Page 1

A

Modular Air Handlers

Celebrity1

TM

Installation and

Operation Manual

October 2004

AON

®

Think Ahead.

Page 2

Since the inception of AAON® in 1988, we have maintained our commitment to design, develop,

manufacture, and deliver heating and cooling products to perform beyond all expectations and to

demonstrate their daily value to our customers.

AAON utilizes extensive product knowledge and state of the art manufacturing to continuously

provide practical HVAC products to the dynamic marketplace.

Our objective remains the same:

Meet the customer specific requirement

at a reasonable first cost.

AAON’s Celebrity1TM Modular Air Handler gives you near limitless capability for conquering

complex projects. Its superior modular design can be as flexible as your application is

demanding. Units can be ordered completely factory wired and assembled, ready for placement

and start-up, or as separate modules, to be manipulated and connected on site. With multiple

factory-installed conservation, air, and control options to choose from, AAON’s modular systems

fit jobs that would normally require a custom system design with intensive post-installation work.

That makes the Celebrity1TM very cost-effective, while creating happier customers for you.

Construction Process Based Design

− Double Wall Insulated Module

− G90 Galvanized Steel

− Maximum Access Doors/Panels

− Stainless Steel Hinges

− Cast Door Handles

− Double Sloped Drain Pan

− Field Ready Duct Flanges

Standard Features

− Multiple Coil Configurations

− External Coil Connection Stubs

− Lift-off Hinged Doors

− Factory Installed TXV on All DX Coils

Other Factory Installed Options

− Hot Gas Reheat

− Hot Gas Bypass

− Face and Bypass Applications

− AAONAIRE

− Left or Right Hand Connections

− Numerous Humidity Control Solutions

− Stainless Steel Drain Pan

®

Heat Wheel

− Horizontal – Vertical Applications

− Panels/Doors Interchangeable

− All Sections Full Perimeter Gasket Sealed

− Multiple Wiring Combinations

− Single or Dual Path Configurable

− Multiple Energy Recovery

Arrangements

− Control Circuit Transformer

− Fan Contactors

− Left or Right Side Access

− Adjustable Belt Drive and Motor Mount

− Oversized and High Efficiency Motors

− Custom Coil Designs

− Factory or Customer Supplied Controls

− Customizable “Blank” Modules

− Power Exhaust Selections

− Multiple Filtration Choices

− Various Safety Devices

2

Page 3

Owner should pay particular attention to the

p

words: NOTE, CAUTION, and WARNING.

Celebrity1 Modular Air Handler

Installation and Operation Manual

October 2004

NOTES are intended to clarify or make the

installation easier. CAUTIONS are given to

prevent equipment damage. WARNINGS are

given to alert owner that personal injury and/or

equipment damage may result if installation

rocedure is not handled properly.

1. Description ……………………….. 4

Important Safety Information

Unit Data

Unit Orientation

2. Model Number Nomenclature .… 6

Number Structure

Base Model Number

Individual Module Numbers

3. Delivery ……………………………. 13

Receipt & Inspection

Storage

4. Installation ………………………… 14

General

Certification

Codes & Ordinances

Handling

Service & Installation Clearance

Mounting & Suspension

Field Assembly

Sealing

Cooling Equipment

Heating Equipment

Condensate Piping

Electrical

Thermostat

Filters

5. Refrigerant Piping &

Line Sizing Information ….……... 20

General

Liquid Line Piping

Suction Line Piping

Other Piping

6. Start-Up ……………………… 24

General

Procedures

Air Balancing

Water Balancing

Controls

7. Operation & Maintenance … 26

General

Maintenance Schedule

Blower Assembly

Coils

Refrigeration Cycle

Charging

Heating

Cleaning

Chilled Water

Lubrication

Service

Filters

8. Hot Gas Bypass (HGBP) ….. 31

9. Hot Gas Reheat (HGRH) ….. 32

10. HGBP & HGRH Together 33

11.

AAONAIRE® Heat Wheel …..

Cleaning

12. Troubleshooting …………… 36

Common Problems

Compressor Check-Out

13. Factory Start-Up Form ……. 39

WARNING WARNING

The information in this manual should be followed

exactly to prevent property damage or personal

injury.

Installation and service must be performed by a

qualified installer or service agency.

34

3

Page 4

r

–

y

f

r

f

r

t

–

r

t

r

r

1. Description

Important Safety Information

ONLY QUALIFIED PERSONNEL SHOULD

PERFORM INSTALLATION, OPERATION, AND

MAINTENANCE OF EQUIPMENT DESCRIBED IN

THIS MANUAL.

Celebrity1

operation when installed, operated, and maintained

within design specifications, and the instructions

set forth in this manual. It is necessary to follow

these instructions to avoid personal injury o

damage to equipment or property during equipmen

installation, operation, and maintenance.

This equipment is protected by a standard limited

warranty under the condition that initial installation,

service, and maintenance is performed according

to the instructions set forth in this manual. This

manual should be read in its entirety prior to

installation, and before performing any service o

maintenance work.

Equipment described in this manual is available

with many optional accessories. If you have

questions after reading this manual in its entirety,

consult other factory documentation, or contac

your Sales Representative to obtain furthe

information before manipulating this equipment, o

its optional accessories.

RISK OF DAMAGE, INJURY, AND LOSS OF

LIFE - Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, personal injury, or loss o

life. A qualified installer or service agency

must perform installation and service.

TM

air handlers are designed for safe

NOTE

IMPORTANT!

WARNING

WARNING

RISK OF ELECTRICAL SHOCK -

Before attempting to perform any service o

maintenance, turn the electrical power to the

unit OFF at disconnect switch(es). Unit may

have multiple power supplies.

WARNING

RISK OF INJURY FROM HOT PARTS

Disconnect all power before servicing electric

resistance heating elements to prevent serious

injury resulting from automatic starts. Unit ma

have multiple power supplies.

WARNING

RISK OF INJURY FROM HOT PARTS

Disconnect all power, close all isolation valves,

and allow equipment to cool before servicing

equipment with hot water and steam heating coils.

Hot water will circulate even after power is off.

Equipment may have multiple power supplies.

WARNING

RISK OF INJURY FROM MOVING PARTS Disconnect all power before servicing motor o

blower to prevent serious injury resulting from

automatic starts. Motor and blower may have

multiple power supplies.

WARNING

NOTE

These units must not be used as a “construction

heater” at any time during any phase o

construction. Very low return air temperatures,

harmful vapors, and misplacement of the filters will

damage the unit and its efficiency.

4

Page 5

Unit Data

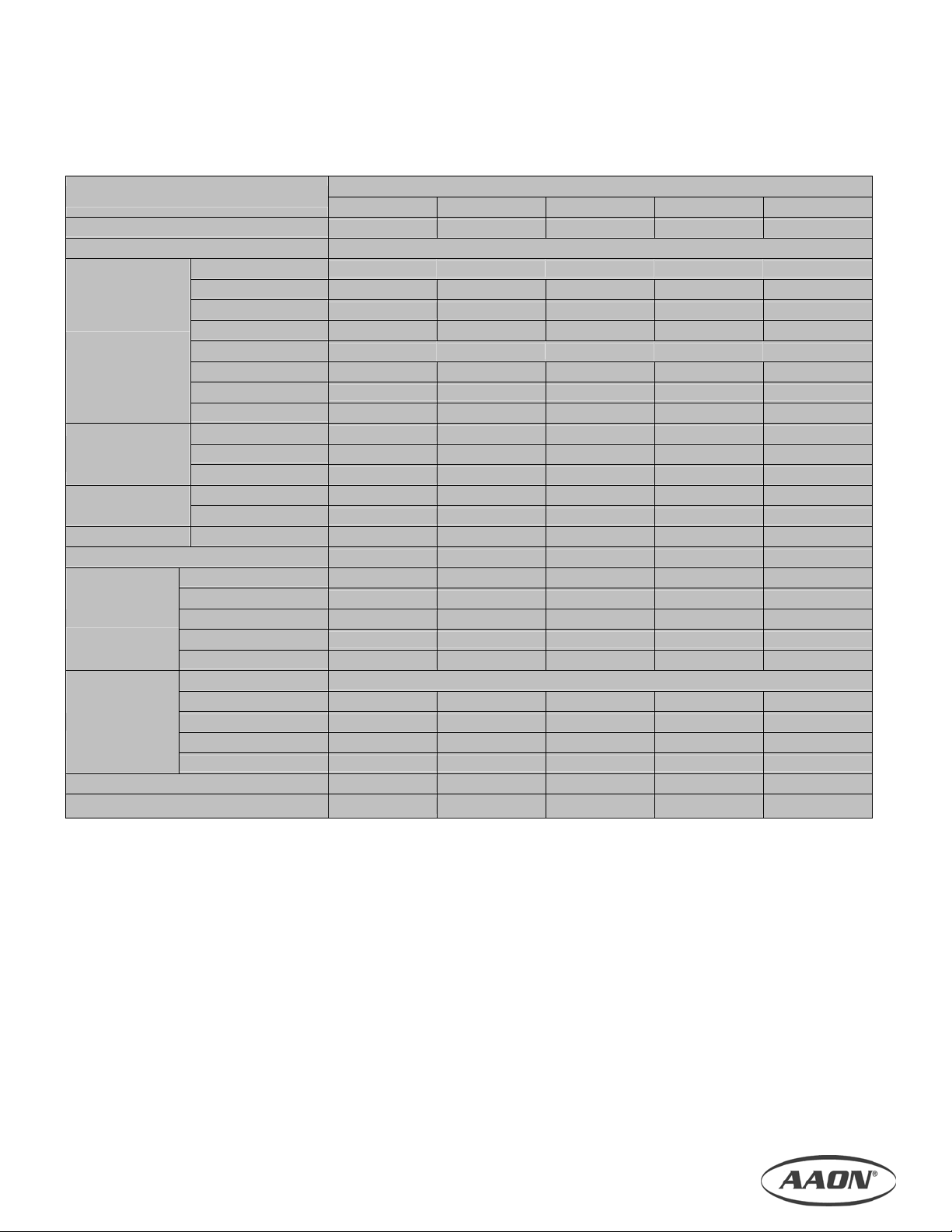

Table 1.1, Unit Data

Features

CFM RANGE

05 08 11 14 18

1,000 to 2,700 2,000 to 4,400 3,100 to 6,000 5,000 to 7,700 6,000 to 10,300

Model Cabinet Size

COOLING COIL SELECTION Face Area Sq. Ft.

DX Single Circuit

4 Row

6 Row

DX Cooling

Chilled Water

Cooling

*Hot Water

Heating

Hot Gas Reheat

8 Row

DX Double Circuit

4 Row

6 Row

8 Row

4 Row

6 Row

8 Row

1 Row

2 Row

2 Row

Min. / Max. Electric Heating kW

Quantity

Type

Fan

Filters

Wheel O.D. (In.)

Max. RPM

Motor HP

Type

Pleated 2" Flat

Pleated 4" Flat

12" Cartridge

12" Bag

Max. Total Static Pressure (In. w.g.)

AAONAIRE Heat Wheel O.D.

4.7 7.7 10.5 13.5 18.0

4.7 7.7 10.5 13.5 18.0

4.7 7.7 10.5 13.5 18.0

4.7 7.7 10.5 13.5 18.0

4.7 7.7 10.5 13.5 18.0

4.7 7.7 10.5 13.5 18.0

4.7 8.0 10.2 13.6 18.1

4.7 8.0 10.2 13.6 18.1

4.7 8.0 10.2 13.6 18.1

4.7 8.0 10.2 13.6 18.1

4.7 8.0 10.2 13.6 18.1

4.7 7.7 10.5 13.5 18.0

5.3 / 21.0 10.5 / 42.0 10.5 / 42.0 10.5 / 42.0 10.5 / 70.0

1 1 1 1 1

Back Incline Back Incline Back Incline Back Incline Back Incline

15 15 / 18.5 18.5 / 22.5 18.5 / 22.5 22.5 / 27

2200 2200 / 2200 2200 / 2200 2200 / 2200 2200 / 1800

1, 2, 3 1, 2, 3, 5, 7.5 3, 5, 7.5, 10 3, 5, 7.5, 10 3, 5, 7.5, 10

Size In. (Qty.)

16 x 20 (2) 16 x 20 (4) 16 x 20 (6) 20 x 20 (6) 25 x 20 (6)

16 x 20 (2) 16 x 20 (4) 16 x 20 (6) 20 x 20 (6) 25 x 20 (6)

16 x 20 (2) 16 x 20 (4) 16 x 20 (6) 20 x 20 (6) 18 x 24 (6)

16 x 20 (2) 16 x 20 (4) 16 x 20 (6) 20 x 20 (6) 20 x 24 (6)

3.2 4.5 4.5 4.0 3.5

29" 44" 56" 56" 68"

*Includes Hot Water Preheat & Reheat

5

Page 6

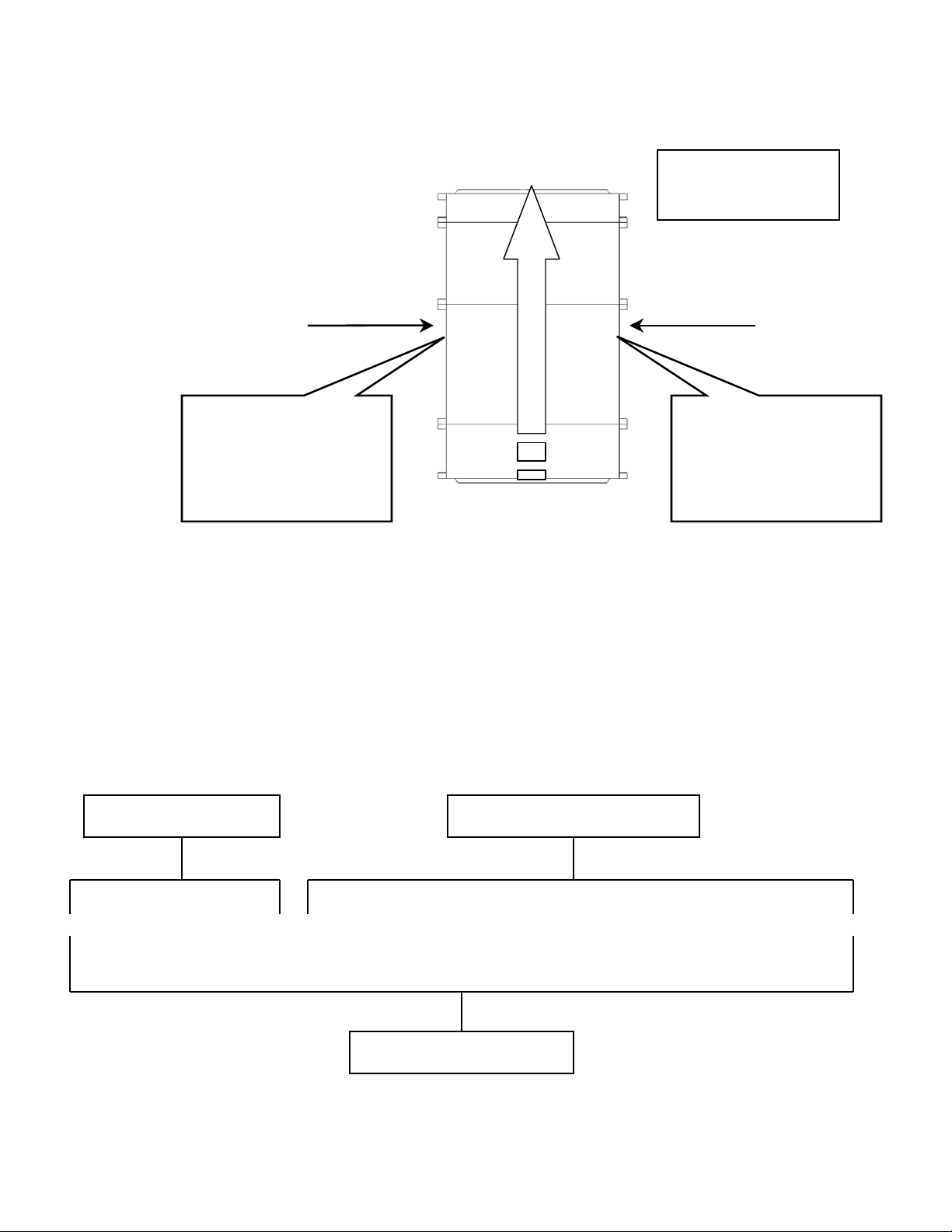

Unit Orientation

A

When determining unit orientation

(or Supply Air Flow as it is

identified in the base model

number below), consider the air to

be “hitting you in the back of the

head” when you are facing the

return air end of the unit.

Figure 1.1, Unit Orientation

Left Hand Side

Supply Air

Top View

Assembled Modular

Air Handler

Right Hand Side

If you have a “Left Hand”

unit, then all connections

will be on the left hand

side of the unit. Air will

flow from right to left as

you look at the left side.

Return Air

If you have a “Right Hand”

unit, then all connections

will be on the right hand

side of the unit. Air will

flow from left to right as

you look at the right side.

2. Model Number Nomenclature

Number Structure

The total unit model number consists of a base model number followed by individual model numbers. The base

model number identifies main unit features. Individual module numbers identify module configurations and optional

features.

Figure 2.1, Model Number Structure

Base Model Number

Individual Module Numbers

M1-H-018-R-2-B-A-0-A-0

:

MBH-101-A-00-00000-00000-0-0 ~ FTB-102-P-A0-00000-00000-0-0 ~

CLC-103-E-00-00000-610I0-S-X ~ CLA-104-0-00-110H0-00000-0-0 ~

SFC-105-K-D0-

008D-00000-0-X

Total Unit Model Number

6

Page 7

Base Model Number

M1

TYPE

- - - - - - - -

H =

V =

Horizontal

Vertical

SIZE

005 =

008 =

011 =

014 =

018 =

5

8

11

14

18

VOLTAGE

1 =

230V/1Ø/60HZ

2 =

230V/3Ø/60HZ

3 =

460V/3Ø/60HZ

4 =

575V/3Ø/60HZ

8 =

208V/3Ø/60HZ

9 =

208V/1Ø/60HZ

WIRING

No Factory Wiring

0 =

Control Panel in Fan Box

A =

Control Panel in Control Box

B =

Loose Control Panel

C =

Control Panel in Standard NEMA Box

D =

Control Panel in Large NEMA Box

E =

BASE RAIL

4” High

A =

8” High

B =

6” High

C =

MAIN FEATURES

SUPPLY AIR FLOW ASSEMBLY WIRING PAINT BASE RAIL SPECIAL

SUPPLY AIR FLOW

L =

Left Hand

R =

Right Hand

ASSEMBLY

Factory Assembled

A =

Loose Boxes

B =

SPECIAL

None

0 =

=

SPA Req’d.

VOLTAGESIZE TYPE

0 =

A =

B =

C =

PAINT

No Paint

Standard White Exterior

Special Color Exterior

Anti-Corrosion Paint

7

Page 8

Individual Module Numbers

-

-

MODULE ID

PHA =

PHB =

RHC =

PHC =

PHD =

E-Heat

Heat

HGRH

Heat / Filter

E-Heat / Filter

FUNCTION

H =

Heating

D =

Dehumidification

B =

Heating & Dehum.

HEATING COIL

COATING

0 =

Standard

P =

Phenolic Coating

S =

Stainless Steel Casing

H =

Stainless Steel Casing

& Copper Fin

CIRCUITING

Single Serpentine

F =

Half Serpentine

H =

FPI

08 =

10 =

12 =

ROWS

1 =

2 =

8 Fins Per Inch

10 Fins Per Inch

12 Fins Per Inch

1 Row

2 Rows

HEAT MODULE

FUNCTION HEATING COIL TYPE

FILTERSPOSITION MODULE ID ELECTRIC HEAT

-

C0 =

D0 =

E0 =

-

FILTERS

00 =

None

A0 =

2” 30% Std.

B0 =

4” 30% Std.

4” 65% Std.

4” 85% Std.

4” 95% Std.

ELECTRIC HEAT

- -

FILTER OPTIONS

0 =

A =

B =

C =

0 =

X =

FILTER

OPTIONS

0 0

None

Magnehelic Gauge

Clogged Filter Switch

Magnehelic Gauge &

Clogged Filter Switch

TYPE

None

Special (SPA Req’d.)

-

00

STAGES

01 =

1 Stage

02 =

03 =

04 =

A =

B =

C =

D =

H =

E =

F =

G =

2 Stage

3 Stage

4 Stage

KW

7 (5.3)

14 (10.5)

21 (15.8)

28 (21.0)

35 (26.3)

42 (35.0)

56 (42.0)

70 (52.5)

8

Page 9

yp

MODULE ID

CLB =

CLC =

CLD =

CLE =

CLF =

CLG =

CLH =

CLI =

CLJ =

CLK =

CLL =

CW / DX

Cool / HGRH

E-Heat / Heat

E-Heat

Heat & Cool

E-Heat / Cool

E-Heat / Cool / HGRH

Cool or Heat w/Face Bypass

HW / DX / HGRH

Vertical CW or DX

Cool and Heat w/ Face Bypass

ELECTRIC HEAT

STAGES

01 =

02 =

03 =

04 =

A =

B =

C =

D =

H =

E =

F =

G =

POSITION MODULE ID ELECTRIC HEAT

COOLING

-

COOLING TYPE

0 =

No Cooling

C =

CW

D =

DX

E =

DX & Hot Gas

ass

B

0 0

1 Stage

2 Stage

3 Stage

4 Stage

KW

7 (5.3)

14 (10.5)

21 (15.8)

28 (21.0)

35 (26.3)

42 (35.0)

56 (42.0)

70 (52.5)

HEATING COIL

COATING

0 =

P =

S =

H =

CIRCUITING

F =

H =

08 =

10 =

12 =

1 =

2 =

COIL MODULE

Standard

Phenolic Coating

Stainless Steel Casing

Stainless Steel Casing

& Copper Fin

Single Serpentine

Half Serpentine

FPI

8 Fins Per Inch

10 Fins Per Inch

12 Fins Per Inch

ROWS

1 Row

2 Rows

HEATING COIL

- - - -

COOLING COIL

DRAIN PAN

0 =

None

S =

Stainless Steel Pan

G =

Galvanized Pan

U =

Stainless Steel Pan

& UV Light

TYPE

0 =

None

Special (SPA Req’d.)

X =

00

COATING

0 =

P =

S =

H =

CIRCUITING

F =

H =

S =

I =

08 =

10 =

12 =

ROWS

4 =

6 =

8 =

COOLING COIL

Standard

Phenolic Coating

Stainless Steel Casing

Stainless Steel Casing

& Copper Fin

Single Serpentine

Half Serpentine

DX Single Circuit

DX Interlaced (Dual)

FPI

8 Fins Per Inch

10 Fins Per Inch

12 Fins Per Inch

4 Row

6 Row

8 Row

DRAIN

TYPE

PAN

--

9

Page 10

r

r

r

r

- -

FILTER TYPE SAFETY CONTROL TYPE

FILTERSPOSITION MODULE ID

-

MODULE ID

FTA =

FTF =

FTC =

FTD =

Flat Filter, Small

Flat Filter, Large

Cartridge Filter

Bag Filte

FILTER TYPE

P =

C =

B =

Pleated

Cartridge

Bag

PLEATED

A0 =

B0 =

C0 =

D0 =

E0 =

2” 30% Eff. Std.

4” 30% Eff. Std.

4” 65% Eff. Std.

4” 85% Eff. Std.

4” 95% Eff. Std.

CARTRIDGE

C0 =

D0 =

E0 =

- -

ACTUATOR SAFETY CONTROL TYPE

FILTERSPOSITION MODULE ID

-

MODULE ID

MBA =

MBB =

MBC =

MBF =

MBH =

MBD =

MBE =

MBI =

MBJ =

Vertical Damper

Horizontal (Top) Damper

Vertical / Horizontal (Bottom) Damper

Horizontal (Bottom) Damper

Vertical / Horizontal (Top) Dampe

Vertical Damper / Filte

Horizontal (Top) Damper / Filter

Horizontal (Bottom) Damper / Filter

Vertical / Horizontal (Top) Damper / Filte

ACTUATOR

0 =

None

A =

Two Position

=

DDC

*Filters compatible with modules MBD, MBE, MBI, & MBJ only.

FILTER MODULE

- - - -

FILTERS

65% Eff.

85% Eff.

95% Eff.

MIXING MODULE

-

FILTERS*

00 =

None

A0 =

2” 30% Std.

B0 =

4” 30% Std.

C0 =

4” 65% Std.

D0 =

4” 85% Std.

E0 =

4” 95% Std.

SAFETY CONTROL

None

0 =

Smoke Detector

1 =

Firestat

2 =

Smoke Detector

3 =

& Firestat

0000 0 0 0 00

SAFETY CONTROL

None

0 =

Smoke Detector

1 =

Firestat

2 =

Smoke Detector

3 =

& Firestat

BAG

B0 =

45% Eff.

C0 =

65% Eff.

D0 =

85% Eff.

E0 =

95% Eff.

0000 0 0 0 0

BYPASS OPEN

0 =

None

A =

Top Open

B =

Bottom Open

BYPASS OPEN

-

BLANK

FILTER OPTIONS

0 =

A =

B =

C =

0 =

X =

FILTER OPTIONS

0 =

A =

B =

C =

0 =

X =

FILTER

OPTIONS

None

Magnehelic Gauge

Clogged Filter Switch

Magnehelic Gauge &

Clogged Filter Switch

TYPE

None

Special (SPA Req’d.)

FILTER

OPTIONS

- -

None

Magnehelic Gauge

Clogged Filter Switch

Magnehelic Gauge &

Clogged Filter Switch

TYPE

None

Special (SPA Req’d.)

10

Page 11

X

X

X

X

MODULE ID

PEA =

RFA =

SFA =

SFB =

SFC =

PEC =

MOTOR SIZE

0 =

E =

F =

G =

H =

J =

K =

MODULE ID

BBA =

BBB =

BBC =

BBD =

POSITION MODULE ID

Power Exhaust

Return Fan

Supply Fan

Supply Fan, Vertical

Supply Fan, Top Discharge

Exhaust Fan, Top Discharge

None

1 HP

2 HP

3 HP

5 HP

7.5 HP

10 HP

-

Small Blank

Large Blank

Small Blank, Top Discharge

Large Blank, Top Discharge

FAN MODULE

MOTOR

SIZE

BLOWER

-

BLOWER

0 =

None

A =

15”

B =

18.5”

C =

22.5”

D =

27”

MOTOR TYPE

0

- - -

MOTOR TYPE

00

-

SAFETY CONTROL

0 =

A =

SPECIAL CONTROL

0 =

A =

B =

00

TYPE

A =

B =

C =

D =

Standard

Premium

Premium w/ VFD

Premium w/ VFD

& Bypass

PULLEYS

Pulley

Combinations

Assigned At

Factory Acc.

To Order

Requirements

0 =

X =

BLANK MODULE

BLANK SAFETY CONTROL

- -

0

BLANK POSITION MODULE ID BYPASS OPEN

0

SAFETY CONTROL

0 =

1 =

2 =

3 =

- -

0

None

Smoke Detector

Firestat

Smoke Detector

& Firestat

0000 0 0 0 0

BYPASS OPEN

0 =

None

A =

Top Open

B =

Bottom Open

SAFETY

CONTROL

0 0 0 0

None

Phase & Brownout

Protection

None

DDC Control & Terminal

DDC Control

TYPE

None

Special (SPA Req’d.)

DRAIN PAN

0 =

S =

G =

U =

0 =

X =

SPECIAL

CONTROL

--

-

None

Stainless Steel Pan

Galvanized Pan

Stainless Steel Pan

& UV Light

TYPE

None

Special (SPA Req’d.)

DRAIN

PAN

TYPE

TYPE

-

11

Page 12

A

-

AAONAIRE HEAT RECOVERY WHEEL MODULE

WHEEL SIZE BLANK

- -

BLANK POSITION MODULE ID BLANK

- - - -

0

0

MODULE ID

HRA =

AONAIRE Heat Wheel

WHEEL SIZE*

Standard

A =

Optional

B =

*Optional wheel size (selection ‘B’) available only in size 5, 8, and 11 units.

-

BLANK SAFETY OPTIONS

- - - - - -

CONTROL PANEL MODULE

BLANK POSITION MODULE ID BLANK

0

MODULE ID

TRA =

Control Panel

SAFETY CONTROL

0 =

1 =

2 =

3 =

None

Smoke Detector

Firestat

Smoke Detector

& Firestat

BLANK

0000 0 0 0 00

0000 0 0 0 00

00

TYPE

0 =

None

Special (SPA Req’d.)

X =

BLANK

000

TYPE

0 =

None

Special (SPA Req’d.)

X =

TYPE

TYPE

12

Page 13

3. Delivery

t

r

ALL SHIPMENTS ARE F.O.B. THE FACTORY. IT IS

THE RESPONSIBILITY OF THE RECEIVING PARTY

TO INSPECT THE EQUIPMENT UPON ARRIVAL.

Receipt & Inspection

The air handler should be inspected for damage that

may have occurred in transit. Do the following upon

receipt:

1. Inspect all items for internal, external, and

concealed damage before accepting

2. Assure carrier is in compliance with Bill of

If damage is found:

If repairs must be made to damaged goods, the factory

must be notified before any repair action is taken.

Equipment alteration, repair, or unauthorized

manipulation of damaged equipment without the

manufacturer’s consent will void all product warranties.

Contact the ACP Warranty Department for assistance

with handling damaged goods, repairs, and freight

claims.

Verify the equipment against the order documents

upon delivery. If what you received does not match

your order exactly, then your sales representative

must be notified at once.

Lading instructions

1. Note all damage on Bill of Lading immediately

− Photograph damage if possible

− Do not move or discard damaged

packaging materials

2. Call carrier immediately to file a freight claim,

and to schedule a freight inspection

3. When damage is repairable, call ACP’s

Customer Care Hotline for parts: 1-903-2479242

4. With permission of carrier, make the repairs

5. Stay in contact with carrier to ensure payment

of your claim

NOTE

LOOSE SHIPMENT ITEMS – Upon receipt, check

shipment for items that ship loose such as

thermostats, and other controls. Consult order and

shipment documentation to identify potential looseshipped items.

NOTICE OF PILFERING – Check packing lis

against delivered goods. Ensure that equipment,

and loose-shipped items have not been stolen, o

misplaced during staging or transit. The factory is

not responsible for missing items after

NOTE

shipment.

Storage

This equipment is not suitable for outdoor use, or

storage. Never place this equipment where it may be

subjected to outdoor conditions such as rain, snow,

humidity, extreme temperatures, or corrosive

chemicals.

If installation will not occur immediately following

delivery, then store equipment in a dry, protected area,

and in the proper orientation as marked on the

packaging with all internal packaging in place. Secure

all loose-shipped items.

Page 14

4. Installation

t

t

A

General

Celebrity1TM modular air handling units are designed

as heating, cooling, or combination units for indoor

installation only. The use of refrigerant, chilled water,

electric resistance, steam, or hot water as operating

mediums will be dictated by design of the heating and

cooling coils installed in the unit. Flexible connectors

are required on all duct connections and installed to

minimize air leaks.

Certification

Cooling Models

a) Certified for use with a commercial

condensing or chilled water remote unit (with

or without compressor(s))

b) Certified for indoor installation only.

Steam or Hot Water Heat Models

a) Certified for indoor installation only.

Electric Heat Models

a) Certified as an electric warm air furnace with

or without cooling coil.

b) Certified for indoor installation only.

Codes & Ordinances

System should be sized in accordance with National

Warm Air Heating and Air Conditioning Association

Literature, or the Guide of American Society of

Heating, Refrigeration and Air Conditioning Engineers.

The installation must conform with local building

codes, or in the absence of local codes, with (United

States) “ANSI / UL 1995”, (Canada) current, C.S.A.

Standard C22.2, No. 236, Canadian Electrical Code

Part 1, and C.S.A. Standard B52 Mechanical

Refrigeration Code, and Local Plumbing or Waste

Water Codes.

It is the responsibility of the installing contractor to

comply with codes, ordinances, local and

municipal building laws, and manufacturer’s

instructions. Personal injury and/or equipmen

damage may result if proper procedures are no

followed.

WARNING

Handling

Be aware of what is contained in the equipment!

Dependent upon the optional accessories that were

ordered, this equipment may contain fragile

components and delicate electronics. Although the

unit is constructed of sturdy materials, avoid impacts

and handling methods that may damage internal

apparatus and structure, or the exterior surfaces of the

unit. Take care not to apply destructive force to coils,

coil and drain stub-outs, or other parts protruding

beyond the extents of the unit casing. Always handle

the unit by its exterior casing, and never by any of the

protruding parts.

Keep equipment free from debris and construction

waste during installation. Foreign materials may

adversely affect unit operation resulting in premature

failures that will not be covered by the manufacturer’s

warranty. Attach all service panels, and cover all

exposed equipment when work is not being performed.

Leave unit protected from other construction activity

until start-up is to occur.

WARNING

lways wear hand and eye protection when

handling, installing, servicing, or maintaining

equipment. Sharp or pointed edges, moving parts,

and flying debris may cause personal injury.

Service & Installation Clearance

Before setting the air handler into place, caution must

be taken to provide clearance for unit panels/doors

that must be accessible for periodic service. These

areas contain the controls, safety devices, refrigerant

or water piping, shut-off valves and filter access.

Celebrity1

from both sides of the unit. Service clearance equal to

the width of the unit is recommended. That is, if the

unit is 4 feet wide, then 4 feet of clearance is

suggested on both sides.

TM

air handler modules may be accessible

Blower Module

The blower module needs to be accessible with

enough clearance to remove the motor or the plenum

fan.

14

Page 15

Coil & AAONAIRE Heat Wheel Modules

r

l

Coils and heat wheels slide out for easier servicing.

There should be enough clearance left on one side of

the unit (usually the piping connection side) to

completely remove the coils and heat wheel for

maintenance or replacement.

Figure 4.1, Service Clearance for Heat Wheel and Coils

AAONAIRE

Heat Wheel

Module

Coil Module

Coil

X

‘X’ is the minimum

required service

clearance for heat whee

and coil modules

Module

Size

5 48 inches

8 64 inches

11 68 inches

14 68 inches

18 89 inches

X =

Mounting & Suspension

CelebrityTM air handlers can be designed for horizontal

or vertical airflow applications, and can be floor

mounted or suspended. Units may be delivered in

separate module components, or completely factory

assembled with all modules connected. In the latter

case, if the unit was received fully assembled on a

skid, then the equipment should be lifted into place

using the shipping skid to prevent damage to the

modules.

An auxiliary (emergency) drain pan is

recommended for all applications where there is a

risk of water damage to surrounding structure o

furnishings. Refer to local codes.

Floor Mounted

NOTE

Make sure the unit is level, and installed with a

minimum height of 6” to allow for proper drainage of

the condensate line. Other installation provisions may

be necessary according to job specifications.

Suspended

Modular air handlers are equipped for suspended

installations. All modules must be connected and the

unit must be completely assembled before the unit is

lifted into position. The base of the unit must be

supported before hoisting. Do not lift the unit by any

part other than the unit base.

Unit base rails are manufactured with suspension rod

holes. To suspend an assembled unit, insert support

rods through the aligned base rail holes on both sides

of the unit. Secure suspension lines to the rods and to

an overhead support structure. The air handler must

be installed level as the internal drain pan is

manufactured with a slope toward the drain. Be sure

not to obstruct service access doors with the

positioning of the suspension lines. Other installation

provisions may be necessary according to job

specifications and requirements.

15

Page 16

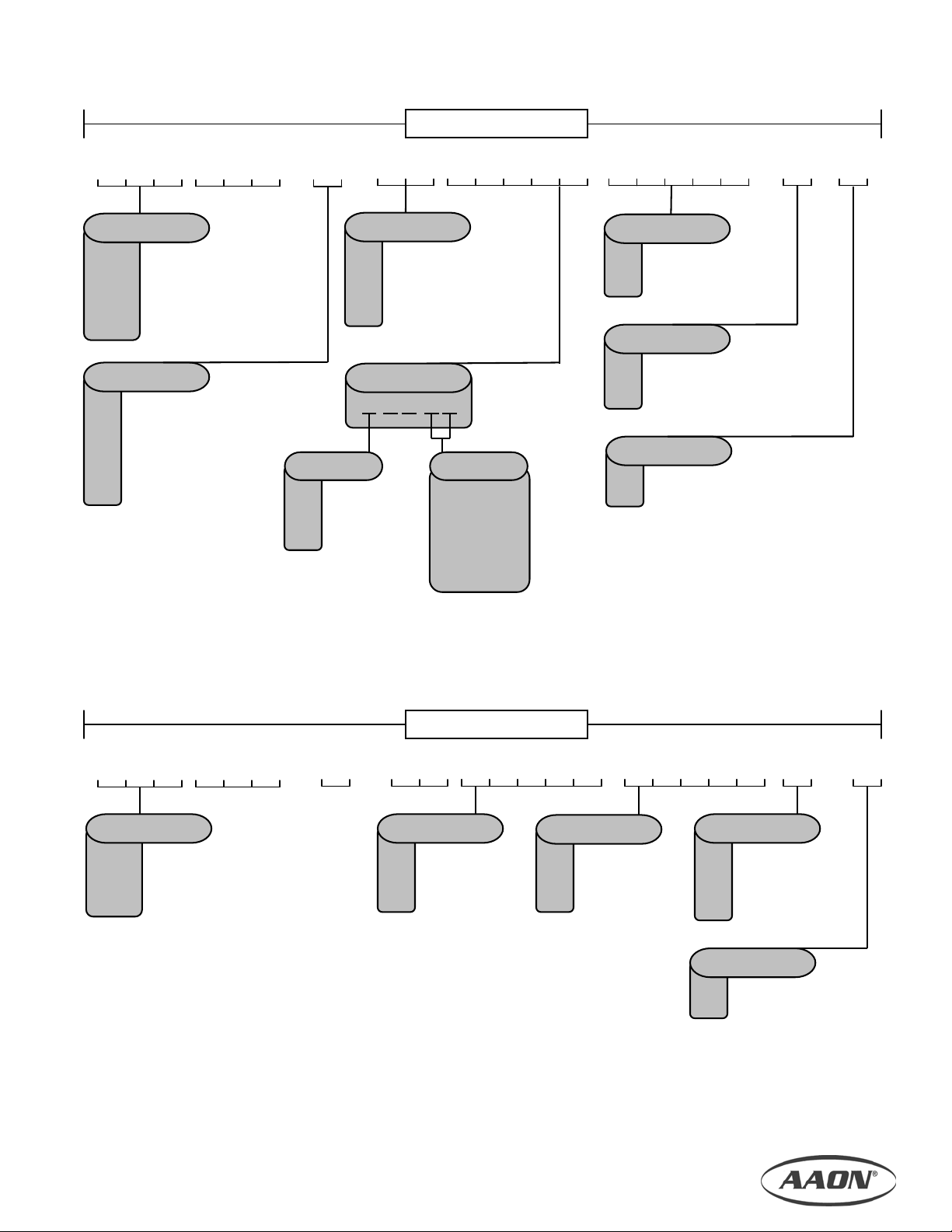

Figure 4.2, Suspended Modular Air Handler

Suspension

lines

Overhead

Support

Base rail

Secure

suspension lines

Insert rods

through aligned

Field Assembly

Although Celebrity1TM air handlers are shipped factory

assembled as a standard, they may be ordered

unassembled for certain applications such as for

assembly in existing structures where modules must

be manipulated separately. If the unit was ordered

unassembled, then you will need to connect the

modules in the field.

Modules present may include any or all of the following

depending on the equipment ordered and the

application:

− Fan Module

– includes the plenum fan and blower

motor

− Coil Module

and/or re-heat coils. May contain electric heat.

− AAONAIRE

– contains heating and/or cooling

Heat Wheel Module – module has

heat wheel installed.

− Air Mixing Module

– module where outside air

combines with return air.

− Filter Module

– contains slide out filter racks and

filters. May also contain special bag, or cartridge

filters.

− Damper Module

– contains motor actuated

horizontal and/or vertical air dampers.

− Power Exhaust Module

– includes power exhaust

fan and motor.

− Blank Module

– an empty module to be used for

additional controls, parts, or can be used as a

plenum.

− Control Panel Module

– an additional module that

contains a control panel when the panel is not

ordered loose, or as part of the fan module.

Locate the configuration schematic in the equipment’s

literature packet. The schematic will have

‘CONFIGURATION’ written in the top left hand corner

followed by the unit model number, and then each

module’s configuration number listed in order.

It is advisable to situate all required modules in the

installation location, and preferably as near as possible

to the order in which they will be connected. Identify

each module by the configuration number on its label.

For example, if a module has a configuration number

of FTF-101-P-A0-00000-00000-0-0, then it is a large

flat filter module (FTF), and should be placed in the

first position (101) of the lower tier i.e. the bottom left.

Although you should have a schematic available, the

configuration numbers have been devised to inform

you of the module assembly without the need for a

schematic. Modules are arranged in order, left to right

with 100 series modules on the first tier, and 200

series modules on the second tier. Module 101 will

always be located on the left end of the bottom tier, or

the bottom left of a right hand assembly, and module

201 will always be located on the left end of the top

tier, or the top left of a right hand assembly. So, it is

possible to identify the exact module arrangement

even without knowing the module type, or having a

configuration schematic.

16

Page 17

p

3

4

2103

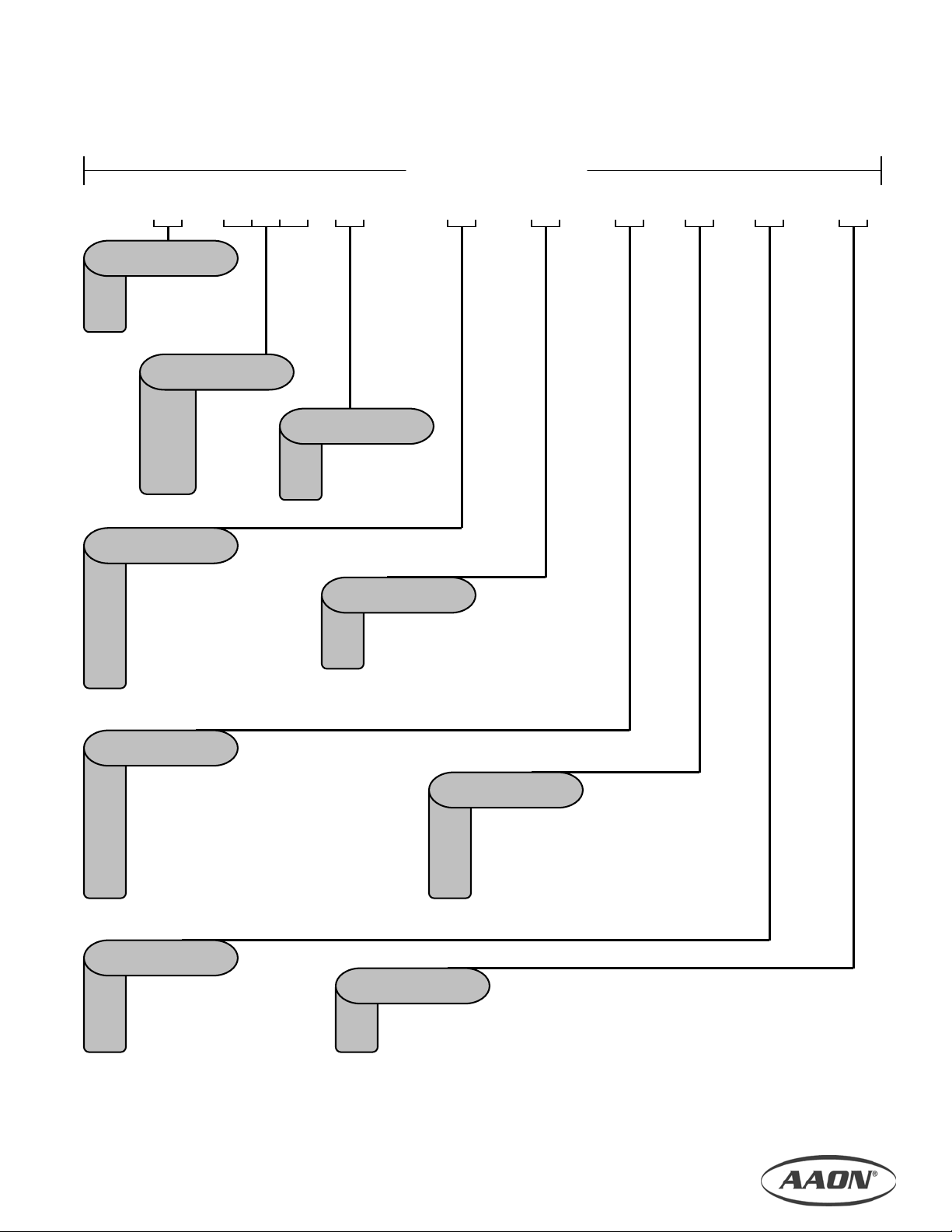

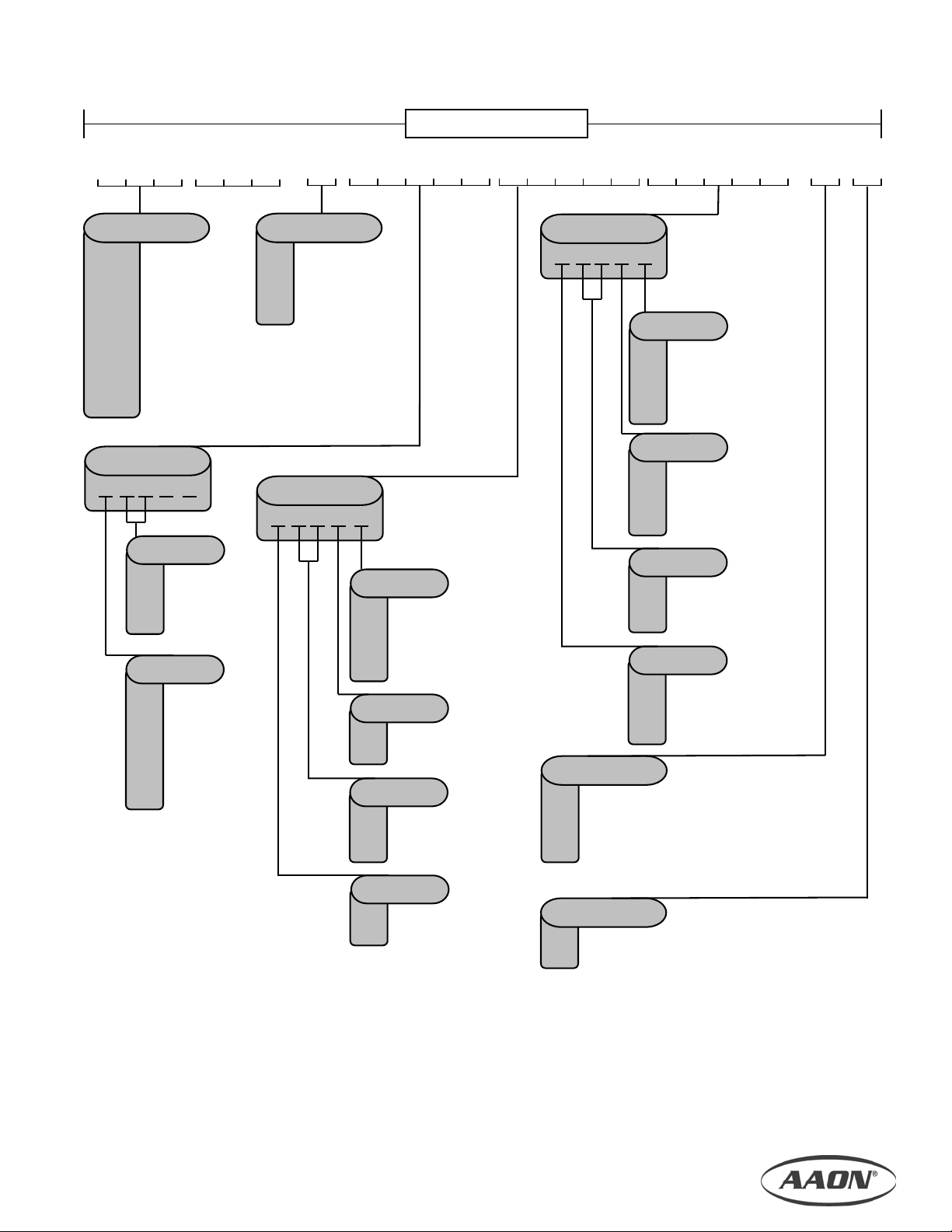

Figure 4.3, Module Configuration Schematic

CONFIGURATION:

M1-H-011-R-2-A-A-0-A-0

FTF-101-P-A0-00000-00000-0-0

HRA-102-A-00-00000-00000-0-0

CLF-103-C-00-210F0-610F0-S-0

SFA-104-K-C0-A0000-00000-0-0

PEC-201-K-B0-A0000-00000-0-0

FTD-203-B-B0-00000-00000-0-0

Module

configuration

numbers.

access clearances for

Table provides

required service

applicable modules.

101

201

Base model

number.

PEC FTD

10

Configuration Schematic

can be found in unit

literature

acket.

Arrows indicate

airflow.

HRA

20

CLF FTF SFA

10

17

Page 18

Note that a heat wheel module will have a 100 series

y

t

number identifying it, but will span both tiers also

utilizing a 200 series space, and effectively “skipping”

one of the top-tiered numbers.

If, for any reason, you are unable to identify any

module, or its position in the final assembly, then

consult the salesperson or project engineer.

Table 4.1, Module Code Chart

Code Description

BBA Small Blank Box

BBB Large Blank Box

CLB Cooling Coil

CLC Cooling Coil/Hot Gas Reheat Coil

CLD Electric Heat/Hot Water Coil

CLE Electric Heat

CLF Hot Water/Cooling Coil

CLG Electric Heat/Cooling Coil

CLH Electric Heat/Cooling Coil/Hot Gas Reheat Coil

CLI Cooling or Heating w/ Face Bypass

CLJ Hot Water/Cooling Coil/Hot Gas Reheat Coil

CLK Vertical Cooling Coil

CLL Cooling and Heating w/ Face Bypass

FTA Small Flat Filter

FTB Angled Filter

FTC Cartridge Filter

FTD Bag Filter

FTF Large Flat Filter

HRA Energy Recovery Wheel

MBA Vertical Damper Mixing Box

MBB Horizontal Damper (top) Mixing Box

MBC Horizontal (bottom)/Vertical Damper Mixing Box

MBD Vertical Damper/Filter Mixing Box

MBE Horizontal Damper (top)/Filter Mixing Box

MBF Horizontal Damper (bottom) Mixing Box

MBG Filter Mixing Box (no damper)

MBH Vertical/Horizontal (top) Damper Mixing Box

MBI Filter/Horizontal (bottom) Damper Mixing Box

MBJ Vertical/Horizontal (top) Damper/Filter Mixing Box

MBK Vertical/Horizontal (bottom) Damper/Filter Mixing Box

PEA Power Exhaust

PHA Electric Heat

PHB Hot Water Coil

PHC Filter/Hot Water Coil

PHD Filter/Electric Heat

RFA Return Fan

RHC Hot Gas Reheat Coil

SFA Supply Fan

SFB Vertical Supply Fan

SFC Supply Fan with Top Discharge

TRA Control Box

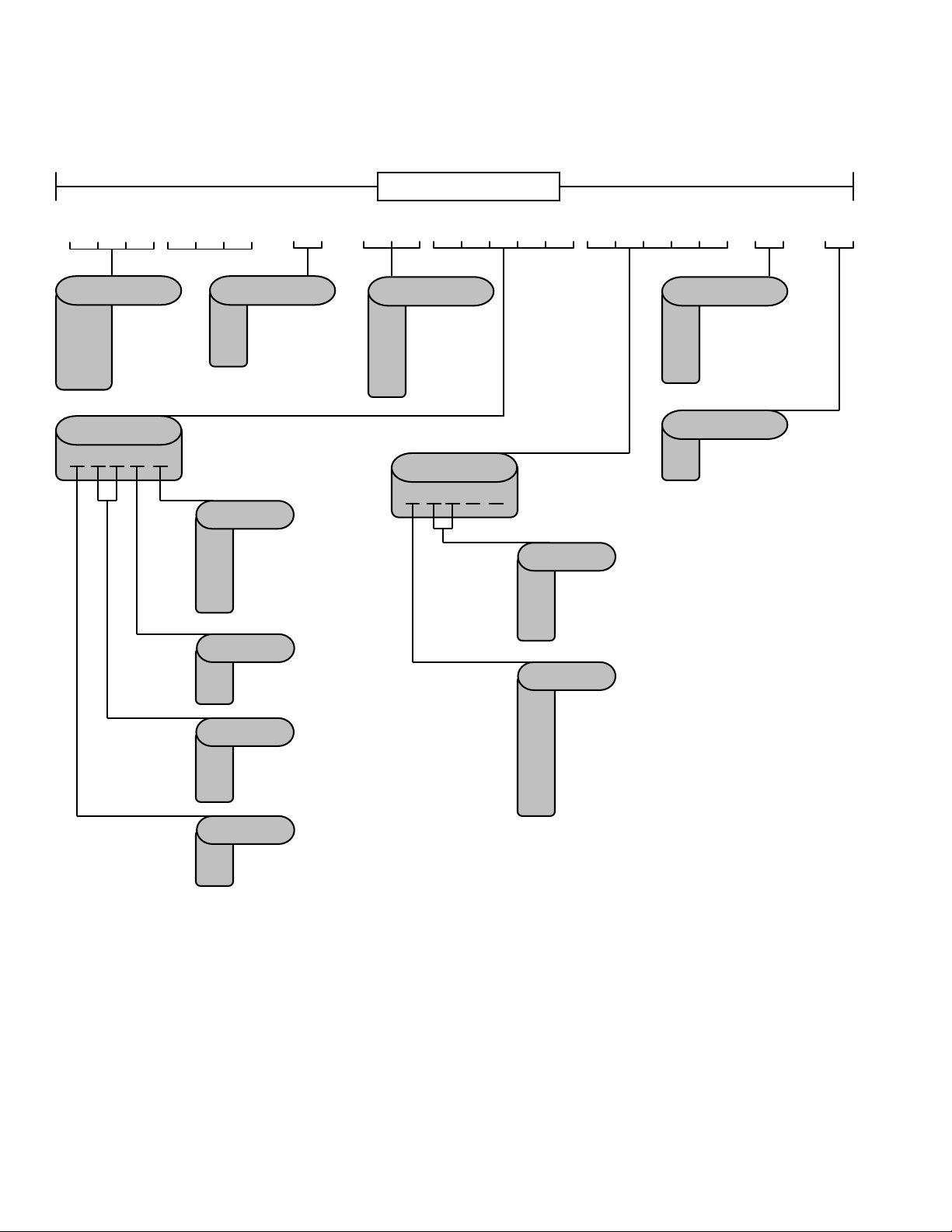

After identifying modules and determining module

arrangement, you can begin connecting the modules.

Modules are to be connected with nuts and bolts that

are shipped with the unit. Bolt holes are located inside

the module frames near the corners, and in the base

rail below the outside bottom corners of the module

(due to various design criteria, some modules may

have additional bolt holes along the inside of the

module top, and should be used if present). Align

modules, and insert bolts through the bolt holes of two

adjacent modules, and secure with nuts to pull the two

modules together tightly. Every bolt hole must be

used to ensure a tight seal between modules, and a

structurally stable assembly.

NOTE

All nuts, bolts, and gasketing required for assembl

are packaged and shipped with unassembled uni

orders.

Figure 4.4, Bolted Base Rail

Sealing

It is very important to keep outside air from infiltrating

the unit cabinet. Seal all piping penetrations with

Armaflex, Permagum, or other suitable sealant. Also

seal around drain connections, electrical connections,

and all other inlets where air may enter the cabinet.

This is especially important when the unit is installed in

an unconditioned area.

Cooling Equipment

Air Handler Equipped with Refrigerant Coil (DX)

This section is not intended to provide all the

information required by the designer or installer of the

refrigerant piping between the condensing units and

the air handler. The appropriate sections of the

ASHRAE Guide and the ASME standards should be

used for final information. Acceptable system design

and installation will include consideration as follows:

18

Page 19

− Piping from the condensing unit to the indoor air

handler is the responsibility of the installing

contractor.

− Only clean “ACR” tubing should be used.

− Piping should conform to generally accepted

practices and codes.

− Care must be taken not to cross the circuits on

multiple circuit systems.

− Once piped, the interconnecting piping and air

handler MUST BE evacuated to 50 microns or

less; leak checked and charged with refrigerant.

− Make sure air handler thermal expansion valve

bulb is mounted with good thermal contact on the

correct suction line on a horizontal section, close

to the evaporator in the 4 or 8 o’clock position and

well insulated. Care must be taken to ensure the

bulb is mounted on the correct suction line on

multiple circuit systems.

− The suction line (and hot gas bypass line if

present) should be insulated for its entire length

Lines should be fastened and supported according to

local codes.

Air Handler Equipped with Chilled Water Coil

Water supply lines must be insulated with closed cell

type pipe insulation or insulation that includes a vapor

barrier. Lines should be properly fastened, drained

and supported according to local code requirements.

Heating Equipment

When heat is called for, the cooling section is

inoperable except for the indoor blower motor. Actual

heating is accomplished by the air handling unit with

hot water, steam or electric heating capabilities.

Air Handler Equipped with Hot Water Coil

Water supply lines must be insulated, properly

fastened, drained and supported according to local

code requirements.

Air Handler Equipped with Steam Coils

The air handling unit MUST BE installed high enough

to allow for a minimum of one foot (1’) condensate

drop leg off of the steam coil (or as recommended by

the steam trap manufacturer). Lines should be

insulated with approved insulation and be properly

fastened, sloped and supported according to local

code requirements.

Air Handler Equipped with Electric Heating

INSTALLATION IS TO BE ADJUSTED TO OBTAIN

AN AIR TEMPERATURE RISE WITHIN THE RANGE

SPECIFIED ON THE RATING PLATE.

Heating is accomplished by passing electrical current

through a specified amount of resistance heaters

which will produce the required heat. The indoor

blower motor will energize at the same time as the

heaters. Wiring to the air handler must be done in

accordance with local electrical codes and/or

standards. Check specified electrical rating and install

with proper wire size.

Condensate Piping

If the air handler is equipped with cooling, a drain trap

must be connected to the drain pan at the unit. A

condensate connection is provided on each side of the

unit. Condensate piping should be installed according

to local codes. The line should be the same pipe size

as the drain nipple and should pitch downward toward

the building drain.

All cooling coils must have drain pans equipped with

“P” traps to avoid pulling air from outside the unit back

through the drain line. The “P” trap is factory supplied,

and is shipped loose in the control access

compartment for field installation. A plug is provided

for the unused condensate connection. The trap

should be located in warm ambient spaces. An

additional drain pan may be installed under the air

handler, and should include a separate drain line for

overflow from the primary drain. An air break should

be used with long runs of condensate lines.

Drain pans in any air conditioning equipment, even

when they have a built-in slope to the drain, will have

moisture present and will require periodic cleaning to

prevent any build-up of algae or bacteria. Cleaning of

the drain pans will also prevent any possible plugging

of the drain lines, and overflow of the pan itself. Some

means to clean out the “P” trap should be provided.

Only qualified personnel should clean drain pans,

drain lines, or the insides of equipment.

Electrical

Check the unit data plate to make sure it agrees with

the power supply. Connect power to the unit

according to the wiring diagram provided with the unit.

The power and control wiring may be brought in

through the holes provided on the unit. Protect the

branch circuit in accordance with code requirements.

19

Page 20

If the control wires are to run inside the same conduit,

use 600-volt wire or as required by applicable codes.

The units must be electrically grounded in accordance

with the National Electric Code, ANSI / UL 1995 when

installed if an external source is utilized; in Canada

use current C.S.A. Standard C22.2, No. 236,

Canadian Electric Code Part 1.

Power wiring is to the unit terminal block. The

manufacturer has done all wiring beyond this point.

Power can be applied to the unit after the control

wiring is connected, and start up checks are complete.

Thermostat

The low voltage room thermostat should be located on

an inside wall 4 to 5 feet a above the floor where it will

not be subjected to drafts, sun exposure or heat from

electrical fixtures or appliances. Control wire size

must be large enough to prevent excess voltage drop

that may cause improper operation of the equipment.

Follow manufacturer’s instructions enclosed with

thermostat for general installation procedure.

Filters

Open filter access door and slide correct filter in with

arrow pointing towards the blower in the direction of

airflow.

5. Refrigerant Piping &

Line Sizing Information

THIS SECTION IS FOR INFORMATION ONLY, AND

IS NOT INTENDED TO PROVIDE ALL THE

INFORMATION REQUIRED BY THE DESIGNER OR

INSTALLER OF THE REFRIGERANT PIPING

BETWEEN THE CONDENSING UNITS AND THE

LOW SIDE COMPONENTS. AAON, INC. IS NOT

RESPONSIBLE FOR INTERCONNECTING

REFRIGERANT PIPING. THE APPROPRIATE

SECTIONS OF THE ASHRAE GUIDE AND THE

ASME STANDARDS SHOULD BE USED FOR FINAL

INFORMATION.

The piping between the condenser and low side must

assure:

1. Minimum pressure drop, and

2. Continuous oil return, and

3. Prevention of liquid refrigerant slugging,

or carryover

Acceptable system design and installation will include

consideration as follows.

General

Use only clean type L copper tubing (type K for

underground) that has been joined with high

temperature brazing alloy.

The pipe sizes must be selected to meet the actual

installation conditions, and not simply based on

the connection sizes at the evaporator and/or

condensing unit.

When sizing refrigerant lines, cost considerations favor

keeping line sizes as small as possible. However,

excessive suction or discharge line pressure drops

cause loss of compressor capacity and increased

power usage, resulting in reduced system efficiency.

Furthermore, excessive liquid line pressure drops can

cause the liquid refrigerant to flash resulting in faulty

expansion valve operation.

Correct sizing must be based on minimizing cost and

maximizing efficiency. Pressure drop calculations are

referenced as normal pressure loss associated with a

change in saturation temperature of the refrigerant.

Typically, the refrigeration system will be sized for

pressure losses of 2°F or less for each segment of the

discharge, suction, and liquid lines.

Liquid Line Piping

Systems are normally designed so that the pressure

drop in the liquid line (due to friction) is not greater

than that corresponding to an approximate 1 to 2°F

change in saturation temperature. Liquid sub cooling

is the only method of overcoming the liquid line

pressure loss to guarantee presence of liquid at the

expansion device in the evaporator.

If the sub cooling is insufficient, flashing will occur

within the liquid line and the system efficiency will

suffer. Accessories such as solenoid valves, filter

driers, and hand valves, as well as the actual pipe,

fittings between the receiver, or condenser outlet, and

the metering device cause friction pressure drops in

the liquid line. Liquid line risers are also a source of

pressure loss, and add to the total loss of the liquid

line. The loss due to risers is approximately 0.5 PSI

per foot of liquid lift. The total loss is the sum of all

friction losses plus the pressure loss from liquid risers.

If the refrigeration system has no liquid risers, and the

evaporator is below the condenser/receiver, then it

benefits from a gain in pressure due to liquid weight,

and can tolerate larger friction losses without flashing.

When flashing takes place, regardless of the routing of

20

Page 21

the liquid lines, the overall efficiency is reduced, and

the system may malfunction.

A pressure loss of 3 psi in the liquid line results in a

1°F loss of sub-cooling temperature with R-22.

Table 5.1, R-22 Liquid Line Capacity w/ 3 PSI (1°F)

°

Pressure Loss per 100 Feet at 100

Line Size (In.) Max. Tons

1/2 4.0

5/8 7.6

7/8 19.1

F Liquid

Note: The equivalent feet for a piping system must include the

equivalent length of straight tubing for all the fittings, and any valves

that are added to the system.

Suction Line Piping

Suction lines are more critical than liquid lines and

discharge lines from a design and construction

standpoint. The proper return of oil to the

compressor(s) is critical, and depends on maintaining

sufficient velocity in the suction lines to carry the oil

along with the refrigerant gas. Simultaneously, high

refrigerant velocities in the suction line bring highpressure losses that reduce capacity.

Suction lines should be sized to:

1. Provide minimum pressure drop at full load,

and

2. return oil from the evaporator to the

compressor under minimum load conditions,

and

3. prevent oil from draining from an active

evaporator into an idle one.

Over sizing of suction lines results in poor oil return to

the compressor. Therefore, minimum suction gas

velocity of 750 fpm in horizontal runs, and 1500 fpm in

vertical runs is necessary.

A pressure drop in the suction line reduces a system’s

capacity because it forces the compressor to operate

at a lower suction pressure to maintain a desired

evaporating temperature in the coil. The suction line is

normally sized to have a pressure drop from friction no

greater than the equivalent of an approximate 2°F

change in saturation temperature.

If oil is entrained up vertical risers at partial loads, and

pipe size must be reduced to provide sufficient gas

velocity, then greater pressure drops are imposed at

full load. These pressure drops can usually be

compensated for by over sizing the horizontal and

down-run lines, and components. As shown in Figure

5.1, a double suction riser may be required in order to

return oil at partial load.

Figure 5.1, Double Suction Riser Example

Evaporator

Suction Line to

Compressor

All vertical suction risers should be checked to confirm

that oil will be returned to the compressor. Use the

tables in this section for pipe sizing information.

Table 5.2, Minimum Tons of Capacity to Carry Oil Up a

°

Suction Riser at 40

Line Size (In.) Min. Tons

All suction lines must be pitched in the direction of flow

and supported to maintain their position. Full

insulation must be used between the evaporator and

condensing unit.

Suction accumulators are not included with AAON

equipment (except with air source heat pumps), and

must be field furnished and installed if required by job

conditions.

Table 5.3, R-22 Suction Line Capacity w/ 3 PSI (2°F)

Pressure Loss per 100 Feet at 40

Line Size (In.) Max. Tons

Discharge Lines

Discharge (hot-gas) lines should be designed to:

F Saturated Suction

5/8 .3

7/8 .8

1 1/8 1.6

1 3/8 2.8

1 5/8 4.4

°

F Saturated Suction

5/8 1.1

7/8 2.7

1 1/8 5.5

1 3/8 9.3

1 5/8 14.9

21

Page 22

1. Avoid trapping oil at part-load operation,

and

2. prevent condensed refrigerant and oil in

the line from draining back to the head of

the compressor, and

3. avoid developing excessive noise from

either hot-gas pulsations, compressor

vibrations, or both.

Pressure loss in hot-gas lines increases the required

compressor power per unit of refrigeration, and

decreases the compressor capacity. Pressure drop is

minimized by over sizing the lines for low friction

losses while maintaining refrigerant line velocities to

entrain and carry oil at all loading conditions. Normally,

pressure drop is designed not to exceed the equivalent

of a 2°F change in saturation temperature, while

recommended sizing is based on a 1°F change in

saturation temperature.

Other Piping

Hot Gas Bypass Lines (Optional)

The hot gas bypass option is a system that maintains

evaporator pressure at or above a minimum value in

order to prevent the coil from freezing, and to keep

refrigerant velocity high enough for proper oil return

when operating at a light load.

Pressure drop in the hot gas line is normally designed

not to exceed the equivalent of a 2°F change in

saturation temperature with R-22. See Table 5.4

below that is based on a 1°F change in saturation

temperature.

Hot gas bypass lines must be insulated to minimize

heat loss and condensation of gas inside the piping

and to prevent injury from high temperature surfaces.

See Section 8 of this manual for more information

about hot gas bypass.

Table 5.4, R-22 Hot Gas Bypass Line Capacity w/ 3 PSI

(1°F) Pressure Loss per 100 Feet at 40°F Saturated

Suction

Line Size (In.) Tons

1/2 .9

5/8 1.6

7/8 4.1

1 1/8 8.4

1 3/8 14.2

Minimum Gas Velocities for

Oil Transport in Risers

On multiple compressor installations, the lowest

possible system loading should be calculated with a

riser size selected to give at least the minimum

capacity for successful oil transport. Some

installations will have excessive pressure drop at

maximum load when multiple compressors exist with

capacity control, a vertical hot-gas line, and that are

sized to transport oil at minimum load. A double riser,

or a single riser with an oil separator can be used to

correct this problem.

Double Hot-Gas Risers

A double hot-gas riser can be used the same way it is

used in a suction line. Figure 5.1 shows the double

riser principle.

Single Riser and Oil Separator

Alternatively, an oil separator located in the discharge

line, just before the riser, permits sizing the riser for a

low-pressure drop. Any oil draining back down the

riser accumulates in the oil separator. With large

multiple compressors, the capacity of the separator

may dictate the use of individual units for each

compressor located between the discharge line, and

the main discharge header. Horizontal lines should be

level, or pitched downward in the direction of gas flow

in order to facilitate travel of oil through the system,

and back to the compressor.

Piping to Prevent Liquid and Oil from Draining to

Compressor Head

Whenever the condenser is located above the

compressor, the hot-gas line should be trapped near

the compressor before rising to the condenser,

especially if the hot-gas riser is long. This minimizes

the possibility that refrigerant, condensed in the line

during off cycles, will drain back to the head of the

compressor. Also, any oil traveling up the pipe wall

will not drain back to the compressor head.

The loop in the hot-gas line serves as a reservoir and

traps liquid resulting from condensation in the line

during shutdown, thus preventing gravity drainage of

liquid, and oil back to the compressor head. A small

high-pressure float drainer should be installed at the

bottom of the trap to drain significant amounts of

refrigerant condensate to a low side component such

as a suction accumulator, or low-pressure receiver.

22

Page 23

This float prevents excessive liquid buildup in the trap,

and reduces the potential for “liquid hammer” when the

compressor is restarted.

In order to prevent gas from active compressors from

condensing on the heads of idle compressors in

multiple compressor arrangements, each discharge

line should have a check valve. For singlecompressor applications, a tightly closing check valve

should be installed in the hot-gas line of the

compressor whenever the condenser, and the receiver

ambient temperature are higher than that of the

compressor. The check valve prevents refrigerant

from boiling off in the condenser, or receiver, and

condensing on the compressor heads during off

cycles. The check valve should be a piston type that

closes by gravity when the compressor stops running.

ECat32 Refrigerant Piping Calculator

This program contained in the AAON

Engineering Tools section of AAON’s

ECat32 equipment rating and selection

software can be used to size liquid,

discharge, and suction lines.

The program calculates the equivalent

length as the sum of the actual length plus

the number of elbows times the equivalent

length per elbow. Pressure drop of other

components should be incorporated using

the ASHRAE Refrigeration Handbook to

determine fitting, and valve losses in

equivalent lengths of pipe. Additional losses

should be added to the total length before

calculation.

Figure 5.2, AAON Ecat32 Screenshot: Refrigerant Piping Calculator

Table 5.5, Fitting Losses in Equivalent Feet of

Straight Copper Tubing

Tubing

Size

(In.)

1/2 1.4 .9 2.3 .7 1.1 2.3

5/8 1.6 1.0 2.5 .8 1.3 2.5

7/8 2.0 1.4 3.2 .9 1.6 3.2

1 1/8 2.6 1.7 4.1 1.3 2.1 4.1

1 3/8 3.3 2.3 5.6 1.7 3.0 5.6

1 5/8 4.0 2.6 6.3 2.1 3.4 6.3

Note: The equivalent feet for a piping system must include the

equivalent length of straight tubing for all the fittings, and any valves

that are added to the system.

90°

Std.

90°

Long

Rad.

90°

Street

45°

Std.

45°

Street

180°

Std.

23

Page 24

6. Start-Up

t

t

y

r

p

General

Equipment power should be on at least 24 hours

before start-up to allow the crankcase heater to

boil off refrigerant that may have accumulated in

the com

ONLY QUALIFIED, AUTHORIZED PERSONNEL

SHOULD POWER ON, OR START-UP THIS

EQUIPMENT.

The use of common sense, and good practice in the

installation, and start-up of equipment will prevent

many potential problems with the system in the future.

Before starting up the equipment, building construction

should be complete, and start-up personnel should:

− Have a working knowledge of general HVAC

− Be familiar with unit functions, features,

− Have appropriate literature on hand for

Equipment operation during construction is no

recommended. Construction site pollution can

affect unit operation, and seriously degrade

performance. Operation during construction will

void all manufacturer’s warranties.

Before the structure is occupied, the installation,

and/or start-up personnel must take three essential

steps:

1. Check Out

2. Start-Up

3. Commissioning

Check Out

Equipment should be thoroughly checked for loose

wiring, a free spinning blower wheel, and well fitting

ressor oil.

and mechanical commissioning procedures

and practices;

optional unit accessories, and all control

sequences;

consultation.

CAUTION

CAUTION

access panels. Air handlers should not be operated

without proper ductwork and access panels installed,

except as required during start-up and air balancing.

1. Check all electrical connections to be sure

they are tight.

2. Open all access panels, and remove all

shipping screws, or restraints.

3. Clean out any debris that may have been left.

4. Check belt alignment, and tightness of fan

drives.

5. Check bearing locking collars, and fan wheel

set screws for tightness.

6. Turn fan wheels to assure free rotation.

7. Ensure electrical supply matches the unit

nameplate.

8. Ensure condensate lines are connected, and

glued.

9. Check local codes for any special provisions.

10. Replace, and/or close all access panels.

11. Ensure that return, and/or supply dampers in

ductwork are open.

Start-Up

Failure to adhere to the following start-up

procedures will void all manufacturer’s warranties.

Install gauges, voltmeter, and ammeter before startup. Observe refrigerant pressures during initial

operation. Note, and determine the cause of any

excessive sound, or vibration. Follow start-up

procedures outlined below to start each piece of

equipment.

NOTE

Procedures

Completed factory test sheets are in the equipmen

literature packet shipped inside the unit. Factor

run-test readings recorded on the test sheets fo

may be helpful to reference during start-up.

Electric Heating Section:

1. Perform final visual inspection. Check all

equipment, ductwork, and piping to verify that

all work is complete, and equipment is

NOTE

24

Page 25

properly installed and mounted. Improperly

installed equipment, or ductwork can affect

readings.

2. Ensure there is no construction debris in the

unit.

3. Check the unit for external damage.

4. Note all accessories installed.

5. Install a filter of the proper size and type.

6. Check all terminal blocks, fuses, fuse blocks,

and contactors for correctness.

7. Check all high and low voltage wiring

connections for correctness, and tightness.

8. Check unit for correct incoming voltage per the

data plate.

9. Check the security of the locking system on all

blower bearings

10. Turn the unit power on.

11. Turn the unit blower on, and check for correct

rotation.

12. If correct, take blower amp readings, and

compare to see if the amp draw is within the

safety factor area of the motor. Once correct,

turn blower off.

13. Turn on the first stage of heating

− Check amp draw of each element of

each stage

− Ensure blower started w/ electric heat

− Check for temperature rise across

heating section while all stages are on

− If temperature rise is within range, turn

all heating calls off

− Check to see that blower stops

14. If equipped with an economizer, when testing

of cooling circuits is complete, turn cooling

circuits off, and leave blower running.

15. Call for the economizer circuit to operate.

16. Check for economizer blades to open fully with

no binding.

17. If equipped with power exhaust, check that it

will operate with the economizer circuit.

18. Take power exhaust motor amp readings.

Refrigerant (DX) Cooling Section:

1. Perform final visual inspection. Check all

equipment, ductwork, and piping to verify that

all work is complete, and equipment is

properly installed and mounted. Improperly

installed equipment, or ductwork can affect

readings.

2. Perform condenser start-up checks in addition

to these air handler checks according to the

condenser manufacturer’s instructions.

3. Ensure there is no construction debris in the

unit.

4. Check the unit for external damage.

5. Note all accessories installed.

6. Install filter of the proper size and type.

7. Ensure that drain P-trap is installed.

8. Check all terminal blocks, fuses, fuse blocks,

and contactors for correctness.

9. Check all high, and low voltage wiring

connections for tightness. Check unit for

correct incoming voltage per the data plate.

10. Check the security of the locking system on all

blower bearings

11. Turn the unit power on.

12. Turn the unit blower on, and check for correct

rotation.

13. If correct, take blower amp readings, and

compare to see if the amp draw is within the

safety factor area of the motor.

14. Check, and record ambient temperature.

15. Check for Guaranteed Off Timers (GOT),

and/or Time Delay Relays (TDR).

16. Start the first stage cooling circuit, and blower

circuit.

17. After all stages of cooling have been on for at

least five minutes, record the return air

temperature, and supply air temperature.

18. Check the temperature difference across the

evaporator coil.

19. If equipped with an economizer, after testing

of cooling circuits is complete, turn cooling

circuits off, and leave blower running.

20. Call for the economizer circuit to operate.

21. Check for economizer blades to open fully with

no binding.

22. If equipped with power exhaust, check that it

will operate with the economizer circuit.

23. Take power exhaust motor amp readings.

Optional Equipment

Operation of each of the following, if equipped in the

unit, must be checked according to that item’s

manufacturer’s specifications:

− Clogged filter switch

− Magnehelic gauge

− Supply air smoke detector

− Return air smoke detector

− Return air fire stat

− Supply air fire stat

− Phase and brownout monitor

− Ground fault circuit interrupter outlet

− Low limit control

− Duct stats

− Hot gas reheat

− Hot gas bypass

− Compressor lockout/ Low ambient

− Heat wheel drive motor

− Null pressure switch

25

Page 26

Commissioning

The commissioning of an air conditioning system is the

process of achieving, verifying, and documenting the

performance of that system to meet the operational

needs of the building. This may not be a formal

process in smaller structures, such as a normal

residence, but some form of owner acceptance will

occur. Adjustments made during the commissioning

phase may include air, or water balancing, or

configuration of controls, and operational sequences.

Air Balancing

High performance systems commonly have complex

air distribution and fan systems. Unqualified personnel

should not attempt to adjust fan operation, or air

circulation, as all systems have unique operating

characteristics. Professional air balance specialists

should be employed to establish actual operating

conditions, and to configure the air delivery system for

optimal performance.

Water Balancing

A hydronic specialist with a complete working

knowledge of water systems, controls, and operation

must be employed to properly balance the entire

system. Unqualified personnel should not attempt to

manipulate temperatures, pressures, or flow rates, as

all systems have unique operating characteristics, and

improper balancing can result in undesirable noises

and operation.

Controls

A variety of controls and electrical accessories may be

provided with the equipment.

Identify the controls on each unit by consulting

appropriate submittal, or order documents, and

operate according to the control manufacturer’s

instructions. If you cannot locate installation,

operation, or maintenance information for the specific

controls, then contact your sales

control manufacturer for assistance.

Do not alter factory wiring. Deviation from the

supplied wiring diagram will void all warranties,

and may result in equipment damage or personal

injury. Contact the factory with wiring

discrepancies.

WARNING

representative, or the

7. Operation & Maintenance

General

Immediately following building occupancy, the air

conditioning system requires a maintenance schedule

to assure continued successful operation. A

maintenance program similar to the example given

below should be scheduled for routine maintenance of

this equipment in order to provide continued efficient,

and reliable operation for the owner.

Maintenance Schedule

One week after start-up:

− Check refrigerant charge. Evacuate and repair

coil if leaking.

− Adjust belt tension on all fan drives.

− Check filters for cleanliness. Measure pressure

loss if applicable. Replace if necessary.

− Check cycling of compressors, fans, and valves.

Correct unusual cycling.

Monthly:

− Lubricate bearings if operating continuously at

1500 rpm, or higher, or in other extreme

conditions.

− Check cleanliness of filters, and replace if

necessary.

− Check cooling coil drain pan to assure proper

drainage.

− Inspect evaporator, and condenser coils. Clean if

dirty, or obstructed in any way.

Quarterly:

− Lubricate bearings if operating at 1000 rpm, or

less, and in temperatures less than 150°F, or other

extreme conditions.

− Check damper operation for freedom of

movement. Correct any binding that may occur.

− Check belts, and pulleys on all fan drives for

tension, and unusual wear.

− Check operation of heating, and cooling section if

seasonal.

− Check inlet, and outlet air temperatures.

Determine cause for abnormal changes.

Annually:

− Clean the condenser, and evaporator coils with

steam, or a non-corrosive coil cleaner.

26

Page 27

− Clean the drain line, “P” trap, and condensate pan.

− Check refrigerant pressures, and temperatures

every Spring, and correct unusual operation.

− Check heating section every Fall. Check all

electrical connections for tightness, and check

heater elements for indications of overheating.

Determine cause and replace elements if

necessary.

Blower Assembly

AAON air handlers use backward inclined airfoil

blower wheels that are non-overloading, very efficient,

and very easy to clean. Clean blower wheels are

necessary to reduce electrical use, maintain capacity

and reduce stress on the unit. The blower wheel, and

blower section need to be inspected periodically, and

cleaned of dust, or debris.

To inspect and clean the blower; set thermostat to the

“OFF” position; turn the electrical power to the unit to

the “OFF” position at the disconnect switch. Clean the

assembly, check the bearings for looseness, inspect

the belt condition and tightness, check screws for

tightness, rotate blower wheel while listening close to

each bearing to check for noise or roughness in the

bearing, which indicates a failing bearing.

Bearings

AAON uses pre-lubricated bearings, and bearings that

have been sized for an average failure rate of 50%

after 200,000 hours, or 22.8 years, of operation (see

heading “Lubrication” in this section for more

information). The bearing sizing tables below are

based on rotational speeds, and radial loading.

However, the alignment of the bearing to the shaft,

and the security of the bearing inner race to the shaft

will greatly affect bearing life. Even though the

manufacturer is responsible for bearing tolerances,

and mounting design, the installer is advised to

check the security of the bearing locking system

before start-up

.

Table 7.1, Bearing Setscrew Torque Recommendations

Size

(In.)

1 1/4 - 28 66 - 85 8 - 32 63 - 70

1 3/16 1/4 - 28 66 - 85 8 - 32 63 - 70

1 7/16 5/16 - 24 126 - 164 10 - 24 81 - 90

1 7/8 3/8 - 24 228 - 296 1/4 - 20 162 - 180

Setscrew Locking Skewzloc Locking Shaft

Thread Torque (In-Lbs) Thread Torque (In-Lbs)

Belts

Belt drive misalignment is one of the most common

causes of premature belt failure. A belt can be

destroyed in a matter of days if the drives have been

aligned incorrectly.

The most common tool for measuring misalignment is

a straightedge. Hold the straightedge flush across one

pulley to gauge the degree of misalignment of the two

sheaves. The maximum allowed misalignment is one

half degree of angular misalignment, and 1/10

inch per foot between sheave centers for parallel

misalignment.

Figure 7.1, Angular Misalignment

Pulley Pulley

Straightedge

Belt

Corrected by moving the position of the motor.

Figure 7.2, Parallel Misalignment

Pulley

Straightedge

Pulley

Belt

Corrected by adjusting sheaves on one, or both shafts.

Frequent belt tensioning is highly recommended. Most

belt manufacturers would suggest a retensioning after

as little as 8 hours of operation. A simplified method of

adjusting tension is to gauge the amount of force

required to deflect the belt by 1/64

th

of an inch per inch

of distance between sheave centers. For example, if

the sheaves are 20 inches apart, then the amount of

deflection with the forces listed below is 20/64

of an inch.

Deflections required for:

“A” belts: 4 to 6 lbs.

“B” belts: 6 to 10 lbs.

“C” belts: 10 to 18 lbs.

th

of an

th

(5/16th)

27

Page 28

Figure 7.3, Belt Deflection

Sheave Centers

Force

Deflection = 1/64th in.

per inch of length

Coils

Coils should be inspected and cleaned annually to

ensure there is no obstruction to airflow.

Evaporator (Indoor/Cooling Coil)

Dirty evaporator coils will eventually freeze up, and

often result in a time consuming, and expensive

service call. Clean filters will help to prevent dirt from

accumulating on the evaporator, however the

evaporator should be cleaned annually with a soft

bristled brush, and/or a non-corrosive coil cleaning

solution.

Condenser (Outdoor Coil)

One of the most overlooked maintenance

requirements is the need to keep air moving freely

across air-cooled condensing coils. Dirty condensers,

like evaporators, can significantly increase cooling

costs during the year. As a minimum, clean the

condenser coil at the beginning of each cooling

season. It is preferable to use a medium pressure

water spray from the inside of the condenser cabinet

with a non-corrosive coil cleaning solution. TURN

OFF all power to the unit before cleaning.

Comb out any visible exterior fin damage to help

maintain unit efficiency. Clean the fan blades if they

are dirty. Always check condenser fan blades to

ensure unobstructed, free rotation after manipulating

the unit cabinet in any way, and before turning power

back on to the condenser.

Refrigeration Cycle

Satisfactory performance of the refrigeration cycle can

be determined by measuring suction line superheat.

In order to determine if refrigerant flowing from the

evaporator is dry, ensure that the system has enough

refrigerant to produce liquid line subcooling, but not so

much to cause abnormally high condensing

temperatures (and pressures). Refrigerant cycle

analysis is best performed in conditions that approach

the conditions where the air conditioner will be

expected to operate.

Superheat

Superheat is the extra heat in vapor when at a

temperature higher than the saturation temperature

corresponding to its pressure. To determine the

superheat, measure the temperature of the suction line

(insulate the temperature probe from surrounding air),

and read the suction line pressure. The difference

between the suction line temperature, and the

temperature indicated on a refrigerant pressuretemperature chart (see inside back cover) at the

suction line pressure is the degree of superheat.

Subcooling

Subcooling enhances unit capacity, and assures that

only liquid appears at the threshold of the expansion

valve, also prolonging expansion valve life, and

providing better expansion valve control. Subcooling

is determined by measuring the difference between

the temperature of liquid refrigerant as it leaves the

condenser coil, and the temperature indicated on a

pressure-temperature chart at the pressure measured

in the liquid line.

Determining Charge

Table 7.2 shows expected discharge superheat levels