Aaon SB-003 Installation Manual

vicinity of this or any other appliance.

WARNING

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

WARNING

SB Series

Vertical Self Contained Units

Installation, Operation

& Maintenance

personal injury or loss of life. Startup

and service must be performed by a

Factory Trained Service Technician.

A copy of this IOM should be kept

with the unit.

QUALIFIED INSTALLER

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

Table of Contents

Safety .............................................................................................................................................. 5

SB Series Feature String Nomenclature ....................................................................................... 11

General Information ...................................................................................................................... 15

Codes and Ordinances .............................................................................................................. 15

Receiving Unit .......................................................................................................................... 16

Storage ...................................................................................................................................... 16

Direct Expansion (DX) Systems ............................................................................................... 16

Wiring Diagrams ....................................................................................................................... 17

Condensate Drain Pans ............................................................................................................. 17

Installation..................................................................................................................................... 18

Locating the Unit ...................................................................................................................... 18

Lifting and Handling the Unit ................................................................................................... 19

Refrigerant-to-Water Heat Exchanger Water Piping ................................................................ 19

Electrical ................................................................................................................................... 23

Duct Connection ....................................................................................................................... 26

Condensate Drain Piping .......................................................................................................... 26

Waterside Economizer .............................................................................................................. 27

Heating Coils ............................................................................................................................ 28

Electric Preheat ......................................................................................................................... 28

Startup ........................................................................................................................................... 29

Supply Fans ............................................................................................................................... 29

Filters ........................................................................................................................................ 32

Adjusting Refrigerant Charge ................................................................................................... 32

Operation....................................................................................................................................... 35

Packaged DX Cooling Operation and Control ......................................................................... 35

Electric Heating Operation ....................................................................................................... 35

Steam or Hot Water Preheating Operation ............................................................................... 35

Modulating Electric Preheat ..................................................................................................... 35

Maintenance .................................................................................................................................. 35

DX Cooling ............................................................................................................................... 35

Condensate Drain Pans ............................................................................................................. 36

E-Coated Coil Cleaning ............................................................................................................ 36

Supply Fans ............................................................................................................................... 37

Filter Replacement .................................................................................................................... 38

Replacement Parts ..................................................................................................................... 38

AAON Longview Product Support ........................................................................................... 38

Filter Information .......................................................................................................................... 39

Appendix A - Heat Exchanger Corrosion Resistance ................................................................... 42

3

Index of Tables and Figures

Tables:

Table 1 - SB Series Clearances ..................................................................................................... 18

Table 2 - Glycol Freezing Points .................................................................................................. 21

Table 3 - Condenser Water Connections ...................................................................................... 22

Table 4 - Control Wiring ............................................................................................................... 25

Table 5 - Drain Trap Dimensions ................................................................................................. 27

Table 6 - Acceptable Water-Cooled Refrigeration Circuit Values ............................................... 33

Table 7 - R-410A Refrigerant Temperature-Pressure Chart ......................................................... 34

Table 8 - 3-5 ton (B Cabinet) Pre and Unit Filters ....................................................................... 39

Table 9 - 6-10 ton (C Cabinet) Pre and Unit Filters ..................................................................... 39

Table 10 - 14-18 ton (D Cabinet) Pre and Unit Filters ................................................................. 39

Table 11- 3-5 ton (B Cabinet) Mixing Box Filters ....................................................................... 40

Table 12 - 6-10 ton (C Cabinet) Mixing Box Filters .................................................................... 40

Table 13 - 14-18 ton (D Cabinet) Mixing Box Filters .................................................................. 41

Figures:

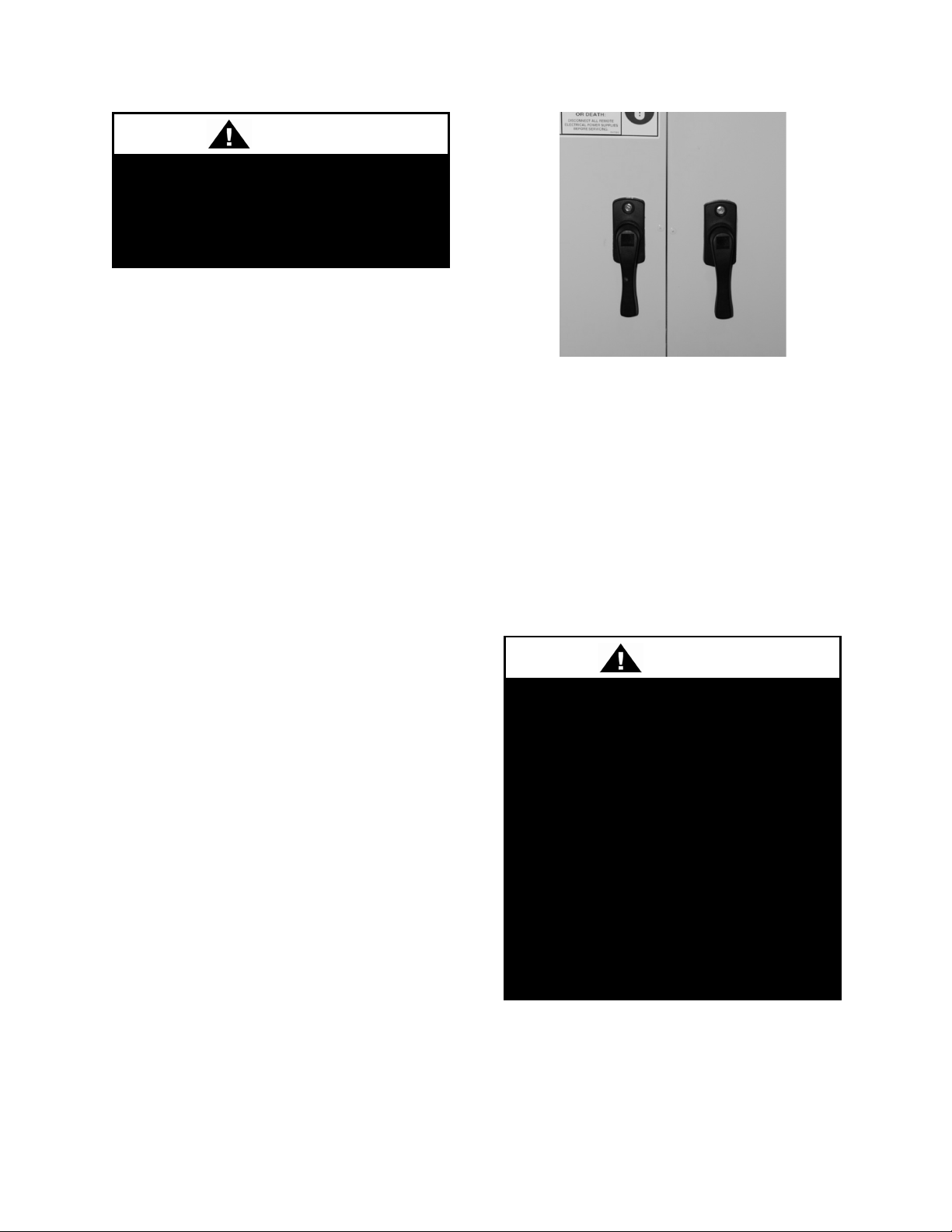

Figure 1 - Lockable Handle .......................................................................................................... 16

Figure 2 - SB Series ...................................................................................................................... 18

Figure 3 - SB Series Unit Orientation ........................................................................................... 19

Figure 4 - Drain Trap .................................................................................................................... 26

Figure 5 - SB Series Supply Fan ................................................................................................... 29

Figure 6 - ECM with Factory Provided Controls.......................................................................... 30

Figure 7 - ECM with Potentiometer Control ................................................................................ 30

Figure 8 - ECM with Field Installed Controls .............................................................................. 31

V14190 · Rev. B · 150727

(ACP 31227)

4

AAON SB Series Features and Options Introduction

Energy Efficiency

• Direct Drive Backward Curved Plenum

Supply Fans

• 10-100% Variable Capacity Scroll

Compressors

• Double Wall Rigid Polyurethane Foam

Injected Panel Construction

• Airside and Waterside Economizers

• Modulating SCR Electric Heat

• Modulating Head Pressure Control

• High Efficiency Electronically

Commutated Motors

• Coaxial Refrigerant-to-Water Heat

Exchanger

• Water-Source and Geothermal Heat

Pumps

• Single Zone Variable Air Volume

Indoor Air Quality

• Up to 100% Outside Air with Optional

Electric Pre-Heat

• Multiple High Efficiency Unit and

Mixing Box Filters

• Double Wall Construction with No

Exposed Insulation

Humidity Control

• 10-100% Variable Capacity Scroll

Compressors

• Modulating Hot Gas Reheat

Safety

• Freeze Stats

• Phase and Brown Out Protection

Installation and Maintenance

• Direct Drive Backward Curved Plenum

Supply Fans

• Clogged Filter Switch and Magnehelic

Gauge

• Color Coded Wiring Diagram

• Isolated Compressor and Controls

Compartment

• Compressor Isolation Valves

• Hinged Access Doors with Lockable

Handles

• Liquid Line Sight Glass

System Integration

• Customer Provided Controls

• Electric, Steam, or Hot Water Heating

• Refrigerant-to-Water Heat Exchangers

• Condensing Unit Only Options

• Split System Configurations

Environmentally Friendly

• R-410A Refrigerant

• Geothermal Heat Pump Configurations

Extended Life

• Standard 5 Year Compressor Warranty

• Double Wall Rigid Polyurethane Foam

Injected Cabinet Construction

• 2,500 Hour Salt Spray Tested Interior

and Exterior Corrosion Protection

• Polymer E-Coated Coils

• Stainless Steel Drain Pans

• Custom Color Paint Options

5

FIRE, EXPLOSION OR CARBON

Failure to replace proper controls

could result in fire, explosion or

to follow safety warnings exactly

and liquids in the vicinity of this

WARNING

Electric shock hazard. Before

servicing, disconnect all electrical

ELECTRIC SHOCK, FIRE OR

Failure to follow safety warnings

n dangerous

operation, serious injury, death or

Improper servicing could result in

Before servicing, disconnect all

may be

wires prior to disconnecting.

Verify proper operation after

Attention should be paid to the following statements:

Safety

NOTE - Notes are intended to clarify the unit installation, operation and maintenance.

CAUTION - Caution statements are given to prevent actions that may result in

equipment damage, property damage, or personal injury.

WARNING - Warning statements are given to prevent actions that could result in

equipment damage, property damage, personal injury or death.

DANGER - Danger statements are given to prevent actions that will result in equipment

damage, property damage, severe personal injury or death.

EXPLOSION HAZARD

exactly could result i

property damage.

dangerous operation, serious injury,

death or property damage.

electrical power to the unit. More

than one disconnect

provided.

When servicing controls, label all

Reconnect wires correctly.

servicing. Secure all doors with

key-lock or nut and bolt.

6

power to the unit, including remote

disconnects, to avoid shock hazard

or injury from rotating parts. Follow

proper Lockout-Tagout procedures.

MONOXIDE POISONING HAZARD

carbon monoxide poisoning. Failure

could result in serious injury, death or

property damage. Do not store or use

gasoline or other flammable vapors

appliance.

power to the unit has been

disconnected and fan wheel has

To prevent injury or death lifting

WARNING

All field installed wiring must be

completed by qualified personnel.

Field installed wiring must comply

to follow code requirements could

result in serious injury or death.

Provide proper unit ground in

accordance with these code

electrical components. Only a

qualified licensed electrician or

live electrical components shall

70E, an OSHA

regulation requiring an Arc Flash

marked for identification of where

appropriate Personal Protective

WARNING

During installation, testing, servicing

and troubleshooting of the equipment

it may be necessary to work with live

individual properly trained in handling

perform these tasks.

Standard NFPABoundary to be field established and

Equipment (PPE) be worn, should be

followed.

GROUNDING REQUIRED

UNIT HANDLING

equipment capacity shall exceed unit

weight by an adequate safety factor.

Always test-lift unit not more than 24

inches high to verify proper center of

gravity lift point to avoid unit damage,

injury or death.

ROTATING COMPONENTS

Unit contains fans with moving parts

that can cause serious injury. Do not

open door containing fans until the

stopped rotating.

with NEC/CEC, local and state

electrical code requirements. Failure

requirements.

Failure to properly drain and vent

coils when not in use during freezing

temperature may result in coil and

equipment damage.

7

not use alkaline chemical coil

CAUTION

CAUTION

A sufficient quantity of

WARNING

Always use a pressure regulator,

ges to control

WARNING

in place of refrigerant and dry

WARNING

Prior to connection of condensing

or death due to instantaneous

on all

should be checked for proper

CAUTION

Rotation must be checked

MOTORS AND COMPRESSORS of

3 phase units at startup by a qualified

service technician. Scroll

compressors are directional and can

be damaged if rotated in the wrong

direction. Compressor rotation must

be checked using suction and

discharge gauges. Fan motor rotation

operation. Alterations should only be

made at the unit power connection

WATER PRESSURE

water supply, verify water pressure is

less than maximum pressure shown

on unit nameplate. To prevent injury

release of high pressure water, relief

valves should be field supplied on

system water piping.

Do not use oxygen, acetylene or air

valves and gau

incoming pressures when pressure

testing a system. Excessive pressure

may cause line ruptures, equipment

damage or an explosion which may

result in injury or death.

Do not work in a closed area where

refrigerant or nitrogen gases may be

leaking.

vapors may be present and cause

injury or death.

Do not clean DX refrigerant coils with

hot water or steam. The use of hot

water or steam on refrigerant coils

will cause high pressure inside the

coil tubing and damage to the coil.

To prevent damage to the unit, do not

use acidic chemical coil cleaners. Do

nitrogen for leak testing. A violent

explosion may result causing injury or

death.

8

cleaners with a pH value greater than

8.5, after mixing, without first using

an aluminum corrosion inhibitor in the

cleaning solution.

by certain

chemicals. Polyolester (POE) oils

410A and other

and fittings and complete piping

CAUTION

Failure of the condenser due to

refrigerant circuit and will cause

verage under AAON

manufacturer warranties.

of chemical corrosion is excluded

from coverage under AAON Inc.

WARNING

Cleaning the cooling tower or the

condenser water loop with harsh

(muriatic acid) or chlorine, can

Care should be taken to avoid

allowing chemicals to enter the

cooled condenser. See

Heat Exchanger

Corrosion Resistance for more

CAUTION

Door compartments containing

CAUTION

Some chemical coil cleaning

Failure to follow

compounds are caustic or toxic. Use

these substances only in accordance

with the manufacturer’s usage

instructions.

instructions may result in equipment

damage, injury or death.

hazardous voltage or rotating parts

are equipped with door latches to

allow locks. Door latch are shipped

with nut and bolts requiring tooled

access. If you do not replace the

shipping hardware with a pad lock

always re-install the nut & bolt after

closing the door.

chemicals, such as hydrochloric acid

damage the water-cooled condenser.

OPEN LOOP APPLICATIONS

Failure of the condenser as a result

warranties and the heat exchanger

manufacturer’s warranties.

WATER FREEZING

freezing will allow water to enter the

extensive damage to the refrigerant

circuit components. Any damage to

the equipment as a result of water

freezing in the condenser is excluded

from co

warranties and the heat exchanger

PVC (Polyvinyl Chloride) and CPVC

(Chlorinated Polyvinyl Chloride) are

vulnerable to attack

waterAppendix A -

information.

used with Rrefrigerants, even in trace amounts,

in a PVC or CPVC piping system will

result in stress cracking of the piping

system failure.

9

To prevent motor overheating

compressors must cycle off for a

To maintain the proper oil level

compressors must cycle on for a

starts per hour.

WARNING

COMPRESSOR CYCLING

5 MINUTE MINIMUM OFF TIME

minimum of 5 minutes.

5 MINUTE MINIMUM ON TIME

minimum of 5 minutes.

The cycle rate must not exceed 6

1. Startup and service must be performed

by a Factory Trained Service

Technician.

2. The unit is for indoor use only. See

General Information section for more

unit information.

3. Every unit has a unique equipment

nameplate with electrical, operational,

and unit clearance specifications.

Always refer to the unit nameplate for

specific ratings unique to the model you

have purchased.

4. READ THE ENTIRE INSTALLATION,

OPERATION AND MAINTENANCE

MANUAL. OTHER IMPORTANT

SAFETY PRECAUTIONS ARE

PROVIDED THROUGHOUT THIS

MANUAL.

5. Keep this manual and all literature

safeguarded near or on the unit.

10

SB Series Feature String Nomenclature

:

SB - 007

- 3 - 0 - E 7 0 9 - 0 0 0

:

Model Options

GEN

SIZE

SB Series Feature String Nomenclature

MODEL OPTIONS

Series and Generation

SB

Unit Size

003 = 3 ton Capacity

004 = 4 ton Capacity

005 = 5 ton Capacity

006 = 6 ton Capacity

007 = 7 ton Capacity

009 = 9 ton Capacity

010 =10 ton Capacity

014 =14 ton Capacity

016 = 16 ton Capacity

018 = 18 ton Capacity

Voltage

1 = 230V/1Φ/60Hz

2 = 230V/3Φ/60Hz

3 = 460V/3Φ/60Hz

4 = 575V/3Φ/60Hz

8 = 208V/3Φ/60Hz

9 = 208V/1Φ/60Hz

Configuration

0 = Right Hand Unit + Top Vertical Discharge

A = Left Hand Unit + Top Vertical Discharge

A1: Refrigerant Style

E = R-410A Variable Capacity Scroll Compressor

A2: Unit Configuration

0 = Water-Cooled Condenser - Condensing Unit

Only

7 = Water-Source/Geothermal Heat Pump + Std

Evap. Coil - Coaxial Heat Exchanger

8 = Water-Source/Geothermal Heat Pump + 6 Row

Evap. Coil - Coaxial Heat Exchanger

9 = Water-Source/Geothermal Heat Pump Condensing Unit Only

A3: Coil Coating

0 = Standard

1 = Polymer E-Coated Cooling Coil

VLT

CONFIG

A1

A2

A3

A4

B1

B2

Unit Feature Options

B3

1A

1B

1C

1D 2 3 4 5A

5B

5C 6A

6B

6C 7 8 9

10

11

0 0 0 0 - 0 0 0 - A B C - 0 A 0 - 0 0 0 0 0 0 Y - E 0

0 0 0 0 0 0 0 A B

15

16

17

18

A4: Cooling / Heat Pump Staging

9 = Modulating - Variable Capacity Compressor

B1: Heating Type

0 = No Heating

3 = Electric Heat

C = Steam Distributing Standard Coil

D = Steam Distributing Polymer E-Coated Coil

E = Hot Water Standard Coil

F = Hot Water Polymer E-Coated Coil

B2: Heating Designation

0 = No Heating

1 = 1 Row Coil

2 = 2 Row Coil

A = 7 kW (5.3 kW @ 208V)

B = 14 kW (10.5 kW @ 208V)

C = 21 kW (15.8 kW @ 208V)

D = 28 kW (21.0 kW @ 208V)

E = 35 kW (26.3 kW @ 208V)

F = 42 kW (31.5 kW @ 208V)

G = 49 kW (37.0 kW @ 208V)

H = 56 kW (42.0 kW @ 208V)

J = 63 kW (47.3 kW @ 208V)

K = 70 kW (52.5 kW @ 208V)

B3: Heating Staging

0 = No Heating

1 = 1 Stage

2 = 2 Stage

3 = 3 Stage

4 = 4 Stage

9 = Modulating/SCR Electric - Potentiometer Control

A = Modulating/SCR Electric - 0-10VDC Control

Signal

H = Single Serpentine 8 fpi

J = Half Serpentine 8 fpi

K = Single Serpentine 10 fpi

L = Half Serpentine 10 fpi

M = Single Serpentine 12 fpi

N = Half Serpentine 12 fpi

12

19

13 14A

20

21

14B

22

23

11

SB Series Feature String Nomenclature

:

1A

1C

1D 2

3 4

5A

5C

6B

6C 7 8 9

: 0 0 0 0 - 0 0 0 - A B C - 0 A 0 - 0 0 0

Model Options

GEN

SIZE

VLT

CONFIG

A1

A2

A3

A4

B1

B2

B3

1B

Unit Feature Options

5B

6A

10

11

12

13 14A

14B

SB - 007 - 3 - 0 - E 7 0 9 - 0 0 0

UNIT FEATURE OPTIONS

1A: Return / Outside Air Section

0 = Standard

2 = Mixing Box - Top and Front Openings

1B: Blank

0 = Standard

1C: Filter Location

0 = Standard

1D: Mixing Box Damper Control

0 = Standard - None

A = 2 Position Actuators (24V)

B = Fully Modulating Actuators (DDC)

C = Fixed Position Dampe r s

2: Waterside Economizer

0 = Standard - None

3: Blank

0 = Standard

4: Maintenance Options

0 = Standard

A = Blower Aux. Contact - Low Voltage Terminal

Block

B = Remote Start/Stop Terminals - Low Voltage

Terminal Block

C = Options A + B

5A: Supply Air Blower Configuration

0 = No Airside - Condensing Unit Only

A = 1 Blower + High Efficiency EC Motor

B = 2 Blowers + High Efficiency EC Motors

5B: Supply Air Blower

0 = No Airside - Condensing Unit Only

A = 310 mm (14”) Direct Drive Backwa rd C ur ve d

Plenum Fan

B = 355 mm (16”) Direct Drive Backward Curved

Plenum Fan

C = 450 mm (18”) Direct Drive Backward Curved

Plenum Fan

0 0 0 0 0 0 0 A B

15

5C: Supply Air Blower Motor

0 = No Airside - Condensing Uni t Only

C = 1.7 kW (2.3 hp)

D = 3.0 kW (4.0 hp)

E = 6.0 kW (8.0 hp)

6A: Pre-Filter Type

0 = No Pre Filter

A = 2” Pleated - 30% Eff. - MERV 8

6B: Unit Filter Type

0 = No Unit Filter

A = 2” Pleated - 30% Eff. - MERV 8

B = 4” Pleated - 30% Eff. - MERV 8

C = 4” Pleated - 65% Eff. - MERV 11

D = 4” Pleated - 85% Eff. - MERV 13

E = 4” Pleated - 95% Eff. - MERV 14

6C: Filter Options

0 = Standard

A = Clogged Filter Switch

B = Magnehelic Gauge

C = Options A + B

7: Refrigeration Control

0 = Standard

C = Freeze Stat - Each Circuit

8: Refrigeration Options

0 = Standard

D = Modulating Hot Gas Reheat

9: Refrigeration Accessories

0 = Standard

A = Sight Glass

B = Compressor Isolation Valves

C = Options A + B

0 0 0 Y - E 0

16

17

18

19

20

21

22

23

12

SB Series Feature String Nomenclature

:

11

0 0 0 Y - E 0

0 0 0

0

15

16

18

Model Options

GEN

SIZE

VLT CONFIG A1

A2

A3

A4 B1

B2

B3 1A

1B

1C

1D 2 3 4 5A

SB - 007 - 3 - 0 - E 7 0 9 - 0 0 0 : 0 0 0 0 - 0 0 0 - A B C - 0 A 0 - 0 0 0

10: Power Options

0 = Standard Power Block

11: Safety Options

0 = Standard

C = Supply Air Smoke Detector

H = Remote Safety Shutoff Terminals

L = Options A + H

12: Controls

0 = Standard

A = Low Limit Controls

B = Phase and Brown Out Protection

C = Options A + B

13: Special Controls

D = VAV Unit Controller - VAV Cool + CV Heat

Y = VAV Single Zone Heat Pump Unit Controller VAV Cool + VAV Heat

Z = Constant Volume Heat Pump Unit Controller CV Cool + CV Heat

1 = Make Up Air Heat Pump Unit Controller - CV

Cool + CV Heat

5 = Field Installed DDC C ontrols by Others with

Isolation Relays

6 = Factory Installed DDC Controls Furnished by

Others with Isolation Relays

14A: Water-Cooled Co ndenser

0 = Standard - None

B = Water Flow Switch

E = Balancing Valves + Option B

H = Motorized Shut-Off Valve + Option B

J = Head Pressure Control + Option B

L = Balancing Valves + Option H

M = Balancing Valves + Option J

T = CuNi Corrosion Resistant Coaxial Heat

Exchanger + Option B

W = CuNi Corrosion Resistant Coaxial Heat

Exchanger + Option E

1 = CuNi Corrosion Resistant Coaxial Heat

Exchanger + Option H

2 = CuNi Corrosion Resistant Coaxial Heat

Exchanger + Option J

4 = CuNi Corrosion Resistant Coaxial Heat

Exchanger + Option L

5 = CuNi Corrosion Resistant Coaxial Heat

Exchanger + Option M

14B: Waterside Economizer Piping

0 = Standard - None

15: Glycol Percentage

0 = Standard - None

A = Minimum 20% Propylene Glycol

B = Minimum 40% Propylene Glycol

16: Interior Cabinet Options

0 = Standard - Double Wall Construction + R-6.5

Foam Insulation + Stainless Steel Drain Pan

A = Overflow Switch

B = Compressor Sound Blanket

C = Options A + B

17: Exterior Cabinet Options

0 = Standard

A = AAON Gray Exterior Paint

B = Special Paint

C = Interior Corrosion Protection

D = Options A + C

18: Blank

0 = Standard

Unit Feature Options

5B

5C 6A

6B

6C 7 8 9

10

12

13

14A

14B

0 0 0 A B

19

20

21

22

17

23

13

SB Series Feature String Nomenclature

:

0 0 0 A B

Model Options

GEN

SIZE

VLT CONFIG A1

A2

A3

A4 B1

B2

B3 1A

1B

1C

1D 2 3 4 5A

SB - 007 - 3 - 0 - E 7 0 9 - 0 0 0 : 0 0 0 0 - 0 0 0 - A B C - 0 A 0 - 0 0 0 0 0 0 Y - E 0

19: Code Options

0 = Standard - ETL U.S.A. Listing

20: Crating

0 = Standard

A = Export Crating

B = Forkliftable Base - 5” Base

D = Options A + B

E = Shipping Shrink Wrap

22: Control Vendors

0 = Standard

A = WattMaster Orion Controls System

23: Type

B = Standard

X = Special Pricing Authorization

F = Options B + E

G = Options A + B + E

21: Unit Splits

0 = Standard - One Piece Unit

A = Two Piece Unit - One Compressorized Section +

One Air Tunnel Section

Unit Feature Options

5B

5C 6A

6B

6C 7 8 9

0 0 0 0

15

10

11

12

13

14A

16

17

18

19

20

21

22

14B

23

14

Coils and sheet metal surfaces

be taken when working with

recovery, recycling, or reclaiming

must be followed.

“construction heater” at anytime

during any phase of construction.

Very low return air temperatures,

CAUTION

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

WARNING

General Information

SB Series self contained units have been

designed for indoor installation only. Units

are assembled, wired, charged and runtested at the factory.

personal injury or loss of life. Startup

and service must be performed by a

Factory Trained Service Technician.

A copy of this IOM should be kept

with the unit.

These units must not be used as a

harmful vapors, and misplacement of

the filters will damage the unit and its

efficiency.

Certification of Steam or Hot Water Heat

Models

a. Certified as a forced air heating system

with cooling.

b. Certified for indoor installation only.

Certification of Electric Heat Models

a. Certified as an electric warm air furnace

with cooling.

b. Certified for indoor installation only.

Certification of Cooling Models

a. Certified as a commercial central air

conditioner with electrically operated

compressors.

b. Certified for indoor installation only.

c. Certified with refrigerant R-410A coils.

Codes and Ordinances

SB Series units have been tested and

certified, by ETL, in accordance with UL

Safety Standard 1995/CSA C22.2 No. 236.

System should be sized in accordance with

the American Society of Heating,

Refrigeration and Air Conditioning

Engineers Handbook.

Installation of units must conform to the

ICC standards of the International

Mechanical Code, the International Building

Code, Installation of Air Conditioning and

Ventilating Systems Standard, NFPA 90A,

and local building, plumbing and waste

water codes. All appliances must be

electrically grounded in accordance with

local codes, or in the absence of local codes,

the current National Electric Code,

ANSI/NFPA 70 or the current Canadian

Electrical Code CSA C22.1.

The Clean Air Act of 1990 bans the

intentional venting of refrigerant as of

July 1, 1992. Approved methods of

present sharp edges and care must

equipment.

15

To prevent motor overheating

compressors must cycle off for a

oil level

compressors must cycle on for a

starts per hour.

WARNING

Failure to observe the following

WARNING

instructions will result in premature

failure of your system and possible

voiding of the warranty.

Receiving Unit

When received, the unit should be checked

for damage that might have occurred in

transit. If damage is found it should be noted

on the carrier’s Freight Bill. A request for

inspection by carrier’s agent should be made

in writing at once.

Nameplate should be checked to ensure the

correct model sizes and voltages have been

received to match the job requirements.

If repairs must be made to damaged goods,

then the factory should be notified before

any repair action is taken in order to protect

the warranty. Certain equipment alteration,

repair, and manipulation of equipment

without the manufacturer’s consent may

void the product warranty. Contact the

AAON Warranty Department for assistance

with handling damaged goods, repairs, and

freight claims: (903) 236-4403.

Note: Upon receipt check shipment for

items that ship loose such as filters and

remote sensors. Consult order and shipment

documentation to identify potential looseshipped items. Loose-shipped items may

have been placed inside unit cabinet for

security. Installers and owners should secure

all doors with locks or nuts and bolts to

prevent unauthorized access.

The warranty card must be completed in full

and returned to AAON not more than 3

months after unit is delivered.

16

Figure 1 - Lockable Handle

Storage

If installation will not occur immediately

following delivery, store equipment in a dry

protected area away from construction

traffic and in the proper orientation as

marked on the packaging with all internal

packaging in place. Secure all loose-shipped

items.

Direct Expansion (DX) Systems

COMPRESSOR CYCLING

5 MINUTE MINIMUM OFF TIME

minimum of 5 minutes.

5 MINUTE MINIMUM ON TIME

To maintain the proper

minimum of 5 minutes.

The cycle rate must not exceed 6

Loading...

Loading...