Page 1

Users Information Manual

ENERGY RECOVERY UNITS

1

Page 2

2

Page 3

CONTENTS

IMPORTANT SAFETY INFORMATION ……… 4

GENERAL INFORMATION …………………… 5

Initial Mechanical Check & Setup

Air Seal Adjustments

Wheel-to-Air Seal Clearance

AIR FLOW BALANCING & CHECKING………… 6

Controls

ROUTINE MAINTENANCE & HANDLING …… 7

Lifting Hole Locations

Cleaning

Wheel Drive Components ……………… 7

INSTALLATION CONSIDERATIONS…………… 7

Accessibility

Orientation & Support

OPERATION ……………………………………… 8

Start Up Procedure

Diameter Seal Adjustment

Hub Seal Adjustment

SERVICE ………………………………………… 9

Segment Installation & Replacement

Segment Retainer

Wheel Drive Motor & Pulley Replacement

Belt Replacement ……………………… 10

DESIGN CONDITIONS & CONTROL

STRATEGIES …………………………………… 11

Standard Temperature Control

Fan Only Mode

Economizer Mode

Cooling Mode

Heating Mode

VENTILATION OF OCCUPIED SPACES

IN INDUSTRIAL APPLICATIONS ……………… 11

CROSS LEAKAGE IN ERV VENTILATION

SYSTEMS ………………………………………… 12

MOISTURE TRANSFER AND FUNGAL

GROWTH IN ENTHALPY WHEELS …………… 12

SILICA GEL DESICCANT………………………… 13

ARI PERFOMANCE CERTIFICATION ………… 14

Owner should pay particular attention to the words: NOTE, CAUTION, and WARNING. NOTES are

intended to clarify or make the installation easier. CAUTIONS are given to prevent equipment damage.

WARNINGS are given to alert owner that personal injury and/or equipment damage may result if installation

is not handled properly.

3

Page 4

IMPORTANT SAFETY INFORMATION

y

installation and service.

ONLY QUALIFIED PERSONNEL SHOULD

PERFORM INSTALLATION, OPERATION, AND

MAINTENANCE OF EQUIPMENT DESCRIBED IN

THIS MANUAL.

AAON package units are designed for safe operation

when installed, operated, and maintained within design

specifications, and the instructions set forth in this

manual. It is necessary to follow these instructions to

avoid personal injury or damage to equipment or

property during equipment installation, operation, and

maintenance.

WARNING

RISK OF ELECTRICAL SHOCK Before attempting to perform any service or

maintenance, turn the electrical power to the unit

OFF at disconnect switch(es). Unit may have

multiple power supplies.

WARNING

RISK OF DAMAGE, INJURY, AND LOSS OF LIFE

- Improper installation, adjustment, alteration,

service or maintenance can cause propert

damage, personal injury, or loss of life. A qualified

installer or service agency must perform

WARNING

RISK OF INJURY FROM MOVING PARTS Disconnect all power before servicing to prevent

serious injury resulting from automatic starts. Unit

may have multiple power supplies.

NOTE

IMPORTANT!

This equipment is protected by a standard limited

warranty under the condition that initial installation,

service, and maintenance is performed according

to the instructions set forth in this manual. This

manual should be read in its entirety prior to

installation, and before performing any service or

maintenance work.

Units described in this manual are available with

many optional accessories. If you have questions

after reading this manual in its entirety, consult

other factory documentation, or contact your sales

representative to obtain further information before

manipulating this equipment, or its optional

accessories.

4

Page 5

GENERAL INFORMATION

The units are designed as self-contained heating,

cooling or combination units using refrigerant, chilled

water, natural or propane gas, electric resistance,

steam or hot water as shown on the unit rating plate.

This AAONAIRE® unit has been equipped with an

energy recovery heatwheel. This booklet is furnished

to assure the energy recovery feature will be properly

setup to perform in accordance with the job

specifications for your particular application.

The AAONAIRE® heatwheel option is designed to

recover energy that would normally be lost through the

ventilation required by today's codes and standards for

comfort and health. The benefits of energy recovery

are significant in that 35 to 40 percent of the unit

heating and cooling capacity can be achieved by

collecting this otherwise lost energy from the exhaust

air and returning this energy to the building. The cost

of removing humidity in the summer is also greatly

reduced by the use of the desiccant coating on the

energy wheel.

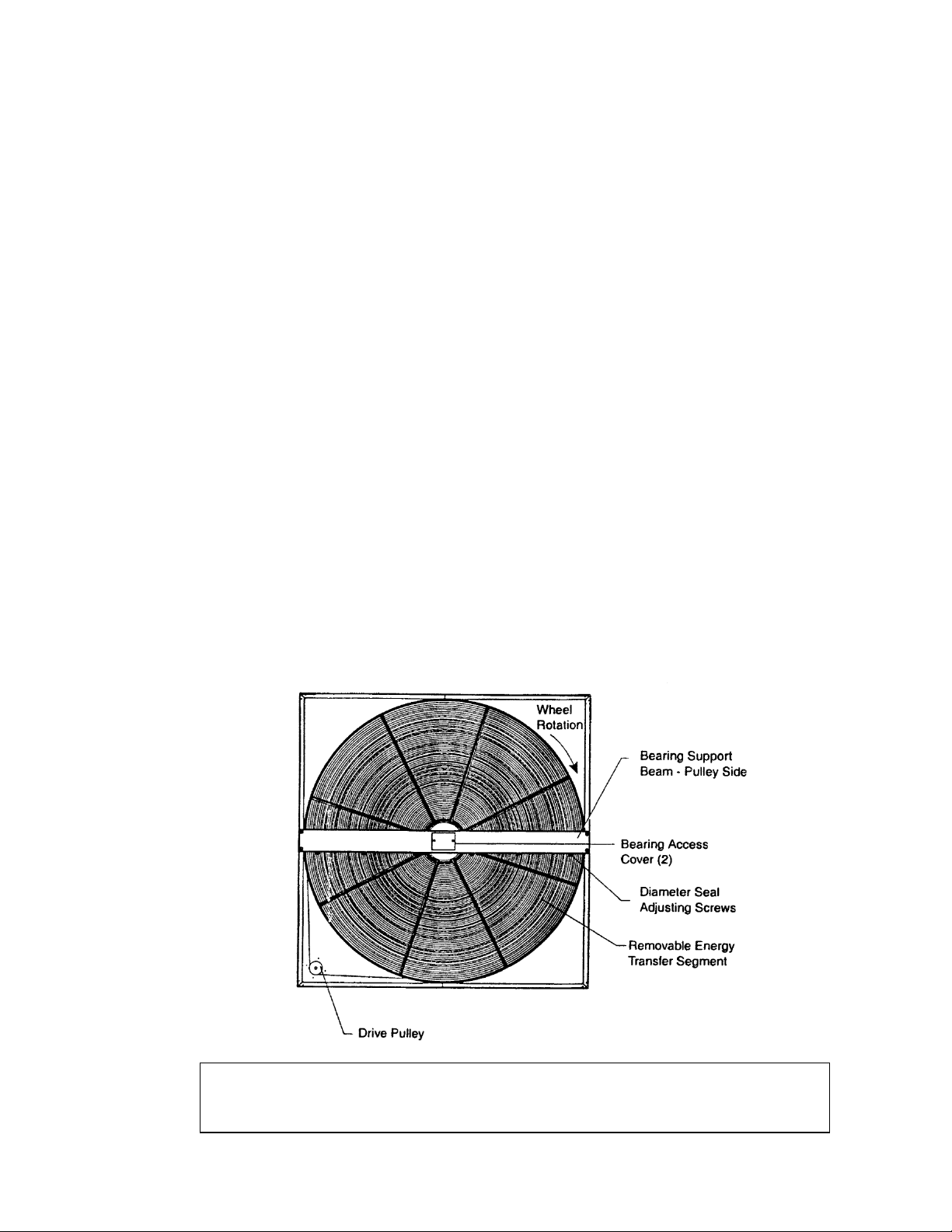

The Energy Recovery Cassette consists of a frame,

wheel, wheel drive system and energy transfer

segments. Segments are removable for cleaning or

replacement. The segments rotate through counter

flowing exhaust and outdoor air supply streams where

they transfer heat and/or water vapor from the warm,

moist air stream to the cooler and/or drier air stream.

This energy recovery process can reduce cooling

design loads by up to 4 tons per 1000 CFM of outdoor

air ventilation while also reducing heating demand and

humidification requirements. Operating savings,

reduced demand charges and first cost equipment

savings provide a rapid payback to the building owner.

INITIAL MECHANICAL CHECK & SETUP

Outdoor units equipped with outside air intake will

have an outside air hood. The outside air hood must

be opened prior to unit operation.

Remove shipping screws from each side of the hood in

the “closed” position. Lift hood to the “open” position,

seal flange, and secure with sheet metal screws.

Outdoor air intake adjustments should be made

according to building ventilation, or local code

requirements.

After the unit installation is complete, open the

cassette access door and determine that the energy

wheel rotates freely when turned by hand. Apply

power and observe that the wheel rotates at

approximately 30 RPM. If the wheel does not rotate

when power is applied, it may be necessary to readjust

the "diameter air seals".

AIR SEAL ADJUSTMENTS

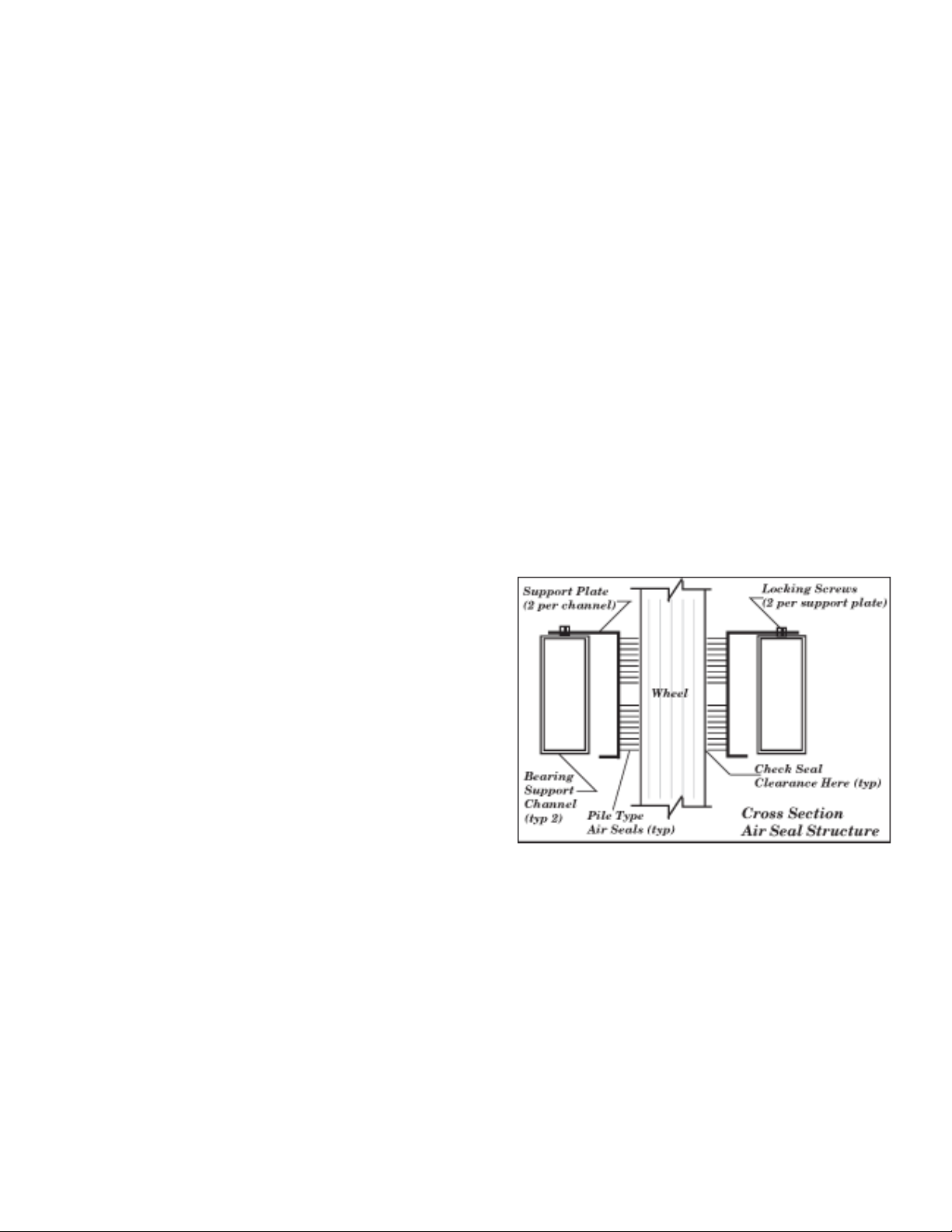

Pile type air seals across both sides of the energy

wheel diameter are factory adjusted to provide close

clearance between the air seal and wheel. Racking of

the unit or cassette during installation, and / or

mounting of the unit on a non level support or in other

than the factory orientation can change seal

clearances. Tight seals will prevent rotation.

The initial set-up and servicing of the heatwheel is very

important to maintain proper operating efficiency and

building occupant comfort.

Normal maintenance requires periodic inspection of

filters, the cassette wheel, drive belts, air seals, wheel

drive motor and its electrical connections.

Wiring diagrams are provided with each motor. When

wired according to wiring diagram, motor rotates

clockwise when viewed from the shaft/pulley side.

By carefully reviewing the information within this

manual and following the instructions, the risk of

improper operation and/or component damage will be

minimized.

It is important that periodic maintenance be performed

to help assure trouble free operation. Should

equipment failure occur, contact a qualified service

organization with qualified, experienced HVAC

technicians to properly diagnose and repair this

equipment.

WHEEL-TO-AIRSEAL CLEARANCE

To check wheel-to-seal clearance; first disconnect

power to the unit. In some units the heatwheel

assembly can be pulled out from the cabinet to view

the airseals. On larger units, the heatwheel may be

accessible inside the walk-in cabinet.

A business card or two pieces of paper can be used as

a feeler gauge, (typically each .004" thick) by placing it

between the face of the wheel and the pile seal.

Using the paper, determine if a loose slip fit exist

between the pile seal and wheel when the wheel is

rotated by hand.

To adjust air seal clearance, loosen all seal plate

retaining screws holding the separate seal retaining

5

Page 6

plates to the bearing support channels and slide the

seal plates away from the wheel. Using the paper

feeler gauge, readjust and retighten one seal plate at a

time to provide slip fit clearance when the wheel is

rotated by hand.

Confirm that the wheel rotates freely. Apply power to

the unit and confirm rotation.

AIRFLOW BALANCING & CHECKING

High performance systems commonly have complex

air distribution and fan systems. Unqualified personnel

should not attempt to adjust fan operation, or air

circulation, as all systems have unique operating

characteristics. Professional air balance specialists

should be employed to establish actual operating

conditions, and to configure the air delivery system for

optimal performance.

Controls

A variety of controls and electrical accessories may be

provided with the equipment. Identify the controls on

each unit by consulting appropriate submittal, or order

documents, and operate according to the control

manufacturer’s instructions. If you cannot locate

installation, operation, or maintenance information for

the specific controls, then contact your sales

representative, or the control manufacturer for

assistance.

WARNING

Do not alter factory wiring. Deviation from the

supplied wiring diagram will void all warranties,

and may result in equipment damage or personal

injury. Contact the factory with wiring

discrepancies.

Lifting Hole Locations

Routine maintenance of the Energy Recovery

Cassettes includes periodic cleaning of the Energy

Recovery Wheel as well as inspection of the Air Seals

and Wheel Drive Components as follows:

Cleaning

The need for periodic cleaning of the energy recovery

wheel will be a function of operating schedule, climate

and contaminants in the indoor air being exhausted

and the outdoor air being supplied to the building.

The heatwheel is “self-cleaning” with respect to dry

particles due to its laminar flow characteristics. Smaller

particles pass through; larger particles land on the

surface and are blown clear as the flow direction is

reversed. Any material that builds up on the face of the

wheel can be removed with a brush or vacuum. The

primary need for cleaning is to remove oil based

aerosols that have condensed on energy transfer

surfaces.

ROUTINE MAINTENANCE & HANDLING

Handle cassettes with care. All cassettes should be

lifted by the bearing support beam. Holes are provided

on both sides of the bearing support beams to facilitate

rigging as shown in the following illustration.

A characteristic of all dry desiccants, such films can

close off micron sized pores at the surface of the

desiccant material, reducing the efficiency by which

the desiccant can adsorb and desorb moisture and

also build up so as to reduce airflow.

In a reasonably clean indoor environment such as a

school or office building, measurable reductions of

airflow or loss of sensible (temperature) effectiveness

may not occur for several years. Measurable changes

in latent energy (water vapor) transfer can occur in

shorter periods of time in applications such as

moderate occupant smoking or cooking facilities. In

applications experiencing unusually high levels of

occupant smoking or oil based aerosols such as

industrial applications involving the ventilation of

machine shop areas for example, annual washing of

energy transfer may be necessary to maintain latent

transfer efficiency. Proper cleaning of the energy

6

Page 7

recovery wheel will restore latent effectiveness to near

original performance.

To clean, gain access to the energy recovery wheel

and remove segments. Brush foreign material from the

face of the wheel. Wash the segments or small wheels

in a 5% solution of non-acid based coil cleaner or

alkaline detergent and warm water.

Soak in the solution until grease and tar deposits are

loosened (Note: some staining of the desiccant may

remain and is not harmful to performance). Before

removing, rapidly run finger across surface of segment

to separate polymer strips for better cleaning action.

Rinse dirty solution from segment and remove excess

water before reinstalling in wheel.

INSTALLATION CONSIDERATIONS

AAONAIRE® Energy recovery cassettes are

incorporated within the design of packaged units,

packaged air handlers and energy recovery

ventilators. In each case, it is recommended that the

following considerations be addressed:

Accessibility

The cassette and all its operative parts; i.e.: motor,

belt, pulley, bearings, seals and energy transfer

segments must be accessible for service and

maintenance. This design requires that adequate

clearance be provided outside the enclosure.

Where cassettes are permanently installed in a

cabinet, access to both sides of the cassette must be

provided.

CAUTION !

Do Not use acid based cleaners, aromatic

solvents, steam or temperatures in excess of

170°F; damage to the wheel my occur!

Air Seals

Four adjustable diameter seals are provided on each

cassette to minimize transfer of air between the

counter flowing airstreams.

To adjust diameter seals, loosen diameter seal

adjusting screws and back seals away from wheel

surface. Rotate wheel clockwise until two opposing

spokes are hidden behind the bearing support beam.

Using a folded piece of paper as a feeler gauge,

position paper between the wheel surface and

diameter seals.

Adjust seals towards wheel surface until a slight

friction on the feeler gauge (paper) is detected when

gauge is moved along the length of the spoke.

Retighten adjusting screws and recheck clearance

with “feeler” gauge.

Wheel Drive Components

The wheel drive motor bearings are pre-lubricated

and no further lubrication is necessary.

The wheel drive pulley is secured to the drive motor

shaft by a combination of either a key or D slot and set

screw.

The set screw is secured with removable locktite to

prevent loosening. Annually confirm set screw is

secure. The wheel drive belt is a urethane stretch

belt designed to provide constant tension through the

life of the belt. No adjustment is required. Inspect the

drive belt annually for proper tracking and tension. A

properly tensioned belt will turn the wheel immediately

after power is applied with no visible slippage during

start-up.

Orientation & Support

The Energy Recovery Cassette may be mounted in

any orientation. However, Care must be taken to

make certain that the cassette frame remains flat

and the bearing beams are not racked.

To verify, make certain that the distance between

wheel rim and bearing beam is the same at each end

of the bearing beam, to within 1/4 of an inch

(dimension A & B). This amount of racking can be

compensated for by adjusting the diameter seals.

If greater than 1/4 inch, racking must be corrected

to ensure that drive belt will not disengage from

wheel.

Avoid Racking Of Cassette Frame

7

Page 8

OPERATION

CAUTION !

Keep hands away from rotating wheel!!

Contact with rotating wheel can cause physical

injury.

Start Up Procedure

1. By hand, turn wheel clockwise (as viewed from the

pulley side), to verify wheel turns freely through 360º

rotation.

2. Before applying power to drive motor, confirm wheel

segments are fully engaged in wheel frame and

segment retainers are completely fastened.

(See Segment Installation Diagram).

3. With hands and objects away from moving parts,

activate unit and confirm wheel rotation. Wheel rotates

clockwise (as viewed from the pulley side).

4. If wheel has difficulty starting, turn power off and

inspect for excessive interference between the wheel

surface and each of the four (4) diameter seals. To

correct, loosen diameter seal adjusting screws and

back adjustable diameter seals away from surface of

wheel, apply power to confirm wheel is free to rotate,

then re-adjust and tighten hub and diameter seals, as

shown in hub seal adjustment diagram.

5. Start and stop wheel several times to confirm seal

adjustment and to confirm belt is tracking properly on

wheel rim (approximately 1/4” from outer edge of rim).

Diameter Seal Adjustment

Hub Seal Adjustment

8

Page 9

SERVICE

CAUTION !

Disconnect electrical power before servicing

energy recovery cassette.

Always keep hands away from bearing support

beam when installing or removing segments.

Failure to do so could result in severe injury to

fingers or hand.

Segment Installation & Replacement

Wheel segments are secured to the wheel frame by a

Segment Retainer which pivots on the wheel rim and

is held in place by a Segment Retaining Catch.

Segment Retainer

To install wheel segments follow steps one through

five below. Reverse procedure for segment removal.

1. Unlock two segment retainers (one on each side of

the selected segment opening.

2. With the embedded stiffener facing the motor side,

insert the nose of the segment between the hub

plates.

Segment Installation

3. Holding segment by the two outer corners, press the

segment towards the center of the wheel and inwards

against the spoke flanges. If hand pressure does not

fully seat the segment, insert the flat tip of a screw

driver between the wheel rim and outer corners of the

segment and apply downward force while guiding the

segment into place.

4. Close and latch each Segment Retainer under

Segment Retaining Catch.

5. Slowly rotate the wheel 180º. Install the second

segment opposite the first for counterbalance. Rotate

the two installed segments 90º to balance the wheel

while the third segment is installed. Rotate the wheel

180º again to install the fourth segment opposite the

third. Repeat this sequence with the remaining four

segments.

Wheel Drive Motor & Pulley Replacement

1. Disconnect power to wheel drive motor.

2. Remove belt from pulley and position temporarily

around wheel rim.

3. Loosen set screw in wheel drive pulley using a hex

head wrench and remove pulley from motor drive

shaft.

4. While supporting weight of drive motor in one hand,

loosen and remove (4) mounting bolts.

5. Install replacement motor with hardware kit

supplied.

6. Install pulley to dimension as shown and secure set

screw to drive shaft.

7. Stretch belt over pulley and engage in groove.

8. Follow start-up procedure.

9

Page 10

Belt Replacement

1. Obtain access to the pulley side bearing access

plate if bearing access plates are provided. Remove

two bearing access plate retaining screws and the

access plate.

2. Using hexagonal wrench, loosen set screw in

bearing locking collar. Using light hammer and drift (in

drift pin hole) tap collar in the direction of wheel

rotation to unlock collar. Remove collar.

3. Using socket wrench with extension, remove two

nuts which secure bearing housing to the bearing

support beam. Slide bearing from shaft. If not

removable by hand, use bearing puller.

4. Form a small loop of belt and pass it through the

hole in the bearing support beam. Grasp the belt at

the wheel hub and pull the entire belt down.

Note: Slight hand pressure against wheel rim will

lift weight of wheel from inner race of bearing to

assist bearing removal and installation.

CAUTION !

Protect hands and belt from possible sharp edges

of hole in Bearing Support Beam.

5. Loop the trailing end of the belt over the shaft (belt

is partially through the opening).

6. Reinstall the bearing onto the wheel shaft, being

careful to engage the two locating pins into the holes

in the bearing support beam. Secure the bearing with

two self locking nuts.

7. Install the belts around the wheel and pulley

according to the instructions provided with the belt.

8. Reinstall diameter seals or hub seal and tighten

retaining screws. Rotate wheel in clockwise direction

to determine that wheel rotates freely with slight drag

on seals.

9. Reinstall bearing locking collar. Rotate collar by

hand in the direction the wheel rotates (see label

provided on each cassette for wheel rotation).

10. Lock in position by tapping drift pin hole with

hammer and drift. Secure in position by tightening set

screw.

11. Reinstall Bearing Access Cover.

12. Apply power to wheel and ensure that the wheel

rotates freely without interference.

Belt Replacement

10

Page 11

DESIGN CONDITIONS & CONTROL STRATEGIES

Standard temperature control

The unit can be configured with normal air flows and

controls but still have the benefit of a large amount of

makeup air, better humidity control and lower

operating cost than a unit without a heat wheel. The

energy recovery unit operates in four (4) basic modes;

fan only; economizer; cooling and heating. Each of

these modes has specific functions as defined below.

Fan only mode: When the unit supply fan is started,

and there is no call for cooling or heating, the unit

economizer moves to its minimum position, the

heatwheel is activated and the heatwheel fan is

started. If the unit is equipped with heatwheel bypass

dampers, these are closed.

Economizer mode: With the unit supply fan in

operation and a call for cooling is made, if the outdoor

air temperature and humidity are below the enthalpy

setpoint, the heatwheel exhaust fan is activated, the

heatwheel is deactivated and the economizer

modulates to maintain the mixed air setpoint. If the unit

is equipped with heatwheel bypass dampers, these

are opened to accommodate the increase in outside

air volume.

Ventilation of Occupied Spaces

In Industrial Applications

General ventilation of occupied spaces in Industrial

facilities is an excellent application for energy

recovery. It can have many significant benefits

including: odor control, a better working environment

for employees, higher productivity, reduced risk from

exposure to volatile compounds and particulates in the

indoor air, improved humidity control (for process and

people) and reduced energy costs to condition the

ventilation air. General ventilation with energy recovery

is not a substitute for fume hood exhaust. The success

of the industrial application depends on proper design

and an understanding of the performance

characteristics of the enthalpy wheel.

Energy recovery wheels or enthalpy wheels have

some inherent exhaust air transfer due to the volume

of air carried by wheel rotation from one airstream to

the other. In addition, while wheels are highly resistant

to fouling due to the counter flowing airflow

arrangement, they can be plugged by large amounts of

semi-volatile compounds or aerosols, which are

allowed to impinge and/or condense on the wheel

surfaces. These characteristics affect the installation

and application as follows:

Cooling mode: With the unit supply fan in operation

and a call for cooling is made, if the outdoor air

temperature and humidity are above the enthalpy

setpoint, the economizer moves to its minimum

position and mechanical cooling is activated. The

heatwheel is activated and the heatwheel exhaust fan

is started. If the unit is equipped with heatwheel

bypass dampers, these are closed.

Heating mode: Upon a call for heat, the heating

function is activated, the supply fan is activated and

the economizer moves to its minimum position. The

heatwheel is activated and the heatwheel exhaust fan

is started. If the unit is equipped with heatwheel

bypass dampers, these are closed.

Notice that in all four (4) basic above modes, the

operation of the heatwheel is determined by the

position of the economizer. With the exception of unit

shutdown or a night setback mode, the heatwheel

exhaust fan is in operation.

When control systems are "by others", all of the above

modes of operation must be considered.

1. Use energy recovery for general dilution

ventilation of the occupied space, not for

recovering energy from dedicated, highly

concentrated or toxic exhaust.

Exhaust air transfer in the energy recovery system

results in a small amount of the exhaust air, typically

less than 5% for wheels operating in balanced flow,

returning to the space. This amount of exhaust air

transfer is appropriate to handling general exhaust in

an environment where continuous exhaust and supply

of outdoor air to the space achieves the required

dilution of contaminants. In space conditioning

applications, where the ventilation system is operating

to maintain acceptable indoor air quality, there should

not be contaminants in concentrations of concern. It is

not appropriate for recovering energy from highly

concentrated machine exhaust, such as hoods

installed on the print heads themselves. Even a small

amount of exhaust air transfer in this case can

increase contaminants and odors in the space. This air

is best exhausted directly outdoors and treated as may

be required by local code. If energy recovery is desired

in these environments, a “run around loop” approach is

suggested.

11

Page 12

2. Take “return” air (air to be exhausted after

recovering energy from it) from the occupied zone,

not from areas containing a high concentration of

dusts or aerosols such as the hood.

If necessary, provide supplemental filtration of the

return air at the inlets to the duct system. The goal of

the dilution ventilation is to preserve a healthful and

comfortable environment in the breathing zone. Supply

and return diffusers and grilles should be located to

achieve this end. Ceiling returns located directly above

machinery can provide additional benefits by directing

contaminants away from operators. In the industrial

application this air may contain high levels of aerosols,

which, once deposited and dried, would be difficult or

impossible to clean from ductwork, fans, dampers and

wheels. Therefore a filter of appropriate efficiency is

recommended to be installed at the inlet or “return

grille”.

Experience in industrial applications from small

facilities to large factories has shown that when these

two recommendations are observed, successful

application of energy recovery and its attendant

benefits is the result. On the other hand, ignoring

these common sense rules can result in reduced

satisfaction and/or equipment damage and a

maintenance challenge.

By contrast, in space conditioning applications, where

the ventilation system is operating to maintain

acceptable indoor air quality, there should be no

contaminants in concentrations of concern. Cross

leakage in the energy recovery system results in a

small amount of the exhaust air, typically less than 5%

for wheels operating in balanced flow, returning to the

space from which it came. This is not “contamination”

as it is often labeled. It is air that effectively never left

the space. The operating cost of moving this air is far

less than that required to operate purge sector.

This amount of cross leakage is appropriate to

handling bathroom exhaust in an environment where

continuous exhaust of the restroom achieves an air

quality on a par with the adjacent space. It is not

appropriate for recovering energy from toxic

environments, laboratory fume hoods, operating

rooms, etc. These are not recommended applications

for rotary based technology without a purge sector.

In fact, many of these environments should not

tolerate any cross leakage and as such should not

utilize rotary technology as even well designed purge

sectors do not achieve zero cross leak.

If energy recovery is required in these environments, a

“run around loop” approach is suggested.

Cross Leakage in Energy

Recovery Ventilation Systems

The issue of cross leakage in rotary wheel based

Energy Recovery used in space conditioning

applications is often misunderstood. As a result, many

systems are installed with purge sectors and the

additional fan capacity required to allow these sectors

to function when in fact they are unnecessary.

Understanding the rationale for the purge sector, its

history, its added first cost, and the associated

continuing cost of operation, the designer will rarely

specify purge.

A purge sector minimizes the carry over cross leakage

from exhaust into the supply airstream by shunting a

portion of the supply air back into the exhaust

airstream across the seal separating the exhaust and

supply. This is required for industrial process

applications where the exhaust contains contaminants

which would be detrimental to the process.

(Historically, heat wheels have been used primarily for

dehumidification and process heat recovery.) The

volume of air required for effective purge is listed at

10% to 20% of rated flow by manufacturers of

industrial process wheels. In addition to the cost of

providing the sector, the system must move 10 to 20%

more air than is required by the application in order to

purge.

The adjustable mechanical purge is capable of

reducing cross leakage to a fraction of one percent.

Nevertheless, purge should only be specified based on

an engineering evaluation of the cost to provide, the

cost to operate and the specific needs of the

application.

Moisture Transfer and Fungal Growth in Desiccant

Based Enthalpy Wheels

There is evidence that fungi germinate when water

condenses onto surfaces of air handling systems

where nutrients are present. Surfaces which remain

wet for a period of 12 to 24 hours allow fungi and mold

spores already present to “bloom”, resulting in a

potential IAQ problem.

This knowledge has led to questions of whether

desiccant energy recovery ventilation wheels, which in

fact transfer water from one airstream to another,

could provide a medium for growth of mold and fungi.

Such is not the case for AAONAIRE® technology, nor

has it been reported in the literature for other enthalpy

wheels.

In silica gel based desiccant wheels, the water

molecules are transferred by sorption, individually,

onto and off of the silica gel surface. Water is present

on the wheel in a molecular layer only. Condensation

does not occur. AAONAIRE® desiccant wheels

experience “dry” moisture transfer in that there is no

12

Page 13

bulk liquid water present which could support fungal

growth or dissolve other chemical species. The

transfer of water onto and off of the wheel’s desiccant

surfaces occurs in the vapor or gas phase. There are

no “wet” surfaces and liquid water does not enter the

air stream.

The sensible (non-desiccant coated) wheel can also

transfer water through the different mechanism of

condensation and re-evaporation, however; again,

there is no accumulation of water, unless the frosting

threshold is violated through misapplication of the

component. In this case, the water is in the form of

frost or ice which does not support fungal growth.

Sensible (uncoated) wheels from all manufacturers are

identical in this regard.

humidity. On the other hand, silica gel has superior

characteristics for the recovery of space conditioning

energy from exhaust air.)

The use of silica gel on rotary regenerators for energy

recovery ventilation applications involves a process

cycle where the silica gel is alternately exposed to

airstreams having nearly equal relative humidity

somewhere in the mid range of this curve (typically

between 40 and 60%). When the air stream with the

higher relative humidity passes over the silica gel

coated wheel, moisture is adsorbed from the air

stream into the silica gel. Then when the air stream

with the lower relative humidity contacts the silica gel,

moisture is desorbed (removed) from the silica gel and

put into the air stream.

Both moisture and nutrients are required to support

fungal growth. Therefore dirt accumulation on heat

wheels is of potential concern. It is also true that any

heat wheel can accumulate semi-volatile compounds

like tars and grease which are deposited on surfaces.

These surfaces can then become odor and

contaminant sources, in the same way that a filter or

any other element of an air handling system can

become a source of compounds accumulated over

time.

The heatwheel was designed to respond to these

issues over the life of the system by providing for

cleaning and maintenance with washable desiccant

surfaces, removable segments and easy to access

cassettes. Many aspects of this technology are

patented and are unique in the industry.

Silica Gel Desiccant

Silica gel is an inert, highly porous solid adsorbent

material that structurally resembles a rigid sponge. It

has a very large internal surface composed of myriad

microscopic cavities and a vast system of capillary

channels that provide pathways connecting the

internal microscopic cavities to the outside surface of

the “sponge”.

The characteristic curve for adsorption of water on

silica gel is shown in Figure 1 (page 13), as % weight

adsorbed versus relative humidity of the air stream in

contact with the silica gel. The amount of water

adsorbed rises almost linearly with increasing relative

humidity until RH reaches about 60%. It then plateaus

out at about 40% adsorbed as relative humidity

approaches 100%. (The curve for molecular sieves, by

contrast, rises rapidly to plateau at about 20%

adsorbed at 20% relative humidity. This helps to

explain why the molecular sieve is an excellent choice

for regenerated applications such as desiccant cooling

and dehumidification systems which are designed to

reduce processed airstreams to very low relative

In this ventilation energy recovery application, the

silica gel has all of its surface area covered with at

least a monomolecular layer of water because it has a

greater affinity for water than any other chemical

species. With all of the adsorption sites occupied by

water, the silica gel will not be able to transfer other

chemical species by adsorption and desorption in its

normal form. Species that are soluble in water could

become dissolved in the adsorbed water and then

released when the water is desorbed but this process

is limited by kinetics and does not present a very

efficient mechanism for contaminant transfer.

An example of this phenomenon is formaldehyde, a

gas which is very highly soluble in water.

In the early 1980’s when energy recovery ventilators

were being used to mitigate excessive formaldehyde

levels in mobile homes, concern was expressed by

some people that enthalpy type heat exchangers that

transferred moisture as well as heat might also

transfer excess amounts of formaldehyde gas due to

its high solubility in water. Accordingly, tests were

conducted by the Lawrence Berkeley Laboratories of

the U.S.D.O.E., on two enthalpy type exchangers to

determine whether this suspicion was justified. Results

were presented in ASHRAE paper No. CH85-03 No. 3

which reported that the rotary type enthalpy heat

exchanger transferred formaldehyde with only 3-6%

efficiency. They concluded that “formaldehyde transfer

between airstreams by processes other than air

leakage does not seriously compromise the

performance of these enthalpy exchangers”.

13

Page 14

ARI Performance Certification

The certified ratings program requires testing, rating

and independent verification of component

performance at standard conditions and rated flow.

Testing is in accordance with ASHRAE Standard 84.

Also, self-certification does not include the necessary

periodic verification tests and challenge procedures

provided by the industry certification program.

Specifications requiring ARI Certification in

accordance with the latest revision of ARI Standard

1060 provide the best assurance that components and

systems will perform as designed.

ARI certified ratings include very complete information,

some of it previously unavailable, to allow designers to

fully characterize thermal and airflow performance. In

addition to separate sensible, latent, and total

effectiveness at two airflows for both summer and

winter test conditions, the standard requires

information on pressure loss as well as air leakage.

Airxchange publishes ARI certified ratings for all

energy recovery ventilation components of their

manufacture in accordance with the requirements of

the ARI program. These ratings may be found on the

ARI website www.ari.org. Application ratings are

provided for the complete range of airflows and all

Airxchange cassettes bear the ARI Certification Seal.

With the ARI industry performance certification

program in place, engineers and building

owners/operators no longer need accept self

certification. It is important to point out that ratings

from non-participating manufacturers are difficult to

compare regardless of whether they are tested in

house or by an “independent” testing agency. This is in

part because the latent performance of a given unit

can change significantly when tested at different

outdoor air conditions and at less than rated airflows.

A product can be made to look better by testing it

“independently” at an easier condition. Lower relative

humidity (lower wet bulb) and less than rated airflow

improves the tested performance.

14

Page 15

15

Page 16

AAON, Inc.

)

2425 S. Yukon

Tulsa, Oklahoma 74107

Tel 918-583-2266

Fax 918-583-6094

Download this manual,

and others from:

www.aaon.com

It is the intent of AAON to provide accurate and current specification

information. However, in the interest of product improvement, AAON,

Inc. reserves the right to change pricing, specifications, and/or design

of its products without notice, obligation, or liability.

AAON is a registered trademark of AAON, Inc.

Effective August 2006

Supercedes August 1998

16

R86610 (Rev. A 8-06

Loading...

Loading...