ABB industry-specific drives

Short form user’s manual

ACS320 drives

Table of contents

Safety

Mechanical installation

Electrical installation

Start-up and control with I/O

List of related manuals

You can find manuals and other product documents in PDF format on the Internet. See section Document

library on the Internet on the inside of the back cover. For manuals not available in the Document library, contact

your local ABB representative.

Purpose of the manual

This short form user’s manual provides the basic information needed for installing and

commissioning the drive.

For information on planning the electrical installation, operation with the control panel,

program features, fieldbus, all accessible actual signals and parameters, fault tracing,

maintenance, additional technical data and dimension drawings, refer to ACS320

user’s manual (3AUA0000062599 [English]). To access it on the Internet, go to

www.abb.com/drives, select Document Library, enter the code in the search field and

click OK.

Applicability

The manual is applicable to the ACS320 drive firmware version 4.03c or later. See

parameter 3301 FIRMWARE in chapter Actual signals and parameters in ACS320

user’s manual (3AUA0000062599 [English]).

Drive manuals Code (English)

ACS320 short form user’s manual 3AUA0000086933

ACS320 user’s manual 3AUA0000062599

Option manuals and guides

MFDT-01 FlashDrop user’s manual 3AFE68591074

MREL-01 output relay module user’s manual 3AUA0000035974

MUL1-R1 installation instructions for ACS150, ACS310,

ACS320, ACS350 and ACS355

3AFE68642868

MUL1-R3 installation instructions for ACS310, ACS320,

ACS350 and ACS355

3AFE68643147

MUL1-R4 installation instructions for ACS310, ACS320,

ACS350 and ACS355

3AUA0000025916

SREA-01 Ethernet adapter module quick start-up guide 3AUA0000042902

SREA-01 Ethernet adapter module user’s manual 3AUA0000042896

Maintenance manuals

Guide for capacitor reforming in ACS50, ACS55, ACS150,

ACS310, ACS350, ACS355, ACS550, ACH550 and R1-R4

OINT-/SINT-boards

3AFE68735190

3AUA0000086933 Rev D

EN

EFFECTIVE: 2016-08-18

2016 ABB Oy. All Rights Reserved.

Table of contents 3

Table of contents

List of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Purpose of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. Safety

Safety in installation and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safe start-up and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Hardware description

Power connections and control interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Type designation label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Type designation key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety

3. Mechanical installation

Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4. Electrical installation

Checking the compatibility with IT (ungrounded) and corner-grounded TN systems . . . . . . . 17

Connecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5. Start-up and control with I/O

How to start up the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

How to control the drive through the I/O interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6. Actual signals and parameters in the short view

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fieldbus equivalent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Default values with different macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Actual signals in the short parameter view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Parameters in the short parameter view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7. Technical data

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Fuses and alternate short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

UL marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4 Table of contents

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Safety 5

1. Safety

Safety in installation and maintenance

These warnings are intended for all who work on the drive, motor cable or motor.

Electrical safety

WARNING! Ignoring the following instructions can cause physical injury or

death, or damage to the equipment.

• Only qualified electricians are allowed to install and maintain the drive!

• Never work on the drive, motor cable or motor when input power is applied. After

disconnecting the input power, always wait for 5 minutes to let the intermediate

circuit capacitors discharge before you start working on the drive, motor or motor

cable.

Always make sure by measuring with a multimeter (impedance at least 1 Mohm)

that there is no voltage between the drive input phases U1, V1 and W1 and the

ground.

• Do not work on the control cables when power is applied to the drive or to the

external control circuits. Externally supplied control circuits may carry dangerous

voltage even when the input power of the drive is switched off.

• Do not make any insulation or voltage withstand tests on the drive.

• Disconnect the internal EMC filter when installing the drive on an IT system (an

ungrounded power system or a high-resistance-grounded [over 30 ohms] power

system), otherwise the system will be connected to ground potential through the

EMC filter capacitors. This may cause danger or damage the drive. See page 17.

Note: When the internal EMC filter is disconnected, the drive is not EMC

compatible.

• Disconnect the internal EMC filter when installing the drive on a corner-grounded

TN system, otherwise the drive will be damaged. See page 17.

Note: When the internal EMC filter is disconnected, the drive is not EMC

compatible.

• All ELV (extra low voltage) circuits connected to the drive must be used within a

zone of equipotential bonding, in other words, within a zone where all

simultaneously accessible conductive parts are electrically connected to prevent

hazardous voltages appearing between them. This is accomplished by a proper

factory grounding.

6 Safety

Note:

• Even when the motor is stopped, dangerous voltage is present at the power

circuit terminals U1, V1, W1 and U2, V2, W2.

• For more technical information, contact the factory or your local ABB sales

representative.

General safety

WARNING! If you ignore the safety instructions, injury or death can occur. If

you are not a qualified electrician, do not do electrical work.

• Never attempt to repair a malfunctioning drive. Contact your local ABB

representative or Authorized Service Center for service support.

• Make sure that dust from drilling does not enter the drive during the installation.

Electrically conductive dust inside the drive may cause damage or lead to

malfunction.

• Make sure of sufficient cooling.

Safe start-up and operation

These warnings are intended for all who plan the operation, start up or operate the

drive.

General safety

WARNING! Ignoring the following instructions can cause physical injury or

death, or damage to the equipment.

• Before adjusting the drive and putting it into service, make sure that the motor and

all driven equipment are suitable for operation throughout the speed range

provided by the drive. The drive can be adjusted to operate the motor at speeds

above and below the speed provided by connecting the motor directly to the

power line.

• Do not activate automatic fault reset functions if dangerous situations can occur.

When activated, these functions will reset the drive and resume operation after a

fault.

• Do not control the motor with an AC contactor or disconnecting device

(disconnecting means). Use the control panel start and stop keys and or

external commands (I/O or fieldbus). The maximum number of charging cycles

allowed with the DC capacitors (i.e power-ups by applying power) is two per

minute and the maximum total number of chargings is 15 000.

Safety 7

LOC

REM

Note:

• If an external source is selected for start command, and it is ON, the drive starts

immediately after an input voltage break or fault reset unless the drive is

configured for 3-wire (a pulse) start/stop.

• When the control location is not set to local (LOC not shown on the display), the

stop key on the control panel will not stop the drive. To stop the drive using the

control panel, press the LOC/REM key and then press the stop key .

8 Safety

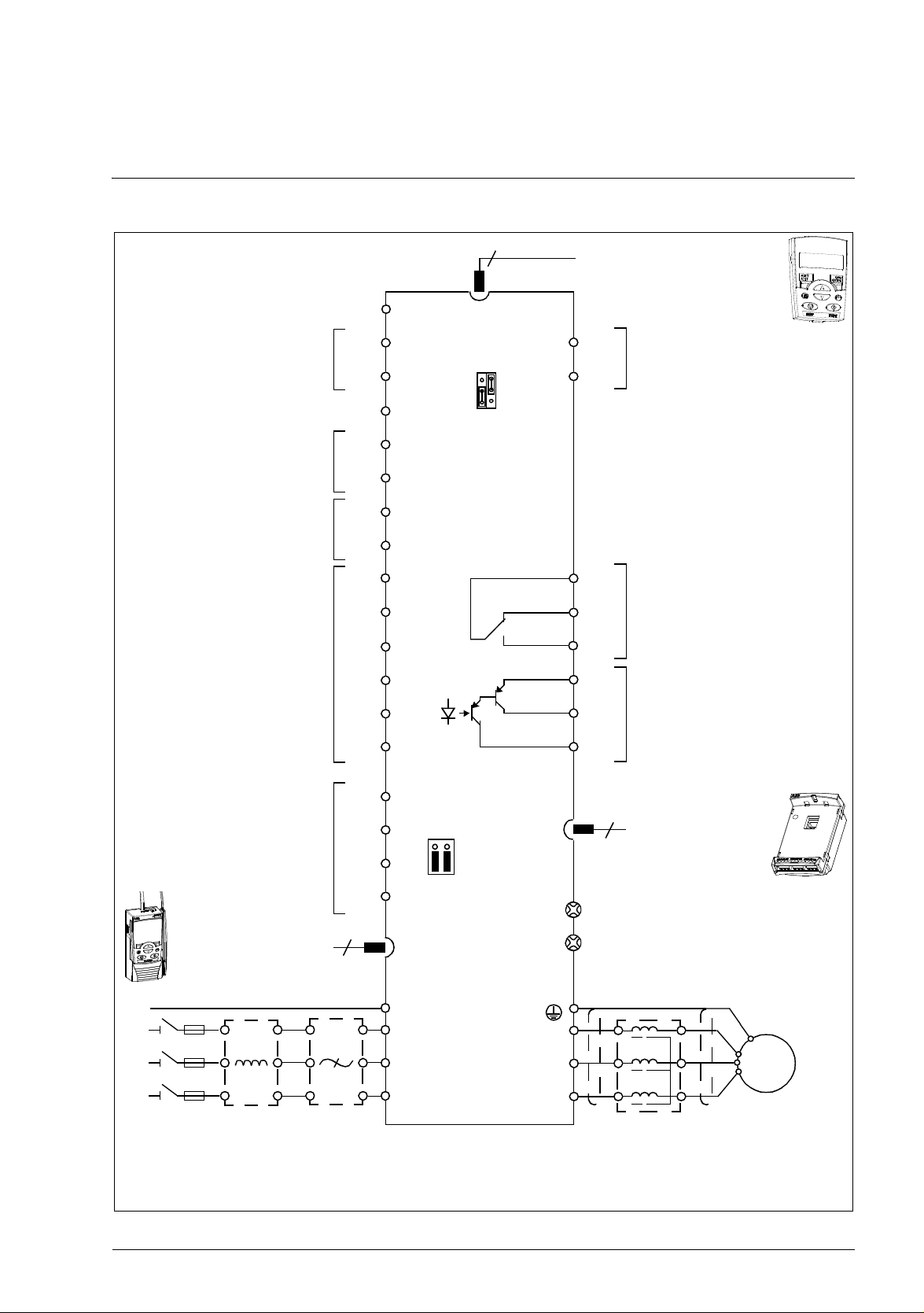

Hardware description 9

RONO

RONC

3

9

DI1

DI2

DI3

DI4

DI5

+24 V

Aux. voltage output

+24 V DC, max. 200 mA

DOSRC

GND

DCOM

DOOUT

DOGND

Digital/frequency output,

PNP transistor type

30 V DC, max. 100 mA

Relay output

250 V AC / 30 V DC / 6 A

V

mAGND

+10V

Reference voltage

+10 V DC, max. 10 mA

AI2

Analog input 2

GND

AI1

Analog input 1

0…10 V

SCR

Screen

Analog output

0…20 mA

AI1

AI2

*) Optional, not provided with the drive.

Note: For 1-phase power supply, connect power to U1/L and V1/N terminals.

EMC

VAR

EMC filter grounding screw

Varistor grounding screw

ROCOM

PROGRAMMABLE RELAY

AND DIGITAL OUTPUTS

Output relay

module MREL-01

11

17

18

19

20

21

22

AO 7

GND 8

12

13

14

15

16

10

6

5

1

2

SHIELD

B

A

GND_A

23

24

25

26

PROGRAMMABLE

DIGITAL INPUTS

4

FlashDrop

S1

J701

8

6

6

DI5 can also be used

as a frequency input

L1

L2

L3

PE

U1

V1

W1

PE

Input choke*

)

EMC filter*

)

3-phase

power supply

U2

V2

W2

AC motor

M

3 ~

Output choke*

)

Control panel (RJ-45)

EFB Comm port

Modbus RTU (EIA-485)

Johnson Controls N2

Siemens Building Technology

FLN (P1), BACnet (MS/TP)

200…480 VAC

2. Hardware description

Power connections and control interfaces

10 Hardware description

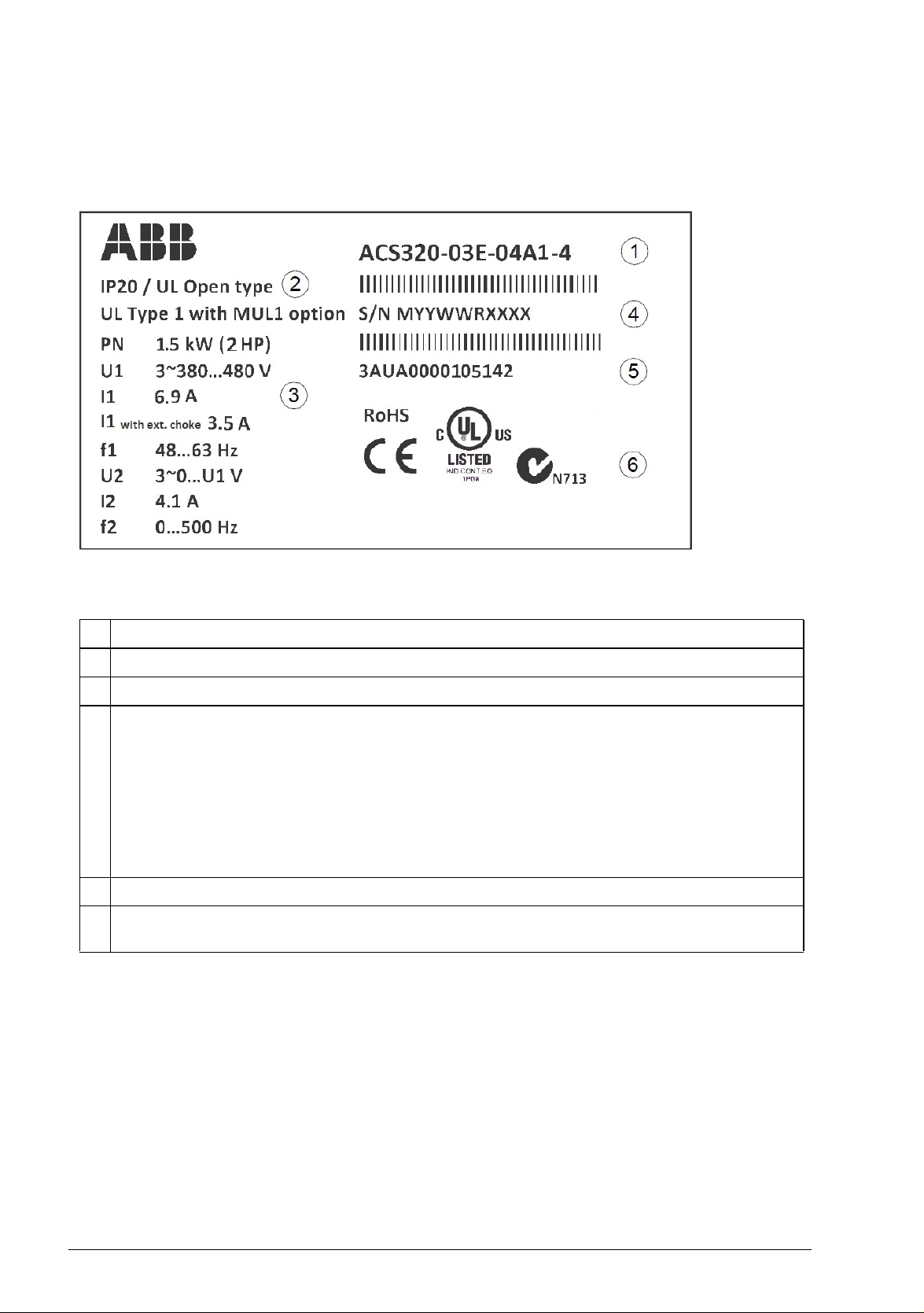

1 Type designation, see section Type designation key on page 11

2 Degree of protection by enclosure (IP and UL/NEMA)

3 Nominal ratings, see section Ratings on page 47 or Definitions on page 48.

4 Serial number of format MYYWWRXXXX, where

M: Manufacturer

YY: 09, 10, 11, … for 2009, 2010, 2011, …

WW: 01, 02, 03, … for week 1, week 2, week 3, …

R: A, B, C, … for product revision number

XXXX: Integer starting every week from 0001

5 ABB MRP code of the drive

6 CE marking and C-Tick, C-UL US and RoHS marks (the label of your drive shows the

valid markings)

Type designation label

The type designation label is attached to the left side of the drive. An example label

and explanation of the label contents are shown below.

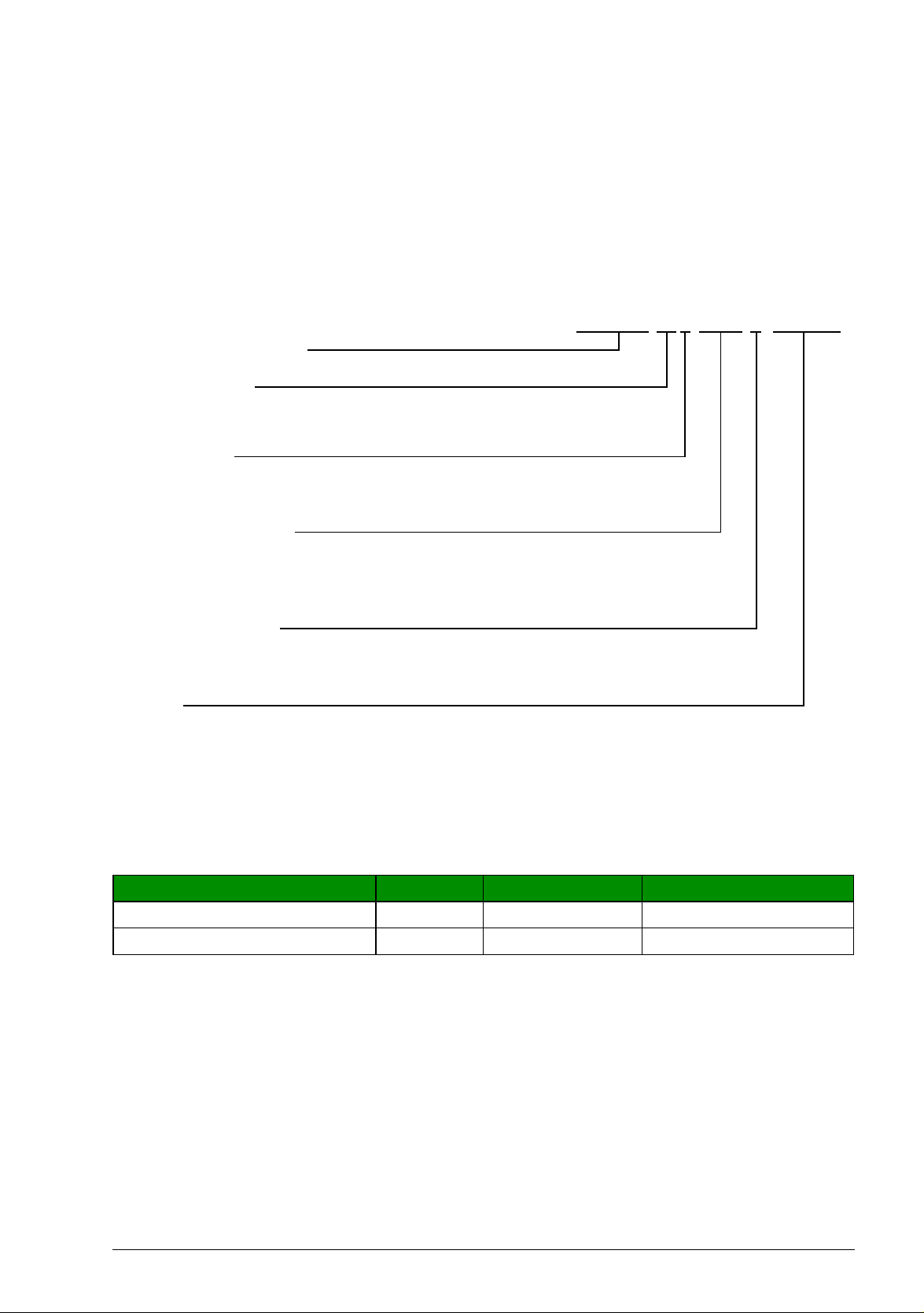

Type designation key

ACS320-03X-08A8-4+J404+...

ACS320 product series

01 = 1-phase input

03 = 3-phase input

1-phase/3-phase

In format xxAy, where xx indicates the integer part and y the fractional part,

e.g, 08A8 means 8.8 A. For more information, see section Ratings on page 47.

2 = 200…240 V AC

4 = 380…480 V AC

Input voltage range

E = EMC filter connected, 50 Hz frequency

U = EMC filter disconnected, 60 Hz frequency

Configuration

J404 = ACS-CP-C basic control panel

1) 2)

J400 = ACH-CP-B advanced HVAC control panel

1)

R700 = ACS320 user’s manual in English (3AUA0000062599 [EN])

E202 = RFI filter (available for European market only)

1)

The ACS320 is compatible with panels that have the following panel revisions and panel

firmware versions. To find out the revision and firmware version of your panel, see chapter

Control panels, section Applicability in ACS320 user’s manual (3AUA0000062599 [English]).

2)

Available for North American market only.

Panel type Type code Panel revision Panel firmware version

Basic control panel

2)

ACS-CP-C M or later 1.13 or later

Advanced HVAC control panel ACH-CP-B X or later 2.04 or later

Options

Output current rating

The type designation contains information on the specifications and configuration of

the drive. You find the type designation on the type designation label attached to the

drive. The first digits from the left express the basic configuration, for example,

ACS320-03E-08A8-4. The optional selections are given after that, separated by +

signs, for example +J404. The explanations of the type designation selections are

described below.

Hardware description 11

12 Hardware description

Mechanical installation 13

1

22

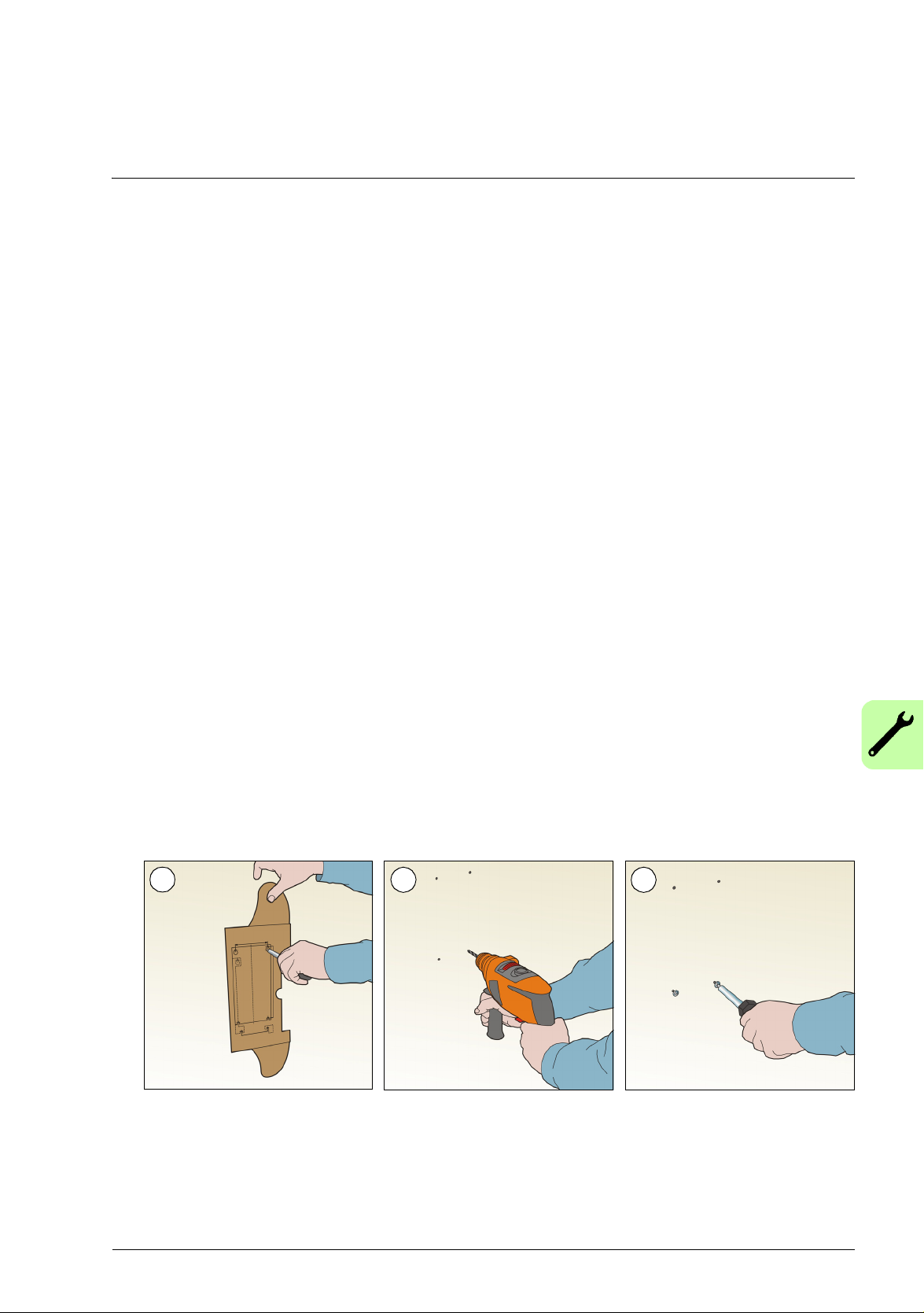

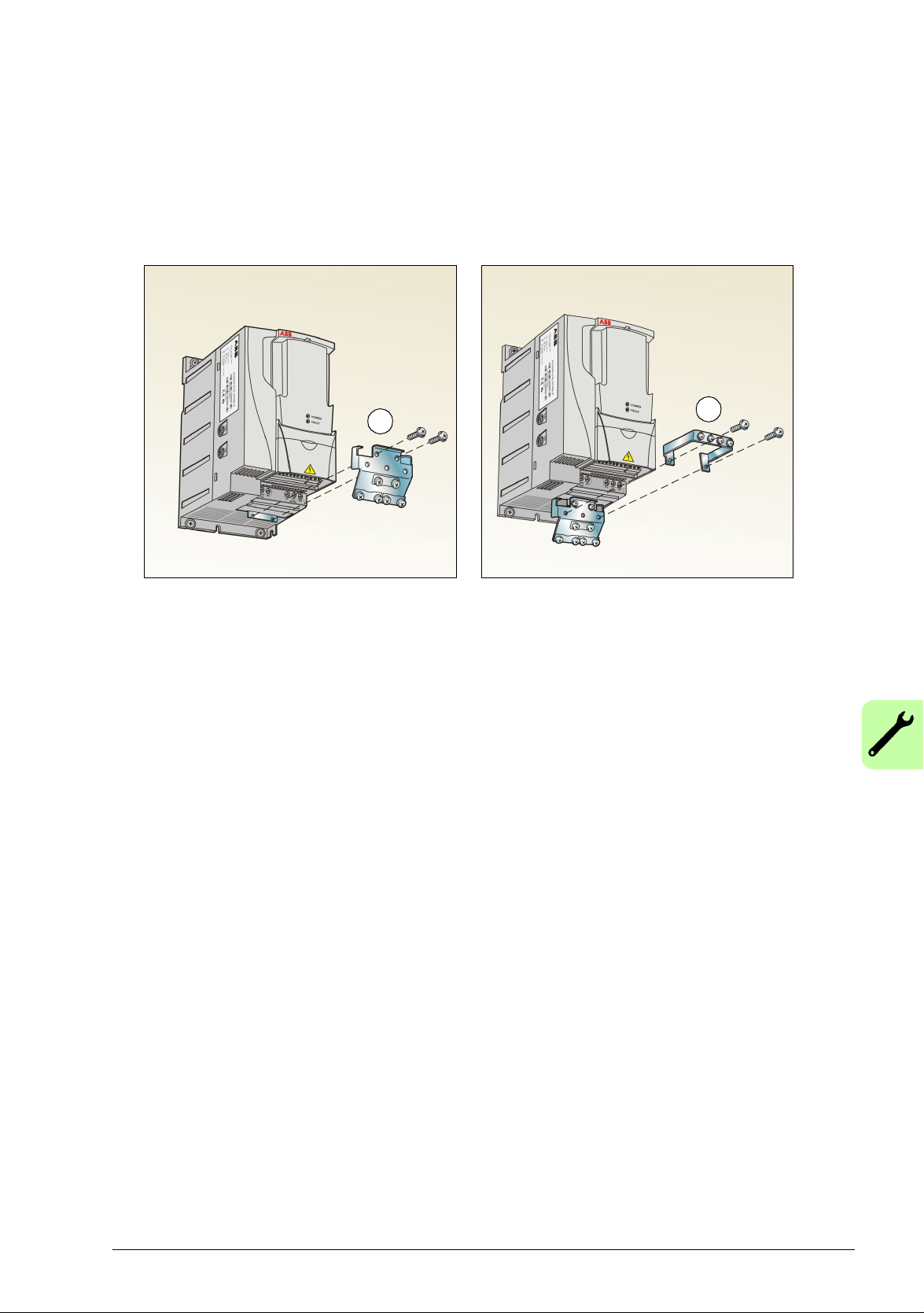

3. Mechanical installation

Installing

The instructions in this manual cover drives with the IP20 degree of protection. To

comply with NEMA 1, use the MUL1-R1, MUL1-R3 or MUL1-R4 option kit, which is

delivered with multilingual installation instructions (3AFE68642868, 3AFE68643147

or 3AUA0000025916, respectively).

Install the drive

Install the drive with screws or on a DIN rail as appropriate.

The required free space for cooling above and below the drive is 75 mm (3 in). No

free space is required on the sides, so drives can be mounted immediately next to

each other.

Note: Make sure that dust from drilling does not enter the drive during the installation.

With screws

1. Mark the hole locations using for example the mounting template cut out from the

package. The locations of the holes are also shown in the drawings in chapter

Dimension drawings in ACS320 user’s manual (3AUA0000062599 [English]). The

number and location of the holes used depend on how the drive is installed:

a) back mounting (frame sizes R0…R4): four holes

b) side mounting (frame sizes R0…R2): three holes; one of the bottom holes is

located in the clamping plate.

2. Fix the screws or bolts to the marked locations.

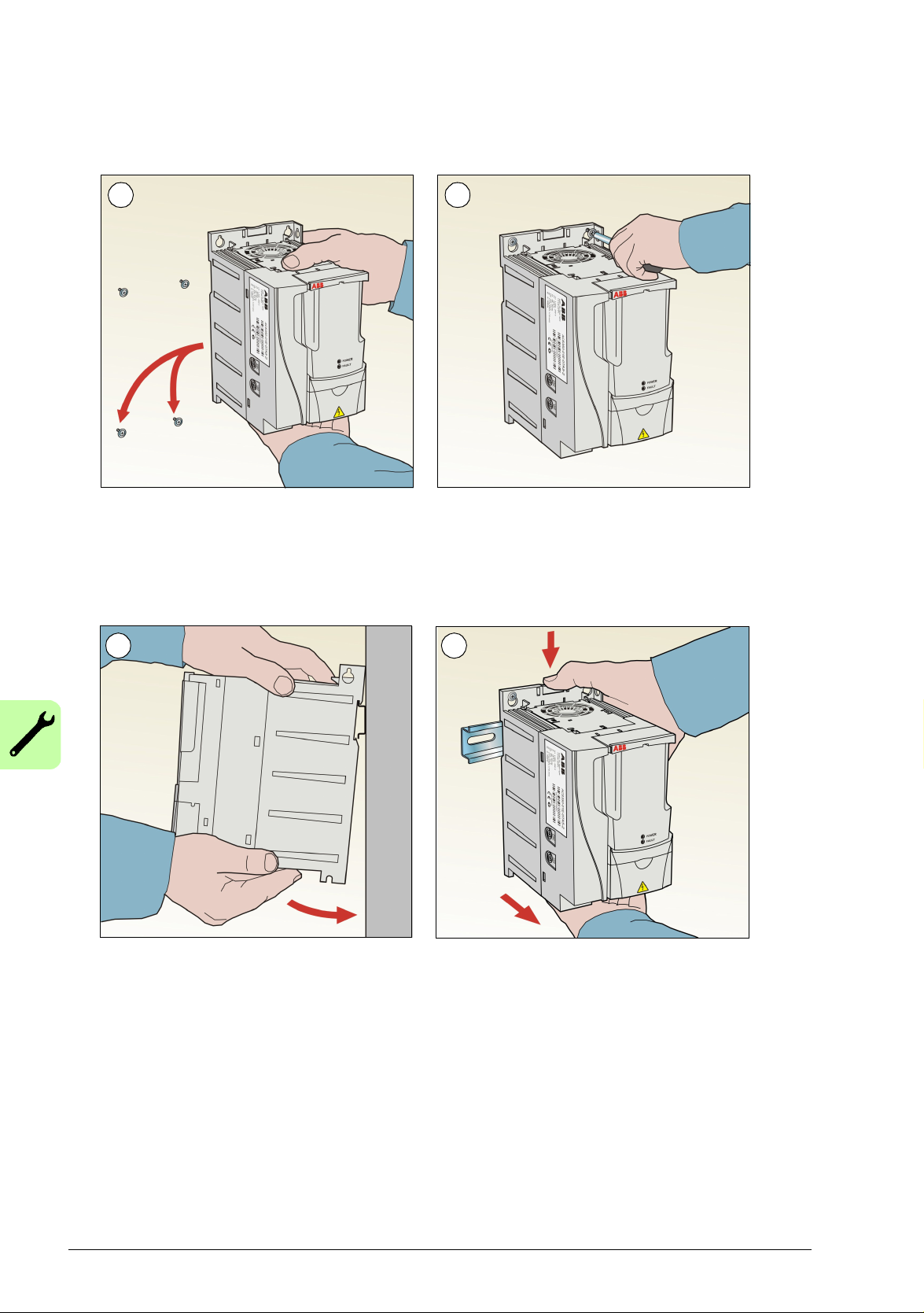

14 Mechanical installation

3 4

1 1b

3. Position the drive onto the screws on the wall.

4. Tighten the screws in the wall securely.

On DIN rail

• Click the drive to the rail.

• To detach the drive, press the release lever on top of the drive (1b).

Mechanical installation 15

1

2

Fasten clamping plates

1. Fasten the clamping plate to the plate at the bottom of the drive with the provided

screws.

2. For frame sizes R0…R2, fasten the I/O clamping plate to the clamping plate with

the provided screws.

16 Mechanical installation

Electrical installation 17

4. Electrical installation

WARNING! Obey the safety instructions. See chapter Safety on page 5. If

you ignore the safety instructions, injury or death can occur. If you are not a

qualified electrician, do not do electrical work.

Make sure that the drive is disconnected from the input power during installation. If

the drive is already connected to the input power, wait for 5 minutes after

disconnecting the input power.

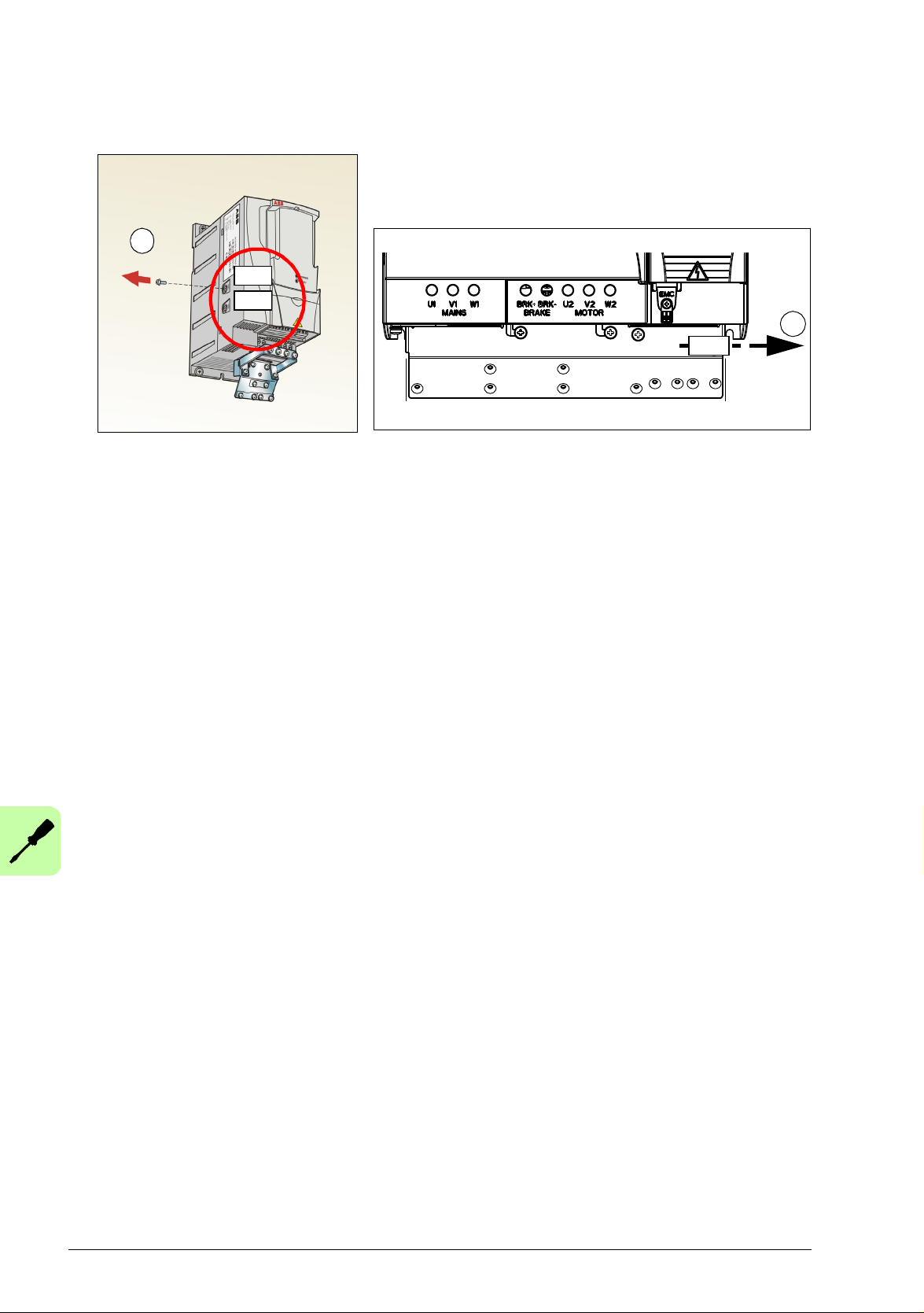

Checking the compatibility with IT (ungrounded) and corner-grounded TN systems

WARNING! Disconnect the internal EMC filter when installing the drive on an

IT system (an ungrounded power system or a high-resistance-grounded [over

30 ohms] power system), otherwise the system will be connected to ground

potential through the EMC filter capacitors. This may cause danger or damage the

drive.

Disconnect the internal EMC filter when installing the drive on a corner-grounded TN

system, otherwise the drive will be damaged.

Note: When the internal EMC filter is disconnected, the drive is not EMC compatible

without an external filter.

1. If you have an IT (ungrounded) or corner grounded TN system, disconnect the

internal EMC filter by removing the EMC screw. For 3-phase U-type drives (with

type designation ACS320-03U-), the EMC screw is already removed at the factory

and replaced by a plastic one.

Pay attention to the screws! Do not confuse the EMC screw to the similar varistor

disconnecting screw. Do not disconnect the varistor. The varistor protects the

drive against power line voltage peaks.

18 Electrical installation

Note: In frame size R4 the EMC screw is located

to the right of terminal W2.

1

EMC

VAR

1

EMC

Loading...

Loading...