ABB Micro drives

User’s manual

ACS250 drives (0.5…20 hp) (600V Variants)

List of related manuals

Option manuals and guides

Code (English)

ACS250 user’s manual for 115-480V variants

3AUA0000137830

You can find manuals and other product documents in PDF format on the Internet. Go to

www.abb.com/drives and select Document Library. You can browse the library or enter selection criteria, for

example a document code, in the search field. For manuals not available in the Document library, contact

your local ABB representative

3

ACS250 drives

0.5…20 hp

User’s manual

3AUA0000138354 Rev A

EN

EFFECTIVE: 2013-06-18

© 2012 ABB Oy. All Rights Reserved.

4

1. Table of Contents

ACS250 – IP20 (600V Variants) EASY START-UP GUIDE ________________________________________ 7

ACS250 – IP66 (600V Variants) EASY START-UP GUIDE ________________________________________ 8

2. Safety ____________________________________________________________________________ 10

What this chapter contains _____________________________________________________________________ 10

Use of warnings ______________________________________________________________________________ 10

Safety in installation and maintenance ____________________________________________________________ 10

Safety in start-up and operation _________________________________________________________________ 11

3. General Information and Ratings ______________________________________________________ 13

3.1. Type designation key ___________________________________________________________________ 13

3.2. Drive model numbers – IP20 _____________________________________________________________ 14

3.3. Drive model numbers – IP66 _____________________________________________________________ 14

4. Mechanical Installation______________________________________________________________ 15

5

4.1. General ______________________________________________________________________________ 15

4.2. Before Installation _____________________________________________________________________ 15

4.3. UL Compliant Installation ________________________________________________________________ 15

4.4. Mechanical dimensions and weights _______________________________________________________ 15

4.5. Guidelines for Enclosure mounting (IP20 Units) ______________________________________________ 17

4.6. Mounting the Drive – IP20 Units __________________________________________________________ 17

4.7. Guidelines for mounting (IP66 Units) _______________________________________________________ 18

4.8. Removing the Terminal Cover ____________________________________________________________ 18

4.9. Routine Maintenance ___________________________________________________________________ 18

5. Electrical Installation ________________________________________________________________ 19

5.1. Grounding the Drive ____________________________________________________________________ 19

5.2. Wiring Precautions _____________________________________________________________________ 20

5.3. Incoming Power Connection ______________________________________________________________ 20

5.4. Compatibility with IT (ungrounded) and corner-grounded TN systems ____________________________ 21

5.5. Drive and Motor Connection _____________________________________________________________ 22

5.6. Motor Terminal Box Connections __________________________________________________________ 22

5.7. Motor Thermal overload Protection. _______________________________________________________ 22

5.8. Control Terminal Wiring _________________________________________________________________ 22

5.9. Connection Diagram ____________________________________________________________________ 23

5.10. Safe Torque Off ________________________________________________________________________ 24

6. Managing the Keypad _______________________________________________________________ 28

6.1. Keypad Layout and Function _____________________________________________________________ 28

6.2. Changing Parameters ___________________________________________________________________ 28

6.3. Resetting Parameters to Factory Default Settings _____________________________________________ 29

6

6.4. Advanced Keypad Operation ShortCuts _____________________________________________________ 30

6.5. Drive Operating Displays ________________________________________________________________ 30

7. Quick Start-up and Control ___________________________________________________________ 31

7.1. Quick Start-up Terminal Control __________________________________________________________ 31

7.2. Quick Start-up Keypad Control ____________________________________________________________ 31

7.3. Sensorless Vector Speed Control Mode _____________________________________________________ 32

8. Application Macros _________________________________________________________________ 33

8.1. Overview of macros ____________________________________________________________________ 33

8.2. Macro wiring configurations. _____________________________________________________________ 34

9. Parameters _______________________________________________________________________ 38

9.1. Parameter Structure ____________________________________________________________________ 38

9.2. Parameters in the Short parameter mode ___________________________________________________ 39

9.3. Read Only Status parameters _____________________________________________________________ 41

9.4. Parameters in the Long parameter mode ___________________________________________________ 43

9.5. Preventing un-authorized parameter editing. ________________________________________________ 55

10. Serial communications ______________________________________________________________ 56

10.1. RJ45 Connector Pin Assignment ___________________________________________________________ 56

10.2. Modbus RTU Communications ____________________________________________________________ 56

11. Technical Data _____________________________________________________________________ 60

11.1. Environmental _________________________________________________________________________ 60

11.2. Input/Output Current ratings and fuses ____________________________________________________ 60

11.3. Overload _____________________________________________________________________________ 60

11.4. Additional Information for UL Approved Installations _________________________________________ 61

11.5. Derating Information ___________________________________________________________________ 61

12. Troubleshooting ___________________________________________________________________ 62

12.1. Fault messages ________________________________________________________________________ 62

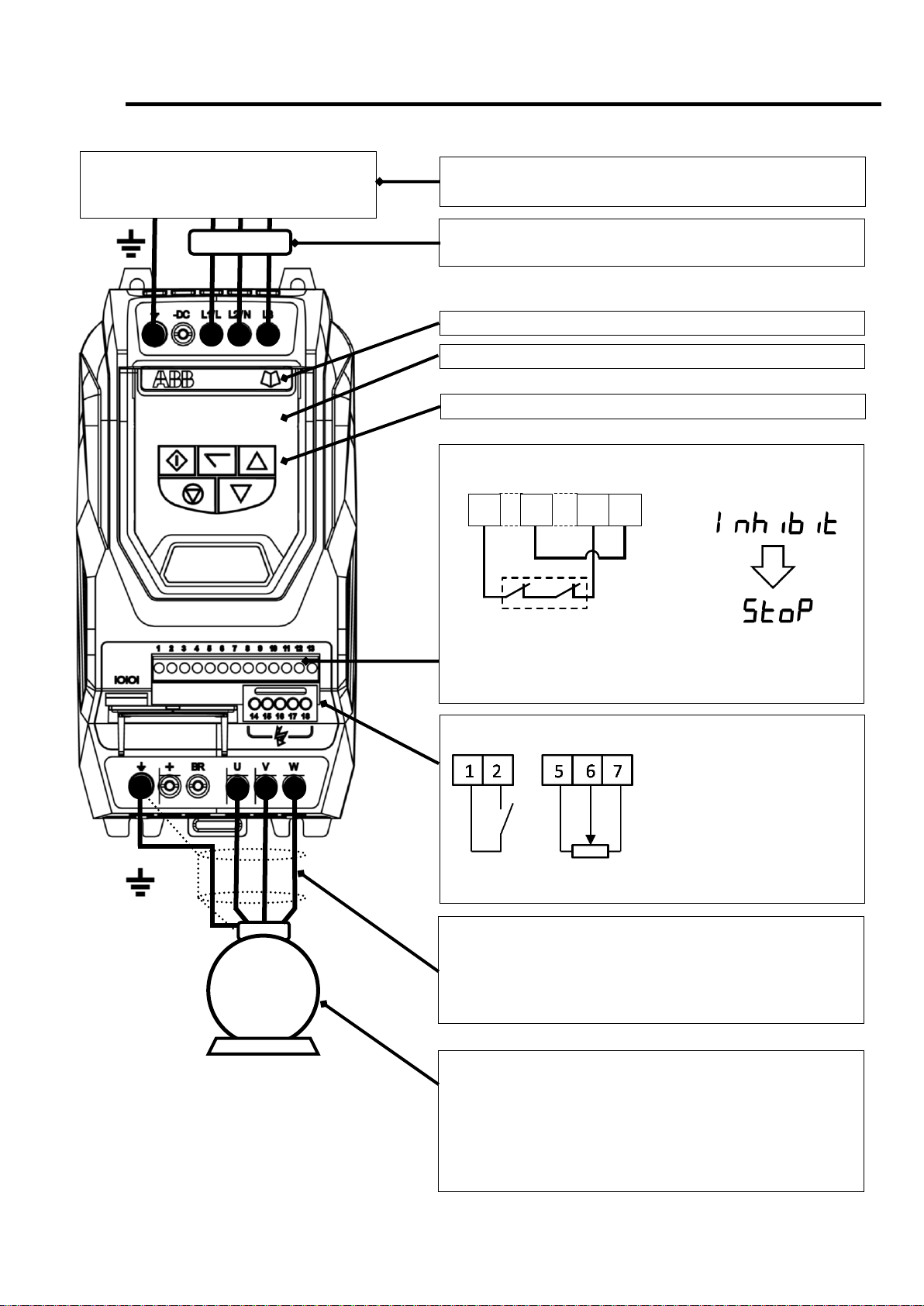

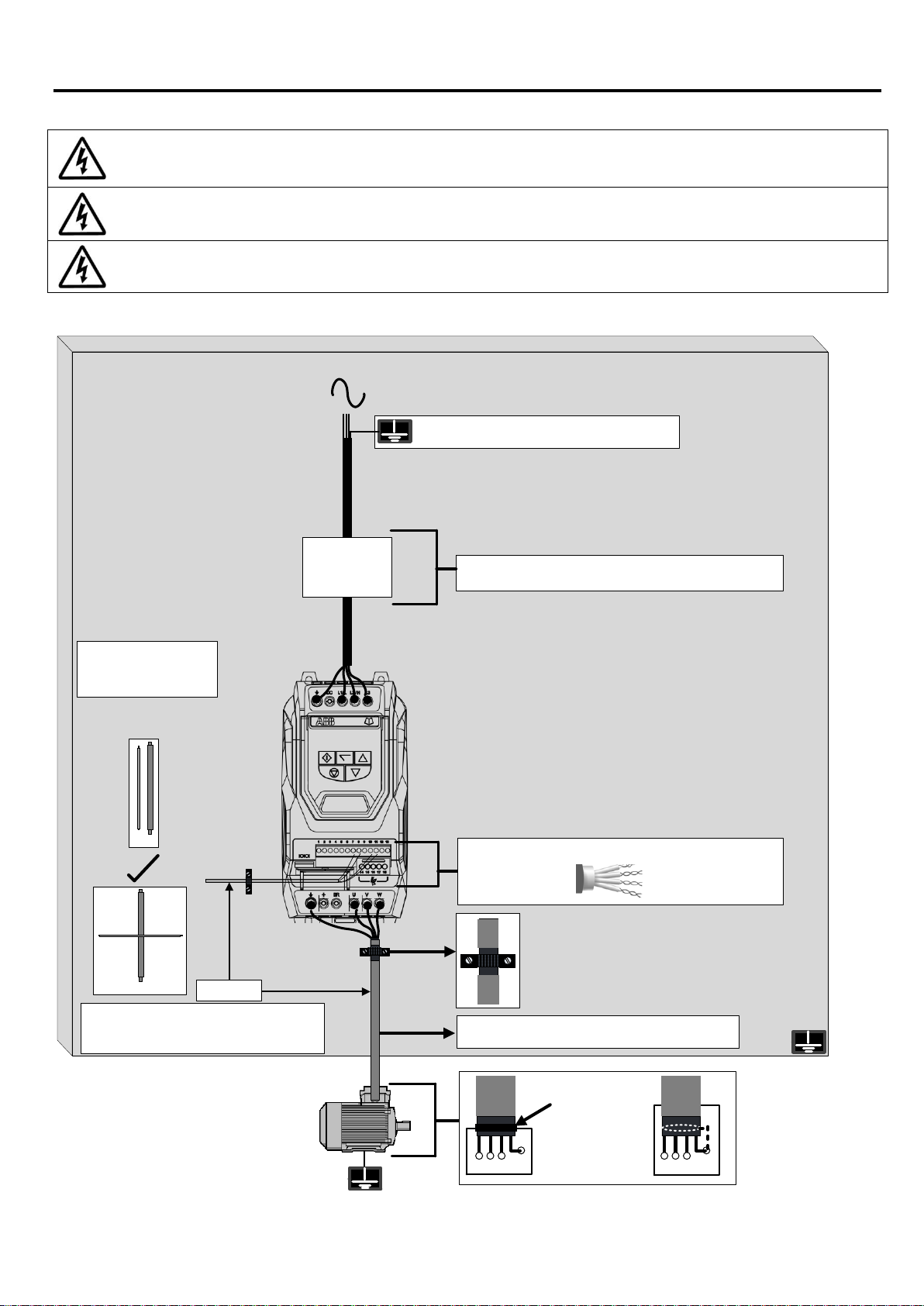

ACS250 – IP20 (600V Variants) EASY START-UP GUIDE

1 9 12 13

Fuses or MCB

M

P20 Easy Start

AC Supply Connection Supply Voltage

3 Phase : Connect L1 L2 L3, PE 500-600 Volts + / - 10%

Fuses

Fuse rating recommendation values given on page 60

Help Card

Display

Keypad Operation can be found in section 6 and 7.2

IMPORTANT!

HARDWARE ENABLE FUNCTION

7

Link the terminals as shown, optionally through switch contacts, to

enable the drive.

Control Terminals

Based on the factory default parameter settings

Run – Stop 10K Speed Pot

Close the switch to run (enable), open to stop

Motor Cable

o Cable size recommendation values given on page 60.

o Observe the maximum permissible motor cable length

o For Motor cable lengths > 50 metres, an output filter is

recommended

o Use a screened (shielded cable)

Motor Connection

Check for Star or Delta Connection according to the motor voltage rating

(See page 22)

Enter the Motor Nameplate Data into the drive Parameters as follows

o Motor Rated Voltage : 9905

o Motor Rated Current : 9906

o Motor Rated Frequency : 9907

o Motor Rated Speed (Optional) : 9908

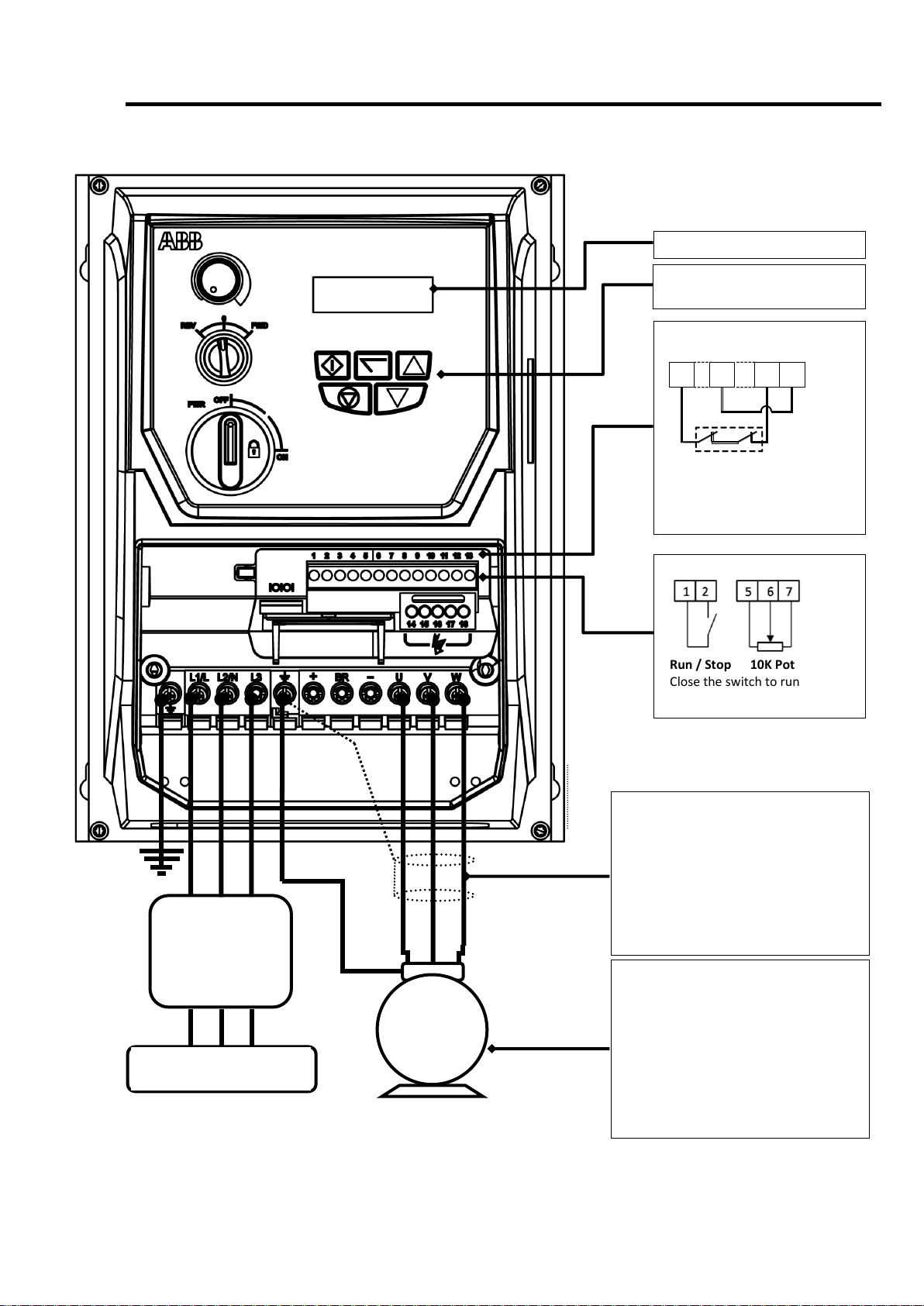

8

M

1 9 12 13

Fuse rating

recommendation

values given on

page 60

AC Supply Connection

500 – 600 Volts + / - 10%

ACS250 – IP66 (600V Variants) EASY START-UP GUIDE

Display

Keypad Operation can be found

In Section 6 and 7.2.

IMPORTANT

HARDWARE ENABLE

Link the terminals as shown

Above, optionally through switch

contacts to enable the drive

Control Terminals

Run / Stop 10K Pot

Close the switch to run (enable)

Open the switch to stop

Motor Cable

Cable size recommendation values given

on page 60.

Observe the maximum permissible motor

cable length

For Motor cable lengths > 50 metres, an

output filter is recommended

Use a screened (shielded) cable. The shield

should be bonded to earth at both ends

Motor Connection

Check for Star or Delta Connection according

to the motor voltage rating (See page 22).

Enter the Motor Nameplate Data into the

drive Parameters as follows

Motor Rated Voltage : 9905

Motor Rated Current : 9906

Motor Rated Frequency : 9907

Motor Rated Speed (Optional) : 9908

Declaration of Conformity:

EN 61800-5-1: 2003

Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy.

EN 61800-3 2nd Ed: 2004

Adjustable speed electrical power drive systems. EMC requirements and specific test methods

EN 55011: 2007

Limits and Methods of measurement of radio disturbance characteristics of industrial, scientific and

medical (ISM) radio-frequency equipment (EMC)

EN60529 : 1992

Specifications for degrees of protection provided by enclosures

Standard

Classification

Independent Approval

EN 61800-5-2:2007

Type 2

*TUV

EN ISO 13849-1:2006

PL “d”

EN 61508 (Part 1 to 7)

SIL 2

EN60204-1

Uncontrolled Stop “Category 0”

EN 62061

SIL CL 2

Drive Type / Rating

EMC Category

First Environment Category C1

First Environment Category C2

Second Environment Category C3

ACS250..

Use additional External EMC Filter

Note

Compliance with EMC standards is dependent on a number of factors including the environment in which the drive is installed,

motor switching frequency, motor, cable lengths and installation methods adopted.

For motor cable lengths greater than 100m, an output dv / dt filter must be used, please refer to the (please refer to the

http://www.abb.com/ProductGuide/ for further details).

Vector Speed and Torque control modes may not operate correctly with long motor cables and output filters. It is recommended to

operate in V/F mode only for cable lengths exceeding 50m.

ABB Drives Ltd hereby states that the ACS250 product range conforms to the relevant safety provisions of the Low Voltage Directive 2006/95/EC

and the EMC Directive 2004/108/EC and has been designed and manufactured in accordance with the following harmonised European

standards:

STO Function

ACS250 incorporates a hardware STO (Safe Torque Off) Function, designed in accordance with the standards listed below.

*Note : TUV Approval of the “STO” function is relevant for drives which have a TUV logo applied on the drive rating label.

Electromagnetic Compatibility

It is the responsibility of the installer to ensure that the equipment or system into which the product is incorporated complies with the EMC

legislation of the country of use. Within the European Union, equipment into which this product is incorporated must comply with the EMC

Directive 2004/108/EC. When using an ACS250 with an internal or optional external filter, compliance with the following EMC Categories, as

defined by EN61800-3:2004 can be achieved:

9

All rights reserved. No part of this User Guide may be reproduced or transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by any information storage or retrieval system without permission in writing from the publisher.

Copyright ABB Drives Ltd © 2012

The manufacturer accepts no liability for any damage caused during or resulting from transport, receipt of delivery, installation or

commissioning. The manufacturer also accepts no liability for damage or consequences resulting from inappropriate, negligent or incorrect

installation, incorrect adjustment of the operating parameters of the drive, incorrect matching of the drive to the motor, incorrect installation,

unacceptable dust, moisture, corrosive substances, excessive vibration or ambient temperatures outside of the design specification.

Contents of this User Guide are believed to be correct at the time of printing. In the interest of a commitment to a policy of continuous

improvement, the manufacturer reserves the right to change the specification of the product or its performance or the contents of the User

Guide without notice.

This User Guide is for use with version 1.20 Firmware.

User Guide Revision A

This user guide is the “original instructions” document. All non-English versions are translations of the “original instructions”.

The manufacturer adopts a policy of continuous improvement and while every effort has been made to provide accurate and up to date

information, the information contained in this User Guide should be used for guidance purposes only and does not form the part of any contract.

10

Electricity warning warns of hazards from electricity which can cause physical injury and/or damage to

the equipment.

General warning warns about conditions, other than those caused by electricity, which can result in

physical injury and/or damage to the equipment.

WARNING! Ignoring the instructions can cause physical injury or death, or damage to the equipment.

Only qualified electricians are allowed to install and maintain the drive!

2. Safety

What this chapter contains

This chapter contains the safety instructions which you must follow when installing, operating and servicing the drive. If ignored,

physical injury or death may follow, or damage may occur to the drive, motor or driven equipment. Read the safety instructions before

you work on the unit.

Use of warnings

Warnings caution you about conditions which can result in serious injury or death and/or damage to the equipment and advice on how

to avoid the danger. The following warning symbols are used in this manual:

Safety in installation and maintenance

These warnings are intended for all who work on the drive, motor cable or motor.

Electricity safety

Never work on the drive, motor cable or motor when input power is applied. After disconnecting the input power, always

wait for 10 minutes to let the intermediate circuit capacitors discharge before you start working on the drive, motor or motor

cable.

Always ensure by measuring with a multimeter (impedance at least 1 Mohm) that:

1. There is no voltage between the drive input phases L1, L2 and L3 and the ground.

2. There is no voltage between terminals + and BR and the ground.

Do not work on the control cables when power is applied to the drive or to the external control circuits. Externally supplied

control circuits may carry dangerous voltage even when the input power of the drive is switched off.

Do not make any insulation or voltage withstand tests on the drive.

Be sure the system is properly grounded before applying power. Do not apply AC power before you ensure that all grounding

instructions have been followed. Electrical shock can cause serious or fatal injury

Note:

Even when the motor is stopped, dangerous voltage is present at the power circuit terminals L1, L2, L3 and U, V, W and + and BR.

General safety

WARNING! Ignoring the following instructions can cause physical injury or death, or damage to the equipment.

The drive is not field repairable. Never attempt to repair a malfunctioning drive; contact your local ABB representative or

Authorized Service Centre for replacement.

Make sure that dust from drilling does not enter the drive during the installation. Electrically conductive dust inside the drive may

cause damage or lead to malfunction.

Ensure sufficient cooling.

Safety in start-up and operation

These warnings are intended for all who plan the operation, start up or operate the drive.

11

WARNING! Ignoring the following instructions can cause physical injury or death, or damage to the equipment.

Before adjusting the drive and putting it into service, make sure that the motor and all driven equipment are suitable for

operation throughout the speed range provided by the drive. The drive can be adjusted to operate the motor at speeds

above and below the speed provided by connecting the motor directly to the power line.

Do not activate automatic fault reset functions if dangerous situations can occur. When activated, these functions reset the

drive and resume operation after a fault.

Do not control the motor with an AC contactor or disconnecting device (disconnecting means); use instead the control panel

start and stop keys and or external commands (I/O). The maximum allowed number of charging cycles of the DC capacitors

(that is, power-ups by applying power) is two per minute.

Note:

When parameter 1103 PRIMARY COMMAND SOURCE MODE is not set to 1 or 2, the stop key on the control panel will not

stop the drive. To stop the drive open terminal 2 of the drive control terminals.

12

Danger : Indicates a risk of electric shock, which, if not

avoided, could result in damage to the equipment and

possible injury or death.

Danger : Indicates a potentially hazardous situation

other than electrical, which if not avoided, could result

in damage to property.

This ACS250 variable speed drive is intended for professional installation and commissioning into complete equipment or systems

as part of a fixed installation. If installed incorrectly it may present a safety hazard. The ACS250 uses high voltages and currents,

carries a high level of stored electrical energy, and is used to control mechanical plant that may cause injury. Close attention is

required to system design and electrical installation to avoid hazards in either normal operation or in the event of equipment

malfunction. Only qualified electricians are allowed to install and maintain this product.

System design, installation, commissioning and maintenance must be carried out only by personnel who have the necessary

training and experience. They must carefully read this safety information and the instructions in this Guide and follow all

information regarding transport, storage, installation and use of the ACS250, including the specified environmental limitations.

Do not perform any flash test or voltage withstand test on the ACS250. Any electrical measurements required should be carried out

with the ACS250 disconnected.

Electric shock hazard! Disconnect and ISOLATE the ACS250 before attempting any work on it. High voltages are present at the

terminals and within the drive for up to 10 minutes after disconnection of the electrical supply. Always ensure by using a suitable

multimeter that no voltage is present on any drive power terminals prior to commencing any work.

Where supply to the drive is through a plug and socket connector, do not disconnect until 10 minutes have elapsed after turning off

the supply.

Ensure correct grounding connections and cable selection as per defined by local legislation or codes. The drive may have a leakage

current of greater than 3.5mA; furthermore the earth cable must be sufficient to carry the maximum supply fault current which

normally will be limited by the fuses. Suitably rated fuses should be fitted in the mains supply to the drive, according to any local

legislation or codes.

Do not carry out any work on the drive control cables when power is applied to the drive or to the external control circuits.

The “Safe Torque Off” Function does not prevent high voltages from being present at the drives power terminals.

Within the European Union, all machinery in which this product is used must comply with the Machinery Directive 2006/42/EC,

Safety of Machinery. In particular, the machine manufacturer is responsible for providing a main switch and ensuring the electrical

equipment complies with EN60204-1.

The level of integrity offered by the ACS250 control input functions – for example stop/start, forward/reverse and maximum speed,

is not sufficient for use in safety-critical applications without independent channels of protection. All applications where

malfunction could cause injury or loss of life must be subject to a risk assessment and further protection provided where needed.

The driven motor can start at power up if the enable input signal is present.

The STOP function does not remove potentially lethal high voltages. ISOLATE the drive and wait 10 minutes before starting any

work on it. Never carry out any work on the Drive, Motor or Motor cable when the input power is still applied.

The ACS250 can be programmed to operate the driven motor at speeds above or below the speed achieved when connecting the

motor directly to the mains supply. Obtain confirmation from the manufacturers of the motor and the driven machine about

suitability for operation over the intended speed range prior to machine start up.

Do not activate the automatic fault reset function on any systems whereby this may cause a potentially dangerous situation.

IP66 drives provide their own pollution degree 2 environments. IP20 drives must be installed in a pollution degree 2 environment,

mounted in a cabinet with IP54 or better.

ACS250s are intended for indoor use only.

When mounting the drive, ensure that sufficient cooling is provided. Do not carry out drilling operations with the drive in place,

dust and metal shavings from drilling may lead to damage.

The entry of conductive or flammable foreign bodies should be prevented. Flammable material should not be placed close to the

drive

Relative humidity must be less than 95% (non-condensing).

Ensure that the supply voltage, frequency and number of phases correspond to the rating of the ACS250 as delivered.

Never connect the mains power supply to the Output terminals U, V, W.

Do not install any type of automatic switchgear between the drive and the motor

Wherever control cabling is close to power cabling, maintain a minimum separation of 4in. (100 mm) and arrange crossings at 90

degrees

Ensure that all terminals are tightened to the appropriate torque setting

Do not attempt to carry out any repair of the ACS250. In the case of suspected fault or malfunction, contact your local ABB Drives

representative for further assistance.

Please read the IMPORTANT SAFETY INFORMATION below, and all Warning and Caution information elsewhere.

13

3. General Information and Ratings

This chapter contains information about the ACS250 including how to identify the drive.

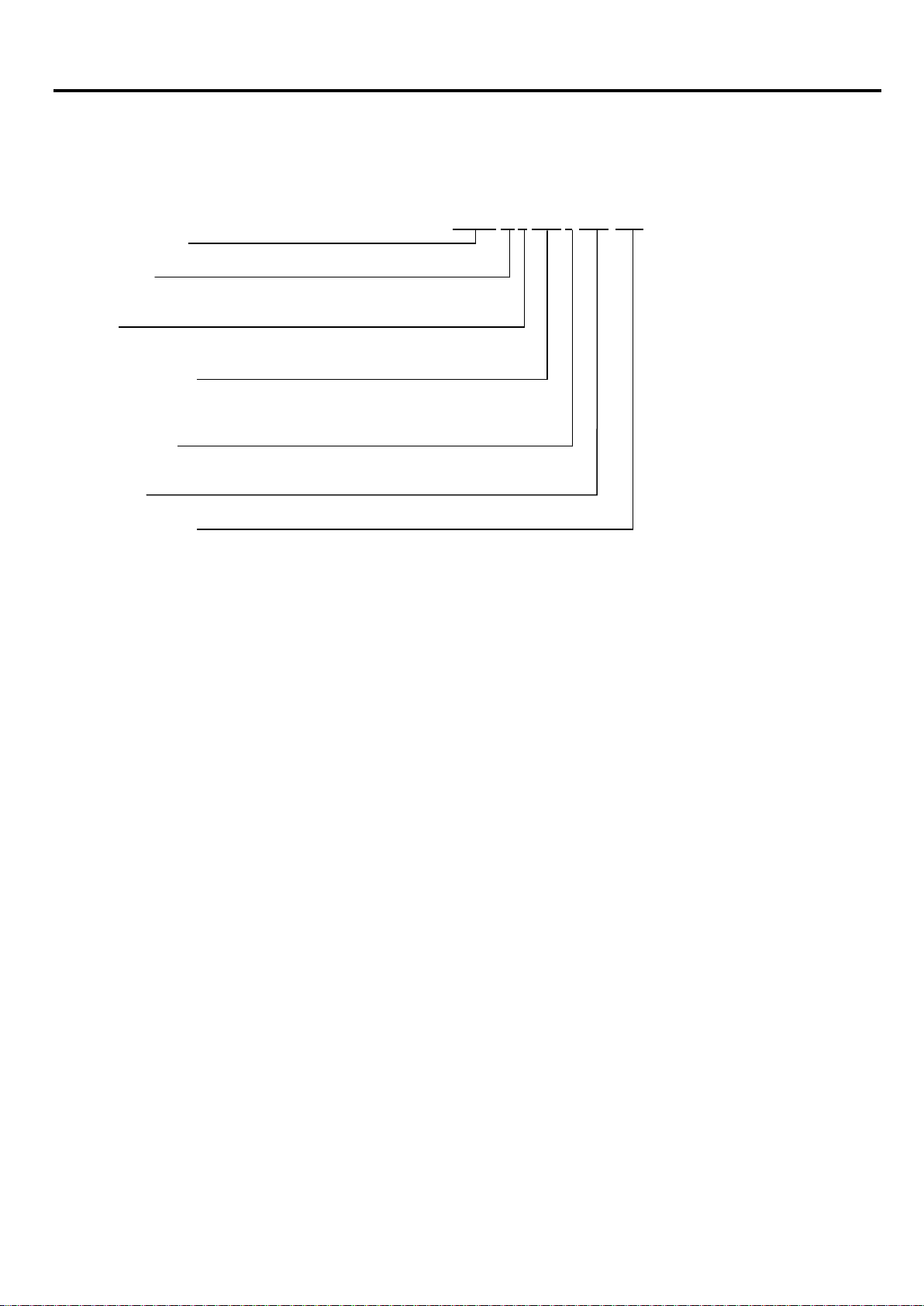

3.1. Type designation key

The type designation contains information on the specification and configuration of the drive. You find the type designation label attached to the

drive. The first digits from the left express the basic configuration, for example ACS250-03U-08A8-6. The explanations of the type designation

label selections are described below.

ACS250-03 U-08A8-6+B063+F278

ACS250 product series

1-phase/3 phase

03 = 3-phase input

EMC Filter

E = Filtered

U = Non-Filtered

Output Current Rating

In format xxAy, where xx indicates the integer part and y the fractional part,

For example, 08A8 means 8.8 A.

Input Voltage Range

6 = 500…600VAC

IP66 Enclosure

Input switch assembly

(Speed potentiometer, run/stop and mains disconnect switch)

14

Model Number

Power

(HP)

Output Current

(A)

Input switch

assembly

Internal DB transistor

Frame Size

ACS250-03U-02A1-6

1

2.1

No

Yes

P2

ACS250-03U-03A1-6

2

3.1

No

Yes

P2

ACS250-03U-04A1-6

3

4.1

No

Yes

P2

ACS250-03U-06A5-6

5

6.5

No

Yes

P2

ACS250-03U-09A0-6

7.5 9 No

Yes

P2

ACS250-03U-12A0-6

10

12

No

Yes

P3

ACS250-03U-17A0-6

15

17

No

Yes

P3

ACS250-03U-22A0-6

20

22

No

Yes

P3

Model Number

Power

(HP)

Output Current

(A)

Input switch

assembly

Internal DB transistor

Frame Size

ACS250-03U-02A1-6 +B063

1

2.1

No

Yes

P2

ACS250-03U-03A1-6 +B063

2

3.1

No

Yes

P2

ACS250-03U-04A1-6 +B063

3

4.1

No

Yes

P2

ACS250-03U-06A5-6 +B063

5

6.5

No

Yes

P2

ACS250-03U-09A0-6 +B063

7.5 9 No

Yes

P2

ACS250-03U-12A0-6 +B063

10

12

No

Yes

P3

ACS250-03U-17A0-6 +B063

15

17

No

Yes

P3

ACS250-03U-02A1-6 +B063 +F278

1

2.1

Yes

Yes

P2

ACS250-03U-03A1-6 +B063 +F278

2

3.1

Yes

Yes

P2

ACS250-03U-04A1-6 +B063 +F278

3

4.1

Yes

Yes

P2

ACS250-03U-06A5-6 +B063 +F278

5

6.5

Yes

Yes

P2

ACS250-03U-09A0-6 +B063 +F278

7.5

9

Yes

Yes

P2

ACS250-03U-12A0-6 +B063 +F278

10

12

Yes

Yes

P3

ACS250-03U-17A0-6 +B063 +F278

15

17

Yes

Yes

P3

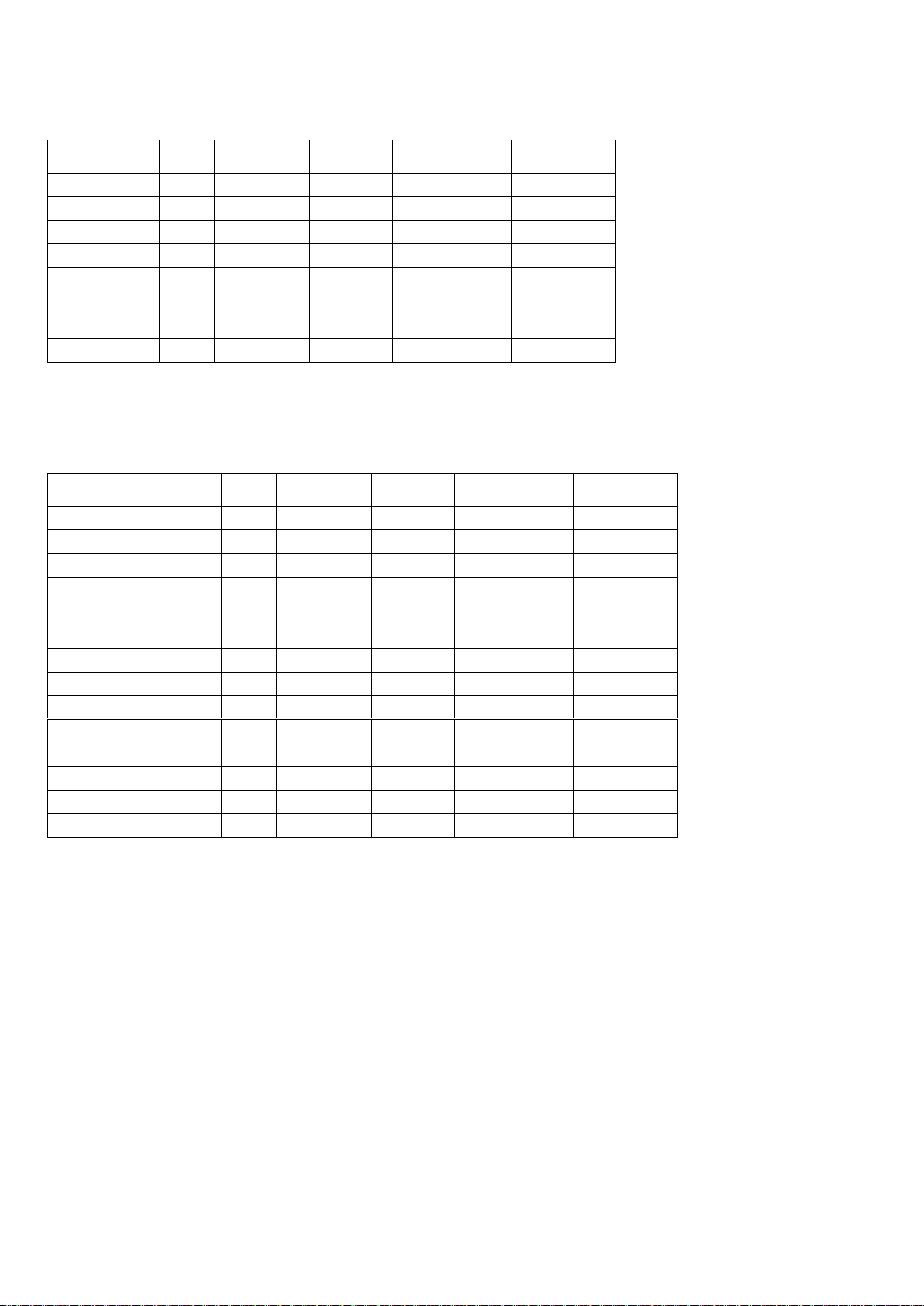

3.2. Drive model numbers – IP20

Mechanical Dimensions and Mounting information is shown from page 15.

Electrical Specifications are shown on page 60.

3.3. Drive model numbers – IP66

Mechanical Dimensions and Mounting information is shown from page 15.

Electrical Specifications are shown on page 60.

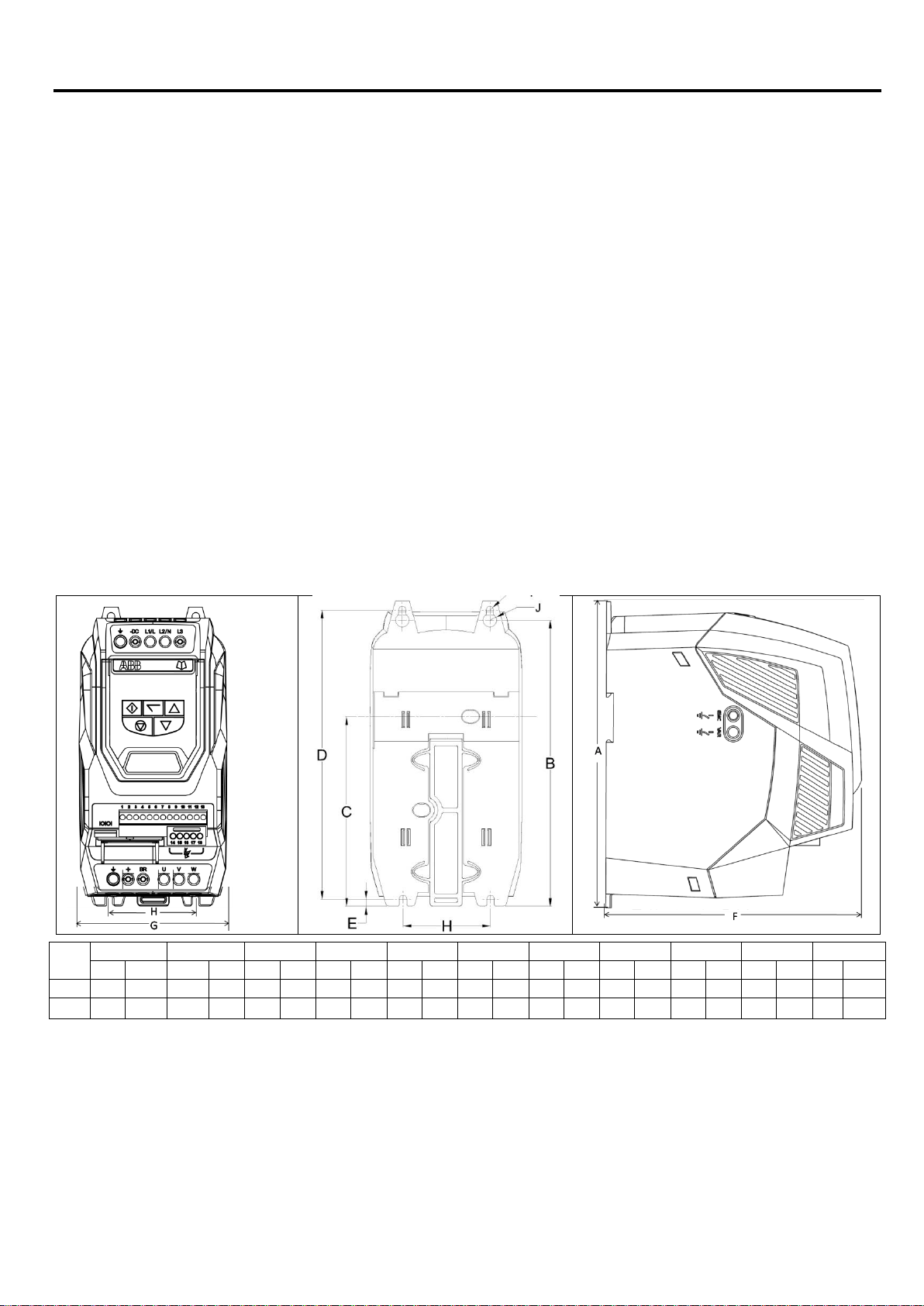

4. Mechanical Installation

Drive

Size

A B C D E F G H I J Weight

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Kg

Ib

2

221

8.70

207

8.15

137

5.39

209

8.23

5.3

0.21

185

7.28

112

4.41

63

2.48

5.5

0.22

10

0.39

1.8

4

3

261

10.28

246

9.69 - -

247

9.72 6 0.24

205

8.07

131

5.16

80

3.15

5.5

0.22

10

0.39

3.5

7.7

4.1. General

The ACS250 should be mounted in a vertical position only, on a flat, flame resistant, vibration free mounting using the integral

mounting holes or DIN Rail clip (Size P2 only).

The ACS250 must be installed in a pollution degree 1 or 2 environment only.

Do not mount flammable material close to the ACS250

Ensure that the minimum cooling air gaps, as detailed in section 4.5 and 4.7 are left clear.

Ensure that the ambient temperature range does not exceed the permissible limits for the ACS250 are given on page 61.

Provide suitable clean, moisture and contaminant free cooling air sufficient to fulfil the cooling requirements of the ACS250.

4.2. Before Installation

Carefully Unpack the ACS250 and check for any signs of damage. Notify the shipper immediately if any exist.

Check the drive rating label to ensure it is of the correct type and power requirements for the application.

To prevent accidental damage always store the ACS250 in its original box until required. Storage should be clean and dry and within

the temperature range –40°C to +60°C.

4.3. UL Compliant Installation

Note the following for UL-compliant installation:

For an up to date list of UL compliant products, please refer to UL listing NMMS.E211945.

The drive can be operated within an ambient temperature range as stated in section 11.1.

For IP20 units, installation is required in a pollution degree 1 environment.

For IP66 units, installation in a pollution degree 2 environmant is permissible.

UL Listed ring terminals / lugs must be used for all bus bar and grounding connections.

4.4. Mechanical dimensions and weights

4.4.1. IP20 Units

15

Mounting Bolts

All Frame Sizes : 4 x M4

Tightening Torques

Recommended Control Terminal Torque Settings : All Sizes : 0.8 Nm (7 lb-in)

Recommended Power Terminal Torque Settings : All Sizes : 1 Nm (8.85 lb-in)

16

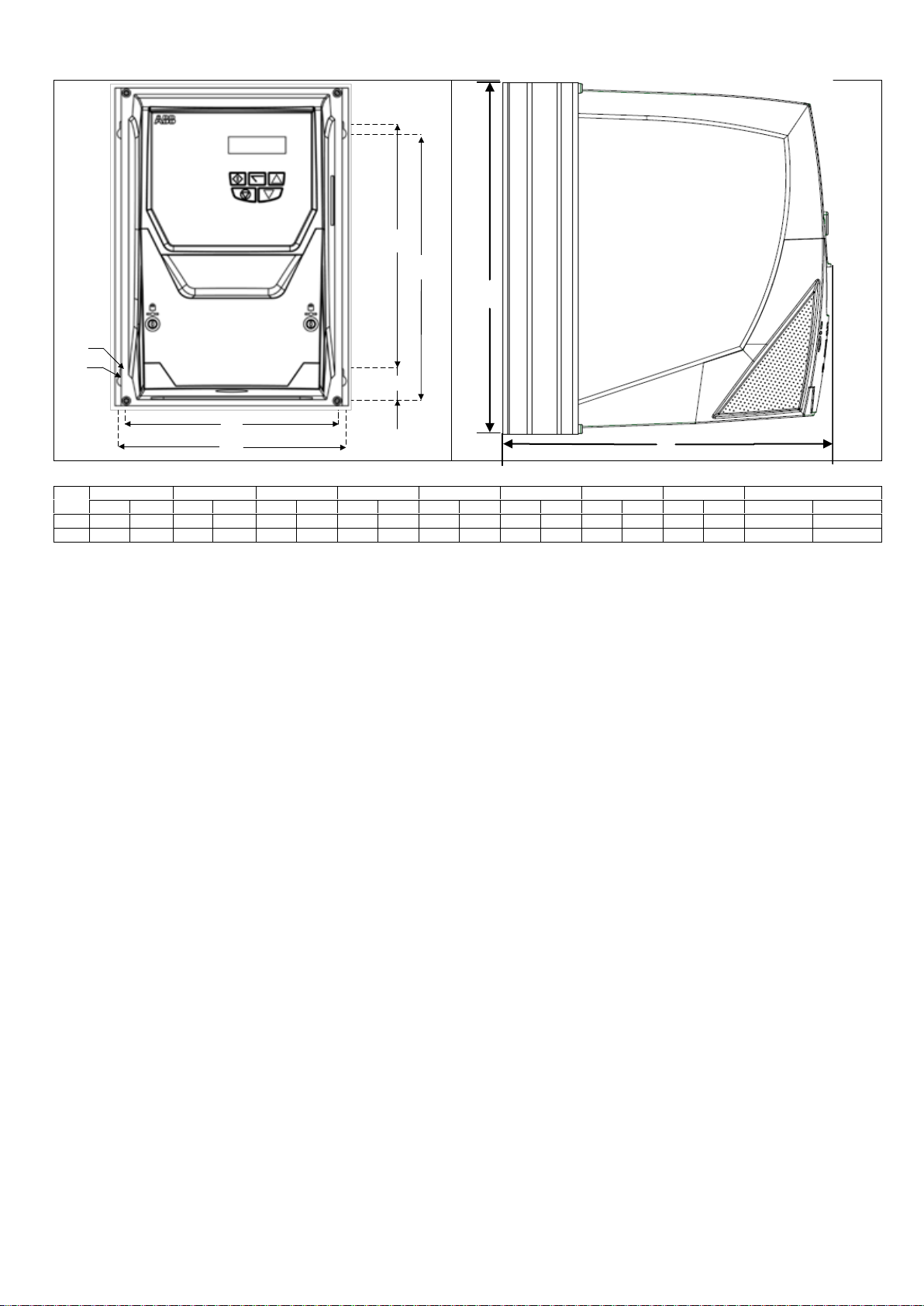

D

B

E

H

G

I

J

F

Drive

Size

A B D F G H I J Weight

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Kg

Ib 2 257

10.12

220

8.66

200

7.87

239

9.41

188

7.40

176

6.93

4.2

0.17

8.5

0.33

4.8

10.6

3

310

12.20

277

10.89

252

9.90

251

9.88

211

8.29

198

7.78

4.2

0.17

8.5

0.33

7.3

16.1

A

4.4.2. IP66 Units

Mounting Bolt Sizes

All Frame Sizes 4 x M4

Tightening Torques

Recommended Control Terminal Torque Settings :All Sizes : 0.8 Nm (7 lb-in)

Recommended Power Terminal Torque Settings : Frame Size 2 : 1.2 – 1.5 Nm (10 – 15 lb-in)

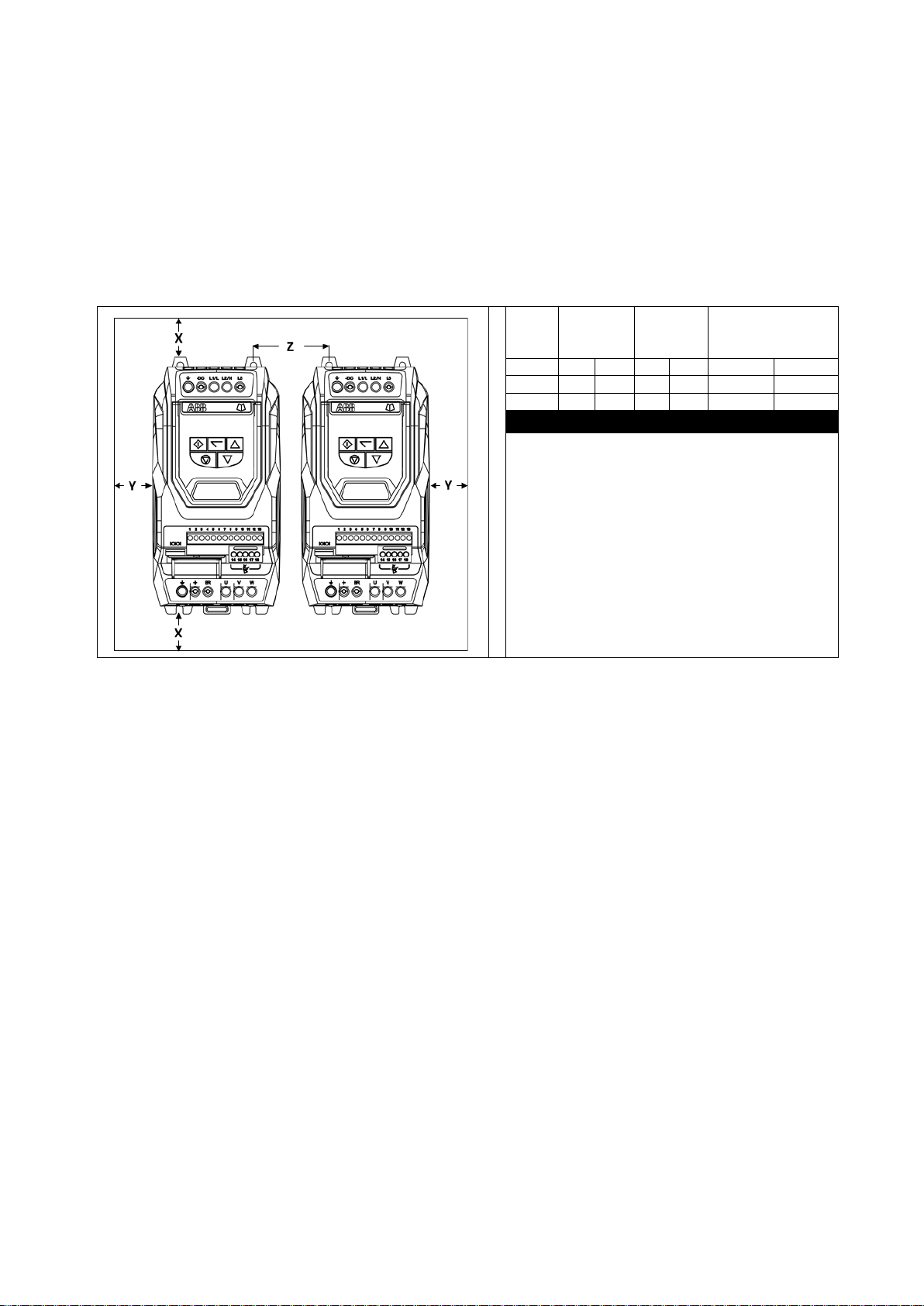

4.5. Guidelines for Enclosure mounting (IP20 Units)

Drive

Frame

Size

X

Above &

Below

Y

Either

Side

Z

Between

mm

in

mm

in

mm

in

2

75

2.95

50

1.97

46

1.81

3

100

3.94

50

1.97

52

2.05

Note :

Dimension Z assumes that the drives are mounted sideby-side with no clearance.

Typical drive heat losses are 3% of operating load

conditions.

Above are guidelines only and the operating ambient

temperature of the drive MUST be maintained at all

times.

IP20 drives must be installed in a pollution degree 2 environment, mounted in a cabinet with IP54 or better.

Installation should be in a suitable enclosure, according to EN60529 or other relevant local codes or standards.

Enclosures should be made from a thermally conductive material.

Where vented enclosures are used, there should be free space clearance above and below the drive to ensure good air circulation –

see the diagram below for minimum free space clearance. Air should be drawn in below the drive and expelled above the drive.

In any environments where the conditions require it, the enclosure must be designed to protect the ACS250 against ingress of airborne

dust, corrosive gases or liquids, conductive contaminants (such as condensation, carbon dust, and metallic particles) and sprays or

splashing water from all directions.

High moisture, salt or chemical content environments should use a suitably sealed (non-vented) enclosure.

The enclosure design and layout should ensure that the adequate ventilation paths and clearances are left to allow air to circulate through the

drive heatsink. Recommend below is the minimum mounting clearance requirements for drives mounted in non-ventilated metallic enclosures.

17

4.6. Mounting the Drive – IP20 Units

IP20 Units are intended for installation within a control cabinet.

When mounting with screws

o Using the drive as a template, or the dimensions shown above, mark the locations for drilling

o Ensure that when mounting locations are drilled, the dust from drilling does not enter the drive

o Mount the drive to the cabinet backplate using suitable M4 mounting screws

o Position the drive, and tighten the mounting screws securely

When Din Rail Mounting (Frame Size 2 Only)

o Locate the DIN rail mounting slot on the rear of the drive onto the top of the DIN rail first

o Press the bottom of the drive onto the DIN rail until the lower clip attaches to the DIN rail

o If necessary, use a suitable flat blade screw driver to pull the DIN rail clip down to allow the drive to mount securely on the

rail

o To remove the drive from the DIN rail, use a suitable flat blade screwdriver to pull the release tab downwards, and lift the

bottom of the drive away from the rail first

18

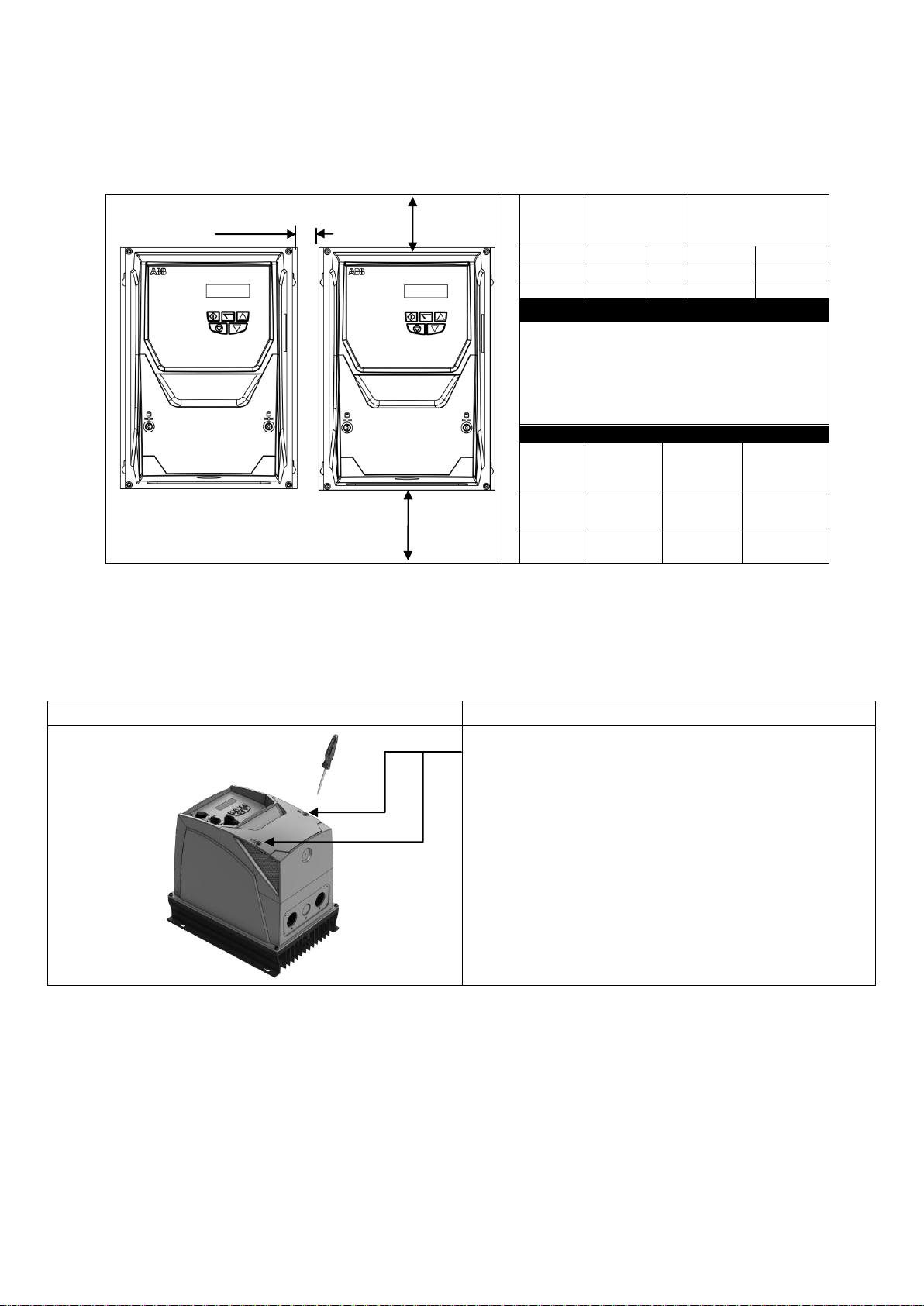

Y

X

X

Drive

Frame

Size

X

Above &

Below

Y

Either

Side

mm

in

mm

in

2

200

7.87

10

0.39

3

200

7.87

10

0.39

Note :

Typical drive heat losses are approximately 3% of

operating load conditions.

Above are guidelines only and the operating

ambient temperature of the drive MUST be

maintained at all times.

Cable Gland Sizes

Drive

Frame

Size

Power

Cable

Motor

Cable

Control

Cables

2

M25

(PG21)

M25

(PG21)

M20

(PG13.5)

3

M25

(PG21)

M25

(PG21)

M20

(PG13.5)

Frame Sizes 2 & 3

Using a suitable flat blade screwdriver, rotate the two retaining

screws indicated until the screw slot is vertical.

X

4.7. Guidelines for mounting (IP66 Units)

Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in

section 11.1.

The drive must be mounted vertically, on a suitable flat surface

The minimum mounting clearances as shown in the table below must be observed

The mounting site and chosen mountings should be sufficient to support the weight of the drives

Using the drive as a template, or the dimensions shown above, mark the locations required for drilling

Suitable cable glands to maintain the ingress protection of the drive are required.

Gland holes for power and motor cables are pre-moulded into the drive enclosure, recommended gland sizes are shown above, gland

holes for control cables may be cut as required.

4.8. Removing the Terminal Cover

4.9. Routine Maintenance

The drive should be included within the scheduled maintenance program so that the installation maintains a suitable operating environment,

this should include:

Ambient temperature is at or below that set out in the “Environment” section on page 60.

Heat sink fans freely rotating and dust free.

The Enclosure in which the drive is installed should be free from dust and condensation; furthermore ventilation fans and air filters

should be checked for correct air flow.

Checks should also be made on all electrical connections, ensuring screw terminals are correctly torqued; and that power cables have no signs of

heat damage.

5. Electrical Installation

This manual is intended as a guide for proper installation. ABB Drives Ltd cannot assume responsibility for the compliance or the

non-compliance to any code, national, local or otherwise, for the proper installation of this drive or associated equipment. A

hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

This ACS250 contains high voltage capacitors that take time to discharge after removal of the main supply. Before working on the

drive, ensure isolation of the main supply from line inputs. Wait ten (10) minutes for the capacitors to discharge to safe voltage

levels. Failure to observe this precaution could result in severe bodily injury or loss of life.

Only qualified electrical personnel familiar with the construction and operation of this equipment and the hazards involved should

install, adjust, operate, or service this equipment. Read and understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

Whenever possible use Shielded motor cablesmaintaining shield as far as possible along the cable.

=/>100mm

Twisted-Pair shielded cables for analog control and motor

feedback signals.

Ensure Filter chassis is making metal-metal contact with

Mounting panel.

RFI Filter

Option

Site Ground Bus-Bar bonded to Metal Back-Panel

panel which is bonded to main power ground.

Metal Back-Panel

U V W

PE

U V W

PE

360° bonding

EMC cable gland

(Best-Practice)

(Shield to Motor

Chassis)

X

Avoid long parallel

runs of motor cables

with other cables

Where control cables must cross power

cables make sure they are as near to 90

degrees as possible.

5.1. Grounding the Drive

5.1.1. Recommended installation for EMC compliance.

19

20

5.1.2. Grounding Guidelines

The ground terminal of each ACS250 should be individually connected DIRECTLY to the site ground bus bar (through the filter if installed).

The ACS250 ground connections should not loop from one drive to another, or to, or from any other equipment. Ground loop impedance must

confirm to local industrial safety regulations. To meet UL regulations, UL approved ring crimp terminals should be used for all ground wiring

connections.

The drive Safety Ground must be connected to system ground. Ground impedance must conform to the requirements of national and local

industrial safety regulations and/or electrical codes. The integrity of all ground connections should be checked periodically.

5.1.3. Protective Earth Conductor

The Cross sectional area of the PE Conductor must be at least equal to that of the incoming supply conductor.

5.1.4. Safety Ground

This is the safety ground for the drive that is required by code. One of these points must be connected to adjacent building steel (girder, joist), a

floor ground rod, or bus bar. Grounding points must comply with national and local industrial safety regulations and/or electrical codes.

5.1.5. Motor Ground

The motor ground must be connected to one of the ground terminals on the drive.

5.1.6. Ground Fault Monitoring

As with all inverters, a leakage current to earth can exist. The ACS250 is designed to produce the minimum possible leakage current while

complying with worldwide standards. The level of current is affected by motor cable length and type, the effective switching frequency, the

earth connections used and the type of RFI filter installed. If a GFCI (Ground Fault Current Interrupter) is to be used, the following conditions

apply:

The device must be suitable for protecting equipment with a DC component in the leakage current

Individual GFCI’s should be used for each ACS250

5.1.7. Shield Termination (Cable Screen)

The safety ground terminal provides a grounding point for the motor cable shield. The motor cable shield connected to this terminal (drive end)

should also be connected to the motor frame (motor end). Use a shield terminating or EMI clamp to connect the shield to the safety ground

terminal.

5.2. Wiring Precautions

Connect the ACS250 according to section 5.9, ensuring that motor terminal box connections are correct. There are two connections in general:

Star and Delta. It is essential to ensure that the motor is connected in accordance with the voltage at which it will be operated. For more

information, refer to section 5.6 Motor Terminal Box Connections.

Type MC continuous corrugated aluminium armour cable with symmetrical grounds or shielded power cable is recommended for the motor

cables if metallic conduit is not used.

The power cables must be rated for 75 °C (167 °F).

5.3. Incoming Power Connection

Power should be connected to L1, L2, and L3. Phase sequence is not important.

For compliance with CE and C Tick EMC requirements, a symmetrical shielded cable is recommended.

For compliance with CSA requirements, transient surge suppression shall be installed on the line side of this equipment and shall be

rated 600V (phase to ground), 600V (phase to phase), suitable for overvoltage category III, and shall provide protection for a rated

impulse withstand voltage peak of 4 kV or equivalent.

A fixed installation is required according to IEC61800-5-1 with a suitable disconnecting device installed between the ACS250 and the AC

Power Source. The disconnecting device must conform to the local safety code / regulations (e.g. within Europe, EN60204-1, Safety of

machinery).

The cables should be dimensioned according to any local codes or regulations. Guideline dimensions are given in section 11.2.

Suitable fuses to provide wiring protection of the input power cable should be installed in the incoming supply line, according to the

data in section 11.2. The fuses must comply with any local codes or regulations in place. In general, type gG (IEC 60269) or UL type T

fuses are suitable; however in some cases type aR fuses may be required. The operating time of the fuses must be below 0.5 seconds.

When the power supply is removed from the drive, a minimum of 30 seconds should be allowed before re-applying the power. A

minimum of 5 minutes should be allowed before removing the terminal covers or connection.

The maximum permissible short circuit current at the ACS250 Power terminals as defined in IEC60439-1 is 100kA.

An optional Input Choke is recommended to be installed in the supply line for drives where any of the following conditions occur:-

o The incoming supply impedance is low or the fault level / short circuit current is high.

o If the transformer kVA rating is more than 10x the kVA rating of the drive or ensure that the per drive source

impedance is less than 0.5%

o The supply is prone to dips or brown outs

o An imbalance exists on the supply (3 phase drives)

o The power supply to the drive is via a busbar and brush gear system (typically overhead Cranes).

In all other installations, an input choke is recommended to ensure protection of the drive against power supply faults.

Loading...

Loading...