ABB ACS255 Technical Catalog

Low Voltage AC Drives

ABB Micro Drives

ACS255

0.5 to 20 hp / 0.37 to 15 kW

Catalog

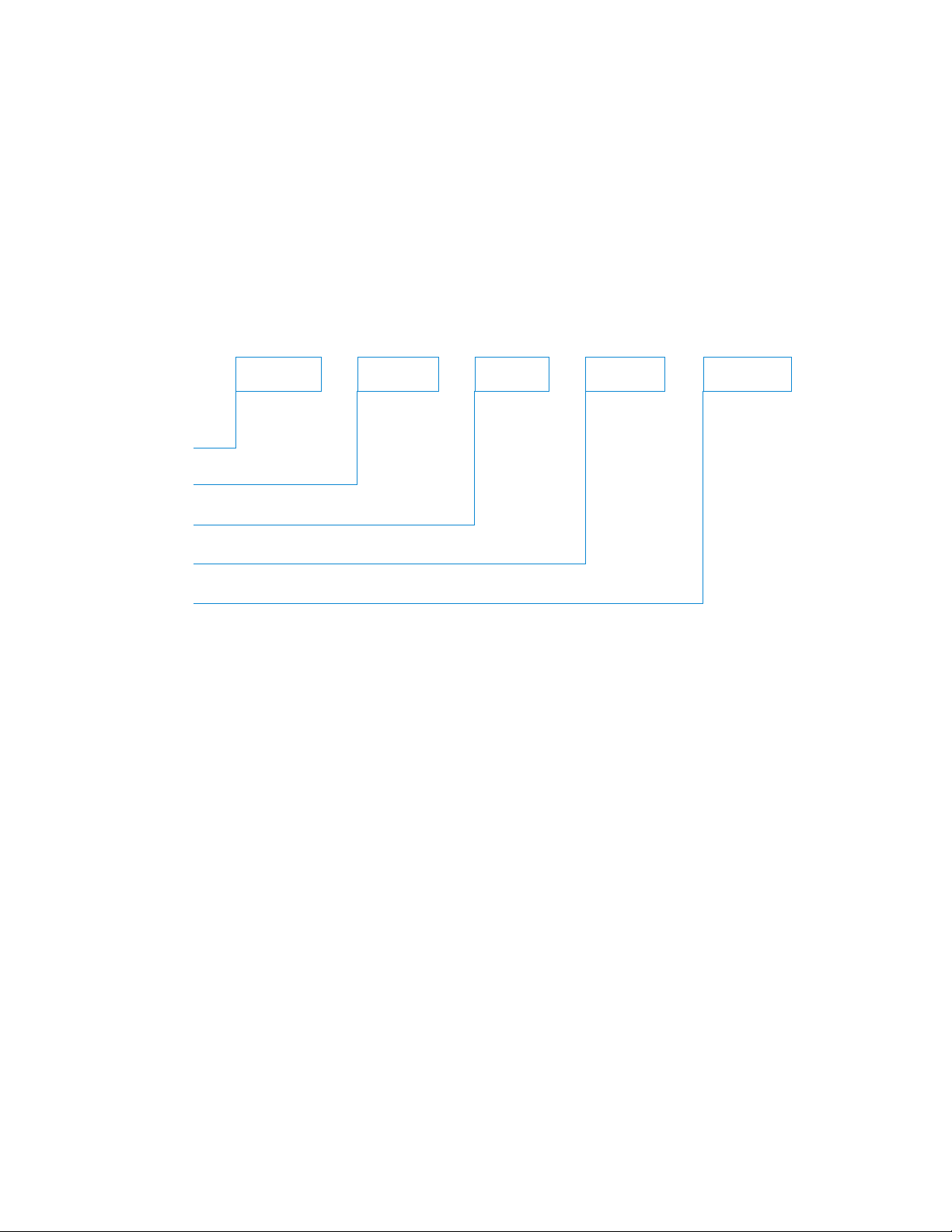

Selecting and ordering your drive

Type designation is a unique reference number that clearly

identifies the drive by construction, power and voltage

rating and selected options. Using the type designation

you can specify your drives from the wide range of options

available. Options are added to the type designation using the

corresponding “plus” (+) code.

Type designation:

AC255 - 0XU - 0XAX - X + XXXX

Product series

Ratings and types

Voltages

Constructions

Options

Build up your own ordering code using the type designation

key below or contact your local ABB drives sales office and let

them know what you want.

2 ABB ACS255 Technical Catalog

ACS255, micro drive

Table of contents

ACS255

Introduction 4

Main features 5

ACS255-IP20

Overview 6

Data sheet 7

Ratings and types 8

Dimensions and weights 9

ACS255-IP66

Overview 10

Data sheet 11

Ratings and types 12

Dimensions and weights 13

Technical data

Cooling 14

Fuses and cable sizes 15

Control connections for 115, 240 and 480 V 16

Control connections for 600 V 17

Options

Options 18

Braking resistors

Single-phase 19

Three-phase 20

Resistor technical data 23

CR case resistor 24

GCE resistor 25

Installation instructions 26

Reactors

Input reactors 27

Output filters 32

Life cycle management

Life cycle management 35

ABB ACS255 Technical Catalog 3

Introduction to the ACS255

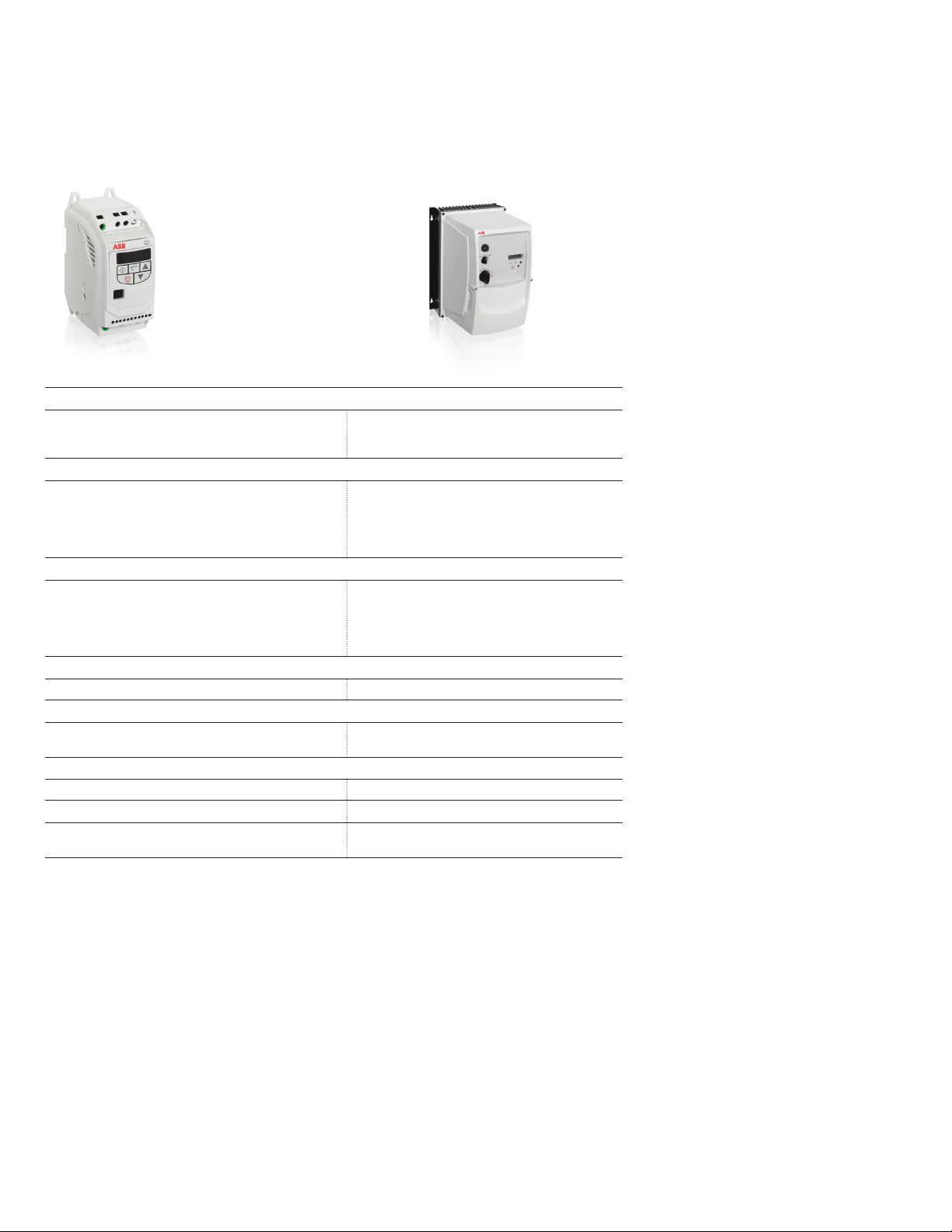

ACS255 IP20 ACS255 IP66 - NEMA 4X

Main attributes

Feed-thru wiring, embedded Modbus-RTU, built-in

macros for simple machine interface

HP range

1~115 V - 0.5 to 1.5 HP

3~600 V - 0.75 - 20 HP

Voltage range

1~120 V In / 3~ 230 V Out

3~600 V In / Out

Enclosure type

UL type 0 (IP20) UL type 4X (IP66)

Control mode

Scalar (V/Hz) variable torque and constant torque V/

Hz profiles

Communications options

Embedded Modbus-RTU Embedded Modbus-RTU

Operator interface Operator interface

Integral and/or

remote mount keypad

Wide range of input voltages, high protection

class enclosure for harsh environments,

Modbus-RTU as standard

1~115 V - 0.5 to 1.5 HP

1~230 V - 0.5 to 5 HP

3~230 V - 0.5 to 5 HP

3~460 V - 1 to 10 HP

3~600 V - 0.75 - 15 HP

1~115 V In / 3~230 V Out

1~230 V In / 3~230 V Out

3~230 V In / Out

3~460 V In / Out

3~600 V In / Out

Scalar (V/Hz) variable torque and constant torque

V/Hz profiles

Integral and/or

remote mount keypad

4 ABB ACS255 Technical Catalog

Main features

ACS255 - 0XU - 0XAX - X

Overview

The new ACS255 drive is an enhanced verison of the popular

ACS250 drive series. New features include: sensorless vector

control for both AC induction and PM motors, enhanced short

circuit protection, and operating mode selection. New ratings

have been added to fill out the product line.

All of the existing features of the ACS250 - parameters, external dimensions, mounting locations, etc. - are the same for the

ACS255. An Advanced parameter menu has been added for

additional functionality.

The ACS255 drive is a part of ABB’s complete range of micro

drives, offering a solution for every need. The IP20 drives offer

115V and 600V options to enhance other IP20 product lines.

The IP66 drives have a complete input voltage range from 115

to 600V.

ACS255 variable frequency drives feature an intuitive integrated

control panel with LED display. Built-in macros and only the

essential parameters make commissioning straightforward.

Built-in Modbus-RTU serial communication provides ready

integration with control and monitoring systems.

ACS255 micro drives are compact and offer flexible mounting

options without the need for accessory mounting kits. Rapid

programming and commissioning are possible using the on

board setup macros. The copy stick tool can be used to transfer parameter sets between drives.

Highlights

− Power range: 0.5 to 20 Hp, 1 & 3 phase input

− 150% peak overload capacity

− Modbus-RTU built-in

− User-friendly control panel with LED display

− Wall or DIN rail mounting options for IP20 drives

− Feed thru wiring on IP20 drives

− PI control

− Built-in brake chopper (Sizes 2 & 3)

− Sensorless vector and V/Hz control - all voltages

− Safe Torque Off (STO) (600V drives only)

− Conformally coated boards

− Operating mode selection

− Easy access to power and I/O connections for rapid instal-

lation

− Selection options for braking resistors, input reactors, &

output filters

Applications

− Conveyors

− Mixers

− Material handling

− Fans and pumps

− Automated Gate Control

− Food and Beverage

− Printing

− Woodworking Machinery

The ACS255 drive is ideal for panel builders and OEM’s needing a micro drive with low cost, flexible mounting options, and

rapid parameter setup.

Feature Advantage Benefit

Simple interface Integrated keypad and display is easy to learn and makes commissioning

Drive & network

connectivity

IP66 Construction with

Optional Controls

Full voltage range in IP66

drives

Feed Through Wiring &

Flexible Mounting Options

(IP20 Drives)

600V Ratings in IP20 and

IP66 Enclosures

straightforward

ABB common programming parameter structure

RS485 serial interface with embedded Modbus RTU for real time control

(or monitoring)

RJ45 connection port can be used with:

Optional Y-splitter for daisy chain networking

Remote control panel

Copy Stick tool for transferring parameters between drives

Optional operator controls: Disconnect, Fwd/Off/Rev, & Speed

Potentiometer

Dust and water proof design built with tough ABS plastic cover, epoxy

coated heatsink that withstands high pressure washdown for food and

beverage applications.

Optional operator controls allows mounting directly on processing

equipment located in extreme environments

IP66 offering throughout the voltage range - 110V to 600V

Global input voltage range to cover a wide range of application

Allows for easy replacement of motor starters or soft starters in existing

panels with power wires in at the top and motor cables out at the bottom

Flexible mounting options - wall or DIN rail

600V capacity in a micro drive with Safe Torque Off (SIL2) Panel design standardization with compact micro

Time and labor cost savings with rapid setup and

commissioning

Flexibility with RJ45 connectivity options

Time savings with simple plug-and-play connectivity

Save panel building cost

Less cost due to shorter motor cables with machine

mounted drive

Operator controls located on the machine

Standardize on one supplier with global input

voltage range save procurement and inventory cost

Saves time and material cost for panel builders

drive sizing in a 600V drive - similar to 115, 230, &

460Vmicro drives

ABB ACS255 Technical Catalog 5

ACS255 IP20

Overview

Replacing a motor starter or soft starter with a drive can help

your customer improve their overall energy efficiency, reduce

mechanical stresses and enhance their process control. With

its feed-thru wiring, the ACS255 can easily replace motor

starters for general purpose low power applications, such as;

augers, mixers, pumps, fans and conveyors. The key features

include a integrated keypad for easy configuration, precise

process control with an enhanced V/Hz control with variable

torque and constant torque V/Hz profiles, sensorless vector

control and embedded, Modbus-RTU communication

interface for real time control and monitoring.

Main features

− Integrated display and keypad

− Feed-thru wiring

− 50°C no de-rate / 60°C max.

− Built-in macros and only the essential parameters make

commissioning straightforward

− Enhanced V/Hz control (all models)

− Open loop vector - speed & torque control - for AC Induc-

tion and permanent magnet motors

− Operating Mode Select quickly configures current limit,

torque characteristic and spin start parameters for Industrial,

Pump, or Fan applications

− Adjustable current limit

− Power loss ride-through

− DC injection braking

− DC magnetizing start (provides maximum starting torque)

− Internal braking chopper (except frame E1)

− Modbus-RTU fieldbus as standard

− Open loop vector - speed & torque control

(600 V only)

− SIL2 Safe torque-off (600 V only)

− Integrated help card

Applications

− Variable torque, constant torque or constant horsepower

applications requiring a compact drive solution for cabinet

mounting

Capabilities

− V /Hz and sensorless vector control with peak overload

capacity of 175%

− Feed-thru wiring DIN rail mountable IP20 enclosure

− Intuitive integrated keypad

− Designed to be easy to program for simple machine inter-

face

6 ABB ACS255 Technical Catalog

ACS255 IP20

Data sheet

0.5 thru 1.5 HP (1~115 V In/ 3~230V Out) 1 thru 20 HP (3~600 V In/Out)

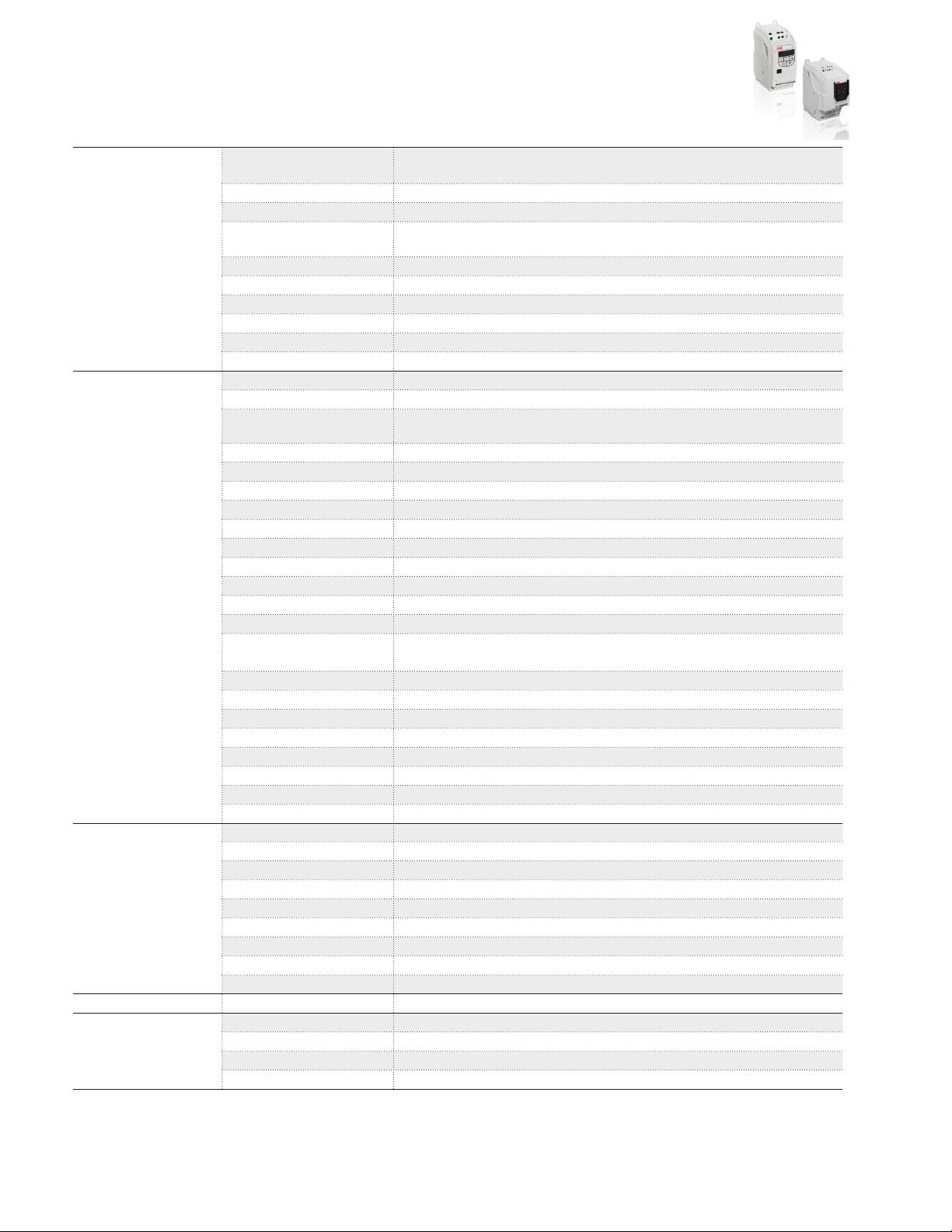

Performance features

Drive specifications

Protective features

Agency certifications

Service conditions

Control modes 115 VAC: V/Hz and open loop vector

Operator interface module Integral drive mounted

Display lines 6-character LED display

Programmable preset

speeds

Analog output: one One (0-10 VDC)

Auto restart Yes – up to 5 attempts

Frequency avoidance One band

Fault history Last four faults

Digital inputs: four Two programmable digital inputs, two user selectable analog/digital inputs

Digital inputs type Pull-up

Analog inputs: two 0-10 VDC, 4 to 20mA

Relay output: one Built-in form C relay

Analog output / digital

outout

Overload capacity Drive output 150% for one minute and 175% for 2 seconds

Maximum load 1.5 HP @ 120 V In/230 V Out, 20 HP @ 600 V In/Out

Input voltage ranges 115 VAC (99-126); 600 VAC (450-660)

Rated input frequency 50-60 Hz (±5%)

Carrier frequency 4-32 kHz (8 kHz default)

Operating temperature -10° to 50°C

Snubber (dynamic braking) Built-in transistor (frames 2 and 3)

Dynamic braking external Up to 150% dynamic braking with appropriately sized resistor

DC injection braking Included

Volts/Hz Linear V/Hz, user defined, energy optimizer & boost function

Sensorless vector Speed and torque with autotune for AC induction and permanent magnet

Frequency control range 0-500 Hz

Accel/decel: Independently adjustable accel. & decel. ramps

Time range 0.00 to 600.0 Seconds

Keypad speed control Ye s

Sink/source inputs Source, 24 VDC logic

Electronic overload trip Electronic motor overload inverse 150% for 1 minute or 175% for 2 seconds

Communications Built-in Modbus-RTU (RS-485) communications

PI control Built-in

Under voltage Level depends on voltage class

Output short circuit Phase-to-phase on drive output

Over temperature Heat sink monitor

DC bus overvoltage DC bus level trip

Drive overload Exceed drive rating of 150% for one minute or 175% for 2 seconds

Over current Over-current/short-circuit protection

Output phase Trips on open output phase

Loss of reference Trips on loss of speed command signal

Communication error Detects a communication error (fault)

Altitude 1,000 m (3,300 ft.), derate by 1% per 100M up to 2,000 on maximum

Ambient temperature -10°C (14°F) to 50°C (102°F)

Storage temperature: -40°C (-40°F) to 60°C (140°F)

Relative humidity 10% to 95%, non-condensing

600 VAC: V/Hz and open loop vector

Four

0-10 VDC: one analog usable for meter (freq., current, voltage) or digital

output

motors

UL, cUL, CE, C-tick, gost

ABB ACS255 Technical Catalog 7

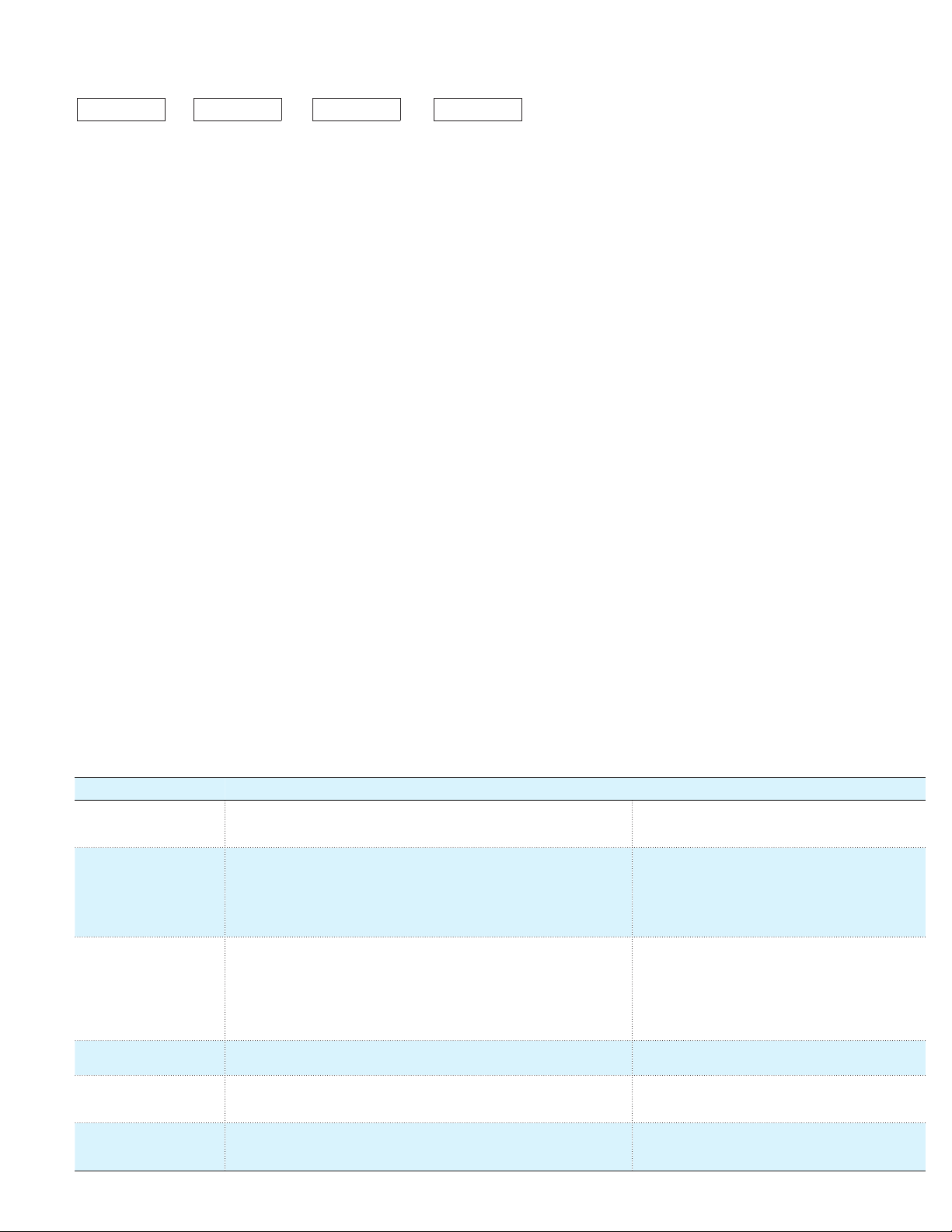

ACS255, IP20

Ratings and types

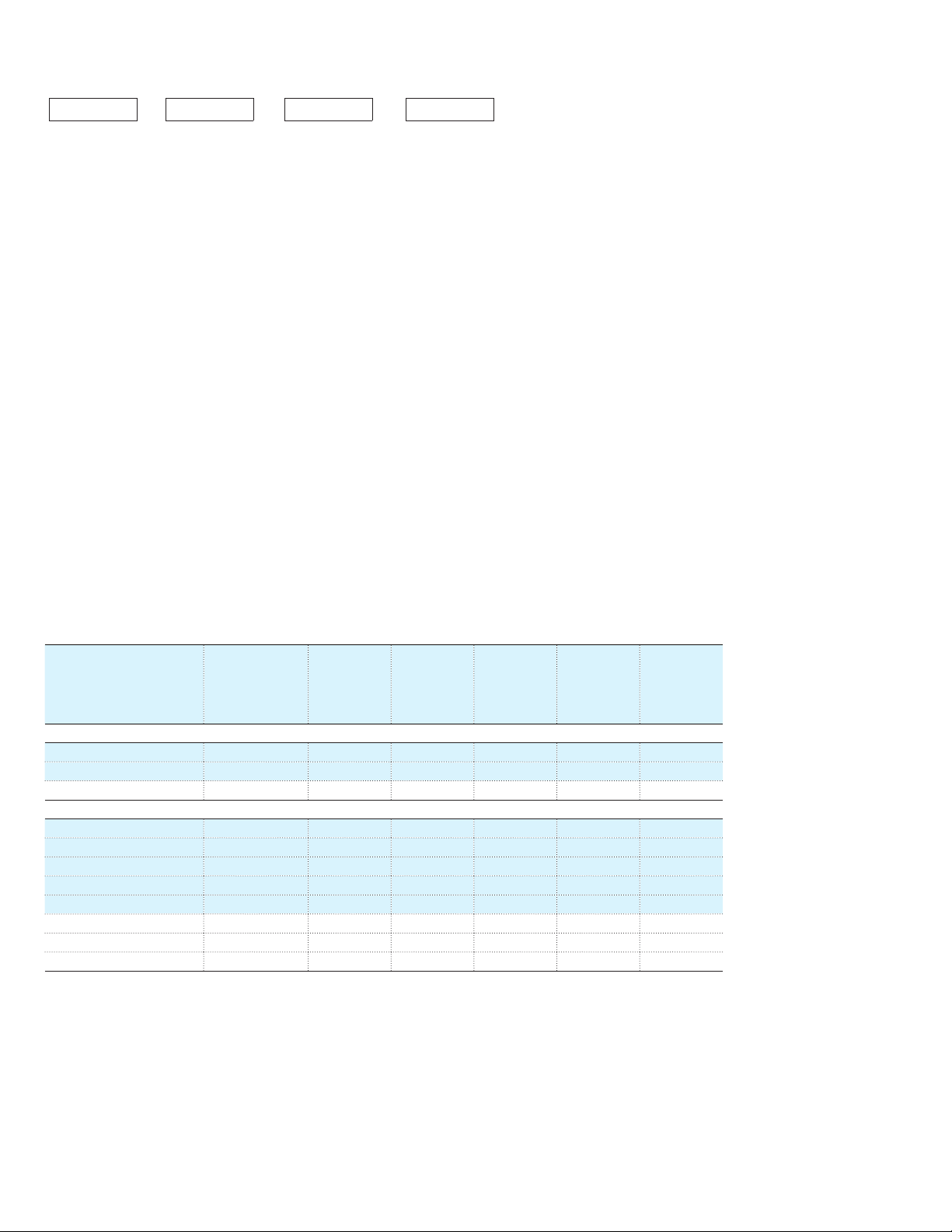

ACS255 - 0XU - 0XAX - X

Type designation

This is the unique reference number (shown above and in

the first column, below) that clearly identifies your drive by

power rating and frame size. Once the drive’s type designation

has been selected, the frame size (column 7) can be used to

determine the drive dimensions, shown on the next page.

Voltages

ACS255 is available in two voltage ranges:

1 = 110 to 120 V

6 = 500 to 600 V

Insert either “1” or “6”, depending on your chosen voltage, into

the type designation shown above.

Construction

“01U” within the type designation (shown above) varies

depending on the drive phase and EMC filtering. Choose below

the one you need.

01 = 1-phase

03 = 3-phase

U = No EMC filter

Type code Braking chopper

1-phase supply voltage 110 to 120 V, +/-10%, 3-phase output 200 to 240 V

ACS255-01U-02A3-1 --- 0.5 0.37 2.3 2.2 E1

ACS255-01U-04A3-1 --- 1 0.75 4.3 2.2 E1

ACS255-01U-05A8-1 STD 1.5 1.1 5.8 3.75 E2

3-phase supply voltage 500 to 600 V, +/-10%

ACS255-03U-02A1-6 STD 1 0.75 2.1 4.0 P2

ACS255-03U-03A1-6 STD 2 1.5 3.1 4.0 P2

ACS255-03U-04A1-6 STD 3 2.2 4.1 4.0 P2

ACS255-03U-06A5-6 STD 5 4.0 6.5 4.0 P2

ACS255-03U-09A0-6 STD 7.5 5.5 9 4.0 P2

ACS255-03U-12A0-6 STD 10 7.5 12 7.7 P3

ACS255-03U-17A0-6 STD 15 11 17 7.7 P3

ACS255-03U-22A0-6 STD 20 15 22 7.7 P3

Notes:

I

: continuous base current with 110% overload for 1 minute / 10 minutes.

2N

: Typical motor power for most 4-pole NEMA motors in normal use.

P

N

(included)

PN

HP

PN

kW

Output

current

I2N

A

Weight

lbs

Frame size

8 ABB ACS255 Technical Catalog

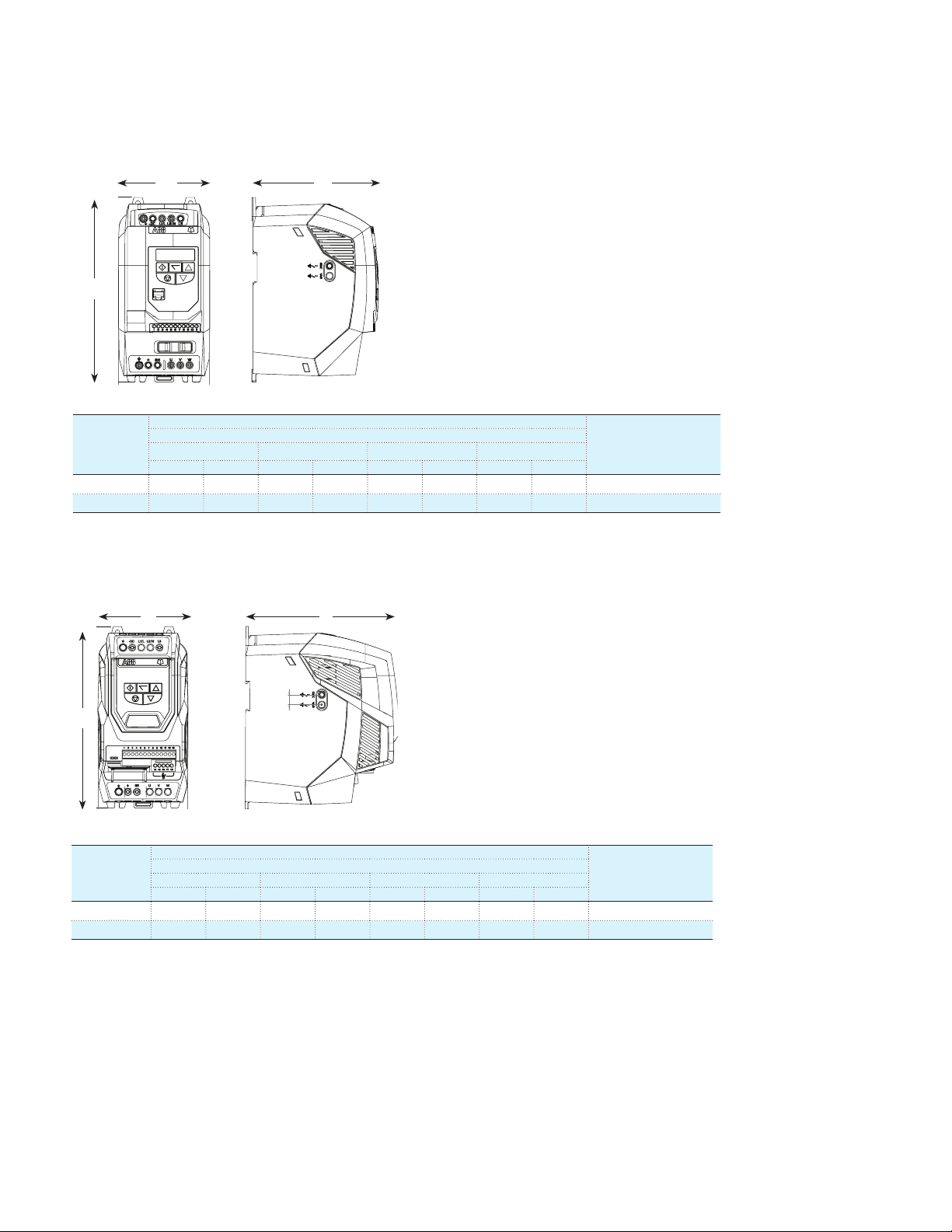

ACS255, IP20

12

Dimensions and weights

W

H

120 V

D

Dimensions and weights

Frame

size

Height Width Depth Weight

IP20 120 V

Dimension

drawing

in mm in mm in mm lb kg

E1 6.81 173 3.23 82 4.84 123 2.20 1 3AXD10000274006

E2 8.70 221 4.29 109 5.91 150 3.75 1.70 3AXD10000274008

H = Height

W = Width

D = Depth

W

D

12

H

600 V

Dimensions and weights

Frame

size

Height Width Depth Weight

IP20 600 V

Dimension

drawing

in mm in mm in mm lb kg

P2 8.70 221 4.41 112 7.28 185 4 1.80 3AXD10000274014

P3 10.28 261 5.16 131 8.07 205 7.70 3.50 3AXD10000274016

H = Height

W = Width

D = Depth

ABB ACS255 Technical Catalog 9

ACS255, IP66

Overview

Screws, mixers, pumps, fans and conveyors are commonly

installed in harsh environments containing dust, moisture

and chemicals. The IP66/NEMA 4X ACS255 was designed

to thrive in these types of conditions. The drive’s design and

ease of setup benefit a broad range of industries that require

machine mounted drives.

Hygienic protection

The drive was designed with materials that meet stringent hygiene standards, preventing the drive from trapping bacteria.

The integrated keypad provides straightforward drive commissioning and maintenance in extreme environments. The drive’s

sealed ABS enclosure and corrosion-resistant heat sink are

ideal for wash-down applications.

Main features

− Built-in macros and only the essential parameters make

commissioning straightforward

− Can be mounted directly on processing equipment installed

in extreme environments

− Conduit cable entry

− Intuitive keypad control

− Optional switch features; speed potentiometer,

− FWD-OFF-REV and disconnect switches

− IP66/NEMA 4X dust and waterproof design

− Designed for wash-down applications

− Specially coated corrosion-resistant heat sink

− Sealed top cover with separate terminal access cover pro-

vides ready access without exposing components

− Widely spaced heat sink fans with no external fans to fail or

get clogged in washdown environments

− Modbus-RTU fieldbus as standard

− Built-in brake chopper (except frame E1)

− Safe torque off function (SIL2) which can be used as

emergency stop or to prevent unexpected startup (600 V

only)

− Open loop vector speed and vector torque control mode

for AC induction and permanent magnet motors - all

ACS255 drives

− Operating Mode Select quickly configures current limit,

torque characteristic and spin start parameters for Industrial, Pump, or Fan applications

Applications

− Variable torque, constant torque or constant horsepower

applications in harsh environments or requiring on machine

mounting

Capabilities

− NEMA 4X IP66 enclosure for indoor use

− V/Hz control with peak overload capacity of 175%

− Embedded Modbus-RTU

− Intuitive integrated keypad

− Designed to be easy to program for simple machine inter-

face local control & disconnect

10 ABB ACS255 Technical Catalog

ACS255, IP66

Data sheet

0.5 thru 1.5 HP (1~115 V In/ 3~230V Out) 0.5 thru 3 HP (1~230 V In/ 3~230V Out)

0.5 thru 5 HP (3~230 V In/Out) 1 thru 10 HP (3~460 V In/Out) 1 thru 15 HP (3~600 V In/Out)

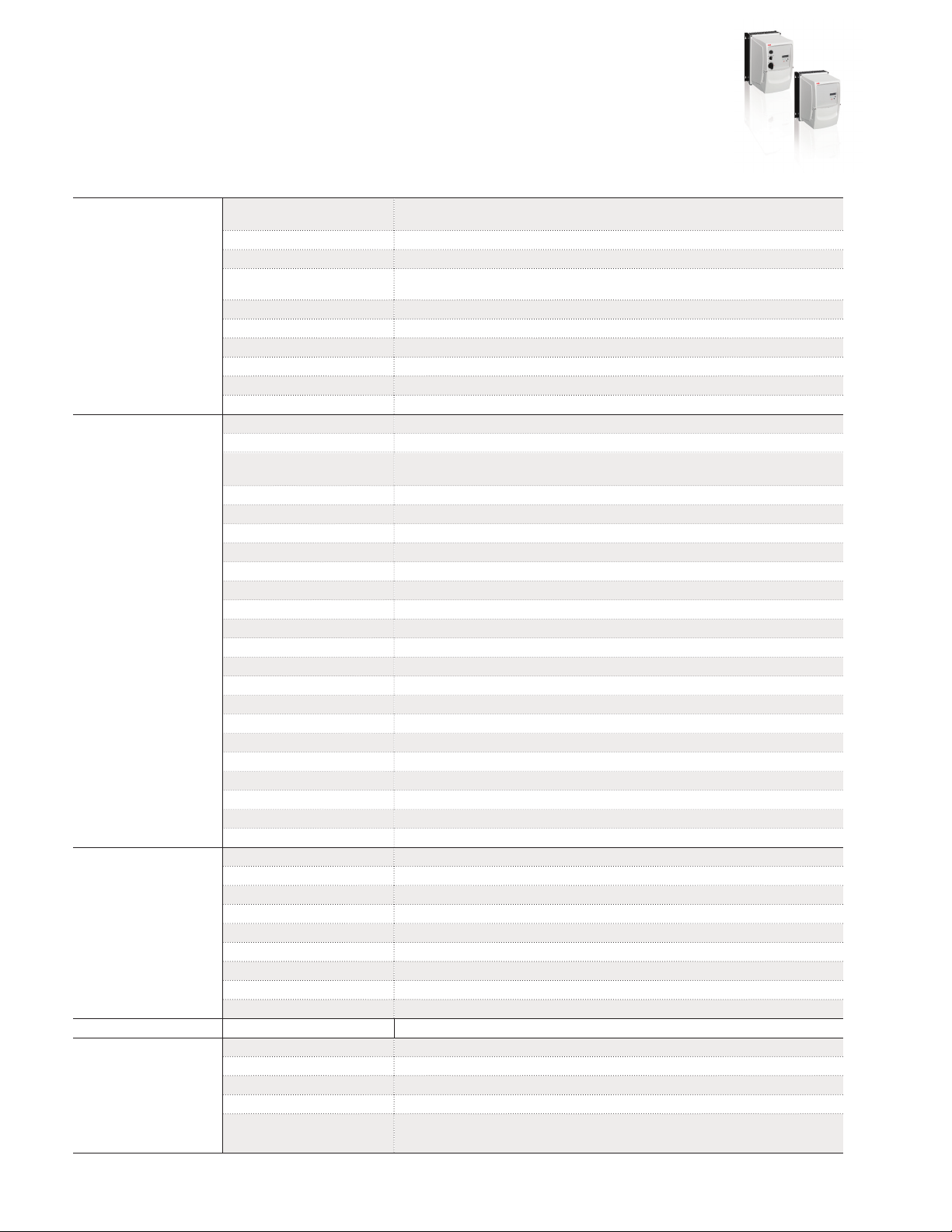

Performance features

Drive specifications

Protective features

Agency certifications

Service conditions

Control modes

Operator interface module Integral drive mounted

Display lines 6-character LED display

Programmable preset

speeds

Analog output: one One (0-10 VDC)

Auto restart Yes- Up to 5 attempts

Frequency avoidance One band

Fault history Last four faults

Digital Inputs: four Three configurable inputs

Digital inputs type Pull-up

Analog inputs: two 0-10 VDC, 4 to 20mA

Relay output: one One built-in form C relay

Analog output / digital

output

Maximum load 5 HP @ 230 VAC, 10 HP @ 460 VAC, 15 HP @ 600 VAC

Overload capacity Drive output 150% for one minute and 175% for 2 seconds

Input voltage ranges 115 VAC (99-126); 230 VAC (198-264); 460 VAC (342-528); 600 VAC (450-660)

Rated input frequency 50-60 Hz (±5%)

Carrier frequency 4-32 kHz (8 kHz default)

Operating temperature -10° to 40°C

Snubber (dynamic braking) Built-in transistor (frames 2 and 3)

Dynamic braking external Up to 150% dynamic braking with appropriately sized resistor

DC injection braking Included

Volts/Hz Linear V/Hz, user defined, energy optimizer & boost function

Sensorless vector Speed and torque with autotune for AC induction and permanent magnet motors

Frequency control range 0-500 Hz

Accel/decel: Independently adjustable accel. & decel. ramps

Time range 0.00 to 600.0 seconds

Keypad speed control Yes

Sink/source inputs Source, 24 VDC logic

Electronic overload trip Electronic motor overload inverse 150% for 1 minute or 175% for 2 seconds

Communications Built-in Modbus-RTU (RS-485) communications

PI control Built-in

Under voltage Level depends on voltage class (120, 240, 480, or 575)

Output short circuit Phase-to-phase on drive output

Over temperature Heat sink monitor

DC bus overvoltage DC Bus level trip

Drive overload Exceed drive rating of 150% for one minute or 175% for 2 seconds

Over current Over-current/short-circuit protection

Output phase Trips on open output phase

Loss of reference Trips on loss of speed command signal

Communication error Detects a communication error (fault)

Altitude 1,000 m (3,300 ft.), derate by 1% per 100M up to 2,000m maximum

Ambient temperature -10°C (14°F) to 40°C (122°C)

Storage temperature: -40°C (-40°F) to 60°C (140°F)

Relative humidity 10% to 95%, non-condensing

Intermittent overload

115-460 VAC: V/Hz and open loop vector

600 VAC: V/Hz and open loop vector

Four

0-10 VDC: one analog usable for meter (freq., current, voltage) or digital output

UL, cUL, CE, C-tick, Gost

150% overload capacity for up to 1 minute, 175% overload capacity for up to 2

seconds

ABB ACS255 Technical Catalog 11

Loading...

Loading...