ABB ACS350 Technical Catalog

ABB General Machinery Drives

ACS350, 0.5 to 30 Hp

Technical Catalog

BUSINESS

PROFILE

PRODUCTS

INDUSTRIES

APPLICATIONS EXPERTISE

PARTNERS

SERVICES

Contents

Choice 1: Simply contact your local ABB drives sales ofce

and let them know what you want. Use page 4 as a reference

section for more information.

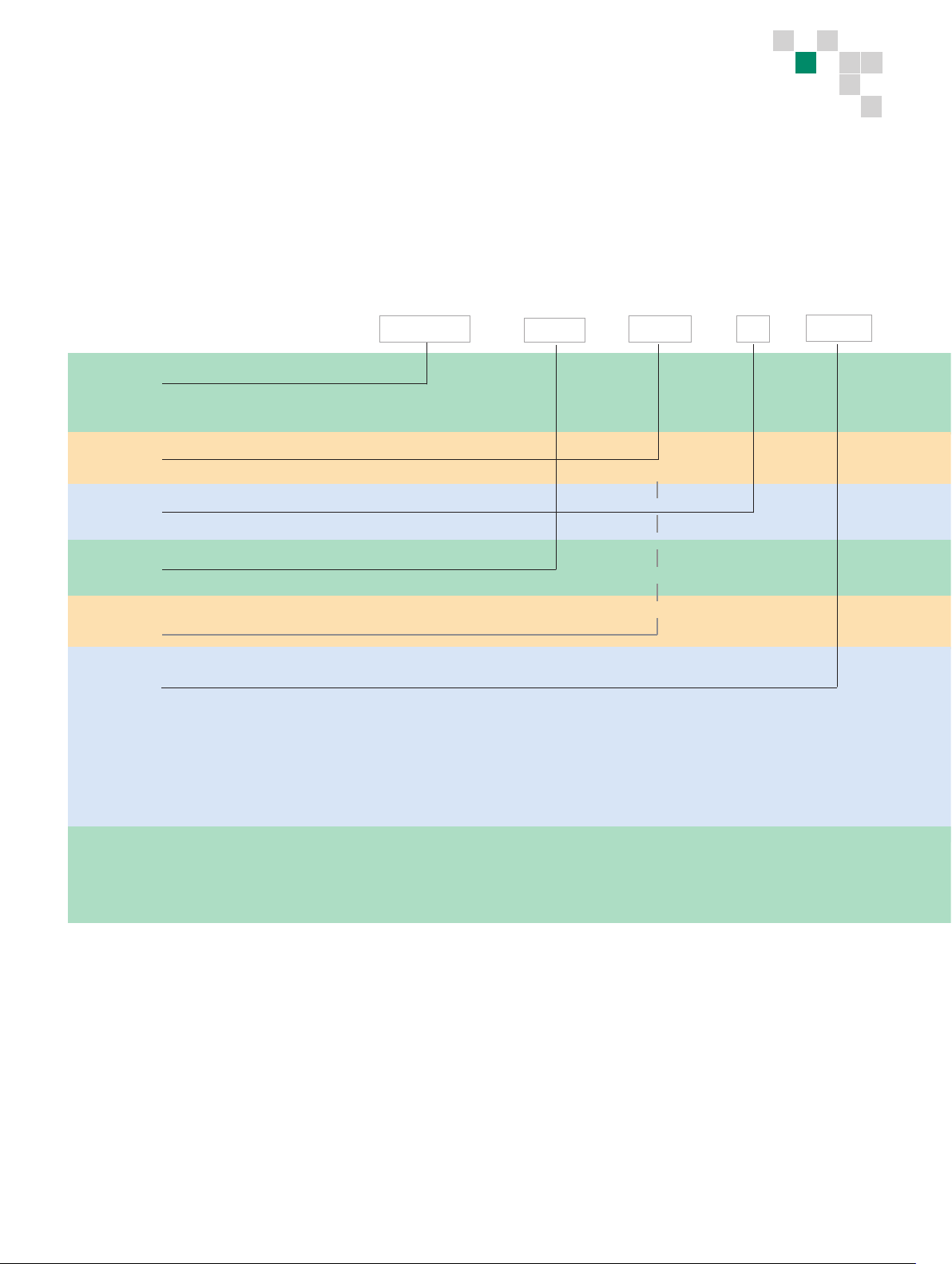

Type code

Product series

ACS350 - 01U - 02A4 - 2 + J400

1

Ratings and Types

2

Voltages

3

Construction (# input phases)

4

OR

Choice 2: Build up your own ordering code using the

simple 7-step approach below. Then, contact your local

ABB Drives sales ofce.

5

6

7

Dimension

Options

Technical Data

Control connections

2

ABB General Machinery Drive, ACS350

ABB General Machinery Drives ................................................. 4

Features ....................................................................................4

Technical Specication ..............................................................5

Output current rating ................................................................. 6

Input voltage rating ....................................................................6

Phases....................................................................................... 6

Electro Magnetic Compatibility (EMC) ....................................... 6

1

2

3

4

Dimensions ................................................................................ 7

How to select options ................................................................7

Interfaces

User interfaces ..................................................................... 8

Machine interfaces ............................................................... 9

External options

Brake resistors ...................................................................10

FlashDrop ........................................................................... 10

Software tools

DriveWindow Light 2.x ........................................................ 11

Cooling ....................................................................................12

Fuse selections........................................................................ 12

Connection examples ..............................................................13

5

6

7

3

ABB General Machinery Drives

ACS350 - 01U - 02A4 - 2 + J400

What is the ACS350 Customer Value?

■ Dramatically reduces programming time and costs with

FlashDrop

■ Optimal installation layout with unied height and depth

for all frames and DIN rail mounting up to 30 Hp

■ Reduced cost with built-in brake chopper and EMC lter

■ Reduced wiring time and costs for easy access I/O and

plug-in Fieldbus modules

■ Increased standard or custom programming capacity,

exibility and capabilities for simple to complex motor

control with:

- Built-in intelligent triggering

- Supervising parameters

- Speed compensation

- User specied macros

- PLC-like functions

- Reference trim

The ABB ACS350 general machinery drive is designed

specically for the OEM machine-building sector. In this

sector, the manufacturing time per unit is critical. The

ACS350 is designed to be the fastest drive in terms of

installation, setting parameters and commissioning. The

ACS350 has been designed to be as user-friendly as possible,

yet provide high application exibility. The ACS350 offers

diverse functionality to cater to the most demanding needs.

Where can it be used?

ABB general machinery drives are designed to meet

the requirements of an extensive range of machinery

applications. The drive is ideal for food and beverage,

material handling, textile, printing, rubber and plastics, and

woodworking applications.

Highlights

■ FlashDrop

■ Sensorless Vector Motor Control

■ Sequence programming

■ Impressive software and compact hardware

■ Optimized interfaces for users and machines

■ Unied height and depth

■ Convenient installation

■ Coated boards as standard

■ Built-in brake chopper as standard

■ RoHS (verify label)

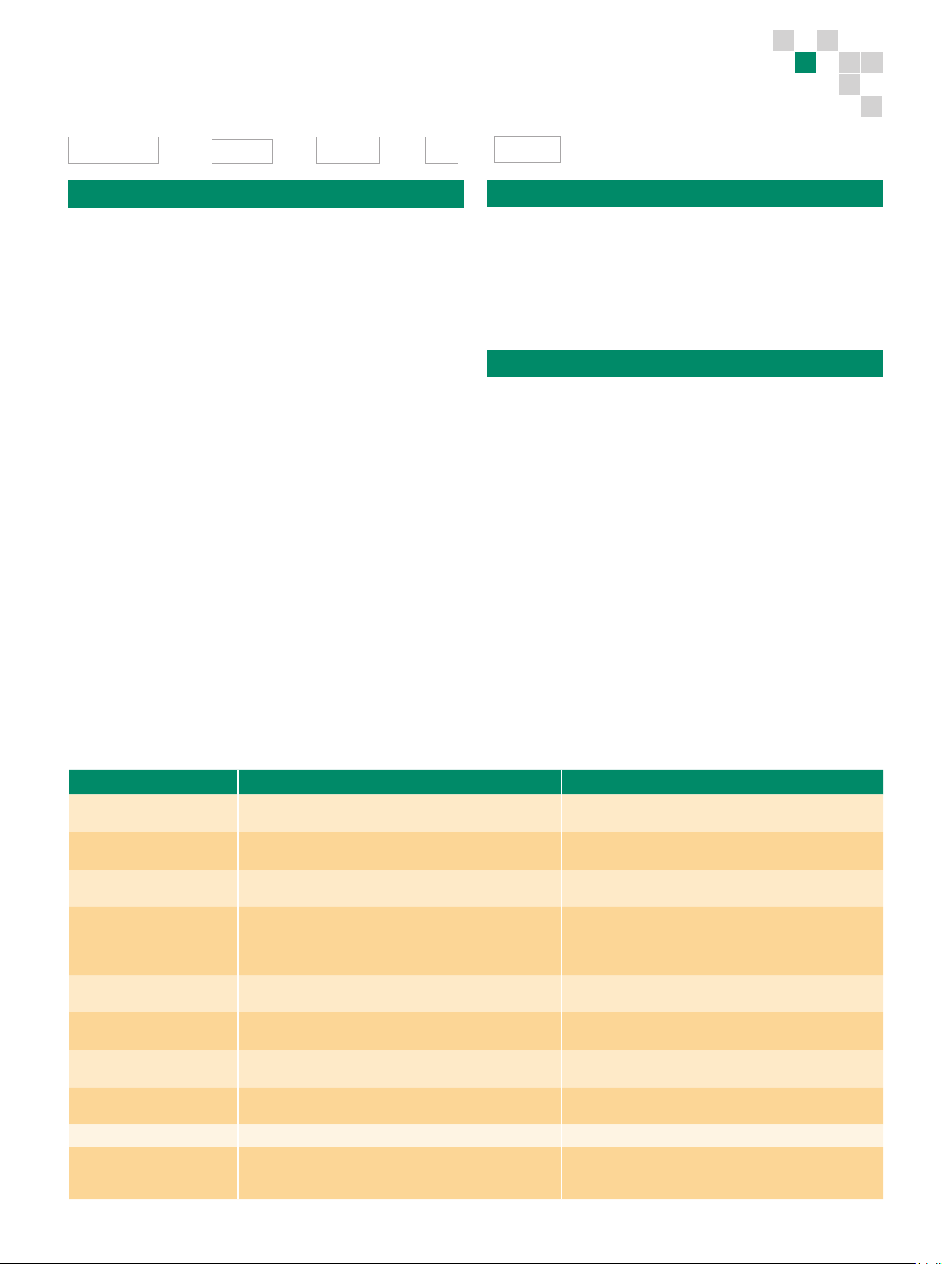

What are the ACS350's Main Features and Benets supporting Customer Value?

Features Benets Notes

FlashDrop Faster and easier drive set up and commissioning. New fast, safe and trouble free method to download

Sequence programming Logic programming included as standard with

Software State of the art technology and performance with

User interfaces Cost efcient approach offering different control panels

Cabinet

compatibility

Fieldbuses High speed communication with compact and robust

Built-in EMC lter No extra space, parts, time or cost required. 2nd environment lter complying with IEC 61800-3 as

Coated boards Longer lifetime in hostile environments. Reduced

Built-in Brake Chopper Reduced costs, saved space and simple wiring. 100% braking capability

Drive Protection Latest solutions to protect the drive and offer trouble-

PLC-like functions.

exceptional exibility.

according to functionality need.

Optimum installation layout and efcient cabinet space

usage.

eldbus design.

service.

free use and the highest quality

4

parameters available without electricity - Patented.

Application specic 8-state programming with

comprehensive triggering conditions.

Sensorless vector and closed loop vector control

Blank cover

Basic panel with numerical display

Advanced control panel with clear alphanumerical

dynamic menus, real time clock and 14 languages.

Screw, DIN-rail, sideways and side-by-side mounting.

Unied height and depth.

Enclosed plug-in type of eldbus adapter.

standard.

Protections against moisture and hostile particles as

standard.

Motor output and I/O protected against miswiring.

Protection against unstable supply networks.

Coated boards included as standard.

Technical Specication

ACS350 - 01U - 02A4 - 2 + J400

Input connection

Voltage and

power range

Frequency 48 to 63 Hz

Power factor 0.98

1-phase, 200 to 240 V ±10%

0.37 to 2.2 kW (0.5 to 3 hp)

3-phase, 200 to 240 V ±10%

0.37 to 11 kW (0.5 to 15 hp)

3-phase, 380 to 480 V ±10%

0.37 to 22 kW (0.5 to 30 hp)

Output connection

Voltage 3-phase, from 0 to U

Frequency 0 to 500 Hz

Continuous loading

capability

(constant torque at a max. ambient

temperature of 400C)

Overload capacity

(at a max. ambient temperature of

400C)

Rated output current I

1.5 x I

for 1 minute every 10 minutes

2N

1.8 x I

for 2 seconds every 10 minutes

2N

Switching frequency

Default

Selectable

4 kHz

4 to 12 kHz with 4 kHz steps (16 kHz,

v 2.41+)

Acceleration time 0.1 to 1800 s

Deceleration time 0.1 to 1800 s

Braking Brake chopper- standard (100% braking

capability)

Speed Control

Static Accuracy

Dynamic Accuracy

20% of motor nominal slip

<1% with 100% torque stop

Torque Control

Torque step rise time

< 10ms with nominal torque

Non-linearity ± 5% with nominal torque

SUPPLY

2N

Environmental limits

Ambient temperature -10 to 40oC (14 to 104oF), no frost allowed

Altitude

Output current Rated current available at 0 to 1000 m

Relative humidity Lower than 95% (without condensation)

Protection class IP 20 / optional NEMA 1

Enclosure color NCS 1502-Y, RAL 9002, PMS 420 C

Contamination levels

Transportation

Storage

Operation

50oC (122oF) with 10% derating

(0 to 3281 ft) reduced by 1% per 100 m

(328 ft) over 1000 to 2000 m

(3281 to 6562 ft)

IEC 60721-3-(1,2,3)

No conductive dust allowed

Class 1C2 (chemical gases)

Class 1S2 (solid particles)

Class 2C2 (chemical gases)

Class 2S2 (solid particles)

Class 3C2 (chemical gases)

Class 3S2 (solid particles)

Programmable control connections

Two analog inputs

Voltage signal

Unipolar

Bipolar

0 (2) to 10 V, R

-10 to 10 V, R

> 312 k

in

> 312 k

in

Ω

Ω

Current signal

Unipolar

Bipolar

0 (4) to 20 mA, R

-20 to 20 mA, R

= 100 Ω

in

= 100 Ω

in

Potentiometer reference

value (X1A:4)

Resolution

Accuracy

10 V ±1% max. 10 mA, R < 10 kΩ

0.1%

± 1%

One analog output 0 (4) to 20 mA, load < 500 Ω

Auxiliary voltage 24 V DC ±10%, max. 200 mA

Five digital inputs

12 to 24 V DC with internal or external

supply, PNP and NPN, pulse train

0 to 16 kHz

Input impedance

2.4 kΩ

One relay output

Type

Maximum switching voltage

Maximum switching current

Maximum continuous current

NO + NC

250 V AC/30 V DC

0.5 A/30 V DC; 5 A/230 V AC

2 A rms

One digital output

Type

Maximum switching voltage

Maximum switching current

Transistor output

30 V DC

100 mA/30 V DC, short circuit

protected

Frequency

Resolution

Accuracy

10Hz to 16 kHz

1 Hz

0.2%

Serial communication

Fieldbuses

Refresh rate

PROFIBUS DP ® 9-pin D-connector

DeviceNet ™ 5-pin screw type connector

CANopen 9-pin D-connector

Modbus RTU ® 4-pin screw type connector

Plug-in type

< 10 ms (between drive and eldbus

module)

Baud rate up to 12 Mbit/s

PROFIBUS DP and PROFIBUS DPV1

Network side based on “PROFIdrive”

prole.

Baud rate up to 500 kbit/s

Network side based on ODVA “AC/DC

drive” prole.

Baud rate up to 1 Mbit/s

Network side based on CiA DS402

prole.

Baud rate up to 115 kbit/s

Product compliance

Low Voltage Directive 73/23/EEC with supplements

Machinery Directive 98/37/EC

EMC Directive 89/336/EEC with supplements

Quality assurance system ISO 9001

Environmental system ISO 14001

UL, cUL, CE, C-Tick and GOST-R approvals

RoHs (Verify RoHS label)

IEC/EN 61800-5-1 (2003)

IEC/EN 60204-1 (1999)

IEC/EN 61800-3 (2004)

5

Loading...

Loading...