Page 1

M3 Series

Modular Indoor and Outdoor Air Handling Units

Installation, Operation

QUALIFIED INSTALLER

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

personal injury or loss of life. Startup

and service must be performed by a

Factory Trained Service Technician.

A copy of this IOM should be kept

with the unit.

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

& Maintenance

Page 2

Page 3

Table of Contents

Safety .............................................................................................................................................. 7

Unit Orientation ............................................................................................................................ 12

Model Number Nomenclature ...................................................................................................... 13

Base Model Feature Description ................................................................................................... 14

Supply Fan Module Feature Description ...................................................................................... 15

Cooling/Preheat Module Feature Description .............................................................................. 18

Heating Coil Module Description ................................................................................................. 21

Blank Module Feature Description ............................................................................................... 23

Filter Module Feature Description ................................................................................................ 24

Mixing Box/Economizer Module Feature Description ................................................................. 25

Discharge Module Feature Description ........................................................................................ 27

Control Panel Module Feature Description .................................................................................. 29

Exhaust Fan Module Feature Description ..................................................................................... 30

Energy Recovery Module Feature Description ............................................................................. 33

Return Fan Module Feature Description ....................................................................................... 35

General Description ...................................................................................................................... 37

Receiving ................................................................................................................................... 37

Storage ....................................................................................................................................... 38

Installation..................................................................................................................................... 38

Location/Clearances .................................................................................................................. 38

Rigging ...................................................................................................................................... 39

Module Location ....................................................................................................................... 39

Module Assembly ..................................................................................................................... 40

Module Disassembly ................................................................................................................. 44

Spring Isolator Adjustment ....................................................................................................... 44

Blower Wheels .......................................................................................................................... 45

Air Adjustment .......................................................................................................................... 45

Condensate Drains ..................................................................................................................... 46

Draw-Through P-Trap Example ............................................................................................ 48

Blow-Through P-Trap Example ............................................................................................ 52

Base Drains ............................................................................................................................... 54

External Control Panel .............................................................................................................. 54

Electrical .................................................................................................................................... 55

Foam Insulated Panel Cutting ................................................................................................ 55

Dampers and Actuators ............................................................................................................. 56

Duct System .............................................................................................................................. 57

Piping ........................................................................................................................................ 57

Operation....................................................................................................................................... 58

Startup Checklist ....................................................................................................................... 58

Procedures ................................................................................................................................. 59

Commissioning .......................................................................................................................... 59

Air Balancing ............................................................................................................................ 59

Water Balancing ........................................................................................................................ 60

Controls ..................................................................................................................................... 60

Maintenance .................................................................................................................................. 60

3

Page 4

Routine Maintenance ................................................................................................................. 60

Blower Assembly ...................................................................................................................... 60

Coils/Drain Pans ........................................................................................................................ 60

Winterizing Coils ...................................................................................................................... 61

Removing Coils ......................................................................................................................... 61

Doors/Panels .............................................................................................................................. 62

Outside Opening Door and Panel .............................................................................................. 62

Filters ......................................................................................................................................... 63

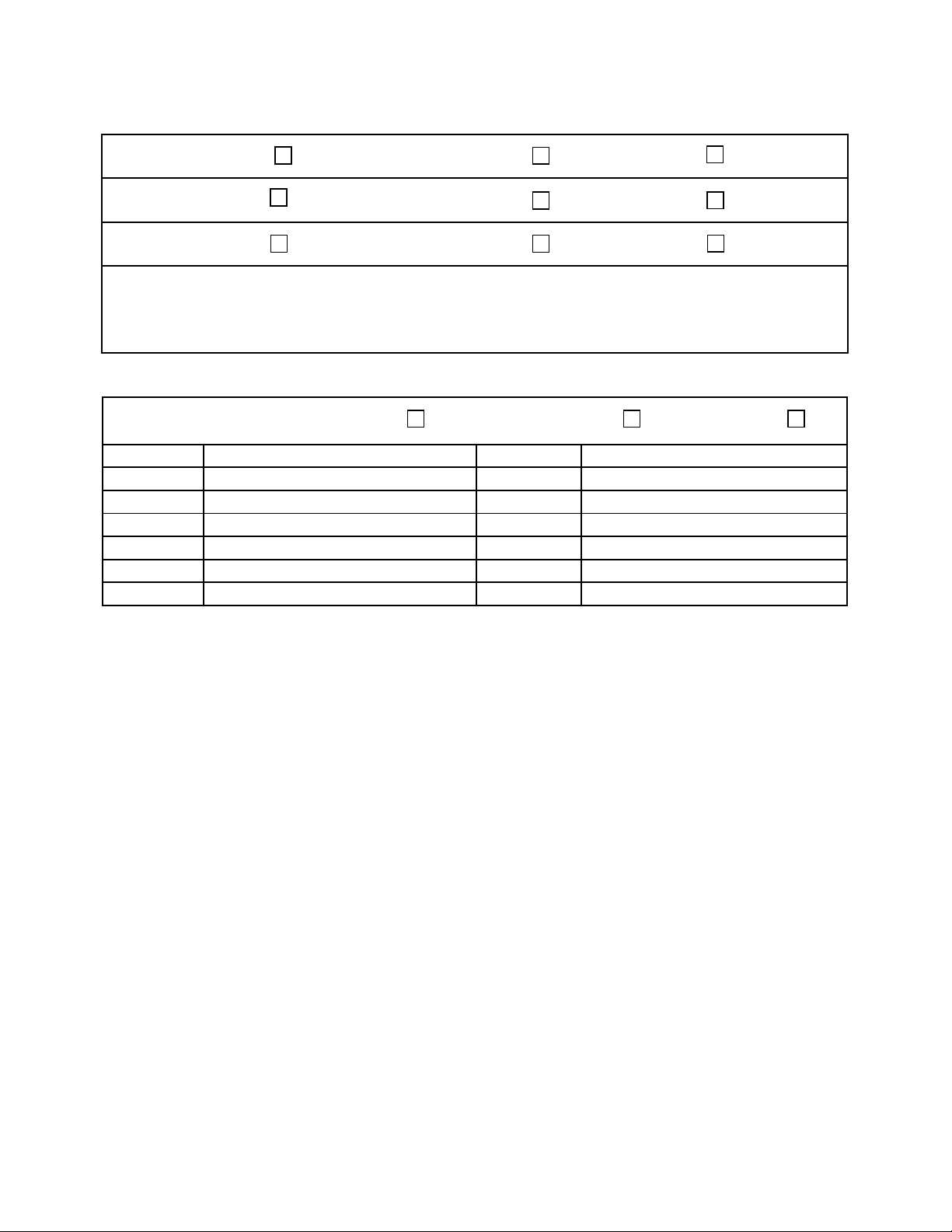

M3 Series Startup Form ................................................................................................................ 66

Maintenance Log .......................................................................................................................... 69

Literature Change History............................................................................................................. 70

R57350 · Rev. D · 140307

4

Page 5

Index of Tables and Figures

Tables:

Table 1 - Draw-Through Drain Trap Dimensions ........................................................................ 47

Table 2 - Blow-Through Drain Trap Dimensions......................................................................... 51

Table 3 - Flat Pleated Filters ......................................................................................................... 64

Table 4 - Angled Pleated Filters ................................................................................................... 64

Table 5 - Cartridge/Bag Filters ..................................................................................................... 64

Figures:

Figure 1 - Unit Orientation ........................................................................................................... 12

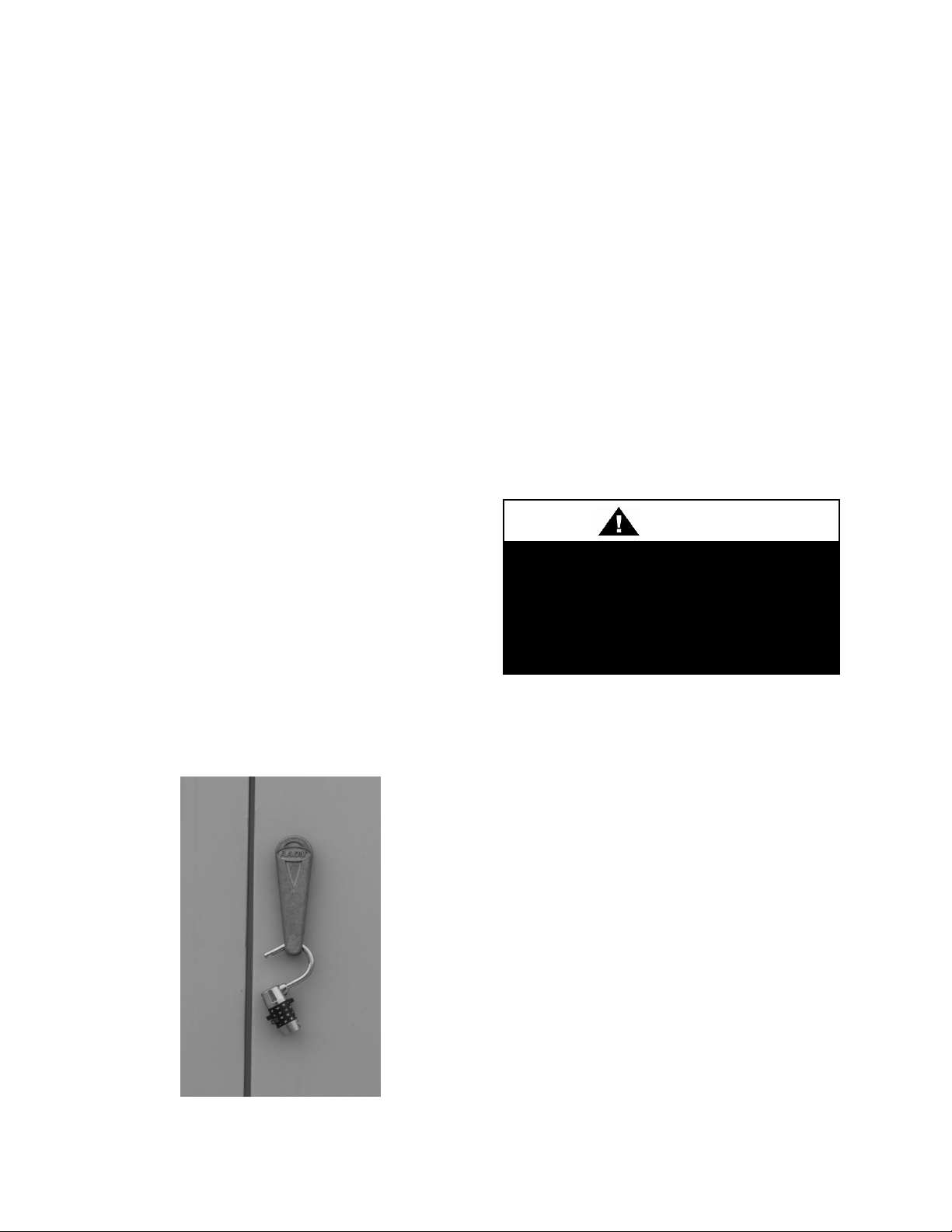

Figure 2 - Lockable Handle .......................................................................................................... 38

Figure 3 - Unit Lifting Example ................................................................................................... 39

Figure 4 - Unit Lifting Side View ................................................................................................. 39

Figure 5 - Module Location Example ........................................................................................... 40

Figure 6 - Moving Module with Pipes .......................................................................................... 41

Figure 7 - Neoprene Gasket .......................................................................................................... 41

Figure 8 - Module Connection ...................................................................................................... 41

Figure 9 - Module Connection Example ....................................................................................... 41

Figure 10 - Top View of Module Connection .............................................................................. 42

Figure 11 - Aligning Two Modules .............................................................................................. 42

Figure 12 - Aligning the Top of a Unit ......................................................................................... 42

Figure 13 - Lifting Lugs and Bolts ............................................................................................... 42

Figure 14 - Come-Along Putting Together Modules .................................................................... 42

Figure 15 - Pulling Sections Together .......................................................................................... 43

Figure 16 - Fastening Sections Together ...................................................................................... 43

Figure 17 - Attaching Splice ......................................................................................................... 43

Figure 18 - Attaching Corner Rail Cover ..................................................................................... 43

Figure 19 - Attaching Base Splice ................................................................................................ 44

Figure 20 - Blower Spring Isolator ............................................................................................... 44

Figure 21 - Spring Isolator Adjustment ........................................................................................ 45

Figure 22 - Supply Fan Banding ................................................................................................... 46

Figure 23 - Draw-Through Drain Trap ......................................................................................... 47

Figure 24 – Draw-Through Drain Pan Connection Locations ...................................................... 48

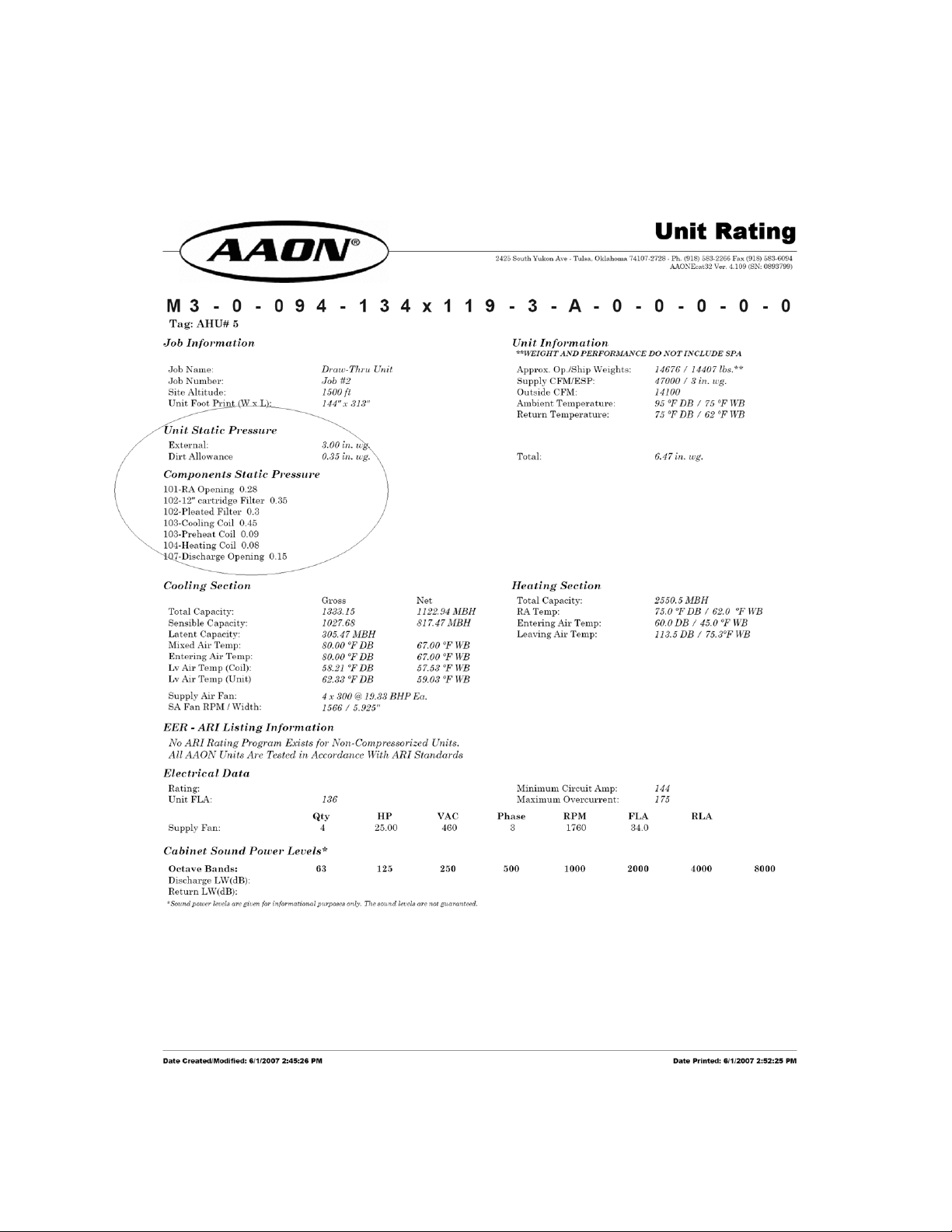

Figure 25 - Example Draw-Through AAONEcat32 Rating Sheet ............................................... 49

Figure 26 - Blow-Through Drain Trap ......................................................................................... 50

Figure 27 - Blow-Through Drain Pan Connection Locations ....................................................... 52

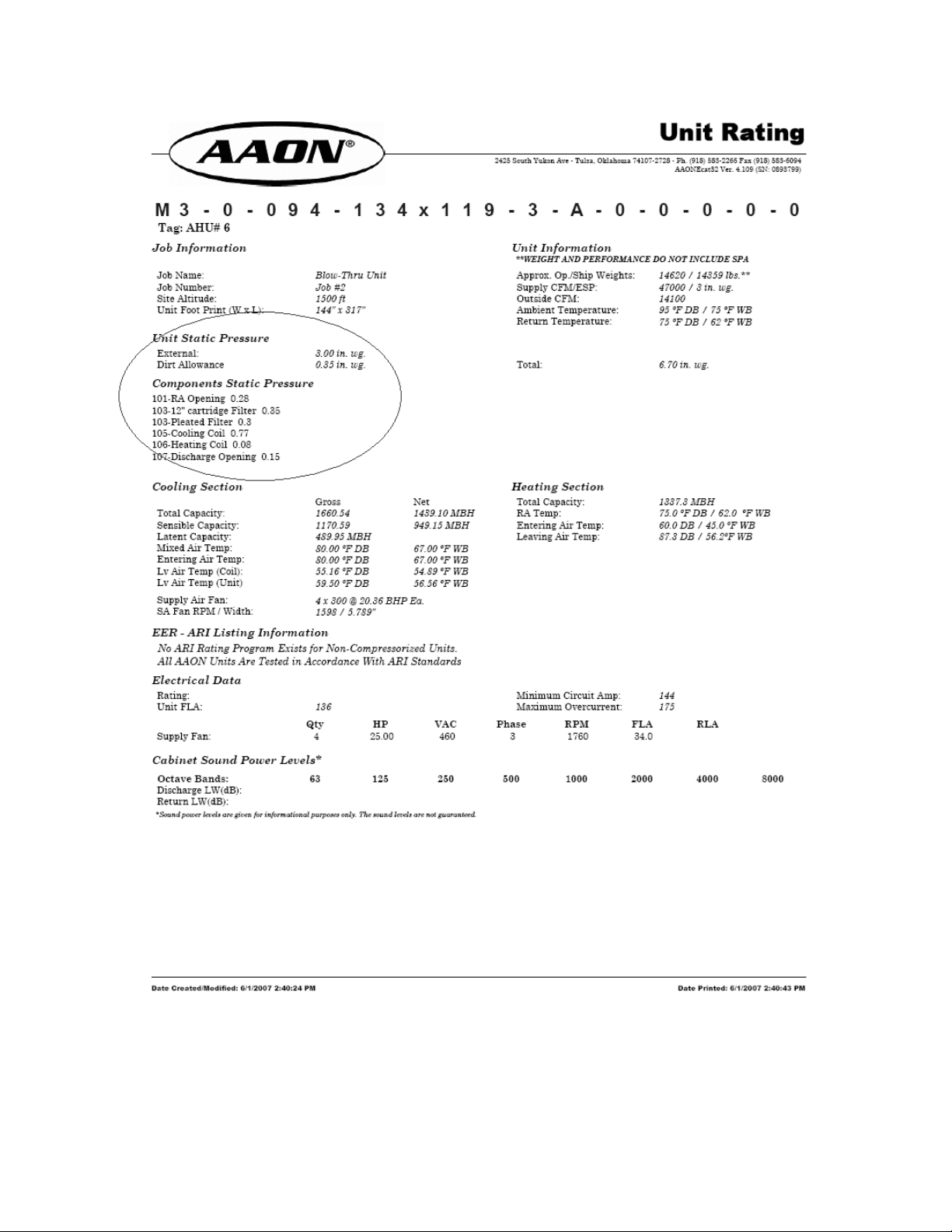

Figure 28 - Example Blow-Through AAONEcat32 Rating Sheet ................................................ 53

Figure 29 - External Control Panel ............................................................................................... 55

Figure 30 - Dampers ..................................................................................................................... 56

Figure 31 - Dampers and Actuator................................................................................................ 57

Figure 32 - Independently Controlled Dampers ........................................................................... 57

Figure 33 - Hydronic Coil Connections ........................................................................................ 58

5

Page 6

Figure 34 - Blower Rotation ......................................................................................................... 59

Figure 35 - Coil Removal ............................................................................................................. 62

Figure 36 - Access Door/Panel Removal ...................................................................................... 62

Figure 37 - Access Door ............................................................................................................... 63

Figure 38 - Cartridge/Bag Filter Layout Viewed from Upstream Side. ....................................... 65

6

Page 7

Safety

Attention should be paid to the following statements:

NOTE - Notes are intended to clarify the unit installation, operation and maintenance.

CAUTION - Caution statements are given to prevent actions that may result in

equipment damage, property damage, or personal injury.

WARNING - Warning statements are given to prevent actions that could result in

equipment damage, property damage, personal injury or death.

DANGER - Danger statements are given to prevent actions that will result in equipment

damage, property damage, severe personal injury or death.

ELECTRIC SHOCK, FIRE OR

EXPLOSION HAZARD

Failure to follow safety warnings

exactly could result in dangerous

operation, serious injury, death or

property damage.

Improper servicing could result in

dangerous operation, serious injury,

death or property damage.

Before servicing, disconnect all

electrical power to the unit. More

than one disconnect may be

provided.

When servicing controls, label all

wires prior to disconnecting.

Reconnect wires correctly.

Verify proper operation after

servicing. Secure all doors with

key-lock or nut and bolt.

Electric shock hazard. Before

servicing, disconnect all electrical

power to the unit, including remote

disconnects, to avoid shock hazard

or injury from rotating parts. Follow

proper Lockout-Tagout procedures.

FIRE, EXPLOSION OR CARBON

MONOXIDE POISONING HAZARD

Failure to replace proper controls

could result in fire, explosion or

carbon monoxide poisoning. Failure

to follow safety warnings exactly

could result in serious injury, death or

property damage. Do not store or use

gasoline or other flammable vapors

and liquids in the vicinity of this

appliance.

7

Page 8

VARIABLE FREQUENCY DRIVES

Do not leave VFDs unattended in

hand mode or manual bypass.

Damage to personnel or equipment

can occur if left unattended. When in

hand mode or manual bypass mode

VFDs will not respond to controls or

alarms.

GROUNDING REQUIRED

All field installed wiring must be

completed by qualified personnel.

Field installed wiring must comply

with NEC/CEC, local and state

electrical code requirements. Failure

to follow code requirements could

result in serious injury or death.

Provide proper unit ground in

accordance with these code

requirements.

During installation, testing, servicing

and troubleshooting of the equipment

it may be necessary to work with live

electrical components. Only a

qualified licensed electrician or

individual properly trained in handling

live electrical components shall

perform these tasks.

Standard NFPA-70E, an OSHA

regulation requiring an Arc Flash

Boundary to be field established and

marked for identification of where

appropriate Personal Protective

Equipment (PPE) be worn, should be

followed.

UNIT HANDLING

To prevent injury or death lifting

equipment capacity shall exceed unit

weight by an adequate safety factor.

Always test-lift unit not more than 24

inches high to verify proper center of

gravity lift point to avoid unit damage,

injury or death.

ROTATING COMPONENTS

Unit contains fans with moving parts

that can cause serious injury. Do not

open door containing fans until the

power to the unit has been

disconnected and fan wheel has

stopped rotating.

Electric motor over-current protection

and overload protection may be a

function of the Variable Frequency

Drive to which the motors are wired.

Never defeat the VFD motor overload

feature. The overload ampere setting

must not exceed 115% of the electric

motors FLA rating as shown on the

motor nameplate.

Failure to properly drain and vent

coils when not in use during freezing

temperature may result in coil and

equipment damage.

8

Page 9

Do not clean DX refrigerant coils with

hot water or steam. The use of hot

water or steam on refrigerant coils

will cause high pressure inside the

coil tubing and damage to the coil.

WATER PRESSURE

Prior to connection of condensing

water supply, verify water pressure is

less than maximum pressure shown

on unit nameplate. To prevent injury

or death due to instantaneous

release of high pressure water, relief

valves should be field supplied on

system water piping.

To prevent damage to the unit, do not

use acidic chemical coil cleaners. Do

not use alkaline chemical coil

cleaners with a pH value greater than

8.5, after mixing, without first using

an aluminum corrosion inhibitor in the

cleaning solution.

Do not use oxygen, acetylene or air

in place of refrigerant and dry

nitrogen for leak testing. A violent

explosion may result causing injury or

death.

Always use a pressure regulator,

valves and gauges to control

incoming pressures when pressure

testing a system. Excessive pressure

may cause line ruptures, equipment

damage or an explosion which may

result in injury or death.

Do not work in a closed area where

refrigerant or nitrogen gases may be

leaking. A sufficient quantity of

vapors may be present and cause

injury or death.

Rotation must be checked on all

MOTORS AND COMPRESSORS of

3 phase units at startup by a qualified

service technician. Scroll

compressors are directional and can

be damaged if rotated in the wrong

direction. Compressor rotation must

be checked using suction and

discharge gauges. Fan motor rotation

should be checked for proper

operation. Alterations should only be

made at the unit power connection

Do not weld or cut foam panel with

plasma cutters or a cutting torch –

When burnt the foam produces

dangerous fumes.

When steam cleaning coils, be sure

areas on both sides of the coil are

clear personnel.

9

Page 10

Some chemical coil cleaning

compounds are caustic or toxic. Use

these substances only in accordance

with the manufacturer’s usage

instructions. Failure to follow

instructions may result in equipment

damage, injury or death.

Door compartments containing

hazardous voltage or rotating parts

are equipped with door latches to

allow locks. Door latch are shipped

with nut and bolts requiring tooled

access. If you do not replace the

shipping hardware with a pad lock

always re-install the nut & bolt after

closing the door.

Check the shipping section weights

on the Bill of Lading to be sure they

can be lifted safely. Rigging should

be adjusted so that all sections are

lifted level.

Do not enter or reach into a fan

cabinet while the fan is still turning.

Never attempt to open an access

door or remove a panel while the unit

is running. Pressure in the unit can

cause excessive force against the

panel.

Never pressurize equipment over 8”

w.c – Equipment and property

damage, personal injury or loss of life

could result.

Ensure that sufficient dampers will be

open to provide air path before fan is

allowed to run.

Risk of injury from hot parts –

Disconnect all power, close all

isolation valves and allow equipment

to cool before servicing equipment

with hot water and steam heating

coils. Hot water will circulated even

after the power is off.

PVC (Polyvinyl Chloride) and CPVC

(Chlorinated Polyvinyl Chloride) are

vulnerable to attack by certain

chemicals. Polyolester (POE) oils

used with R-410A and other

refrigerants, even in trace amounts,

in a PVC or CPVC piping system will

result in stress cracking of the piping

and fittings and complete piping

system failure.

10

Page 11

HOT PARTS

Disconnect all power, close all

isolation valves and allow equipment

to cool before servicing equipment to

prevent serious injury. Equipment

may have multiple power supplies.

Electric resistance heating elements

and hot water or steam heating coils

may have automatic starts. Hot water

will circulate even after power is off.

1. Startup and service must be performed

by a Factory Trained Service

Technician.

2. The unit is for indoor or outdoor use.

See General Information section and unit

specifications for more unit information.

3. Every unit has a unique equipment

nameplate with electrical, operational,

and unit clearance specifications.

Always refer to the unit nameplate for

specific ratings unique to the model you

have purchased.

4. READ THE ENTIRE INSTALLATION,

OPERATION AND MAINTENANCE

MANUAL. OTHER IMPORTANT

SAFETY PRECAUTIONS ARE

PROVIDED THROUGHOUT THIS

MANUAL.

5. Keep this manual and all literature

safeguarded near or on the unit.

11

Page 12

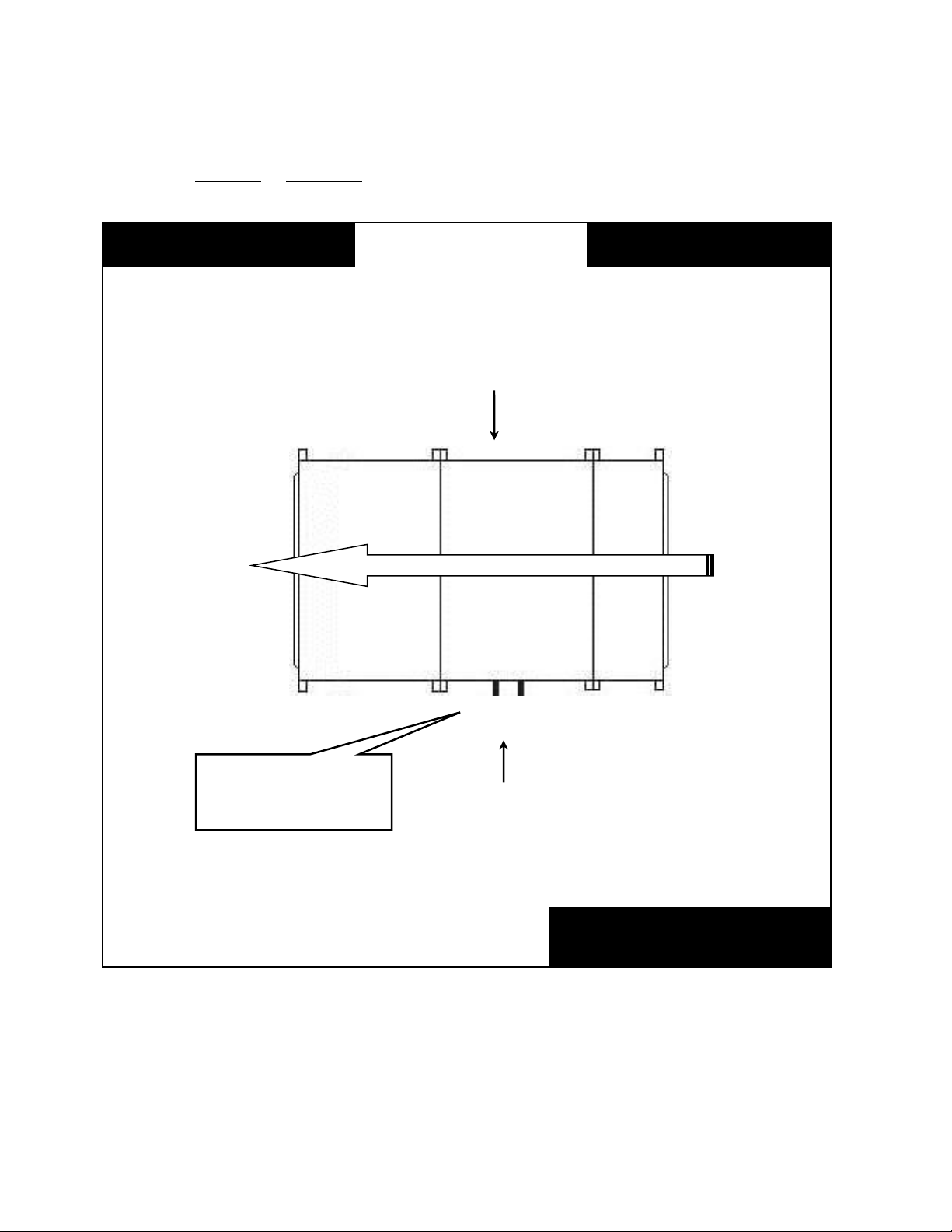

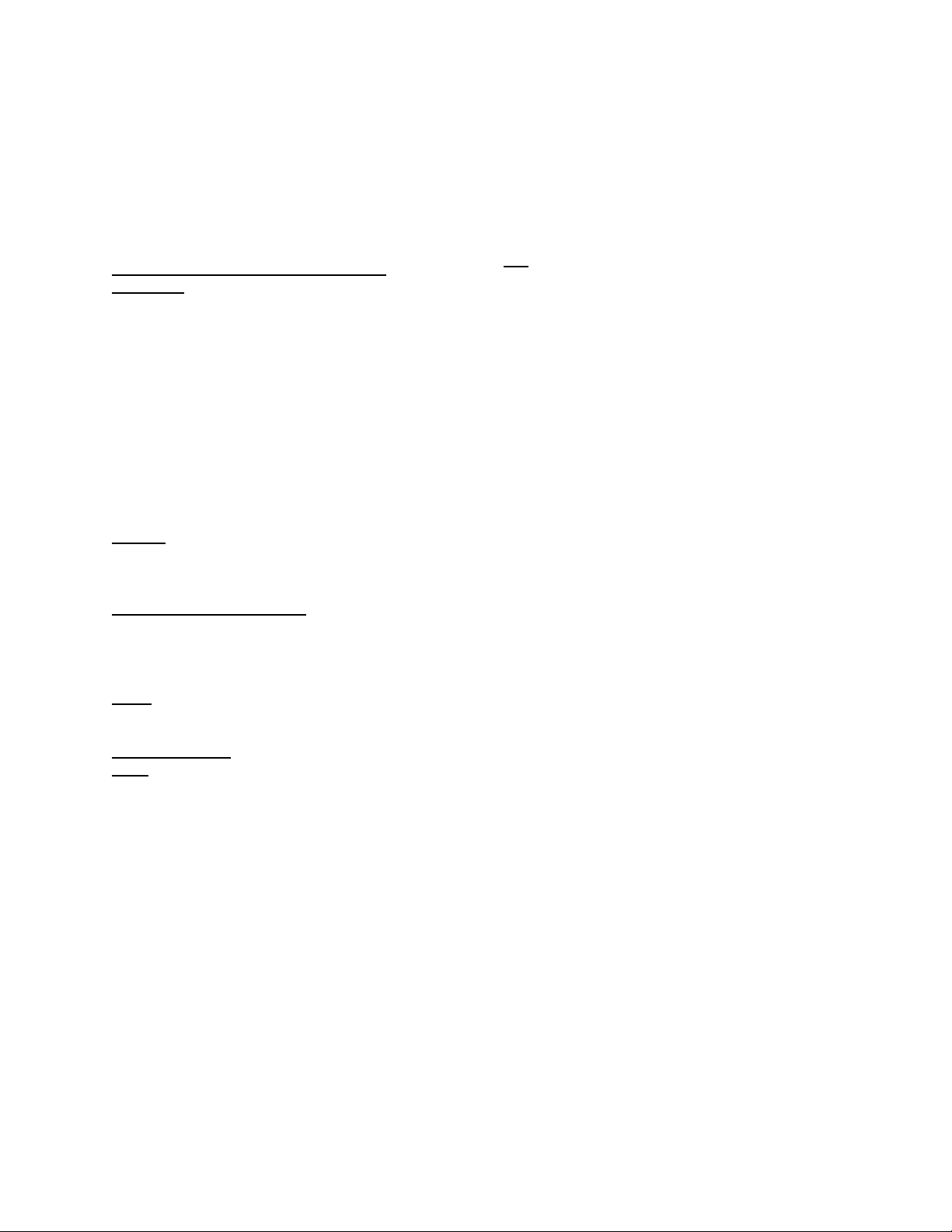

Unit Orientation

Consider the air flow to be

hitting the back of your head.

M3 Series

Top View

Return Air

Supply Air

Left Hand Side

Right Hand Side

Connections & service

access on left side for

left hand orientation

AIR FLOW

Filter

Coil

Supply Fan

Determine left hand or right hand orientation (connections):

12

Figure 1 - Unit Orientation

Page 13

Model Number Nomenclature

Base Model Number

Individual Module Model Numbers

Identifies the main unit features and options.

Identifies module configurations, features, and options.

MBA-101-0-00-0F0A0-000A0-0-0

FMB-102-0-00-B00C0-00000-0-0

CLA-103-A-00-CNCA0-00000-0-0

M3-0-094-134x119-3-A-A-A-0-A-0

:

BMA-104-A-00-00000-00000-0-0

SFA-105-0-AA-CPTB0-00000-0-0

DPA-106-0-00-D0000-0000C-M-0

Complete Model Number

The complete unit model number consists of

a base model number followed by a series of

individual module numbers. In the

individual module model number, the three

numbers after the three letter Module ID

indicate the position of the module in final

air handling unit assembly, increasing in

value from the return/outside air section to

the discharge air section. In the above

example, the cooling coil module, CLA103-A-00-CNCA0-00000-0-0, would be the

third module in the air handling unit.

13

Page 14

GEN UNIT TYPE UNIT SIZE CROSS

SECTION

VOLTAGE ASSEMBLY WIRING

ACCESSORIES

COROSSION

PROTECTION

BASE RAIL TYPE

M3

- 0 -

060

-

108

x

099

- 3 - B - A - B - C - B -

0

Base Model Feature Description

BASE MODEL

Series and Generation

M3

Type

0 = Indoor Unit

A = Outdoor Unit

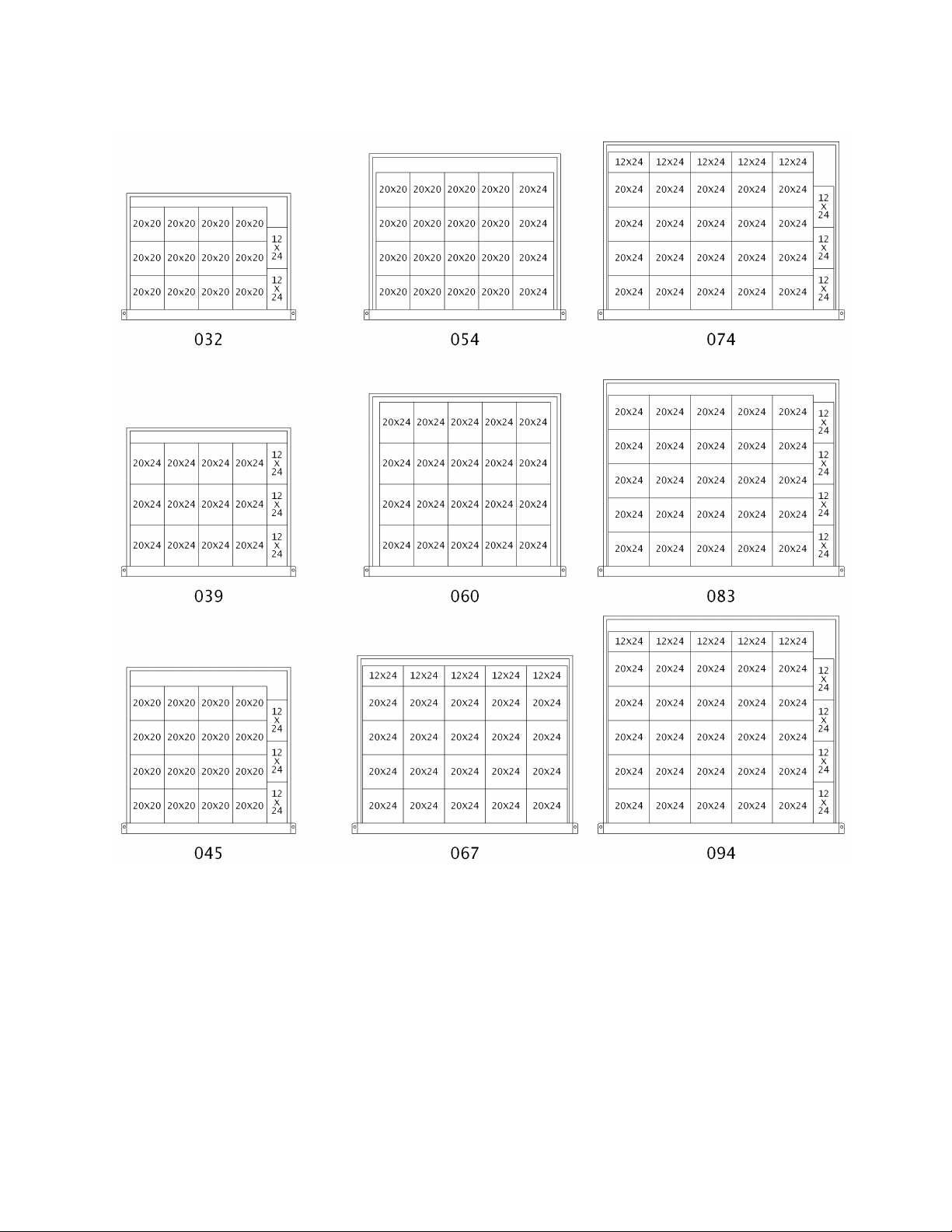

Unit Size

032 = 32 ft2 Coil

039 = 39 ft2 Coil

045 = 45 ft2 Coil

054 = 54 ft2 Coil

060 = 60 ft2 Coil

067 = 67 ft2 Coil

074 = 74 ft2 Coil

083 = 83 ft2 Coil

094 = 94 ft2 Coil

Cross Section

092 x 066 = 92” x 66”

092 x 079 = 92” x 79”

092 x 089 = 92” x 89”

108 x 089 = 108” x 89”

108 x 099 = 108” x 89”

122 x 096 = 122” x 96”

134 x 096 = 134” x 96”

134 x 107 = 134” x 107”

134 x 119 = 134” x 119”

Voltage

2 = 230V/3Φ/60Hz

3 = 460V/3Φ/60Hz

4 = 575V/3Φ/60Hz

6 = 380-415V/3Φ/50Hz

8 = 208V/3Φ/60Hz

M3 Series Base Feature String Nomenclature

Assembly

A = Factory Assembled

B = Shipping Splits

Wiring

0 = No Wiring

A = Wiring, Motor Starters & Branch Fusing

Accessories

0 = None

A = 115V Outlet, Factory Wired (13Amp)

B = 115V Outlet, Field Wired (20 Amp)

Corrosion Protection

0 = No Paint

A = Interior Corrosion Protection

B = Exterior Corrosion Protection

C = Shipping Shrink Wrap

D = Options A + B

E = Options A + C

F = Options B + C

G = Options A + B + C

Base Rail

0 = 6” High

A = 8” High

B = 10” High

Type

0 = None

U= Special Exterior Paint and Special Pricing

Authorization

X = Special Pricing Authorization and Standard Paint

14

Page 15

Supply Fan Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

CTRL TYPE

CTRL MANU

BLWR

QUANTITY

BLWR

TYPE

BLWR HP

BLOWER

BLWR

ISOLATION FILT TYPE

FILT

ACCESSORY

POWER

SWITCH

CTRL

PANEL

MODULE

ACCESSORY

ACCESS TYPE

SFA

-

000

- 0 - 0 0 - C P H

G A - A C B 0 R - B -

0

Supply Fan Module Feature Description

SUPPLY FAN MODULE

Module ID

SFA = Supply Fan

SFB = Supply Fan with Flat Filter Bank

SFC = Supply Fan with External Control Panel

SFD = Supply Fan with Flat Filter Bank and External

Control Panel

Position

### = Level and Position of Module in Air Handling

Unit

Connections

0 = No End Wall

B = Air Leaving Side End Wall

CONTROLS

Type

0 = No Wiring

A = Terminal Strip, Branch Fusing

B = VAV Controller, Motor Starters, Branch Fusing

C = CAV Controller, Motor Starters, Branch Fusing

D = MUA Controller, Motor Starters, Branch Fusing

Manufacturer

0 = No Wiring

A = Terminal Strip

B = WattMaster

D = WattMaster with Specials

BLOWERS AND MOTORS

Quantity

0 = 1 Blower with ODP Motor

A = 2 Blowers with ODP Motors

B = 3 Blowers with ODP Motors

C = 4 Blowers with ODP Motors

D = 1 Blower with TEFC Motor

E = 2 Blowers with TEFC Motors

F = 3 Blowers with TEFC Motors

G = 4 Blowers with TEFC Motors

Blower Type

0 = Standard Efficiency

A = Premium Efficiency

B = Premium Eff with 1 VFD

C = Premium Eff with 1 VFD and Bypass

D = Premium Eff with Field Installed VFD

E = Premium Eff with 1 VFD Shipped Loose

F = Premium Eff with 2 VFDs

G = Premium Eff with 2 VFDs and Bypass

H = Premium Eff with 2 Field Installed VFDs

J = Premium Eff with 2 VFDs Shipped Loose

K = Premium Eff with 3 VFDs

L = Premium Eff with 3 VFDs and Bypass

M = Premium Eff with 3 Field Installed VFDs

N = Premium Eff with 3 VFDs Shipped Loose

P = Premium Eff with 4 VFDs

Q = Premium Eff with 4 VFDs and Bypass

R = Premium Eff with 4 Field Installed VFDs

S = Premium Eff with 4 VFDs Shipped Loose

Blower HP

0 = 1 hp, 1170 rpm

A = 2 hp, 1170 rpm

B = 3 hp, 1170 rpm

C = 5 hp, 1170 rpm

D = 7.5 hp, 1170 rpm

E = 10 hp, 1170 rpm

F = 15 hp, 1170 rpm

G = 20 hp, 1170 rpm

H = 25 hp, 1170 rpm

J = 30 hp, 1170 rpm

K = 40 hp, 1170 rpm

L = 50 hp, 1170 rpm

M = 1 hp, 1760 rpm

N = 2 hp, 1760 rpm

P = 3 hp, 1760 rpm

Q = 5 hp, 1760 rpm

R = 7.5 hp, 1760 rpm

S = 10 hp, 1760 rpm

T = 15 hp, 1760 rpm

U = 20 hp, 1760 rpm

V = 25 hp, 1760 rpm

W= 30 hp, 1760 rpm

Y = 40 hp, 1760 rpm

Z = 50 hp, 1760 rpm

1 = 60 hp, 1760 rpm

15

Page 16

Supply Fan Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

CTRL TYPE

CTRL MANU

BLWR

QUANTITY

BLWR

TYPE

BLWR HP

BLOWER

BLWR

ISOLATION FILT TYPE

FILT

ACCESSORY

POWER

SWITCH

CTRL

PANEL

MODULE

ACCESSORY

ACCESS TYPE

SFA

-

000

- 0 - 0 0 - C P H

G A - A C B 0

R - B - 0

Blower

0 = 24” Diameter

A = 27” Diameter

B = 30” Diameter

C = 33” Diameter

D = 36.5” Diameter

E = 42.5” Diameter

Blower Isolation

0 = Springs (Unhoused 1” Deflection)

A = Springs (Unhoused 2” Deflection)

B = Springs (Seismic 1” Deflection)

C = Springs (Seismic 2” Deflection)

D = Option 0 + Backdraft Dampers

E = Option A + Backdraft Dampers

F = Option B + Backdraft Dampers

G = Option C + Backdraft Dampers

Filter Type

0 = None

A = 2” Pleated, 30% Eff, MERV 8

B = 4” Pleated, 30” Eff, MERV 8

Filter Accessories

0 = None

A = Clogged Filter Switch

B = Magnehelic Gauge

C = Options A + B

D = Air Flow Measurement

E = Options A + D

F = Options B + D

G = Options A + B + D

Power Switch

0 = No Wiring

A = Power Block (No Power Switch)

B = 60 Amp Non-fused Disconnect Switch

C = 100 Amp Non-fused Disconnect Switch

D = 150 Amp Non-fused Disconnect Switch

E = 250 Amp Non-fused Disconnect Switch

F = 400 Amp Non-fused Disconnect Switch

G = 600 Amp Non-fused Disconnect Switch

H = 60 Amp Fused Disconnect Switch

J = 100 Amp Fused Disconnect Switch

K = 150 Amp Fused Disconnect Switch

L = 250 Amp Fused Disconnect Switch

M= 400 Amp Fused Disconnect Switch

N = 600 Amp Fused Disconnect Switch

Control Panel / Opening

0 = None

A = Left Control Panel

B = Right Control Panel

C = Left Discharge Opening

D = Options B + C

E = Right Discharge Opening

F = Options A + E

G = Top Discharge Opening

H = Options A + G

I = Options B + G

16

Page 17

Supply Fan Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

CTRL TYPE

CTRL MANU

BLWR

QUANTITY

BLWR

TYPE

BLWR HP

BLOWER

BLWR

ISOLATION FILT TYPE

FILT

ACCESSORY

POWER

SWITCH

CTRL

PANEL

MODULE

ACCESSORY

ACCESS TYPE

SFA

-

000

- 0 - 0 0 - C P H G A - A C B

0

R - B - 0

Module Accessories

0 = None

A = Treadplate Floor

B = Base Drain

C = Marine Light

D = Door Window

F = Options A + B

G = Options A + C

H = Options A + D

J = Options B + C

K = Options B + D

L = Options C + D

P = Options A + B + C

Q = Options A + B + D

R = Options A + C + D

S = Options B + C + D

U = Options A + B + C + D

Access

0 = Left Door, No Drain

A = Right Door, No Drain

B = Both Doors, No Drain

C = Left Door, Left Drain

D = Left Door, Right Drain

E = Left Door, Both Drains

F = Right Door, Left Drain

G = Right Door, Right Drain

H = Right Door, Both Drains

J = Both Doors, Left Drain

K = Both Doors, Right Drain

L = Both Doors, Both Drains

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

17

Page 18

Cooling/Preheat Coil Module Feature String Nomenclature

MODULE ID POSITION AIRFLOW BLANK

BLANK COOLING

ROWS

FPI

CKTING

COATING

ACCESSORIES

PREHEAT

ROWS

FPI

TYPE

COATING

MODULE

ACCESSORY

ACCESS TYPE

CLD

-

000

- A - 0 0 - A

A

0 0 A - C A C 0 G - B - 0

Cooling/Preheat Module Feature Description

COOLING/PREHEAT MODULE

Module ID

CLA = Chilled Water Coils, External Connection,

Standard Drain Pan (30.5”)

CLC = Chilled Water Coils, Hydronic Preheat,

External Connection, Standard Drain Pan (30.5”)

CLD = DX Coils

CLE = DX Coils, Hot Gas Reheat

CLF = DX Coils, Hydronic Preheat

CLG = DX Coils, Hot Gas Reheat, Hydronic Preheat

CLH = Chilled Water Coils, External Connection,

Short Drain Pan (9”)

CLJ = Chilled Water Coils, Hydronic Preheat,

External Connection, Short Drain Pan (9”)

Position

### = Level and Position of Module in Air Handling

Unit

Compartment Pressurization

0 = Blow-Through, No End Wall

A = Draw-Through, No End Wall

B = Blow-Through, Air Leaving Side End Wall

Blank

00 = Standard

COOLING COIL

Rows

0 = 4 Rows, 1/2” Tubes, 50/50 Split

A = 6 Rows, 1/2” Tubes, 50/50 Split

B = 8 Rows, 1/2” Tubes, 50/50 Split

C = 4 Rows, 5/8” Tubes, 50/50 Split

D = 6 Rows, 5/8” Tubes, 50/50 Split

E = 8 Rows, 5/8” Tubes, 50/50 Split

FPI

0 = 8 FPI, 0.0060” Fin Thick, 0.017” Tube Wall

A = 10 FPI, 0.0060” Fin Thick, 0.017” Tube Wall

B = 12 FPI, 0.0060” Fin Thick, 0.017” Tube Wall

C = 8 FPI, 0.0075” Fin Thick, 0.017” Tube Wall

D = 10 FPI, 0.0075” Fin Thick, 0.017” Tube Wall

E = 12 FPI, 0.0075” Fin Thick, 0.017” Tube Wall

F = 8 FPI, 0.0100” Fin Thick, 0.017” Tube Wall

G = 10 FPI, 0.0100” Fin Thick, 0.017” Tube Wall

H = 12 FPI, 0.0100” Fin Thick, 0.017” Tube Wall

J = 8 FPI, 0.0060” Fin Thick, 0.025” Tube Wall

K = 10 FPI, 0.0060” Fin Thick, 0.025” Tube Wall

L = 12 FPI, 0.0060” Fin Thick, 0.025” Tube Wall

M = 8 FPI, 0.0075” Fin Thick, 0.025” Tube Wall

N = 10 FPI, 0.0075” Fin Thick, 0.025” Tube Wall

P = 12 FPI, 0.0075” Fin Thick, 0.025” Tube Wall

Q = 8 FPI, 0.0100” Fin Thick, 0.025” Tube Wall

R = 10 FPI, 0.0100” Fin Thick, 0.025” Tube Wall

S = 12 FPI, 0.0100” Fin Thick, 0.025” Tube Wall

T = 8 FPI, 0.0060” Fin Thick, 0.035” Tube Wall

U = 10 FPI, 0.0060” Fin Thick, 0.035” Tube Wall

V = 12 FPI, 0.0060” Fin Thick, 0.035” Tube Wall

W = 8 FPI, 0.0075” Fin Thick, 0.035” Tube Wall

Y = 10 FPI, 0.0075” Fin Thick, 0.035” Tube Wall

Z = 12 FPI, 0.0075” Fin Thick, 0.035” Tube Wall

1 = 8 FPI, 0.0100” Fin Thick, 0.035” Tube Wall

2 = 10 FPI, 0.0100” Fin Thick, 0.035” Tube Wall

3 = 12 FPI, 0.0100” Fin Thick, 0.035” Tube Wall

18

Page 19

Cooling/Preheat Coil Module Feature String Nomenclature

MODULE ID POSITION AIRFLOW BLANK

BLANK COOLING

ROWS

FPI

CKTING

COATING

ACCESSORIES

PREHEAT

ROWS

FPI

TYPE

COATING

MODULE

ACCESSORY

ACCESS TYPE

CLD

-

000

- A - 0 0 - A

A

0 0 A - C

A

C 0 G - B - 0

Circuiting

0 = Full Serpentine

A = Half Serpentine

B = 1 1/2 Serpentine

C = Double Serpentine

D = DX Single Systems

E = DX Two Interlaced Systems

Coating

0 = Galvanized Coil Casings

A = Polymer E-Coated Coils

B = Stainless Steel Coil Casings

C = Stainless Steel Coil Casings, Copper Fins

Accessories

0 = None

A = UV Lights

B = 2” Pleated Filters, 30% Eff, MERV 8, Coil Inlet

C = 4” Pleated Filters, 30% Eff, MERV 8, Coil Inlet

D = Options A + B

E = Options A + C

PREHEAT COIL

Rows

0 = No Preheat Coil

A = 1 Rows, 1/2” Tubes

B = 2 Rows, 1/2” Tubes

C = 1 Rows, 5/8” Tubes

D = 2 Rows, 5/8” Tubes

FPI

0 = No Preheat Coil

A = 8 FPI, 0.0060” Fin Thick, 0.017” Tube Wall

B = 10 FPI, 0.0060” Fin Thick, 0.017” Tube Wall

C = 12 FPI, 0.0060” Fin Thick, 0.017” Tube Wall

D = 8 FPI, 0.0075” Fin Thick, 0.017” Tube Wall

E = 10 FPI, 0.0075” Fin Thick, 0.017” Tube Wall

F = 12 FPI, 0.0075” Fin Thick, 0.017” Tube Wall

G = 8 FPI, 0.0100” Fin Thick, 0.017” Tube Wall

H = 10 FPI, 0.0100” Fin Thick, 0.017” Tube Wall

J = 12 FPI, 0.0100” Fin Thick, 0.017” Tube Wall

K = 8 FPI, 0.0060” Fin Thick, 0.025” Tube Wall

L = 10 FPI, 0.0060” Fin Thick, 0.025” Tube Wall

M = 12 FPI, 0.0060” Fin Thick, 0.025” Tube Wall

N = 8 FPI, 0.0075” Fin Thick, 0.025” Tube Wall

P = 10 FPI, 0.0075” Fin Thick, 0.025” Tube Wall

Q = 12 FPI, 0.0075” Fin Thick, 0.025” Tube Wall

R = 8 FPI, 0.0100” Fin Thick, 0.025” Tube Wall

S = 10 FPI, 0.0100” Fin Thick, 0.025” Tube Wall

T = 12 FPI, 0.0100” Fin Thick, 0.025” Tube Wall

U = 8 FPI, 0.0060” Fin Thick, 0.035” Tube Wall

V = 10 FPI, 0.0060” Fin Thick, 0.035” Tube Wall

W = 12 FPI, 0.0060” Fin Thick, 0.035” Tube Wall

Y = 8 FPI, 0.0075” Fin Thick, 0.035” Tube Wall

Z = 10 FPI, 0.0075” Fin Thick, 0.035” Tube Wall

1 = 12 FPI, 0.0075” Fin Thick, 0.035” Tube Wall

2 = 8 FPI, 0.0100” Fin Thick, 0.035” Tube Wall

3 = 10 FPI, 0.0100” Fin Thick, 0.035” Tube Wall

4 = 12 FPI, 0.0100” Fin Thick, 0.035” Tube Wall

19

Page 20

Cooling/Preheat Coil Module Feature String Nomenclature

MODULE ID POSITION AIRFLOW BLANK

BLANK COOLING

ROWS

FPI

CKTING

COATING

ACCESSORIES

PREHEAT

ROWS

FPI

TYPE

COATING

MODULE

ACCESSORY

ACCESS TYPE

CLD

-

000

- A - 0 0 - A A 0 0 A - C

A

C 0 G - B - 0

Preheat Coil Type

0 = No Preheat Coil

A = Hot Water, Full Serpentine (2 Rows Only)

B = Hot Water, Half Serpentine

C = Hot Water, Quarter Serpentine

D = Steam Distributing

Coating

0 = No Preheat Coil

A = Galvanized Coil Casing

B = Polymer E-Coated Coil

C = Stainless Steel Coil Casing

D = Stainless Steel Coil Casing, Copper Fins

Module Accessories

0 = None

A = Marine Light

B = Door Window

C = Options A + B

Access

0 = Left Door, Left Drain, Left Coil Connections

A = Left Door, Left Drain, Right Coil Connections

B = Left Door, Right Drain, Left Coil Connections

C = Left Door, Right Drain, Right Coil Connections

D = Left Door, Both Drains, Left Coil Connections

E = Left Door, Both Drains, Right Coil Connections

F = Right Door, Left Drain, Left Coil Connections

G = Right Door, Left Drain, Right Coil Connections

H = Right Door, Right Drain, Left Coil Connections

J = Right Door, Right Drain, Right Coil Connections

K = Right Door, Both Drains, Left Coil Connections

L = Right Door, Both Drains, Right Coil Connections

M = Both Doors, Left Drain, Left Coil Connections

N = Both Doors, Left Drain, Right Coil Connections

P = Both Doors, Right Drain, Left Coil Connections

Q = Both Doors, Right Drain, Right Coil Connection

R = Both Doors, Both Drains, Left Coil Connections

S = Both Doors, Both Drains, Right Coil Connections

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

20

Page 21

Heating Coil Module Feature String Nomenclature

MODULE ID POSITION AIRFLOW ELEC HEAT

CAPACITY

STAGING

HEAT COIL

SIZE

ROWS

FPI

TYPE

COATING BLANK

BLANK

BLANK

BLANK

MODULE

ACCESSORY

ACCESS TYPE

HCD

-

000

- A - H E - B

B

C A A - 0 0 0 0 0 - B - 0

Heating Coil Module Description

HEATING COIL MODULE

Module ID

HCA = Hot Water Coil, External Connections

HCB = Steam Coil, External Connections

HCC = Electric Heat

HCD = Hot Water Coil with Internal Face and

Bypass Dampers

HCE = Hot Water Coil with External Face and

Bypass Dampers

HCF = Integral Face and Bypass Hot Water Coil

HCG = Steam Coil with Internal Face and Bypass

Dampers

HCH = Steam Coil with External Face and Bypass

Dampers

HCJ = Integral Face and Bypass Steam Coil

Position

### = Level and Position of Module in Air Handling

Unit

Compartment Pressurization

0 = Blow-Through

A = Draw-Through

ELECTRIC HEAT

Capacity

0 = No Electric Heat

A = 40 kW

B = 80 kW

C = 120 kW

D = 160 kW

E = 200 kW

F = 240 kW

G = 280 kW

H = 320 kW

J = 360 kW

K = 400 kW

L = 440 kW

M = 480 kW

Staging

0 = No Electric Heat

A = 2 Stage

B = 3 Stage

C = 4 Stage

D = 6 Stage

E = 8 Stage

F = 12 Stage

G = SCR Controlled - Potentiometer

H = SCR Controlled - 0-10VDC External Control

HEATING COIL

Size

0 = No Heating Coil

A = Size A

B = Size B

C = Size C

D = Size D

Rows

0 = No Heating Coil

A = 1 Row, 1/2” Tubes

B = 2 Rows, 1/2” Tubes

C = 1 Row, 5/8” Tubes

D = 2 Rows, 5/8” Tubes

21

Page 22

Heating Coil Module Feature String Nomenclature

MODULE ID POSITION AIRFLOW ELEC HEAT

CAPACITY

STAGING

HEAT COIL

SIZE

ROWS

FPI

TYPE

COATING BLANK

BLANK

BLANK

BLANK

MODULE

ACCESSORY

ACCESS TYPE

HCD

-

000

- A - H E - B

B

C A A - 0 0 0 0 0 - B - 0

FPI

0 = No Heating Coil

A = 8 FPI, 0.0060” Fin Thick, 0.017” Tube Wall

B = 10 FPI, 0.0060” Fin Thick, 0.017” Tube Wall

C = 12 FPI, 0.0060” Fin Thick, 0.017” Tube Wall

D = 8 FPI, 0.0075” Fin Thick, 0.017” Tube Wall

E = 10 FPI, 0.0075” Fin Thick, 0.017” Tube Wall

F = 12 FPI, 0.0075” Fin Thick, 0.017” Tube Wall

G = 8 FPI, 0.0100” Fin Thick, 0.017” Tube Wall

H = 10 FPI, 0.0100” Fin Thick, 0.017” Tube Wall

J = 12 FPI, 0.0100” Fin Thick, 0.017” Tube Wall

K = 8 FPI, 0.0060” Fin Thick, 0.025” Tube Wall

L = 10 FPI, 0.0060” Fin Thick, 0.025” Tube Wall

M = 12 FPI, 0.0060” Fin Thick, 0.025” Tube Wall

N = 8 FPI, 0.0075” Fin Thick, 0.025” Tube Wall

P = 10 FPI, 0.0075” Fin Thick, 0.025” Tube Wall

Q = 12 FPI, 0.0075” Fin Thick, 0.025” Tube Wall

R = 8 FPI, 0.0100” Fin Thick, 0.025” Tube Wall

S = 10 FPI, 0.0100” Fin Thick, 0.025” Tube Wall

T = 12 FPI, 0.0100” Fin Thick, 0.025” Tube Wall

U = 8 FPI, 0.0060” Fin Thick, 0.035” Tube Wall

V = 10 FPI, 0.0060” Fin Thick, 0.035” Tube Wall

W = 12 FPI, 0.0060” Fin Thick, 0.035” Tube Wall

Y = 8 FPI, 0.0075” Fin Thick, 0.035” Tube Wall

Z = 10 FPI, 0.0075” Fin Thick, 0.035” Tube Wall

1 = 12 FPI, 0.0075” Fin Thick, 0.035” Tube Wall

2 = 8 FPI, 0.0100” Fin Thick, 0.035” Tube Wall

3 = 10 FPI, 0.0100” Fin Thick, 0.035” Tube Wall

4 = 12 FPI, 0.0100” Fin Thick, 0.035” Tube Wall

Type

0 = No Heating Coil

A = Hot Water, Full Serpentine (2 Rows Only)

B = Hot Water, Half Serpentine

C = Hot Water, Quarter Serpentine

D = Steam Distributing

Coating

0 = No Heating Coil

A = Galvanized Coil Casing

B = Polymer E-Coated Coil

C = Stainless Steel Coil Casing

D = Stainless Steel Coil Casing, Copper Fins

Blank

0000 = Standard

Module Accessories

0 = None

A = Heating Coil Drain Pan

Access

0 = No Drain, Left Coil Connections

A = No Drain, Right Coil Connections

B = Left Drain, Left Coil Connections

C = Left Drain, Right Coil Connections

D = Right Drain, Left Coil Connections

E = Right Drain, Right Coil Connections

F = Both Drain, Left Coil Connections

G = Both Drain, Right Coil Connections

H = No Drain, No Coil Connections

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

22

Page 23

Blank Module Feature String Nomenclature

MODULE ID POSITION AIRFLOW BLANK

BLANK DRAIN PAN

BLANK

BLANK

BLANK

BLANK BLANK

BLANK

BLANK

BLANK

MODULE

ACCESSORY

ACCESS TYPE

BMC

-

000

- A - 0 0 - 0 0 0 0 0 - 0 0 0 0 Q - B - 0

Blank Module Feature Description

BLANK MODULE

Module ID

BMA = 2’ Access Section

BMB = 2.5’ Access Section

BMC = 3’ Access Section

BMD = 4’ Access Section

Position

### = Level and Position of Module in Air Handling

Unit

Compartment Pressurization

0 = Blow-Through, No End Wall

A = Draw-Through, No End Wall

B = Blow-Through, Air Leaving Side End Wall

Blank

00 = Standard

Drain Pan

0 = None

A = Stainless Steel Drain Pan

Blank

0 = None

Blank

0 = None

Blank

0 = None

Blank

0 = Standard

Blank

0000 = Standard

Module Accessories

0 = None

A = Treadplate Floor

B = Base Drain

C = Marine Light

D = Door Window

F = Options A + B

G = Options A + C

H = Options A + D

J = Options B + C

K = Options B + D

L = Options C + D

P = Options A + B + C

Q = Options A + B + D

R = Options A + C + D

S = Options B + C + D

U = Options A + B + C + D

Access

0 = Left Door, No Drain

A = Right Door, No Drain

B = Both Doors, No Drain

C = Left Door, Left Drain

D = Left Door, Right Drain

E = Left Door, Both Drains

F = Right Door, Left Drain

G = Right Door, Right Drain

H = Right Door, Both Drains

J = Both Doors, Left Drain

K = Both Doors, Right Drain

L = Both Doors, Both Drains

M = No Door, No Drain

N = No Door, Left Drain

P = No Door, Right Drain

Q = No Door, Both Drains

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

23

Page 24

Filter Module Feature String Nomenclature

MODULE ID POSITION BLANK BLANK

BLANK PREFILTER

FINAL

FILTER

FINAL

FILTER EFF

ACCESSORIES

BLANK BLANK

BLANK

BLANK

BLANK

BLANK BLANK TYPE

FMA

-

000

- 0 - 0 0 - A B C A 0 - 0 0 0 0 0 - 0 - 0

Filter Module Feature Description

FILTER MODULE

Module ID

FMA = Flat Filter Bank

FMB = Angle Filter Bank

FMC = Flat Cartridge Filter Bank

FMD = Staggered Cartridge Filter Bank

FME = Bag Filter Bank

FMF = HEPA Filter Bank

Position

### = Level and Position of Module in Air Handling

Unit

Blank

0 = Standard

Blank

00 = Standard

Pre-filter

0 = None

A = 2” Pleated, 30% Eff, MERV 8

B = 4” Pleated, 30% Eff, MERV 8

Final Filter

0 = None

A = 4” Cartridge Filter

B = 12” Cartridge Filter

C = 30” Bag Filter

Final Filter Efficiency

0 = None

A = MERV 11 (65% Eff)

B = MERV 13 (85% Eff)

C = MERV 14 (95% Eff)

Accessories

0 = None

A = Clogged Filter Switch

B = Magnehelic Gauge

C = Options A + B

Blank

0 = Standard

Blank

00000 = Standard

Blank

0 = Standard

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

24

Page 25

Mixing Box/Economizer Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

BLANK

BLANK OA LOC

RA LOC

EA LOC

ACTUATOR

TYPE

OPENING

ACCESSORY

FILTER

FILT

ACCESSORY

BLANK

BLANK

MODULE

ACCESSORY

ACCESS TYPE

MBA

-

000

- 0 - 0 0 - B B C A 0 - A B 0

0

Q - B - 0

Mixing Box/Economizer Module Feature Description

MIXING BOX/ECONOMIZER

MODULE

Module ID

MBA = Mixing Box (RA & OA Openings)

MBB = Mixing Box, Flat Filter Bank

MBC = Economizer Box (RA, EA, & OA Openings)

MBD = Economizer Box, Flat Filter Bank

Position

### = Level and Position of Module in Air Handling

Unit

Connections

0 = No End Wall

A = Air Entering End Wall

Blank

00 = Standard

Outside Air Location

0 = None

A = End

B = Bottom

C = Left

D = Right

E = Top

F = End, Dampers

G = Bottom, Dampers

H = Left, Dampers

J = Right, Dampers

K = Top, Dampers

Return Air Location

0 = None

A = End

B = Bottom

C = Left

D = Right

E = Top

F = End, Dampers

G = Bottom, Dampers

H = Left, Dampers

J = Right, Dampers

K = Top, Dampers

Exhaust Air Location

0 = None

A = End

B = Bottom

C = Left

D = Right

E = Top

F = End, Dampers

G = Bottom, Dampers

H = Left, Dampers

J = Right, Dampers

K = Top, Dampers

L = End, Barometric Relief Damper

M = Left, Barometric Relief Damper

N = Right, Barometric Relief Damper

0 = None

A = Standard Damper, No Actuator

B = Standard Damper, On/Off Actuator

C = Standard Damper, 0-10 VDC Actuator

Opening Accessories

0 = None

A = Burglar Bars

B = Outdoor Air Hood

C = Outdoor Air Louvers

D = Options A + B

D = Options A + C

Filter

0 = None

A = 2” Pleated, 30% Eff, MERV 8

B = 4” Pleated, 30% Eff, MERV 8

Filter Accessories

0 = None

A = Clogged Filter Switch

B = Magnehelic Gauge

C = Options A + B

Blank

00 = Standard

25

Page 26

Mixing Box/Economizer Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

BLANK

BLANK OA LOC

RA LOC

EA LOC

ACTUATOR

TYPE

OPENING

ACCESSORY

FILTER

FILT

ACCESSORY

BLANK

BLANK

MODULE

ACCESSORY

ACCESS TYPE

MBA

-

000

- 0 - 0 0 - B B C A 0 - A B 0

0

Q - B - 0

Module Accessories

0 = None

A = Treadplate Floor

B = Base Drain

C = Marine Light

D = Door Window

F = Options A + B

G = Options A + C

H = Options A + D

J = Options B + C

K = Options B + D

L = Options C + D

P = Options A + B + C

Q = Options A + B + D

R = Options A + C + D

S = Options B + C + D

U = Options A + B + C + D

Access

0 = Left Door, No Drain

A = Right Door, No Drain

B = Left and Right Doors, No Drain

C = Left Door, Left Drain

D = Left Door, Right Drain

E = Left Door, Both Drains

F = Right Door, Left Drain

G = Right Door, Right Drain

H = Right Door, Both Drains

J = Left and Right Doors, Left Drain

K = Left and Right Doors, Right Drain

L = Left and Right Doors, Both Drains

M = Left and End Doors, No Drain

N = Left and End Doors, Left Drain

P = Left and End Doors, Right Drain

Q = Left and End Doors, Both Drains

R = Right and End Doors, No Drain

S = Right and End Doors, Left Drain

T = Right and End Doors, Right Drain

U = Right and End Doors, Both Drains

V = End Door, No Drain

W = End Door, Left Drain

Y = End Door, Right Drain

Z = End Door Both Drains

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

26

Page 27

Discharge Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

CTRL TYPE

CTRL MANU

DISCH

OPEN LOC

ACTUATOR

TYPE

OPENING

ACCESSORIES

BLANK

PWR SWITCH

BLANK

BLANK

BLANK

CTRL PANEL

MODULE

ACCESSORY

ACCESS TYPE

DPA

-

000

- 0 - A A - B A 0 0 B - 0 0 0 0 Q

- B -

0

Discharge Module Feature Description

DISCHARGE MODULE

Module ID

DPA = Discharge Plenum

DPB = Discharge Plenum with Control Panel

Position

### = Level and Position of Module in Air Handling

Unit

Connections

0 = No End Wall

A = Air Leaving Side End Wall

CONTROLS

Controls Type

0 = No Wiring

A = Terminal Strip, Branch Fusing

B = VAV Controller, Motor Starters, Branch Fusing

C = CAV Controller, Motor Starters, Branch Fusing

D = MUA Controller, Motor Starters, Branch Fusing

Controls Manufacturer

0 = No Wiring

A = Terminal Strip

B = WattMaster

D = WattMaster with Specials

Discharge Opening Location

0 = End

A = Bottom

B = Left

C = Right

D = Top

E = End, Dampers

F = Bottom, Dampers

G = Left, Dampers

H = Right, Dampers

J = Top, Dampers

Damper Actuator Type

0 = None

A = Standard Damper

B = Standard Damper, On/Off Actuator

C = Standard Damper, 0-10 VDC Actuator

Opening Aceessories

0 = None

A = Burglar Bars

Blank

0 = Standard

Power Switch

0 = No Wiring

A = Power Block (No Power Switch)

B = 60 Amp Non-fused Disconnect Switch

C = 100 Amp Non-fused Disconnect Switch

D = 150 Amp Non-fused Disconnect Switch

E = 250 Amp Non-fused Disconnect Switch

F = 400 Amp Non-fused Disconnect Switch

G = 600 Amp Non-fused Disconnect Switch

H = 60 Amp Fused Disconnect Switch

J = 100 Amp Fused Disconnect Switch

K = 150 Amp Fused Disconnect Switch

L = 250 Amp Fused Disconnect Switch

M= 400 Amp Fused Disconnect Switch

N = 600 Amp Fused Disconnect Switch

Blank

000 = Standard

Control Panel

0 = No Control Panel

A = Left Control Panel

B = Right Control Panel

C = Center Control Panel

Module Accessories

0 = None

A = Treadplate Floor

B = Base Drain

C = Marine Light

D = Door Window

F = Options A + B

G = Options A + C

H = Options A + D

J = Options B + C

K = Options B + D

L = Options C + D

P = Options A + B + C

Q = Options A + B + D

R = Options A + C + D

S = Options B + C + D

U = Options A + B + C + D

27

Page 28

Discharge Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

CTRL TYPE

CTRL MANU

DISCH

OPEN LOC

ACTUATOR

TYPE

OPENING

ACCESSORIES

BLANK

PWR SWITCH

BLANK

BLANK

BLANK

CTRL PANEL

MODULE

ACCESSORY

ACCESS TYPE

DPA

-

000

- 0 - A A - B A 0 0 B - 0 0 0 0 Q

- B -

0

Access

0 = Left Door, No Drain

A = Right Door, No Drain

B = Both Doors, No Drain

C = Left Door, Left Drain

D = Left Door, Right Drain

E = Left Door, Both Drains

F = Right Door, Left Drain

G = Right Door, Right Drain

H = Right Door, Both Drains

J = Both Doors, Left Drain

K = Both Doors, Right Drain

L = Both Doors, Both Drains

M = No Door, No Drain

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

28

Page 29

Control Panel Module Feature String Nomenclature

MODULE ID POSITION AIRFLOW CTRL TYPE

CTRL MANU

BLANK

BLANK

BLANK

BLANK

PWR SWITCH

BLANK

BLANK

BLANK

CTRL PANEL

MODULE

ACCESSORY

ACCESS TYPE

CMB

-

000

- 0 - A A - 0 0 0 0 A - 0 0 0 0 Q - B - 0

Control Panel Module Feature Description

CONTROL PANEL MODULE

Module ID

CMA = 36” Access Selection

CMB = 48” Access Selection

CMC = 60” Access Selection

Position

### = Level and Position of Module in Air Handling

Unit

Compartment Pressurization

0 = Blow-Through

A = Draw-Through

CONTROLS

Controls Type

0 = No Wiring

A = Terminal Strip, Branch Fusing

B = VAV Controller, Motor Starters, Branch Fusing

C = CAV Controller, Motor Starters, Branch Fusing

D = MUA Controller, Motor Starters, Branch Fusing

Controls Manufacturer

0 = No Wiring

A = Terminal Strip

B = WattMaster

D = WattMaster with Specials

Blank

0000 = Standard

Power Switch

0 = No Wiring

A = Power Block (No Power Switch)

B = 60 Amp Non-fused Disconnect Switch

C = 100 Amp Non-fused Disconnect Switch

D = 150 Amp Non-fused Disconnect Switch

E = 250 Amp Non-fused Disconnect Switch

F = 400 Amp Non-fused Disconnect Switch

G = 600 Amp Non-fused Disconnect Switch

H = 60 Amp Fused Disconnect Switch

J = 100 Amp Fused Disconnect Switch

K = 150 Amp Fused Disconnect Switch

L = 250 Amp Fused Disconnect Switch

M= 400 Amp Fused Disconnect Switch

N = 600 Amp Fused Disconnect Switch

Blank

000 = Standard

Control Panel Location

0 = No Control Panel

A = Left Control Panel

B = Right Control Panel

Module Accessories

0 = None

A = Treadplate Floor

B = Base Drain

C = Marine Light

D = Door Window

F = Options A + B

G = Options A + C

H = Options A + D

J = Options B + C

K = Options B + D

L = Options C + D

P = Options A + B + C

Q = Options A + B + D

R = Options A + C + D

S = Options B + C + D

U = Options A + B + C + D

Access

0 = No Door, No Drain

C = Left Door, No Drain

D = Right Door, No Drain

E = Left Door, Left Drain

F = Right Door, Left Drain

G = Left Door, Right Drain

H = Right Door, Right Drain

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

29

Page 30

Exhaust Fan Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

PREHEAT

TYPE

PREHEAT

SIZE BLWR

QUANTITY

BLWR

TYPE

BLWR HP

BLOWER

BLWR

ISOLATION OA FILTER

OA LOC

EA LOC

ACTUATOR

TYPE

MODULE

ACCESSORY

ACCESS TYPE

EFA

-

000

- A - A B - A B B

A A - B B E C R - 0 -

0

Exhaust Fan Module Feature Description

EXHAUST FAN MODULE

Module ID

EFA = Exhaust Fan

EFB = Exhaust Fan for Energy Recovery Wheel

Position

### = Level and Position of Module in Air Handling

Unit

Connections

0 = No Air Entering End Wall

A = Air Entering Side End Wall

PREHEAT COIL

Type

0 = No Preheat

A = Hot Water Preheat

B = Steam Preheat

Size

0 = None

A = Preheat Size A

B = Preheat Size B

C = Preheat Size C

D = Preheat Size D

BLOWERS AND MOTORS

Quantity

0 = 1 Blower with ODP Motor

A = 2 Blowers with ODP Motors

B = 3 Blowers with ODP Motors

C = 4 Blowers with ODP Motors

D = 1 Blower with TEFC Motor

E = 2 Blowers with TEFC Motors

F = 3 Blowers with TEFC Motors

G = 4 Blowers with TEFC Motors

Blower Type

0 = Standard Efficiency

A = Premium Efficiency

B = Premium Eff with 1 VFD

C = Premium Eff with 1 VFD and Bypass

D = Premium Eff with Field Installed VFD

E = Premium Eff with 1 VFD Shipped Loose

F = Premium Eff with 2 VFDs

G = Premium Eff with 2 VFDs and Bypass

H = Premium Eff with 2 Field Installed VFDs

J = Premium Eff with 2 VFDs Shipped Loose

K = Premium Eff with 3 VFDs

L = Premium Eff with 3 VFDs and Bypass

M = Premium Eff with 3 Field Installed VFDs

N = Premium Eff with 3 VFDs Shipped Loose

P = Premium Eff with 4 VFDs

Q = Premium Eff with 4 VFDs and Bypass

R = Premium Eff with 4 Field Installed VFDs

S = Premium Eff with 4 VFDs Shipped Loose

Blower HP

0 = 1 hp, 1170 rpm

A = 2 hp, 1170 rpm

B = 3 hp, 1170 rpm

C = 5 hp, 1170 rpm

D = 7.5 hp, 1170 rpm

E = 10 hp, 1170 rpm

F = 15 hp, 1170 rpm

G = 20 hp, 1170 rpm

H = 25 hp, 1170 rpm

J = 30 hp, 1170 rpm

K = 40 hp, 1170 rpm

L = 50 hp, 1170 rpm

M = 1 hp, 1760 rpm

N = 2 hp, 1760 rpm

P = 3 hp, 1760 rpm

Q = 5 hp, 1760 rpm

R = 7.5 hp, 1760 rpm

S = 10 hp, 1760 rpm

T = 15 hp, 1760 rpm

U = 20 hp, 1760 rpm

V = 25 hp, 1760 rpm

W= 30 hp, 1760 rpm

Y = 40 hp, 1760 rpm

Z = 50 hp, 1760 rpm

1 = 60 hp, 1760 rpm

30

Page 31

Exhaust Fan Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

PREHEAT

TYPE

PREHEAT

SIZE BLWR

QUANTITY

BLWR

TYPE

BLWR HP

BLOWER

BLWR

ISOLATION OA FILTER

OA LOC

EA LOC

ACTUATOR

TYPE

MODULE

ACCESSORY

ACCESS TYPE

EFA

-

000

- A - A B - A B B

A A - B B

E

C R - 0 -

0

Blower

0 = 24” Diameter

A = 27” Diameter

B = 30” Diameter

C = 33” Diameter

D = 36.5” Diameter

E = 42.5” Diameter

F = 36” Diameter, 3 Blade, 6W Prop

G = 42” Diameter, 4 Blade, 6W Prop

H = 42” Diameter, 6 Blade, 6W Prop

I = 48” Diameter, 6 Blade, 6W Prop

Blower Isolation

0 = None

A = Springs (Unhoused 1” Deflection)

B = Springs (Unhoused 2” Deflection)

C = Springs (Seismic 1” Deflection)

D = Springs (Seismic 2” Deflection)

E = Option 0 + Backdraft Dampers

F = Option A + Backdraft Dampers

G = Option B + Backdraft Dampers

H = Option C + Backdraft Dampers

Outside Air Filters

0 = None

A = 2” Pleated, 30% Eff, MERV 8

B = 4” Pleated, 30” Eff, MERV 8

C = Option A + Clogged Filter Switch

D = Option B + Clogged Filter Switch

E = Option A + Magnehelic Gauge

F = Option B + Magnehelic Gauge

G = Option A + Clogged Filter Switch + Magnehelic

Gauge

H = Option B + Clogged Filter Switch + Magnehelic

Gauge

Outside Air Location

0 = None

A = End

B = Left

C = Right

D = Left and Right

E = Top

F = End, Dampers

G = Left, Dampers

H = Right, Dampers

J = Left and Right, Dampers

K = Top, Dampers

L = End, Hood

M = Left, Hood

N = Right, Hood

P = Left and Right, Hood

Q = End, Dampers, Hood

R = Left, Dampers, Hood

S = Right, Dampers, Hood

T = Left and Right, Dampers, Hood

U = End, Louvers

V = Left, Louvers

W = Right, Louvers

Y = Left and Right, Louvers

Z = End, Dampers, Louvers

1 = Left, Dampers, Louvers

2 = Right, Dampers, Louvers

3 = Left and Right, Dampers, Louvers

Exhaust Air Location

A = End

B = Left

C = Right

D = Left and Right

E = End, Dampers

F = Left, Dampers

G = Right, Dampers

H = Left and Right, Dampers

J = End, Barometric Relief Damper

K = Left, Barometric Relief Damper

L = Right, Barometric Relief Damper

M = Left and Right, Barometric Relief Damper

31

Page 32

Energy Recovery Module Feature String Nomenclature

MODULE ID POSITION BLANK ERW TYPE

& QTY

ERW SIZE BLANK

BLANK

BLANK

BLANK

BLANK RA FILT

RA LOC

ERW

ACCESSORY

ACTUATOR

TYPE

MODULE

ACCESSORY

ACCESS TYPE

HRA

-

000

- 0 - A C - 0 0 0 0 0 - G A A A C

- D -

0

Damper Actuator Type

0 = None

A = Standard Damper

B = Standard Damper, On/Off Actuator

C = Standard Damper, 0-10 VDC Actuator

Module Accessories

0 = None

A = Treadplate Floor

B = Base Drain

C = Marine Light

D = Door Window

F = Options A + B

G = Options A + C

H = Options A + D

J = Options B + C

K = Options B + D

L = Options C + D

P = Options A + B + C

Q = Options A + B + D

R = Options A + C + D

S = Options B + C + D

U = Options A + B + C + D

Access

0 = Left Door, No Drain

A = Right Door, No Drain

B = Both Doors, No Drain

C = Left Door, Left Drain

D = Left Door, Right Drain

E = Left Door, Both Drains

F = Right Door, Left Drain

G = Right Door, Right Drain

H = Right Door, Both Drains

J = Both Doors, Left Drain

K = Both Doors, Right Drain

L = Both Doors, Both Drains

M = No Doors, No Drain

N = No Doors, Left Drain

P = No Doors, Right Drain

Q = No Doors, Both Drain

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

32

Page 33

Energy Recovery Module Feature String Nomenclature

MODULE ID POSITION BLANK ERW TYPE

& QTY

ERW SIZE BLANK

BLANK

BLANK

BLANK

BLANK RA FILT

RA LOC

ERW

ACCESSORY

ACTUATOR

TYPE

MODULE

ACCESSORY

ACCESS TYPE

HRA

-

000

- 0 - A C - 0 0 0 0 0 - G A A A C

- D -

0

Energy Recovery Module Feature Description

ENERGY RECOVERY MODULE

Module ID

HRA = AAONAIRE Energy Recovery Wheel

Position

### = Level and Position of Module in Air Handling

Unit

Blank

0 = Standard

Energy Recovery Wheel Type and Quantity

0 = 1 Total Energy Recovery Wheel

A = 2 Total Energy Recovery Wheels

B = 1 Sensible Energy Recovery Wheel

C = 2 Sensible Energy Recovery Wheels

Energy Recovery Wheel Size

0 = 25” Wheel

A = 36” Wheel

B = 52” Wheel

C = 64” Wheel

D = 74” Wheel

E = 81” Wheel

F = 86” Wheel

G = 92” Wheel

H = 99” Wheel

J = 104” Wheel

K = 110” Wheel

Blank

00000 = Standard

Return Air Filters

0 = None

A = 2” Pleated, 30% Eff, MERV 8

B = 4” Pleated, 30” Eff, MERV 8

C = Option A + Clogged Filter Switch

D = Option B + Clogged Filter Switch

E = Option A + Magnehelic Gauge

F = Option B + Magnehelic Gauge

G = Option A + Clogged Filter Switch + Magnehelic

Gauge

H = Option B + Clogged Filter Switch + Magnehelic

Gauge

Return Air Opening Location

0 = None

A = Bottom

B = Left

C = Right

D = Bottom, Dampers

E = Left, Dampers

F = Right, Dampers

G = Bottom, Burglar Bars

H = Left, Burglar Bars

J = Bottom, Dampers

K = Bottom, Dampers, Burglar Bars

L = Left, Dampers, Burglar Bars

M = Right, Dampers, Burglar Bars

Energy Recovery Wheel Accessoris

0 = None

A = Energy Recovery Wheel Purge

C = Defrost Timer

D = Rotation Detector

G = Options A + C

H = Options A + D

N = Options C + D

U = Options A + C + D

Damper Actuator Type

0 = None

A = Standard Damper

B = Standard Damper, On/Off Actuator

C = Standard Damper, 0-10 VDC Actuator

Module Accessories

0 = None

A = Treadplate Floor

B = Base Drain

C = Marine Light

D = Door Window

F = Options A + B

G = Options A + C

H = Options A + D

J = Options B + C

K = Options B + D

L = Options C + D

P = Options A + B + C

Q = Options A + B + D

R = Options A + C + D

S = Options B + C + D

U = Options A + B + C + D

33

Page 34

Energy Recovery Module Feature String Nomenclature

MODULE ID POSITION BLANK ERW TYPE

& QTY

ERW SIZE BLANK

BLANK

BLANK

BLANK

BLANK RA FILT

RA LOC

ERW

ACCESSORY

ACTUATOR

TYPE

MODULE

ACCESSORY

ACCESS TYPE

HRA

-

000

- 0 - A C - 0 0 0 0 0 - G A A A C

- D -

0

Access

0 = Left Door, Left Drain

1 = Left Door, No Drain

2 = Right Door, No Drain

3 = Both Doors, No Drain

B = Left Door, Right Drain

D = Left Door, Both Drains

F = Right Door, Left Drain

H = Right Door, Right Drain

K = Right Door, Both Drain

M = Both Doors, Left Drain

P = Both Doors, Right Drain

R = Both Doors, Both Drains

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

34

Page 35

Return Fan Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

BLANK

BLANK BLWR

QUANTITY

BLWR

TYPE

BLWR HP

BLOWER

BLWR

ISOLATION BLANK

BLANK

BLANK

CONNECTION

MODULE

ACCESSORY

ACCESS TYPE

RFA

-

000

- 0 - 0 0 - C P H D A

- 0 0 0 A R - B -

0

Return Fan Module Feature Description

RETURN FAN MODULE

Module ID

RFA = Return Fan Module

Position

### = Level and Position of Module in Air Handling

Unit

Connections

0 = No End Wall

A = Air Entering End Wall

Blank

0 = Standard

Blank

0 = Standard

BLOWERS AND MOTORS

Quantity

0 = 1 Blower with ODP Motor

A = 2 Blowers with ODP Motors

B = 3 Blowers with ODP Motors

C = 4 Blowers with ODP Motors

D = 1 Blower with TEFC Motor

E = 2 Blowers with TEFC Motors

F = 3 Blowers with TEFC Motors

G = 4 Blowers with TEFC Motors

Blower Type

0 = Standard Efficiency

A = Premium Efficiency

B = Premium Eff with 1 VFD

C = Premium Eff with 1 VFD and Bypass

D = Premium Eff with Field Installed VFD

E = Premium Eff with 1 VFD Shipped Loose

F = Premium Eff with 2 VFDs

G = Premium Eff with 2 VFDs and Bypass

H = Premium Eff with 2 Field Installed VFDs

J = Premium Eff with 2 VFDs Shipped Loose

K = Premium Eff with 3 VFDs

L = Premium Eff with 3 VFDs and Bypass

M = Premium Eff with 3 Field Installed VFDs

N = Premium Eff with 3 VFDs Shipped Loose

P = Premium Eff with 4 VFDs

Q = Premium Eff with 4 VFDs and Bypass

R = Premium Eff with 4 Field Installed VFDs

S = Premium Eff with 4 VFDs Shipped Loose

Blower HP

0 = 1 hp, 1170 rpm

A = 2 hp, 1170 rpm

B = 3 hp, 1170 rpm

C = 5 hp, 1170 rpm

D = 7.5 hp, 1170 rpm

E = 10 hp, 1170 rpm

F = 15 hp, 1170 rpm

G = 20 hp, 1170 rpm

H = 25 hp, 1170 rpm

J = 30 hp, 1170 rpm

K = 40 hp, 1170 rpm

L = 50 hp, 1170 rpm

M = 1 hp, 1760 rpm

N = 2 hp, 1760 rpm

P = 3 hp, 1760 rpm

Q = 5 hp, 1760 rpm

R = 7.5 hp, 1760 rpm

S = 10 hp, 1760 rpm

T = 15 hp, 1760 rpm

U = 20 hp, 1760 rpm

V = 25 hp, 1760 rpm

W= 30 hp, 1760 rpm

Y = 40 hp, 1760 rpm

Z = 50 hp, 1760 rpm

1 = 60 hp, 1760 rpm

Blower

0 = 24” Diameter

A = 27” Diameter

B = 30” Diameter

C = 33” Diameter

D = 36.5” Diameter

E = 42.5” Diameter

F = 36” Diameter, 3 Blade, 6W Prop

G = 42” Diameter, 4 Blade, 6W Prop

H = 42” Diameter, 6 Blade, 6W Prop

I = 48” Diameter, 6 Blade, 6W Prop

Blower Isolation

A = Springs (Unhoused 1” Deflection)

B = Springs (Unhoused 2” Deflection)

C = Springs (Seismic 1” Deflection)

D = Springs (Seismic 2” Deflection)

E = Option 0 + Backdraft Dampers

F = Option A + Backdraft Dampers

G = Option B + Backdraft Dampers

H = Option C + Backdraft Dampers

35

Page 36

Return Fan Module Feature String Nomenclature

MODULE ID POSITION

CONNECTION

BLANK

BLANK BLWR

QUANTITY

BLWR

TYPE

BLWR HP

BLOWER

BLWR

ISOLATION BLANK

BLANK

BLANK

CONNECTION

MODULE

ACCESSORY

ACCESS TYPE

RFA

-

000

- 0 - 0 0 - C P H D A

- 0 0 0 A R - B -

0

Blank

000 = Standard

Connection

0 = No End Wall

A = Air Entering End Wall

Module Accessories

0 = None

A = Treadplate Floor

B = Base Drain

C = Marine Light

D = Door Window

F = Options A + B

G = Options A + C

H = Options A + D

J = Options B + C

K = Options B + D

L = Options C + D

P = Options A + B + C

Q = Options A + B + D

R = Options A + C + D

S = Options B + C + D

U = Options A + B + C + D

Access

M = No Door, No Drain

N = No Door, Left Drain

P = No Door, Right Drain

Q = No Door, Both Drains

Type

0 = Standard

A = Stainless Steel Interior

B = Stainless Steel Exterior

C = Options A + B

X = Special Pricing Authorization

Y = Options A + X

Z = Options B + X

1 = Options A + B + X

36

Page 37

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

personal injury or loss of life.

Installation and service must be

performed by a trained, qualified

installer. A copy of this IOM should

be kept with the unit.

These units must not be used as a

“construction heater” at anytime

during any phase of construction.

Very low return air temperatures,

harmful vapors, and misplacement of

the filters will damage the unit and its

efficiency.

This equipment is protected by a