ABB component drives

User’s manual

ACS150 drives (0.37…4 kW, 0.5…5 hp)

2

List of related manuals

Drive manuals Code (English)

ACS310 User’s Manual 1), 2) 3AFE68576032

Option manuals and guides

MUL1-R1 Installation instructions for ACS150,

ACS310, ACS320, ACS350 and ACS355

MFDT-01 FlashDrop user's manual 1), 2) 3AFE68591074

Maintenance manuals

Guide for capacitor reforming in ACS50, ACS55,

ACS150, ACS310, ACS350, ACS355, ACS550,

ACH550 and R1-R4 OINT-/SINT-boards

1)

Delivered as a printed copy with the drive or optional equipment.

2)

Available in the Internet.

All manuals are available in PDF format on the Internet. See section Further information on the inside of the back cover.

1), 2) 3AFE68642868

2) 3AFE68735190

ACS150 drives

0.37…4 kW

0.5…5 hp

User’s manual

© 2010 ABB Oy. All Rights Reserved.

3AFE68576032 Rev C

EN

EFFECTIVE: 2011-01-01

Table of contents

List of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of contents

Safety

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Use of warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety in installation and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety in start-up and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Introduction to the manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Purpose of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Contents of this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Categorization according to the frame size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Quick installation and commissioning flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5

Operation principle and hardware description

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power connections and control interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Type designation label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Type designation key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mechanical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Checking the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Requirements for the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Operation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Free space around the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table of contents

6

Checking the delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Install the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

With screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

On DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Horizontally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fasten clamping plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Planning the electrical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Implementing the AC power line connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Selecting the supply disconnecting device (disconnecting means) . . . . . . . . . . . . . . . . . . . . . . . . 29

European union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Other regions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Checking the compatibility of the motor and drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Selecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

General rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Alternative power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Motor cable shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Additional US requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Armored cable / shielded power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Selecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

General rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Relay cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Control cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Protecting the drive, input power cable, motor and motor cable in short-circuit situations and against

thermal overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Protecting the drive and input power cable in short-circuit situations . . . . . . . . . . . . . . . . . . . . 35

Protecting the motor and motor cable in short-circuit situations . . . . . . . . . . . . . . . . . . . . . . . . 35

Protecting the drive, motor cable and input power cable against thermal overload . . . . . . . . . 36

Protecting the motor against thermal overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Residual current device (RCD) compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Implementing a bypass connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Protecting the contacts of relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Electrical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Input power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Checking the compatibility with IT (ungrounded) and corner-grounded TN systems . . . . . . . . . . . 40

Connecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table of contents

I/O terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

PNP and NPN configuration for digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

External power supply for digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Default I/O connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Installation checklist

Checking the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Start-up and control with I/O

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

How to start up the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

How to control the drive through the I/O interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Control panel

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Integrated control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

How to perform common tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

How to start, stop and switch between local and remote control . . . . . . . . . . . . . . . . . . . . . . 61

How to change the direction of the motor rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

How to set the frequency reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Output mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

How to browse the monitored signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Reference mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

How to view and set the frequency reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Parameter modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

How to select a parameter and change its value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

How to select the monitored signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Changed parameters mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

How to view and edit changed parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7

Application macros

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Overview of macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Summary of I/O connections of application macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

ABB standard macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Default I/O connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3-wire macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Default I/O connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Alternate macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Default I/O connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Motor potentiometer macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Default I/O connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table of contents

8

Hand/Auto macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Default I/O connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

PID control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Default I/O connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

User macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Actual signals and parameters

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Default parameter values with different macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Parameters in the Short parameter mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

99 START-UP DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

04 FAULT HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

11 REFERENCE SELECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12 CONSTANT SPEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13 ANALOG INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

20 LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

21 START/STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

22 ACCEL/DECEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Actual signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

01 OPERATING DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

04 FAULT HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Parameters in the Long parameter mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10 START/STOP/DIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11 REFERENCE SELECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

12 CONSTANT SPEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

13 ANALOG INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

14 RELAY OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

16 SYSTEM CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

18 FREQ INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

20 LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

21 START/STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

22 ACCEL/DECEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

25 CRITICAL SPEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

26 MOTOR CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

30 FAULT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

31 AUTOMATIC RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

32 SUPERVISION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

33 INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

34 PANEL DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

40 PROCESS PID SET 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

99 START-UP DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Fault tracing

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Alarm and fault indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

How to reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Table of contents

Fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Alarm messages generated by the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Fault messages generated by the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Maintenance

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Fan replacement (R1 and R2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Reforming the capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Technical data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Current and power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Temperature derating, I2N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Altitude derating, I2N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Switching frequency derating, I2N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Power cable sizes and fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Dimensions, weights and free space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Free space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Losses, cooling data and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Losses and cooling data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Terminal and lead-through data for the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Terminal data for the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Electric power network specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Motor connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Control connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Brake resistor connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Compliance with the European EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Compliance with the EN 61800-3:2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

9

Table of contents

10

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Category C1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Category C2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Category C3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

UL marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

UL checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

C-Tick marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

RoHS marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Brake resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Selecting the brake resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Selecting the brake resistor cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Placing the brake resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Protecting the system in brake circuit fault situations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Protection of the system in cable and brake resistor short-circuit situations . . . . . . . . . . . . 153

Protection of the system in brake resistor overheating situations . . . . . . . . . . . . . . . . . . . . 153

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Dimension drawings

Frame sizes R0 and R1, IP20 (cabinet installation) / UL open . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Frame sizes R0 and R1, IP20 / NEMA 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Frame size R2, IP20 (cabinet installation) / UL open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Frame size R2, IP20 / NEMA 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Appendix: Process PID control

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Process PID control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Quick configuration of process PID control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Pressure boost pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

How to scale the PID actual (feedback) signal 0…10 bar / 4…20 mA . . . . . . . . . . . . . . . . 163

How to scale the PID setpoint signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

PID sleep functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Table of contents

Safety

What this chapter contains

The chapter contains safety instructions that you must follow when installing,

operating and servicing the drive. If ignored, physical injury or death may follow, or

damage may occur to the drive, motor or driven equipment. Read the safety

instructions before you work on the drive.

Use of warnings

Warnings caution you about conditions which can result in serious injury or death

and/or damage to the equipment, and advise on how to avoid the danger. The

warning symbols are used as follows:

Electricity warning warns of hazards from electricity which can cause

physical injury and/or damage to the equipment.

11

General warning warns about conditions, other than those caused by

electricity, which can result in physical injury and/or damage to the

equipment.

Safety in installation and maintenance

These warnings are intended for all who work on the drive, motor cable or motor.

Electrical safety

WARNING! Ignoring the instructions can cause physical injury or death, or damage

to the equipment.

Only qualified electricians are allowed to install and maintain the drive!

• Never work on the drive, motor cable or motor when input power is applied. After

disconnecting the input power, always wait for 5 minutes to let the intermediate

circuit capacitors discharge before you start working on the drive, motor or motor

cable.

Always ensure by measuring with a multimeter (impedance at least 1 Mohm) that:

1. There is no voltage between the drive input phases U1, V1 and W1 and the

ground.

2. There is no voltage between terminals BRK+ and BRK- and the ground.

• Do not work on the control cables when power is applied to the drive or to the

external control circuits. Externally supplied control circuits may carry dangerous

voltage even when the input power of the drive is switched off.

• Do not make any insulation or voltage withstand tests on the drive.

Safety

12

• Disconnect the internal EMC filter when installing the drive on an IT system (an

ungrounded power system or a high-resistance-grounded [over 30 ohms] power

system), otherwise the system will be connected to ground potential through the

EMC filter capacitors. This may cause danger or damage the drive. See page 40.

Note: When the internal EMC filter is disconnected, the drive is not EMC

compatible.

• Disconnect the internal EMC filter when installing the drive on a corner-grounded

TN system, otherwise the drive will be damaged. See page 40. Note: When the

internal EMC filter is disconnected, the drive is not EMC compatible.

• All ELV (extra low voltage) circuits connected to the drive must be used within a

zone of equipotential bonding, ie within a zone where all simultaneously

accessible conductive parts are electrically connected to prevent hazardous

voltages appearing between them. This is accomplished by a proper factory

grounding.

Note:

Even when the motor is stopped, dangerous voltage is present at the power circuit

terminals U1, V1, W1 and U2, V2, W2 and BRK+ and BRK-.

General safety

WARNING! Ignoring the following instructions can cause physical injury or death, or

damage to the equipment.

• The drive is not field repairable. Never attempt to repair a malfunctioning drive;

contact your local ABB representative or Authorized Service Center for

replacement.

• Make sure that dust from drilling does not enter the drive during the installation.

Electrically conductive dust inside the drive may cause damage or lead to

malfunction.

• Ensure sufficient cooling.

Safety

Safety in start-up and operation

LOC

REM

These warnings are intended for all who plan the operation, start up or operate the

drive.

WARNING! Ignoring the following instructions can cause physical injury or death, or

damage to the equipment.

• Before adjusting the drive and putting it into service, make sure that the motor

and all driven equipment are suitable for operation throughout the speed range

provided by the drive. The drive can be adjusted to operate the motor at speeds

above and below the speed provided by connecting the motor directly to the

power line.

• Do not activate automatic fault reset functions if dangerous situations can occur.

When activated, these functions reset the drive and resume operation after a

fault.

• Do not control the motor with an AC contactor or disconnecting device

(disconnecting means); use instead the control panel start and stop keys

and or external commands (I/O). The maximum allowed number of charging

cycles of the DC capacitors (that is, power-ups by applying power) is two per

minute and the maximum total number of chargings is 15 000.

13

Note:

• If an external source for start command is selected and it is ON, the drive starts

immediately after an input voltage break or fault reset unless the drive is

configured for 3-wire (a pulse) start/stop.

• When the control location is not set to local (LOC not shown on the display), the

stop key on the control panel does not stop the drive. To stop the drive using the

control panel, press the LOC/REM key and then the stop key .

Safety

14

Safety

Introduction to the manual

What this chapter contains

The chapter describes applicability, the target audience and purpose of this manual.

It describes the contents of this manual and refers to a list of related manuals for

more information. It also contains a flowchart of steps for checking the delivery,

installing and commissioning the drive. The flowchart refers to chapters/sections in

this manual.

Applicability

The manual is applicable to the ACS150 drive firmware version 1.35b or later. See

parameter 3301 FIRMWARE on page 115.

Target audience

15

The reader is expected to know the fundamentals of electricity, wiring, electrical

components and electrical schematic symbols.

This manual is written for readers worldwide. Both SI and imperial units are shown.

Special US instructions for installations in the United States are given.

Purpose of the manual

This manual provides information needed for planning the installation, installing,

commissioning, using and servicing the drive.

Contents of this manual

The manual consists of the following chapters:

• Safety (page 11) gives safety instructions you must follow when installing,

commissioning, operating and servicing the drive.

• Introduction to the manual (this chapter, page 15) describes applicability, target

audience, purpose and contents of this manual. It also contains a quick

installation and commissioning flowchart.

• Operation principle and hardware description (page 19) describes the operation

principle, layout, type designation label and type designation information. It also

shows a general diagram of power connections and control interfaces.

• Mechanical installation (page 23) tells how to check the installation site, unpack,

check the delivery and install the drive mechanically.

• Planning the electrical installation (page 29) tells how to check the compatibility of

the motor and the drive and select cables, protections and cable routing.

Introduction to the manual

16

• Electrical installation (page 39) tells how to check the insulation of the assembly

and the compatibility with IT (ungrounded) and corner-grounded TN systems as

well as connect power cables and control cables.

• Installation checklist (page 49) contains a checklist for checking the mechanical

and electrical installation of the drive.

• Start-up and control with I/O (page 51) tells how to start, stop, change the

direction of the motor rotation and adjust the motor speed through the I/O

interface.

• Control panel (page 57) describes the control panel keys, LED indicators and

display fields and tells how to use the panel for control, monitoring and changing

the settings.

• Application macros (page 69) gives a brief description of each application macro

together with a wiring diagram showing the default control connections. It also

explains how to save a user macro and how to recall it.

• Actual signals and parameters (page 79) describes actual signals and

parameters. It also lists the default values for the different macros.

• Fault tracing (page 127) tells how to reset faults and view fault history. It lists all

alarm and fault messages including the possible cause and corrective actions.

• Maintenance (page 133) contains preventive maintenance instructions.

• Technical data (page 137) contains technical specifications of the drive, such as

ratings, sizes and technical requirements as well as provisions for fulfilling the

requirements for CE and other marks.

• Dimension drawings (page 155) shows dimension drawings of the drive.

• Appendix: Process PID control (page 161) contains instructions on quick

configuration of the process control, gives an application example and describes

the PID sleep functionality.

• Further information (page 169) (inside of the back cover, page 169) tells how to

make product and service inquiries, get information on product training, provide

feedback on ABB Drives manuals and find documents on the Internet.

Related documents

See List of related manuals on page 2 (inside of the front cover).

Categorization according to the frame size

The ACS150 is manufactured in frame sizes R0...R2. Some instructions and other

information which only concern certain frame sizes are marked with the symbol of

the frame size (R0...R2). To identify the frame size of your drive, see the table in

section Ratings on page 137.

Introduction to the manual

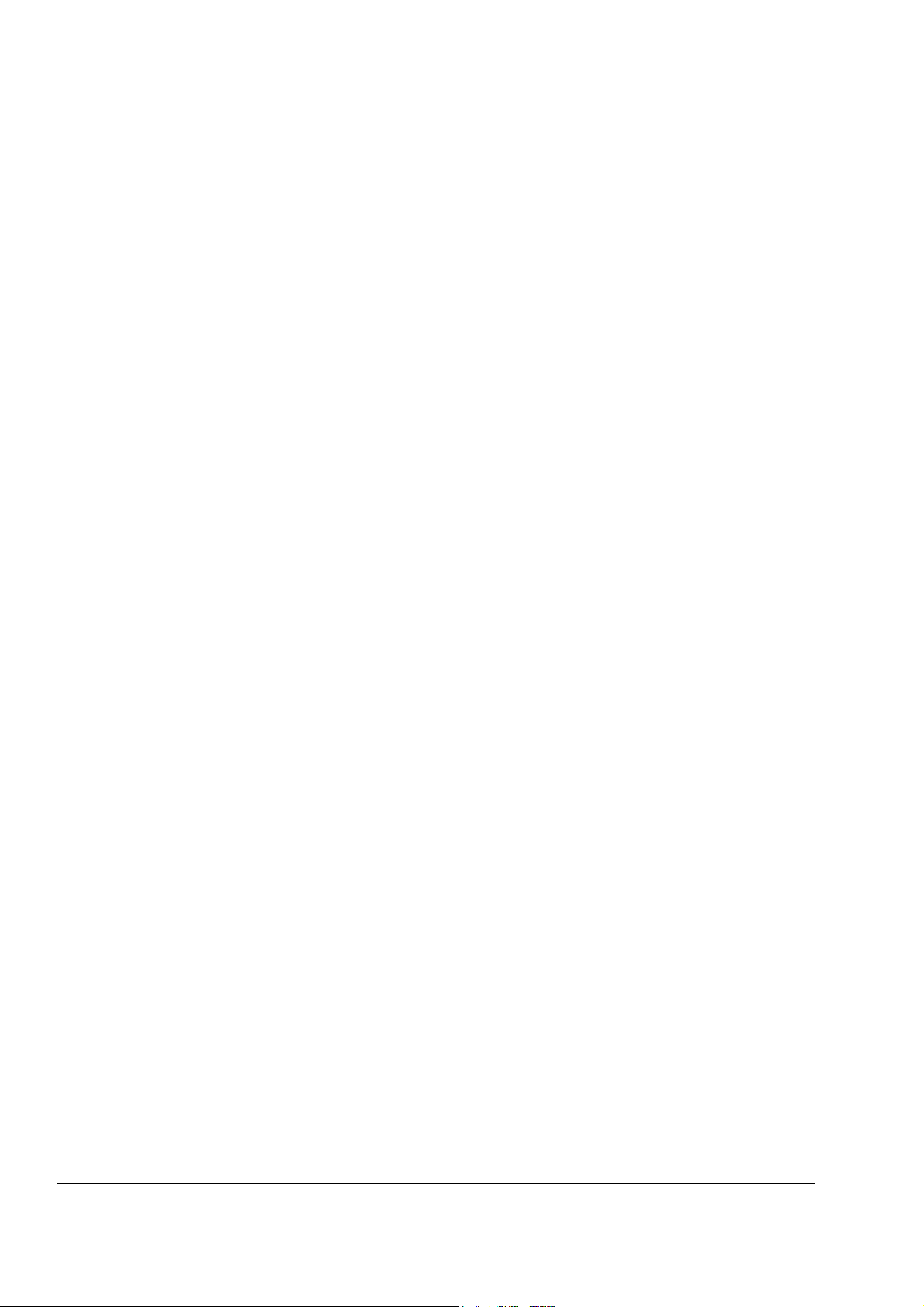

Quick installation and commissioning flowchart

Task See

Identify the frame size of your drive: R0…R2. Operation principle and hardware description:

Type designation key on page 22

Technical data: Ratings on page 137

17

Plan the installation: select the cables, etc.

Check the ambient conditions, ratings and required

cooling air flow.

Unpack and check the drive. Mechanical installation: Unpacking on page 24

If the drive is connected to an IT (ungrounded) or

corner-grounded system, check that the internal EMC

filter is not connected.

Install the drive on a wall or in a cabinet. Mechanical installation on page 23

Route the cables. Planning the electrical installation: Routing the

Planning the electrical installation on page 29

Technical data on page 137

Operation principle and hardware description:

Type designation key on page 22 Electrical

installation: Checking the compatibility with IT

(ungrounded) and corner-grounded TN

systems on page 40

cables on page 34

Check the insulation of the input cable and the motor

and the motor cable.

Connect the power cables. Electrical installation: Connecting the power

Connect the control cables. Electrical installation: Connecting the control

Check the installation. Installation checklist on page 49

Commission the drive. Start-up and control with I/O on page 51

Electrical installation: Checking the insulation of

the assembly on page 39

cables on page 41

cables on page 44

Introduction to the manual

18

Introduction to the manual

Operation principle and hardware description

Capacitor

bank

U2

V2

W2

AC motor

M

3~

Rectifier Inverter

Brake chopper

U1

V1

W1

BRK- BRK+

AC supply

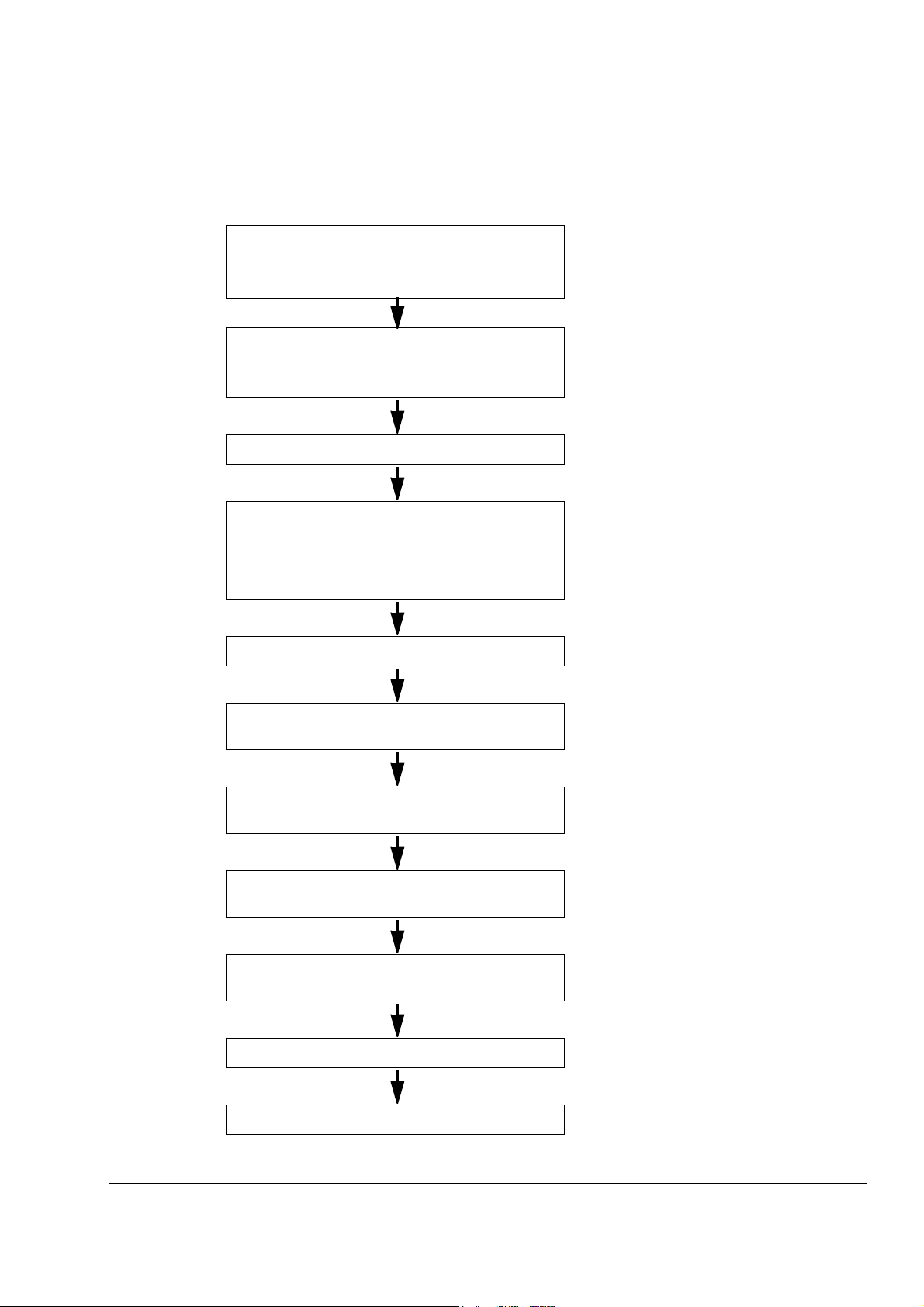

What this chapter contains

The chapter briefly describes the operation principle, layout, type designation label

and type designation information. It also shows a general diagram of power

connections and control interfaces.

Operation principle

The ACS150 is a wall or cabinet mountable drive for controlling AC induction motors.

The figure below shows the simplified main circuit diagram of the drive. The rectifier

converts three-phase AC voltage to DC voltage. The capacitor bank of the

intermediate circuit stabilizes the DC voltage. The inverter converts the DC voltage

back to AC voltage for the AC motor. The brake chopper connects the external brake

resistor to the intermediate DC circuit when the voltage in the circuit exceeds its

maximum limit.

19

Operation principle and hardware description

20

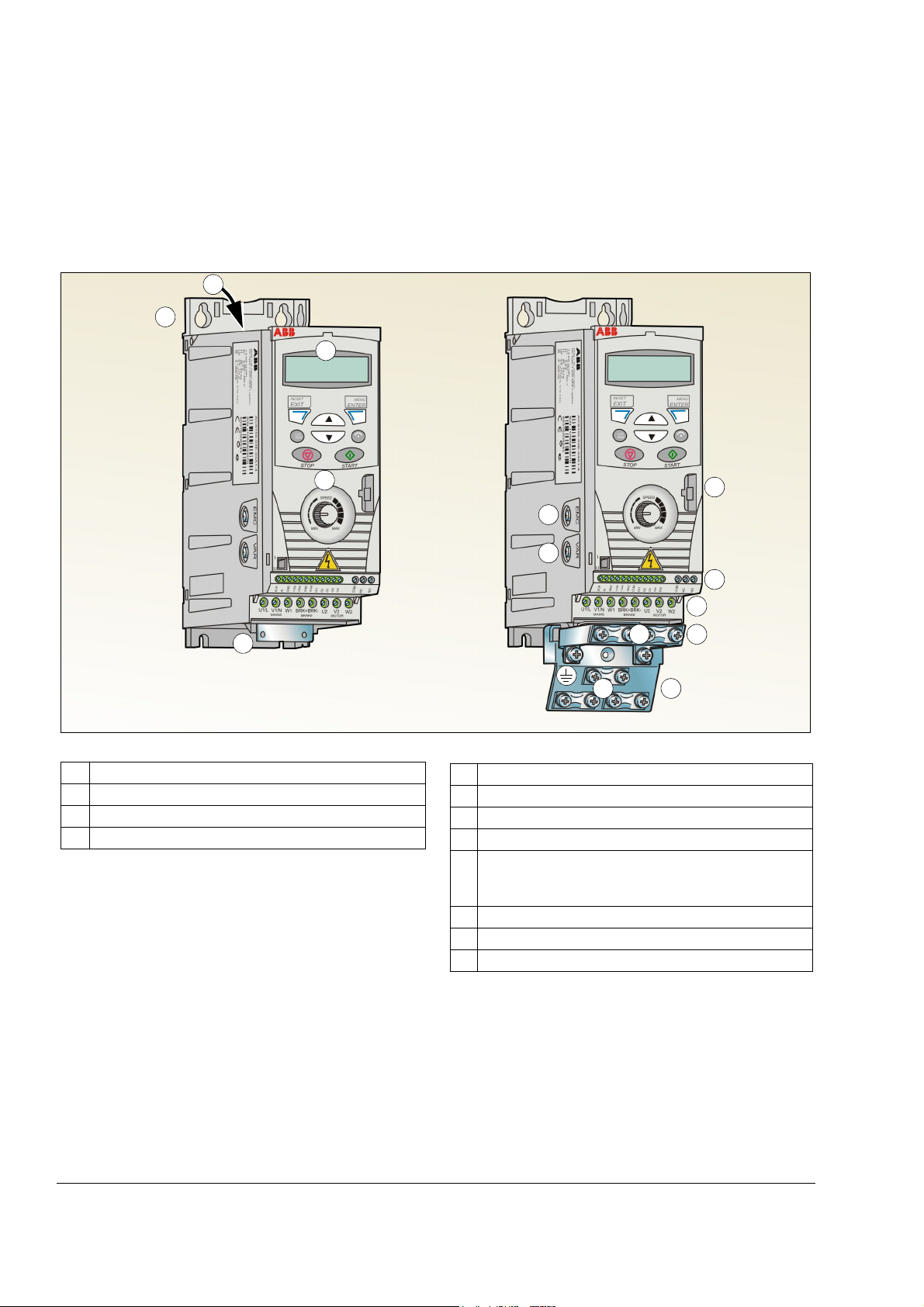

5

9

8

6

7

10

1112

12

5 FlashDrop connection

6 EMC filter grounding screw (EMC)

7 Varistor grounding screw (VAR)

8 I/O connections

9 Input power connection (U1, V1, W1), brake resistor

connection (BRK+, BRK-) and motor connection (U2,

V2, W2)

10 I/O clamping plate

11 Clamping plate

12 Clamps

1 Cooling outlet through top cover

2 Mounting holes

3 Integrated control panel

4 Integrated potentiometer

With plates (R0 and R1)

Without plates (R0 and R1)

1

2

3

4

2

Product overview

Layout

The layout of the drive is presented below. The construction of frame sizes R0…R2

varies to some extent.

Operation principle and hardware description

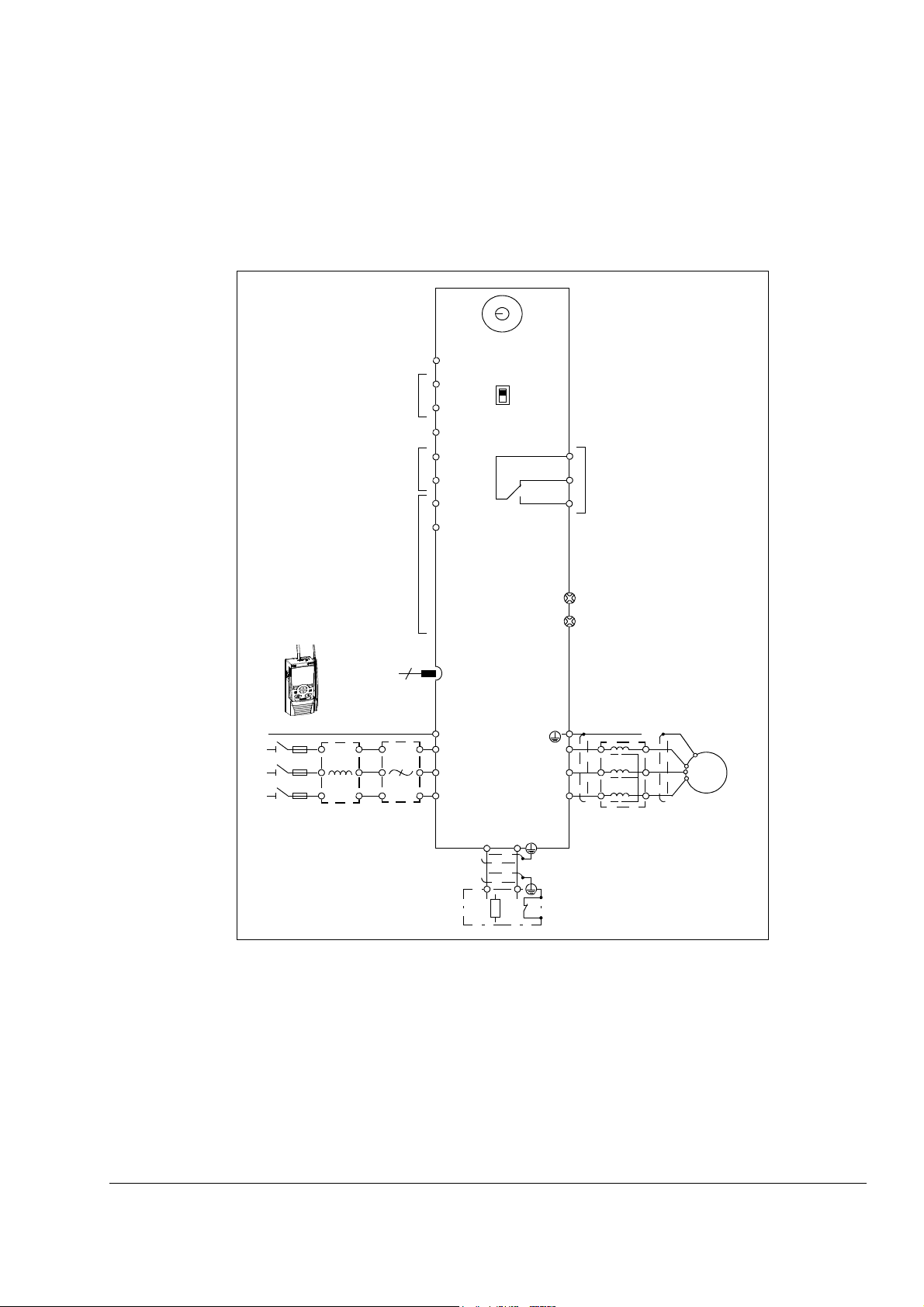

Power connections and control interfaces

NO

NC

DI1

DI2

DI3

DI4

DI5

+24 V

Aux. voltage output

+24 V DC, max. 200 mA

GND

COM

Relay output

250 V AC / 30 V DC / 6 A

GND

+10V

Reference voltage

+10 V DC, max. 10 mA

AI

Analog input

0…10 V

SCR

Screen

L1

U2

V2

W2

AC motor

M

3 ~

EMC

VAR

EMC filter grounding screw

Varistor grounding screw

COM

L2

L3

PE

PROGRAMMABLE

DIGITAL INPUTS

U1

V1

W1

DI5 can also be used

as a frequency input

t°

Brake resistor

BRK+ BRK-

Brake chopper

Output

choke

PE

Input

choke

EMC

filter

3-phase

power

supply,

200…480

VAC

U

I

S1

AI

Potentiometer

FlashDrop

6

The diagram gives an overview of connections. The I/O connections are

parameterable. See chapter Application macros on page 69 for the I/O connections

for the different macros and chapter Electrical installation on page 39 for installation

in general.

21

Note: For 1-phase power supply, connect power to U1/L and V1/N terminals. For

connecting the power cables, see Connecting the power cables on page 41.

Operation principle and hardware description

22

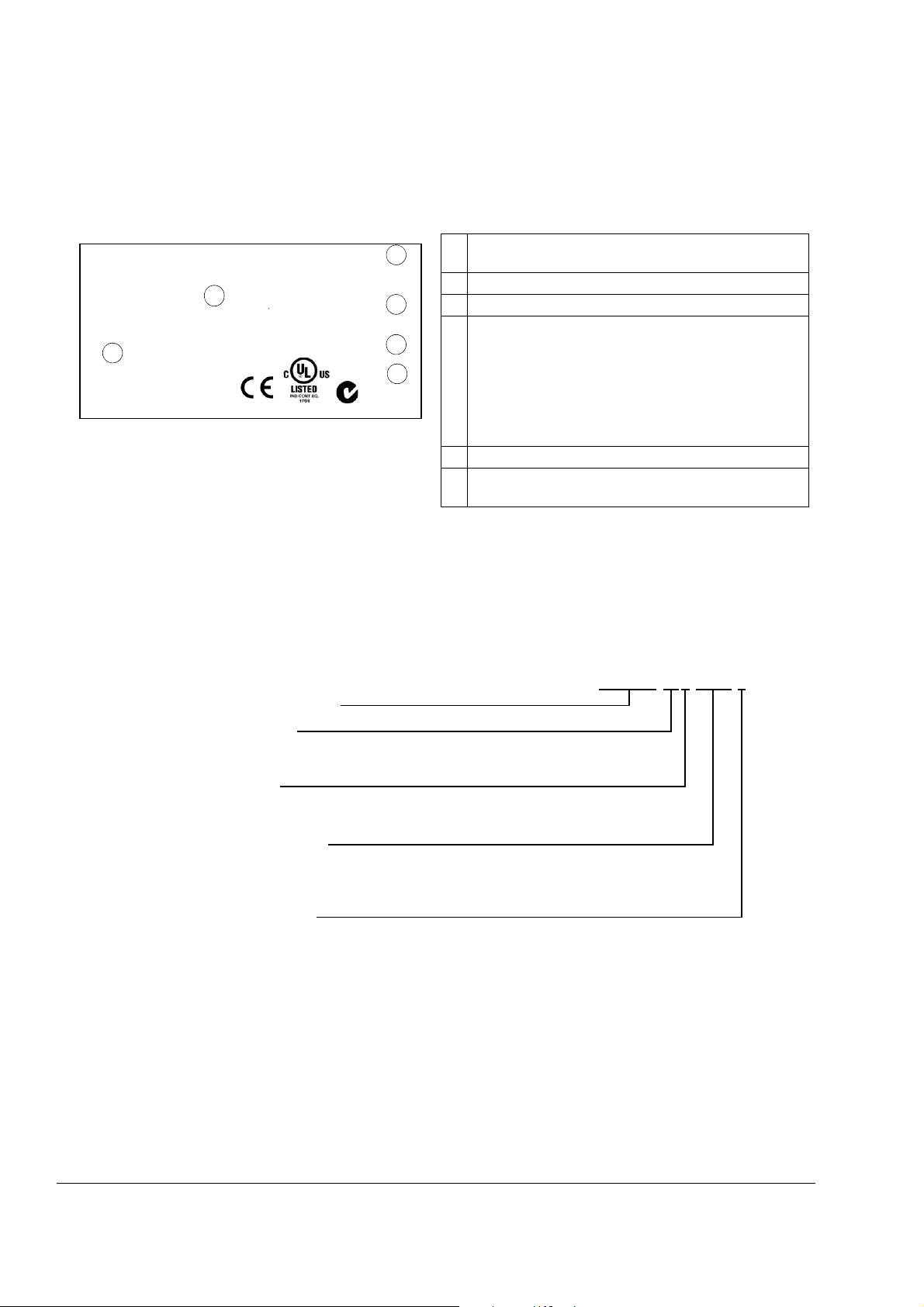

1 ! ! ""!#

$% &'() ///////////////////////

#*+,$- &.++////

'0 1" 2#"

////////////////////////////

0 034 4"581818

0 #"245

'% 1 2'0

% "3",0 60&0 7-

% 2 5

MYYWWRXXXX

4"581818

Type designation label

1 Type designation, see section Type designation key on

page 22

2 Degree of protection by enclosure (IP and UL/NEMA)

3 Nominal ratings, see section Ratings on page 137.

4 Serial number of format MYYWWRXXXX, where

M: Manufacturer

YY: 09, 10, 11, … for 2009, 2010, 2011, …

WW: 01, 02, 03, … for week 1, week 2, week 3, …

R: A, B, C, … for product revision number

XXXX: Integer starting every week from 0001

5 ABB MRP code of the drive

6 CE marking and C-Tick, C-UL US and RoHS marks

(the label of your drive shows the valid markings)

2

3

4

5

1

RoHS

6

ACS150-03E-08A8-4

ACS150 product series

01 = 1-phase input

03 = 3-phase input

1-phase/3-phase

In format xxAy, where xx indicates the integer part and y the fractional part,

for example, 08A8 means 8.8 A.

For more information, see section Ratings on page 137.

Output current rating

2 = 200…240 V AC

4 = 380…480 V AC

Input voltage range

E = EMC filter connected, 50 Hz frequency

U = EMC filter disconnected, 60 Hz frequency

Configuration

Type designation label

The type designation label is attached to the left side of the drive. An example label

and explanation of the label contents are shown below.

Type designation key

The type designation contains information on the specifications and configuration of

the drive. You find the type designation label attached to the drive. The first digits

from the left express the basic configuration, for example ACS150-03E-08A8-4. The

explanations of the type designation label selections are described below.

Operation principle and hardware description

Mechanical installation

What this chapter contains

The chapter describes tells how to check the installation site, unpack, check the

delivery and install the drive mechanically.

Checking the installation site

The ACS150 may be installed on the wall or in a cabinet. Check the enclosure

requirements for the need to use the NEMA 1 option in wall installations (see chapter

Technical data on page 137).

The drive can be mounted in four different ways:

a) vertical back mounting (all frame sizes)

b) horizontal back mounting (frame sizes R1…R2)

c) vertical side mounting (all frame sizes)

23

d) vertical DIN rail mounting (all frame sizes).

Check the installation site according to the requirements below. Refer to chapter

Dimension drawings on page 155 for frame details.

Requirements for the installation site

Operation conditions

See chapter Technical data on page 137 for the allowed operation conditions of the

drive.

Wall

The wall should be as close to vertical and even as possible, of non-flammable

material and strong enough to carry the weight of the drive.

Floor

The floor/material below the installation should be non-flammable.

Free space around the drive

In vertical mounting, the required free space for cooling above and below the drive is

75 mm (3 in). No free space is required on the sides of the drive, so the drives can

be mounted immediately next to each other.

When you install the drive horizontally, you need to have free space both above and

below AND on the sides of the drive. For more information, see the figure in section

Horizontally on page 27.

Mechanical installation

24

1

2

4

3

Required tools

To install the drive, you need the following tools:

• screwdrivers (as appropriate for the mounting hardware used)

• wire stripper

• tape measure

• drill (if the drive is installed with screws/bolts)

• mounting hardware: screws or bolts (if the drive is installed with screws/bolts). For

Unpacking

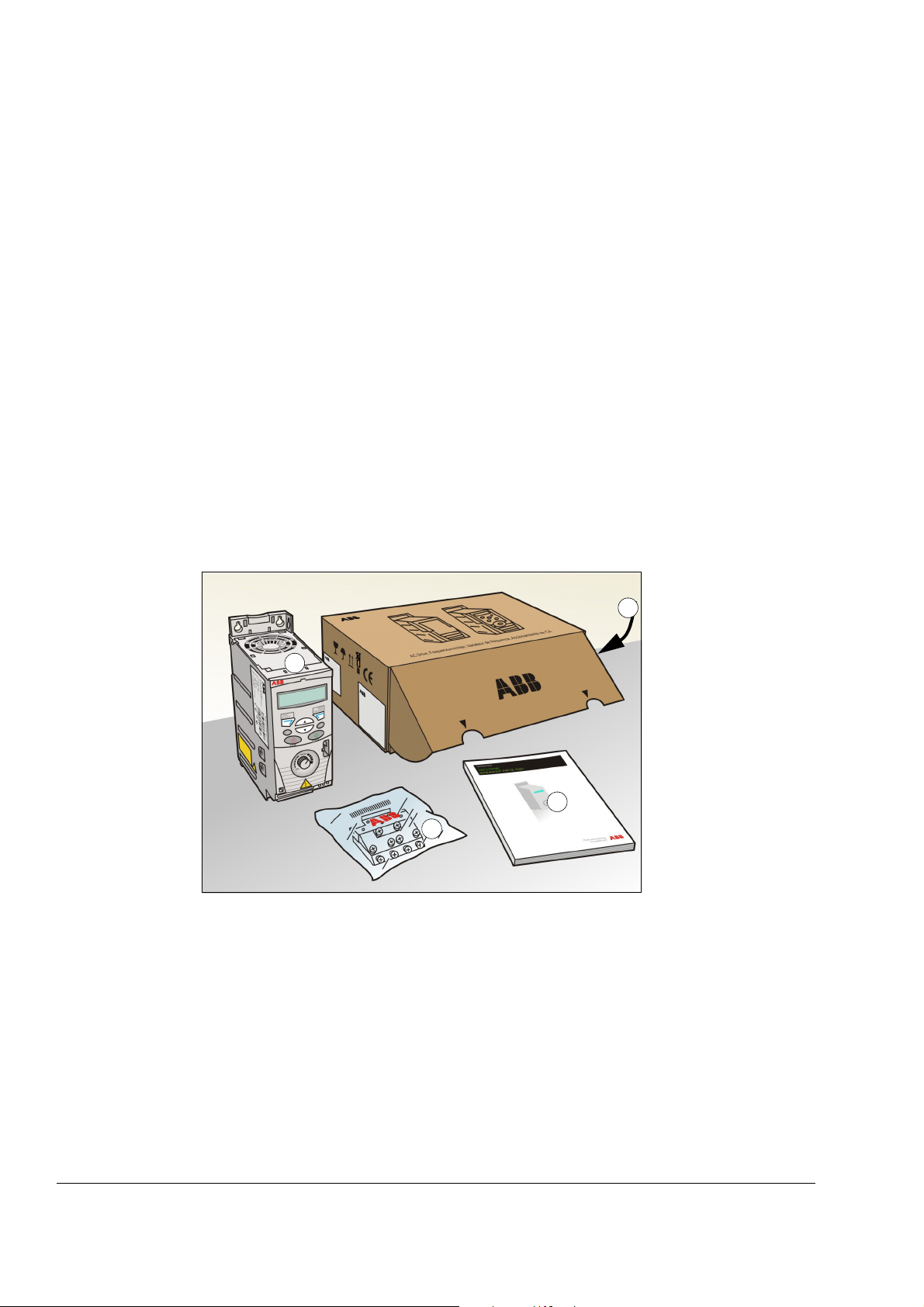

The drive (1) is delivered in a package that also contains the following items (frame

size R0 shown in the figure):

• plastic bag (2) including clamping plate, I/O clamping plate, clamps and screws

• mounting template, integrated into the package (3)

• user’s manual (4).

the number of screws/bolts, see section With screws on page 25.

Mechanical installation

Checking the delivery

1

2

2

Check that there are no signs of damage. Notify the shipper immediately if damaged

components are found.

Before attempting installation and operation, check the information on the type

designation label of the drive to verify that the drive is of the correct type. See

section Type designation label on page 22.

Installing

The instructions in this manual cover drives with the IP20 degree of protection. To

comply with NEMA 1, use the MUL1-R1 option kit, which is delivered with

multilingual installation instructions (3AFE68642868).

Install the drive

Install the drive with screws or on a DIN rail as appropriate.

Note: Make sure that dust from drilling does not enter the drive during the

installation.

25

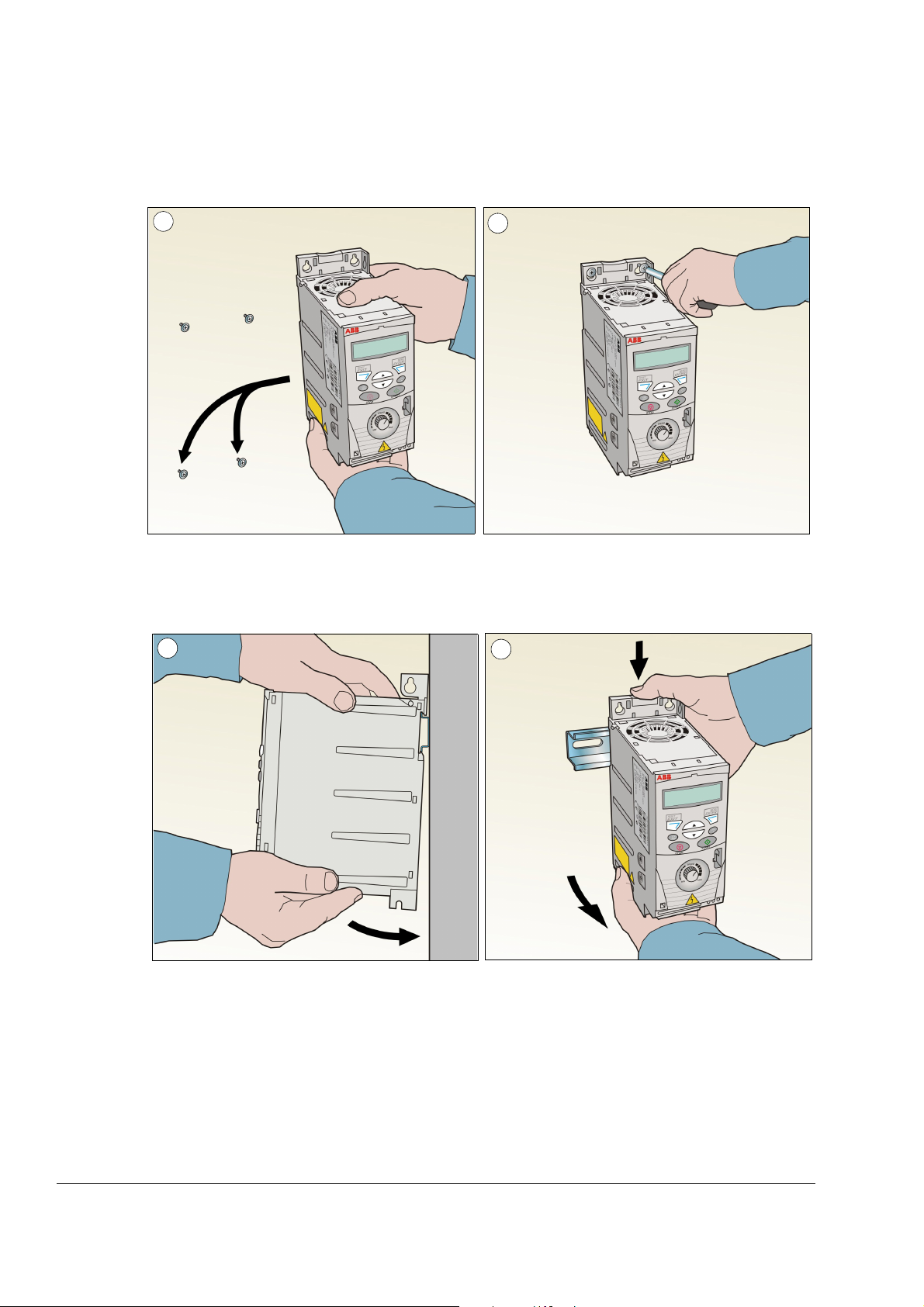

With screws

For installing the drive horizontally, see section Horizontally on page 27.

1. Mark the hole locations using for example, the mounting template cut out from the

package. The locations of the holes are also shown in the drawings in chapter

Dimension drawings on page 155. The number and location of the holes used

depend on how the drive is installed:

a) back mounting: four holes

b) side mounting: three holes; one of the bottom holes is located in the clamping

plate.

2. Fix the screws or bolts to the marked locations.

Mechanical installation

26

3

4

1

1b

3. Position the drive onto the screws on the wall.

4. Tighten the screws in the wall securely.

On DIN rail

1. Click the drive to the rail. To detach the drive, press the release lever on top of the

drive as shown in Figure 1b.

Mechanical installation

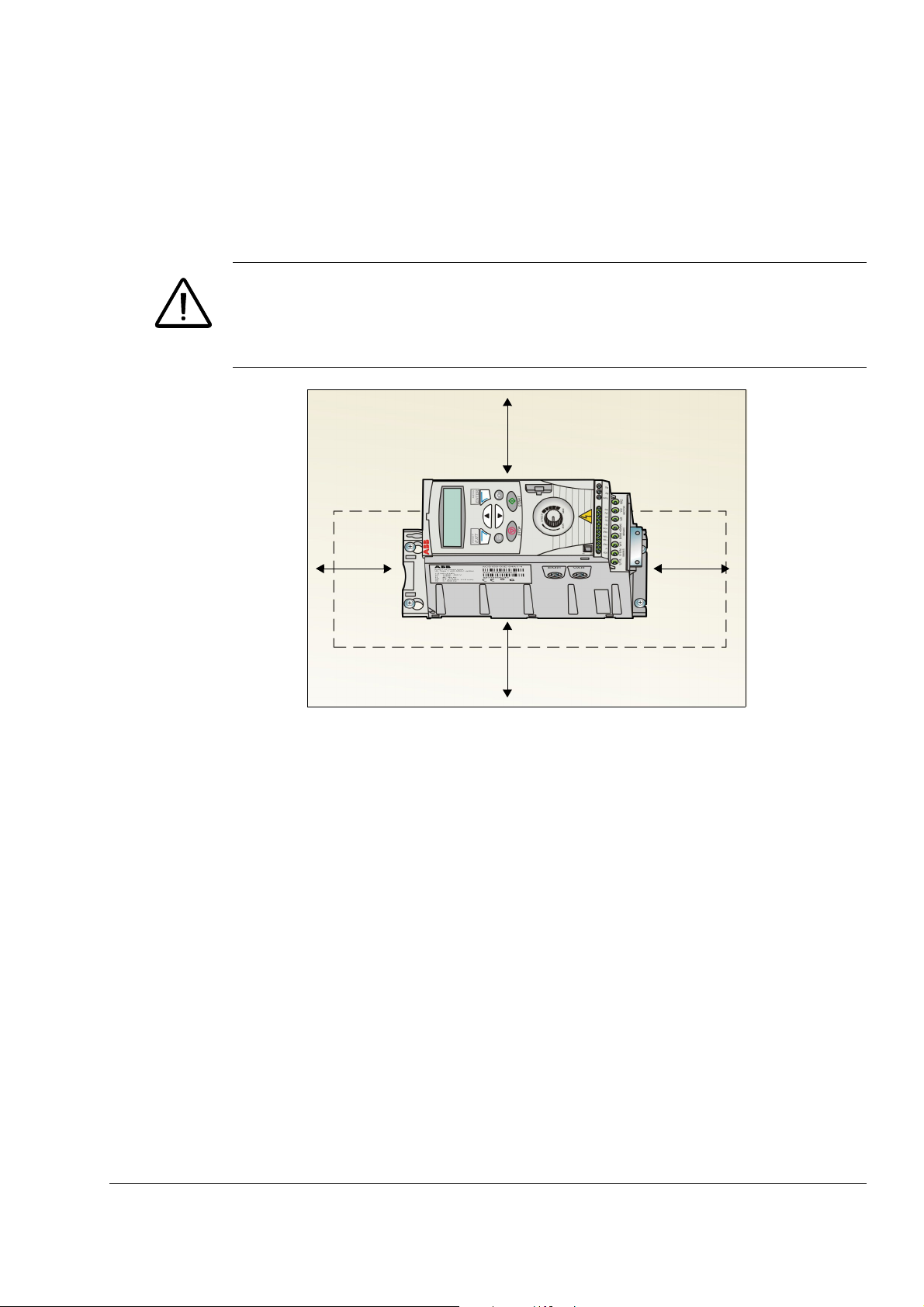

Horizontally

25 cm

25 cm

75 cm 75 cm

You can install the drive horizontally with screws (only back mounting, four holes).

For the installation instructions, see section With screws on page 25.

Note: For the required free space, see the following figure.

WARNING! Horizontal mounting is permitted only for frame sizes R1 and R2

because they include a cooling fan. Position the drive so that the connectors at the

bottom of the drive are situated to the right and the fan to the left as shown in the

following figure. Do not install frame size R0 horizontally!

27

Mechanical installation

28

1

2

Fasten clamping plates

Note: Make sure that you do not throw the clamping plates away as they are

required for proper grounding of the power and control cables.

1. Fasten the clamping plate to the plate at the bottom of the drive with the provided

screws.

2. Fasten the I/O clamping plate to the clamping plate with the provided screws.

Mechanical installation

Planning the electrical installation

What this chapter contains

The chapter contains the instructions that you must follow when when checking the

compatibility of the motor and drive, and selecting cables, protections, cable routing

and way of operation for the drive.

Note: The installation must always be designed and made according to applicable

local laws and regulations. ABB does not assume any liability whatsoever for any

installation which breaches the local laws and/or other regulations. Furthermore, if

the recommendations given by ABB are not followed, the drive may experience

problems that the warranty does not cover.

Implementing the AC power line connection

See the requirements in section Electric power network specification on page 144.

Use a fixed connection to the AC power line.

29

WARNING! As the leakage current of the device typically exceeds 3.5 mA, a fixed

installation is required according to IEC 61800-5-1.

Selecting the supply disconnecting device (disconnecting means)

Install a hand-operated supply disconnecting device (disconnecting means) between

the AC power source and the drive. The disconnecting device must be of a type that

can be locked to the open position for installation and maintenance work.

European union

To meet the European Union Directives, according to standard EN 60204-1, Safety

of Machinery, the disconnecting device must be one of the following types:

• a switch-disconnector of utilization category AC-23B (EN 60947-3)

• a disconnector having an auxiliary contact that in all cases causes switching

devices to break the load circuit before the opening of the main contacts of the

disconnector (EN 60947-3)

• a circuit breaker suitable for isolation in accordance with EN 60947-2.

Other regions

The disconnecting device must conform to the applicable safety regulations.

Planning the electrical installation

30

Checking the compatibility of the motor and drive

Check that the 3-phase AC induction motor and the drive are compatible according

to the rating table in section Ratings on page 137. The table lists the typical motor

power for each drive type.

Selecting the power cables

General rules

Dimension the input power and motor cables according to local regulations.

• The input power and the motor cables must be able to carry the corresponding

load currents. See section Ratings on page 137 for the rated currents.

• The cable must be rated for at least 70

the conductor in continuous use. For US, see section Additional US requirements

on page 32.

• The conductivity of the PE conductor must be equal to that of the phase

conductor (same cross-sectional area).

• 600 V AC cable is accepted for up to 500 V AC.

• Refer to chapter Technical data on page 137 for the EMC requirements.

A symmetrical shielded motor cable (see the following figure) must be used to meet

the EMC requirements of the CE and C-Tick marks.

A four-conductor system is allowed for input cabling, but a shielded symmetrical

cable is recommended.

Compared to a four-conductor system, the use of a symmetrical shielded cable

reduces electromagnetic emission of the whole drive system as well as motor

bearing currents and wear.

°C maximum permissible temperature of

Planning the electrical installation

Loading...

Loading...