Page 1

Product brochure

Medium voltage AC drive

ACS 2000, 250 – 1600 kW,

4.0 – 6.9 kV

Page 2

2 ACS 2000 brochure | ABB

Page 3

ACS 2000 – simple and reliable motor control

The ACS 2000 is the latest member of the ABB medium voltage

AC drives family providing reliable motor control for a wide range

of applications.

The ACS 2000 is designed for high reliability, easy installation

and fast commissioning reducing the total cost of ownership.

With the integration of an Active Front End (AFE), line side

harmonics are minimized without the use of expensive, spe-

cialized transformers and with the added benet of regeneration

and power factor correction.

With its compact footprint, the ACS 2000 can be retrofitted

to control standard induction motors via a direct connection

to 4.0 – 6.9 kV line supplies (direct-to-line). Alternatively, the

ACS 2000 can be operated with an input isolation transformer

to allow for flexible line side power voltages. It is available with

an integrated transformer or it can be connected to an external

two-winding transformer.

The ACS 2000 direct-to-line combines the cost savings of a

transformerless variable speed drive system with the benefits

of Voltage Source Inverters (VSIs), including excellent availability and reliability, high and constant power factor and

superior dynamic control performance.

The heritage of ABB’s VSI topology, along with a patented

IGBT-based multi-level control, provides a proven track

record for reliable and motor friendly medium voltage AC

drive solutions.

Key product features

– Suitable for use with or without an input isolation transformer

– Direct-to-line connection (transformerless) provides lowest

cost of ownership

– Active Front End (AFE) for minimal line side harmonics,

regeneration and power factor correction

– Simple drive system integration

– Three in - three out cabling technique for quick and easy

installation

– Suitable for new or existing induction motors

– Modular design provides high reliability and low mainte-

nance costs

Fields of application

Industries Applications

Cement, mining and minerals Conveyors, crushers, mills, mine hoists, fans and pumps

Chemical, oil and gas Pumps, compressors, extruders, mixers and blowers

Metals Fans and pumps

Pulp and paper Fans, pumps, refiners, vacuum pumps and chippers

Power generation Fans, pumps, conveyors and coal mills

Water Pumps

Other applications Test stands, wind tunnels and sugar mills

ABB | ACS 2000 brochure 3

Page 4

Key features

The ACS 2000 general purpose drive offers unique features

which provide superior application flexibility with a standard

solution.

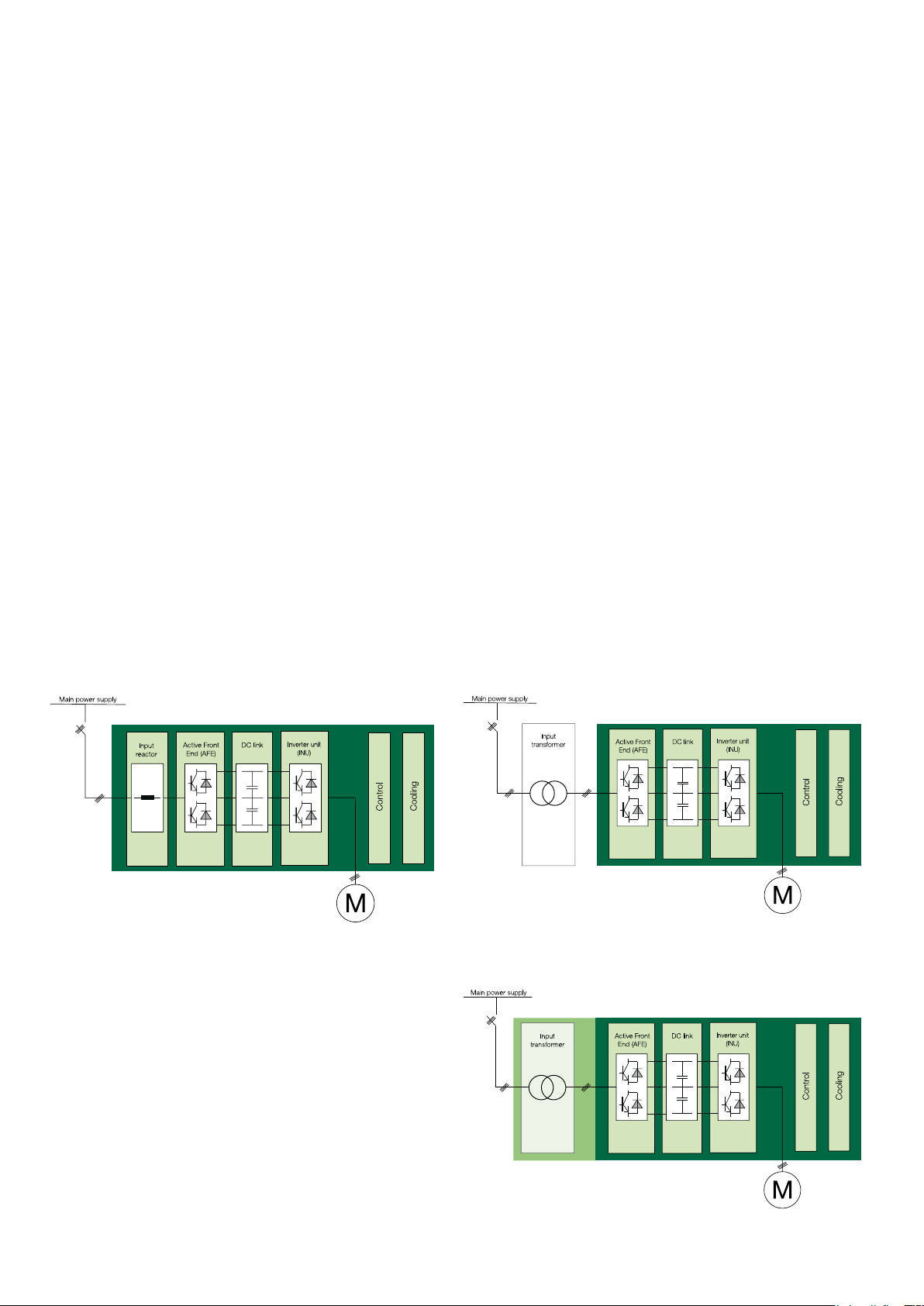

Line supply connection flexibility

The ACS 2000 provides different line supply connection

options, each offering unique benefits. The ACS 2000 is

available for connection to an external input isolation

transformer, with an integrated input isolation transformer

or for use without a transformer. The latter allows a direct

connection to the industrial line supply (direct-to-line).

Direct-to-line

The ACS 2000 direct-to-line can lower investment costs substantially. Due to its compact size and lighter weight compared

to a drive requiring a transformer, it also results in lower transportation costs and needs less space in the electrical room.

The ACS 2000 can be easily retrofitted to fixed speed motors

while the direct-to-line technology results in quick and easy

installation and commissioning.

For operation with a transformer

External transformer

For applications where a voltage-matching input transformer

is needed or galvanic isolation from the power supply is

required, the ACS 2000 can be connected to a conventional

two-winding oil or dry-type converter transformer.

Integrated transformer

Alternatively, the ACS 2000 is also available with an integrated

input isolation transformer.

Topology of the ACS 2000 for direct-to-line connection

4 ACS 2000 brochure | ABB

Topology of the ACS 2000 for operation with an external transformer

Topology of the ACS 2000 with an integrated input transformer

Page 5

Active Front End for network friendly and energy

Volts

Volts

Volts

Volts

efficient operation

The ACS 2000 is available with an Active Front End (AFE)

which can be used in conjunction with a simple input isolation

transformer or for direct connection to 4.16 or 6.0 – 6.9 kV line

supply. It provides low harmonics and enables regeneration and

reactive power compensation.

Low harmonic signature

The AFE provides a low harmonic signature which meets the

most stringent requirements for harmonic distortion as defined

by relevant standards. This avoids the need for harmonic analysis

or the installation of network filters.

Regeneration

For applications with high braking energy, the ACS 2000 is

available with optional regeneration capability, which feeds back

braking energy to the line supply. This further reduces the overall

energy consumption.

Power factor correction

For applications where other loads connected to the same line

supply cause leading or lagging power factor, the ACS 2000 is

available with a static VAR compensation option. With static

VAR compensation, a smooth line supply voltage profile can

be maintained and reactive power penalties can be avoided.

Powerful performance with DTC

Precise and reliable process control, together with low energy

consumption, results in top performance. The ACS 2000 drive

control platform uses ABB’s award-winning Direct Torque Control

(DTC), resulting in the highest torque and speed performance

as well as the lowest losses ever achieved in medium voltage

AC drives. Control of the drive is immediate and smooth under all

conditions.

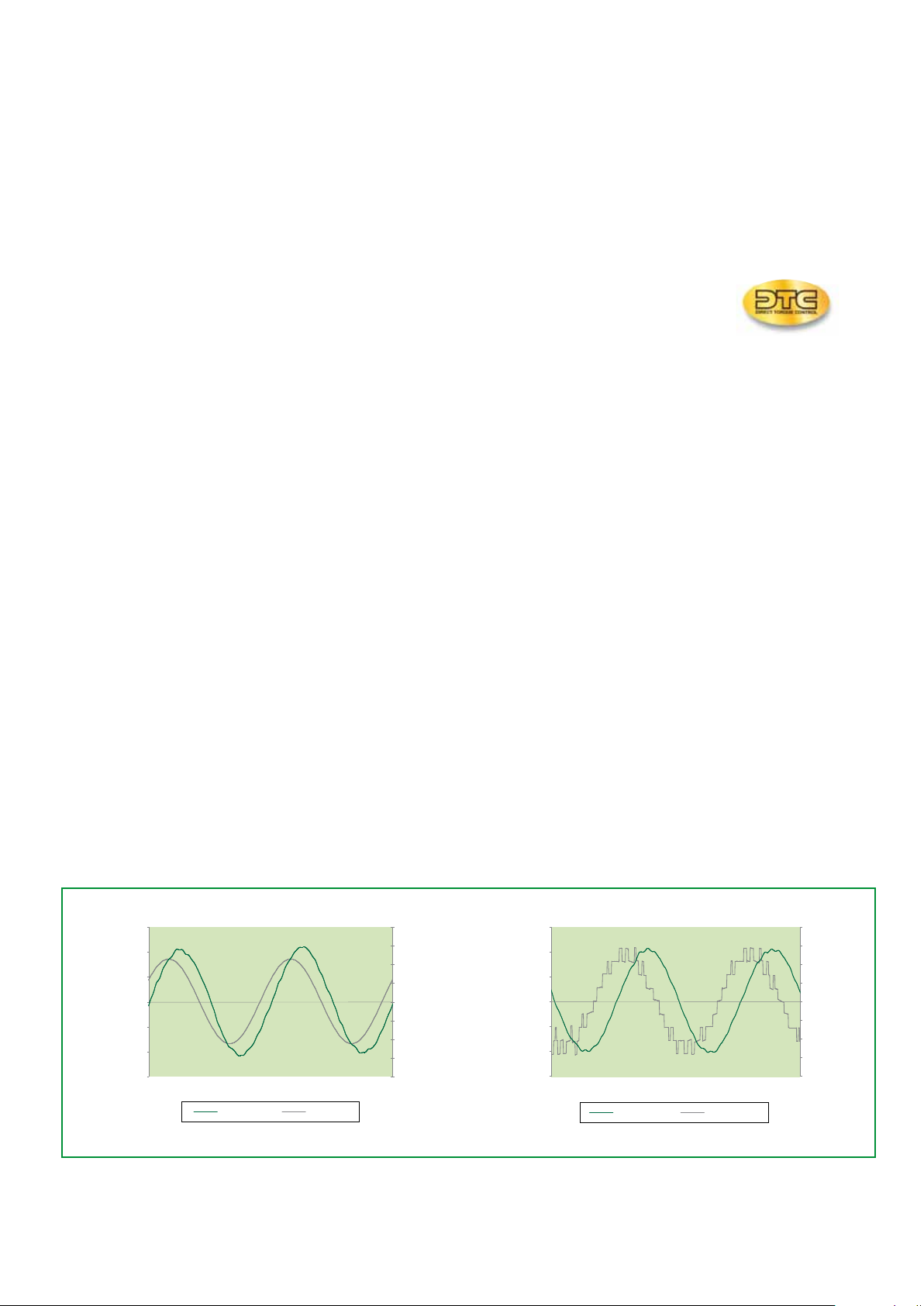

Motor friendly output waveform for use with new or

existing motors

The ACS 2000 provides near sinusoidal current and voltage

waveforms making it compatible for use with standard motors and

cable insulation. This is achieved with ABB’s patented multilevel

topology which utilizes one DC link enabling a multi-level output

waveform with a minimum number of power components.

15000

10000

5000

0

Volts

-5000

-10000

-15000

Line and motor current and voltage

50 Hz operation point

Line current Line voltage

200

150

100

50

0

Amps

-50

-100

-150

-200

15000

10000

5000

Volts

-5000

-10000

-15000

0

50 Hz operation point

Motor current Motor voltage

ABB | ACS 2000 brochure 5

200

150

100

50

0

-50

-100

-150

-200

Amps

Page 6

ACS 2000 – the right choice for general purpose applications

Depending on the application, variable speed drives have to

fulfill different requirements. The ACS 2000 provides the right

solution for general purpose applications.

ACS 2000, low harmonic drives

ABB’s low harmonic drives offer optimal low harmonic performance which does not require any additional filtering.

They feature an Active Front End (AFE), which minimizes line side

harmonics without the use of specialized transformers. Due to

the AFE, line side harmonics of the ACS 2000 are compliant

with all relevant standards. This avoids the need for harmonic

analysis or the installation of a multi-pulse transformer, network

filters or other additional equipment for harmonics reduction.

ACS 2000, regenerative drives

ACS 2000 regenerative drives provide enhanced active braking and power factor correction.

Regenerative braking

The AFE enables regenerative braking which allows full power

flow both in motoring and generating mode. Regeneration

offers significant energy savings compared to other braking

methods as energy is fed back to the supply network.

Regeneration is especially suitable for applications with frequent

starts and stops. It allows energy efficient continuous braking

of applications such as downhill conveyors or expanders in

gas pipelines.

Power factor correction

The AFE can also provide reactive power (VAR) compensation.

With VAR compensation, the voltage level can be controlled to

stay within tight limits. A smooth network voltage profile can

be maintained and reactive power penalties can be avoided.

Different rectifier designs generate different line currents. An active front end (AFE) is a superior way to minimize harmonics.

6 ACS 2000 brochure | ABB

Page 7

ACS 2000

The air-cooled general purpose drive provides simple and

reliable motor control for a wide range of applications.

ACS 2000 direct-to-line,

800 kW, 4.0 – 4.16 kV

Electromechanically

interlocked doors for

safety

DC bus grounding

switch for safety

Input reactor with

common mode filter

for direct-to-line

connection

User-friendly drive control panel for local operation

– Keypad with multi-language display

– Main supply on/off pushbuttons

– Emergency off pushbutton

ABB | ACS 2000 brochure 7

Page 8

ACS 2000

It is designed for easy installation, fast commissioning and

efficient maintenance reducing the total cost of ownership.

ACS 2000, 800 kW, 6.6 kV,

for operation with an external

transformer

Control unit

Cable connection

section for top

and bottom entry

Inverter unit

(INU)

Withdrawable phase

modules

Active Front

End (AFE)

8 ACS 2000 brochure | ABB

Page 9

Features and benefits

Features Advantages Benefits

Operation without transformer (direct-to-line)

No transformer required Reduces capital expenditure

Easy retrofit to fixed-speed motors Minimizes investment

Easy and fast commissioning Lowers downtime

Lowers transportation costs; less

space required in electrical room

Easy integration into existing

infrastructure

No special input isolation transformer

required

Operation under ground fault without

impact on the drive

Heating losses are not dissipated

into electrical room, reducing load

on HVAC system

Lowers downtime

Harmonic emissions compliant with

all relevant standards

Reduces energy loss in distribution

system, avoiding need for larger

cables and utility penalties

Flexibility of installation

Minimizes energy consumption

Low parts count, which boosts drive

availability

Compatible with standard new or

existing motors

Higher uptime of plant or process

Safe ride through during supply voltage dips and better process control

Higher productivity

Operation with transformer

The ACS 2000 is available with an integrated

transformer or for operation with an external

transformer

Active Front End (AFE)

Multilevel topology

Voltage Source Inverter (VSI) topology

Direct Torque Control (DTC)

Compact size

Compact and light drive system

Connection to any voltage level

Conventional two-winding oil or dry-type

input isolation transformer

Galvanic isolation to the line supply

Separate input isolation transformer can

be located outside

Integrated transformer for quick installation and commissioning

Inherent low harmonic signature

Power factor adjusted to compensate

for reactive power

Allows operation with an input isolation

transformer or for direct connection to

the line supply

Four-quadrant operation (regenerative

braking)

Patented multilevel topology

Provides near sinusoidal current and

voltage waveforms

Excellent availability, reliability and

efficiency

High and constant power factor Eliminates utility penalties

Superior dynamic control performance

Precise and reliable process control with

superior performance

Requires less space in electrical room Frees up valuable floor space

ABB | ACS 2000 brochure 9

Page 10

Simple drive system integration

Installing a medium voltage AC drive could not be easier with

ABB’s three in - three out concept. Simply disconnect the directon-line cable, connect the drive, and connect the drive to the motor.

Along with its flexible line supply connection options and

advanced software tools the ACS 2000 allows smooth and

simple drive system integration into any industrial environment.

Flexible control interface

ABB offers an open communication strategy, enabling connection

to higher-level process controllers. The ACS 2000 can be installed

with all major eldbus adapters for smooth integration, monitoring

and controlling of different processes, according to customer

requirements.

DriveOPC

DriveOPC is a software package, which allows communication

between ABB drives and the customer’s Windows

applications.

DriveStartup

The commissioning wizard DriveStartup is an advanced tool

which simplifies and speeds-up commissioning, reducing

plant downtime considerably.

Maintenance

Simple and efficient maintenance is an important factor in

keeping operating costs down.

®

-based

10 ACS 2000 brochure | ABB

The ACS 2000 is designed to maximize uptime as well as to

facilitate quick repair. The modular design lends itself to quick

and effective replacement of components, resulting in industry

leading Mean Time to Repair (MTTR).

Reliable components

ABB drive technologies, such as the multilevel VSI topology,

provide a low parts count, which increases reliability, extends

Mean Time Between Failures (MTBF) and improves availability.

Easy access

The ACS 2000 has been designed to allow easy front access

to all drive components.

Redundant cooling

The ACS 2000 is available with redundant fans which increases availability.

Page 11

Service and support

The ACS 2000 is backed by comprehensive service and support,

from the customer’s initial inquiry throughout the entire life cycle

of the drive system.

Installation and commissioning

Proper installation and commissioning of the equipment, done

by qualified and certified commissioning engineers, reduces

start-up time, increases safety and reliability and decreases

life cycle costs. In addition, operators can be given practical

training by experienced specialists on site.

With its three in - three out principle, exible line supply connection

options and advanced software tools, such as the commissioning

wizard, start-up of the ACS 2000 is easy and fast, thereby

minimizing plant downtime.

Life cycle management

ABB’s drive life cycle management model maximizes the value of

the equipment and maintenance investment by maintaining high

availability, eliminating unplanned repair costs and extending

the lifetime of the drive.

Life cycle management includes:

– providing spare parts and expertise throughout the life cycle

– providing efficient product support and maintenance for

improved reliability

– adding functionality to the initial product

Training

ABB provides extensive training for its medium voltage AC drives.

A range of training programs is offered from basic tutorials to

programs tailored to the customer’s specific needs.

Global network, local presence

After sales service is an integral part of providing the customer

with a reliable and efficient drive system. The ABB Group of

companies operates in more than 100 countries and has a

worldwide network of service operations.

Services for ABB‘s medium voltage AC drives

– Supervision of installation and commissioning

– Local support

– Worldwide service network

– Spare parts and logistics network

– Training

– Remote services

– 24 x 365 technical support

– Preventive maintenance

– Customized service agreements

ABB | ACS 2000 brochure 11

Page 12

Data sheet ACS 2000

Inverter type

Voltage Source Inverter (VSI), 9 levels line-to-line, with high voltage

IGBT (Insulated Gate Bipolar Transistor) power semiconductors

Motors

Induction motors; 250 – 1,600 kW

Standards

All common standards

4 kV according to NEMA, IEEE 1566, UL 347A

6 kV according to EN, IEC, CE, NEMA

Input

5-level self-commutated IGBT Active Front End (AFE) for operation with two-winding input isolation transformer or direct-to-line

(DTL), i.e. without transformer

Rated input voltages:

4.16 kV, +10% to -10% (-30% with derating)

6.0 / 6.6 kV, +10% to -10% (-30% with derating)

6.9 kV, +5% to -10% (-35% with derating)

The ACS 2000 with integrated transformer is available with

primary transformer voltages of 6.0, 6.6, 10 and 11 kV

(+10% to -10%).

Input frequency 50 / 60 Hz

Auxiliary supply voltage

400, 440, 480 or 600 VAC, 3-phase, 50 / 60 Hz

UPS (Uninterruptible Power Supply) / Single phase

control supply

If available, an external UPS can be connected for control

power supply, 110 – 240 VAC, single phase or 110/220 VDC.

Alternatively, the control can be powered via the auxiliary supply

voltage or an internal UPS can be provided.

Ambient temperature

o

+ 1 to 40

C (higher with derating)

Enclosure classes

IP21 to IP42

Control interface (optional)

All common eldbuses including Probus, Modbus, DeviceNet,

Ethernet, ACS Drivebus, ABB Advant Fieldbus AF100, others

Standard protection functions

Auxiliary voltage fault, overtemperature supervision, overcurrent,

short circuit detection, motor overload, motor stall and overspeed protection, communication fault (I/O watchdog), earth

fault, main circuit breaker supervision/tripping, emergency off

signal supervision

Example options

– Motor supervision I/Os

– Fault/alarm: overtemperature, vibration of bearings

– PT 100: winding and bearing temperatures

– Transformer supervision I/Os

– Fault/alarm: overtemperature, Buchholz

– PT 100: winding temperatures

– Hardwired signals for remote drive control

– References: start/stop, speed/torque etc.

– Status feedback signals: ready/running

– Analog signals: current/voltage/power etc.

– Redundant cooling fans with automatic switch over for duty

cycling and upon fan failure

– ABB DriveWindow service and diagnostic software

TM

– ABB DriveMonitor

for remote monitoring and diagnostics

Output frequency

0 to 75 Hz

Rated output voltage

4.0 – 6.9 kV

Efficiency of converter

Typically 97.5%

Input power factor

Controlled to 1 or adjustable to compensate for reactive power

of other loads connected to the same network

12 ACS 2000 brochure | ABB

Page 13

Data sheet ACS 2000, 4.0 – 4.16 kV

No

over-

Nominal rating * Light overload * Heavy duty * Type code ** Power Length Weight Length Weight Length Weight

load *

P

cont. maxIcont. maxImax

hp

(kW)

330

(246)

385

(287)

440

(328)

495

(369)

550

(410)

660

(492)

770

(574)

880

(656)

945

(705)

1000

(746)

A A

44 48

52 57

59 65

67 74

74 81

89 98

103 114

119 131

127 140

135 149

Motor data Converter

P

hp

(kW)

I

N

P

N

hp

A

(kW)

I

hd

hd

A

4,000 — 4,160 V ***

300

(224)

350

(261)

400

(298)

450

(336)

500

(373)

600

(447)

700

(522)

800

(597)

900

(671)

1000

(746)

108

121

135

40

47

54

61

67

81

94

220

(164)

257

(192)

293

(218)

330

(246)

367

(274)

440

(328)

513

(383)

587

(438)

660

(492)

733

(547)

29 ACS 2040-1x-AN1-a-0C 280 1,941 2,500 n/a n/a n/a n/a

34 ACS 2040-1x-AN1-a-0D 326 1,941 2,500 n/a n/a n/a n/a

40 ACS 2040-1x-AN1-a-0E 373 1,941 2,500 n/a n/a n/a n/a

45 ACS 2040-1x-AN1-a-0F 420 1,941 2,500 n/a n/a n/a n/a

49 ACS 2040-1x-AN1-a-0H 466 1,941 2,500 n/a n/a n/a n/a

59 ACS 2040-1x-AN1-a-0L 560 1,941 2,500 n/a n/a n/a n/a

69 ACS 2040-1x-AN1-a-0Q 653 1,941 2,500 n/a n/a n/a n/a

79 ACS 2040-1x-AN1-a-0R 746 1,941 2,500 n/a n/a n/a n/a

89 ACS 2040-1x-AN1-a-0T 839 1,941 2,500 n/a n/a n/a n/a

99 ACS 2040-1x-AN1-a-0V 933 1,941 2,500 n/a n/a n/a n/a

Con-

verter

data

Converter length and weight (approx. values)

direct-to-line

for operation

with external

transformer

with integrated

transformer

kVA mm kg mm kg mm kg

Notes:

* Indicative information referring to typical 4-pole motor, under nominal supply voltage conditions.

The ratings apply at 40°C. At higher temperatures (up to 50°C) the derating is 1.5% / 1°C.

No-overload use

P

Nominal ratings

I

I

Light-overload use

P

IN: Continuous current rating of particular sub-frame allowing 110% IN at 40°C for

1 minute every 10 minutes.

Heavy-duty use

P

Ihd: Continuous current rating of particular sub-frame allowing 150% Ihd at 40°C for

1 minute every 10 minutes.

** ‘x‘ indicates the different converter types

T - direct-to-line, regenerative

L - direct-to-line, low harmonic

*** 4.16 kV, +10% to -10%

: Typical motor power in no-overload use.

cont. max

: Rated current available continuously without overloadability at 40°C.

cont. max

: Maximum output current, available for 10 seconds at start.

max

: Typical motor power in light-overload use.

N

: Typical motor power in heavy-duty use.

hd

Dimensions:

Height: 2,107 mm cabinet height

2,285 mm (incl. cooling fans on top)

2,515 mm with redundant cooling fans

Depth: 1,177 mm

ABB | ACS 2000 brochure 13

Page 14

Data sheet ACS 2000, 6.0 – 6.9 kV

Motor data Converter

verter

data

No

over-

Nominal rating * Light overload * Heavy duty * Type code ** Power Length Weight Length Weight Length Weight

load *

Con-

P

cont. maxIcont. maxImax

kW A A kW A kW A kVA mm kg mm kg mm kg

275 33 36 250 30 183 22 ACS 2060-1x-AN1-a-0D 344 2,200 2,000 1,740 1,500 3,440 4,000

347 42 46 315 38 231 28 ACS 2060-1x-AN1-a-0E 434 2,200 2,000 1,740 1,500 3,440 4,000

390 47 52 355 43 260 31 ACS 2060-1x-AN1-a-0G 488 2,200 2,000 1,740 1,500 3,440 4,000

440 53 58 400 48 293 35 ACS 2060-1x-AN1-a-0J 550 2,200 2,000 1,740 1,500 3,440 4,000

495 60 65 450 54 330 40 ACS 2060-1x-AN1-a-0L 619 2,200 2,000 1,740 1,500 3,440 4,000

550 66 73 500 60 367 44 ACS 2060-1x-AN1-a-0N 688 2,200 2,000 1,740 1,500 3,440 4,000

616 74 82 560 67 411 49 ACS 2060-1x-AN1-a-0Q 770 2,200 2,000 1,740 1,500 3,440 4,000

693 83 92 630 76 462 56 ACS 2060-1x-AN1-a-0S 866 2,200 2,000 1,740 1,500 3,440 4,000

781 94 100 710 85 521 63 ACS 2060-1x-AN1-a-0U 976 2,200 2,000 1,740 1,500 3,440 4,000

800 96 100 730 87 533 64 ACS 2060-1x-AN1-a-0V 1,000 2,200 2,000 1,740 1,500 3,440 4,000

880 106 116 800 96 587 71 ACS 2060-2x-AN1-a-0W 1,100 3,800 4,300 3,000 3,000 n/a n/a

990 119 131 900 108 660 79 ACS 2060-2x-AN1-a-0Y 1,238 3,800 4,300 3,000 3,000 n/a n/a

1,100 132 146 1,000 120 733 88 ACS 2060-2x-AN1-a-1A 1,375 3,800 4,300 3,000 3,000 n/a n/a

1,232 148 163 1,120 135 821 99 ACS 2060-2x-AN1-a-1C 1,540 3,800 4,300 3,000 3,000 n/a n/a

1,386 167 183 1,260 152 924 111 ACS 2060-2x-AN1-a-1E 1,733 3,800 4,300 3,000 3,000 n/a n/a

1,562 188 200 1,420 171 1,041 125 ACS 2060-2x-AN1-a-1G 1,953 3,800 4,300 3,000 3,000 n/a n/a

1,600 192 200 1,455 175 1,067 128 ACS 2060-2x-AN1-a-1H 2,000 3,800 4,300 3,000 3,000 n/a n/a

275 30 33 250 27 183 20 ACS 2066-1x-AN1-a-0D 344 2,200 2,000 1,740 1,500 3,440 4,000

347 38 42 315 34 231 25 ACS 2066-1x-AN1-a-0E 434 2,200 2,000 1,740 1,500 3,440 4,000

390 43 47 355 39 260 28 ACS 2066-1x-AN1-a-0G 488 2,200 2,000 1,740 1,500 3,440 4,000

440 48 53 400 44 293 32 ACS 2066-1x-AN1-a-0J 550 2,200 2,000 1,740 1,500 3,440 4,000

495 54 60 450 49 330 36 ACS 2066-1x-AN1-a-0L 619 2,200 2,000 1,740 1,500 3,440 4,000

550 60 66 500 55 367 40 ACS 2066-1x-AN1-a-0N 688 2,200

616 67 74 560 61 411 45 ACS 2066-1x-AN1-a-0Q 770 2,200 2,000 1,740 1,500 3,440 4,000

693 76 83 630 69 462 51 ACS 2066-1x-AN1-a-0S 866 2,200 2,000 1,740 1,500 3,440 4,000

781 85 94 710 78 521 57 ACS 2066-1x-AN1-a-0U 976 2,200 2,000 1,740 1,500 3,440 4,000

880 96 100 800 87 587 64 ACS 2066-1x-AN1-a-0W 1,100 2,200 2,000 1,740 1,500 3,440 4,000

990 108 119 900 98 660 72 ACS 2066-2x-AN1-a-0Y 1,238 3,800 4,300 3,000 3,000 n/a n/a

1,100 120 132 1,000 109 733 80 ACS 2066-2x-AN1-a-1A 1,375 3,800 4,300 3,000 3,000 n/a n/a

1,232 135 148 1,120 122 821 90 ACS 2066-2x-AN1-a-1C 1,540 3,800 4,300 3,000 3,000 n/a n/a

1,386 152 167 1,260 138 924 101 ACS 2066-2x-AN1-a-1E 1,733 3,800 4,300 3,000 3,000 n/a n/a

1,562 171 188 1,420 155 1,041 114 ACS 2066-2x-AN1-a-1G 1,953 3,800 4,300 3,000 3,000 n/a n/a

1,650 180 198 1,500 164 1,100 120 ACS 2066-2x-AN1-a-1H 2,063 3,800 4,300 3,000 3,000 n/a n/a

1,760 192 200 1,600 175 1,173 128 ACS 2066-2x-AN1-a-1J 2,200 3,800 4,300 3,000 3,000 n/a n/a

P

I

N

P

N

I

hd

hd

6,000 V ***

6,600 V ***

Converter length and weight (approx. values)

direct-to-line

2,000 1,740 1,500 3,440 4,000

for operation

with external

transformer

with integrated

transformer

14 ACS 2000 brochure | ABB

Page 15

Data sheet ACS 2000, 6.0 – 6.9 kV, continued

Converter length and weight (approx. values)

direct-to-line

for operation

with external

transformer

with integrated

transformer

Motor data Converter

Con-

verter

data

No

over-

Nominal rating * Light overload * Heavy duty * Type code ** Power Length Weight Length Weight Length Weight

load *

P

cont. maxIcont. maxImax

P

I

N

P

N

I

hd

hd

kW A A kW A kW A kVA mm kg mm kg mm kg

6,900 V ***

275 30 33 250 27 183 20 ACS 2069-1x-AN1-a-0D 344 2,200 2,000 1,740 1,500 n/a n/a

347 38 42 315 34 231 25 ACS 2069-1x-AN1-a-0E 434 2,200 2,000 1,740 1,500 n/a n/a

390 43 47 355 39 260 28 ACS 2069-1x-AN1-a-0G 488 2,200 2,000 1,740 1,500 n/a n/a

440 48 53 400 44 293 32 ACS 2069-1x-AN1-a-0J 550 2,200 2,000 1,740 1,500 n/a n/a

495 54 60 450 49 330 36 ACS 2069-1x-AN1-a-0L 619 2,200 2,000 1,740 1,500 n/a n/a

550 60 66 500 55 367 40 ACS 2069-1x-AN1-a-0N 688 2,200 2,000 1,740 1,500 n/a n/a

616 67 74 560 61 411 45 ACS 2069-1x-AN1-a-0Q 770 2,200 2,000 1,740 1,500 n/a n/a

693 76 83 630 69 462 51 ACS 2069-1x-AN1-a-0S 866 2,200 2,000 1,740 1,500 n/a n/a

781 85 94 710 78 521 57 ACS 2069-1x-AN1-a-0U 976 2,200 2,000 1,740 1,500 n/a n/a

880 96 100 800 87 587 64 ACS 2069-1x-AN1-a-0W 1,100 2,200 2,000 1,740 1,500 n/a n/a

990 108 119 900 98 660 72 ACS 2069-2x-AN1-a-0Y 1,238 3,800 4,300 3,000 3,000 n/a n/a

1,100 120 132 1,000 109 733 80 ACS 2069-2x-AN1-a-1A 1,375 3,800 4,300 3,000 3,000 n/a n/a

1,232 135 148 1,120 122 821 90 ACS 2069-2x-AN1-a-1C 1,540 3,800 4,300 3,000 3,000 n/a n/a

1,386 152 167 1,260 138 924 101 ACS 2069-2x-AN1-a-1E 1,733 3,800 4,300 3,000 3,000 n/a n/a

1,562 171 188 1,420 155 1,041 114 ACS 2069-2x-AN1-a-1G 1,953 3,800 4,300 3,000 3,000 n/a n/a

1,650 180 198 1,500 164 1,100 120 ACS 2069-2x-AN1-a-1H 2,063 3,800 4,300 3,000 3,000 n/a n/a

1,760 192 200 1,600 175 1,173 128 ACS 2069-2x-AN1-a-1J 2,200 3,800 4,300 3,000 3,000 n/a n/a

Notes:

* Indicative information referring to typical 4-pole motor, under nominal supply voltage conditions.

The ratings apply at 40°C. At higher temperatures (up to 50°C) the derating is 1.5% / 1°C.

No-overload use

P

Nominal ratings

I

I

Light-overload use

P

IN: Continuous current rating of particular sub-frame allowing 110% IN at 40°C for

1 minute every 10 minutes.

Heavy-duty use

P

Ihd: Continuous current rating of particular sub-frame allowing 150% Ihd at 40°C for

1 minute every 10 minutes.

** ‘x‘ indicates the different converter types

A - for operation with external transformer, regenerative

D - for operation with external transformer, low harmonic

T - direct-to-line, regenerative

L - direct-to-line, low harmonic

I - with integrated transformer, regenerative

M - with integrated transformer, low harmonic

*** 6.0 / 6.6 kV, +10% to -10%; 6.9 kV, +5% to -10%

: Typical motor power in no-overload use.

cont. max

: Rated current available continuously without overloadability at 40°C.

cont. max

: Maximum output current, available for 10 seconds at start.

max

: Typical motor power in light-overload use.

N

: Typical motor power in heavy-duty use.

hd

Dimensions:

Height: 2,100 mm cabinet height

2,490 mm (incl. cooling fans on top)

2,700 mm with redundant cooling fans

Depth: 1,140 mm

ABB | ACS 2000 brochure 15

Page 16

Contact us

www.abb.com/drives

© Copyright 2009 ABB. All rights reserved. Specications subject to change without notice. 3BHT490640R0001 Rev. C

Loading...

Loading...