ABB ACS320 Technical Catalog

Low voltage AC drives

ABB HVAC Pump and Fan AC Drives

ACS320

1.2 to 50.8 A

Catalog

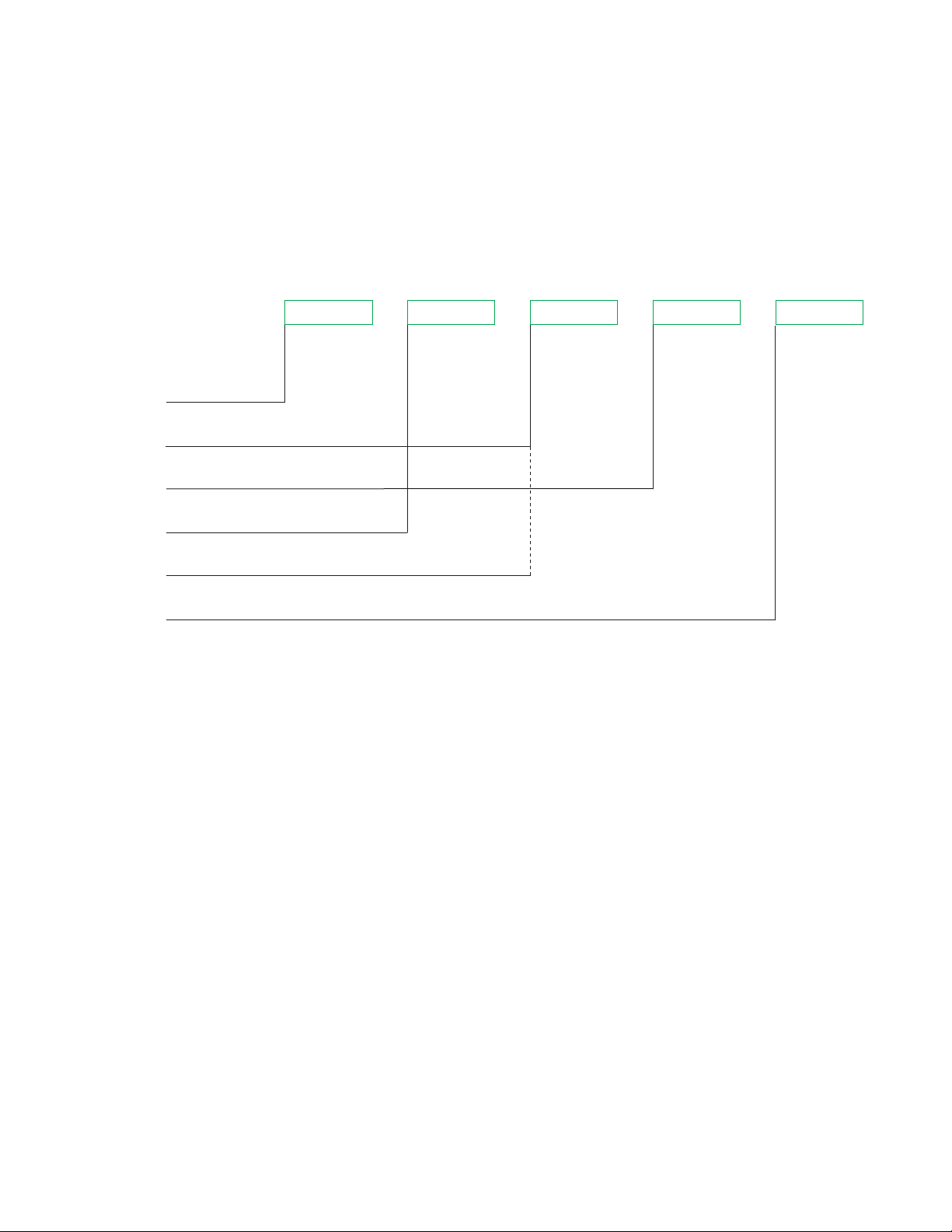

Selecting and ordering your drive

Build up your own ordering code using the type designation

key below or contact your local ABB drives HVAC sales office

and let them know what you want. Use page 3 as a reference

section for more information.

Type designation:

Product series

Ratings and types

Voltages

Constructions

Dimensions

Options

ACS320 - 0XU - XXXX - 2 + XXXX

2 ABB HVAC Pump and Fan AC Drive ACS320 | Catalog

Contents

ABB HVAC pump and fan AC drive, ACS320

Introduction to ACS320, AC drives for pump and fan applications 4

Typical applications 5

Main features 6

Features, advantages and benefits

Ratings and types 7

Type designation

Voltages

Construction

Technical data 8

Dimensions and weights 9

Cabinet-mounted drives (IP20 UL Open)

Wall-mounted drives (NEMA 1/UL Type 1)

Cooling 10

Circuit protection 11

Control connections 12

Application macros

Options 13

How to select options 13

User interfaces 14

Protection and installation 14

Serial communication 15

Extension module 15

DriveWindow Light 16

FlashDrop tool 17

Services 18

Catalog | ABB HVAC Pump and Fan AC Drive ACS320 3

Introduction to ACS320

AC drives for pump and fan applications

ACS320 - XXU - XXXX - 2 + XXXX

Making HVAC user friendly

The preprogrammed application macros and easy to use control

panel make installation and drive setup simple. The control

panel on the ACS320 uses HVAC terms and units, removing any

guess work, and comes with 18 languages built-in. The unified

height and depth of the drive frame sizes minimizes needed

installation space.

Energy savings

With energy savings of up to 70 percent, the ACS320 can help

to attain sustainability targets. The drive’s energy optimizer

tunes the drive’s performance to help save even more energy.

Built-in energy efficiency calculators monitor the energy used

and saved. The savings are shown in kilowatt-hours and in local

currency. Carbon dioxide (CO2) emission reductions are also

shown.

Complete HVAC functionality

The ACS320 comes standard with four embedded

communication protocols, including BACnet (MS/TP) for easy

integration into building management systems. Built-in real

time clock and timers help you optimize energy use. The drive

provides full output current at ambient temperatures of up to

50°C without derating. Built-in software for controlling common

HVAC applications includes:

− 2 PID controllers

− Timers with real time clock

− Pump and fan control

− Cooling fan control

− Pump cleaning

− Underload (broken belt) detection

− Pump protection

− Sleep function

− Pipe fill (precharge)

Typical applications for the ACS320 include:

− Supply and return fans

− Condenser fans

− Exhaust fans

− Fume hood fans

− Booster pumps

− Submersible pumps

4 ABB HVAC Pump and Fan AC Drive ACS320 | Catalog

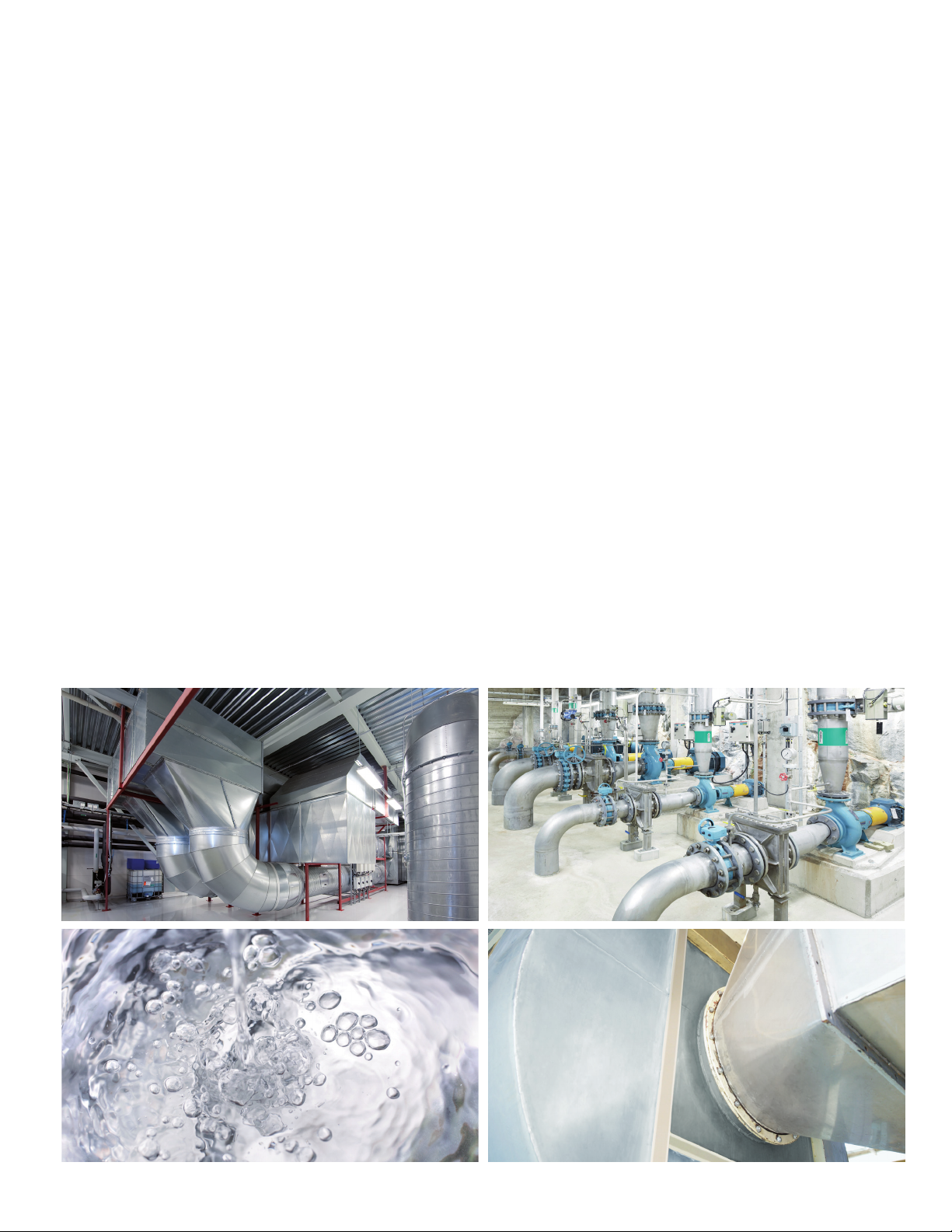

Typical applications

The ACS320 drive is specically designed to meet the variable

torque loads demanded by centrifugal fans and pumps. The

result is maximum application uptime, reduced maintenance cost

and higher energy savings.

A booster pump system is designed to boost supplied water

pressure to a predetermined level in commercial buildings. The

ACS320 drive features pump and fan control (PFC) for use where

several parallel pumps are operated together and the required

flow rate is variable.

PID control is available to allow the process to accurately

maintain a pressure setpoint by adjusting the control outputs,

thus allowing for precise control within difficult processes.

A sleep & boost function detects slow rotation and runs the

pump to boost pressure prior to shutdown. The pressure

is continuously monitored and pumping restarts when the

pressure falls below the minimum level.

Fan arrays use multiple motors that are often controlled by

individual drives. The ACS320 offers exibility in mounting with

its compact footprint. Multiple drives in this arrangement provide

redundancy ensuring year round comfort. With the optional UL

type 1 kit installed on ACS320 drives the drive is plenum rated

and suitable for use in the air stream. Built in building automation

protocols that come standard with the product allow the user to

easily set up and run the drive using BACnet, FLN, N2 or Modbus

RTU reducing commission time.

Supply and return fans need to maintain air quality in spaces

throughout commercial buildings, schools and hospitals. The

ACS320 provides a selection of single phase 230V, three phase

230V and three phase 480V drives rated up to 30 Hp in a

compact, exible design. Whether it is cold winter nights or hot

summer days, the rugged design can handle the environmental

extremes with a -10 to 50 °C (14 to 122 °F) ambient temperature

rating, while keeping occupants comfortable.

Catalog | ABB HVAC Pump and Fan AC Drive ACS320 5

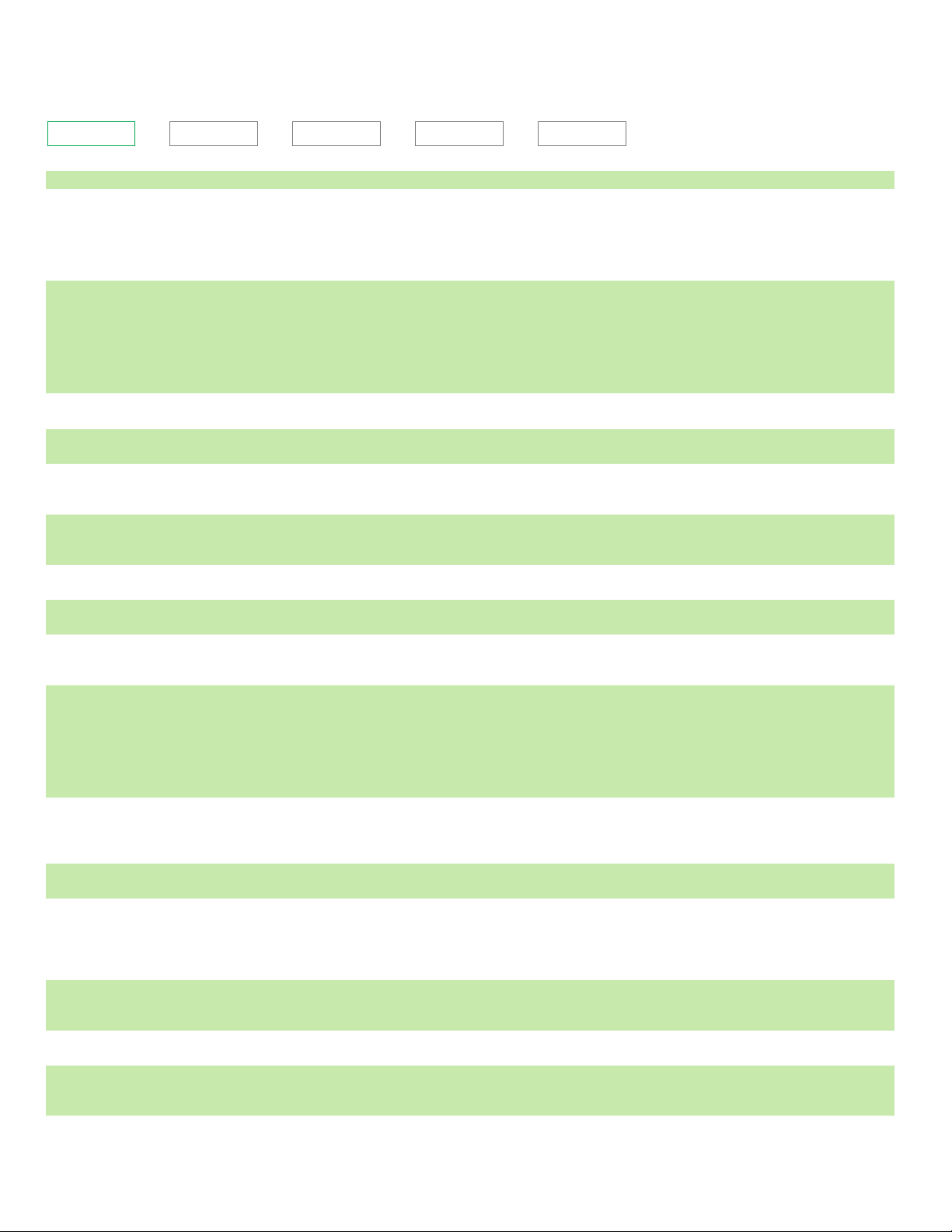

Main features

ACS320 - 0XU - XXXX - 2 + XXXX

Feature Advantage Benefit

Embedded Fieldbus Protocols:

Modbus RTU (EIA-485);

Johnson Controls N2;

Siemens Building Technology FLN (P1);

BACnet (MS/TP)

No need for external eldbus options.

Integrated and compact design.

Saves costs of external fieldbus devices.

Increases reliability.

Pump protection functions Integrated protection and control with preprogrammed features

On/off cooling fan control Cooling fan rotates only when the drive is running, thereby cooling

Software controlled phase inversion Fast and easy way to change the phase order of the motor

Short parameter menu view Only the most needed drive parameters are shown on the drive’s

Energy optimizer Improved motor efciency with intelligent drive control method,

Energy efficiency counters Several counters to illustrate saved energy (kWh), carbon-dioxide

Full output current at

50 °C ambient

Load analyzer Load analyzer saves process data, such as current and

Pump and fan control (PFC) feature to

control pumps and fans in parallel

Soft pump and fan control feature

(SPFC)

PID controllers Varies the drive’s performance according to the need of the

Compact size and flexible mounting

options

User interfaces Advanced control panel with clear alphanumerical dynamic menus,

Maintenance assistant Monitors consumed energy (kWh), running hours or motor rotation. Assists in preventive maintenance of the

Commissioning assistants Easy setup of parameters for PID controllers, real-time clock and

Drive protection Motor output and I/O protected against wiring faults.

like pump cleaning, pipefill, inlet/outlet pressure supervision and

detection of under or over load for preventive maintenance.

Improves process control and system reliability. Integrates system

protection.

Smoother processes: improved and optimized system. Longer life

for pump and fan systems, reduced maintenance costs.

only when needed.

rotation.

parameter view. Complete parameter view can be changed by

setting one parameter.

especially while operating on partial centrifugal loads.

emissions (CO

The drive can be operated in ambient temperatures up to

50 °C without derating the output current.

torque values, which can be used to analyze the process and

dimensioning of the drive and motor.

One drive controls several pumps or fans and eliminates the need

for an external programmable logic controller.

Reduces motor stress and increases lifetime when auxiliary motors

are driven according to the needed pump/fan capacity.

Interlock function enables one motor to be disengaged from the

mains supply while others continue operating in parallel.

Reduces unwanted pressure peaks in pumps and pipelines when

an auxiliary motor is started.

Reduces inrush current to the power network while connecting

new auxiliary motors.

application.

The high power-to-size ratio of the drive facilitates efficient cabinet

space usage.

Optimum installation layout.

Flexible installation with screw or DIN rail mounting.

Drive can be installed sideways or side-by-side.

real time clock and 14 languages. Basic panel with numerical

display.

serial communication.

Protection against unstable supply networks.

Coated boards as standard.

) and cost in local currency.

2

Reduces maintenance costs.

Longer life and reliable operation of pump

systems.

Silent operation.

Improves drive’s energy efficiency.

Time savings as there is no need to change

the output cable order manually.

Time savings as the user quickly sees the

most important parameters.

Fast commissioning of the drive.

Boosts energy efficiency due to lower motor

currents.

Reduces audible noise from the motor.

Shows direct impact on energy bill and helps

control operational expenditure (OPEX).

Optimized drive dimensioning for wide

temperature ranges.

Optimized dimensioning of the drive, motor

and process.

Saves cost of additional drives and external

PLC.

Longer life for pump or fan systems while

reducing maintenance time and costs.

Maintenance can be carried out safely

without stopping the process.

Reduces maintenance costs.

Longer life for pump or fan systems.

Smoother processes.

Control process - pressure, flow, temperature

Space savings.

Different control panels available according to

functionality needs.

drive, motor or run application.

Time savings with reduced need to set the

parameters manually.

Ensures all required parameters are set.

Latest solution to protect the drive and offer

trouble free use and the highest quality.

6 ABB HVAC Pump and Fan AC Drive ACS320 | Catalog

Loading...

Loading...