Page 1

RSMD

Technical Guide

Page 2

TABLE OF CONTENTS

OVERVIEW ....................................................................................................................................... 4

Features and Applications ........................................................................................................................................ 4

Module Dimensions ................................................................................................................................................. 5

INSTALLATION & WIRING ............................................................................................................... 6

Input Wiring .............................................................................................................................................................. 6

Suction Pressure Sensor ....................................................................................................................................6

Head Pressure Sensor ....................................................................................................................................... 6

Compressor Discharge Temperature Sensors ....................................................................................................6

Output Wiring ...........................................................................................................................................................7

Modulating Compressor ...................................................................................................................................... 7

Condenser Fan Signal ........................................................................................................................................7

INPUTS & OUTPUTS ....................................................................................................................... 8

SEQUENCE OF OPERATIONS ........................................................................................................ 10

Cooling Mode ......................................................................................................................................................... 10

Dehumidifi cation Operation .................................................................................................................................... 10

Head Pressure Control .......................................................................................................................................... 11

AAON/WattMaster Controls Inc.

8500 NW River Park Drive · Parkville, MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 ·

E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

Copeland Digital Scroll™ is a registered trademark

of Copeland Corporation, Sidney, OH

2

www.aaon.com

WattMaster Form: AA-RSMD-TGD-01D

Copyright April 2018 WattMaster Controls, Inc.

AAON Part Number: V87380

®

is a registered trademark of AAON, Inc., Tulsa, OK.

AAON

Neither WattMaster Controls, Inc. nor AAON® assumes any

responsibility for errors or omissions in this document.

This document is subject to change without notice.

RSMD Technical Guide

Page 3

TABLE OF CONTENTS

RSMD LCD SCREENS .................................................................................................................... 12

RSMD Main Screens Map ..................................................................................................................................... 13

RSMD Module Screens ......................................................................................................................................... 13

System Status Screens ..........................................................................................................................................14

Sensor Status Screens .......................................................................................................................................... 15

Setpoint Status Screens ........................................................................................................................................ 16

Alarms Screen and Defi nitions ............................................................................................................................... 17

Alarm History Screen .............................................................................................................................................18

Protected Screens Map ......................................................................................................................................... 18

Confi guration Screens ........................................................................................................................................... 19

Diagnostics Screens .............................................................................................................................................. 19

Alarm Count Screen ...............................................................................................................................................21

Address Screen ..................................................................................................................................................... 21

TROUBLESHOOTING ..................................................................................................................... 22

LED Diagnostics .................................................................................................................................................... 22

OE275-01 Suction Pressure Transducer Testing for R410A .................................................................................. 23

Copeland

Leaving Water Temperature Sensor Testing .......................................................................................................... 25

Head Pressure Transducer Troubleshooting .........................................................................................................26

®

Discharge Thermistor Temperature Sensor Testing ............................................................................. 24

APPENDIX: CONDENSER CONFIGURATION OPTIONS ................................................................ 27

Two Condenser Per RSMD .................................................................................................................................... 28

One Condenser Per RSMD ................................................................................................................................... 30

One Condenser Per 2 RSMDs ...............................................................................................................................32

One Condenser Per 3 RSMDs ...............................................................................................................................34

Two Condensers Per 2 RSMDs ............................................................................................................................. 36

On/Off Condenser Options..................................................................................................................................... 39

RSMD Technical Guide

3

Page 4

OVERVIEW

RSMD Overview

Features & Applications

The OE370-26-RSMD Refrigerant System Module for Digital

Compressors (RSMD) (AAON Part No: V61520) can monitor and

control up to two compressors and condensers. The compressors can

be in either a tandem or non-tandem confi guration. The module is

designed for R410-A refrigerant.

The RSMD is connected to the VCC-X / VCCX2 Controller.

Up to 4 RSMD’s can be connected, depending on the size of the

system. There are 2 E-BUS Expansion Ports which allow the use of

communicating sensors and the E-BUS Modules.

The RSMD provides 3 analog inputs, 4 binary inputs, 5 relays, and

2 analog outputs. See Figures 2 & 3, pages 6 & 7 for wiring.

The RSMD Module provides the following:

• Modulates the Compressors to satisfy the Suction

Coil (Saturated) Temperature. The Suction Coil (Satu rated) Temperature Setpoint is reset by the VCC-X /

VCCX2 Controller to maintain the Supply Air

Temperature during Cooling mode. During Dehumidi fi cation mode, it controls the Compressors to the

Suction (Saturation) Temperature Setpoint.

• In Heating mode, the RSMD modulates and stages

the compressors to maintain a given Supply Air

Temperature Setpoint.

• Modulates the Condenser Fan or Valve to maintain

the Head Pressure Setpoint.

• Provides alarms and safeties for the Compressor and

Condenser operation.

• Allows connection of the Modular Service Tool SD

to the module when required communication wire is

run to the VCC-X / VCCX2 Controller.

• Provides a 2 x 8 LCD character display and 4 buttons

that allow for status of system operation, system

setpoints, system con gurations, sensors, and alarms,

and to change the module’s address, if necessary.

4

RSMD Technical Guide

Page 5

OVERVIEW

M

ENTER

UP

DOWN

ALARM

MENU

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

AAON No.: V61520

+24 VAC

GND

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

CONDENSER 1

COMP 1

COMP 2

ANALOG OUTPUTS

REVERSING VALVE

COMMON

RELAYOUTPUT

TERMINALS

www.aaon.com

WattMaster Overlay

# 000072 Rev1DSW

CONDENSER 1

CONDENSER 2

GND

24 VAC

POWER ONLY

WARNING!

POLARITY

MUST BE

OBSERVED

OR THE

CONTROLLER

WILLBE

DAMAGED

CONDENSER 2

SUCTION

PRESSURE 1

SENSOR

HEAD

PRESSURE 1

SENSOR

TEMP

SENSORS

BINARY

INPUTS

+5 V

+5 V

COMP DIS TEMP1

COMP STATUS 1

SP-1

HP-1

COMP DIS TEMP2

COMP 2STATUS

GND

GND

OUTSIDE COILTEMP / POWF

EMERGENCY SHUTDOWN

GND

LEAVING WATERTEMP

GND

SUCTION

PRESSURE 2

SENSOR

HEAD

PRESSURE 2

SENSOR

+5 V

+5 V

SP-2

HP-2

GND

GND

R+

SHD

T-

HH COMMUNICATIONS

E-BUS

R+ SHD T-

DUAL E-BUS

EXPANSION

RSMD Dimensions

G5Q-1A4

OMRON

DC12V

CHINA

10A250VAC~

5A30VDC

SA

VDE

Figure 1: RSMD Dimensions

RSMD Technical Guide

5

Page 6

WIRING

M

ENTER

UP

DOWN

ALARM

MENU

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

AAON No.: V61520

+24 VAC

GND

RELAY CONTACT

RATING IS 1AMP

MAX @ 24 VAC

CONDENSER 1

COMP 1

COMP 2

ANALOG OUTPUTS

REVERSING VALVE

COMMON

RELAY OUTPUT

TERMINALS

www.aaon.com

WattMaster Overlay

# 000072 Rev1DSW

CONDENSER 1

CONDENSER 2

GND

24 VAC

POWER ONLY

WARNING!

POLARITY

MUST BE

OBSERVED

OR THE

CONTROLLER

WILL BE

DAMAGED

CONDENSER 2

SUCTION

PRESSURE 1

SENSOR

HEAD

PRESSURE 1

SENSOR

TEMP

SENSORS

BINARY

INPUTS

+5 V

+5 V

COMP DIS TEMP 1

COMP STATUS 1

SP-1

HP-1

COMP DIS TEMP 2

COMP 2STATUS

GND

GND

OUTSIDE COIL TEMP / POWF

EMERGENCY SHUTDOWN

GND

LEAVING WATER TEMP

GND

SUCTION

PRESSURE 2

SENSOR

HEAD

PRESSURE 2

SENSOR

+5 V

+5 V

SP-2

HP-2

GND

GND

R+

SHD

T-

HH COMMUNICATIONS

E-BUS

R+ SHD T-

DUAL E-BUS

EXPANSION

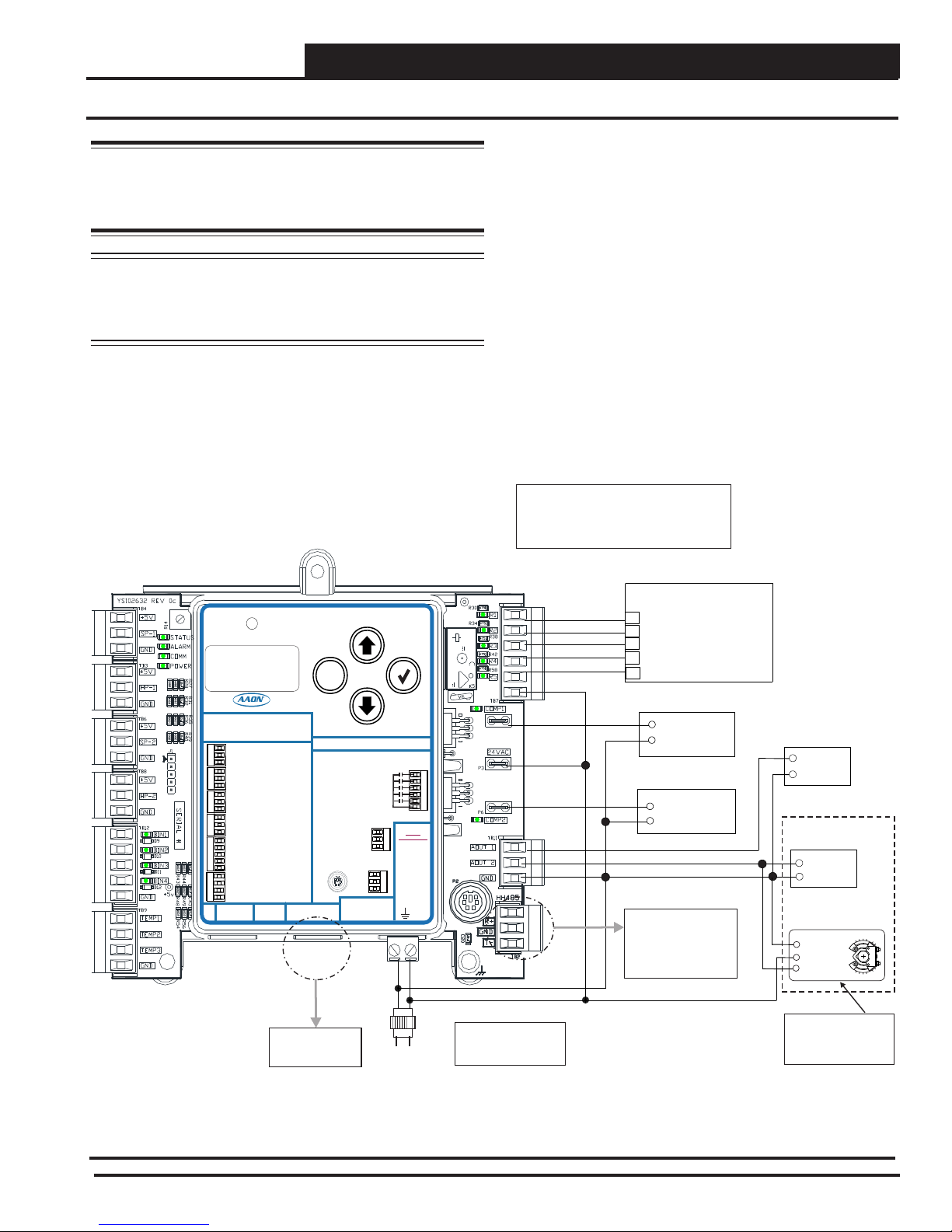

RSMD Inputs Wiring

RSMD Wiring

The RSMD monitors and controls one refrigeration circuit of the

HVAC unit. The module is designed for R410-A refrigerant.

The RSMD is connected to the VCC-X or VCCX2 Controller.

Up to 4 RSMD’s can be connected, depending on the size of the

system. There are 2 E-BUS Expansion Ports which allow the use of

communicating sensors and the E-BUS Modules.

The RSMD provides 3 analog inputs, 4 binary inputs, 5 relays, and

2 analog outputs. See Figure 2, below for inputs wiring and Figure

3, page 7 for outputs wiring.

Suction Pressure Sensor Wiring

The OE275-01 Suction Pressure Transducers must be wired as

shown in Figure 2, below. It is typically required for all VCC-X /

VCCX2 applications.

The Suction Pressure Sensors are used to measure suction pressure

at the HVAC unit’s DX evaporator coil suction line. This suction

line pressure is converted to saturated refrigerant temperature.

The saturated refrigerant temperature is used to properly control

the compressors to maintain a given Suction Coil (Saturated)

Temperature Setpoint. In Cooling mode, the VCC-X / VCCX2 resets

the Suction Coil (Saturated) Temperature Setpoint to maintain a

given supply air temperature setpoint. In Dehumidifi cation mode, the

Suction Coil (Saturated) Temperature Setpoint is a user confi gurable

setpoint that can be reset based on indoor humidity levels.

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

SUCTION PRESSURE 1

SENSOR

RD

WH

BK

HEAD PRESSURE 1

SENSOR

(BY OTHERS)

SUCTION PRESSURE 2

SENSOR

HEAD PRESSURE 2

SENSOR

(BY OTHERS)

RD

WH

BK

RD

WH

BK

RD

WH

BK

COMP STATUS 1

COMP STATUS 2

OUTSIDE COIL TEMP/POWF

COMP. DISCHARGE

TEMP. 1 SENSOR

COMP. DISCHARGE

TEMP. 2 SENSOR

Figure 2: RSMD Inputs Wiring

6

LEAVING WATER

TEMP SENSOR

EMERGENCY SHUTDOWN

+V

SP

GND

+V

HP

GND

+V

SP

GND

+V

HP

GND

BIN1

BIN2

BIN3

BIN4

GND

TEMP 1

TEMP 2

TEMP 3

GND

Size Transformer For

Correct Total Load.

RSMD = 18 VA

RSMD Technical Guide

GND

Line Voltage

24VAC

G5Q-1A4

OMRON

DC12V

CHINA

10A250VAC ~

5A30VDC

SA

VDE

Page 7

WIRING

M

ENTER

UP

DOWN

ALARM

MENU

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

AAON No.: V61520

+24 VAC

GND

RELAY CONTACT

RATING IS 1AMP

MAX @ 24 VAC

CONDENSER 1

COMP 1

COMP 2

ANALOG OUTPUTS

REVERSING VALVE

COMMON

RELAYOUTPUT

TERMINALS

www.aaon.com

WattMaster Overlay

# 000072 Rev1DSW

CONDENSER 1

CONDENSER 2

GND

24 VAC

POWER ONLY

WARNING!

POLARITY

MUST BE

OBSERVED

OR THE

CONTROLLER

WILL BE

DAMAGED

CONDENSER 2

SUCTION

PRESSURE 1

SENSOR

HEAD

PRESSURE 1

SENSOR

TEMP

SENSORS

BINARY

INPUTS

+5 V

+5 V

COMP DIS TEMP 1

COMP STATUS 1

SP-1

HP-1

COMP DIS TEMP 2

COMP 2STATUS

GND

GND

OUTSIDE COIL TEMP / POWF

EMERGENCY SHUTDOWN

GND

LEAVING WATER TEMP

GND

SUCTION

PRESSURE 2

SENSOR

HEAD

PRESSURE 2

SENSOR

+5 V

+5 V

SP-2

HP-2

GND

GND

R+

SHD

T-

HH COMMUNICATIONS

E-BUS

R+ SHD T-

DUAL E-BUS

EXPANSION

RSMD Outputs Wiring

CAUTION: The Shraeder port used for installation of the

suction pressure transducer should be located in a vertical

position of the suction line to prevent refrigerant oil from

accumulating in the sensor.

NOTE: If there are two Compressors on a single circuit

(a tandem circuit), Suction Pressure 2, Head

Pressure 2, and Condenser Signal 2 would not be

used.

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

CHINA

10A250VAC ~

5A30VDC

Head Pressure Control

The Head Pressure Transducers are used to measure Head Pressure at

the discharge line. This Head Pressure is used to drive the Condenser

Fans with a 0-10 VDC output signal or valve with a 2-10 VDC output

signal to maintain a given Head Pressure Setpoint.

Compressor Discharge Sensors

The Digital Compressor Discharge Temperature Sensor monitors

the discharge temperature from the Digital Compressor to protect

against overheating.

Leaving Water Temperature Sensor

The Leaving Water Temperature Sensor is used to measure the

Leaving Water Temperature when used on a WSHP unit.

NOTE:

ALL RELAY OUTPUTS ARE NORMALLY

OPEN AND RATED FOR 24 VAC POWER

ONLY - 1 AMP MAXIMUM LOAD

24 VAC ONLY

G5Q-1A4

OMRON

DC12V

SA

VDE

RLY1

RLY2

RLY3

RLY4

RLY5

COMM

UNLOAD

24 VAC

UNLOAD

AOUT1

AOUT2

GND

COMPRESSOR 1 ENABLE

COMPRESSOR 2 ENABLE

CONDENSER 1 ENABLE

CONDENSER 2 ENABLE

REVERSING VALVE

DIGITAL

COMPRESSOR 1

+

GND

DIGITAL

COMPRESSOR 2

+

GND

CONDENSER

SIGNAL 1

+

COM

CONDENSER

SIGNAL 2

+

COM

Connect to

VCC-X or

VCCX2 Controller

Figure 3: RSMD Outputs Wiring

RSMD Technical Guide

GND

Line Voltage

24VAC

Size Transformer For

Correct Total Load.

RSMD = 18 VA

Connects To VCC-X

or VCCX2 Loop

Communications

Connector When Used

On A Split System.

WSE BYPASS

VALVE ACTUATOR

1 COM

2 +

3Y1

Belimo Actuator Wiring

Shown. Consult Factory

For Other Manufacturer

Wiring Instructions

7

Page 8

INPUTS & OUTPUTS

RSMD Input/Output Map

REFRIGERATION SYSTEM MODULE

FOR DIGITAL COMPRESSORS

Analog Inputs

1 Suction Pressure 1 Sensor (SP-1)

2 Head Pressure 1 Sensor (HP-1)

3 Suction Pressure 2 Sensor (SP-2)

4 Head Pressure 2 Sensor (HP-2)

Compressor Discharge Temperature Sensor 1

5

(TEMP1)

Compressor Discharge Temperature Sensor 2

6

(TEMP2)

7 Leaving Water Temperature Sensor (TEMP3)

Binary Inputs

1 Compressor Status 1 (BIN1)

2 Compressor Status 2 (BIN2)

Outside Coil Temperature / Proof of Water Flow

3

(BIN3)

4 Emergency Shutdown (BIN4)

Analog Outputs (0-10 VDC)

1 Condenser 1 Fan Signal (AOUT1)

Condenser 2 Fan Signal (0-10 VDC) or WSE

2

Bypass Actuator (2-10 VDC) (AOUT2)

Binary Outputs (24 VAC)

1 Compressor 1 Enable Relay (RLY1)

2 Compressor 2 Enable Relay (RLY2)

3 Condenser 1 Enable Relay (RLY3)

Zone

Zone

4 Condenser 1 Enable Relay (RLY4)

Table 1: RSMD Inputs & Outputs

8

RSMD Technical Guide

Page 9

INPUTS & OUTPUTS

RSMD Inputs & Outputs

RSMD - Inputs & Outputs

+5V VDC Power

This output is a 5 VDC output that supplies power to the Suction

Pressure Transducers.

SP-1 & SP-2 - Suction Pressure Transducers

The Suction Pressure Sensors are used to measure suction pressure

at the HVAC unit’s DX evaporator coil suction line. This suction

line pressure is converted to saturated refrigerant temperature. The

saturated refrigerant temperature is used to properly control the

compressors to maintain a given Suction Coil (Saturated) Temperature

Setpoint. In Cooling mode, the VCC-X / VCCX2 resets the Suction

Coil (Saturated) Temperature Setpoint to maintain a given supply air

temperature setpoint. In Dehumidifi cation mode, the Suction Coil

(Saturated) Temperature Setpoint is a user confi gurable setpoint that

can be reset based on indoor humidity levels.

+5V VDC Power

This output is a 5 VDC output that supplies power to the Head Pressure Transducer.

HP-1 & HP-2 - Head Pressure Transducers

The Head Pressure Transducers are used to measure Head Pressure at

the discharge line. This Head Pressure is used to drive the Condenser

Fans to maintain a given Head Pressure Setpoint.

TEMP1 & TEMP2 - Compressor Discharge Temperature Sensor 1 & Sensor 2 Input

The Digital Compressor Discharge Temperature Sensors monitor

the discharge temperature from the Digital Compressor to protect

against overheating.

TEMP3 - Leaving Water Temperature Sensor Input

This input monitors the Condenser Leaving Water Temperature and

determines if the water source condenser is operating in a safe water

temperature range.

BIN1 - Compressor Status 1

When this wet contact input closes, a 24 volt signal to Binary Input

#1 indicates that Compressor 1 is running. Typically, the source for

this is relay output 1. If Binary Input 1 opens, Compressor 1 Enable

Relay will de-energize and a Compressor Alarm will be generated.

BIN2 - Compressor Status 2

When this wet contact input closes, a 24 volt signal to Binary Input

#2 indicates that Compressor 2 is running. Typically, the source for

this is relay output 2. If Binary Input 2 opens, Compressor 2 Enable

Relay will de-energize and a Compressor Alarm will be generated

BIN3 - Outside Coil Temperature / Proof of Water

Flow Status

This input can be used for the following two options:

Air to Air Heat Pump

This wet contact input monitors a Defrost Coil Temperature Switch

on air to air heat pump units. If the compressors are operating in the

Heating Mode and this switch closes, it will initiate a Defrost Mode.

Water Source Heat Pump

This wet contact input is for the Water Proof of Flow Switch. If

the Water Proof of Flow Switch contact opens while the Condenser

Valve is operating, the controller will react to protect the system

depending on the current mode of operation.

BIN4 - Emergency Shutdown

This wet contact input is used to initiate shutdown of the HVAC unit

when a N.C. Smoke Detector (by others), Firestat (by others), or other

shutdown condition (by others) contact is opened. The controller

remains active and can initiate alarm relays.

NOTE: The Binary Inputs require wet contacts (24 VAC

only) to recognize an active input. If you provide dry

contacts, the contact closure will not be recognized.

AOUT1 - Condenser Fan 1 Signal

This 0-10 VDC output is used to control/modulate the Condenser 1

Fan /Valve to maintain the Head Pressure Setpoint.

AOUT2 - Condenser Fan 2 Signal or Waterside

Economizer Bypass Actuator Valve

This 0-10 VDC output is used to control/modulate the Condenser

2 Fan /Valve to maintain the Head Pressure Setpoint or this output

signal is a Direct Acting 2-10 VDC output signal that is used to

modulate the Water Side Economizer Bypass Actuator.

RLY1 - Compressor 1 Enable

This relay enables the Compressor 1.

RLY2 - Compressor 2 Enable

This relay enables the Compressor 2.

RLY3 - Condenser 1 Enable

This relay enables the Condenser 1 Fan / Water Valve.

RLY4 - Condenser 2 Enable

This relay enables the Condenser 2 Fan / Water Valve.

.

RLY5 - Reversing Valve Enable

This relay enables the Reversing Valve.

RSMD Technical Guide

9

Page 10

Zone

SEQUENCE OF OPERATIONS

Cooling Mode & Dehumidifi cation Operation

Zone

Cooling Mode Operation

In the Cooling Mode, as the Supply Air Temperature (SAT) rises

above the Active SAT Cooling Setpoint, the compressors will stage

on and modulate to maintain the Active Evaporator Coil Suction

(Saturated) Temperature Setpoint. Two compressors are controlled

per Refrigerant System Module (RSMD). Multiple RSMDs are

needed when there are more than two compressors

In units with one digital and one fi xed compressors, if the digital

compressor modulates to 100% and the SAT is still above the SAT

Cooling Setpoint for the Cooling Stage Up Delay, then the fi xed

compressor will stage on. The digital compressor will then be

allowed to modulate as necessary to maintain the Active Evaporator

Coil Suction (Saturated) Temperature Setpoint. Minimum off times

must also be met before compressors can stage on.

In units with multiple digital compressors, if the 1st digital

compressor modulates to 100% and the SAT is still above the SAT

Cooling Setpoint for the Cooling Stage Up Delay, then the 2nd digital

compressors will enable and the two digital Compressors will then

modulate together to maintain the Active Evaporator Coil Suction

(Saturated) Temperature Setpoint.

To stage down compressors, if the digital compressor(s) have

modulated down to 30% for the Stage Down Delay period and the

SAT has fallen below the SAT Cooling Setpoint minus the Stage

Control Window, then the last compressor to have staged on (digital

or Fixed) will stage off – assuming its Minimum Run Time has

been met. Any remaining digital compressors are then allowed to

modulate as needed. If the last remaining digital compressor reaches

0% for the Stage Down Delay, it will stage off .

Dehumidifi cation Operation

The RSMD activates the Cooling Stages based on the actual

Evaporator Coil Temperature compared to the Evaporator Coil

Suction (Saturation) Temperature Setpoint. The Evaporator Coil

Suction (Saturation) Temperature is calculated by using the Suction

Pressure Sensor and converting the pressure to temperature.

For Copeland Digital Scroll™ Compressor units, the RSMD will

modulate the Copeland Digital Scroll™ Compressor to maintain

the Evaporator Coil Suction (Saturation) Temperature Setpoint and

activate the Compressors as necessary.

On units that have one Digital and one Fixed Capacity Compressor,

if the Fixed Capacity Compressor is activated, the Copeland Digital

Scroll™ Compressor will only be allowed to modulate within the

range of 70% - 100% in order to prevent the loss of reheat capacity

during low load conditions. If, with both compressors on, the 1st

digital compressor has modulated down to its 70% minimum and

the Coil Suction Temperature falls below the Coil Temperature

Setpoint minus the Cooling Stage Control Window, then the second

compressor will stage off once its Compressor Minimum Run Time

and the Stage Down Delay Timers have been met. At that point, the

Copeland Digital Scroll™ Compressor can modulate down as needed

to maintain the Coil Temperature Setpoint.

If the RSMD has two Digital Compressors, the 1st Compressor will

be locked at 100% and the 2nd Compressor will modulate.

10

RSMD Technical Guide

Page 11

SEQUENCE OF OPERATIONS

Head Pressure Control

The Refrigeration System Module for Digital Compressors (RSMD)

can monitor a Head Pressure Transducer and control a Condenser

Fan to maintain a Head Pressure Setpoint. The RSMD must be

confi gured for an Air Cooled Condenser.

A Condenser Relay is commanded on when the fi rst compressor is

enabled (except if the unit is in Heat Pump Defrost Mode). On an

Air Cooled Unit, the Condenser Fan will be controlled with 0-10

VDC output signal.

When the Condenser Signal fi rst activates, it maintains at 100% for

10 seconds.

In the Cooling Mode, the Condenser Signal will modulate to maintain

the Cooling Head Pressure Setpoint. The signal can modulate

between 15% and 100%. If the Head Pressure exceeds 550 PSIG,

the condenser control signal will immediately go to 100% and a

High Head Pressure Alarm will be generated. The alarm will be

deactivated when the Head Pressure drops below 540 PSIG.

Head Pressure Control

In the Dehumidifi cation Mode, the Condenser Output Signal controls

to the Reheat Head Pressure Setpoint. High Head Pressure conditions

produce the same eff ects as in the Cooling Mode.

If no Head Pressure Sensor is detected, the Condenser Output Signal

will be maintained at 100%.

RSMD Technical Guide

11

Page 12

LCD SCREENS

LCD Display Screen & Navigation Keys

LCD Display Screen & Navigation

Keys

The LCD display screens and buttons allow you to view status and

alarms, and enable force modes. See Figure 4, below and refer to

Table 2 for descriptions.

Figure 4: LCD Display and Navigation Keys

NAVIGATION

KEY

MENU

UP

DOWN

ENTER

Use the MENU key to move through

screens within Main Menu categories and

return to the Main Menu while at other

screens.

Use this key to adjust setpoints and change

confi gurations.

Use this key to adjust setpoints and change

confi gurations.

Use the ENTER key to navigate through the

Main Menu Screen categories.

KEY FUNCTION

Table 2: Navigation Key Functions

12

RSMD Technical Guide

Page 13

RSMD LCD SCREENS

Main Screen Map & RSMD Module Screens

RSMD Main Screens Map

Refer to the following map when navigating through the LCD Main

Screens. To scroll through the screens, press the <MENU> button.

RSMD

1067vxxx

Press to scroll through REFRIG MODULE Screens.

Press to go to SYSTEM STATUS Screens.

SYSTEM

STATUS

Press to scroll through SYSTEM STATUS Screens.

Press to go to SENSOR STATUS Screen.

SENSOR

STATUS

RSMD Module Screens

Refer to the following map when navigating through the RSMD

Screens. From the RSMD Screen, press <ENTER> to scroll

through the screens.

RSMD

1067vxxx

EBUS COMM

PACKETS

E-BUS COMMUNICATION DIAGNOSTICS

Number of COMM packets received.

SOFTWARE

1067vXXX

Press to scroll through SENSOR STATUS Screens.

Press to go to ALARMS Screens.

ALARMS

Press to scroll through ALARMS Screens.

Press to go to ALARM HISTORY Screens.

ALARM

HISTORY

Press to scroll through ALARM HISTORY Screens.

Press to go to SETPOINT STATUS Screens.

SETPOINT

STATUS

CURRENT SOFTWARE VERSION

You can access the protected

screens from this screen by holding

the <UP> button for 5 seconds.

BOARD/EBUS

ADDRESS

CURRENT BOARD ADDRESS

#COMP

CONFIGURED

# OF COMPRESSORS CONFIGURED

#COND

CONFIGURED

Press to scroll through SETPOINT STATUS Screens.

RSMD Technical Guide

# OF CONDENSERS CONFIGURED

13

Page 14

RSMD LCD SCREENS

System Status Screens

COMP A1-B1

FIXED OR DIG

COMPRESSOR A1 or B1 - Fixed or Digital

COMP A2-B2

FIXED OR DIG

COMPRESSOR A2 or B2 - Fixed or Digital

System Status Screens

Refer to the following map when navigating through the System

Status Screens. From the SYSTEM STATUS Screen, press

<ENTER> to scroll through the screens.

COMP A2-B2

ON/OFF

COMPRESSOR A2, B2

(based on board address)

ON, OFF, FORCE

ON: Compressor is on.

OFF: Compressor is off .

COND 1 FAN

OFF/

MODULATING %

CONDENSER FAN 1

OFF, MOD POSITION

OFF: Condenser is off .

MODULATING PERCENTAGE: 0-100%

SYSTEM

STATUS

MODE OF

OPERATION

SYSTEM MODE OF OPERATION

Possible choices are

OFF, COOL, HEAT, DEHUMID, FORCE

COMP A1-B1

OFF/

MODULATING %

COMPRESSOR A1, B1

(based on board address)

OFF / MOD POSITION

OFF: Compressor is off .

MODULATING PERCENTAGE: 0-100%

COND 2 FAN

OFF/

MODULATING %

CONDENSER FAN 2

OFF, MOD POSITION

OFF: Condenser is off .

MODULATING PERCENTAGE: 0-100%

OR

IF CONFIGURED FOR WATER SIDE ECONOMIZER BYPASS

BYPS VLV

CLOSED OR

% VALVE

WATER SIDE ECONOMIZER BYPASS VALVE

CLOSED OR MOD POSITION

CLOSED: Valve is closed.

MODULATING PERCENTAGE: 0-100%

IF CONFIGURED FOR AIR TO AIR HEAT PUMP

DEFROST

# MINUTES

14

DEFROST INTERVAL TIMER

# MINUTES

RSMD Technical Guide

Page 15

OR

IF CONFIGURED FOR WATER SOURCE HEAT PUMP

H2O FLOW

YES/NO

WATER FLOW

YES/NO

Sensor Status Screens

RSMD LCD SCREENS

Sensor Status Screens

CALC CT1

XX DEG

CALCULATED COIL TEMPERATURE 1 FROM

SUCTION PRESSURE 1 INPUT

Refer to the following map when navigating through the Sensor

Status Screens. From the SENSOR STATUS Screen, press

<ENTER> to scroll through the screens.

SENSOR

STATUS

SUCTION 1

XXX PSI

SUCTION PRESSURE 1 READING FROM INPUT

HEAD PR1

XXX PSI

HEAD PRESSURE 1 READING FROM INPUT

CALC CT2

XX DEG

CALCULATED COIL TEMPERATURE 2 FROM

SUCTION PRESSURE 2 INPUT

COMPTMP1

XX DEG

COMPRESSOR TEMPERATURE 1 READING FROM

HEAD PRESSURE 1 INPUT

COMPTMP2

XX DEG

COMPRESSOR TEMPERATURE 2 READING FROM

HEAD PRESSURE 2 INPUT

SUCTION 2

XXX PSI

SUCTION PRESSURE 2 READING FROM INPUT

HEAD PR2

XXX PSI

HEAD PRESSURE 2 READING FROM INPUT

RSMD Technical Guide

IF CONFIGURED FOR WATER SOURCE HEAT PUMP

H2O TEMP

XX DEG

WATER TEMPERATURE READING FROM

LEAVING WATER TEMPERATURE SENSOR

15

Page 16

RSMD LCD SCREENS

Setpoint Status Screens

Setpoint Status Screens

Refer to the following map when navigating through the Setpoint

Status Screens. From the SETPOINT STATUS Screen, press

<ENTER> to scroll through the screens.

SETPOINT

STATUS

COILT SP

35 DEG

COIL TEMPERATURE SETPOINT STATUS

Valid range is 35 to 70 degrees. Default is 35 degrees.

IF CONFIGURED FOR MODULATING CONDENSER,

THE SCREEN BELOW WILL DISPLAY

IF CONFIGURED FOR WATER SOURCE HEAT PUMP,

THE THREE SCREENS BELOW WILL DISPLAY

GLYCOL %

%

GLYCOL PERCENTAGE STATUS

LOW SUCT

95 PSI

LOW SUCTION PRESSURE SETPOINT STATUS

Default is 95 PSI.

HEADPRSP

340 PSI

HEAD PRESSURE SETPOINT STATUS

Valid range is 275 to 475 PSI. Default is 340 PSI.

IF CONFIGURED FOR FAN CYCLE,

THE TWO SCREENS BELOW WILL DISPLAY

FAN ON

XX PSI

HEAD PRESSURE READING WHEN FAN CYCLE IS ON

FAN OFF

XX PSI

LOW H2O

37 DEGF

LOW LEAVING WATER TEMPERATURE SETPOINT STATUS

Default is 37 Degrees F.

IF CONFIGURED FOR AIR TO AIR HEAT PUMP,

THE SCREEN BELOW WILL DISPLAY

DEFR INT

30 MIN

DEFROST INTERVAL SETPOINT STATUS

Default is 30 minutes.

HEAD PRESSURE READING WHEN FAN CYCLE IS OFF

16

RSMD Technical Guide

Page 17

RSMD LCD SCREENS

Alarms Screen & Alarm History

Alarms Screen

If an alarm is present, the ALARM LED above the LCD display will

light up red and blink. The Alarms will display and scroll automatically

from the ALARMS screen when alarms are present.

ALARMS

The alarms are as follows:

NO ALARMS: This will be shown if there are no current alarms.

EBUS SLAVE (SLV) TIMEOUT: This alarm indicates that com-

munication has been lost between the RSMD and the Main controller

or other E-BUS modules that may be connected. This can be the result

of a bad cable, a missing cable, or the module not being confi gured

properly.

NO SUCTION PRESSURE SENSOR 1 (SUCT1) DETECTED:

This alarm indicates the Suction Pressure Sensor 1 is not detected by

the system. There is no compressor failure from this alarm. The failure

will be unsafe suction pressure.

NO SUCTION PRESSURE SENSOR 2 (SUCT2) DETECTED:

This alarm indicates the Suction Pressure Sensor 2 is not detected by

the system. There is no compressor failure from this alarm. The failure

will be unsafe suction pressure.

NO HEAD PRESSURE SENSOR 1 (HEAD1) DETECTED: This

alarm indicates the Head Pressure Sensor 1 is not detected by the

system. This will cause the condenser fan/valve to go to 100%.

NO HEAD PRESSURE SENSOR 2 (HEAD2) DETECTED: This

alarm indicates the Head Pressure Sensor 2 is not detected by the

system. This will cause the condenser fan/valve to go to 100%.

HIGH HEAD PRESSURE 1 (HP1) DETECTED: This indicates a

High Head Pressure Alarm condition which is activated when the Head

Pressure 1 rises above 550 PSIG. This will cause the condenser to go

to 100%.

HIGH HEAD PRESSURE 2 (HP2) DETECTED: This indicates a

High Head Pressure Alarm condition which is activated when the Head

Pressure 2 rises above 550 PSIG. This will cause the condenser to go

to 100%.

LOW SUCTION PRESSURE 1 (SP1) FAILURE: This alarm

will occur if suction pressure 1 stays below the low suction pressure

setpoint for 1 minute or falls below 40 psi for 5 seconds. This alarm will

shut down the system. Power must be cycled to clear the alarm.

LOW SUCTION PRESSURE 2 (SP2) FAILURE: This alarm

will occur if suction pressure 2 stays below the low suction pressure

setpoint for 1 minute or falls below 40 psi for 5 seconds. This alarm will

shut down the system. Power must be cycled to clear the alarm.

LOW SUCTION PRESSURE 1 (SP1) DETECTED: This alarm

will occur if suction pressure 1 falls below the low suction pressure

setpoint for 20 seconds. The system will try to protect by lowering compressor modulation percentage.

LOW SUCTION PRESSURE 2 (SP2) DETECTED: This alarm

will occur if suction pressure 2 falls below the low suction pressure

setpoint for 20 seconds. The system will try to protect by lowering compressor modulation percentage.

COMPRESSOR (COMP1) 1 FAULT: This alarm will occur if the

compressor fails to run 45 seconds after the relay is activated or if the

signal is lost after activation. This will cause an alarm and will shut

down the compressor (relay). The system will retry after 5 minutes.

COMPRESSOR (COMP) 2 FAULT: This alarm will occur if the

compressor fails to run 45 seconds after the relay is activated or if the

signal is lost after activation. This will cause an alarm and will shut

down the compressor (relay). The system will retry after 5 minutes.

COMPRESSOR (COMP1) 1 BAD TEMPERATURE: This alarm

will occur if the discharge temp sensor 1 measures less than -40

degrees F or more than 356 degrees F. This will cause an alarm and

will shut down the compressor (relay). The system will retry after 5

minutes.

COMPRESSOR (COMP2) 2 BAD TEMPERATURE: This alarm

will occur if the discharge temp sensor 2 measures less than -40

degrees F or more than 356 degrees F. This will cause an alarm and

will shut down the compressor (relay). The system will retry after 5

minutes.

COMPRESSOR (COMP) 1 CUTOFF: This alarm will occur if the

discharge temp sensor 1 measures more than 265 degrees F. This will

cause an alarm and will shut down the compressor (relay). The system

will can be restarted after 30 minutes.

COMPRESSOR (COMP) 2 CUTOFF: This alarm will occur if the

discharge temp sensor 2 measures more than 265 degrees F. This will

cause an alarm and will shut down the compressor (relay). The system

will can be restarted after 30 minutes.

COMPRESSOR (COMP) 1 or 2 LOCKOUT: If active cutoff oc-

curs 5 times within a 4 hour period, the compressor will be locked out.

Must cycle power to RSMD to clear the alarm.

• If a circuit’s Suction Pressure falls below the Low Suction

Pressure Setpoint for longer than one minute twice within a

two hour window, the compressor on that circuit will be

locked out. Manual reset or change of mode is required to

return to normal operation.

• If the Suction Pressure falls below the Unsafe Suction

Setpoint for 5 seconds, that circuit’s compressor will locked

out. Power will need to be cycled to restart the unit.

• If the Leaving Water Temperature falls below setpoint,

the last compressor will be locked out until the Leaving Water

Temperature rises 6 degrees above setpoint.

• The Leaving Water Temperature remains below setpoint for

1 minute or falls 3 degrees below setpoint. This alarm will

disable when the leaving water temperature rises 12 degrees

above the setpoint.

NO PROOF OF H2O FLOW: There is a call for a compressor and

there is no Proof of Flow Input Enable for more than 3 minutes or if during Heat Pump heating, the Proof of Flow Enable is open for more than

2 seconds. This alarm will disable when Proof of Flow is enabled.

LOW H2O TEMPERATURE: If both compressors are on and water

temp goes below setpoint, compressor 2 will fail. If both compressors

are on and water temp goes 3 degrees below setpoint, both compressors will fail. If second compressor is off or failed and water temp is still

low for 1 minute, the fi rst compressor will also fail. This alarm will disable

when the leaving water temperature rises 6 degrees above the setpoint.

RSMD Technical Guide

17

Page 18

RSMD LCD SCREENS

Alarm History & Protected Screens

EMERGENCY SHUTDOWN: If the Emergency Shutdown binary in-

put is not activated, the compressors will shut off .

COMPRESSOR 1 FALSE ACTIVE INPUT: If the compressor relay

is off but the compressor binary active input is activated for 60 seconds,

it will cause an alarm.

COMPRESSOR 1 FALSE ACTIVE INPUT: If the compressor relay

is off but the compressor binary active input is activated for 60 seconds,

it will cause an alarm.

Alarm History Screens

The ALARM HISTORY Screen displays past alarms, if any, and how

long ago the last of each type occurred. From the ALARM HISTORY

Screen, press <ENTER> to scroll through the history screens.

ALARM

HISTORY

Protected Screens Map

Refer to the following map when navigating through the LCD

Protected Screens. From the RSMD Screen, press

twice to get to the Software Screen. Then hold the <UP> button

for 5 seconds. To scroll through the rest of the screens, press the

<MENU> button.

RSMD

1067vxxx

E-BUS

+0

SOFTWARE

1067vxxx

Hold for 5 seconds.

<ENTER>

The Alarm will appear on the fi rst line and the second line will display

how long ago each alarm last occurred. As a result, the alarms listed

on the ALARMS screen will be abbreviated as follows in order of

the way they are listed in the prior ALARMS screen section.

NOTE: The screen will display minutes for the fi rst 60 minutes

of alarm occurrence, hours for the next 72 hours of

alarm occurrence, and days for the next 30 days of

alarm occurrence. After 30 days, the alarm will clear.

Alarm history is not stored in memory. So, if power

is lost, the alarms will clear.

CONFIG

DIAGNSTC

ALARM

COUNTS

ADDRESS

1(152)

ENTER TO

EXIT

18

RSMD Technical Guide

Page 19

RSMD LCD SCREENS

Confi guration & Diagnostic Screens

Confi guration Screens

Refer to the following map when navigating through the

Confi guration Screens. From the CONFIG Screen, press

to scroll through the screens.

CONFIG

<ENTER>

EPROM:

HOLD

DOWN

TO

COND FAN

LOCKED/UNLOCKED

CONDENSER FAN LOCKED OR UNLOCKED

LOCK POS

100%

CONDENSER FAN LOCKED POSITION

Diagnostic Screens

Refer to the following map when navigating through the Diagnostic

Screens. From the DIAGNSTC Screen, press <ENTER> to scroll

through the screens.

DIAGNSTC

LOAD

DEFAULTS

SP-1 VLT

X.XX

SUCTION PRESSURE SENSOR 1 VOLTAGE

Displays the current voltage of the Suction Pressure Sensor 1.

HP-1 VLT

X.XX

HEAD PRESSURE SENSOR 1 VOLTAGE

Displays the current voltage of the Head Pressure Sensor 1.

WDOG CNT

#

WATCH DOG TIMER

Displays the number of times the board has been reset due to

watchdog timer overfl ow.

POWR CNT

#

POWER LOSS COUNT

Displays the number of times the board has been reset

due to power loss.

RSMD Technical Guide

SP-2 VLT

X.XX

SUCTION PRESSURE SENSOR 2 VOLTAGE

Displays the current voltage of the Suction Pressure Sensor 2.

HP-2 VLT

X.XX

HEAD PRESSURE SENSOR 2 VOLTAGE

Displays the current voltage of the Head Pressure Sensor 2.

19

Page 20

RSMD LCD SCREENS

Diagnostic Screens

BIN 1 - BIN 4

ON/OFF

BINARY INPUTS #1 - #4

Displays the current status of each Binary Input.

TMP1 VLT

X.XX

COIL TEMPERATURE SENSOR 1 VOLTAGE

Displays the current voltage of the 1st Coil Temperature Sensor.

TMP2 VLT

X.XX

IF FORCE MODE IS ON, THE FOLLOWING SCREENS

WILL APPEAR:

RLY 1-5

ON/OFF

RELAYS 1 - 5 FORCE MODE

Press the <UP> and <DOWN> buttons to select ON or OFF

for each relay

TRIAC 1

ON/OFF

TRIAC 1

Displays the current status of Digital Compressor 1.

Values are ON/OFF.

TRIAC 2

ON/OFF

COIL TEMPERATURE SENSOR 2 VOLTAGE

Displays the current voltage of the 2nd Coil Temperature Sensor.

TMP3 VLT

X.XX

TEMPERATURE SENSOR 3 VOLTAGE

Displays the current voltage of the Leaving Water Temperature Sensor.

FORCE MODE

ON/OFF

FORCE MODE

Displays the current status of Force Mode. Values are ON/OFF.

Displays the current status of Digital Compressor 2.

TRIAC 2

Values are ON/OFF.

AOUT-1 V

0.0-10.0

vdc

CONDENSER SIGNAL 1 FORCE

0.0 to 10.0 = Active Force Mode.

Press the <UP> and <DOWN> buttons to increase

and decrease the value.

AOUT-2 V

1.0-10.0

vdc

CONDENSER SIGNAL 2 FORCE

1.0 to 10.0 = Active Force Mode.

Press the <UP> and <DOWN> buttons to increase

and decrease the value.

20

RSMD Technical Guide

Page 21

RSMD LCD SCREENS

Alarm Counts & Address Screen

ALARM COUNTS Screens

From the ALARM COUNTS Screen, press <ENTER> to scroll

through the screens. Each screen will display the name of the alarm

and how many times the alarm has occurred since you last cleared

the alarms. The only way to clear these alarm counts is by using

Prism 2 and selecting, “Select Alarms to Delete” from the ALARM

button menu. See “Alarm Polling” in the Prism 2 Technical Guide

for more information.

Address Screen

ADDRESS

1(152)

CURRENT BOARD ADDRESS

Confi gure the address according to which refrigerant circuit

this module represents—1=A, 2=B, 3=C, 4=D

Number in parentheses is E-BUS address.

Module 1’s address is 152, Module 2’s address is 153,

Module 3’s address is 154, Module 4’s address is 155

RSMD Technical Guide

21

Page 22

TROUBLESHOOTING

M

ENTER

UP

DOWN

ALARM

MENU

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

AAON No.: V61520

+24 VAC

GND

RELAY CONTACT

RATING IS 1AMP

MAX @ 24 VAC

CONDENSER 1

COMP 1

COMP 2

ANALOG OUTPUTS

REVERSING VALVE

COMMON

RELAYOUTPUT

TERMINALS

www.aaon.com

WattMaster Overlay

# 000072 Rev1CSW

CONDENSER 1

CONDENSER 2

GND

24 VAC

POWER ONLY

WARNING!

POLARITY

MUST BE

OBSERVED

OR THE

CONTROLLER

WILL BE

DAMAGED

CONDENSER 2

SUCTION

PRESSURE 1

SENSOR

HEAD

PRESSURE 1

SENSOR

TEMP

SENSORS

BINARY

INPUTS

+5 V

+5 V

COMP DIS TEMP 1

COMP STATUS 1

SP-1

HP-1

COMP DIS TEMP 2

COMP 2STATUS

GND

GND

OUTSIDE COIL TEMP / POWF

EMERGENCY SHUTDOWN

GND

LEAVING WATER TEMP

GND

SUCTION

PRESSURE 2

SENSOR

HEAD

PRESSURE 2

SENSOR

+5 V

+5 V

SP-2

HP-2

GND

GND

E-BUS

E-BUS

RSM LED Diagnostics

Zone

Zone

Using RSM LEDs To Verify Operation

The RSMs are equipped with LEDs that can be used to verify

operation and perform troubleshooting. There are LEDs for

communication, operation modes, and diagnostic codes. See Figure

5, below for the LED locations. The LEDs associated with these

inputs and outputs allow you to see what is active without using a

voltmeter. The LEDs and their uses are as follows:

Diagnostic LEDs

STATUS - If the software is running, this LED should blink at a rate

of 1 blink per second.

ALARM (on board) - If the module does not receive communications

for more than 1 minute, this LED will light up, the relays will turn

off , and the Analog Outputs will go to 0 VDC.

ALARM (above LCD display) - This red LED will light up and stay

lit when there is an alarm present. The type of alarm will display on

the LCD display. The ALARM LED also blinks when the expansion

valve is initializing at startup.

COMM - Every time the module receives a valid E-BUS request

from the VCC-X / VCCX2 Controller, this LED will blink on and

then off , signifying that it received a valid request and responded.

POWER - This LED will light up to indicate that 24 VAC power has

been applied to the controller.

Binary Input LEDs

BIN1 - This green LED will light up when Compressor Status 1

contact is closed.

BIN2 - This green LED will light up when Compressor Status 2

switch is closed.

BIN3 - This green LED will light up when the Outside Coil

Temperature switch is closed.

BIN4 - This green LED will light up when the Emergency Shutdown

switch is closed.

Relay LEDs

RLY1 - RLY5 - These green LEDs will light up when the relays are

enabled and will stay lit as long as they are active.

Digital Compressor LEDs

COMP1 - This green LED will light up when Digital Compressor

1 is unloading.

COMP2 - This green LED will light up when Digital Compressor

2 is unloading.

STATUS

ALARM

COMM

POWER

LEDs

BINARY

INPUT

LEDs

Figure 5: RSMD LED Locations

22

ALARM

LED

RSMD

G5Q-1A4

OMRON

DC12V

CHINA

10A250VAC ~

5A30VDC

SA

VDE

RELAY

LEDs

COMP-1

LED

COMP-2

LED

RSMD Technical Guide

Page 23

TROUBLESHOOTING

OE275-01 Suction Pressure Transducer Testing

OE275-01 Suction Pressure

Transducer Testing for R410A

Refrigerant

The Evaporator Coil Temperature is calculated by converting the

Suction Pressure to Temperature. The Suction Pressure is obtained by

using the OE275-01 Suction Pressure Transducer, which is connected

into the Suction Line of the Compressor.

Use the voltage column to check the Suction Pressure Transducer while

connected to the RSMD Module(s). The VCC-X/VCCX2 and the

RSMD Module(s) must be powered for this test. Read voltage with

a meter set on DC volts. Place the positive lead from the meter on

the SP1/SP2 terminal located on the RSMD Module(s) terminal

block. Place the negative lead from the meter on the ground (GND)

terminal located adjacent to the SP1/SP2 terminal on the RSMD

Module(s) terminal block. Use a refrigerant gauge set and/or an

accurate electronic thermometer to measure the temperature or

suction line pressure near where the Suction Pressure Transducer

is connected to the suction line. Measure the Voltage at the SP1/

SP2 and GND terminals and compare it to the appropriate chart

depending on the refrigerant you are using. If the temperature/

voltage or pressure/voltage readings do not align closely with the

chart, your Suction Pressure Transducer is probably defective and

will need to be replaced.

See the OE275-01 Suction Pressure Transducer, Pressure,

Temperature, and Voltage Chart for R410A Refrigerant testing.

The charts show a temperature range from 20°F to 80°F. For

troubleshooting purposes, the DC Voltage readings are also listed

with their corresponding temperatures and pressures.

OE275-01 Suction Pressure Transducer

Coil Pressure

– Temperature – Voltage Chart for R410A

Refrigerant

°F

Temperature

21.19 80.94 1.8 59.03 168.10 3.2

24.49 87.16 1.9 61.17 174.32 3.3

27.80 93.39 2.0 63.19 180.55 3.4

30.99 99.62 2.1 65.21 186.78 3.5

33.89 105.84 2.2 67.23 193.00 3.6

36.80 112.07 2.3 69.24 199.23 3.7

39.71 118.29 2.4 71.15 205.46 3.8

42.30 124.52 2.5 72.95 211.68 3.9

44.85 130.75 2.6 74.76 217.91 4.0

47.39 136.97 2.7 76.57 224.14 4.1

49.94 143.2 2.8 78.37 230.36 4.2

52.23 149.42 2.9 80.18 236.59 4.3

54.50 155.65 3.0

56.76 161.88 3.1

Pressure

PSI

Signal

DC Volts

Temperature

°F

PSI

Pressure

Signal

DC Volts

Table 3: Coil Pressure/Voltage/Temp for OE275-01

Suction Pressure Transducers - R410A Refrigerant

RSMD Technical Guide

23

Page 24

Zone

TROUBLESHOOTING

Zone

Copeland® Discharge Thermistor Temperature Sensor Testing

Copeland® Discharge Thermistor

Temperature Sensor Testing

The following sensor voltage and resistance table is provided to aid

in checking sensors that appear to be operating incorrectly. Many

system operating problems can be traced to incorrect sensor wiring.

Be sure all sensors are wired per the wiring diagrams in this manual.

If the sensors still do not appear to be operating or reading correctly,

check voltage and/or resistance to confi rm that the sensor is operating

correctly per the table. Please follow the notes and instructions the

appear after the chart when checking sensors.

Discharge Thermistor Temperature/

Resistance

Temp

(ºF)

-40 -40 2889.60 4.98

-31 -35 2087.22 4.97

-22 -30 1522.20 4.96

-13 -25 1121.44 4.95

-4 -20 834.72 4.94

5 -15 627.28 4.92

14 -10 475.74 4.89

23 -5 363.99 4.86

32 0 280.82 4.82

41 5 218.41 4.77

50 10 171.17 4.72

59 15 135.14 4.65

68 20 107.44 4.57

77 25 86.00 4.47

86 30 69.28 4.36

95 35 56.16 4.24

104 40 45.81 4.10

113 45 37.58 3.94

122 50 30.99 3.77

131 55 25.68 3.59

140 60 21.40 3.40

149 65 17.91 3.20

158 70 15.07 3.00

167 75 12.73 2.80

176 80 10.79 2.59

185 85 9.20 2.39

Temp

(ºC)

Resistance

(K Ohms)

Voltage @

Input (VDC)

Discharge Thermistor Temperature/

Resistance

Temp

(ºF)

194 90 7.87 2.19

203 95 6.77 2.01

212 100 5.85 1.84

221 105 5.09 1.68

230 110 4.45 1.53

239 115 3.87 1.39

248 120 3.35 1.25

257 125 2.92 1.12

266 130 2.58 1.02

275 135 2.28 0.92

284 140 2.02 0.83

293 145 1.80 0.76

302 150 1.59 0.68

311 155 1.39 0.61

320 160 1.25 0.55

329 165 1.12 0.50

338 170 1.01 0.45

347 175 0.92 0.42

356 180 0.83 0.38

Temp

(ºC)

Resistance

(K Ohms)

Voltage @

Input (VDC)

Table 4, cont.: Discharge Thermistor Temperature/

Resistance

Thermistor Sensor Testing Instructions

Use the resistance column to check the thermistor sensor while

disconnected from the controllers (not powered).

Use the voltage column to check sensors while connected to powered

controllers. Read voltage with meter set on DC volts. Place the “-”

(minus) lead on GND terminal and the “+” (plus) lead on the sensor

input terminal being investigated.

If the voltage is above 4.98 VDC, then the sensor or wiring is “open.”

If the voltage is less than 0.38 VDC, then the sensor or wiring is

shorted.

Table 4: Discharge Thermistor Temperature/

Resistance

24

RSMD Technical Guide

Page 25

TROUBLESHOOTING

Temperature Sensor Testing

Leaving Water Temperature Sensor

Testing

The following sensor voltage and resistance table is provided to aid

in checking sensors that appear to be operating incorrectly. Many

system operating problems can be traced to incorrect sensor wiring.

Be sure all sensors are wired per the wiring diagrams in this manual.

If the sensors still do not appear to be operating or reading correctly,

check voltage and/or resistance to confi rm that the sensor is operating

correctly per the tables. Please follow the notes and instructions that

appear after the chart when checking sensors.

Temperature – Resistance – Voltage for Type

III 10 K Ohm Thermistor Sensors

Temp

(ºF)

-10 -23.33 93333 4.51

-5 -20.55 80531 4.45

0 -17.77 69822 4.37

5 -15 60552 4.29

10 -12.22 52500 4.2

15 -9.44 45902 4.1

20 -6.66 40147 4.002

25 -3.88 35165 3.891

30 -1.11 30805 3.773

35 1.66 27140 3.651

40 4.44 23874 3.522

45 7.22 21094 3.39

50 10 18655 3.252

52 11.11 17799 3.199

54 12.22 16956 3.143

56 13.33 16164 3.087

58 14.44 15385 3.029

60 15.55 14681 2.972

62 16.66 14014 2.916

64 17.77 13382 2.861

66 18.88 12758 2.802

68 20 12191 2.746

69 20.55 11906 2.717

70 21.11 11652 2.691

71 21.66 11379 2.661

72 22.22 11136 2.635

73 22.77 10878 2.605

Temp

(ºC)

Resistance

(Ohms)

Voltage @

Input (VDC)

Temperature – Resistance – Voltage for Type

III 10 K Ohm Thermistor Sensors

Temp

(ºF)

74 23.33 10625 2.576

75 23.88 10398 2.549

76 24.44 10158 2.52

77 25 10000 2.5

78 25.55 9711 2.464

80 26.66 9302 2.41

82 27.77 8893 2.354

84 28.88 8514 2.3

86 30 8153 2.246

88 31.11 7805 2.192

90 32.22 7472 2.139

95 35 6716 2.009

100 37.77 6047 1.884

105 40.55 5453 1.765

110 43.33 4923 1.65

115 46.11 4449 1.54

120 48.88 4030 1.436

125 51.66 3656 1.339

130 54.44 3317 1.246

135 57.22 3015 1.159

140 60 2743 1.077

145 62.77 2502 1.001

150 65.55 2288 0.931

Temp

(ºC)

Resistance

(Ohms)

Voltage @

Input (VDC)

Table 5, cont.: Temperature/Resistance for Type III

10K Ohm Thermistor Sensors

Thermistor Sensor Testing Instructions

Use the resistance column to check the thermistor sensor while

disconnected from the controllers (not powered).

Use the voltage column to check sensors while connected to powered

controllers. Read voltage with meter set on DC volts. Place the “-”

(minus) lead on GND terminal and the “+” (plus) lead on the sensor

input terminal being investigated.

If the voltage is above 4.88 VDC, then the sensor or wiring is “open.”

If the voltage is less than 0.05 VDC, then the sensor or wiring is

shorted.

Table 5: Temperature/Resistance for Type III 10K

Ohm Thermistor Sensors

RSMD Technical Guide

25

Page 26

Zone

TROUBLESHOOTING

Head Pressure Transducer Troubleshooting

Head Pressure Transducer

Troubleshooting

If you suspect there is a problem related to the head pressure

transducer, measurements can be taken at the HP1 and HP2 terminals.

Reference Table 6, below.

Head Pressure Transducer Chart

Voltage Pressure Voltage Pressure

0.5 0 2.6 350

0.6 17 2.7 367

0.7 33 2.8 384

0.8 50 2.9 400

0.9 67 3.0 417

1.0 83 3.1 434

1.1 100 3.2 450

1.2 117 3.3 467

1.3 133 3.4 484

1.4 150 3.5 500

1.5 167 3.6 517

1.6 183 3.7 534

1.7 200 3.8 550

1.8 217 3.9 567

1.9 233 4.0 584

2.0 250 4.1 600

2.1 267 4.2 617

2.2 283 4.3 634

2.3 300 4.4 650

2.4 317 4.5 667

2.5 334

Zone

Table 6: Head Pressure Transducer Chart

26

RSMD Technical Guide

Page 27

TROUBLESHOOTING

Notes

RSMD Technical Guide

27

Page 28

APPENDIX: CONDENSER OPTIONS

M

ENTER

UP

DOWN

ALARM

MENU

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

AAON No.: V61520

+24 VAC

GND

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

CONDENSER 1

COMP 1

COMP 2

ANALOG OUTPUTS

REVERSING VALVE

COMMON

RELAYOUTPUT

TERMINALS

www.aaon.com

WattMaster Overlay

# 000072 Rev1DSW

CONDENSER 1

CONDENSER 2

GND

24 VAC

POWER ONLY

WARNING!

POLARITY

MUST BE

OBSERVED

OR THE

CONTROLLER

WILL BE

DAMAGED

CONDENSER 2

SUCTION

PRESSURE 1

SENSOR

HEAD

PRESSURE 1

SENSOR

TEMP

SENSORS

BINARY

INPUTS

+5 V

+5 V

COMP DIS TEMP 1

COMP STATUS 1

SP-1

HP-1

COMP DIS TEMP 2

COMP 2STATUS

GND

GND

OUTSIDE COIL TEMP / POWF

EMERGENCY SHUTDOWN

GND

LEAVING WATERTEMP

GND

SUCTION

PRESSURE 2

SENSOR

HEAD

PRESSURE 2

SENSOR

+5 V

+5 V

SP-2

HP-2

GND

GND

R+

SHD

T-

HH COMMUNICATIONS

E-BUS

R+ SHD T-

DUAL E-BUS

EXPANSION

Default: Two Condenser Operation

Two Condenser Operation

See Figure 6, below for Two Condenser Operation wiring. Refer to

the fi gures on the following page for Prism 2 confi guration, Modular

Service Tool Screen selection, and HVAC unit application.

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

GND

24VAC

NOTE:

ALL RELAY OUTPUTS ARE NORMALLY

OPEN AND RATED FOR 24 VAC POWER

ONLY - 1 AMP MAXIMUM LOAD

24 VAC ONLY

G5Q-1A4

OMRON

DC12V

CHINA

10A250VAC ~

5A30VDC

SA

VDE

RLY1

RLY2

RLY3

RLY4

RLY5

COMM

UNLOAD

24 VAC

UNLOAD

COMPRESSOR 1 ENABLE

COMPRESSOR 2 ENABLE

CONDENSER 1 ENABLE

CONDENSER 2 ENABLE

REVERSING VALVE

DIGITAL

COMPRESSOR 1

+

GND

DIGITAL

COMPRESSOR 2

+

GND

Connects To VCC-X

Loop Communications

Connector When Used

On A Split System.

Only Used When Unit

Is Controlling Digital

Compressors

Condenser

Signal 1

+

COM

Condenser

Signal 2

+

COM

Connect to

VCC-X Controller

Figure 6: Default: Two Condenser RSMD Module Wiring

28

Line Voltage

Size Transformer For

Correct Total Load.

RSMD = 18 VA

RSMD Technical Guide

Page 29

APPENDIX: CONDENSER OPTIONS

Default: Two Condenser Operation

Figure 7: Prism 2 Condenser Confi guration

RSMD Main Confi guration Screen #2 -

Condenser Options

RSMD CONFIGURATION

Condenser Options

2 Cond per RSMD

USE < or > TO CHANGE

Select the “2 Condensers for per RSMD” option on the above Hand

Held Service Tool Screen.

HVAC Unit Application

The Two Condenser per RSMD confi guration is used with the

following HVAC units:

• D-BOX 26-40 Ton

• C-BOX 16-20 Ton

• B-BOX

RSMD Technical Guide

29

Page 30

APPENDIX: CONDENSER OPTIONS

M

ENTER

UP

DOWN

ALARM

MENU

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

AAON No.: V61520

+24 VAC

GND

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

CONDENSER 1

COMP 1

COMP 2

ANALOG OUTPUTS

REVERSING VALVE

COMMON

RELAYOUTPUT

TERMINALS

www.aaon.com

WattMaster Overlay

# 000072 Rev1DSW

CONDENSER 1

CONDENSER 2

GND

24 VAC

POWER ONLY

WARNING!

POLARITY

MUST BE

OBSERVED

OR THE

CONTROLLER

WILL BE

DAMAGED

CONDENSER 2

SUCTION

PRESSURE 1

SENSOR

HEAD

PRESSURE 1

SENSOR

TEMP

SENSORS

BINARY

INPUTS

+5 V

+5 V

COMP DIS TEMP 1

COMP STATUS 1

SP-1

HP-1

COMP DIS TEMP 2

COMP 2STATUS

GND

GND

OUTSIDE COIL TEMP / POWF

EMERGENCY SHUTDOWN

GND

LEAVING WATERTEMP

GND

SUCTION

PRESSURE 2

SENSOR

HEAD

PRESSURE 2

SENSOR

+5 V

+5 V

SP-2

HP-2

GND

GND

R+

SHD

T-

HH COMMUNICATIONS

E-BUS

R+ SHD T-

DUAL E-BUS

EXPANSION

Single Condenser Per Module

Single Condenser Per Module

See Figure 8, below for Single Condenser Per Module wiring.

Refer to the fi gures on the following page for Prism 2 confi guration,

Modular Service Tool Screen selection, and HVAC unit application.

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

GND

24VAC

NOTE:

ALL RELAY OUTPUTS ARE NORMALLY

OPEN AND RATED FOR 24 VAC POWER

ONLY - 1 AMP MAXIMUM LOAD

24 VAC ONLY

G5Q-1A4

OMRON

DC12V

CHINA

10A250VAC ~

5A30VDC

SA

VDE

RLY2

RLY3

RLY4

RLY5

COMM

UNLOAD

24 VAC

UNLOAD

RLY1

COMPRESSOR 1 ENABLE

COMPRESSOR 2 ENABLE

CONDENSER 1 ENABLE

NOT USED

REVERSING VALVE

DIGITAL

COMPRESSOR 1

+

GND

DIGITAL

COMPRESSOR 2

+

GND

Connects To VCC-X

Loop Communications

Connector When Used

On A Split System.

Only Used When Unit

Is Controlling Digital

Compressors

Condenser

Signal 1

+

COM

Connect to

VCC-X Controller

Figure 8: Single Condenser Per RSMD Module Wiring

30

Line Voltage

Size Transformer For

Correct Total Load.

RSMD = 18 VA

RSMD Technical Guide

Page 31

APPENDIX: CONDENSER OPTIONS

Single Condenser Per Module

Figure 9: Prism 2 Condenser Confi guration

RSMD Main Confi guration Screen #2 -

Condenser Options

RSMD CONFIGURATION

Condenser Options

1 Cond for 1 RSMD

USE < or > TO CHANGE

Select the “1 Condenser for 1 RSMD” option on the above Hand

Held Service Tool Screen.

HVAC Unit Application

The One Condenser per RSMD confi guration is used with the

following HVAC units:

• B-BOX Air to Air Heat Pump

• B-BOX WSHP

• C-BOX 25-30 Ton

• C-BOX Air to Air Heat Pump

• C-BOX WSHP

RSMD Technical Guide

31

Page 32

APPENDIX: CONDENSER OPTIONS

M

ENTER

UP

DOWN

ALARM

MENU

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

AAON No.: V61520

+24 VAC

GND

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

CONDENSER 1

COMP 1

COMP 2

ANALOG OUTPUTS

REVERSING VALVE

COMMON

RELAYOUTPUT

TERMINALS

www.aaon.com

WattMaster Overlay

# 000072 Rev1DSW

CONDENSER 1

CONDENSER 2

GND

24 VAC

POWER ONLY

WARNING!

POLARITY

MUST BE

OBSERVED

OR THE

CONTROLLER

WILL BE

DAMAGED

CONDENSER 2

SUCTION

PRESSURE 1

SENSOR

HEAD

PRESSURE 1

SENSOR

TEMP

SENSORS

BINARY

INPUTS

+5 V

+5 V

COMP DIS TEMP 1

COMP STATUS 1

SP-1

HP-1

COMP DIS TEMP 2

COMP 2STATUS

GND

GND

OUTSIDE COIL TEMP / POWF

EMERGENCY SHUTDOWN

GND

LEAVING WATERTEMP

GND

SUCTION

PRESSURE 2

SENSOR

HEAD

PRESSURE 2

SENSOR

+5 V

+5 V

SP-2

HP-2

GND

GND

R+

SHD

T-

HH COMMUNICATIONS

E-BUS

R+ SHD T-

DUAL E-BUS

EXPANSION

Single Condenser Per Two Modules

Single Condenser Per 2 Modules

See Figure 10, below for Single Condenser Per 2 Modules wiring.

Refer to the fi gures on the following page for Prism 2 confi guration,

Modular Service Tool Screen selection, and HVAC unit application.

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

GND

24VAC

NOTE:

ALL RELAY OUTPUTS ARE NORMALLY

OPEN AND RATED FOR 24 VAC POWER

ONLY - 1 AMP MAXIMUM LOAD

24 VAC ONLY

G5Q-1A4

OMRON

DC12V

CHINA

10A250VAC~

5A30VDC

SA

VDE

RLY1

RLY2

RLY3

RLY4

RLY5

COMM

UNLOAD

24 VAC

UNLOAD

COMPRESSOR 1 ENABLE

COMPRESSOR 2 ENABLE

CONDENSER 1 ENABLE

NOT USED

REVERSING VALVE

DIGITAL

COMPRESSOR 1

+

GND

DIGITAL

COMPRESSOR 2

+

GND

Connects To VCC-X

Loop Communications

Connector When Used

On A Split System.

Not Used on 2nd Module

& 4th Module

Only Used When Unit

Is Controlling Digital

Compressors

Condenser

Signal 1

+

COM

Not Used on 2nd Module

& 4th Module

NOTE: If There Are 4 Modules,

1 & 3 Match and 2 & 4 Match.

Connect to

VCC-X Controller

32

Figure 10: Single Condenser Per 2 RSMD Modules Wiring

Line Voltage

Size Transformer For

Correct Total Load.

RSMD = 18 VA

RSMD Technical Guide

Page 33

APPENDIX: CONDENSER OPTIONS

Single Condenser Per Two Modules

Figure 11: Prism 2 Condenser Confi guration

RSMD Main Confi guration Screen #2 -

Condenser Options

RSMD CONFIGURATION

Condenser Options

1 Cond for 2 RSMDs

USE < or > TO CHANGE

Select the “1 Condenser for 2 RSMDs” option on the above Hand

Held Service Tool Screen.

HVAC Unit Application

The One Condenser per Two RSMDs confi guration is used with the

following HVAC units:

• RLA BOX

• RLB BOX

• RLE BOX

RSMD Technical Guide

33

Page 34

APPENDIX: CONDENSER OPTIONS

M

ENTER

UP

DOWN

ALARM

MENU

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

AAON No.: V61520

+24 VAC

GND

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

CONDENSER 1

COMP 1

COMP 2

ANALOG OUTPUTS

REVERSING VALVE

COMMON

RELAYOUTPUT

TERMINALS

www.aaon.com

WattMaster Overlay

# 000072 Rev1DSW

CONDENSER 1

CONDENSER 2

GND

24 VAC

POWER ONLY

WARNING!

POLARITY

MUST BE

OBSERVED

OR THE

CONTROLLER

WILL BE

DAMAGED

CONDENSER 2

SUCTION

PRESSURE 1

SENSOR

HEAD

PRESSURE 1

SENSOR

TEMP

SENSORS

BINARY

INPUTS

+5 V

+5 V

COMP DIS TEMP 1

COMP STATUS 1

SP-1

HP-1

COMP DIS TEMP 2

COMP 2STATUS

GND

GND

OUTSIDE COIL TEMP / POWF

EMERGENCY SHUTDOWN

GND

LEAVING WATERTEMP

GND

SUCTION

PRESSURE 2

SENSOR

HEAD

PRESSURE 2

SENSOR

+5 V

+5 V

SP-2

HP-2

GND

GND

R+

SHD

T-

HH COMMUNICATIONS

E-BUS

R+ SHD T-

DUAL E-BUS

EXPANSION

Single Condenser For Three Modules

Single Condenser for 3 Modules

See Figure 12, below for Single Condenser for 3 Modules wiring.

Refer to the fi gures on the following page for Prism2 confi guration,

Modular Service Tool Screen selection, and HVAC unit application.

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

GND

24VAC

NOTE:

ALL RELAY OUTPUTS ARE NORMALLY

OPEN AND RATED FOR 24 VAC POWER

ONLY - 1 AMP MAXIMUM LOAD

24 VAC ONLY

G5Q-1A4

OMRON

DC12V

CHINA

10A250VAC~

5A30VDC

SA

VDE

RLY1

RLY2

RLY3

RLY4

RLY5

COMM

UNLOAD

24 VAC

UNLOAD

COMPRESSOR 1 ENABLE

COMPRESSOR 2 ENABLE

CONDENSER 1 ENABLE

NOT USED

REVERSING VALVE

DIGITAL

COMPRESSOR 1

+

GND

DIGITAL

COMPRESSOR 2

+

GND

Connects To VCC-X

Loop Communications

Connector When Used

On A Split System.

Only Used on 1st Module.

Not Used on 2nd & 3rd.

Only Used When Unit

Is Controlling Digital

Compressors

Condenser

Signal 1

+

COM

Only Used on 1st Module.

Not Used on 2nd & 3rd.

Connect to

VCC-X Controller

Figure 12: Single Condenser for 3 RSMD Modules Wiring

34

Line Voltage

Size Transformer For

Correct Total Load.

RSMD = 18 VA

RSMD Technical Guide

Page 35

APPENDIX: CONDENSER OPTIONS

Single Condenser For Three Modules

Figure 13: Prism 2 Condenser Confi guration

RSMD Main Confi guration Screen #2 -

Condenser Options

RSMD CONFIGURATION

Condenser Options

1 Cond for 3 RSMDs

USE < or > TO CHANGE

Select the “1 Condenser for 3 RSMDs” option on the above Hand

Held Service Tool Screen.

HVAC Unit Application

The One Condenser per Three RSMDs confi guration is used with

the following HVAC units:

• RLC BOX

• RLD BOX

RSMD Technical Guide

35

Page 36

APPENDIX: CONDENSER OPTIONS

M

ENTER

UP

DOWN

ALARM

MENU

OE370-26-RSMD

RSM FOR DIGITAL

COMPRESSORS

AAON No.: V61520

+24 VAC

GND

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

CONDENSER 1

COMP 1

COMP 2

ANALOG OUTPUTS

REVERSING VALVE

COMMON

RELAYOUTPUT

TERMINALS

www.aaon.com

WattMaster Overlay

# 000072 Rev1DSW

CONDENSER 1

CONDENSER 2

GND

24 VAC

POWER ONLY

WARNING!

POLARITY

MUST BE

OBSERVED

OR THE

CONTROLLER

WILL BE

DAMAGED

CONDENSER 2

SUCTION

PRESSURE 1

SENSOR

HEAD

PRESSURE 1

SENSOR

TEMP

SENSORS

BINARY

INPUTS

+5 V

+5 V

COMP DIS TEMP 1

COMP STATUS 1

SP-1

HP-1

COMP DIS TEMP 2

COMP 2STATUS

GND

GND

OUTSIDE COIL TEMP / POWF

EMERGENCY SHUTDOWN

GND

LEAVING WATERTEMP

GND

SUCTION

PRESSURE 2

SENSOR

HEAD

PRESSURE 2

SENSOR

+5 V

+5 V

SP-2

HP-2

GND

GND

R+

SHD

T-

HH COMMUNICATIONS

E-BUS

R+ SHD T-

DUAL E-BUS

EXPANSION

Two Condensers Per Two Modules

A1/B1 and A2/B2 Condenser Fans

See Figure 14, below and Figure 15 on the facing page for Two

Condensers for 2 Modules wiring. Refer to the fi gures on page 38

for Prism 2 confi guration, Modular Service Tool Screen selection,

and HVAC unit application.

OE370-26-RSMD

A1 / B1

Address 1

GND

24VAC

NOTE:

ALL RELAY OUTPUTS ARE NORMALLY

OPEN AND RATED FOR 24 VAC POWER

ONLY - 1 AMP MAXIMUM LOAD

24 VAC ONLY

G5Q-1A4

OMRON