Page 1

Advant® OCS

with Master software

Advant Controller 410

Version 1.5/2

Product Guide

3BSE 015 966R201 Rev B

Page 2

Use of DANGER, WARNING, CAUTION, and NOTE

This publication includes, DANGER, WARNING, CAUTION, and NOTE information where appropriate to point out safety

related or other important information.

DANGER Hazards which could result in severe personal injury or death

WARNING Hazards which could result in personal injury

CAUTION Hazards which could result in equipment or property damage

NOTE Alerts user to pertinent facts and conditions.

Although DANGER and WARNING hazards are related to personal injury, and CAUTION hazards are associated with

equipment or property damage, it should be understood that operation of damaged equipment could, under certain operational

conditions, result in degraded process performance leading to personal injury or death. Therefore, comply fully with all

DANGER, WARNING, and CAUTION notices.

TRADEMARKS

Master, MasterPiece, MasterView and MasterAid are registered trademarks of ABB Ltd MasterNet, MasterBus, and

MasterBatch are trademarks of ABB A sea Brown Bo veri Ltd. Advan t, AdvaComman d, AdvaIn form, AdvaB uild, AdvaS oft and

AdvaControl are reg. trademarks of ABB Process Automation Corp. HART is a trademark of HART Communication

Foundation. Echelon, LON, LonTalk, L

ONWORKS, LONMARK, and Neuron are registered trademarks of Echelon Corporation.

HP and all HP-products are registered trademarks of Hewlett-Packard Company. IBM and all IBM-products are trademarks of

International Business Machines Corporation. KERMIT is copyright 1985, Trustees of Colombia University. Lotus 1-2-3 is a

trademark of Lotus Development Corporation. MATLAB is a registered trademark of The MathWorks Inc, USA. MODBUS is a

registered trademark of GOULD Electronics. MOTIF and OSF are trademarks of Open Software Foundation. MS-DOS,

Microsoft, Microsoft Excel, and Word for Windows are registered trademarks of Microsoft Corporation. Postscript is a

registered trademark of Adobe Systems Inc.

PROFIBUS and PROFIBUS-DP are trademarks of Profibus International (P.I.).

Siemens and all Siemens-products mentioned in this publication are trademarks of Siemens AG. UNIX is a registerd trademark

of AT&T Corporation. VAX, VMS, Digital, DEC, VT100 - VT420 are trademarks of Dig ital Eqipmen t Corporat ion. X-window

Systems is a trademark of Massachusetts Institute of Technology. All rights to other Trademarks reside with their respective

owners.

NOTICE

The information in this document is subject to change without notice and should not be construed as a commitment by ABB

Automation Products AB. ABB Automation Products AB as sumes no responsibility for any errors that may appear in this

document.

In no event shall ABB Automation Products AB be liable for direct, indirect, special, incidental or consequential damages of

any nature or kind arising from the use of this document, nor shall ABB Automation Products AB be liable for incidental or

consequential damages arising from use of any software or hardware described in this document.

This document and parts thereof must not be rep roduced or cop ied without ABB Auto mation Produ cts AB’s written permission,

and the contents thereof must not be imparted to a third party nor be used for any unauthorized purpose.

The software described in this document is furnished under a license and may be used, copied, or disclosed only in accordance

with the terms of such license.

CE MARKING

This product meets the requirements specified in EMC Directive 89/336/EEC and in Low Voltage Directive 72/23/EEC.

Copyright © ABB Automation Products AB 2001

Template: 3BSE001286/E

3BSE 015 966R201 Rev B

3BSE001264/E

Page 3

Advant Controller 410 Product Guide

Table of Contents

TABLE OF CONTENTS

Chapter 1 - Overview

1.1 Product Benefits.................................................................................. ..... ...... .......... 1-1

1.2 Features....................................................................................................................1-2

Chapter 2 - Functional Description

2.1 General Controller Utilities ..................................................................................... 2-1

2.1.1 CPU......................................................................................................... 2-1

2.1.2 Memory and Backup.............................. ..... ...... ...................................... 2-1

2.1.3 System Clock, External Clock Synchronization ..................................... 2-2

2.1.4 Configuration.......................................................................................... 2-2

2.1.5 Execution................................................................................................2-2

2.1.6 Start-up....................................................................................................2-3

2.2 Process Control........................................................................................................ 2-3

2.3 I/O System Support................................................. ............................................. ....2-5

2.4 Time Tagging of Events and Alarms....................................................................... 2-5

2.5 Pulse Counting and Positioning............................................................................... 2-5

2.6 Switchgear Integration............................................................................................. 2-6

2.7 Drives Integration.................................................................................................... 2-6

2.8 Variable Speed Drive Control..................................................................................2-7

2.9 Communication........................................................................................................ 2-7

2.10 AdvaCommand Support .......................................................................................... 2-8

2.11 Local Operator Station MasterView 320 ................................................................. 2-9

2.12 Local Printer .......................................................................................................... 2-10

2.13 Scope of Controller Functions...............................................................................2-10

Chapter 3 - Software Components

3.1 Overview.................................................................................................................. 3-1

3.2 Basic Program Module, QC01-BAS11....................................................................3-1

3.3 Optional Program Module, QC01-LIB11................................................................ 3-4

3.4 Optional Program Module, QC01-LIB12................................................................ 3-5

3.5 Optional Program Module, QC01-OPF11...............................................................3-6

3.6 Optional Program Module, QC01-LOS11............................................................... 3-6

3.7 Optional Program Module, QC01-BAT11...............................................................3-6

3.8 Optional Program Module, QC01-UDP11 .............................................................. 3-6

3BSE 015 966R201 Rev B i

Page 4

Advant Controller 410 Product Guide

Table of Contents

Chapter 4 - Hardware Components

4.1 Processor Module.....................................................................................................4-1

4.2 Program Card...........................................................................................................4-3

4.3 Submodule Carriers..................................................................................................4-3

4.4 Submodules..............................................................................................................4-3

4.5 Subrack.....................................................................................................................4-4

4.6 System Unit........................................... ...... ............................................. ...... ..... .....4-5

4.7 I/O Systems..............................................................................................................4-5

4.8 Communication........................................................................................................4-5

4.9 Power Supply System ............................................................................................4-11

4.10 ESD Protection.......................................................................................................4-13

4.11 CE marked equipment............................................................................................4-13

CONTENTS (continued)

4.8.1 Control Network......................................................................................4-6

4.8.2 Fieldbus Communication................. ............................................. ..... .....4-6

4.8.3 External Communication ......................................................................4-10

4.8.4 Telecontrol & SPA Bus .........................................................................4-11

4.9.1 Mains Network Types ...........................................................................4-12

4.9.2 Redundancy, Mains Power Supply .......................................................4-12

4.9.3 Configuration Alternatives....................................................................4-12

Chapter 5 - Mechanical Design

5.1 Cabinet Design.........................................................................................................5-1

5.2 Product Design.........................................................................................................5-2

5.2.1 Standard Version of Advant Controller 410............................................5-2

5.2.2 Compact Version of Advant Controller 410............................................5-4

Chapter 6 - Technical Data and Performance

6.1 PC Program..............................................................................................................6-1

6.2 I/O Signals................................................................................................................6-1

6.3 I/O Boards................................................................................................................6-2

6.3.1 Connection Unit Dimensions.................................................. ...... ..........6-3

6.4 Functional Units.................................................................................................. .....6-4

6.5 Communication........................................................................................................6-5

6.5.1 Data Set and Text Set..............................................................................6-5

6.5.2 Data Set Peripheral (DSP).......................................................................6-5

6.5.3 Communication buses.............................................................................6-5

ii 3BSE 015 966R201 Rev B

Page 5

Advant Controller 410 Product Guide

Table of Contents

CONTENTS (continued)

6.6 Time Synchronization..............................................................................................6-7

6.7 Time Tagging of Events (Alarms)...........................................................................6-7

6.8 Trend Data Storage..................................................................................................6-8

6.9 CPU Load Calculation.............................................................................................6-9

6.9.1 CPU Load from Data Set Communication............................................6-11

6.9.2 CPU Load from Data Set Peripheral Communication...........................6-11

6.10 Read/Write Memory (RAM) Requirements .......................................................... 6-12

6.11 Program Module Size on Program Card................................................................ 6-14

6.12 Controller Subrack.................................................................................................6-15

6.13 Cabinet RM500....................................................... ..... ..........................................6-15

6.13.1 Mounting Bars for Connection Units.................................................... 6-16

Chapter 7 - Environmental Immunities

7.1 Environmental Considerations............................................................................. ....7-1

Chapter 8 - Ordering

8.1 Price List Structure .................................................................................................. 8-1

8.2 Basic Software License...................................................... ......................................8-1

8.3 Assembled Delivery or Loose Part Delivery ........................................................... 8-2

8.4 Loose Part Delivery and CE-marking......................................................................8-2

8.5 Non Standard Program Modules.............................................................................. 8-2

8.6 Heat Exchanger........................................................................................................8-2

8.7 Reference Guide for standard Advant Controller 410............................................. 8-3

8.7.1 General Requirements............................................................................. 8-3

8.7.2 System Units........................................................................................... 8-3

8.7.3 Software Licenses...................................................................................8-4

8.7.4 Software Options.................................................................................... 8-4

8.7.5 Special Applications............................................................................... 8-5

8.7.6 System Software Back-up Card.................................................... ...... ....8-6

8.7.7 Hardware Options ..................................................................................8-6

8.7.8 Communication....................................................................................... 8-7

8.7.9 Printers.................................................................................................. 8-12

8.7.10 Power Supply System ............... ............................................. ...... ...... ..8-13

8.7.11 S100 I/O System................................................................................... 8-17

8.7.12 Cabinets ................................................................................................ 8-26

8.7.13 Documentation......................................................................................8-27

8.7.14 Software Utilities.................. ................................................................ 8-32

3BSE 015 966R201 Rev B iii

Page 6

Advant Controller 410 Product Guide

Table of Contents

8.8 Reference Guide for Compact Version of AC 410.................................................8-32

CONTENTS (continued)

8.8.1 System Units .......................................................................................8-32

8.8.2 Software Licenses.................................................................................8-33

8.8.3 Software Options ..................................................................................8-33

8.8.4 Special Applications..............................................................................8-33

8.8.5 System Software Back-up Card ............................................................8-34

8.8.6 Hardware Options.................................................................................8-35

8.8.7 Communication.....................................................................................8-35

8.8.8 Documentation......................................................................................8-41

8.8.9 Software Utilities ..................................................................................8-44

iv 3BSE 015 966R201 Rev B

Page 7

Advant Controller 410 Product Guide

Table of Contents

ILLUSTRATIONS

Figure 1-1. Advant Controller 410 with S100 I/O.......................................................... 1-1

Figure 2-1. AC 400 Series configuration with INSUM Motor Controller......................2-6

Figure 2-2. AC 400 Series configuration with drive....................................................... 2-7

Figure 2-3. Example of display from MasterView 320................................................... 2-9

Figure 4-1. Front View of the PM150V Processor Module............................................4-2

Figure 4-2. The processor module, PM150V, within the S100 I/O subrack...................4-4

Figure 4-3. MasterBus 300/300E connected to Advant Controller 410..........................4-6

Figure 4-4. Advant Fieldbus 100 using Coaxial Media connected to

Advant Controller 410................................................................................. 4-6

Figure 4-5. Advant Fieldbus 100 using Twisted Pair Media connected to

Advant Controller 410.................................................................................. 4-7

Figure 4-6. Advant Fieldbus 100 using Media Redundancy connected to

Advant Controller 410.................................................................................. 4-7

Figure 4-7. Advant Fieldbus 100 using Bus Redundancy connected to

Advant Controller 410................................................................................. 4-8

Figure 4-8. RCOM/RCOM+ connected to Advant Controller 410................................. 4-8

Figure 4-9. PROFIBUS-DP connected to Advant Controller 410.................................. 4-9

Figure 4-10. LONWORKS connected to Advant Controller 410..................................... 4-9

Figure 4-11. MasterFieldbus connected to Advant Controller 410................................. 4-10

Figure 4-12. EXCOM connected to Advant Controller 410........................................... 4-10

Figure 4-13. MultiVendor Interface connected to Advant Controller 410......................4-10

Figure 4-14. GCOM connected to Advant Controller 410...............................................4-11

Figure 4-15. Telecontrol and SPA Bus connected to Advant Controller 410..................4-11

Figure 4-16. Block diagram of power supply without redundancy................................. 4-13

Figure 4-17. Block diagram of power supply with redundancy.................................... ..4-13

Figure 5-1. Typical Cabinet Configuration, Redundant Power Supply.......................... 5-1

Figure 5-2. Maximum cabinet configuratio n for Advan t Controller 410 with

S100 I/O assembled in RM500V1 cabinets.................................................. 5-2

Figure 5-3. Cabinet configuration for Advant Controller 410 assembled in RM500V2

cabinets......................................................................................................... 5-3

Figure 5-4. Compact version of Advant Controller 410 .................................................5-4

Figure 5-5. The size of the compact version of the Advant Controller 410.................... 5-5

Figure 6-1. The division of the I/O subrack.................................................................. 6-15

3BSE 015 966R201 Rev B v

Page 8

Advant Controller 410 Product Guide

Table of Contents

vi 3BSE 015 966R201 Rev B

Page 9

Advant Controller 410 Product Guide

Table of Contents

TABLES

Table 2-1. S800 I/O modules supported by Advant Controller 410..............................2-5

Table 2-2. Functions and configuration alternatives for Advant Controller 410......... 2-10

Table 3-1. PC elements in the basic program module QC01-BAS11............................ 3-2

Table 3-2. Functional units in the base program module QC01-BAS11....................... 3-3

Table 3-3. Additional PC elements in program module QC01-LIB11.......................... 3-4

Table 3-4. Additional PC elements in program module QC01-LIB12.......................... 3-5

Table 3-5. Functional units in the program module QC01-LIB12 ................................ 3-5

Table 4-1. Submodules.................................................................................................. 4-3

Table 4-2. System unit with single voltage regulator....................................................4-5

Table 4-3. System unit with redundant voltage regulator.............................................. 4-5

Table 4-4. Different power supply arrangements for Advant Controller 410 with

S100 I/O.....................................................................................................4-12

Table 5-1. RM500V1 configurations for Advant Controller 410 with S100 I/O .......... 5-3

Table 5-2. RM500V2 configurations for Advant Controller 410 with S100 I/O .......... 5-3

Table 6-1. The I/O limits of Advant Controller 410......................................................6-1

Table 6-2. The max. I/O configuration of Advant Controller 410.................................6-2

Table 6-3. The Width of the Connection Units.............................................................. 6-3

Table 6-4. The functional units limits of Advant Controller 410 ..................................6-4

Table 6-5. Number of buses/channels that can be connected to Advant Controller 4106-5

Table 6-6. Submodules that are possible to mount into the processor module.............. 6-6

Table 6-7. Relative time errors between events (DI signals).........................................6-8

Table 6-8. Data logging capabilities.............................................................................. 6-8

Table 6-9. Execution times............................................................................................ 6-9

Table 6-10. Examples of CPU load ............................................................................... 6-10

Table 6-11. The CPU load caused by data set communication......................................6-11

Table 6-12. T he CPU load caused by data set peripheral communication (cycle time of scan

task = 512 ms) .............................................................................................6-11

Table 6-13. Calculation of RAM Requirement.............................................................. 6-12

Table 6-14. Program module memory area on program card ........................................ 6-14

Table 6-15. The no. of slots in the I/O subrack ............................................................. 6-15

Table 6-16. RM500 cabinets dimensions....................................................................... 6-15

Table 6-17. RM500 cabinet protection classes..............................................................6-16

Table 6-18. Numbers of mounting bars in RM500V1 cabinets.....................................6-16

Table 6-19. Numbers of mounting bars in RM500V2 cabinet ......................................6-17

Table 8-1. General and Normative Requirements.........................................................8-3

Table 8-2. System Units................................................................................................. 8-3

Table 8-3. Processor Modules........................................................................................ 8-4

Table 8-4. AdvaControl Basic Functions and Incremental Licenses............................. 8-4

3BSE 015 966R201 Rev B vii

Page 10

Advant Controller 410 Product Guide

Table of Contents

Table 8-5. Optional Standard Program Modules ...........................................................8-4

Table 8-6. Optional Program Modules for Special Applications...................................8-5

Table 8-7. Telecontrol & SPA Bus.................................................................................8-5

Table 8-8. System Software Back-up Card....................................................................8-6

Table 8-9. Pr ogram Card Interface and back-up flash-PROMs.....................................8-6

Table 8-10. Free-programmable Module .........................................................................8-6

Table 8-11. MasterBus 300 and MasterBus 300E............................................................8-7

Table 8-12. G COM ..........................................................................................................8-7

Table 8-13. Advant Fieldbus 100 for coaxial cable ........................................................8-8

Table 8-14. Advant Fieldbus 100 for twisted pair cable.................................................8-8

Table 8-15. Modems for Advant Fieldbus 100................................................................8-8

Table 8-16. MasterFieldbus..............................................................................................8-9

Table 8-17. Details for MasterFieldbus............................................................................8-9

Table 8-18. Details for PROFIBUS-DP.........................................................................8-10

Table 8-19. Details for LON WORKS Network............................................................8-10

Table 8-20. Connection of MasterView 320, Printer and Excom..................................8-10

Table 8-21. Multi Vendor Interfaces ..............................................................................8-10

Table 8-22. Miscellaneous Communication Equipment................................................8-11

Table 8-23. P rinters........................................................................................................8-12

Table 8-24. Power Supply in RM500V1 Cabinet..........................................................8-13

Table 8-25. Power Supply in RM500V2 Cabinet..........................................................8-14

Table 8-26. Extra Power Supply for Field equipment ...................................................8-15

Table 8-27. Miscellaneous Power Supply Equipment................................................... 8-16

Table 8-28. Mains Supply Filter ....................................................................................8-16

Table 8-29. A nalog Input Sets for S100 I/O ..................................................................8-17

Table 8-30. Redundant Analog Input Sets for S100 I/O................................................8-18

Table 8-31. Analog Output Sets for S100 I/O................................................................8-18

Table 8-32. Analog Input/Output Sets for S100 I/O......................................................8-18

Table 8-33. Redundant Analog Input/Output Sets for S100 I/O....................................8-19

Table 8-34. Pulse Input and Positioning Sets for S100 I/O ...........................................8-19

Table 8-35. Digital Input Sets for S100 I/O...................................................................8-20

Table 8-36. Digital Output Sets for S100 I/O................................................................8-21

Table 8-37. Connection of Thyristor Converters...........................................................8-22

Table 8-38. S100 I/O boards for HART Protocol Interface...........................................8-22

Table 8-39. S100 I/O for Intrinsic Safety Isolator support (without connection units) .8-23

Table 8-40. Mounting Bars for Connection Units..........................................................8-25

Table 8-41. RM500V1 Cabi nets With=800 mm (3 1.5”), Depth=512 mm (20.2”).......8-26

Table 8-42. RM500V2 Cabinets

Table 8-43. RM500 Cabinet Accessories.......................................................................8-26

Width=700 mm (27.6”), Depth=637 mm (25.1”), Height=2225 mm (87.6”)8-26

viii 3BSE 015 966R201 Rev B

Page 11

Advant Controller 410 Product Guide

Table of Contents

Table 8-44. Documentation ........................................................................................... 8-27

Table 8-45. Software Utilities........................................................................................ 8-32

Table 8-46. System Unit ................................................................................................ 8-32

Table 8-47. Processor Modules......................................................................................8-32

Table 8-48. Software Licenses ....................................................................................... 8-33

Table 8-49. Optional Standard Program Modules.........................................................8-33

Table 8-50. Optional Program Modules for Special Application.................................. 8-33

Table 8-51. Telecontrol and SPA Bus............................................................................ 8-34

Table 8-52. System software Back-up Card ..................................................................8-34

Table 8-53. Program Card Interface and back-up flash-PROMs...................................8-35

Table 8-54. Free-programmable Module....................................................................... 8-35

Table 8-55. MasterBus 300 and MasterBus 300E.........................................................8-35

Table 8-56. GCOM ........................................................................................................ 8-36

Table 8-57. Advant Fieldbus 100 for coaxial cable....................................................... 8-36

Table 8-58. Advant Fieldbus 100 for twisted pair cable...............................................8-37

Table 8-59. Modems for Advant Fieldbus 100.............................................................. 8-37

Table 8-60. MasterFiel dbus ...........................................................................................8-38

T able 8-61. Details for PROFIBUS-DP.........................................................................8-38

T able 8-62. Details for LONWORKS Network .................................................... ...... ..8-38

Table 8-63. Connection of MasterView 320, Printer and Excom..................................8-38

Table 8-64. Multi Vendor Interfaces.............................................................................. 8-39

Table 8-65. Miscellaneous Communication Equipment................................................ 8-39

Table 8-66. Documentation on Compact version of Advant Controller 410.................8-41

Table 8-67. Software Utilities........................................................................................ 8-44

3BSE 015 966R201 Rev B ix

Page 12

Advant Controller 410 Product Guide

Table of Contents

x 3BSE 015 966R201 Rev B

Page 13

Chapter 1 Overview

Advant Controller 410 is a medium sized process controller for binary, regulatory and

supervisory control. Its wide-ranging process control and communication capabilities make it

the right choice for medium-sized, but functionally demanding applications in industrial

environments, either standing alone o r as an integrated par t of an Advant OC S system as well as

in any other distributed control system

Advant Controller 410 Product Guide

Section 1.1 Product Benefits

Figure 1-1. Advant Controller 410 with S100 I/O

1.1 Product Benefits

Advant Controller 410 is a full-function process controller in a minimal hardware configuration.

You will have the latest equipment concerning functionality, interoperability and performance.

You will be able to maximize your productivity and at the same time be prepared for easy

integration of tomorrow’s technology at a reasonable cost.

3BSE 015 966R201 Rev B 1-1

Page 14

Advant Controller 410 Product Guide

Chapter 1 Overview

1.2 Features

Advant Controller 410 covers a wide range of funct i ons such as:

• Logic and sequence control.

• Data and text handling.

• Arithmetic, reporting, positioning and regulatory control.

• Highly extended flexibility and scalability - hardware as well as software.

• Self-configuration capabilit ies which makes it possible to add units while the controller is

in full operation.

• Support of a wide range of central and distribu ted I/O modules for maximum configuration

possibilities, with a maximum I/O capacity of 4300 I/O points.

• Support of local and central HMI for manual control operations, event and alarm handling,

trend curve presentation etc.

• Interoperability concerning all commun ication levels from plant floor fieldbuses to highspeed plant network.

• Support of redundant Fieldbus Communication with Advant Fiel dbus 100.

• Support of Advant Fieldbus 100 with cable length up to 13300 meter (43300 feet).

1-2 3BSE 015 966R201 Rev B

Page 15

Chapter 2 Functional Description

2.1 General Controller Utilities

2.1.1 CPU

The processor module PM150V contains the total amount of RAM (Random Access Memory),

which is an 4 or 8 Mbyte dynamic RAM with error correction code. This memory holds the

system program which is in use as well as the controller system configuration and application

program, that is, all memory executed in run time. The processor module is built-up around

a microprocessor, Motorola 68020, running at 25 MHz.

The module front contains the following functions:

• Indicators and a character display for high level system diagnostics.

• The main operable equipment is a four-position rotary switch for start and working mode

selection and a restart push button.

Advant Controller 410 Product Guide

Section 2.1 General Controller Utilities

• The module front also includes a program card interface and four slots for submodules.

• You can connect a configuration and maintenance tool on the module front.

2.1.2 Memory and Backup

System Program Backup

The system program is backed up in flash PROM and loaded to the RAM in connection to

system start. Physically , the st andard system program is stored in one program card (PCMCIA).

Normally the program card should be in place during operation. Additional program cards are

located in program card interface MB510.

Application Program Backup

The controller system configuration and the application program is normally created in an offline or sometimes an on-line configuration session suppo rt ed b y an engineering station.

The work is basically backed up in the en gineerin g st ation e nviro nmen t (har d d isc, flexible disc

or likely ).

To restore a RAM which has been cleared by an accident or a fatal error some measures have

to be taken, automatically and manually. In addition to the automatic loading of the system

program, described above under the heading System Program Backup , somebody has

to manually load the application program backup (including the controller system config uration)

using an engineering station.

As an alternative the Advant Controller 410 can be equipped with an optional flash card

of similar type as the one used for the system pr ogram. The flash card is contained with a DUmp

of Application Programs (DUAP) preferably taken while the controller is in the operation mode.

3BSE 015 966R201 Rev B 2-1

Page 16

Advant Controller 410 Prod uct Guid e

Chapter 2 Functional Description

At need, the controller system configuration and the application program is likewise

automatically loaded from its flash card into the controller RAM. No manual intervention is

needed to get into operation after the interruption.

Flash cards are available in different memory-sizes (2, 4 or 10 Mbytes). Select a type that take

the actual application program.

The system program backup and the application pr ogram b ackup can not be mixed in one si ngle

program card.

Memory Backup Power Supply

The RAM is secured against loss of power for a minimum of four hours by a backup power

supply and battery. This is important for the configured application program, which is basically

not otherwise backed up.

If a longer backup time is desirable, you can use an application program backup (see heading

above).

2.1.3 System Clock, External Clock Synchronization

The processor module PM150V is provided with a calendar clock which is backed up by

the same battery used for memory backup. You can set the date and time from the programming

unit or from a local operator station, for example, MasterView 320. A slow, smaller adjustment

in the interval ±100 s can also be perfor med with the programming unit.

With Advant Controller 410 connected to MasterNet, as a part in a distributed control system,

the synchronization occurs automatically with other stations via a network with an accuracy

better than 3 ms.

2.1.4 Configuration

2.1.5 Execution

If extreme synchronization accuracy is required between controllers (in the order of 2 ms) and

synchronization to an external clock, an external minute pulse signal can be connected to all

systems concerned.

The supervision module SB171 has a special input for external synchronization of

the calendar clock.

You configure the system in accordance with the hardware and software selected, for example,

the number of I/O boards, communication lines, functional units and PC programs.

This is performed using commands from a configuration tool su ch as Advant Station 140 (with

AMPL Control Configuration 1.7 or later product versio ns ) and results in the internal

organization and activation of the data base and program areas.

The execution units in a PC program are normally given cycle times of 10 ms - 2 s (5 ms - 32 s

after reconfiguration). The internal program system (operating system and PC interpreter)

organizes the execution of the units with the periodicity selected, simultaneously performing

other tasks such as communication with a MasterView 320 and programming units.

Ordinarily, you can select the same cycle times for reading in values from digital and analog

boards.

2-2 3BSE 015 966R201 Rev B

Page 17

2.1.6 Start-up

2.2 Process Control

Advant Controller 410 Product Guide

Section 2.1.6 Start-up

The CPU front panel has a rotary switch to select start and working mode. The normal position

of the switch is 1 (AUTO). This means an automatic start when voltage is switched on or when

voltage is recovered after a power failure. At an interruption of voltage, the system stores all

the information necessary for restarting. Whether the system is to continue operations from its

status at the interruption of the voltage or if it is to be reset to zero before restart is selected with

parameters.

The different ways to start are CLEAR, STOP, AUTO or OFF LINE. The way to start is selected

on the basis of the duration of the voltage failure.

You can connect a control module which is activated when the voltage returns and which

executes one cycle to each start alternative. All start modules must belong to the same

PC program. You can define how the process is to start with these control modules.

Alarm can also be blocked at initialization of the I/O boards.

Process control applications are programmed in the ABB Master Programming Language

(AMPL). AMPL is a function-block language with graphic representation.

The building blocks are called PC elements. There is a wide range of PC elements, from simple

AND blocks to complete PID regulators.

Besides the functional PC elements, AMPL also contains several structural elements for

dividing a PC program into suitable modules which can be managed and executed individually.

The controller can be programmed fully on-line, that is, with the program running and

controlling the process.

PC Elements

The range of ready-to-use PC elements is wide and powerful. It contains, for example,

elements for:

• Logic and Time Delays

• Sequence Control

• Data and Text Handling

• Calendar Time Functions

• Arithmetic

• Feedback Control

• Pulse counting and Frequency Measurement

• Positioning

• Reports

• Communication via Fieldbuses

The PC elements are listed under the program modules in Chapter 3, Software Components.

3BSE 015 966R201 Rev B 2-3

Page 18

Advant Controller 410 Prod uct Guid e

Chapter 2 Functional Description

User Defined PC Elements

Another way to implement your frequently used control solution and ensure a fully integrated

engineering environment is to make use of the optional program module User Defined

PC Elements.

A user defined PC element appears in every sense as a standard PC element. Actually

the control solution of a user defined PC element is defined by other PC elements.

By designing your application with user defined PC elements you gain:

• Significant reductio n in tr anslation time.

• Memory saving with reuse.

• Similar documentation in Function Chart Builder and On-line Builder.

• User defined PC element hierarchy.

• Reduc ed man-hours in commissioning and mai ntenance.

Functional Units

A functional unit is a package of different functions, such as PC elements, DB elements, display

elements, dialogs and event and alarm handling. Functional units extend the power of AMPL

and supplement the PC element library for more complex control functions.

Since the functional units are ready-to-use, it simplifies documentation and implementation of

functions with both control function and associated operator’s action via display screen and

keyboard. The operator interface is always co nsistent to impr ove the operator’s interaction with

the process. Application include regulators, sequence control and motor/valve controls.

PC elements and functional units can be used freely together.

The functional units are listed under the program modules in Chapter 3, Software Components

2-4 3BSE 015 966R201 Rev B

Page 19

2.3 I/O System Support

S100 I/O System

S100 I/O boards (up to 15 boards) are located in the same subrack as the CPU. For further

information about S100 I/O, please refer to the Product Guide for S100 I/O.

S800 I/O System

The distributed S800 I/O modules communicate with the Advant Controller 410 over the

Advant Fieldbus 100, via the CI522A interface module. The fieldbus communication between

the controller and the modulebus in the S800 I/O station can be doubled (redundancy).

The range of supported S800 I/O modules is shown in Table 2-1.

Module type Type designation

Advant Controller 410 Product Guide

Section 2.3 I/O System Support

Table 2-1. S800 I/O modules supported by Advant Controller 410

FCI CI810xx, CI820, CI830

AI AI801, AI810, AI820, AI830, AI835, AI890, AI895

AO AO801, AO810, AO820, AO890, AO895

DI DI801, DI810, DI811, DI814, DI820, DI821, DI830, DI831, DI885,

DI890

DO DO801, DO810, DO814, DO815, DO820, DO821, DO890

DP DP820

For further information about S800 I/O please refer to the Product Guide for S800 I/O.

2.4 Time Tagging of Events and Alarms

The time tagging of digital input signals can be done in the system software of the controller or

on certain digital input (DI) boards belonging to S100 I/O. Time tagging on a DI board results in

a high time accuracy. Signals created in AMPL can also be time tagged but with an accuracy

corresponding to the PC program cycle time.

2.5 Pulse Counting and Positioning

Pulse Counting

Different S100 I/O and S800 I/O boards are used for pulse counting. Low pulse frequencies

(lower than 40Hz) are counted without PC element support.

For higher frequencies (up to 2.5 MHz), PC elements are connected to the boards.

3BSE 015 966R201 Rev B 2-5

Page 20

Advant Controller 410 Prod uct Guid e

Chapter 2 Functional Description

Positioning

Positioning and length measurement uses a set of PC elements connected to the board

DSDP 140A. Fast positioning creates substantial load in the controller CPU. Normally,

max. 10 positioning axes per Advant Controller 410, can be used.

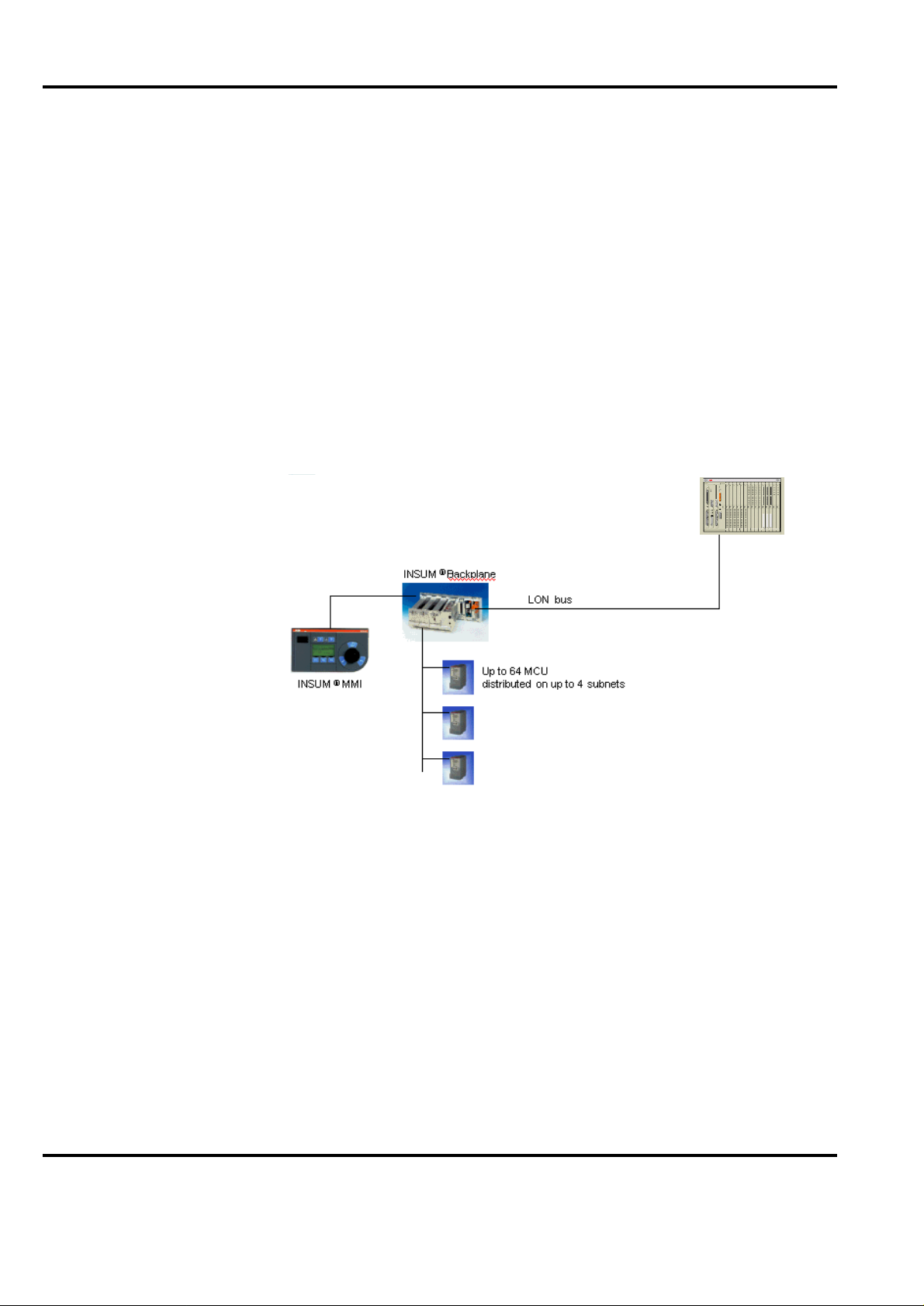

2.6 Switchgear Integration

Connection to the INSUM Motor Control Unit (MCU) is done via the LONWORKS Network.

ONWORKS channel (on CI572 Communication Module) can connect one INSUM Motor

Each L

Controll er, includi ng u p to 64 MCU’s. A series of PC element is used for sending/receiving data

to/from the MCU’s.

To minimize engineering efforts, a predefined type circuit is offered.

For configuration of the L

ONWORKS Network the configuration tool LNT505 is required in

addition to the ordinary Advant Control Configuration tool. See Advant Engineering Products,

Product Guide for further information.

Advant Controller 410

with CI57x LON interface

Figure 2-1. AC 400 Ser ies co nfiguration with INSUM Motor Controller

2.7 Drives Integration

Connection to ACS 600, DCS 600 and DCS 5008 drive systems, is done via Advant Fieldbus

100. Each fieldbus node connects up to 24 drives via a S800 I/O Fieldbus Communication

Interface (FCI). A series of PC elements is used for sending/receiving data to/from the drives.

In order to minimize engineering efforts, a predefined type circuit is offered.

2-6 3BSE 015 966R201 Rev B

Page 21

AF 100

Section 2.8 Variable Speed Drive Control

Adva nt C o ntroller 40 0 Se ries

I/O I/O

S8 0 0 I/ O

Advant Controller 410 Product Guide

AdvaCom man d

O p t ic a l M od u le B u s

2.8 Variable Speed Drive Control

Converters for both d.c. and a.c. motor drives can be connected to Advant Controller 410 via

Advant Fieldbus 100 or MasterFieldbus. For TYRAK, which has a built in modem for

the MasterFieldbus, the following limitations apply:

• The max. no. of convertors connected to the same LDB is 9.

• The max. no. of convertors connected to one Advant Controller 410 is 64.

2.9 Communication

Detailed information about the various networks and busses that can be integrated in Advant

Controller 410 is given in Product Guide for Advant OCS with Master Software, Overview.

Below is a list of communication functions in Advant Controller 410.

Control Network

• MasterBus 300

Communication is done with Data Sets

• MasterBus 300E

Communication is done with Data Sets

Figure 2-2.

$&6HULHVFRQILJXUDWLRQZLWKGULYH

Fieldbus Communication

• Advant Fieldbus 100

Communication is done with Data Set Peripherals or with PC elements

• PROFIBUS-DP

Communication is done with PC elements

• RCOM/RCOM+

Communication is done with MVI Sets

• Master Fieldbus

Communication is done with PC elements

• L

ONWORKS Network Interface

Communication is done with PC elements

3BSE 015 966R201 Rev B 2-7

Page 22

Advant Controller 410 Prod uct Guid e

Chapter 2 Functional Description

External Communication

• EXCOM

Communication is done with Data Sets

• MultiVendor Interface (MVI)

Communication is done with MVI Sets

The following protocols are supported:

– MODBUS (via CI532V02 and database element MS)

– MODBUS (via CI534V02 and database element MVB)

– Siemens 3964(R) (via CI532V03 and database element MS)

– Allen-B radley DF1 (via CI534V04 and database element MVB)

– Free-programmable protocol (via CI535 and database element MS)

– Free-programmable protocol (via CI538 and database element MVB)

• GCOM

Communication is done with Data Sets

• HART data routing

HART data can be routed between S800 I/O modules supporting HART and a

configuration tool supported by the AMPL Control Configuration.

Telecontrol & SPA Bus

• RCS protocol RP570/RP571 Master

• RTU protocol RP570 Slave

• RTU protocol IEC870-5-101 unbalanced Secondary Station

• SPA Server protocol SPA Bus

Communication is done with PC elements. For further information s ee res pective

Product Guide.

2.10 AdvaCommand Support

Advant Controller 410 supports several functions in an Advant Operator Workplace:

• Subscription

• Order and presentation

• System Status Displays

• Status List

• Trend displays

• Event List

2-8 3BSE 015 966R201 Rev B

Page 23

Section 2.11 Local Operator Station MasterView 320

For further information, please see the Product Guide for Advant Operator Workplace with

AdvaCommand.

2.11 Local Operator Station MasterView 320

MasterView 320 provides functions for presentation of process information on user defined

displays, for manual data entry via a keyboard, and for presentation of an event list with events

generated by application programs in Advant Controller 410.

Advant Controller 410 Product Guide

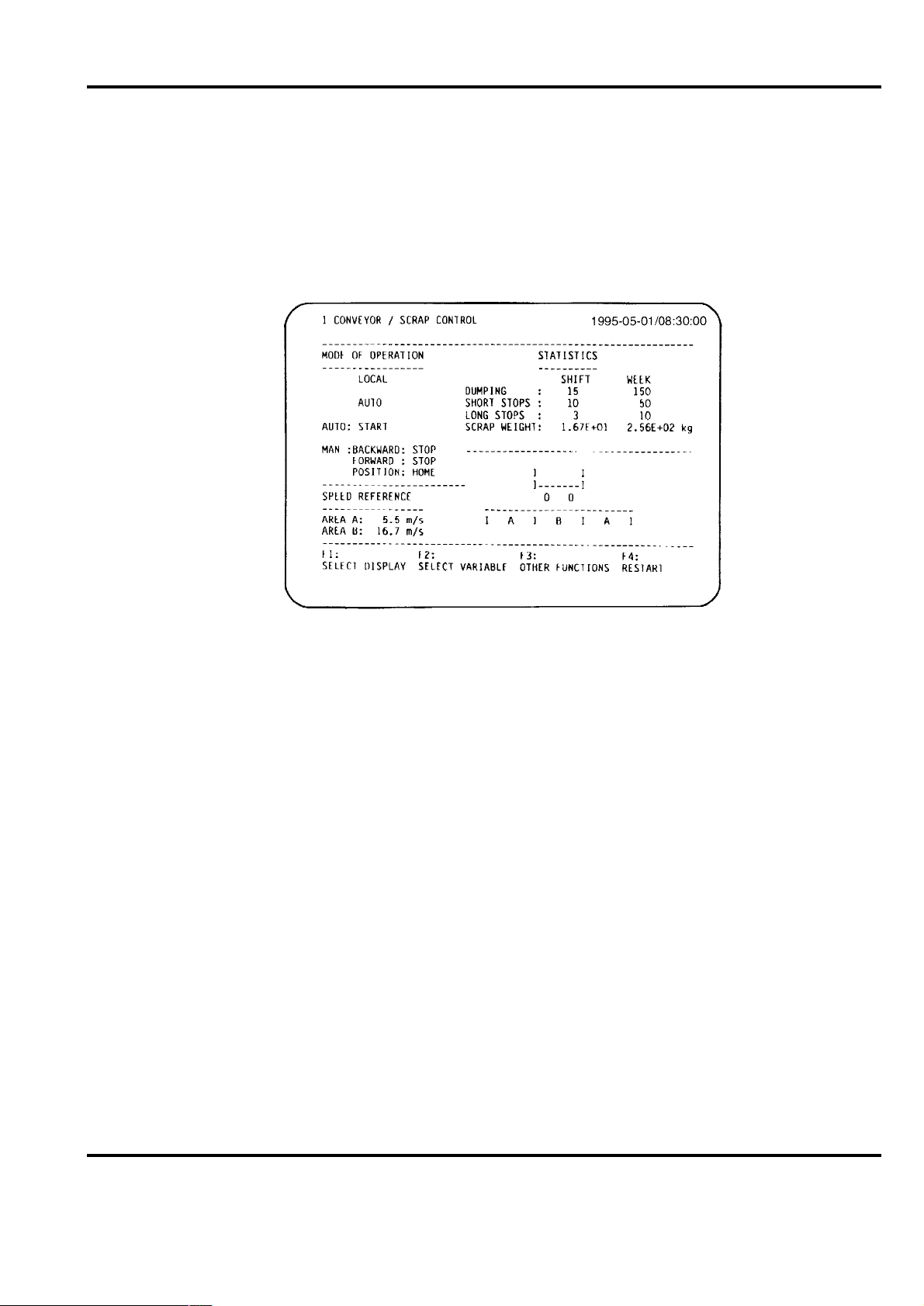

Figure 2-3. Example of display from MasterView 320

Hard-copy printout of displays and event list is possible.

Display Presentation and Operator Dialog

MasterView 320 is a VT100 or VT100 compatible terminal, 24 lines with 80 characters per line.

16 of the lines are available for user defined displays. The remaining eight lines are used by

the system for display identity and description presentation, time and date, dynamic function

key menu and a command entry line. Displays are generated and modified directly on the

screen. Standard VT 100 attributes, such as reverse video, flashing, underscore and reduced

intensity are supported. The static part of a display is built using text strings.

Depending on terminal, simple character oriented graphics are supported. Dynamic fields are

defined for the presentation of information from variables in the data base. Integer and real

values are presented in numerical form. Time is presented in the form HH:MM:SS. Boolean

values can be presented with user defined text strings; ON/OFF, UP/DOWN and AUTO/

MANUAL. Each display is given an identity and a description; presented on the display’s first

line. You can protect displays from unauthorized modification by a parameter in the database.

A simple operator dialog is engaged into through the function keys on the keyboard. By setting

a parameter value, you select one of the following languages: Danish, Dutch, English, Finnish,

French, German, Italian, Norwegian, Portuguese, Spanish, and Swedish.

3BSE 015 966R201 Rev B 2-9

Page 24

Advant Controller 410 Prod uct Guid e

Chapter 2 Functional Description

Event List

Event list is available via MasterView 320. It can be presented on the terminal screen and

printed on a printer connected to the controller. A separate list is associated with each screen.

The event generation is configured with PC programs, using PC element EVENT. Event texts

are user defined. The time of each event is automatically incorporated, with a resolution

determined by the scanning cycle of the PC program where the event is generated.

Hard Copy

A printer, connected to the same Advant Controller 410, can be used for hard-copy printouts

from MasterView 320. The printout can be activated from the keyboard, or automatically from

an PC program in the controller. The hard-copy function of MasterView 320 can be used for

efficient report generation with the controller. All necessary calculations of report data is done

with PC programs. The report is built with the normal display generatio n functio ns of

MasterView 320. Once the report is defined, the video terminal is not required any more, only

the hard-copy printer. Printout is then activated from PC programs. Thus reports can be

generated at regular points in time or on special events.

2.12 Local Printer

With a printer, directly connected to the Advant Controller 410 via conn ector on the C PU fron t,

reports (generated in AMPL report function) or report/event lists from MasterView 320 can be

printed.

2.13 Scope of Controller Functions

A large variety of configuration alternatives is possible with Advant Controller 410 and its I/O,

both software and hardware. Software options are available as one or several program modules.

Optional hardware units are I/O boards, communication units etc. Table 2-2 summarizes the

various options and configuration alternatives applying to Advant Controller 410.

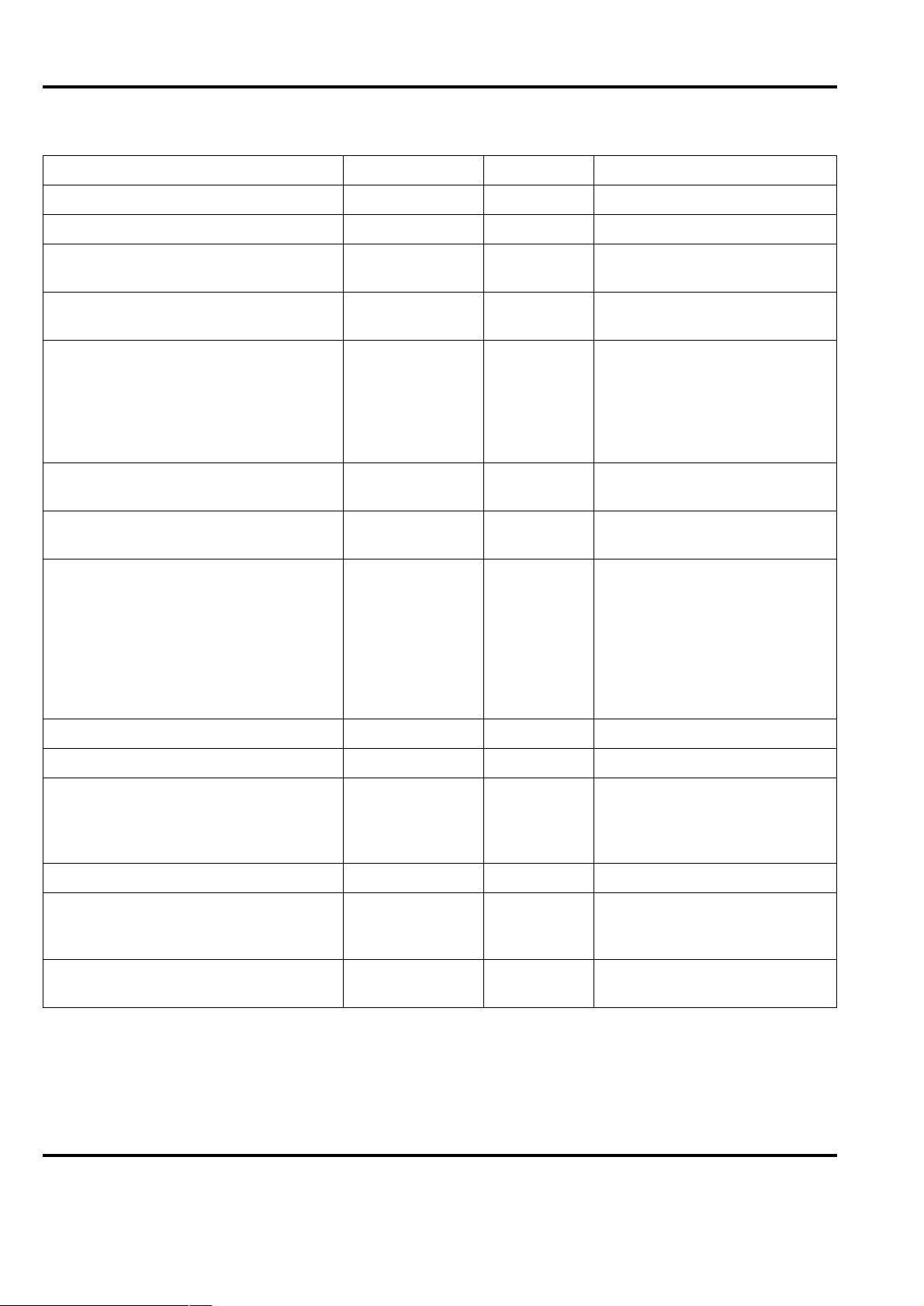

Table 2-2. Functions and configuration alternatives for Advant Controller 410

Function Program module Hardware Peripherals

S100 I/O boards with Board Oriented Connection Units

Redundant S100 I/O boards with Board

Oriented Connection Units

S400 I/O units QC01-BAS11

QC01-BAS11 See Refer-

QC01-BAS11 DSAX 110

ence Guide

DSAX 110A

DSAI 133

DSAI 133A

DSTA 001

DSTA 001B

DSTA 002

DSTA 002B

(1)

MasterFieldbus

2-10 3BSE 015 966R201 Rev B

Page 25

Advant Controller 410 Product Guide

Section 2.13 Scope of Controller Functions

Table 2-2. Functions and configuration alternatives for Advant Controller 410 (Continued)

Function Program module Hardware Peripherals

S800 I/O modules QC01-BAS11 See S800 I/O

Product Guide

Local time-tagging on DI-board with down

to 1 ms resolution

QC01-BAS11 DI885, DI830,

DI831

DSDI 1 10A

DSDI 1 10AV1

DSDI 120A

DSDI 120AV1

PC elements for logic, arithmetic & data

QC01-BAS11

handling

PC elements for logic, arithmetic, data

handling and process control

PC elements for logic, arithmetic, data

handling and advanced process control

QC01-BAS11+

QC01-LIB11

QC01-BAS11+

QC01-LIB11+

QC01-LIB12

Functional units QC01-BAS11+

(QC01-LIB12)+

QC01-OPF11

Positioning QC01-BAS11 DSDP 140A

DSTD 150A or

DSDP 140A

DSTD 190

Advant Fieldbus 100

AdvaCommand

Pulse transmitter

Fast pulse counting and frequency measurement

QC01-BAS11 DSDP 150

DSTD 150A or

DSDP 150

DSTD 190 or

DSDP 170

DSTX 170

Local operator station

MasterView 320

Local printer

(2)

(2)

QC01-BAS11+

QC01-LOS11

QC01-BAS11 CI531

CI531

Modem

Modem

External computer communication using

EXCOM

QC01-BAS11 CI531

Modem

MasterBus 300 QC01-BAS11 CS513/CI547

Transceiver

MasterBus 300E QC01-BAS11 CS513/CI547

Transceiver

Pulse transmitter

VT 100-compatible terminal

Printer

External computer with EXCOM.

MasterNet

MasterNet

3BSE 015 966R201 Rev B 2-11

Page 26

Advant Controller 410 Prod uct Guid e

Chapter 2 Functional Description

Table 2-2. Functions and configuration alternatives for Ad vant Controller 410 (Continued)

Function Program module Hardware Peripherals

GCOM QC01-BAS11 CI543

Communication using RCOM/RCOM+ QC01-BAS11 CI532V01

MultiVendor Interface QC01-BAS11 CI532Vxx

CI534Vxx

Free-programmable

MultiVendor Interface

Telecontrol & SPA Bus QC01-BAS11+

QC01-BAS11 CI535 or

CI538

CI535V24

YC571

CI535V29

CI535V23

CI535V26

CI535V30

Telecontrol & SPA Bus QC01-BAS11+

YC565

MasterFieldbus QC01-BAS11 CI570,

TC570

Advant Fieldbus 100 QC01-BAS11 CI522A

TC512V1

TC513xx

TC514xx

TC515xx

TC516

TC625

TC630

PROFIBUS-DP QC01-BAS11 CI541V1

Software development environment required

S400 I/O units, TYRAK, SAMI

Advant Controller 70/110,

S800 I/O, DCS 500B, DCS 600,

ACS 600

ONWORKS Network Interface QC01-BAS11 CI572 INSUM2

L

Support for AdvaCommand, AdvaSoft

for Windows, AdvaInform and MV 800/1

QC01-BAS11+

QC01-OPF11

CS513/CI547

Transceiver

MasterNet

(Subscription, Order/Presentation, System

Status, Status List, Trend, Event List)

Table handling QC01-BAS11

On-line PC program editing QC01-BAS11 On-line Builder (AdvaBuild, AMPL

Control Configuration, AdvaCommand)

Connection to analog thyristor converters,

variable speed control

QC01-BAS11+

QC01-LIB11

DSDC 111

DSTX 110

Thyristor converter

2-12 3BSE 015 966R201 Rev B

Page 27

Advant Controller 410 Product Guide

Section 2.13 Scope of Controller Functions

Table 2-2. Functions and configuration alternatives for Advant Controller 410 (Continued)

Function Program module Hardware Peripherals

MasterBatch 200/1 support QC01-BAS11+

QC01-BAT11

CS513/CI547

Transceiver

Intrinsic Safety support QC01-BAS11 DSAI 130

DSAI 130A

DSAI 133

DSAI 133A

DSAO 120

DSAX 110

DSAX 110A

DSDI 1 10A

DSDI 1 10AV1

DSDO 115A

DSDP 150

HART Protocol support QC01-BAS11 DSAI 133

DSAI 133A

DSAX 110

DSAX 110A

DSAO 120

DSAO 130

DSAO 130A

Support for ACS 600, DCS 600 and DCS

500B motor drives

QC01-BAS11 See Advant

Fieldbus 100

MasterNet

Intrinsic Safety Isolator

modules.

See S100 I/O Product Guide for

more information.

HART multiplexer

See S100 I/O Product Guide for

more information.

Motor Drives ACS 600, DCS 600

and DCS 500B Advant Fieldbus

100

User Defined PC elements QC01-BAS11+

QC01-UDP11+

(QC01-LIB11)+

(QC01-LIB12)

PROM back-up of application program

QC01-BAS11 MB510

(PC programs and data base)

(1) A classic product and no longer includ ed i n sta nda rd offeri ng

(2)Modem TC562 is required for distances longer than 15 m (49 ft.)

Flash-PROM

card

Engineering station

Engineering station with PCMCIA

card support

3BSE 015 966R201 Rev B 2-13

Page 28

Advant Controller 410 Prod uct Guid e

Chapter 2 Functional Description

2-14 3BSE 015 966R201 Rev B

Page 29

Chapter 3 Software Components

3.1 Overview

Advant Controller 410 system software comprises a real-time operating system and an AMPL

execution machine.

The functional extent of Advant Controller 410 is determined by adding optional software and

hardware units to the basic unit. The software options are delivered as program modules which

may be selected to create the desired functional configuration. Optional hardware units are

I/O and communication modules etc.

The software system for Advant Controller 410 is built around one Basic program module to

which Optional alternative program modules can be added. The Optional program modules can

be combined in a number of combinations needed to solve the application tas k. A descriptio n of

the program modules and a specification of their contents is given below. The Basic program

module, QC01-BAS11, together with the optional software below are stored in one program

card, placed on the CPU PM150V.

Advant Controller 410 Product Guide

Section 3.1 Overview

3.2 Basic Program Module, QC01-BAS11

The Basic program module has the following functional contents:

• Logic control and time delays

• Arithmetic

• Data and text handling

• Sequence control

• Calendar time functions

• Table handling

• Fast pulse counting and frequency measurement

• Positioning

• Reports

• Functional units, binary

• Functional units, analog

• Functional units, motor and valve control, group start

• Support for MasterBus 300/300E

• Support for GCOM

• Support for RCOM/RCOM+

1. The PC elements and database parts of the functional units are included in the Basic program modul e .

The presentation and di alog support require the opti onal Program Module QC01-OPF11. Special dedicated

interface boards are not included in the system unit.

1

1

1

3BSE 015 966R201 Rev B 3-1

Page 30

Advant Controller 410 Prod uct Guid e

Chapter 3 Software Components

• Support for MultiVendor Interface

• Support for fieldbus communica t ion (Advant Fie l dbus 100, PRO F IBUS-DP, L

ONWORKS

Network, MasterFieldbus).

• Strain-gauge weighing support

• Support for motor drives

• Data Set/DAT communication

• Back-up of application program in flash-PROM card

Most of the above mentioned functions are realized with one or several PC elements.

The contents of the PC element library in the basic program module is shown in Table 3-1.

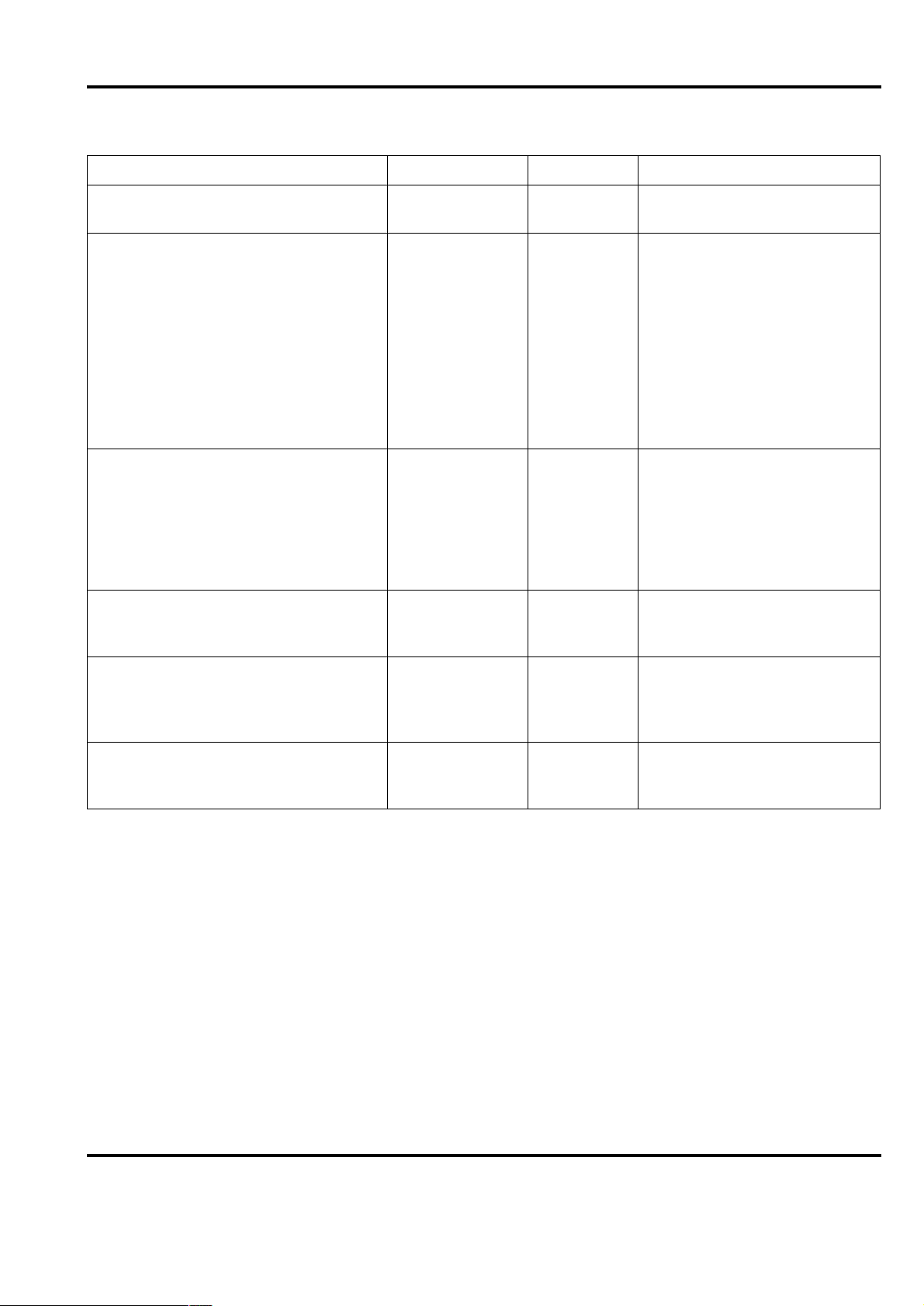

Table 3-1. PC elements in the basic program module QC01-BAS11

T ype PC element

Structure elements PCPGM, CONTRM, FUNCM, MASTER, SLAVEM,

BLOCK, SEQ, STEP

Logic elements AND, OR, AND-O, OR-A, XOR, INV, SR, SR-D, SR-AA,

SR-AO, SR-OO, SR-OA

Arithmetic elements ADD, SUB, MUL, DIV, ADD-MR1, ADD-MR,

DIV-MR, SQRT, ABS, LIM-N

Time delays TON, TOFF, MONO, TON-RET, TRIGG, OSC-B

Calendar time elements TIME, DATE, TIMER

Registers SHIFT, SHIFT-L, FIFO, REG-RET, EXPAND, EXPAND-

A, FIFO-RW, REG, REG-G

Multiplexers MUX-I, MUX-N, MUXA-I, MUX-MI, MUX-MN,

DEMUXA-M, DEMUX-MI

Code converters CONV-BI, CONV-IB, CONV-AI, CONV-IA,

CONV-SA, CONV

Counters COUNT, COUNT-L

Comparators COMP-I, COMP-R, COMP, MAX, MIN

Fault elements F AUL T

Printing and text generation

TEXT, PRINT

elements

Elements for functional

units

GENBIN-I, GENBIN-O, GENUSD-I, GENUSD-O, GEN-

CON-I, GENCON-O, MOTCON,

VALVECON, MMC-IND, MMC-ORD

Switches SW, SW-C

Positioning elements POS-A, POS-O, POS-L

3-2 3BSE 015 966R201 Rev B

Page 31

Advant Controller 410 Product Guide

Section 3.2 Basic Program Module, QC01-BAS11

Table 3-1. PC elements in the basic program module QC01-BAS11 (Continued)

Type PC element

Pulse counting and frequency measurement

PULSE-S, COUNT-DP, FREQ-SP, FREQ-MP, PCU-I,

PCU-O, PCU-COM, PCU-SS

elements

Data handling elements MOVE, MOVE-A

Event handling element EVENT

Report element REPORT

Elements for programma-

FPM-COM, FPM-I, FPM-IA, FPM-O, FPM-OA

ble module

Weighing elements SCALE, SCALEDOS

Table handling elements TBL-R, TBL-RG, TBL-W, TBL-WG

Ramp generators RAMP-S1

Supervision elemen ts ANALYSE, COM-STAT

MasterFieldbus

communication elements

Advant Fieldbus 100

COM-MP51, MFB-OUT, MFB-IN, COM-CVI1, COMCVO1

DSP-R, DSP-S, DRI-CNV, DRI-R, DRI-S

communication elements

PROFIBUS-DP

PB-DIAG, PB-R, PB-S

communication elements

ONWORKS Network

L

LON-R, LON-S

Interface

communication elements

Data Set elements SENDREQ

Besides the PC element library , the b asic program modu le also includes a functional u nit library.

The functional units supplement the PC elements and they are primarily intended for realizing

instrumentation functions. The contents of the functional unit library is shown in Table 3-2.

Table 3-2. Functional units in the base program module QC01-BAS11

Functional unit Description

AI Analog input signal, including AI, Temp. (Pt100), TC

(thermocouple), AIC (cal cu la ted AI)

AO Analog output signal, including AO and AOC (calculated

AO)

DI Digital input signal, including DI and DIC (calculated DI)

DO Digital output signal, including DO and DOC (calculated

DO)

3BSE 015 966R201 Rev B 3-3

Page 32

Advant Controller 410 Prod uct Guid e

Chapter 3 Software Components

Table 3-2. Functional units in the base program module QC01-BAS11 (Continued)

DAT General data base value

TEXT Text in data base

GENUSD General user-defined device controller

GENBIN User-defined on/off controller

GENCON User-defined regulatory controller

SEQ Sequence controller

GROUP Device group controller

MOTCON Motor controller

VALVECON Valve controller

DRICONE Engineered Drives Controller

DRICONS Standard Drives Controller

Functional unit Description

MOTCONI INSUM Motor Controller

3.3 Optional Program Module, QC01-LIB11

The Optional program module QC01-LIB11 extends the PC element library that is included in

the Basic program module with PC element for supporting the function:

• Feedback control

• Connection to analog thyristor conv e rters .

Feedback control is realized with PC elements. The contents of PC elements in QC01-LIB11 is

shown in Table 3-3.

Table 3-3. Additional PC elements in program module QC01-LIB11

T y pe PC element

Logic elements THRESH-L

Arithmetic elements MED-R, MAJ-R, LN, EXP

Multiplexers MUXGR-MI, MUXGE-MI

Time controlled elements OSC-SQW, OSC-SIN

Function generators FUNG-1V, FUNG-2V, FUNG-T

Filter elements FIL T-1P, FILT-2P

3-4 3BSE 015 966R201 Rev B

Page 33

Advant Controller 410 Product Guide

Section 3.4 Optional Program Module, QC01-LIB12

Table 3-3. Additional PC elements in program module QC01-LIB11 (Continued)

Type PC element

Feedback control elements P-DEADB, P-1, INT, DER, PI, PIP, PDP, CON-PU1,

RAMP

Analog thyristor converter

CVB-I, CVB-O

elements

3.4 Optional Program Module, QC01-LIB12

The Optional program module QC01-LIB12 extends the PC element and functional units

libraries that are included in the Basic program module with PC element for supporting

the functions below:

• Regulatory control

• Functional units, PID loop control, PIDCON

• Self-tuning adaptive control, Novatune.

The functions are realized with the PC elements in Table 3-4.

Table 3-4. Additional PC elements in program module QC01-LIB12

Type PC element

Elements for functional

units

Self-tuning controller NOVATUNE

PIDCON, RATIOSTN, MANSTN

1

The PC elements PIDCON, RA TI OSTN and MANSTN are also part of the following functional

units, which is shown in Table 3-5.

Table 3-5. Functional units in the program module QC01-LIB12

Functional unit Description

PIDCON Regulatory controller

RA TIOSTN Ratio station

MANSTN Manual statio n

1. The PC el em e n t s and database parts of the functional units are included in QC01-BAS11 and QC01-LIB12. The

presentation and dialog support require QC01-OPF11.

3BSE 015 966R201 Rev B 3-5

Page 34

Advant Controller 410 Prod uct Guid e

Chapter 3 Software Components

3.5 Optional Program Module, QC01-OPF11

The Optional program module QC01-OPF11 extends the functionality of the controller with

support for operator station functions in for example Advant Operator Wo rkplace or

MasterView 800/1.

The Optional program module QC01-OPF11 extends the functionality given by the Basic

program module with the following functions:

• Functional units, binary

• Functional units, analog 1

• Functional units, PID lo op control, PIDCON

• Functional units, motor and v alve control, group start

• Support for AdvaCommand Functions

(Subscription, Order/Presentation, System Status, Status List, Trend, Event/Alarm)

• Log data storage

• Group alarm, a function in AdvaCommand Event and Alarm

1

1

1

3.6 Optional Program Module, QC01-LOS11

Optional program module QC01-LOS11 extends the functionality of the controller with

MasterView 320. A VT100 terminal (or compatible) is used as operator interface.

Three such terminals can be connected to an Advant Controller 410, thus providing three local

operator workplaces. Optional program module QC01-LOS11 extends the functionality given

by the Basic program module with the following functions:

• MasterView 320

• Reports for MasterView 320.

3.7 Optional Program Module, QC01-BAT11

The Optional program module QC01-BAT11 extends the functionality of the controller with

support for connecting it to the batch station MasterBatch 200/1.

MasterBatch 200/1 is connected to Advant Controller 410 through MasterNet.

3.8 Optional Program Module, QC01-UDP11

The Optional program module QC01-UDP11 makes it possible to execute user defined PC

elements in the Advant Controller 410. The user defined PC element is created in AMPL

Control Configuration (1.7 or a later product version) and built-up of a combination of normal

PC elements from the standard PC element libraries of the Advant Controller 4 10. After the user

defined PC element is installed in the Advant Controller 410 it can be us ed freely in all

PC programs as a normal PC element.

3-6 3BSE 015 966R201 Rev B

Page 35

Chapter 4 Hardware Components

4.1 Pro cessor Module

PM150V is a processor module for Advant Controller 410. It is designed to fit into

DSRF 198/199 S100 I/O subracks.

The processor module, PM150V (Figure 4-1 refers), has the following characteristics:

• 25 MHz 68020 Proces sor

• 4 or 8 Mbyte Dynamic RAM with ECC

• The RAM houses the system software as well as the user built application

• Interface to up to four submodules on module front (see Figure 4-1 slot #1-4)

• Two RS-232-C interfaces

– one for MasterView 320 (connector X17)

Advant Controller 410 Product Guide

Section 4.1 Processor Module

– one for printer connection (connector X6)

• One slot for PCMCIA program card on front (see Figure 4-1 slot #5)

• Service tool, Advant Station 100 Series, interface on front (see Figure 4-1 connector X27)

The processor module exists in two versions which have the same type designation on the front,

PM150V, and can be separated by the label on the component side of the module.

• PM150V04 with 4 Mbyte read/write memory (RAM)

• PM150V08 with 8 Mbyte read/write memory (RAM).

PM150V04 is upgradable to PM150V08 with a special kit containing 8 Mbyte RAM.

3BSE 015 966R201 Rev B 4-1

Page 36

Advant Controller 410 Product Guide

Chapter 4 Hardware Components

RUN

HLT

MIB

X17

COM1

F

2

1

3

ENTER

TO

1=AUTO

2=STOP

3=CLEAR

4=OFFLINE

4

PM

150V

X6

COM2

DCOK

INHIB

BC

SERVICE

5

X27

4

1

2

3

Figure 4-1. Front View of the PM150V Processor Module

Indicator LEDs on module front are:

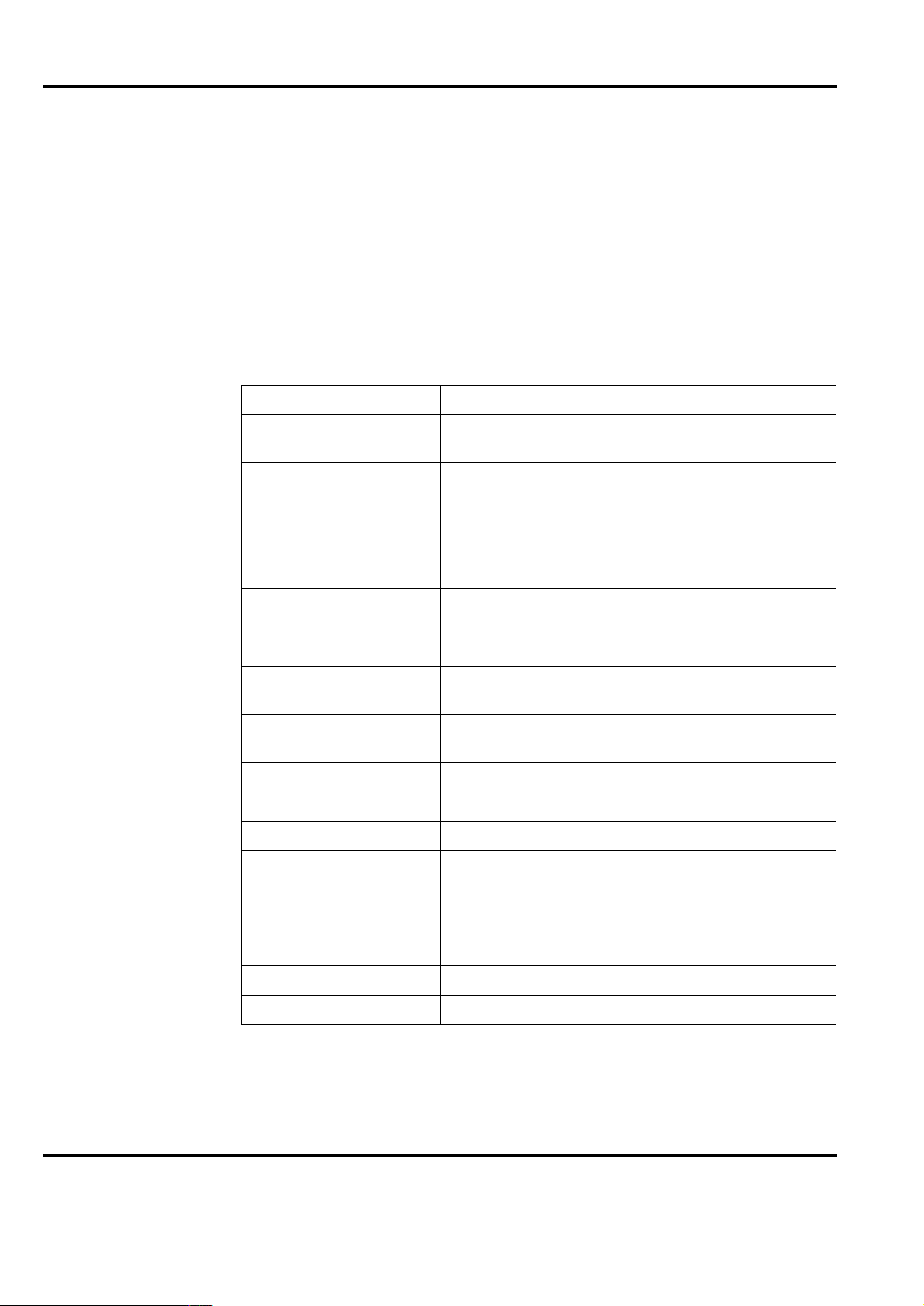

Name LED Color Description

F red Module Error

RUN green Module running normally

HLT red CPU h alted

TO yellow Bus Time-out

MIB yellow MP150 is current bus master on MIB

DCOK green 24 V d.c. supply is within range

INHIB yello w INHIB is active

BC green Backup voltage for RAM connected

4-2 3BSE 015 966R201 Rev B

Page 37

4.2 Program Card

The controller system software is stored on a flash memory card of type PCMCIA.

This card is located in a slot (see Figure 4-1 slot #5) on the CPU PM150V. It is accessed during

start-up of the controller and supervised in run-time.

4.3 Submodule Carriers

The purpose of the submodule carrier is to carry communication interfaces and other

submodules. The CPU, PM150V, is the submodule carrier containing four slots.

4.4 Submodules

Communication interfaces and a few other functions are realized as submodules which fits into

a slot on the CPU. Modules can be exchanged while the system is running. New modules can

also be inserted live. Every unit has a red LED to indicate fault, see Table 4-1.

Submodule Description

Advant Controller 410 Product Guide

Section 4.2 Program Card

Table 4-1. Submodules

CI531 RS-232-C communication interface for printer, EXCOM or

MasterView 320. Each interface holds two RS-232-C lines.

CS513 or CI547 MasterBus 300, MasterBus 300E communication. Each interface

holds one line. CI547 includes a slave CPU and will thereby

reduce load from the main CPU module (PM150)

CI532V01 RCOM/RCOM+ communication. Each interface holds two lines.

CI532V02 MODBUS communication with DB element MS. Each interface

holds two lines.

CI532V03 Siemens 3964(R) communication. Each interface holds two lines.

CI534V02 MODBUS communication with DB element MVB. Each interface

holds two lines.

CI534V04 Allen-Bradley DF1 communication with DB element MVB. Each

interface holds two lines.

CI535V24 RCS protocol RP570 Master

CI535V29 RCS protocol RP571 Master

CI535V23 RTU protocol RP570 Slave

CI535V26 RTU protocol IEC870-5-101 Unbalanced

CI535V30 SPA Server protocol SPA Bus

CI535 Free-programmable MVI communication with DB element MS.

Each interface holds two lines.

CI538 Free-programmable MVI communication with DB element MVB.

Each interface holds two lines.

3BSE 015 966R201 Rev B 4-3

Page 38

Advant Controller 410 Product Guide

Chapter 4 Hardware Components

Submodule Description

CI541V1 PROFIBUS-DP communication. Each interface holds one line.

Table 4-1. Submodules (Continued)

4.5 Subrack

CI572 L

CI543 GCOM communication. Each interface holds one line.

CI570 MasterFieldbus communication. Each interface holds one line

CI522A Advant Fieldbus 100 communication. Each interface holds one

MB510 Program card interface for extra system software or application

PU535 Free-programmable module

The processor module (PM150V) for Advant Controller 410 is a unit which fits into a special

version of the S100 I/O subr ack.

ONWORKS Network communication, 1250 kbit/s. Each interface

holds two lines.

with cable redundancy capabilities.

line with cable redundancy capabilities.

backup

PM150V

Figure 4-2. The processor module, PM150V, within the S100 I/O subr ack

The subrack can contain PM150V and up to 15 S100 I/O boards. On the backside of the subrack

the voltage regulator (DSSR 122 or 3xDSSR 170) is located together with the supervision unit

SB171.

4-4 3BSE 015 966R201 Rev B

Page 39

4.6 System Unit

Advant Controller 410 Product Guide

Section 4.6 System Unit

The system units for Advant Controller 410 are described in Table 4-2 and Table 4-3.

Table 4-2. System unit with single voltage regulator

Units Description

DSRF 198 Controller and S100 I/O subrack

DSSR 122 Voltage regulator

SB171 Supervision unit and battery charger

SB522 Battery unit

TK457V030 Cable

Table 4-3. System unit with redundant voltage regulator

Units Description

DSRF 199 Controller and S100 I/O subrack

4.7 I/O Systems

4.8 Communication

3 x DSSR 170 Voltage regulator

SB171 Supervision unit and battery charger

SB522 Battery unit

TK451, TK461 Cable

S100 I/O System

All 15 S100 I/O are located in the same subrack as the CPU. Only one subrack can be used.

The Reference Guide details the various I/O boards available for Advant Controller 410.

Further information about S100 I/O is given in the Product Guide for S100 I/O.

S800 I/O System

The S800 I/O Station is physically connected to an Advant Controller 410 via Advant Fieldbus

100. Table 2-1 lists the various I/O modules available for Advant Controller 410.

Further information about S800 I/O is given in the Product Guide for S800 I/O.

Below follows configuration examples for all buses in Advant Co ntroller 410 showing how

the buses are connected to the controller.

3BSE 015 966R201 Rev B 4-5

Page 40

Advant Controller 410 Product Guide

Chapter 4 Hardware Components