Page 1

VERTICAL SELF-CONTAINED UNITS

SB

Features:

• Water-source and geothermal heat

pump vertical self contained units with

capacities from 3-18 tons

• Remote air-cooled condenser and airsource heat pump configurations

• 10%-100% variable capacity R-410A

scroll compressors for load matching

cooling and heating with improved part

load efficiency

• Double wall rigid polyurethane foam

injected panel construction reduces air

leakage and dampens resonated sound

• Electronically Commutated Motor (ECM)

driven direct drive backward curved

plenum supply fans provide precise

air flow control and reduced power

consumption

• Optional modulating hot gas reheat

humidity control

• Hinged service access doors with

lockable handles

• Corrosion resistant stainless steel drain

pans

• Split configuration for retrofit or space

limited applications

• Factory installed high performance

electric, hot water, or steam heating

Series

Makeup Air Applications

Up to 100% Outside Air

Application Flexibility

Minimizes Installation Time and Reduces Cost

Dehumidification and

Filtration Capabilities

Variable Capacity

Scroll Compressors

Factory Provided or Customer

Provided Controls Options

Page 2

SB

Series

Self-Contained Units

SB Series self-contained units are

engineered for high performance and energy

ecient full and part load operation. Variable

capacity scroll compressors, ECM direct

drive backward curved plenum supply fans,

double wall rigid polyurethane foam insulated

cabinet construction and heat pump

conguration provide the SB Series with

unmatched performance.

Superior Features

• Double wall rigid polyurethane foam injected panel cabinet construction has a

higher thermal resistance, or R-value, compared with berglass construction.

Panels include a thermal break, with no metal contact from inside to outside,

to prevent heat transfer through the panel and prevent condensation on the

outside of the cabinet. This construction also makes the cabinet more rigid

and resistant to damage, provides increased sound dampening, and reduces

air leakage and inltration.

• Split conguration with refrigerant-to-water heat exchanger and compressor

compartment shipped separate from the air tunnel section for retrot or space

limited applications.

• Access doors with chrome plated steel hinges and quarter turn lockable

handles make the unit easily serviceable.

• Unit control and compressors are contained within a compartment isolated

from the air stream for ease of service and quiet operation.

• Perforated, galvanized steel sound attenuators are installed in the compressor

compartment.

• Double sloped stainless steel drain pans eliminate standing water which can

support microbial growth and stainless steel construction prevents corrosion

that could lead to water leaks and contaminants in the air stream.

• Direct drive backward curved plenum fans are more energy ecient, quieter,

and require less maintenance than belt driven fans.

• ECM (Electronically Commutated Motor) supply fans provide precise airow

control and reduced power consumption.

• Air-Source, water-source, and geothermal heat pump congurations allow for

energy ecient heating and cooling.

• Labeled electrical components and color-coded wiring match the unit specic

color-coded wiring diagram that is laminated and permanently axed inside

the control compartment.

• Factory run test report, wiring diagram, and Installation, Operation,

and Maintenance manual with startup form are provided in the control

compartment of every unit.

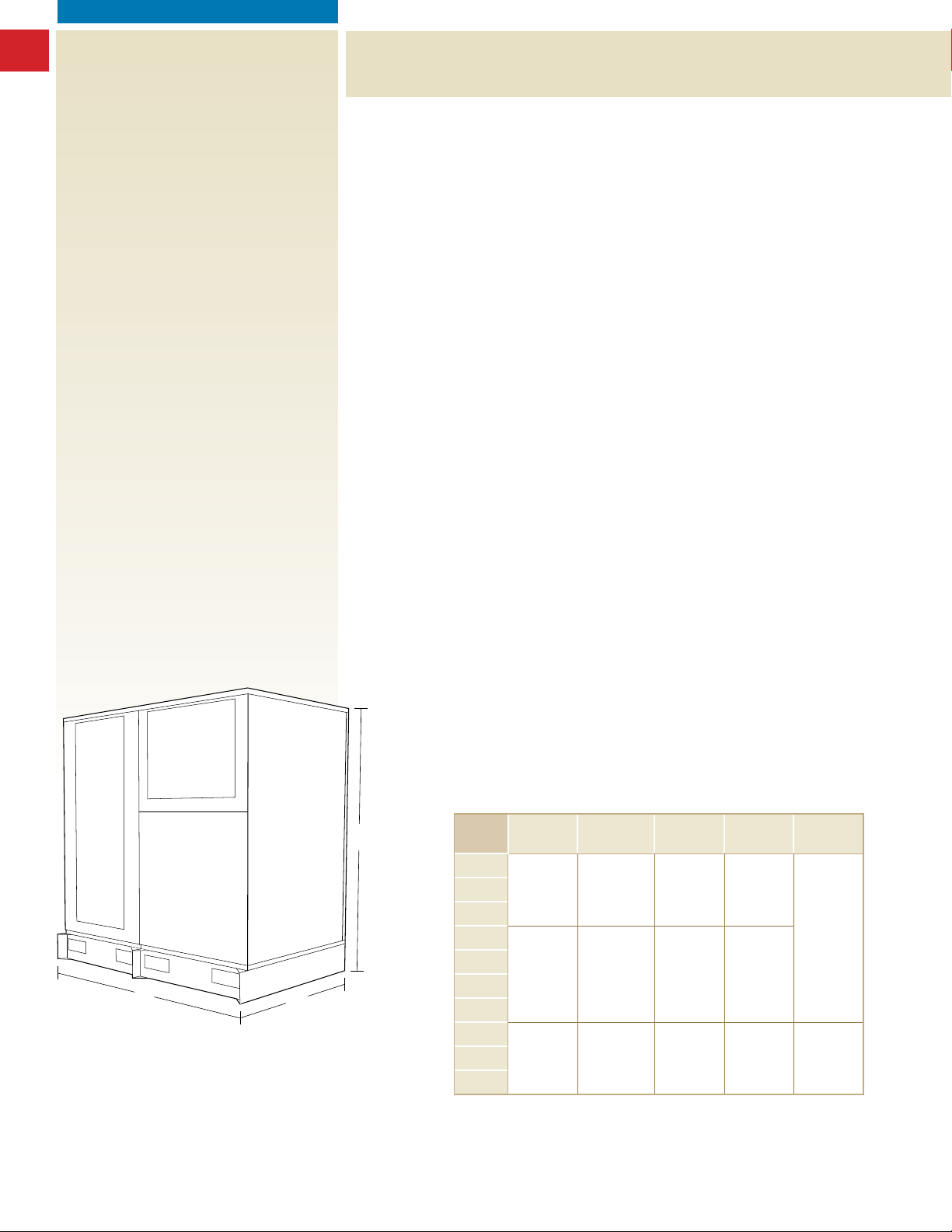

H

L

W

SB

Model

003

004

005

006

007

009

010

014

018

Cabinet cfm Width Height* Length*

B 1,000-2,000 30 53

65

C 1,800-4,000 42 72

D 3,000-6,000 56 73 69016

All dimensions are in inches

Design cfm may be 30-50% greater or less than nominal cfm.

“Units can be shipped in a split conguration for ease of installation

such that each section will t through a standard 36” door.

*Dimension may vary depending on options selected

Page 3

SB

Self-Contained Units

Series

Premier Options

• Makeup air ventilation with up to 100% outside air.

• Factory provided or customer provided controller can be

selected to meet existing or new building control architecture.

• Modulating humidity control provides energy ecient

dehumidication, even with low sensible heat loads, without

the temperature swings common with on/o reheat systems.

• Polymer e-coated coils, copper nned coils, and stainless steel

coil casings are available to extend the life of the coils and

protect them in corrosive environments.

• Multiple high eciency ltration options, with up to a MERV

14 eciency rating.

• SCR (Silicon Controlled Rectier) electric heat control for

reduced power consumption, longer heater life and improved

occupant comfort.

• Factory installed constant or variable ow waterside

economizer allows for free cooling at low ambient conditions.

• Interior and exterior corrosion protection is available to protect

the cabinet in corrosive environments.

• Factory installed mixing boxes with gear driven outside air and

return air dampers allow for airside economizer free cooling.

Additional high eciency ltration is also available in the

mixing box.

• Modulating head pressure control allows unit operation with

lower temperature condenser supply water.

• Factory installed total or sensible AAONAIRE energy recovery

wheels.

Variable capacity scroll compressors provide

load matching cooling and heat pump heating

and improve part load eciency.

Compact Construction

Variable Capacity Scroll

Compressors

With 10-100% capacity control these scroll compressors can match the load needed by the unit.

The compressors vary the volume of refrigerant that

ows through the cooling system allowing the unit

to tightly control the air temperature and save energy

when the unit is not running at full load.

Variable Speed Supply Fans

ECM (Electronically Commutated Motor) driven

direct drive backward curved plenum supply fans are

available on SB Series units to provide precise air ow

control and reduced power consumption. Direct drive

fans do not have belt energy losses and backward

curved plenum fans are more energy ecient than

housed forward curved fans.

AAONAIRE Energy Recovery

Wheels

AAONAIRE energy recovery wheels, total or sensible,

provide energy savings by recycling energy instead

of losing energy through the exhaust air steam.

AAONAIRE systems also enhance indoor air quality by

allowing larger amounts of outside air to be provided

to the space with improved humidity control

Compressor & Heat

Exchanger Section

Air Handling Section

Factory installed AAONAIRE energy recovery wheel

saves heating and cooling energy.

High Eciency Filtration

Mixing Box Section

Water-Source and Geothermal

Heat Pump Configuration

An SB Series water-source/geothermal heat pump

unit can heat the air as energy eciently as it cools

it. By transferring heat from the earth to the building,

the SB Series heat pump requires no fossil fuels.

Ease of Installation

SB series units (B cabinet) are designed to t through

standard 36in wide by 80in tall doors for ease of installation and retrot applications. C and D cabinets

can be shipped from the factory in a split conguration in order to t through a standard door opening.

SB series units can be shipped from the factory with a

forklift capable base to further ease installation.

Page 4

AAON Environmentally Friendly HVAC Product Family

Custom & Cataloged

Air Handling Units

(800-200,000+ cfm)

Condensers & Condensing Units

(2-230 tons)

Heating and Cooling for...

Auditoriums

Chillers (Air-Cooled &

Evaporative-Cooled)

(4-540 tons)

Rooftop Units

(2-240 tons)

Outdoor Equipment Rooms

(Chillers, Boilers & Pumps)

Self-Contained Units

(3-70 tons)

Residential Systems

(2-5 tons)

Convenience Stores

Health Clubs

Healthcare Facilities

Homes

Lodgings

Manufacturing

Museums & Libraries

Natatoriums

Ofce Buildings

Restaurants

Retail Stores

Schools

Supermarkets

Geothermal & WSHP Units

(2-230 tons)

Air-Source Heat Pumps

(2-230 tons)

2425 S. Yukon Ave.

Heating and Cooling Coils

(Booster, Hydronic, & DX)

Tulsa, OK 74107-2728

www.AAON.com

Fluid Coolers

(50-450 tons)

It is the intent of AAON to provide accurate and current product information. However, in the interest of product improvement, AAON reserves the right to change

pricing, specications, and/or design of its product without notice, obligation, or liability. Copyright © AAON, all rights reserved throughout the world. AAON® and

AAONAIRE® are registered trademarks of AAON, Inc., Tulsa, OK.

SB • R94530 • 151015

Loading...

Loading...