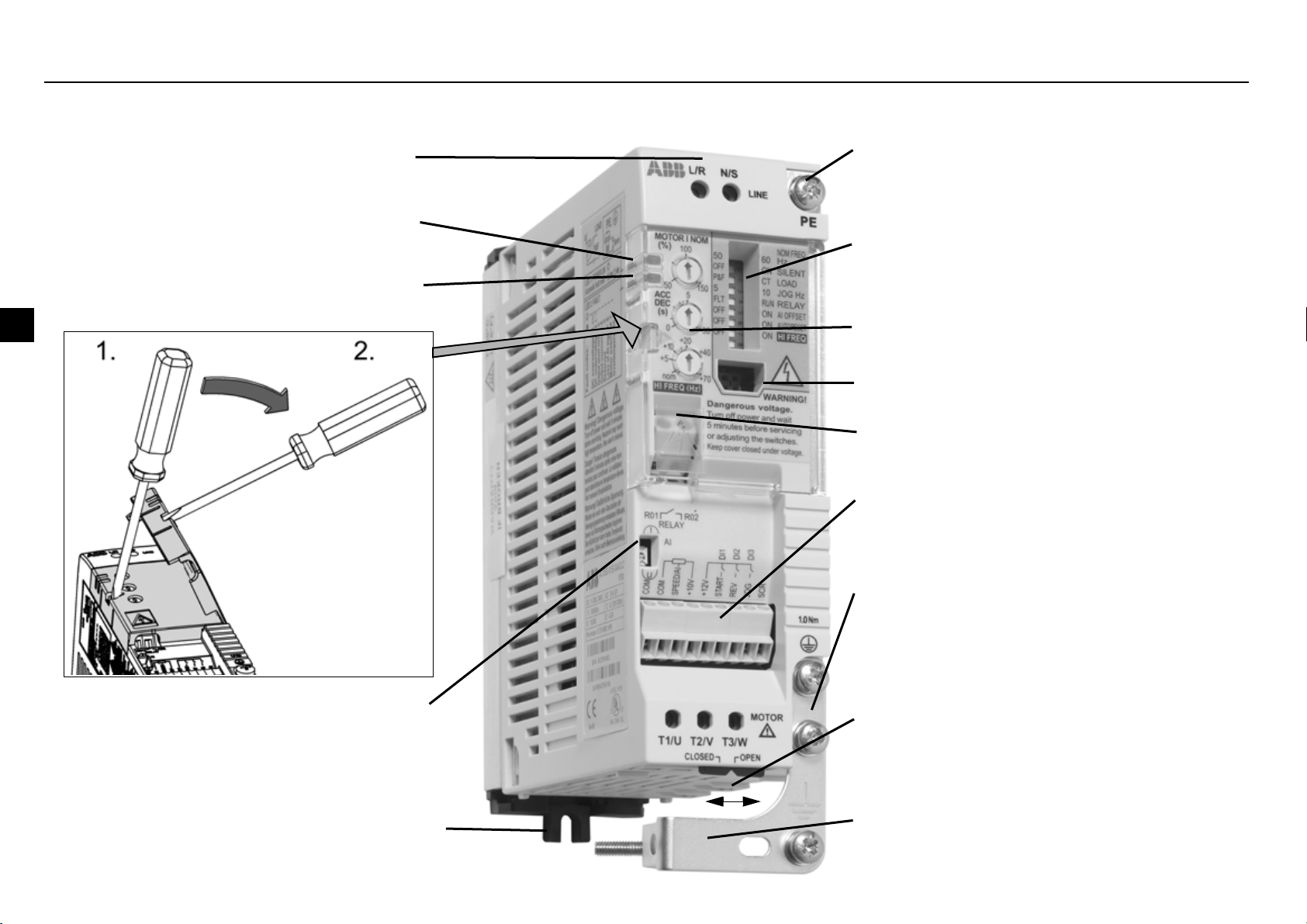

Overview of the unit

ACS55 drive controls the speed of a 3-phase AC induction motor.

Protective earth (PE), page 17

Input terminals, page 17

Power on LED, page 21

Fault LED, page 21

Analogue input signal selector

(voltage/current), page 18

DIP switches, page 14

Control potentiometers, page 16

DriveConfig kit interface, page 24

Relay output terminals, page 18

Control cable terminals, page 18

Motor cable shield, page 17

Motor cable terminals, page 17. Sliding

cover provides additional insulation. Slide

the cover left to close.

Mounting clip, pages 12 - 13

Clamp plate, page 19 (EMC units only)

EN 9

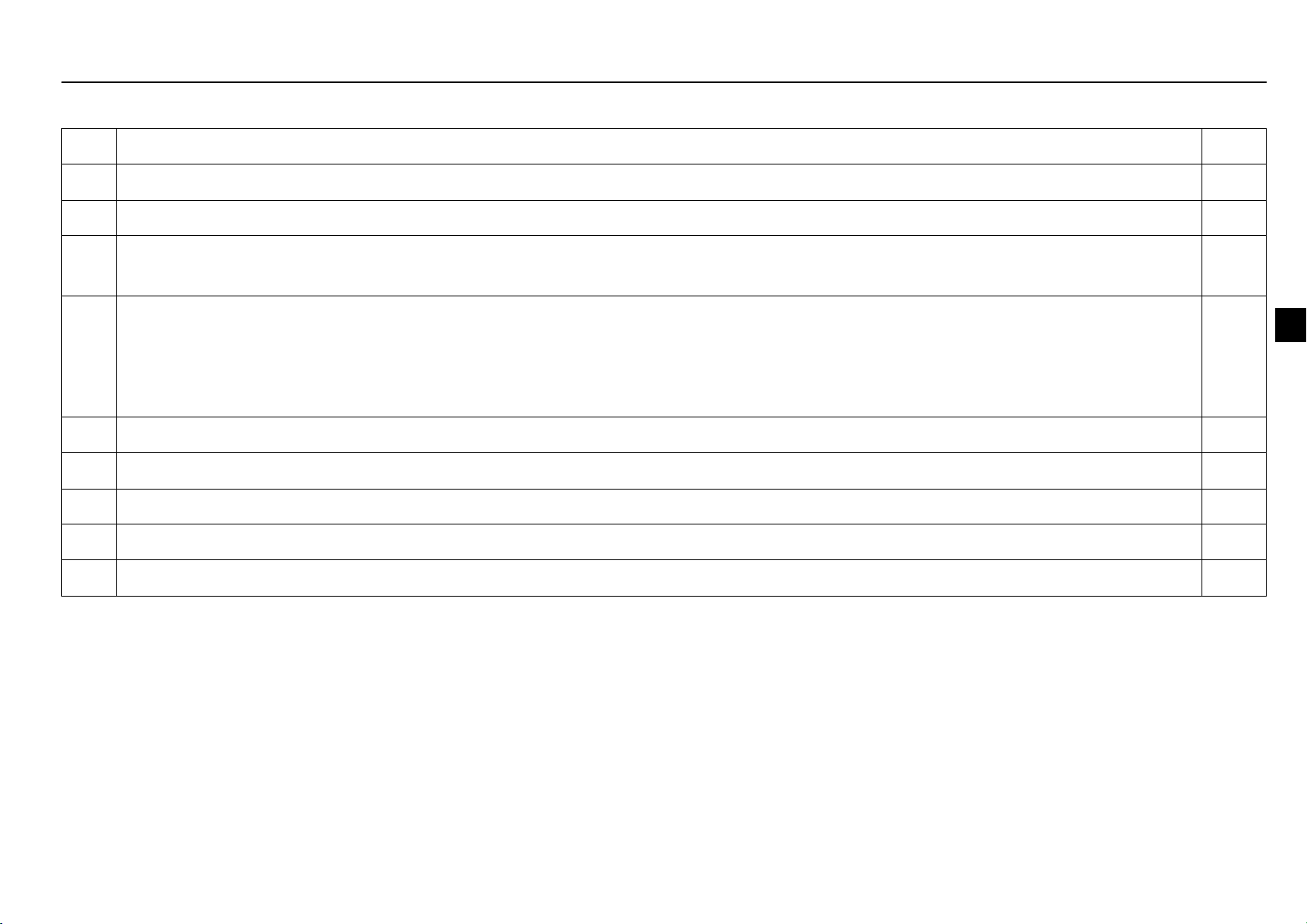

Installation and start-up steps

Read Safety instructions on page 7 before proceeding.

Action Pg.

1 Check the delivery. 7

2 Ensure that the installation environment is suitable for ACS55. 10

3 Mount the unit. 12 -

13

4 Check applicability of the standard settings: Motor nominal frequency is 50 Hz; load is a pump or a fan; maximum output

frequency is 50 Hz. If the standard settings are not suitable, adjust the DIP switches.

5 Make sure the MOTOR I NOM potentiometer matches the rated current of the motor. It defines operation of the motor

thermal protection function.

6 Adjust the acceleration/deceleration time potentiometer ACC/DEC if necessary. 16

7 Connect the power supply cable and motor cables. 17

8 Connect the control wires. 18

9 Turn the power on. Green LED is illuminated. Note: Motor rotates if the start signal is active.

10 Set the speed reference and activate the start signal. The motor accelerates to the given speed reference. 20

14

16

10 EN

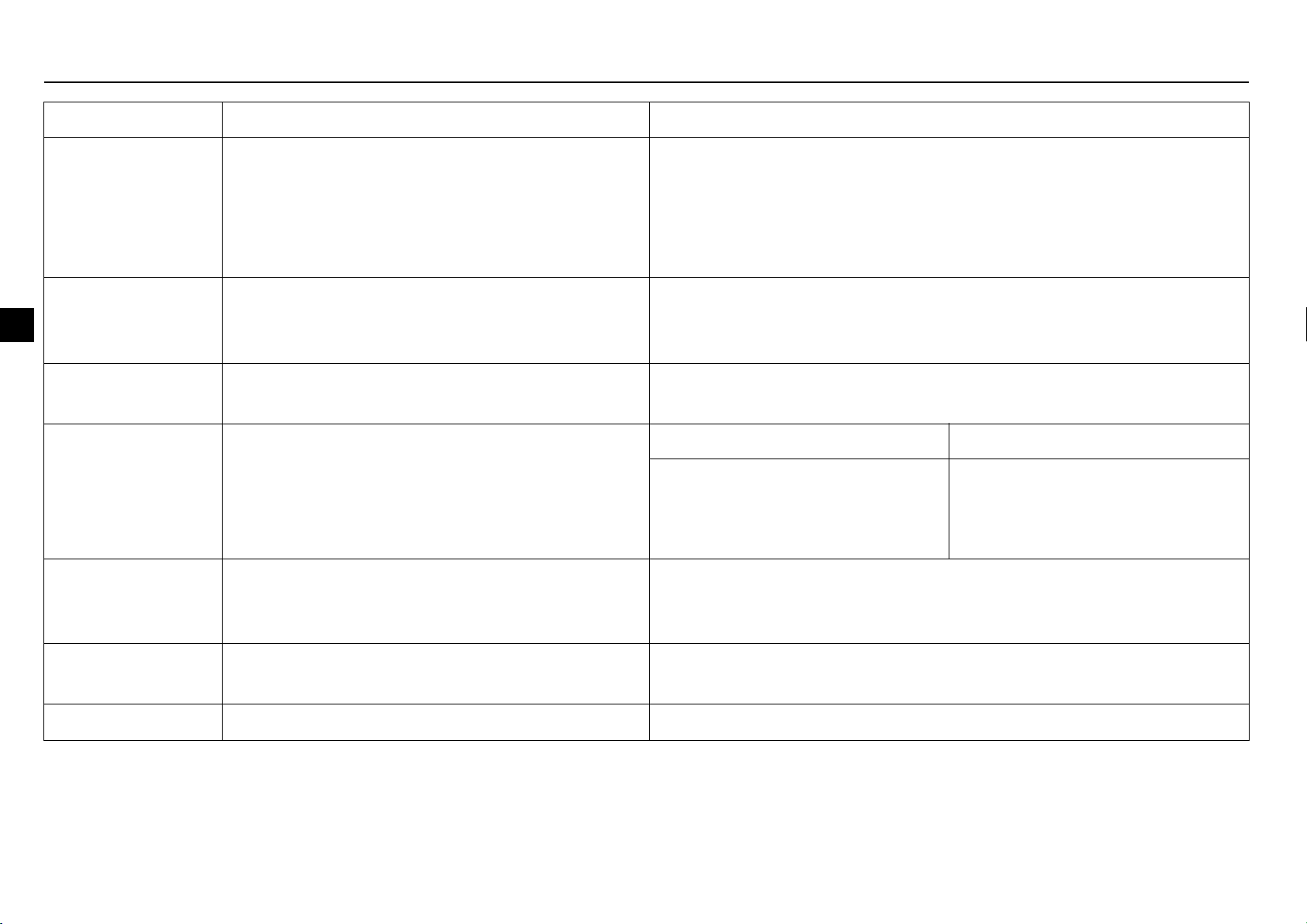

Environmental limits

Installation site Storage and transportation in a protective package

Air temperature -20°C (-4°F), no frost allowed

1)

-40°C (-40°F) to +70°C (158°F)

+40°C (104°F), with nominal load

+50°C (122°F), if continuous output current is

max. 85% of the nominal output current I

Altitude 0…2000 m (0...6,600 ft). At altitudes

1000...2000 m (3,300...6,600 ft), P

and I2 are

N

.

2

No limitation

decreased by 1% for every 100 m.

Relative humidity Less than 95%, non-condensing Less than 95%, non-condensing

Contamination

levels

(IEC 60721-3-3)

• No conductive dust allowed

• Air must be clean, free from corrosive

materials and conductive dust

• Chemical gases: Class 3C2

Storage Transportation

• No conductive dust allowed

• Chemical gases: Class 1C2

• Solid particles: Class 1S2

• Solid particles: Class 3S2

Sinusoidal

vibration

Frequency range: 5...150 Hz

Constant peak acceleration: 1 g

In accordance with ISTA 1A specification

(IEC 60068-2-6)

• No conductive dust allowed

• Chemical gases: Class 2C2

• Solid particles: Class 2S2

Shock

Not allowed Max. 100 m/s

2

(330 ft/s2), 11 ms (36 fts)

(IEC 60068-2-29)

Free fall Not allowed Not allowed

1) When operating the drive in subzero temperatures, keep the input power connected. Install the drive inside an enclosure. Ensure that

heat generated by the drive will be properly dissipated.

Degree of protection of ACS55 is IP20.

EN 11

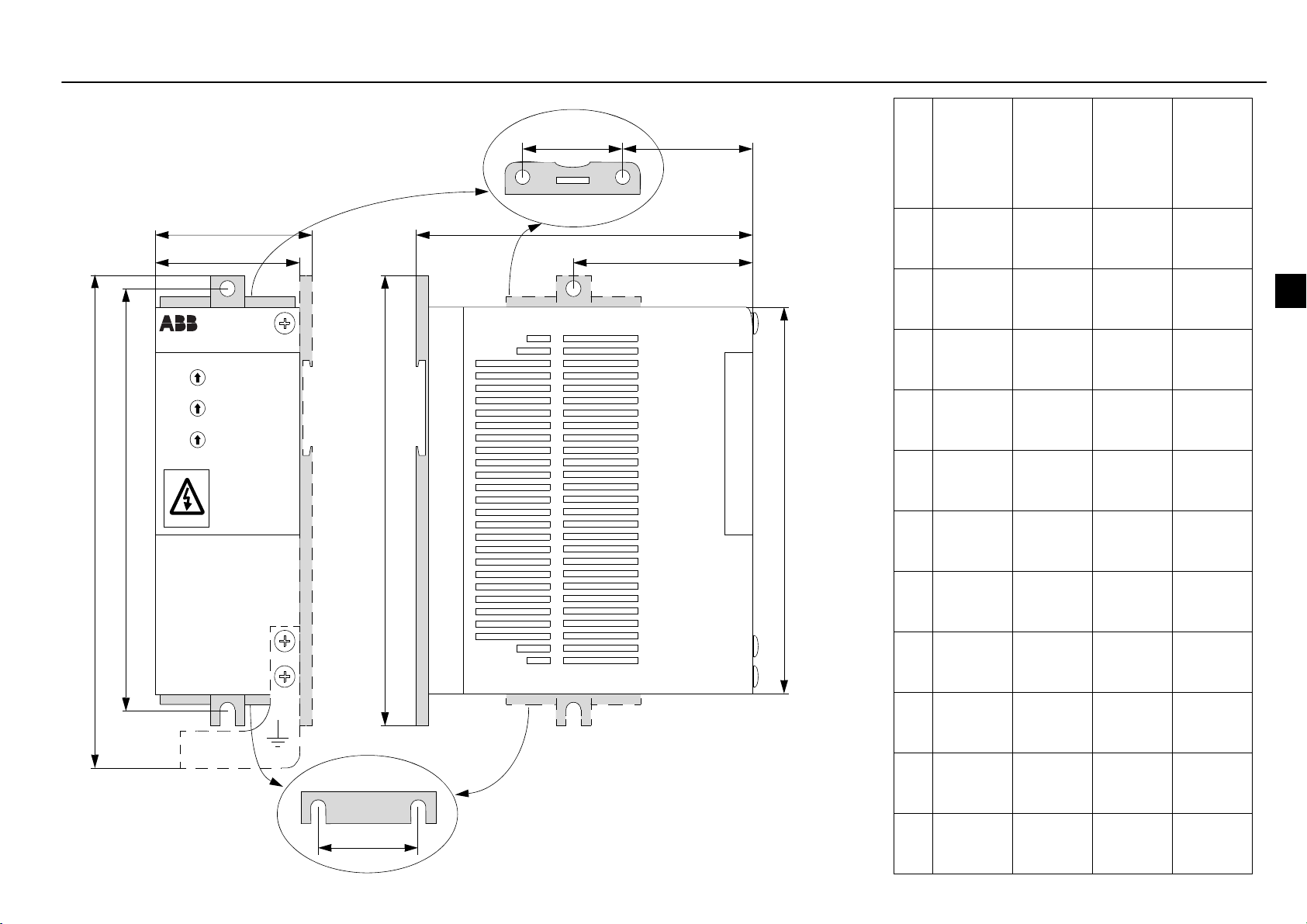

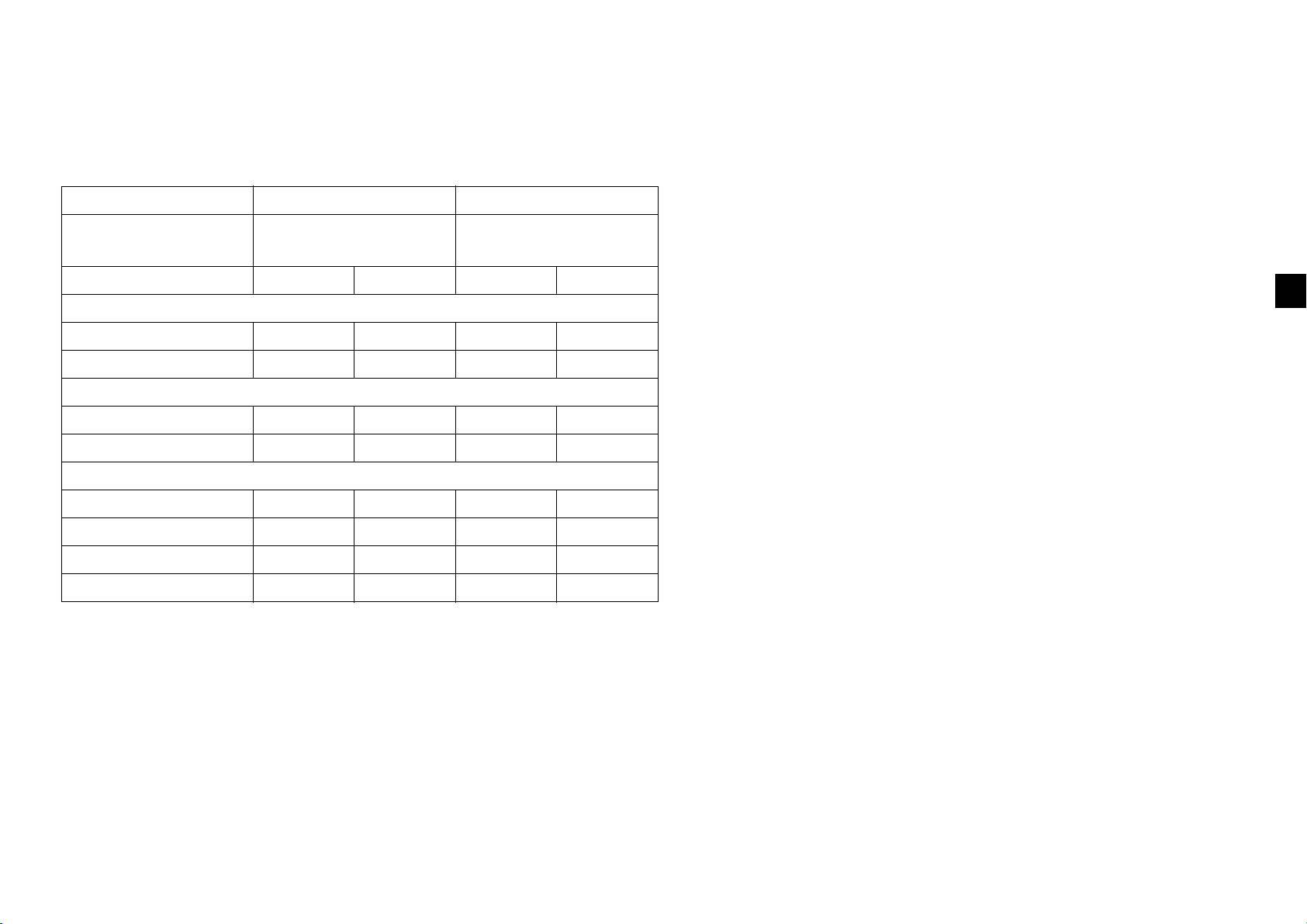

Dimensions

Frame

f

e

A

mm

(in.)

a

b

c

d

a53

(2.09)72(2.83)74(2.91)74(2.91)

b45

(1.77)

c128

(5.04)

d67.5

(2.66)

Frame

B

mm

(in.)

Frame

C

mm

(in.)

Frame

D

mm

(in.)

67.5

(2.66)70(2.76)70(2.76)

128

(5.04)

67.5

159

(6.26)

159

(6.26)

--

(2.66)

e- - 77

i

h

j

k

(3.03)77(3.03)

f- - 40

(1.57)40(1.57)

g- - 40

(1.57)40(1.57)

h183

(7.20)

i156

(6.14)

j170

(6.69)

g

k146.5

(5.77)

183

(7.20)

156

(6.14)

170

(6.69)

146.5

(5.77)

- 230

182

(7.17)

194

(7.64)

171

(6.73)

(9.06)

214

(8.43)

226

(8.90)

203

(7.99)

12 EN

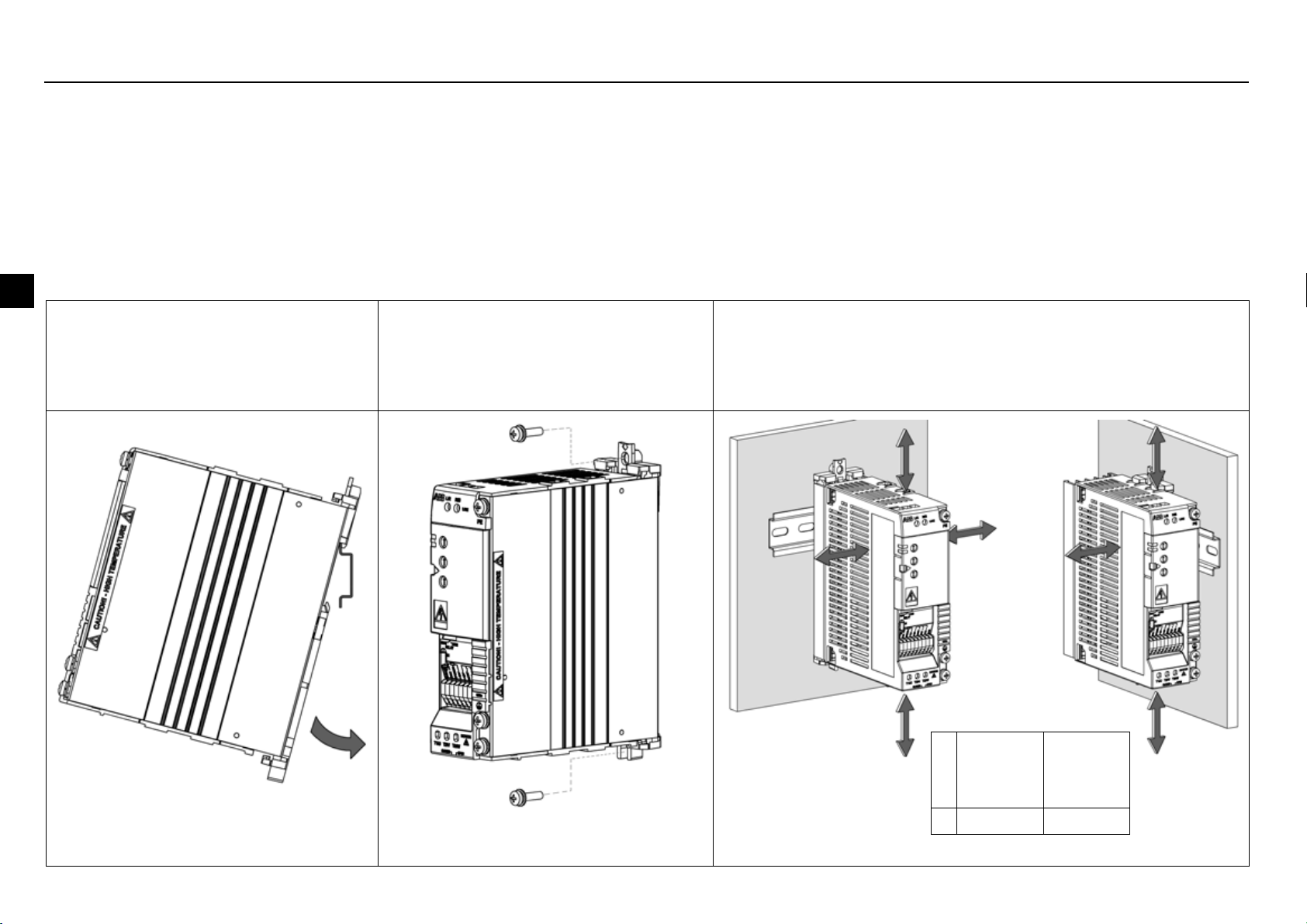

Mounting

Warning! The unit will warm up to high temperature during normal operation. Ensure sufficient cooling air flow in all conditions:

- Always install ACS55 so that cooling fans are vertical.

- Leave sufficient space around frame A and B units. Frame C and D units are fan cooled, so they can be installed side by side without

extra space between them.

Install the unit using the mounting clip on a 35 mm DIN rail or on a wall.

Mounting on DIN rail

"Click" ACS55 to the rail. Press the

lever on top of the mounting clip to

detach.

Mounting on wall

Install the unit onto the wall through

the mounting clip. Use M4 screws.

Clearance distances

Always leave sufficient space around the unit to ensure

proper cooling.

5 cm

(2 in.)

5 cm

(2 in.)

X

5 cm

(2 in.)

5 cm

(2 in.)

X

X

Frames

A and B

cm (in.)

X 1.5 (0.6) 0 (0)

Frames

C and D

cm (in.)

EN 13

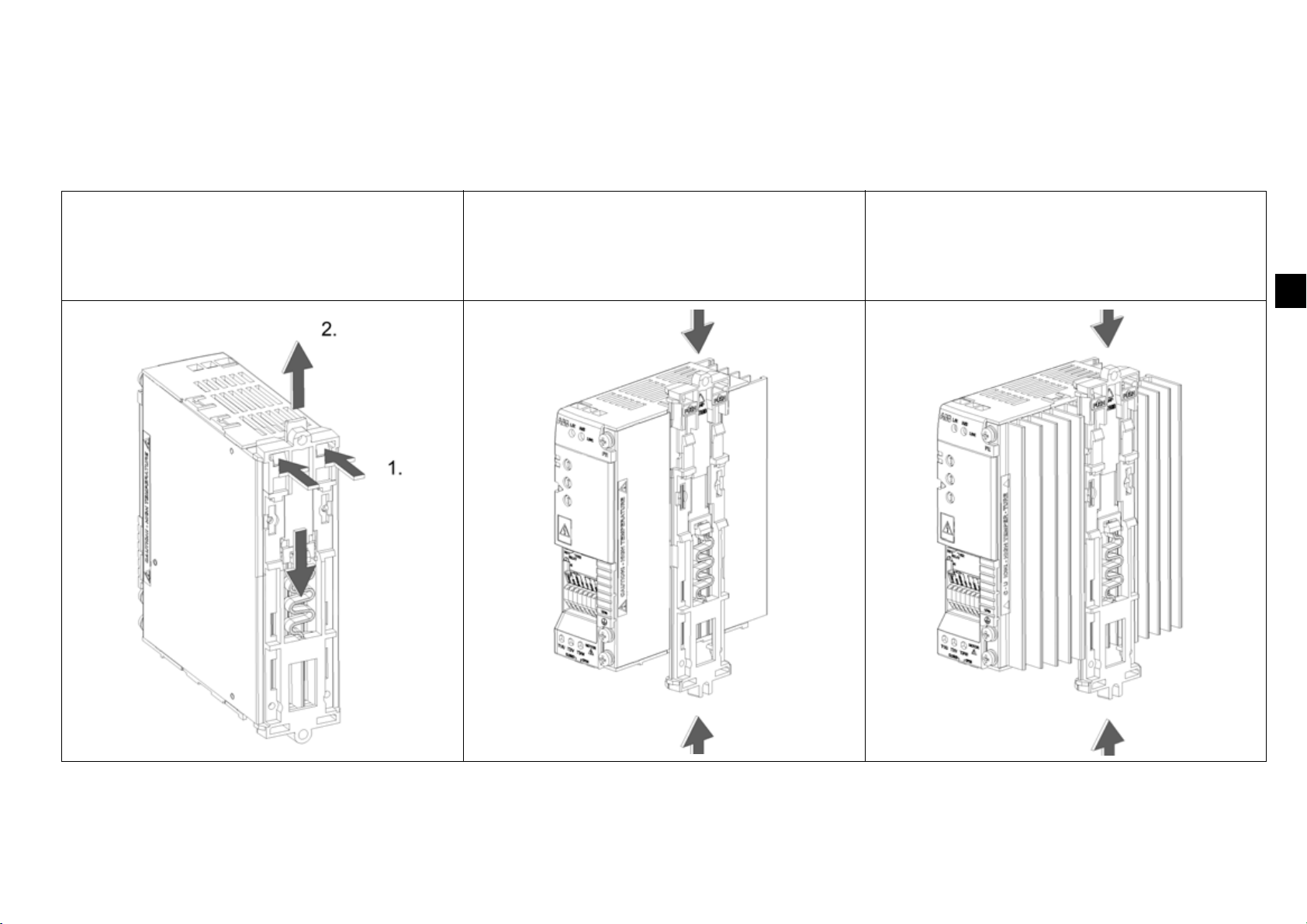

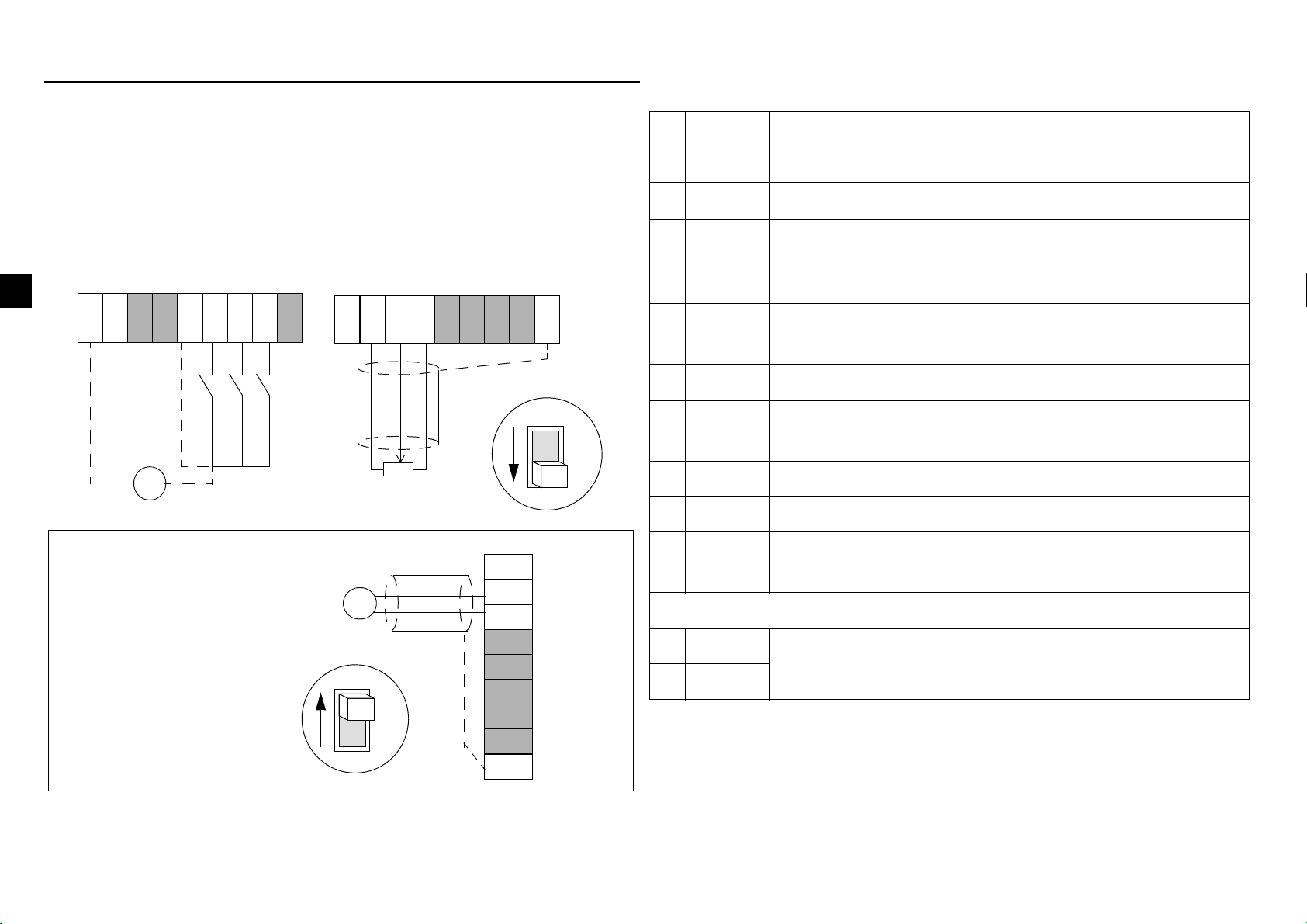

Attaching and detaching the wall mounting clip

The unit can be mounted either with the wide or the narrow side against the wall. Install the mounting clip on the desired side. See

instructions below for frames A and B. Detach the mounting clip of frames C and D by pulling downward and attach it by pushing

upward.

Detaching the mounting clip, Frames A

and B: Press the two plastic buttons to

detach the upper and lower part of the clip

from each other.

Attaching the mounting clip, Frame A:

Place the two parts as shown and click

them together.

Attaching the mounting clip, Frame B:

Push the two parts between the cooling

fins and click them together.

14 EN

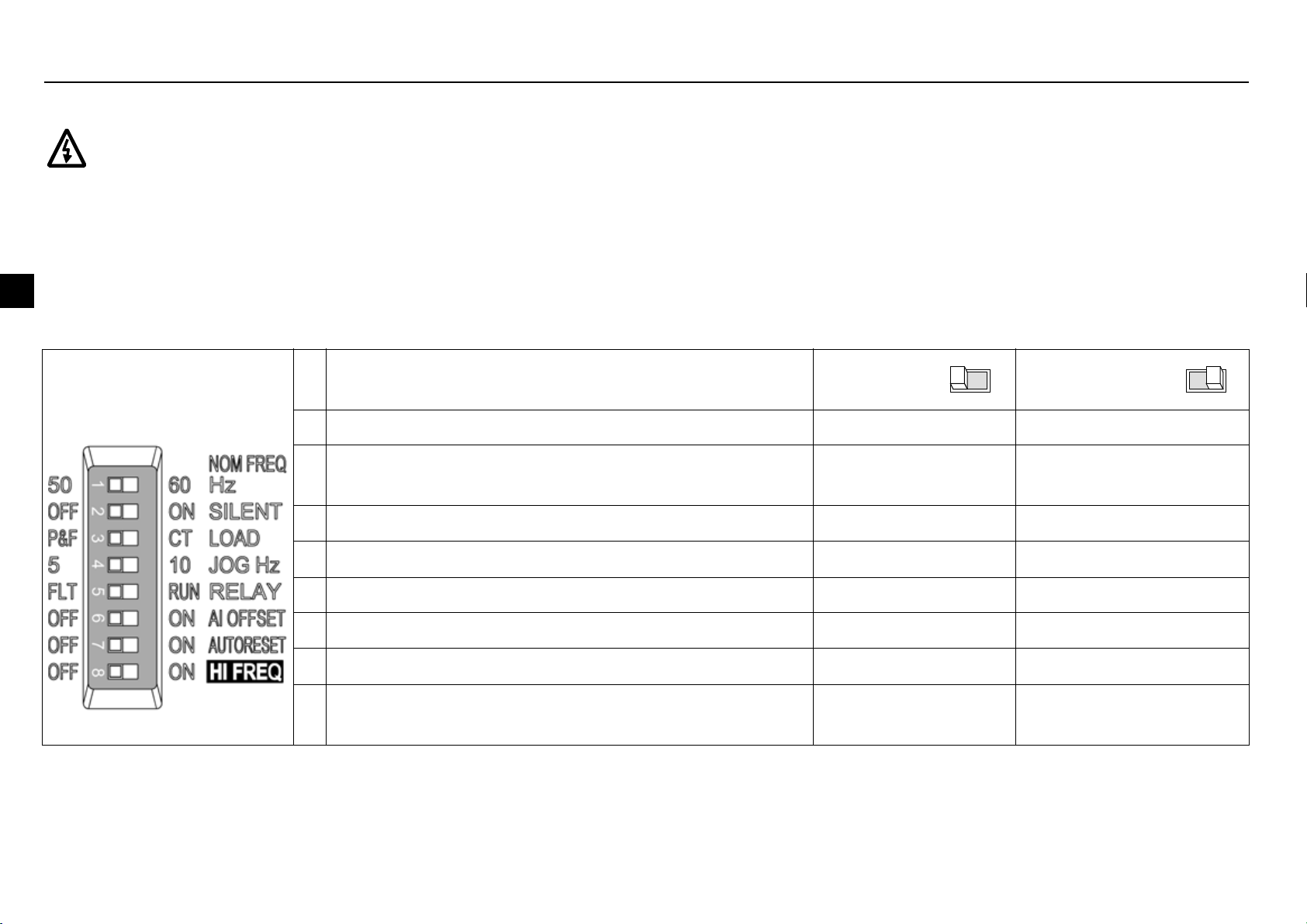

DIP switches

DIP switches are used to adapt ACS55 to the motor and the application.

Warning! The DIP switch is at a dangerous voltage (200 V). Turn off power and wait for 5 minutes before adjusting the switches.

Keep the protective cover closed when ACS55 is powered.

Configuration

• Open the front cover using the tip of a screwdriver, and adjust the DIP switches.

• Use the tip of a screwdriver to slide the switch to the left or right. By default, all switches are in their left position.

• Close the front cover.

Basic information

DIP switch

# Name and function Default

setting

1 NOM FREQ HZ: Motor nominal frequency 50 Hz 60 Hz

2 SILENT: Motor noise level (PWM switching

frequency)

3 LOAD: Load torque type (U/f curve) P&F - Pump/fan CT - Constant torque

4 JOG HZ: Constant frequency for the jogging function 5 Hz 10 Hz

5 RELAY: Relay output operation FLT - Fault RUN - Motor running

6 AI OFFSET: Minimum value for analogue input OFF - 0 mA (0 V) ON - 4 mA (2 V)

7 AUTORESET: Automatic fault reset function OFF - No autoreset ON - Autoreset enabled

8 HI FREQ: High frequency mode OFF - Standard ON - High frequency

OFF - Normal

(5 kHz)

Alternative

setting

ON - Silent (16 kHz)

enabled

EN 15

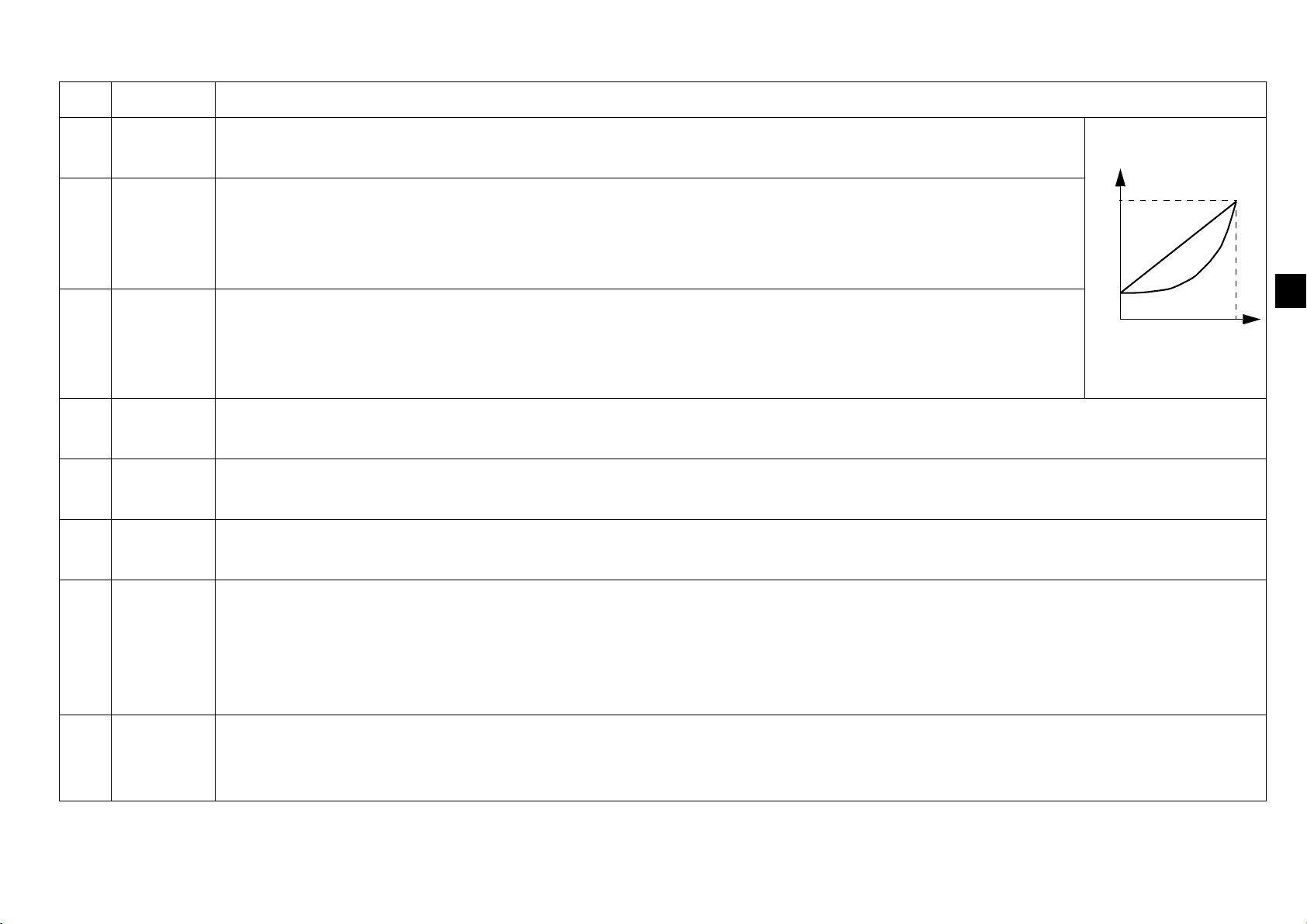

Additional information

No. Name Information

1NOM

FREQ Hz

2 SILENT Defines the drive switching frequency. Note: The higher the frequency the more electromagnetic

Defines the motor nominal frequency (see the motor rating plate).

noise and the shorter the allowed motor cable length to comply with the European EMC

U

U

N

CT

regulations. See Technical data on page 22. Note: The switching frequency adapts to the

ACS55 temperature.

3 LOAD Optimises the output voltage and frequency characteristics according to the load. Select P&F for

10%

the squared torque (e.g. pumps and fans) and CT for the constant torque loads (e.g. conveyors).

P&F

f

N

ACS55 automatically boosts the starting voltage 10% to compensate the motor losses and to

increase the starting torque.

4 JOG Hz Defines the jogging frequency. Activate the jogging function on by connecting 12…24 VDC to digital input 3 ("JOG").

(Drive accelerates or decelerates to the jogging frequency, and keeps it until the input is switched off.)

5 RELAY Selects the drive state the normally open contact of the relay output indicates. FLT = Fault. Contact is opened while

at a fault state or at a power off state. RUN = Running. Contact is closed while running.

6AI

OFFSET

Activates a living zero supervision for the analogue input. 4 mA (2 V) = ACS55 trips on a fault if the value drops

below the limit. See section Speed controlling on page 20 for information on analogue input scaling.

f

7AUTO-

RESET

Activates the automatic reset function for the following faults: Undervoltage, overvoltage, analogue input loss.

ON = ACS55 will try to reset automatically three seconds after a fault trip. Maximum number of resets is ten in three

minutes. If exceeded, ACS55 stops and will not attempt a new reset. See also Status indications and fault tracing on

page 21.

Warning! If the start signal is on, the motor will be started after a reset. Make sure that this will not cause danger.

8 HI FREQ Defines the maximum output frequency. OFF: Max. frequency = value defined by the NOM FREQ HZ switch. ON:

Max. frequency = value defined by the NOM FREQ HZ switch + value of HI FREQ potentiometer. See Control

potentiometers on page 16.

16 EN

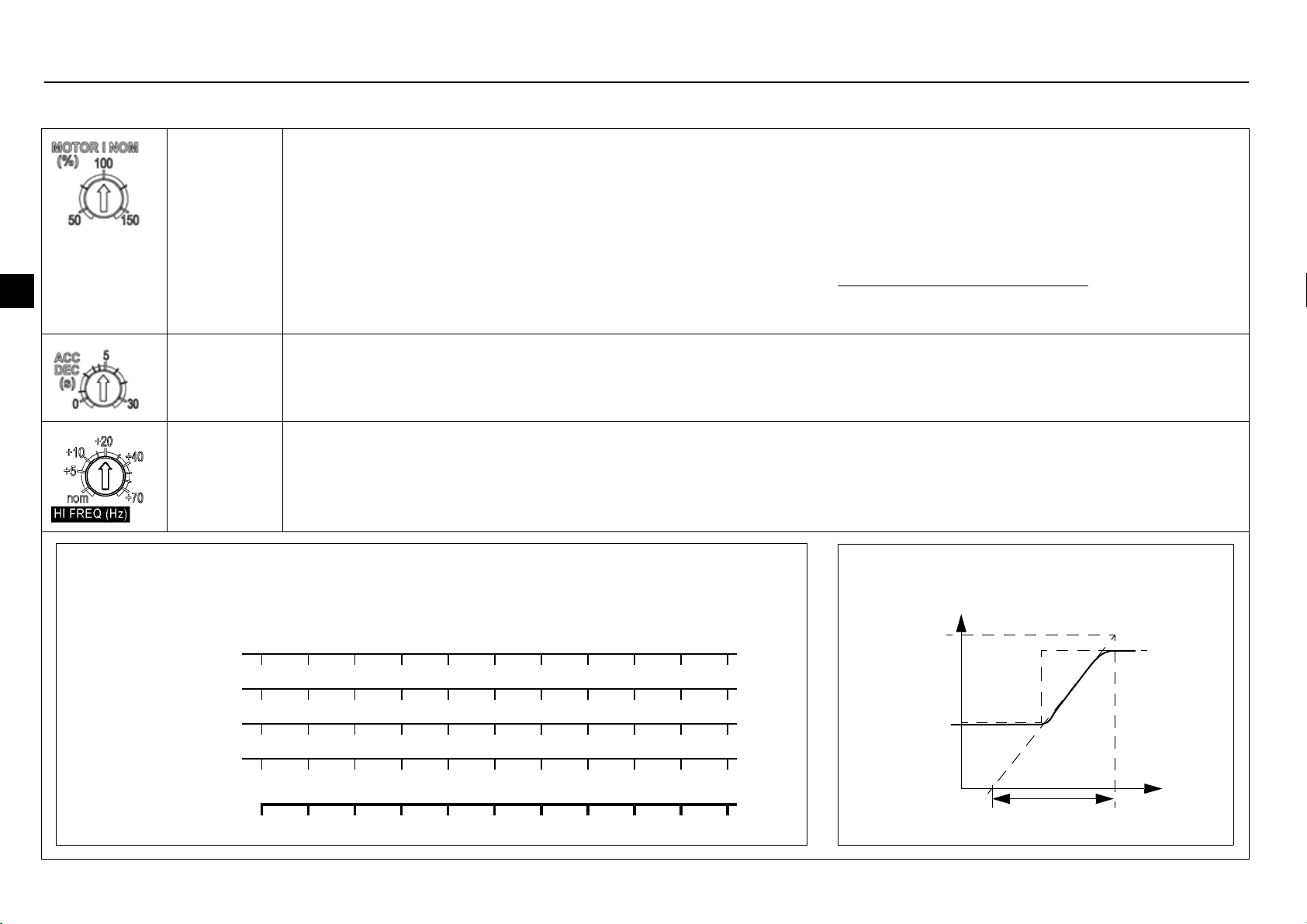

Control potentiometers

The control potentiometers can be adjusted using a screwdriver. By default, all potentiometers are in their middle position.

MOTOR I

NOM

Calculate MOTOR I NOM with the equation below or pick a value from the MOTOR I NOM selection chart

below. ACS55 estimates the temperature of the motor based on the measured output current and the

defined motor nominal current. The drive trips if the estimated temperature implies motor overheating.

Note: If motor cables are long causing large capacitive currents, it might be necessary to increase the

MOTOR I NOM setting.

MOTOR I NOM (%) =

Motor nominal current [A]

ACS55 nominal current [A]

• 100%

ACC/DEC Defines the acceleration and deceleration time from minimum to maximum frequency and vice versa in

seconds. The longer the ACC/DEC time, the more slowly ACS55 will follow the given reference.

HI FREQ Limits the output frequency to a desired value between nominal frequency and nominal frequency + 70 Hz.

To use this potentiometer, turn the high frequency mode on with the HI FREQ DIP switch. See DIP switches

on page 14.

MOTOR I NOM selection chart

ACC/DEC time

ACS55-01x-

-01A4-x

-02A2-x

-04A3-x

-07A6-x

-09A8-x

MOTOR I NOM

Motor nominal current (A)

0,7 0,8 1,0 1,2

1,11,31,51,82,0

2,2 2,6 3,0 3,5 4,0

3,84,65,36,16,8

4,95,96,97,88,8

50 60 70 80 90

1,4

2,2

4,3

7,6

9,8

100

1,6 1,8 2,0 2,1

2,4 2,6 2,8 3,0 3,3

4,7 5,2 5,6 6,0 6,5

8,4 9,3 10,2 11,4

10,8 12,0 13,3 14,7

110 120 130 140 150%

Ref. [%]

100

t

ACC/DEC

EN 17

Connecting power supply and motor

1-phase

input voltage

Warning! Before installation ensure that the main supply is off.

Note: Ensure power supply is correct! Connecting 230 VAC to the ACS55 unit rated for 115 VAC input will damage

the drive!

Terminal Description Wire size Tightening

torque

L/R, N/S 1~ power supply input Max. 2.5 mm

2

T1/U, T2/V, T3/W Power output to motor

4mm

(frames C and D) single core copper

2

(frames A and B) or max.

0.5 Nm /

0.6 Nm

wire

PE Protective earth.

Motor cable protective

conductor and shield.

Use multi-strand copper wire. Size of the

wire is not allowed to be smaller than the

size of the power cable used.

1 Nm(*)

Warning! If the heat sink is not earthed properly, you can get an electric shock if you touch the heat sink.

Note: Use only supplied M4x8 Combi screws. Maximum allowed intrusion depth for the grounding screws is

6mm.

Follow local rules for cable cross sections. Use 60°C (140°F) rated power cable, or 75°C (167°F) rated cable if

ambient temperature is above 30°C (86°F). See also Additional cabling and EMC instructions on page 19.

Earth leakage current of the ACS55 can exceed 3.5 mA AC / 10 mA DC. According to EN50178, ACS55 may only

be used in permanent installation.

Input fuse

See Technical data on page 22 for recommended fuse types.

Motor

The motor must be a 3-phase AC induction motor, with nominal voltage U

frequency f

either 50 or 60 Hz. Motor nominal current must be less than or equal to the nominal output current (I2)

N

from 200 to 240 V and nominal

N

of the drive.

If the phases are connected, U-U, V-V and W-W, and the selected direction is forward, the shaft rotates clockwise

as seen from the drive shaft end.

18 EN

Connecting control wires

Internal (1) or external (2) power supply can be used for the digital

inputs. Analogue control voltage is 0…10 VDC as default. (The AI

jumper must be in voltage ("U") position).

+10V

1)

+12V

2)

COM

COM

SPEED/AI

START

+-

12...24 VDC supply

REV

SCR

JOG

COM

SPEED/AI

COM

+10V

1...10 kohm

START

+12V

REV

JOG

SCR

I

AI

U

Control terminals

2

Use multi-strand 0.5...1.5 mm

wire (AWG22 - AWG16).

# Name Description

1 COM Common for digital or analogue inputs

2 COM Common for digital or analogue input

1)

1)

3 AI Analogue input: Speed (frequency) reference.

0/2…10 VDC (Ri=190 kohm), or 0/4…20 mA

(Ri=100 ohm). Resolution 0.1%, accuracy +/-1%.

4 +10V Reference voltage for analogue input.

Accuracy +/-2%. Max. 10 mA.

5 +12V Auxiliary voltage for digital inputs. Max. 30 mA.

6 START Digital input 1: Start (resets the drive after a fault

2)

trip)

7 REV Digital input 2: Reverse rotation direction

8 JOG Digital input 3: Activate jog speed

2)

2)

Using 0/4…20 mA current signal:

- Change AI jumper to current

("I") position.

- Set AI OFFSET switch to ON

position if 4…20 mA current

signal is desired.

U

9 SCR Earth for signal cable screen. Connected internally

COM

+-

COM

SPEED/AI

+10V

Relay output

1 RO1 Fault: Relay opens.12 V...250 VAC / 30 VDC

+12V

I

AI

START

REV

JOG

2RO2

1) Connected internally to frame (earth) through 1 Mohm resistor.

2) Digital input impedance is 1.5 kohm.

to frame earth.

10 mA...2 A

SCR

EN 19

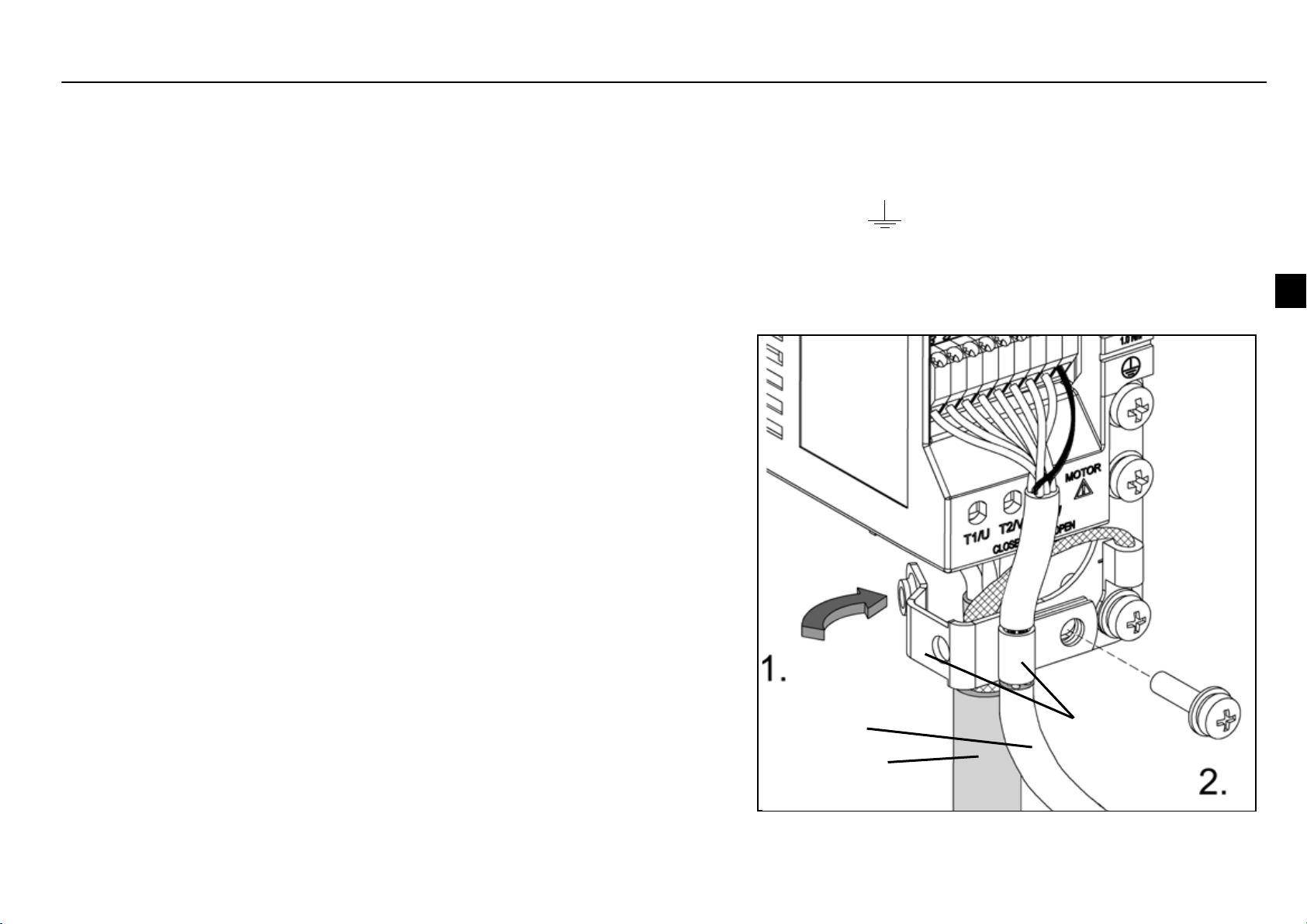

Additional cabling and EMC instructions

Follow these instructions for trouble free operation and to ensure compatibility with the European EMC directive.

Motor cable

The motor cable must be a symmetrical three conductor cable with a concentric PE conductor or a four conductor cable with a

concentric shield. Braided metallic screen is recommended, e.g. type MCCMK (NK Cables).

- Twist the cable screen wires together into a bundle, and connect to the earthing terminal . Keep the bundle as short as possible.

- Clamp the cable screen as shown in the figure when internal or external EMC filter is used.

- At the motor end the motor cable screens must be earthed 360 degrees with an EMC cable gland or the screen wires must be twisted

together into a bundle not longer than 5 times its width and connected to the PE terminal of the motor.

Control cables

Control cables must be multi-core cables with a braided copper wire screen.

A double shielded twisted pair cable is recommended for the analogue

signals.

- Twist the screen together into a bundle and connect to terminal SCR. Keep

the bundle as short as possible.

- Clamp the control cable as shown in the figure (EMC units only).

- Route the motor cable away from the control wires and the power supply

cable to avoid electromagnetic interference (distance > 20 cm).

Note: Never mix 24 VDC and 115/230 VAC signals in the same cable.

control cable

motor cable

clamps

20 EN

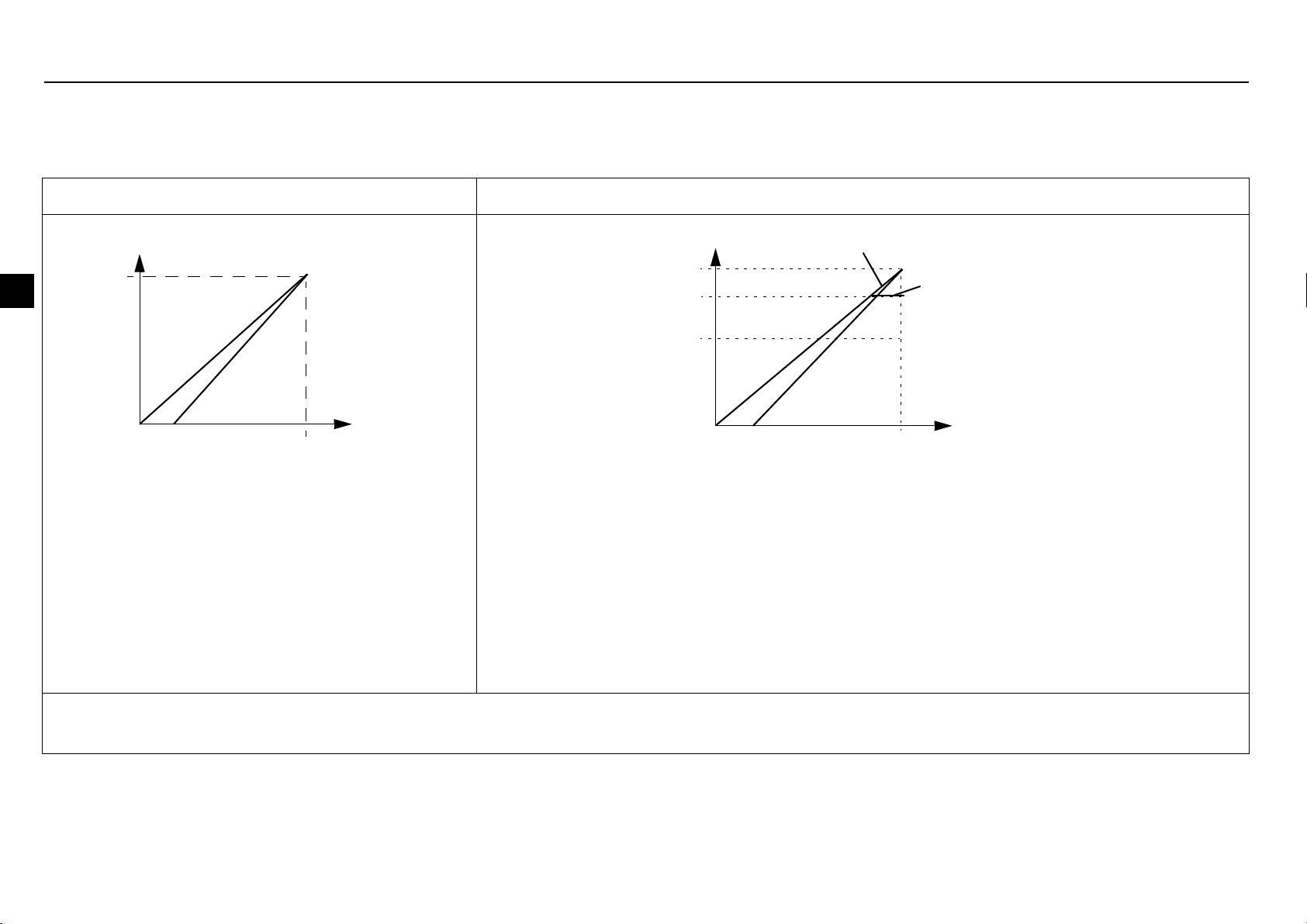

Speed controlling

The analogue input gives the speed (frequency) reference for ACS55. The correspondence between the analogue input and the

reference depends on the settings of the DIP switches as shown below. Output frequency follows the reference changes as defined by

the ACC/DEC potentiometer.

High frequency mode OFF (default) High frequency mode ON

f

f

N

a

b

Input*

0

2 V

4 mA

10 V

20 mA

[V, mA]

DIP switch settings:

HI FREQ = OFF

AI OFFSET = OFF (curve a) or ON** (curve b)

MOTOR NOM FREQ = 50 or 60 Hz

The output frequency is limited to the selected

nominal frequency of the motor.

+ 70 Hz

f

N

f

f

N

frequency reference

output frequency limit

a

b

0

2 V

4 mA

10 V

20 mA

Input*

[V, mA]

DIP switch settings:

HI FREQ = ON

AI OFFSET = OFF (curve a) or ON** (curve b)

MOTOR NOM FREQ = 50 or 60 Hz

Actual output frequency is limited to a value between f

and fN + 70 Hz by the

N

HI FREQ potentiometer. The potentiometer does not affect the scaling of the

analogue input.

* Use AI jumper to select voltage or current signal. See page 18.

** To protect the drive against analogue input signal loss, the drive trips if the signal value is below 2 V (4 mA).

EN 21

Status indications and fault tracing

ACS55 has two status indication LEDs, visible

through the front cover.

Green LED Red LED Description

On Off ACS55 operates normally.

If the drive detects a problem, the red LED will

blink. After fixing the problem, reset by

switching the start signal off. If start is off

already, turn it first on and then off again.

See the table below for the fault codes (= the

number of LED blinks).

On Blinking Protective function has been activated. Number of

On

Off

12

Blinking Blinking

blinks indicates the fault code.

ACS55 will reset automatically within 3 seconds. (*)

Warning! Motor starts, if start signal is on.

# Possible causes and what to do # Possible causes and what to do

1 DC overvoltage (*). 1) Mains voltage is too high: Check

supply. 2) Deceleration ramp time is too short compared to

6 Analogue input value is less than 4 mA/2 V. (*) Note: This

supervision is active if AI OFFSET is ON.

the load inertia: Increase ACC/DEC time with potentiometer.

2 DC undervoltage (*). Mains voltage is too low: Check supply. 7 Motor overload (I

2

t overload): 1) Check the load, and verify

that the motor size is suitable for ACS55. 2) Verify that setting

of MOTOR I NOM potentiometer is correct.

3 Output short circuit: Switch off the power and check the motor

windings and motor cable.

8 Inverter overload or excessive internal temperature: 1) Load

is too high or 2) drive cooling is insufficient.

4 Output overcurrent. 1) Acceleration time is too short

compared to the load inertia: Increase ACC/DEC time with

9 Other fault. Internal error. Turn power off and on again. If

problem persists, replace the unit.

potentiometer. 2) Motor and drive sizes do not match: Check

motor.

5 Reserved 10 Parametrization fault. Note: Both LEDs will blink. DIP

switches have been moved from default setting after the drive

has been parametrized with DriveConfig tool. Put the

switches back to default position.

(*) Automatically reset if the AUTORESET is ON. See DIP switches on page 14.

22 EN

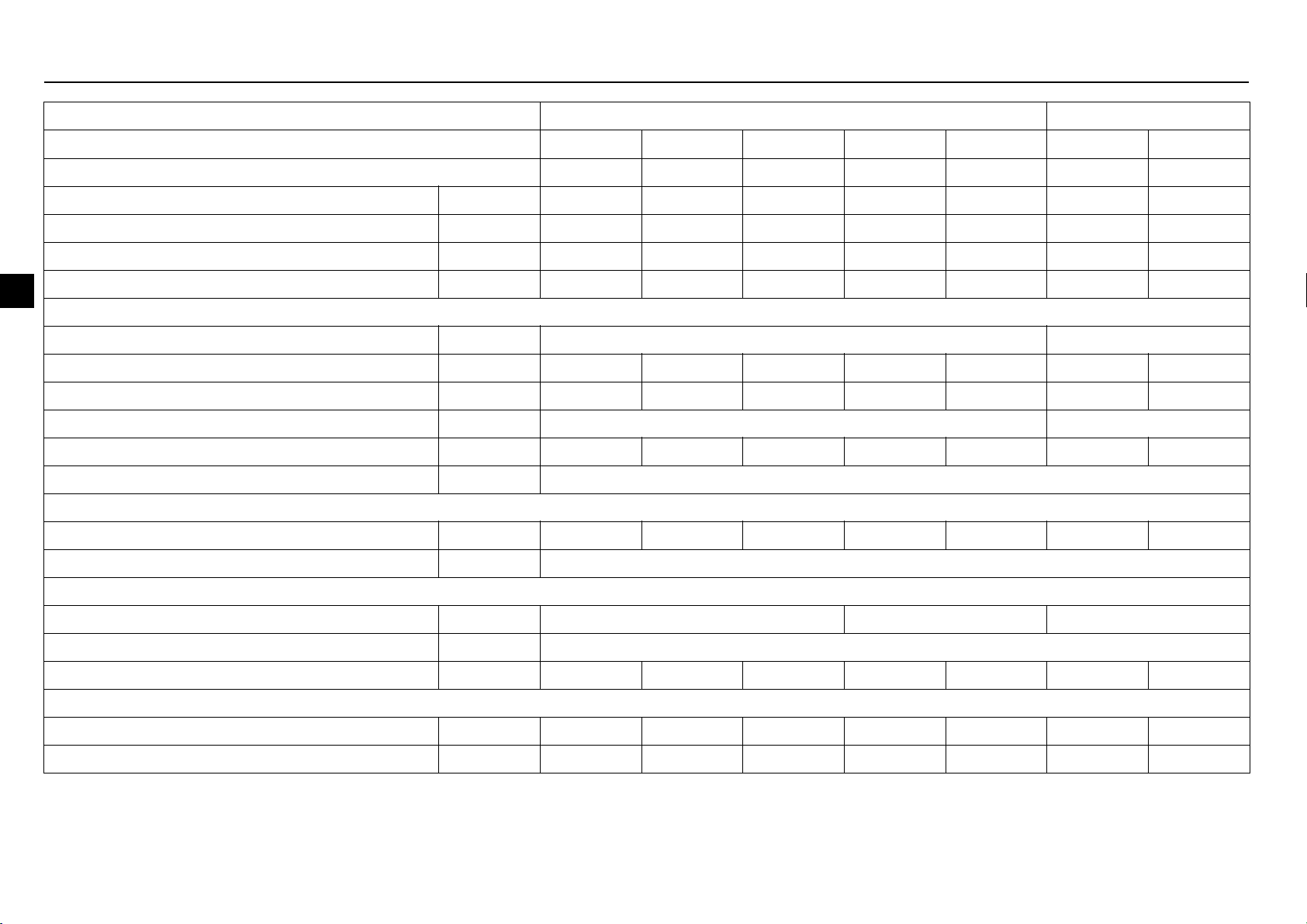

Technical data

230 V 115 V

Built-in EMC, ACS55-01E- 01A4-2 02A2-2 04A3-2 07A6-2 09A8-2 01A4-1 02A2-1

No EMC, ACS55-01N- 01A4-2 02A2-2 04A3-2 07A6-2 09A8-2 01A4-1 02A2-1

Motor continuous output power kW 0.18 0.37 0.75 1.5 2.2 0.18 0.37

hp 1/4 1/2 1 2 3 1/4 1/2

Frame size (no EMC) A A B C C A A

Frame size (EMC) A A B D D A A

Nominal ratings

Input voltage U

1

Continuous output current I

Max. output current I

Output voltage U

Input current I

2

1

* A 2.1 3.3 6.5 11.4 14.7 2.1 3.3

2max

2

V 200-240 (+10/-15%) 110-120 (+10/-15%)

A 1.42.24.37.69.81.42.2

V0-U1, 3-phase 0-2xU1, 3-phase

A 4.4 6.9 10.8 18.2 22.0 6.4 9.5

Switching frequency kHz 5 (max. 16)

Protection limits

Overcurrent (peak) A 4.4 6.9 13.5 23.9 30.9 4.4 6.9

Overtemperature 95°C / 203°F (heat sink)

Maximum wire sizes

Power terminals mm2 2.5 (AWG 14) 4 (AWG 12) 2.5 (AWG 14)

Control terminals mm2 1.5 (AWG 16)

Power losses W 21 32 51 74 103 24 35

Line fuse size**

IEC, type IEC269 gG A 10 16 16 25 32 10 16

UL, types CC and T A 10 15 20 25 30 10 15

* Allowed for 1 minute.

** Recommended values. Do not use ultra rapid or low peak fuses. Follow local rules.

EN 23

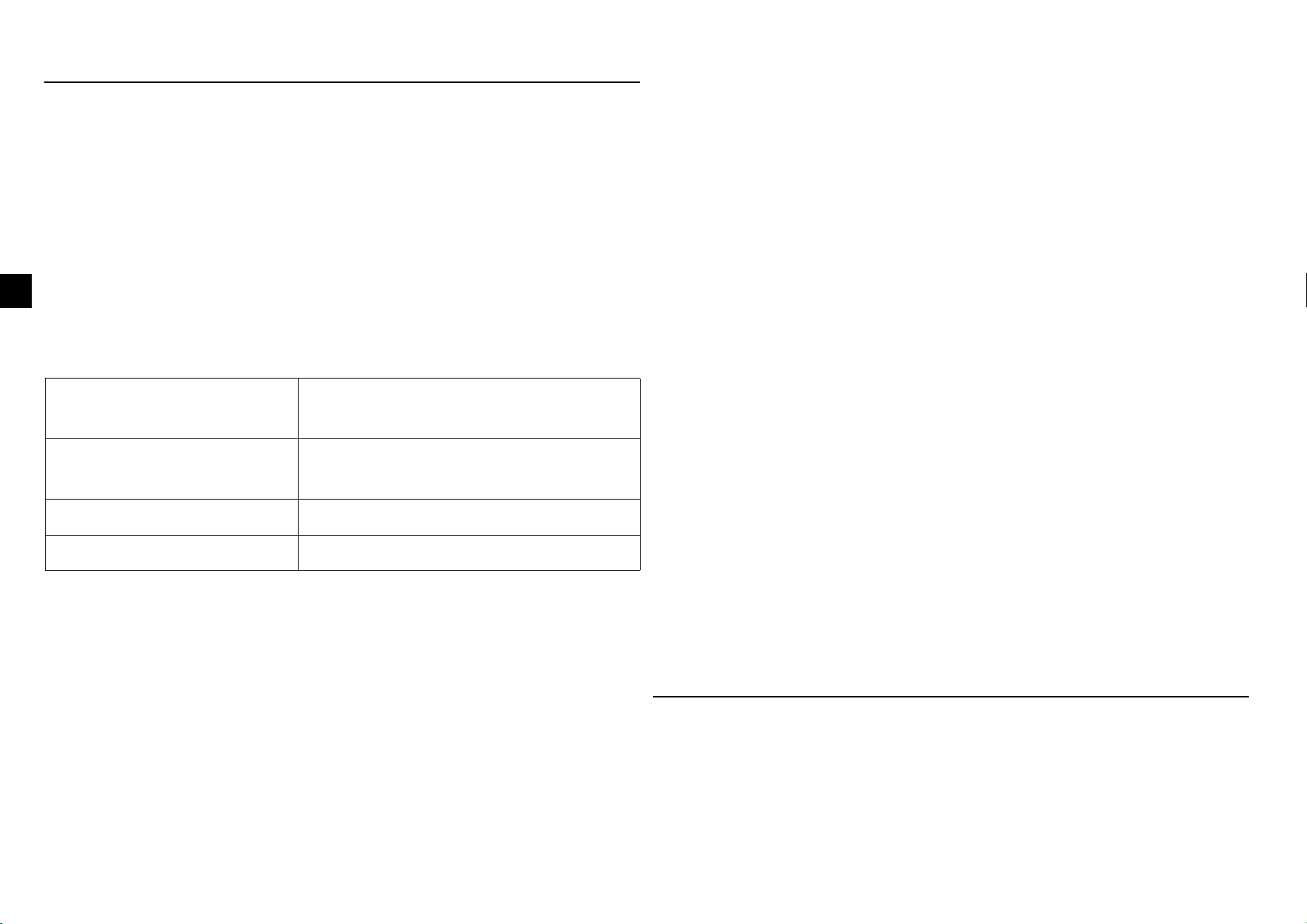

Maximum motor cable lengths

To comply with European EMC regulations, the motor cable length

has to be limited as specified in the table below. The shorter the

motor cable, the lower the noise emissions to the supply line and

the environment.

Built-in EMC filter External EMC filter

ACS55-01E- ACS55-IFAB-01 and

ACS55-01N/E

Converter type 5 kHz 16 kHz

1)

5 kHz 16 kHz

EN61800-3, First environment, unrestricted distribution

2)

1)

01A4-2, …, 02A2-1 10 m 3 m - 07A6-2, …, 09A8-2 10 m 3 m - -

EN61800-3, First environment, restricted distribution

3)

01A4-2, …, 02A2-1 10 m 10 m 30 m 10 m

07A6-2, …, 09A8-2 20 m 10 m - -

EN61800-3, Second environment

3)

01A4-2, …, 02A2-2 10 m 10 m 50 m 10 m

04A3-2 10 m 10 m 75 m 10 m

01A4-1, …, 02A2-1 10 m 10 m 50 m 10 m

07A6-2, …, 09A8-2 30 m 10 m - -

1) Switching frequency can be selected with the DIP switch. See

page 15.

2) Applicable for conducted emissions only.

3) Applicable for conducted and radiated emissions.

Protections

Overvoltage, undervoltage, output short circuit, overcurrent,

analogue input loss, motor overload, inverter overload.

Distribution networks isolated from earth

Drives with built-in EMC filter, or ACS55-IFAB-01 external input

filter must not be used in a floating network or in a high impedance

earthed industrial distribution network.

Environmental information

A product to be disposed contains valuable raw material that

should be recycled, thus preserving energy and natural resources.

Instructions for disposal are available from ABB sales and service

companies.

Liability limits

The manufacturer is not responsible for:

• Any costs resulting from a failure if the installation,

commissioning, repair, alteration or ambient conditions of the

drive do not fulfil the requirements specified in the

documentation delivered with the unit and other relevant

documentation.

• Units subjected to misuse, negligence or accident.

• Units comprised of materials provided or designs stipulated by

the purchaser.

In no event shall the manufacturer, its suppliers or subcontractors

be liable for special, indirect, incidental or consequential damages,

losses or penalties.

If you have any question concerning your ABB drive, please

contact the local distributor or ABB office. The technical data,

information and specifications are valid at the time of printing.

The manufacturer reserves the right to modifications without prior

notice.

24 EN

Approvals

CE

The ACS55 complies with the requirements of the European

• Low Voltage Directive 73/23/EEC with amendments

• EMC Directive 89/336/EEC with amendments.

Corresponding declarations and a list of main standards are

available on request.

Electromagnetic compatibility:

The ACS55 fulfils the following standards provided that installation

is done properly and according to the instructions of this manual:

Conductive high

frequency emissions

Radiated high frequency

emissions

Immunity EN61800-3 second environment

Line current harmonics IEC61000-3-2

1) Observe the maximum allowed motor cable lengths and

switching frequency, page 23. See also cabling instructions on

page 19.

EN61800-3 first environment,

unrestricted/restricted distribution

EN61800-3 first environment,

restricted distribution

1)

UL, cUL:

The ACS55 is suitable for use on a circuit capable of delivering not

more than 65 kA rms symmetrical amperes, 230 volts maximum,

when protected by CC or T class fuses.

C-Tick:

For the electromagnetic compatibility, see the specification in

section CE above.

Product protection in the USA

This product is protected by one or more of the following US

patents

4,920,306 5,301,085 5,463,302 5,521,483 5,532,568 5,589,754

5,612,604 5,654,624 5,799,805 5,940,286 5,942,874 5,952,613

6,094,364 6,147,887 6,175,256 6,184,740 6,195,274 6,229,356

6,252,436 6,265,724 6,305,464 6,313,599 6,316,896 6,335,607

6,370,049 6,396,236 6,448,735 6,498,452 6,552,510 6,597,148

6,741,059 6,774,758 6,844,794 6,856,502 6,859,374 6,922,883

6,940,253 6,934,169 6,956,352 6,958,923 6,967,453 6,972,976

6,977,449 6,984,958 6,985,371 6,992,908 6,999,329 7,023,160

7,034,510 7,036,223 7,045,987 7,057,908 7,059,390 7,067,997

7,082,374 7,084,604 7,098,623 7,102,325 D503,931 D510,319

D510,320 D511,137 D511,150 D512,026 D512,696 D521,466

Other patents pending.

The current harmonic levels can be reduced by fitting external input

chokes.

UL, cUL and C-Tick markings

See the rating plate.

Accessories

EMC filter: ACS50-IFAB-01

Input chokes: CHK-A1, CHK-B1, CHK-C1, CHK-D1

Output choke: ACS-CHK-B3, ACS-CHK-C3

Potentiometer unit: ACS50-POT

DriveConfig kit, for more information please contact your local ABB

office.

DA 25

Brugermanual

for type ACS55

AC drev

fra 0,18 til 2,2 kW

Dansk DA

26 DA

Produkt- og serviceforespørgsler

Har De spørgsmål om produktet, beder vi Dem henvende Dem til Deres lokale ABB selskab. Vi beder Dem venligst

oplyse typekode og serienummer på det drev, det drejer sig om. På ABBs hjemmeside findes en oversigt over

salgs-, support- og servicekontakter. Gå ind på www.abb.com/drives

network

Produkttræning

i det højre felt.

og vælg Drives – Sales, Support and Service

Oplysninger om ABBs produkttræning findes på www.abb.com/drives. Vælg herefter Drives – Training courses i det

højre felt.

Feedback vedr. ABB drevmanualer

Vi er meget interesseret i at modtage Deres eventuelle kommentarer til vore manualer. Gå ind på www.abb.com/

drives. Herefter vælges Drives – Document Library – Manuals feedback form (LV AC drives) i det højre felt.

3AFE68929300 Rev B

DA

Gældende fra: 25.02.2008

© 2008 ABB Oy. All Rights reserved.

ABB A/S

Meterbuen 33

DK-2740 Skovlunde

Tlf: 45 44 50 44 50

Fax: 45 44 50 43 65

Internet www.abb.com

DA 27

8

I

,

8

I

,

$&6($

,3

61<::5;;;;

$)(;;;;;;;;

3QPRWRUN:+3

a9

+]

$

a8

+]

$

5R+6

Sikkerhedsinstruktioner

Læs omhyggeligt nedenstående instruktioner, inden installationen

påbegyndes.

Advarsel! Farlig spænding!

Kun en uddannet elektriker må installere ACS55.

Der må aldrig arbejdes med drevet, motorkablet eller motoren, når

netspændingen er indkoblet. Efter at have udkoblet

netspændingen, skal man vente mindst 5 minutter for at lade

mellemkredskondensatorerne aflade, inden arbejdet med drevet

påbegyndes.

Advarsel! Hvis kølepladen ikke er jordet rigtigt, kan man få stød,

hvis man rører kølepladen.

Bemærk: DIP switches har farlig spænding.

Bemærk: Selv når motoren er standset, er der farlig spænding ved

effektklemmerne L/R, N/S, T1/U, T2/V og T3/W.

Bemærk: Selv når enheden ikke er tilsluttet netspændingen, kan

der være farlige, eksterne spændinger forbundet til

relæudgangsklemmerne.

Tilslut ikke netspænding til enheden mere end én gang hvert tredje

minut.

En ændring af DIP switchene vil have indflydelse på ACS55's

funktion og ydelse. Undersøg at ændringerne ikke vil kunne

forårsage skader på personer eller ejendom.

Om denne manual

Denne guide giver de nødvendige informationer om installation og

opstart af enheden.

Kontrol ved levering

Leverancen indeholder

1. ACS55

2. Brugermanual

2. To bøjler for styrepanelet (kun EMC

omformere)

Kontroller mærkepladen og vær sikker på, at den

leverede enhed svarer til ordren.

Advarsel! Varme overflader!

Under driften kan køleelementet nå en høj temperatur (>80 °C).

Vær sikker på, at installationsinstruktionerne overholdes.

Generelle sikkerhedsinstruktioner

ACS55 starter automatisk motoren efter en netafbrydelse, hvis det

eksterne startsignal er aktivt.

Forsøg aldrig at reparere en enhed, der er ødelagt. ACS55 er ikke

en enhed, der kan repareres på montagestedet. Tag kontakt til

leverandøren for at få en erstatningsenhed.

Installer ACS55 et sted, hvor den kan stå aflåst, eller kun er

tilgængelig ved brug af værktøj.

ACS55-01_-____-_

EMC filter: E = Indbygget, N = Nej

Max. kontinuerlig udgangsstrøm (I2):

01A4 = 1,4 A, 02A2 = 2,2 A, 04A3 = 4,3 A

07A6 = 7,6 A, 09A8 = 9,8 A

Netspænding (U1):

1 = 110…120 VAC +10%/-15%

2 = 200…240 VAC +10%/-15%

Serienummer (S/N) er trykt på mærkepladen.

(Y = Fremstillingsår, WW = fremstillingsuge)

28 DA

Oversigt

ACS55 drevet styrer en 3-faset asynkronsmotors hastighed.

Indgangsterminaler, side

37

Net LED, side 41

Fejl LED, side 41

Beskyttelsesjord (PE), side

DIP switches, side 34

Styrepotentiometre, side 36

DriveConfig kit interface, side 44

Relæudgangsterminaler, side 38

Styrekabelterminaler, side 38

Motorkabelskærm, side

37

37

Valg af analog inputsignal

(spænding/strøm), side

Monteringsflap, side 32 - 33

38

Motorkabelterminaler, side 37. Dækslet giver ekstra isoaltion. Skub dækslet mod venstre for at lukke.

Bøjleplade, side 39 (Kun EMC omformere)

DA 29

Installation og opstart

Læs Sikkerhedsinstruktioner på side 27, inden der fortsættes.

Handling Side

1 Check leverancen. 27

2 Vær sikker på, at installationsmiljøet er egnet for ACS55. 30

3 Monter omformeren. 32 -

33

4 Check standardinstillingerne: Motorens nominelle frekvens er 50 Hz; belastningen er en pumpe eller en ventilator; den

maksimale udgangsfrekvens er 50 Hz. Hvis standardindstillingerne ikke passer, reguleres DIP-switchene.

5 Vær sikker på, at MOTOR I NOM potentiometeret passer til motorens mærkestrøm. Det definerer virkning af motorens

termiske beskyttelsesfunktion.

6 Tilpas om nødvendigt accelerations-/decelerationstidspotentiometeret ACC/DEC. 36

7 Tilslut net- og motorkabler. 37

8 Tilslut styrekablerne. 38

9 Tilslut indgangsspændingen. Grøn LED tænder. Bemærk: Motoren roterer, hvis startsignalet er aktivt.

10 Indstil hastighedsreferencen og aktiver startsignalet. Motoren accelererer op til den valgte hastighedsreference.

34

36

40

30 DA

Omgivelsesbetingelser

Montagested Lagring og transport i beskyttelsesemballage

Lufttemperatur -20 °C (-4 °F), frost ikke tilladt 1)

+40 °C (104 °F), ved nominel last

+50 °C (122 °F), hvis kontinuerlig

udgangsstøm er max. 85% af nominel

udgangsstrøm

I

.

2

Højde over havet 0…2000 m (0...6,600 ft). Ved højder mellem

1000...2000 m (3,300...6,600 ft), reduceres

P

og I2 med 1% for hver 100 m.

N

Relativ

Mindre end 95%, kondens ikke tilladt Mindre end 95%, kondens ikke tilladt

luftfugtighed

Forurenings-

niveau

(IEC 60721-3-3)

• Ledende støv ikke tilladt

• Luften skal være ren og fri for korroderende

materialer og ledende støv.

• Kemiske gasser: Klasse 3C2

• Faste partikler: Klasse 3S2

Sinusformet

vibration

Frekvensområde: 5...150 Hz

Konstant acceleration: 1 g

(IEC 60068-2-29)

-40 °C (-40 °F) til +70 °C (158 °F)

Ingen begrænsning

Lagring Transport

• Ledende støv ikke tilladt

• Kemiske gasser: Klasse 1C2

• Faste partikler: Klasse 1S2

• Ledende støv ikke tilladt

• Kemiske gasser: Klasse 2C2

• Faste partikler: Klasse 2S2

I henhold til ISTA 1A specifikationer

Chok

Ikke tilladt Max. 100 m/s

2

(330 ft/s2), 11 ms (36 fts)

(IEC 60068-2-29)

Frit fald: Ikke tilladt Ikke tilladt

1) Når drevet benyttes ved minustemperaturer, skal drevet fortsat være tilsluttet spændingen. Monter drevet indvendig i en ekstra

kapsling. Det skal sikres, at varmen, som genereres af drevet, kan bortskaffes.

Beskyttelsesgraden for ACS55 er IP20.

Loading...

Loading...